Page 1

Operating instructions en

DS-WSS 30

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 2

2

ORIGINAL OPERATING INSTRUCTIONS

Contents

General information 3

1. General description and technical data for the DS-WSS 30 wire saw 4

2. General warnings 6

3. Warnings and safety precautions for the DS-WSS 30 wire saw 7

4. D-LP 32 (30) / DS-TS 32 (30) modular saw system 10

5. D-LP 32 (30) / DS-TS 32 (30) / DS-WSS30 modular wire saw system 10

6. Setting up the wire saw system 11

7. Basic applications 14

8. Diamond wire store 19

9. Instructions for connecting Hilti DS-W 10.5 diamond wire 20

10. DS-WSS 30 wire saw system - checks, operation, and sawing procedure 24

11. Care and maintenance 27

12. Troubleshooting 28

13. Disposal of the DS-WSS 30 / D-LP 32 wire saw 32

14. Manufacturer's warranty – tools 33

15. EC declaration of conformity (original) 34

Congratulations!

On purchasing the Hilti DS-WSS 30 wire saw as an addition to the D-LP 32 (30) / DS-TS 32 (30) wall saw system, you

have acquired a quality product that provides the highest level of performance, safety and reliability. Uncompromising

quality assurance during its manufacture ensures that the system will have a long service life.

This manual describes the operating procedures for the DS-WSS 30 only. The saw system functions only in conjunction with the Hilti D-LP 32 hydraulic power unit. Please refer to the D-LP 32 / DS-TS 32 operating instructions for information about operation of the power unit.

These operating instructions are intended for the use of concrete cutting service contractors and their experienced personnel, referred to on the following pages as “the operator”. Before operating the Hilti D-LP 32 (30) / DS-TS 32 (30) /

DS-WSS 30 wire saw system, the operator must read and understand these operating instructions and receive training from a Hilti specialist.

Thanks to its modular design, the DS-WSS30 wire saw system can be quickly and easily fitted to the standard saw

system. Its new design concept, offering maximum convenience and safety in use, opens up an almost endless range

of applications in demolition, cutting and remedial work in steel reinforced concrete, masonry and stone. The variable

oil flow rate of the D-LP 32 (30) / DS-TS 32 (30) wall saw system used to power the wire saw ensures smooth, gentle

starting, and automatic regulation of the wire sawing process and greatly reduces strain on the operator.

This system therefore provides the prerequisites for efficient, economical and safe operation. We would like to wish you

every success in your work and thank you for placing your confidence in Hilti products.

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 3

3

General information

The operating instructions must be read carefully

before the equipment is put into operation.

Always keep these operating instructions with the

equipment.

The wire saw system should be handed over to

other persons only complete with the operating

instructions.

Safety notices and their meaning

DANGER

Draws attention to imminent danger that will lead to

serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation

that could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation

that could lead to slight personal injury or damage to

the equipment or other property.

NOTE

Draws attention to an instruction or other useful information.

Explanation of the pictograms and other information

General warning Warning:

electricity

Warning:

avoid hand injuries

Wear protective gloves.

Wear safety footwear. Wear respiratory

protection.

Wear ear protection.

Wear eye protection. Wear a hard hat.

Warning signs

Obligation signs

Warning:

Risk of cutting injury

Return waste

material for

recycling.

Read the operating

instructions before use.

Symbols

A

Amps

V

Volts Alternating current

∅

Diameter

W

Watts

Hz

Hertz

n

o

Nominal speed

under no load

mm

Millimeters

/min

Revolutions per minute

rpm

Revolutions per minute

STOP

Stop

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 4

4

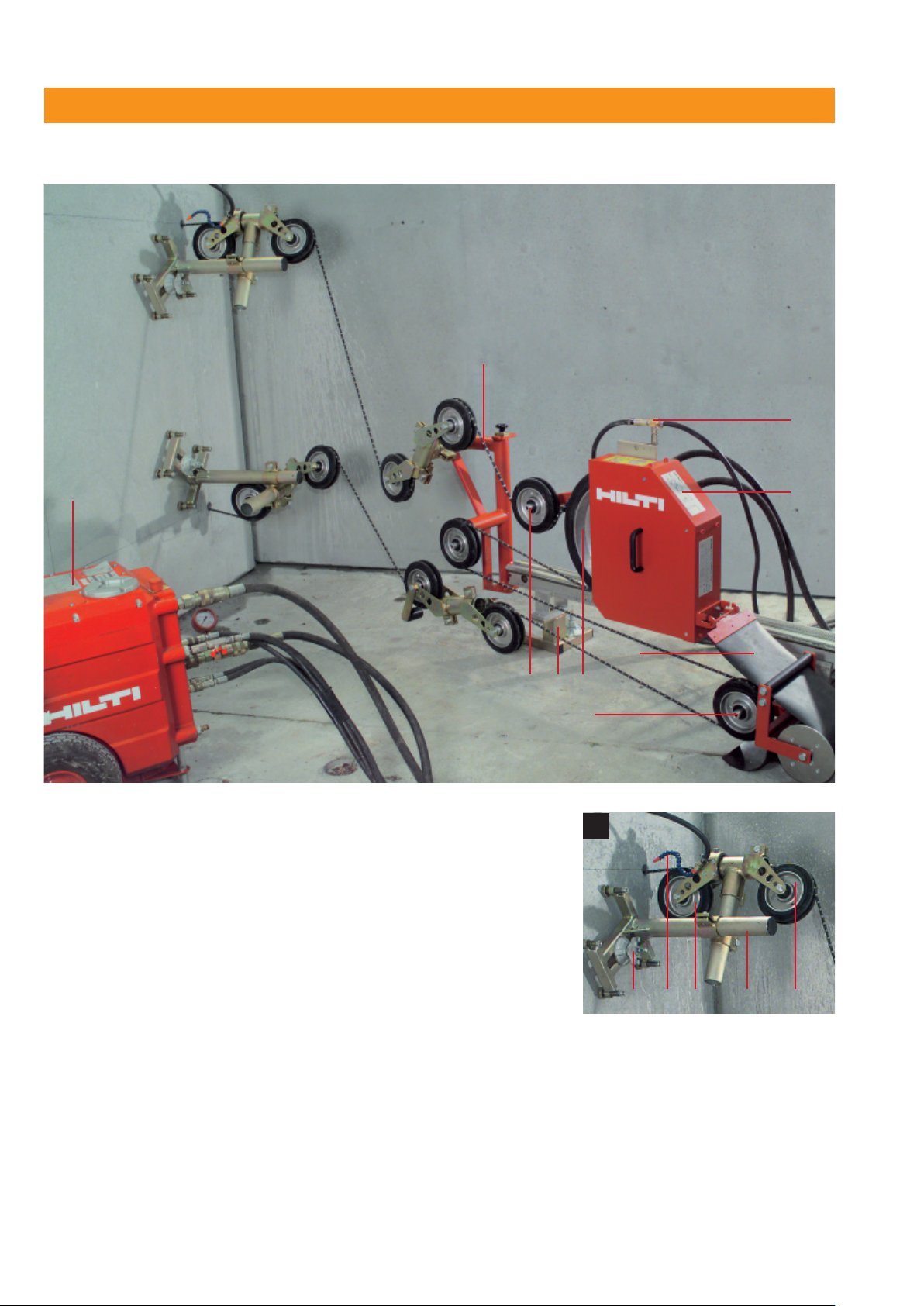

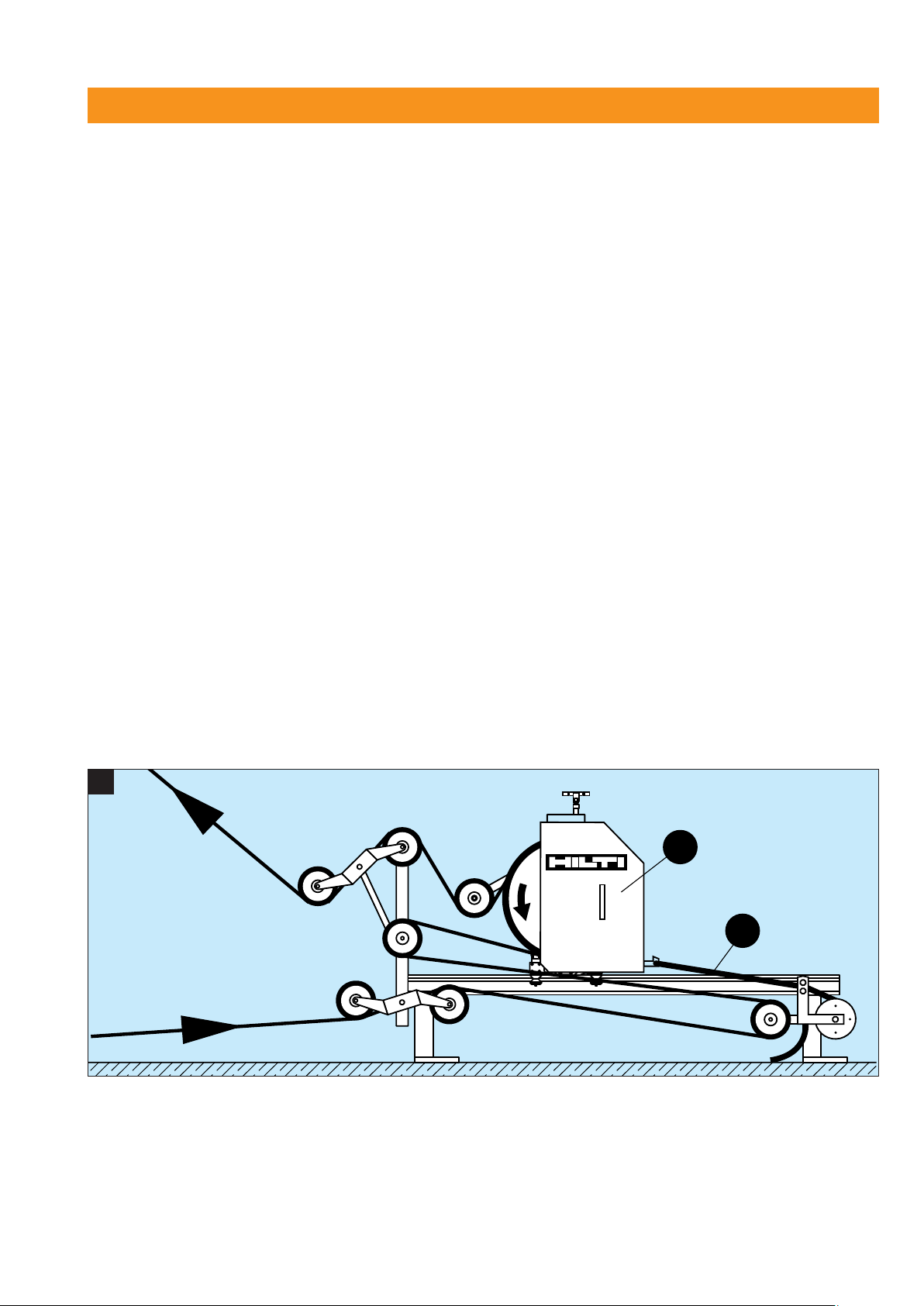

1.2 Single-pair pulley stand

Fastening spindle/nut for rail support or pulley stand

DS-WSSP single-pair pulley stand

Water supply to kerf

DS-WSW 200 guide pulley

DS-WSW 500 drive wheel

DS-WSTA tensioning arm

DS-WSWD wire distributor

DS-WSRP wire length adjustment pulley

DS-WSRF rail support (2×)

Drive wheel guard

Diamond wire guard

DS-WSWS water supply

D-LP 32 (30) power unit

1.1 System

1.2

1. General description and technical data for the DS-WSS 30 wire saw

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 5

5

1. General description and technical data for the DS-WSS 30 wire saw

1.3 Technical data

DS-DS 30

Drive wheel: 500 mm dia.

Guide pulley: 200 mm dia.

Speed (DS-TS 30, 1stgear): 800 r.p.m.

Cutting speed: approx. 20 m / sec.

Wire store capacity: 8 m diamond wire

Max. diamond wire length: 30 m

D-LP 32 hydraulic power unit

Rated power input at 63A 43 kW

Rated output 32 kW

Rated voltage 400 V / ~ 50 Hz, 3P+N+PE or 3P+PE

Ground fault circuit breaker (30 mA) in mains supply on site

Max. operating pressure 210 bar

Oil flow rate 30–100 l/min

Dimensions (L×W×H) 790×540×1090 mm

Weight 220 kg

IP protection code IP 44

Water cooling with 7 l/min. at max. 6 bar and water temperature 20° C

D-RC-LP32 remote control unit

Control voltage 24 V = (direct current)

Dimensions (L×W×H) 390×180×120 mm

Weight 2.2 kg

IP protection code IP 65

Cable length 10 m

Cable length with extension 20 m

Noise information (measured in accordance with EN 15027)

Wear ear protection!

Mean A-weighted sound power level LwA105 dB (A)

Mean A-weighted emission sound pressure level at the workplace LpA85 dB (A)

Uncertainty for the stated sound level: 3 dB (A)

1.4 Special accessories

Special stand with 140 mm dia. plunging pulley

Release pulley

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 6

6

2. General warnings

2.1 Don’t attempt to use the hydraulic saw system and DS-WSS 30 wire saw accessory modules without having

received the appropriate training from an authorised Hilti specialist.

2.2 Always use the hydraulic saw system in accordance with the wall saw operating instructions and supplementary

wire saw system operating instructions. The operating instructions must always be kept at hand. The instructions

on anchoring and securing the system must be observed.

2.3 Approval must be obtained from the site engineer or site management before sawing. Sawing work can negatively

affect the stability of a building or other structure, particularly when reinforcing bars or supporting members are

cut through. Ensure that there are no concealed gas, water, electricity or other supply lines in the area in which

sawing work is to be carried out.

2.4 The area in front of, behind or below the surface where sawing work or drilling is to be carried out must be secured

in such a way that persons or equipment cannot be injured or damaged by falling blocks of concrete or by concrete slurry. Where necessary, cores or blocks of concrete should be secured to prevent them from falling.

2.5 Operators and all other persons must stay clear of the area when a load is being lifted by a crane.

2.6 Concrete blocks with a weight of several tons may be sawn out with the Hilti saw. Measures for securing and

transporting these concrete blocks must be planned and implemented. Make use of the steel wedges contained

in the set of tools for securing concrete blocks. Keep the working area clean and tidy and cordon off openings.

2.7 National regulations and laws, as well as the operating instructions and the safety information applicable to

the accessories employed must be observed.

2.8 The D-LP 32 (30) / DS-TS 32 (30) / DS-WSS 30 saw system must NOT be operated in environments where a risk

of explosion exists unless special safety precautions are taken.

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 7

7

3.1 Make sure sufficient space is available for working safely. If possible, the wire saw should be set up on the floor

in an upright position.

3.2 Check the entire system, accessories, power unit, electric cables, hydraulic hoses and accessories for damage and

proper functioning before use. Wearing parts, accessories and safety-relevant devices, such as the diamond wire

drive wheel, return pulleys, diamond wire and couplings, diamond wire guard and drive wheel guard, end stop,

drive wheel mounting screw, hydraulic couplings, etc., must be checked particularly carefully. Check that all parts

have been assembled correctly and consider all other factors that could influence operation of the equipment.

Contact your Hilti representative or Hilti service centre if faults or deficiencies are found. Repairs to electrical parts

must be carried out by a qualified electrical specialist.

3.3 Metal anchors of M12 size should be used for fastening the DS-WSRF rail support and DS-WSSPP single-pair pulley stand. The fastening used must be suitable for the base material in question and must not work loose. Suitable

Hilti anchors are, e.g. HKD-D, HSA-A, HIT or HEA. If masonry is loose or crumbling, we recommend that through

holes are drilled and M16 threaded rods with clamping nuts used for fastening.

3.4 Fastening screws of at least 8.8 grade as per ISO should be used for the rail supports or, alternatively, use the

DD-CS M12 S-SM clamping spindle with DD-CN-SML quick-release clamping nut.

3.5 An end stop must always be fitted at the end of the rail to prevent unintentional advance beyond this point (prevents the saw head coming off the end of the rail).

3.6 It is essential that the specified checks are carried out before sawing.

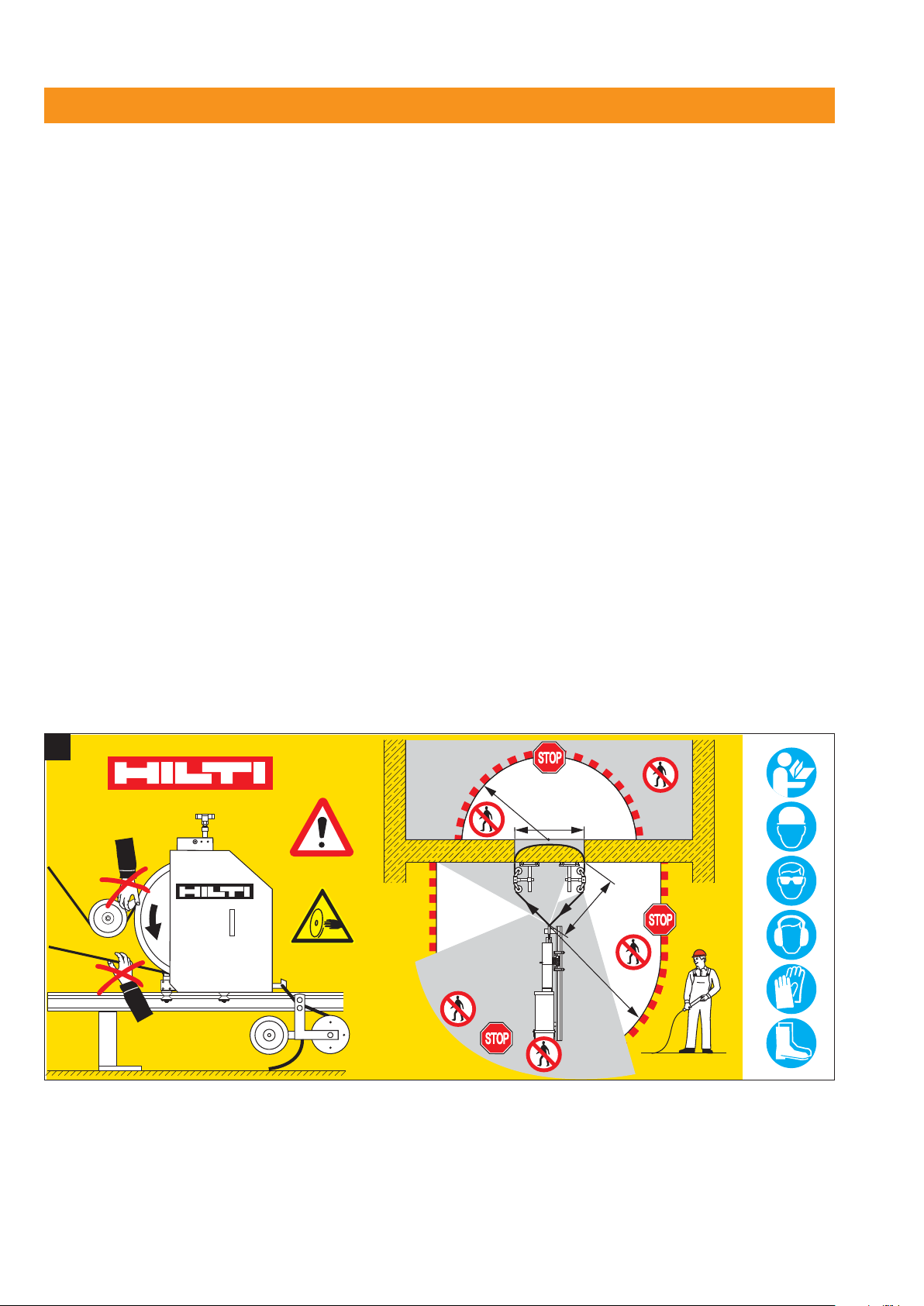

3.7 The drive wheel guard (see fig. 3.7, no. 1) and diamond wire guard (see fig. 3.7, no. 2) MUST ALWAYS BE FITTED

when the saw is in use. These guards prevent parts flying out in the direction of tension should the diamond wire

break. NEVER stand in a position in line with the diamond wire while the saw is running.

12

2

1

3.7

3. Warnings and safety precautions for the DS-WSS 30 wire saw

3.8 ■ Safety measures must be implemented in the area where sawing is taking place so that operators and

bystanders cannot be injured or property damaged by a broken sawing wire or debris that may fly off

during the sawing operation (wire connectors, diamond beads, spacing springs, small stones, sawing slurry, etc.). Safety measures must also be implemented in the area not directly visible to the operator, i.e. behind where sawing is taking place.

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 8

8

■ Persons must NEVER enter the danger area while sawing is in progress.

■ Always keep the free wire lengths between the drive unit and object being cut as short as possible

(max. 3.5 m) and mount guide pulleys at the wire entry and exit points in order to reduce the risk of

whiplash in the event of wire breakage. The whiplash effect causes great acceleration of the sawing

wire, resulting in parts of the wire lashing out or flying off with great force.

■ Make sure there are no objects such as scaffolding etc. within the wire whiplash area. In the event of

wire breakage, the whiplashing end of the wire may be deflected in an unexpected direction by such

objects.

■ The danger area has a radius of at least twice the free length of wire that would be unleashed in the

event of wire breakage (shown in yellow) and also includes the areas in the extended axes of the direction in which the wire is running (shown in gray). The danger area cannot be limited unless suitable

means of protection are employed (protective walls, curtains or wire guards etc.). The protective

devices must be arranged and mounted in a way that stops the wire lashing out in the event of wire

breakage and reliably prevents objects or fragments flying off.

■ The operator is responsible for cordoning off the area. If necessary, safety personnel must be posted

to prevent access to a wide area around the workplace

■ When setting up and operating the saw system and when removing parts that have been cut away,

always ensure that no persons are below the area in which you are working. Falling objects could

cause serious injury.

■ Children must be instructed not to play with the machine.

■ The machine is not intended for use by children, by debilitated persons or those who have received

no instruction or training.

■ Before beginning work, check the working area (e.g. with a metal detector) to ensure that no concealed electric cables or gas and water pipes are present.

External metal parts of the machine may become live if, for example, an electric cable is damaged

inadvertently. This presents a serious risk of electric shock.

3.9 ALWAYS SWITCH OFF THE WIRE SAW BEFORE ADJUSTING THE WATER SUPPLY. Readjustment of the water supply nozzle at the single-pair pulley stand or at any other position while the saw is running, in order to bring it into

line with the diamond wire, is STRICTLY PROHIBITED.

3.10 The wire length adjusting pulley (DS-WSRP wire store) must always be fitted, even when not in use. The flexible

wire guard can then be fitted in accordance with the instructions.

276377 05.06

r2=l2 x 2

l

2

l

1

r

1

=l

1

x 2

3.8

3. Warnings and safety precautions for the DS-WSS 30 wire saw

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 9

9

3. Warnings and safety precautions for the DS-WSS 30 wire saw

3.11 Never connect or disconnect hydraulic hoses while the power unit is running or while the hoses are under pressure.

3.12 Wear suitable clothing. Don’t wear loose clothing or jewellery which could become caught in moving parts of the

machinery. Wear a hard had, protective goggles, protective gloves, safety shoes, ear protectors and a hairnet if

you have long hair. A face mask should be worn to protect the respiratory system when working in enclosed areas.

3.13 Avoid body positions in which the back is bent when carrying motor units or other heavy components. Maintain

a secure stance and always stay in balance, especially when using ladders or when working from scaffolding.

3.14 Check all screws on the DS-TS 32 (30) saw, tensioning arm, diamond wire guard and drive wheel guard which

could work loose due to vibration.

3.15 Disconnect the electric extension cable from the mains supply when the equipment is not in use, during transport and before inspection or maintenance. Ensure that the hydraulic power unit is switched off before changing

the diamond wire or before adjusting the position of the guide pulleys. As an additional safety measure, it is recommended that the EMERGENCY STOP button is pressed and left in the OFF position.

3.16 Use of the Hilti diamond wire saw system is permitted only in conjunction with the other DS-WSS 30 components

listed in these instructions. The use of individual components for wire sawing, e.g. only the drive wheel, is prohibited as this could present a serious hazard to the operating personnel.

3.17 For further information, please refer to the D-LP 32 (30) / DS-TS 32 (30) operating instructions.

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 10

10

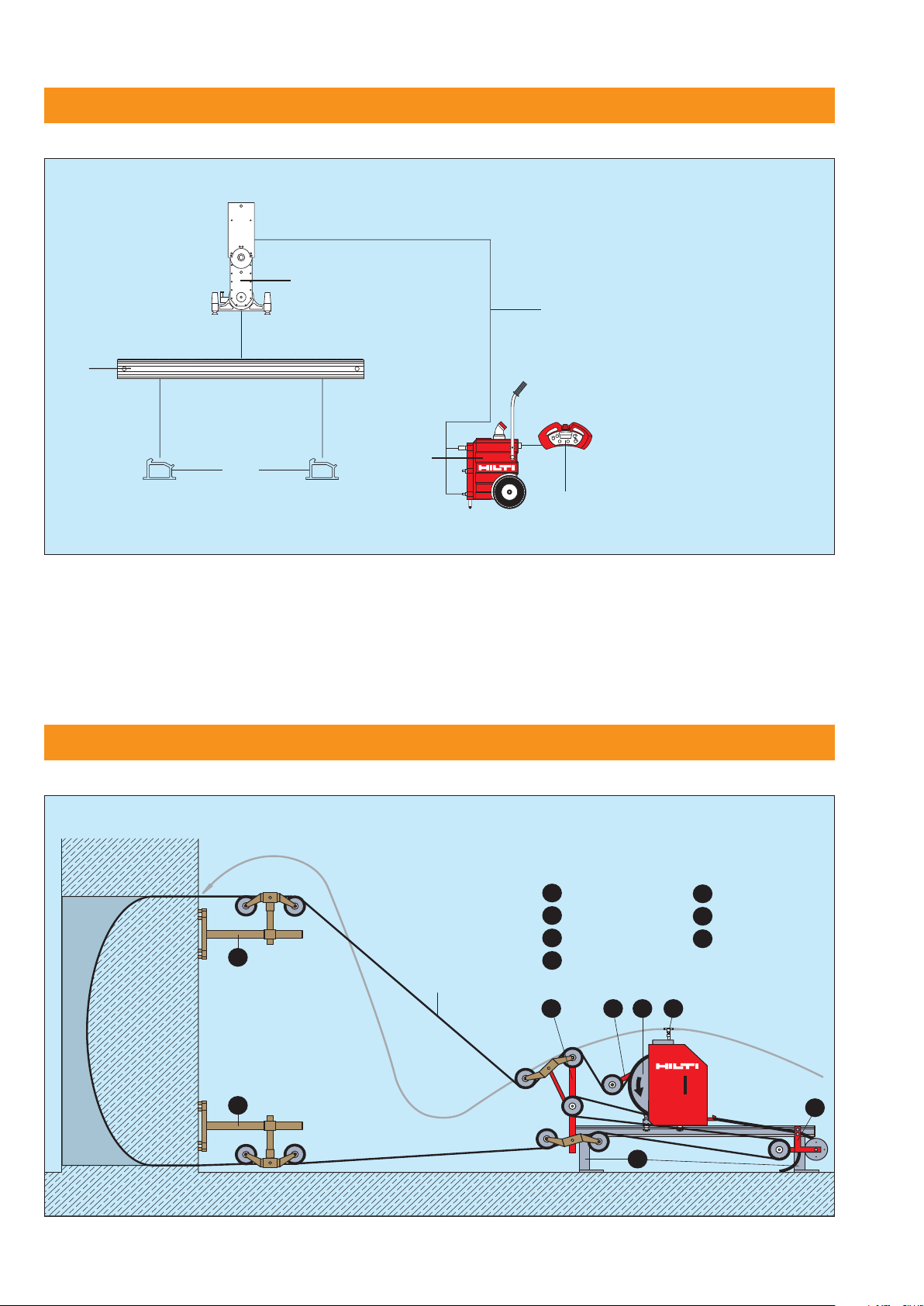

4. D-LP 32 (30) / DS-TS 32 (30) modular saw system

5. D-LP 32 (30) / DS-TS 32 (30) / DS-WSS30 modular wire saw system

DS-R 230L

DS-TS32

DS-RF

D-PH34-10 (2x)

D-FH4/14-10

DS-RF

D-LP 32

D-RC-LP 32

comprising:

1 D-LP 32 (30)

2 D-RC- LP 32 (DS-CB)

3 D-PH34-10 (2x)

4 D-FH4/14-10

5 DS-RF

6 DS-R 230L

7 DS-TS32 (30)

1

6

5

3

/

4

7

2

2x DS-WS-SPP

7

DS-WSWS

6

2x DS-WSRF

5

DS-WSRP

4

DS-WSWD

3

DS-WSTA

2

DS-WSW500

1

DS-W10.5

7

6

5

7

4

123

DS-WSS30 comprising:

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 11

11

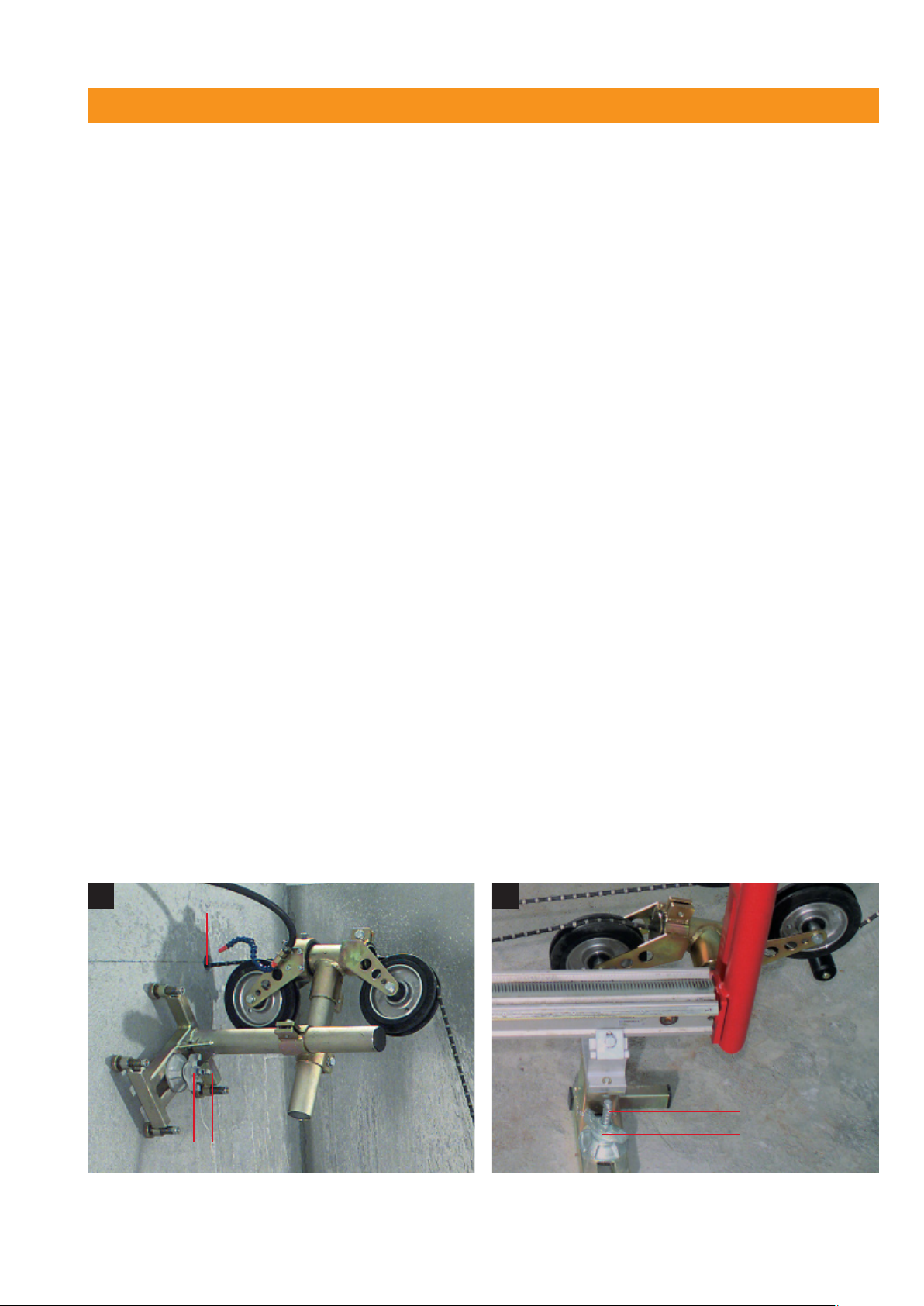

6. Setting up the wire saw system

6.1 Through-holes for the diamond wire

– Plan the working procedure carefully and precisely before beginning to install the system and before drilling the

through-holes.

– Drill the through-holes for the diamond wire (see fig. 6.1, no. ).

Use a suitable drilling machine, depending on the situation and the base material:

킞 Combihammer TE 70 with 16 mm dia. drill bit

킞 Diamond drilling machine DD 200 with the core bit DD-BS 52

6.2 Fastening to the base material

WARNING

Use an anchor suitable for the material on which you are working and observe the anchor manufacturer’s instructions.

NOTE

Hilti M12 metal expansion anchors are usually suitable for fastening diamond core drilling equipment

to uncracked concrete. Under certain conditions it may be necessary to use an alternative fastening

method. Please contact Hilti Technical Service if you have any questions about secure fastening.

– Rigid and secure fastenings are the basic prerequisite for efficient and safe sawing. We recommend the use of

Hilti drilling and anchoring systems.

– Fasteners suitable for the base material in question should be used to fasten the rail supports and single-pair

pulley stands. For example, a minimum edge distance of 18 cm must be observed when setting the Hilti HKD

M12 metal expansion anchor. As a general rule, this anchor should be set ≥ 5 mm below the surface of the concrete. After drilling the hole, the dust should be blown out.

– Hilti HIT adhesive anchors can be used in masonry etc. or, alternatively, through-holes drilled and threaded rods

used.

6.3 Recommended fastening method using the clamping spindle and clamping nut

For fastening the rail supports and single-pair pulley stands, Hilti recommends use of the HKD-D anchor in conjunction with the double-thread clamping spindle and clamping nut with pivoting baseplate.

Advantages

1. Flexible clamping nut / baseplate provides secure fastening even on uneven surfaces and when anchor holes

are drilled at an angle.

2. Coarse thread pitch for rapid assembly and disassembly

3. The anchor can be set deeper.

6.1 6.2

Clamping nut with pivoting baseplate

Double-thread clamping spindle

Through-hole for the diamond wire

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 12

12

Accessories for fastening the wire saw and pulley stands

Description Use Package Ordering designation Item no.

contents

Combihammer Drilling anchor holes 1 TE70

000000

Hammer drill bit

Drilling anchor holes 1 TE-YX-16/35

333760

Blow-out bulb Cleaning anchor holes 1 BB

059725

Flush anchor

Fastening the wire saw / pulley stands 50 HKD-D M12x 50

252961

Manual setting tool Expanding the anchors 1 HSD-G M12x 50

243743

Clamping spindle

Fastening the wire saw / pulley stands 1 DD-CS M12 S-SM

251830

Clamping nut Fastening the wire saw / pulley stands 1 DD-CN-SML

251834

Accessories for drilling through holes

Description Use Package Ordering designation Item no.

contents

Combihammer Drilling through holes 1 TE 70

000000

Hammer drill bit

Drilling through holes 1 TE-YX 16/55

333761

Hammer drill bit Drilling through holes 1 TE-YX 16/92

370564

Pointed chisel

Rounding edges of holes 1 TE-YP-SM28

282263

Diamond coring machine Drilling through holes 1 DD 200

000000

Diamond core bit

Drilling through holes 1 DD BS52/430

000000

Extension Drilling through holes 1 11/4" UNC

009850

Diamond coring is recommended for corner holes in very thick walls, in heavily reinforced concrete and where very precise

cuts must be made.

6.4 Recommended fastening set

Advantages

■ Can be set deeper: special HKD-D anchor without collar

■ High holding power: HKD-D M12 metal expansion anchor with 16 mm outside diameter

■ Flexible clamping nut / baseplate for secure fastening even when anchor holes are drilled at an angle or on

uneven surfaces

■ Coarse thread pitch for rapid assembly and disassembly

■ Avoids damage to the baseplate or rail support

6. Setting up the wire saw system

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 13

13

6. Setting up the wire saw system

DSW-WG wire guards

(Item no. 365426)

Wire guards must be fitted in situations where it cannot be ensured that persons do not enter the area in

which flying objects present a risk of injury while the

equipment is in operation or where there is a risk of

damage to property or other equipment within this

area. When wire guards are used, check to ensure

they are fitted correctly.

DS-WS-SPP single-pair pulley stand

(Item no. 365427)

In applications where, due to restricted access, it is

impossible to mount the compact wire saw directly on

the object to be cut or where longer cuts of up to a

maximum of 2 meters are to be made, the sawing wire

is guided to the cutting face by the pulley stand.

DS-WSRW release pulley

(Item no. 315834

)

The release pulley is used to reduce the length of wire

in contact or to increase the radius of the arc followed

by the wire (avoiding a tight radius) at the rear of the

object to be cut.

DSW-PW plunge wheel

(Item no. 365428)

For plunge applications of all kinds. At least 2 are

required. Can also be mounted on the single-pair pulley stand if necessary.

DS-WSS 30 guard

(Item no. 276388)

DS-WSS 30 guard

(Item no. 276379)

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 14

14

7.1 Standard vertical cut

– Optimum cutting length

– No tight diamond wire radius in the

concrete

– Average cutting performance

– Normal rate of wire wear

7.2 Vertical cut with release

pulley

1

st

step

– Relatively short cutting / contact

length

– High cutting performance

– High rate of wire wear

Note

When the kerf is at the height of

pulley , the pulley should be

turned and positioned below the

wire.

2

nd

step

Note

At the end of the cut, when the diamond wire is pulled out of the kerf, it

is caught by pulleys and .

– No danger of the wire lashing

back

– Avoids damage to the wire

Note

The optimum cutting length for the Hilti DS-WSS 30 wire saw system is 1 to 4.5 metres, i.e the diamond wire is

in contact with the workpiece over a length of 1 to 4.5 metres.

12

12

12

Water

Water

Water

Water

WaterRelease pulley

Diamond wire

Tension side

Diamond wire

Tension side

Diamond wire

Tension side

Release pulley

7. Basic applications

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 15

15

7.3 Standard horizontal cut

7.4 Flush horizontal cut

A At the beginning of the cut

Wall saw

Pivoting pulley

with ball-bearing

pivot

Pivoting pulley

with ball-bearing

pivot

7. Basic applications

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 16

16

Note

In order to prevent the diamond wire from jumping off the pivoting guide pulleys, we recommend that the wire saw

is switched off shortly before completing the cut and that a combihammer is used to break away the small amount

of remaining material.

B At the end of the cut

Pivoting pulley

with ball-bearing

pivot

Pivoting pulley

with ball-bearing

pivot

Side view

Diamond wire

Pivoting pulley

Saw kerf

7. Basic applications

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 17

17

7.6 Flush cutting

– For flush cutting, the pulleys

with ball-bearing pivot must

always be used. These pulleys

are designed to pivot easily

and follow the movement of

the diamond wire. They can be

easily differentiated from the

type with plain bearings (see

fig. 10.3).

– The pulleys with ball-bearing

pivot should always be positioned at the points where the

diamond wire enters or leaves

the concrete.

7.5 Aligning the guide pulleys

As a general rule, all guide pulleys must be aligned with each other so that the diamond wire always runs in the

middle of the pulley (minimises pulley wear and reduces the risk of the diamond wire jumping off).

Exception

Two guide pulleys on the slack

side, between the wire distribu-

tor pulleys and the pulley stand

at the point the diamond wire

enters the concrete, should be

set up at a slight angle (see fig.

7.5). This assists the diamond

wire to rotate about its own axis

while cutting, thereby achieving

more even wear.

12

Water

Water

Diamond wire

Tension side

7.5

Slack side

7. Basic applications

Pulley with

ball-bearing pivot

Pulley with

ball-bearing pivot

Diamond wire

Clamping screw

Ball bearing

Pivoting pulley

Kerf

Plain bearing

Can be clamped

in position

Clamping screw

Loosen screw

for flush cutting

7.6

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 18

18

7.7 Wire saw application using plunging pulleys

Note

When cutting over a length of 2–3 m, the plunging pulleys must always be positioned 20 to 30 cm below the

desired depth as a slight curve always remains at the end of the cut.

7.7a

7.7c

7.7b

Special stands

Pivoting plunging pulleys

140 mm dia.

Radius at end of cut

20–30 cm

Desired

depth of cut

Tubular

extension

2ʺ dia.

Tubular

extension

2ʺ dia.

Length of cut

Pivoting pulleys (to saw head)

200 mm dia.

Hole

162 mm dia.

Pivoting plunging pulleys

140 mm dia.

Radius at end of cut

20–30 cm

Tubular

extension

2ʺ dia.

Tubular

extension

2ʺ dia.

Length of cut

Pivoting pulleys (to saw head)

200 mm dia.

Hole

∅ 162 mm

20–30 cm

Radius at end of cut

Length of cut

Tubular

extension

2ʺ dia.

Tubular

extension

2ʺ dia.

Pivoting plunging pulleys

140 mm dia.

Pivoting pulleys (to saw head)

200 mm dia.

7. Basic applications

7.7d

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 19

19

The built-in return pulley and wire store pulley can be used to reduce the effective length of the diamond wire by up

to 8 m with a rail length of only 2 m (DS-R 200 L).

Important

No matter how the wire saw is set up, the DS-WSRP wire length adjusting pulley must always be fitted and the

diamond wire guard belonging to it attached at the bottom of the drive wheel guard.

Configuration 1

Configuration 2

Configuration 3

Configuration 4

2×1.5 m

2×0.5 m

2×0.5 m

2×1.5 m

= 3 m

+

+

+

= 1 m

= 1 m

= 3 m Total 8 m

Drive wheel guard End stop

Diamond wire guard

Wire length adjusting pulley

2 m rail (DS-R200 L)

8.Diamond wire store

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 20

20

Cutting direction

Important: The connectors must be fitted, relative to the cutting direction, as shown in the illustration. The

diamond wire must be used to cut in one direction only (see arrows).

Preparations for the first cut

■ Connectors are already fitted to new diamond wires.

■ The diamond wire must be twisted before joining the connectors by inserting the pin. Twist the diamond wire,

approx. 1–1.5 turns per metre length of wire, in a counter-clockwise direction (to the left) as seen when looking straight at the cut face of the end of the wire.

■ The corners on the workpiece should be rounded off to a radius of approx. 10 cm (using a hammer and chis-

el or a Hilti combihammer) and/or the diamond wire pulled through by hand.

■ Mount the water supply nozzle at the point where the wire enters the workpiece. Depending on the length of

the cut, it may be necessary to apply cooling water at several points. It is essential that the wire is cooled

perfectly if good cutting results are to be achieved.

■ Use the advance movement to tighten the wire. Move away from the machine to a safe distance and start the

motor. Start the saw gently and then increase the running speed gradually until the optimum drive speed

(r.p.m.) and cutting speed is reached.

■ The sawing operation must be monitored continuously.

■ The wire saw must be stopped before making adjustments to the water supply nozzles.

General information

■ Do not kink or bend the wire sharply.

■ Do not join diamond wires of different diameters together.

■ To ensure even wear of the beads, the diamond wire must be retwisted after each long cut, applying a dif-

ferent number of turns, before beginning the next cut.

9. Instructions for connecting Hilti DS-W 10.5 diamond wire

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 21

21

10 mm

13 mm

1

쩸

쩹

2

4

쩺

5

3

1 mm

Instructions for fitting

DS-WC connectors

(Item no. 340427)

Fitting the connector (first

end, clevis piece)

Clamp the diamond wire

in the vice with the cutting direction as shown

(see arrow) and use an

angle grinder to cut off

the end 13 mm from the

first bead.

Use pliers to remove the

spring (pull out).

Remove the rubber neatly

over a length of 10 mm

(using a knife, cigarette

lighter or wire brush).

Fit an O-ring 쩸 (Item no.

235844) pushing it onto

the wire until seated

against the bead. Fit the

clevis piece 쩹 onto the

wire so that the end of the

bare wire section contacts

the base of the hole.

Use the crimping pliers

쩺 (Item no. 235845) and

the corresponding crimping jaws to crimp the

connector fully in one

operation. When doing so, the crimping jaws should be positioned 1 mm from the end of the connector.

Worn or deformed crimping jaws should not be used.

Fitting the connector (second end, opposite piece) and joining the connectors

■ To fit and crimp the second part of the connector (opposite piece) proceed as described at steps to .

■ Joining the connectors

Twist the diamond wire, approx. 1–1.5 turns per metre length of wire, in a counterclockwise direction (to

the left) as seen when looking straight at the cut face of the end of the wire. Bring the connectors together

and insert the pin (item no. 235842) using a hammer to drive it in flush.

Opening the connectors

■ Use a punch to drive the pin out of the connector. Replace the pin if it is badly worn (replacement pin, item

no. 235842).

9. Instructions for connecting Hilti DS-W 10.5 diamond wire

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 22

22

Instructions for fitting

DS-WS repair sleeves

(Item no. 235841)

Fitting a repair sleeve (first

end)

Important: The service life of

the connectors is several

times that of the repair sleeve.

Clamp the diamond wire

in the vice and use an

angle grinder to cut off

the end 13 mm from the

first bead.

Use pliers to remove the

spring (pull out).

Remove the rubber neatly

over a length of 10 mm

(using a knife, cigarette

lighter or wire brush).

Fit an O-ring 쩸 (Item no.

235844) pushing it onto

the wire until seated

against the bead. Fit a

repair sleeve 쩺 onto the

wire so that the end of the

bare wire section contacts

the base of the hole.

Use the crimping pliers

쩺 (Item no. 235845) and

the corresponding

crimping jaws to crimp

the connector fully in oneoperation. When doing so, the crimping jaws should be positioned 1 mm from

the end of the connector. Worn or deformed crimping jaws should not be used.

Fitting a repair sleeve

(second end)

■ Proceed as described at steps to .

■ Twist the diamond wire, approx. 1–1.5 turns per metre length of wire, in a counterclockwise direction (to the

left) as seen when looking straight at the cut face of the end of the wire.

■ Proceed as described at steps to .

ED

CA

E

D

C

B

A

13 mm

A

B

10 mm

C

쩸

쩻

D

쩺

E

9. Instructions for connecting Hilti DS-W 10.5 diamond wire

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 23

23

Hilti sawing wires and accessories

Special wires

(electroplated beads)

Standard diamond wires

(sintered beads)

DS-W10.5 diamond wires

Hilti DS-W10.5 diamond wires for DS-W 15, DS-WS 30 and DS-WS10 wire saw systems

Designation

Wire length DS-W 10.5 BC DS-W 10.5 LC DS-W 10.2 steel 20% DS-W 10.8 steel 100%

(m)

10 m 235835 * 235834 * – –

14 m 235836 * 235838 * 376982 371987

18 m 315019 * 315020 * 371983 371988

22 m 315022 * 315023 * 371984 371989

26 m 315025 * 315026 * – –

30 m 315028 * 315029 * – –

50 m 370500 376630 371985 371990

100 m 370426 376631 371986 371991

150 m 376633 376632 373130 –

per/m 376635 376634 377830 377781

* with factory-fitted flexible connectors

Recommendations: Which specification for which material?

Material

Desired characteristics

Reinforced concrete

Fast cutting Long life – –

Heavily reinforced

concrete

Solid steel

BC LC Steel 20% Steel 100%

Accessories for Hilti diamond wires

Designation Use Package Ordering designation Item no.

contents

Crimping pliers For crimping connectors / repair sleeves 1 DS-WSTHY

235845

Flexible connectors

Quick-release type 1 DS-WCMV

340427

Set of flexible connectors* Quick-release type with pin and O-ring 5 DS-WCSet

371383

Pin

Replacement pin for quick-release connectors 10 DS-WP

235842

Sleeve Repair sleeve 5 DS-WS

!

235841

O-ring

Fitted between connector and bead 10 O-ring 10/4.7×2.5

"

235844

Crimping jaws Replacement jaws for crimping pliers 2 DS-WJ

#

340426

Angle grinder

For cutting diamond wire 1 AG 125-S

$

000000

* Includes a special tool for opening the flexible connector

"

!

#

$

9. Instructions for connecting Hilti DS-W 10.5 diamond wire

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 24

24

10.1 Checks before sawing

– The rail supports and guide pulley stands must be correctly fastened (all screws tightened securely.

– The saw head must be mounted without play, the saw arm in the vertical position (at 90° to the rail), the cam-

action rollers engaged (DS-TS 30 1

st

gear).

– The wire tensioning pulley and drive wheel guard must be fitted and secured in position with the clamping

screw at the side of the blade guard holder.

– The drive wheel must be fitted and secured with the standard saw blade flange and central mounting screw.

– The drive wheel guard cover must be fitted.

– The wire distributor assembly must be fitted at the front end of the rail using the standard rail taper and eccen-

tric pin.

– The end stop must be fitted at the rear end of the rail.

– The wire length adjusting pulley and rolled-up diamond wire guard must be fitted and the rubber diamond wire

guard attached to the drive wheel guard.

– The hydraulic hoses and water hoses must be connected correctly. (The two control hoses for the saw arm

plunge movement do not have to be connected as only the longitudinal advance movement is required for wire

sawing.)

– Electric power and water must be available. The EMERGENCY STOP buttons on the hydraulic power unit and

remote control unit must be disengaged (pulled out) and all controls on the electric remote control unit set to

the OFF / 0 or neutral position.

– The working area must be cordoned off. All safety distances must be observed.

– The diamond wire must be connected correctly, aligned properly and it must be possible to pull the wire through

easily by hand.

32-50 A

D-RC-LP 32

Start

Ampere

II

I

32 63

45

100

1

6

0

0

1

2

0

0

1

0

0

0

9

0

0

8

0

0

m

m

60

40

80

10. DS-WSS 30 wire saw system - checks, operation and the sawing procedure

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 25

25

10.2 Remote control unit: controls

Pos.1: Electric motor ON (I 킞 II 킞 Start 킞 Release 킞 II)

Electric motor OFF (II 킞 I)

Pos.2: Hydraulic oil flow rate 0 –100 l / min. (controls speed of diamond wire drive wheel)

Pos.3: Plunge movement (right / left). As the control hoses necessary for this function may not be connected to

the wall saw when used for wire sawing, this rotary switch has no function.

Pos.4: Advance (right / left, diamond wire tension / release tension)

Pos.5: Speed of advance for (4)

Pos.6: Power input setting in amps, depends on mains supply

Pos.7: EMERGENCY STOP button

10.3 Remote control unit: starting and operating the saw system

1. Adjust the current (6) to a value between 32 amps and approx. 50 amps depending on the mains supply available on the jobsite.

2. Switch on the water supply.

3. Knobs (3), (4), (5) and (7) should be set to the «0» (neutral position). Switch on the electric motor (1) and check

that the hydraulic unit switches from star to delta ( takes approx. 2–5 seconds).

4. Use the longitudinal advance control (4) to select the correct direction of movement for wire tension and use the

advance speed control (5) to tension the diamond wire slightly.

5. Use the potentiometer (2) to start the drive wheel motor slowly and, at the same time, adjust the advance speed

control knob (5) in order to maintain or increase tension on the diamond wire.

As soon as the diamond wire is running correctly, the speed of the drive wheel can be increased to maximum,

by adjusting the potentiometer (2). This corresponds to a speed of 800 r.p.m. The cutting speed of the diamond

wire is then 20 m / sec.

Subsequently, only the advance speed control (5) requires adjustment in order to control the diamond wire tension and, thus, the sawing performance. A visible indication of correct tension is given by the wire tensioning arm,

which should rise approx. 10 to 15 cm.

The saw should be operated at a pressure of approx. 120 bar (max. 140 bar) in the main hydraulic circuit in order

to achieve optimum sawing performance without excessive strain on the diamond wire.

D-RC-LP 32

Start

Ampere

II

I

32 63

45

1

0

0

1

6

0

0

1200

1000

9

0

0

800

m

m

8

0

6

0

40

3 4 7 8 9 2

6 1 10 5

10. DS-WSS 30 wire saw system - checks, operation and the sawing procedure

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 26

26

Once initially set, the system regulates itself by way of the automatic advance system. This means that when the diamond wire encounters heavy reinforcement, the drive unit advance speed is reduced automatically until the reinforcement is cut trough. The rate of advance then returns automatically to the speed previously set.

10.4 Switching off the saw system

1. Switch off the saw advance control – turn the knob (4) to the “0” or neutral position

2. Switch off the drive wheel motor – turn the knob (2) to the “0” position.

3. Switch off the electric motor – turn the knob (1) to the “I” position.

4. Press the EMERGENCY STOP button.

10. DS-WSS 30 wire saw system - checks, operation and the sawing procedure

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 27

27

CAUTION

Disconnect the supply cord plug from the power outlet.

CAUTION

Keep the machine, especially its grip surfaces, clean and free from oil and grease. Do not use cleaning agents

which contain silicone.

11.1 Cleaning using high-pressure or steam-cleaning systems

Avoid directing the jet towards the bearings and seals when systems of this kind are used for cleaning the guide

pulley stands and saw head.

11.2 Maintenance of the single-pair pulley stand

As the guide pulleys used for flush cutting are

equipped with two ball bearings at the pivot, these

should be lubricated at least once a month.

Procedure: Unscrew the locking bolt completely and

inject a little oil into the threaded opening. Reinsert

the bolt (see fig. 11.2).

11.3 Rubber rim on the pulleys

The rubber rim on the drive wheel and guide / return pulleys should be checked at regular intervals. A wheel or

pulley should be replaced as soon as the aluminium beneath the rubber is visible (rubber worn through).

11.4 Diamond wire guard and drive wheel guard

These parts should be cleaned daily and checked to ensure that the rolling-up mechanism of the diamond wire

guard always functions correctly.

11.5 Maintenance of the hydraulic power unit, saw head and other saw modules

Please refer to the D-LP 32 (30) / DS-TS 32 (30) operating instructions.

11. 2

Locking bolt

11. Care and maintenance

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 28

28

Solution / measures

– Use a Hilti combihammer to break

away sharp corners and ensure

that the diamond wire can be

moved to and fro initially by hand.

– Use the worn wire to finish the

cut.

– Drill an additional hole where

the new wire can be pulled

through.

– Additional guide pulleys must be

installed.

– Reduce wire tension by adjusting

the saw head advance (observe

the tensioning arm).

– Increase wire tension by adjusting

the saw head advance.

(Observe the tensioning arm.)

– Adjust the guide pulleys to increa se

the length of contact between the

wire and drive wheel perimeter.

– Additional guide pulleys must be

installed.

– Replace the drive wheel.

– Twist the wire in a counter-clock-

wise direction (as seen when looking straight at the cut end of the

wire) approx. 1–1.5 turns for each

metre length of wire.

– The wire must be retwisted after

each large cut by applying a different number of turns.

Problem

1. The diamond wire does not run.

2. The diamond wire slips on the

drive wheel.

3. The diamond wire is badly worn,

irregularly and on one side.

Possible cause

– Corners on concrete too sharp

– A new diamond wire is being used

in a cut made by a worn diamond

wire.

– The section of diamond wire in con -

tact with the concrete is too long.

– Excessive tension on the diamond

wire

– Insufficient tension on the diamond

wire

– Insufficient length of contact bet -

ween the wire and drive wheel

perimeter.

– The section of wire in contact with

the concrete is too long.

– The rubber rim on the drive wheel

is too badly worn.

– Diamond wire not twisted before

coupling the ends together

Persons may enter the danger zone only when the

drive unit is switched off and the drive pulley has stopped rotating. Press the EMERGENCY STOP button

before entering the danger zone.

Disconnect the equipment from the electric supply

(unplug the supply cord from the power outlet) before

opening the control unit.

12. Troubleshooting

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 29

29

Solution / measures

– The guide pulleys on the slack side

of the wire between the wire distributor and the pulley stand, at the

point where the diamond wire enters

the concrete, should be set at a

slight angle. This causes the diamond wire to rotate when running.

– Set up as explained above

(see fig. 12.3).

– Increase the distance between the

wire distributor pulleys and the

single-pair pulley stand at the point

where the diamond wire enters the

concrete (see fig. 12.4).

– Reduce the wire tension by adjust-

ing the saw head advance.

Solution / measures Possible cause

– Guide pulleys at the slack side of

the wire not

set at an angle

12

12

12 .3

12 .4

Water

Water

Water

Water

Slack side

Diamond wire

Tension side

Diamond wire

Tension side

RIGHT!

WRONG!

12. Troubleshooting

– Guide pulleys set at the wrong

angle therefore counteracting the

desired twist

– The slack side of the diamond wire

is too short.

– The saw is operated with the

diamond wire under excessive

tension.

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 30

30

Solution / measures

– Install additional guide pulleys.

– Reduce the wire tension by adjust-

ing the saw head advance. Don’t

exceed the specified pressure of

120–160 bar in the main hydraulic

circuit.

– Fit shorter wire couplings.

– Use the cardan-type, flexible cou-

plings recommended by Hilti.

– Check the setting of the crimping

pliers.

– Use Hilti crimping pliers with a

minimum pressure of 7 t.

– Check the crimping jaws and

replace if necessary.

– With all couplings available

from Hilti, the wire must always

be pushed in as far as it will

go.

– Reduce the wire tension by adjust-

ing the saw head advance.

– Increase wire tension by adjusting

the saw head advance.

– Install additional guide pulley

stands.

– Fit a shorter diamond wire.

– The front rail support (at the wire

distributor) should be fitted as

close as possible to the end of the

rail.

Problem

4. The wire breaks immediately

beside the coupling

5. The diamond wire is pulled out of

the crimped coupling.

6. The diamond wire thrashes about

and vibrates badly.

Possible cause

– The cutting radius of the diamond

wire in the concrete is too small.

– The wire has been used too long

under excessive tension.

– The wire coupling is too long.

– Crimping pliers incorrectly adjusted

– Insufficient pressure applied to the

crimping pliers

– Incorrect or worn crimping jaws

– The wire was not pushed far

enough into the coupling.

– Constantly excessive wire tension

during operation.

– Insufficient wire tension

– The pulley stands are too far apart

(excessively long unsupported wire

length).

– Rail support incorrectly positioned

12. Troubleshooting

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 31

31

Solution / measures

– Reduce the wire tension by adjust-

ing the saw head advance.

– Reduce speed

– Ensure that the speed potentiome-

ter on the remote control unit is set

to max.

– Install more water jets at the cut-

ting face.

– Increase the length of cut.

– Reduce the wire tension by adjust-

ing the saw head advance.

– Select a different diamond wire

specification.

– The diamond wire should be

installed so that it always runs in

the same direction, as specified.

– Always ensure that sufficient water

reaches the cutting face.

– Steel wedges must be used to pre-

vent movement of the concrete

sections.

– Any loose fragments or aggregates

must be removed from the kerf.

– Also refer to the D-LP 32 /

DS-TS 32 diamond wall saw

system operating instructions.

Problem

7. The diamond wire vibrates fiercely

and at a high frequency.

8. Diamond wire wear is excessively

high.

9. The diamond wire collapses.

(The diamond beads, connecting

pieces and separating springs are

bunched together on the wire.)

10. For information on finding and

eliminating faults in the

D-LP 32 (30) / DS-TS 32 (30)

wall saw system.

Possible cause

– Excessive wire tension

– Speed (r.p.m.) of the drive wheel is

too high.

– Drive wheel running too slowly.

The cutting speed of the diamond

wire is thus also too low.

– Inadequate cooling of the diamond

wire

– Length of cut too short

– Wire tension is too high in relation

to the length of cut.

– Very abrasive base material

– The direction of movement of the

wire is changed constantly.

– Inadequate cooling or no cooling of

the diamond wire

– The diamond wire becomes stuck

in the kerf and stalls during sawing.

12. Troubleshooting

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 32

32

Only for EU countries

Do not dispose of electric tools together with household waste material!

In observance of European Directive on waste electrical and electronic equipment and its implementation in

accordance with national law, electric tools that have reached the end of their life must be collected separately

and returned to an environmentally compatible recycling facility.

13. Disposal

Most of the materials from which Hilti appliances are manufactured can be recycled.

The materials must be correctly separated before they can be recycled. Hilti has already made arrangements in

many countries for taking back your old appliance for recycling. Please ask your Hilti customer service department or a Hilti sales representative for further information.

Return waste material for recycling

Disposal of drilling and sawing slurry

NOTE

With regard to environmental aspects, allowing drilling or sawing slurry to flow directly into rivers, lakes or the sewerage system without suitable pre-treatment is problematical.

In addition to the following recommended pretreatment procedures, the applicable national regulations must be observed when disposing of drilling or sawing slurry. Ask the local authorities concerned for further information.

We recommend the following pre-treatment

1. Collect the drilling and sawing slurry (e.g. using a suitable industrial vacuum cleaner).

2. The fine content of the drilling and sawing slurry should be separated from the water by allowing it to settle (e.g.

leave standing for some time or add a coagulation agent).

3. Solid material from the drilling and sawing slurry should be deposited at a construction waste disposal site.

4. Water from the drilling and sawing slurry should be neutralized (e.g. by adding a large quantity of water or other neutralization agents) before it is allowed to flow into the sewerage system.

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 33

33

Please contact your local Hilti representative if you have questions about the warranty conditions.

14. Manufacturer's warranty – tools

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 34

34

15. EC declaration of conformity (original)

Description: Hydraulic saw system

Designation: DS-WSS 30 / D-LP 32

Year of design: 2001

We declare under our sole responsibility that this product complies with the following directives and standards:

until 19th April 2016: 2004/108/EC, from 20th April 2016: 2014/30/EU, 2006/42/EC, 2011/65/EU,

EN 60204‑1, EN 12100.

This equipment complies with the applicable standard provided that the short-circuit power S

SC

at the interface point between the user’s supply and the public supply network is greater than or equal to 3.2 MVA. It is

the responsibility of the installer or user of the equipment to ensure, by consultation with the supply network

operator if necessary, that the equipment is connected only to a supply with a short-circuit power S

SC

of

greater than or equal to 3.2 MVA.

Technical documentation filed at:

Hilti Entwicklungsgesellschaft mbH

Zulassung Elektrowerkzeuge

Hiltistrasse 6

86916 Kaufering

Deutschland

Hilti Corporation, Feldkircherstrasse 100, FL-9494 Schaan

Paolo Luccini Johannes Wilfried Huber

Head of BA Quality and Process Management Senior Vice President

Business Area Electric Tools & Accessories Business Unit Diamond

06 / 2015 06 / 2015

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 35

35

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Page 36

*315911*

315911

Hilti = registered trademark of Hilti Corp., Schaan

en I 20150922

Hilti Corporation

LI-9494 Schaan

Tel.: +423 /234 2111

Fax: +423 /234 2965

www.hilti.com

Printed: 07.03.2016 | Doc-Nr: PUB / 5069762 / 000 / 02

Loading...

Loading...