Hilti DSH 700-X, DSH 700, DSH 900, DSH 900-X Instructions Manual

DSH 700

DSH 700-X

DSH 900

DSH 900-X

English

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

English 1

1 Information about the documentation

1.1 About this documentation

• Read this documentation before initial operation or use. This is a prerequisite for safe, trouble-free

handling and use of the product.

• Observe the safety instructions and warnings in this documentation and on the product.

• Always keep the operating instructions with the product and make sure that the operating instructions

are with the product when it is given to other persons.

1.2 Explanation of symbols used

1.2.1 Warnings

Warnings alert persons to hazards that occur when handling or using the product. The following signal words

are used:

DANGER

DANGER !

▶ Draws attention to imminent danger that will lead to serious personal injury or fatality.

WARNING

WARNING !

▶ Draws attention to a potential threat of danger that can lead to serious injury or fatality.

CAUTION

CAUTION !

▶

Draws attention to a potentially dangerous situation that could lead to slight personal injury or damage

to the equipment or other property.

1.2.2 Symbols in the documentation

The following symbols are used in this document:

Read the operating instructions before use.

Instructions for use and other useful information

Dealing with recyclable materials

Do not dispose of electric equipment and batteries as household waste

1.2.3 Symbols in the illustrations

The following symbols are used in illustrations:

These numbers refer to the corresponding illustrations found at the beginning of these operating

instructions

The numbering reflects the sequence of operations shown in the illustrations and may deviate

from the steps described in the text

Item reference numbers are used in the overview illustrations and refer to the numbers used in

the product overview section

This symbol is intended to draw special attention to certain points when handling the product.

Wireless data transfer

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

2 English

1.3 Product-dependent symbols

1.3.1 Symbols on the product

The following symbols are used on the product:

Direction-of-rotation arrow on the guard

Engine stop position

Engine run position

Primer bulb

Idling jet adjusting screw

Full-throttle jet adjusting screw

Idling adjusting screw

Fuel mixture

Fuel-tank cap opening direction

Choke (not -X)

Half throttle (not -X)

Wear ear protection, eye protection, respiratory protection and a hard hat

Wear protective gloves

Wear protective footwear

Wireless data transfer

1.4 Adhesive labels on the machine

Warning signs

Warning: Risk of fire due to flying sparks

Warning: Risk of kickback

Warning: Do not inhale toxic vapors or exhaust fumes

Maximum spindle speed

Warning: Hot surface

Prohibition symbols

Do not use toothed cutting discs

Do not use damaged cutting discs

No smoking, no naked flame

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

English 3

1.5 Product information

products are designed for professional users and only trained, authorized personnel are permitted

to operate, service and maintain the products. This personnel must be specifically informed about the

possible hazards. The product and its ancillary equipment can present hazards if used incorrectly by

untrained personnel or if used not in accordance with the intended use.

The type designation and serial number are printed on the rating plate.

▶ Write down the serial number in the table below. You will be required to state the product details when

contacting Hilti Service or your local Hilti organization to inquire about the product.

Product information

Abrasive-disc cut-off saw DSH 700 | DSH 900 | DSH 700-X | DSH 900-X

Generation: 02

Serial no.:

1.6 Declaration of conformity

We declare, on our sole responsibility, that the product described here complies with the applicable directives

and standards. A copy of the declaration of conformity can be found at the end of this documentation.

The technical documentation is filed and stored here:

Hilti Entwicklungsgesellschaft mbH | Tool Certification | Hiltistrasse 6 | 86916 Kaufering, Germany

2 Safety

2.1 Personal safety

▶ Use the right tool for the job. Do not use the tool for purposes for which it was not intended. Use it only

as directed and when in technically faultless condition.

▶ Never tamper with or modify the tool in any way.

▶ Only persons who are familiar with it, who have been trained on how to use it safely and who understand

the resulting hazards are permitted to use the tool. The tool is not intended for use by children.

▶ Stay alert, watch what you are doing and use common sense when operating the tool. Do not use the

tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention

while operating the tool can result in serious personal injury.

▶ The user and persons in the vicinity must wear suitable protective goggles, a hard hat, ear defenders,

protective gloves, protective footwear and light respiratory protection while the tool is in use.

▶ Always hold the tool firmly with both hands on the grips provided. Keep the grips dry, clean and free

from oil and grease.

▶ Never use the tool without the guard (hood). Adjust the guard to the correct position. The guard must be

securely attached and positioned for maximum safety, so that the smallest possible part of the cutting

disc is exposed to the operator. Make sure that sparks created during use do not present a hazard. The

guard helps to protect the operator from broken disc fragments, inadvertent contact with the cutting disc

and uncontrolled flying sparks.

▶ Do not touch rotating parts – risk of injury!

▶ Maintain a firm footing and balance at all times. This will allow you to control the tool better, even in

unexpected situations. Avoid unusual postures.

▶ Wear suitable work clothes. Do not wear jewelry or loose clothing. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry or long hair can be snagged by moving parts.

▶ If the tool or the cutting disc has been dropped or has fallen, check the tool and the cutting disc for

damage. Change the cutting disc if necessary.

▶ Switch the tool off before adjusting the guard or changing the cutting disc.

▶ Wear protective gloves also when changing the cutting disc. Touching the cutting disc presents a risk of

injury (cuts or burns).

▶ Wear eye protection. Flying fragments present a risk of injury to the body and eyes.

▶ Use of the wet cutting method is preferable in order to reduce the amount of dust produced when cutting

mineral materials and asphalt.

▶ Avoid skin contact with the slurry created when using the wet cutting method.

▶ Dust from materials such as paint containing lead, some types of wood, minerals and metal can be

harmful to health. Contact with or inhalation of the dust can cause allergic reactions and/or respiratory or

other diseases to the operator or bystanders. To reduce the amount of dust produced when cutting, we

recommend use of the wet cutting method. Make sure that the workplace is well ventilated. It is advisable

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

4 English

to wear a filter class P2 dust mask. Comply with national regulations applicable to the materials you will

be working with.

▶ Cutting material containing asbestos is not permissible.

▶ Take breaks between working and do relaxation and finger exercises to improve the blood circulation in

your fingers. Exposure to vibration during long periods of work can lead to disorders of the blood vessels

and nervous system in the fingers, hands and wrists.

▶ Consult the responsible structural engineer, architect or person in charge of the building project before

starting work. Slits cut into load-bearing walls or other structures can influence the statics of the structure,

especially when reinforcing bars or load-bearing components are cut.

▶ If the work involves breaking through, always secure the area on the side opposite to where the work is

being carried out. Pieces of debris could drop out and/or fall down and injure other persons.

▶ Never leave the tool running while unattended. Switch the engine off and wait until the cutting disc has

come to a complete standstill before placing the tool on the ground or before transporting it.

▶ Make sure that the pump cover is installed if you operate the tool without an external water pump.

▶ Switch the tool off after use.

▶ Maintain the tool carefully. Check whether parts are broken or damaged to the extent that the tool is not

in full working order. Have damaged parts repaired before using the tool.

▶ To avoid risk of injury, use only genuine Hilti accessories and accessory tools.

▶ Have the tool repaired only by qualified specialists using only genuine Hilti spare parts. The safety of the

tool can thus be maintained.

▶ Comply with national health and safety requirements.

2.2 Electrical safety

▶ Before beginning work, check the working area for concealed electric cables or gas and water pipes.

External metal parts of the machine may give you an electric shock if you damage an electric cable

accidentally.

2.3 Safety at the workplace

▶ Ensure that the workplace is well lit.

▶ Don’t work in closed rooms. Carbon monoxide, unburned hydrocarbons and benzene in the exhaust gas

may cause asphyxiation.

▶ Keep the workplace tidy. Objects which could cause injury should be removed from the working area.

Untidiness at the workplace can lead to accidents.

▶ Hot exhaust gases containing sparks or sparks generated by the cutting operation may cause fire or

explosion. Take care to ensure that the sparks generated do not ignite flammable (gasoline, dry grass,

etc.) or explosive (gas, etc.) substances.

▶ Before fitting the water pump, check to ensure that the maximum permitted water supply pressure of 6

bar is not exceeded.

▶ Fit the filled water tank only after the saw has been mounted on the saw trolley. This will help to prevent

the trolley falling over.

▶ Do not stand the product and the saw trolley on an inclined surface. Always check to ensure that the

product and the saw trolley are standing securely.

2.4 Liquids (gasoline and oil) and vapors

▶ Allow the product to cool before refueling.

▶ Never smoke while refueling.

▶ Don’t refuel the product at the workplace area. When refueling, take care to avoid fuel spillage. Use a

suitable funnel.

▶ Avoid inhaling gasoline vapors and exhaust fumes. Take care to ensure adequate ventilation.

▶ Don’t use the gasoline or other flammable liquids for cleaning.

2.5 Cutting work using cutting discs

▶ Use only cutting discs with a rated maximum permissible speed that’s at least as high as the highest

spindle speed.

▶ Check that the outside diameter and the thickness of the cutting disc comply with the capacity rating of

the product.

▶ Never use cutting discs that are damaged, run untrue or vibrate.

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

English 5

▶ Do not use damaged diamond cutting discs (cracks in the steel disc, broken or polished segments,

damaged arbor hole, bent or distorted steel disc, heavy discoloration due to overheating, steel disc worn

away beneath the segments, diamond segments with no lateral overhang, etc.).

▶ Do not use toothed accessory cutting tools (e.g. toothed saw blades).

▶ When fitting the cutting disc, always take care to ensure that the disc’s specified direction of rotation

corresponds to the direction of rotation of the spindle.

▶ The cutting disc and flange or any other accessory must fit the arbor of the product exactly. Cutting

discs or accessories with arbor holes that do not match the mounting hardware of the product will run

out of balance, vibrate excessively and may cause loss of control.

▶ Always use an undamaged clamping flange of the correct diameter which fits the cutting disc used.

The correctly fitting clamping flange supports the cutting disc and thus reduces the possibility of disc

breakage.

▶ Guide the product smoothly and do not apply lateral pressure to the cutting disc. Always bring the cutting

disc into contact with the workpiece at right angles. Don’t attempt to alter the line of cut by applying

lateral pressure or by bending the cutting disc while cutting is in progress.

▶ Wear protective gloves when changing the cutting disc as the disc will get hot during use.

▶ Abrasive cutting discs which are used for wet cutting must be used up the same day as long periods of

exposure to moisture have a negative effect on the strength of the disc.

▶ Observe the expiry date for resin-bonded cutting discs and don’t use the discs after this date.

2.6 Transport and storage

▶ Switch the product off before transporting it.

▶ Remove the cutting disc from the product after use. The cutting disc may suffer damage during transport

with the disc fitted.

▶ Handle the cutting disc carefully and store it in accordance with the manufacturer’s instructions.

▶ Always store and transport the product in an upright position, not lying on its side.

▶ Do not carry the saw trolley and the product together. Remove the water tank before transporting the

saw trolley.

▶ Do not lift the product and the saw trolley by crane. This is not permissible.

▶ Store the product in a secure place when not in use. Products which are not in use must be stored in a

dry, high place or locked away out of reach of children.

▶ When laying the product down, make sure that it stands securely.

▶ After use, allow the product to cool down before packing it away or placing a cover over it.

▶ Store gasoline and oil in a well-ventilated room in fuel containers that comply with regulations.

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

6 English

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

English 7

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

8 English

3 Description

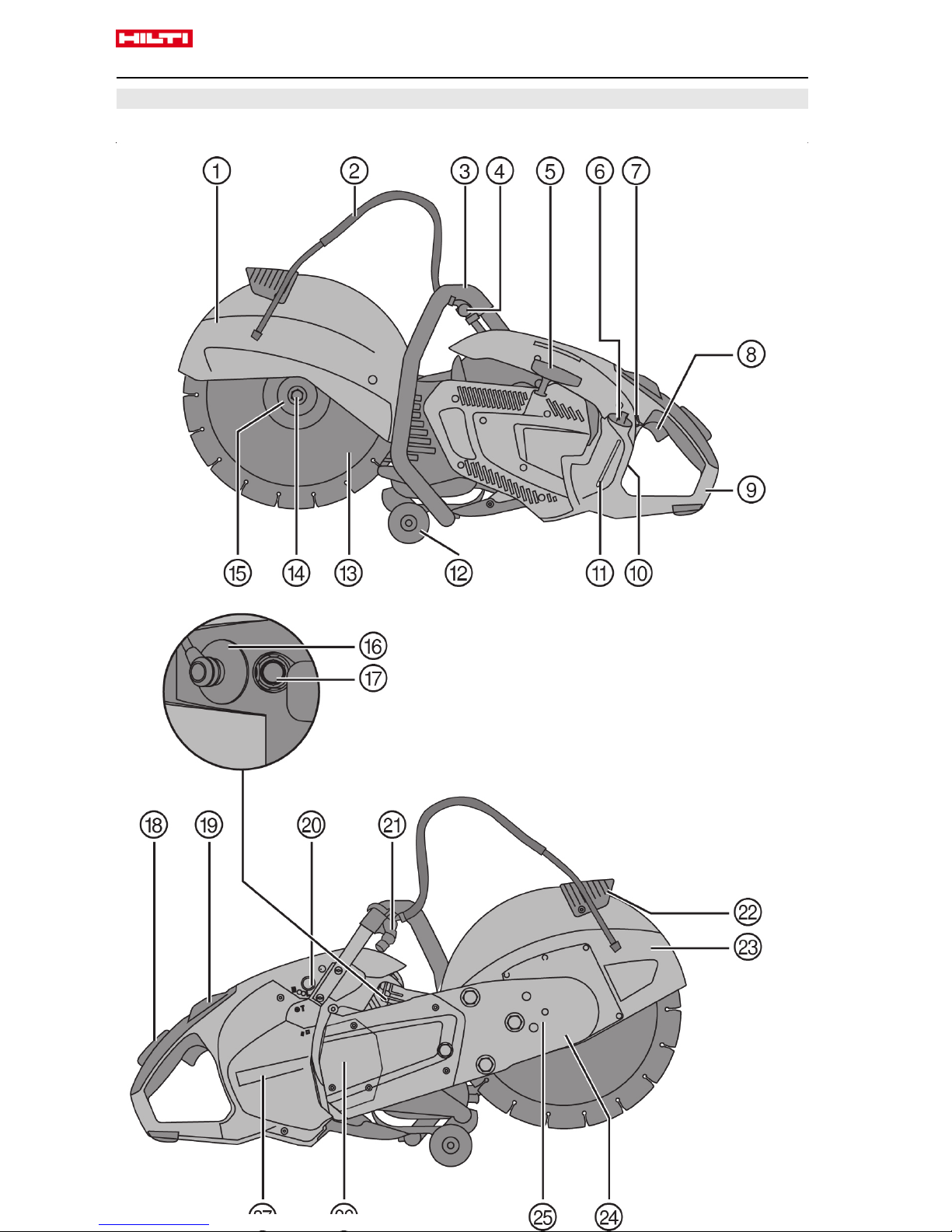

3.1 Product overview

3.1.1 Gasoline-powered cut-off saw

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

English 9

@

Guard

;

Water supply

=

Front grip

%

Water valve

&

Pull start

(

Fuel tank cap

)

Choke lever / half-throttle lock (DSH 700

OR DSH 900)

+

Throttle trigger

§

Rear grip

/

Type identification plate

:

Fuel-level sight glass

∙

Guide rollers

$

Cutting disc

£

Clamping screw

|

Clamping flange

¡

Spark plug connector

Q

Decompression valve

W

Throttle safety grip

E

Start/stop switch (DSH 700 OR DSH 900)

E

Start/stop switch with integrated halfthrottle lock (DSH 700-X OR DSH 900-X)

R

Primer bulb

T

Water connection

Z

Grip for guard adjustment

U

Disc direction-of-rotation indicator (arrow at

front of guard)

I

Saw arm

O

Hole for locking pin for changing cutting

discs

P

Pump cover

Ü

Air filter cover

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

Loading...

Loading...