Page 1

GX 120-ME

Bedienungsanleitung de

Operating instructions en

Mode d’emploi fr

Manual de instrucciones es

Istruzioni d’uso it

Gebruiksaanwijzing nl

Brugsanvisning da

Bruksanvisning no

Bruksanvisning sv

Käyttöohje fi

Manual de instruções pt

Οδηγιες χρησεως el

Kulllanma Talimatı tr

Lietošanas pamācība lv

Instrukcija lt

Kasutusjuhend et

ko

zh

ar

Printed: 28.11.2013 | Doc-Nr: PUB / 5125187 / 000 / 01

Page 2

2

1

+[

8

7+#+≠

9

3

4

+±

5

6

+“

Ga

s

+Ç

5

1

Printed: 28.11.2013 | Doc-Nr: PUB / 5125187 / 000 / 01

Page 3

3

1

2

2

1

2

3

3

1

2

3

4

4

6

3

1

5

2

4

6

7

2

1

3

8

2

1

9

+[

GAS

5

Printed: 28.11.2013 | Doc-Nr: PUB / 5125187 / 000 / 01

Page 4

1

1

2

2

1

3

+“

1

2

3

+

-

10

11

12

14

16

13

15

17

Printed: 28.11.2013 | Doc-Nr: PUB / 5125187 / 000 / 01

Page 5

ORIGINAL OPERATING INSTRUCTIONS

GX 120‑ME gas-driven fastening tool

It is essential that the operating instructions

are read before the tool is operated for the

en

first time.

Always keep these operating instructions to-

gether with the tool.

Ensure that the operating instructions are

with the tool when it is given to other persons.

Contents Page

1 General information 14

2Description 15

3 Accessories, consumables 15

4 Technical data 16

5 Safety instructions 17

6Beforeuse 19

7 Operation 19

8 Care and maintenance 21

9 Troubleshooting 22

10 Disposal 25

11 Manufacturer’s warranty - tools 25

12 EC declaration of conformity (original) 26

13 Health and safety of the operator 26

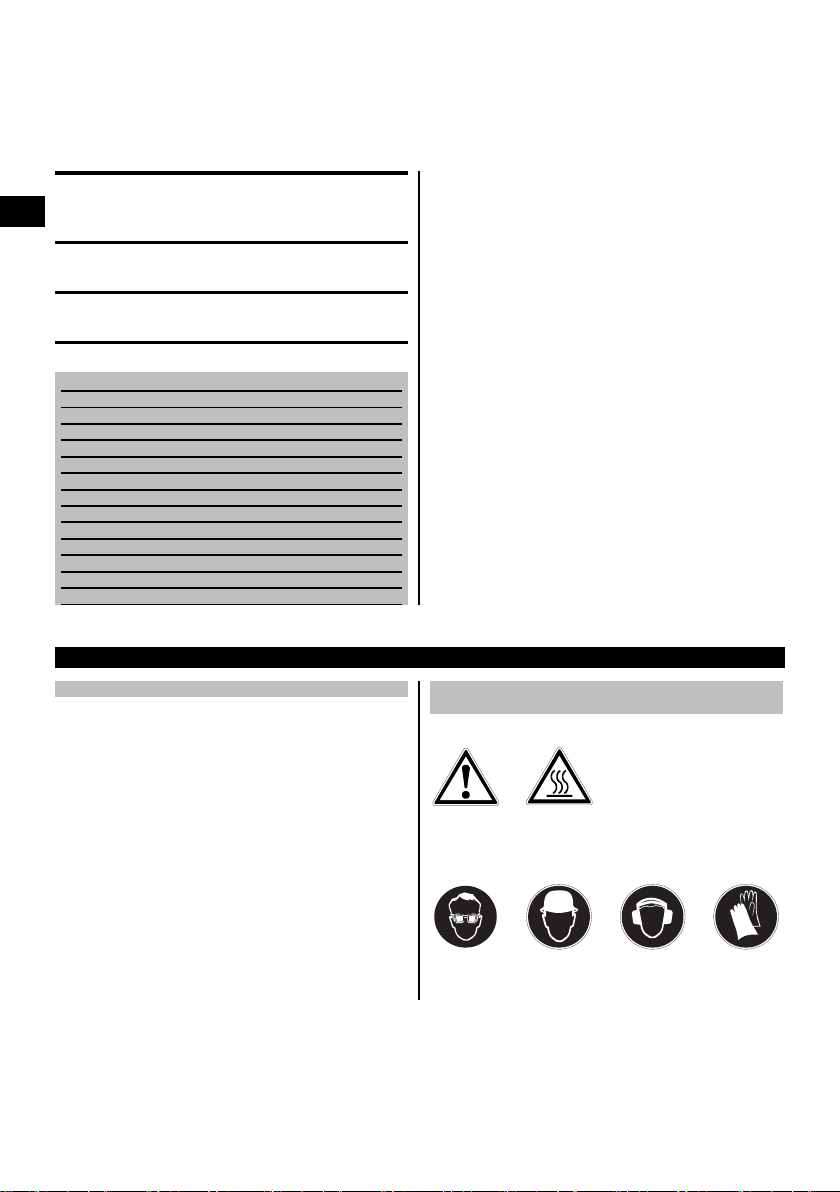

1 General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that will lead to

seriousbodilyinjuryorfatality.

WARNING

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation that

could lead to slight personal injury or damage to the

equipment or other property.

NOTE

Draws attention to an instruction or other useful information.

1 These numbers refer to the corresponding illustrations. The illustrationscan be found on the fold-out cover

pages. Keep these pages open while studying the operating instructions.

In these operating instructions, the designation “the tool”

always refers tothe GX 120-ME gas-drivenfastening tool.

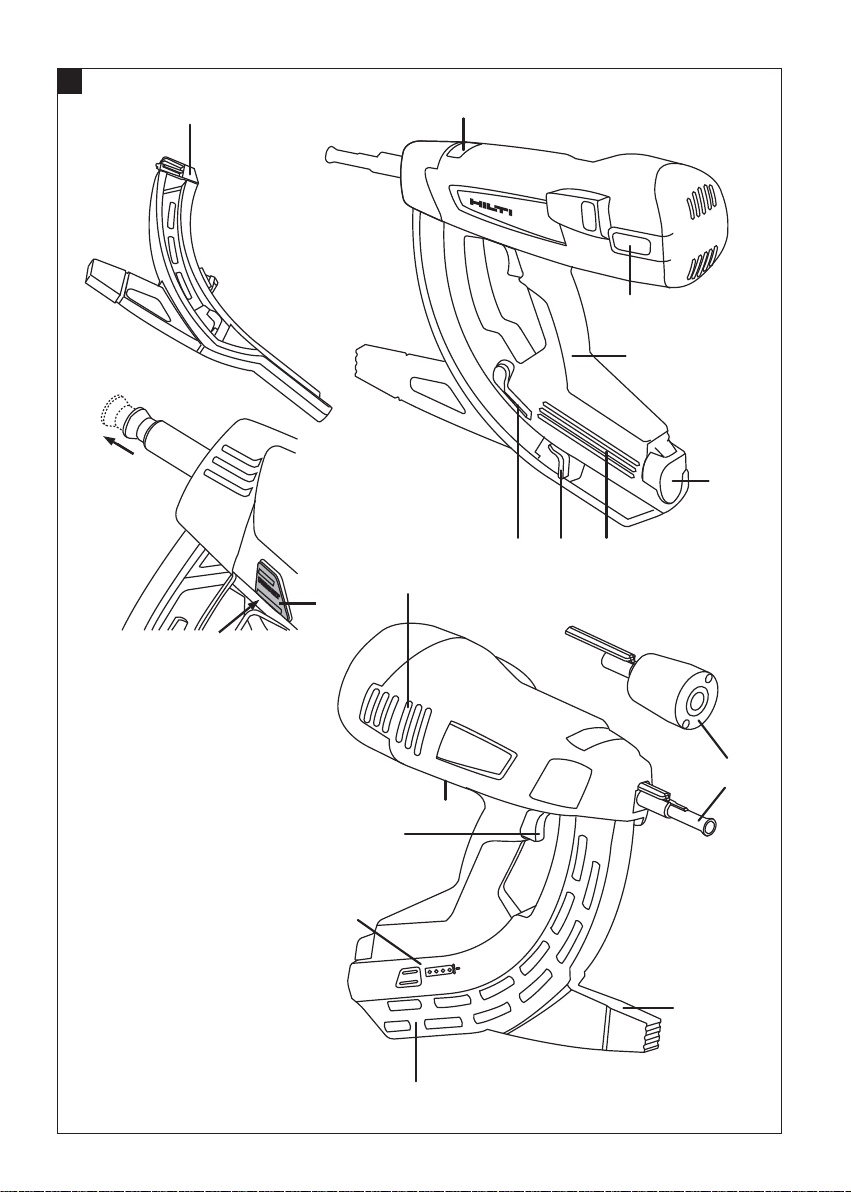

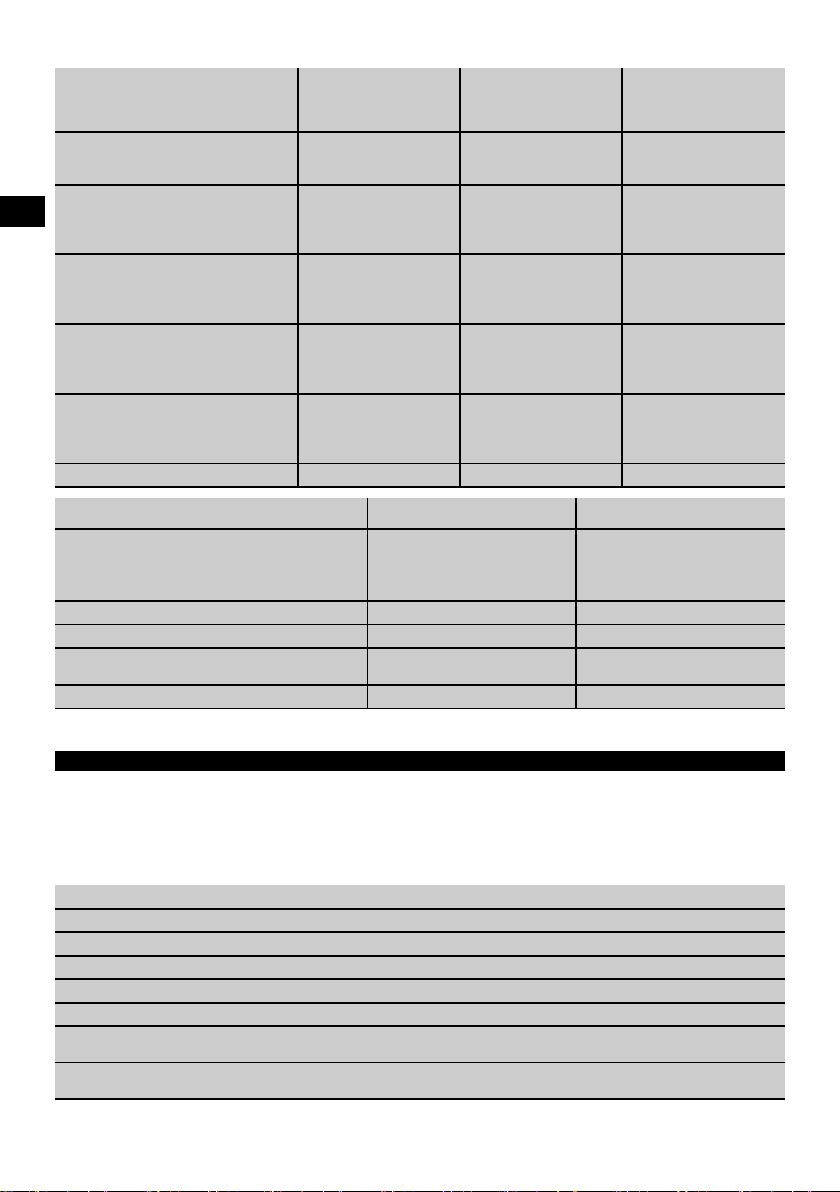

Parts, operating controls and indicators 1

Grip

@

Lockbutton and power regulator

;

Nosepieces

=

Support leg

%

Magazine (20 nails or 40 nails)

&

Type identification plate

(

Gas can compartment

)

Gas can compartment cover

+

Ventilation slots

§

Locking lever

/

Trigger

:

Reset button

·

Nail pusher

$

Belt hook

£

Gas level indicator

|

1.2 Explanation of the pictograms and other

information

Warning signs

General

warning

Obligation signs

Wear eye

protection.

Warning: hot

surface

Wear a hard

hat.

Wear ear

protection.

Wear

protective

gloves.

14

Page 6

Symbols

Read the

operating

instructions

before use.

2 Description

2.1 Use of the product as directed

The tool is designed for driving specially manufactured

nails (fasteners) into concrete, steel and other materials

suitable for the direct fastening technique (please refer to

the Fastening Technology Manual).

The tool is designed for professional use in fastening

applications in the drywall installation trade and other

building trades where fasteners are driven into concrete,

steel, sand-lime block, concrete block and rendered

masonry.

Thetool,gascanandfastenersformasingletechnical

unit. This means that the tool can achieve optimum

fastening performance only when used in conjunction

Location of identification data on the tool

The type designation and serial number can be found on

thetypeidentificationplateonthetool.Makeanoteof

this data in your operating instructions and always refer

to it when making an enquiry to your Hilti representative

or service department.

Type:

Generation: 01

Serial no.:

with the Hilti fasteners and gas cans specially designed

and manufactured for it. The fastening and application

recommendations given by Hilti apply only when these

conditions are observed.

The tool is for hand-held use only.

The tool may be operated, serviced and repaired only by

trained personnel. This personnel must be informed of

any special hazards that may be encountered.

Modification of the tool is not permissible.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

The tool and its ancillary equipment may present hazards

when used incorrectly by untrained personnel or when

used not as directed.

en

3 Accessories, consumables

Designation Description

Gas can GC 21/ GC 22

Nosepiece X‑120 ME TN

Additional nosepieces X‑120 WH (washers)

Magazine X‑120 GM 40/ X‑120 GM 20

Support leg X‑120 SL

Set of pin punches X‑120 NP set

Tool clip X‑120 TS

Nails Length In magazine strips of

X‑EGN 14MX 14 mm (¹/₂") 10 Steel

X‑EGN 18MX 18 mm (¹¹/₁₆") 10 Hard concrete /

X‑EGN 20MX 20 mm (³/₄") 10 Hard concrete /

For use on (please

contact Hilti for detailed information)

precast concrete /

steel

precast concrete /

steel

15

Page 7

Nails Length In magazine strips of

X‑EGN 24MX 24 mm (¹⁵/₁₆") 10 Hard concrete /

X‑GN 20 MX 20 mm (³/₄") 10 Concrete / rendered

en

X‑GN 27 MX 27 mm (1") 10 Concrete / rendered

X‑GN 32 MX 32 mm (1 ¹/₄") 10 Concrete / rendered

X‑GN 39 MX 39 mm (1 ⁹/₁₆") 10 Concrete / rendered

X‑GPN 37 MX 37 mm (1¹/₂") 10 Sheet steel / thin steel

For use on (please

contact Hilti for detailed information)

precast concrete /

steel

masonry (1cm / ³/₈")

/ sand-lime block /

concrete block

masonry (1cm / ³/₈")

/ sand-lime block /

concrete block

masonry (1cm / ³/₈")

/ sand-lime block /

concrete block

masonry (1cm / ³/₈")

/ sand-lime block /

concrete block

Other fasteners

Rings and clips for pipes and conduits X‑FB; X‑DFB

Holder for clips and cables X‑EKB Up to 16 cables

Holder for cable ties X‑ECT

Hanger for threaded rods and wire X‑HS

Universal plastic washer X‑ET

Designation

X‑BX; X‑EMTC

X‑EMTSC

X‑EKS; X‑EKSC

X‑CC

Sizes

8…40 mm

³/₈"‑1"

¹/₂"‑1"

16…40 mm

M4‑M8

W6 thread

4 Technical data

Right of technical changes reserved.

NOTE

The tool is equipped with a transmitter module.

Tool with magazine

Weight 3.8 kg (8.41 lbs)

Dimensions (L x W x H) 431 mm X 134 mm X 392 mm (17" x 5 ¼" x 15 ½")

Nail length Max. 39 mm (max. 1 ⁹/₁₆")

Nail diameter ∅ 3 mm (∅ 0.118 in) / ∅ 2.6 mm (∅ 0.102 in)

Magazine capacity 40 + 2 nails or 20 + 2 nails

Contact movement 40 mm (1 ⁹/₁₆")

Operating temperature / ambient temperature with

GC 21 gas can

Operating temperature / ambient temperature with

GC 22 gas can

-5…+45°C(23°Fto113°F)

-10…+45°C (14°F to 113°F)

16

Page 8

Maximum fastener driving rate 1,200/h

Energy-equivalent acceleration, a

Gas can

Capacity 1 can for 750 nails

Recommended transport and storage temperature +5…+25°C (41°F to 77°F)

Substances contained Isobutane, propene

Gas can Not refillable

The gas can is pressurized. Protect the gas can from

the heat of the sun.

hw, RMS(3)

Recoil: Applicable to 1 mm sheet metal on B45 concrete: 4.04 m/s²

Never expose the gas can to temperatures over 50°C

(122°F).

5 Safety instructions

5.1 Basic information concerning safety

In addition to the information relevant to safety given

in each of thesections ofthese operatinginstructions,

the following points must be strictly observed at all

times.

5.1.1 Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a direct fastening

tool. Do not use a tool while you are tired or under

the influence of drugs, alcohol or medication.

A moment of inattention while operating tools may

result in serious personal injury.

b) Avoid unfavorable body positions. Make sure you

work from a safe stance and stay in balance at all

times.

c) Never point the tool toward yourself or other per-

sons.

d) Neverpress the nosepiece of thetool against your

hand or against any other part of your body (or

other person’s hand or part of their body).

e) Keep other persons, especially children, away

from the area in which the work is being carried

out.

5.1.2 Fastening tool use and care

a) Use the right tool for the job. Do not use the tool

for purposes for which it was not intended. Use it

only as directed and when in faultless condition.

b) Pressthe tool against theworking surface at right

angles.

c) Never leave a loaded tool unattended.

d) Remove the gas can from the tool before trans-

porting the tool.

e) Always unload the tool (remove the gas can and

fasteners) before cleaning, before carrying out

care and maintenance, before work breaks and

before storing the tool.

f) When not in use, tools must be unloaded and

stored in a dry place, locked up or out of reach of

children.

g) Check the tool or machine and its accessories for

damage and ensure that they function faultlessly

andas intended.Check thatmoving parts function

correctly without sticking and that no parts are

damaged. All parts must be fitted correctly and

fulfill all conditions necessary for correct operation of the tool. Damaged guards, safety devices

and other parts must be repaired or replaced

properly at a Hilti service center unless otherwise

indicated in the operating instructions.

h) Keep the arms slightly bent while operating the

tool (do not straighten the arms).

i) Pull the trigger only when the tool is pressed

against the working surface at right angles.

j) Always hold the tool securely and at right angles

to the working surface when driving a fastener.

This will helpto prevent fasteners being deflected

by the working surface.

k) Never redrive a fastener. This may cause the

fastener to break and the tool may jam.

l) Never drive fasteners into existing holes unless

this is recommended by Hilti.

m) Always observe the application guidelines.

5.1.3 Work area safety

a) Ensure that the workplace is well lit.

b) Operate the tool only in well-ventilated working

areas.

c) Do not attempt to drive fasteners into unsuitable

materials. Materials that are too hard, e.g. welded

steel and cast iron. Materials that are too soft, e.g.

wood and drywall panel (gypsum board). Materials

that are too brittle, e.g. glass and ceramic tiles.

Driving a fastener into these materials may cause

the fastener to break, shatter or to be driven right

through.

d) Before driving fasteners, check that no one is

present immediately behind or below the working

surface.

en

17

Page 9

e) Keep the workplace tidy. Objects which could

cause injury should be removed from the working area. Untidiness at the workplace can lead to

accidents.

f) Keep the grips dry, clean and free from oil and

grease.

g) Wear non-skid shoes.

h) Take the influences of the surrounding area into

en

account. Do not expose the tool to rain or snow

and do not use it in damp or wet conditions. Do

notusethetoolwherethereisariskoffireor

explosion.

5.1.4 Mechanical hazards

a) Select the correct fastener guide and fastener

combination for the job on hand. Failure to use

the correct combination of these items may result in

damage to the tool and/or unsatisfactory fastening

quality.

b) Useonly fasteners of a type approved for usewith

the tool.

c) Never fill the magazine with fasteners unless it is

correctly fitted to the tool. The fasteners could be

ejected uncontrollably.

5.1.5 Thermal hazards

a) If the tool has overheated, allow it to cool down.

Do not exceed the recommended fastener driving

rate.

b) Always wear gloves if the tool has to be dis-

mantled for cleaning or maintenance before it

has been allowed to cool down.

5.1.6 Gasses

Liquid gas under pressure:

Observe the hazard warnings and first-aid instructions printed on the gas can and in the instructions

for use.

The gas is extremely flammable (contains: isobutane,

propene).

Refilling the gas can is not permissible.

a) Do not use damaged gas cans.

b) Do not attempt to force the gas can open. Do not

incinerate or crush the can and do not attempt to

reuse it for any other purpose.

c) Neverspray the gastoward personsor otherliving

beings.

d) Keep the gas away from all sources of ignition

such as naked flames, sparks, pilot lights, static

discharge and very warm surfaces.

e) Do not smoke while using the tool.

5.1.6.1 Storage

a) Do not store gas cans in inhabited rooms or in

rooms connected to inhabited rooms.

b) Store the gas cans in a dry, well-ventilated place.

c) Store the gas cans out of reach of children.

d) Do not expose gas cans to direct sunlight or

temperatures above 50°C (122°F).

e) Recommended storage temperature: 5°C to 25°C

(41°F to 77°F).

5.1.6.2 First aid

Read the material safety data sheet for information

about use, care and maintenance and first-aid measures.

a) Direct skin contact with the liquid gas may cause

frostbite or a serious freezing injury similar to a

burn.

b) In case of inhalation of the gas: The person af-

fected should be taken into the open air and

brought into a comfortable position.

c) In case of unconsciousness: Bring the person af-

fected into a securerecovery position. Should the

person stop breathing, apply artificial respiration

and supply oxygen if necessary.

d) In case of gas contact with the eyes: Rinse the

open eyes under running water for one minute.

e) In case of gas contact with the skin: Wash the

contact surface carefully with warm water and

soap. Subsequently apply a skin cream.

f) Consult a doctor if necessary.

5.1.7 Protective device

Never use the tool if the applicable safety devices

have been damaged or removed.

18

Page 10

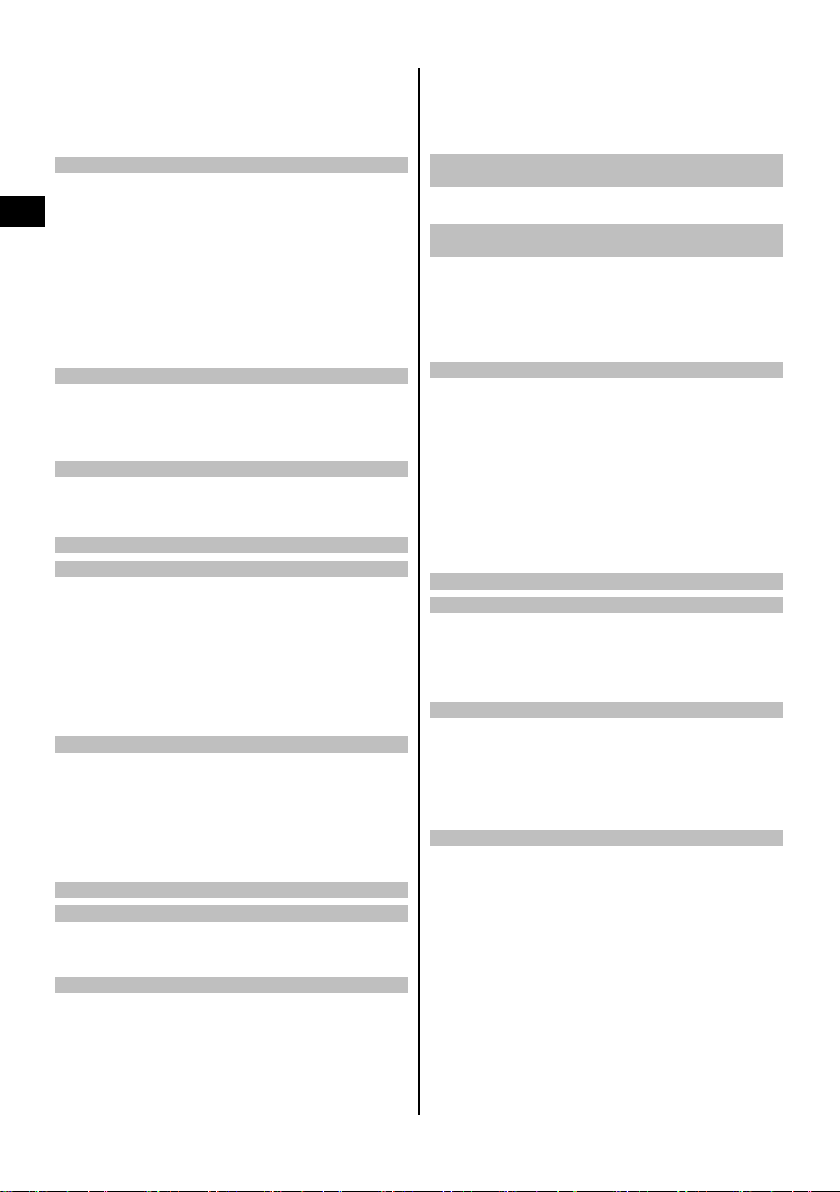

6Beforeuse

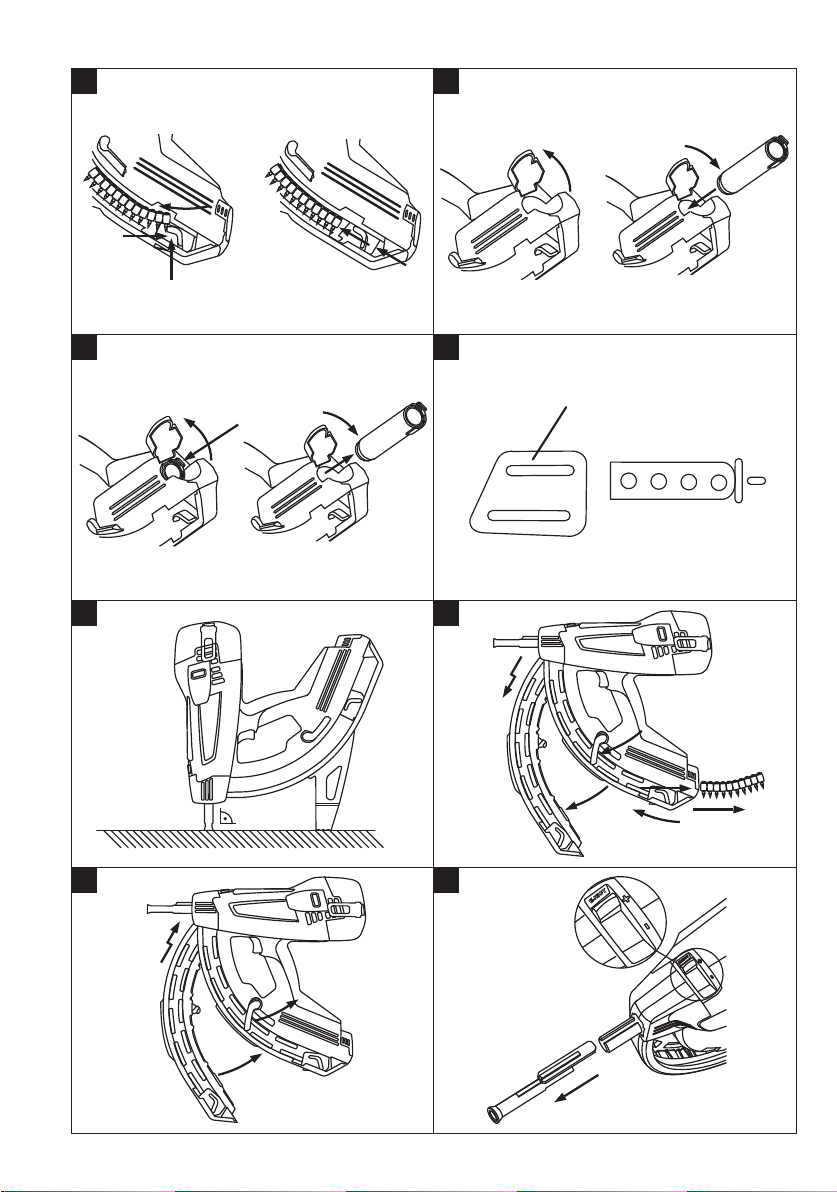

3. Release the nail pusher and allow it to slide forward

slowly.

6.2 Inserting the gas can 3

NOTE

Read the operating instructions before using the tool.

6.1 Inserting nails 2

1. Pull the nail pusher back until it engages.

NOTE The nail pusher must engage in this position.

2. Slide the nails into the magazine (maximum of 4

strips of 10 nails).

6.4 Checking the gas can 5

NOTE

- To check the gas level in the can, press the button marked GAS. When doing so,takecaretoensurethatthetoolis

not pressed against the working surface.

- Even when the indicator shows “empty”, a small quantity of gas, for technical reasons, still remains in the can.

4 LEDs light green constantly. The gas can is full.

2 LEDs light green constantly. The gas can is half full.

1 LED blinks green. The gas can is almost empty. The gas can should be changed.

1 LED lights red constantly. The gas can is empty, no gas can fitted or wrong gas can fitted.

1. Open the cover.

2. Push the gas can into the gas can compartment,

valve first, until the clip engages.

3. Close the cover.

4. Press the tool against the working surface 3 times

without pulling the trigger.

6.3 Removing the gas can 4

1. Open the cover of the gas can compartment.

2. Press the can retaining clip.

3. Remove the gas can.

4. Close the cover of the gas can compartment.

en

7Operation

NOTE

When holding the tool steady with the second hand, the

hand must be positioned in such a way that no ventilation

slots or openings are covered.

CAUTION

Never redrive a fastener. This may cause the fastener

to break and the tool may jam.

WARNING

Material may splinter when the fastener is driven or fragments of the magazine strip may fly off. Splintering material presents a risk of injury to the eyes and body. The

user of the tool and all persons in the vicinity must

wear eye protection and a hard hat.

CAUTION

The fastener is driven by theenergy releasedon ignitionof

a gas-air mixture. Exposure to noise can cause hearing

loss. The operator and bystanders must wear ear

protectors.

WARNING

Never make the tool ready to fire by pressing it against a

part of the body (e.g. the hand). When the tool is ready

to fire, fasteners could be driven inadvertently into parts

of the body. Never press the tool against parts of the

body.

WARNING

Never pull the tool nosepiece back by the fastening

component inserted in it (e.g. soft washer, pipe ring

or clip etc.). This presents an increased risk of accident.

WARNING

The tool must always be unloaded before changing

the magazine and before carrying out cleaning or

maintenance (see section “Unloading the tool”).

19

Page 11

WARNING

Parts of the tool outside the grip area may get hot when

fasteners are driven at a rapid rate over a long period of

time. Wear protective gloves.

NOTE

If the nail is still driven too deeply when the power

regulator is set to “-”, it may be necessary to use a longer

nail.

7.1 Operation 6

NOTE

It is possible to drive a fastener only when more than 3

en

nails are in the magazine.

1. Position the nose of the tool at right angles to

the working surface and then press it against the

working surface as far as it will go.

2. Drive the fastener by pulling the trigger.

3. After driving the fastener, lift the tool away completely from the working surface.

7.1.1 Using pipe rings and other fasteners

If you wish to use pipe rings and other types of fastener,

push the plastic part of the fastener into the tool

nosepiece.

7.2 Gas level indicator 5

Please refer to section 6.4 “Checking the gas can (for 2

seconds)”.

7.3 Fitting and removing the magazine

7.3.1 Removing the magazine 7

1. Pull the nail pusher back until it engages.

NOTE The nail pusher must engage in this position.

2. Remove all fasteners from the magazine.

3. Release the nail pusher and allow it to slide forward

slowly.

4. Push the locking lever down toward the magazine.

5. Pivot the magazine forward away from the tool.

6. Disengage the magazine from the tool.

7.3.2 Fitting the magazine 8

1. Engage the magazine with the tool.

NOTE The locking lever must be in the open position.

2. Guide the magazine toward the tool until the shaped

parts fit together.

3. Close the locking lever and check that it engages.

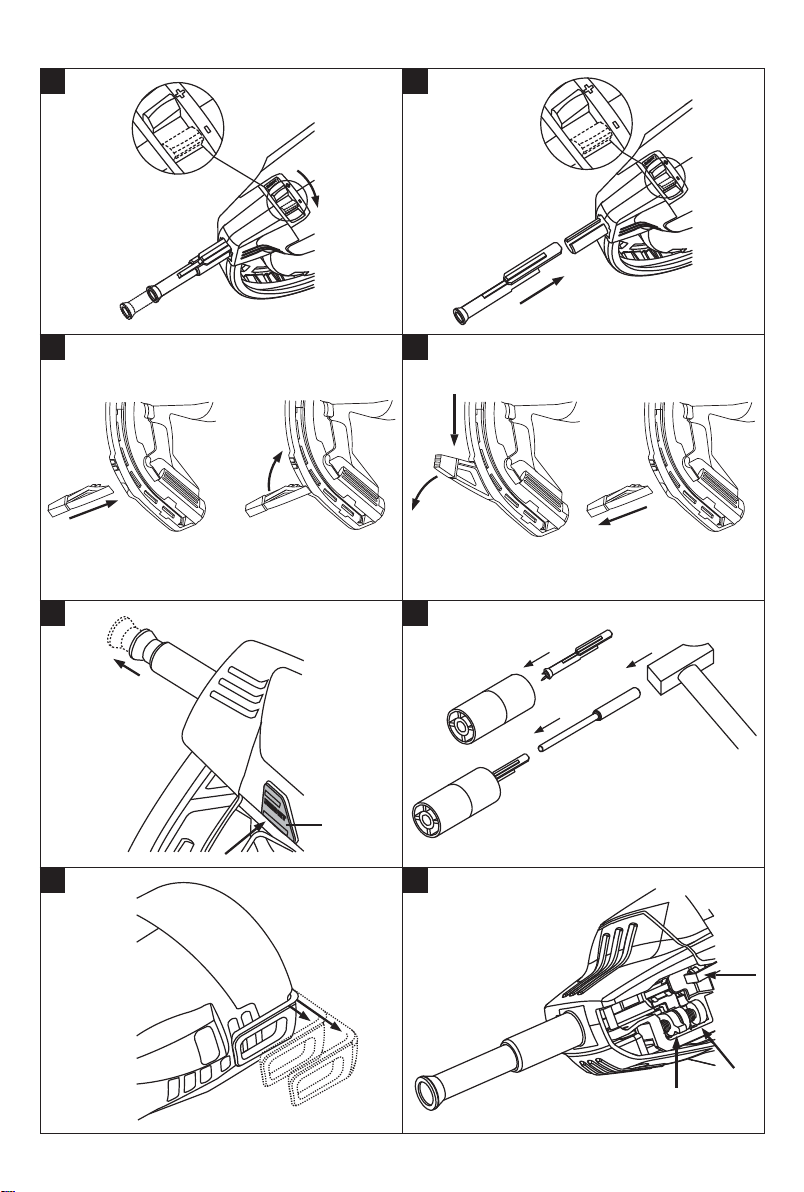

7.4 Nosepiece

7.4.1 Removing the nosepiece 9

1. Set the power regulator to “Eject”.

2. Remove the nosepiece.

7.4.2 Settings at the nosepiece

NOTE

When the power regulator is set to “+”, the nosepiece is

set to the standard fastener driving depth.

NOTE

When the power regulator is set to “-”, the nosepiece is

set to the reduced fastener driving depth.

7.4.2.1 Setting the standard fastener driving

depth

Set the power regulator to “+”.

7.4.2.2 Setting the reduced fastener driving

depth

NOTE

This setting is suitable for fastening thin sheet metal to

soft materials (e.g. young / green concrete).

Set the power regulator to “-”.

7.4.3 Fitting the tool nosepiece

WARNING

Check to ensure that the tool is not loaded. The tool

could be made ready to fire inadvertently by pressing the

nosepiece in by hand.

1. Align the nosepiece with the slot in the tool.

2. Push the nosepiece onto the tool.

3. While holding the nosepiecewith thehand, press the

tool against the working surface until the nosepiece

engages in position.

7.5 Support leg

7.5.1 Fitting the support leg

1. Push the support leg into the slot in the magazine at

right angles.

2. Turn the support leg through 90° and engage it in

position.

7.5.2 Removing the support leg

1. Release the support leg by pressing the spring

catch.

2. Turn the support leg through 90°.

3. Pull the support leg away from the magazine at right

angles.

7.6 Bringing the piston into the correct position

NOTE

The piston is incorrectly positioned when the tool

nosepiece has not extended to its original position after

the tool is lifted away from the working surface and the

reset button is projecting.

The piston can be returned to the correct position by

pressing the reset button. Fasteners can then be driven.

In exceptional cases, the tool may fire without driving a

fastener when the tool is operated for the first time after

resetting the piston.

Press the reset button.

20

Page 12

7.7 Removing a jammed fastener

1. Remove the magazine.

2. Remove the nosepiece.

3. Fit the nosepiece into the support supplied.

4. Use the pin punch to remove the fastener.

7.9 Application guidelines

NOTE

For detailed information, please ask the Hilti marketing organization in your country for a copy of the Hilti Fastening

Technology Manual or the applicable national regulations.

Concrete

A = min. distance from edge = 70 mm (2¾")

B = min. fastener center spacing = 80 mm (3¹/₈")

C = min. base material thickness = 100 mm (4")

7.8 Unloading the tool

1. Open the cover of the gas can compartment.

2. Press the can retaining clip and remove the gas can.

3. Close the cover of the gas can compartment.

4. Pull the nail pusher back until it engages.

NOTE Thenailpushermustengageinthisposition.

5. Remove the fasteners from the magazine.

6. Release the nail pusher in the magazine and allow it

to slide forward slowly.

B A

ET

C

Steel

A = min. distance from edge = 15 mm (⁵/₈")

B = min. fastener center spacing = 20 mm (¾")

C = min. base material thickness = 4 mm (⁵/32")

en

B A

C

7.10 Belt hook

The belt hook can be used to attach the tool in position

1toabeltorinposition2toaladderorscaffold.

8 Care and maintenance

WARNING

The tool must be unloaded (gas can and fasteners

removed from the tool) before carrying out cleaning

or maintenance.

CAUTION

The tool may get hot during use. You could burn your

hands. Wear protective gloves before carrying out

care and maintenance. Allow the tool to cool down.

21

Page 13

8.1 Care of the tool

CAUTION

Take care not to damage the piston detector, nail

detector and magazine detector.

1. Removeplasticdebrisfromthenosepieceatregular

intervals.

2. Never operate the tool when the ventilation slots are

en

blocked. Clean the ventilation slots carefully using a

dry brush.

3. Do not permit foreign objects to enter the interior of

the tool.

4. Clean the outside of the tool at regular intervals with

a slightly damp cloth.

5. Do not use a spray, steam pressure cleaning equipment or running water for cleaning.

6. Always keep the grip surfaces of the tool free from

oil and grease.

7. Do not use cleaning agents which contain silicone.

8. Do not use Hiltispray orsimilar lubricantsor cleaning

agents.

8.2 Maintenance

Check all external parts of the tool for damage at regular

intervals and check that all controls operate faultlessly.

Do not operate the tool if parts are damaged or when

the controls do not function faultlessly. Have the tool

repaired by Hilti Service.

8.3 Checking the tool after care and maintenance

After cleaning orservicing, check that the powerregulator

is correctly set (standard setting “+”) before inserting the

gas can.

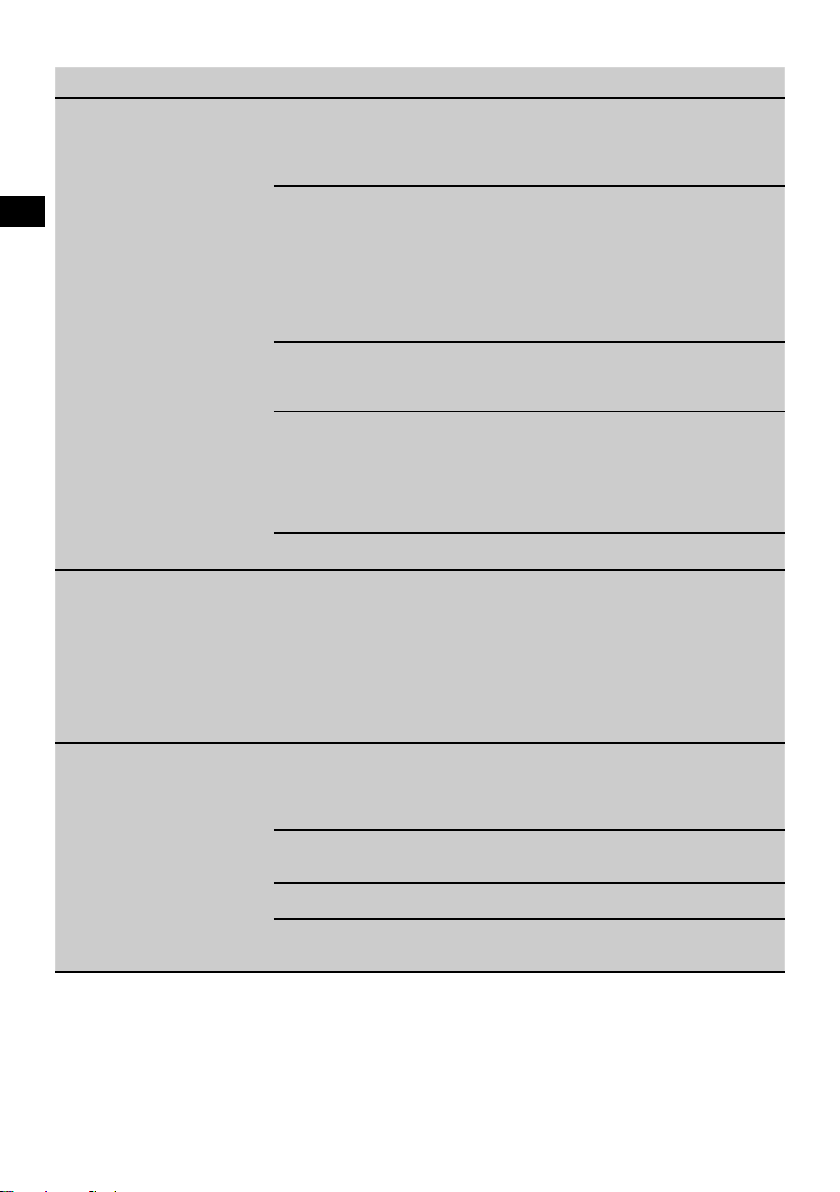

9 Troubleshooting

WARNING

The tool must be unloaded (gas canand fasteners removed fromthe tool) before carrying out cleaning or maintenance.

Fault Possible cause Remedy

Fastener head stand-off is frequently too high.

The power regulator is set to “-”. Set the power regulator to “+”.

The fastener used is too long. Use a shorter fastener.

The base material is too hard. Use a DX fastening tool.

The intake/exhaust valve is dirty or

covered over.

The fastener is frequently driven

too deeply (punches through)

and/or the ring or clip breaks.

Fastener breakage. The power regulator is set to “-”. Set the power regulator to “+”.

22

Driving power is too high. Set the power regulator to “-”.

The fastener is too short. Use a longer fastener.

The fastener used is too long. Use a shorter fastener.

The base material is too hard. Use a DX fastening tool.

The tool is pressed against the surface at an angle.

Clean the tool and pay attention to

the hand position.

Contact Hilti if the problem persists.

Hold the tool at right angles to the

working surface. Use the support leg.

See section: 7.5 Support leg

Page 14

Fault Possible cause Remedy

Fasteners are bent. The power regulator is set to “-”. Set the power regulator to “+”.

The fastener used is too long. Use a shorter fastener.

The tool is pressed against the surface at an angle.

Fastener doesn’t hold in steel. The base material is not thick enough

Gas can doesn’t last for the

whole box of fasteners.

The tool remains compressed

(does not extend when pressure

is released).

Fastener driving failure rate too

high.

The tool doesn’t fire.

(less than 4 mm).

Frequently pressing the tool against

the working surface without pulling

the trigger causes increased gas consumption.

The piston is incorrectly positioned. Press the reset button.

The nail detector is jammed; The reset button still projects after it has

been pressed (white edge still visible).

A fastener is jammed in the tool. Remove the magazine and the tool

The tool is pressed against the surface at an angle.

Wrong type of nail used. Use X-GHP nails if necessary.

The base material is too hard. Use a DX fastening tool.

The nail pusher is in the rearmost po-

sition.

Insufficient number of fasteners in the

magazine (2 or less).

Fastener feed malfunction. Use a different strip of fasteners (strip

Hold the tool at right angles to the

working surface. Use the support leg.

See section: 7.5 Support leg

Use a different fastening technique.

Avoid pressing the tool against the

working surface without pulling the

trigger.

See section: 7.6 Bringing the piston

into the correct position

Remove the gas can and the

magazine from the tool and remove

any dirt or debris from the nail

detector.

nosepiece. Fit the tool nosepiece into

the support supplied and use the pin

punch to remove the fastener.

CAUTION

Do not damage the tool nosepiece.

See section: 7.7 Removing a jammed

fastener

See section: 7.3.1 Removing the

magazine 7

See section: 7.4.1 Removing the

nosepiece 9

See section: 7.8 Unloading the tool

Contact Hilti if the problem persists.

Hold the tool at right angles to the

working surface. Use the support leg.

See section: 7.5 Support leg

Release the nail pusher.

See section: 7.3 Fitting and removing

the magazine

Reload fasteners.

is possibly damaged).

Clean the magazine.

en

23

Page 15

Fault Possible cause Remedy

The tool doesn’t fire. The gas can is empty. Check the gas level by pressing the

No gas can fitted or wrong type of

en

When hot, the tool doesn’t fire

after a pause between use.

The tool doesn’t fire or fires

sporadically.

gas can fitted to the tool.

New gas can fitted, but the tool has

not been pressed against the working

surface 3 times without pulling the

trigger.

Foreign object in the tool nosepiece

section.

The tool is too hot. Allow the tool to cool down.

The fastener driving rate was considerably higher than 1200 per hour and

the gas can is almost empty.

Operation outside the limits of the

permissible ambient conditions.

The gas can is not at the operating

temperature.

Gas bubbles have formed in the gas

injection system.

The tool is not lifted away completely

from the working surface.

button marked GAS.

If only 1 LED lights red constantly, the

gas can is empty. Fit a new gas can.

See section: 7.2 Gas level indicator.

Open the gas can compartment cover

and check the contents.

If a gas can is present in the tool,

press the button marked GAS.

If 1 LED lights red constantly, the

wrong type of gas can has been inserted in the tool. Insert the correct

type of gas can.

See section: 7.2 Gas level indicator.

Press the tool against the working

surface 3 times without pulling the

trigger.

Remove the magazine and nosepiece

and then remove the foreign object

from the tool.

See section: 7.3.1 Removing the

magazine 7

See section: 7.4.1 Removing the

nosepiece 9

Contact Hilti if the problem persists.

Remove the gas can and then refit it.

Then press the tool against the working surface 3 times without firing it.

Check the gas level indicator. If the

LED lights red constantly, the gas can

is empty. Fit a new gas can.

Allow the tool to cool down.

Observe the maximum fastener driving rate (1200 per hour).

Contact Hilti if the problem persists.

If possible, take measures to ensure

that the ambient conditions in the

working environment remain within

the permissible limits.

Use a different fastening technique.

Bring the gas can to the operating

temperature (-5°C to 45°C with

GC 21, -10°C to 45°C with GC 22).

Remove the gas can and then refit it.

Take care to ensure that the tool is lifted away completely from the working

surface after driving each fastener.

24

Page 16

Fault Possible cause Remedy

Fastener cannot be removed

from nosepiece.

Pipe rings and other fasteners

cannot be inserted in the tool

nosepiece.

A fastener is jammed in the tool

nosepiece.

Fragments of the magazine strip are

lodged in the tool nosepiece.

Remove the tool nosepiece from the

tool. Fit the tool nosepiece into the

support supplied and use the pin

punch to remove the fastener.

CAUTION

Do not damage the tool nosepiece.

See section: 7.4.1 Removing the

nosepiece 9

See section: 7.7 Removing a jammed

fastener

Remove the fragments of the

magazine strip from the tool

nosepiece.

10 Disposal

Most of the materials from which Hilti tools or appliances are manufactured can be recycled. The materials must

be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for

taking back old tools and appliances for recycling. Ask Hilti customer service or your Hilti representative for further

information. If you wish to bring the tool to a materials separation facility yourself: Regional and international directives

and regulations must be observed.

11 Manufacturer’s warranty - tools

Hilti warrants that the tool supplied is free of defects in

materialandworkmanship.Thiswarrantyisvalidsolong

as the tool is operated and handled correctly, cleaned

and serviced properly and in accordance with the Hilti

Operating Instructions, and the technical system is maintained. This means that only original Hilti consumables,

components and spare parts may be used in the tool.

This warranty provides the free-of-charge repair or replacement of defective parts only over the entire lifespan

of the tool. Parts requiring repair or replacement as a

result of normal wear and tear are not covered by this

warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular, Hilti

is not obligated for direct, indirect, incidental or con-

sequential damages, losses or expenses in connection with, or by reason of, the use of, or inability to

use the tool for any purpose. Implied warranties of

merchantability or fitness for a particularpurpose are

specifically excluded.

For repair or replacement, send the tool or related parts

immediately upon discovery of the defect to the address

of the local Hilti marketing organization provided.

This constitutes Hilti’s entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

NOTE

Observe the gas can expiry date printed on the edge of

the can.

en

25

Page 17

12 EC declaration of conformity (original)

Designation: Gas-driven fastening tool

Type: GX 120‑ME

Generation: 01

Year of design: 2007

en

We declare, on our sole responsibility, that this

product complies with the following directives and

standards: 75/324/EEC, 91/155/EEC, 64/548/EEC,

EN ISO 12100, EN 13752‑1:2008‑12, EN 50081‑2,

EN 1127‑1, EN 417, ISO 8662‑11 AMD 1:2001-12,

EN 792‑13:A1:2008‑09, EN 60529:2000‑09,

64/548/EEC, EN 55011:1998+A1:1999, CISPR 11:2003,

A1:2004, IEC 61000‑6‑2:2005, EN 61000‑6‑2:2001,

IS1:2005, IEC 61000‑6‑3:1996, EN 61000‑6‑3:2001,

IEC 61000‑4‑2:1995, IEC 61000‑4‑3:2006,

IEC 61000‑4‑8:1993: A1:2000, 2006/42/EC, 2011/65/EU.

Hilti Corporation, Feldkircherstrasse 100,

FL‑9494 Schaan

Norbert Wohlwend Tassilo Deinzer

Head of Quality & Processes Management

BU DirectFastening BU Direct Fastening

04/2013 04/2013

Head of BU Direct Fastening

Technical documentation filed at:

Hilti Entwicklungsgesellschaft mbH

Zulassung Elektrowerkzeuge

Hiltistrasse 6

86916 Kaufering

Deutschland

13 Health and safety of the operator

13.1 Noise information

Gas-actuated fastening tool

Type GX 120-ME

Model Series

Caliber GC 22

Power regulation

Application Fastening 1 mm sheet metal to concrete (C40) with the

+

X-ECT

Declared measuredvalues of noise characteristicsaccording to 2006/42/ECMachinery Directive in conjunction

with DIN EN 15895

Noise (power) level, L

Emission sound pressure level at the workplace,

2

L

pA, 1s

Peak sound pressure emission level, L

1

±2dB(A)

2

±2dB(A)

3

±2dB(C)

WA, 1S

1

pC, peak

3

106 dB (A)

102 dB (A)

137 dB (C)

Operation and set-up conditions: Set-up and operation of the pin driver in accordance with E DIN EN 15895-1 in the

semi-anechoic test room of Müller-BBM GmbH. The ambient conditions in the test room conform to DIN EN ISO 3745.

Testing procedure: Enveloping surface method in anechoic room on reflective surface area in accordance with

E DIN EN 15895, DIN EN ISO 3745 and DIN EN ISO 11201.

NOTE The noise emissions measured and the associated measurement uncertainty represent the upper limit for the

noise values to be expected during the measurements.

Variations in operating conditions may cause deviations from these emission values.

14. FCC statement

This device complies with Part 15 of the FCC Rules and to RSS-210 of Canada.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

26

Page 18

Hilti Corporation

LI-9494 Schaan

Tel.:+423 /234 2111

Fax:+423 /234 29 65

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan

W 3410 | 1013 | 2-Pos. 1 | 1

Printed in Germany © 2013

Right of technical and programme changes reserved S. E. & O

Printed: 28.11.2013 | Doc-Nr: PUB / 5125187 / 000 / 01

*39199*

.

39199 / A3

39199

Loading...

Loading...