Page 1

DX460

Operating instructions 1–17

*371665*

371665

en

Page 2

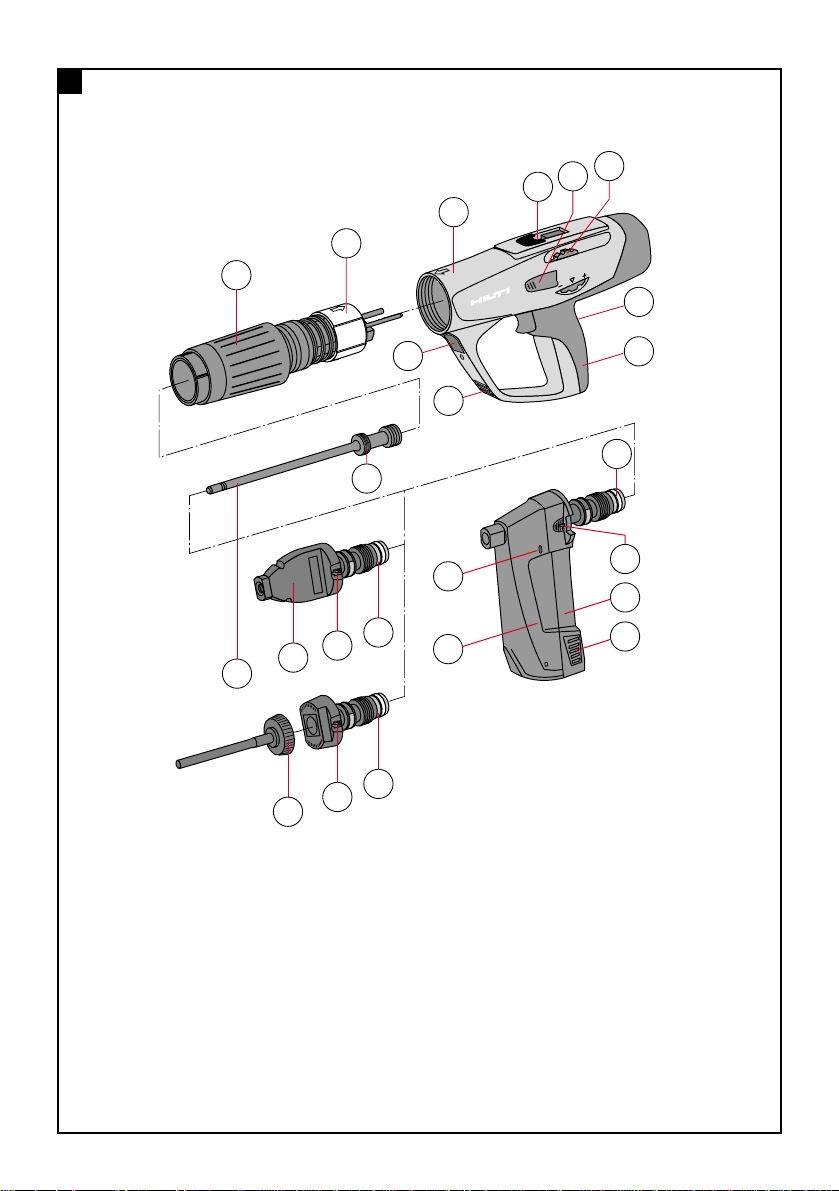

1

3

5

4

6

13

15

15

14

11

12

1

2

9

10

7

8

D

X

4

6

0

DX 460

16

20

M

X

7

2

MX 72

19

17

18

15

14

21

Page 3

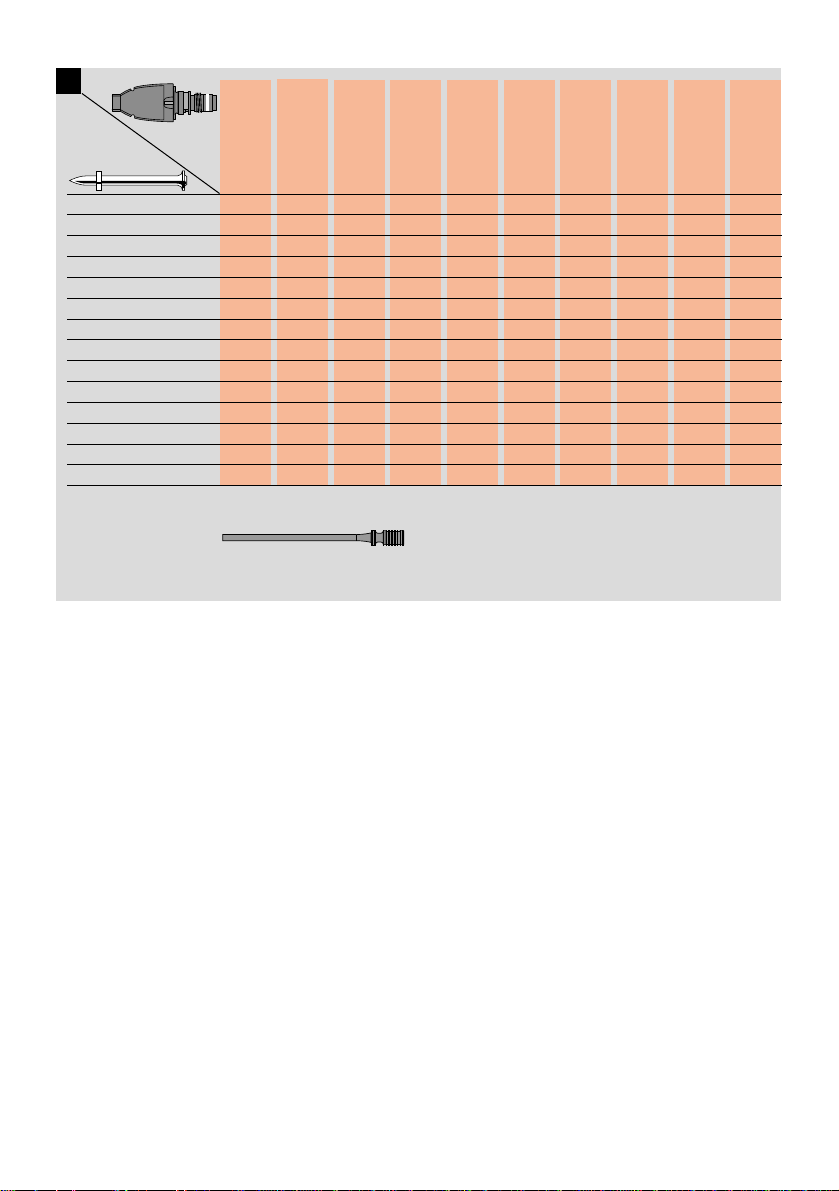

XMX72

X-460-F8

X-460-F8N15

X-460-F8N10

X-460-F8S12

X-460-F8SS

X-460-F10

X-460-F810SS

X-460-FIE

X-460-FIE-L

X-DNI S/W S/W S/W S/W S

X-ZF S/W S/W S/W S/W

X-SL S/W S/W S/W S/W

X-EDNI S S S S

X-CR S S S

X-DAK S S S S

X-AL-H AL AL AL

X-FS S/W S/W

X-SW S/W S/W

X-M8/X-W8 ... P8 S S

X-M6/W6 ... P8 S S

X-M10/W10 ... P10 10 10

X-IE IE

X-IE / XI-FV IE-L

S = X-460-P8

W = X-460-P8W

AL = X-460-P8AL

10 = X-460-P10

IE = X-460-PIE

IE-L = X-460-PIE-L

6.2

Page 4

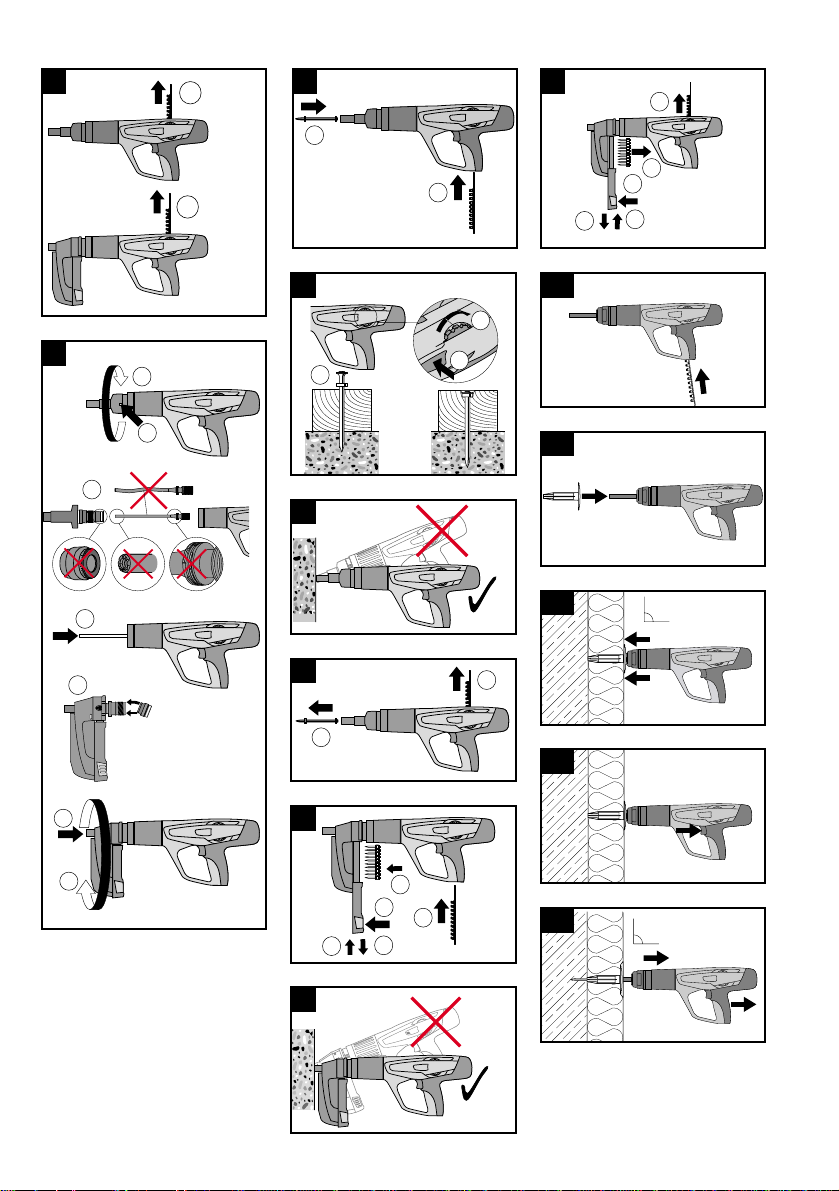

7.8

7.11

7.9

90

7.12

90

7.10

1

1

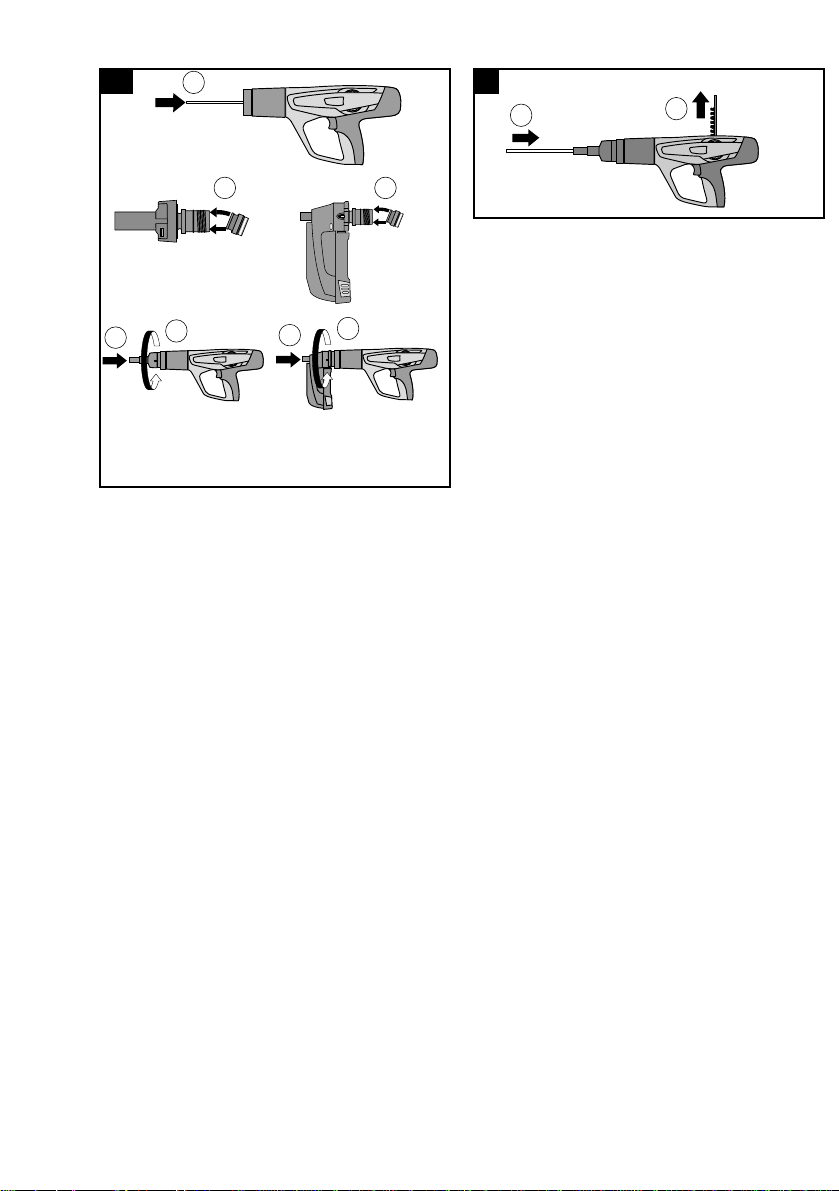

6.1

2

3

5

6

7

8

4

6.3

1

2

7.1

2

3

1

7.2

7.3

1

2

7.4

1

2

3

4

5

7.5

7.6

1

2

3

4

5

7.7

Page 5

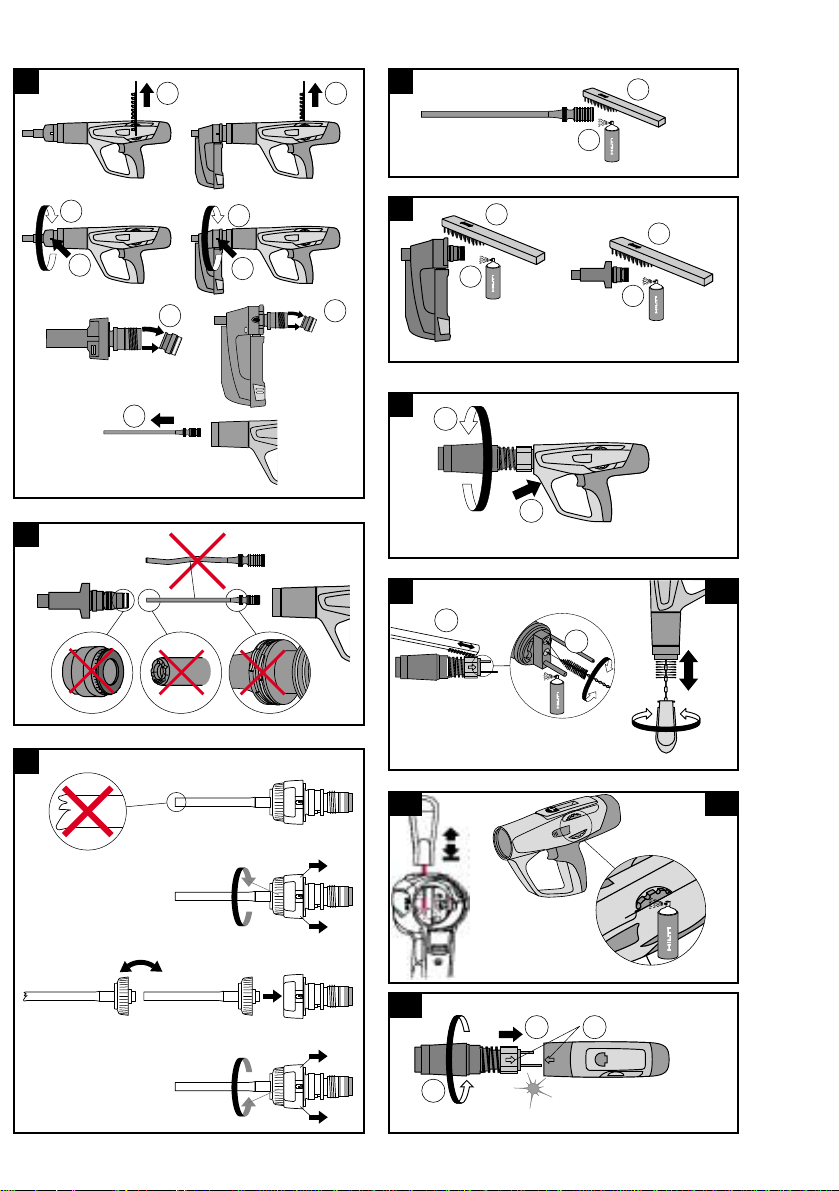

1

2

8.3

3

4

5

4

2

2

3

11

8.4

8.6

1

2

8.7

1

2

1

2

8.8

1

2

8.9 8.10

8.11 8.12

2 1

3

CLICK

8.13

8.5

Page 6

2 2

4

3

4

3

1

8.14

1

2

9.1

Page 7

1

DX460 powder -actuated tool

Warning signs

General

warning

Warning:

hot surface

Description of main parts

@ Exhaust gas piston return unit

; Guide sleeve

= Housing

% Cartridge guideway

& Power regulation wheel release button

( Power regulation wheel

) Trigger

+ Grip

§ Piston return unit release button

/ Ventilation slots

: Piston rings

· Piston *

$ Fastener guide *

£ Fastener guide release button

| Buffer *

¡ Magazine *

Q Magazine cover

W Magazine cover release button

E Magazine release button

R Load status indicator

T Replaceable fastener guide nosepiece *

* These parts may be replaced by the user/operator .

Obligation signs

Wear eye

protection

Wear a

safety helmet

Wear ear

protection

Symbols

Read the opera-

tion instructions

before use

It is essential that the operating

instructions are read before the

tool is operated for the first time.

Always keep these operating

instructions together with the tool.

Ensure that the operating instructions are with the tool when it is

given to other persons.

Contents Page

1. General information 1

2. Description 2

3. Accessories 3

4. Technical data 5

5. Safety precautions 5

6. Before use 6

7. Operation 7

8. Care and maintenance 9

9. Troubleshooting 11

10. Disposal 16

11. Warranty 17

1. General information

1.1 Signal words and their meaning

WARNING

The word WARNING is used to draw attention to a potentially dangerous situation which could lead to severe

personal injury or death.

CAUTION

The word CAUTION is used to draw attention to a potentially dangerous situation which could lead to minor personal injury or damage to the equipment or other property.

1.2 Pictograms

The numbers refer to the illustrations. The illustrations can be found on the fold-out cover pages. Keep

these pages open while you read the operating instructions.

In these operating instructions, the designation “the

tool” always refers to the DX 460 powder-actuated tool.

Location of identification data on the tool

The type designation and the serial number are printed

on the type plate on the tool. Make a note of this information in your operating instructions and always refer

to it when making an enquiry to your Hilti representative or service department.

Type: DX460

Serial no.:

Page 8

2

2. Description

The tool is designed for professional use in fastening

applications where nails, threaded studs and composite

fasteners are driven into concrete, steel and sand-lime

block masonry.

The tool works on the well-proven piston principle and

is therefore not related to high-velocity tools. The piston principle provides an optimum of working and fastening safety. The tool works with cartridges of 6.8/11

caliber .

The piston is returned to the starting position and the

cartridges are fed to the firing chamber automatically

by gas pressure from the fired cartridge. This permits

fastenings to be made very quickly and economically

with nails and threaded studs. The use of a nail magazine greatly increases the speed and convenience of fastening with the tool, above all when making large numbers of identical fastenings of all kinds.

As with all powder-actuated tools, the tool, magazine,

fastener program and cartridge program form a “technical unit”. This means that optimal fastening with this

system can only be assured if the fasteners and cartridges are specially manufactured for it, or products of

equivalent quality, are used. The fastening and application recommendations given by Hilti are only applicable

if these conditions are observed.

The tool features 5-way safety – for the safety of the

operator and bystanders.

The piston principle

The energy from the propellant charge is transferred to

a piston, the accelerated mass of which drives the fastener into the base material. As approximately 95 % of

the kinetic energy is absorbed by the piston, the fastener

is driven into the base material at much reduced velocity (less than 100 m/sec.) in a controlled manner . The

driving process ends when the piston reaches the end

of its travel. This makes dangerous through-shots virtually impossible when the tool is used correctly .

The drop-firing safety device is the result of coupling

the firing mechanism with the cocking movement. This

prevents the Hilti DX tool from firing when it is dropped

onto a hard surface, no matter at which angle the impact

occurs.

The trigger safety device ensures that the cartridge

cannot be fired simply by pulling the trigger only. The

tool can be fired only when pressed against the work

surface.

3

2

The contact pressure safety device requires the tool

to be pressed against the work surface with a significant force. The tool can be fired only when pressed fully against the work surface in this way.

In addition, all Hilti DX tools are equipped with an unintentional firing safety device . This prevents the tool

from firing if the trigger is pulled and the tool then pressed

against the work surface. The tool can be fired only when

it is first pressed (1.) against the work surface correctly and the trigger then pulled (2.).

5

4

1

2

4

2

5

3

1

Page 9

3

3. Cartridges, accessories and fasteners

Fasteners

Ordering designation Application

X-DNI, X-ZF Nails with differing application profile for a wide variety of fastenings

X-SL Easily removable formwork nail for temporary fastenings

X-EDNI Magazined standard nails for efficient fastening to steel

X-CR Stainless-steel nails for fastenings in damp or corrosive surroundings

X-AL-H High-strength nails for fastening to steel and concrete of higher strength

X-FS The ideal fastener for positioning formwork

X-IE The ideal fastener for fastening insulation material to concrete, plastered solid

masonry and steel

X-SW Flexible washer fasteners for fastening insulating foils / sheeting to concrete and steel

23/36 mm Washers for Hilti nails: simple securing of joint seals, foils / sheeting and timber to

concrete and steel using the X-460 WH23/36 washer holder

X-(E)M/W/6/8 ... P8, Studs for bolted fastenings on concrete and steel

X-M/W10 ... P10

X-(D)FB Metal conduit clip for fastening conduits or cable ducts and insulated pipes (hot or

cold) for plumbing and heating

X-EFC Plastic conduit clip for fastening flexible electric cable ducts and water or heating

pipes (hot or cold)

X-EKB Cable clasp for fastening electric cables flat on ceilings and walls

X-ECH Bunched cable holder for fastening cables on ceilings and walls

X-JH For fastening electric cables in accordance with fire prevention regulations (LAR)

X-ET Fastener for plastic (PVC) electric cable trunking

X-CC Clip for securing suspended fastening systems using wires or chains

X-HS Suspension system with threaded connection

For further equipment contact your local Hilti organisation.

Magazine

MX 72 Magazine – For quick and convenient fastenings

Fastener guides

Ordering designation Application

X-460-F8 Standard

X-460-F8N15 15 mm width for improved accessibility

X-460-F8N10 10 mm width for improved accessibility

X-460-S12 Fastener guide for fasteners with a 12 mm steel washer – higher pull over values

X-460-F8SS Spall stop for 8 mm studs – reduces spalling

X-460-F10 For 10 mm studs and nails

X-460-F10SS Spall stop for 10 mm studs – reduces spalling

X-460-FIE For driving X-IE insulation fasteners

X-460-FIE-L For driving XI-FV and X-IE insulation fasteners

Page 10

4

Accessories

Ordering designation Application

X-SGF8 Splinter guard for the X-460-F8 standard fastener guide

X-460-SGMX Splinter guard for the X-460-MX72

X-460-STAB For the X-460-F10 fastener guide

X-460-TIE Replacement nosepiece for the X-460-FIE fastener guide

X-460-TIE-L Replacement nosepiece for the X-460-FIE-L fastener guide

X-EF adaptor X-EF adaptor for stabilizing the tool perpendicular to the work surface and for reduc-

ing concrete spalling when fastening the X-EKB and X-ECH (only with X-460-F8 fas-

tener guide)

X-460-B Rubber buffer – protects the fastener guide when the tool is used incorrectly

X-460-WH23/36 Washer holder – For fastening 23 and 36 mm steel washers with the magazine. The

washer holder can be mounted on the magazine.

X-PT 460 Pole tool extension – Extension system for various ceiling application

Pistons

Ordering designation Application

X-460-P8 Standard piston

X-460-P8AL AL piston – Only for AL nails. Gives the nail better guidance and increases the applica-

tion limit.

X-460-P8W Wood piston – With a tapered point. For applications when overdriving the nail into

wood is desired. Allows proper piston return.

X-460-P10 10 mm piston – For fastening M 10 / W10 studs

X-460-PIE Piston for driving X-IE insulation fasteners using the X-460-FIE fastener guide

X-460-PIE-L Piston for driving X-IE insulation fasteners using the X-460-FIE-L fastener guide

Cartridges

Ordering designation Colour code Power level

6.8/11 M green Green Low

6.8/11 M yellow Yellow Medium

6.8/11 M red Red Heavy

6.8/11 M black Black/purple Extra heavy

Safety accessory and cleaning set

Safety goggles, earplugs, Hilti spray, ramrod, flat brush, large round brush, small round brush, scraper, cleaning

cloth.

Page 11

5

4. T echnical data

DX 460 tool

Weight 3.25 kg (7.16 lb),

3.51 kg (7.78 lb) with magazine

Tool length 458 mm (18.03″),

475 mm (18.7″) with magazine

Nail length Max. 72 mm (27/8″)

Recommended maximum fastening rate 700 per hour

Cartridges 6.8/11 M (27 cal. short) green, yellow, red, black

Power regulation 4 cartridge power levels, regulation wheel with locking

function

MX 72 magazine

Weight 0.653 kg (1.44 lb)

Nail length Max. 72 mm (27/8″)

Magazine capacity Max. 13 nails

Right of technical changes reserved

5. Safety precautions

5.1 Basic safety instructions

In addition to the safety precautions listed in the individual sections of these operating instructions, the

following points must be strictly observed at all times.

5.2 Use as intended

The tool is designed for professional use in fastening

applications in construction where nails, threaded studs

and composite fasteners are driven into concrete, steel

and sand-lime block masonry.

5.3 Improper use

● Manipulation or modification of the tool is not permissible.

●Do not operate the tool in an explosive or flammable

atmosphere, unless the tool is approved for such use.

●To avoid the risk of injury, use only original Hilti fasteners, cartridges, accessories and spare parts or those

of equivalent quality.

● Observe the information printed in the operating

instructions concerning operation, care and maintenance.

●Never point the tool at yourself or any bystander .

●Never press the muzzle of the tool against your hand

or other part of your body.

●Do not drive nails into materials such as glass, marble,

plastic, bronze, brass, copper , natural rock, insulation

material, hollow brick, glazed tile, thin-gauge sheet metal

(< 4 mm), grey cast iron, spheroidal cast iron and gas

concrete.

5.4 Technology

● This tool is designed with the latest available tech-

nology.

●The tool and its ancillary equipment may present haz-

ards when used incorrectly by untrained personnel or

not as directed.

5.5 Making the workplace safe

●Avoid unfavourable body positions.

●Objects which could cause injury should be removed

from the working area.

●The tool is for hand-held use only .

●Keep other persons, children in particular, outside the

working area.

● Before using the tool, make sure that no one

is standing behind or below the point where fasteners

are to be driven.

●Keep the grip dry, clean and free from oil and grease.

5.6 General safety precautions

●Operate the tool only as directed and only when it is

in faultless condition.

●Use the stabiliser/splinter guard when the application

permits.

●If a cartridge misfires or fails to ignite, proceed as fol-

lows:

1. Keep the tool pressed against the working surface

for 30 seconds.

2. If the cartridge still fails to fire, withdraw the tool

from the working surface, taking care that it is not

pointed towards your body or bystanders.

Page 12

6

3. Manually advance the cartridge strip one cartridge.

Use up the remaining cartridges on the strip.

Remove the used cartridge strip and dispose of it in

such a way that it can be neither reused nor misused.

● If 2–3 cartridge misfires occur in succession (with-

out clearly audible noise of the cartridge firing and the

fastener being driven with significantly less power), proceed as follows:

1. Stop using the tool immediately.

2. Disassemble the tool (see 8.3).

3. Check that the correct combination of fastener

guide, piston and fastener are used (see 6.2).

4. Check the buffer, piston and fastener guide / magazine for wear and replace the parts if necessary

(See 6.3 and 8.4. X-IE see 8.5).

5. Clean the tool.

6. Do not continue to use the tool if the problem persists after carrying out the steps described above.

Have the tool checked and repaired if necessary at

a Hilti repair center .

● Never attempt to pry a cartridge from the magazine

strip or the tool.

● Keep the arms flexed when the tool is fired (do not

straighten the arms).

●Never leave the loaded tool unattended.

● Always unload the tool before beginning cleaning,

servicing or changing parts and before storage.

●Store cartridges and unused tools unloaded, in a dry,

high or locked place out of the reach of children.

5.7 Temperature

●Do not disassemble the tool while it is hot.

●Never exceed the recommended maximum fastener

driving rate (number of fastenings per hour). The tool

may otherwise overheat.

●Should the plastic cartridge strip begin to melt, stop

using the tool immediately and allow it to cool down.

5.8 Requirements to be met by users

●The tool is intended for professional use.

●The tool may be operated, serviced and repaired only

by authorised, trained personnel. This personnel must

be informed of any special hazards that may be encountered.

●Proceed carefully and do not use the tool if your full

attention is not on the job.

●Stop working with the tool if you feel unwell.

5.9 Personal protective equipment

●The operator and other persons in the immediate vicin-

ity must always wear eye protection, a hard hat and ear

protection.

6. Before use

6.1 Tool inspection

● Ensure that there is no cartridge strip in the tool. If

there is a cartridge strip in the tool, remove it by hand

from the tool.

●Check all external parts of the tool for damage at regular intervals and check that all controls operate properly. Do not operate the tool when parts are damaged or

when the controls do not operate properly. If necessary ,

have the tool repaired at a Hilti service centre.

● Check the buffer and piston for wear (see “8. Care

and maintenance”).

6.2 Choosing the right fastener guide / piston / fastener combination

Use of the wrong combination may result in damage to

the tool and / or affect fastening quality (see table on last

page of these instructions).

6.3 Conversion from single-fastener tool to maga-

zine tool (changing the fastener guide)

1. Ensure that no cartridge strip or fastener is loaded in

the tool. Remove the cartridge strip by pulling it

upwards out of the tool and remove the fastener from

the fastener guide / magazine.

2. Press the release button on the side of the fastener

guide.

3. Unscrew the fastener guide.

4. Check the buffer and piston for wear (see "Care and

maintenance").

5. Push the piston into the tool as far as it will go.

6. Press the buffer onto the magazine until it snaps into

place.

7. Push the magazine firmly onto the piston return unit.

8. Screw the magazine onto the tool until it engages.

Page 13

7

7. Operation

CAUTION

■ The nail or stud is driven by a cartridge being fired.

■ Excessive noise may damage the

hearing.

■ Wear ear protection (users and

bystanders).

WARNING

■ The tool could be made ready to

fire if pressed against a part of

the body (e.g. hand)..

■ This could cause a nail to be driven into a part of the body.

■ Never press the muzzle of the tool

against parts of the body.

WARNING

■ Under certain circumstances, the

tool could be made ready to fire

by pulling back the magazine, fastener guide or the fastener by

hand.

■ When in the “ready to fire” state,

a fastener could be driven into a

part of the body.

■ Never pull back the magazine,

fastener guide or fastener by hand.

CAUTION

■ The base material may splinter

when a fastener is driven or fragments of the cartridge strip may

fly off.

■ Flying fragments may injure parts

of the body or the eyes.

■ Wear safety goggles and a hard

hat (users and bystanders).

X-DNI nail (concrete/steel)

MD

ET

SL

SD

Length of nails for steel

Penetration depth (ET) 22± 5 mm

(nail point must protrude)

+material thickness (MD) = shank length

steel thickness (SD) = min. 4 mm,

max. 10 mm

Length of nail for concrete

Penetration depth (ET) 27±5 mm

+ material thickness (MD) = shank

length

Penetration depth (ET) 12± 2 mm

+material thickness (MD)

= shank length (SL) min.

steel thickness (SD) = min. 4 mm

X-EDNI nail (steel)

Penetration depth

concrete: 27±5 mm

steel: 12±2 mm

Threaded studs

for concrete or steel

Concrete

A = min. edge distance = 70 mm (2

3

/4")

B = min. spacing = 80 mm (3

1

/8")

C = min. base material thickness = 100 mm (4")

Steel

A = min. edge distance = 15 mm (

5

/8")

B = min. spacing = 20 mm (

3

/4")

C = min. base material thickness = 4 mm (

5

/32")

MD

ET

SL

Fastening guidelines

NOTE

These application recommendations must always be

observed. For more specific information, refer to the

Hilti Fastening T echnology Manual, which is available

from your local Hilti organisation.

BA

d

C

X-IE fastener (concrete, solid rendered masonry, steel)

On all base materials, fastener length corresponds to thickness of insulating

material.

SD

MD

ET

SL

BA

ET

C

Page 14

8

There are more than There are 3 or less nails in

3 nails in the magazine. the magazine. A strip of

10 nails may be loaded.

WARNING

●All nails in the magazine must be of the same length.

7.6 Fastening with the magazine tool

1. Press the tool firmly against the work surface at right

angles.

2. Fire the tool by pulling the trigger.

WARNING

●Never attempt to drive a fastener in an existing hole

except where recommended by Hilti, e.g. when using

the DX Kwik system.

●Never attempt to redrive the same fastener .

●Never exceed the maximum fastener driving rate.

7.7 Unloading the magazine tool

1. Ensure that there is no cartridge strip in the tool. If

there is a cartridge strip in the tool, remove it by pulling

it upwards out of the tool.

2. Release the magazine cover by pressing the release

button.

3. Pull the magazine cover down as far as it will go.

4. Ensure that there is no nail strip in the magazine.

5. Push the magazine cover up until it snaps closed.

7.8

Load the cartridge strip (narrow end first) by inserting

it into the bottom of the tool grip until flush. If the strip

has been partly used, pull it through until a live cartridge

is in the chamber . (The last visible number on the back

of the cartridge strip indicates which cartridge is next to

be fired.)

7.9

Push the X-IE fastener onto the nosepiece of the DX 460

IE as far as it will go.

7.10

Press the tool against the insulating material at right

angles so that the X-IE is pushed through the insulating

material and lies flush with its surface.

7.11

Drive the fastener by pulling the trigger .

7.12

Pull the tool out of the X-IE fastener at right angles.

7.1 Loading the single-fastener tool

1. Insert the fastener (head first) until the washer is held

in the tool.

2. Load the cartridge strip (narrow end first) by inserting it into the bottom of the tool grip until flush. If the

strip has been partly used, pull it through until a live

cartridge is in the chamber. (The last visible number

on the back of the cartridge strip indicates which cartridge is next to be fired.)

7.2 Adjusting the driving power

Start with the lowest cartridge power level and the tool

set at the lowest power setting.

1. Press the release button.

2. Turn the power regulation wheel to 1.

3. Drive a nail.

4. If the fastener doesn't penetrate deeply enough,

increase the power level and repeat steps 1 to 3.

Repeat until the desired depth of penetration is reached.

Use a more powerful cartridge if necessary.

7.3 Fastening with the single-fastener tool

1. Press the tool firmly against the work surface at right

angles.

2. Fire the tool by pulling the trigger.

WARNING

●Never attempt to drive a fastener in an existing hole

except where recommended by Hilti, e.g. when using

the DX Kwik system.

●Never attempt to redrive the same fastener .

●Never exceed the maximum fastener driving rate.

7.4 Reloading the single-fastener tool

Ensure that no cartridge strip or fastener is loaded in the

tool. Remove the cartridge strip by pulling it upwards

out of the tool and remove the fastener from the fastener

guide.

7.5 Loading the magazine tool

1. Release the magazine cover by pressing the release

button.

2. Pull the magazine cover down as far as it will go.

3. Load a new nail strip into the magazine.

4. Push the magazine cover up until it snaps closed.

5. Load the cartridge strip (narrow end first) by pushing it into the grip from below until flush. If the strip

has been partly used, pull it through until an unused

cartridge is in the chamber. (The last visible number

on the back of the cartridge strip indicates which cartridge is next to be fired.)

When the indicator shows red, or partly red, there are 3

or less nails in the magazine. A strip of 10 nails may then

be loaded.

Page 15

9

CAUTION

■ The tool can get hot while operating.

■ You could burn your hands.

■ Do not disassemble the tool while

it is hot. Let the tool cool down.

8. Care and maintenance

8.1 Care of the tool

The outer casing of the tool is manufactured from impactresistant plastic. The grip comprises a synthetic rubber

section.

The ventilation slots must be unobstructed and kept

clean at all times. Do not permit foreign objects to enter

the interior of the tool. Use a slightly damp cloth to clean

the outside of the tool at regular intervals. Do not use a

spray or steam-cleaning system for cleaning.

8.2 Maintenance

Check all external parts of the tool for damage at regular intervals and check that all controls operate properly. Do not operate the tool when parts are damaged or

when the controls do not operate properly. If necessary ,

have the tool repaired at a Hilti service centre.

Servicing the tool

The tool should be serviced if:

1. Cartridges misfire

2. Fastener driving power is inconsistent

3. If you notice that:

●contact pressure increases,

●trigger force increases,

●power regulation is difficult to adjust (stiff),

●the cartridge strip is difficult to remove.

8.3 Disassemble the tool

1. Ensure that no cartridge strip or fastener is loaded in

the tool. Remove the cartridge strip by pulling it

upwards out of the tool and remove the fastener from

the fastener guide.

2. Press the release button at the side.

3. Unscrew the fastener guide / magazine.

4. Remove the buffer by bending it away from the fastener guide / magazine.

5. Remove the piston.

8.4 Check the buffer and piston for wear

Replace the buffer if:

●the metal ring is loose or broken,

●the buffer no longer holds on the fastener guide,

● excessive, uneven wear beneath the metal ring is

noticed.

Replace the piston if:

●it is broken,

●the tip is heavily worn (i.e. a 90°segment is chipped

off),

●piston rings are broken or missing,

●it is bent (check by rolling on an even surface).

NOTE

Do not use worn pistons. Do not modify or grind pistons.

8.5 Check the fastener guide for wear

The nosepiece of the X-460-FIE and X-460-FIE-L fastener guides should be replaced if the tubular section is

damaged (e.g. bent, widened or cracked). For instructions on replacing the nosepiece, please refer to sections 6.3 and 8.5.

1. Ensure that no cartridge strip or fastener is loaded

in the tool. Remove the cartridge strip by pulling it

upwards out of the tool and remove the fastener

from the fastener guide.

2. Press the release button on the side of the fastener

guide.

3. Unscrew the fastener guide.

4. Check the buffer and piston for wear (see care and

maintenance instructions).

5. Pull the moveable ring downwards and unscrew and

remove the clamping nut.

6. Replace the fastener guide nosepiece.

7. Pull the moveable ring downwards and screw on

the clamping nut.

8. Push the piston into the tool as far as it will go.

9. Press the buffer onto the fastener guide until it

engages.

10. Push the fastener guide firmly onto the exhaust gas

piston return unit.

11. Screw the fastener guide onto the tool until it engages.

8.6 Clean the threaded section of the fastener guide/

magazine

1. Clean the thread with the flat brush.

2. Spray the thread lightly with Hilti spray .

8.7 Disassemble the piston return unit

1. Press the release button at the gripping part.

2. Unscrew the piston return unit.

8.8 Clean the piston return unit

1. Clean the spring with the flat brush.

2. Clean the front end with the flat brush.

3. Use the small round brush to clean the two holes at

the end face.

4. Spray the piston return unit lightly with Hilti spray .

8.9 Clean inside the housing

1. Use the large round brush to clean inside the hous-

ing.

2. Spray the inside of the housing lightly with Hilti spray .

Page 16

10

8.10 Clean the cartridge strip guideway

Use the scraper provided to clean the right and left cartridge strip guideways. The rubber cover must be lifted

slightly to facilitate cleaning of the guideway .

8.11 Spray the power regulation wheel lightly with

Hilti spray

8.12 Fit the piston return unit

1. Bring the arrows on the housing and on the exhaust

gas piston return unit into alignment.

2. Push the piston return unit into the housing as far as

it will go.

3. Screw the piston return unit onto the tool until it

engages.

8.13 Assemble the tool

1. Push the piston into the tool as far as it will go.

2. Press the buffer onto the fastener guide / magazine

until it snaps into place.

3. Press the fastener guide / magazine firmly onto the

piston return unit.

4. Screw the fastener guide / magazine onto the tool

until it engages.

8.14 Checking the tool following care and mainte-

nance

After carrying out care and maintenance on the tool,

check that all protective and safety devices are fitted and

that they function correctly.

NOTE

●The use of lubricants other than Hilti spray could dam-

age rubber parts, especially the buffer .

Page 17

11

Cartridge strip cannot be

removed

9. T roubleshooting

Piston is stuck in the base

material

Cartridge not transported

Cause

■ Fastener too short

■ Fastener without washer

■ Driving power too high

■ Damaged cartridge strip

■ Carbon build up

■ Tool damaged

■ Tool overheated because of high

setting rate

■ Tool damaged

WARNING

Never attempt to pry a cartridge

from the magazine strip or tool.

■ Bad cartridge

■ Carbon build-up

WARNING

Never attempt to pry a cartridge

from the magazine strip or the tool.

Possible remedies

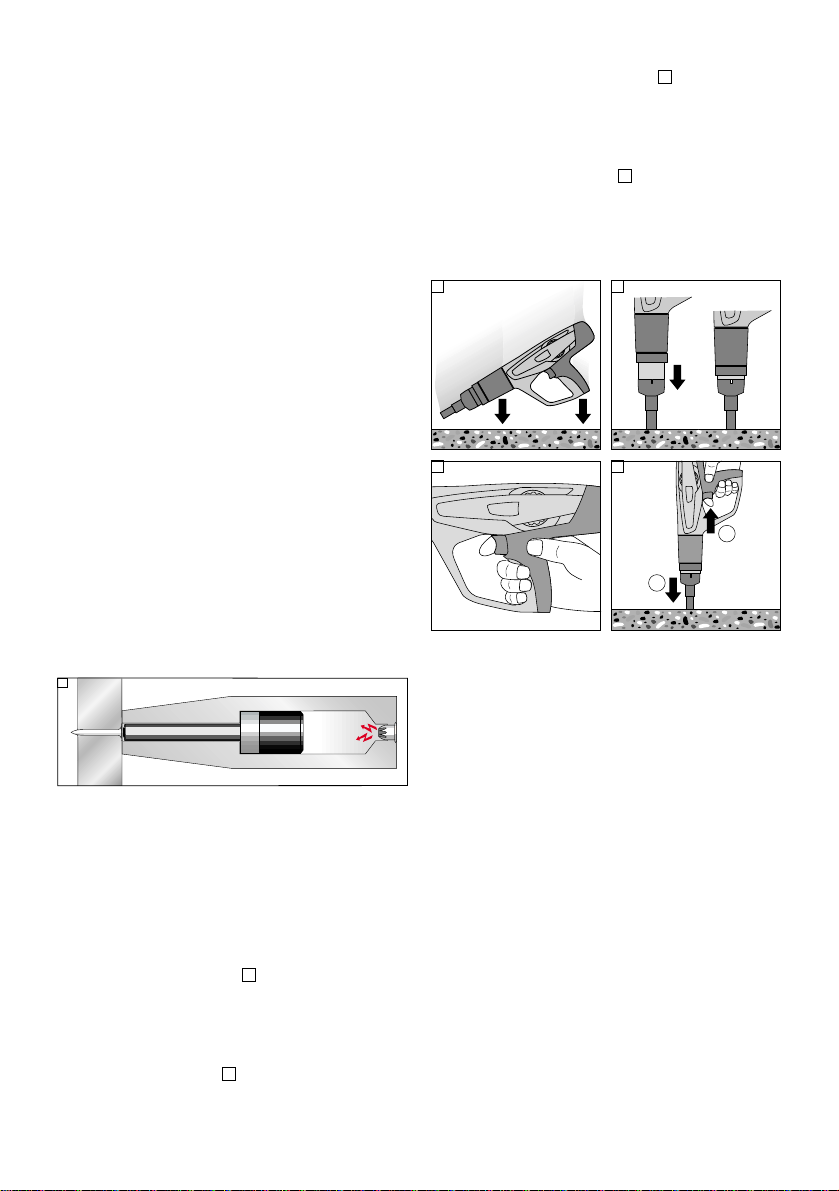

■ Remove cartridge strip and use

pushrod provided to push piston

fully back (See 9.1)

■ Use longer fastener

■ Use fastener with washer for

wood applications

■ Reduce power setting

• Power regulation

• Lower cartridge power level

■ Change cartridge strip

■ Clean the cartridge strip guide-

way (see 8.10)

If the problem persists:

■ Contact Hilti Repair Centre

■ Let the tool cool down and then

carefully try to remove the

cartridge strip

If not possible:

■ Contact Hilti Repair Centre

■ Manually advance the cartridge

strip one cartridge

If the problem occurs more

often: Clean the tool

If the problem persists:

■ Contact Hilti Repair Centre

■ Tool is compressed too long

while fastening.

■ Fastening frequency is too high

■ Compress the tool less long

while fastening.

■ Remove the cartridge strip

■ Disassemble the tool (see 8.7)

for fast cooling and to avoid

possible damage

If the tool cannot be disassembled:

■ Contact Hilti Repair Centre

Cartridge strip melts

Cartridge cannot be fired

Page 18

12

Piston is stuck in the piston return

unit and cannot be removed

Cartridge falls out of the

cartridge strip

The operator notices:

– increased contact pressure

– increased trigger force

– power regulation stiff to adjust

– cartridge strip is difficult to

remove

■ Fastening frequency is too high

WARNING:

Never attempt to pry a cartridge

from the magazine strip or tool.

■ Carbon build-up

■ Immediately discontinue using

the tool and let it cool down

■ Remove cartridge strip

■ Let the tool cool down.

■ Clean the tool and remove loose

cartridge.

If it is impossible to disassemble

the tool:

■ Contact Hilti Repair Centre

■ Clean the tool

(see 8.3–8.13)

■ Incorrect piston position

■ Carbon build-up

■ Remove cartridge strip and use

enclosed pushrod to push piston

fully back (see 9.1)

If problem persists:

■ Clean the tool

(see 8.3–8.13)

■ Check piston and buffer, replace

if necessary (see 8.4)

Varying depths of penetration

Misfire: the nail is only partly

driven into the base material

■ Incorrect piston position

■ Bad cartridge

■ Remove cartridge strip and use

enclosed pushrod to push piston

fully back (see 9.1)

If problem persists:

■ Change cartridge strip (possibly

use a new/dry package)

■ Clean the tool (see 8. –8.13)

■ Damaged piston

■ Buffer debris inside the piston

return unit

■ Damaged buffer

■ Carbon build-up

■ Remove cartridge strip

■ Unscrew piston return unit and

push out the piston through the

cartridge chamber using the

pushrod provided

■ Check buffer and piston, if

necessary, change (see 8.4)

■ Clean the tool

(see 8.3–8.13)

Cause Possible remedies

Page 19

13

Magazine fastener guide is stuck

Piston stuck in magazine fastener

guide

Trigger cannot be pulled

Piston return unit is stuck

■ Carbon build-up ■ Manually pull the front part of

the piston return unit out of the

tool

■ Clean the tool

(see 8.3–8.13)

If the problem persists:

■ Contact Hilti Repair Centre

■ Incorrect piston position

■ Tool not fully compressed

■ Safety mechanism activated

because:

– Magazine not loaded

– Plastic debris inside the

magazine

– Incorrect piston position

– Nail incorrectly positioned in

magazine

■ Piston and/or buffer damaged

■ Plastic debris inside the

magazine

■ Excess power when fastening on

steel

■ Tool fired with high power

without fastener in place

■ Fastener guide damaged

■ Remove cartridge strip and use

enclosed pushrod to push piston

fully back (see 9.1)

If problem persists:

■ Clean the tool (see 8.3–8.13)

■ Release the tool and fully com-

press it again

■ Load fastener strip

■ Open magazine, remove fastener

strip and plastic debris

■ Remove cartridge strip and use

pushrod provided to push piston

fully back (see 9.1)

If problem persists:

■ Clean the tool (see 8.3–8.13)

■ Unscrew the magazine

■ Check buffer and piston and

replace if necessary (see 8.4)

■ Open magazine, remove fastener

strip and plastic debris

■ Change magazine

The tool fires but no nail is driven

Cause Possible remedies

Page 20

14

Fastener does not penetrate

deeply enough

Fastener penetrates too deeply

■ Fastener too short

■ Driving power too high

■ Fastener too long

■ Driving power too low

■ Use longer fastener

■ Reduce power setting

■ Use lighter cartridge

■ Use shorter fastener

■ Increase power setting

■ Use heavier cartridge

Base material is spalling

Nail bends

■ Hard and/or large aggregate in

concrete

■ Rebar close to surface of

concrete

■ Hard surface (steel)

■ High strength concrete

■ Hard and/or large aggregate in

concrete

■ Old concrete

■ Use shorter nail

■ Use thicker nail DNI => AL

■ Use DX-Kwik (predrill)

■ Use co-acting principle/fastener

guide

■ Use stepped shank nail DAK

or X-ZFAH

■ Stud application

Use spall stop:

X-SS....

■ Nail application

Use shorter nail

Use DX-Kwik (predrill)

Use DAK16 or X-ZFAH16

(for high-strength precast

concrete)

Cause Possible remedies

■ Wrong type of fastener used

■ Fastener driving power set incor-

rectly

■ Concrete contains hard and/or

large aggregates

■ Rebar located just beneath the

surface

■ Hard surface

■ Use a fastener with a length suit-

able for the insulation material to

be fastened

■ Adjust the fastener driving power

■ Use a different cartridge power

level

Page 21

15

Nail head penetrates through

material fastened (metal sheet)

Nail breaks

Nail does not hold in base

material

Nail does not

penetrate surface

■ Driving power too low

■ Application limit exceeded

(very hard surface)

■ Unsuitable system

■ Thin steel base material

(3 to 5 mm steel)

■ Driving power too low

■ Application limit exceeded

(very hard surface)

■ Driving power too high

■ Try higher power setting or heavier

cartridge

■ Short nail application:

try DAK 16 P8 (TH) or

X-ZFAH 16 S8 TH

■ Long nail application:

try DAA or X-AL-H

■ Use co-acting principle/fastener

guide

■ Switch to more powerful system

like DX 750, DX 600 N

■ Try different power setting or

different cartridge

■ Try EDNK 20P8H or

ENKK 20-S12 for fastening sheet

metal

■ Try ESD MK...MA for fastening

wood

■ Try higher power setting or

heavier cartridge

■ Use shorter nail

■ Use stronger nail (X-...-H)

■ Use stepped shank nail:

DAK 16 P8 (TH) or

X-ZFAH 16 S8 TH

■ Reduce power setting

■ Use lighter cartridge

■ Use nail with top hat

■ Use nail with washer e.g.

EDNI ... S12

Fastening on steel

Cause Possible remedies

Damaged nail head

■ Driving power too high

■ Wrong piston used

■ Damaged piston

■ Reduce power setting

■ Use lighter cartridge

■ Check nail/piston combination

■ Change piston

Page 22

16

10. Disposal

Most of the materials from which Hilti power actuated tools are manufactured can be recycled. The materials

must be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for taking back your old powder actuated tools for recycling. Please ask your Hilti customer service

department or Hilti sales representative for further information.

Should you wish to return the power actuated tool yourself to a disposal facility for recycling, proceed as follows: Dismantle the tools as far as possible without the need for special tools.

Separate the individual parts as follows:

Part / assembly Main material Recycling

Toolbox Plastic Plastics recycling

Outer casing Plastic / synthetic rubber Plastics recycling

Screws, small parts Steel Scrap metal

Used cartridge strip Plastic / steel According to local regulations

Damaged nail head

■ Driving power too high

■ Wrong piston used

■ Worn-out piston

■ Reduce power setting

■ Use lighter cartridge

■ Check nail/piston combination

■ Change piston

Fastening on steel

Cause Possible remedies

Page 23

17

Noise information

as per German legislation (3, GSGV dated January 18, 1991):

The noise (power) level L

WA, 1S

as per § 1 (2) 1b) applicable to the tool and, due to different workplaces depend-

ing on the application for which the tool is used, also the noise (pressure) level L

pAImax

, at the measurement surface of 1 metre as per § 1 (2) 1e), are given in addition to the workplace related noise emission value in accordance

with the noise measurement standard. Operating conditions and circumstances of use: most powerful cartridge

power load in accordance with instructions for use with suitable nail or stud fired vertically downwards into a steel

plate and in accordance with the means of measurement DIN 45635, part 34 “Measurement of the noise emitted

by powder-actuated fastening tools”.

Noise information: With black cartridge and maximum power setting:

Application: Plywood to concrete – fastener X-DNI72MX

1b) Noise(power) level L

WA, 1S

= 108 dB (A)

workplace relevant emission value L

pAImax

= 103 dB (A)

(measured at operator ear level)

1e) Noise (pressure) level L ’

pA, 1s

= 95 dB (A)

Variations in operating conditions may cause deviations from these noise emission values.

11. Warranty

Hilti warrants that the tool supplied is free of defects in

material and workmanship. This warranty is valid so

long as the tool is operated and handled correctly, cleaned

and serviced properly and in accordance with the Hilti

Operating Instructions, all warranty claims are made

within 5 years for the tool and 1 year for the fastener

magazine and fastener guide from the date of the sale

(invoice date), and the technical system is maintained.

This means that only original Hilti consumables, components and spare parts, or other products of equivalent quality, may be used in the tool.

This warranty provides the free-of-charge repair or

replacement of defective parts only. Parts requiring repair

or replacement as a result of normal wear and tear are

not covered by this warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular , Hilti is

not obligated for direct, indirect, incidental or consequential damages, losses or expenses in connection

with, or by reason of, the use of, or inability to use the

tool for any purpose. Implied warranties of merchantability or fitness for a particular purpose are

specifically excluded.

For repair or replacement, send tool and/or related parts

immediately upon discovery of the defect to the address

of the local Hilti marketing organisation provided.

This constitutes Hilti's entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

Confirmation of CIP testing

The Hilti DX 460 has been system and type tested. As a

result, the tool bears the PTB approval mark of square

shape showing approval number S 812. In this way , Hilti

guarantees compliance with the approved type.

Unacceptable/inadmissible defects, deficiencies, etc.

that are determined during use of the tool must be reported to the manager responsible at the approval authority (PTB) and to the Office of the Permanent International

Commission (C.I.P.).

Page 24

Hilti = registered trademark of Hilti Corp., Schaan W 2678 0503 2-engl. 1 Printed in Liechtenstein © 2003

Right of technical and programme changes reserved S. E. & O.

371665/E

Hilti Corporation

FL-9494 Schaan

Tel.:+423/234 2111

Fax: +423 /2342965

www.hilti.com

Loading...

Loading...