Page 1

Page 2

Page 3

12

3

I-IH

-E--

-E

S*

"{

Page 4

Deluxe equipment

DX400B complete

pislon

l

4/NK

lor NK drive

1 baseplate

4BlF1

Selector

Instruction manual

chart

incli.rding:

pins

(DX400

(DX400

0402219

0402101

B)

4995440

4995376

kit also inclL.rdes:

Deluxe

kit

1

box

4754596 1

piston

4tw 6-20

o402270

l baseplate

4S/F6

0402106

1 cleaning c oth

5

,l

4995312 1

'l

I

1 .27 ca . bore brush O4O29O4

rino

stop

pacKage

r

ol 5 stop rings 0451655

extractor 0402984

HHl:IHhI

E!TTIf

I rounc wtre

B)

1 Hilti spray ubrlcanl

:Flfl-fl'

..

-..

-

E:-

!.

4804672

_l-*-

brush %"

1 flat wire brush

3/T69

4553776

4553840

pair

1

goggles

satety

4654032

Tool

parts

DX400B

(ox4oo

123456

t-Qm

No.

1

baseplate

2 front cap 0402931

guide

3

4

stop

5 stop ring 0451655

pressure

6

piston

7

B chamber bushing 0402913

firing

9

10 firing

11 firing

12 firing

13

end cap

4BlF1 0402101

sleeve

ring holder 0402986

spring

pin

return

pin

pin guide

pin

spring 0402930

Operating

1. Never load the tool until

ready to use d.

are

2. Never cock the toolagainst

the hand or

anyone.

3. lf a booster tails to

Keep the lool

a)

against the work surface

thirty

lf the boosterdoes not ignile,

b)

withdraw the tool approximately

2" from the work

(30)

point

seconds.

Catalog

o4o2941

O4O2937

o4o292g

spring

0402924

0402926

O4O2922

precautions

you

tool at

the

igniie:

pressed

for

(to

surface

recock the tiring mechanism),

taking care thal

at

Do not

c) Beposition

the work surface, fully depress

the

the trigger.

d) lf the boosler still fails to

ignite,

seconds,

toolfrom the

E conversion

rE

9

r,.;''li

yourself

or

pullthe

guide,

and again squeeze

wait

another

carefully remove the

work

parts

-li_

points

it never

anyone else.

baseplate out.

the tool against

(30)

thirty

surface,

above)

shown

10

/i,i'i',i'lV

1t

lM;\l,i

$

pull

oui the baseplate untilthe

top of the booster magazine

protrudes

tool.

e) Remove the entire booster

magazine

carefully dispose of it by

ing il in a container of water

or oil.

other boosters on the magaztne.

4. Always unload the tool

from the top of the

from

the tooland

Do not aitempt to

12

N,,VVJ..ll

plac-

use

r

t-r

13

o

before:

Work breaks

Changing

Cleaning and servicing

Storing at the end of the day.

-

Never leave

5.

unattended.

6. Use the

whenever

7. Always wear safety

and

powder-actuated

parts

a

rubber

possible.

hard hat when

ll

ll

loaded

tool

stabilizer

goggles

operating

tools. Use ear

8

-ri

-l

protection

confined areas.

B. Do not attemptto use a

defeclive

9. Keep boosters of ditferent

types segregated and clearly

identified.

10. Only use auihenlic Hilli

fasleners.

!n

your

tool.

when working in

tool.

boosters, and

parts

Application restrictions

1 . Never attempt to

an angle to the work surface.

2. Neverfasten through

hole unless adequate

drilled

guidance is

Never fasten into a spalled

3.

area on concrete.

fasten at

a

provided.

Warranty

I his new fasrenrng lool is a

developed through study and research

fastening methods and

has been taken in the manufaciure of the tool to assure

caution

that it complies

The Hilli tool is warranted lor 5

from the date of shipment.

material

accordance with Hilli instructions; repairs

by

damage

been abused or misused: and lhe defective

r

workmanship,

or

persons

olher than

is not due to normal wear and tear; the

rll

applications. Every reasonable

with Hilti's

authorized Hilti service

4. Never make fastenings in an

explosive orflammable

pre-

atmosphere.

5. Never attempt

very hard or brittle materials,

such as cast

suriace-hardened

quality product

standard

years

The warranty is against defects in

provided

of Hihi.

into

construction

quality.

of high

to the original

that the system

have not been made

iool is returned

to lasten into

glazed

iron,

or high-

lt has

purchaser

is

used

personnel;

tool has not

pre-

tile,

been

in

tensile-strength steel,

block, live rock, face brick, or

hollow

lile.

6. Never fasten to concrete

closerthan

unsupported edge or corner,

unless a special

to the

Center. Parts which are found lo be defective in material or

workmanship will

the cost of shipping and insurance. Under no circumstances will

Hilti be obligated

expenses in connection with or by reason of the use or inability

to use the toolfor any

This warranty, which is

other

and oftitness for

warranty or

2 inches trom an

local Hilti representative for forwarding to the Hilti Repair

wafianiies,

guarantee

glass

jig,

guard,

replaced or repaired without cost

be

for

consequential or other damages,

purpose.

expressed or

particular

made by

fixure is

used orthe specific

application is approved.

7. Minimum iastener

in concrete is 2%".

8. Minimum fastener

in steel is 1".

or

given

expressly and in lieu of all

implied, of merchantability,

purpose,

conslitutes the only

Hilti.

spacing

spacing

other

losses

lhan

or

l\rinimum

9.

steel is %i'.

thickness of base

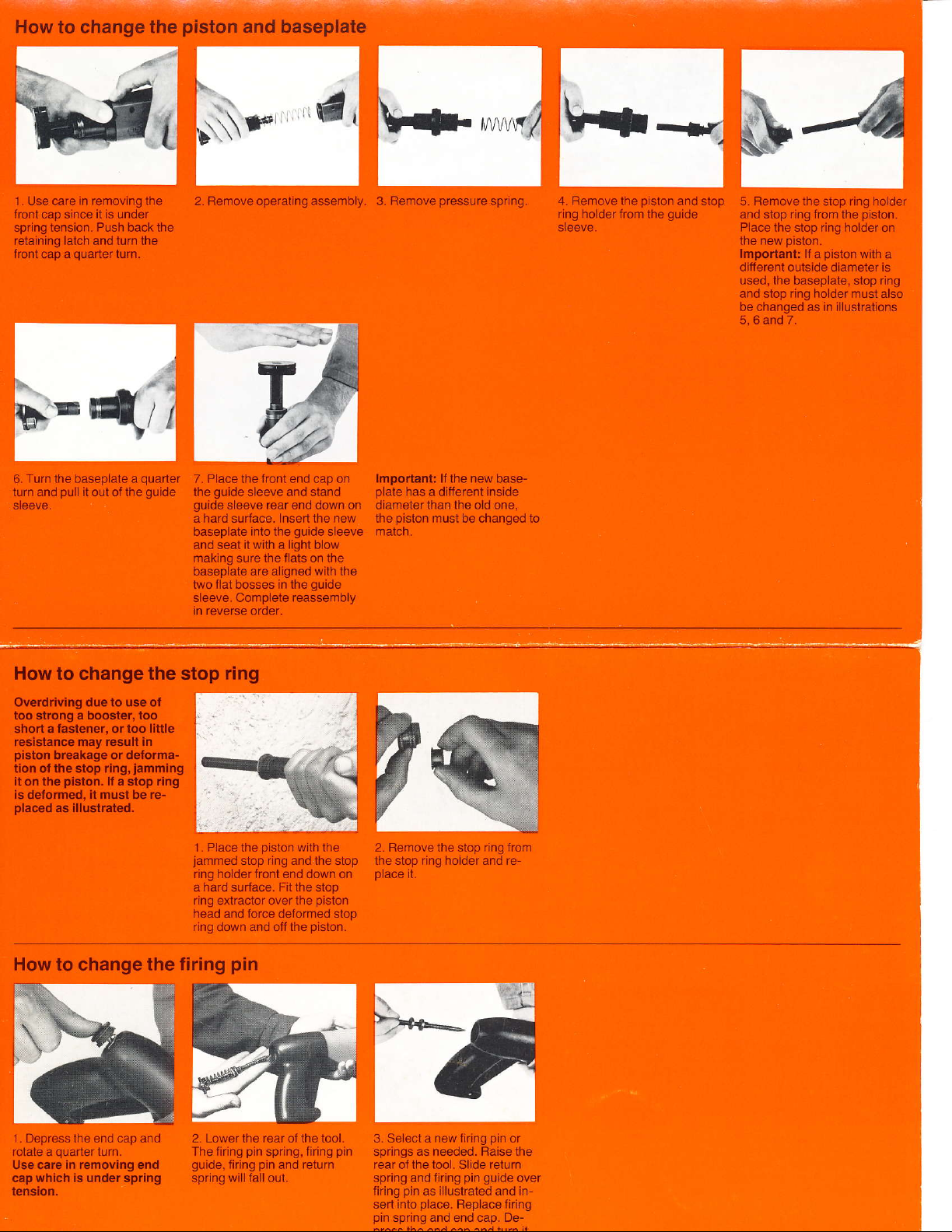

Loading...

Loading...