Page 1

iil|tililtilil||tilt il||ililtililil]

309899

0X350

Page 2

Technical

Hilti

The

iuJt"ning

oiinciote.-trrus

As wiitr all

cirtridg"

tasteniriq

ii,J"ijirirnunuiiJtul"O

fdsteninb

tfris con"Oition

iil*r]g.-

may

there

parts

Spare

ifi" rsbr/o*net

prJ""ii,r"d O"rCribed

bn/care and

negatively

Safety

Failure

Awamings

T Neuer

on

reoresentative

Z. n]ilr:vs

ooer6tinq

3. Njever odint

;.it6;; b;;.;'ttre

bodY.

ihe'operator,

5.

table

Safety

6. Us-e'the

7.f',leuer

nlnq-cfeininq

dari

e.w6iiear orotectors

descriPtion

is a

DX350

T""hnology'Manual).

providiriq

powder-actuated

[rogramme

ri,itfr"tfris

and

affect

application

id bbserved.

hour.

#|.

risk of

be a

the tool

of

maintenance)

functional

system

precautions

these

follow

to

to use

aiempt

,se

its

brotective

precautions

before

associated

ahd

for assisiance'

iooiJtiictty

ihe

,-sei

instructions

tool

the

and any

goggles

stabiliser/guard

loaded

a

leave

and

work

powder-actuated

an

form

ft,i.

explosion.

thes6

in

precautions

at

muizie

servicing,

breaks,

The

optiinum

the

tools.

.technical

a

only

can

pioducts

or

tor it.

recommendations

recommended

The

not approved

is

tool

replace

may

opeiating

useid.

be

should

of the

safety

could

without

tool

the

safety

in accordance

always

should

yourself

or

the

of

persons in the

other

helmet

a

and

whenever

tool unatteniled.

before

before

and

using

when

DX350

working

of

tool'

assured

be

parts listed on

the

inhructions

Any

tool.

result

first

precautions. Contact

be kept

bystander'

any

tool-aghinst

while

possible'

putting

changing

tool

the

fastening

and

magazine,

This

unit".

if the

equivatent

of

given

by

maximum

for use

(disass6mbly/assembly/operati-

unauthorised

other

personal injury'

in

having

the

with

with

your

immediate

tool ls

the

unload

Always

ihe

parts'

indoors

designed

tool

works

for

the

on

fastener

means

fasteners

quality,

Hilti are

fastening-.rate

under

page

received

operating

tool'

the

hand

vicinity.

In use'

the

away

tool

in enclosed

or

driving

well-proven

safety'

programme ano

troubleTree

that

and

are

appllcaole^rr

only

conditions

(parts

1-8)

2

manipulations

prgeel,

your local

instructions'

part

oiher

or

must

before

tool

the end

at

spaces.

nails.(see

piston

cartridges

uTdr

Jh9

ls.5UU

where

Only

may

il:liu-cli9l

Hlltl sales

The

your

of

wear

begin-

of

g.Always

used.

Keep

10.

workino

f f .Af*avJf'ofO

which

rz.Arwavs

equivalent

13. N6ver

14. lf a

r

. iiif,!

-

I cvcle"

-

the

tS.

fO.Aiwavi-Xe'ep

f Z. tjo

t S.Aoolicaii6n

ig.ij!i.i"

20. bo

Zi. tteuer

General

22.

Z5.f66ippl""ble

sul-

Throuqh-shot

iiili;i;

excess

Contact

if iJiateW

the

;;*t

6i"oirig

bnd

check

attempt

Never

arms

the

with

the fastener

u.Jg"nJln"

quality.

attempt

cartridqe

tool aqainst

th6

Keeo

durtlOSe

care

tat<inq

q6.

itiio Jno

Ne-vliattempt

mended

wher-i

tool

ooint

fastenings

Never

those

coCking

tool so

the

up

Use

bispose

bv Hilti,

in use.

not

not operate

is approved

recommendations

,ii"S

where

disassemble

not

exceed

per

notes

attempt

relating

and

ti;ipie

power.

onvlng

pressure

device

*orking

;in'

ii iguin"t

movement

the tool

that

to

when

fleied

you

if

the tool

toot

ihe

misfires

fasteners

ferpendicular

is to

Hilti

pry

tci

a

or

fails

ititt

not

it is

t6at

that

the remaining

of

to drive

g.

when

e.

the tolol

tool

the

such

for

toot,

169

are

the tool

recommended

the

The

hour).

to redrive

national

to accident

ricochet

emptoyiro

device

satety

prev6nts

surface.

workiry

ifrE

of 16

is undamaged

incomplele

use an

the tool

feel unwell.

be driven.

fasteners,

cartridge

to ignite.

fails

working

to fir6,

pointed

magazine

the

cartiidges

it in"such

fastener

a

using

cartr-idges

and

explosive

in an

use.

must

make sure

to be

while

may othenruise

tool

the same

regulations

prevention'

prevention

results

loaded

the

The toot

sudace,

mm.

is fired

to the

cartridges

magazine

from

proceed

surface

withdraw

towards

way

a

in an

the

always

that

driven.

it is

maximum

fastener.

in tow

tool

can only

overcoiting

and

malfunclioning

or

(do

working

as

seconds'

for 30

tool

the

your

is transpotted

strip

the strip.

in

it can

that

existing

DX-Kwik

closed

in a

or flammable

be observed'

n6 one

hot.

fastener

overheat'

always

must

fastener

from

be

fully

straighten

not

surface

spare

and

or

strip

tollows:

from

or

body

Remove

neither

be

hole,

system'

container

atmosphere,

standing

be

vetocity

fired unless

being

firedafter

a cocking

functional

tool'

tne arms)'

and

parts,

tool'

the working

bystanders'

the next

to

the used

reused

except

in a

behind

rate

driving

observed,

and

been

it has

of at

force

before

material

those

or

surface,

canrlo-

cartridge

nor

recom-

where

safe

unless

or below

(number of

particularly

dissipation

pressed

it is

cocked_by

least

it

stop

of

mis-

place

the

the

110

is

in

of

N

Page 3

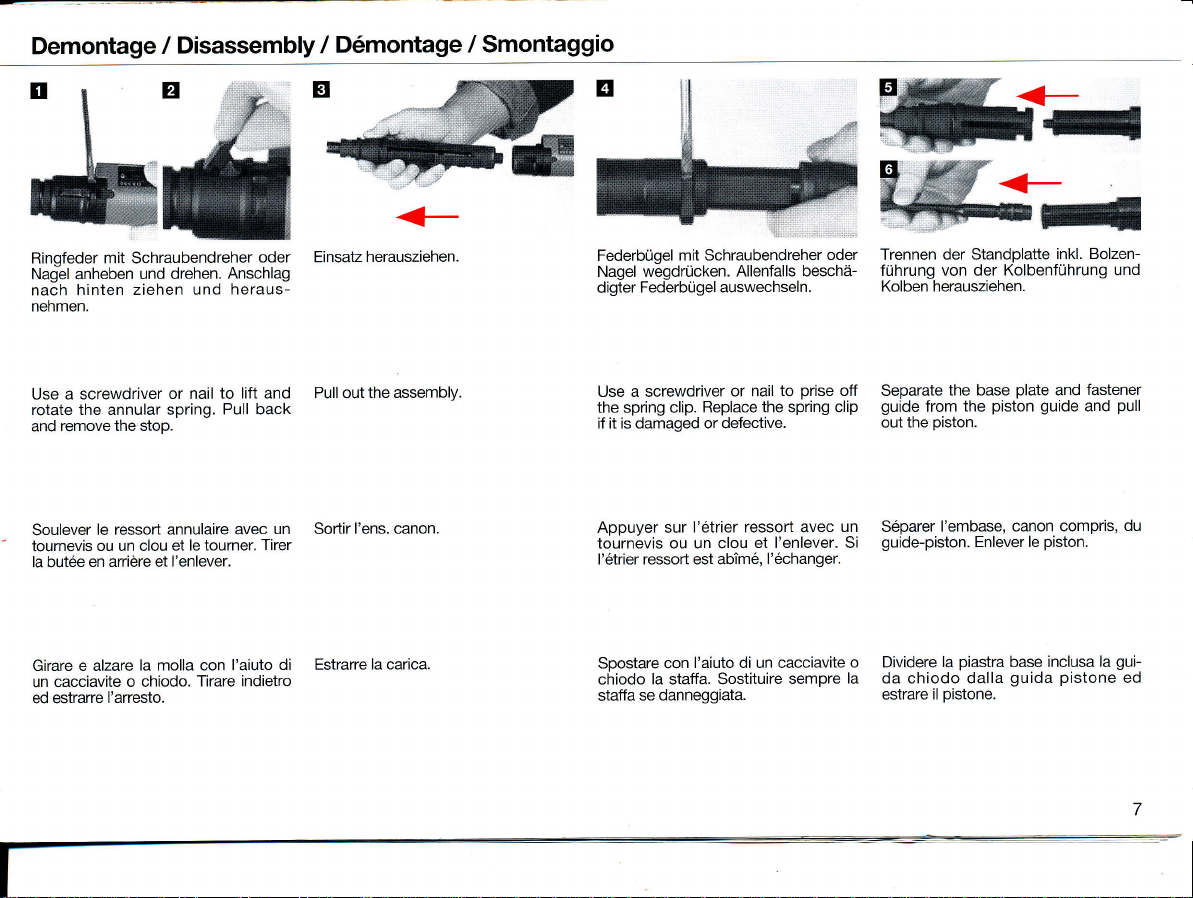

Disassembly /

Demontage

Ringfeder mit Schraubendreher

Nagel anheben

nach hinten

nehmen.

/

und drehen.

ziehen und

Anschlag

heraus-

oder

D6montage

+

herausziehen.

Einsatz

I Smontaggio

Federbugel

Nagel wegdn-icken.

digter

mit Schraubendreher

Federbugel auswechseln.

Allenfalls beschd-

oder

Trennen der

frihrung von der

Kolben herausziehen.

Standolatte

inkl. Bolzen-

Kolbenfuhrung und

Use a screwdriver

rotate the annular spring.

remove the'stop.

and

Soulever le

toumevis

la but6e

Girare e alzare

un cacciavite o chiodo.

ed estrarre

ou un clou et

en anidre et

l'arresto.

or nail

ressort annulaire avec

le tourner. Tirer

I'enlever.

la molla con

Tirare indietro

to lift and

Pull back

Pull out

un Sortir

l'aiuto di Estrarre

the assembly.

l'ens. canon.

la carica.

Use a screwdriver

the spring clip.

if ii is damaoed or defective.

Appuyer sur

tournevis ou un clou

l'6trier ressort est abime,

Soostare con

chiodo la staffa. Sostituire

staffa se

danneggiata.

or nail

Replace the spring clip

l'6trier ressort avec

l'aiuto di un cacciavite

et l'enlever. Si

l'6changer.

prise

to

sempre

off

Separate

guide

out the

un

S6parer

guide-piston.

o

Dividere

la

da chiodo dalla

estrare

piston guide

the

Enlever le

piastra

plate

and

piston.

base inclusa

pistone

guida

the base

from

piston.

l'embase, canon compris,

la

pistone.

il

fastener

pull

and

gui-

la

du

ed

Page 4

Montage

Bolzenfiihrung

oen.

fastener

the

Slide

plate.

Enfoncer

le

AssemblY

/

in Standplatte

guide into

dans

canon

einschie-

the

l'embase'

R"-@

/

%'%

Nuten

piston

grooves for

guide-piston

le

gories

in

ftir

guide into

pdur la but6e

base-

Kolben

fiihrung

the

Slide

far as

as

Enfoncer

guide.

zum

bis

einschieben'

piston

into

go'

it will

le

Piston

Ende

the

fond

d

Kolben-

in

piston

dans

guide

son

Kolbenftihrung

schieben.

ubereinstimmen.

the

Slide

plate.

The

alignment.

in

be

Enfoncer

Les

se.

align6es.

6tre

Standplatte

Anschlag

the

miissen

the

stop

dans

ein-

base-

must

l'emba-

doivent

Federbugel

the

Press

Enfoncer

menr.

in Aussparung

clip

spring

ressort

l'6trier

into

drilcken'

groove'

the

dans

l'6vide-

Inserire

base.

guida chiodo

la

nella

piastra

lnserire

guida.

sua

fino

in

fondo

pistone

il

nella

Inserare

base.

devono

guida

la

stanalature

Le

coincidere.

pistone

nella

per

piastra

I'arresto

lnserire

la staffa

nella

rientranza'

Page 5

Einsatz

in das

dass die Nut mit

ubereinstimmt.

Gerdt so einfr-.ihren,

der Anschlagoffnung

tr@l

SF.

r-I_^l-

rrff

Anschlag

Schraubendreher

-=-

zenen.

einsetzen und Ringfeder

oder

T

Nagel dariiber-

mit

Handhabung/Operation/ManiemenVManutenzione

Einsatz

bis zum

und wieder

vorgang).

Anschlag

zurr-ickstossen

ausziehen

(Repetier-

Nagel einschieben,

Bolzenfiihrung

gehalten

bis

Rondelle in

wird

der

Insert the

tool

ning

Introduire l'ens.

de

de la but6e.

Inserire la

che la

tura

complete

so that the

for the

stop are in alignment.

telle

sorte

carica nell'attrezzo

scanalatura

del dispositivo

assembly into the

groove

and the

canon

que

dans l'appareil

la

fente l'ouverlure

coincida con l'aoer-

di arresto.

ope-

in modo

Fit the stop

nail to

into

lntroduire la

ressort

nevis

Inserire l'arresto

molla

ooo.

and use

pull

the

place.

ou un clou.

con

annular spring over it

but6e et faire

annulaire dessus

l'aiuto

a screwdriver or

avec un tour-

e sovrapporgli

di un

cacciavite o chi-

oasser le

Pull

out the

go

and then

(cocking

/ cycling

lmprimer

vient.complet

menr).

la

Estrare

la carica

rimandarla indietro

petibile).

assemblv as far

push

it

6ack into the tool

action).

un mouvement

d l'ens.

canon

fono al suo

(orocedura

as it will

de va-et-

(arme-

arresto e

ri-

lnsert

a nail.

is held in

Enfoncer

delle tienne

Inserire

della viene trattenuta

Push it in

the fastener

le

clou

bien

il chiodo,

jusqu'd

dans le canon.

fino

until the washer

guide.

que

ce

la ron-

quando

a

nella

guida.

la ron-

Page 6

Handhabung

/ Operation / Maniement

a

Manutenzione

/

Kartuschenmagazinstreifen

ben, bis mit

Insert a cartridge

tridge strip in

is flush with the

Enfoncer

cadouches en-dessous de la

Inserire il nastro dei

quando

pade

der Griffunterseite btlndig.

Push the

strip.

the

until

end of the strip

base of the

ras la

d

bande-chargeur de

lo

stesso

inferiore dell'impugnatura.

propulsori

non

d alla

einschie-

grip.

poign6e.

fino

pari

con la

Warnung!

Bolzenfiihrung nie mit

fldche

oder iiber die

zurtickziehen;

car-

Caution!

Never use the

push,back

never

of the nail/washer. This could

sent a risk of iniury to the operator!

Attention:

jamais

Ne

paume

la

la rondelle

blesser!

Attenzione!

a

Non spingere mai indietro la

pistone

sopra

lo di lesioni!

Verletzungsgefahr!

the fastener

attempt to

repousser le

la main

de

du clou

palmo

con il

la rondella

palm

pull

del chiodo, Perico-

Hand-

der

Nagelrondelle

of the hand to

guide

it

back by way

canon avec

par-dessus

ou

pour

6viter de se

mano

della

and

pre-

guida

Gerat senkrecht auf

pressen

Hold the tool at right

material in which,the

driven,

sudace and

Appuyer l'appareil

lairement

ner la

Posizionare l'inchiodatrice

colarmente alla suoerJicie di lavoro e

o

azionare il orilletto.

Abzug

und

press

pull

d la surface de tir et action-

d6tente.

Setzfldche an-

bettitigen.

angles

fastener is to be

the muzzle against the

the trigger.

perpendicu-

bien

to

the

perpendi-

Page 7

Wartung

Pflege

Die foloenden

ihe

N;i6v;;1;;"p6;;i

und

foil,rwing

Teile

pads

fJi66r"ntip"rti

sind

must

ci_dessous

devono

/ Gleaning

mitgeliefertenReinigungsblirsten

mit den

cleaned

be

es!-ie

t,aide

d

pulite

using

de-s

con

the

brosses

lo spazzolino

and

brush-es

fournies

seruicing

supplleo'

avec

in

fornito

Nettoyage

/

zu sdubern'

..

I'appareil.

dotazione'

entreHeryTulizia

et

manutenzione

e

Bolzenfiihrung

lnner

lnt6rieur

Interno

I

I

N

Das

The

L,appareil

i,"iti*i"

surfaces

du

guida

Geriit

shourd

toor

innen

the

of

canon.

chiodo

entweder

sollte

be

Ctre

doit

oourenoe

a

Kolben

sudaces

pro

Outer

Ext6rieur

Esterno

woche

fois

,n"

_oder

J univorta

guide

fastener

einmal

"r"un"oion"6'J*"briolitt",

nettoye

u"rur"liriiiJ'u'r-rn"no

i,

n1oin"

aussen.

du

Piston.

pistone

nach

targeh-umo6r

a

par

""*1uin"

of

alla

the

.ieder

Piston

grosseren

of

o, ip6s

settimana

E

w

l,

Kolbenfiihrung

sowie

lnner and

ouide

6artridge

Int6rieur

int6rieur

Anzahl

fasteners.have

un

dopo

o

certain

ca.

nombre

''i,

aussen

und

innen

Kartuschenlager

outer

the

and

chamber

et ext6rieur

chambre

la

de

esterno

ed

lnterno

come Dure

propulsori.

gesetzter Befestigungselemente

5000

been

spari'

l'interno

driven

tirs

de

innen.

surfaces

inner

(env

of

surfaces

guide-piston et

du

d cadouches.

guida

della

dell'alloggiamento

(approx'

5,000

5000

the

pistone

fixations)

Gehiiuse

piston Inner

the

of

Int6rieur

lnterno

(ca.

5000

fasteners)'

innen'

ofthe

surfaces

du boitier'

carcasso

Befestigungen)

housing

gereinigt werclen'

11

Page 8

Stcirungen

Wiederholte

Stark unterschiedliche Eintreibtiefen:

und

Behebung

ziehen.

Eventuell

rung

aus. Olen Sie die Kolbenfiihrung

und Standplatte mit dem Hilti

Sprav.

Anomalies

Anomalies

Percussion rat6e:

Nouueau

rat6

et

comment y rem6dier

(perc

Diminutionbrusq@

Clous enfenc6s trds diff6remment:

ffitffi

Comment y rem6dier

Armer compldtement

sodir compldtement I'ens.

Huiler

6ventuellement I'embase

trds

s'il est

piston

d6form6. Huiler le

et l'embase

I'appareil, c.-a-d.

avec du sp'rav Hilti.

canon.

ouid5-

-

et

Malfunctioning

Malfunction

Misfire:

Reoeated

Widely varying

Stiff cycling act

depth of

and remedies

penetra

Remedies

See "Cadridge misfire".

assembly all the way. lt may be

necessary to lubricate the baseplate

it is badly deformed.

lubricate the

ptate.

piston guide

and

slightly using Hilti

ng clip and replaceltll

piston guide

Use

Hilti

spray

and base-

Problemie

guasto

Tipo di

Accensione

Ripetizione accensio

prestazione

La

sensibilmente:

to

Procedimento

soluzioni

a vuoto:

di carica lento.

Rimozione

del

Vedi accensione a vuoto

I'altrezzo.

fondo, ciod estrarre

carica. Eventualmente

base e la

oesante: Controllare la

deformata,

base

Hitti.

Hitti

guida

sostituirla. Oliare la

guida pistone

la

e

guasto

di un

di carica a

completamente la

oliare la oiastra

pistone

con lo

staffa e, se d molto

con lo spray

propul-

spray

piastra

Page 9

Garantie

garantiert,

Hilti

von Material-

se Garantie

dass das

Hilti Bedienungsanleitung

und

wird,

von

kaufsdatum (Rechnungsdatum)

dass die technische

d.h. dass nur

material, Zubehor-

andere,

dem Gerdt verwendet

Diese

Reparatur

defekten

schleiss

Garantie.

Weitergehende

geschlossen,

nationale

Insbesondere

telbare

Mangelfolgeschdden,

Kosten im Zusammenhang

wendung

der Verwendung

einen Zweck.

rungen

einen

drticklich

FLir Reparatur

und/oder betroffene

Feststellung

Hilti Marktorganisation

Die vorliegende

Garantieverpflichtungen

ersetzt alle frllheren

Erkliirungen,

Verabredungen

oder Fedigungsfehlem

gilt

Gerdt

gehandhabt,

dass alle Garantieanspruche

5 Jahren fLlr

qualitativ

Garantie

oder den kostenlosen

Teile. Teile,

unterliegen, fallen

Vorschriften

oder mittelbare,

oder wegen

ffir Ven rendung

bestimmten Zweck

ausgeschlossen,

des Mangels an

schrift lichen

gelieferte

dass das

unter

der Voraussetzung,

in

Ubereinstimmung mlt

gepflegt

das Gerat ab dem Ver-

Einheit

Original Hilti Verbrauchs-

und Ersatzteile

gleichwertige

werden.

umfasst die kostenlose

die dem normalen Ver-

Anspriiche

soweit nicht

entgegenstehen.

haftet Hilti

der Unm6glichkeit

des

Gerates fiir irgend-

Stillschweigende Zusiche-

betreffend

oder Eignung

oder Ersatz sind

Teile unvezrjglich

zu sender.

Garantie

umfasst samtliche

seitens Hilti

oder

oder mundlichen

Garantien.

Gerat frei

ist. Die-

richtig

eingesetzt

gereintgt

und

innerhalb

erfolgen

gewahrt

Produkte mii

Ersatz der

nicht unter

sind aus-

zwingende

nicht fi.ir

unmit-

Mangel-

Verluste

mit der Ver-

werden aus-

die zustandige

gleichzettigen

und

wird,

oder

diese

oder

oder

Gerat

nach

und

der

fi.ir

Warranty

Hilti warrants

defects in material

warranty

ted and handled

viced

Hilti

claims are made within

from the daie

the technical

means that

components

ducts

the

This warranty

repair or replacement

Pads requiring

result

ed by this warranty.

Additional

stringent

exclusion.

ted

sequential damages,

in connection

use of,

purpose,

tability

are specif ically

For repair

related

the

marketing organization

This constitutes

regard to warranty

or

conremporaneous comments

written

that the tool

rs valid

properly

Operating Instructions,

of equivalent

tool.

of normal wear

for direct, indirect,

or

lmplied warranties

or fitness for

parts

defect to the

agreements

and workmanship. This

long

so

correctly, cleaned

and in accordance

the

of

sale

system is maintained.

only original Hilti

and spare

quality,

provides

of defective

repair

or replacement

and tear are not

claims are

national rules

particular,

In

losses

with, or by reason

inability

to use the

a

excluded.

or replacement,

immediately

address of the local

provided.

Hilti's entire

and supersedes

concernjng wananties.

supplied is free

as the tool is

years

5

(invoice

parts,

the free-of-charge

excluded, unless

Hilti is not

incidental

particular

send tool and/or

upon discovery

opera-

and ser-

with the

all warranty

for the tool

date), and

consumables,

or other

may be used in

parts

only.

as a

cover-

prohibit

such

obliga-

or con-

or expenses

of, the

tool for

of merchan-

purpose

obligation with

all

and orat

prior

Garantie

of

Hilti

de matidre

est

utilise et mani6

revise

ti,

garantie

pour

This

vente

systdme technique

pro-

sous reserve

I'appareil

pidces

tres

Cette

r6paration

gratuit

vre

normate.

Toutes autres

pour

nationales

pas.

tenu

any

tions,

rectes

cause

utiliser l'appareil

soit. Hilti exclut

of

ties implicites

Hilti

l'aptitude

Pour

envoyer I'appareil

cern6es d I'adresse

or

Vente Hilti la

aprds d6couverte

Telles

matiere

tes

temporaines

oraux

garantit

l'appareil

ou de fabrication.

octroyee e condition

conformement

que

les appareils,

(de

produits

garantie

des

pas

autant

En

responsable

pertes

de I'utilisation

toute r6paration

sont les seules

d6clarations

ou ecrits concernant

correctement. nettov6

toutes

r6clamations

soient adress6es

de rechange

les

particulier,

ou cons6cutives,

a compter de la

la date

de la facture)

d'utilisation

de consommables,

qualit6

de

se limite rigoureusement

gracieuse

pidces

d6fectueuses. Elle ne

pieces

pr6tentions

que

des

imp6ratives

ou d6penses

pour quelque

en

concernant

pour

un but

de votre

plus proche,

du d6faut.

garantie,

de

ant6rieures

de meme

livr6

contre tous vices

Cette

que

l'appareil

au mode

d'empl6i Hil-

concernant la

dans les

soit maintenu,

d'origine Hilti

6quivalente.

ou

soumises A

dispositions l6gales

Hilti ne

de toutes

ou de I'incapacit6

particulier

bien

et/ou les

obligations

lesquelles

et

exclusive dans

composants

au remplacement

une usure

sont exclues,

ne s'y

opposent

saurait 6tre

d6t6riora-

directes, indi-

en relation

but

les

l'utilisation

pr6cis.

ou tout

6change,

pidces

Organisation de

imm6diatement

d'Hjlti en

annulent tou-

ou con-

que

tous accords

des

oaranties.

garantie

soit

5 ans

date de

que

c.-a-d.

ou d'au-

a la

cou-

ou d

que

ce

garan-

ou

con-

Garanzia

Garantiamo

dalla

data di vendita

garanzia

La

et

di fabbricazione

pulito

usato,

secondo

vengona

le

Condizione

vengano

La

et

sostituzione

riparazioni

sti ad usura normale

ni di

devono

to

Hilti

in nessuna

o spese

conseguenziali

causa

zo

cificatamente le

commercializzazione

qualsiasi

a

Per le riparazioni

Vostro

danno, all organizzazione

Questi sono

di

tutte

poranee

cernenti le

le istruzioni

effettuate

non

autorizzate.

usati solo i

garanzia

di

garanzia.

essere richieste

e a conoscenza

pud

non

dirette, indirette,

di uso

per qualsiasi

scopo.

attrezzo,

garanzia,

le dichiarazioni

e tutti

garanzie.

i

questo

copre

tutti i materiali

patto

a

e sottoposto

preliminare

si limita rigorosamente

gratuita

parti

difettose- I

Le riparazioni

dell'utiltzzatore-

essere tenuta responsabile

circostanza

in

inabiliti

o

scopo, Hilti

garanzie

e/o sostituzioni

subito dopo

gli

unici obblighi

quali

annullano e

gli

accordi orali

per

attrezzo

(data

per

modifiche o riparazioni

della

prodotti

dell'apparecchio

non rientrano

connessione

antecedenti

di fatturazione).

l'attrezzo

che

a manutenzione

I'uso

e che non

garanzia

indicati

pezzi

in

non apoena

per

danni,

accidentali

all'uso

dell'attrez-

esclude spe-

implicite

idoneiti

e

aver scoperto il

piu

Hilti

vicina.

Hilti in materia

sostituiscono

o contem-

o scritti con-

un 5 anni

difettosi

sottopo-

nei termF

garanzia

con o a

inviate il

venga

d che

da Hilti.

alla

e alle

il difet-

perdite

per

per

o

o

la

un

IJ

Loading...

Loading...