Page 1

Ferroscan System FS10

Bedienungsanleitung

Operating instructions

Page 2

16

Contents Main functions

1. Safety / care and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2. Items supplied. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3. Preparing the system for operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 RV10 monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Function keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 RS10 scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Paper reference grid and ruler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4 TCU12H charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.5 RB10 battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5. Using the system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Scanning an image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 Determination of position, coverage and diameter of reinforcement. . . . . . . . . . . . . . . . 25

5.4 Rapid detection and verification of minimum coverage . . . . . . . . . . . . . . . . . . . . . . . . .26

5.5 Identifying, recalling and printing images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.6 PC software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6. Working range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7. Ferroscan FS10 system - technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

The Ferroscan FS10 system provides the following main functions:

● Rapid detection and verification of minimum concrete coverage (see section 5.4).

● Scanning and recording of images, with determination of depth of coverage and diameter of

reinforcement (see sections 5.2 and 5.3).

● Printing out of images (see section 5.5).

● PC software for data evaluation (see section 5.6)

Right of technical modifications reserved

Page 3

17

1. Safety / care and maintenance

Safety precautions Ferroscan System Safety precautions TCU12 H

Important: The following safety precautions must be

observed

● The mains supply must correspond to the information printed

on the rating plate. 230 volt units may also be connected to a

220 volt supply.

● Only Hilti RB10 batteries should be charged using this charger.

The TCU12H charger and RB10 battery have been designed to

work together optimally.

● The charger must be able to give off heat during the charging procedure. Please ensure that the ventilation slits are not

obstructed.

Do not use the charger in closed containers!

● Do not short circuit the contacts.

● The charger should be located in a dry, clean and cool place

but protected from frost.

As this unit is connected to the mains supply, safety precautions

must be observed.

Care and maintenance

Always disconnect the mains plug from the mains supply before

cleaning or servicing the TCU12 H. The contacts in the battery

compartment must be kept clean (free of oil and grease).

The ventilation slits must be free of dirt and dust.

A damaged supply cord must be replaced by a Hilti repair centre, as special tools are required for carrying out the repair correctly.

Safety precautions RB1O

Important: The enclosed safety precautions must be

observed

● Before operating the unit, check that the RB10 battery has

been fitted securely.

● Do not continue to operate the unit until the RB 10 battery

becomes totally exhausted (unit completely inoperative). The

battery cells may suffer damage if completely discharged.

● The BP 10 battery should be stored in a dry place and protected from frost. Heat sources such as direct sunlight or radiators should be avoided.

● The RB10 battery should be used only in the units indicated

by Hilti. Use only the charger specified by Hilti for charging the

RB10 battery.The charger,battery and other units of the system

are designed to work together optimally.

● If necessary, clean the RB10 battery terminals before inserting it into the charger or into the unit.

● Do not short circuit the RB10 battery terminals.

● New RB 10 batteries or batteries which have not been used

for a long period only reach full capacity after several

charge/discharge cycles.

Care and maintenance

Battery terminals must be kept clean (free of oil and grease). If,

after having been subjected to considerable use, battery capacity drops below an acceptable level, we recommend that the

battery is checked by Hilti.

Important: RB10 batteries which have reached the end of their

life should be returned to Hilti for recycling.

Important: The following safety precautions must be

observed

● A qualified technical expert (e.g. civil engineer) must be

consulted when making use of the measurement data for

safety relevant purposes (e.g. structural design).

Care and maintenance

The Ferroscan FS10 system is a testing instrument. Although it

has been designed for arduous jobsite conditions (impact and

vibration resistance) it should be treated with the appropriate

care.

The LCD display is suitable for operation in temperatures within

the range –10°C

% to % +50°C. Extreme temperatures resulting from exposure to direct sunlight for long periods and other

sources of heat such as radiators should be avoided!

The PC and printer connections should always be covered when

not in use in order to protect the instrument from the effects of

dust and water spray.

The RS10 scanner required to be recalibrated after a period of

use of approx. two years. It is recommended that the RS10

scanner is returned to the nearest Hilti centre for recalibration

after a period of two years. If the measurement characteristics

lie outside tolerance limits, the complete system becomes inoperative. No further readings can be taken.

The lithium auxiliary battery has a life of approx. six years. It is

recommended that this battery is checked at the two-yearly calibration intervals.

Page 4

18

➜

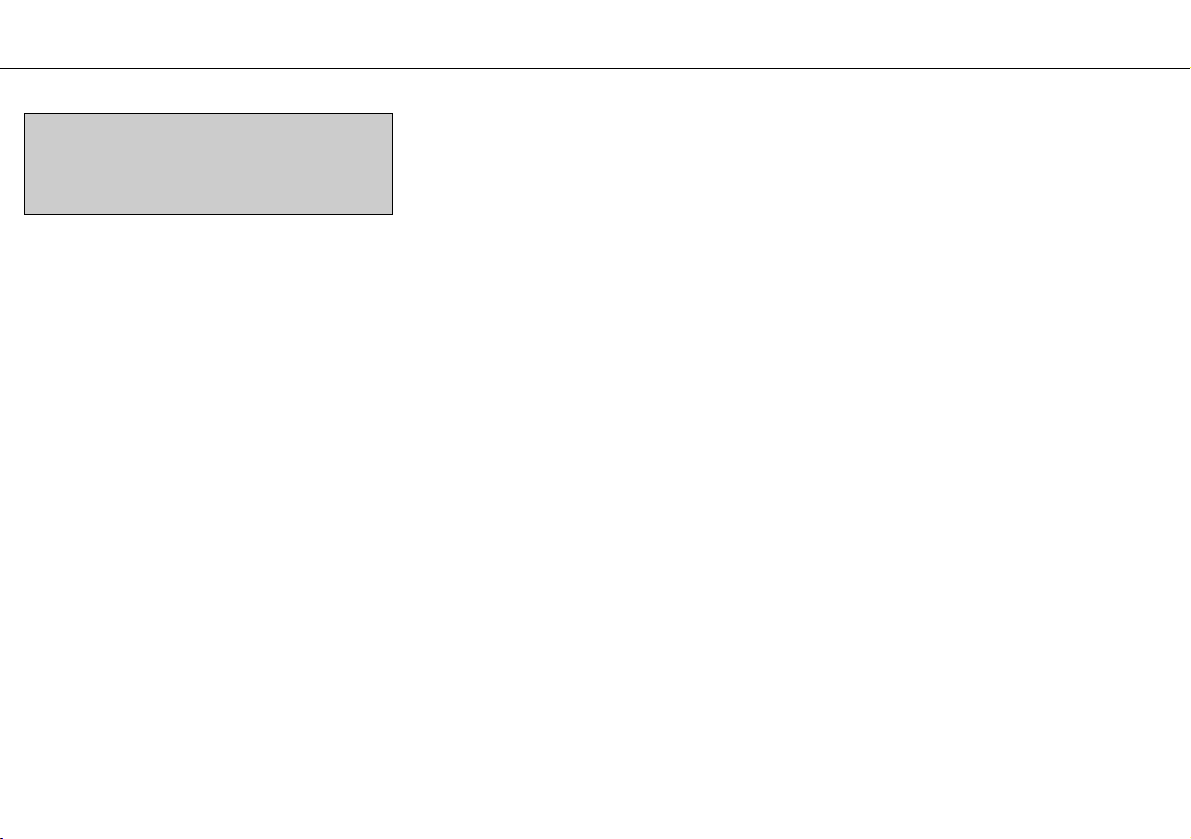

2. Items supplied 3. Preparing the system for operation

The Ferroscan FS10 system is supplied in a standard impactresistant Hilti case. The case contains:

1 RV10 monitor (evaluation module)

1 RS10 scanner (detection probe)

1 RC10 connecting cable

1 RB10 battery

1 TCU12 H charger

10 RG10 paper reference grids

1 roll of adhesive tape

1 serial interface connecting cable

1 PC program for data analysis

Before the system can be operated, the RB10 battery must be

charged using the TCU12 H charger (see section 4.4).

The charged RB10 battery should be inserted in the compartment on the base of the RV10 monitor (locking lever facing

upwards).

Press the button to switch on the RV10 monitor. If the system is being operated for the first time, after running through an

automatic self test, a short description of basic functions

appears on the screen. Alternatively, the last recorded image will

appear on the screen. The battery must be recharged when the

symbol, which appears at the left-hand edge of the screen,

begins to blink. Charge the battery using the TCU12 H charger

(see page 21). The RS10 scanner must be connected to the

RV10 monitor using the RC10 connecting cable before readings

can be taken.

I/O

Page 5

19

6

5

1

7

432

8 9

12

10

11

Scan...

Analyse...

Quickscan...

Set Up...

Main Menu

Delete

Image...

1254 22-OCT-92 09:35

25 of 26

Scan...

Analyse...

Quickscan...

Set Up...

Main Menu

Delete

Image...

"Scan"creates and stores a

600mm square image. Up to 42

images can be stored.

"Analyse"provides detailed

measurement functions for

the stored images.

"Quickscan"gives rapid

assesment of coverage over

a large surface.

"Delete image"removes one

or more images from the

memory.

"Set up"sets volume, time,

date and language.

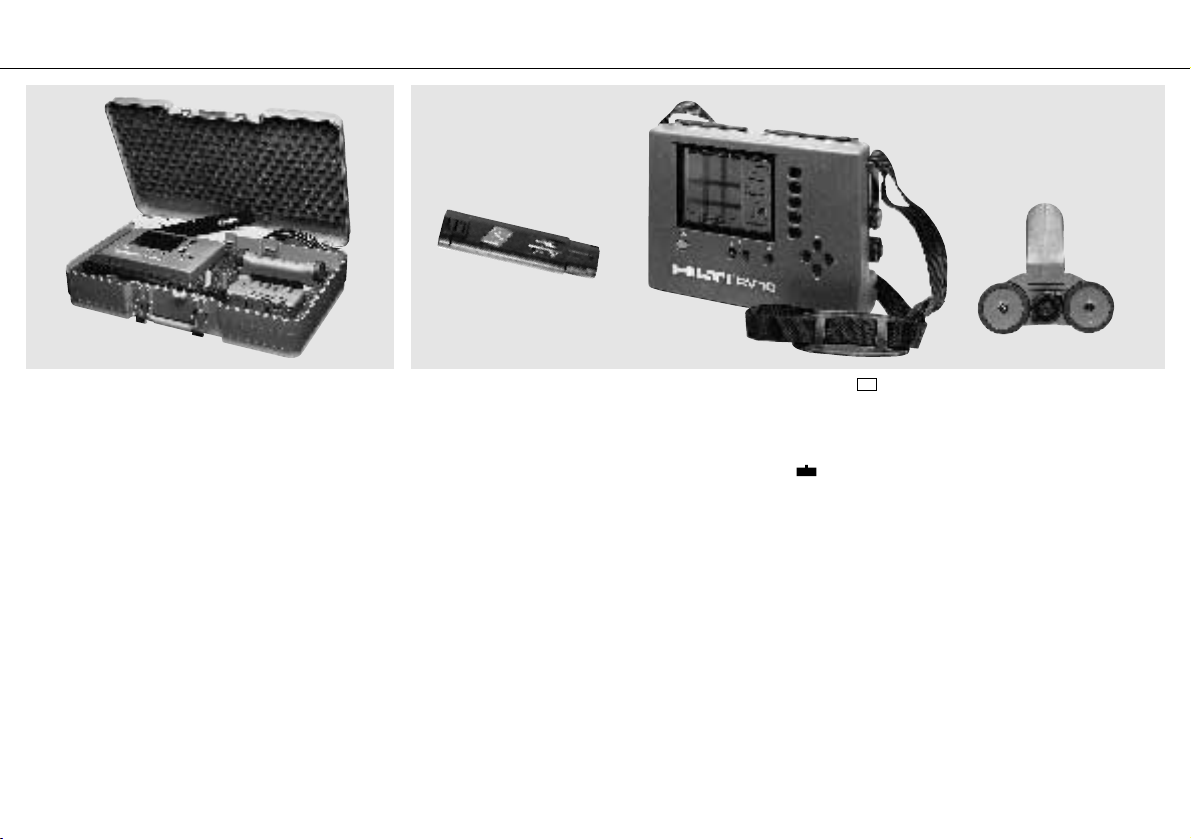

4. Operation

4.1 RV10 monitor

Operating controls

1 On/off button

2 Increase image contrast

3 Reduce image contrast

4 Print

5 Cursor keys

6 Function keys

7 Printer connection

8 PC connection

9 DC power supply socket

10 Scanner connection

11 Battery compartment

12 Carrying strap

Warning: for DC power supply a regulated output voltage of

12 V is required.

Note: To save battery power, the monitor switches off automatically if no button is pressed for a period of 5 minutes.

Function keys

The five function keys are used to select a function from the

main menu which appears on the right-hand side of the screen.

When a function has been selected, the function menu is displayed. If no function is allocated to a particular key, the corresponding position on the screen remains blank. If a function is

not available for a particular operating mode, the menu position

is displayed in grey.

To return to the main menu from a function menu, press the

key.

Done

Display

Normally, when the RV 10 monitor is switched on, the last

recorded image appears on the screen. If no image is stored in

the RV10's memory, a brief description of the main functions is

displayed.

Page 6

20

3

2

1

4

View +

View -

Depth/¿

Done

Analyse

Hide Grid

1254 22-OCT-92 09:35

View Range: o-6o

Depth: 53 ¿: 12

381

312

0 15 30 45 60

015304560

4.3 Paper reference grid and ruler4.2 RS10 scanner

The screen is divided into three main areas.

– The function menu, which can consist of up to five different

functions, is displayed on the right-hand side of the screen. Each

function is activated by selecting the appropriate function key to

the immediate right of the screen.

– At the foot of the screen,the following data is displayed: Righthand side – position of the cursor; left-hand side – depth of coverage and diameter.

– The scanned image is displayed on the main area of the

screen. Each image can be identified by its consecutive number

and date/time, which appears at the top of the screen, and is

recorded with the image in the RV10's memory.

Note: Any additional information relating to the construction site,

position on the structure, etc. must be recorded by the operator

and allocated to the image number.

1 Start/stop button for the scanning procedure

2 Screw for removing the grip

3 Marks for effective scanning width

4 Cable connection

The grip can be removed from the scanner,allowing readings to

be taken where conditions are cramped (e.g. scaffolding close to

the surface to be scanned).

Note: The marks on the left or at the top indicate the start

positions of the scanner rear wheels.

The paper reference grid represents the pre-programmed

600

×600 mm area to be scanned by the Ferroscan RV10 /

RS10.The paper grid, which serves as a direct representation of

the area scanned and for guidance of the RV10 scanner, should

be attached to the surface of the structure using adhesive tape.

If the paper reference grid cannot be attached to the surface of

the structure (due to dampness, dust or dirt), auxiliary means

e.g. a ruler should be used to draw the reference grid directly on

the surface.

Page 7

21

4.4 A TCU12H charger

Preparing the charger for use

1. Connect the charger to the mains supply. The

green LED must light.

2. Insert the RB10 battery into the battery compartment. The battery must engage securely in

the charger.

The charger can be mounted on a wall. (See

wall-mounting holes ➃ on base of charger).

Recommended screws: Round head wood

screws with plastic anchors.

Charging functions

➀ Charger ready LED (green)

The charger ready LED (green) lights continuously when the charger is connected to the

mains supply.

➁ Charging indicator LED (red)

The charging indicator LED (red) lights continously when the RB10 battery is being

charged. The charging indicator LED (red)

blinks (20.5 sec. off, 1 sec. on) after the charger has switched to trickle charge mode.

➂ Battery compartment

In order to ensure correct contact, the RB10

battery engages with a “click” in the battery

compartment. This feature is particularly important when the charger is mounted on a wall.

➃ Wall mounting

Make use of the holes provided on the base of

the charger housing for wall mounting.

Notes on charging procedure

If charging does not begin immediately after

inserting the RB10 battery into the charger,

then the battery is either too cold or too warm.

The battery can remain in the charger. The

charging procedure begins automatically after

the RB10 battery has reached the specified

temperature (0°–45°C). The charger is equipped with an electronic temperature-monitoring

device. Under normal conditions,the RB10 battery is charged after approx. one hour, after

which a trickle charge current counteracts the

battery's inherent tendency to lose its charge.

Technical data

Mains voltage: 110 / 115 / 230 / 240 Volt

Frequency: 50 Hz / 60 Hz

Output current: Charging current 1.6 A

Trickle charge current 80 mA

Charging time: Approx. 1 hour; For 1.4 Ah battery cells

Output voltage: Adapted to NiCd cell charging

characteristics U max. ≈ 17 volts

Weight: 1.5 kg

Supply cord length: 2 m

Indicators: Connected to mains supply – green LED lights

continuously

Charging – red LED lights continuously

Trickle charge – red LED blinks

(20.5 sec. off, 1 sec. on)

➀ Green LED – charger ready

➁ Red LED – charging indicator

➂ Battery compartment

➃ Wall mount

➄ Supply cord

The RB10 battery will suffer no damage

even if left in the charger for long periods.

LED LED

red green

Charger connected to mains

No battery in charger off on

Charger connected to mains

Battery charging on on

Charger connected to mains

Battery is charged blinks on

Charger connected to mains

Battery is too cold or too warm off on

Safety precautions:

See page 17, section 2

Page 8

Technical data

Type of cell: Nickel-cadmium sub C

Number of cells: 10

Capacity: > 1.4 Ah

Nominal voltage: 12 volts DC

Weight: 0.62 kg

Preparing the battery for use

● Charge the RB10 battery before use.

● Always begin work with the system with the battery at room

temperature (max. 40°C).

● Charging only begins when battery temperature is within the

range 0°–45°C. If the battery is too warm, it must be allowed to

cool. The charger begins charging automatically as soon as the

specified temperature range is reached. The battery can remain

in the charger.

Environmental protection / recycling

The RB10 battery contains 10 nickel-cadmium

cells. Not only Hilti but also Hilti customers carry

the responsibility for ensuring that batteries

which have reached the end of their life are

returned for recycling.

● Return used batteries to a Hilti centre for recycling.

● The raw materials, nickel and cadmium, can be extracted

from used Hilti batteries in a special recycling process.

Important: Never dispose of RB 10 nickel-cadmium batteries

with household waste. Do not throw the batteries into a fire or

into water.

22

1 2

➀ RB 10 battery release lever

➁ Contacts

4.5 RB10 battery

Using the battery

1. RB10 battery release lever

Press the release lever to remove the RB10 battery from the

monitor unit.

2. Battery terminals

The battery is charged and provides its power via the two power

terminals (a).

The charger monitors battery cell temperature via the temperature control terminal (b), protecting the battery from damage due

to overheating.

Notes

● The RB10 battery can be recharged more than 1000 times.

● The RB10 battery does not suffer damage even when left in

the charger for long periods.

Safety precautions: See page 17, section 3

Page 9

23

Volume

Time

Date

Done

Set up

Volume:

Time:

Display

Date:

Display:

Use cursor keys

5

16:38

17 -Nov -93

Deutsch

Select item

Set value

1

2

3

4

5 6 7 8

Start

Repeat

Set

Origin

Done

Scan

5. Using the system

5.2 Scanning an image5.1 Set up

The volume of the acoustic signal, the date, the time and the

operating language (German, English, French),can be set by the

operator as desired.

Starting point: Main menu

Press the button. The menu appears at the right-

hand side of the screen.

Select the , , or keys. Language and

unit of measurement (mm/inch) can be set by selecting .

Press the cursor keys to select the day or month.

Press the cursor keys to set the value.

Press the key to return to the main menu.

Done

mi

ko

Display

Display

TimeDateVolume

Set upSet up

Note: As a result of the detection principle utilised, reinforcement which runs parallel to the direction of movement of the

scanner cannot be detected. The grid area must be scanned in

two directions, at right angles to each other.

Note: In order to receive a correct image, it is necessary to follow the prescribed scanning traces in the prescribed sequence.

A) Attach the supplied paper reference grid, using adhesive tape,

to the surface of the concrete. Alternatively, if the condition of the

surface does not allow the use of adhesive tape, the grid can be

marked directly on the concrete using the ruler. Mark out trace

numbers one to eight.

Optimum results will be achieved when the grid axis lies parallel to the reinforcement.

B) Connect the RS10 scanner to the RV10 monitor using the

RC10 connecting cable. Press the button. Press the

key.The starting position of the scanner is shown on the screen

in black.

Scan

I/O

Page 10

24

1

2

3

4

5 6 7 8

Start

Repeat

Set Origin

Done

Scan

0 15 30 45 60

015304560

C) Position the RS10 scanner exactly at the beginning of trace

no. 1 on the grid. Press the start/stop button on the scanner or

the key on the monitor.

Note: Incorrect or inaccurate positioning of the scanner will

result in “shifting” of the image and the indicated location of the

reinforcement will be incorrect. In order to cover the entire area

completely, it must be scanned according to the specified grid,

in vertical and horizontal directions.

Start

Marks are printed on the papier reference grid as an aid to positioning the scanner. If the reference grid is marked directly on

the concrete surface using the ruler, the scanner must be positioned according to the effective scanning width represented by

the grid. Guide the scanner along the trace lines. The distance

covered is displayed on the screen. When the 600 mm trace has

been fully scanned, an acoustic signal is given automatically.

The scan can be interrupted before reaching the end of the 600

mm trace (e.g. because of an obstruction). In this case, the

start/stop button on the scanner or the key on the monitor

must be pressed. The scanned trace is displayed on the monitor

as a shaded area. On the screen, the starting position for the

scanner moves automatically to the next trace.

Stop

D) Repeat the procedure described at C) in the correct order for

the remaining seven traces. The vertical and horizontal scanned

areas are displayed on the screen in black. Press the

function key.The scanned image appears on the screen.

The trace presently being scanned can be interrupted. By pressing the key, the scanner can be returned to the starting

position.

By pressing the key several times, it is possible to move

back and repeat several scan traces.

Note: An image is received only when an area ha been scanned

vertically and horizontally.Areas which have been scanned only

vertically or only horizontally are shown on the screen in grey

and no image is displayed.

Repeat

Repeat

Done

Page 11

25

View +

View -

Depth/¿

Done

Analyse

Hide Grid

1254 22-OCT-92 09:35

View Range: o-6o

Depth: 53 ¿: 12

381

312

The quickscan function provides a quick overview of the position

of the reinforcing bars. The Depth+ and Depth– functions permit the operator to select the depth of coverage. The reinforcing

bars located between the surface and the selected depth of coverage are shown on the screen in a black and white image.

The depth viewed is indicated at the bottom of the screen.

Note

Optimum accuracy of all measurements can be obtained only

when the reinforcing bars are scanned at right angles.

Outset situation: Main menu and image to be evaluated are on

the screen (recalling a recorded image – see section 5.4).

Press function key.

Position the cursor on the desired piece of reinforcement by

using the cursor keys ( ) situated at bottom right

of the screen. The coordinates of the cursor, or respectively, the

reinforcement, are displayed on the right at the bottom of the

screen.

Press the function key. Depth of coverage and diameter (∅) are displayed on the left at the bottom of the screen.

Note: The diameter (∅) is displayed if and only if a reliable read-

ing is allowed for by the detection signals i.e. if the distance

between rebars corresponds to min. twice the coverage and the

reinforcement is not too close to the edge of the image. This

information can be obtained at a depth of coverage of up to 60

mm.

Depth / ∅

miko

Analyse

5.3 Determination of position, depth of coverage and diameter of reinforcement

The unit of the display diameter depends on the scanner used

for the measurement. If the scanner is calibrated for standard

diameters according to american ACI standard (see section 7),

the diameter is shown in standard number #. Otherwise it is displayed in “mm”.

The coordinates of the cursor and the coverage (depth) are in

general displayed in “mm”. If the option “Display” (Engl.: in.) is

chosen (see section 5.1), they will be shown in “in”.

Due to the lack of space available, the units “in.” or “mm” are

not explicitly displayed. The coordinates and the depth in “mm”

are shown in integers. In “in.” they are displayed with a deci-

mal point.

Page 12

26

Start

Depth +

Depth -

Done

Quickscan

Quickscan...

Trigger depth:

Distance:

Coverage:

20

727

30

0

100

Record

5.4 Rapid detection and verification of minimum coverage

Outset situation: Main menu.

– Select function.

– Set minimum coverage

,

keys).

– Position the scanner on the surface.

– Press the start key on the monitor or the button on the scanner.

– Move the scanner along the surface at right angles to the

expected position of the reinforcement.

– An acoustic signal is given each time a reinforcing bar is

detected within the preset minimum coverage range (adjustment of volume – see section 5.1).

– Mark the position of the rebar, using the mark at the free end

of the scanner.

Record function

After pressing the key, depth of coverage data can be

recorded while scanning over a distance of up to 10 m. The

function key can be used to set the maximum

distance to be recorded and direction of movement.

Start/set length

Record

Depth–Depth+

Quickscan

The and keys are used to set the minimum

depth of coverage. When the scan is started, all reinforcing bars

at a depth of up to 100 mm will be recorded. The actual depth

is displayed.

An acoustic signal is emitted when a reinforcing bar is detected

within the set minimum depth of coverage. All reinforcing bars

within this minimum depth of coverage are counted. At the end

of the scan, the number of reinforcing bars detected is displayed

on the screen.

The scan can be interrupted by pressing the button and

continued by pressing the button. Press the key to

end the scan and save the data. If the scanner is moved too

quickly, an error message is displayed on the screen and the

scan is stopped. If this occurs, proceed according to one of the

following alternatives:

– Press the key to abort the present scan.

– Press the key to record the scan up to this point.

Record

Restart

Done

Start

Stop

Depth –

Depth +

Note: Reinforcement which lies parallel to the direction of the

scan cannot be detected. Optimum detection accuracy is

achieved when the scanning direcion is at right angles to the

position of the reinforcement. If the position is not known, an

image of the reinforcement should first be made (see section

5.2).

Start

Tiefe +

Tiefe -

Beenden

Aufnahme

Messweg

Tiefe einstellen

Start/LŠnge

festlegen

†berdeckung

4721

40

78

100

0

0

10

M

Page 13

27

Scan...

Analyse...

Quickscan...

Set Up...

Main Menu

Delete

Image...

1259 22-OCT-92 09:40

30 of 31

The RV10 monitor can store up to 42 images in its memory.

When the monitor is switched on, the last recorded image

appears on the screen automatically. Each image is identified at

the top of the screen by a consecutive number and date/time of

scanning. The number of images in the system's memory is displayed at the foot of the screen.

Two types of image are possible. A picture image records all

data for the reinforcing bars within the area of the scan. This

enables position, depth and diameter to be determined subsequently.A quickscan image records the length of the scan, position and number of bars as well as depth of coverage over the

bars that lie at right angles to the direction of the scan.

Press the cursor keys in order to recall a particular

image.

When the image to be printed appears on the screen:

– connect the printer

– press the key

It is recommended that the operator keeps a systematic record

of the information relating to each image.

k

o

5.5 Identifying, recalling and printing images

Note: To connect the printer a printer cable (36-pin Centronics /

25-pin sub D type) is required. The connected printer must be

compatible to following standard: IBM Proprinter X24, Epson FX

or Diconix 701.

For the printer to work properly the DIP-switches have to be

positionned accordingly (refer to the printer manual).

The Ferroscan PC software permits data to be transferred from

the RV10 to a PC, through the serial interface, for further processing. All data evaluation functions available on the RV10 can

also be carried out on the PC.

Additional functions permit the data and images to be exported

to other PC programs. The printer configured in the Windows

operating system can be used for printing out the data.

Use of the PC program and the functions available are described

in the manual supplied with the software.

Installation under Windows

In the File Manager or Program Manager, type a:\setup. Press

the Enter key and follow the instructions that appear on the

screen.

System requirements

IBM PC or 100% compatible

INTEL 386 processor or higher (486 recommended)

8 MB RAM

2 MB free space on the hard disk

3

1

/2″ floppy disk drive

VGA video adapter (or higher)

Mouse or compatible pointing device

1 free serial interface

MS Windows 3.1 or higher

Windows is a registered trademark of Microsoft Corp., USA.

5.6 PC software

Page 14

28

Max. depth (mm)

for image

processing

Max. depth (mm)

for determination

of coverage

Max. depth (mm)

for determination

of diameter

130

90

60

6

136

94

60

8

142

98

60

10

148

102

60

12

154

106

60

14

160

110

60

16

160

110

60

20

160

110

60

25

164

118

60

28

172

134

60

32

180

150

60

36

d/T 1

± 10%

± 1ø

Resolution/

accuracy

Standard diameters (mm) as per DIN 488

d/T 2

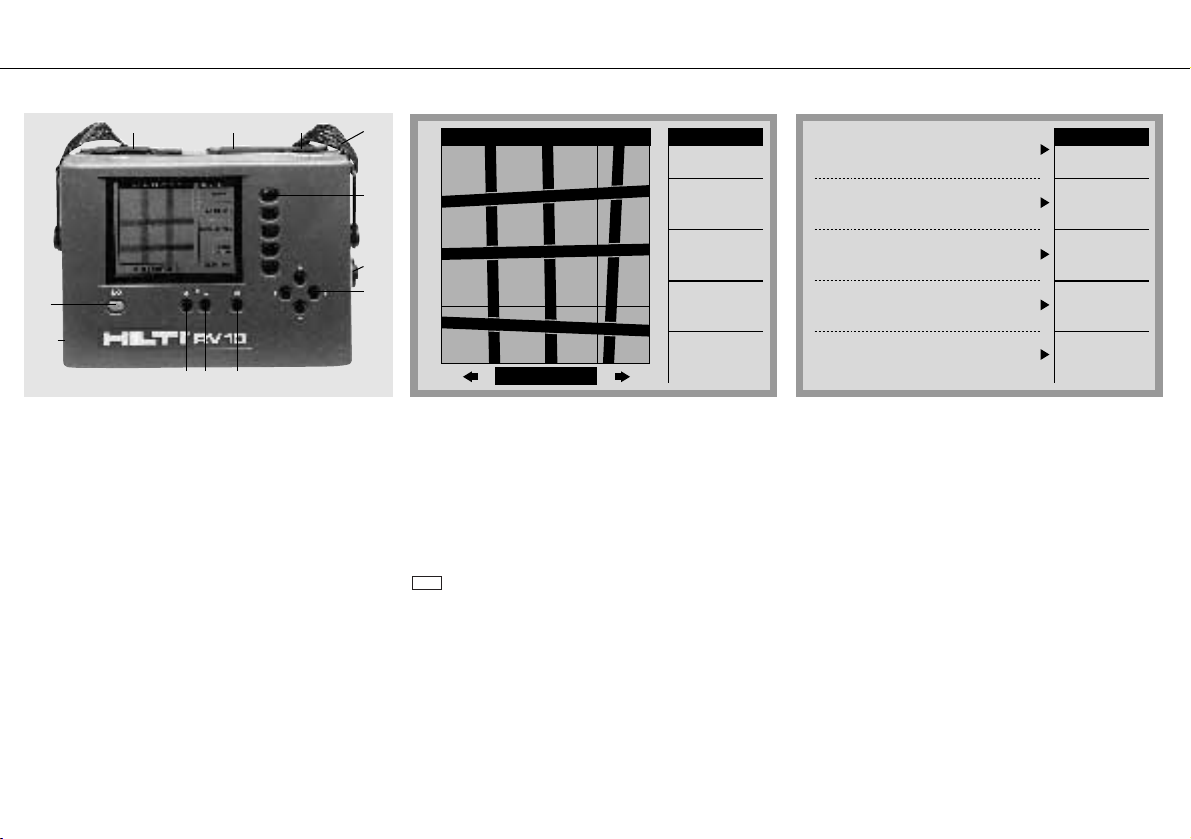

6. Measurement range

* d = distance between reinforcing bars, T = coverage (depth)

The figures given for accuracy apply to the following test conditions:

Smooth surface, circular rebars; permeability range 85–105; reinforcement Iying at right angles

to scanning direction.

Caution: A qualified technical expert (e.g.construction engineer) must be consulted when the

results are to be used for structures where safety is at stake (e.g. structural design).

Diameters (inch) as per ACI standard 318-106

#3 #4 #5 #6 #7 #8 #9 #10 #11

3/8

4/8

5/8

6/8

7/8

1.13

1.27

Max. depth (mm)

for image

processing

Max. depth (mm)

for determination

of coverage

Max. depth (mm)

for determination

of diameter

Max. depth (mm)

for image

processing

Max. depth (mm)

for determination

of coverage

Max. depth (mm)

for determination

of diameter

141

150

160

97

103

110

60

60

60

Diameter (inch) as per CPCI

#10

11.3

150

100

60

1

160

160

160

165

110

110

110

121

60

60

60

#15 #20 #25 #30 #36

25.2

19.5

16.0

160

160

110

110

60

60

173

135

60

60

29.9

170

130

60

1.41

180

149

60

35.7

180

150

60

Resolution/

accuracy

d/T 1

± 10%

d/T 2

Resolution/

accuracy

d/T 1

± 10%

d/T 2

± 1ø

± 1ø

Page 15

29

8. Warranty

Hilti warrants that the tool supplied is free of defects in material and workmanship. This warranty

is valid as long as the tool is operated and handled correctly, cleaned and serviced properly and

in accordance with the Hilti Operating Instructions, all warranty claims are made within 12 months

from the date of the sale (invoice date), and the technical system is maintained. This means that

only original Hilti consumables, components and spare parts may be used in the tool.

This warranty provides the free-of-charge repair or replacement of defective parts only. Parts

requiring repair or replacement as a result of normal wear and tear are not covered by this warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In

particular, Hilti is not obligated for direct, indirect, incidental or consequential damages,

losses or expenses in connection with, or by reason of, the use of, or inability to use the

tool for any purpose. Implied warranties of merchantability or fitness for a particular purpose are specifically excluded.

For repair or replacement, send tool and/or related parts immediately upon discovery of the defect

to the address of the local Hilti marketing organization provided.

This constitutes Hilti’s entire obligation with regard to warranty and supersedes all prior or contemporaneous comments and oral or written agreements concerning warranties.

Right of technical modifications reserved

7. Ferroscan FS 10 System – technical data

General data

Operating temperature: –10°C bis +50°C

Storage temperature: –20°C bis +60°C

Max. relative humidity: 90%

Dust/water protection: IP 54 (DIN 40 050)

Radio interference suppression: EN 55 011

RV10 monitor

Dimensions: 270×195×80 mm

Weight: 2.2 kg (incl. battery)

Screen: Back-lit LCD 115×86 mm,

320×240 pixels,

9 grey shades

Main battery: 12 V NiCd, at least 4 hours

continuous operation

Automatic switch-off: After 5 minutes without key activity

Auxiliary battery: Lithium

(standard life 6 years)

Permanent image memory: 42 images

Microprocessor: 16 bit

Printer interface: Parallel Centronics

PC interface: Serial RS 232

RS10 scanner

Dimensions: 230×133×140 mm

Weight: 1.0 kg

Effective scanning width: 150mm

Permitted scanning speed: % 0.5 m/s

Microprocessor: 16 bit

Technical data for RB1O battery: See page 22

Technical data for TCU12 H charger: See page 21

Loading...

Loading...