Page 1

DX462

CM/HM

-

-

-

-

-N

:lTl

-l\

-ryr

Page 2

Page 3

Page 4

Page 5

-.w

@tf

Nsr

t-

Jr"

Wsi"

WI

-.@

e

$o

@

W

jt

=

Page 6

DX-462

CM

DX-462 HM

I

powder-

actuated

ll|s

essentialthal the operaling:::.

tool

instruclions are reqd before lhe,,:

loot is operated for the first time.

Always keep these operating

instructions

Ensui0

tionsare

given

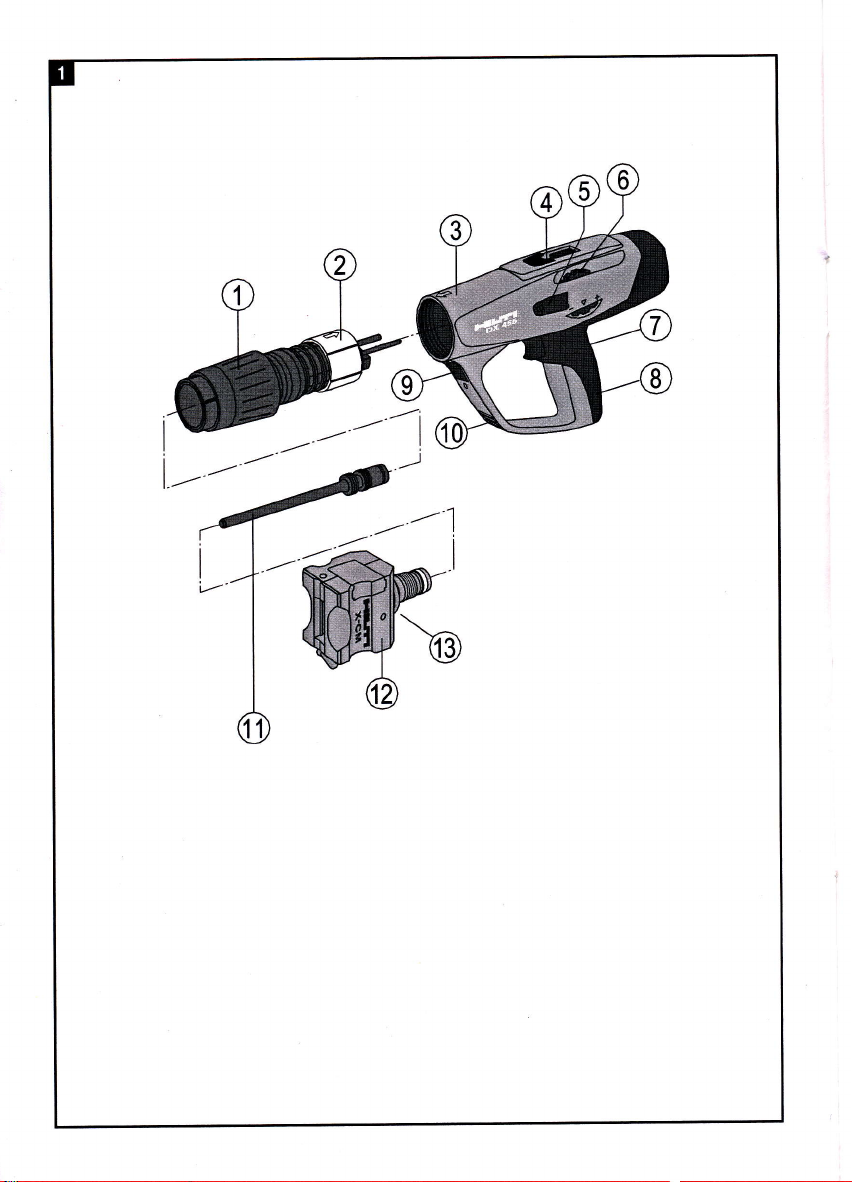

Description of

O Exhaust

@ Guide sleeve

@ Housing

@ Cartridge

Powder regulation wheel release button

@

Power regulation wheel

@

OTrigger

@Grip

Piston return

@

@Ventilation slots

@ Piston"

Marking head.

@

@ Marking head release button

-

parts

These

togelher

that lhd

with

to other

gas

piston

guideway

unit

may

replaced

be

lhe loolwhen,it

persons.

main

return

release

with

the tool.

operating iirstruG.

is,,,

parts

E

unit

button

by the user/operator.

1. General

:t:

1.1 Signal

::

WARNING

The word WARNING is used to draw attention to a ooten-

tially dangerous situation

personal

CAUTION

word

The

:ri

tially

dangerous situation

injury or damage

sonal

::,

ertv.

Pictograms

1.2

Warning signs

'A.

t\

information

words

and their

injury or death.

CAUTI0N is used to draw attention to a Doten-

meaning

which

which

to

the equipment or other

'A,

could

could

lead to

lead to minor

./t\

,r':\

General

warnrng

0bligation

signs

.-.

tl7/t

'&l.

weaieye

pr0tecti0n

The numbers refer to

E

tions

these

l0ns.

be found on the fold-out cover

can

pages

open while

Warning:

hot surface

,r-

,l

w7

Wear a

safety helmet

illustrations. The illustra-

the

you

read the

operating

severe

per-

prop-

Symbols

-^r-i

l--L-J

Read the opera-

tion instructions

use

before

^tL.

r-l

V

Wear ear

protection

pages.

Keep

instruc-

1. General information

Descriotion 2

2.

3. Accessories 3

4. Technical

5. Safetv orecautions

6. Before use 5

7. Ooeration

8. Care and maintenance

9. Troubleshootino

Disposal 10

10.

11. Wanantv 1 l

data

these

In

operating instructions,

tool"

der-actuated tool.

Localion of identification dala on the lool

The

the type

on

mation in

4

it

to

tive or

refers to the DX-462

always

type

designation and

plate

your

making

when

service

the

on the tool. Make a note of this infor-

operating instructions and always refer

an enquiry

deoartment.

serial

Tvoe: DX-462

Serial no

to

the

CM /

your

designation

DX-462 HM

number

are

Hilti representa-

"the

pow-

printed

Page 7

2. Description

The Hilti DX-462 HM

the

marking

a wide variety

of

and DX-462 CM

of base materials.

are suitable

(less

ity

than 100 m/sec.) in

process

driving

travel.

for

of its

This makes dangerous through-shots

tually impossible when the tool

ends

a controlled manner. The

when

piston

the

is used correctly.

reaches the

end

vir-

The tool works

and is therefore not

piston

principle provides

fastening

6.8/'11

The

cartridges

by

The

fortably,

of base

safety. The tool works with

caliber.

piston

are

gas pressure

system

quickly

materials with temperatures

for the DX-462

800'C with DX-462 HM.

5 seconds or roughly

are changed.

The X-462

marking heads accept

acters or 10 of the

heights

of 6, 10 or

As

with all

the

on

well-proven

related to high-velocity tools. The

an optimum of working and

is returned to the

fed to the

lrom

permits

and

starting

firing chamber automatically

the fired cartridge.

quality

a high

economically applied to a

CM and with temperatures

A mark can be made every

every 30 seconds if characters

polyurethane

CM

12

powder-actuated

and the X-462 HM

either 7 of

mm type

5,6

mm.

tools, the

the

and the DX-462 CM, the X-462 HM

marking

tridges form

blefree marking with this

if the

characters and

tured for the

are used. The

given

tions

is

observed.

the

heads,

"technical

a

marking

characters and

unit". This means that trou-

system can only

cartridges specially manufacproducts

tool, or

of equivalent

marking and application recommenda-

Hilti

by

are only applicable if this

piston principle

cartridges ol

position

and the

mark to be

up

to

com-

variety

50'C

up to

8 mm type char-

steel

characters, with

DX-462 HM

and X-462 CM

the

car-

assured

be

quality,

condition

The drop{iring

firing

the

prevents

onto a

occurs.

trigger

The

cannot be

tool can be fired

surface.

The contact

pressed

to

be

force.

cant

ly

against

In

addition, all Hilti

tentional firing

from firing if the trigger is

against the work

it is first

ly

and

safety device El is

mechanism with the

the Hilti DX toolfrom

hard

surface, no matteratwhich

safety device B

fired

simply by

only

pressure

safety device El requires the tool

against the work

The tool can

the

work surface in this way.

DX

safety device E. This

surface.

pressed

(1.)

the trigger

against the work surface

then

ln

the

cocking movement. This

firing

ensures

pulling

the trigger

pressed

when

surface

fired

be

only

tools are

pulled

pulled

The tool

(2.).

equipped

the

and

can be

result

of coupling

when

it is dropped

angle the impact

that

the cartridge

only.

against the work

with

a signifi-

pressed

when

with

an unin-

prevents

tool then

fired

the tool

pressed

only when

correct-

The

ful-

The tool features

operator

and bystanders.

piston principle

The

w

The energy from the

piston,

a

the

tener into the

the kinetic

is driven into the

2

accelerated

base

energy is absorbed

base material at much reduced veloc-

5-way

propellant

material.

for the

safety

-

charge is transferred to

mass

of

As approximately 95 %

the

by

which

piston,

safety of

drives

the fastener

the

the

t

fas-

of

Page 8

3. Cartridges, accessories and characters

Markino heads

orderino desionalion Annlicalion

x-462 CM Polvurethane head for markino uo to 50'C

X-462 HM Steel head for markino uo to 800"C

Pistons

ordedno desionation Annlicalion

X-462 PM Standard oiston for markino aDDlications

Accessories

orderino desionation

X-PT 460 Also known as the

pack

Spares

HM1

Centering devices

Characlers

0rderino deslonalion Anolicalion

X-MC-S characters Sharp characters cut into

X-MC-LS characters For use in more sensitive applications. With a rounded radius,

X-MC-MS

Please

characters

contactyour

local Hilti

AoDlication

pole

tool. An extension system

that

allow marking on very hot

materials at a safe distance. Used with DX-462 HM

To replace the screws and the

For marking on curve surfaces. 0nly with X-462 CM marking head.

alwavs reouired when centerino device

Thev

used where the influence of markino on the

can be

deform, rather than cut, the surface of

it is reduced

on

Mini-stress characters exert

low-stress. Like these, they have a rounded,

mini-stress characteristics

Center or Hilti

representative for

ring. Only with X-462 HM marking head

0

is

used)

the

surface of the base

the

less influence on the

even

material

base material. In this way, their inlluence

deforming

from

details of otherfasteners and

interrupted

the

pattern

dot

accessories.

to

base

base

radius, but

(onlv

(Axle

A40-CML

form

an impression.

material is non-critical

low-stress

material

surface

derive

characters

than

their

available on sDecial)

Gailrid0es

ordeilno desionation ColoIr code Pouer lewl

6.8x11 M oreen Green

6.8x11 M vellow Yellow Medium

90%

the

ot

all

piston,

marking can

head

impact

out

be canied

and marking characters to a minimum

using

the

green

Use the cartridge with the lowest

cartridge.

Safely accessoru and cleaning sel

goggles,

Safety

earplugs, Hilti

ramrod, flat brush, large round

spray,

cloth.

small round brush,

brush,

possible

power

in

keep wear

ordert0

scraper, cleaning

on

Page 9

4. Technical data

Weioht

Tool lenqth

Cartridoes

DX-462 CM DX-462 HM

3.92 Ko

435 mm

1 M

6.8/1

(8.64lb)

(17.13')

oreen and vellow

4.62 Ko

425mm

(10.19Ib)

(16.73)

5. Safety

5.1 Basic

In

addition to the safety

vidual

following

precaulions

instluctions

safety

sections of these operating instructions, the

points

precautions

must be strictly observed

listed

5.2 Use as intended

The tool is designed for

tool unless

safe use. For

representative.

5.3

O

missible.

O

atmosphere, unless the tool is approved for

O

acters, cartridges, accessories

of

you

assistance, contact

lmproper

Manipulation

Do

not operate the tool in

To

avoid the risk of iniury

equivalent

quality.

O 0bserve the information

instructions

nance.

Never

O

O Never

or other

Do not

O

plastic,

glazed

O Never use

parts.

concerning operation,

point

press

part

of

mark into materials such

bronze, brass, copper, natural rock, hollow

tile and

grease

Use only Hilti

professional

have received

use

or modification

proper

of

an explosive orflammable

use only original Hilti char-

and spare

printed

the tool at

the muzle

your

gas

yourself

of the tool against

body.

concrete.

for maintenance/lubrication

spray or such of equivalent

use. Never use this

instruction

your

local Hilti sales

the tool is not

parts

in the operating

care and

or any bystander.

glass,

as

in the indi-

times.

at all

on its

such use.

or those

mainte-

your

hand

marble,

brick,

of tool

quality.

5.4 Iechnology

O This tool is

nology.

O The tool and its

when

ards

not as directed.

A

/l\

/z-s

5.5 Make the workplace

O Avoid

O Objects which could

from the working

The

O

tool is for hand-held

Keep

O

working

O Keep the

per-

,A^

/f\

14-$\

5.6 General salety

O Operate

in faultless

lf a

O

cartridge

lows:

1 . Keep the

30 seconds.

2. lf the

the working surface, taking

towards

Manually

3.

up the remaining

Use

the

used cartridge strip and dispose of it in such

wav that

designed

used

with the

latest available tech-

ancillary equipment may

incorrectly

by untrained

sale

cause

children in

clean and

positions.

injury

use only.

particular,

free from

unfavourable body

area.

persons,

other

area.

grip

dry,

precaulions

the

tool only as directed and

condition.

mislires

or fails to ignite,

pressed

tool

cartridge still

your

advance the cartridge strip

it

can be neither reused nor misused.

against the working

body

fails to fire,

or

withdraw the tool from

that it is not

care

bystanders.

cartridges on the strip. Remove

present

haz-

personnel

should be removed

outside the

grease.

oil and

when

only

proceed

one cartridge.

as

surface

pointed

it is

fol-

for

or

a

Page 10

lf 2-3 cartridges

O

out clearly

with

1. Stop using

2.

3.

4. Clean

5.

O

strip

o

straighten

O

O

servicing

O Store

high

audible

significantly

tridges

Disassemble

Check

Do

sists after carrying

Have the

Hilti

Never attempt

Keep the arms

Never leave the

from the

piston

the

the tool for

not continue

tool checked

repair center

the tool.

or

the

the

the tool

arms).

Always unload

or changing

cartridges

place

locked

or

,A

r'N

/t,-$,,

5.2Irmpet.ture

not disassemble

O Do

Never exceed

O

driving

otherwise overheat.

O Should

using

(number

rate

plastic

the

the tool immediately

occur

misfires

the cartridge

noise of

less

power),

proceed

tool immediately.

tool.

(see

8.3)

(see

wear

to use

pry

to

flexed

loaded

the

and unused

out

recommended

the

8.4)

the tool

the

out

steps

repaired if necessary

and

a cartridge

when the

tool unattended.

tool before beginning

parts

and before storage.

tools unloaded,

reach of children.

of the

tool when it

per

marks

of

cartridge

strip begin

and allow

in

succession

firing and

follows

as

Remove

problem per-

if the

described

from the

tool is fired

is hot.

maximum

The tool

hour).

to

it to cool down.

(with-

marK

:

the car-

above.

at a

magazine

(do

not

cleaning,

in a dry,

fastener

may

melt, stop

Betore use

6.

Tool inspection

6.1

Ensure

O

is cartridge

there

the tool.

O Check

intervals

ular

Do not operate

erly.

the

when

the tool

have

O Check

nance").

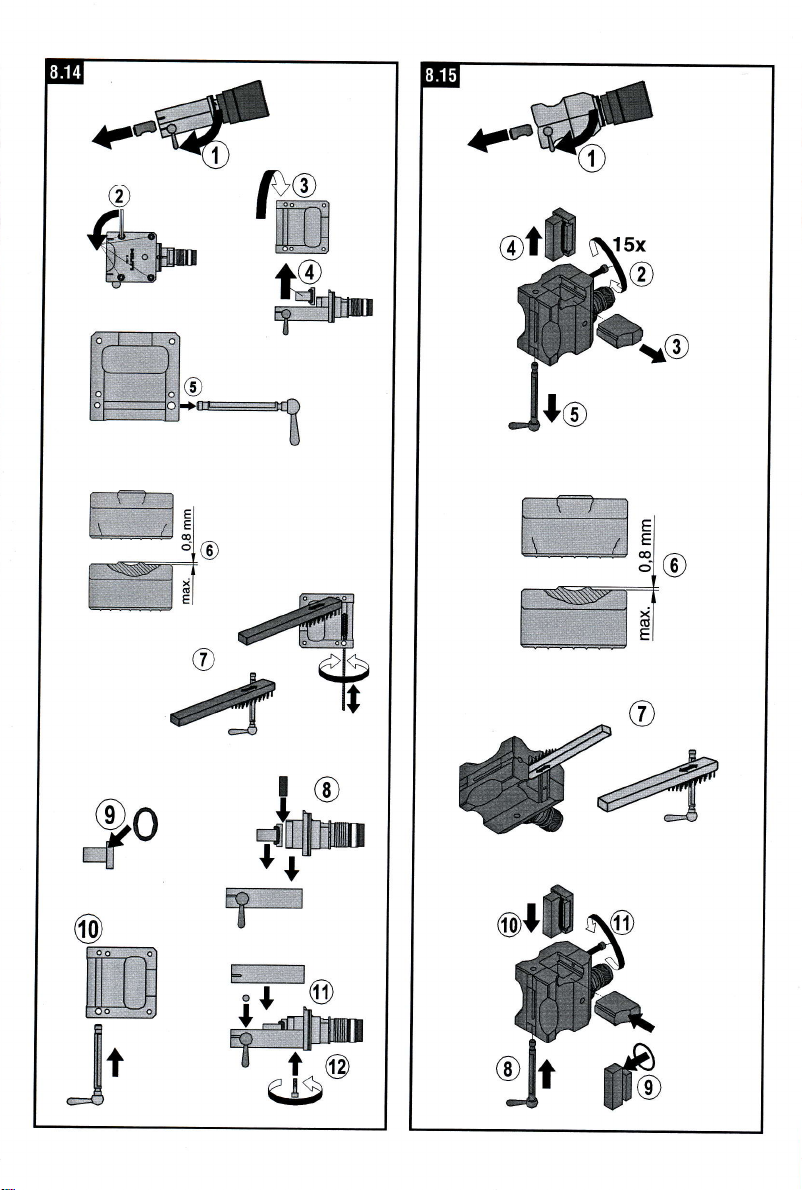

Changing the

6.2

1. Ensure

Remove

the tool.

of

the release button

Press

2,

Unscrew

3.

4.

Check

maintenance").

and

the

Push

5.

the marking

Push

6.

unit.

7. Screw

that there

all external

controls

the

is no cartridge

in the

strip

parts

and check

the

not operate

do

repaired at a

piston

for wear

marking

that no cartridge

the cartridge

the marking

the marking

piston

marking head

the

head

into

head firmly

strip

tool, remove

the tool for damage

of

that

controls operate

all

tool when

pafts

properly.

Hilti service centre.

"8.

(see

head

strip is loaded

pulling

by

strip

the

on

side

heac.

piston

for

tool

as

the tool until

onto

far as

onto the

the

in the

it

hand

by

are.damaged

lf necessary

Care and

in

it upwards

of marking

(see

wear

it will

piston

it engages.

tool. lf

from

reg'

at

prop-

mainte-

the tool.

out

head.

"Care

go.

return

or

met by

Requiremenb

5.8

t00l is intended

The

O

The tool may be operated,

o

authorised,

by

informed of any

be

tered.

Proceed carefully

o

attention

O Stop

5.9

is not on

working

Personal

to be

trained

special

and

the

with the

proteclive

for

personnel.

do not use

iob.

tool i{

equipment

@@@

The operator and

o

must always

vicinity

protection.

ear

other

wear

users

professional

serviced and

This

that may

hazards

you

persons

protection,

eye

use.

repaired

personnel

be encoun'

the tool

feel unwell.

immediate

in the

hard

a

if

your

hat

only

must

full

and

Page 11

7. Operation

m

@

@

CAUTl0l'l

I The

base

orfnagments of

may fly off.

Flying

I

fragments may

the

of

body or

I Wear safety

(users

hat

material may splinter

the

cartridge strip

parts

inlure

the eyes.

goggles

and bystanders).

and a hard

Loading

Eil

The marking head can receive

10

or

characters

1. Insert the characters according to the

Locking lever

2. Always insert the marking characters

of the marking

acters should

of characters.

3. When using a

fie desired character string.

is achieved.

4. After inserting the

must be secured by turning

The tool

5.

oosition.

characters

the

5.6 mm width

in the

head.

be inserted on

'-",

head

and

7

characters 8 mm

unblocked

An equal number of space char-

insert it at

desired

are

position.

side of the string

each

one end

In

fiis way, an even impact

marking characters, they

the

locking

now in the ready to

mark

in

the middle

or the

lever.

width

desired.

other

operate

of

CAUTION

I

The marking is achieved by a car-

tridge

I

I

being fired.

Excessive

hearing.

Wear ear

bystanders).

noise may damage the

protection

(users

and

I The tool could be made readyto

pressed

lire if

the

body

I

When

a marking head could be driven

into

a

I Never

the tool against

I

Under certain circumstances,

tool

could

pulling

by

I

When

a marking head could be driven

into a

I Never

bv hand.

against a

(e.9.

hand)..

"ready

in the

part

of the body.

press

the marking head of

parts

be made ready to fire

back the

"ready

in the

part

of the body.

pull

backthe marking head

part

to fire"

state,

of the body.

marking head.

to fire"

state,

GAUTION:

O Use only original space characters as blank space.

emergency, a

useo.

Do not

O

results in

reduces the marking

E

Load

it into the

has been

tridge is in the chamber.

back of

to be fired.)

next

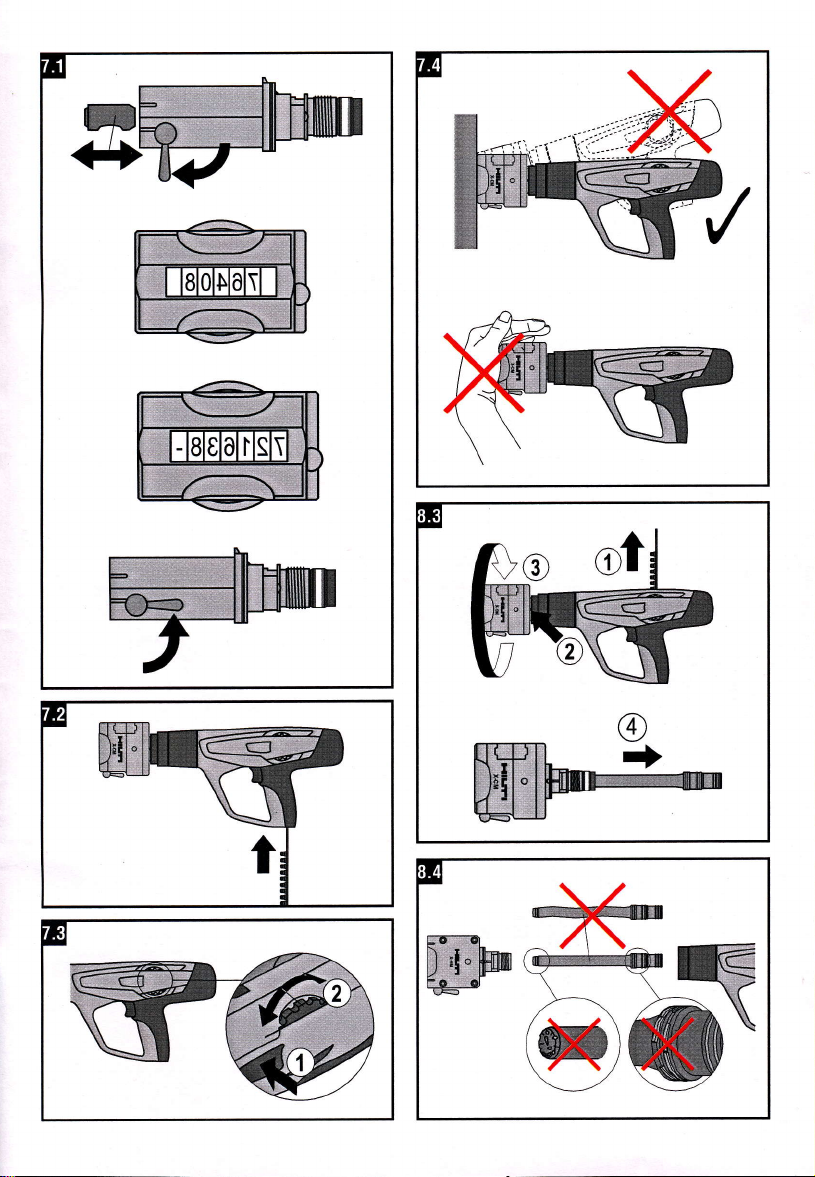

Enoiusting

Start

set at

of

1. Press the release button.

Turn the

2.

normal

marking

insert

life length of

shorter

Loading the tool

the

cartridge strip

of the tool

bottom

partly

used,

the

cartridge strip

with

the lowest

the driving

the lowest cartridge

power

power

character can

characters upside-down.

the

quality

(narrow

pull

(The

setting.

regulation wheel to 1.

impact extractor and

end

grip

until

it through

last

visible

indicates which

power

power

3. Drive a nail.

4. lfthe mark doesn't

the

the desired depth 0f

more

EMarking

1 . Press the tool

angle.

2. Fire

the

WARNING

O Never

hand.

Never exceed

O

7.5 Reloading the tool

Remove the

of

out

power

powerful

the

tool by

press

This is

the

tool. Load a new cartridge strip.

penetrate

level and repeat steps 1 to 3. Repeat until

cartridge

with the tool

firmly

pulling

the marking

accident hazard.

an

the

maximum

cartridge strip by

used

deeply enough, increase

penetration

if necessary.

the

against

the trigger

head with the

fastener

ground

be

first) by inserting

flush.

lf the strip

an

until

unused

number

cartridge

level and the tool

is reached.

sudace

work

palm

driving

pulling

it upwards

off and

This

car-

the

on

Use

right

at

your

of

rate.

In

is

a

Page 12

8. Gare

8.1 Care of

The

resistant

section.

The

clean at all

the interior of

the outside of

spray 0r steam-cleaning system

8.2 Maintenance

Check

lar intervals and

ly. Do not

when the controls

and maintenance

the lool

outer casing of

plastic.

ventilation

all external

the tool is manufactured from impact-

The

slots

times.

Do not

the

tool. Use a slightly damp cloth

the

tool at regular

parts

check

the tool when

operate

do

grip

comprises a synthetic

must

be unobstructed and

permit

the tool for

of

that all controls

not

operate

foreign

intervals.

for

cleaning.

parts

properly.

CAUTION

objects

Do

damage

operate

damaged or

are

lf necessary,

rubber

to

enter

to

clean

not

use a

at regu-

proper

f,ECheckthe

Replace the

piston

piston

if:

O lt is broken

The tip is heavily worn

O

off)

Piston rings are

O

lt is

O

NOTE

Do

tons

not

bent

use

kept

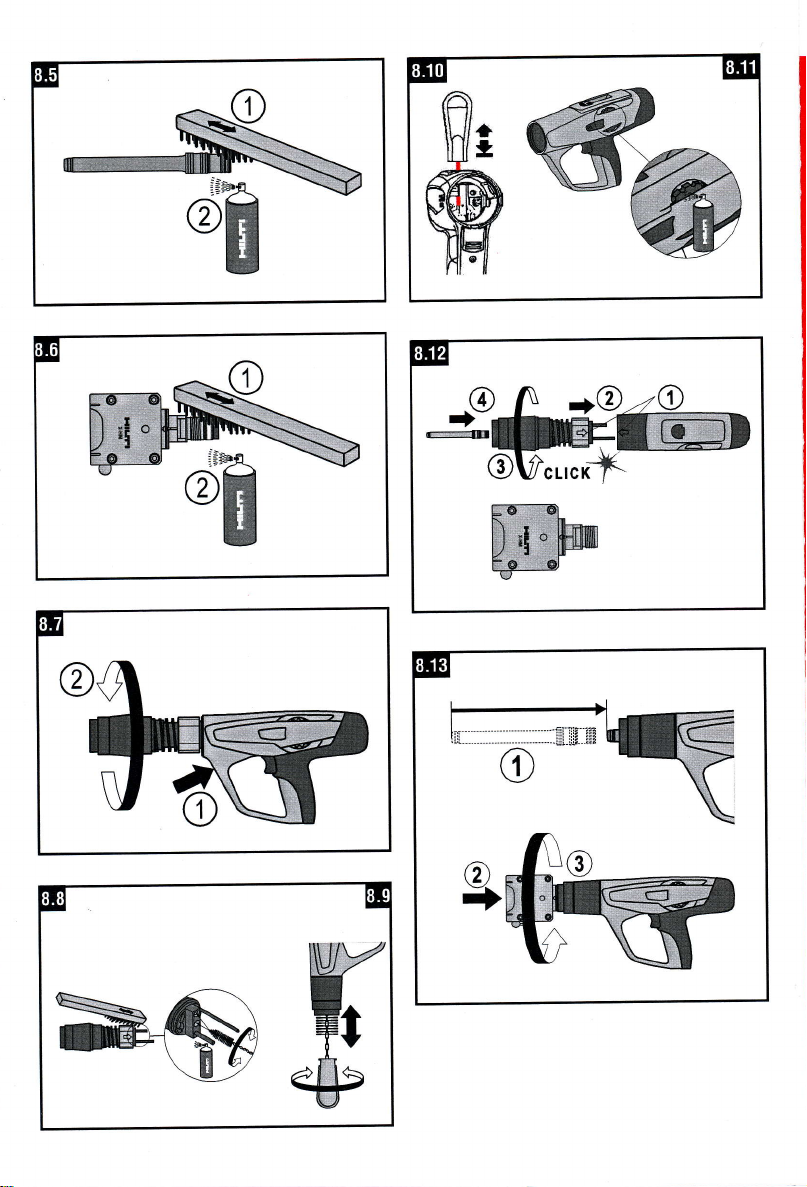

EECleaning

1.

the flat brush to clean the

Use

2. Spray the

Clean lne threaded section ol the marking head

m

1. Clean the thread with the flat brush.

2. Spray the thread lightly with Hilti spray.

(check

worn

the

piston

broken

rolling on a even

by

pistons.

piston

rings lightly

wear

for

(i.e.

a 90' segment is chipped

or missing

Do not modify

surface)

rings

piston

rings.

with

Hilti spray.

grind pis-

or

could

get

burn

your

hot while oper-

hands.

I The tool can

ating.

I You

I Do not disassemble the

it is hot. Let the tool

have the tool repaired at a Hilti service centre.

Servicing

The tool

1.

2. Fastener driving

3. lfyou

O contact

O trigger

O

O the cartridge strip is difficult

GAUTI0N

O

parts.

tool.

O Difi

endangering

-

-

-

EE

1. Ensure that no

2. Press the release

3. Unscrew

4. Remove

lhe lool

should be serviced

Caftridges

power

Never use

Do

Keep dust away from food.

Wash

misfire

power

notice that:

pressure

force increases,

regulation is ditficult

while

This may

Use only

from DX tool

not

breath

your

Disassemble the tool

increases,

cleaning

grease

for maintenance/lubrication of tool

strongly affect

Hilti

spray or such

contains substances

your

health.

in

the dust

hands after cleaning

cartridge

Remove the cartridge

the tool.

of

the marking head.

the

marking

strip

button at

head

if:

is inconsistent

to

to remove.

the tool:

the functionality of the

from

strip is loaded in the tool.

by

the marking head side.

and

adjust

of

equivalent

cleaning.

the

tool.

pulling

piston.

the

cool

(stitf),

that

it upwards out

tool while

down.

quality.

could be

piston

f,flDisassemble

1. Press the release

2. Unscrew

Clean the

f,E

1. Clean the spring with the

2. Clean the

3. Use the small round brush

4.

5. Spray

face.

the end

the large round brush to clean the large hole.

Use

the

EECtean

1.

the large round

Use

ing.

2. Spray

m

Use

tridge strip

slightly

ffi

Hilti

EfP

1. Bring the arrows

2. Push the

3. Screw

the inside

spray.

Clean the cartridge strip

the scraper

to lacilitate

Spray

spray.

Fit

the

gas piston

go.

will

it

the

engages.

the

button

piston

the

pislon

front

end with

piston

return unit lightly with Hilti spray.

inside

the

of

provided

guideways.

cleaning

power

me

pislon

retum

on

return

unit

piston

return

piston

return

return

gripping part.

at the

return

unit.

retum

unit

flat

brush,

the flat

brush.

to

clean the two

housing

to clean inside the hous-

brush

the housing lightly with Hilti

guideway

The rubber cover must be lifted

of the

guideway.

the

to clean

regulation wheel lightly with

unit

the housing and on the exhaust

into alignment.

into the housing as far as

unit

unit onto

unit

holes

right and left car-

the tool

until

at

it

Page 13

Assemble

ffi

1. Push the

2. Press the marking head firmly onto the

unit.

3.

the marking head

Screw

Cleaning and servicing the

ffi

the

piston

tool

into the tool as

the tool until it engages.

onto

far

as it will

X-462

marking head

The

large number of markings

occur

quality

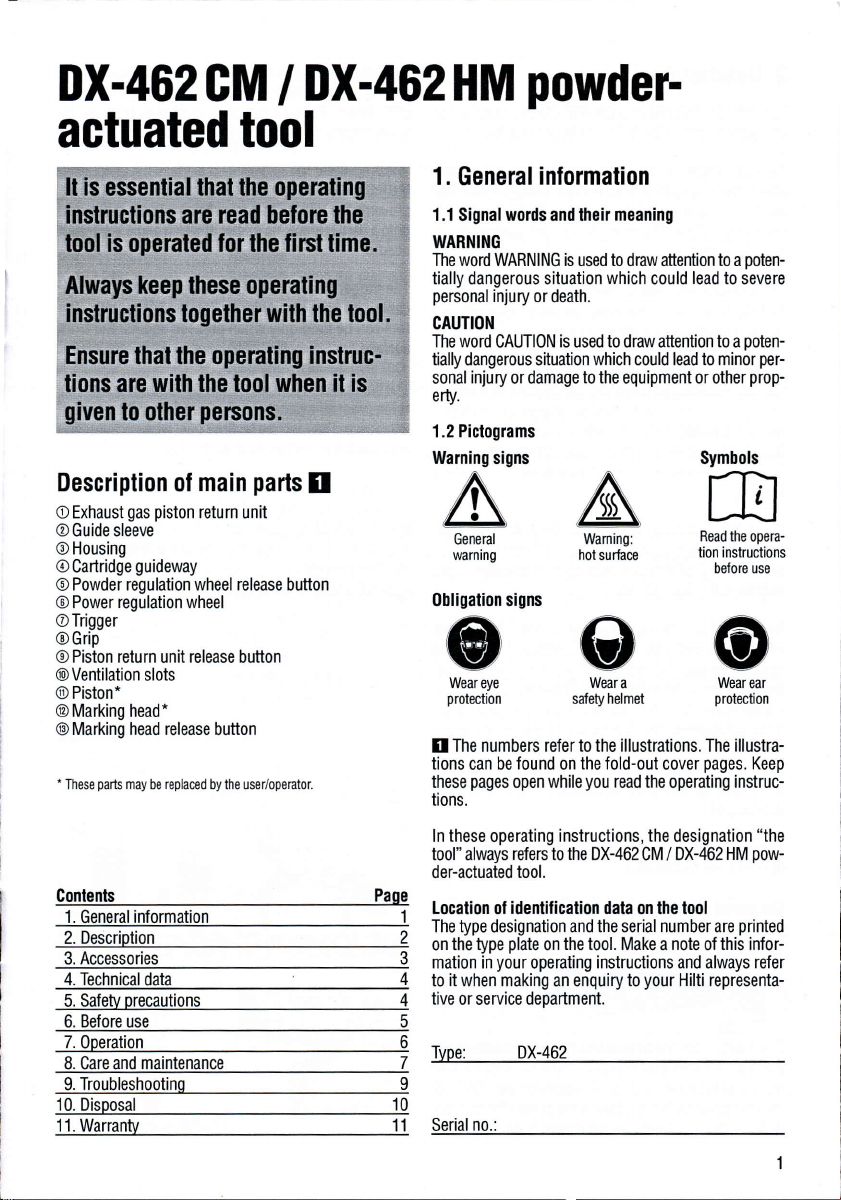

1. Remove the marking

2. Remove the 4 locking

3. Sepante

4. Remove and individually check

5.

6. Pay special attention to fie wmr on the

7.

8. Install

9.

10. Insert the axle with

1

1 . Afier

1 2.

marking head

steel

impact extractor damaged

e.g.

disimproves

chancters by

the open

upper and

with

premature

position

0-dng,

wom

a

and

piece

0-ring

locking lever

lever to

ing

key

the

ing

mer

impact extractor

tor

Remove the locking lever with axle

tor.

force, for example by using a rubber ham-

some

assembly

Failure to replace

tor can cause

quality.

ing

the inside head

Clean

the

Mount a new rubber

extractor

Join

ing screws M6x30 using loctite and Allen key.

adaptor

inshlling fie impact

the upper and lower housing.

be

should

(20,000)

cleaned:

when

/

/

tuming the lock-

M6x30 with an Allen

screws

lower housing

for

wear and

he absorbers and adap

or cncked

breakage and

the axle

the housing

in

on the impact

in the bore

place

extnctor

Secure

go.

piston

return

HM steel

after a

problems

when marking

parb

by

apply-

tmr,

the

impact

extrac-

impact

extnc-

poor

mark-

the absorbers

the 4 lock-

extractor.

impact extractor can cause

and

7.

Clean

8. lnseft

firmly

9.Mount

Failure to replace a worn 0r cracked

premature

poor

the inside head and the axle

the

press

a new rubber

quality.

marking

with locking lever in the

axle

it until it

clicks

0-ring

place

into

on the impact extrac-

breakage

bore and

tor

placing

10.After

insert

11.lnsert the

secure

Ghecking the toolfollowing

ffi

nance

After

carrying

check that

that they function correctly.

and

NOTE

the

absorber on

the impact extractor,

them inlo the marking head

the

locking screw

M6x30 with

into the marking head and

breech

care and mainte-

out care and maintenance on the tool,

protective

all

and safety devices

Allen key

an

are fitted

o The use of lubricants other than Hilti spray could

parts.

dammage

rubber

ffiGleaning

head

marking

polyurethane

The

scrvicing

and

marking head should be cleaned:

tre

X462 GM

after a large number of markings

problems

marking

when

occur e.g.

quality

impact

extractor damaged /

disimproves

polyurefiane

(20,000)

/

when

l.Remove the marking characters by turning the

lever

locking

2. Unscrew the locking screw

15 times with an Allen key

Remove the

3.

4. Remove and individually check for wear and tear,

the

impact

to the open

breech

extractor

and adaptor assembly.

punch

drift

5. Remove the locking

the unlocked

6. Pay special attention

8

through the

position

position

M6x30

approximately

from the marking head

with

0-ring,

the absorbers

lf it is necessary, insert a

bore.

lever with

and applying some

to the wear

axle by

on

turning it to

the impact

force.

Page 14

9. Troubleshooting

Gartridge

not lransporled

>f

7ffi

Carlridge

removed

Gartridge

strip cannot be

xw

I\--r-

\

-(-a-.-

-

\s

cannol be fired

/ \

xr

f

Gause

I

Damaged cartridge

:

I Carbon build up

I Tool damaged

I Tool overheated

rate

setting

I Tool damaged

WAR]IING

ItrdvdiiliJmpt to

from the

magazine strip or tool.

I Bad

cartridge

strip

because of hioh

pry

a cartridge

Cartridge strip melts

Garlridge lalls

carlridge slrip

out of the

.-:-

t Tool is compressed

while fastening.

I Fastening frequency is

r r.:

i

l

l

t l

a ::: l i i : l::: ii :

, i

i

I Fastening

frequency is too high

long

too

too high

. .

: ,: :

-,.',:li::,:::ll:].:,r]::

:t..1:::::::l:::l:::::i:il:l

,r:

.

I ::

i I

l

i

l:::

:

i:

l

.-l

Page 15

Fcause

The

opelator

increased

-

increased trigger

-

power

-

cailridge slrip is difficull lo

-

rem0ve

Piston is

unit and cannol be removed

Piston return

notices:

contacl

regulation

in

stuck

unil

pressure

force

stiff to

the

is

stuck

piston

adiusl

I Carbon,build-up

I Damaged

l,Carbon,build-up

I Carbon build-up

piston

Variation in marking

quality

LPiston damaged

I Damaged

I Worn characters

10. Disposal

power

Hilti

actuated

information.

power

actuated tool

without the need for

tools for recycling. Please ask

your

tools

old

lrom

powder

far

as

which

as oossible

Most of the materials

be conectly separated before they can be

taking

back

Hilti sales reoresentative for further

you

Should

Dismantle the

10

wish to return the

parts

pact

(im

extractor, 0-ring)

into the marking head

tools

actuated

recycled. In many

yourself

are

to

soecial

,:1,

,,,,

manufactured can be recycled.

countries,

a disposal

Hilti has already made arrangements for

your

Hilti customer service department or

facility for recycling,

tools.

The materials

proceed

as follows:

must

Page 16

Senarate the individual 0arts as

Pail /assemblv lllain maleilal

0uter casino

Screws. small oarts

cartridoe strio

Used

lollows:

Plastic

/

Steel Scrao

Plastic

/ steel

11. Warranty

Plastics recvclino

svnthetic rubber Plastics recvclino

metal

Accordinq to local reoulations

Hilti warrants that the

material and workmanship. This warrantv is valid so

the tool

long as

and serviced

operating

within 5

head from the

technical system is maintained. This

original

or other

the tool.

instructions,

years

Hilti

consumables, components and spare

products

This warranty

replacement

or replacement as a result of normal

not

Additional claims are ercluded, unless sfringenl

al rules

not otligated

quential

wilh, or by

tool

of defective

covered by

prohibit

damages, losses or expenses in connection

reason

lor any

tool

is operated and

properly

and in

for the tool

the

date of

ol equivalent

provides

parts

this warranty.

such erclusion.

for

direct,

of, the use 0f, ff

purpose.

all warranty claims are

the

indirecl, incidenhl or conse-

lmplied warranties ol

is free

supplied

handled con6cfly,

accordance

'l

year

and

(invoice

sale

quality,

free-of-charge

Parts requiring repair

only.

wear

parlicular,

In

inability

of defects

cleaned

with the Hilti

for the marking

made

and the

date),

means

that only

parts,

may be used in

repair or

tear are

and

nati0n-

Hilti is

use the

t0

mer-

in

chantability or

specifically

Send the

covery

tion for

This constitutes Hilti's entire obligation with regard to

warranty and

tool

of a

repair

excluded.

and/or

defect

lilness for

related

to the local Hilti marketing organiza-

or replacement.

supersedes

comments and oral or

warranties.

particular purpose

a

parts

immediately

prior

all

written

or contemporaneous

agreements concerning

Confirmation of GIP lesting

The Hilti DX 462 has been system and type tested.

result, the tool bears the PTB approval mark of square

shape showing approval number S 808.

guarantees

Unacceptable/inadm

determined during

the manager responsible

and to the Otfice of the

mission

compliance

(C.l.P.).

with the approved type.

issible

defects,

use

the tool must

of

the approval

at

Permanent International

In this way, Hilti

def iciencies, etc.

be

authority

are

upon dis-

As

reported to

(PIB)

Com-

a

Page 17

X-462

HM

marking

head:

ornnfifv 0rderino desionation

Piece

Piece detent

Piece

Piece

Piece

Piece

HM

Item no.

268017

4892

267979

Page 18

X-462GM

marking

head:

absorber

annular

detent

CM

extractor

HM

CM

Page 19

Loading...

Loading...