Page 1

GX100

*338046*

338046

Bedienungsanleitung de

Operating instructions en

Hilti Corporation

FL-9494 Schaan

Tel.:+423 / 2342111

Fax: +423 /23429 65

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 2767 0203 25-Pos. 1 1 Printed in Liechtenstein © 2003

Right of technical and programme changes reserved S. E. & O.

338046/B

Page 2

2

3

1

2

1

2

3

GX 100

GX 100

1

2

3

4

GX 100

R

GX 100GX 100

R

5

GX 100

GX 100

GX 100

GX 100GX 100

1

2

2

3

5

4

6

GX 100GX 100

GX 100

GX 100

1

1

2

7

GX 100

GX 100

GX 100

GX 100

1

3

2

8

GX 100

GX 100

GX 100

1

3

2

9

GX 100

R

13

11

10

1

12

R

GX 100

3

7

4

8

5

6

9

2

9

14

1

1

2

10

3

1

2

11

12

GX 100

R

1

14

1

15

1

2

13

3

1

2

Page 3

13

en

It is essential that the operating instructions

are read before the tool is operated for the

first time.

Always keep these operating instructions

together with the tool.

Ensure that the operating instructions are

with the tool when it is given to other persons.

GX100 gas-powered fastening tool

Contents Page

1. General information 13

2. Description 14

3. Accessories and consumables 14

4. Technical data 15

5. Safety precautions 15

6. Before use 17

7. Operation 18

8. Care and maintenance 20

9. Troubleshooting 20

10. Disposal 23

11. Warranty 23

12. CE declaration of conformity 24

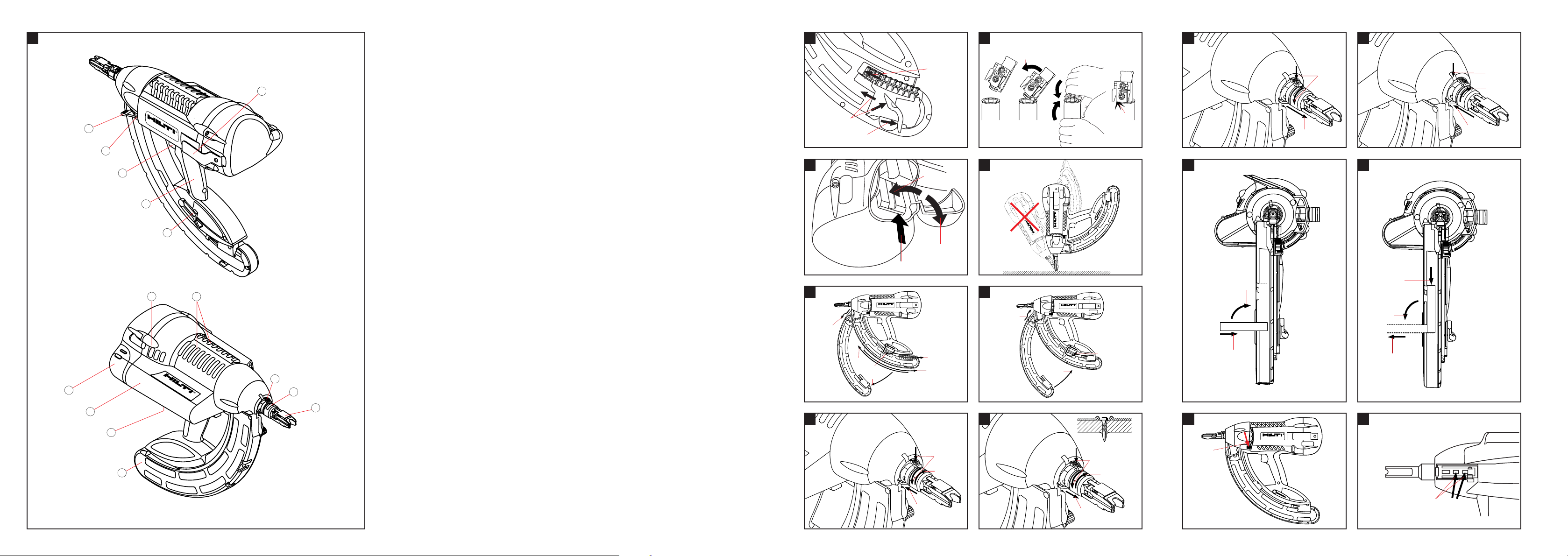

Parts of the tool

Grip

Lockbutton

Nosepiece

Sliding sleeve

Magazine

Type plate

Gas can compartment

Gas can compartment cover

Ventilation slots

Locking lever

Trigger

Reset button

Nail pusher

Belt hook

The numbers refer to the illustrations. The illustrations can be found on the fold-out cover pages. Keep

these pages open while you read the operating instructions.

In these operating instructions, the designation “the tool”

always refers to the GX 100 gas-powered fastening tool.

Location of identification data on the tool

The type designation and serial number are printed on

the type plate on the tool. Make a note of this information in your operating instructions and always refer to it

when making an enquiry to your Hilti representative or

service department.

Type: GX100

Serial no.:

Warning signs

General

warning

Warning:

explosive substance

Warning:

hot surface

Obligation signs

Wear a hard

hat

Wear ear

protection

Wear eye

protection

Read the operating

instructions before

use.

Symbols

1. General information

1.1 Signal words and their meaning

-WARNING-

The word WARNING is used to draw attention to a potentially dangerous situation which could lead to severe personal injury or death.

-CAUTION-

The word CAUTION is used to draw attention to a potentially

dangerous situation which could lead to minor personal injury or damage to the equipment or other property.

-NOTE-

The word NOTE is used to indicate instructions and other useful information. It is not used to indicate potentially

dangerous situations or situations where damage may

occur.

1.2 Pictograms

Page 4

14

en

2. Description

The tool is designed for driving specially manufactured

nails (fasteners) into concrete, steel and other materials

suitable for the direct fastening technique (please refer

to the Fastening Technology Manual). The piston principle employed ensures maximum operating safety and

fastening reliability. Gas is used as a propellant.

The tool, gas can and fasteners form a single technical

unit. This means that the tool can achieve optimum fastening performance only when used in conjunction with

the Hilti fasteners and gas cans specially designed and

manufactured for it. The fastening and application recommendations given by Hilti apply only when these conditions are observed.

2.1 Piston principle

The energy from the propellant charge is transferred to

a piston, the accelerated mass of which drives the fastener into the base material. As approximately 95 % of

the kinetic energy is absorbed by the piston, the fastener is driven into the base material at much reduced veloc-

3. Accessories and consumables

Gas can GC 11

Nosepiece X-100TN

Magazine X-GM40

Support X-100SL

Nails Length In magazine strips of Suitable base materials

X-EGN 14 MX 14 mm (1/2″) 10 Steel

X-GHP 18 MX 18 mm (11/16″) 10 Hard concrete / pre-cast concrete / steel

X-GN 20 MX 20 mm (

3

/4″) 10 Concrete / masonry with plaster coating (1cm) /

sand-lime blocks / concrete blocks

X-GN 27 MX 27 mm (1″) 10 Concrete / masonry with plaster coating (1cm) /

sand-lime blocks / concrete blocks

X-GN 32 MX 32 mm (1

1

/4″) 10 Concrete / masonry with plaster coating (1cm) /

sand-lime blocks / concrete blocks

X-GN 39 MX 39 mm (1

9

/16″) 10 Concrete / masonry with plaster coating (1cm) /

sand-lime blocks / concrete blocks

ity (less than 100 m/sec.) in a controlled manner. The

fastener driving process ends when the piston reaches

the end of its travel. This makes dangerous through-shots

virtually impossible when the tool is used correctly.

2.2 Drop-firing safety device

The drop-firing safety device is the result of coupling the

firing mechanism with the cocking movement. This prevents the tool from firing when dropped onto a hard surface, no matter at which angle the impact occurs.

2.3 Trigger safety device

The trigger safety device ensures that a fastener cannot

be driven simply by pulling the trigger only. The tool must

be pressed against a firm surface before a fastener can

be released.

2.3.1 Contact pressure safety device

The tool can be fired only when pressed against a firm

surface with a significant force.

Page 5

4. Technical data

Tool with magazine and gas can

Weight 3.95 kg (8.7 lbs)

Dimensions (L×W×H) 425×172×370 mm (163/4″×63/4″×141/2″)

Nail length max. 39 mm (19/16″)

Nail diameter 3.0 mm and 2.6 mm (.118 and 102 in.)

Magazine capacity 40 + 2 nails

Contact movement approx. 36 mm (17/16″)

Contact pressure approx. 120 N (27 lbs)

Operating temperature range / ambient temperature –5°C to 45°C (23°F to 113°F)

Max. fastener driving rate 600 per 30 min.

1000 per hour

3000 per day

Noise information (applicable to 1mm sheet metal on B45 concrete):

1b) Noise (power) level L

WA, 1S

109 dB (A)

Workplace-relevant emission value L

pAImax

102 dB (A)

(measured at operator ear level)

1e) Noise (pressure) level L’

–

pA, 1s

96 dB (A)

(Variations in operating conditions may cause deviation from these noise emission values.)

Gas can

Capacity 1 can for 750 nails

Recommended transport and storage temperature +5°C to +25°C (41°F to 77°F)

The can is pressurized.

Avoid prolonged exposure to direct sunlight and temperatures above 50°C (122°F).

Substances contained Dimethyl ether, isobutane, propylene,

propane, butane, ethanol and isoparaffin

Can Not refillable

Right of technical changes reserved.

15

en

5. Safety precautions

5.1 Basic safety instructions

In addition to the safety precautions listed in the individual sections of these operating instructions, the following points must be strictly observed at all times.

5.2 Use as intended

The tool is intended mainly for professional use. It designed

for driving nails into concrete, steel, sand-lime block,

concrete block masonry and masonry with a plaster or

cement rendering finish when installing drywall partitions and for other suitable fastening applications in the

construction industry and associated trades.

● Manipulation or modification of the tool is not per-

missible.

● To avoid the risk of injury, use only original Hilti acces-

sories and consumables.

● Observe the information printed in the operating instruc-

tions concerning operation, care and maintenance.

● Never point the tool at yourself or at any bystander.

● Never press the nosepiece of the tool against your hand

or other part of your body (or other person’s hand or

parts of their body).

● Do not attempt to drive fasteners into unsuitable mate-

rials:

- Materials that are too hard, e.g. welded steel and cast

iron

- Materials that are too soft, e.g. wood and drywall

panel

- Materials that are too brittle, e.g. glass and ceramic

tiles

Driving a nail into these materials may cause the nail

to break, shatter or to be driven right through.

Page 6

16

en

● The tool and its ancillary equipment may present haz-

ards when used incorrectly by untrained personnel or

not as directed.

● Pull the trigger only when the nosepiece of the tool is

in contact with the base material.

● Always hold the tool securely, perpendicular to the

work surface. This will reduce the possibility of the nail

ricocheting off the work surface.

● Never redrive a fastener. This may cause the fastener

to break or shatter.

● Never drive a fastener into an existing hole, except as

recommended by Hilti.

● Always observe the application guidelines.

5.3 Take the necessary precautions to make the

workplace safe

● Wear non-slip shoes and always ensure that you have

a secure stance.

● Avoid unfavorable body positions.

● Do not expose the tool to rain or snow and do not use

it in wet or damp environments or in the vicinity of

inflammable liquids or gasses.

● Ensure that the working area is well lit.

● Objects which could cause injury should be removed

from the working area.

● The tool is for hand-held use only.

● Keep the arms flexed when the tool is fired (do not

straighten the arms).

● Keep other persons, children in particular, outside the

working area.

● Before using the tool, make sure that no one is stand-

ing behind or below the point where fasteners are to

be driven.

● Keep the grip dry, clean and free from oil and grease.

5.4 General safety precautions

● Operate the tool only as directed and only when it is in

faultless condition.

● Never leave the tool unattended when it is loaded.

● Always unload the tool before beginning cleaning, ser-

vicing or changing parts and before work breaks (remove

the gas can and nails).

● When not in use, the tool must be unloaded and stored

separate from the gas can in a dry, locked place or

where it is out of reach of children.

● Remove the gas can before transporting the tool.

● Do not use the tool if parts of it are damaged or bro-

ken.

5.4.1 Mechanical

● Use only nails that have been approved for use with

the tool.

● Do not load nails into the magazine when it is not cor-

rectly attached to the tool. The nails may be forcibly

ejected.

5.4.2 Thermal

● Allow the tool to cool when it becomes hot.

● Do not exceed the maximum fastener driving rate (num-

ber of fasteners driven per given time interval). The

tool may otherwise overheat.

5.4.3 Gas

-WARNING-

Liquid gas under pressure.

Observe the hazard warnings and first-aid instructions

printed on the gas can.

The gas is highly inflammable (contains dimethyl ether,

isobutane, propene, propane, butane, ethanol and isoparaffin).

The gas can cannot be refilled.

● Do not use a gas can if it has been damaged.

● Do not attempt to open a gas can.

● Never spray the gas toward persons or animals.

● Keep the gas away from all sources of ignition such as

naked flames, sparks, pilot lights, static discharge and

very warm surfaces.

● Do not smoke while using the tool.

● Do not attempt to force the gas can open. Do not incin-

erate or crush the can and do not attempt to reuse it

for any other purpose.

Storage

● Do not store gas cans in inhabited rooms or in rooms

connected to inhabited rooms.

● Store the gas cans in a dry, well-ventilated place.

● Store the gas cans out of reach of children.

● Do not expose gas cans to direct sunlight or temper-

atures above 50°C (122°F).

● Recommended storage temperature: 5°C to 25°C (41°F

to 77°F).

First aid

-WARNING-

● Direct skin contact with the liquid gas may cause

chilblains or a serious freezing injury similar to a burn.

● If the gas has been inhaled, the person affected should

be taken into the open air and brought into a comfortable position.

● In case of unconsciousness, bring the person affect-

ed into a secure recovery position. Should the person

stop breathing, apply artificial respiration and supply

oxygen if necessary.

● In case of gas contact with the eyes: Rinse the open

eyes under running water for one minute.

Page 7

17

en

● In case of gas contact with the skin: Wash the contact

surface carefully with warm water and soap and apply

a skin cream when dry.

● Consult a doctor if necessary.

5.5 Requirements to be met by users

● The tool is intended for professional use.

● The tool may be operated, serviced and repaired only

by authorized, trained personnel. This personnel must

be informed of any special hazards that may be encountered.

● Always concentrate on your work. Proceed carefully

and do not use the tool if your full attention is not on

the job.

5.6 Personal protective equipment

● The operator and other persons in the immediate vicin-

ity must always wear eye protection, a hard hat and

ear protection while the tool is in use or when checking the tool in case of a fault.

5.7 Safety devices

● Never use the tool if the sliding sleeve (safety device)

is damaged or missing.

6. Before use

-WARNING-

The magazine must be empty.

The gas can must be removed from the can compartment.

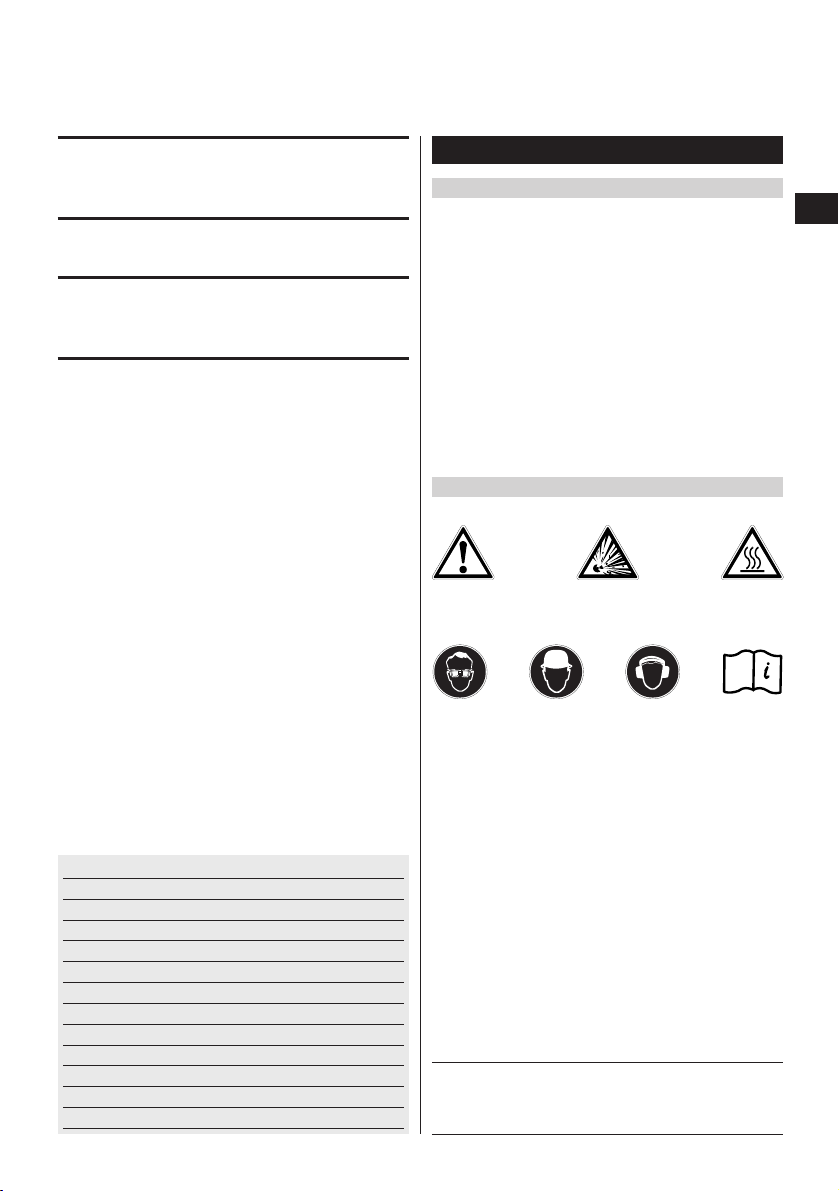

6.1 Inserting nails

1. Pull the nail pusher back until it engages.

-NOTE-

The nail pusher must engage.

2. Slide the nails into the magazine (maximum of 4 strips

of 10 nails).

3. Disengage the nail pusher and allow it to slide forward

slowly.

6.2 Preparing the gas can for use

1. Position the valve head on the inside edge of the gas

can.

2. Press the valve head onto the valve seat until it engages.

-NOTE-

Check that the valve head is fitted correctly on the valve

seat. Slight play is normal.

-CAUTION-

Once the valve head has been fitted to the valve seat on

the gas can it should not be removed (except when the

can is disposed of).

6.3 Inserting the gas can

1. Open the cover of the gas can compartment on the

tool.

2. Slide the gas can into the can compartment, base first,

until it engages.

-NOTE-

The arrow on the valve head must point to the outside

and the white plate must be positioned toward the tool.

3. Close the cover of the gas can compartment and ensure

that it engages in the closed position.

Page 8

18

en

-WARNING-

● Driving the nail may cause flying frag-

ments.

● Flying fragments may injure parts of

the body or the eyes.

● Wear eye protection and a hard hat.

GX 100

R

-WARNING-

● Making the tool ready to fire by press-

ing it against a part of the body (e.g.

the hand) is not permissible.

● This could cause a nail to be driven

into a part of the body.

● Never press the tool against a part of

the body.

-CAUTION-

● The nail is driven by the energy released

on ignition of a gas-air mixture.

● An excessively high noise level may

damage the hearing.

● Wear ear protection.

7. Operation

-NOTE-

When holding the tool with the second hand, care must

be taken to position the hand so that no ventilation slots

or openings are covered.

-CAUTION-

Never attempt to redrive the same fastener.

7.1 Operation

-NOTE-

The magazine must contain at least 2 nails, otherwise no

nail can be driven.

1. Hold the tool at right angles to the work surface and

then press it against the surface as far as it will go.

2. Drive the fastener by pulling the trigger.

7.2 The magazine

-NOTE-

The tool must be unloaded each time before the magazine is changed (see 7.6).

7.2.1 Removing the magazine

1. Pull the nail pusher back until it engages.

-NOTE-

The nail pusher must engage correctly.

2. Remove all nails from the magazine.

3. Disengage the nail pusher and allow it to slide forward

slowly.

4. Push the locking lever down toward the magazine.

5. Swing the magazine forwards away from the tool.

6. Detach the magazine from the tool.

7.2.2 Fitting the magazine

1. Attach the front end of the magazine to the tool.

-NOTE-

The locking lever must be in the open position.

2. Swing the magazine toward the tool, taking care to

ensure that its contours match the shape of the tool.

3. Close the locking lever and check that it engages

securely.

7.3 Adjusting the fastener driving depth at the

nosepiece of the tool

-NOTE-

● When the red ring is not visible, the nosepiece is set

to the standard fastener driving depth (standard setting for fastening wood to concrete).

● When the red ring is visible, the nosepiece is set to a

reduced fastener driving depth.

● When the red ring is visible and the nail is still driven

to deeply, it may be necessary to use a longer nail.

7.3.1 Setting the standard fastener driving depth

1. Press the lockbutton and turn the nosepiece of the tool

in the opposite direction to the arrow.

2. Slide the nosepiece toward the tool.

3. Turn the nosepiece in the direction of the arrow until

it engages.

-NOTE-

The red ring must not be visible.

7.3.2 Setting the reduced fastener driving depth

- NOTE -

This setting is suitable for fastening thin sheet metal to

soft materials (e.g. young / green concrete).

1. Press the lockbutton and turn the nosepiece of the tool

in the opposite direction to the arrow.

2. Slide the nosepiece away from the tool.

3. Turn the nosepiece in the direction of the arrow until

it engages.

-NOTE-

The red ring must be visible.

7.3.3 Removing the nosepiece

1. Press the lockbutton and turn the nosepiece of the tool

in the opposite direction to the arrow.

2. While pressing the lockbutton, pull the nosepiece away

from the tool.

Page 9

19

en

7.3.4 Fitting the nosepiece

1. Bring the nosepiece lockbutton into alignment with

the notch on the tool.

2. Slide the nosepiece onto the tool into the desired position.

3. Turn the nosepiece in the direction of the arrow until

it engages.

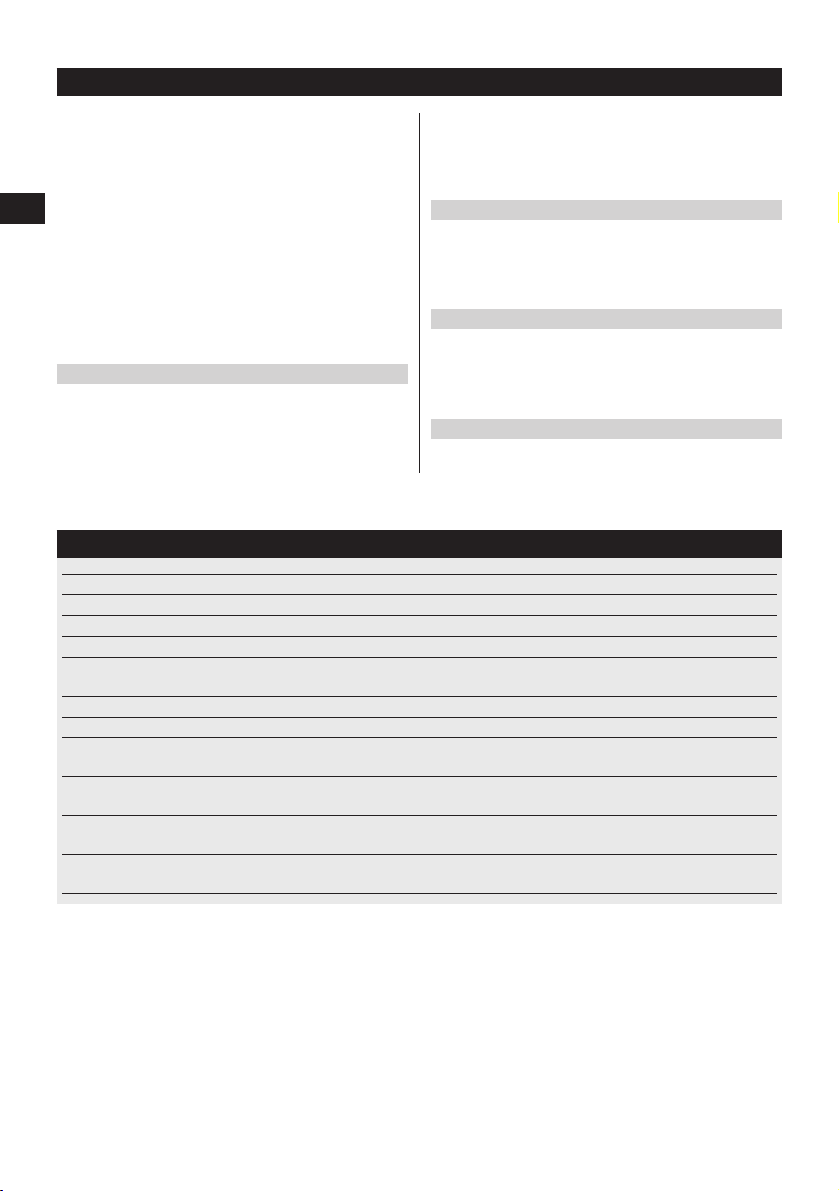

7.4 Support

7.4.1 Fitting the support

1. Push the support at right angles into the slot in the

magazine.

2. Pivot the support through 90° and engage it in position.

7.4.2 Removing the support

1. Release the support by pressing the spring catch.

2. Pivot the support through 90°.

3. Pull the support away from the magazine at right

angles.

7.5 Bringing the piston into the correct position

-NOTE-

The piston is incorrectly positioned when the nosepiece

of the tool has not extended to its original position after

the tool is lifted away from the work surface.

The piston can be returned to the correct position by

pressing the reset button. Nails can then be driven. In

exceptional cases, the tool may fire without driving a nail

when the tool is actuated for the first time after it has

been reset.

1. Press the reset button (the direction of movement is

downwards at a slight angle).

7.6 Unloading the tool

1. Open the cover of the gas can compartment.

2. Release the gas can by pressing the valve head in the

direction of the arrow.

3. Remove the gas can from the compartment.

-CAUTION-

Once the valve head has been fitted to the valve seat

on the gas can it should not be removed (except when

the can is disposed of). Place the gas can complete

with valve head in the toolbox.

4. Close the cover of the gas can compartment.

5. Pull the nail pusher back until it engages.

-NOTE-

Ensure that the nail pusher engages.

6. Remove the nails from the magazine.

7. Disengage the nail pusher at the magazine and allow

it to slide forward slowly.

7.7 Application guidelines

For more detailed information, please ask the Hilti marketing organization in your country for a copy of the Hilti

Fastening Technology Manual or the applicable national

regulations.

Concrete

A = min. distance from edge = 70 mm (2

3

/4″)

B = min. fastener center spacing = 80 mm (3

1

/8″)

C = min. base material thickness = 100 mm (4″)

Steel

A = min. distance from edge = 15 mm (

5

/8″)

B = min. fastener center spacing = 20 mm (

3

/4″)

C = min. base material thickness = 4 mm (

5

/32″)

BA

C

BA

ET

C

Page 10

20

en

8. Care and maintenance

-WARNING-

Always remove the gas can and nails from the tool before

performing any work or maintenance on the tool.

8.1 Care of the tool

● Carefully remove any scraps of plastic from the nose-

piece of the tool.

● Never operate the tool if the ventilation slots are blocked.

Clean the ventilation slots carefully with a dry brush.

● Do not permit foreign objects to enter the interior of

the tool.

● Use a slightly damp cloth to clean the outside of the

tool at regular intervals.

● Do not use a spray, steam cleaning system or running

water to clean the tool.

● Always keep the grip surfaces of the tool free from oil

and grease.

● Do not use cleaning agents containing silicone.

● Do not use Hilti spray or similar lubricants.

-CAUTION-

● Do not damage the nail detector

8.2 Maintenance

Check all external parts of the tool for damage at regular

intervals and check that all operating controls function

faultlessly. Do not operate the tool when parts are damaged or when operating controls do not function faultlessly. The tool should be repaired at a Hilti service center.

9. Troubleshooting

-WARNING-

Always unload the tool (remove the gas can and nails) before checking it for faults.

Problem Possible cause Remedy

Low power (nails not Gas can almost empty Fit a new gas can.

driven deeply enough) Valve head defective Fit a new valve head on a new gas

can.

Foreign object jammed in the area Remove the magazine. Remove the foreign

of the magazine / nosepice object. If the problem persists, have the

(nosepiece does not extend to its tool repaired at a Hilti repair center.

original position after lifting tool

away from work surface or extends

too slowly).

Check axial play at nosepiece:

(should be 1–2 mm).

Operating temperature too low Use a gas can that has been warmed to

room temperature (~20°C / ~68°F)

(Warm the can beforehand in a

trouser pocket or in a warm room.)

-WARNING-

Never heat the gas can on a hot

surface or with a flame.

Piston in wrong position See “Piston in wrong position”.

-CAUTION-

● The tool may get hot when in use.

● You could burn your hands.

● Allow the tool to cool.

8.3 Checking the tool after maintenance

After performing maintenance work on the tool and before

inserting the gas can, check that the sliding sleeve (safety device) is fitted and that it functions correctly (easy

sliding movement).

Page 11

21

en

Piston in wrong position Tool is too hot Free the mechanism by pressing the reset

button . Drive the next nail (the tool may

fire once without driving a nail after resett-

ing). Allow the tool to cool if necessary.

Gas can almost empty Use a new gas can

(fit the valve head to the new can).

Tool doesn’t fire Gas can almost empty Insert a new gas can.

Valve head is defective Fit a new valve head on a new gas can.

Valve head fitted incorrectly / not Fit the valve head to the can correctly.

fully seated

Gas can not inserted correctly in the Insert the gas can in the tool correctly.

tool

Operating temperature too low Use a gas can that has been warmed

to room temperature (~20°C / ~68°F)

Ferromagnetic foreign objects Remove foreign objects from the

adhering to the magazine magazine.

Magazine is defective Try using another magazine.

Valve head does not dispense the Remove the gas can and allow it to

correct gas quantity cool or operate the valve head manually

several times (press the white plate toward

the valve head) until it functions correctly.

-WARNING-

Never point the nozzle toward persons, animals, naked flames or hot objects).

Electronics defective If electronics are defective, no

immediate remedy is possible. Have

the tool repaired at a Hilti repair center.

-CAUTION-

Wait 10 seconds and then, if possible, remove the gas can and valve head from the tool before manipulating the

tool as described in the instructions below (*).

Nail jammed in the Several nails driven on top of each * Remove the magazine and nosepiece and

fastener guide other pull the nail out toward the front.

* Remove the nosepiece and tap the nail

back with a hammer and pin punch.

Nail jammed in the Nail has become jammed during * Remove the magazine.

“guide” (steel part the driving operation Remove the nail.

of the magazine)

Tool cycling mechanism Piston in wrong position * See “Piston in wrong position”

jammed (no movement of Nail jammed under the button * Remove magazine, remove nail.

nosepiece after lifting tool -CAUTION-

away from work surface) Do not damage the button and nail detector

Nail detector jammed (possibly * Pull the nosepiece forward

due to dirt or debris) by hand or use pliers.

Trigger jammed in rearmost position * Bring the trigger into its outset

position (by hand or use pliers).

Loose nails / foreign objects * Remove the magazine, remove

under the cover foreign objects. Have the tool

repaired at a Hilti repair center.

Gas can cannot be Tool cycling mechanism jammed Remove the magazine. Remove the nail.

removed Open the cover of the gas can compartment

and press the valve head toward the outside,

in the direction of the arrow, until the valve

head is released from the can. Remove the

valve head and the gas can individually.

Page 12

22

en

Magazine: Dirt or debris Clean from the outside.

Nail pusher jammed

Foreign objects Remove foreign objects from the outside.

Magazine cannot be fitted Rubber buffer on the magazine Replace the rubber buffer.

retaining piece is missing

Locking lever not turned all the way Turn the locking lever all the way

down (90°) down (90°).

Tool cannot be pressed Magazine empty, or possible only 1 Load the magazine.

against the work surface or 2 nails in the magazine

(cycling movement) Tool pressed against a foreign object Press the tool against an unobstructed

surface.

Plastic debris jammed in the Remove plastic debris.

nosepiece

Nail pusher engaged in rearmost Release the nail pusher.

position

Nail pusher jammed Free the nail pusher, clean the magazine /

remove foreign objects

Sleeve turned out of position, not Bring sleeve into correct position.

engaged

Gas can not fitted correctly in the Fit the gas can correctly.

tool

Nail has slid forward in fastener Remove the magazine and remove the

guide nail.

Loose nails or foreign objects under Remove the magazine, remove

the cover foreign objects. Have the tool

repaired at a Hilti repair center.

Nosepiece doesn’t engage Lockbutton broken or deformed Fit a replacement nosepiece. Have the tool

repaired at a Hilti repair center.

Leakage from the gas can Faulty interface between gas can and Remove the gas can, remove the valve

or leakage at the interface valve head head from the can and dispose of both

between the can and the parts. Use a new gas can fitted with a

valve head new valve head.

Please send the tool to a Hilti repair center if these measures fail to remedy the problem.

Page 13

23

en

10. Disposal

Most of the materials from which Hilti tools are manufactured can be recycled. The materials must be correctly

separated before they can be recycled. In many countries, Hilti has already made arrangements for taking back

your old fastening tools for recycling. Please ask your Hilti customer service department or Hilti sales representative for further information. Please observe regional and international guidelines and regulations.

Separate the individual parts as follows:

Component / assembly Main material Recycling

Toolbox Plastic Plastics recycling

Tool casing Plastic / synthetic rubber Plastics recycling

Battery Battery recycling

(-NOTE- (observe specific national regulations)

The battery is designed to last the life of the tool.)

Electronics parts Various Electronics scrap

Screws, small parts Steel Scrap metal

Valve head Plastic Plastics recycling

Gas can Disposal of gas cans by incineration (at a

garbage incineration plant) is not permissible. Do not dispose of gas cans with other

scrap for recycling.

11. Warranty

Hilti warrants that the tool supplied is free of defects in

material and workmanship. This warranty is valid as long

as the tool is operated and handled correctly, cleaned

and serviced properly and in accordance with the Hilti

operating instructions, all warranty claims are made within 12 months (unless other mandatory national regulations prescribe a longer minimum period) from the date

of sale (invoice date) and the technical system is maintained. This means that only original Hilti consumables,

components and spare parts may be used in the tool.

This warranty provides the free-of-charge repair or replacement of defective parts only. Parts requiring repair or

replacement as a result of normal wear and tear are not

covered by this warranty.

Additional claims are excluded, unless stringent

national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental or

consequential damages, losses or expenses in connection with, or by reason of, the use of, or inability to

use the tool for any purpose. Implied warranties of

merchantability or fitness for a particular purpose are

specifically excluded.

Send the tool and/or related parts immediately upon discovery of a defect to the local Hilti marketing organisation for repair or replacement.

This constitutes Hilti’s entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

11.1 Gas can

Observe the use-by date for the gas can (printed on the

edge of the can).

Page 14

24

en

12. CE declaration of conformity

We declare, on our sole responsibility, that this product

complies with the following standards or standardization documents: 75/324/EWG, 91/155/EWG, 67/548/EWG,

EN 292, EN 792-13, EN 563, EN 50081-2, EN 60529,

EN 1127-1, EN 417, EN 61000-4-3, EN 55011:1998,

EN 61000-6-2:2001, IEC 61000-6-2:1999, EN 61000-63:2001, IEC 61000-6-3:1996, CISPR11:1997.

Designation: Gas-powered fastening tool

Type: GX100

Year of design: 2002

Hilti Corporation

Raimund Zaggl Dr. Walter Odoni

Senior Vice President Vice President Development

Business Area Direct Fastening Business Unit Direct Fastening

January 2003 January 2003

Loading...

Loading...