Page 1

DX 76-PTR

*384005*

384005

Hilti Corporation

LI-9494 Schaan

Tel.:+423 /234 2111

Fax: +423/2342965

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 3249 0308 00-Pos. 1 1 Printed in Liechtenstein © 2008

Right of technical and programme changes reserved S. E. & O.

384005 / C

Bedienungsanleitung de

Operating instructions en

Mode d’emploi fr

Gebruiksaanwijzing nl

Brugsanvisning da

Bruksanvisning no

Bruksanvisning sv

Käyttöohje fi

Lietoßanas pamåcîba lv

Instrukcija lt

Kasutusjuhend et

12

13

11

14

14

18

16

15

15

9

6

8

7

13

Page 2

1

+{

2

3+]+[ 4 5 6 7

8

9

+≠

"±

"≠

"“

+±+“+#+|+Ç

+}

X-76-P-PTR

X-ENP

X-76-P-PTR

ENP2K

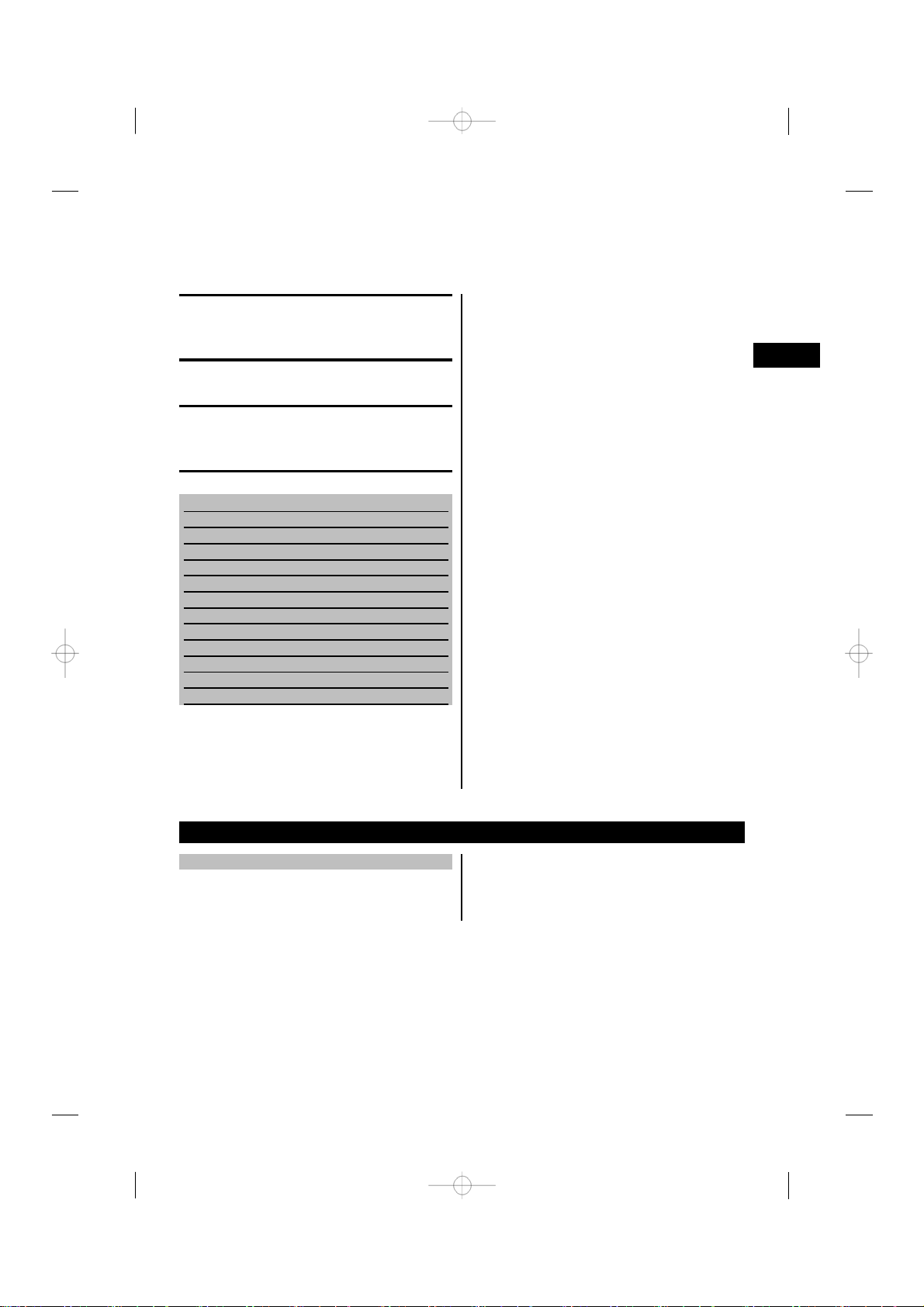

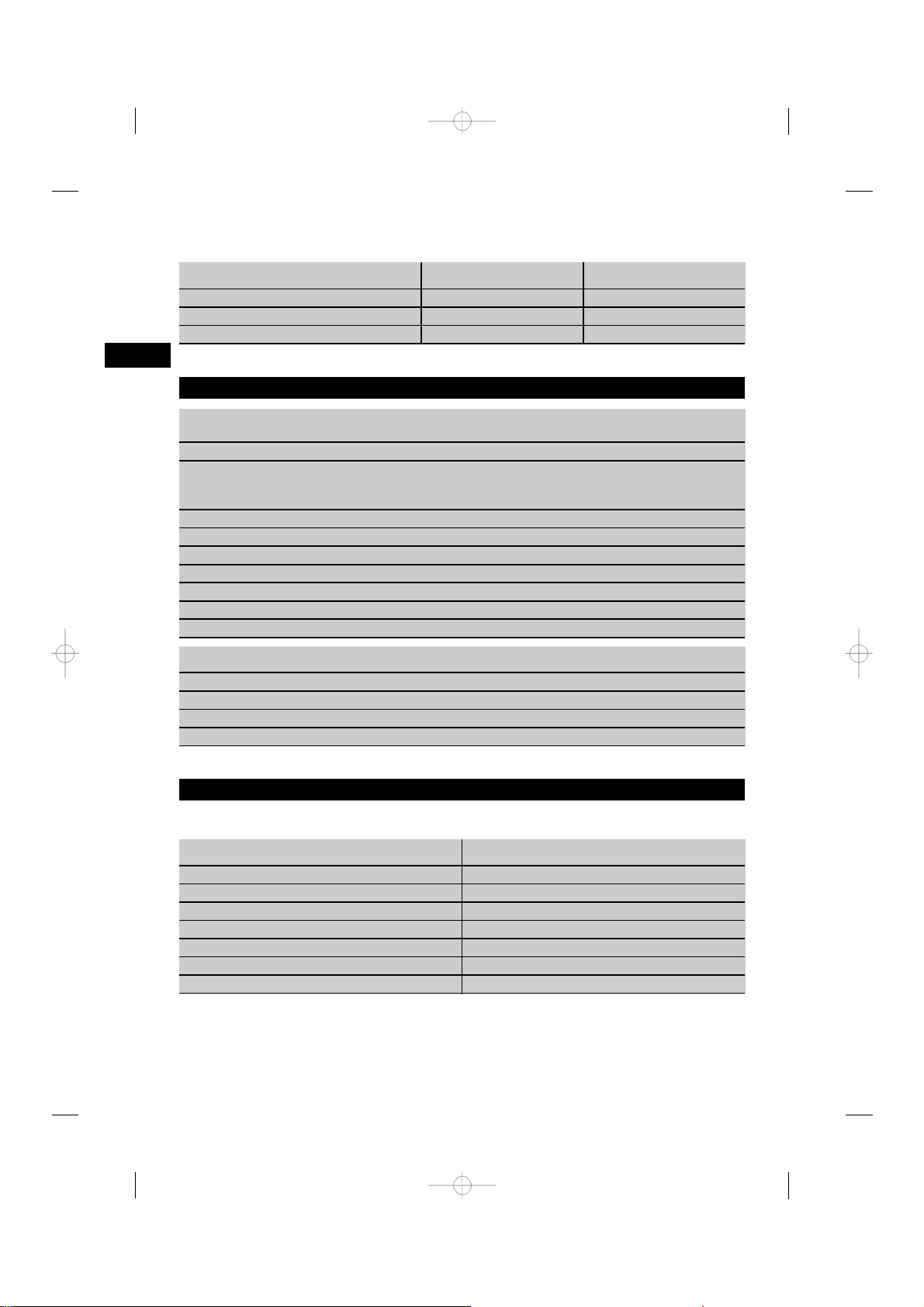

1 2

Nail

Nagel

Clou

mm

X-ENP2K X-ENP 19

3.32.7 6 10

> 20

For / Für / Pour

X-ENP2K + X-ENP

* Blue cartridges might be used as well for low strength steel up to 10 mm thickness.

* Für Standard Stahl bis zu einer Dicke von 10 mm können auch blaue Kartuschen verwendet werden.

* Des cartouches bleues peuvent également être utilisées pour de l’acier standard d’une épaisseur jusqu’à 10 mm.

red *

rot *

rouge *

X-ENP2K-20 X-ENP-19

Power regulation to be set according to nail stand-off.

Geräte Leistungseinstellung gemäss Nagelvorstand.

Réglage de la puissance selon l’enfoncement du clou.

green

grün

vert

blue

blau

bleu

black

schwarz

noir

Cartridge

Kartusche

Cartouche

3

1

2

3

4

6

2

1

7

5

8

2

1

9

2

4

3

1

10

5

4

12

1

2

3

11

2

3

1

Page 3

DX 76 PTR direct fastening tool

It is essential that the operating instructions

are read before the tool is operated for the

first time.

Always keep these operating instructions

together with the tool.

Ensure that the operating instructions are

with the tool when it is given to other

persons.

Contents Page

1. General information 17

2. Description 18

3. Accessories, consumables 20

4. Technical data 20

5. Safety instructions 21

6. Before use 23

7. Operation 23

8. Care and maintenance 26

9. Troubleshooting 28

10. Disposal 31

11. Manufacturer’s warranty ‐ tools 31

12. Confirmation of CIP testing 32

1 These numbers refer to the corresponding illustrations. The illustrations can be found on the fold‐out

cover pages. Keep these pages open while studying

the operating instructions.

In these operating instructions, the designation “the

tool” always refers to the DX 76 PTR powder‐actuated

fastening tool.

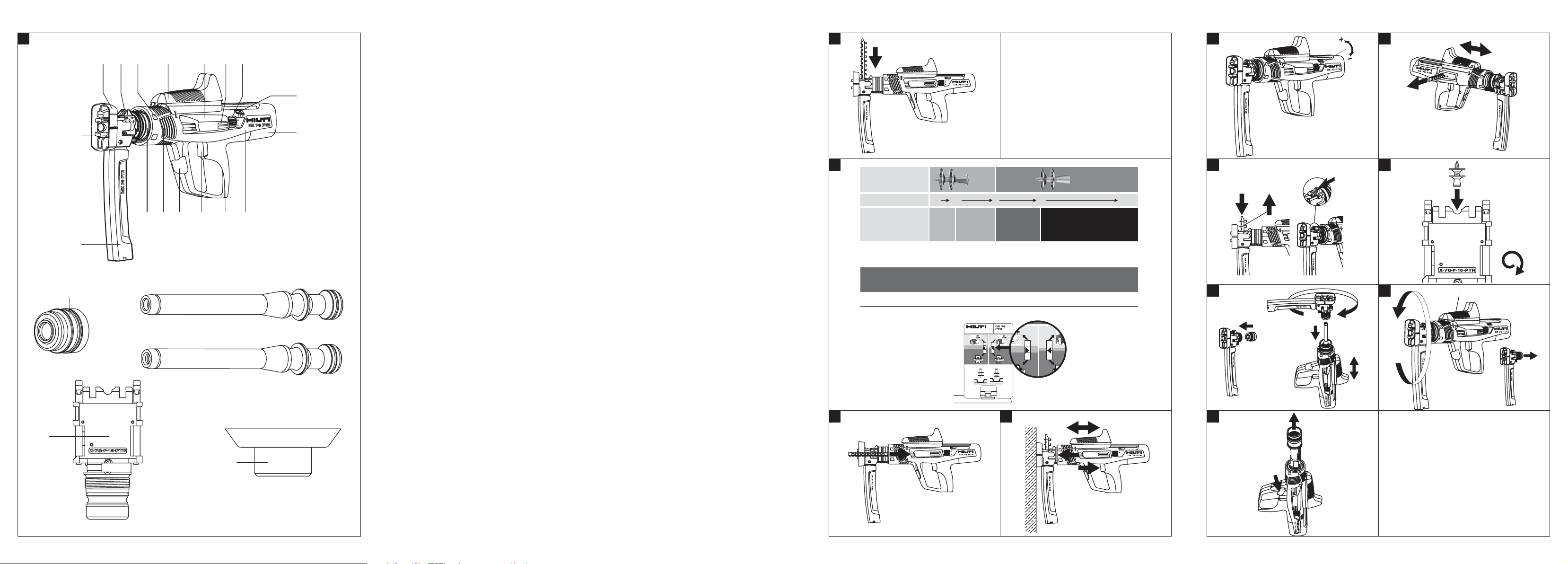

Parts and operating controls 1

DX 76 PTR tool

MX 76‑PTR fastener magazine

@

Contact pins

;

Protective cap

=

Cycling grip

%

Cartridge strip guideway

&

Loading status control window

(

Power regulation wheel

)

Power regulation indicator

+

Padded end cap

§

Tool casing

/

Grip pad

:

Trigger

·

Piston guide release lever

$

Piston guide

£

Fastener magazine spall guard

|

Fastener stop piece

¡

Ventilation slots

Q

X‑76‑F‑15‑PTR fastener guide

W

Tool spall guard

E

Wearing parts

X‑76‑P‑ENP‑PTR piston

R

X‑76‑P‑ENP2K‑PTR piston

T

Piston brake

Z

en

1. General information

1.1 Safety notices and their meaning

WARNING

Draws attention to a potentially dangerous situation

that could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation

that could lead to slight personal injury or damage to

the equipment or other property.

17

Page 4

NOTE

Draws attention to an instruction or other useful

information.

Symbols

1.2 Explanation of the pictograms and other

information

Warning signs

en

Read the

operating

instructions

before use

Location of identification data on the tool

The type designation and serial number can be found

General

warning

Obligation signs

Warning:

explosive

substances

Warning: hot

surface

on the type identification plate on the tool. Make a

note of this data in your operating instructions and

always refer to it when making an enquiry to your

Hilti representative or service department.

Type:

Serial no.:

Wear eye

protection

Wear a hard

hat

Wear ear

protection

Wear

protective

gloves

2. Description

2.1 Use of the product as directed

The tool is intended for use in the construction industry and associated trades for driving fasteners into steel.

The tool is for hand‐held use only.

Modification of the tool is not permissible.

The tool may not be used in an explosive or flammable atmosphere unless it has been approved for use under

these conditions.

To avoid the risk of injury use only genuine Hilti fasteners, cartridges, accessories and spare parts or those of

equivalent quality.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

The tool and its ancillary equipment may present hazards when used incorrectly by untrained personnel or

when used not as directed.

The tool may be operated, serviced and repaired only by trained personnel. This personnel must be informed

of any special hazards that may be encountered.

2.2 Piston principle with piston brake

The energy from the propellant charge is transferred to a piston, the accelerated mass of which drives the

fastener into the base material. Due to use of this piston principle, the tool is classified as a “low velocity

tool”. Approximately 95 % of kinetic energy is taken up by the piston when the tool is fired. As the piston is

always stopped by the piston brake as it reaches the end of its travel, excess energy is absorbed by the tool.

Accordingly, when the tool is used correctly, dangerous through‐shots become virtually impossible.

2.3 Drop‐firing safety device

The drop‐firing safety device is the result of coupling the firing mechanism with the cocking movement. This

prevents the tool from firing when dropped onto a hard surface, no matter at which angle the impact occurs.

18

Page 5

2.4 Trigger safety device

The trigger safety device ensures that a fastener cannot be driven simply by pulling the trigger only. The tool

must be pressed against a firm surface before a fastener can be released.

2.5 Contact pressure safety device

The tool can be fired only when pressed fully against a firm surface with a force of at least 50 N.

2.6 Unintentional firing safety device

The tool is also equipped with an unintentional firing safety device. This prevents the tool from firing if the

trigger is first pulled and the tool then pressed against the work surface. The tool can be fired only when it is

first pressed correctly against the work surface and the trigger subsequently pulled.

2.7 Noise information

As per German legislation (3, GSGV dated January 18, 1991): The noise (power) level LWA,1S as per

§ 1 (2) 1b) applicable to the tool and, due to different workplaces depending on the application for which the

tool is used, also the noise (pressure) level LpAImax at the measurement surface of 1 metre as per § 1 (2) 1e),

are given in addition to the workplace related noise emission value in accordance with the noise measurement

standard. Operating conditions and circumstances of use: most powerful cartridge power load in accordance

with instructions for use with suitable fastener or stud fired vertically downwards into a concrete block and

in accordance with the means of measurement DIN 45635, part 34 “Measurement of the noise emitted by

machines – airborne noise, surface sound transmission – methods – powder‐actuated fastening tools”.

2.8 DX 76 PTR tool: applications and suitable fasteners

Fastening profile metal sheet to steel, steel thickness 6 mm – solid steel

Items required Ordering designation Comments

Fasteners X‑ENP‑19 L15 MX

Fastener magazine MX 76‑PTR

Piston set X‑76‑P‑ENP‑PTR

Fastening profile metal sheet to steel, steel thickness 3‑6mm

Items required Ordering designation Comments

Fasteners X‑ENP2K‑20 L15 MX

Fastener magazine MX 76‑PTR

Piston set X‑76‑P‑ENP2K‑PTR

10 fasteners per magazine

strip

10 fasteners per magazine

strip

en

2.9 DX 76 PTR tool with single fastener guides: accessories, applications and suitable fasteners

Fastening profile metal sheet to steel, steel thickness 6 mm – solid steel

Items required Ordering designation Comments

Fasteners X‑ENP‑19 L15

Fastener guide X‑76‑F‑15‑PTR

Piston set X‑76‑P‑ENP‑PTR

Single fastener

19

Page 6

Fastening profile metal sheet to steel, steel thickness 3‑6mm

Items required Ordering designation Comments

Fasteners ENP2K‑20 L15

Fastener guide X‑76‑F‑15‑PTR

Piston set X‑76‑P‑ENP2K‑PTR

Single fastener

en

3. Accessories, consumables

Hilti toolbox DX 76 PTR KFD, large, with lockable cartridge

compartment

Toolbox for magazine tool

Cleaning set

Protective glasses

Protective glasses

Ear protectors

Hilti spray

Piston and piston brake set X‑76‑P‑ENP‑PTR and X‑76‑P‑ENP2K‑PTR

Spall guard for magazine and single fastener guides

DX 76 PTR test gauge

Cartridge type Ordering designation

Extra heavy 6.8/18 M black

Very heavy 6.8/18 M red

Heavy 6.8/18 M blue

Light 6.8/18 M green

DX 76 PTR

DX 76 / 860‑ENP, Flat brush, 25 mm dia. round

brush, 8 mm dia. round brush, pusher rod, cleaning

cloth

I‑VO 805 PS, clear

I‑VO 808 PS, tinted

Small

4. Technical data

Right of technical changes reserved.

Tool DX 76 PTR

Weight 4.37 kg

Dimensions (L × W × H) 464 mm × 104 mm × 352 mm

Magazine capacity

Contact movement

Contact pressure

Ambient operating temperature range

Maximum average fastener driving frequency*

NOTE

*for trouble‐free operation.

20

10 fasteners

32 mm

90…130 N

-15…+50°C

600/h

Page 7

Noise information with typical application of X‑ENP nail with 6.8/18 M10 blue cartridges and power setting

4 on 8mm steel with 400N/mm²:

Noise (power) level, L

WA, 1S

Workplace‐relevant emission value, L

Noise (pressure) level, L

pA, 1s

pAlmax

119 dB (A)

124 dB (A)

106 dB (A)

5. Safety instructions

5.1 Basic information concerning safety

In addition to the information relevant to safety

given in each of the sections of these operating

instructions, the following points must be strictly

observed at all times.

5.1.1 Personal safety

a) Stay alert, watch what you are doing and use

common sensewhen operating a direct fastening

tool. Do not use tool while tired or under the

influence of drugs, alcohol or medication. A

moment of inattention while operating tools may

result in serious personal injury.

b) Avoid unfavorable body positions. Make sure you

work from a safe stance and stay in balance at

all times.

c) Never point the tool toward yourself or other

persons.

d) Never press the nosepiece of the tool against

your hand or against any other part of your body

(or other person’s hand or part of their body).

e) Keep other persons, especially children, away

from the area in which the work is being carried

out.

f) Keep the arms slightly bent while operating the

tool (do not straighten the arms).

5.1.2 Use and care of powder‐actuated fastening

tools

a) Use the right tool for the job. Do not use the tool

for purposes for which it was not intended. Use it

only as directed and when in faultless condition.

b) Press the tool against the working surface at

right angles.

c) Never leave a loaded tool unattended.

d) Always unload the tool (remove cartridges and

fasteners) before cleaning, before maintenance,

before work breaks and before storing the tool.

e) When not in use, tools must be unloaded and

stored in a dry place, locked up or out of reach

of children.

f) Check the tool or machine and its accessories

for any damage. Guards, safety devices and any

slightly damaged parts must be checked carefully to ensure that they function faultlessly and

as intended. Check that moving parts function

correctly without sticking and that no parts are

damaged. All parts must be fitted correctly and

fulfill all conditions necessary for correct operation of the tool or machine. Damaged guards,

safety devices and other parts must be repaired

or replaced properly at a Hilti service center

unless otherwise indicated in the operating instructions.

g) Pull the trigger only when the toolis fully pressed

against the working surface at right angles.

h) Always hold the tool securely and at right angles

to the working surface when driving in fasteners. This will help to prevent fasteners being

deflected by the working surface.

i) Never redrive a fastener. This may cause the

fastener to break and the tool may jam.

j) Never drive fasteners into existing holes unless

this is recommended by Hilti.

k) Always observe the application guidelines.

l) Use the spall guard when the application per-

mits.

m)Never pull the magazine or fastener guide back

by hand as this could, under certain circumstances, make the tool ready to fire. This could

cause a fastener to be driven into a part of the

body.

en

21

Page 8

5.1.3 Work area safety

a) Ensure that the workplace is well lit.

b) Operate the tool only in well‐ventilated working

en

areas.

c) Do not attempt to drive fasteners into unsuitable

materials: Materials that are too hard, e.g. welded

steel and cast iron. Materials that are too soft, e.g.

wood and drywall panel (gypsum board). Materials

that are too brittle, e.g. glass and ceramic tiles.

Driving a fastener into these materials may cause

the fastener to break, shatter or to be driven right

through.

d) Never attempt to drive fasteners into materials

such as glass, marble, plastic, bronze, brass,

copper, rock, insulation material, hollow brick,

ceramic brick, thin sheet metal (< 2.7 mm), cast

iron or cellular concrete.

e) Before driving fasteners, check that no one is

present immediately behind or below the working surface.

f) Keep the workplace tidy. Objects which could

cause injuryshould be removed fromthe working

area. Untidiness at the workplace can lead to

accidents.

g) Keep the grips dry, clean and free from oil and

grease.

h) Wear non‐skid shoes.

i) Take the influences of the surrounding area into

account. Do not expose the tool to rain or snow

and do not use it in damp or wet conditions. Do

not use the tool where there is a risk of fire or

explosion.

5.1.4 Mechanical safety precautions

damage to the tool and/or unsatisfactory fastening

quality.

b) Use only fasteners of a type approved for use

with the tool.

c) Never fill the magazine with fasteners unless it

is correctly installed onto the tool. The fasteners

could be ejected uncontrollably.

d) Never use worn or damaged piston brakes and do

not attempt to manipulate or modify the piston.

5.1.5 Thermal safety precautions

a) If the tool has overheated, allow it to cool down.

Do notexceed the recommended fastener driving

rate.

b) Always wear gloves if the tool has to be dis-

mantled for cleaning or maintenance before it

has been allowed to cool down.

c) The tool must be allowed to cool down if melting

of the plastic cartridge strip is observed.

5.1.6 Danger of explosion

a) Use only cartridges of a type approved for use

with the tool.

b) Remove the cartridge strip from the tool care-

fully.

c) Do not attempt to forcibly remove cartridges from

the magazine strip or tool.

d) Unused cartridges must be stored in a dry, high

place, locked up or out of reach of children.

5.1.7 Personal protective equipment

a) Select the correct fastener guide and fastener

combination forthe job on hand. Failure to use the

correct combination of these items may result in

22

The user and any other persons in the vicinity must

wear suitable eye protection, a hard hat and ear

protection while the tool is in use or when checking

the tool for faults etc. The user must also wear

protective gloves.

Page 9

DX 76

M

X

7

6

6. Before use

NOTE

Read the operating instructions before the tool is

operated for the first time.

6.1 Check the tool

Check that no cartridge strip is loaded in the tool. If a

cartridge strip is present in the tool, use the cycling

7. Operation

grip to cycle the tool several times until the cartridge

strip projects from the tool at the cartridge strip exit

and it can be pulled out and removed from the tool.

Check all external parts of the tool for damage and

check that all controls operate faultlessly. Do not

operate the tool when parts are damaged or when the

controls do not function correctly. If necessary, have

the tool repaired at an authorized Hilti service center.

Check thepiston and piston brakefor wear and ensure

that the parts have been fitted correctly.

CAUTION

Never redrive a fastener. This may cause the

fastener to break and the tool may jam.

en

1234

DX 76

6

7

X

M

NOTE

When you grip the tool with your other hand, care

must be taken to ensure that this hand does not cover

any ventilation slots or openings.

WARNING

The material may splinter or fragments of the

magazine strip may fly off when the fastener is

driven. The user of the tool and other persons in the

immediate vicinity must wear protective glasses

and a hard hat. Splintering material presents a risk

of injury to the eyes and body.

CAUTION

The fastener driving action is initiated by ignition

of a propellant charge. The user of the tool and

other persons in the immediate vicinity must wear

ear protectors. Exposure to noise can cause hearing

loss.

WARNING

Making the tool ready to fire by pressing it against a

part of the body (e.g. the hand) should never be done.

This could cause a nail or the piston to be driven into

a part of the body. Never press the tool against a

part of the body.

7.1 Operation

Fastening guidelines: These guidelines must be observed at all times.

NOTE

For detailed information, please ask your local Hilti

representative for a copy of the applicable technical

guidelines or national technical regulations.

7.2 Driving fasteners with the magazine tool

If a cartridge fails to fire or misfires, always proceed

as follows:

Keep the tool pressed at right angles against the

working surface for 30 seconds.

If the cartridge still fails to fire, lift the tool away from

the working surface, taking care to avoid pointing it

at yourself or other persons.

Load the next cartridge on the strip by cycling the

tool. Use up the remaining cartridges on the strip and

remove the used cartridge strip from the tool. The

(partly) used cartridge strip must then be disposed of

suitably in order to prevent further use or misuse of

any unfired cartridges.

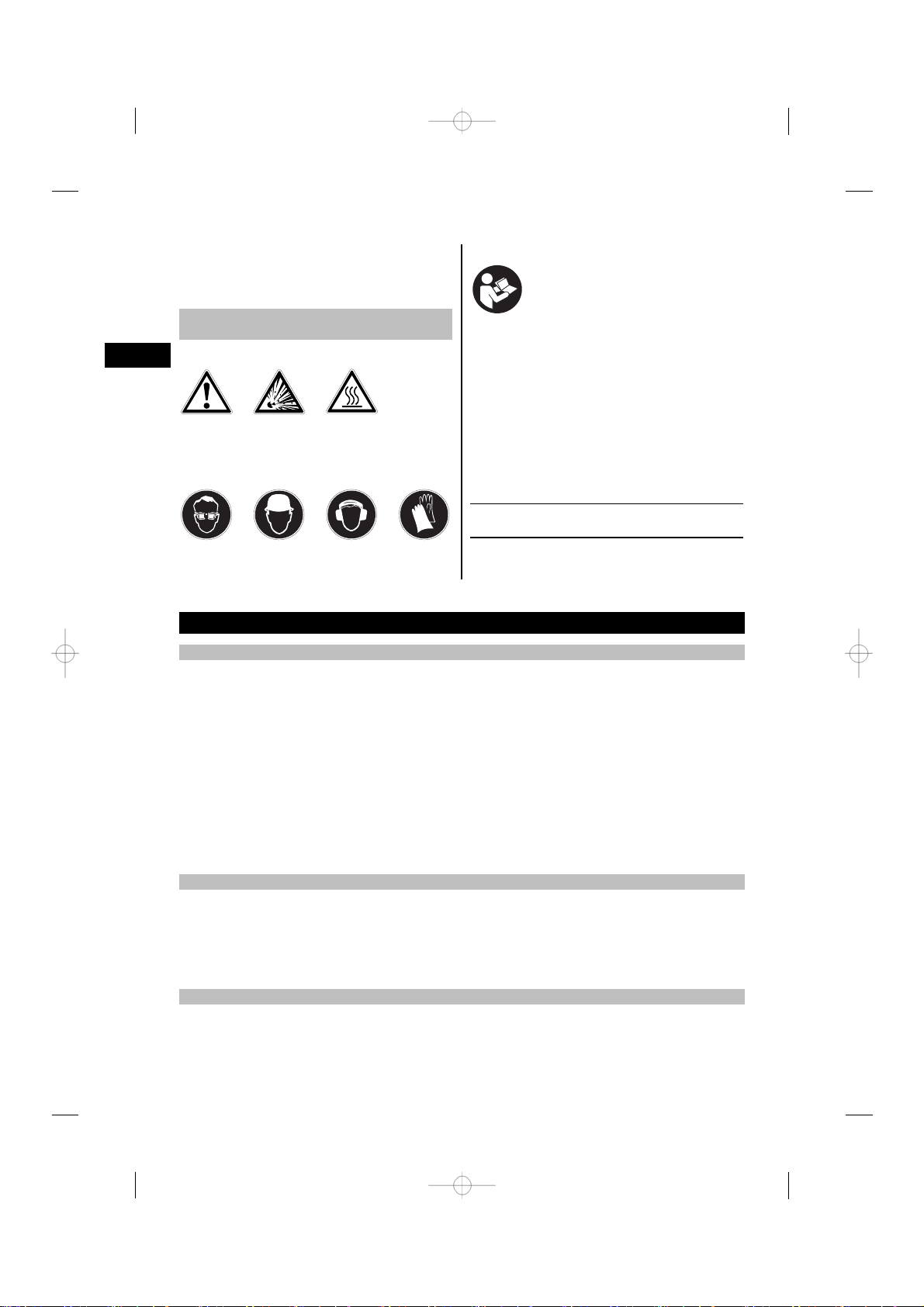

7.2.1 Loading fastener strips in the magazine 2

Push the fastener strip into the magazine from above

until the washer of the final fastener engages in the

magazine.

23

Page 10

7.2.2 Selecting the cartridge 3

1. Determine the thickness of the supporting material.

2. Select a suitable cartridge and power setting according to the cartridge recommendations.

7.2.3 Inserting the cartridge strip 4

en

Push the cartridge strip, as far as it will go, into the

cartridge strip guideway on the side of the tool.

7.2.4 Driving fasteners with the magazine

tool 5

CAUTION

Never drive fasteners into existing holes unless this

is recommended by Hilti.

CAUTION

Never redrive a fastener. This may cause the

fastener to break and the tool may jam.

CAUTION

If the tool has overheated, allow it to cool down. Do

not exceed the recommended fastener driving rate.

1. Press the tool against the working surface at right

angles.

2. Drive the fastener by pulling the trigger.

3. Prepare the tool for driving the next fastener by

pushing the cycling grip back toward the rear of

the tool and then forward to its original position.

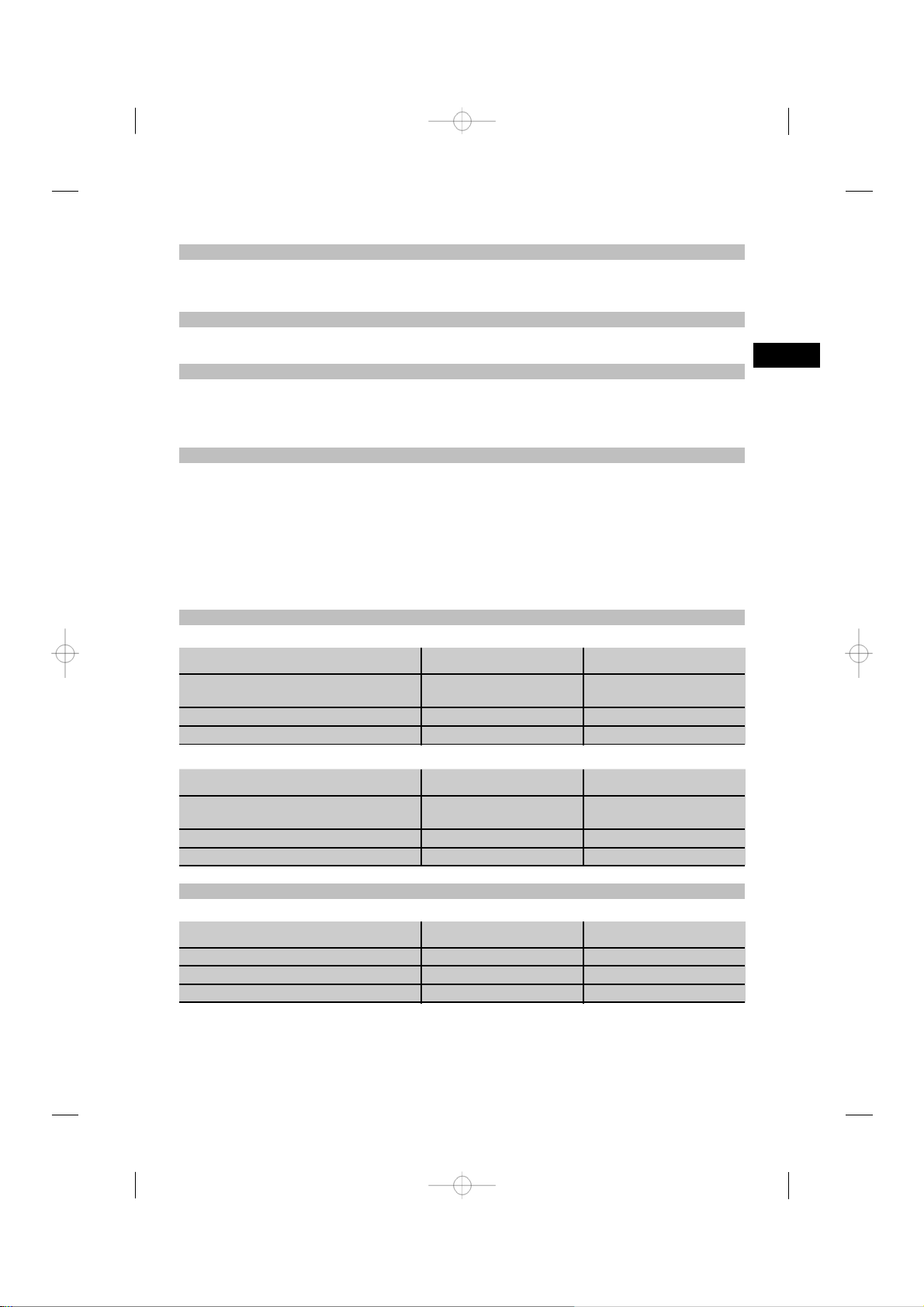

7.2.5 Checking and adjusting fastener driving

depth 36

NOTE

Fastener driving depth can be adjusted by turning

the power regulation wheel on the tool. (setting 1 =

minimum; setting 4 = maximum)

1. Use the test gauge to check nail stand‐off.

2. If a fastener is not driven deeply enough, driving power must be increased. Adjust the power

regulation wheel to the next higher setting. If a

fastener is driven too deeply, check to ensure that

supporting material (e.g. a beam) is present at

this point. A fastener should not be driven into

unsupported sheet metal. Check to ensure that

the sheet metal to be fastened lies tightly against

the supporting structure, with no gaps or space

underneath.

3. Drive a fastener.

4. Use the test gauge to check nail stand‐off.

5. If the fastener is still not driven deeply enough

or, respectively, is driven too deeply, steps 2

to 4 must be repeated until the correct depth

is achieved. If necessary, use a cartridge with a

higher or lower power rating.

7.3 Unloading the tool

7.3.1 Removing cartridges from the tool 7

WARNING

Do not attempt to forcibly remove cartridges from

the magazine strip or tool.

1. Advance the cartridge strip through the tool by

moving the cycling grip until the strip is visible at

the exit aperture.

2. Pull the cartridge strip out of the tool at the

cartridge strip exit aperture.

7.3.2 Removing fastener strips from the tool 8

WARNING

Check that no cartridge strip is loaded in the tool. If

a cartridge strip is still present in the tool, operate

the cycling grip until the strip projects from the tool

and then pull the strip out of the cartridge strip exit

by hand and remove it from the tool.

CAUTION

The fastener strip will be ejectedby springpressure.

1. Push the fastener strip 5 mm further into the

magazine and hold it securely in this position.

2. Push the catch forward with the thumb and hold

it in this position.

3. Remove the fastener strip from the magazine.

7.4 Driving fasteners with the single‐fastener

tool (accessories required)

WARNING

Check that the spall guard 19 is fitted to the tool.

7.4.1 Inserting the fastener in the single‐

fastener tool 9

1. Turn the tool so that the fastener guide is pointing

upwards.

2. Insert the fastener in the tool from above.

7.4.2 Selecting the cartridge 3

1. Determine the thickness of the supporting material.

24

Page 11

2. Select a suitable cartridge and power setting according to the cartridge recommendations.

7.4.3 Inserting the cartridge strip 4

Push the cartridge strip, as far as it will go, into the

cartridge strip guideway on the side of the tool.

7.4.4 Driving fasteners with the single‐fastener

tool

CAUTION

Never drive fasteners into existing holes unless this

is recommended by Hilti.

CAUTION

Never redrive a fastener. This may cause the

fastener to break and the tool may jam.

CAUTION

If the tool has overheated, allow it to cool down. Do

not exceed the recommended fastener driving rate.

1. Press the tool against the working surface at right

angles.

2. Drive the fastener by pulling the trigger.

3. Prepare the tool for driving the next fastener by

pushing the cycling grip back toward the rear of

the tool and then forward to its original position.

7.4.5 Checking and adjusting fastener driving

depth 36

NOTE

Fastener driving depth can be adjusted by turning

the power regulation wheel on the tool. (setting 1 =

minimum; setting 4 = maximum)

1. Use the test gauge to check nail stand‐off.

2. If a fastener is not driven deeply enough, driving power must be increased. Adjust the power

regulation wheel to the next higher setting. If a

fastener is driven too deeply, check to ensure that

supporting material (e.g. a beam) is present at

this point. A fastener should not be driven into

unsupported sheet metal. Check to ensure that

the sheet metal to be fastened lies tightly against

the supporting structure, with no gaps or space

underneath.

3. Drive a fastener.

4. Use the test gauge to check nail stand‐off.

5. If the fastener is still not driven deeply enough

or, respectively, is driven too deeply, steps 2

to 4 must be repeated until the correct depth

is achieved. If necessary, use a cartridge with a

higher or lower power rating.

7.5 Changing the nail magazine (or fastener

guide)

7.5.1 Assembly

1. Insert the piston brake, the right way round, in

the piston guide (or fastener magazine) that is to

be fitted to the tool.

2. Insert the piston in the piston guide in the tool.

3. Screw the fastener guide (or fastener magazine)

onto the piston guide as far as it will go and then

turn it back until it engages.

4. Cycle the tool once with the cycling grip.

7.5.2 Disassembly

WARNING

All cartridges must be removed from the tool. The

fastener magazine must be empty.

CAUTION

After the tool has been in use, the parts to be handled

may be very hot. It is essential that gloves are worn

if the following maintenance operations have to be

carried out before the tool has been allowed to cool

down.

1. Check that the tool cycling grip is in its starting

position.

2. Unscrew and remove the fastener guide (or

fastener magazine).

3. Remove the piston brake from the fastener guide.

en

25

Page 12

8. Care and maintenance

CAUTION

en

When this type of tool is used under normal operating

conditions, dirt and residues build up inside the tool

and functionally relevant parts are also subject to

wear. Regular inspections and maintenance are

thus essential in order to ensure reliable operation.

We recommend that the piston and piston brake are

checked and inspected at least daily when the tool

is subjected to intensive use, and at the latest after

driving 3,000 fasteners.

WARNING

The tool must be unloaded before carrying out care

and maintenance.

CAUTION

The tool may get hot during use. You could burn your

hands. Wear protective gloves when carrying out

care and maintenance. Allow the tool to cool down.

8.1 Care of the tool

Clean the outside of the tool at regular intervals with

a slightly damp cloth.

NOTE

Do not use a spray or steam/water jet system for

cleaning! Never operate the tool when the ventilation

slots are blocked. Do not permit foreign objects to

enter the interior of the tool.

8.2 Maintenance

Check all external parts of the tool for damage at

regular intervals and check that all controls operate

faultlessly. Do not operate the tool if parts are damaged or when the controls do not function faultlessly.

If necessary, the tool should be repaired by Hilti

Service.

Use the tool only with the recommended cartridges

and power settings. Use of the wrong cartridges or

use of excessively high power settings may lead to

premature failure of parts of the tool.

CAUTION

Dirt and residues in DX tools contain substances that

may be hazardous to your health. Do not inhale dust

/ or dirt from cleaning. Keep the dust or dirt away

from foodstuffs. Wash your hands after cleaning

the tool. Never use grease for the maintenance/

lubrication of parts of the tool. This may lead to

malfunctions. Use only Hilti lubricant spray or a

product of equivalent quality.

8.2.1 Checking and replacing the piston and

piston brake

WARNING

All cartridges must be removed from the tool. The

fastener magazine must be empty.

CAUTION

After the tool has been in use, the parts to be handled

may be very hot. It is essential that gloves are worn

if the following maintenance operations have to be

carried out before the tool has been allowed to cool

down.

NOTE

Firing the tool repeatedly without driving a fastener

stresses the piston and piston brake and causes these

parts to wear. If the piston shows signs of chipping

and / or the synthetic rubber part of the piston brake

is badly worn, then these parts have reached the end

of their life.

NOTE

The condition of the piston and piston brake must be

checked at regular intervals and at least daily.

NOTE

To replace the piston and the piston brake it is

necessary only to unscrew the fastener magazine or

the fastener guide. It is not necessary to remove the

piston guide.

1. Unscrew and remove the fastener guide (or

fastener magazine).

2. Pull the piston out of the piston guide.

26

Page 13

3. Check the piston for damage. If signs of damage

are found, the piston AND the piston brake must

be replaced. Check the piston brake for signs of

wear of the synthetic rubber part.

NOTE Check the piston for straightness by rolling

it on a smooth surface. Never use worn or damaged pistons and do not attempt to manipulate or

modify the piston.

4. If the piston has to be replaced, remove the piston

brake from the fastener guide.

5. Insert the new piston brake, the right way round,

in the fastener guide (or fastener magazine) that

is to be fitted to the tool.

6. Insert the piston in the piston guide in the tool.

7. Screw the fastener guide (or fastener magazine)

onto the piston guide as far as it will go and then

turn it back until it engages.

8. Cycle the tool once with the cycling grip.

8.2.2 Cleaning the piston guide

WARNING

All cartridges must be removed from the tool. The

fastener magazine must be empty.

CAUTION

After the tool has been in use, the parts to be handled

may be very hot. It is essential that gloves are worn

if the following maintenance operations have to be

carried out before the tool has been allowed to cool

down.

1. Check that the tool cycling grip is in its starting

position.

2. Unscrew and remove the nail magazine (or the

fastener guide).

3. Remove the piston from the piston guide and

remove the piston brake from the nail magazine

(or fastener guide).

4. CAUTION It is essential that the tool is held

with thepiston guide facing upwards. The piston

guide may otherwise fall out.

Open the piston guide release lever.

5. Pull the piston guide out of the tool.

NOTE Further disassembly of the piston guide is

not necessary.

6. Use the large brushes to clean the inside and

outside surfaces of the piston guide.

7. Use the small round brush to clean the bore for

the regulating pin and use the tapered brush to

clean the cartridge chamber.

8. Clean the seat of the piston guide in the tool.

9. Lubricate the slider and the collar of the piston

guide with Hilti spray.

10. Lubricate the steel parts inside the tool with Hilti

spray.

NOTE Use of lubricants other than Hilti spray

may cause damage to rubber parts.

11. Insert the piston guide into the tool.

12. Apply light pressure to the piston guide.

NOTE The lever can be closed only when the

piston guide is pressed (several mm) into the tool.

If the lever still cannot be closed, please refer to

the information in section 9 “Troubleshooting”.

13. Close the piston release lever with light pressure

applied to the piston guide.

14. Insert the piston in the piston guide.

15. Fit the piston brake.

16. Screw the fastener guide (or fastener magazine)

onto the piston guide as far as it will go and then

turn it back until it engages.

17. Lubricate the cartridge transport mechanism by

spraying Hilti lubricant into the gap in the housing

behind the cycling grip.

18. Cycle the tool once with the cycling grip.

8.3 Checking the tool after care and

maintenance

After carrying out care and maintenance and before

loading the cartridges, check that all safety devices

have been fitted and that they function faultlessly.

en

27

Page 14

9. Troubleshooting

WARNING

The tool must be unloaded before taking any steps to remedy faults.

Fault Possible cause Remedy

en

Cartridges are not transported.

Cartridge strip can’t be removed.

Cartridge doesn't fire. The tool is not pressed fully against

Fastener penetrates too

deeply (inadequate fastener

stand‐off).

h

The cartridge strip is damaged.

The tool is damaged.

The tool is damaged or has

overheated as a result of an

excessively high fastener driving

rate.

the working surface.

The cartridge strip is used up. Remove the used cartridge strip.

The magazine or fastener guide is

not screwed on far enough.

One of the cartridges is faulty. Cycle the tool and use up the

The tool is defectiveor the cartridges

are faulty.

The tool is not cycled.

The fastener missed the steel beam. Mark the position of the beam. Drive

There is space between the sheet

and the supporting material.

The wrong piston has been fitted. Check that the right combination

Change the cartridge strip.

See section: 7.3.1 Removing

cartridges from the tool 7

Contact Hilti.

Allow the tool to cool and then

carefully try again to remove the

cartridge strip. Remove the piston

guide from the tool. If a cartridge

sleeve remains jammed in the

cartridge chamber, use the round

rod from the cleaning set to remove

it. If this is still not possible, contact

Hilti.

NOTE

Do not attempt to forcibly remove

cartridges from the magazine strip

or tool.

Press the tool fully against the

working surface and pull the trigger.

Load a new strip.

Screw the magazine farther onto the

tool.

remaining cartridges.

Contact Hilti.

Cycle the tool.

another fastener into the beam.

Check to ensure that the sheet

rests tightly against the supporting

material.

of piston and fastener is used.

Use the X‑76‑P‑ENP‑PTR piston

for X‑ENP fasteners. Use the

X‑76‑P‑ENP2K‑PTR piston for

ENP2K fasteners.

28

Page 15

Fault Possible cause Remedy

Fastener doesn’t penetrate

deeply enough (excessive

fastener stand‐off).

h

Fastener driven into the rib of the

beam.

Supporting material is too thick, or

the thickness has changed.

Drive a second fastener.

Increase fastener driving power in

accordance with recommendations

or, respectively, use a more

powerful cartridge.

See section: 7.2.2 Selecting the

cartridge 3

Fastener driving power is too low.

Increase fastener driving power in

accordance with recommendations

or, respectively, use a more

powerful cartridge.

See section: 7.2.2 Selecting the

cartridge 3

The tool needs to be cleaned.

The piston is broken.

The tool is damaged.

Clean the tool.

Change the piston and piston brake.

Contact Hilti.

The wrong piston has been fitted. Check that the right combination

of piston and fastener is used.

Use the X‑76‑P‑ENP‑PTR piston

for X‑ENP fasteners. Use the

X‑76‑P‑ENP2K‑PTR piston with

green mark for ENP2K fasteners.

Fastener stand‐off (head projection) varies considerably.

h

h

The tool was pressed against the

working surface with a jolt.

The tool is cycled unevenly,

sometimes not fully.

Irregular driving power.

Press the tool against the working

surface smoothly and avoid jolting.

Cycle the tool fully.

Clean the tool. Replace wearing

parts with new parts. Contact Hilti

if irregular driving power is still

experienced.

Shear breakage. The face of the piston is worn or

Change the piston and piston brake.

chipped.

Fastener driven into the rib of the

beam.

The tool is pressed against the

working surface at an angle.

Supporting material is too thick, or

the thickness has changed.

Drive a second fastener beside the

first one.

Press the tool against the working

surface at right angles.

Check that the recommended type

of fastener is used. If the right type

of fastener is used, increase driving

power in accordance with cartridge

recommendations or use a more

powerful cartridge.

The tool remains compressed

(doesn’t extendwhen pressure

is released).

The piston is sticking in the piston

brake.

Change the piston and piston brake.

See section: 7.5.2 Disassembly

See section: 7.5.1 Assembly

en

29

Page 16

Fault Possible cause Remedy

The tool remains compressed

(doesn’t extendwhen pressure

is released).

The tool needs to be cleaned.

The cartridge strip has jammed, the

tool has overheated.

en

The tool can’t be fired.

No fastener is driven.

The fastener guide can’t be

screwed on to the tool fully.

The piston can’t be fitted.

The tool wasn’t cycled correctly, the

cycling grip is not in the starting

position.

The trigger is pulled before the tool

is pressed fully against the working

surface.

Fastener transport malfunctions See section: 7.2.1 Loading fastener

The magazine or fastener guide is

not screwed on far enough.

The tool is damaged.

The tool wasn’t cycled correctly, the

cycling grip is not in the starting

position.

No fasteners in the tool. Load fastener(s) into the tool.

The magazine fastener transport

mechanism is faulty.

No piston in the tool. Fit the piston.

The piston is broken.

The piston doesn’t return to its

starting position.

The fastener guide needs to be

cleaned.

Fasteners are jammed inthe fastener

guide.

The piston guide needs to be

cleaned at the end of the threaded

section.

The tool, especially the piston guide,

needs to be cleaned.

Pins are visible in the piston guide.

See section: 8.2.2 Cleaning the

piston guide

Please refer to the fault: “Cartridge

strip can’t be removed”. Do not

exceed the maximum recommended

fastener driving rate.

Cycle the tool completely and return

the cycling grip to the starting

position.

Press the tool fully against the

working surface and then pull the

trigger.

strips in the magazine 2

See section: 7.3.2 Removing

fastener strips from the tool 8

Screw the magazine farther onto the

tool.

Contact Hilti.

Cycle the tool completely and return

the cycling grip to the starting

position.

Contact Hilti.

Change the piston and piston brake.

Contact Hilti.

Use the brushes provided to clean

the fastener guide and associated

parts. Lubricate with Hilti spray.

Remove the jammed fasteners.

Remove magazine strip plastic

scraps from the tool magazine.

Avoid shear breakage (see above).

Avoid missing the beam (driving

the fastener into unsupported sheet

metal); mark the position of the

beams accurately if necessary.

Clean and lubricate the thread.

Clean the fastener guide and the

tool and refit the piston.

Pull the pins forward until they can

engage.

30

Page 17

Fault Possible cause Remedy

The piston guide can’t be

fitted.

Stiff cycling action.

The lever is in the closed position.

The piston guide is incorrectly

positioned.

The tool needs to be cleaned.

The piston and piston brake have

almost reached the end of their

service life.

The tool is damaged.

See section: 8.2.2 Cleaning the

piston guide

See section: 8.2.2 Cleaning the

piston guide

Clean the tool.

See section: 8.2.2 Cleaning the

piston guide

Change the piston and piston brake.

Contact Hilti.

10. Disposal

Most of the materials from which Hilti tools or appliances are manufactured can be recycled. The materials must

be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements

for taking back old tools and appliances for recycling. Ask Hilti customer service or your Hilti representative for

further information. If you wish to bring the tool to a recycling facility yourself: Follow regional and international

directives and regulations.

Separate the individual parts as follows:

Part / assembly Main material Recycling

Hilti toolbox Plastic Plastics recycling

Outer casing Plastic/Synthetic rubber

Piston

Piston brake

Screws, small parts Steel Scrap metal

Used/partly‐used cartridge strips

Steel Scrap metal

Steel/Plastic Scrap metal

Steel/Plastic

Plastics recycling

In accordance with local regulations

en

11. Manufacturer’s warranty ‐ tools

Hilti warrants that the tool supplied is free of defects

in material and workmanship. This warranty is valid

so long as the tool is operated and handled correctly,

cleaned and serviced properly and in accordance with

the Hilti Operating Instructions, and the technical

system is maintained. This means that only original

Hilti consumables, components and spare parts, or

other products of equivalent quality, may be used in

the tool.

This warranty provides the free‐of‐charge repair or

replacement of defective parts only over the entire

lifespan of the tool. Parts requiring repair or replacement as a result of normal wear and tear are not

covered by this warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental

31

Page 18

or consequential damages, losses or expenses in

connection with, or by reason of, the use of, or

inability to use the tool for any purpose. Implied

warranties of merchantability or fitness for a particular purpose are specifically excluded.

en

12. Confirmation of CIP testing

The Hilti DX 76 PTR has been system and type

tested. As a result, the tool bears the rectangular PTB

approval mark showing approval number S 816. Hilti

thus guarantees compliance with the approved type.

For repair or replacement, send the tool or related

parts immediately upon discovery of the defect to

the address of the local Hilti marketing organization

provided.

This constitutes Hilti’s entire obligation with regard

to warranty and supersedes all prior or contemporaneous comments and oral or written agreements

concerning warranties.

Unacceptable defects or deficiencies, etc. determined

during use of the tool must be reported to the person

responsible at the approval authority (PTB) and to the

Office of the Permanent International Commission

(C.I.P.).

32

Loading...

Loading...