Page 1

Gasoline

Powered

Rotary Hammer Drill

Type:

Speed:

hole to

Data

(5000

Air Cooled

Combustion

(1

22.6 cc

0.8 hp-7000RPM

Recoil

Starter

(0.132

liter

0.5

T.C.l. Electronic

Mixture 25:1

2-stroke oil)

liter/hour

0.5

RPM

0-440

lmpacUMin

3150

(159+"

LxHxW

11|q"

lbs.

157+

1lz

7

inlmin with

1" in concrete

Technical

Engine Type:

Piston

Displacement:

Maximum

Horsepower:

Starter

Fuel Tank Capacity:

lgnition Type:

Fuel:

Fuel

Consumption

Rate:

Full Load

Percussion:

Dimensions:

Closest

colner:

Weight:

Drilling rate

psi

concrete):

Max.

bit diameter:

Features

.

Equals or exceeds the HILTITE-2z

Hammer

o

Two

and rotary

.

Permanent lubrication

.

Two finger

Drill in

only

throttle

oerformance

lever

drilling modes; hammer drilling

Instruction

2-Stroke

Engine

.38 cu. in.)

Gal.)

U.S.

(Gasoline

(0.132 gal./houQ

and

x81lz")

xlosle"

lslsz"

diameter

.

Side handle is locked in

tightening hand

.

gauge

Depth

positively

locks

.

Easy

to operate recoil starter

llzliter

c

(0j32

full load

refueling

bit

grip

is readily

gal.)

operation for t hour without

Manual

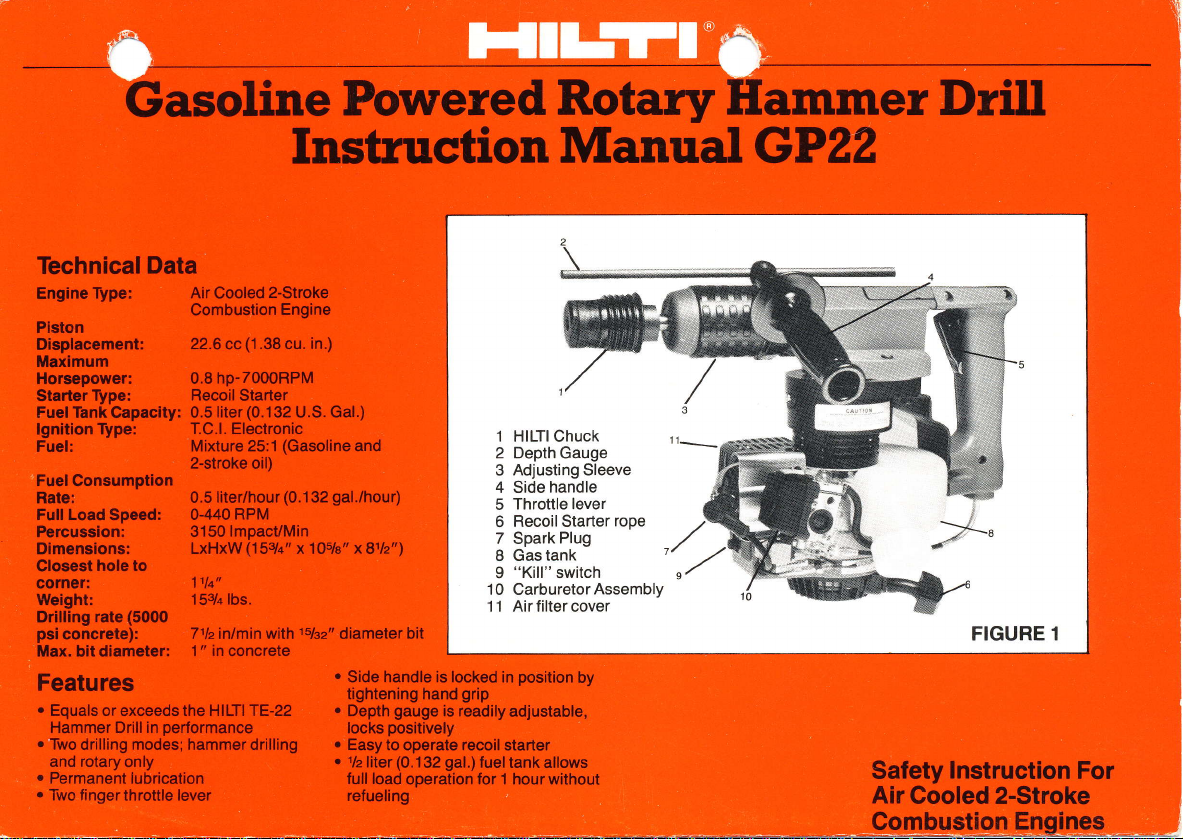

1 HILTI Chuck

2 Depth

3 Adjusting Sleeve

4 Side

5

6

7

8 Gas

9

10

11 Air filter cover

fuel tank allows

Gauge

handle

Throttle

Recoil

Starter

Plug

Spark

tank

"Kill"

switch

Carburetor

position

adjustable,

lever

by

rope

Assembly

,r/

GP22

FIGURE 1

Safety

Air

Instruction

Gooled 2-Stroke

Com[uslion

For

Eng_ines

Page 2

Operation

SAVE

1. Side

THESE

Handle and

INSTRUCTIONS

Depth Gauge

Adiustment:

Loosen the side

counter-clockwise.

gauge

the handle to the

position.

Note: When

surc

insure correct

proper

to the

Retighten the

setting depth

that the drill bit

setting.

handle by

most comfortable

turning

Adiust the

length and

side handle.

gauge

pushed

is

2. Lubrication of theChuck:

Always

end of the bit shank before

in the

with Hilti

and lubricate the chuck

clean

To lubricate, spray

drill.

spray

lubricant.

inserting

depth

rotate

be

back to

lightly

Bit

3.

Chucking

Pull the locking sleeve back

insert the bit

locking sleeve and

the

bit until the

back into its original

I;:i;l:,i:ii

For hammer drilling:

4.

With the drill stopped,

adjusting sleeve

twisting a

by

clockwise.

work surface, apply

switch the drill on.

Note: lf the machine

before being

hammering

in the chuck.

locking

sleeve

position.

pull

all the

quarter

placed

turn counter

light

is switched on

in

Place the drill

will occur.

turn the drill

way and lock

against the

pressure,

position,

and

Release

snaps

the

back

no

For rotary drilling:

5.

With the drill stopped, unlock the

adjusting sleeve with a

clockwise. A spring

ward

allthe way.

sleeve a

wise to lock in the

position.

work surface and switch on

FUELING/REFUELING

1. Read the

for air cooled

tions

ouarter

Place

first six safety

combustion

2. Fill tank

with a

gasoline (regular)

2-stroke oil.

equivalent

gasoline

gal.

gal.)

available

two

quickly;

container

this manual.

to

or 5 tluid oz.

gasoline.

of

gasoline/oil

from HILTI

tanks of

instructions

appear

quarter

push

will

Turn

turn

"drilling

the drill against the

engines.

25

to

A 25 to

1/s

pint

A

mixing container

properly

it

the adjusting

counter clock-

only"

instruc-

two stroke

1 ratio of

and high

is

1 ratio

1

oil to

of oil to

liter

one

provide

will

mixed

for using this

near the end

turn

for-

quality

gal.

1

(.264

fuel

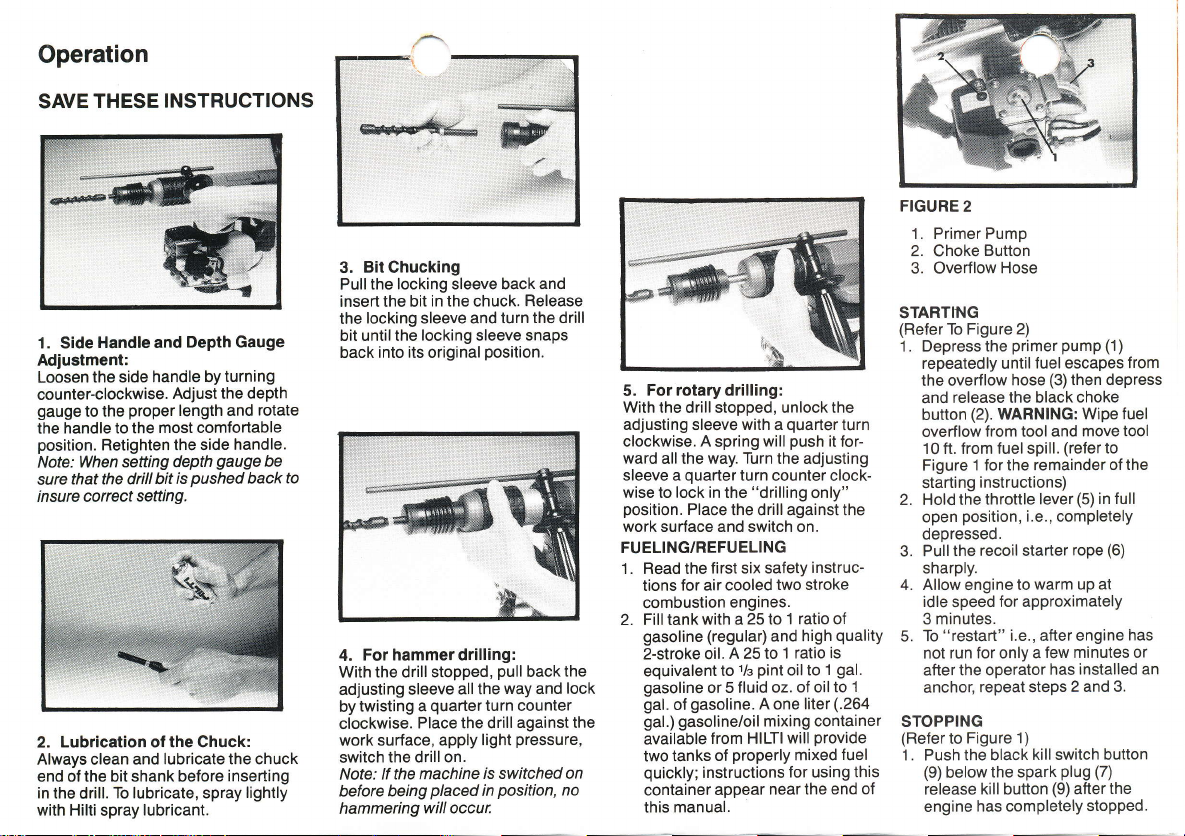

FIGURE

'1

. Primer Pumo

2.

Choke

3. Overflow Hose

START]NG

(Refer

1 . Depress the

repeatedly until

the overflow

and release the black

button

overflow

10 ft. f rom fuel spill.

Figure 1 for the remainder

starting

2. Hold the

open

deoressed.

3. Pullthe

sharply.

4. Allow engine to

idle speed for approximately

3 minutes.

5. To

not run tor only a

after the oDerator

anchor,

STOPPING

(Refer

1. Push the black

of

(9)

release

engine

2

Button

To Figure

2)

primer pump

fuel escapes

hose

(2).

WARNING:

from tool and move tool

instructions)

throttle lever

position,

"restart"

to

below

i.e.,

recoil starter

warm up at

i.e., after engine

few minutes or

repeat steps

Figure 1)

kill switch button

the spark

kill

button

has completely

(3)

then depress

choke

Wipe fuel

(refer

(5)

in full

completely

rope

installed an

has

2 and 3.

plug

(7)

(9)

after

stopped.

(1)

from

to

of the

(6)

has

the

Page 3

Maintenance

Accessories

Servicing

AIR FILTER

(Referto

Replace

every 10

often in dusty

drilling

overhead): Remove

in

black

cover

and air

Remove

in fuel

mix, wring

the spring. Re-install

spring assembly.

(11)

make

the locating

CAUTION:

the

air filter installed.

SPARK PLUG

Check

spark

(D24-.027

To

clean

sandpaper

after

cleaning.

FUEL

FILTER

No

maintenance

(1)

Figure

or thoroughly

hours

of operation

conditions

filter

cover

tilter spring

spring from

out filter

Replace

sure the

points

Never run

plug gap

in).

plug

spark

or wire brush.

required.

GEAROIL

GP22 is

permanently

reouired.

The

No

maintenance

clean air filter

and when

(1

1)

and

assembly.

filter, wash

and replace

the air filter

filter

spring fits

in the

cover

engine

0.6-0.7 mm

electrode

Reset

lubricated.

(more

2

screws

remove

cover

over

(1

without

use

gap

filter

1

).

Fuel Mixing Container

Provides

20, 25.

set of marks for a 25:1 ratio.

TE-C-BF

For use

speed

diameter

in

accurate fuel/oil ratios

and 30 to 1.

Keyless

with

smooth

steel twist

and

hammer

wood bits.

mode.

the

Use

Chuck Assembly

shank,

bits up

to

Do not

center

high

112,

All repairs

HILTI GP22 should be

the designated HILTI

(HlLTl

Tulsa.

and adjustments

National Parts Warehouse) in

OK.

Warranty

This new fastening tool is

product

of

through

fastening methods and applications

of

ciated trades. Every reasonable

orecaution

manufacture

compliance with

high

operation and maintenance

tool

Salesman.

90 Day Limited

days trom

original

use

Hilti.

of

study and

the

building

has

quality.

Consultation

is

available from

the date of shipment,

purchaser

lt has been developed

industry

been taken in

of

this tool to assure its

Warranty: For

conducted by

Repair Center

a

research into

and asso-

Hilti's

standards of

on the

our Territory

the

of

tool will not

to the

quality

the

of the

90

the

the

be charged for the

required

rials

tool is returned

and

has not been removed

only Hilti

parts

and no

been

not

the cost

This

to correct defects in mate-

and workmanship

inspection,

compatible bits

have been

unauthorized servicing has

performed.

cover normal

of shipping

is

the only warranty

antee made

in lieu

of all other

including

merchantability

particular

circumstances

gated

for

damages, losses

expenses in

reason

of

use the tool for

,

parts

to Hilti for

the serial number

used

The wananty

wear and

by Hilti

warranties.

implied

warranties

and of fitness

purpose.

will Hilti

connection

the use

of, or inability

any

labor

and

provided

servicing

or defaced,

Hilti

and

with

the tool,

does

tear and

and insurance.

and it is

or

guargiven

of

Under no

be obli.

or

with or

purpose.

the

for

a

by

to

HILTI

P.O. Box 21148

(91

c

252-6000

8)

Tulsa.

OK 74121

HILTI is

@Copyright

Hilti

registered

a

is an equal

1986

by HlLTl,

opportunity

tradem..

Inc.

company

rHlLTl

Corp.

Page 4

Safety

Instructions

READ ALL

INSTRUCTIONS

1. Keep Work Area

Cluttered areas and benches invite

injuries.

Clean

2. Keep Children Away

Do not let visitors

visitors

should be kept away from

worK area.

3. Store

When not in

stored in dry,

olace - out of

4. Don't Force Tool

It will do the

the

ldle Tools

use, tools should be

and

reach

job

rate for which it was intended.

better and safer at

contact

high

or

of children.

tool. All

locked-up

5. Use Right Tool

Don't force

to

do the

Don't use tool for

intended.

Dress Properly

6.

Do not wear

They

can be caught

gloves

Rubber

recommended

are

outdoors.

ering to contain long hair.

tool

small

job

of a heavy-duty tool.

loose

Wear

or attachment

purpose

clothing or

in movlng

and non-skid footwear

when working

orotective hair cov-

not

jewelry.

parts.

7. Use Salety Glasses

Also use face or dust mask if cuttinq

operation

is

dusty.

8. Secure Work

Use clamos or a

It's safer than using

frees both hands to operate tool.

Don't

9.

proper

Keep

all times.

10. Maintain Tools With

Keeo tools

and safer r

vise

to hold work.

your

hand

Overreach

footing and balance at

e

-

r

and clean

,rance.

Care

Follow

for

and

better

instructions tubricatingand

I

Do not

changing accessories.

periodically

cords

have repaired

facility.

free from

1 1. Remove

by authorized service

Keep handles

oil and

Adiusting Keys and

Inspect

and if

dry, clean, and

grease.

tool

damaged

Wrenches

Form

habit of checking to see that

keys and adjusting wrenches

removed from

it on.

12.

Stay Alert

Watch

common sense. Do not

when

13.

CheckDamaged

Before further use of the tool

that is

checked to deterrnine

operate

intended functions.

ment

of moving

any

other conditions that may atfect

its operation. Any

damaged should be

replaced

or

tool before turnino

you

what

you

damaged should be carefully

are doing.

are tired.

properly

and

Check for align-

parts,

part

by an authorized service

properly

Use

ooerate tool

Parts

it

that

will

perform

mounting,

is

that

are

part

any

its

and

repaired

center unless otherwise indicated

elsewhere in this instruction

14. Replacement

When

servicing use

replacement

15. Wear Ear Protectors

Wear

extended

16,

it

ments

Do not

flammable

Caution

The metal

made

Only the handles

be

or other concealed

protectors

ear

periods.

Avoid Flammable Environ-

use tool

parts

live if

contacted when drilling into a wall

Parts

parts.

in

the

liquids

or

of the drill can be

the tool drills into wiring.

of the GP-22 shculd

space.

manual.

identical

only

when using for

presence

gasses.

of

L

9.

10.

11.

12.

use any other

than a 25:1 mixture of regular

gasoline

Refuel in

away from

sources,

in

and

a safe

possible

such as

clothes dryers,

furnaces, etc. Always stop

engine before

Do not open tank with more than

1/+

because of oossible overflow.

Open

pressure

Move tool at least 10 ft. from

fueling area

prevent

Wipe away any excess fuel

spilled on tank or engine.

allow dust, dirt, fuel, or debris to

fuel remaining

tank of

gas

cap slowly to relieve

in tank.

alire

before

build up on engine. Before

starting make sure that engine

has dried completely and that no

fuel leaks

Do not

operating the GP22.

Do not

poorly

Do not run

muffler. Keep screens and batfles

clean.

Do not let

come in contact with hot

muffler,

immediately

stopped.

Do not touch

while

attempt to change spark

until

Do

areas where flammable materiai

is oresent.

"Kill"

drill bits, setting anchors, etc.

exist.

smoke

use tool

ventilated areas.

equipment without a

your

etc. while operating or

operating and do not

has

engine

not set a hot

engine

fuel

other

2-stroke

oil.

place.

Keep tool

ignition

gas pilot

water heaters,

ref

ueling.

starting to

hazard.

Do

while fueling

indoors

or

hands or body

after engine

spark

engine down

before changing

plug

cooled.

engine,

has

wire

plug

lights

not

or

in

in

Loading...

Loading...