Page 1

Test report no. 18011440 Page 1 of 1

EUT: GX-IE, GX-IE XL

FCC ID: SDL-GXR02

FCC Title 47 CFR Part 15

Date of issue: 2018-07-30

Date: 2018-06-06

Created: P4 Reviewed: P9 Released: P1

Vers. No. 1.18

TÜV NORD Hochfrequenztechnik GmbH & Co. KG

Rottland 5a, 51429 Bergisch Gladbach, Germany

Tel: +49 2207 9689-0

Fax +49 2207 9689-20

Annex acc. to FCC Title 47 CFR Part 15

relating to

Hilti Corporation

GX-IE, GX-IE XL

Annex no. 5

User Manual

Functional Description

Title 47 - Telecommunication

Part 15 - Radio Frequency Devices

Subpart C – Intentional Radiators

ANSI C63.4-2014

ANSI C63.10-2013

Page 2

GX-IE

GX-IE XL

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

English 1

Français 11

Português 22

Español 33

Page 3

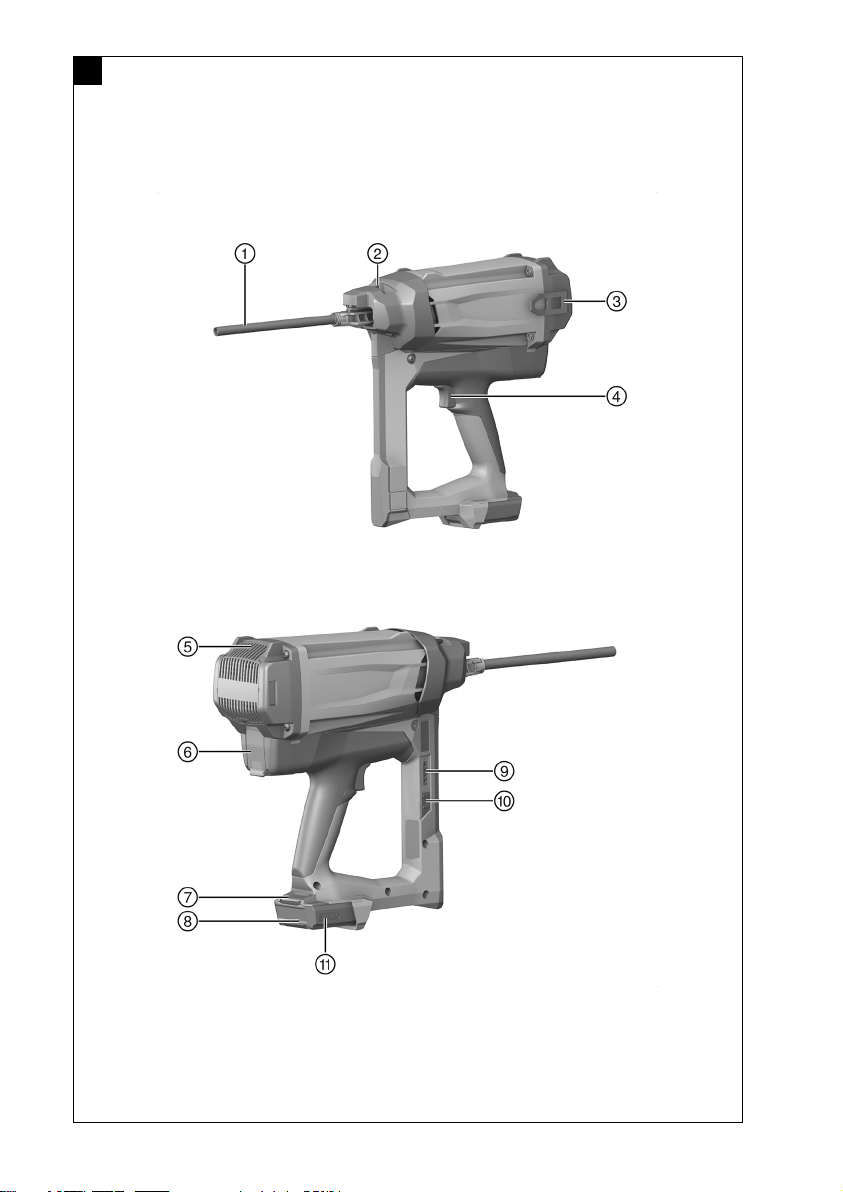

1

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

Page 4

2

3

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

Page 5

GX-IE

GX-IE XL

en Original operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

fr Mode d'emploi original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

pt Manual de instruções original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

es Manual de instrucciones original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

Page 6

1 Information about the documentation

1.1 About this documentation

• Read this documentation before initial operation or use. This is a prerequisite for safe, trouble-free

handling and use of the product.

• Observe the safety instructions and warnings in this documentation and on the product.

• Always keep the operating instructions with the product and make sure that the operating instructions

are with the product when it is given to other persons.

1.2 Explanation of symbols used

1.2.1 Warnings

Warnings alert persons to hazards that occur when handling or using the product. The following signal words

are used:

DANGER

DANGER !

▶ Draws attention to imminent danger that will lead to serious personal injury or fatality.

WARNING

WARNING !

▶ Draws attention to a potential threat of danger that can lead to serious injury or fatality.

CAUTION

CAUTION !

▶

Draws attention to a potentially dangerous situation that could lead to slight personal injury or damage

to the equipment or other property.

1.2.2 Symbols in the documentation

The following symbols are used in this document:

Read the operating instructions before use.

Instructions for use and other useful information

Dealing with recyclable materials

Do not dispose of electric equipment and batteries as household waste

1.2.3 Symbols in the illustrations

The following symbols are used in illustrations:

These numbers refer to the corresponding illustrations found at the beginning of these operating

instructions

The numbering reflects the sequence of operations shown in the illustrations and may deviate

from the steps described in the text

Item reference numbers are used in the overview illustrations and refer to the numbers used in

the product overview section

This symbol is intended to draw special attention to certain points when handling the product.

Wireless data transfer

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 English 1

Page 7

1.3 Product-dependent symbols

1.3.1 Symbols on the product

The following symbols are used on the product:

General mandatory sign

Wear eye protection

Wear ear protection

Wear a hard hat

Return waste material for recycling

1.3.2 Highlighting of designations and markings

Designations and markings are indicated as follows:

‚ ‛ Description of marked operating controls on the fastening tool

« » Markings on the fastening tool

1.4 Product information

Hilti products are designed for professional users and only trained, authorized personnel are permitted to

operate, service and maintain the products. This personnel must be specifically informed about the possible

hazards. The product and its ancillary equipment can present hazards if used incorrectly by untrained

personnel or if used not in accordance with the intended use.

▶ In the table below, enter the designation and serial number from the type identification plate.

▶ Always quote this information when you contact a Hilti representative or Hilti Service to make an inquiry

about the product.

Product information

Fastening tool, gas-actuated GX-IE

Generation: 01

Serial number:

GX-IE XL

1.5 Declaration of conformity

We declare, on our sole responsibility, that the product describedhere complies with the applicabledirectives

and standards. A copy of the declaration issued by the certification department can be found at the end of

this documentation.

The technical documentation is filed and stored here:

Hilti Entwicklungsgesellschaft mbH | Tool Certification | Hiltistrasse 6 | 86916 Kaufering, Germany

2 Safety

2.1 Safety instructions

These safety instructions apply for fastening tools with and without magazine.

Working safely with the fastening tool

▶ Pressing the nosepiece of the fastening tool against a part of the body may lead to serious injury due to

inadvertent actuation and release of a fastener. Never press the nosepiece of the tool against your

hand or any other part of the body.

▶ When inserting/loading application-specific fasteners (e.g. washers, clips or clamps, etc.) in/on the

fastener guide there is a risk of serious injury due to inadvertent actuation of the tool resulting in

discharge of a fastener. When inserting/loading an application-specific type of fastener, never press

a hand or any other part of the body against the fastener guide.

▶ Never point the fastening tool towards yourself or any other person.

2 English 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 8

▶ Keep your arms flexed when operating the tool (do not straighten the arms).

▶ When pulling back the nail pusher, always take care to ensure that it engages.

▶ When disengaging the nail pusher, do not release it and allow it to jump forward. Guide it forward

slowly. There is a risk of pinching the fingers.

▶ Do not attempt to drive fasteners into materials that are too hard, such as welded steel or cast steel.

Attempting to drive fasteners into these materials may lead to malfunctions, incorrectly driven fasteners

or breakage of fasteners.

▶ Do not attempt to drive fasteners into materials that are too soft, such as wood or drywall/gypsum

board. Attempting to drive fasteners into these materials may lead to malfunctions and fasteners being

driven incorrectly or driven right through the material.

▶

Do not attempt to drive fasteners into materials that are too brittle, such as glass or tiles. Attempting

to drive fasteners into these materials may lead to malfunctions, fasteners being driven incorrectly and

may cause the material to shatter.

▶ Before driving fasteners, check that there is no risk of injuring persons or of damaging objects present

behind or below the working surface.

▶ Pull the safety trigger only when the fastening tool is pressed against the working surface in such a way

that the fastener guide is pushed into the tool as far as it will go.

▶ Always wear gloves if you have to carry out maintenance work on the fastening tool while it is still

hot.

▶ If fasteners are driven at a high rate or if the tool used for a long period, surfaces of the tool beyond the

grip areas may get hot. Wear protective gloves to avoid burning injuries.

▶ If the fastening tool overheats, remove the gas can and allow the tool to cool down. Do not exceed the

specified maximum fastener driving rate.

▶ Driving fasteners may cause flying fragments or result in parts of the nail strip material being forcibly

ejected from the tool. Flying fragments present a risk of injury to the body and eyes. Wear eye

protection, ear protection and a hard hat. Depending on the application and type of fastening tool in

use, wearing personal protective equipment such as a dust mask, non-slip safety footwear, hard hat and

ear protection reduces the risk of injury. Other persons in the vicinity must also wear eye protection and

a hard hat.

▶ Wear suitable ear protection ( see noise information in the technical data section). Fasteners are driven

through ignition of a gas/air mixture. The resulting noise exposure may cause damage to the hearing.

Other persons in the vicinity should also wear suitable hearing protection.

▶ When driving a fastener, always hold the fastening tool securely and at right angles to the supporting

material. This helps to avoid deflection of the fastener by the supporting material.

▶ Never drive a second fastener at the same location. This may lead to breakage or jamming of fasteners.

▶ Always remove the gas can and battery and empty the magazine before changing the magazine and

before undertaking cleaning, servicing or maintenance work, in preparation for storage or transport and

before leaving the fastening tool unattended.

▶ To ensure that the fastening tool functions faultlessly and as intended, always check the tool and

accessories for possible damage before use. Check that moving parts function faultlessly, without

sticking, and that no parts are damaged. In order to ensure faultless operation of the fastening tool, all

parts must be fitted correctly and must meet the necessary requirements. Damaged protective devices

or other parts must be properly repaired or replaced by Hilti Service unless otherwise stated in the

operating instructions.

▶ Have the fastening tool repaired only by trained and qualified specialists using genuine Hilti spare parts.

This will ensure that the safety of the fastening tool is maintained.

▶ Tampering with or modification of the fastening tool is not permissible.

▶ Do not use the fastening tool where there is a risk of fire or explosion.

▶ Take influences of the surrounding area into account. Do not expose the fastening tool to rain or snow

and do not use it in damp or wet conditions.

▶ Use the fastening tool only in well-ventilated working areas.

▶ Select the correct combination of fastener guide and fastener. The wrong combination may result in

damage to the tool and in reduced fastening quality.

▶ Always observe the application guidelines.

Hazards presented by electricity

▶ Before beginning work, check the working area (e.g. using a metal detector) to ensure that no

concealed electric cables or gas and water pipes are present.

▶ Hold the fastening tool only by the insulated grip when working in areas where fasteners may be driven

inadvertently into concealed electric cables. Contact with a live electric cable may cause metal parts of

the fastening tool also to become live, leading to a risk of electric shock.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 English 3

Page 9

Use and care of battery-powered tools

▶ Check that the tool is switched off before inserting the battery. Inserting a battery into an electric

tool that is switched on can lead to accidents.

▶ Do not expose batteries to high temperatures, the direct heat of the sun, and keep them away

from fire. There is a risk of explosion.

▶ Do not disassemble, squash or incinerate batteries and do not subject them to temperatures over

80°C. This presents a risk of fire, explosion or injury through contact with caustic substances.

▶ Avoid ingress of moisture. Ingress of moisture may cause a short circuit, resulting in burning injuries or

fire.

▶ Use only batteries of the type approved for use with the applicable tool. Use of other batteries or

use of the batteries for purposes for which they are not intended presents a risk of fire and explosion.

▶ Observe the special guidelines applicable to the transport, storage and use of Li-ion batteries.

▶ Remove the battery from the tool before transport or storage.

▶ Avoid short circuiting the battery terminals. Check that the contacts on the battery and on the tool

are free from foreign objects before inserting the battery into the tool. Short circuiting the battery

terminals presents a risk of fire, explosion and chemical burns.

▶ Do not continue to use or attempt to charge damaged batteries (e.g. batteries with cracks, broken

parts, bent or pushed-in / pulled-out contacts).

▶ A battery that is too hot to hold may be defective. Allow the battery to cool down in a place where there

is no risk of causing a fire. Check that there are no flammable materials nearby. Contact Hilti Service.

Instructions for handling the propellant gas

▶ Observe the instructions printed on the gas can and in the accompanying information.

▶ Escaping gas is harmful to the lungs, skin and eyes. Keep your face and eyes away from the gas can

compartment for up to about 10 seconds after removing the gas can.

▶ Do not operate the gas can valve manually.

▶ If a person has inhaled gas, take the person into the open air or into a well-ventilated area and place the

person in a comfortable position. Consult a doctor if necessary.

▶ Call a doctor if the person is unconscious. Bring the person into a well-ventilated area and place the

person in the stable recovery position (i.e. lying on the side). If the person is not breathing, administer

artificial respiration and, if necessary, supply oxygen.

▶ After eye contact with gas, rinse the open eyes thoroughly under running water for several minutes.

▶ After skin contact with gas, wash the contact area carefully with soap and warm water. Subsequently

apply a skin cream.

General instructions concerning personal safety

▶ Take care to adopt an ergonomic body position. Work from a safe stance and take care to stay in balance

at all times. This will allow you to control the fastening tool better, even in unexpected situations.

▶ Keep other people away from the working area, especially children.

4 English 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 10

3 Description

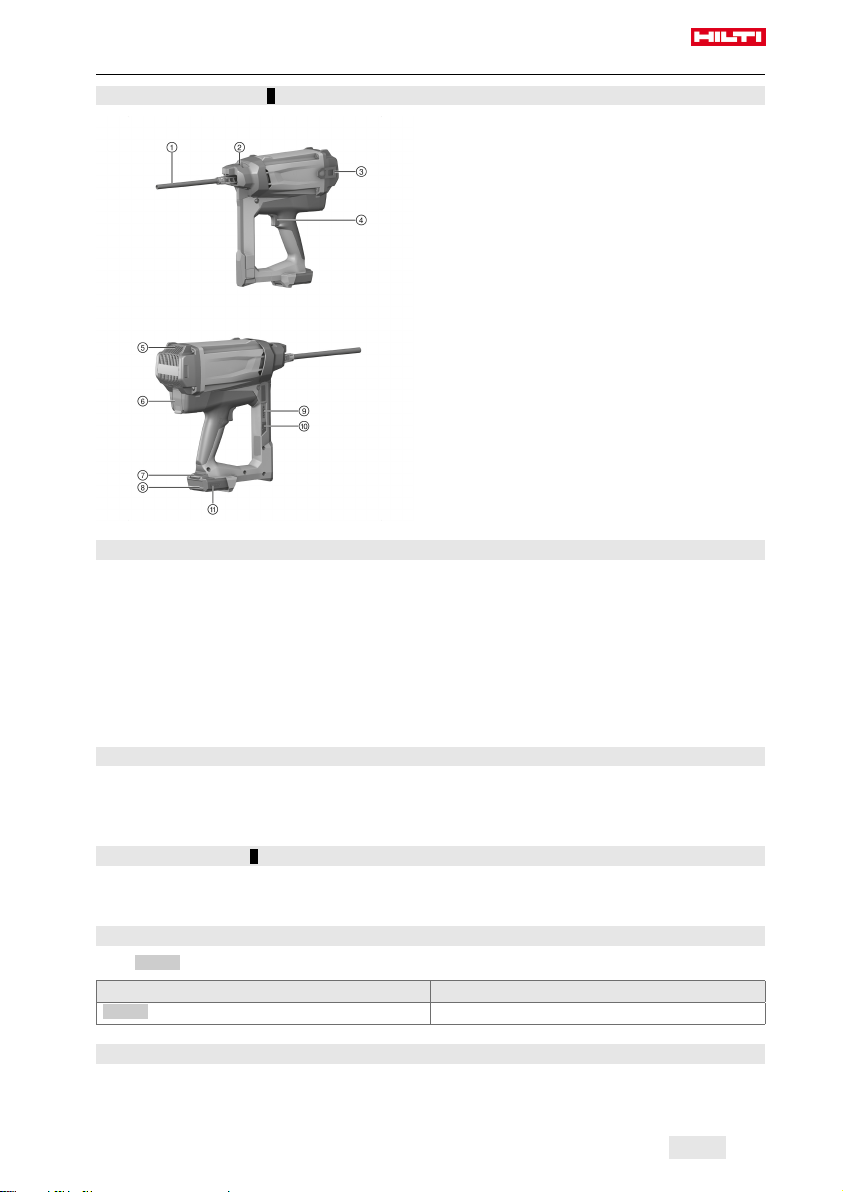

3.1 Product overview 1

Fastener guide

@

Fastener guide release slider

;

Belt hook

=

Safety trigger

%

Cooling air slots

&

Gas can compartment

(

Battery release button

)

Battery state of charge indicator

+

Gas can status indicator button

§

Gas can status indicator

/

Battery

:

3.2 Intended use

The product described is a gas-actuated fastening tool. It is for driving suitable fasteners into concrete and

other materials suitable for use of the direct fastening technique.

The fastening tool, gas can, battery and fasteners form a technical unit. This means that trouble-free

fastening with this fastening tool can be ensured only when it is used together with the fasteners, gas cans

and batteries specially manufactured for it by Hilti. The fastening and application recommendations made

by Hilti apply only when these conditions are observed.

The fastening tool is for hand-held use only.

▶ Use only Hilti Liion batteries of the B 12 series with this product.

▶ Use only Hilti battery chargers of the C 4/12-50 series for charging these batteries.

3.3 Items supplied

Gas-actuated fastening tool with fastener guide, 2 batteries, charger, toolbox and operating instructions.

Other system products approved for use with this product can be found at your local Hilti Center or online

at: www.hilti.com

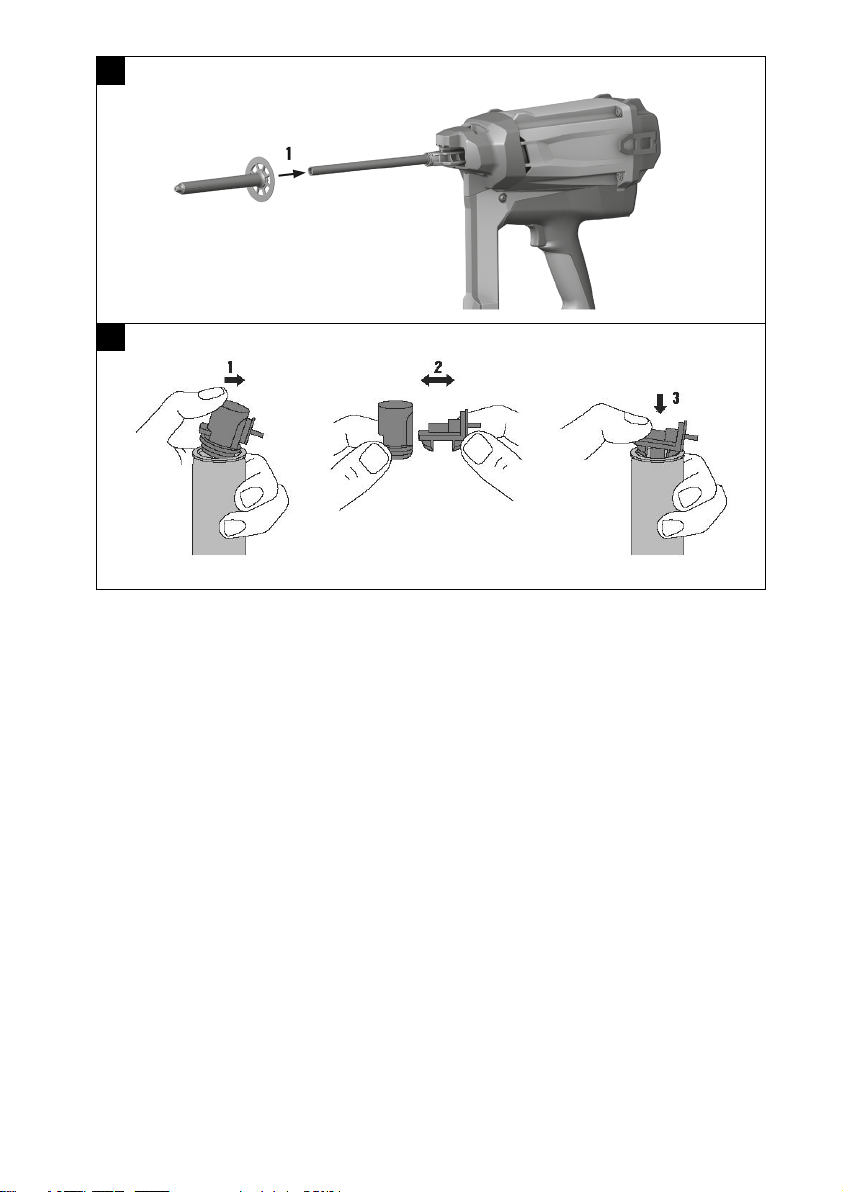

3.4 Fastener guide 2

The fastener guide holds the insulation plug and in the driving process it directs the fastener to the desired

position in the material.

3.5 Fastener guide release slider

In the EJECT position, the slider releases the fastener guide for removal.

Status Meaning

EJECT

3.6 Belt hook

The belt hook can be extended in three stages.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 English 5

• Fastener guide release

Page 11

Status Meaning

Position 1 • Position for attaching to a waist belt

Position 2 • Position for attaching to ladders, scaffolds,

Position 3 • Belt hook removed

3.7 Gas can

Observe the safety instructions provided with the gas can!

In order to operate the fastening tool, the gas can must be inserted in the gas can compartment.

The gas can status can be read from the LED display after pressing the GAS button.

The gas can must be removed before breaks between working, before maintenance and before transporting

or storing the fastening tool.

3.8 Indication of gas can status

After pressing the GAS button, the LED display indicates the status of the gas can.

Status Meaning

All four LEDs light green. • The level is between 100 % and 75 %.

Three LEDs light green. • The level is between 75 % and 50 %.

Two LEDs light green. • The level is between 50 % and 25 %.

One LED lights green. • The level is between 25 % and 10 %.

One LED blinks green. • Level is below 10 %. Replacement of the gas

One LED blinks red. • No gas can or the wrong type of gas can is

platforms, etc.

can is recommended.

• The gas can is empty or is malfunctioning.

Replacement of the gas can is recommended.

Even when the level is indicated as “empty”, the

gas can, for technical reasons, still contains a little

gas.

present in the fastening tool.

3.9 Indication of battery charge status

After pressing a battery release button, the display shows the status of the battery and the fastening tool.

Status Meaning

All four LEDs light green. • Charge status is 75 % to 100 %.

Three LEDs light green. • Charge status is 50 % to 75 %.

Two LEDs light green. • Charge status is 25 % to 50 %.

One LED lights green. • Charge status is 10 % to 25 %.

One LED blinks green. • Charge status is below 10 %.

• The fastening tool is overloaded or overheated

and thus not ready for operation.

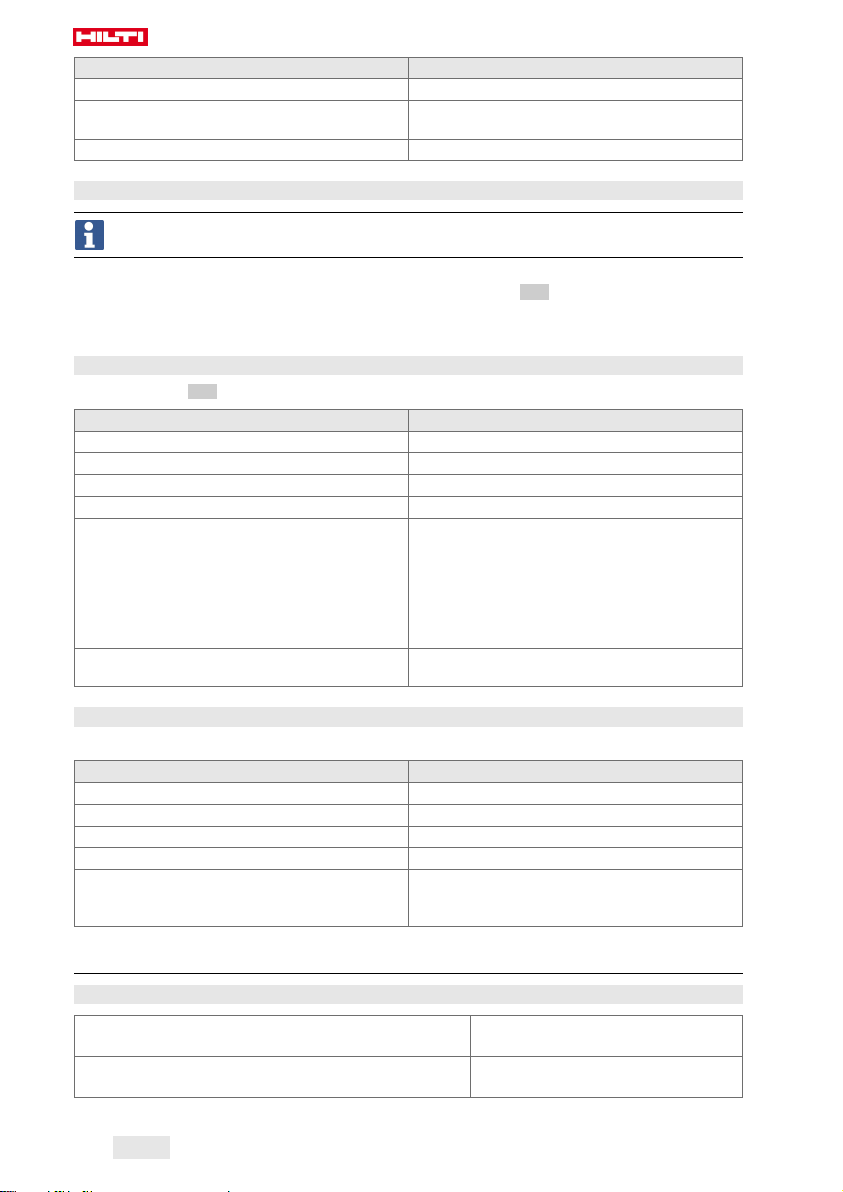

4 Technical data

4.1 Fastening tool

Weight (empty) GX 2-IE

Weight (empty) GX 2-IE-XL

6 English 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

3.3 kg

(7.3 lb)

3.4 kg

(7.5 lb)

*2208858*

Page 12

Tool length for GX 2-IE

Tool length for GX 2-IE-XL

Application temperature, ambient temperature

Maximum fastener length

Maximum fastener length for GX 2-IE-XL

Fastener diameter

Compression stroke

Maximum fastener driving frequency (Fasteners per hour)

500 mm

(19.7 in)

550 mm

(21.7 in)

−10 ℃ … 45 ℃

(14 ℉ … 113 ℉)

39 mm

(1.5 in)

200 mm

(7.9 in)

• 60 mm (2.4 in)

• 3.90 mm (0.154 in)

20 mm

(0.8 in)

800

5 Loading the fastening tool

5.1 Equipment required for driving fasteners

The fasteners are pushed manually on to the fastener guide.

5.2 Inserting the gas can

1. If you are using a new gas can, remove the transport safety device.

2. Open the gas can compartment cover.

3. Push the gas can (with metering valve fitted) into the red adapter in the gas can compartment.

4. Close the gas can compartment cover.

5.3 Inserting the battery

1. Check that the contacts on the battery and on the fastening tool are undamaged and free from foreign

objects.

2. Fit the battery and make sure that it is heard to engage.

◁ Once the battery has been fitted, the charge status LEDs light for a short time.

CAUTION

A falling battery presents a hazard. If the battery is not secured correctly it may drop out and fall while the

work is in progress.

▶ Check that the battery is seated securely.

3. Check that the battery is securely seated in the fastening tool.

6 Driving fasteners

WARNING

Risk of injury due to accidental actuation! The uncontrolled driving of a fastener can cause serious injury

▶ Never press the nosepiece of the tool against your hand or any other part of the body.

▶ Never pull back the magazine, fastener guide or fastener by hand.

1. Penetrate the insulating material with the fastener that is on the fastener guide.

2. Press the fastening tool against the working surface as far as it will go (until fully compressed).

3. Make sure that the fastener guide is perpendicular to the working surface and is seated against the

insulation.

4. Pull the safety trigger to drive a fastener.

It is not possible to drive a fastener if the fastening tool and the fastener are not pressed fully

against the working surface.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 English 7

Page 13

5. Lift the fastening tool completely away from the working surface after driving a fastener.

6. When you finish work or are going to leave the fastening tool unattended, remove the gas can ( → page 8)

and the battery ( ).

7 Unloading the fastening tool

7.1 Removing the battery

▶ Press the release button and pull the battery out of the fastening tool.

7.2 Removing the gas can

1. Open the gas can compartment.

2. Remove the gas can.

3. Close the gas can compartment.

8 Optional operating steps

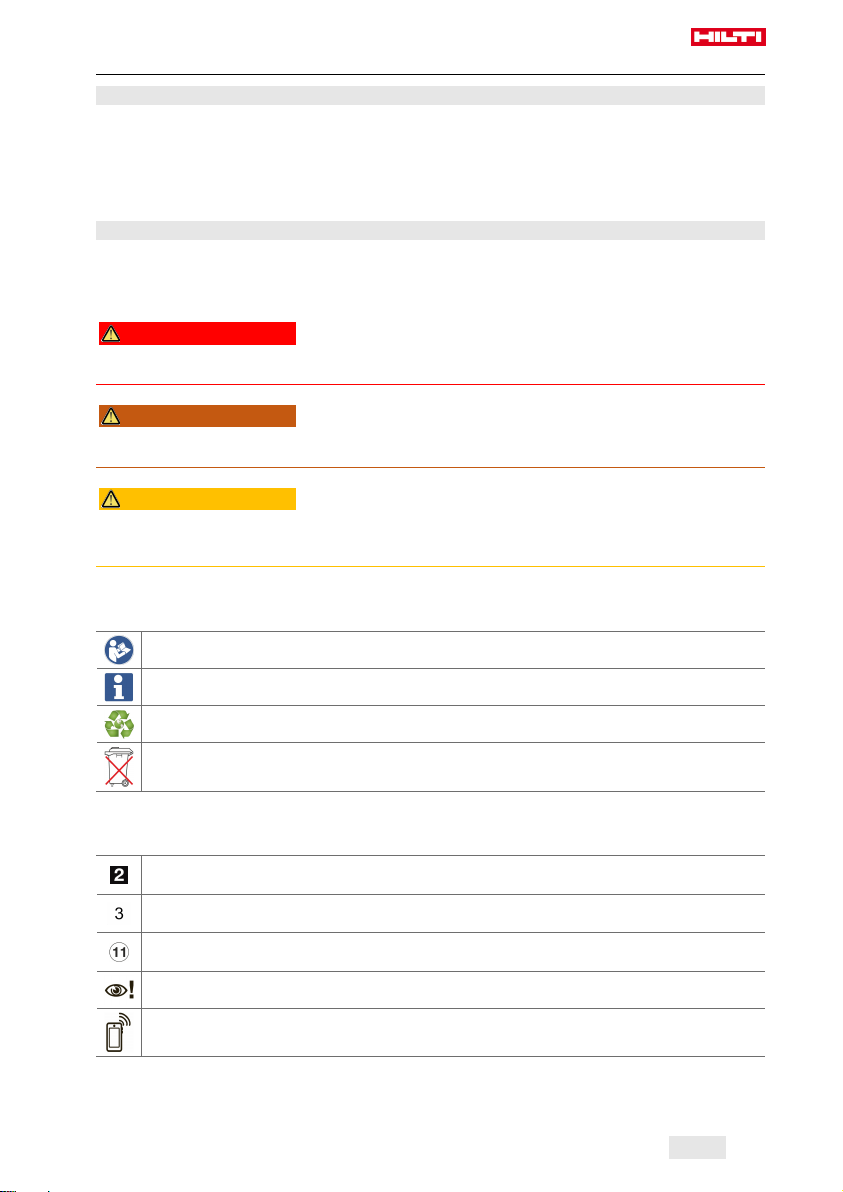

8.1 Removing the transport safety device from a new gas can 3

1. Lift the transport safety device, containing the metering valve, away from the gas can.

2. Remove the metering valve from the transport safety device.

3. Fit the metering valve onto the gas can, with the foremost of the two grooves on the lip of the can.

4. Press the metering valve firmly onto the gas can, bringing the rearmost groove towards the lip of the can,

until the metering valve is heard to snap into place over the lip and it then lies flush with the can.

8.2 Checking the status of the gas can

1.

After inserting the battery, press the GAS button without pressing the fastening tool against the working

surface.

2. Read the gas can status from the display.

8.3 Removing the fastener guide

1. Remove the battery.

2. Remove the gas can.

3.

Move the fastener guide release slider to the EJECT position.

4. Remove the fastener guide.

8.4 Inserting the fastener guide

1. Remove the gas can.

2. Remove the battery.

3.

Push the fastener guide release slider in the direction indicated by the arrow to the EJECT position and

hold it there.

The fastener guide can be inserted only when the slider is held in the EJECT position.

4. Slide the fastener guide into the slot in the nose of the fastening tool until it engages with an audible click.

5. Check that the fastener guide is seated correctly.

9 Remedying possible malfunctions

9.1 Removing foreign objects from the area of the fastener guide

1. Remove the battery.

2. Remove the gas can.

3. Remove the fastener guide.

4. Remove all foreign objects from the area of the fastener guide.

5. Insert the fastener guide.

8 English 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 14

10 Care and maintenance

10.1 Caring for the fastening tool

▶ Clean the fastening tool regularly with a cloth.

▶ Keep the grip areas free from oil and grease.

▶ Do not use spray equipment, pressure jet washers or running water for cleaning.

▶ Do not use cleaning agents containing silicone.

▶ Do not use sprays or similar lubricating and cleaning agents.

▶ Never operate the fastening tool if the cooling air slots are blocked.

10.2 Cleaning the fastening tool

The fastening tool must be cleaned and serviced regularly. We recommend that a cleaning service is

carried out, at the latest, after driving 25,000 fasteners.

▶ Clean the fastening tool, or have it cleaned, if malfunctions such as misfiring occur increasingly.

▶ For cleaning, use the cleaning set (available as an accessory) and observe the illustrated cleaning

instructions enclosed with it.

10.3 Maintenance

▶ To help ensure safe and reliable operation, use only genuine Hilti spare parts and consumables. Spare

parts, consumables and accessories approved by Hilti for use with the product can be found at your

local Hilti Center or online at: www.hilti.group.

▶ Check all external parts of the fastening tool for signs of damage at regular intervals and make sure that

all the controls function correctly.

▶ Do not use the fastening tool if parts are damaged or if the controls do not function correctly.

▶ Have a defective fastening tool repaired by Hilti Service.

10.4 Checks after care and maintenance work

▶ After maintenance, check that the fastener guide is fitted.

11 Troubleshooting

If the trouble you are experiencing is not listed in this table or you are unable to remedy the problem by

yourself, please contact Hilti Service.

Trouble or fault Possible cause Action to be taken

The content of the gas can is

inadequate for the number of

fasteners in the package.

The fastener guide hasn’t

fully extended after driving

a fastener.

No fastener is driven. The battery is discharged ▶ Change the battery or charge

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 English 9

High gas consumption due to frequent compression of the tool

nosepiece without driving a fastener.

Foreign matter or debris has

jammed in the fastener guide.

Fastener guide is worn. ▶ Replace the fastener guide.

Empty gas can ▶ Check the status of the gas can.

LED 1 lights red ▶ Check the status of the gas can.

Incorrect piston position due to

lifting the tool away too soon after

driving the fastener.

▶ Avoid compressing the tool

nosepiece without driving a

fastener.

▶ Remove the fastener guide.

▶ Clean the fastener guide.

▶ Remove foreign matter from the

area of the fastener guide.

the empty battery.

→ page 8

→ page 8

▶ Keep the tool pressed against

the surface for longer.

Page 15

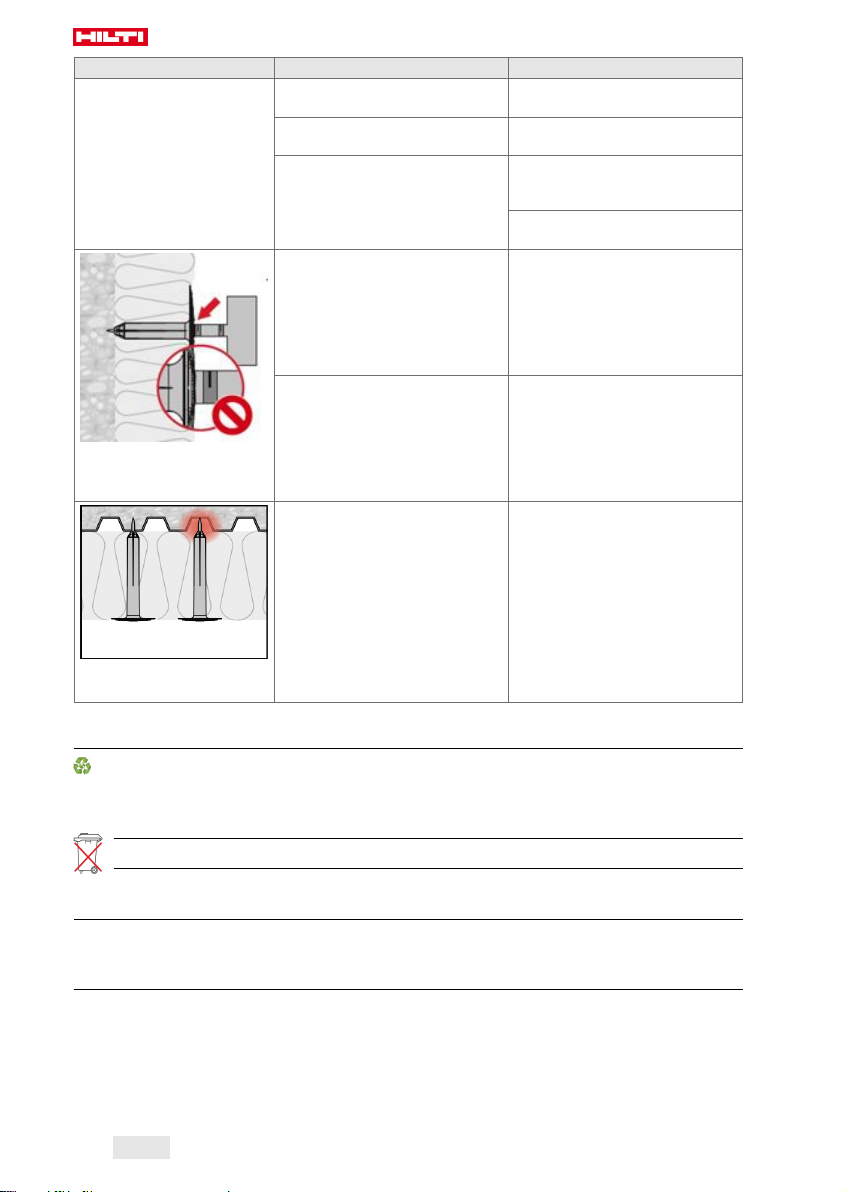

Trouble or fault Possible cause Action to be taken

No fastener is driven. Incorrect piston position due to

foreign-matter build-up

Foreign object in the area of the

fastener guide.

Electronic fault. ▶ Remove the gas can and then

The system is unsuitable. The supporting material is too hard.

▶ Clean the fastening tool.

▶ Remove foreign objects from

the area of the fastener guide.

reinsert it. If the problem

persists, use a new gas can.

▶ Remove the battery and then

reinsert it.

▶ Switch to a Hilti DX system.

Drive energy too low. ▶ Check the tool. Contact Hilti

Fastener does not penetrate

deeply enough into the material.

Surface of the material is too uneven.

Surface of the material is too

uneven.

Service.

▶ Switch to a Hilti DX system.

12 Disposal

Most of the materials from which Hilti tools and appliances are manufactured can be recycled. The

materials must be correctly separated before they can be recycled. In many countries, your old tools,

machines or appliances can be returned to Hilti for recycling. Ask Hilti Service or your Hilti representative

for further information.

▶ Do not dispose of power tools, electronic equipment or batteries as household waste!

13 Manufacturer’s warranty

▶ Please contact your local Hilti representative if you have questions about the warranty conditions.

14 FCC statement (applicable in US) / IC statement (applicable in Canada)

This device complies with Part 15 of the FCC Rules and RSS-210 of IC. Operation is subject to the following

two conditions:

1. This device shall cause no harmful interference.

2. This device must accept any interference received, including interference that may cause undesired

operation.

10 English 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 16

1 Indications relatives à la documentation

1.1 À propos de cette documentation

• Lire intégralement la présente documentation avant la mise en service. C'est la condition préalablement

requise pour assurer la sécurité du travail et un maniement sans perturbations.

• Bien respecter les consignes de sécurité et les avertissements de la présente documentation ainsi que

celles figurant sur le produit.

• Toujours conserver le mode d'emploi à proximité du produit et uniquement le transmettre à des tiers

avec ce mode d'emploi.

1.2 Explication des symboles

1.2.1 Avertissements

Les avertissements attirent l'attention sur des dangers liés à l'utilisation du produit. Les termes de

signalisation suivants sont utilisés :

DANGER

DANGER !

▶ Pour un danger imminent qui peut entraîner de graves blessures corporelles ou la mort.

AVERTISSEMENT

AVERTISSEMENT !

▶ Pour un danger potentiel qui peut entraîner de graves blessures corporelles ou la mort.

ATTENTION

ATTENTION !

▶ Pour attirer l'attention sur une situation pouvant présenter des dangers entraînant des blessures

corporelles légères ou des dégâts matériels.

1.2.2 Symboles dans la documentation

Les symboles suivants sont utilisés dans la présente documentation :

Lire le mode d'emploi avant d'utiliser l'appareil

Pour des conseils d'utilisation et autres informations utiles

Maniement des matériaux recyclables

Ne pas jeter les appareils électriques et les accus dans les ordures ménagères

1.2.3 Symboles dans les illustrations

Les symboles suivants sont utilisés dans les illustrations :

Ces chiffres renvoient à l'illustration correspondante au début du présent mode d'emploi

La numérotation détermine la séquence des étapes de travail dans l'image et peut se différencier

de celles des étapes de travail dans le texte

Les numéros de position sont utilisés dans l'illustration Vue d’ensemble et renvoient aux numé-

ros des légendes dans la section Vue d'ensemble du produit

Ce signe doit inviter à manier le produit en faisant particulièrement attention.

Transmission de données sans fil

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Français 11

Page 17

1.3 Symboles spécifiques au produit

1.3.1 Symboles sur le produit

Les symboles suivants sont utilisés sur le produit :

Symboles d'obligation généraux

Porter des lunettes de protection

Porter un casque antibruit

Porter un casque de protection

Recycler les déchets

1.3.2 Mise en évidence de désignations et inscriptions

Les désignations et inscriptions sont mises en évidence comme suit :

‚ ‛ Désignation des organes de commande pourvus d'une inscription sur le cloueur.

« » Inscriptions sur le cloueur

1.4 Informations produit

Les produits Hilti sont conçus pour les utilisateurs professionnels et ne doivent être utilisés, entretenus et

réparés que par un personnel agréé et formé à cet effet. Ce personnel doit être au courant des dangers

inhérents à l'utilisation de l'appareil. Le produit et ses accessoires peuvent s'avérer dangereux s'ils sont

utilisés de manière incorrecte par un personnel non qualifié ou de manière non conforme à l'usage prévu.

▶ Reporter la désignation et le numéro de série qui se trouvent sur la plaque signalétique dans le tableau

suivant.

▶ Toujours fournir ces informations en cas de questions relatives au produit pour communiquer avec notre

représentant ou agence Hilti.

Caractéristiques produit

Cloueur à gaz GX-IE

Génération : 01

Numéro de série :

GX-IE XL

1.5 Déclaration de conformité

Nous déclarons sous notre seule et unique responsabilité que le produit décrit ici est conforme aux directives

et normes en vigueur. Une copie de l'attestation délivrée par l'organisme de certification se trouve en fin de

la présente documentation.

Pour obtenir les documentations techniques, s'adresser à :

Hilti Entwicklungsgesellschaft mbH | Zulassung Geräte | Hiltistraße 6 | 86916 Kaufering, DE

2 Sécurité

2.1 Consignes de sécurité

Ces consignes de sécurité valent pour les appareils avec et sans chargeur.

Travail en toute sécurité avec le cloueur

▶

Si le cloueur est appuyé contre une partie du corps, un déclenchement d'un tir par mégarde peut

entraîner de graves blessures. Ne jamais appuyer le cloueur contre la main ou contre toute autre

partie du corps.

▶ Lors du montage des fixations spécifiques aux applications sur le canon (p. ex. rondelles, colliers de

fixation, attaches, etc.), un déclenchement d'un tir par mégarde peut entraîner de graves blessures. Ne

jamais appuyer une main ou une partie du corps contre le canon lors du montage des fixations

spécifiques aux applications sur le canon.

▶ Ne jamais diriger le cloueur vers soi ou vers une autre personne.

12 Français 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 18

▶ Lors du maniement du cloueur, garder les bras fléchis (ne pas tendre les bras).

▶ Lors du retrait du poussoir à clous, toujours veiller à ce qu'il s'encliquette.

▶ Lors du déblocage de l'enclenchement de sécurité, guider le poussoir à clous vers l'avant afin

d'éviter qu'il ne se dégage trop rapidement. L'utilisateur risque de se coincer les doigts.

▶ Ne pas implanter d'éléments de fixation dans un matériau support trop dur, comme de l'acier soudé

ou de l'acier fondu. Une implantation dans ces matériaux peut entraîner des ratés de tir ou rendre les

éléments de fixation cassants.

▶ Ne pas implanter d'éléments de fixation dans un matériau support trop mou, comme du bois ou du

placoplâtre. Une implantation dans ces matériaux peut entraîner des ratés de tir et des perforations du

matériau support.

▶

Ne pas implanter d'éléments de fixation dans un matériau support trop fragile, comme du verre ou du

carrelage. Une implantation dans ces matériaux peut entraîner des ratés de tir et une projection d'éclats

du matériau support.

▶ Avant d'implanter, vérifier qu'il n'y a aucun risque de blesser une personne ou d'endommager des objets

à l'arrière du matériau support.

▶ Actionner le déclencheur uniquement lorsque le cloueur est complètement appuyé contre le matériau

support, de telle sorte que le canon rentre jusqu'en butée dans le cloueur.

▶ Porter impérativement des gants de protection lorsque des opérations d'entretien doivent être

effectuées sur un cloueur chaud.

▶ En cas de cadences de tir élevées pendant une période prolongée, les surfaces hors de la partie

préhensible risquent de devenir brûlantes. Porter des gants de protection contre les brûlures.

▶ En cas de surchauffe du cloueur, retirer la cartouche de gaz et laisser le cloueur refroidir. Ne pas

dépasser la cadence de tir maximale.

▶ Pendant le tir, le matériau peut s'écailler ou des fragments du matériau de bande-chargeur peuvent

être projetés. Les éclats de matière peuvent entraîner des blessures corporelles et aux yeux. Utiliser

des lunettes de protection, un casque antibruit et un casque de protection. Le fait de porter

des équipements de protection personnels tels que masque anti-poussières, chaussures de sécurité

antidérapantes, casque de protection ou protection acoustique, suivant le travail à effectuer avec le

cloueur, réduit le risque de blessures. Les autres personnes se trouvant à proximité doivent également

porter des lunettes de protection et un casque de protection.

▶ Porter un casque antibruit approprié (voir les données d'émissions acoustiques dans les caractéristiques

techniques). L'implantation des éléments de fixation est déclenchée par la mise à feu d'un mélange

air-gaz. Les nuisances sonores ainsi générées peuvent entraîner une perte d'acuité auditive. Même les

personnes environnantes doivent porter un casque antibruit approprié.

▶ Toujours maintenir le cloueur fermement et perpendiculairement au matériau support pour déclencher

un tir. Cela contribue à ce que l'élément de fixation ne soit pas dévié du matériau support.

▶ Ne jamais implanter un deuxième élément de fixation au même endroit. Cela risque de rendre les

éléments de fixation cassants et de les coincer.

▶ Toujours retirer la cartouche de gaz et l'accu et vider le chargeur, avant de remplacer le chargeur ou de

procéder aux travaux de nettoyage, de service et d'entretien, ainsi qu'avant le stockage et le transport,

ou si le cloueur est laissé sans surveillance.

▶ Vérifier que le cloueur et les accessoires ne sont pas endommagés, pour assurer un fonctionnement

sans défaillances et conforme à sa destination. Vérifier que toutes les pièces mobiles fonctionnent

parfaitement et ne coincent pas, et que les pièces ne sont pas abîmées. Toutes les pièces doivent être

montées correctement et remplir toutes les conditions propres à garantir le parfait fonctionnement du

cloueur. Les dispositifs de sécurité et les pièces endommagés doivent être réparés ou remplacés de

manière professionnelle par le S.A.V. Hilti, sauf indication contraire dans le mode d'emploi.

▶ Ne faire réparer le cloueur que par un personnel qualifié et seulement avec des pièces de rechange

d'origine. Ceci permet d'assurer la sécurité du cloueur.

▶ Toute manipulation ou modification du cloueur est interdite.

▶ Ne pas utiliser le cloueur dans des endroits présentant un danger d'incendie ou d'explosion.

▶ Prêter attention aux influences de l'environnement. Protéger le cloueur des intempéries, et ne pas

l'utiliser dans un environnement humide ou mouillé.

▶ Utiliser le cloueur uniquement dans des emplacements bien aérés.

▶ Utiliser les combinaisons de canon et d'éléments de fixation appropriées. Une combinaison erronée

risque d'endommager le cloueur ou de nuire à la qualité de la fixation.

▶ Toujours respecter les consignes d’utilisation.

Risques liés au courant électrique

▶ Avant d'entamer les travaux, contrôler l'espace de travail, p. ex. à l'aide d'un détecteur de métaux,

afin de vérifier l'absence de câbles ou gaines électriques, conduites de gaz ou d'eau cachés.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Français 13

Page 19

▶ Tenir le cloueur uniquement par la poignée isolée s'il y a un risque lors des travaux de toucher des câbles

électriques cachés. Le contact avec un câble sous tension risque de mettre les parties métalliques du

cloueur sous tension et de provoquer une décharge électrique.

Utilisation et emploi soigneux des appareils sans fil

▶ S'assurer que l’appareil est effectivement en position d’arrêt avant de monter l’accumulateur. Le

fait de monter un accumulateur dans un outil électroportatif en position de fonctionnement peut causer

des accidents.

▶ Ne pas exposer les accus à des températures élevées, ni au rayonnement direct du soleil ni au

feu. Il y a risque d'explosion.

▶ Les accus ne doivent pas être démontés, écrasés, chauffés à une température supérieure à 80 °C

ou jetés au feu. Sinon, il y a risque d'incendie, d'explosion et de brûlure par l'acide.

▶

Éviter toute pénétration d'humidité. Toute infiltration d'humidité risque de provoquer un court-circuit

et des brûlures ou un incendie.

▶ Utiliser uniquement les accus homologués pour l'appareil concerné. En cas d'utilisation d'autres

accus ou d'utilisation des accus à d'autres fins, il y a risque d'incendie et d'explosion.

▶ Respecter les directives spécifiques relatives au transport, au stockage et à l'utilisation des accus

LiIon.

▶ Pour le stockage et le transport, sortir l'accu de l'appareil.

▶

Éviter tout court-circuit sur l'accu. S'assurer que les contacts de l'accu et de l'appareil sont

exempts de corps étrangers, avant d'introduire l'accu dans l'appareil. Si les contacts d'un accu sont

court-circuités, il y a risque d'incendie, d'explosion et de brûlure par acide.

▶ Les accus endommagés (p. ex. accus fissurés, pièces cassées, contacts tordus, déformés vers

l'intérieur ou l'extérieur) ne doivent plus être chargés ni utilisés.

▶ Si un accu est trop chaud pour être touché, il peut être défectueux. Laisser l'accu refroidir dans un

endroit ininflammable. S'assurer qu'il n'y a aucun matériau inflammable à proximité. Contacter le S.A.V.

Hilti.

Consignes quant au maniement du gaz utilisé

▶ Respecter les consignes d'utilisation figurant sur la cartouche de gaz et les informations descriptives qui

l'accompagnent.

▶ Les émanations de gaz sont nocives pour les poumons, la peau et les yeux. Tenir le visage et les yeux

éloignés du compartiment à cartouche de gaz pendant 10 secondes après avoir retiré la cartouche de

gaz.

▶ Ne pas actionner manuellement la soupape de la cartouche de gaz.

▶ Si une personne a inhalé du gaz, l'accompagner sans tarder à l'air libre ou dans un local bien ventilé et

lui faire adopter une position confortable. Si nécessaire, consulter un médecin.

▶ Si une personne est inconsciente, consulter un médecin. Installer la personne dans un local bien

ventilé et la mettre sur le côté dans une position stable. Si la personne ne respire plus, lui faire du

bouche-à-bouche et, si nécessaire, utiliser une source d'oxygène.

▶ En cas de contact du gaz avec les yeux, rincer les yeux ouverts pendant plusieurs minutes à l'eau

courante.

▶ En cas de contact du gaz avec la peau, nettoyer soigneusement les zones de contact avec du savon et

de l'eau chaude. Appliquer ensuite une crème de soins pour la peau.

Consignes générales relatives à la sécurité personnelle

▶ Veiller à adopter une posture ergonomique. Veiller à toujours garder une position stable et équilibrée.

Ceci permet de mieux contrôler le cloueur dans des situations inattendues.

▶ Lors des travaux, tenir toute tierce personne, notamment les enfants, éloignés du champ d'action.

14 Français 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 20

3 Description

3.1 Vue d'ensemble du produit 1

Canon

@

Curseur de déverrouillage du canon

;

Patte d'accrochage à la ceinture

=

Déclencheur

%

Ouïes d'aération

&

Compartiment de la cartouche de gaz

(

Bouton de déverrouillage de l'accu

)

Indicateur de l'état de charge de l'accu

+

Touche pour l'affichage de la cartouche de

§

gaz

Affichage de la cartouche de gaz

/

Accu

:

3.2 Utilisation conforme à l'usage prévu

Le produit décrit est un cloueur à gaz. Il est conçu pour planter des éléments de fixation appropriés dans le

béton et d'autres matériaux support appropriés à montage direct.

Le cloueur, la cartouche de gaz, l'accu et les éléments de fixation forment une unité technique. Cela signifie

que des fixations sans problèmes avec ce cloueur peuvent uniquement être garanties, si les éléments de

fixation ainsi que les recharges de gaz et les accus de Hilti spécifiquement conçus pour le cloueur sont

utilisés. Les recommandations de Hilti concernant les fixations et applications sont uniquement valables

dans ces conditions.

Le cloueur ne doit être utilisé que tenu à la main.

▶ Pour ce produit, utiliser exclusivement les accus LiIon Hilti de la série B 12.

▶ Pour ces accus, utiliser exclusivement les chargeurs Hilti de la série C 4/12-50.

3.3 Équipement livré

Cloueur à gaz avec canon, 2 accus, chargeur, coffret, mode d'emploi.

D'autres produits système autorisés pour votre produit peuvent être obtenus auprès du S.A.V. Hilti ou en

ligne sous : www.hilti.com

3.4 Canon 2

Le canon maintient la cheville isolant et dirige l'élément de fixation lors du tir à l'endroit voulu dans le matériau

support.

3.5 Curseur de déverrouillage du canon

Dans la position EJECT, le curseur déverrouille le canon pour le retrait.

État Signification

EJECT

3.6 Patte d'accrochage à la ceinture

La patte d'accrochage à la ceinture peut être tirée à trois niveaux.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Français 15

• Déverrouillage du canon

Page 21

État Signification

Niveau 1 • Position pour l'accrochage à la ceinture

Niveau 2 • Position pour l'accrochage à une échelle, un

échafaudage, un portique, etc.

Niveau 3 • Patte d'accrochage à la ceinture enlevée

3.7 Cartouche de gaz

Respecter les consignes de sécurité qui sont fournies avec la cartouche de gaz !

Pour son utilisation, la cartouche de gaz doit être introduite dans le compartiment à cartouche du cloueur.

L'état de la cartouche de gaz peut être lu sur l'afficheur à LED après avoir appuyé sur la touche GAS.

En cas d'interruptions de travail, avant les travaux d'entretien et avant le stockage et le transport du cloueur,

il faut retirer la cartouche de gaz.

3.8 Indication du niveau de charge de la cartouche de gaz

Après avoir appuyé sur la touche GAS, l'afficheur à LED indique l'état de la cartouche de gaz.

État Signification

Toutes les quatre LED sont allumées en vert. • L'état de charge est de 100 % à 75 %.

Trois LED sont allumées en vert. • L'état de charge est de 75 % à 50 %.

Deux LED sont allumées en vert. • L'état de charge est de 50 % à 25 %.

Une LED est allumée en vert. • L'état de charge est de 25 % à 10 %.

Une LED clignote en vert. • Niveau de remplissage inférieur à 10 %. Il est

recommandé de remplacer la cartouche de gaz.

• La cartouche de gaz est vide ou non opérationnelle. Il est recommandé de remplacer la

cartouche de gaz.

Même si l'état de remplissage affiché est "vide", la

cartouche de gaz contient pour des raisons techniques encore un peu de gaz.

Une LED clignote en rouge. • Soit il n'y a pas de cartouche de gaz dans le

cloueur, soit le type de cartouche ne convient

pas.

3.9 Indication du niveau de charge de l'accu

Lorsque la touche de déverrouillage de l'accu est actionnée, l'afficheur indique le niveau de charge de l'accu

et du cloueur.

État Signification

Toutes les quatre LED sont allumées en vert. • L'état de charge est de 75 % à 100 %.

Trois LED sont allumées en vert. • L'état de charge est de 50 % à 75 %.

Deux LED sont allumées en vert. • L'état de charge est de 25 % à 50 %.

Une LED est allumée en vert. • L'état de charge est de 10 % à 25 %.

Une LED clignote en vert. • L'état de charge est inférieur à 10 %.

• Le cloueur n'est pas prêt à fonctionner car il est

surchargé ou surchauffé.

16 Français 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 22

4 Caractéristiques techniques

4.1 Cloueur

Poids (à vide) GX 2-IE

Poids (à vide) GX 2-IE-XL

Longueur de l'appareil pour GX 2-IE

Longueur de l'appareil pour GX 2-IE-XL

Température de service, température ambiante

Longueur maximale des éléments de fixation

Longueur maximale des éléments de fixation pour GX 2IE-XL

Diamètre des éléments de fixation

Course d'implantation

Cadence de tir maximale (Éléments de fixation/h)

3,3 kg

(7,3 lb)

3,4 kg

(7,5 lb)

500 mm

(19,7 in)

550 mm

(21,7 in)

−10 ℃ … 45 ℃

(14 ℉ … 113 ℉)

39 mm

(1,5 in)

200 mm

(7,9 in)

• 60 mm (2,4 in)

• 3,90 mm (0,154 in)

20 mm

(0,8 in)

800

5 Chargement du cloueur

5.1 Équipements pour l'implantation d'éléments de fixation

Les éléments de fixation sont poussés à la main sur le canon.

5.2 Insertion de la cartouche de gaz

1. Si une nouvelle cartouche de gaz est mise en place, retirer la sécurité de transport.

2. Ouvrir le couvercle du compartiment à cartouche de gaz.

3. Pousser la cartouche de gaz avec lavanne de dosagemontée et l'adaptateur rouge dans le compartiment

de la cartouche de gaz.

4. Fermer le couvercle du compartiment à cartouche de gaz.

5.3 Introduction de l'accu

1. S'assurer que les contacts de l'accu et du cloueur sont exempts de corps étrangers et qu'ils ne sont pas

endommagés.

2. Insérer l'accu et veiller à ce qu'il s'encliquette en butée de manière audible.

◁ Une fois l'accu introduit, les LED indicateurs de l'état de charge s'allument brièvement.

ATTENTION

Risques en cas de chute de l'accu. Si l'accu n'est pas correctement verrouillé, il risque de tomber pendant

le travail.

▶ Vérifier que l'accu est bien en place.

3. Vérifier que l'accu est bien en place dans le cloueur.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Français 17

Page 23

6 Tir d'éléments de fixation

AVERTISSEMENT

Risque de blessures entraînées par un déclenchement d'un tir par mégarde ! Une implantation

incontrôlée peut entraîner de graves blessures

▶ Ne jamais appuyer le cloueur contre la main ou contre toute autre partie du corps.

▶ Ne jamais retirer à la main le chargeur, le canon ou des éléments de fixation.

1. Pénétrer dans le matériau isolant avec l'élément de fixation qui se trouve sur le canon.

2. Appuyer le cloueur jusqu'en butée contre le matériau support.

3. Veiller à ce que le canon soit perpendiculaire au matériau support et qu'il repose sur le matériau isolant.

4. Pour implanter, appuyer sur le déclencheur.

L'implantation n'est pas possible si le cloueur et l'élément de fixation ne sont pas appuyés jusqu'en

butée contre le matériau support.

5. Une fois l'implantation terminée, relever complètement le cloueur du matériau support.

6. En fin de travail ou si le cloueur est laissé sans surveillance, retirer la cartouche de gaz ( → Page 18) et

l'accu ( ).

7 Déchargement du cloueur

7.1 Retrait de l'accu

▶ Appuyer sur le bouton de déverrouillage et sortir l'accu du cloueur.

7.2 Retrait de la cartouche de gaz

1. Ouvrir le compartiment à cartouche de gaz.

2. Retirer la cartouche de gaz.

3. Fermer le compartiment à cartouche de gaz.

8 Opérations optionnelles

8.1 Retrait de la sécurité de transport de la cartouche de gaz neuve 3

1. Lever la sécurité de transport avec la vanne de dosage qu'elle contient de la cartouche de gaz.

2. Sortir la vanne de dosage de la sécurité de transport.

3. Poser la vanne de dosage avec la rainure avant des deux rainures sur la lèvre de la cartouche de gaz.

4. Presser fortement la vanne de dosage avec la rainure arrière contre la lèvre de la cartouche de gaz,

jusqu'à ce que la rainure s'encliquette de manière audible sur la lèvre de la cartouche de gaz et que la

vanne de dosage soit à plat.

8.2 Contrôle de la cartouche de gaz

1.

Avec l'accu inséré, appuyer sur la touche GAS sans presser le cloueur.

2. Vérifier l'état de la cartouche de gaz.

8.3 Retrait du canon

1. Enlever l'accu.

2. Retirer la cartouche de gaz.

3.

Mettre le curseur de déverrouillage du canon sur la position EJECT.

4. Sortir le canon.

8.4 Mise en place du canon

1. Retirer la cartouche de gaz.

2. Enlever l'accu.

18 Français 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 24

3.

Mettre le curseur de déverrouillage du canon sur la position EJECT dans la direction de la flèche et le

maintenir dans cette position.

Le canon peut seulement être introduit si la position EJECT est maintenue.

4. Introduire le canon dans la fente du nez du cloueur jusqu'à ce qu'il s'encliquette de manière audible.

5. Vérifier que le canon est bien en place.

9 Dépannage

9.1 Retrait des corps étrangers dans et aux alentours du canon

1. Enlever l'accu.

2. Retirer la cartouche de gaz.

3. Retirer le canon.

4. Enlever tous les corps étrangers dans et aux alentours du canon.

5. Mettre le canon en place.

10 Nettoyage et entretien

10.1 Maniement soigneux du cloueur

▶ Nettoyer régulièrement le cloueur avec un chiffon.

▶ Veiller à ce que les parties préhensibles soient toujours exemptes d'huile et de graisse.

▶ Pour le nettoyage, n'utiliser ni pulvérisateur, ni appareil à jet de vapeur, ni eau courante.

▶ Ne pas utiliser de nettoyants à base de silicone.

▶ Ne pas utiliser de spray ou tout autre lubrifiant et/ou nettoyant similaires.

▶ Ne jamais faire fonctionner le cloueur si ses ouïes d'aération sont bouchées.

10.2 Nettoyage du cloueur

Le cloueur doit être régulièrement entretenu et nettoyé. Nous recommandons un service de nettoyage

au plus tard toutes les 25.000 fixations.

▶ Nettoyer le cloueur ou le faire nettoyer, dès lors que des défaillances à répétition surviennent, telles que

des ratés de mise à feu du gaz.

▶ Pour nettoyer, utiliser le kit de nettoyage disponible en tant qu'accessoire et respecter les instructions

d'utilisation illustrées se rapportant au kit de nettoyage.

10.3 Entretien

▶ Pour une utilisation en toute sécurité, utiliser uniquement des pièces de rechange et consommables

d'origine. Les pièces de rechange, consommables et accessoires autorisés convenant pour le produit

sont disponibles auprès d'un centre Hilti ou sous : www.hilti.group.

▶ Contrôler régulièrement toutes les pièces extérieures du cloueur afin de vérifier qu'elles ne sont pas

abîmées et s'assurer que tous les organes de commande fonctionnent correctement.

▶ Ne pas utiliser le cloueur si des pièces sont abîmées ou si des organes de commande ne fonctionnent

pas parfaitement.

▶ Faire réparer tout cloueur défectueux par le service Hilti.

10.4 Contrôle après des travaux de nettoyage et d'entretien

▶ Après des travaux de nettoyage et d'entretien, s'assurer que le canon est en place.

11 Aide au dépannage

En cas de défaillances non énumérées dans ce tableau ou auxquelles il n'est pas possible de remédier sans

aide, contacter le S.A.V. Hilti.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Français 19

Page 25

Défaillance Causes possibles Solution

Le contenu de la cartouche

de gaz ne suffit pas pour

l'unité de conditionnement

Consommation de gaz accrue du

fait d'un actionnement trop fréquent sans implantation.

▶ Éviter d'actionner sans implan-

ter.

des éléments de fixation.

Après un tir, le canon n'est

pas complètement sorti.

Un corps étranger ou des débris

sont restés coincés dans le canon.

▶ Retirer le canon.

▶ Nettoyer le canon.

▶ Enlever tout corps étranger

dans et aux alentours du canon.

Le canon est usé. ▶ Remplacer le canon.

Le cloueur n'implante pas. Accu vide ▶ Remplacer l'accu ou charger

l'accu vide.

La cartouche de gaz est vide ▶ Contrôler l'état de la cartouche

de gaz. → Page 18

LED 1 allumée en rouge ▶ Contrôler l'état de la cartouche

de gaz. → Page 18

Position incorrecte du piston du

fait du retrait trop précoce après le

▶ Laisser le cloueur appuyé plus

longtemps.

tir

Position incorrecte du piston à

▶ Nettoyer le cloueur.

cause d'encrassement

Corps étrangers dans et aux alen-

tours du canon

▶ Enlever tout corps étranger

dans et aux alentours du canon.

Défaut électronique ▶ Retirer la cartouche de gaz

et la remettre en place. Si le

problème persiste, mettre une

cartouche de gaz neuve.

▶ Enlever l'accu et le remettre en

place.

Système inapproprié. Matériau

▶ Passer à un système Hilti DX.

support trop dur

Force motrice trop faible. ▶ Contrôler l'appareil. Contacter

le S.A.V. Hilti.

L'élément de fixation ne pénètre pas suffisamment profondément dans le matériau

support.

Surface du matériau support trop

▶ Passer à un système Hilti DX.

inégale.

Surface du matériau support

trop inégale.

20 Français 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 26

12 Recyclage

Les appareils Hilti sont fabriqués pour une grande partie en matériaux recyclables. Le recyclage

présuppose un tri adéquat des matériaux. Hilti reprend les appareils usagés dans de nombreux pays en vue

de leur recyclage. Consulter le service clients Hilti ou un conseiller commercial.

▶ Ne pas jeter les appareils électriques, électroniques et accus dans les ordures ménagères !

13 Garantie constructeur

▶ En cas de questions sur les conditions de garantie, veuillez vous adresser à votre partenaire Hilti local.

14 Déclaration FCC (applicable aux États-Unis / Déclaration IC (applicable au Ca-

nada)

Cet appareil est conforme au paragraphe 15 des dispositions FCC et RSS210 de IC. La mise en service est

soumise aux deux conditions suivantes :

1. Cet appareil ne devrait pas générer de rayonnements nuisibles.

2. L'appareil doit absorber toutes sortes de rayonnements, y compris les rayonnements entraînant des

opérations indésirables.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Français 21

Page 27

1 Indicações sobre a documentação

1.1 Sobre esta documentação

• Antes da colocação em funcionamento, leia esta documentação. Esta é a condição para um trabalho

seguro e um manuseamento sem problemas.

• Tenha em atenção as instruções de segurança e as advertências nesta documentação e no produto.

• Guarde o manual de instruções sempre junto do produto e entregue-o a outras pessoas apenas

juntamente com este manual.

1.2 Explicação dos símbolos

1.2.1 Advertências

As advertências alertam para perigos durante a utilização do produto. São utilizadas as seguintes palavras

de aviso:

PERIGO

PERIGO !

▶ Indica perigo iminente que pode originar acidentes pessoais graves ou até mesmo fatais.

AVISO

AVISO !

▶ Indica um possível perigo que pode causar graves ferimentos pessoais, até mesmo fatais.

CUIDADO

CUIDADO !

▶ Indica uma situação potencialmente perigosa que pode originar ferimentos ligeiros ou danos materiais.

1.2.2 Símbolos na documentação

Nesta documentação são utilizados os seguintes símbolos:

Leia o manual de instruções antes da utilização

Instruções de utilização e outras informações úteis

Manuseamento com materiais recicláveis

Não deitar as ferramentas eléctricas e baterias no lixo doméstico

1.2.3 Símbolos nas figuras

Em figuras são utilizados os seguintes símbolos:

Estes números referem-se à respectiva imagem no início deste Manual

A numeração reproduz uma sequência dos passos de trabalho na imagem e pode divergir dos

passos de trabalho no texto

Na figura Vista geral são utilizados números de posição que fazem referência aos números da

legenda na secção Vista geral do produto

Este símbolo pretende despertar a sua atenção durante o manuseamento do produto.

Transferência de dados sem fios

1.3 Símbolos dependentes do produto

1.3.1 Símbolos no produto

No produto são utilizados os seguintes símbolos:

22 Português 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 28

Sinal de obrigação geral

Use óculos de protecção

Use protecção auricular

Use capacete de segurança

Recicle os desperdícios

1.3.2 Realce de designações e inscrições

Designações e inscrições estão identificadas do seguinte modo:

Designação de elementos de comando com inscrições na ferramenta de fixação.

‚ ‛

Inscrições na ferramenta de fixação

« »

1.4 Dados informativos sobre o produto

Os produtos Hilti foram concebidos para uso profissional e só devem ser utilizados, mantidos e reparados

por pessoal autorizado e devidamente credenciado. Estas pessoas deverão estar informadas em particular

sobre os potenciais perigos. O produto e seu equipamento auxiliar podem representar perigo se usados

incorrectamente por pessoas não qualificadas ou se usados para fins diferentes daqueles para os quais

foram concebidos.

▶ Registe a designação e o número de série da placa de características na tabela seguinte.

▶ Faça referência a estas informações sempre que entrar em contacto com o nosso representante ou

posto de serviço de atendimento aos clientes para colocar questões sobre o produto.

Dados do produto

Ferramenta de fixação, a gás GX-IE

Geração: 01

N.° de série:

GX-IE XL

1.5 Declaração de conformidade

Declaramos sob nossa exclusiva responsabilidade que o produto aqui descrito está em conformidade com

as directivas e normas em vigor. Na parte final desta documentação encontra uma reprodução do organismo

de certificação.

As documentações técnicas estão aqui guardadas:

Hilti Entwicklungsgesellschaft mbH | Zulassung Geräte | Hiltistraße 6 | 86916 Kaufering, DE

2 Segurança

2.1 Normas de segurança

Estas normas de segurança são válidas para ferramentas com e sem carregador.

Trabalho seguro com a ferramenta de fixação

▶ Em caso de pressionamento da ferramenta de fixação contra uma parte do corpo podem ocorrer

ferimentos graves devido a um accionamento acidental de uma fixação. Nunca pressione a ferramenta

de fixação contra a sua mão ou uma outra parte do corpo.

▶

Ao encaixar fixadores específicos para uma determinada aplicação na guia de pregos (por exemplo,

chapas redondas, abraçadeiras, grampos, etc.) podem ocorrer ferimentos devido ao accionamento

acidental de uma fixação. Ao encaixar fixadores específicos para uma determinada aplicação,

nunca pressione com a mão ou outra parte do corpo contra a guia de pregos.

▶ Nunca aponte a ferramenta de fixação na sua direcção ou na direcção de terceiros.

▶ Mantenha os braços flectidos quando utilizar a ferramenta de fixação (não estique os braços).

▶ Ao puxar para trás o dispensador de pregos, certifique-se de que este engata.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Português 23

Page 29

▶ Não permita que o dispensador de pregos ressalte para a frente quando solta o retentor; em vez

disso desloque-o para a frente. Pode entalar os dedos.

▶ Não fixe os elementos de fixação numa material base demasiado duro, como aço soldado ou aço

fundido. A fixação nestes materiais pode causar fixações erradas e a ruptura de elementos de fixação.

▶ Não fixe os elementos de fixação num material base demasiado macio, como madeira ou gesso

cartonado. A fixação nestes materiais pode causar fixações erradas e a perfuração do material base.

▶ Não fixe os elementos de fixação num material base demasiado quebradiço, como vidro ou ladrilhos.

A fixação nestes materiais pode causar fixações erradas e a fragmentação do material base.

▶ Antes da fixação, certifique-se de que não existe a possibilidade de ferir pessoas ou danificar objectos

que se encontrem atrás do material base.

▶ Accione o disparador apenas se a ferramenta de fixação estiver pressionada contra o material base, de

forma a que a guia de pregos esteja introduzida até ao encosto na ferramenta de fixação.

▶ Utilize impreterivelmente luvas de protecção quando tem de realizar manutenções na ferramenta

de fixação quente.

▶ Em caso de elevadas frequências de fixação após longos períodos de utilização, as superfícies no

exterior do punho podem ficar quentes. Utilize luvas para protecção contra queimaduras.

▶ Se a ferramenta de fixação estiver sobreaquecida, retire a lata de gás e deixe a ferramenta de fixação

arrefecer. Não exceda o número máximo de fixações recomendado.

▶ Quando se efectua uma fixação, pode acontecerque o material estilhace ou que seja projectado material

da fita. Use óculos de protecção e capacete de segurança. Utilize óculos de protecção, protecção

auricular e capacete de segurança. Equipamento de segurança, como, por exemplo, máscara

antipoeiras, sapatos de segurança antiderrapantes, capacete de segurança ou protecção auricular, de

acordo com o tipo e aplicação da ferramenta de fixação, reduzem o risco de lesões. Também outras

pessoas na área envolvente devem utilizar óculos de protecção e um capacete de segurança.

▶ Utilize uma protecção auricular adequada (consultar a Informação sobre ruído nos Dados Técnicos). A

fixação dos elementos de fixação é activada através da ignição de uma mistura de gás e ar. A carga

sonora daí resultante pode prejudicar a audição. Também as pessoas na área envolvente devem utilizar

um protecção auricular adequada.

▶ Quando efectuar uma fixação, segure a ferramenta de fixação com firmeza e perpendicularmente à base.

Assim, ajuda a evitar que o elemento de fixação faça ricochete no material base.

▶ Nunca fixeum segundo elemento de fixação no mesmolocal. Tal podecausar rupturase o emperramento

de elementos de fixação.

▶ Retire sempre a lata de gás e a bateria) e esvazie o carregador), antes de substituir o carregador

ou realizar trabalhos de limpeza, reparação e manutenção, bem como, antes do armazenamento e

transporte, ou se deixar a ferramenta de fixação sem qualquer supervisão.

▶ Verifique a ferramenta de fixação e os acessórios quanto a eventuais danos para assegurar um

funcionamento correcto. Certifique-se de que todas as peças móveis estão perfeitamente operacionais,

sem encravar e sem avarias. Todas as peças devem estar correctamente encaixadas e preencher

todos os requisitos de segurança da ferramenta de fixação. Dispositivos de protecção e componentes

danificados devem ser reparados ou substituídos adequadamente pelo Centro de Assistência Técnica

Hilti, desde que não seja indicado nada em contrário no manual de instruções.

▶ A sua ferramenta de fixação só deve ser reparada por pessoal qualificado e só devem ser utilizadas

peças sobresselentes originais. Isto assegurará que a segurança da ferramenta de fixação se mantenha.

▶ Não é permitida a modificação ou manipulação da ferramenta de fixação.

▶ Não utilize a ferramenta de fixação onde exista risco de incêndio ou de explosão.

▶ Considere as influências ambientais. Não exponha a ferramenta de fixação à chuva, neve ou outras

condições atmosféricas adversas. Não a utilize em locais húmidos ou molhados.

▶ Utilize a ferramenta de fixação apenas em áreas de trabalho bem ventiladas.

▶ Seleccione as combinações certas de guia de pregos e elemento de fixação. Uma combinação errada

pode danificar a ferramenta de fixação ou reduzir a qualidade da fixação.

▶ Observe sempre as regras de aplicação.

Perigos devido a corrente eléctrica

▶ Antes de iniciar os trabalhos, verifique o local de trabalho relativamente a cabos eléctricos

encobertos, bem como tubos de gás e água, por ex., com um detector de metais.

▶ Segure a ferramenta de fixação apenas pelo punho isolado, quando realizar trabalhos em que possa

encontrar cabos eléctricos encobertos. O contacto com um cabo sob tensão também pode colocar

partes metálicas da ferramenta de fixação sob tensão e causar um choque eléctrico.

24 Português 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

*2208858*

Page 30

Utilização e manutenção de ferramentas com bateria

▶ Antes de introduzir a bateria, certifique-se de que a ferramenta está desligada. A introdução de

uma bateria numa ferramenta eléctrica ligada pode causar acidentes.

▶ Mantenha as baterias afastadas de temperaturas elevadas, radiação solar directa e fogo. Existe

risco de explosão.

▶ As bateriasnão podemser desmanteladas,esmagadas, aquecidas acima dos 80 °C ou incineradas.

Caso contrário, existe risco de incêndio, explosão ou queimaduras/corrosão.

▶ Evite a entrada de humidade. A humidade infiltrada pode provocar um curto-circuito e originar

queimaduras ou um incêndio.

▶ Utilize exclusivamente as baterias aprovadas para a respectiva ferramenta. A utilização de outras

baterias ou a utilização das baterias para outras finalidades pode originar risco de fogo e explosão.

▶ Observe as regras específicas sobre transporte, armazenamento e utilização de baterias de iões

de lítio.

▶ Retire a bateria da ferramenta antes do armazenamento e transporte.

▶

Evite curto-circuitar os terminais da bateria. Antes de inserir a bateria na ferramenta, certifique-se

de que os contactos da bateria e da ferramenta estão livres de corpos estranhos. Se os contactos

de uma bateria forem curto-circuitados, existe risco de incêndio, explosão e de queimaduras/corrosão.

▶ Baterias danificadas (por ex., com fissuras, peças partidas, contactos dobrados, empurrados para

trás e/ou puxados para fora) não podem ser carregadas nem continuar a ser utilizadas.

▶ Uma bateria demasiado quente ao toque pode estar defeituosa. Deixe a bateria arrefecer num local à

prova de fogo. Certifique-se de que não se encontra qualquer material combustível na sua proximidade.

Contacte um Centro de Assistência Técnica Hilti.

Indicações para o manuseamento do gás utilizado

▶ Observe as indicações na lata de gás e nas informações fornecidas em conjunto.

▶ O gás que sai é prejudicial para os pulmões, pele e olhos. Mantenha o rosto e os olhos afastados do

compartimento da lata de gás até aprox. 10 segundos após a remoção da lata de gás.

▶ Não accione a válvula da lata de gás manualmente.

▶ Em caso de inalação de gás, leve a pessoa para o ar livre ou um compartimento com boa ventilação e

mantenha-a em posição confortável. Caso necessário, procure um médico.

▶ Se uma pessoa estiver inconsciente, procure um médico. Leve essa pessoa para um compartimento

com boa ventilação e coloque-a na posição lateral estável. Se a pessoa tiver deixado de respirar, aplique

respiração artificial e administre-lhe oxigénio, se necessário.

▶ Após contacto do gás com os olhos, lave-os muito bem com água, por alguns minutos.

▶ Em caso de contacto do gás com a pele, lave a superfície de contacto muito bem com água morna e

sabão. Utilize ainda um creme para a pele.

Informações gerais sobre a segurança pessoal

▶ Mantenha uma postura corporal ergonómica. Mantenha sempre uma posição correcta, em perfeito

equilíbrio. Desta forma será mais fácil manter o controlo sobre a ferramenta de fixação em situações

inesperadas.

▶ Mantenha outras pessoas, e principalmente as crianças, afastadas do raio de acção da ferramenta

durante os trabalhos.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Português 25

Page 31

3 Descrição

3.1 Vista geral do produto 1

Guia de pregos

@

Corrediça para destravamento da guia de

;

pregos

Gancho de cinto

=

Disparador

%

Saídas de ar

&

Compartimento da lata de gás

(

Botão de destravamento da bateria

)

Indicação do estado de carga da bateria

+

Botão para indicação da lata de gás

§

Indicação de lata de gás

/

Bateria

:

3.2 Utilização correcta

O produto descrito é uma ferramenta de fixação a gás. Destina-se à fixação de elementos de fixação

adequados em betão e outros materiais base apropriados para a fixação directa.

A ferramenta de fixação, a lata de gás, a bateria e os elementos de fixação formam uma unidade técnica.

Isto significa que só se pode garantir uma fixação óptima, se forem utilizados elementos de fixação, latas

de gás e baterias da Hilti concebidos especialmente para a ferramenta de fixação. As recomendações de

fixação e aplicação indicadas pela Hilti só serão aplicáveis se estas condições forem observadas.

A ferramenta de fixação pode apenas ser utilizada manualmente.

▶ Para este produto, utilize apenas as baterias de iões de lítio Hilti da série B 12.

▶ Para estas baterias, utilize apenas os carregadores Hilti da série C4/4/12-50.

3.3 Incluído no fornecimento

Ferramenta de fixação a gás com guia de pregos, 2 baterias, carregador, mala, manual de instruções.

Poderá encontrar outros produtos de sistema aprovados para o seu produto no seu Centro de Assistência

Hilti ou online, em: www.hilti.com

3.4 Guia de pregos 2

A guia de pregos segura a bucha de material isolante e, durante o processo de fixação, direcciona o

elemento de fixação para o local desejado no material base.

3.5 Corrediça para destravamento da guia de pregos

Na posição EJECT, a corrediça destrava a guia de pregos para a remoção.

Estado Significado

EJECT

3.6 Gancho de cinto

O gancho de cinto tem três posições de remoção.

26 Português 2208858

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

• Destravamento da guia de pregos

*2208858*

Page 32

Estado Significado

Posição 1 • Posição para engatar no cinto

Posição 2 • Posição para engatar em escadas, andaimes,

plataformas, etc.

Posição 3 • Gancho de cinto removido

3.7 Lata de gás

Observe as normas de segurança fornecidas com a lata de gás!

Para o funcionamento, a lata de gás tem de ser introduzida no compartimento da lata de gás da ferramenta

de fixação.

O estado da lata de gás pode ser consultado se premir a tecla GAS no visor de LEDs.

Em caso de interrupções do trabalho, antes de trabalhos de manutenção, bem como antes do transporte e

armazenamento da ferramenta de fixação, é necessário retirar a lata de gás.

3.8 Indicação do estado da lata de gás

Após premir a tecla GAS, o visor de LEDs exibe o estado da lata de gás.

Estado Significado

Todos os quatro LEDs acendem a verde. • O nível de enchimento é de 100 % a 75 %.

Três LEDs acendem a verde. • O nível de enchimento é de 75 % a 50 %.

Dois LEDs acendem a verde. • O nível de enchimento é de 50 % a 25 %.

Um LED acende a verde. • O nível de enchimento é de 25 % a 10 %.

Um LED pisca a verde. • O nível de enchimento é inferior a 10 %.

Recomenda-se a substituição da lata de gás.

• A lata de gás está vazia ou não funciona.

Recomenda-se a substituição da lata de gás.

Mesmo quando é exibido o nível de enchimento

"vazio", a lata de gás contém, por motivos técnicos, ainda algum gás.

Um LED pisca a vermelho. • Não existe nenhuma ou está inserida uma lata

de gás errada na ferramenta de fixação.

3.9 Indicação do estado da carga da bateria

Quando é premido o botão de destravamento da bateria, o ecrã mostra o estado da bateria e da ferramenta

de fixação.

Estado Significado

Todos os quatro LEDs acendem a verde. • O estado da carga é de 75 % a 100 %.

Três LEDs acendem a verde. • O estado da carga é de 50 % a 75 %.

Dois LEDs acendem a verde. • O estado da carga é de 25 % a 50 %.

Um LED acende a verde. • O estado da carga é de 10 % a 25 %.

Um LED pisca a verde. • O estado da carga é inferior a 10 %.

• A ferramenta de fixação está sobrecarregada ou

sobreaquecida e, por isso, não operacional.

*2208858*

Printed: 07.05.2018 | Doc-Nr: PUB / 5426547 / 000 / 00

2208858 Português 27

Page 33

4 Características técnicas

4.1 Ferramenta de fixação

Peso (vazio) GX 2-IE

Peso (vazio) GX 2-IE-XL

Comprimento da ferramenta para GX 2-IE

Comprimento da ferramenta para GX 2-IE-XL

Temperatura operacional, temperatura ambiente

Comprimento máximo de elementos de fixação

Comprimento máximo de elementos de fixação para GX

2-IE-XL

Diâmetro de elementos de fixação

Movimento de contacto