Page 1

DX 5

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

English

Page 2

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 3

1 Information about the documentation

1.1 About this documentation

• Read this documentation before initial operation or use. This is a prerequisite for safe, trouble-free

handling and use of the product.

• Observe the safety instructions and warnings in this documentation and on the product.

• Always keep the operating instructions with the product and make sure that the operating instructions

are with the product when it is given to other persons.

1.2 Explanation of signs used

1.2.1 Warnings

Warnings alert persons to hazards that occur when handling or using the product. The following signal words

are used in combination with a symbol:

DANGER! Draws attention to imminent danger that will lead to serious personal injury or fatality.

WARNING! Draws attention to a potential hazard that could lead to serious personal injury or

fatality.

CAUTION! Draws attention to a potentially dangerous situation that could lead to minor personal

injury or damage to the equipment or other property.

1.2.2 Symbols in the documentation

The following symbols are used in this document:

Read the operating instructions before use

Instructions for use and other useful information

1.2.3 Symbols in the illustrations

The following symbols are used in illustrations:

These numbers refer to the corresponding illustrations found at the beginning of these operating

instructions.

The numbering reflects the sequence of operations shown in the illustrations and may deviate

from the steps described in the text.

Item reference numbers are used in the overview illustrations and refer to the numbers used in

the product overview section.

These characters are intended to specifically draw your attention to certain points when handling

the product.

1.3 Product-dependent symbols

1.3.1 Symbols

The following symbols are also used:

Warning! Observe the instructions.

Wear a hard hat while working with the tool.

Wear protective glasses while working with the tool.

Wear ear protection while working with the tool.

1.3.2 Symbols on the product

The following symbols are used on the product:

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

English 1

Page 4

Black lock on a red background on the tool casing: On the release button for removing the exhaust gas piston return unit.

White lock on a black background on the fastener guide or on the magazine: On the fastener

guide release button.

1.3.3 Information shown on the display

The following information may be shown on the display:

This symbol indicates the battery’s state of charge. When the battery is empty, the maintenance

symbol is shown.

This symbol indicates whether Bluetooth is switched on. If the symbol is not shown on the display

then Bluetooth is switched off.

This symbol indicates when the tool requires cleaning. One segment stands for 500 fasteners

driven. There are 5 segments in total, which means that 2,500 fasteners can be driven before

cleaning is required.

This symbol indicates when servicing is due. It appears after 5 years, when 30,000 fasteners have

been driven, or when the battery is empty. Our recommendation: Please contact Hilti Service.

1.4 Product information

Hilti products are designed for professional use and may be operated, serviced and maintained only by

trained, authorized personnel. This personnel must be informed of any particular hazards that may be

encountered. The product and its ancillary equipment can present hazards if used incorrectly by untrained

personnel or if used not in accordance with the intended use.

The type designation and serial number are stated on the rating plate.

▶ Write down the serial number in the table below. You will be required to state the product details when

contacting Hilti Service or your local Hilti organization to inquire about the product.

Product information

Fastening tool DX 5

DX 5 GR

DX 5 SM

Generation 01

Serial no.

2 Safety

2.1 Safety instructions

Basic information concerning safety

WARNING! Read all safety precautions and other instructions. Failure to observe the safety

precautions and other instructions may result in electric shock, fire and/or serious injury.

Keep all safety precautions and instructions for future reference.

Using cartridges

▶ Use only Hilti cartridges or cartridges of equivalent quality.

◁ Use of cartridges of inferior quality in Hilti tools may lead to a build-up of unburned powder, which

may suddenly explode and cause severe injuries to operators and bystanders. The cartridges must

be either verifiably tested by the manufacturer in accordance with EU standard EN 16264 or they

must bear the CE conformity marking.

Requirements to be met by users

▶ Only authorized, appropriately trained persons may operate or service this tool.

Personal protective equipment

▶ You and any other persons in the vicinity must wear suitable eye protection and a hard hat while the tool

is in use.

▶ Wear ear protectors.

◁ The fastener driving action is initiated by ignition of a propellant charge. Exposure to noise can cause

hearing loss.

2 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 5

Personal safety

▶ Observe the information printed in the operating instructions concerning operation, care and maintenance.

▶ Stay alert, watch what you are doing and use common sense when operating a direct fastening tool.

Don’t use the tool when you are tired or under the influence of drugs, alcohol or medication. Take a

break if you experience pain or feel unwell. A moment of inattention while operating tools may result in

serious personal injury.

▶ Avoid working in awkward body positions. Make sure you work from a safe stance and stay in balance

at all times.

▶ Wear non-skid shoes.

▶ Never pull back the magazine, fastener guide or fastener by hand.

◁ Under certain circumstances, the tool could be made ready to fire by pulling back the magazine,

fastener guide or the fastener by hand. When the tool is ready to fire, fasteners or the piston could

be driven inadvertently into parts of the body.

▶ Keep the arms slightly bent while operating the tool (do not straighten the arms).

▶ Keep other people away from the working area, especially children.

Use and care of direct fastening tools

WARNING! Danger of fasteners penetrating right through. Before driving fasteners, check to make

sure that no one is present behind or below the object into which the fastener is to be driven.

▶ Before beginning the work, check the cartridge power level and the power regulator setting.

◁ Carry out a test by driving 2 fasteners into the material you are working on.

▶ Use the right tool for the work you are carrying out. Do not use the tool for purposes for which it was not

intended. Use it only as directed and when in faultless condition.

▶ Use a spall stop / protective cap when the application permits.

▶ Never leave a loaded tool unattended.

▶ Transport and store the tool in a secured toolbox.

▶ Always unload the tool (remove cartridges and fasteners) before cleaning, maintenance, changing the

fastener guide, before work breaks and before storing the tool.

▶ When not in use, the tool should be unloaded and stored in a locked, dry place where it is inaccessible

to children.

▶ Check the tool and the accessories for any damage. Check that moving parts function faultlessly, without

sticking, and that no parts are damaged.

◁ All parts must be fitted correctly and fulfill all conditions necessary for correct operation of the tool.

Damaged parts must be properly repaired or replaced by Hilti Service unless otherwise stated in the

operating instructions.

▶ Before driving fasteners, check that there is no electrical wiring behind the surface into which you want

to drive them.

▶ Do not attempt to drive fasteners into unsuitable materials.

◁ Unsuitable materials include welded steel and cast steel, cast iron, glass, marble, plastic, bronze,

brass, copper, insulating material, hollow brick, ceramic brick, thin sheet metal (< 4 mm) and cellular

concrete. Driving a fastener into these materials may cause the fastener to break, shatter or to be

driven right through.

▶ Pull the trigger only when the tool is fully pressed against the working surface at right angles.

▶ When driving fasteners, always hold the fastening tool at right angles to the working surface in order to

prevent the fastener being deflected by the surface.

▶ Keep the grips dry, clean and free from oil and grease.

▶ Do not use the tool in places where there is a risk of fire or explosion unless the tool is specially approved

for this type of use.

▶ Never drive fasteners into existing holes unless this is recommended by Hilti (e.g. DX-Kwik).

Workstation

▶ Keep the workplace tidy. Objects which could cause injury should be removed from the working area.

◁ Untidiness in the working area can lead to accidents.

▶ Make sure that the working area is well lit and well ventilated.

Mechanical safety rules

▶ Do not tamper with or modify the tool or parts of it, especially the piston.

▶ Use only fasteners of a type approved for use with the tool.

Thermal safety rules

▶ Do not exceed the recommended maximum fastener driving rate.

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

English 3

Page 6

▶ If the tool has overheated, allow it to cool down.

▶ Do not dismantle the tool while it is hot. Allow the tool to cool down.

▶ Allow the tool to cool down if the plastic cartridge strip begins to melt.

Risk of explosion with cartridges

▶ Use only cartridges of a type approved for use with the tool.

▶ Remove the cartridge strip from the tool when you have completed the work or before transporting the

tool.

▶ Never attempt to forcibly remove cartridges from the magazine strip or tool.

▶ Store unused cartridges in a secure place where they are not exposed to dampness or excessively high

temperatures.

3 Description

3.1 Intended use

The product described is a fastening tool for use in applications in which nails, threaded studs and

combination fasteners are driven into concrete, steel and sand-lime block.

When using the tool, always ensure that the correct equipment is used. The fastener guide, magazine, piston

and fasteners must be compatible with one another.

3.2 Cartridges

All Hilti cartridges for powder-actuated tools have been tested successfully in accordance with EN 16264.

These tests are carried out by the certification authorities using specific combinations of cartridges and

tools. The tool designation, the name of the certification authority and the system test number are printed on

the cartridge packaging.

Ordering designation Color Power level

6.8/11 M green green light

6.8/11 M yellow yellow medium

6.8/11 M red red heavy

6.8/11 M black Black extra heavy

3.3 Minimum distances and spacing

3.3.1 Fastening to concrete

Always observe the following minimum distances and spacing when fastening to concrete:

• The minimum distance from the edge of the working surface to the fastener must be at least 70 mm.

• The minimum center-to-center distance between two fasteners must be at least 80 mm.

• The working surface must be at least 100 mm thick.

3.4 Information about the app

To find out more about the app, to download it and start it, scan the QR code in the case.

3.5 Information about the field of applications

Please refer to the Hilti product page for more information about the field of applications.

4 Technical data

4.1 Direct fastening tool

DX 5

Weight

Tool length

Nail length

DX 5

DX 5

7.41 lb

(3.36 kg)

19.0 in

(483 mm)

≤ 2.8 in

(≤ 72 mm)

4 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 7

DX 5

Recommended maximum fastening rate

Application temperature (ambient temperature)

Compression stroke

Pressure required

DX 5

DX 5

700 rev/h

5 ℉ …122 ℉

(−15 ℃ …50 ℃)

1.3 in

(32 mm)

≥ 39 lb

f

(≥ 174 N)

4.2 Vibration

The vibration value that must be specified in accordance with 2006/42/EC does not exceed 2,5 m/s².

5 Operation

5.1 Safety devices

Note

Before commencing work, check that all safety devices are fitted and that they are functioning correctly.

All parts must be fitted correctly and fulfill all conditions necessary for the correct operation of the tool.

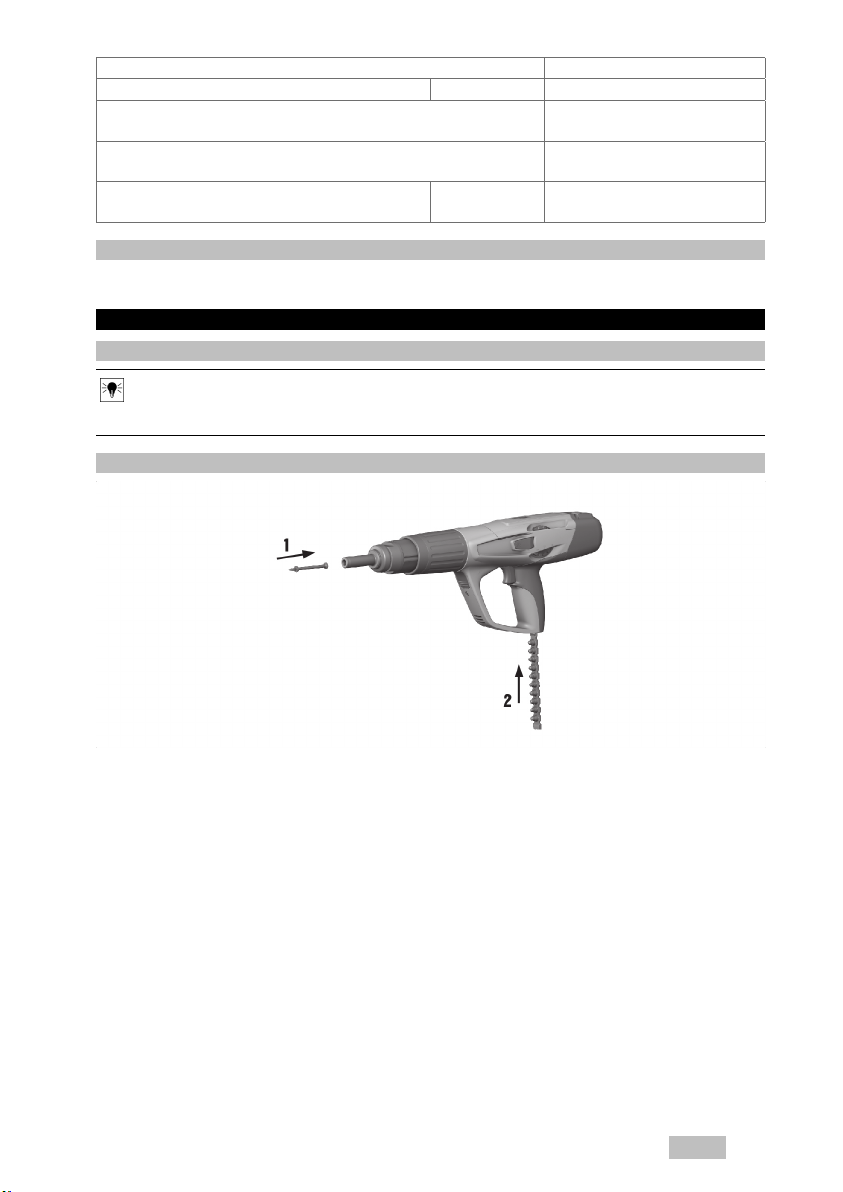

5.2 Loading the single-fastener tool

1. Push the fastener into the tool from the front until it is held in place in the tool by the fastener’s washer.

2. Push the cartridge strip, narrow end first, into the grip of the tool from below until the full length of the

cartridge strip is inside the tool. If you wish to use a cartridge strip in which some of the cartridges have

already been used, start pulling the strip up and out the top of the tool by hand until the first unused

cartridge is in place in the cartridge chamber.

English 5

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 8

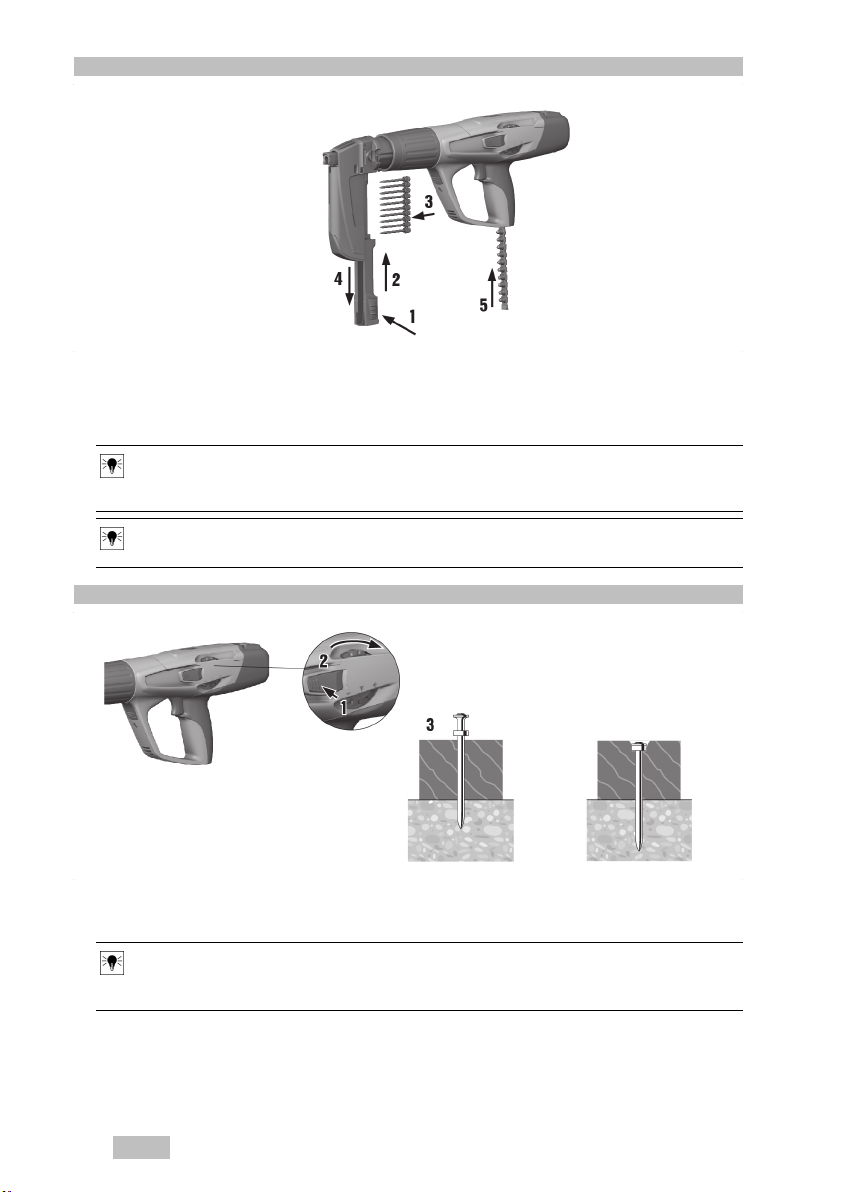

5.3 Loading the magazine tool

1. Pull the magazine cover down and insert the fastener strip (strip of ten) in the tool.

2. Push the cartridge strip, narrow end first, into the grip of the tool from below until the full length of the

cartridge strip is inside the tool. If you wish to use a cartridge strip in which some of the cartridges have

already been used, start pulling the strip up and out the top of the tool by hand until the first unused

cartridge is in place in the cartridge chamber.

Note

If the loading status indicator is partly or completely red, there are 3 or less fasteners in the

magazine. The magazine may then be reloaded with a strip of ten nails.

Note

All fasteners in the magazine must be of the same length.

5.4 Setting the power level

1. Press the power regulator release button.

2. Turn the power regulating wheel to set the power level you require.

3. Check the quality of the fastening in accordance with Hilti standards.

Note

Select a cartridge power level and power setting to suit the application.

If you have no previous experience of using the tool, always begin with the lowest power.

6 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 9

5.5 Driving fasteners with the single-fastener tool

1. Position the tool.

2. Hold the tool perpendicular to the working surface and then press it against the surface.

3. Press the trigger to drive the fastener.

5.6 Driving fasteners with the magazine tool

1. Position the tool.

2. Hold the tool perpendicular to the working surface and then press it against the surface.

3. Press the trigger to drive the fastener.

5.7 Unloading the single-fastener tool

1. Pull the cartridges out of the tool.

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

English 7

Page 10

2. Pull the fastener out of the tool.

5.8 Unloading the magazine tool

1. Pull the cartridges out of the tool.

2. Pull the magazine cover down and remove the fastener strip.

5.9 Switching Bluetooth on and off

▶ Press and hold the pushbutton for 1-2 seconds to switch on Bluetooth.

Note

Bluetooth switches itself off automatically after 2 minutes.

5.10 Resetting the cleaning indicator

▶ Press and hold the pushbutton for 10-12 seconds to reset the cleaning indicator.

Note

The cleaning indicator consists of 5 bars. Each bar stands for 500 fastenings.

5.11 Procedure if a cartridge fails to fire

1. Keep the nose of the tool pressed at right angles against the working surface for 30 seconds.

2. If the cartridge still fails to fire, lift the tool away from the working surface. Take care to avoid pointing it

at yourself or other persons.

3. Pull the cartridge strip by hand to advance it to the next cartridge and use up the remaining cartridges

on the strip.

5.12 Tool misfires (cartridge doesn't fire)

WARNING

Heat The tool can get hot through use.

▶ Wear protective gloves.

▶ Allow the tool to cool down.

1. Stop using the tool immediately.

2. Unload and dismantle the tool.

3. Check that you are using the correct combination of magazine, piston and fasteners.

4. Check the buffer, piston and magazine for wear, and replace the parts if necessary.

5. Clean the tool.

◁ If the problem persists after taking the measures described above, further use of the tool is not

permissible.

8 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 11

◁ Have the tool checked and, if necessary, repaired by Hilti Service.

Note

Dirt and residues build up in the tool under normal operating conditions and functional parts are

also subject to wear.

Carry out regular inspections and servicing. Servicing must be carried out after 30,000 fasteners

have been driven.

Clean the tool after every 2,500 - 3,000 fastenings. The fastener counter shows how many fasteners

have been driven since the cleaning indicator was last reset. One bar stands for 500 fasteners.

Check the piston and the buffer daily when the tool is subjected to intensive use, or at the very

least, before the end of the recommended regular cleaning interval of 2,500 - 3,000 fastenings.

The inspections, service intervals and cleaning intervals are based on typical tool use. If you find

that the tool is not functioning correctly before a scheduled interval is reached, service the tool

immediately.

6 Care and maintenance

6.1 Care of the tool

WARNING

Cleaning Pay attention to the following points when cleaning the tool:

▶ Do not clean with a spray system or pressure jet washer.

▶ Do not permit foreign objects to enter the interior of the tool.

WARNING

Risk of injury due to deflagration Powder residue in the tool may ignite and cause uncontrolled

triggering or fragmentation.

▶ Clean the tool regularly. Comply with all maintenance and cleaning information and instructions in

this documentation.

▶ If inferior-quality cartridges are used, cleaning the tool will not reduce the risk of powder

residue inside the exhaust gas piston return unit igniting and causing uncontrolled triggering or

fragmentation. This can only be reduced by having the tool taken to Hilti Service for maintenance.

▶ Clean the exterior of the tool with a slightly damp cloth at regular intervals.

6.2 Maintenance

WARNING

Dangerous substances The deposits inside DX tools contain substances that may present a health

hazard.

▶ Do not inhale dust or dirt while cleaning.

▶ Keep dust and dirt away from foodstuffs.

▶ Wash your hands after cleaning the tool.

▶ Never use grease to clean or lubricate tool components. This may lead to malfunctions. To avoid

malfunctions caused by the use of unsuitable cleaning agents, use Hilti spray.

1. Regularly check all external parts of the tool for damage.

2. Regularly check all operating controls to ensure that they work properly.

3. Use the tool only with the recommended cartridges and at the recommended power settings.

◁ Use of the wrong cartridges or excessively high power settings may lead to premature failure of the

tool.

6.3 Servicing the tool

▶ Service the tool in the following situations:

◁ If power fluctuations occur.

◁ If cartridge misfires occur.

◁ If the tool becomes noticeably less easy to operate.

◁ If the required contact pressure increases noticeably.

English 9

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 12

◁ If the trigger resistance increases.

◁ If the power regulation wheel is stiff.

◁ If the cartridge strip is difficult to remove.

◁ If the maintenance indicator shows that a tool service is necessary.

6.4 Dismantling the single-fastener tool

1. Check that there is no cartridge strip or fastener in the tool. If there is a cartridge strip or fastener in

the tool, pull the cartridge strip up out of the tool by hand from above and remove the fastener from the

fastener guide.

2. Press the release button on the side of the fastener guide to unscrew the fastener guide.

3. Unscrew and remove the exhaust gas piston return unit.

4. Remove the buffer by bending it sharply out of the fastener guide. Remove the buffer.

5. Remove the piston.

6.5 Dismantling the magazine tool

1. Check that there is no cartridge strip or fastener in the tool. If there is a cartridge strip or fastener in

the tool, pull the cartridge strip up out of the tool by hand from above and remove the fastener from the

fastener guide.

2. Press the release button on the side of the fastener guide to unscrew the magazine.

3. Unscrew and remove the exhaust gas piston return unit.

4. Remove the buffer by bending it sharply out of the magazine. Remove the buffer.

5. Remove the piston.

10 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 13

6.6 Checking the piston and buffer for wear

WARNING

Checking the buffer and piston for wear Check the buffer and piston for wear.

▶ Check the buffer and piston for wear. Do not tamper with or modify the piston.

1. The piston must be replaced in the following cases:

◁ The piston is broken.

◁ The piston is badly worn or chipped (e.g. a 90° segment broken away).

◁ The piston rings are cracked or missing.

◁ The piston is bent (check by rolling the piston on a smooth, flat surface).

2. The buffer must be replaced in the following cases:

◁ The metal ring of the buffer is loose or broken.

◁ The buffer no longer holds on the fastener guide.

◁ The rubber is badly worn at certain points under the metal ring.

6.7 Checking the fastener guide for wear

1. Check the fastener guide for wear and replace it if part of it is damaged (e.g. broken, bent, widened or

cracked).

2. Contact Hilti Service if necessary.

English 11

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 14

6.8 Cleaning and lubricating the single-fastener tool

1. Spray the piston rings lightly with oil and then use the flat brush to clean them using the flat brush until

the rings are free to move.

2. Use the flat brush to clean the thread on the fastener guide.

3. Use the large round brush to clean the inside of the housing.

4. Dismantle the exhaust gas piston return unit.

5. Clean the exhaust gas piston return unit.

6. Spray the cleaned parts with the supplied Hilti lubricant spray.

Note

Use only Hilti lubricant spray or a product of comparable quality. Use of other lubricants may

damage the tool.

7. Fit the exhaust gas piston return unit.

8. Assemble the tool.

12 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 15

6.9 Cleaning and lubricating the magazine tool

1. Spray the piston rings lightly with oil and then use the flat brush to clean them using the flat brush until

the rings are free to move.

2. Use the flat brush to clean the thread on the fastener guide.

3. Use the large round brush to clean the inside of the housing.

4. Dismantle the exhaust gas piston return unit.

5. Clean the exhaust gas piston return unit.

6. Spray the cleaned parts with the supplied Hilti lubricant spray.

Note

Use only Hilti lubricant spray or a product of comparable quality. Use of other lubricants may

damage the tool.

7. Fit the exhaust gas piston return unit.

8. Assemble the tool.

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

English 13

Page 16

6.10 Assembling the single-fastener tool

1. Check whether there is a cartridge in the tool, and remove it if there is.

2. Fit the exhaust gas piston return unit.

3. Fit the piston.

4. Fit the buffer onto the fastener guide.

5. Screw on the fastener guide.

6.11 Assembling the magazine tool

1. Check whether there is a cartridge in the tool, and remove it if there is.

2. Fit the exhaust gas piston return unit.

3. Fit the piston.

4. Fit the buffer onto the fastener guide.

5. Screw on the fastener guide.

6.12 Final check of the tool

1. After carrying out care and maintenance work, check that all safety devices are fitted and that they are

functioning correctly.

2. After checking the tool, press and hold the pushbutton for 10 - 12 seconds to reset the maintenance

counter.

14 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 17

7 Troubleshooting

7.1 Problems with the tool

Malfunction Possible cause Action to be taken

The fastener is too short. ▶ Use a longer fastener.

The fastener has no washer. ▶ Use a fastener with washer for

applications on wood.

Driving power is too high. ▶ Reduce driving power (adjust

the power regulating wheel).

The piston gets stuck in the

base material.

▶ Use a less powerful cartridge.

▶ Use the nails with a "top hat".

▶ Use the nails with a washer.

Higher force required to press

Build-up of combustion residues. ▶ Service the tool.

the tool against the surface.

Trigger resistance increases. Build-up of combustion residues. ▶ Service the tool.

Stiff movement of power reg-

Build-up of combustion residues. ▶ Service the tool.

ulation wheel.

The piston is incorrectly

positioned.

▶ Remove the cartridge strip and

clean the tool.

▶ Check the piston and buffer and

replace if necessary.

The fastener is not driven

deep enough.

Bad cartridge. ▶ Pull the cartridge strip through

to the next cartridge.

The piston is damaged. ▶ Change the piston.

The piston jams in the exhaust gas piston return unit.

Rubber dust or debris in the piston

return unit.

Build-up of combustion residues. ▶ Service the tool.

▶ Check the piston and buffer and

replace if necessary.

▶

Contact Hilti Service if the

problem persists.

Build-up of combustion residues. ▶ Service the tool.

The exhaust gas piston return

unit jams.

No fastener driven: The tool

fires, but no fastener is

driven.

The tool cannot be fired.

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

The piston is incorrectly

positioned.

▶ Remove the cartridge strip and

clean the tool.

▶ Check the piston and buffer and

replace if necessary.

The tool was not pressed fully

against the working surface.

▶ Press the tool fully against the

working surface.

The magazine is not loaded. ▶ Load the magazine.

Plastic fragments in the magazine. ▶ Open the magazine, remove the

nail strip and plastic fragments.

The piston is incorrectly

positioned.

▶ Remove the cartridge strip and

clean the tool.

▶ Check the piston and buffer and

replace if necessary.

English 15

Page 18

Malfunction Possible cause Action to be taken

Nails in the magazine are not cor-

▶ Reload the tool.

rectly positioned.

The tool cannot be fired.

The piston and/or buffer are damaged.

▶ Unscrew the magazine, check

the piston and buffer and

replace if necessary.

Plastic fragments in the magazine. ▶ Open the magazine, remove the

nail strip and plastic fragments.

The piston jams in the fastener guide.

Use of excessively high driving

power on steel.

Firing the tool at a high power setting without a fastener loaded.

▶ Reduce the driving power.

▶ Avoid firing the tool without a

fastener loaded.

The magazine is damaged. ▶ Replace the magazine.

The fastener guide in the

magazine jams.

7.2 Problems with fasteners to be driven into concrete

Malfunction Possible cause Action to be taken

The piston is incorrectly

positioned.

▶ Remove the cartridge strip and

clean the tool.

▶ Check the piston and buffer and

replace if necessary.

Fastener driving depth varies.

The tool has too much built-up dirt

and residues.

▶ Service the tool.

▶ If necessary, have the tool

checked by Hilti Service.

Hard surface (steel, concrete). ▶ Increase driving power (adjust

power regulating wheel).

Hard aggregates in concrete ▶ Use a more powerful cartridge.

▶ Use the single-fastener tool

instead of the magazine tool.

The fastener bends.

A rebar is located just below the

concrete surface.

▶ Use a shorter nail.

▶ Use a nail with a higher

application limit.

▶ Drive the fastener in at a

different position.

Wrong fastener. ▶ Use a fastener of the correct

length for the insulation thickness.

Wrong power setting. ▶ Adjust the power setting on the

tool.

The fastener is not driven

flush.

Hard aggregates in concrete ▶ Use a more powerful cartridge.

▶ Use the single-fastener tool

instead of the magazine tool.

16 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 19

Malfunction Possible cause Action to be taken

A rebar is located just below the

concrete surface.

▶ Use a shorter nail.

▶ Use a nail with a higher

application limit.

▶ Drive the fastener in at a

different position.

The fastener is not driven

flush.

Hard surface (steel, concrete). ▶ Increase driving power (adjust

power regulating wheel).

Hard/old concrete. ▶ Driving threaded studs: Spall

stop: X-SS...

Hard aggregates in concrete ▶ Use a more powerful cartridge.

▶ Use the single-fastener tool

Concrete spalling.

instead of the magazine tool.

Driving power is too high. ▶ Reduce driving power (adjust

the power regulating wheel).

▶ Use a less powerful cartridge.

▶ Use the nails with a "top hat".

▶ Use the nails with a washer.

Damaged fastener head.

The wrong piston has been fitted. ▶ Check that the right combina-

tion of piston and fastener is

used.

The piston is damaged. ▶ Change the piston.

7.3 Problems with fasteners to be driven into steel

Malfunction Possible cause Action to be taken

Driving power is too high. ▶ Reduce driving power (adjust

the power regulating wheel).

▶ Use a less powerful cartridge.

▶ Use the nails with a "top hat".

▶ Use the nails with a washer.

Damaged fastener head.

The wrong piston has been fitted. ▶ Check that the right combina-

tion of piston and fastener is

used.

The piston is damaged. ▶ Change the piston.

Driving power is too low. ▶ Increase driving power (adjust

power regulating wheel).

▶ Use a more powerful cartridge.

The application limits have been

exceeded (very hard material).

The fastener doesn’t penetrate deep enough.

▶ Use a nail with a higher

application limit.

▶ Use the single-fastener tool

instead of the magazine tool.

▶ Use shorter nails.

The system is unsuitable. ▶ Use a more powerful system ,

e.g. DX 76 (PTR).

Thin supporting steel (45 mm). ▶ Use a different power setting or

different cartridge power level.

▶ Use a nail suitable for thin

supporting steel.

The fastener doesn’t hold in

the base material.

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

English 17

Page 20

Malfunction Possible cause Action to be taken

Driving power is too low. ▶ Increase driving power (adjust

power regulating wheel).

▶ Use a more powerful cartridge.

The application limits have been

exceeded (very hard material).

Fastener breakage.

▶ Use a nail with a higher

application limit.

▶ Use the single-fastener tool

instead of the magazine tool.

▶ Use shorter nails.

Driving power is too high. ▶ Reduce driving power (adjust

the power regulating wheel).

▶ Use a less powerful cartridge.

▶ Use the nails with a "top hat".

▶ Use the nails with a washer.

Driving power is too high. ▶ Reduce driving power (adjust

the power regulating wheel).

▶ Use a less powerful cartridge.

▶ Use the nails with a "top hat".

▶ Use the nails with a washer.

The head of the fastener perforates the fastened material.

7.4 Problems with the cartridges

Malfunction Possible cause Action to be taken

The cartridge strip is damaged. ▶ Change the cartridge strip.

The tool has too much built-up dirt

and residues.

▶ Service the tool.

▶ If necessary, have the tool

checked by Hilti Service.

The cartridge strip doesn’t

advance.

The tool is damaged. ▶ If the problem persists, contact

Hilti Service.

The tool has overheated. ▶ Allow the tool to cool down.

▶ Then, carefully remove the

cartridge strip from the tool.

▶ If the problem persists, contact

Hilti Service.

The cartridge strip cannot be

removed.

Bad cartridge. ▶ Pull the cartridge strip through

to the next cartridge.

The cartridge doesn’t fire.

The cartridge strip melts.

18 English

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

The tool is fouled with combustion

residues.

The tool is pressed against the

working surface for too long before

firing.

The fastener driving rate is too

high.

▶ Service the tool.

▶ Fire the tool sooner after

pressing it against the working

surface.

▶ Remove the cartridge strip.

▶ Stop using the tool immediately.

▶ Remove the cartridge strip and

allow the tool to cool.

Page 21

Malfunction Possible cause Action to be taken

The fastener driving rate is too

high.

▶ Stop using the tool immediately.

▶ Remove the cartridge strip and

allow the tool to cool.

A cartridge detaches itself

from the cartridge strip.

Build-up of combustion residues. ▶ Service the tool.

The cartridge strip cannot be

removed.

7.5 Other malfunctions

If the trouble you are experiencing is not listed in this table or you are unable to remedy the problem by

yourself, please contact Hilti Service.

8 Disposal

Most of the materials from which Hilti tools and appliances are manufactured can be recycled. The

materials must be correctly separated before they can be recycled. In many countries, your old tools,

machines or appliances can be returned to Hilti for recycling. Ask Hilti Service or your Hilti representative

for further information.

9 Manufacturer’s warranty

▶ Please contact your local Hilti representative if you have questions about the warranty conditions.

10 Confirmation of C.I.P. testing

The following applies to C.I.P. member states outside the EU and EFTA judicial area: The Hilti DX 5 has

been system and type tested. As a result, the tool bears the rectangular PTB approval mark showing

approval number S 995. Hilti thus guarantees compliance with the approved type. Unacceptable defects

or deficiencies, etc. determined during use of the tool must be reported to the person responsible at the

approval authority (PTB) and to the Office of the Permanent International Commission (C.I.P.).

English 19

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 22

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 23

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

Page 24

Hilti = registered trademark of Hilti Corp., Schaan

**

Printed: 29.09.2017 | Doc-Nr: PUB / 5292580 / 000 / 01

20170912

Loading...

Loading...