Hilti DSH 700, DSH 900 Original Operating Instructions

DSH 700/

DSH 900

*288291*

288291

HiltiCorporation

LI-9494Schaan

Tel.:+423/ 2342111

Fax:+423/ 2342965

www.hilti.com

Hilti= registeredtrademarkofHilti Corp.,Schaan W 35030310 00-Pos.2 1 Printed inItaly © 2010

Rightof technicalandprogrammechanges reserved S.E. &O.

288291/ D

Operatinginstructions en

Brugsanvisning da

Bruksanvisning sv

Bruksanvisning no

Käyttöohje fi

Instrukcjaobsługi pl

Инструкцияпо зксплуатации ru

1/3

1/3

1/3

15

1

3/8

6

5

2/6

4/7

16

17

15

4

5

0.5mm

2/8

14

6

7

5

1/12

2

10

8

4

4

3

12

2

3

13

00_Cover_DSH700_900_P2.qxd:00_Cover_DSH700_900_P1.qxd 25.3.2010 15:47 Uhr Seite 1

19

2

"≠

+# +] +[

"Ç

+|

5 +}

+≠ 7 6

+±

4 +{ "#

+“ "“

"[

+Ç

3 "±

8

1

ꨍ

ꨏ

ꨔ

ꨑ

ꨎ

ꨐ

ꨕ

ꨒ

ꨓ

2

1/8

1/8

4

2/7/9

3

3

1/15

14

2/4

5/13

4

6

3/10

8

7

9

11

4

1

2

5

1

5

7

3

2/4

3

6

6

6

2

5

6

3

4

8

9/10

8

7

3/4

3/4

3/4

3/4

11

1/5

1/5

2

10

8 9

00_Cover_DSH700_900_P2.qxd:00_Cover_DSH700_900_P1.qxd 25.3.2010 15:47 Uhr Seite 5

ORIGINAL OPERATING INSTRUCTIONS

DSH 700/ DSH 900 cut-off saw

It is essential that the operating instructions

are read before the machine is operated for

the first time.

Always keep these operating instructions

together with the machine.

Ensure that the operating instructions are

with the machine when it is given to other

persons.

Contents Page

1. General information 2

2. Description 3

3. Accessories 4

4. Technical data 5

5. Safety instructions 7

6. Before use 10

7. Operation 14

8. Care and maintenance 15

9. Troubleshooting 19

10. Disposal 21

11. Manufacturer’s warranty 21

12. EC declaration of conformity 22

1 These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out

cover pages. Keep these pages open while studying

the operating instructions.

In these operating instructions, the designation “the

machine” always refers to the DSH 700 or DSH 900

hand-held gas saw.

Parts, operating controls and indicators (DSH 700 /

DSH 900) 1

@

Forward grip

;

Rear grip

=

Guide wheels

%

Start/stop switch

&

Choke lever / half-throttle lock

(

Throttle safety grip

)

Throttle trigger

+

Decompression valve

§

Fuel pump

/

Starter handle

:

Cutting disc

·

Clamping screw

$

Hole for locking pin for changing cutting discs

£

Clamping flange

|

Guard (hood)

¡

Disc guard adjustment grip

Q

Water valve

W

Water connection

E

Fuel tank cap

R

Air filter cover

T

Belt tensioner

Z

Exhaust / muffler

U

Spark filter

I

Spark plug connector

O

Type identification plate

DSH-FSC saw carriage 2

@

Grip

;

Throttle trigger

=

Cutting depth adjustment

%

Hold-down device

&

Water tank

(

Water connection

)

Axial adjustment

+

Throttle cable

§

Machine cradle

en

1

5100

r

p

m

m

a

x.

1. General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that could lead

to serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation

that could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation

that could lead to slight personal injury or damage to

the equipment or other property.

NOTE

Draws attention to an instruction or other useful

information.

1.2 Explanation of the pictograms and other

information

Prohibition signs

Transport by

crane is not

permissible.

Warning signs

General

warning

Warning: hot

surface

Warning:

Flying sparks

present a fire

risk.

Warning: Risk

of kickback.

Warning:

Don’t inhale

toxic vapors or

exhaust

fumes.

Minimum

permissible

speed rating of

the cutting

discs used

Obligation signs

Wear

protective

gloves.

Wear safety

shoes.

Wear ear

protection, eye

protection,

respiratory

protection and

a hard hat.

Don’t use

toothed

cutting discs.

Don’t use

damaged

cutting discs.

Smoking and

naked flames

prohibited.

Symbols

Read the

operating

instructions

before use.

Motor stop

system

Fuel pump

Location of identification data on the machine

The type designation and serial number can be found

on the type identification plate on the machine. Make

a note of this data in your operating instructions and

always refer to it when making an enquiry to your

Hilti representative or service department.

Type:

Generation: 01

Serial no.:

en

2

2. Description

2.1 Use of the product as directed

The machine is intended for hand-held or walk-behind

use for dry or wet cutting of asphalt and mineral

or metallic construction materials using abrasive or

diamond cutting discs.

To reduce the amount of dust produced when cutting,

we recommend use of the wet cutting method.

The working environment may be as follows: construction site, workshop, renovation, conversion or

new construction.

To avoid the risk of injury, use only genuine Hilti

accessories and cutting tools.

Observe the safety rules and operating instructions

for the accessories used.

Working on materials hazardous to the health (e.g.

asbestos) is not permissible.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

Nationally applicable industrial safety regulations

must be observed.

The machine is designed for professional use and

may be operated, serviced and maintained only by

trained, authorized personnel. This personnel must

be informed of any special hazards that may be encountered. The machine and its ancillary equipment

may present hazards when used incorrectly by untrained personnel or when used not as directed.

Take the influences of the surrounding area into

account. Do not use the power tool or appliance

where there is a risk of fire or explosion.

Modification of the machine or tampering with its

parts is not permissible.

Don’t work in closed, poorly ventilated rooms.

2.2 Items supplied as standard

1 Machine

1 DSH tool set

1 Operating instructions

1 DSH consumables kit

2.3 Abrasive cutting discs for hand-guided

gasoline-powered cut-off saws

Abrasive cutting discs for gasoline-powered cut-off

saws are composed of synthetic resin-bonded ab-

rasive granulate. These cutting discs feature fabric

or fiber reinforcement which improves their strength,

toughness and breakage resistance.

NOTE

Abrasive cutting discs for gasoline-powered cut-off

saws are used mainly for cutting ferrous and nonferrous metals.

NOTE

Various grit types such as aluminum oxide, silicon

carbide, zirconium, etc., with a different bonding

material (matrix) or matrix hardness, are available

depending on the construction material to be cut.

2.4 Diamond cutting discs for hand-guided

gasoline-powered cut-off saws

Diamond cutting discs for gasoline-powered cut-off

saws consist of a steel core (disc) with diamond

segments (metallically bonded industrial diamonds).

NOTE

Segmented diamond cutting discs or those with a

continuous cutting face are mainly used for cutting

asphalt and mineral construction materials.

2.5 Cutting disc specifications

Diamond cutting discs in compliancewith the requirements of EN 13236 are to be used with the machine.

Synthetic resin-bonded fiber-reinforced cutting discs

in compliance with EN 12413 (straight, not offset,

type 41) may also be used with this machine for

working on metals. The mounting instructions and

instructions for use issued by the disc manufacturer

must also be observed.

2.6 Recommendations for use

We recommend that the workpiece is not cut through

in a single operation. Advance to the required depth

of cut by making several to-and-fro movements.

To avoid damaging the diamond cutting disc when

dry cutting, lift the blade out of the cut for approx. 10

seconds every 30 to 60 seconds while the machine is

still running.

To reduce the amount of dust produced when cutting,

we recommend use of the wet cutting method.

en

3

3. Accessories

Accessories for the DSH 700 and DSH 900

Diamond cutting disc

000000, See main catalog.

Abrasive cutting disc

000000, See main catalog.

Two-stroke oil

DSH (1 L)

365827

Water supply unit DWP 10 365595

Saw carriage DSH-FSC

431364

Hard hat 267736

Protective glasses

I-VO B05 PS clear

285780

Container DSH

365828

Consumables kit DSH

365602

Consumables and wearing parts for the DSH 700

Air filter DSH

261990

Cord (5 pcs) DSH

412230

Starter DSH 700

359425

Drive belt

DSH 12/14"

359476

Filter element

DSH

412228

Spark plug DSH

412237

Tool set

DSH

359648

Cylinder set DSH 700

412245

Fastening screw assy.

DSH

412261

Flange (2)

DSH

412257

Centering ring 20 mm / 1" DSH

412264

Consumables and wearing parts for the DSH 900

Air filter DSH

261990

Cord (5 pcs) DSH

412230

Starter DSH 900

359427

Drive belt

DSH 12/14"

359476

Drive belt

DSH 16"

359477

Filter element

DSH

412228

Spark plug DSH

412237

Tool set

DSH

359648

Cylinder set DSH 900

412384

Fastening screw assy.

DSH

412261

Flange (2)

DSH

412257

Centering ring 20 mm / 1" DSH

412264

en

4

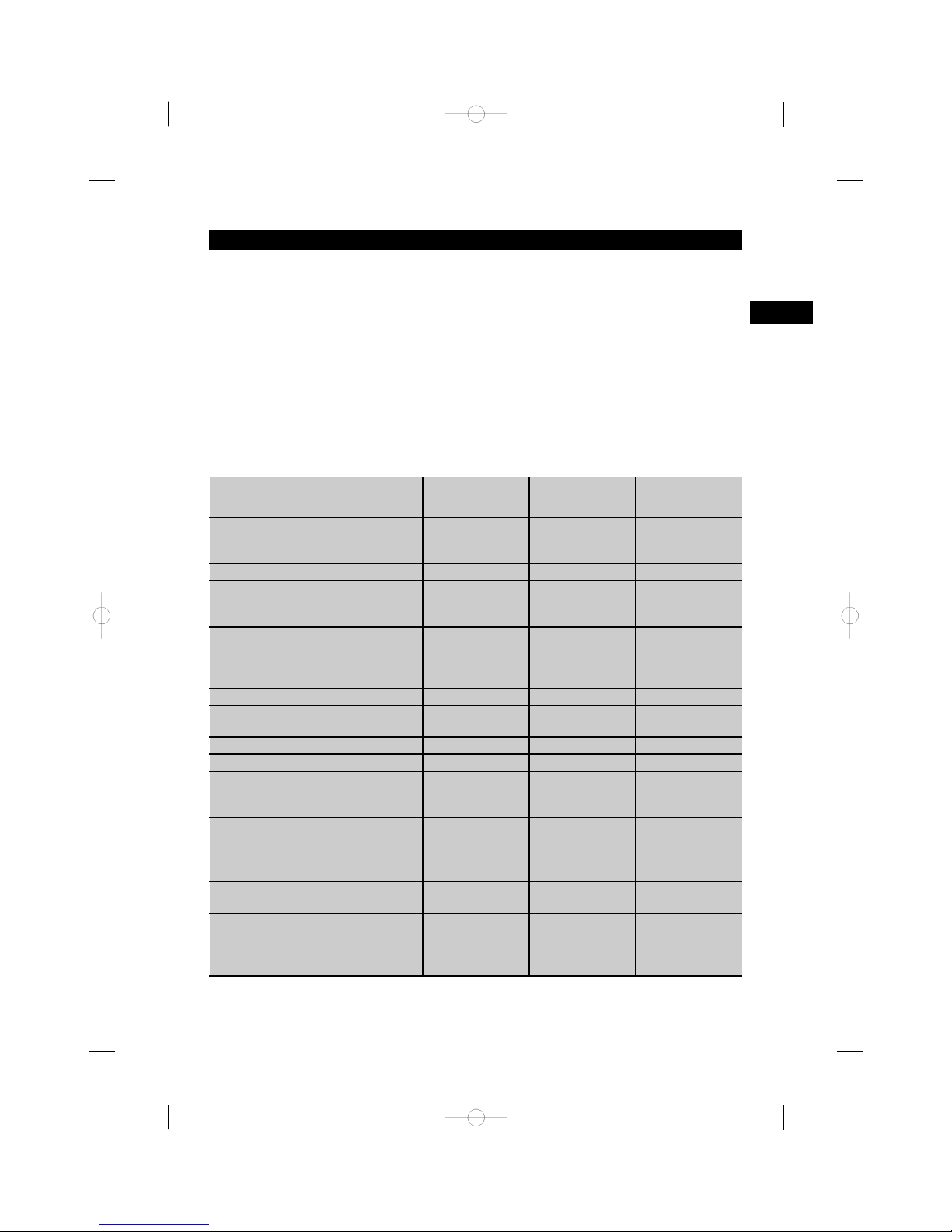

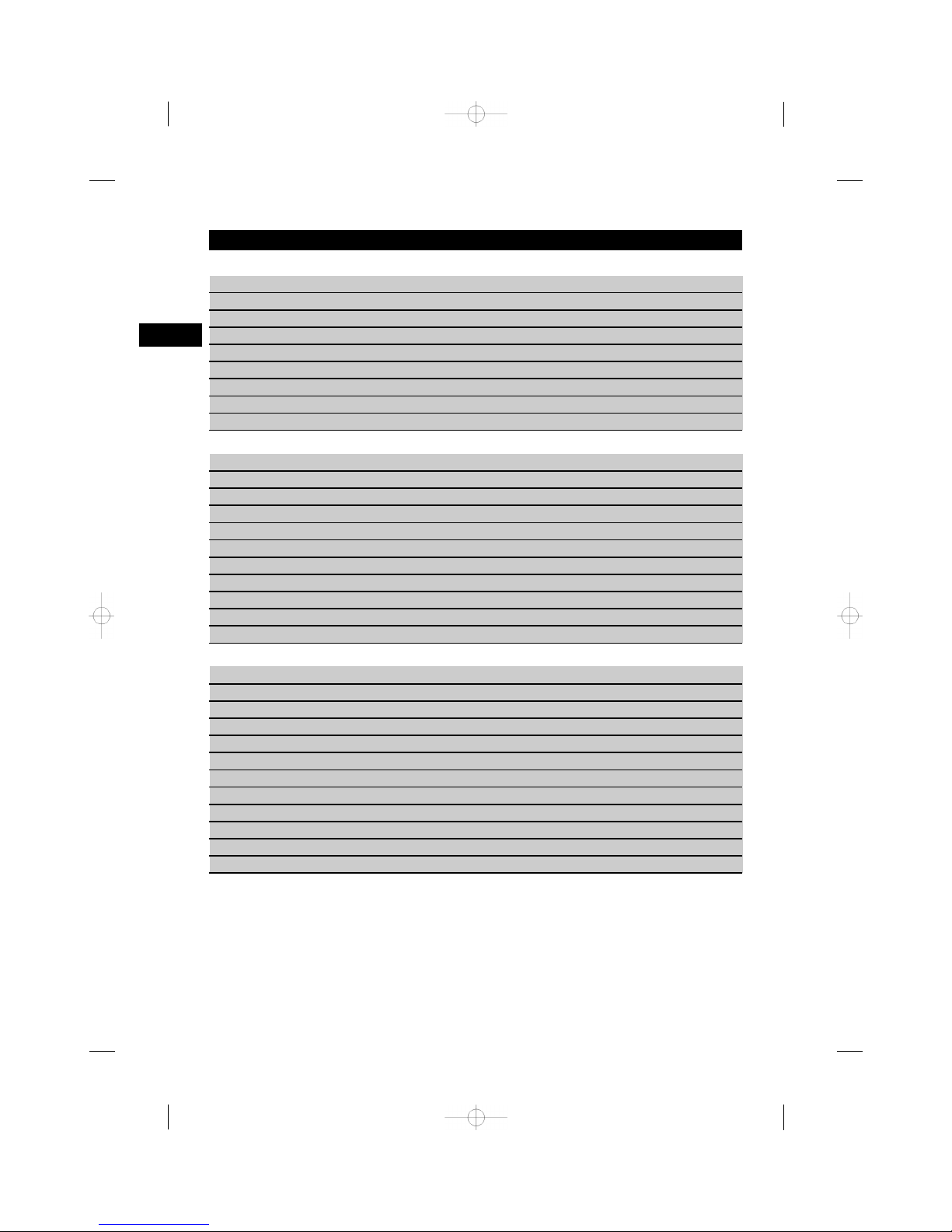

4. Technical data

Right of technical changes reserved.

NOTE

The vibration emission level given in this information sheet has been measured in accordance with a

standardised test given in EN 19432 and may be used to compare gasoline-powered cut-off saws with

each other. It may be used for a preliminary assessment of exposure. The declared vibration emission level

represents the main applications of the machine. However if the machine is used for different applications, with

different accessories or poorly maintained, the vibration emission may differ. This may significantly increase

the exposure level over the total working period. Note that excessive exposure of the hand-arm system to

vibration may cause blood circulation disorders (e.g. Raynaud’s disease). An estimation of the level of exposure

to vibration should also take into account the times when the machine is switched off or when it is running

but not actually doing the job. This may significantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator from the effects of vibration such as: maintain the

machine and the accessories, keep the hands warm, organisation of work patterns.

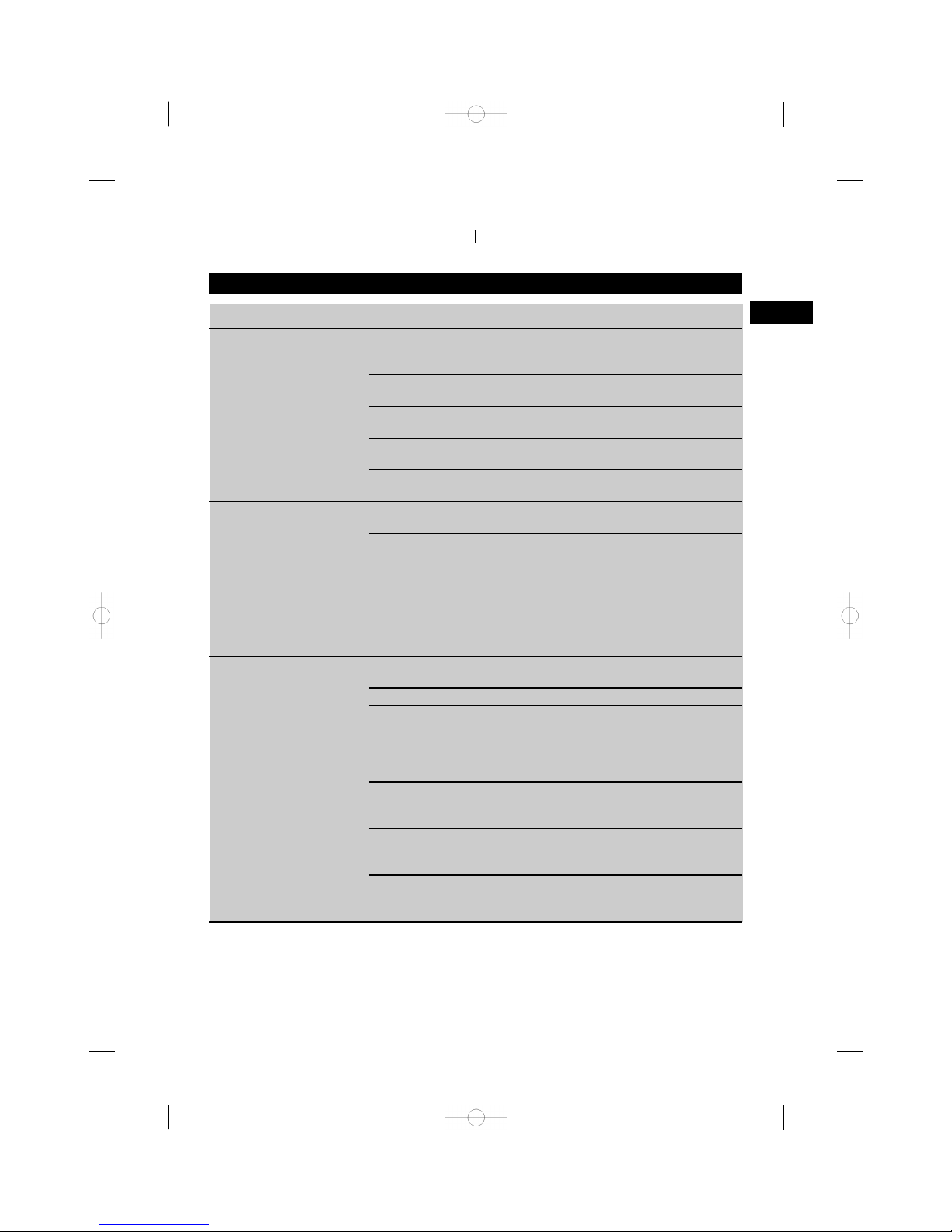

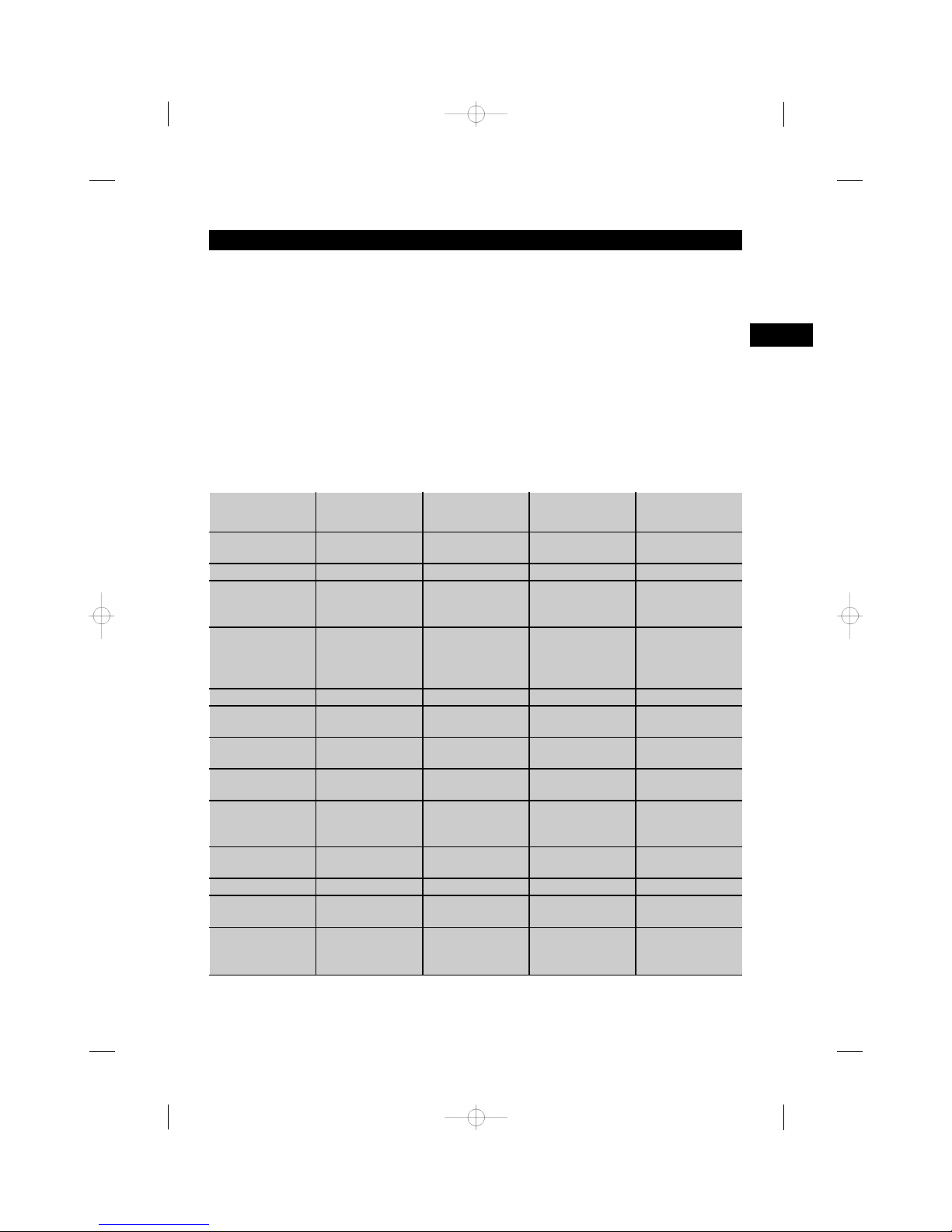

Machine

DSH 700 30 cm

/ 12"

DSH 700 35 cm

/ 14"

DSH 900 35 cm

/ 14"

DSH 900 40 cm

/ 16"

Motor type Two-stroke /

single-cylinder /

air-cooled

Two-stroke /

single-cylinder /

air-cooled

Two-stroke /

single-cylinder /

air-cooled

Two-stroke /

single-cylinder /

air-cooled

Cubic capacity

68.7 cm³ 68.7 cm³ 87 cm³ 87 cm³

Weight without

cutting disc, tank

empty

11.3 kg 11.5 kg 11.7 kg 11.9 kg

Weight with saw

carriage, without

cutting disc, tank

empty

42.3 kg 42.5 kg 42.7 kg 42.9 kg

Power rating 3.7 kW 3.7 kW 4.5 kW 4.5 kW

Maximum arbor

speed

5,100/min 5,100/min 5,100/min 4,700/min

Engine speed 10,000±200/min 10,000±200/min 10,000±200/min 10,000±200/min

No-load speed 2,500…3,000/min 2,500…3,000/min 2,500…3,000/min 2,500…3,000/min

Dimensions with

cutting disc (L x

W x H) in mm

783 X 261 X 434 808 X 261 X 434 808 X 261 X 434 856 X 261 X 466

Ignition (type) Electronically-

controlled ignition

timing

Electronicallycontrolled ignition

timing

Electronicallycontrolled ignition

timing

Electronicallycontrolled ignition

timing

Electrode gap 0.5 mm 0.5 mm 0.5 mm 0.5 mm

Spark plug Manufacturer: NGK

Type: CMR7A-5

Manufacturer: NGK

Type: CMR7A-5

Manufacturer: NGK

Type: CMR7A-5

Manufacturer: NGK

Type: CMR7A-5

Carburetor Manufacturer: Wal-

bro

Model: WT

Type: 895

Manufacturer: Walbro

Model: WT

Type: 895

Manufacturer: Walbro

Model: WT

Type: 895

Manufacturer: Wal-

bro

Model: WT

Type: 895

en

5

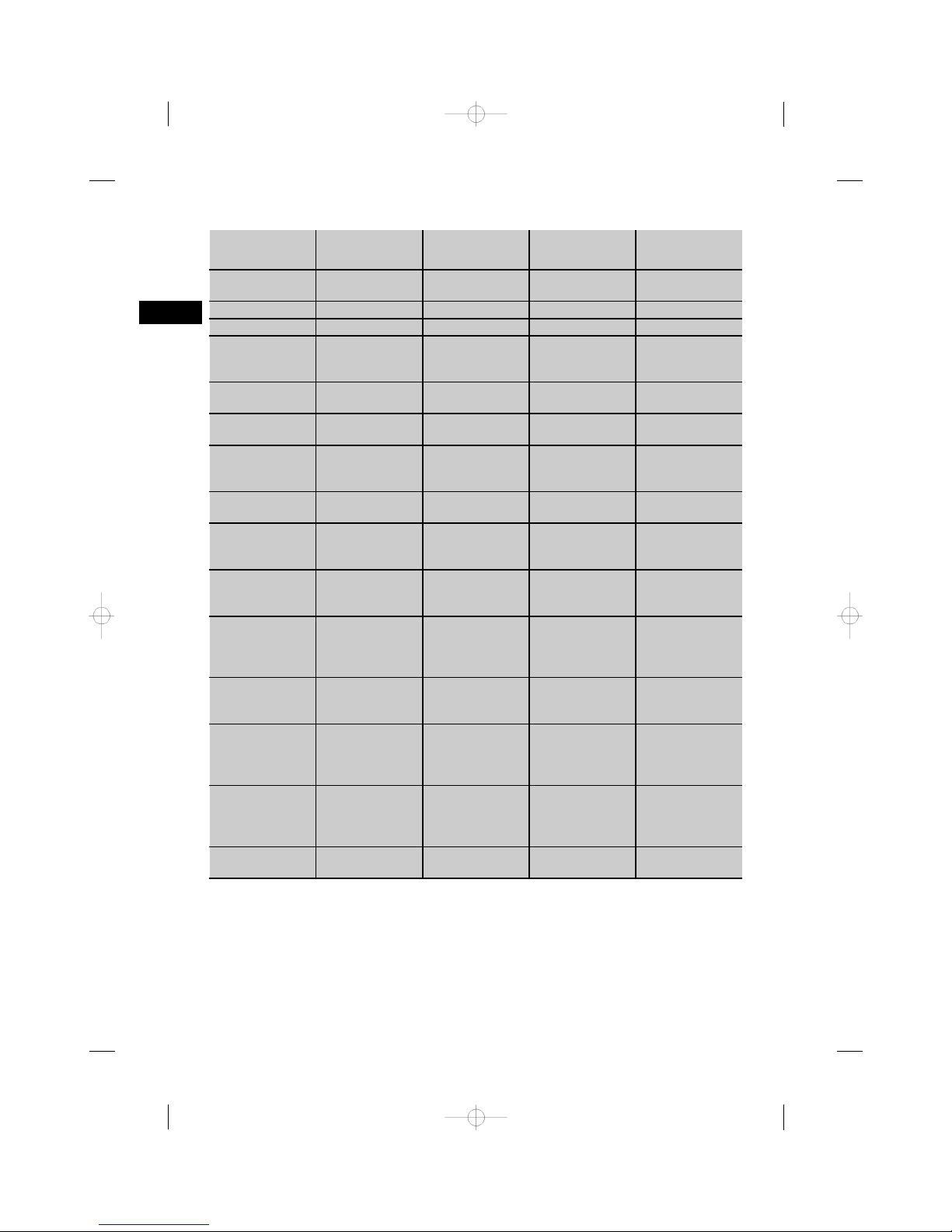

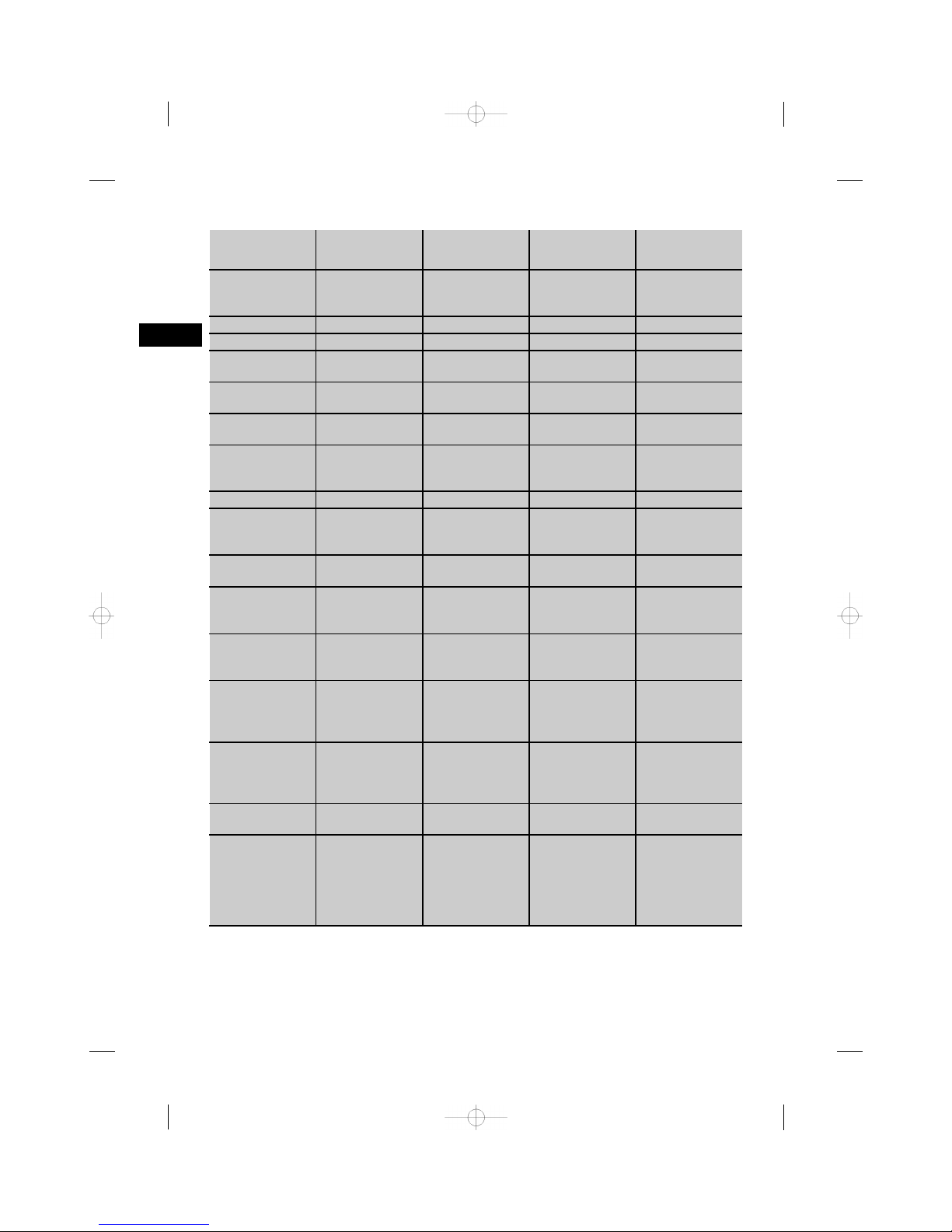

Machine

DSH 700 30 cm

/ 12"

DSH 700 35 cm

/ 14"

DSH 900 35 cm

/ 14"

DSH 900 40 cm

/ 16"

Fuel mixture Hilti oil 2% (50:1)

or TC oil 4% (25:1)

Hilti oil 2% (50:1)

or TC oil 4% (25:1)

Hilti oil 2% (50:1)

or TC oil 4% (25:1)

Hilti oil 2% (50:1)

or TC oil 4% (25:1)

Tank capacity 900 cm³ 900 cm³ 900 cm³ 900 cm³

Cutting disc mount

Reversible Reversible Reversible Reversible

Disc drilling diameter/arbor holding bore

20 mm or 25.4 mm 20 mm or 25.4 mm 20 mm or 25.4 mm 20 mm or 25.4 mm

Max. disc outside

diameter

308 mm 359 mm 359 mm 410 mm

Min. flange outside

diameter

102 mm 102 mm 102 mm 102 mm

Max. disc thickness (steel disc

thickness)

5.5 mm 5.5 mm 5.5 mm 5.5 mm

Maximum cutting

depth

100 mm 125 mm 125 mm 150 mm

Sound pressure

level* LpA,eq ISO

19432 (ISO 11201)

99 dB (A) 99 dB (A) 102 dB (A) 102 dB (A)

Uncertainty for

noise pressure

level LpA,eq

2.8 dB (A) 2.8 dB (A) 3.0 dB (A) 3.0 dB (A)

Measured sound

power level

2000/14/EC (ISO

3744)

108 dB (A) 108 dB (A) 112 dB (A) 112 dB (A)

Uncertainty for

measured sound

power level

2.5 dB (A) 2.5 dB (A) 2.5 dB (A) 2.5 dB (A)

Guaranteed sound

power level LwA

2000/14/EC (ISO

3744)

111 dB (A) 111 dB (A) 115 dB (A) 115 dB (A)

Vibration value*

ahv,eq front/rear

grip ISO 19432 (EN

12096)

4.5 / 3.2 m/s² 4.7 / 5.0 m/s² 6.3 / 6.2 m/s² 5.2 / 4.5 m/s²

Uncertainty for

vibration value

2.4 / 2.1 m/s² 2.2 / 2.1 m/s² 1.9 / 2.7 m/s² 2.3 / 2.1 m/s²

en

6

Machine

DSH 700 30 cm

/ 12"

DSH 700 35 cm

/ 14"

DSH 900 35 cm

/ 14"

DSH 900 40 cm

/ 16"

Comment

* The sound pressure level and the

vibration values

were determined

allowing for 1/7

no-load operation

and 6/7 full-load

operation.

* The sound pressure level and the

vibration values

were determined

allowing for 1/7

no-load operation

and 6/7 full-load

operation.

* The sound pressure level and the

vibration values

were determined

allowing for 1/7

no-load operation

and 6/7 full-load

operation.

* The sound pres-

sure level and the

vibration values

were determined

allowing for 1/7

no-load operation

and 6/7 full-load

operation.

5. Safety instructions

In addition to the information relevant to safety

given in each of the sections of these operating

instructions, the following points must be strictly

observed at all times.

5.1 General safety rules

a) Use the right tool or machine for the job. Do not

use the tool or machine for purposes for which

it was not intended. Use it only as directed and

when in faultless condition.

b) Avoid touching rotating parts. Switch the power

tool on only after bringing it into position at

the workpiece. Touching rotating parts, especially

rotating drill bits, discs or blades, etc. may lead to

injury.

c) Use only the genuine Hilti accessories or ancil-

lary equipment listed in the operating instructions. Use of accessories or ancillary equipment

not listed in the operating instructions may present

a risk of personal injury.

d) Always hold the saw and the saw carriage se-

curely with both hands on the grips provided.

Keep the grips dry, clean and free from oil and

grease.

e) Cuts made in loadbearing walls of buildings or

other structures may influence the statics of the

structure, especially when steel reinforcing bars or

load-bearing components are cut through. Consult

the structural engineer, architect, or person in

charge of the building project before beginning

the work.

f) Do not overload the machine. It will work more

efficiently and more safely within its intended

performance range.

g) Never use the power tool without the guard

(hood).

h) Take steps to ensure that flying sparks from

the power tool do not present a hazard, i.e.

by striking yourself or other persons. Adjust the

position of the disc guard accordingly.

i) Adjust the position of the disc guard on the

machine correctly. The guard must be securely

attached to the machine and positioned for maximum safety, so the least amount of cutting disc

is exposed towards the operator. The guard helps

to protect the operator from broken disc fragments

and accidental contact with the disc.

j) Store machines in a secure place when not in

use. When not in use, machines must be stored

in a dry, high place or locked away out of reach

of children.

k) Switch the machine off before transporting it.

l) When laying the machine down, make sure that

it stands securely.

m)Switch the machine off after use.

n) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

o) Maintain the machine carefully. Check for mis-

alignment or binding of moving parts, breakage

of parts and any other condition that may affect

the machine’s operation. If damaged, have the

machine repaired before use. Poor maintenance

is the cause of many accidents.

p) Set the switch to the “stop” position before

changing the cutting disc or adjusting the guard.

q) Don’t leave the machine unattended while the

motor is running.

r) Always apply full throttle when cutting.

s) Hold the machine by insulated gripping surfaces

when performing an operation where the cutting

en

7

disc may contact hidden wiring. Contact with a

“live” wire will make exposed metal parts of the

machine “live” and shock the operator.

t) Children must be instructed not to play with the

machine.

u) The machine is not intended for use by debilit-

ated persons or children.

v) Lifting the saw and saw carriage by crane is not

permissible.

w) Do not stand the saw and saw carriage on an

inclined surface. Always check to ensure that the

saw and saw carriage are standing securely.

5.2 Proper organization of the work area

a) Ensure that the workplace is well lit.

b) Ensure that the workplace is well ventilated.

Exposure to dust at a poorly ventilated workplace

may result in damage to the health.

c) Don’t work in closed rooms. Carbon monoxide,

unburned hydrocarbons and benzene in the exhaust gas may cause asphyxiation.

d) Keep the workplace tidy. Objects which could

cause injury should be removed from the working

area. Untidiness at the workplace can lead to

accidents.

e) Secure the workpiece. When necessary, use

clamps or a vice to secure the workpiece. Don’t

hold the workpiece by hand.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) It is recommended that non-slip shoes or boots

are worn when working outdoors.

h) Keep children away. Keep other persons away

from the working area.

i) Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of

the power tool in unexpected situations.

j) Fit the filled water tank to the saw carriage only

after fitting the saw to the saw carriage. This

will prevent the saw carriage falling over.

k) Concealed electric cables or gas and water pipes

present a serious hazard if damaged while you

are working. Accordingly, check the area in

which you are working beforehand (e.g. using

a metal detector). External metal parts of the

machine may become live, for example, when an

electric cable is damaged accidentally.

l) Don’t work from a ladder.

m)Don’t work above shoulder height.

n) If the work involves breaking right through, also

apply the appropriate safety measures at the

opposite side. Parts breaking away could fall out

and / or fall down and injure other persons.

o) Secure the area below the working area.

p) When using the wet cutting technique, take care

to ensure that the waterdrains away incontrolled

fashion and check that the water or water spray

presents no hazard and causes no damage to the

surrounding area.

q) Secure the area below the working area.

5.3 Thermal

a) Wear protective gloves when changing cutting

tools as they get hot during use.

b) The exhaust system and motor get very hot. Al-

ways hold the machine securely with both hands

on the grips provided.

5.4 Liquids (gasoline and oil)

a) Store gasoline and oil in a well-ventilated room

in fuel containers in compliance with regulations.

b) Allow the machine to cool before refueling.

c) Use a suitable funnel when refueling.

d) Don’t usethe gasoline or other flammable liquids

for cleaning.

e) Don’t refuel the machine at the workplace.

f) When refueling, take care to avoid spillage of

gasoline.

5.5 Sawing slurry

Avoid skin contact with sawing slurry.

en

8

5.6 Vapors

a) Don’t smoke when filling the tank with fuel!

b) Avoid inhaling gasoline vapors and exhaust

fumes.

c) Hot exhaust gases containing sparks or sparks

generated by the cutting operation may cause fire

or explosion. Take care to ensure that the sparks

generated do not ignite flammable (gasoline, dry

grass, etc.) or explosive (gas, etc.) substances.

5.7 Dusts

a) Large quantities of dust hazardous to the health

are generated when cutting (especially when dry

cutting). The operator and bystanders must wear

suitable dust masks while the machine is in use.

b) Dust or vapors containing chemical substances

may be generated when working on unknown

materials. These substances could cause serious

damage to the health. Obtain information about

hazards presented by the materials from the client or the authorities responsible. The operator

of the machine and any bystanders must wear

respiratory protection that is approved for use in

conjunction with the applicable substance.

c) To reduce the amount of dust generated when

cutting mineral materials and asphalt, we recommend use of the wet cutting technique.

d) Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust

may cause allergic reactions and/or respiratory

diseases to the operator or bystanders. Material containing asbestos must only be treated by

specialists. To reduce the amount of dust pro-

duced when cutting, we recommend use of the

wet cutting method. Ensure that the workplace

is well ventilated. The use of a dust mask of

filter class P2 is recommended. Follow national

requirements for the materials you want to work

with.

5.8 Requirements to be met by users

a) Improve the blood circulation in your fingers by

relaxing your hands and exercising your fingers

during breaks between working.

b) Stay alert, watch what you are doing and use

common sense when operating the machine.

Don’t use the machine when you are tired or

under the influence of drugs, alcohol or medication. A moment of inattention while operating

machines may result in serious personal injury.

5.9 Safety warnings for abrasive cutting-off

operations

a) Check that the cutting disc is fitted in accordance

with the manufacturer’s instructions.

b) Cutting discs must be stored and handled care-

fully in accordance with the manufacturer’s instructions.

c) Use only cutting discs with a rated maximum

permissible speed which is at least as high as

the machine’s highest running speed.

d) Cutting discs which are damaged or out of round

(causing vibration) must not be used.

e) The outside diameter and the thickness of the

cutting disc must be within the capacity rating of

the machine. Incorrectly sized accessories cannot

be adequately guarded or controlled.

f) Don’t use toothed cutting discs (saw blades or

similar). Blades or discs of this kind frequently

cause kickback or loss of control of the machine.

g) Guide the machine evenly and do not apply

lateral pressure to the cutting disc. Always bring

the machine into contact with the workpiece at

right angles. Don’t attempt to alter the line of

cut by applying lateral pressure or by bending

the cutting disc while cutting is in progress. This

presents a risk of damaging or breaking the cutting

disc.

h) Don’t attempt to brake the cutting disc with the

hand.

i) The cutting disc and flange or any other access-

ory must fit the arbor of the machine exactly.

Cutting discs or accessories with arbor holes that

do not match the mounting hardware of the ma-

en

9

chine will run out of balance, vibrate excessively

and may cause loss of control.

j) Always use undamaged disc mounting flanges of

the correct diameter for the cutting discs used.

Correctly sized flanges support the cutting disc

and thus reduce the possibility of disc breakage.

k) When fitting the cutting disc, always take care

to ensure that the disc’s specified direction of

rotation corresponds to the direction of rotation

of the machine.

l) Store the cutting disc in accordance with the

manufacturer’s recommendations. Incorrect or

careless storage may damage the cutting disc.

m)Don’t use cutting discs with a thickness greater

than 5.5 mm (0.22").

n) Remove the cutting disc from the machine after

use. The cutting disc may suffer damage if the

machine is transported with the disc fitted.

o) Abrasive cutting discs for gasoline-powered cut-

off saws which are used for wet cutting must

be used up the same day as long periods of

exposure to moisture have a negative effect on

the strength of the disc.

p) Observe the expiry date for resin-bonded cutting

discs and don’t use the discs after this date.

q) Resharpen polished diamond segments (no dia-

monds project from the segment matrix) by cutting with the disc in a very abrasive material

such as sandstone.

r) Don’t use damaged diamond cutting discs

(cracks in the steel disc, broken or polished

segments, damaged arbor hole, bent or

distorted steel disc, heavy discoloration due to

overheating, steel disc worn away beneath the

segments, diamond segments with no lateral

overhang, etc.)

5.10 Personal protective equipment

The user and any other persons in the vicinity

must wear suitable eye protection, a hard hat, ear

protection, protective gloves and safety footwear

while the machine is in use.

6. Before use

6.1 Fuel

NOTE

The two-stroke motor runs on a mixture of gasoline

and oil. The quality of the fuel mixture decisively

influences the running and life expectancy of the

motor.

CAUTION

Avoid direct skin contact with gasoline.

CAUTION

Ensure that the workplace is well ventilated in order

to avoid breathing in gasoline fumes.

CAUTION

Use a fuel container that complies with the applicable regulations.

CAUTION

Alkylate gasoline does not have the same density

(specific weight) as conventional gasoline. To avoid

damage when alkylate gasoline is used, the machine

must be readjusted by Hilti Service. Alternatively, the

oil content can be increased to 4% (1:25).

6.1.1 Two-stroke oil

Use Hilti two-stroke oil for air-cooled motors or a

good quality two-stroke oil with the TC classification.

6.1.2 Gasoline

Use regular or super gasoline with an octane rating

of at least 90 ROZ.

The alcohol content (e.g. ethanol, methanol...) of the

fuel used must not exceed 10%, otherwise the life

expectancy of the motor will be greatly reduced.

en

10

5100

r

p

m

m

a

x.

6.1.3 Mixing fuel

CAUTION

The motor will suffer damage if run with fuel mixed

in the wrong ratio or with unsuitable oil. Use the

following mix ratio with Hilti two-stroke oil: 1 part

oil + 50 parts gasoline. Use the following mix ratio

with quality two-stroke oilwith the TC classification:

1 part oil + 25 parts gasoline.

1. Pour the required quantity of two-stroke oil into

the fuel container.

2. Add the gasoline to the fuel container.

3. Close the cap on the fuel container.

4. Mix the fuel by shaking the fuel container.

6.1.4 Storing the fuel mixture

CAUTION

Pressure may build up in the fuel tank. Accordingly,

take care when opening the fuel tank cap.

CAUTION

Store the fuel in a dry, well-ventilated room.

Mix only enough fuel for a few days’ use.

Clean the fuel container occasionally.

6.1.5 Filling the machine with fuel

CAUTION

Don’t refuel the machine right at the place where

you are working (move at least 3 meters (10 feet)

away from the object you have been cutting).

DANGER

Don’t smoke when filling the tank with fuel!

CAUTION

Don’t refuel the machine in a room where a naked

flame or sparks could ignite the gasoline vapors.

CAUTION

Don’t refuel the machine while the motor isrunning.

CAUTION

Don’t refuel the machine while the motor is hot.

CAUTION

Wear suitable protective gloves when refueling.

CAUTION

Take care to avoid spilling fuel.

CAUTION

If your clothing becomes soiled with gasoline while

refueling, you must change your clothing.

CAUTION

After refueling, clean the machine and accessories

to remove any spilt fuel.

DANGER

Check to ensure there is no leakage from the machine. Don’t start the machine if fuel is found to be

leaking from it.

1. Mix the fuel (two-stroke oil / gasoline mixture) by

shaking the fuel container.

2. Place the machine in a steady upright position.

3. Open the fuel tank cap by turning it counterclockwise.

4. Fill the tank slowly using a funnel.

5. Close the fuel tank cap by turning it clockwise.

6. Close the cap on the fuel container.

6.2 Fitting and changing the cutting disc 3

CAUTION

Cutting discs which are damaged or out of round

(causing vibration) must not be used.

CAUTION

The maximum permissible speed of the disc or

blade must be at least as high as the maximum

speed printed on the machine. Accessories driven

at a speed above their maximum permissible speed

may break and fly apart.

CAUTION

Use only cutting discs with a 20 mm or 25.4 mm

(1") arbor hole.

CAUTION

The cutting discs, flanges or other accessories

must properly match the arbor size of the machine.

Cutting discs or accessories with arbor holes that do

not match the mounting hardware of the machine will

en

11

run out of balance, vibrate excessively and may cause

loss of control.

CAUTION

Don’t use synthetic resin-bonded fiber-reinforced

cutting discs that have exceeded their use-by date.

CAUTION

Don’t use damaged diamond cutting discs (cracks in

the steel disc, broken or polished segments, damaged arbor hole, bent or distorted steel disc, heavy

discoloration due to overheating, steel disc worn

away beneath the segments, diamond segments

with no lateral overhang, etc.)

1. Insert the locking pin in the hole in the drive belt

cover and turn the cutting disc until the locking

pin engages.

2. Use the wrench to release the clamping screw by

turning it counterclockwise.

3. Remove the clamping flange and the cutting disc.

4. Check that the mounting bore of the cutting disc

to be fitted corresponds with the centering collar

of the cutting disc mounting flange. The mounting flange is provided with a 20 mm diameter

centering collar on one side and a 25.4 mm (1")

diameter centering collar on the opposite side.

5. Clean the clamping and centering surfaces on the

machine and on the cutting disc.

6. CAUTION Take care to ensure that the direction

of rotation of the cutting disc (indicated by an

arrow) matches the direction of rotation shown

on the machine.

Place the cutting disc on the centering collar of

the clamping flange.

7. Place the clamping flange on the drive arbor and

tighten the cutting disc clamping screw by turning

it clockwise.

8. Insert the locking pin in the hole in the drive belt

cover and turn the cutting disc until the locking

pin engages.

9. Tighten the cutting disc clamping screw to a

torque of 25 Nm.

6.3 Adjusting the guard

DANGER

Don’t operate the machine without the protective

devices that belong to it.

DANGER

Adjust the guard to the correct position. Direct

the particles of material removed away from the

operator and the machine.

WARNING

The motor and the cutting disc must have come

to a complete stop before making adjustments or

changing parts etc.

Hold the guard by the grip provided and rotate it to

the desired position.

6.4 Converting the saw from normal cutting

mode to flush cutting mode 4

DANGER

Adjust the guard to the correct position. Direct

the particles of material removed away from the

operator and the machine.

NOTE

After completion of flush cutting it is recommended

that thesaw is converted back to normal cutting mode

due to the more favorable balance in this position.

NOTE

After doing this, check that the cutting disc can be

turned easily by hand and that all screws have been

tightened securely.

en

12

DANGER

Don’t operate the machine without the protective

devices that belong to it.

In order to facilitate cutting as closely as possible to

edges and walls etc., the forward section of the saw

arm can be turned and fitted in the reversed position

so that the cutting disc, when seen from behind, is

positioned to the right of the saw arm.

1. Remove the spray jets from the guard.

2. Slacken the three clamping nuts on the forward

section of the saw arm approx. one complete turn.

3. Release the tension on the drive beltby turning the

belt tensioning cam counterclockwise carefully as

far as it will go (until resistance is felt, i.e. approx.

¼ of a turn).

4. Remove the three clamping nuts and the two

securing screws from the forward section of the

saw arm, then remove the drive belt cover and

the forward section of the saw arm.

5. Release the four securing screws on the rear drive

belt cover and remove the cover.

6. Remove the stop screw that limits rotation of the

forward section of the saw arm.

7. Place the drive belt carefully over the drive pulley.

8. Fit the forward section of the saw arm onto the

rear section of the saw arm. Fit only the middle

clamping nut. Tighten the nut only finger-tight.

9. Rotate the disc guard until the opening is at the

rear.

10. Tension the drive belt by turning the belt tensioning cam clockwise carefully as far as it will go

(until resistance is felt, i.e. approx. ¼ of a turn).

11. Secure the forward drive belt cover with the two

clamping nuts and two securing screws.

12. Tighten the three clamping nuts securely (18 Nm).

13. Fit the rear drive belt cover and secure it with the

four screws.

14. Rotate the disc guard until the opening is at the

front.

15. Fit the spray jets in the openings at the front of

the blade guard.

6.5 Locking rotary movement of the guide

wheels 5

WARNING

When working on roofs, scaffolds and/or slight

slopes, always lock the guide wheels to prevent the

saw rolling away inadvertently and possibly falling.

Use the built-in safety feature which allows you

to lock the wheels by fitting them in the reversed

position (turned through 180°).

1. Release the guide wheel mounting screws and

remove the guide wheels.

2. Reverse the guide wheels (turn through 180°)

and refit the mounting screws.

3. Check that the guide wheels are mounted securely.

6.6 Saw carriage 6

NOTE

We recommend use of the saw carriage when the

machine is used extensively for floor sawing.

NOTE

Especially when using the machine in this configuration for the first time, check to ensure that the

throttle cable is correctly adjusted. When the throttle

control is pressed fully, the machine must run up to

maximum speed. If this is not the case, the throttle

cable can be readjusted by way of the cable tensioner.

CAUTION

Switch off the saw at the stop switch immediately if

the throttle cable on the saw carriage gets stuck.

DANGER

Before starting the engine, check that the saw is

correctly secured to the saw carriage.

1. Move the cutting depth adjustment lever into the

upper position.

2. Open the hold-down device by releasing the screw

knob.

3. Fit the saw into the forwardmount with the wheels

as shown and swing the grip of the saw under the

hold-down device.

4. Secure the saw by tightening the screw knob.

5. Fit the water tank after filling it.

6. Adjust the grip to a convenient working height.

7. Adjust the guard to the correct position.

en

13

7. Operation

7.1 Starting the motor 7

CAUTION

Working on the material may cause it to splinter.

Wear eye protection and protective gloves. Wear

breathing protection if no dust removal system is

used. Splintering material presents a risk of injury to

the eyes and body.

CAUTION

The power tool and the cutting operation generate

noise. Wear ear protectors. Exposure to noise can

cause hearing loss.

CAUTION

The cutting disc and parts of the machine get hot

during use. Wear protective gloves when changing

the cutting disc. Touch the machine only at the grips

provided. You may otherwise burn your hands. Take

care to ensure that the machine, when hot, does

not come into contact with inflammable materials

during transport or storage.

WARNING

Keep other persons approx. 15 m away from your

workplace. Pay special attention to the working

area behind you.

DANGER

Don’t work in closed rooms. Carbon monoxide, un-

burned hydrocarbons and benzene in the exhaust gas

may cause asphyxiation.

WARNING

When the motor is idling, the cutting disc must

come to a complete stop. If this is not the case, the

idling speed must be reduced accordingly. If this is

not possible or does not achieve the desired result,

the machine must be returned for repair.

WARNING

If you notice that the throttle trigger has jammed,

stop the motor immediately by operating the on /

off switch.

WARNING

After fitting a new cutting disc, the machine must

be allowed to run at full speed under no load for

approx. 1 minute.

WARNING

Before using the machine, check to ensure that the

start / stop switch functions correctly. The motor

must stop running when the switch is moved to the

“stop” position.

1. Stand the machine on a solid surface on the floor.

2. Move the start / stop switch to the “start” position.

3. Press the fuel pump button (P) 2 to 3 times (until

the pump button is seen to be completely filled

with fuel).

4. Press the decompression valve.

5. If the motor is cold, pull the choke lever upwards.

This activates the choke and engages half throttle.

6. If the motor is hot, pull the choke lever up and

then push it back down. This engages half throttle

(with no choke).

7. Check that the cutting disc is free to rotate.

8. Hold the forward grip securely with the left hand

and place your right foot in the lower section of

the rear grip.

9. Pull the starter handle slowly with your right hand

until resistance is felt.

10. Pull the starter handle vigorously.

11. When the motor fires for the first time (after 2 to

5 pulls of the starter), move the choke lever back

to its original position.

12. Repeat this procedure, with the choke disengaged, until the motor starts.

NOTE The motor will flood if the starting procedure is repeated too many times with the choke

engaged.

en

14

13. Press the throttle as soon as the motor starts.

This disengages the half-throttle position and the

choke (if previously engaged), and the motor then

runs at idling speed when the throttle is released.

7.2 Cutting techniques

DANGER

Always hold the saw and the saw carriage securely

with both hands on the grips provided. Keep the

grips dry, clean and free from oil and grease.

DANGER

Check that no persons are present within the working area and, in particular, in the area ahead of the

saw (in the cutting direction).

DANGER

Guide the machine evenly and do not apply lateral pressure to the cutting disc. Always bring the

machine into contact with the workpiece at right

angles. Don’t attempt to alter the line of cut by

applying lateral pressure or by bending the cutting

disc while cutting is in progress. This presents a

risk of damaging or breaking the cutting disc.

CAUTION

Secure the workpiece and the part to be cut off in

order to prevent uncontrolled movement.

NOTE

Always apply full throttle when cutting.

NOTE

Avoid making excessively deep cuts. Cutting through

thick workpieces should be accomplished, as far as

possible, by making a several cuts.

7.2.1 Avoiding stalling 8

CAUTION

Avoid applying excessive pressure when cutting

and don’t allow the cutting disc to stick and stall.

Don’t attempt to cut to great depth immediately.

Application of excessive pressure increases the risk

of cutting disc distortion. Allowing the cutting disc to

stick or stall increases the probability of kickback or

disc breakage.

CAUTION

Support slabs or large workpieces so that the kerf

remains open during the cutting operation.

7.2.2 Avoiding kickback 9

CAUTION

Always bring the machine into contact with the

workpiece from above. Allow the cutting disc to

contact the workpiece only at a point below its

rotational axis.

CAUTION

Take special care when inserting the cutting disc in

an existing kerf.

7.3 Stopping the motor

WARNING

If the motor cannot be stopped by operating the on

/ off switch, the motor must be stopped, if need be,

by pulling the choke lever.

WARNING

Do not lay the machine down until the cutting disc

has stopped rotating. The machine must always be

stored and transported in an upright position.

1. Release the throttle trigger.

2. Move the start / stop switch to the “stop” position.

8. Care and maintenance

WARNING

Set the switch to “stop” before carrying out any

maintenance or repairs and before cleaning the

machine.

8.1 Maintenance

8.1.1 Each day before use

Check that the machine is complete and in faultless

condition. Have it repaired if necessary.

Check the machine for leakage. Have it repaired if

necessary.

en

15

Check the machine for dirt and dust and clean it if

necessary.

Check that all operating controls function correctly.

Have them repaired if necessary.

Check that the cutting disc is in faultless condition.

Replace it if necessary.

8.1.2 Every 6 months

Check the tightness of all screws and nuts accessible

from the outside.

Check that the fuel filter is clean (no dirt or deposits)

and replace it if necessary.

Retension the drive belt if it slips when the cutting

disc is under load.

8.1.3 When necessary

Check the tightness of all screws and nuts accessible

from the outside.

Replace the air filter if the machine doesn’t start or

motor performance drops noticeably.

Check that the fuel filter is clean (no dirt or deposits)

and replace it if necessary.

Clean or replace the spark plug if the machine doesn’t

start or is difficult to start.

Retension the drive belt if it slips when the cutting

disc is under load.

Readjust the motor idling speed if the cutting disc

doesn’t stop rotating when the machine is idling.

8.2 Replacing the air filter

DANGER

The operator and bystanders must wear breathing

protection if the work causes dust.

CAUTION

Dust entering the machine may cause irreparable

damage. Never operate the machine if the air filter

is damaged or missing. When changing the air filter,

the machine should stand upright and should not be

laid on its side. Take care to ensure that no dust finds

its way onto the underlying filter screen.

NOTE

Change the air filter if motor performance drops

noticeably or if the machine becomes difficult to

start.

NOTE

In this machine, most of the dust is removed from

the air flow by a maintenance-free cyclone-type prescreening system. This preliminary air cleaning process greatly reduces the amount of maintenance

required compared to conventional systems.

1. Release the securing screw on the air filter cover

and remove the cover.

2. Carefully remove the dust adhering to the air filter

and the filter chamber (use a vacuum cleaner).

3. Release the screws retaining the filter holder and

remove the air filter.

4. Fit thenew filter and secure it with the filter holder.

5. Fit the air filter cover and tighten the retaining

screws.

8.3 Replacing a broken starter cord

CAUTION

The housing may suffer damage if the starter cord is

too short. Never shorten the starter cord.

1. Unscrew the three securing screws and remove

the starter assembly.

2. Remove the remaining pieces of the starter cord

from the spool and the starter handle.

3. Make a secure knot in the end of the replacement

starter cord and then pass the free end of the cord

through the hole in the spool from above.

4. Pass the end of the cord through the opening

in the starter housing from below, also through

the starter handle from below, and then make a

secure knot in the end of the cord.

5. Pull a length of the starter cord out of the housing

as shown in the illustration and pass it through

the slot in the spool.

6. Hold the cord securely close to the slot in the

spool and then rotate the spool in a clockwise

direction as far as it will go.

7. Rotate the spool back from its end point at least a

½ revolution, max. 1 ½ revolutions, until the slot

in the spool is in alignment with the opening in

the starter housing.

8. Hold the spool securely and pull the free end of

the cord at the starter handle out of the housing.

9. Hold the cord under tension, release the spool

and allow the starter cord to be pulled in.

en

16

10. Pull the starter cord out as far as it will go and

check to ensure that the spool can be turned by

hand at least a further ½ turn in a clockwise direction. If this is not possible, spring tension must be

reduced by one revolution in a counterclockwise

direction.

11. Fit the starter assembly to the machine and press

it down gently.

Pull the starter cord slightly until the coupling

engages and the starter assembly is fully seated.

12. Secure the starter assembly with the three retaining screws.

8.4 Checking and replacing the fuel filter

NOTE

Check the condition of the fuel filter regularly.

NOTE

When refueling the machine, take care to ensure that

no dirt or foreign matter finds its way into the fuel

tank.

1. Remove the cap from the fuel tank.

2. Pull the fuel filter out of the fuel tank.

3. Check the condition of the fuel filter.

The filter must be replaced if badly soiled.

4. Push the fuel filter back into the fuel tank.

5. Close the cap on the fuel tank.

8.5 Cleaning the spark plug / setting the spark

plug gap / replacing the spark plug

CAUTION

The spark plug and parts of the motor may be hot

immediately after the machine has been running. To

avoid burning your hands, wear suitable protective

gloves or allow the machine to cool down before

touching its parts.

Use only spark plugs of the type NGK‑CMR7A-5.

1. Use a gentle twisting motion to pull the cable

connector off the spark plug.

2. Use the spark plugwrench tounscrew and remove

the spark plug from the cylinder.

3. If necessary, clean the spark plug electrode with

a soft wire brush.

4. Check the spark plug gap (0.5 mm) with the aid

of a feeler gauge and reset it to the correct gap if

necessary.

5. Fit the ignition cable connector to the spark plug

and hold the threaded section of the spark plug

against the cylinder.

6. Move the start / stop switch to the “start” position.

7. CAUTION Avoid touching the spark plug elec-

trode.

Pull the starter cord (press the decompression

valve first).

An ignition spark must now be clearly visible.

8. Use the spark plug wrench to screw the spark

plug into the cylinder (12 Nm).

9. Fit the ignition cable connector to the spark plug.

8.6 Retensioning the drive belt

CAUTION

A slack drive belt can damage the machine. Reten-

sion the drive belt if it slips when a load is applied to

the cutting disc.

NOTE

The drive belt must be replaced as soon as the

wear mark on the saw arm becomes visible after

retensioning.

This machine is equipped with a semi-automatic,

spring-assisted drive belt tensioning system.

1. Slacken the three clamping nuts on the forward

section of the saw arm approx. one complete turn.

2. After releasing the nuts, the drive belt is tensioned

automatically by spring pressure.

3. Retighten the three clamping nuts securely (18

Nm).

8.7 Changing the drive belt

NOTE

After doing this, check that the cutting disc can be

turned easily by hand and that all screws have been

tightened securely.

1. Slacken the three clamping nuts on the forward

section of the saw arm approx. one complete turn.

2. Release the tension on the drive beltby turning the

belt tensioning cam counterclockwise carefully as

far as it will go (until resistance is felt, i.e. approx.

¼ of a turn).

3. Remove the upper and lower clamping nuts and

the two securing screws from the forward section

of the saw arm and remove the drive belt cover.

4. Release the four securing screws on the rear drive

belt cover and remove the cover.

5. Remove the defective drive belt. Place the new

drive belt carefully over the two drive pulleys.

en

17

6. Tension the drive belt by turning the belt tensioning cam clockwise carefully as far as it will go

(until resistance is felt, i.e. approx. ¼ of a turn).

7. Fit the rear drive belt cover and secure it with the

four screws.

8. Secure the forward drive belt cover with the two

clamping nuts and two securing screws.

9. Tighten thethree clamping nuts securely (18 Nm).

8.8 Adjusting the carburetor

CAUTION

Tampering with the carburetor settings may cause

damage to the motor.

The carburetorof this machine (jets H and L) has been

factory set for optimum performance and sealed to

prevent tampering. The idling speed of the machine

(jet T) may be adjusted by the user. All other adjustments must be carried out at a Hilti service center.

NOTE

Use a suitable flat screwdriver (tip width 4 mm/ ⁵/₃₂ ")

and do not force the adjusting screw beyond its

intended adjustment range.

1. Clean the air filter.

2. Allow the machine torun until it reaches its normal

operating temperature.

3. Adjust the idling speed jet (T) so that the motor

runs smoothly when idling but the cutting disc

does not begin to rotate.

8.9 Cleaning

Careful cleaning of the machine is one of the main

prerequisites for trouble-free, reliable operation.

Heavy dirt and dust deposits on the motor and in the

cooling openings may lead to overheating.

Don’t permit foreign objects to enter the interior of

the machine.

Don’t use a high pressure jet system or running water

for cleaning.

Don’t use cleaning agents which contain silicone.

Clean the exterior of the machine at regular intervals

with a slightly damp cloth or a dry brush.

Check that all grips are clean, dry and free from oil

and grease.

8.10 Maintenance

Check all external parts of the machine and the

accessories for damage at regular intervals and check

that all controls operate faultlessly. Don’t operate the

machine if parts are damaged or when the controls

do not function faultlessly. If necessary, the machine

should be repaired by Hilti Service.

8.11 Checking the power tool after care and

maintenance

After carrying out care and maintenance, check that

all protective and safety devices are fitted and that

they function faultlessly.

8.12 Transporting the machine in a vehicle

CAUTION

To avoid a fire hazard, allow the machine to cool

down completely before transporting it.

CAUTION

The fuel tank must be completely empty before

the machine is shipped by a parcels service. We

recommend that the original packaging is kept for

use in the event of a need to transport the machine

in this way.

1. Remove the cutting disc.

2. Secure the machine to prevent it falling over,

causing damage or fuel spillage.

3. Transport the saw carriage only when the water

tank is empty.

8.13 Storing the machine for a long period of

time

DANGER

Store machines in a secure place when not in use.

When not in use, machines must be stored in a dry,

high place or locked away out of reach of children.

1. Empty the fuel tank and then start the motor and

allow it to idle until all remaining fuel is used up.

2. Remove the cutting disc.

3. Clean the machine thoroughly and grease the

metal parts.

4. Remove the spark plug.

5. Pour a little two-stroke oil into the cylinder (1 to

2 teaspoons).

6. Pull the starter handle a few times.

This will distribute the oil in the cylinder.

7. Replace the spark plug.

en

18

8. Wrap the machine in plastic foil. 9. Put the machine into storage.

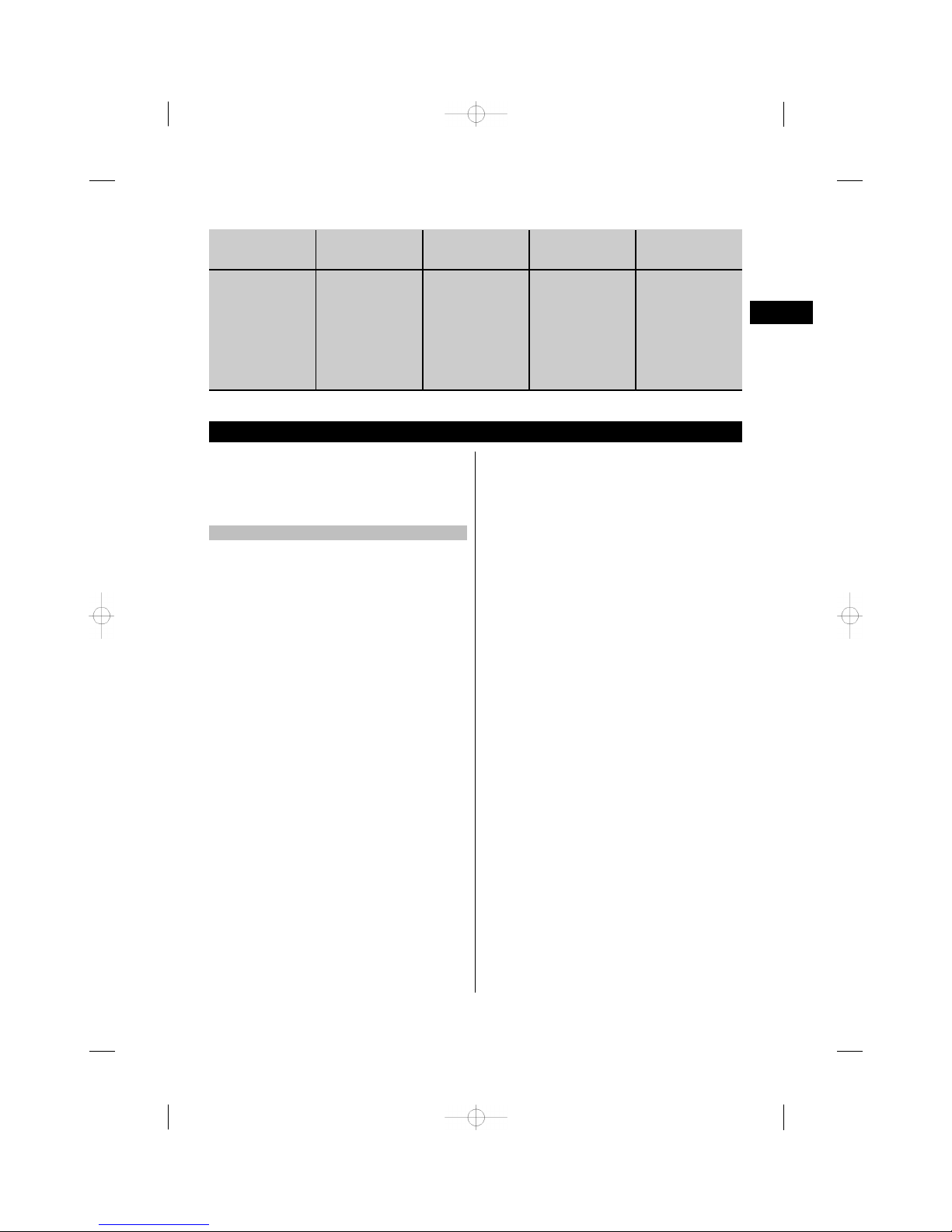

9. Troubleshooting

Fault Possible cause Remedy

Cutting disc slows down or

stops completely while cutting

Excessive cutting pressure applied

(cutting disc sticks and stalls in the

kerf).

Reduce cutting pressure and guide

the machine in a straight line.

Drive belt tension too low or the

drive belt is broken.

Re-tension the drive belt or fit a new

belt.

Cutting disc incorrectly fitted or not

tightened properly.

Check that the disc is fitted and

tightened correctly.

Cutting disc direction of rotation is

incorrect.

Check the direction of rotation and

correct if necessary.

The forward section of the saw arm

is loose.

Tighten the clamping nuts.

High vibration, disc wanders

off the cutting line

Cutting disc incorrectly fitted or not

tightened properly.

Check that the disc is fitted and

tightened correctly.

Cutting disc is damaged (or unsuitable specification, cracked,

segments missing, bent, overheated, deformed, etc.).

Fit a new cutting disc.

The centering bushing is fitted

incorrectly.

Check that the mounting bore of the

cutting disc to be fitted corresponds

with the centering collar of the

cutting disc mounting flange.

Saw doesn’t start or is difficult

to start

The fuel tank is empty (no fuel in

the carburetor).

Fill the fuel tank.

Air filter clogged with dirt or dust. Replace the air filter.

The motor is flooded (spark plug

wet).

Dry the spark plug and cylinder

(remove the spark plug).

Disengage the choke lever and

repeat the starting procedure

several times.

Wrong fuel mixture. Empty the fuel tank and flush out

the tank and fuel lines. Fill the tank

with the correct fuel.

Air in the fuel line (no fuel reaching

the carburetor).

Remove the air from the fuel line

by operating the fuel pump several

times.

The fuel filter is dirty or blocked (no

fuel or too little fuel reaching the

carburetor).

Clean the tank and fit a new fuel

filter.

en

19

Fault Possible cause Remedy

Saw doesn’t start or is difficult

to start

No ignition spark visible or spark

is too weak (when spark plug is

removed).

Clean the spark plug to remove

carbon deposits.

Check the spark plug gap and adjust

it if necessary.

Fit a new spark plug.

Check the ignition coil, cable,

connectors and switch and replace

the parts if necessary.

Motor compression is too low.

Check the motor compression and,

if necessary, replace worn parts

(piston rings, cylinder, etc.

Very low temperatures. Allow the machine to warm up

slowly to room temperature and

repeat the starting procedure.

Dirt or dust in the spark guard /

exhaust exit.

Clean the parts.

The decompression valve is stiff to

operate.

Release the valve.

Low motor power / poor

cutting performance

Air filter clogged with dirt or dust. Replace the air filter.

No ignition spark visible or spark

is too weak (when spark plug is

removed).

Clean the spark plug to remove

carbon deposits.

Check the spark plug gap and adjust

it if necessary.

Fit a new spark plug.

Check the ignition coil, cable,

connectors and switch and replace

the parts if necessary.

The wrong fuel or dirt and water in

the fuel tank.

Flush out the fuel system, replace

the fuel filter and refill with fuel.

The disc specification is unsuitable

for the material to be cut.

Change the specification or request

advice from Hilti.

Drive belt or cutting disc slips.

Check the drive belt tension and

disc clamping parts and eliminate

the fault.

Motor compression is too low.

Check the motor compression and,

if necessary, replace worn parts

(piston rings, cylinder, etc.

The machine is operated or handled

incorrectly (excessive cutting

pressure applied, cutting disc

overheats, disc sticks in the kerf,

unsuitable disc type, etc.).

Observe the information provided in

the operating instructions.

The machine is used at an altitude

greater than 1500 m above sea

level.

Have the carburetor adjusted by

Hilti Service.

Incorrect carburetor setting (fuel /

air mixture).

Have the carburetor adjusted by

Hilti Service.

en

20

Fault Possible cause Remedy

Cutting disc rotates while the

motor is idling

Idling speed is too high.

Check the idling speed and adjust if

necessary.

The half-throttle position is engaged.

Disengage the half-throttle setting.

Faulty centrifugal clutch. Replace the centrifugal clutch.

Starter unit doesn’t work

The clutch claws are not engaging.

Clean the parts so that they can

move freely.

10. Disposal

Most of the materials from which Hilti machines or appliances are manufactured can be recycled. The

materials must be correctly separated before they can be recycled. In many countries, Hilti has already made

arrangements for taking back old machines and appliances for recycling. Ask Hilti customer service or your

Hilti representative for further information.

NOTE

Disposing of slurry directly into rivers, lakes or the sewerage system without suitable pretreatment presents

environmental problems. Ask the local public authorities for information about current regulations.

1. Collect the slurry (e.g. using a wet-type industrial vacuum cleaner)

2. Allow the slurry to settle and dispose of the solid material at a construction waste disposal site (the addition

of a flocculent may accelerate the separation process).

3. The remaining water (alkaline, pH value > 7) must be neutralized by the addition of an acidic neutralizing

agent or diluted with a large volume of water before it is allowed to flow into the sewerage system.

11. Manufacturer’s warranty

Hilti warrants that the tool supplied is free of defects

in material and workmanship. This warranty is valid

so long as the tool is operated and handled correctly,

cleaned and serviced properly and in accordance with

the Hilti Operating Instructions, and the technical

system is maintained. This means that only original

Hilti consumables, components and spare parts may

be used in the tool.

This warranty provides the free-of-charge repair or

replacement of defective parts only over the entire

lifespan of the tool. Parts requiring repair or replacement as a result of normal wear and tear are not

covered by this warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental

or consequential damages, losses or expenses in

connection with, or by reason of, the use of, or

inability to use the tool for any purpose. Implied

warranties of merchantability or fitness for a particular purpose are specifically excluded.

For repair or replacement, send the tool or related

parts immediately upon discovery of the defect to

the address of the local Hilti marketing organization

provided.

This constitutes Hilti’s entire obligation with regard

to warranty and supersedes all prior or contemporaneous comments and oral or written agreements

concerning warranties.

en

21

12. EC declaration of conformity

Designation:

cut-off saw

Type:

DSH 700/ DSH 900

Year of design:

2008

We declare, on our sole responsibility, that this

product complies with the following directives

and standards: until 28.12.2009 98/37/EC, as of

29.12.2009 2006/42/EC, 2004/108/EC, 2000/14/EC,

EN 55012, EN ISO 19432.

Hilti Corporation

Dietmar Sartor Johannes Wilfried Huber

Head of BA Quality and Process

Management

Senior Vice President

Business Area Electric Tools & Accessories

Business Unit Diamond

07 2009 07 2009

en

22

ORIGINAL BRUGSANVISNING

DSH 700/ DSH 900 Benzindrevet skæremaskine

Læs brugsanvisningen grundigt igennem,

inden maskinen tages i brug.

Opbevar altid brugsanvisningen sammen

med maskinen.

Sørg for, at brugsanvisningen altid følger

med ved overdragelse af maskinen til

andre.

Indholdsfortegnelse side

1. Generelle anvisninger 24

2. Beskrivelse 25

3. Tilbehør 26

4. Tekniske specifikationer 27

5. Sikkerhedsanvisninger 29

6. Ibrugtagning 32

7. Anvendelse 36

8. Rengøring og vedligeholdelse 37

9. Fejlsøgning 41

10. Bortskaffelse 43

11. Producentgaranti - Produkter 43

12. EF-overensstemmelseserklæring 44

1 Disse tal henviser til illustrationer. Illustrationerne

kan du finde på udfoldssiderne på omslaget. Kig på

disse sider, når du læser brugsanvisningen.

I denne brugsanvisning betegner »maskinen« altid

den benzindrevne skæremaskine DSH 700 eller den

benzindrevne skæremaskine DSH 900.

Maskindele, betjenings- og visningselementer DSH

700 / DSH 900 1

@

Forreste håndtag

;

Bageste håndtag

=

Styreruller

%

Start/stop-kontakt

&

Choker / Halvgasindstilling

(

Sikkerhedsgasgreb

)

Gashåndtag

+

Dekompressionsventil

§

Brændstofindsugningspumpe

/

Rekylstart

:

Skæreskive

·

Spændeskrue

$

Låseboring til skæreskiveskift

£

Spændeflange

|

Beskyttelsesafskærmning

¡

Greb til klingebeskyttelsesindstilling

Q

Vandventil

W

Vandtilslutning

E

Brændstoftankdæksel

R

Luftfilterdæksel

T

Remstrammer

Z

Udstødning/lyddæmper

U

Gnistfilter

I

Tændrørsstik

O

Typeskilt

Føringsvogn DSH-FSC 2

@

Håndtag

;

Gashåndtag

=

Skæredybdeindstilling

%

Nedholder

&

Vandtank

(

Vandtilslutning

)

Akselindstilling

+

Gaswiretræk

§

Maskinkonsol

da

23

5100

r

p

m

m

a

x.

1. Generelle anvisninger

1.1 Signalord og deres betydning

FARE

Står ved en umiddelbart truende fare, der kan medføre

alvorlige kvæstelser eller døden.

ADVARSEL

Advarer om en potentielt farlig situation, der kan

forårsage alvorlige personskader eller døden.

FORSIGTIG

Advarer om en potentielt farlig situation, der kan

forårsage lettere personskader eller materielle skader.

BEMÆRK

Står ved anvisninger om brug og andre nyttige oplysninger.

1.2 Forklaring af piktogrammer og yderligere

anvisninger

Forbudssymboler

Transport på

kranen er ikke

tilladt

Advarselssymboler

Generel fare Advarsel om

varm overflade

Advarsel om

brandfare som

følge af

flyvende

gnister

Advarsel mod

tilbageslag

Advarsel mod

indånding af

giftige dampe

og udstød-

ningsgasser

Mindst tilladte

omdrejningstal

for de

anvendte

skæreskiver

Påbudssymboler

Brug beskyt-

telseshandsker

Brug

sikkerhedssko

Anvend

høreværn,

øjenbeskyt-

telse,

ånde-

drætsværn og

beskyttelses-

hjelm

Anvend ikke

skæreskiver

med tænder

Anvend ikke

beskadigede

skæreskiver

Rygning og

håndtering

med åben ild

er forbudt

Symboler

Læs brugsanvisningen før

brug

Motorstopan-

ordning

Brændsto-

findsugnings-

pumpe

Placering af identifikationsoplysninger på maskinen

Typebetegnelse og serienummer fremgår af maskinens typeskilt. Notér disse oplysninger i brugsanvisningen, og henvis til disse, når du henvender dig til

vores kundeservice eller værksted.

Type:

Generation: 01

Serienummer:

da

24

2. Beskrivelse

2.1 Anvendelsesformål

Maskinen er beregnet til hånd- eller vognført tør- og

vådskæring af asfalt samt mineralske eller metalliske materialer med abrasive skæreskiver eller diamantskæreskiver.

For at reducere støvudviklingen ved skæring anbefaler

vi fortrinsvis at arbejde med vådskæring.

Maskinen kan anvendes følgende steder og til følgende formål: på byggepladser, på værksteder, til

renovering, til ombygning, til nybygning.

Brug kun originalt Hilti-tilbehør og ekstraudstyr for at

undgå ulykker.

Overhold også sikkerheds- og betjeningsanvisningerne for det anvendte tilbehør.

Det er ikke tilladt at bearbejde sundhedsfarlige materialer, f.eks. asbest.

Overhold forskrifterne i denne brugsanvisning med

hensyn til drift, pleje og vedligeholdelse.

Overhold desuden gældende arbejdsmiljøregler.

Maskinen er beregnet til professionel brug og må

kun betjenes, efterses og vedligeholdes af autoriseret

og instrueret personale. Dette personale skal i særdeleshed informeres om de potentielle farer, der er

forbundet med brugen af denne maskine. Der kan

opstå farlige situationer ved anvendelse af maskinen

og det tilhørende udstyr, hvis den anvendes af personer, der ikke er blevet undervist i dets brug, eller hvis

det ikke anvendes korrekt i henhold til forskrifterne i

denne brugsanvisning.

Tag hensyn til påvirkning fra omgivelserne. Brug ikke

maskinen, hvisder er risikofor brand eller eksplosion.

Det er ikke tilladt at modificere eller tilføje ekstra dele

til maskinen.

Arbejd ikke i lukkede, dårligt ventilerede rum.

2.2 Medfølgende dele:

1 Maskine

1 Værktøjssæt DSH

1 Brugsanvisning

1 Forbrugsdelesæt DSH

2.3 Abrasive skæreskiver til håndførte

benzindrevne skæremaskine

Abrasive skæreskiver til benzindrevne skæremaskiner

består af kunstharpiksbundet slibegranulat. For at for-

bedre brudegenskaberne og bindingsevnen er disse

skæreskiver forsynet med strukturforstærkende væv

eller fibre.

BEMÆRK

Abrasive skæreskiver til benzindrevne skæremaskiner

anvendes fortrinsvis til skæring af jernmetaller og

mineralske materialer.

BEMÆRK

Alt efter det materiale, der skal skæres i, findes der

forskellige slibekornstørrelser såsom aluminiumoxid,

siliciumkarbid, zirkonium, osv. med forskellige bindingstyper og bindingsstyrker.

2.4 Diamantskæreskiver til håndførte

benzindrevne skæremaskiner

Diamantskæreskiver til benzindrevne skæremaskiner

består af et stålstamblad med diamantsegmenter(metallisk bundne industridiamanter).

BEMÆRK

Segmenterede diamantskæreskiver eller diamantskæreskiver med lukket skærekant anvendes fortrinsvis

til skæring af asfalt og mineralske materialer.

2.5 Specifikation af skæreskiverne

Til maskinen skal der anvendes diamantskæreskiver i

overensstemmelse med bestemmelserne i EN 13236.

Maskinen kan også anvende kunstharpiksbundne fiberarmerede skæreskiver i overensstemmelse med

EN 12413 (lige, ikke krum form, type 41) til bearbejdning af metalliske materialer. Overhold altid skæreskiveproducentens anvendelses- og monteringsanvisninger.

2.6 Anbefalinger vedrørende anvendelse

Vi anbefaler, at du ikke gennemskærer det emne, der

skal skæres, i én arbejdsgang, men gradvis opnår

den ønskede skæredybde ved at bevæge skæreskiven

frem og tilbage flere gange.

Ved tørskæring anbefaler vi for at undgå skader på

diamantskæreskiven, at du for hver 30 til 60 sekunder

løfter skæreskiven op af snittet i ca. 10 sekunder,

mens maskinen stadig kører.

For at reducere støvudviklingen ved skæring anbefaler

vi fortrinsvis at arbejde med vådskæring.

da

25

3. Tilbehør

Tilbehør til DSH 700 og DSH 900

Diamantskæreskive

000000, Se hovedkatalog

Abrasiv skæreskive

000000, Se hovedkatalog

Totaktsolie

DSH (1 L)

365827

Vandtilførselsenhed

DWP 10 365595

Føringsvogn

DSH-FSC

431364

Beskyttelseshjelm 267736

Beskyttelsesbriller

I-VO B05 PS klar

285780

Beholder

DSH

365828

Forbrugsdelesæt

DSH

365602

Forbrugsmaterialer og sliddele til DSH 700

Luftfilter DSH

261990

Snor (5 stk.) DSH

412230

Starter DSH 700

359425

Rem

DSH 12/14"

359476

Filterelement

DSH

412228

Tændrør

DSH

412237

Værktøjssæt

DSH

359648

Cylindersæt DSH 700

412245

Monteringsskrue kompl.

DSH

412261

Flange (2 stk.)

DSH

412257

Centrerring 20 mm / 1" DSH

412264

Forbrugsmaterialer og sliddele til DSH 900

Luftfilter DSH

261990

Snor (5 stk.) DSH

412230

Starter DSH 900

359427

Rem

DSH 12/14"

359476

Rem

DSH 16"

359477

Filterelement

DSH

412228

Tændrør

DSH

412237

Værktøjssæt

DSH

359648

Cylindersæt DSH 900

412384

Monteringsskrue kompl.

DSH

412261

Flange (2 stk.)

DSH

412257

Centrerring 20 mm / 1" DSH

412264

da

26

4. Tekniske specifikationer

Ret til tekniske ændringer forbeholdes!

BEMÆRK

Det vibrationsniveau, der angives i disse anvisninger, er målt med en målemetode, der opfylder bestemmelserne i EN ISO 19432, og kan anvendes i forbindelse med en sammenligning af forskellige benzindrevne

skæremaskiner. Det kan også anvendes til en foreløbig vurdering af vibrationsbelastningen. Det angivne

vibrationsniveau dækker de væsentlige anvendelsesformål for maskinen. Hvis maskinen imidlertid anvendes til