Page 1

DD-REC 1

Bedienungsanleitung de

Operating instructions en

Mode d’emploi fr

zh

ja

ko

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 2

0

/

1

1

쐊

햲

0

/

1

DD EC-1

0/1

쐊

씈

쐆

씋씉

쐅쐂쐎

햳

햸

햻

햵

쐈 쐉

햹

햺

햴

햶

씊

햷

쐇

쐄쐃쐋쐏

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 3

11

General information

In these operating instructions, this symbol indi-

cates points of particular importance to safety. The

instructions at these points must always be observed

in order to avoid a risk of serious injury.

Caution: High voltage

The numbers refer to the illustrations on the fold-out

cover pages (front and rear cover).

/ The numbers refer to the operating controls /

component parts of the unit.

In these operating instructions, the electric appliance to

which these operating instructions apply is referred to

as “the unit”.

It is essential that the operating

instructions are read before the

unit is used for the first time.

Always keep these operating

instructions together with the unit.

Ensure that the operating instructions are with the unit when it is

given to other persons.

Contents Page

General information 11

Description 11

Technical data 12

Accessories 13

Safety precautions 13

Before use 14

Operation 14

Care and maintenance 17

Manufacturer's warranty – tools 17

Disposal 18

Troubleshooting 19

Declaration of conformity (original) 20

Operating controls

ON / OFF switch

ON indicator lamp

Water warning lamp

Temperature warning lamp

Keyed plug connection for electric cable

(supply cord socket)

Water level / slurry volume sight glass

Trolley release lever

Trolley handle lock

Container grip

Housing grip

Air release valve

Container cover latch

Main filter

Extraction hose coupling

Water supply hose coupling

Keyed plug connection for electric cable

(Plug for drilling machine)

DD-REC1 water recycling system

Description

The DD-REC1 is an electrically powered water recycling

unit for use with the DD EC-1 diamond core drilling

machine.

Items supplied: recycling unit, wheel assembly, operating instructions, cleaning pad

The following conditions must always be observed

when the unit is in use:

– The unit must be connected to an alternating current

electric mains supply in compliance with the information given on the type plate.

– The unit may be used only with the supply cord for

the DD EC-1 diamond drilling machine.

– The unit must not be operated in areas where there

is a risk of explosion.

Component parts

Housing

Container

Cover

Wheel assembly / Trolley

Nipple

Hose set

Pocket for documents about the unit

Float

Sedimentation tube

Type plate

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 4

12

Technical data

Nominal power input: 300 W

Nominal voltage: ✱ 100 V 110 V 120 V 220 V 230 V 240 V

Mains frequency: 50–60 Hz

Weight of unit (without water): 25 kg

Water volume: 4–13 l

Max. number of holes per filling: ✱✱ Approx. 50

Dimensions (without wheels): 500×330×420 mm

Max. water pressure: 6 bar

Permissible operating temperature range: + 3 … +50°C

Permissible storage or transport temperature range: –15 … +50°C (without water, remove the filter)

✱✱ The unit is offered in different versions for various mains voltages. Please refer to the information on the

type plate for the nominal voltage and nominal current input of your unit.

✱✱ Measured at 20 mm dia. and 125 mm drilling depth; depends on base material, drilling direction and type

of hole drilled (through hole, blind hole)

Noise information (in accordance with EN 61029)

Typical A-weighted emission sound pressure level (LpA): 76 dB (A) ≤ 80 dB (A

Main features of the unit

– Class I electrical protection

– Extraction of drilling slurry

– Water is retrieved from the drilling slurry (recycling)

– Supplies water and power for the DD EC-1 diamond core drilling machine

– Integrated supply and return hose set for connecting the DD EC-1 diamond core drilling machine

– Automatic filter flushing

– Filter can be regenerated

- Stand-by operation

– Warning indicators for:

– inadequate water flow

– overheating

– Self-check of the electronics carried out each time the unit is switched on

– Removable container for water and drilling slurry

– Removable wheel assembly, also provides suitable surface for laying down the toolbox for the diamond core

drilling machine

Right of technical changes reserved

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 5

13

Intended uses

The unit is intended for the following uses

– Extraction of drilling slurry and supplying water and

power to the DD EC-1 diamond core drilling machine

for drilling in mineral materials (reinforced concrete,

masonry and natural stone)

– The unit may be operated only when standing on a

horizontal surface and in an upright position.

– Clean water should be used as the cooling and flush-

ing medium.

The water recycled by the unit is almost entirely

free of particles but may contain substances released

by the material in which the hole is drilled. Under no circumstances should this water be considered suitable

for use as drinking water.

Accessories

– Replacement main filter, item number 377255 (wear-

ing part)

Eye protection

must be worn.

Protective gloves

must be worn.

Safety precautions

When using the unit, the following fundamental safety

precautions must always be observed in order to avoid

the risk of injury, electric shock and fire hazards. Please

read and observe the instructions before using the unit.

Wear suitable working clothing.

Wear shoes with non-slip soles.

Make the working area safe.

Objects which could cause injury should be removed

from the working area. Ensure that the area is well lit.

When working, keep other persons, children in particular, away from the unit.

Take the influences of the surrounding area into account.

Do not expose the unit to rain or snow and do not operate it in damp or wet environments or in the vicinity of

flammable liquids or gases.

Check the unit each time before use.

First check the condition of the supply cord with

PRCD/GFCI residual current device (supplied with the

DD EC-1 diamond core drilling machine) and then check

the condition of the unit, including the supply cord and

the plug (an integral part of the hose set, except for the

GB version). Do not operate the unit if any parts of it are

found to be damaged, if the unit is not complete or when

the operating controls cannot be operated faultlessly.

Use the correct accessories.

Use only the recommended original Hilti accessories.

Use the unit only for the purposes for which it is intended.

Apply a safe working method.

Always ensure that you have a safe stance

and that the unit is standing securely. On scaffolding or

similar platforms, the unit should be used without the

wheel assembly. Never stand on the unit. The wheel

assembly, housing and container grips should never be

used as attachment points for lifting by a crane hook or

similar means. If the unit is to be transported by crane,

the applicable safety regulations must be observed.

Ensure that the unit, supply cord and hose set are positioned where they are free of obstructions. When working, always guide the hose set away from the diamond

Use

protective

equipment.

Do not, under any circumstances, use this product in any way other than as described in these

operating instructions.

Drilling slurry and recycled drilling water may irritate the

skin and eyes. Rinse with water immediately after skin

contact. If allowed to come into contact with the eyes,

rinse with plenty of water and consult a doctor. The water,

container and hoses may become very hot after long

periods of use and present a risk of burning or scalding.

Read the operating

instructions

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 6

14

core drilling machine to the rear. Never carry the unit by

the supply cord or hose set and never pull on these parts.

Never drive over the hoses or supply cord. Don’t unplug

the unit by pulling on the supply cord. Don’t expose the

hoses or supply cord to heat, oil or sharp edges. If the

supply cord becomes damaged while working, don’t

touch it – unplug the mains plug immediately and have

the unit or supply cord repaired at a Hilti service centre.

Never expose the plug connections for the unit to water.

If a plug interface has become wet, always disconnect

the supply cord plug from the mains socket before touching it and wiping it dry. Check that the pins of the plug

and the supply cord are clean and dry before they are

connected. Unplug the supply cord from the mains socket before cleaning.

Avoid unintentional starting.

Always switch off the unit and unplug the

supply cord from the mains socket before

removing the container, when the unit is not in use (e.g.

during pauses between work), before cleaning and before

carrying out any maintenance.

Keep the unit in good condition.

Follow the instructions on care and maintenance.

Repairs to the unit may be carried out only by an authorised electrical specialist using original Hilti spare parts.

Failure to observe this point may result in damage to the

unit or present a risk of accident. Accordingly, if necessary, have the unit repaired at a Hilti service centre or

authorised Hilti repair workshop. In accordance with

national safety regulations, the safety function of the

earth / ground conductor must be checked at regular

intervals.

Before use

It is essential that the safety precautions print-

ed in these operating instructions are read

and observed. Also read and observe the instructions

and safety precautions listed in the operating instructions for the DD EC-1 diamond core drilling machine.

The DD-REC1 water recycling system should

be used exclusively with the DD EC-1 diamond core drilling machine and the corresponding supply cord with built-in PRCD residual current device (supplied with the DD EC-1 diamond core drilling machine).

In Great Britain, the 110 V units must be connected to

an isolating transformer.

The mains voltage must comply with the information on the type plate.

If extension cables are used: only extension cables

of a type approved for the intended use and of adequate cross section may be used. Failure to observe this

point may result in reduced performance and could cause

the cable to overheat. Damaged extension cables must

be replaced.

The recommended cable cross sections and maximum

lengths are as follows:

Mains Conductor cross section

voltage 1.5 mm22.0 mm22.5 mm23.5 mm

2

100 V 20 m 40 m

110 V 20 m 40 m

220–230 V 50 m 80 m

Operation

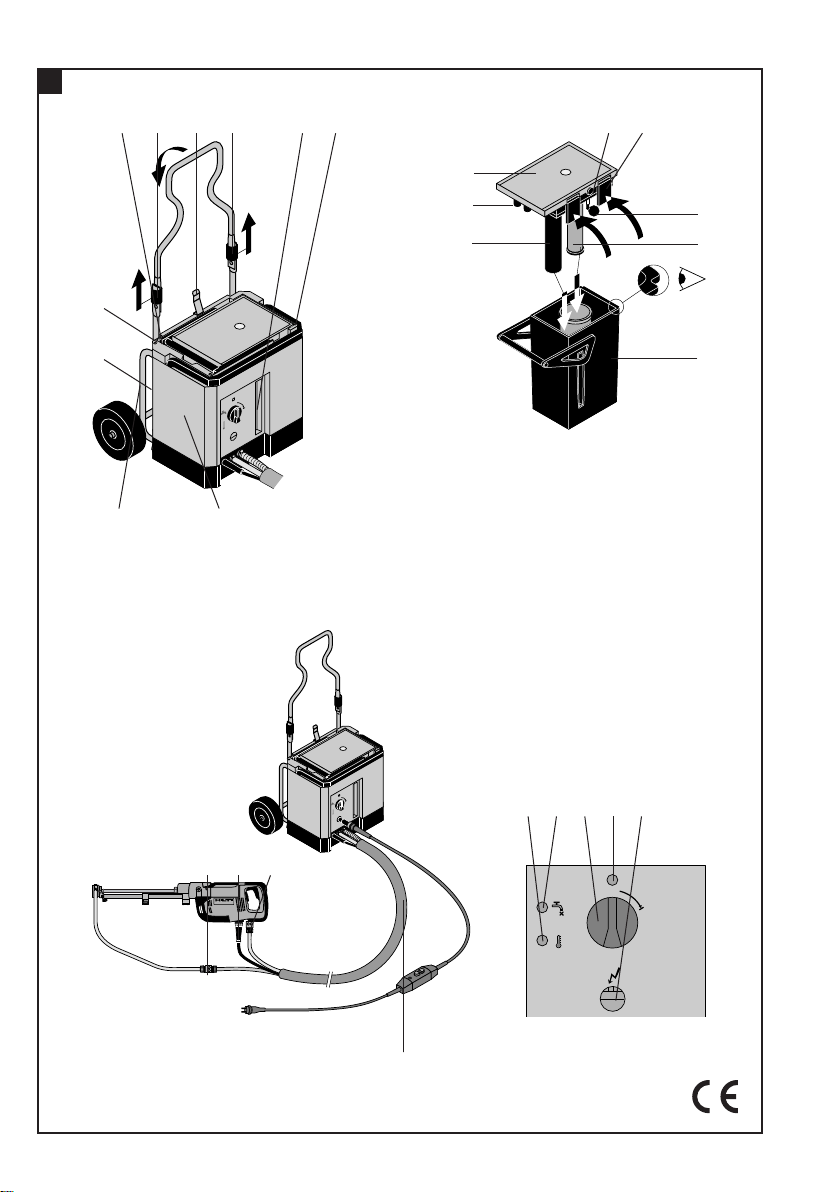

Connecting the hose set to the drilling machine

– Connect the keyed electric supply cord plug from the

hose set to the socket on the underside of the drilling

machine. To do this, bring the marks on the plug and

the socket into alignment and then push the plug into

the socket on the machine as far as it will go. While

maintaining slight pressure on the plug, rotate it in a

clockwise direction until it is heard to engage .

– Connect the thin end of the hose from the hose set to

the drilling machine and the thick end of the hose to

the water collector hose connector. The couplings

must be heard to engage when connected.

Removing and opening the container

– Never remove the container while the unit is

switched on. Switch the unit off by turning the

on / off switch in a clockwise direction and disconnect the mains plug .

– Wear protective gloves and protec-

tive goggles. The contents of the container may irritate the skin and eyes. The container

and its contents may be hot after long periods of use.

Observe the safety precautions. When handling the

container, take care to avoid pinching your fingers at

the edges of the housing, grips and latches.

– Lift the container grip approx. 45° and hold it in this

position until pressure compensation is heard to be

complete (approx. 2 seconds). Failure to observe this

point may cause a large quantity of the container contents to escape at the nipples.

– Lift the container grip to the vertical position and pull

the container upwards out of the housing .

– Always transport the container in an upright position

or place it on a horizontal surface.

– Ensure that it stands securely.

– Open the four container cover latches .

– Lift the cover off the container, taking care to ensure

that the float ball doesn’t get stuck. Lay the cover down

carefully.

Filling, closing and inserting the container

– Fill the inner container up to the top edge with clean

water . Fill the outer container to the desired level

between the min. and max. marks.

– Check the inner and outer cover seals for damage.

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 7

15

(please refer to the operating instructions for the DD

EC-1 diamond core drilling machine).

– Automatic filter flushing begins (takes about 15 to 20

seconds) when the switch on the DD EC-1 diamond

core drilling machine is not operated for several seconds. The unit supplies no water during this time.

– After completion of the filter flushing procedure, the

unit is again ready for use and the next drilling operation can be started (ready mode).

– Stand-by mode: If the switch on the diamond core

drilling machine is not pressed for a period of more

than 15 minutes, the unit automatically releases pressure and enters stand-by mode. In this case, before

beginning the next drilling operation, the switch on

the diamond core drilling machine must be pressed

briefly in order to re-pressurise the unit. After a few

seconds, the unit is again ready to supply water.

Warning indicators

– Acoustic warning signal (without warning lamp): This

indicates inadequate water flow which could be caused

by incorrect adjustment of the regulator valve in manual operation or other malfunctions (please refer to

the “Troubleshooting“ section).

– Water warning lamp (simultaneous acoustic warn-

ing signal): This indicates inadequate water pressure.

Could be caused by the container being empty, blocked

filter or other malfunctions (see “Troubleshooting” section).

– Temperature warning lamp (simultaneous acoustic

warning signal): This indicates excessively high water

temperature. Stop using the system immediately (see

“Troubleshooting” section).

– Water level / slurry volume sight glass : This indi-

cates the drilling slurry level and the remaining quantity of water in the container. It provides useful faultfinding information in case of malfunctions and makes

it possible to estimate the number of holes which can

be drilled before emptying and refilling. Due to widely varying conditions (diameter, depth, etc.), it is not

possible to give an exact indication of the number of

holes which can be drilled.

Cleaning the container

The container should be emptied and cleaned in the following cases (it is generally recommended that the main

filter is cleaned at the same time):

– Malfunctions caused by the slurry level being too high

or the water level being too low (see “Troubleshooting” section).

– Unit is switched off permanently (e.g. at the end of

the working day).

– Remove the container from the housing and open

it as described above. Observe the safety precautions.

– Dispose of the container contents in accordance with

the information in the “Disposal” section and under

observance of local regulations.

– Rinse out the remaining slurry and, if necessary,

Carefully remove dirt from the surfaces of the seals.

Ensure that the main filter is seated securely. Check

that the air release valve moves easily .

– Place the cover on the container. Take care to ensure

that it is positioned correctly, the right way round (the

lugs at both corners of the cover located in the corresponding recesses in the container and ). The

nipple block is then positioned at the same side as

the container water level sight glass. When the cover is placed in position, take care to ensure that the

container latches and the float hose are not pinched

between the container and the cover. Care must also

be taken to ensure that the suction hose hangs down

into the water and that the float ball is free to float .

– Close the container latches. To do this, first engage

the latches on the container and then press the latches towards the cover. The container latches must be

heard to engage. It may be necessary to press the

cover down slightly.

– Always use all four container latches. Never use

the unit when the container latches are dam-

aged.

– Lift the container by its handle and insert it carefully,

the right way round, in the housing. When doing so,

the guide ribs on the container must be carefully inserted into the corresponding openings in the housing. Do

not allow the container to drop into the housing .

– Fold the container handle down to the nipples side

until it is flush with the top surface of the housing. It

may be necessary to press the cover down slightly.

– Never attempt to fill the unit through the hoses. It

must always be filled as described above.

Operation

– Check the sight glass to ensure that sufficient water

is in the container.

– Connect the unit to the mains supply. Use the supply

cord with the built-in PRCD residual current device

(supplied with the diamond core drilling machine).

Insert the keyed plug in the socket as described above.

Insert the mains plug in the mains socket.

– Switch on the residual current device by pressing the

green button. The self-test function of the unit is then

activated. All warning lamps light briefly and an acoustic

signal is emitted.

– Test the residual current device for correct func-

tionality. To do this, press the black test button.

The ON indicator on the unit must extinguish. After

testing, switch on again by pressing the green button.

– Switch on the unit by turning the ON / OFF switch in

a clockwise direction as far as it will go. It then takes

about 20 seconds for the internal parts of the system

to fill with water. During this time, the water supply

system is not fully operational. Subsequently, the

green ON indicator lights to show that the unit is ready

for use.

– Start the water supply system by operating the switch

on the DD EC-1 diamond core drilling machine. Adjust

the water volume as desired by turning the regulator

on the diamond core drilling machine and begin drilling

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 8

16

remove dried-on remains. Wipe the inside of the sight

glass with a soft cloth. Clean the surfaces of the seals

on the container carefully . Rinse out the con tainer

under running water. Do not use a high-pressure cleaning system.

– Clean the main filter (see below).

– Fill the container as described above, close it and then

insert it in the housing.

Regenerating the main filter

– Regeneration of the main filter is recommended in

the following situations:

– When malfunctions caused by blockage of the main

filter are experienced

– Each time the container is refilled

– Remove the container from the housing as described

above and open it. Observe the safety precautions.

– Unscrew the main filter from the cover. When doing

so, do not hold the filter by the ceramic body. Instead,

grip it only by the grip section on the underside of the

main filter (reduces risk of breakage) .

– Clean the main filter under running water, using the

sandpaper supplied, by rubbing it in a longitudinal

direction on all sides until the light colour of the ceramic body reappears .

During this process, the outermost surface of the

ceramic body is rubbed off. This regeneration procedure can be repeated up to about 20 times until the

mini mum wall thickness of the ceramic body is reached.

– Check the wall thickness of the ceramic body. The

main filter must be replaced as soon as the diameter

of the ceramic body reaches a minimum of 42 mm.

Failure to observe this point could result in cracking

or breakage of the ceramic body .

– Check the main filter. Replace it immediately if cracked

or broken. A defective main filter may cause damage

to the recycling unit and to the diamond core drilling

machine.

– Screw the main filter into the cover until resistance is

clearly felt. Then continue to turn the filter a further

45° (maximum). Screwing the filter in beyond this

point does not improve the efficiency of the filter seal

and may result in permanent damage to the filter or

cover parts.

– Fill the container as described above, close it and then

insert it in the housing.

Drying the main filter

– In rare cases, regeneration of the main filter may not

be sufficient to clear a blockage. Should this be experienced, allow the main filter to dry for at least 24

hours, standing upright with the thread at the top, in

a warm, dry place before it is reused.

Replacement main filter

– The main filter is a wearing part with a limited life

expectancy. The housing has provision for storing a

spare main filter (not supplied). A spare filter is

recomended. The container must be removed on order

to access the storage location and insert a spare filter.

Insert the grip section of the spare main filter in the

holder in the base of the housing at an angle and then

bring the filter into a vertical position until it engages

with the plastic tab. To remove the spare main filter,

lift the plastic tab slightly and pull the filter out of the

holder to the side.

Switching off after use

– Before each long break between periods of use (e.g.

after finishing work for the day). The recycling unit

must be switched off as follows:

1. Disconnect the mains plug.

2. Release the hose connectors to the diamond core

drilling machine. Connect the extraction hose and

water supply hose connectors together.

3. Release the keyed plug from the diamond core drilling

machine. To do this, pull on the ring and turn the plug

in a counterclockwise direction, as far as it will go,

and then pull it out.

– Proceed as follows in order to avoid malfunctions

caused by dirt deposits:

1. Clean the container tank and main filter.

2. Refill with fresh water.

3. Plug the supply cord into the mains socket.

4. Switch on the PRCD by pressing the green button.

5. Switch on the unit by turning the ON/OFF switch in a

clockwise direction, as far as it will go.

6. Run the recycling unit for 10 minutes. Switch the recyc ling unit on/off at the main switch four times during

these 10 minutes. This will flush out the internal tubing and valves of the recycling unit.

7. Disconnect the mains plug.

– Clean the container and regenerate the main filter.

Transport without wheel assembly

– A handle , which can be folded out easily, is pro-

vided for transporting the unit by hand. Grip sections

are provided at the sides for lifting the unit with both

hands. Take care to avoid pinching your fingers at the

grips.

– A suitable means (net or straps) must be used

when the unit is lifted by a crane. The wheel

assembly, housing or container grip must never be

used as a lifting point for a crane hook or other similar

lifting tackle. When transporting the unit by crane, the

applicable safety regulations must be observed .

Transport with wheel assembly

– Attaching the wheel assembly: Hold the unit against

the guide tubes on the wheel assembly and allow it

to slide down until the catch engages automatically.

Take care to ensure that the feet of the unit are located

in the corresponding sockets in the wheel assembly

.

– Wind the hose set around the wheel assembly handle

for transport. If desired, the toolbox for the DD EC-1

diamond core drilling machine can be placed on the

unit first.

– Detaching the wheel assembly: Push the lever to dis-

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 9

17

engage the catch and, at the same time, lift the unit

away from the wheel assembly.

– When using the wheel assembly, care must be

taken to ensure that the wheels and the unit are

standing securely. For safety reasons, the wheel assembly must not be used when working from scaffolding

or similar platforms.

Care and maintenance

Care

The housing, container and cover are made of impactresistant plastic. The protective sleeve of the cable and

the hoses are made of an elastomer material. The outer sheath of the hose set consists of a hard-wearing

woven synthetic material.

Clean the parts of the unit regularly with a

damp cloth. Do not use spray equipment, a

steam cleaning system or running water for cleaning.

This may negatively affect the electrical safety of the unit.

Always keep the grip sections of the unit free of oil and

grease. Do not use cleaning agents which contain silicone. Do not allow foreign objects to enter the interior

of the unit.

Regenerate the main filter and clean the container at

regular intervals, particularly before each long pause

between periods of use (e.g. at the end of the working day). Check the entire diamond drilling system for

leakage before each period of operation. Check and

clean the seals at regular intervals. Never leave drilling

slurry or water in the container for long periods.

Maintenance

Check all functional components and operating

controls of the unit for damage and correct operation at regular intervals. Do not operate the unit if parts

of it are damaged or when the operating controls do not

operate faultlessly. The unit should be repaired at a Hilti

service centre if necessary.

See: – Regenerating the filter

– Switching off after use.

Manufacturer's warranty – tools

Please contact your local Hilti representative if you have

questions about the warranty conditions.

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 10

Disposal

Handling drilling slurry

Drilling in mineral materials (e.g. concrete) with the DD EC-1 diamond core drilling machine produces drilling slurry. As with fresh cement mortar, this slurry may cause irritation if allowed to come into contact with the skin or

eyes. Wear protective clothing, protective gloves and goggles.

With regard to environmental aspects, allowing this slurry to flow directly into rivers, lakes or the sewerage system without suitable pre-treatment is problematical.

Disposal procedure

In addition to the following recommended pre-treatment procedures, the applicable national regulations must

be observed when disposing of drilling slurry.

Ask the local authorities concerned for further information.

Recommended pre-treatment

■ Water from the drilling slurry must be neutralised (e.g. by adding a large quantity of water or other neutralisa-

tion agent) before it is allowed to flow into the sewerage system.

■ Solid material from the drilling slurry should be deposited at a construction waste disposal site.

18

Return waste material for recycling

Most of the materials from which Hilti electric tools are manufactured can be recycled. The materials must be

correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for

taking back your old electric tools for recycling. Please ask your Hilti customer service department or Hilti representative for further information.

Only for EU countries

Disposal of electric tools together with household waste is not permissible!

In observance of European Directive on waste electrical and electronic equipment and its implementa-

tion in accordance with national law, electric tools that have reached the end of their life must be collected separately and returned to an environmentally compatible recycling facility.

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 11

19

Troubleshooting

Fault Possible cause Solution

Unit doesn’t start Fault in mains supply Plug in another electric appliance and

check whether it works.

Supply cord or plug defective The cord should be checked and replaced

if necessary by an electrical specialist.

Unit defective The unit should be repaired at a Hilti

service centre.

Acoustic warning signal Core bit or diamond core drilling Check for free flow and eliminate

(without warning lamp) machine blocked blockage.

Regulating valve on diamond core Open the regulating valve on the diamond

drilling machine set too low in core drilling machine.

manual operation.

Water supply hose not connected Connect the water supply hose to the

to the diamond core drilling diamond core drilling machine.

machine.

Water warning lamp lights; Too little water or too much Clean the container and refill it.

acoustic warning signal slurry in the container

Inner container not completely Fill the inner container completely with

filled with water water.

Main filter blocked Regenerate the main filter.

Regulating valve opened in manual Close the regulating valve on the diamond

operation when the diamond core core drilling machine.

drilling machine is switched off

Seals defective Check the seals on the cover and in the

nipples for damage and have them

replaced at a Hilti service centre if

necessary.

Container not inserted correctly Check the position of the container in the

in the unit housing; close the container handle care-

fully.

Air release valve sticking Check the air release valve to ensure free

movement; have it repaired at a Hilti service centre if necessary.

Pressure pump defective Have it repaired at a Hilti service centre.

Temperature warning lamp lights; Water temperature too high Allow the container to cool or clean it and

acoustic warning signal then refill it. Caution: Risk of burning or

scalding!

Suction performance inadequate Coarse filter in the water Remove coarse particles.

(leakage at water collector on the collector of the diamond

diamond core drilling machine) drilling machine blocked

Suction pump defective Have it repaired at a Hilti service centre.

The seals of the water tank Check if the surface and seals of the

don’t seal off completely cover from the water tank are clean.

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 12

20

EC declaration of conformity (original)

Description: Water recycling unit

Designation: DD-REC1

Year of design: 2000

We declare, under our sole responsibility, that this

pro duct complies with the following directives and

standards: until 19th April 2016: 2004/108/EC, from

20th April 2016: 2014/30/EU, 2006/42/EC, 2011/65/EU,

EN 60335-1, EN 12100.

Hilti Corporation, Feldkircherstrasse 100,

FL-9494 Schaan

Paolo Luccini Johannes W. Huber

Head of BA Quality and Process Management Senior Vice President

BA Electric Tools & Accessories Business Unit Diamond

06/2015 06/2015

Technical documentation filed at:

Hilti Entwicklungsgesellschaft mbH

Zulassung Elektrowerkzeuge

Hiltistrasse 6

86916 Kaufering

Deutschland

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Page 13

*337353*

337353

Hilti Corporation

LI-9494 Schaan

Tel.:+423 /234 21 11

Fax:+423 / 23429 65

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan

Pos. 4 | 20150922

Printed: 06.11.2015 | Doc-Nr: PUB / 5139943 / 000 / 01

Loading...

Loading...