Hilti DD 30-W User Manual

DD 30-W

English

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

English 1

1 Information about the documentation

1.1 About this documentation

• Read this documentation before initial operation or use. This is a prerequisite for safe, trouble-free

handling and use of the product.

• Observe the safety instructions and warnings in this documentation and on the product.

• Always keep the operating instructions with the product and make sure that the operating instructions

are with the product when it is given to other persons.

1.2 Explanation of signs used

1.2.1 Warnings

Warnings alert persons to hazards that occur when handling or using the product. The following signal words

are used in combination with a symbol:

DANGER! Draws attention to imminent danger that will lead to serious personal injury or fatality.

WARNING! Draws attention to a potential hazard that could lead to serious personal injury or

fatality.

CAUTION! Draws attention to a potentially dangerous situation that could lead to minor personal

injury or damage to the equipment or other property.

1.2.2 Symbols in the documentation

The following symbols are used in this document:

Read the operating instructions before use

Instructions for use and other useful information

1.2.3 Symbols in the illustrations

The following symbols are used in illustrations:

These numbers refer to the corresponding illustrations found at the beginning of these operating

instructions.

The numbering reflects the sequence of operations shown in the illustrations and may deviate

from the steps described in the text.

Item reference numbers are used in the overview illustrations and refer to the numbers used in

the product overview section.

These characters are intended to specifically draw your attention to certain points when handling

the product.

1.3 Product-dependent symbols

1.3.1 Symbols on the product

The following symbols are used on the product:

Warning: hazardous electrical voltage

Warning: hot surface

Revolutions per minute

Rated speed under no load

Wear eye protection

Wear a hard hat

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

2 English

Wear ear protection

Wear protective gloves

Wear safety shoes.

Lock symbol

Service indicator

Drilling performance indicator

1.4 Product information

Hilti products are designed for professional use and may be operated, serviced and maintained only by

trained, authorized personnel. This personnel must be informed of any particular hazards that may be

encountered. The product and its ancillary equipment can present hazards if used incorrectly by untrained

personnel or if used not in accordance with the intended use.

The type designation and serial number are stated on the rating plate.

▶ Write down the serial number in the table below. You will be required to state the product details when

contacting Hilti Service or your local Hilti organization to inquire about the product.

Product information

Type: DD 30-W

Generation: 01

Serial no.:

1.5 Declaration of conformity

We declare, on our sole responsibility, that the product described here complies with the applicable directives

and standards. A copy of the declaration of conformity can be found at the end of this documentation.

The technical documentation is filed and stored here:

Hilti Entwicklungsgesellschaft mbH | Tool Certification | Hiltistrasse 6 | 86916 Kaufering, Germany

2 Safety

2.1 General power tool safety warnings

WARNING

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

▶ Keep work area clean and well lit. Cluttered or dark areas invite accidents.

▶ Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

▶ Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

Electrical safety

▶ Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of

electric shock.

▶ Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

▶ Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

English 3

▶ Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the

risk of electric shock.

▶ When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

▶ If operating a power tool in a damp location is unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of electric shock.

Personal safety

▶ Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious personal injury.

▶ Use personal protective equipment. Always wear eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

▶ Prevent unintentional starting. Ensure the switch is in the off‐position before connecting to power

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on

the switch or energising power tools that have the switch on invites accidents.

▶ Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

▶ Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

▶ Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

▶ If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dust-related hazards.

Power tool use and care

▶ Do not force the power tool. Use the correct power tool for your application. The correct power tool will

do the job better and safer at the rate for which it was designed.

▶ Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

▶ Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

▶ Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

▶ Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained power tools.

▶ Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

▶ Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous situation.

Service

▶ Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

2.2 Drill safety warnings

▶ Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

▶ Hold power tool by insulated gripping surfaces, when performing an operation where the cutting

accessory may contact hidden wiring or its own cord. Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live" and could give the operator an electric shock.

2.3 Additional safety instructions

Personal safety

▶ During hand-held use, always hold the machine securely with both hands on the grips provided.

▶ The machine and the diamond core bit are heavy. There is a risk of crushing parts of the body. Wear

a hard hat, protective gloves and safety footwear.

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

4 English

▶ Keep the grips dry, clean and free from oil and grease.

▶ Improve the blood circulation in your fingers by relaxing your hands and exercising your fingers

during breaks between working.

▶ Avoid touching rotating parts. Switch the machine on only after bringing it into position at the

workpiece. Touching rotating parts, especially rotating accessory tools, may lead to injury.

▶ Always lead the supply cord, the extension cord and, if applicable, the suction hose away from the

machine to the rear when working. This helps to avoid tripping over the cord or hose while working.

▶ Do not allow drilling slurry to come into contact with the skin or eyes. Wear protective gloves and

protective glasses.

▶ Children are not permitted to play with the machine and must be instructed accordingly.

▶ The machine is not intended for use by debilitated persons who have received no special training.

Keep the machine out of reach of children.

▶ The accessory tool may become hot during use or during sharpening. There is a risk of burning or

cutting injuries. Wear protective gloves when touching or handling the accessory tool.

▶ When the machine is mounted on the drill stand, lay it down safely on the floor or ground during

breaks between use.

▶ Never tamper with or modify the machine in any way.

Protection from dust

Dust from material such as paint containing lead, some wood species, minerals and metal may be harmful.

Contact with or inhalation of the dust may cause allergic reactions and/or respiratory diseases to the operator

or bystanders. Certain kinds of dust are classified as carcinogenic such as oak and beech dust especially

in conjunction with additives for wood conditioning (chromate, wood preservative). Material containing

asbestos may be worked on only by specialists.

▶ Use a dust removal system that is as effective as possible. To achieve a high level of dust

collection, use a suitable vacuum cleaner of the type recommended by Hilti for wood dust and/or

mineral dust and which is designed for use with this machine. Ensure that the workplace is well

ventilated. The use of a dust mask of filter class P2 is recommended. Follow national requirements

for the materials you want to work with.

Careful handling and use of electric tools and machines

▶ Secure the workpiece. Use clamps or a vice to secure the workpiece. The workpiece is thus held

more securely than by hand and both hands remain free to operate the machine.

▶ Ensure that the accessory tools used have a mounting system that is compatible with the drilling

machine and that they are secured in the chuck correctly.

▶ Switch the machine off and unplug the supply cord in the event of an interruption in the electric

supply in order to avoid inadvertent restarting when the power returns.

▶ Operate the machine only when the cooling air slots are unobstructed.

Electrical safety

▶ Before beginning the work, check the working area for concealed electrical cables, gas and water

pipes, e.g. using a metal detector. External metal parts of the machine may become live, for example,

when an electric cable is damaged accidentally. This presents a serious risk of electric shock.

▶ Never operate the machine without the accompanying PRCD (machines without PRCD: Never

operate the machine without an isolating transformer). Test the PRCD each time before use.

▶ Check the machine’s supply cord at regular intervals and have it replaced by a qualified specialist

if found to be damaged. If the machine’s supply cord is damaged it must be replaced with

a specially-prepared and approved supply cord available from Hilti Customer Service. Check

extension cords at regular intervals and replace them if found to be damaged. Do not touch the

supply cord or extension cord if it is damaged while working. Disconnect the supply cord plug

from the power outlet. Damaged supply cords or extension cords present a risk of electric shock.

▶ Avoid body contact with earthed or grounded surfaces such as pipes, radiators, cookers, stoves

and refrigerators. There is an increased risk of electric shock if your body is grounded.

▶ Do not use a plug adapter.

Workplace

▶ Ensure that the workplace is well ventilated. Exposure to dust at a poorly ventilated workplace may

result in damage to the health.

▶ Do not drill into hazardous materials (e.g. asbestos).

▶ Approval must be obtained from the site engineer or architect prior to beginning drilling work.

Drilling work on buildings and other structures may influence the static equilibrium of the structure,

especially when steel reinforcing bars or load-bearing components are cut through.

▶ It is recommended that rubber gloves and non-skid shoes are worn when working outdoors.

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

English 5

▶ Suitable protective glasses, a hard hat, ear protection, protective gloves and safety footwear must

be worn while the machine is in use. Other persons in the vicinity must also wear personal protective

equipment.

3 Description

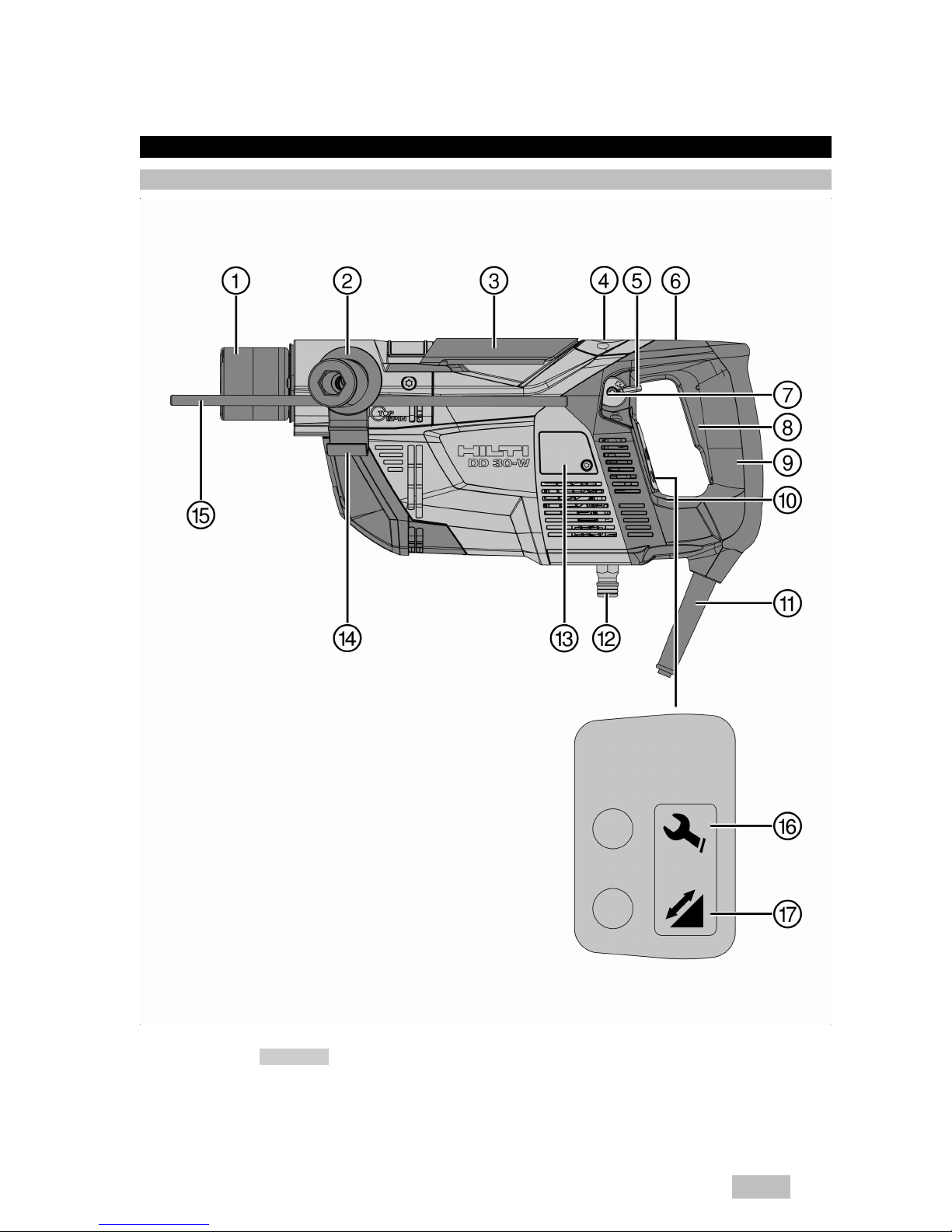

3.1 Overview of the product

@

Chuck

;

Side handle DD-SH-30

=

Chuck locking lever

%

Water flow rate indicator

&

Water regulating lever

(

Switch lockbutton for operation on drill

stand

)

Circular bubble level for vertical drilling

+

On/off switch

§

Grip

/

Tubular bubble level for horizontal drilling

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

6 English

:

Supply cord with PRCD

∙

Water connection

$

Carbon brush cover

£

Suction hose holder

|

Depth gauge for hand-guided drilling

¡

Service indicator

Q

Drilling performance indicator

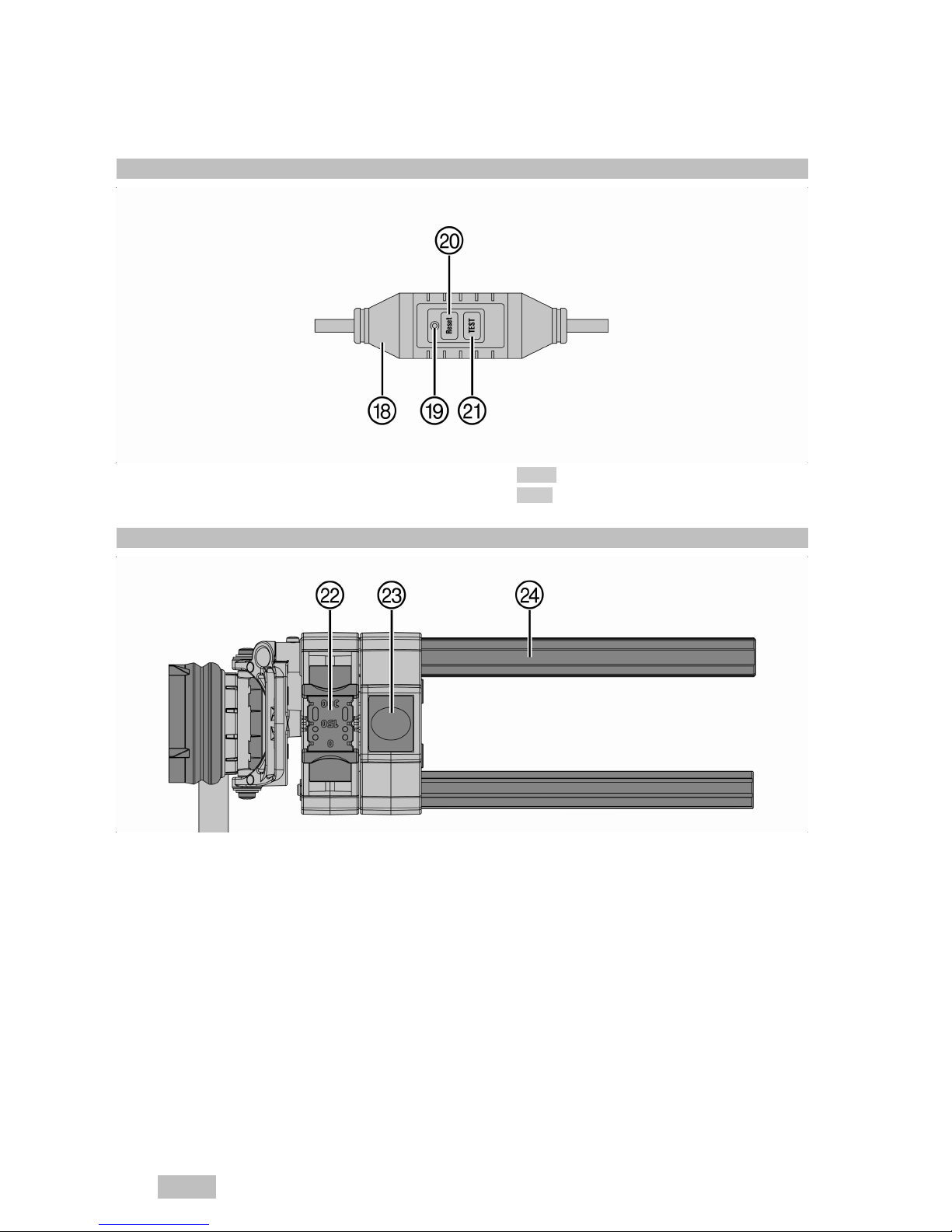

3.2 Ground fault circuit interrupter (PRCD)

W

PRCD in the supply cord

E

LED on the PRCD

R

Reset button on the PRCD

T

TEST button on the PRCD

3.3 Water collection system

Z

Slider for longitudinal adjustment of the

water collector holder

U

Water collector holder release catch

I

Water collector holder

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

English 7

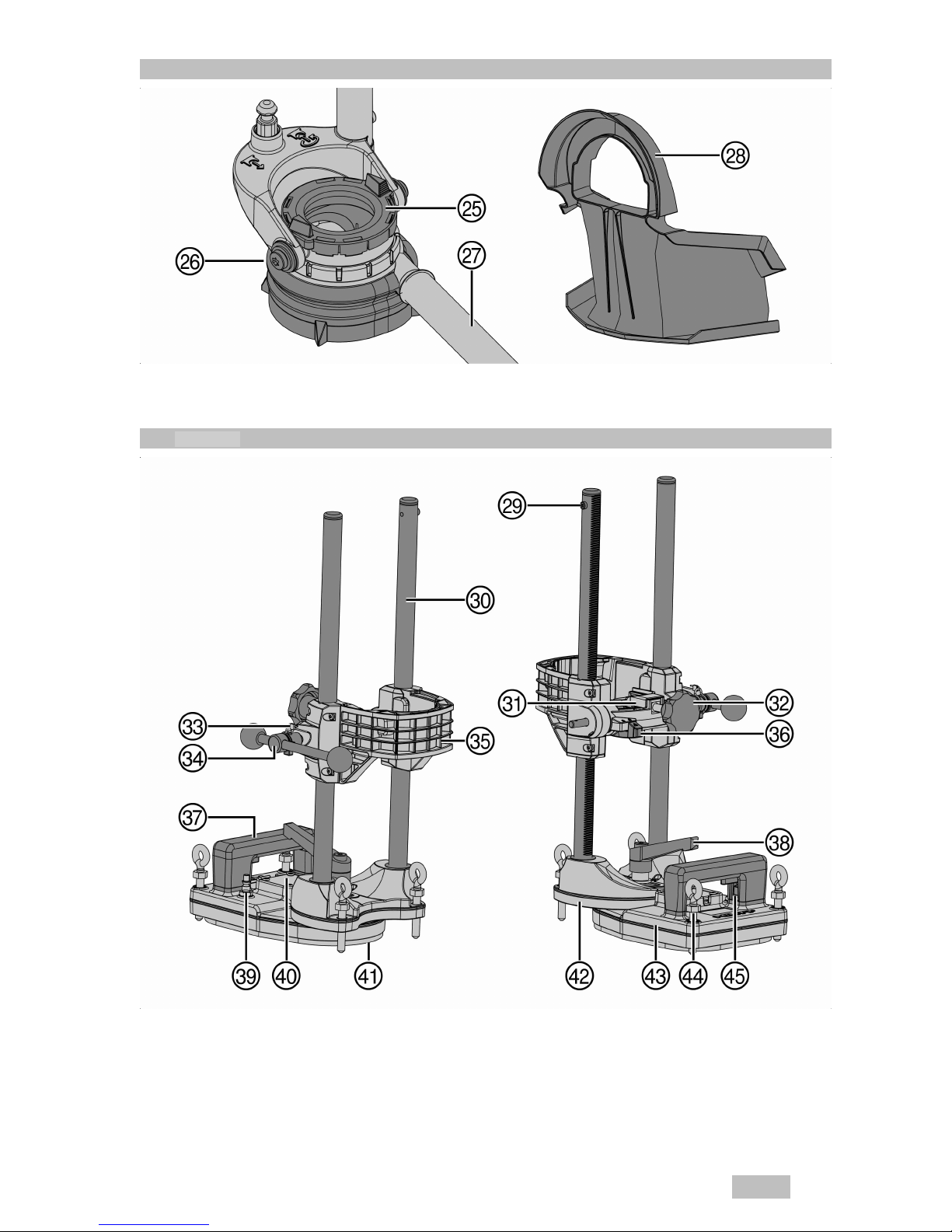

3.4 Accessories

O

Centering ring

P

Water collector

Ü

Water collector hose

[

Spray guard

3.5 DD-ST 30 drill stand accessories

]

End stop screw

Æ

Column

º

Clamping piece

~

Locking screw

A

Retaining pin

S

Hand wheel

D

Carriage

F

Carriage lock

G

Grip

H

Clamping lever

J

Vacuum hose connector

K

Pressure gauge

L

Vacuum seal

Ö

Adapter plate

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

8 English

Ä

Vacuum base plate

†

Leveling screws

Œ

Vacuum release valve

3.6 Intended use

The product described is an electrically powered diamond core drilling system. It is designed to be used handheld or mounted on a drill stand, for wet drilling in concrete and other mineral materials. The drill stand can

be fastened to the working surface by a suitable anchor (accessory) or by the vacuum base plate (accessory).

▶ Connect the machine only to an electric supply providing the voltage and frequency specified on the type

identification / rating plate.

▶ Depending on the application and drilling direction (see following table → page 8), the diamond core

drilling machine’s water collection system must be connected to an all-purpose vacuum cleaner of a type

recommended by Hilti and the necessary additional equipment selected accordingly.

Product sticker

The water collection system and the correct combination

of core bit and sealing ring, with the correct length setting, must be fitted and used for all drilling applications.

Product sticker

Drilling in an upwards direction is permissible only when

the water collection system and additional spray guard

are used.

Drilling in an upwards direction using the drill stand is

not permissible as the spray guard cannot be fitted when

the machine is mounted on the drill stand.

3.7 Inadmissible misuse

• This product is not suitable for working on hazardous materials.

• Drilling into materials that produce electrically conductive dust (e.g. magnesium) is not permissible.

• Dry drilling is not permissible.

3.8 Application-specific equipment

Equipment required for various applications / drilling directions

Application Drilling

direction

Equipment

Hand-held use Horizontal and

in a downwards

direction

With/without vacuum cleaner, without

spray guard

Hand-held use In an upwards

direction

With vacuum cleaner and spray guard

Mounted on a drill stand, fastened with

the vacuum base plate

Downwards With/without vacuum cleaner, without

spray guard

Mounted on the drill stand, fastened with

the vacuum base plate

Horizontal With/without vacuum cleaner, without

spray guard and with the drill stand

secured additionally

Mounted on the drill stand, fastened with

an anchor

Downwards

and horizontal

With/without vacuum cleaner, without

spray guard

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

English 9

3.9 Service indicator

LED display / operating status Service status

Lights red / the machine runs. The carbon brushes are badly worn. When the indicator lights for

the first time the machine may continue to be used for several hours

until it switches itself off automatically. Have the carbon brushes

changed in good time so that the machine is always ready for use.

Lights red / the machine doesn’t

run.

Have the carbon brushes replaced.

Blinks red Temporary fault, see “Troubleshooting”

3.10 Drilling performance indicator

LED display Contact pressure

Orange Too low

Green Optimal

Red Too high

3.11 Speed settings

The machine has two speeds: low speed for starting holes and high speed for normal drilling.

When the control switch is pressed only half way, only the low-speed hole-starting mode is active. The

water flow rate should also be set while the machine is running at this speed. Maximum drilling speed for the

selected speed setting will be reached when the control switch is pressed in all the way.

3.12 Items supplied

machine with side handle, chuck and operating instructions

You can find other system products approved for use with your product at your local Hilti Center or online

at: www.hilti.group.

3.13 Accessory tools

Designation Designation

Diamond core bit DDC

Core breaking tool DDCB

3.14 Accessories

Designation Designation

Drill stand DDST 30

Core bits DD-C, 8 ‒ 35 mm diameter

Accessory set for fastening the drill stand with an

anchor

DD M12 S

Depth gauge for the drill stand DD-ST 30-ES

Spray guard DD-30-W-CV

4 Technical data

4.1 Diamond coring machine

Note

For details of the rated voltage, current, frequency and input power, please refer to the machine’s

country-specific type identification plate.

When powered by a generator or transformer, the generator or transformer’s power output must be at

least twice the rated input power shown on the rating plate of the machine. The operating voltage of the

transformer or generator must always be within +5% and -15% of the rated voltage of the machine.

Printed: 06.07.2017 | Doc-Nr: PUB / 5283534 / 000 / 05

Loading...

Loading...