Page 1

DD.CR

1

@

@

@

@

@

Bedienungsanleitung

Operating

Mode

d'empfoi

instructions

Gebruiksaanwijzing

Manuaf

de

instrucciones

1_

7-12

13-18

t'-l24

2b_30

6

;

!

-

:

:

!

i

!

!

't\

:w

,c!

i

f--

Page 2

C€

Page 3

Page 4

DD-CR1

drill

stand

It is

essential

instructions

equipment

that the operating

read before the

are

is

operated

for the first

time.

Always keep these operating

tions together with the equipment.

Ensure that

tions

given

it is

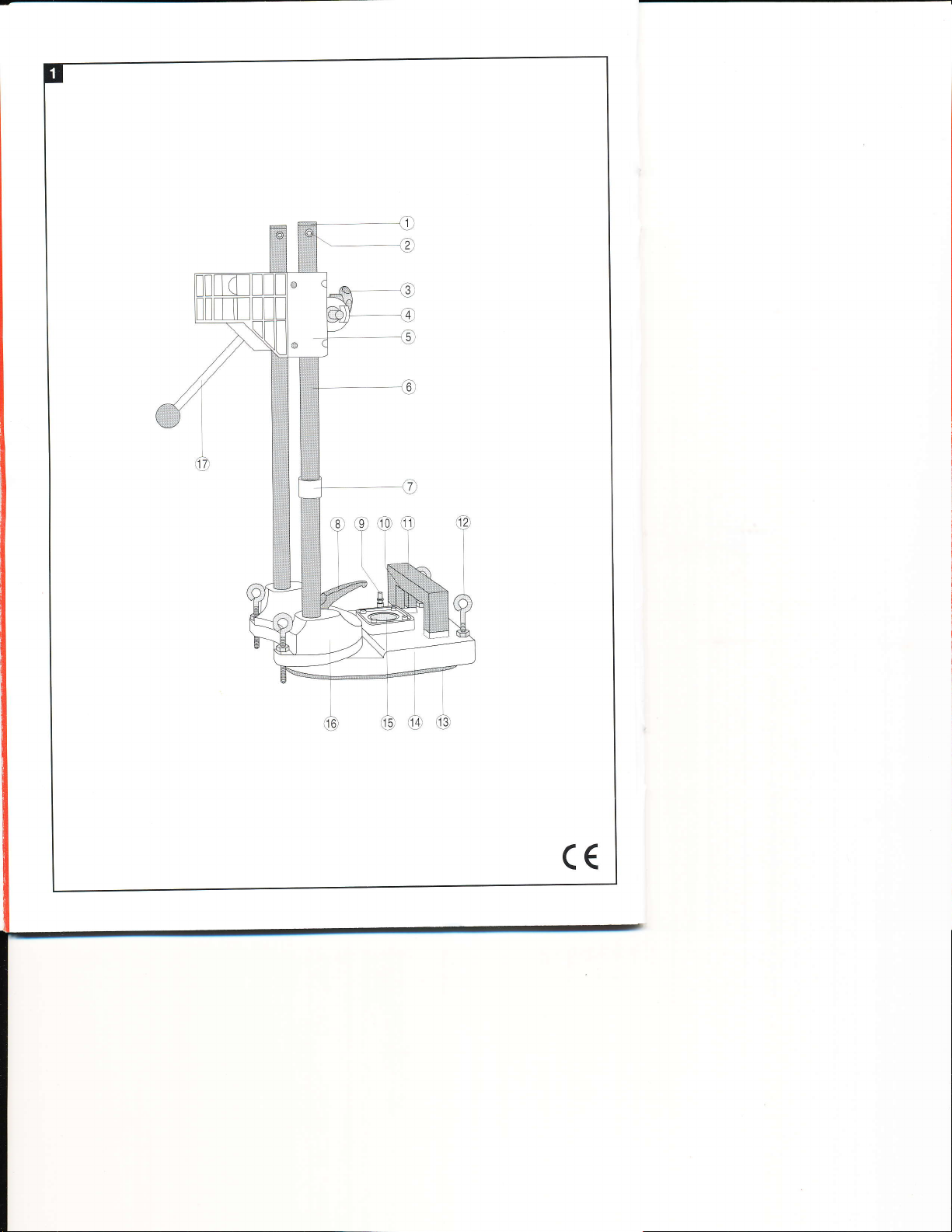

0perating

components

and

End caps

Q

Stop screws

@

Securing

@

Lockbutton

@

Carriage

@

Columns

@

Depth

@

Locking lever

@

Vacuum

@

Vacu u m release

@

OGrip

Leveling screws

@

Vacuum seal

@

Baseplate

@

Pressure

@

Adjustable

@

Lever

@

Contenls

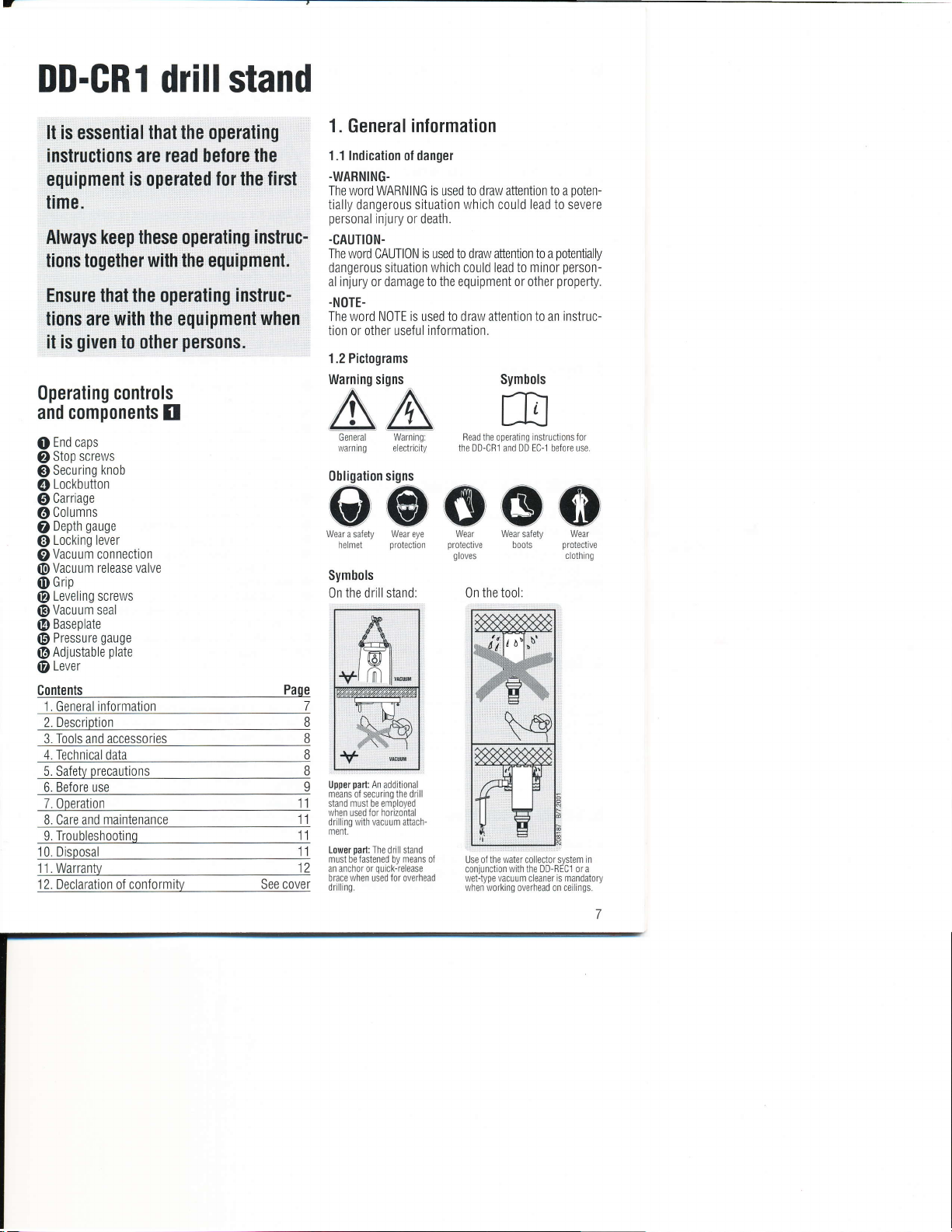

1. General information

Descriotion

2.

Tools

3.

4. Technical

5. Safetv

Before

6.

7. Ooeration 1.1

B. Care and maintenance

Troubleshootino

9.

Disoosal

1 0.

1 1. Warrantv

12. Declaration

the operating

with the

are

to other

equipment

persons.

controls

I

knob

gauge

connection

valve

gauge

plate

accessories

and

data

precautions

use

conformitv See cover

of

inslruc-

instruc-

when

1.

General

1.1 Indicalion of

-WARNING-

The word WARNING is used

tially

dangerous situation

personal

-CAUTION-

The

word CAUTION

dangerous situation which could

inlury

al

-NOTEThe word NOTE is used

tion

or other

1.2 Pictograms

Warning

information

danger

injury or death.

damage to the equipment or other

or

useful information.

signs Symbols

/\/\

/\ ft\

Jeneral

warn ng € ectrlcty

0bligation signs

o@$

Wear

a salety

helmet

Symbols

the

0n

B

Upper

means

stand must be employed

vr'hen

11

drilling v/ th

ment.

11

Lower

11

must lre fastened by means ol

an

anchor of

12

brace when used lor

drilling.

warningr Read the

Wear

proteclon

stand:

drill

parl:

An

additjonal

of securing

for horizontal

used

vac!um

part:

The dri I

quick-release

the

dr

attach

stand

overhead

eye

ll

to

draw attention

which could lead to severe

is

to

used

draw attention

lead to

to

draw attention to an

tl-J

0perat

the

DD"CRI and

Wear safety

W€aT

protectjve

gloves

0n the tool

the water collector

Use ol

conjunction

u/et-type vacuum

when wofkinq overhead

poten-

to

a

potentially

t0

a

person-

minor

propefi.

instruc-

ng nstrlctions fof

DD EC-1

before use.

Wear

cleaner

pr0Ieclrve

clothin0

system

is mandatory

ceilings

on

boots

\ryith the DD-REC1 or a

n

Page 5

These numbers refer to the

Il

tions.

The illustrations can be found on the fold-out cov-

pages.

er

operating

In these

stand" always refers to the DD-CR 1.

Keep these

instructions.

operating

instructions,

pages

corresponding

while

0pen

the designation drill

illustra-

studying

the

5.2 Correcl

The drill stand

ing machine.

permits

It

ing surface.

holes

use

is for

use with the DD EC-l diamond cor-

to

be drilled at right angles to the work-

Location

The type designation and

0n the

data in

it when making

or service department.

TVpe:

of identilicalion data on the drill stand

plate

type

your

on the drill stand. Make a note of this

operating instructions

an enquiry

serial

to

Serial

number

your

and always

Hilti representative

no.:

can be

2. Description

The DD-CR1 drill stand is an accessory

DD EC-1

diamond

Tools and accessories

3.

4.5

DD-VP

Quick-release

Adaptor

Anchors, HKD M8

for

Seal

vacuum baseplate

Wet-type vacu um cleaner

DD-REC1 water recycling

4. Technical

Stroke

for

Anchors

stand

drill

vacuum

brace

fastening

coring machine.

pump

larger

or

unit

data

the

Loading capacity

at

Weight

5. Safety

5.1 Basic

In

addition to the safety

vidual sections

lowing

precautions

information

salety

points

must be strictly observed at all times:

of

these

precautions

operating

instructions, the fol-

listed in

least

found

refer t0

for the

300 mm

.100

8.5

the

indi-

Do not

5.3 Take the necessary

place

use

sale

the

drill stand

with

other drilling machines.

precaulions

to make lhe work-

,\,\

/r\ /h\

z--:-\ z--!l

O f nsrre ttrat ttre wort<ing area is well lit.

O Ensure that the working

is well ventilated.

area

O Objects which could cause injury should be removed

from the working area.

I When drilling

above, secure the

presenting

O When working, keep other

dren, outside

O Avoid unfavorable body

a Always

ceed carefully and do not use the equipment if

attention is not

a Use a

interruoter switch).

O Wear non-slip safety boots or shoes and always work

Trom a secure slance.

Wear

O

O Wear

D0 not wear loose

O

as it can become caught up in moving

ry

Wear

O

O To avoid tripping while working, always

ply

cord, extension cord

of the electric

O Concealed electric

sent a serious hazard iI damaged while

ing. Accordingly, check the

ing

beforehand

parts

metal

ple,

when

O Avoid contact between

ko

ed objects such as

kq

5.4

General

holes

through ceilings or

below as the

area

risk

injury

a

of

or damage.

the range

concentrate on the

PRCD

suitable working clothing.

protective gloves.

goggles.

tool.

of the equipment may become live, for

an electric cable

safety

0f the equipment.

positions.

job.

the

on

residual current device

clothing, loose long hair or

and

cables

(e.9.

area

using a metal detector). External

is

your

pipes

or

precautions

core

persons, particularly

job

you

are doing. Pro-

water hose

or

drilled

body and

radiators.

gas

and

in which

away

water

you

into

eafihed /

,\

/l\

z-$

i Operate ttre equipment only

it is in faultless

O Use only the original accessories or

ment listed in the operating instructions.

items 0r accessories may

InJUry.

condition.

directed

as

present

additional equip-

a risk of

floors f

may fall

chil-

your

(ground

fault

jewel-

parts.

guide

the sup-

to

the

pipes pre-

you

are work-

were work-

exam-

inadvertently.

ground-

when

and only

Use of other

personal

rom

out,

full

rear

8

Page 6

Do not

grips

overload

designed.

clean, dry and

the

equipment.

free

O Keep the

O

efficiently and more safely within the

for which it is

0f

lt will

performance

oil

and

operate

grease.

more

range

O Never leave the equipment unsupervised.

O Switch

bringing it into

is to be drilled.

O

dry

d ren.

O Avoid unintentional starting. Check that the 0N

switch is in the

cord into the mains socket.

O Always

coring machine

the

diamond coring

position

When not in

place

or locked away where it is out of reach of chil-

the

use,

position

OFF

the

unplug

is

not in use, e.g, during

supply cord

work, before carrying

before changing core bits.

machine

at the workpiece where the hole

drill stand must be kept

before

care and maintenance and

out

on only after

plugging

when the

pauses

in

a high,

the

supply

diamond

between

/

OFF

O Switch the diamond coring machine off before trans-

portjng

it.

O Ensure that the electric tool is switched off

the

(ground

O Test the PRCD

O Check that all moving

they f unction

be fitted correctly and fulfil all of the conditions neces-

sary to ensure faultless operation.

O 0bserve

(Section

O lf necessary, have the

vice center in order to ensure that original Hilti spare

parts

sent a risk of injury to the user.

lock insert)

switch

fault interrupter).

the instructi0ns

B).

are used.

before switching on at

time

each

properly

parts

without

drill stand

Failure to

before use.

are undamaged and that

sticking.

on care and

repaired

this

observe

(remove

the PRCD

parts

All

maintenance

Hilti

at a

point

may

must

ser-

pre-

5.5 Requirements to be met by users

O The equipment is intended for

The

O

equipment

only by authorized, trained

must

be

enc0 u nle reO.

Always

O

ceed carefully and do not use the equipment if

attention

Personal

5.6

The user and

wear eye

safety boots and

ts tn use.

'@,

Wear €ye Wear a safety W€ar

protection

may

be operated, serviced and

informed

of any special

concentrate on

on

the

job.

is not

protective

persons

protection,

in the immediate vicinity must

a safety helmet,

protective

@'@,

helmet

protective

professional

personnel.

job

the

equipment

clothing

gloves

use.

repaired

personnel

This

hazards that may

you

are doing.

protective gloves,

while the

Pro-

your

equipment

'@'($),

Wear safety Wear

boots

protectrve

clotlr ng

full

Before

6.

Read the

DD-CR 1 and the DD EC-1.

-NOTE-

The

diamond coring machine must be disconnected

form the electric supply and water

use

operating

instructions

before using the

supply.

6.1 Fitting the lever

1 . Push the lever

2. Secure the lever on the spindle by insefiing the retain-

prn.

rng

3, Use the locking ring t0 secure the retaining

The lever may

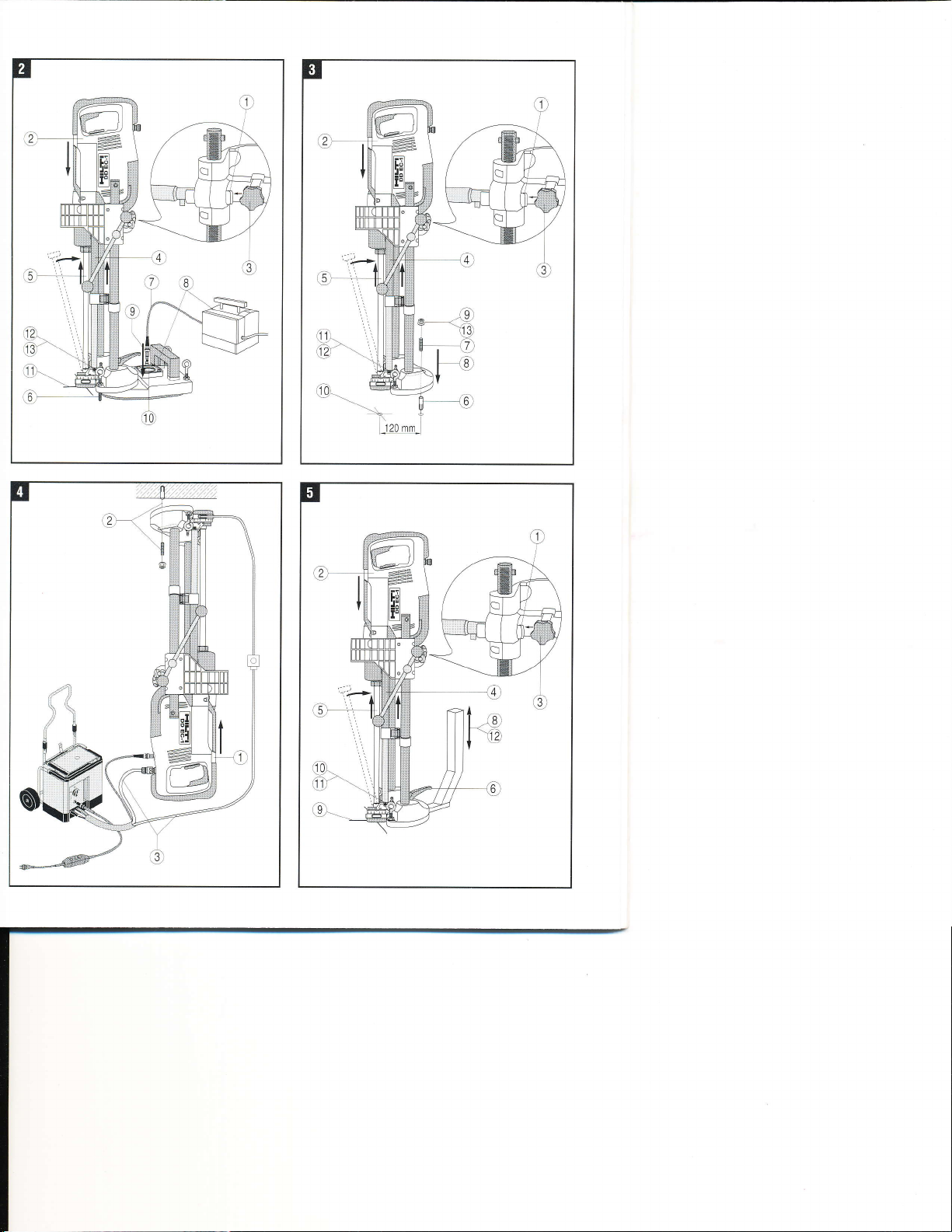

6.2

stand

-WARNINGOverhead drilling

means of the vacuum

1.

2. Lower the

be

3. Attach the diamond

4. From below,

5. Fit a core bit into the diam0nd

6. Unscrew the leveling screws

7. Connect the hose between the vacuum connection

8, Switch on the vacuum

9.

the vacuum baseplate t0 lasten

Using

E

the

Secure

slan0.

the

turning

the diamond coring machine

DD EC-1

about

the baseplate

baseplate

vacuum retease vatve.

When the

diamond coring

carriage from above.

the securing knob.

operating

2 mm

in to the

baseplate

onto

fitted

be

with

carriage

slide

beyond

and

the

spindle.

on either side of

the drill stand fastened only by

baseplate

in its

highest

machine to the

coring

the water

permissible.

is n0t

position

machine into

into

collector

(DD

EC-l) until it engages.

coring

instructions).

the

bottom edge of the baseplate.

the vacuum

pump

desired

positioned

is

they

until

pump.

and bring the vacuum

position

while

correctly,

firmly against the working surface and remove

finger from the vacuum release valve.

-NOTEWhen drilling horizontally, employ an additional means

the

securing

drill stand

(e.9.

a chain fastened to an anchor).

the

drill stand.

on the drill

position

carriage by

position

machine

project

pressing

pin.

the drill

(see

only

the

press

y0ur

on

on

on

it

of

Page 7

10. Before

11. Align the diamond coring machine with the center

1 2.

1 3, Secure the leveling screws

1 4.

6.3 Using anchors

'l

.

2. Lowerthe

beginning, and

check to ensure that the

remains in the

the hole to be

of

Level the drill stand by turning the leveling screws

(the

diamond coring

level).

bubble

the

Connect

and connect the water supply hose

operatin

supply cord

g

instructions).

g

the

Secure

stand.

the carriage

carriage

diamond coring

from

green

drilled.

(HKD

in its highest

above.

while

drilling is taking

pressure gauge

area.

machine is

bytightening

to

the electric

MB)

fasten

t0

machine into

equipped

position

3. Attach the diamond c0ring machine t0 the

turning the

by

securing

knob.

4. From below, slide the water collector into

the

on

diamond c0ring machine

engages.

Fit a

5.

DD EC-1 operating instructions).

core bit

into the

diamond coring machine

(DD

6. Settheanch0ratadistance of 120 mm

tance) from the center

7.

8.

9.

10. Align the

-1.1

12

IJ

1 4.

the threaded rod into the

Screw

Place the

approximate alignment with the

hole to be drilled.

Screwthe

but do

point

. Level the

(the

bubble level),

Secure

Use an open-end wrench to tighten the nut on the

threaded rod

Connect the supply cord to the

and connect

operating instructions).

drill stand over the threaded rod and in

nutwith thewasherontothethreaded rod

not

tighten

diamond coring

the hole to

of

drill stand by

diamond coring

the leveling screws

securely.

the water

6.4 Fastening the drill sland 0n a ceiling

of the hole to

ooint

it

fully.

machine with the

be drilled.

turning the leveling

machine

tightening the

by

electric

hose

supply

anchor.

center

is equipped with a

place,

indicator

with

the lock nuts.

power

supply

(see

DD EC-1

the drill stand

the

on

position

carriage

position

EC-1

until it

)

(see

(ideal

dis-

drilled.

be

point

of

center

screws

lock nuts.

power

supply

(see

DD EC-1

4

l--=--]

tal

l*/H-11".I

@l

I trU_l

twl

lif

"*

|

-NOTE.

a

drill

0n

the water

Use of

DD-REC

1

um

cleaner

head

on ceilings.

1. Mountthe

2.

Use an anchor

fasten the drill stand to the ceiling.

3. Connect

DD-REC 1 water recycling unit or a wet-type vacuum

cleaner.

suitable means.

4.

Connect

suppry nose.

6.5 Using a

stand

1.

Secure

slan0.

2. Lower the

the carriage from above.

3. Attach the

by turning the securing knob.

4. From

on the diamond coring machine

engages.

c0llect0r

water recycling

is

absolutely essential

diamond

(HKD

the hose

Relieve the

the electric

quick-release

E

the

carriage

diamond coring

diamond coring

below, slide

in conjunction with the

system 0r a wet-type vacu-

when working

coring machine on the

between the

M8) or

strain on

power

quick-release

water

the hose set

cord and the water

supply

column t0 secure the drill

in its

the water

position

highest

machine

machine to the

collector

(DD

5. Flt a core bit into the diamond coring machine

DD EC-1

operating

6. Screw

the

7. Screw the

the

8.

9.

10. Level the

1 1. Secure the leveling screws by tightening the lock

1

2, Use an open-end wrench t0 tighten the nut 0n the

1

3. Connect the supply cord to the electric

6.6 Using drill bits

-NOTEThe columns

drill bits with a

1 . Predrill the hole with

2.

3. Pull the carriage

4. Fit the drill

6.7 Removing the diamond

1.

quick-release

Fix the

tighten it.

Bring the

with the

diamond coring

center ooint

drill stand by

(the

diamond coring machine is equipped with a

level).

bubble

nuts.

threaded rod

and

connect

g

operatin

of

the

Remove

end of

stop screws and end caps from the columns.

the

columns.

bit

drill stand

the

Secure

stand.

carriage in its highest

instructions).

adaptor onto the drill stand.

quick-release

column

of the hole to

securely.

the water

turning

supply

onto the

column

posltion

in

machine

the leveling screws

hose

instructions).

with a length

the drill

stand

length

of 600 mm.

drill

a

and diamond coring

with a length of

ol600 mm

are too short for

with a length

bit

mm.

600

machine from the

coring

position

over-

stand.

drill

brace to

collector and the

by some

the

on

drill

position

into

carriage

position

into

EC-1

until it

)

(see

adaptor.

but d0 not

into alignment

drilled.

be

power

supply

(see

DD EC-1

with

use

300 mm.

of

machine

on

the

off

the drill

0n

Page 8

2. Disconnect the supply cord from the electric

operating

the water

instructions).

pressing

(DD

supply

EC-l

supply and disconnect

(see

the

core bit from the diamond coring machine

DD EC-l

3. Remove

4. Release the water c0llector by

the top of the water collector

Detach the

5.

stand by turning the securing knob.

7.

Operation

Read the DD-CR1 and DD EC-] ooeratino instructions

before using the equipment.

-NOTEHold the lever securely and release the drill stand car-

riage lockbutton.

Troubleshooting

9.

diamond coring machine f rom

power

hose.

the button at

).

the

drill

8.

The diamond coring machine

from the electric

8.1 Cleaning

Clean the outer surfaces of the drill stand at regular inter-

vals with

cleaning systems or

guide

and maintenance

Care

must

power

supply.

the

drill stand

damp

a slightly

columns should be lubricated lightly with Hilti

cloth.

running water for

be disconnected

Do not use

cleaning.

sprays, steam

The

two

Spray.

8.2 Mainlenance

pafis

Check all external

ular intervals and check that all controls operate faultlessly.

not

Do

when the controls do not operate faultlessly. lf necessary,

have the

8.3 Ghecking the drill stand atter care and maintenance

After all care and maintenance work, the drill stand must

be checked

and that it ooerates faultlesslv.

operate

equipment

t0

the

ensure

the

of

drill stand

repaired

that

all safety equipment

drill stand

pafis

when

Hilti

at a

for

damage at

are damaged or

service center

is

reg-

fitted

pressure gauge

The

points

to the red

indicator

area.

Possible cause

lnsufficient vacuum under the

late.

basep

Check the seal on the baseplate and

-

replace it if

Check that the working surface is

-

clean. Clean

Check that the working surface is

-

smooth.

method cannot be used on rough,

damaged or defective.

The vacuum fastening

surl

10. Disposal

as

as

powertools

they

possible

tollows:

and accessories are manufactured can be recycled. The mate-

be recycled. In many

can

information.

udher

yourself

without the need for

countries,

to a disposal facility for recycling,

tools.

special

Plastic Plastics recvclino

Aluminum Scrap metal

SteelColu mns Scran metal

plastic

Plastics recvclinq

Hilti has

your

Most of the materials from which Hilti

rials must

ments for taking back

deDartment or

Should

lows: Dismantle the item

Separate

Part

be correctly separated before

you

wish to return the electric tool 0r accessory

the individual

assemblv Main material

/

Hilti

your

old electric tools and accessories for recycling. Please ask

re0resentative for f

sales

far

as

parts

Carrraoe

Adiustable

Vacuum baseolate Aluminum Sorao metal

Grio Plastic Plastics recvclino

Pressure

Vacuum

Hand wheel Steel and

Screws. small oarts Steel Scrao metal

plate

oauoe

valve

it if necessary.

made

already

Hilti customer service

arrange-

proceed

as {ol-

Page 9

11. Warranty

Hilti warrants that the tool supplied is free of defects in

material

as the

and serviced

Operating

within 12 months from the

and

only original Hilti consumables, c0mp0nents and spare

parts

workmanship. This warranty

and

tool is

operated and handled correctly, cleaned

properly

lnstructions,

the technical

may be

used

system

in the tool.

valid

is

in accordance with the Hilti

and

warranty

all

date of

is maintained. This means that

claims are made

(invoice

the sale

as

long

date),

This warranty

replacement of defective

or replacement as a result

not covered by

Additional claims

al rules

not

obligaled

quential

with, or

toolfor any

chantability or

provides

this warranty.

prohibit

for

damages,

reason of, the

by

purpose.

the free-of-charge repair

parts

only. Parts requiring repair

normal wear and tear are

of

are excluded, unless stringent nation-

such exclusion. ln

indirect, incidental

direct,

losses

or expenses in connection

or inability

use ol,

lmplied

warranties of mer-

fitness tor a

pailicular purpose

particular,

or

to

Hilti is

conse-

use the

specifically excluded.

For repair

immediately upon discovery of the defect to the address

the local Hilti marketing

of

This

warranty

comments

warranties.

replacement,

or

constitutes

Hilti's entire

and supersedes all

oral or written

and

send t00l and/or

organization

obligation

prior

agreements concerning

provided.

with regard to

or contemporaneous

related

parts

or

are

Page 10

1 2.

EG-Konlormitiitserkldrung 1

2.

EG-conform iteitsverklaring

Bezeichnung Bo h rstdnde

f rir Diamantkernbohrgerdt DD EC-1

Typenbezeichnung: DD-CR 1

Konstru

ktionsiah r:

Wir erkldren in alleiniger Verantwortung,

Produkt in Verbindung mit

geriit

DDEC-1 mit den folgenden Richtlinien

men

tibereinstimmt: 98/37lEG, 89/336/EWG,

73t23tEWG,

1, EN

55 01

EN 50 1 44-1

4-2,

EN 61 000-3-2, EN 61 000-3-3

12.EC declaration

Designation

Tvpe

desionation: DD-CR 1 Denominaci6n del modelo: DD-CR 1

Year

of desiqn:

We

declare, on our sole

uct, in

machine,

standardization

73t23tEWG, EN

EN 55014-2, EN

for DD EC-1

conjunction

complies with

documents: 98137 lEG, 89/336iEWG,

50144-1,

61000-3-2,

with the DD EC-1 diamond

12.Dficlaration

D6signation

Modele:

Ann6e

de construction: 2002

Nous

ddclarons sous

que

bilit6

mant DD EC-1

suivantes: 98137

50144-1, EN

61 000-3-2, EN 61

ce

oourforeuse

produit,

est conforme aux directives et

,

lEG,

50144-2-1,

000-3-3

dem Diamantkernbohr-

EN

44-2-1

501

,

of conformity

diamond corino

responsibility,

the

following standards or

EN

50144-2-1, EN 55014-1,

EN

61000-3-3

de

conformitd GE

Colonne de forage

diamant DD EC-1

au

notre

seule et unique responsa-

en liaison avec la foreuse au dia-

B9/336/EWG, 73123/EWG EN

EN

55014-1

EN

dieses

dass

und

EN 55 01 4-

,

Drillstand Denominacion Bastidor de

machines

prod-

that this

coring

DD-CR 1

normes

55014-2, EN

Product: Boorstandaard

r

voor

diamantkernboormachine

Tvpe:

Bouwiaar: 2002

2002

Wij verklaren, op

product

Nor-

ne DD EC-1 voldoet

n0 rmen

EN50 1 44-1

EN

in combinatie met de diamantkernboormachi-

61 000-3-2,

onze eigen

: 98137 lEG, 89/336/EWG,

EN 50 1 44-2-1 , EN

,

EN

61 000-3-3

12. Declaraci6n

para

la oerforadora de diamante DD EC-1

2002

Aflo

de construcci6n

Declaramos, como Inicos responsables,

producto,

mante DD EC-1, cumple las siguientes directrices

n0rmas:

50144-1, EN 50144-2-1, EN 55014-1, EN 55014-2, EN

61

en combinaci6n con la

98137lEG,89/336/EWG,

000-3-2, EN 61

000-3-3

verantwoording,

de volgende richtlijnen

aan

55 01

de conformidad de

7

4-1 , EN

perforadora

73l23i

DD EC-1

DD-CR1

dat

3 l23l EW G,

4-2

55 01

la

UE

perforacion

2002

que

este

de dia-

EN

EWG,

dit

en

y

Hilti Corporation

/7

Dr.

Senior Vice President

Business

December 2000

/-/t

Andreas

Meyer

lJnit

0iamond

27""^<

Dr. Andreas Bong

Head

Development

of

Business lJnit Diamond

December 2000

Page 11

Loading...

Loading...