Page 1

DD 250

DD 200/HD 30

DD 200/ST 200

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

English en

Français fr

ﻋﺮﺑﻲ ar

日本語 ja

한국어 ko

中文 cn

繁體中文 zh

Page 2

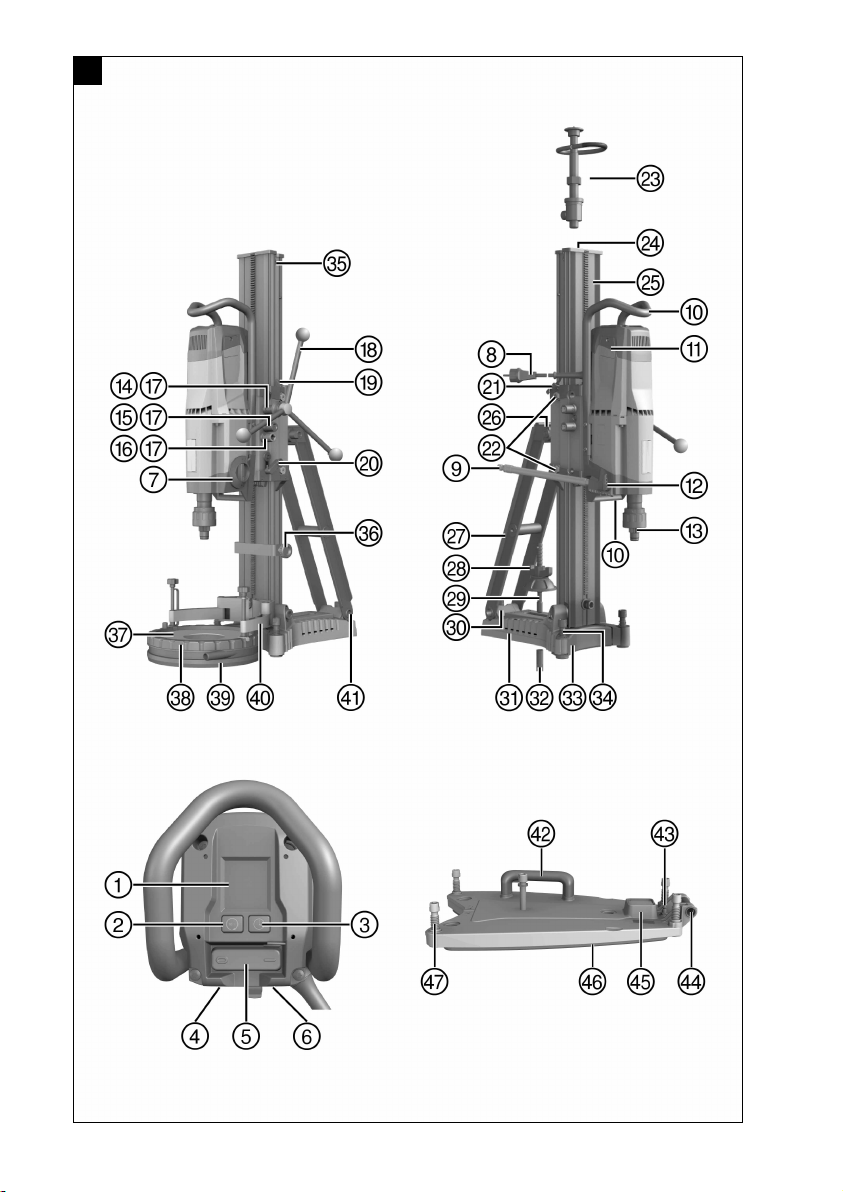

1

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 3

2

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 4

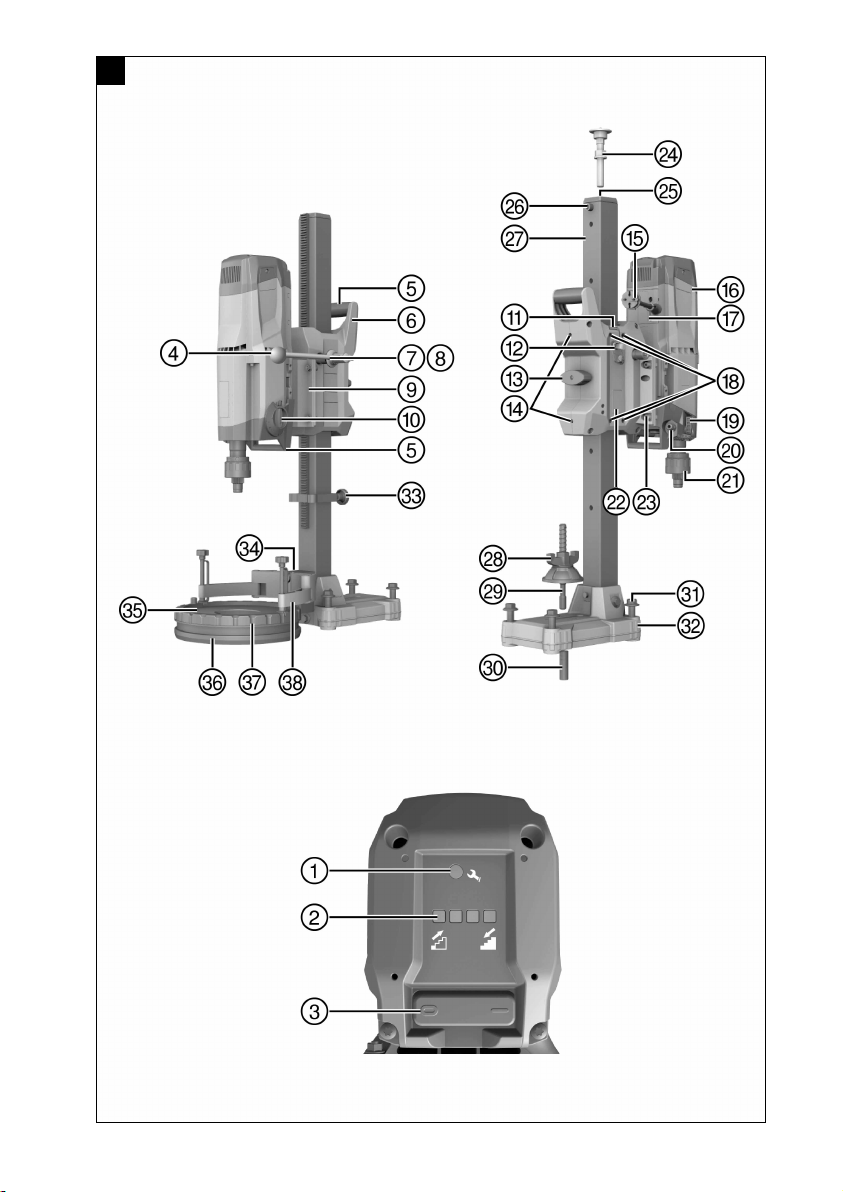

3

4

5

6

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 5

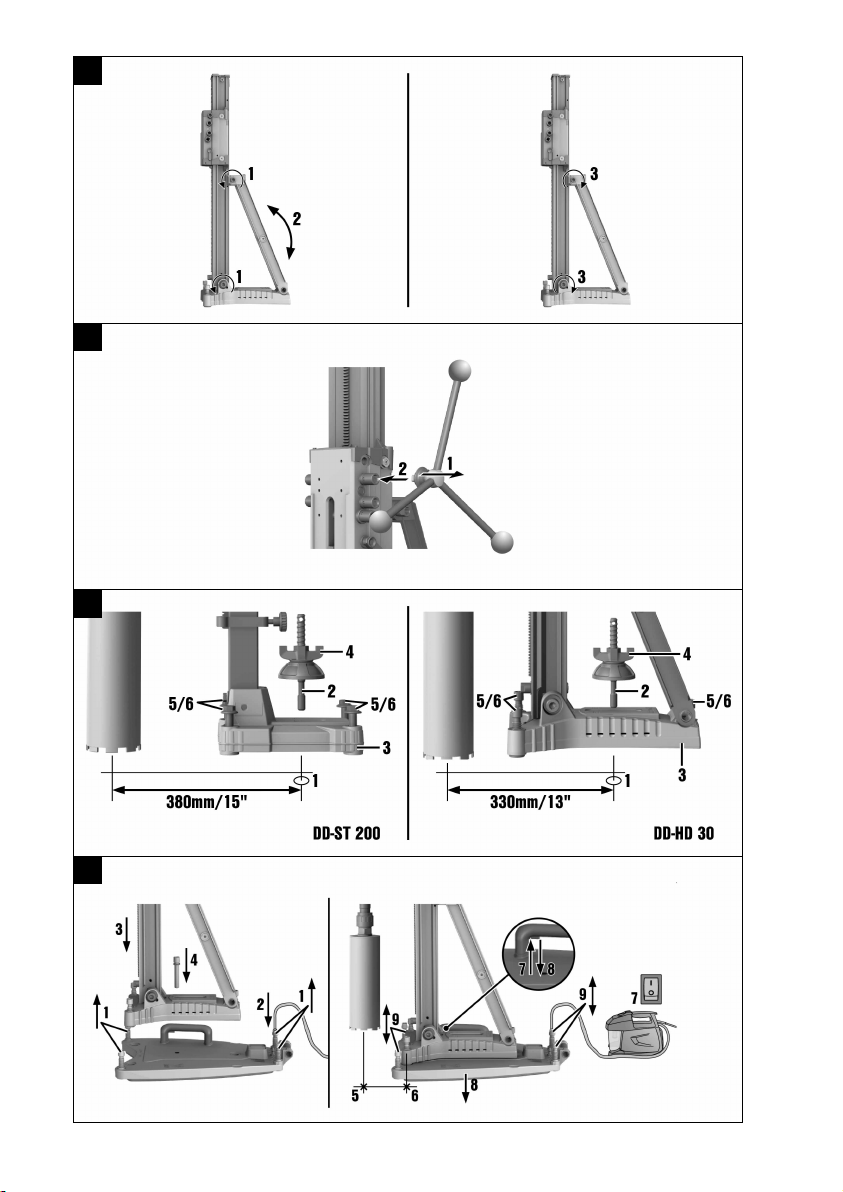

7

8

9

10

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

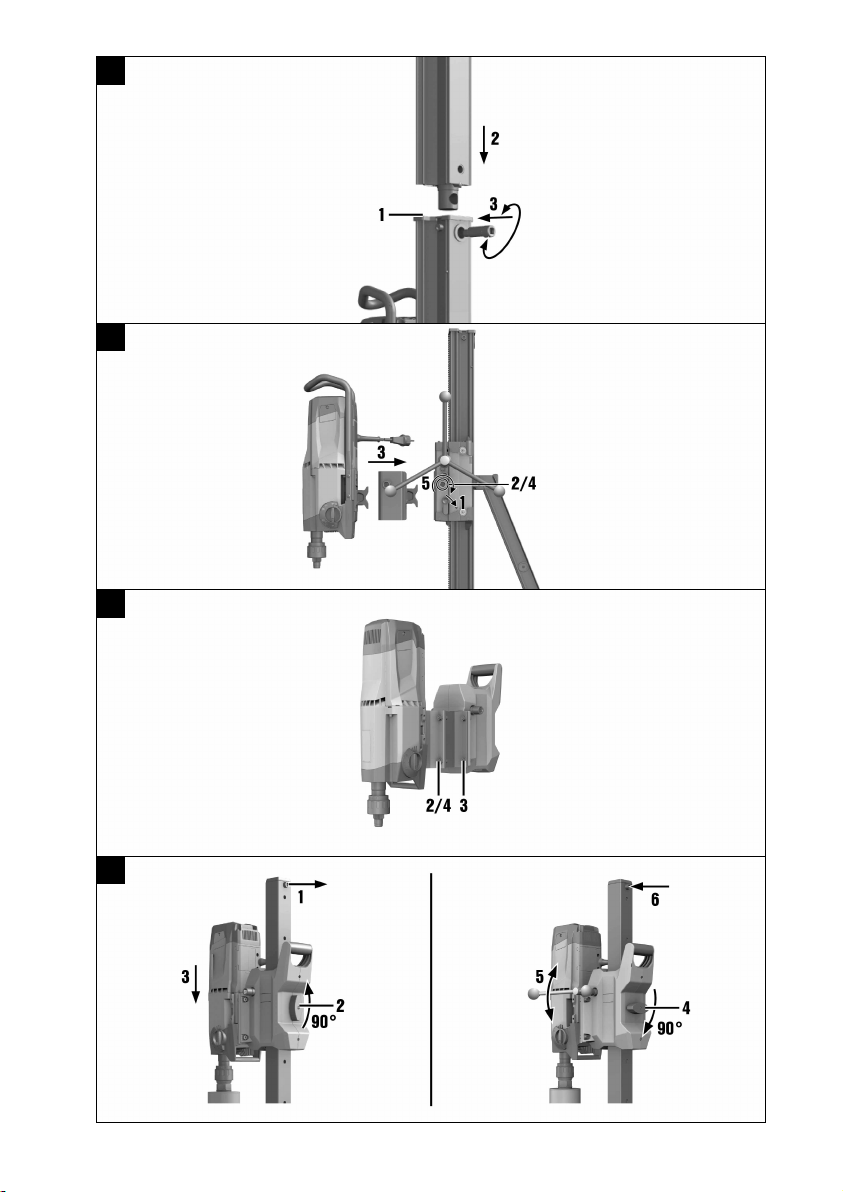

Page 6

11

12

13

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 7

DD 250

DD 200/HD 30

DD 200/ST 200

en Original operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

fr Mode d'emploi original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ar ﺩﻟﻴﻞﺍﻻﺳﺘﻌﻤﺎﻝﺍﻷﺻﻠﻲ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

ja オリジナル取扱説明書 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

ko 오리지널 사용설명서 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

cn 原版操作说明 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

zh 原始操作說明 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 8

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 9

1 Information about the documentation

1.1 Conventions

1.1.1 Prohibition signs

The following prohibition signs are used:

Transport by crane is not permissible

1.1.2 Warning signs

The following warning signs are used:

General warning

Warning: hot surface

Warning: hazardous electrical voltage

1.1.3 Mandatory signs

The following mandatory signs are used:

Read the operating instructions before use.

Wear protective gloves

1.1.4 Symbols

The following symbols are used:

Service indicator

Hole-starting mode

Runtime counter

Drilling performance indicator: Increase contact pressure

Drilling performance indicator: Reduce contact pressure

Protective earth

Rated speed under no load

Instructions for use and other useful information

1.1.5 Typographical emphasis

The following typographic features are used to emphasize important passages in this technical documentation:

These numbers refer to the corresponding illustrations.

1

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

1

Page 10

1.2 Information notices

On the drill stand, base plate or diamond core drilling machine

On the vacuum base plate

Upper half of the image: An additional means of securing the drill stand

must be employed when the machine is used for horizontal drilling with the

vacuum securing method.

Lower half of the image: Use of the vacuum securing method without

an additional means of securing is prohibited for drilling in an upward

direction.

On the diamond core drilling machine

Use of the water collection system in conjunction with a wet-type industrial

vacuum cleaner is a mandatory requirement for working overhead.

On the diamond core drilling machine

Operate the system only with a properly functioning PRCD.

1.3 Operating instructions

▶ It is essential that the operating instructions are read before initial operation.

▶ Always keep these operating instructions together with the power tool.

▶ Ensure that the operating instructions are with the power tool when it is given to other persons.

Changes and errors excepted.

2

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 11

1.4 Product information

▶ The type designation and serial number can be found on the rating plate on the product. Make a note of

this data in the following table and always refer to it when making an inquiry to your Hilti representative

or Hilti Service Center.

Product information

Diamond core drilling

machine

DD 250

DD 200/HD 30

DD 200/ST 200

Generation 02

Serial no.

2 Safety

2.1 Warnings

The purpose of warnings

Warnings alert persons to hazards that occur when handling or using the product.

Description of the key words used

DANGER

Draws attention to imminent danger that will lead to serious personal injury or fatality.

WARNING

Draws attentionto apotentially dangeroussituation thatcould leadto seriouspersonal injuryor fatality.

CAUTION

Draws attention toa potentially dangeroussituation that could lead to slight personalinjury or damage

to the equipment or other property.

2.2 Safety precautions

The safety precautions given in the following section contain all general safety precautions for power tools

which, in accordance with the applicable standards, require to be listed in the operating instructions.

Accordingly, some of the rules listed may not be relevant to this power tool.

2.2.1 General safety precautions for power tools WARNING Ensure that your read all safety precautions, instructions and technical data with which

this power tool is provided. Failure to follow the instructions below may result in electric shock, fire and/or

serious injury.

Keep all safety precautions and instructions for future reference.

The term “power tool” used in the safety precautions refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

▶ Keep your work area clean and well lit. Cluttered or dark work areas invite accidents.

▶ Do not operate the power tool in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

▶ Keep bystanders, children and visitors away while operating a power tool. Distractions can cause

you to lose control of the tool.

Electrical safety

▶ The plug on the supply cord of the power tool must match the power outlet. Do not change the

plug in any way. Do not use adapter plugs with earthed (grounded) power tools. Unmodified plugs

and matching power outlets reduce the risk of electric shock.

▶ Avoid body contact with earthed or grounded surfaces such as pipes, radiators, cookers, stoves

and refrigerators. There is an increased risk of electric shock if your body is grounded.

▶ Do not expose the power tool to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

▶ Do not abuse the supply cord. Never use the supply cord for carrying, pulling or unplugging the

power tool. Keep the supply cord away from heat, oil, sharp edges or moving parts. Damaged or

tangled supply cords increase the risk of electric shock.

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

3

Page 12

▶ When operating a power tool outdoors, use only extension cords of a type suitable for outdoor

use. Use of an extension cord suitable for outdoor use reduces the risk of electric shock.

▶ If use of the power tool in a damp environment cannot be avoided, use a ground fault circuit

interrupter. Use of a ground fault circuit interrupter reduces the risk of electric shock.

Personal safety

▶ Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating the power tool may result in serious personal injury.

▶ Wear your personal protective equipment and always wear protective glasses. Depending on the

purpose for whichthe power tool is to be used, wearing safetyequipment such as adust mask, non-skid

safety shoes, hard hat, or hearing protection will reduce the risk of injury.

▶ Avoid accidental starting. Check that the power tool is switched off before you connect it to the

power supply and/or the battery and before picking it up or carrying it. Carrying power tools with

your finger on the switch or plugging in power tools that are already switched on invites accidents.

▶ Remove adjusting keys or switches before turning the power tool on. A tool or a key left attached to

a rotating part of the machine may result in personal injury.

▶ Avoid unaccustomed body positions. Maintain proper footing and balance at all times. This will

allow you to control the power tool better, even in unexpected situations.

▶ Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

▶ If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. The use of a dust removal system can reduce dust-related hazards.

▶ Do not lull yourself into a false sense of security and do not flout the safety rules for power tools,

even if you are familiar with the power tool after using it many times. Caress handling could cause

serious injury within fractions of a second.

Use of the power tool

▶ Do not overload the tool. Use the correct power tool for your application. The correct power tool

will do the job better and more safely within the performance range for which it is designed.

▶ Do not use a power tool if it has a faulty On/Off switch. Any power tool that cannotbe controlled with

the switch is dangerous and must be repaired.

▶ Disconnect the plug from the power outlet and/or remove a removable battery before making any

adjustments, changing accessories, or storing the tool. This precautionreduces the risk ofthe power

tool starting accidentally.

▶ Store idle power tools out of the reach of children . Do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

▶ Maintain power tools and accessories carefully. Check that moving parts operate satisfactorily

and do not jam, and whether any parts are broken or so damaged that the correct operation of the

power tool is adversely affected. If parts are damaged, have the parts repaired before using of the

tool. Many accidents are caused by poorly maintained power tools.

▶ Keep cutting tools sharp and clean. Properly maintained tools with sharp cutting edges are less likely

to bind and are easier to control.

▶ Use power tools, accessories, insert tools, etc. only as described in this manual. Take the working

conditions and the work to be performed into account. Use of the power tool for operations different

from those intended could result in a hazardous situation.

▶ Keep grips and gripping surfaces dry, clean and free from oil and grease. Slippery grips andgripping

surfaces do not allow the power tool to be safely operated and controlled in unforeseen situations.

Service

▶ Have your power tool repaired only by qualified,skilled personnel, using only genuine Hilti spare

parts. The safety of the power tool can thus be maintained.

2.2.2 Diamond drill safety warnings

▶ When performing drilling that requires the use of water, route the water away from the operator’s

work area or use a liquid collection device. Such precautionary measures keep the operator’s work

area dry and reduce the risk of electrical shock.

▶ Operate power tool by insulated grasping surfaces, when performing an operation where the

cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a “live”

wire may make exposed metal parts of the power tool “live” and could give the operator an electric

shock.

4

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 13

▶ Wear hearing protection when diamond drilling. Exposure to noise can cause hearing loss.

▶ When the bit is jammed, stop applying downward pressure and turn off the tool. Investigate and

take corrective actions to eliminate the cause of the bit jamming.

▶ When restarting a diamond drill in the workpiece check that the bit rotates freely before starting. If

the bit is jammed, it may not start, may overload the tool, or may cause the diamond drill to release from

the workpiece.

▶ When securing the drill stand with anchors and fasteners to the workpiece, ensure that the

anchoring used is capable of holding and restraining the machine during use. If the workpiece is

weak or porous, the anchor may pull out causing the drill stand to release from the workpiece.

▶ When securing the drill stand with a vacuum pad to the workpiece, install the pad on a smooth,

clean, non-porous surface. Do not secure to laminated surfaces such as tiles and composite

coating. If the workpiece is not smooth, flat or well affixed, the pad may pull away from the workpiece.

▶ Ensure there is sufficient vacuum before and during drilling. If the vacuum is insufficient, the pad

may release from the workpiece.

▶ Never perform drilling with the machine secured by the vacuum pad only, except when drilling

downwards. If the vacuum is lost, the pad will release from the workpiece.

▶ When drilling through walls or ceilings, ensure to protect persons and the work area on the other

side. The bit may extend through the hole or the core may fall out on the other side.

▶ When drilling overhead, always use the liquid collection device specified in the instructions. Do

not allow water to flow into the tool. Water entering the power tool will increase the risk of electric

shock.

2.2.3 Additional safety precautions

Personal safety

▶ Tampering with or modification of the machine is not permitted.

▶ The machine is not intended for use by inexperienced persons who have received no special

training.

▶ Keep the machine out of reach of children.

▶ Avoid touching rotating parts. Switch the machine on only after it is in position at the workpiece.

Touching rotating parts, especially rotating accessory tools, may lead to injury.

▶ Avoid skin contact with drilling slurry.

▶ Dust from materials, such as paint containing lead, some kinds of wood, concrete / masonry / stone

containing silica, and minerals as well as metal, may be injurious to health. Contact with or inhalation of

the dust may cause allergic reactions and/or respiratory or other diseases to the operator or bystanders.

Certain kindsof dust areclassified as carcinogenic suchas oak andbeech dust, especially inconjunction

with additives for wood conditioning (chromate, wood preservative). Material containing asbestos must

only be handled by specialists. Use a dust removal system that is as effective as possible. Accordingly,

use a suitable vacuum cleaner of the type recommended by Hilti for wood dust and/or mineral dust and

which is designed for use with this power tool. Ensure that the workplace is well ventilated. The use

of a dust mask suitable for the particular type of dust is recommended. Observe national regulations

applicable to the materials on which you intend to use the machine.

▶ The diamond core drilling machine and the diamond core bit are heavy pieces of equipment. There is a

risk of crushing parts of the body. The user and any other persons in the vicinity must wear suitable

eye protection, a hard hat, ear protection, protective gloves and safety footwear while the machine

is in use.

Careful handling and use of electric tools

▶ Make sure that the machine is correctly fastened in the drill stand.

▶ Take care to ensure that an end stop is always fitted to the drill stand. The safety-relevant end-stop

function becomes inoperative if this component is not fitted.

▶ Ensure that the accessory tools used have a mounting system that is compatible with the drilling

machine and that they are secured in the chuck correctly.

Electrical safety

▶ Avoid using extension cords with multiple power outlets and the simultaneous use of several

machines connected to one extension cord.

▶ The machine may be operated only whenconnected to an adequately-rated power supply equipped

with an earth (ground) conductor.

▶ Before beginning work, check the working area (e.g. using a metal detector) to ensure that no

concealed electric cables or gas and water pipes are present. External metal parts of the machine

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

5

Page 14

may become live, for example, when an electric power line is damaged accidentally. This presents a

serious risk of electric shock.

▶ Make sure that the supply cord is not pinched and damaged as the carriage advances.

▶ Never operate the machine without the accompanying PRCD (machines without PRCD: Never

operate the machine without an isolating transformer). Test the PRCD each time before use.

▶ Check the machine’s supply cord at regular intervals and have it replaced by a qualified specialist

if found to be damaged. If the machine’s supply cord is damaged it must be replaced with

a specially-prepared and approved supply cord available from Hilti Customer Service. Check

extension cords at regular intervals and replace them if found to be damaged. Do not touch the

supply cord or extension cord if it is damaged while working. Disconnect the supply cord plug

from the power outlet. Damaged supply cords or extension cords present a risk of electric shock.

▶ Never operate the machine when it is dirty or wet. Dust (especially dust from conductive materials)

or dampness adhering to the surface of the machine may, under unfavorable conditions, lead to electric

shock. Dirty or dusty machines should thus be checked by Hilti Service at regular intervals, especially if

used frequently for working on conductive materials.

Workplace

▶ Approval must be obtained from the site engineer or architect prior to beginning drilling work.

Drilling work on buildings and other structures may influence the static equilibrium of the structure,

especially when steel reinforcing bars or load-bearing components are cut through.

▶ If the drill stand has not been fastened correctly, always move the machine mounted on the drill

stand all the way down in order to prevent the stand from falling over.

▶ Keep the supply cord, extension cord, water hose and vacuum hose away from rotating parts of

the machine.

▶ Use of the water collection system in conjunction with a wet-type industrial vacuum cleaner is a

mandatory requirement for wet drilling overhead.

▶ Use of the vacuum securing method without an additional means of fastening is prohibited for

drilling in an upward direction.

▶ An additional means of securing the drill stand must be employed when the machine is secured

with the vacuum securing method (accessory) for horizontal drilling.

3 Description

3.1 Parts, indicators and operating controls for diamond core drilling machine DD 250/drill stand

DDHD 30 1

Diamond core drilling machine DD 250

@ Multifunction display

; Button for hole-starting mode

= Runtime counter button

% Rating plate

& On/Off switch

( Supply cord cover

+ Supply cord with PRCD

§ Water connection

/ Carrying handle (2x)

: Carbon brush cover (2x)

∙ Water flow regulator

$ Chuck

) Gear selector

Carriage DD-HD 30

£ Hand wheel shaft 1:1

| Hand wheel shaft 1:3

¡ Eccentric pin (lock for the diamond core

drilling machine)

Q Shear pin (5x)

Drill stand DD-HD 30

U Threaded spindle (accessory)

I Cover

O Rail

P Carrying handle

Ü Brace

[ Clamping nut

] Clamping spindle

W Hand wheel

E Leveling indicator (2x)

R Carriage lock

T Supply cord guide

Z Carriage play adjusting screw (4x)

Æ Rating plate

º Base plate

~ Anchor

A Hole center indicator

S Leveling screw (3x)

D End stop screw

F Depth gage (accessory)

6

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 15

G Sealing washer for water collector (acces-

sory)

H Water collector (accessory)

Vacuum base plate (accessory)

Ö Vacuum release valve

Ä Vacuum hose connector

† Traversing mechanism adapter

3.2 Parts, indicators and operating controls for diamond core drilling machine DD 200/drill stand

DDST 200 2

Diamond core drilling machine DD 200

@ Service indicator

; Drilling performance indicator

= On/Off switch

% Hand wheel

& Carrying handles (2x)

( Carriage casing

) Hand wheel shaft

+ Shear pin (2x)

§ Intermediate piece

/ Gear selector

: Adjusting screw hexagon socket wrench

∙ Supply cord guide

DDST 200 drill stand

I Threaded spindle (accessory)

O Threaded spindle chuck

P End stop screw

Ü Rail

[ Clamping nut

] Clamping spindle

Æ Anchor

º Leveling screw (4x)

J Seal (accessory)

K Water collector holder (accessory)

L Traversing mechanism adapter

ΠPressure gage

Å Vacuum seal

ª Leveling screw (4x)

$ Carriage lock

£ Screw for adjusting the play between

carriage and roller (2x)

| Supply cord with PRCD

¡ Carbon brush cover (2x)

Q Supply cord cover

W Screw for adjusting the play between

carriage and sliding piece (4x)

E Water flow regulator

R Water connection

T Chuck

Z Rating plate

U Intermediate piece screw (4x)

~ Base plate

A Depth gage (accessory)

S Spacer for water collector holder (acces-

sory)

D Sealing washer for water collector (acces-

sory)

F Seal (accessory)

G Water collector (accessory)

H Water collector holder (accessory)

3.3 Intended use

The product described is an electrically powered diamond core drilling machine. It is designed for drilling

through-holes and blind holes in (reinforced) mineral base materials using a drill stand and the wet drilling

technique. Hand-held use of the diamond core drilling machine is not permitted.

The product described is designed for professional use and may be operated, serviced and maintained only

by trained, authorized personnel. This personnel must be informed of any particular hazards that may be

encountered. The productdescribed and its ancillaryequipment may present hazardswhen used incorrectly

by untrained personnel or when used not as directed.

▶ Always use adrill stand when using thediamond core drillingmachine. The drillstand must be sufficiently

anchored in the base material by an anchor or vacuum base plate.

▶ Do not use a hammer or other heavy object when making adjustments to the base plate.

▶ The tool may be operated only when connected to a power supply providing a voltage and frequency in

compliance with the information given on its rating plate.

▶ Observe the national health and safety requirements.

▶ Observe the safety rules and operating instructions for the accessories used.

▶ To reduce the risk of injury, use only genuine Hilti core bits and accessories.

3.4 DD 250: Display symbols and explanations on the multifunction display of the diamond core drilling machine

For the following indicators, the diamond core drilling machine must be ready for operation (plugged in and

with a switched-on PRCD).

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

7

Page 16

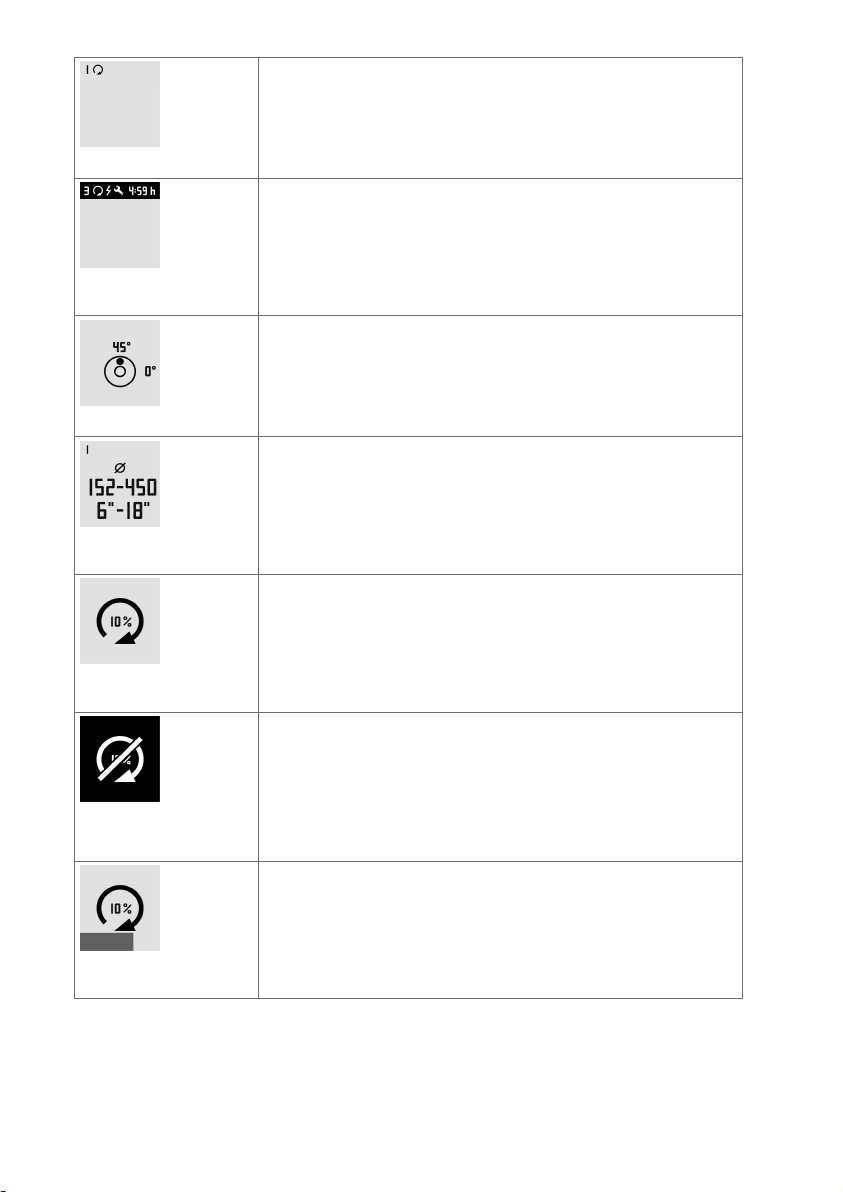

Status bar for information

Status bar for warning

messages

Spirit level

Gear indicator for first to

fourth gear

Hole-starting mode is

active

The hole-starting mode

cannot be activated

Running time for the holestarting mode

The status bar displays various pieces of information regarding the machine’s current status, such as the gear engaged or the activated holestarting mode.

The status bar displays various warning indicators that do not cause the

diamond core drilling machine to stop immediately, such as (from right to

left) time remaining until the carbon brushes have to be replaced, when

service is necessary or if there is a fault in the power supply.

The diamond core drilling machine is not switched on. The indicator helps

level the system and align the drill stand when drilling at an angle. The

indicator displays the alignment of the diamond core drilling machine

symbolically and in degrees.

Note

Angular accuracy at room temperature: ±2°

The diamond core drilling machine is running under no load. The indicator

helps ensure that the gear engaged is suitable for the diamond core bit

used. At the top left, the indicator displays the gear engaged and in the

center, the recommended core bit diameter range in millimeters and inches

for this gear.

The diamond core drilling machine is switched off or running under no load.

The function makes it possible to start holes with low vibration in the case

of core bits with a large diameter. This function can be deactivated at any

time by pressing the button for the hole-starting mode again

Note

The indicator is automatically hidden after a few seconds.

The diamond core drilling machine is drilling. The button for activating

hole-starting mode was pressed while the diamond core drilling machine

was under load, was being run-in after the carbon brushes had been

changed, or was in cool-down mode, or immediately after the diamond

core drilling machine had been operated for two minutes in hole-starting

mode. Activation is not possible.

Note

The indicator is automatically hidden after a few seconds.

The diamond core drilling machine is drilling. The hole-starting mode is

active. The indicator displays the time remaining until the diamond core

drilling machine automatically switches off.

Note

To protect the diamond core drilling machine, the hole-starting mode

automatically switches off after a maximum of two minutes.

8

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 17

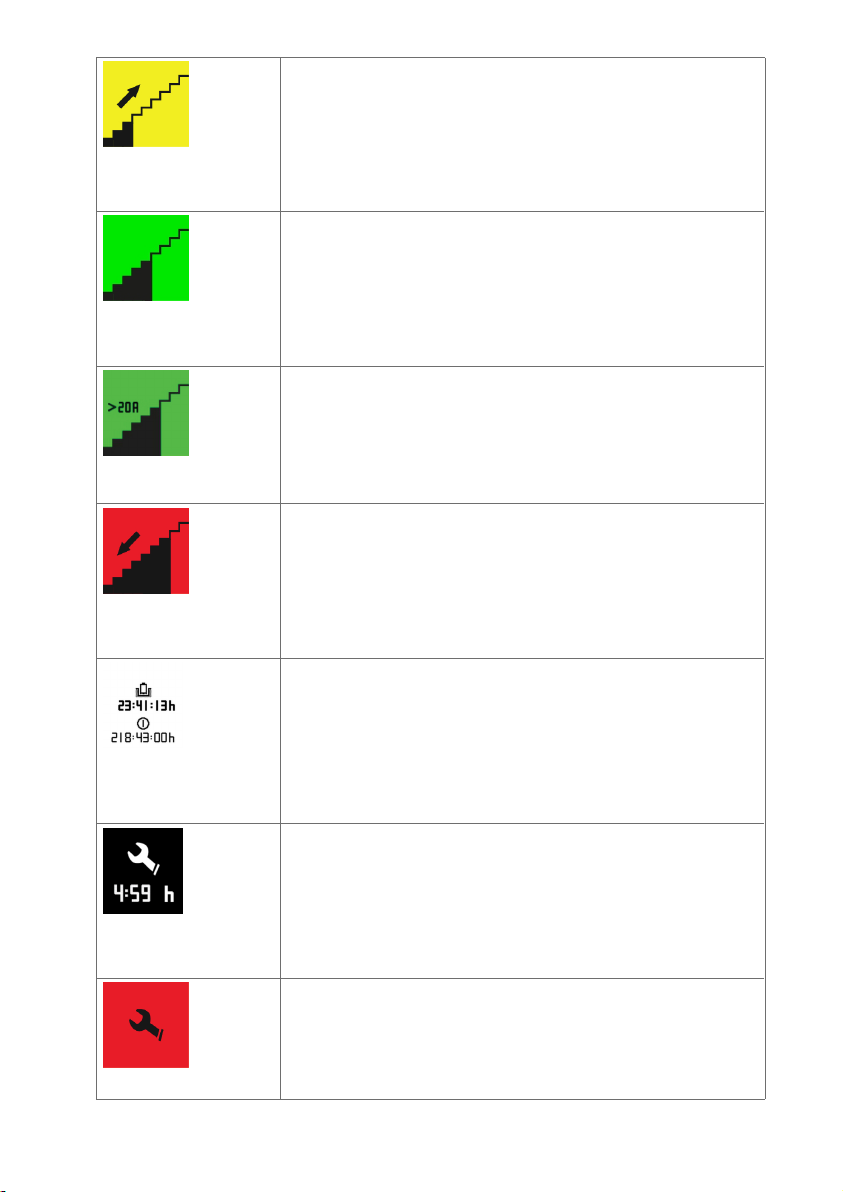

Drilling performance

indicator: Contact pressure

is too low

Drilling performance

indicator: Optimum contact

pressure

Rated current limit has

been exceeded

Drilling performance

indicator: Contact pressure

is too high

Runtime counter

Time remaining until the

carbon brushes are to be

replaced

The diamond core drilling machine is drilling. The hole-starting mode is not

active. The indicator helps ensure that the diamond core drilling machine is

being operated in the optimal range. Background color: Yellow.

The contact pressure is too low. Increase the contact pressure.

The diamond core drilling machine is drilling. The hole-starting mode is not

active. The indicator helps ensure that the diamond core drilling machine is

being operated in the optimal range. Background color: Green.

The contact pressure is at the optimum level.

The diamond core drilling machine is drilling. The hole-starting mode is

not active. It is indicated that rated current has exceeded the limit of 20 A.

Background color: Green.

The contact pressure is too high. Reduce the contact pressure.

The diamond core drilling machine is drilling. The hole-starting mode is not

active. The indicator helps ensure that the diamond core drilling machine is

being operated in the optimal range. Background color: Red.

The contact pressure is too high. Reduce the contact pressure.

The button for the runtime counter has been pressed. At the top, the indicator displays the drilling time (the diamond core drilling machine is drilling)

and, at the bottom, the diamond core drilling machine's operating hours

(diamond core drilling machine is switched on) in hours, minutes and seconds. Press the button for the runtime counter for a few seconds to reset

the drilling time total to zero.

Note

The indicator is automatically hidden after a few seconds or by pressing the

button again.

The diamond core drilling machine is running. The carbon brush wear

limit has almost been reached. The indicator helps ensure that the carbon

brushes are replaced in good time. The time remaining until the diamond

core drilling machine automatically switches off is displayed in hours and

minutes. The indicator is automatically hidden after a few seconds.

The carbon brushes are worn. The carbon brushes must be replaced.

An internal fault has occurred.

Service indicator

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

9

Page 18

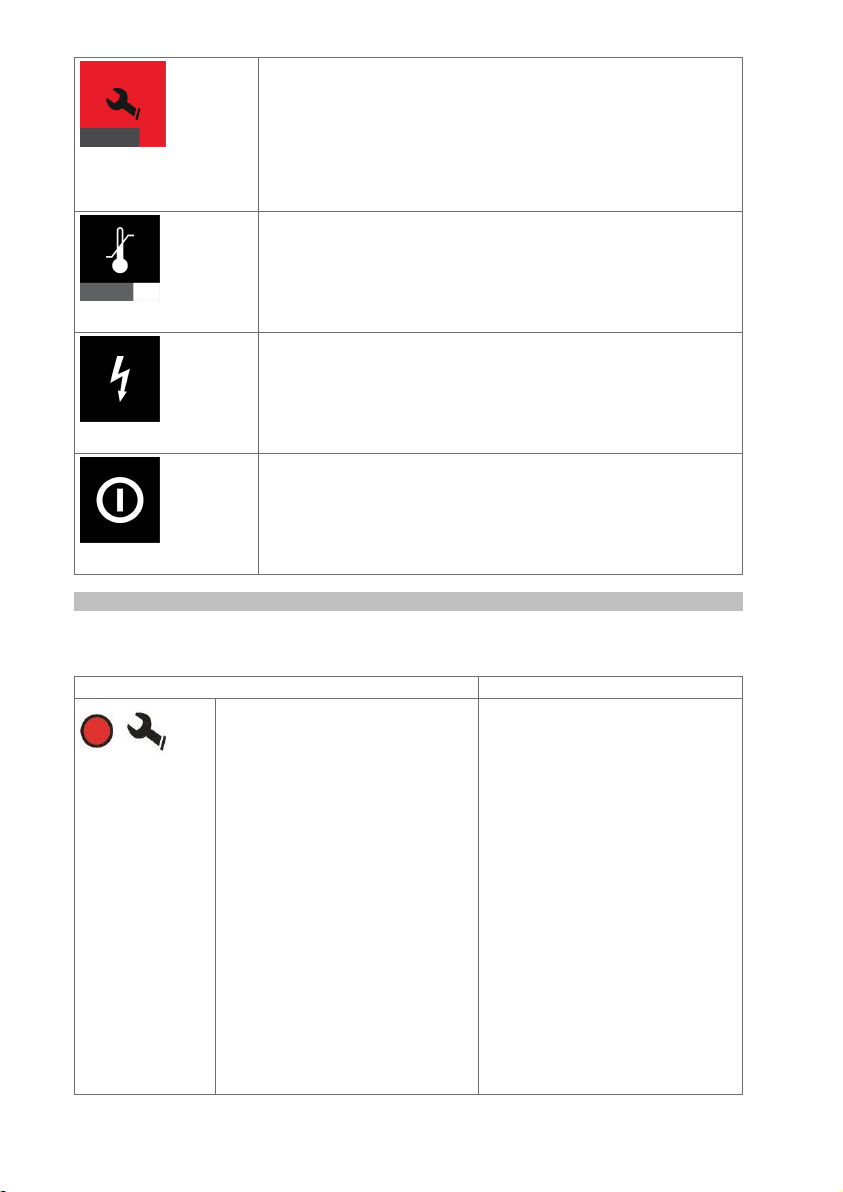

The diamond core drilling machine is running. The carbon brushes have

been changed and must be run in by letting the machine run under no load

for at least one minute without interruption, in order to achieve the optimum

service life. The indicator displays the time remaining until the running-in

process is completed.

Running in after the carbon brushes have been

replaced

The diamond core drilling machine has overheated. It is no longer running

or is in cool-down mode. The indicator displays the time remaining until

the diamond core drilling machine cools down. If the diamond core drilling

machine is still too hot after this time has elapsed, the remaining running

time starts from the beginning again.

Overheating

Undervoltage occurred in the supply network. In the event of undervoltage,

the diamond core drilling machine cannot be operated at full power.

Note

The indicator is automatically hidden after a few seconds.

Fault in the power supply

Maximum running time with hole-starting mode active has been exceeded;

Fault in the power supply; The diamond core drilling machine has been

overloaded; Overheated, water has entered the motor or the cooling running time has ended.

Restart interlock

3.5 DD 200: Service indicator and drilling performance indicator

The diamond core drilling machine is equipped with a service indicator and an LED drilling performance

indicator. For the following indicators, the diamond core drilling machine must be ready for operation

(plugged in and with a switched-on PRCD).

Status Meaning

Lights up red • The diamond core drilling machine is

in working order. The carbon brush

wear limit has almost been reached.

The indicator helps ensure that the

carbon brushes arereplaced in good

time. After the lamp lights up for the

first time, the machine may continue

to be used for several hours before

the automatic cut-out is activated.

• The diamond core drilling machine

is in working order. The carbon

brushes have been changed and

must be runin by letting the machine

run under no load for at least one

minute without interruption, in order

to achieve the optimum service life.

• The diamond core drilling machine

is no longer in working order. The

carbon brushes are worn. The

carbon brushes must be replaced.

• The diamond core drilling machine is

no longer in working order. Damage

to thediamond core drilling machine.

10

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 19

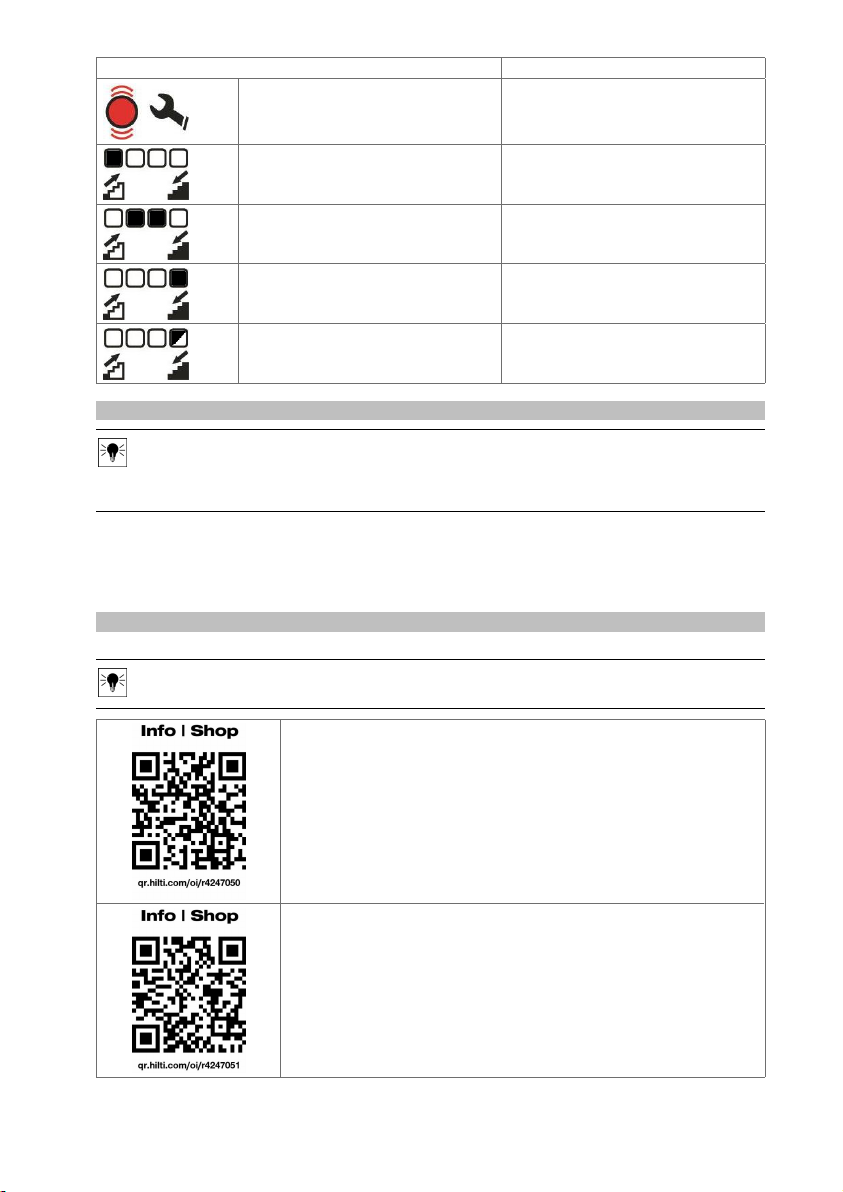

Status Meaning

Flashing red light • Overheating. See “Troubleshooting”.

The LED on the left lights yellow. • Contact pressure is too low.

The LEDs in the middle light green. • The contact pressure is at the

optimum level.

The LED on the right lights red. • Contact pressure is too high.

LED on the right-hand side flashes red • Contact pressure is too high.

The rated current limit has been

exceeded.

3.6 Items supplied

Note

To help ensuresafe and reliable operation,use only genuine Hiltispare parts and consumables. Spare

parts, consumables and accessories approved by Hilti for use with the product can be found at your

local Hilti Center or online at: www.hilti.com

Items supplied: DD 250/DD 200 for DDHD 30

Diamond core drilling machine, operating instructions.

Items supplied: DD 200 for DDST 200

Diamond core drilling machine, hand wheel/lever, hexagon socket wrench, operating instructions.

3.7 Accessories and spare parts

QR codes

Note

Scan the applicable QR code with your smartphone for further information.

DD 200 for drill standDD-HD 30

DD 200 for drill standDD-ST 200

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

11

Page 20

DD 250 for drill standDD-HD 30

Spare parts

Item number Designation

51279 Hose connector

2006843 Carbon brushes 220-240 V

2104230 Carbon brushes 100-127 V

4 Technical data

4.1 Diamond core drilling machine

When powered by a generator or transformer, the generator or transformer’s power output must be at least

twice the rated input power shown on the rating plate of the power tool. The operating voltage of the

transformer or generator must always be within +5% and -15% of the rated voltage of the power tool.

The information given applies to a rated voltage of 230 V. The data may vary in the event of deviations from

the rated voltage and for country-specific versions. Please refer to the power tool’s rating plate for details of

its voltage, frequency, current and input power ratings.

Information for users as per EN 61000-3-11: Switching on causes a brief drop in voltage. Other appliances

may be negatively affected on mains supplies where conditions are unfavorable. No malfunctions are to be

expected in mains supplies with an impedance of less than 0.4287 ohms.

Weight in accordance with EPTA

DD 250 DD 200 for

DDHD 30

15.3 kg 14.6 kg 20.4 kg

DD 200 for

DDST 200

procedure 01/2003

Weight of the drill

DD-HD 30

21.4 kg 21.4 kg •/•

stand in accordance with EPTA

procedure 01/2003

DDST 200

Drilling depth without extension

Permissible water supply pressure

Rated speed under

no load

1st gear

2nd gear

3rd gear

4th gear

Optimum core bit

diameter

1st gear

2nd gear

3rd gear

4th gear

Ideal distance between the marking

•/• •/• 12.3 kg

500 mm 500 mm 500 mm

≤ 6 bar ≤ 6 bar ≤ 6 bar

240 rpm 240 rpm 240 rpm

580 rpm 580 rpm 580 rpm

1,160 rpm 1,160 rpm 1,160 rpm

2,220 rpm •/• •/•

152 mm … 450 mm 152 mm … 500 mm 152 mm … 500 mm

82 mm … 152 mm 82 mm … 152 mm 82 mm … 152 mm

35 mm … 82 mm 35 mm … 82 mm 35 mm … 82 mm

12 mm … 35 mm •/• •/•

330 mm 330 mm 380 mm

on the anchor base plate and the

hole center

Ideal distance between the marking

165 mm 165 mm 215 mm

on the vacuum base plate and the

hole center

12

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 21

4.2 Permissible core bit diameters for various items of equipment

Note

The approved drilling directions for the various items of equipment must be observed.

Use of a wet/dry vacuum cleaner with a water collection system is mandatory for drilling upwards.

DD 250 DD 200 for DDHD 30 DD 200 for DDST 200

Ø without accessories

Ø with spacer

Ø with water collec-

12 mm … 300 mm 35 mm … 300 mm 35 mm … 400 mm

12 mm … 450 mm 35 mm … 500 mm 35 mm … 500 mm

12 mm … 250 mm 35 mm … 250 mm 35 mm … 250 mm

tion system and wettype industrial vacuum

cleaner

4.3 Noise information and vibration values determined in accordance with EN 62841

The sound pressure and vibration values given in these instructions have been measured in accordance

with a standardized test and may be used to compare one power tool with another. They may be used

for a preliminary assessment of exposure. The data given represents the main applications of the power

tool. However, if the power tool is used for different applications, with different accessory tools, or is poorly

maintained, the data may vary. This may significantly increase exposure over the total working period. An

accurate estimation of exposure should also take into account the times when the power tool is switched

off, or when it is running but not actually being used for a job. This may significantly reduce exposure over

the total working period. Identify additional safety measures to protect the operator from the effects of noise

and/or vibration, for example: maintain the tool and the accessories, keep the hands warm, organization of

work patterns.

Noise emission values determined in accordance with EN 62841

Sound (power) level (LWA)

Uncertainty for the sound power level (KWA)

Sound pressure level (LpA)

Uncertainty for the sound pressure level (KpA)

109 dB(A)

3 dB(A)

93 dB(A)

3 dB(A)

Total vibration (vector sum of three directions), measured in accordance with EN 62841

Triaxial total vibration (vector sum of vibration) at the hand wheel (star handle) does not exceed 2.5 m/s²

(including uncertainty K) in accordance with EN 62841-3-6.

5 Operation

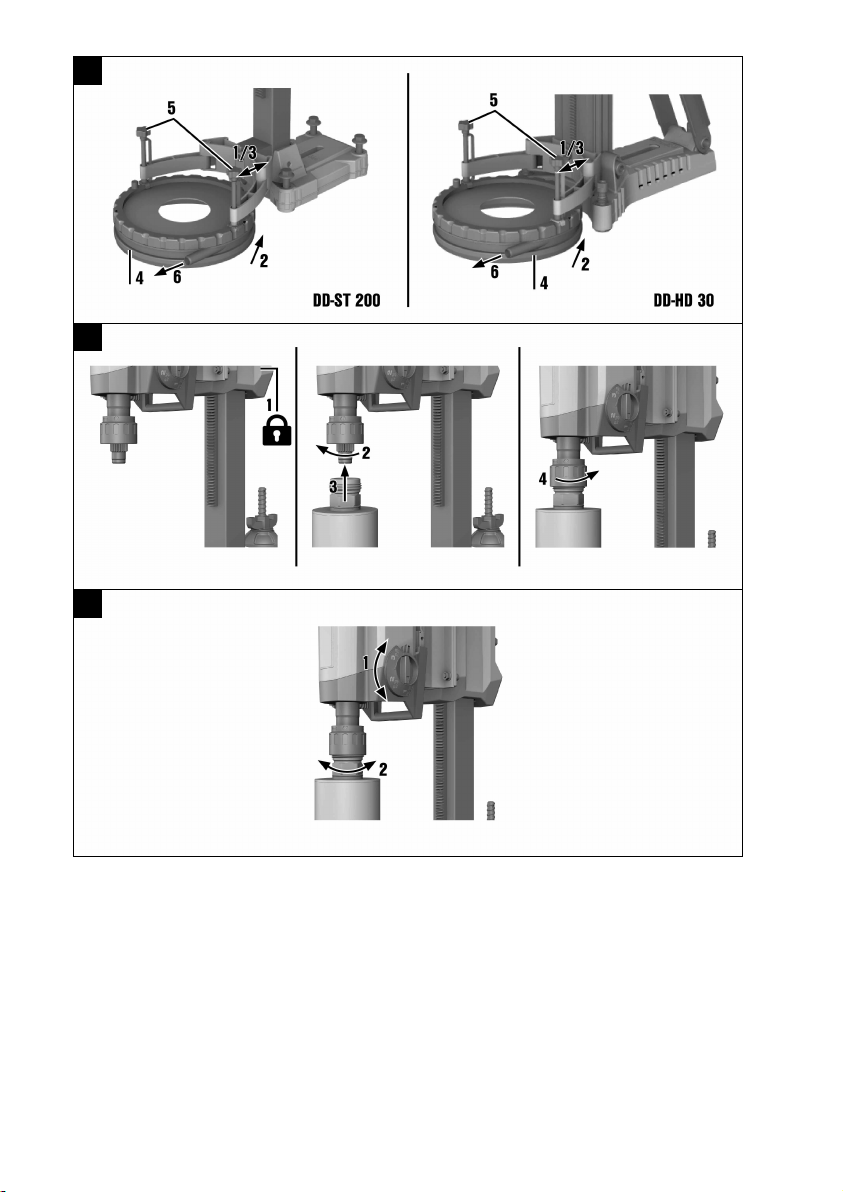

5.1 DD-HD 30: Setting up the drill stand and setting the drilling angle 3

CAUTION

Risk of injury Risk of crushing parts of the body. Releasing the tilt mechanism on the drill stand may

cause the rail to tilt suddenly.

▶ Exercise caution. Wear protective gloves.

CAUTION

Risk of injury Hazard presented by a falling diamond core drilling machine.

▶ Always fit the cover at the end of the rail. The cover provides protection and acts as an end stop.

1. Loosen the screw at the pivoting joint at the bottom end of the rail and the screw at the top end of the

brace.

2. Adjust the rail to the desired angle.

Note

The angle scale at the rear serves as an adjustment aid.

3. Retighten the two screws securely.

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

13

Page 22

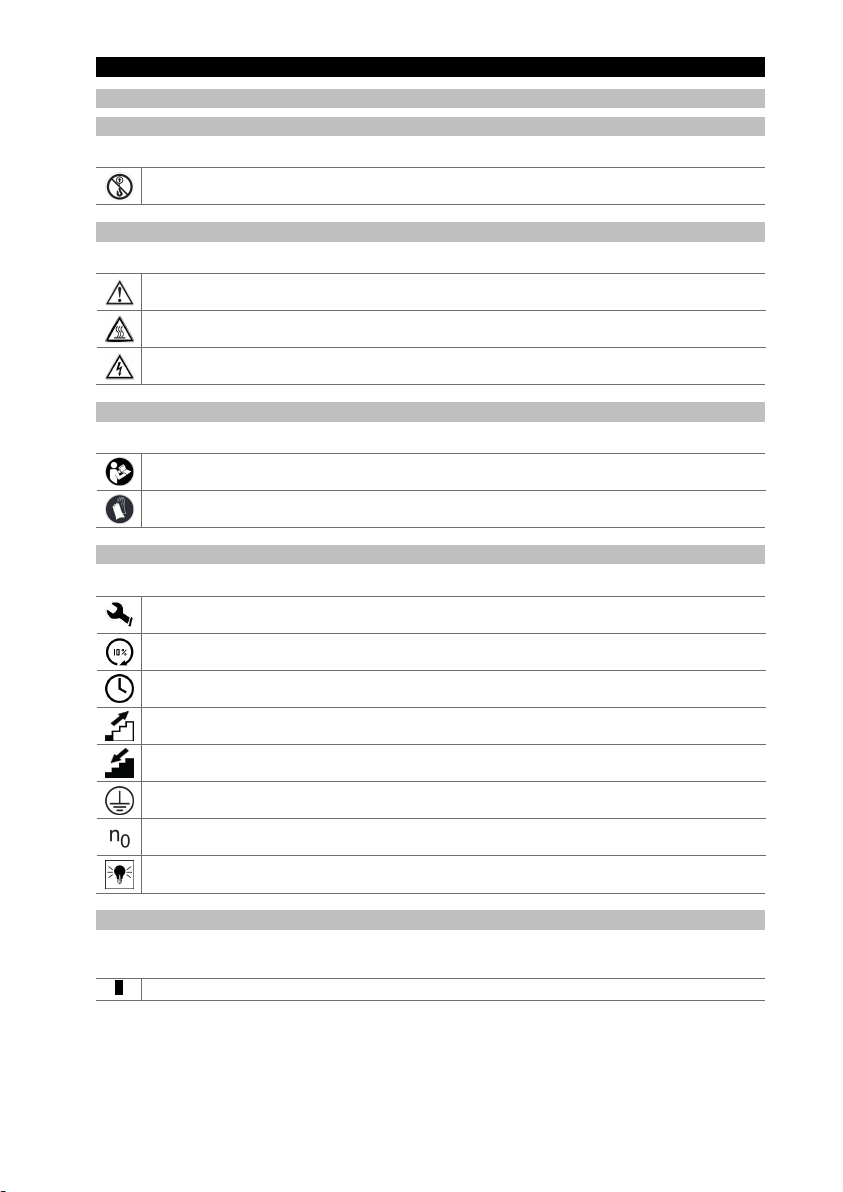

5.2 DD-HD 30: Locking the carriage on the drill stand

1. Pivot the carriage lock in the locked position.

◁ The locking pin must engage in this position.

2. Slightly turn the hand wheel to ensure that the carriage is securely locked.

5.3 Fitting the hand wheel on the drill stand 4

Note

The hand wheel may be fitted on the left-hand or on the right-hand side of the carriage.

In the case of the DDHD 30 drill stand, the hand wheel may be fitted on the carriage on two different

axes. The upper axis directly affects the carriage drive and the lower axis affects the carriage drive

with a gear reduction of 1:3.

1. Pull the black ring back to fit the hand wheel.

2. Fit the hand wheel onto the axle.

5.4 Fastening the drill stand with an anchor 5

WARNING

Risk of injury The tool may become detached and cause damage if the wrong anchor is used.

▶ Use an anchor suitable for the base material on which you are working and observe the anchor

manufacturer’s instructions. Please contact HiltiTechnical Serviceif you haveany questionsabout

secure fastening.

Note

Hilti metal expansion anchors M16 (5/8") are usually suitable for fastening diamond core drilling

equipment to uncracked concrete. Under certain conditions, however, it may be necessary to use an

alternative fastening method. Please contact Hilti Technical Service if you have any questions about

secure fastening.

1. Fit the anchor that is suitable for the corresponding base material. Select the distance according to the

base plate used.

Note

Ideal distance from the hole center for DD-HD 30: 330 mm (13 in)

Ideal distance from the hole center for DD-ST 200: 380 mm (15 in)

2. Screw the clamping spindle (accessory) into the anchor.

3. Place the drill stand over the spindle and align it. When using the DD-HD 30 drill stand, use the hole

center indicator to help you align the drill stand. When a spacer is used, the drill stand cannot be aligned

using the hole center indicator.

4. Screw the clamping nut onto the spindle but do not tighten it.

5. Level the base plate by turning the leveling screws. Use the leveling indicators for this purpose. Take

care to ensure that the leveling screws make firm contact with the underlying surface.

6. Tighten the leveling screws evenly until the drill stand is securely fastened.

7. Make sure that the drill stand is fastened securely.

5.5 Fastening the drill stand with the vacuum base plate (accessory) 6

DANGER

Risk of injury Hazard presented by a falling diamond core drilling machine.

▶ Fastening the drill stand to the ceiling only by means of the vacuum securing method is not

permissible. A heavy structural support or a threaded spindle, for example, can serve as an

additional means of fastening.

14

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 23

WARNING

Risk of injury Hazard presented by a falling diamond core drilling machine.

▶ When drilling horizontally, the drill stand must be secured additionally by a chain.

WARNING

Risk of injury Pressure check

▶ Before beginning drilling andduring operation, it must be ensured that the pressuregage indicator

remains within the green area.

Note

Make sure that the anchor base plate lies flat against the vacuum base plate and that the two plates

are securely connected when using the drill stand with an anchor base plate. Screw the anchor base

plate securely onto the vacuum base plate. Make sure that the core bit selected for use will not

damage the vacuum base plate.

Before positioning the drill stand, ensure that there is sufficient space available for assembly and

operation.

Use the vacuum fastening method only together with core bits of up to 300 mm (12") in diameter and

when no spacer is fitted.

A vacuum release valve,which can be used to increase the vacuum again, is fitted to thehand grip on

the vacuum base plate.

1. Turn all leveling screws back until they project approximately 5 mm (1/5 in) beneath the vacuum base

plate.

2. Connect the vacuum connector on the vacuum base plate to the vacuum pump.

3. Place the drill stand on the vacuum base plate.

4. Fit the drill stand using the screw supplied with a washer underneath on the vacuum base plate and

tighten the screw.

Note

DD-HD 30: Use the thinner of the two washers supplied.

DD-ST 200: Use the thicker of the two washers supplied.

5. Locate the center point of the hole to be drilled. Draw a line from the center of the hole to be drilled

towards where the drill stand is to be positioned.

6. Make a mark on the line at the distance stated from the center of the hole to be drilled. Bring the middle

of the front edge of the vacuum base plate into alignment with the mark made.

Note

Take care to ensure that the base material on which the vacuum base plate is positioned is flat

and clean.

Ideal distance from the hole center for DD-HD 30: 165 mm (6 1/2 in)

Ideal distance from the hole center for DD-ST 200: 215 mm (8 1/2 in)

7. Switch on the vacuum pump, press the vacuum release valve and keep it pressed.

8. Once the drill stand has been positioned correctly, release the vacuum release valve and press the

vacuum base plate against the base material.

9. Level the vacuum base plate by turning the leveling screws. Use the leveling indicators for this purpose.

Note

The anchor base plate cannot and should not be leveled on the vacuum base plate.

10. Make sure that the drill stand is fastened securely.

5.6 DD-HD 30: Fastening the drill stand with the threaded spindle (accessory)

1. Remove the cover (with built-in end stop) from the top end of the rail.

2. Fit the cylindrical connector on the threaded spindle into the end of the rail on the drill stand.

3. Secure the threaded spindle by turning the eccentric pin.

4. Position the drill stand on the work surface.

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

15

Page 24

5. Level the base plate by turning the leveling screws.

6. Secure the drill stand with the threaded spindle and tighten the threaded spindle.

7. Make sure that the drill stand is fastened securely.

5.7 DDST 200: Fastening the drill stand with the threaded spindle (accessory)

1. Fasten the threaded spindle at the upper end of the rail.

2. Position the drill stand on the work surface.

3. Level the base plate by turning the leveling screws.

4. Secure the drill stand with the threaded spindle and tighten the threaded spindle.

5. Make sure that the drill stand is fastened securely.

5.8 DD-HD 30: Extending the rail (accessory) on the drill stand 7

Note

When starting holes, use only core bits or extended core bits with a maximum total length of 650 mm

(25 1/2 in).

A depth gage on the rail can be used as an additional end stop.

After removing theextension rail, the cover(with integrated end stop)must be refitted tothe drill stand

in order to ensure that the safety-relevant end-stop function is restored. The safety-relevant end-stop

function becomes inoperative if this component is not fitted.

1. Remove the cover (with built-in end stop) from the top end of the rail. Fit the cover on the extension rail.

2. Fit the cylindrical connector on the extension rail into the end of the rail on the drill stand.

3. Secure the extension rail by turning the eccentric pin.

5.9 DD-HD 30: Fitting the spacer (accessory) 8

WARNING

Risk of injury. The fastening may become overloaded.

▶ When one or more spacers are used, the contact pressure must be reduced in order to avoid

overloading the fastening.

Note

The diamond core drilling machine should not already be mounted on the drill stand when the spacer

is being fitted.

Note

When core bits with a diameter of 300 mm (11 1/2 in) or greater are used, the distance between

the drill stand and the drilling axis must be increased by fitting one or two spacers. The hole center

indicator is no longer functional when spacers are used.

1. Lock the carriage on the rail with the carriage lock.

2. Pull out the eccentric pin for locking the diamond core drilling machine on the carriage.

3. Place the spacer into the carriage.

4. Push the eccentric pin into the carriage as far as it will go.

5. Tighten the eccentric pin.

6. Check to ensure that the spacer is securely fastened.

5.10 DDST 200: Fitting the spacer (accessory) 9

WARNING

Risk of injury. The fastening may become overloaded.

▶ When one or more spacers are used, the contact pressure must be reduced in order to avoid

overloading the fastening.

16

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 25

Note

When core bits with a diameter of 400 mm (15 3/4 in) or greater are used, the distance between the

drill stand and the drilling axis must be increased by fitting a spacer.

1. Detach the diamond core drilling machine from the drill stand.

2. Separate the carriage from the diamond core drilling machine by loosening the four screws on the

carriage.

3. Screw the spacer tightly to the carriage with the four screws that are additionally supplied.

4. Re-screw the diamond core drilling machine tightly to the spacer with the four screws.

5.11 DD-HD 30: Attaching the diamond core drilling machine to the drill stand 8

CAUTION

Risk of injury Hazard presented by inadvertent starting of the diamond core drilling machine.

▶ The diamond core drilling machine should not be connected to the power supply during set-up.

1. Lock the carriage on the rail with the carriage lock.

2. Pull out the eccentric pin for locking the diamond core drilling machine on the carriage.

3. Fit the diamond core drilling machine onto the carriage or the spacer.

4. Push the eccentric pin into the carriage or the spacer as far as it will go.

5. Tighten the eccentric pin.

6. Fasten the supply cord in the cord guide to the carriage cover.

7. Check to ensure that the diamond core drilling machine is securely fastened to the drill stand.

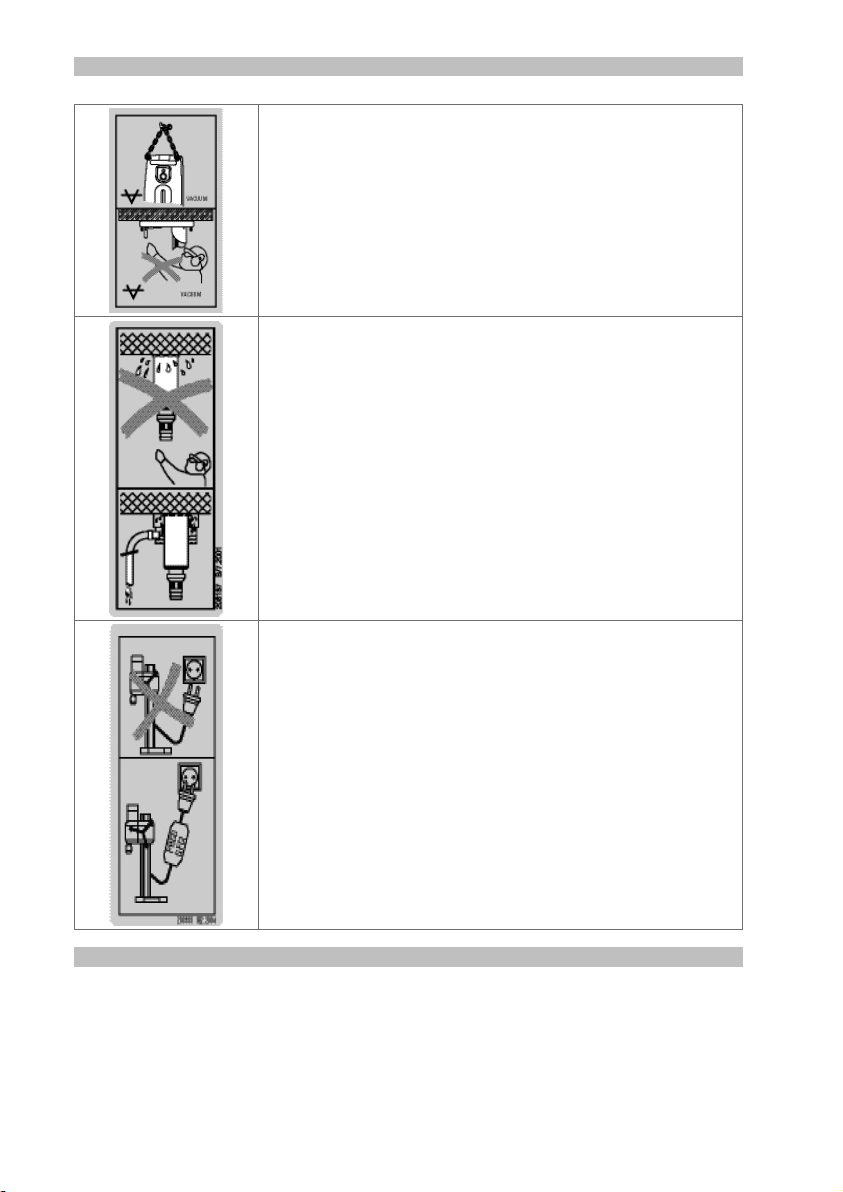

5.12 DDST 200: Attaching the diamond core drilling machine to the drill stand 10

DANGER

Risk of injury Impact as a result of a fast-moving lever or hand wheel when the carriage is in motion.

▶ The lever and the hand wheel must not be fitted on the drill stand when the diamond core drilling

machine is being fitted.

CAUTION

Risk of injury Hazard presented by inadvertent starting of the diamond core drilling machine.

▶ The diamond core drilling machine should not be connected to the power supply during set-up.

Note

The drive unit and the carriage form a unit. The diamond core drilling machine can thus be removed

from the drill stand together with the carriage.

Adjust the play between the rail and carriage before using the tool for the first time.

1. Remove the end stop screw from the end of the rail.

2. Ensure that the carriage lock is open.

3. Mount thediamond core drilling machine onthe drill stand by sliding the opening in the carriage over the

end of the rail.

4. Lock the carriage on the rail by turning the carriage lock through 90°.

5. Slightly turn the hand wheel to ensure that the diamond core drilling machine is securely fastened.

6. Refitthe end stopscrew to theend of the rail. The safety-relevant end-stopfunction becomes inoperative

if this component is not fitted.

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

17

Page 26

5.13 Fitting the water connection (accessory)

CAUTION

Risk of personal injury and material damage The hose maybecome damaged ifit isused incorrectly.

▶ Regularly check the hoses for damage and make sure that the maximum permissible water supply

pressure of 6 bar is not exceeded.

▶ Make sure that the hose does not come into contact with rotating parts.

▶ Make sure that the hose is not damaged as the carriage advances.

▶ Maximum water temperature: 40 °C.

▶ Check the water supply system to ensure there are no leaks.

Note

To avoid damage to the components, use only fresh water containing no dirt particles.

A flow meter (accessory) may be fitted between the tool and the water supply hose.

1. Connect the water flow regulator to the diamond core drilling machine.

2. Connect the water supply (hose connection).

5.14 Fitting the water collection system (accessory) 11

WARNING

Risk of personal injury and material damage The diamond core drilling machine may become

damaged and the risk of electric shock is increased.

▶ Water must not be allowed to run over the motor and cover.

▶ Use of a wet-type industrial vacuum cleaner is a mandatory requirement for drilling in an upwards

direction.

Note

The diamond core drilling machine must be at a 90° angle to the ceiling. The water collection system

sealing disc must match the diamond core bit diameter.

Note

Use of the water collection system allows water to be led away under control, thus preventing the

surrounding area from being heavily soiled. The best results are achieved with a wet-type industrial

vacuum cleaner.

Note

When using the drill stand DDST 200: Before fitting the water collector holder, screw the spacer for

the water collector holder tightly to the drill stand.

1. Loosen the screw on the front of the drill stand at the bottom end of the rail.

2. Slide the water collector holder into position under the screw from below.

3. Tighten the screw securely.

4. Position the water collector, with seal and water collector sealing disc fitted, between the two movable

arms of the holder.

5. Secure the water collector to the holder with the two screws.

6. Connect a wet-type industrial vacuum cleaner to the water collector or establish a hose connection

through which the water can drain away.

5.15 Setting the depth gage (accessory)

1. Turn the hand wheel until the core bit is in contact with the base material.

2. Set the desired drilling depth by adjusting the distance of the depth gage from the carriage.

3. Lock the depth gage in position.

18

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 27

5.16 Fitting the diamond core bit (BL chuck) 12

DANGER

Risk of injury Fragments of the workpiece or of broken insert tools may be ejected and cause injury

beyond the immediate area of operation.

▶ Do not use damaged insert tools. Check the insert tools for chipping, cracks, or heavy wear each

time before use.

CAUTION

Risk of injury The tool becomes hot as a result of use. It may have sharp edges.

▶ Wear protective gloves when changing the tool.

Note

Diamond core bits must be replaced when the cutting performance and/or rate of drilling progress

drops significantly. This generally is the case when the diamond segments reach a height of less than

2 mm (1/16 in).

1. Lock the carriage on the rail with the carriage lock. Check to ensure that it is securely fastened.

2. Open the chuck by turning it in the direction of the "Open brackets" symbol.

3. Frombelow, push the connection end of the diamond corebit into thechuck on the diamond core drilling

machine, making sure that the teeth engage.

4. Close the chuck by turning it in the direction of the "Closed brackets" symbol.

5. Check that the diamond core bit is seated securely in the chuck.

5.17 Fitting the diamond core bit with an alternative type of chuck

1. Lock the drive spindle with a suitable open-end wrench.

2. Tighten the core bit with a suitable open-end wrench.

5.18 Selecting the speed 13

Note

Press the switch only when the tool is stationary.

1. Select the switch setting according to the core bit diameter used.

2. When turning the switch, rotate the core bit by hand at the same time until the switch can be set in the

recommended position.

5.19 PRCD ground fault circuit interrupter

1. Plug the diamond core drilling machine’s mains plug into an earthed/grounded power outlet.

2. Press the "I" or "RESET" button on the PRCD ground fault circuit interrupter.

◁ The indicator lights up.

3. Press the "0" or "TEST" button on the PRCD ground fault circuit interrupter.

◁ The indicator goes out.

WARNING

Risk of injury Risk of electric shock.

▶ If the indicator continues to light up, further operation of the diamond core drilling machine

is not permissible. Have your diamond core drilling machine repaired by Hilti Service.

4. Press the "I" or "RESET" button on the PRCD ground fault circuit interrupter.

◁ The indicator lights up.

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

19

Page 28

5.20 Operating the diamond core drilling machine

WARNING

Risk of personal injury and material damage The diamond core drilling machine may become

damaged and the risk of electric shock is increased.

▶ Use of the water collection system in conjunction with a wet-type industrial vacuum cleaner is a

mandatory requirement for wet drilling overhead.

DANGER

Risk of personal injury and material damage The wet-type industrial vacuum cleaner switches on

and off with a delay. This allows water to run over the diamond core drilling machine. The diamond

core drilling machine may become damaged and the risk of electric shock is increased.

▶ When drilling in an upward direction, the wet-type industrial vacuum cleaner must be switched on

manually before opening the water supply valve and switched off again manually after closing the

water supply valve.

DANGER

Risk of personal injury and material damage The diamond core drilling machine may become

damaged and the risk of electric shock is increased.

▶ When drilling in an upward direction, stop working if the suction removal system stops working

(e.g. the wet-type industrial vacuum cleaner is full).

WARNING

Risk of personal injury and material damage The water collector cannot function correctly during

drilling in an upward direction at an angle. The diamond core drilling machine may become damaged

and the risk of electric shock is increased.

▶ Do not drill in an upward direction at an angle.

Note

DD 250: Pressing thebutton for the hole-startingmode (when the machineis idling or operating under

no load) reduces the speed for starting holes. This makes it possible for diamond core bits of large

diameters to start holes with greater ease and less vibration. Pressing the button for the hole-starting

mode again deactivates this function and the diamond core drilling machine adjusts up to the preset

speed. If the function for starting holes is not deactivated before a maximum of two minutes has

expired, the diamond core drilling machine automatically switches off.

1. Slowly open the water flow regulator until the desired volume of water is flowing.

2. Press the On/Off switch on the diamond core drilling machine to "I".

3. Release the carriage locking mechanism.

4. Turn the hand wheel until the core bit is in contact with the base material.

5. When beginning drilling, apply only light pressure, until the core bit has centered itself. Only increase the

pressure afterwards.

6. Regulate the contact pressure while observing the drilling performance indicator.

5.21 Switching off the diamond core drilling machine

WARNING

Risk of personal injury and material damage The diamond core bit fills with water during overhead

drilling. The diamond core drilling machine may become damaged and the risk of electric shock is

increased.

▶ As a first step, carefully allow the water to drain away after completing overhead drilling. This is

done by disconnecting the water supply from the water flow regulator and draining the water by

opening the water flow regulator. Do not allow the water to run over the motor and cover.

1. Connect the water flow regulator to the diamond core drilling machine.

20

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 29

2. Remove the diamond core bit from the hole.

3. Switch off the diamond core drilling machine.

4. Lock the carriage on the rail with the carriage lock.

5. Switch off the wet-type industrial vacuum cleaner (if used).

5.22 DD-HD 30: Detaching the diamond core drilling machine from the drill stand

1. Lock the carriage on the rail with the carriage lock.

2. Remove the supply cord from the cord guide on the carriage cover.

CAUTION

Risk of personal injury and material damage Hazard presented by a falling diamond core drilling

machine.

▶ Hold the core drilling machine tightly with one hand by the carrying handle.

3. Loosen the eccentric pin for locking the tool on the carriage.

4. Pull out the eccentric pin.

5. Remove the diamond core drilling machine from carriage.

6. Push the eccentric pin into the carriage as far as it will go.

5.23 DDST 200: Detaching the diamond core drilling machine from the drill stand

Note

The drive unit and the carriage form a unit. The diamond core drilling machine can thus be removed

from the drill stand together with the carriage.

1. Remove the end stop screw from the end of the rail.

2. Release the carriage locking mechanism.

3. Detach the diamond core drilling machine from the drill stand.

4. Refitthe end stopscrew to theend of the rail. The safety-relevant end-stopfunction becomes inoperative

if this component is not fitted.

6 Care, maintenance, transport and storage

6.1 Care of the product

▶ Keep the product, especially its grip surfaces, clean and free from oil and grease. Do not use

cleaning agents containing silicone.

▶ Never operate theproduct when the airvents are blocked. Cleanthe air vents carefully using a drybrush.

Do not allow foreign objects to enter the interior of the product.

▶ Clean the outside of the tool at regular intervals with a slightly damp cloth. Do not use a spray, steam

pressure cleaning equipment or running water for cleaning.

▶ Always keep the connection end of the core bit clean and lightly greased.

▶ After carrying out care and maintenance, check that all protective and safety devices are fitted and that

they function with no defects.

▶ If service or repair is required, please contact your salesperson or refer to our contact details at

www.hilti.com .

6.1.1 DD-HD 30: Adjusting the play between rail and carriage

Note

You can adjust the play between rail and carriage using the four adjusting screws on the carriage.

1. Loosen the adjusting screws using a 5 mm hexagon socket wrench (do not remove the screws).

2. Usinga 19 mmopen-end wrench,turn the adjustingscrews sothat the rollersare pressedslightly against

the rail.

3. Tighten the adjusting screws firmly. The carriage is correctly adjusted when it remains inposition without

a diamond core drilling machine fitted and moves down when a drilling machine is mounted.

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

21

Page 30

6.1.2 DD 200 for the DD-ST 200: Adjusting play between rail and carriage

Note

You can adjust the play between rail and carriage using the 6 adjusting screws on the carriage.

1. Use a hexagon socket wrench to tighten the adjusting screws hand-tight.

Technical data

Tightening torque 3 Nm

2. Then loosen the four adjustingscrews at the side by turning themhalf of a turn and thetwo rear adjusting

screws by turning them quarter of a turn.

3. Thecarriage is correctlyadjusted when itremains in positionwithout a diamondcore bit but moves down

when a diamond core bit is fitted.

6.2 Replacing the carbon brushes

DANGER

Risk of injury Risk of electric shock.

▶ The machine may be operated, serviced and repaired only by trained, authorized personnel. This

personnel must be specially informed of any possible hazards.

Note

The indicator withthe open-end wrench symbollights up whenthe carbon brushes needto be changed.

Always change all the carbon brushes at the same time.

1. Disconnect the diamond core drilling machine from the power supply.

2. Open the carbon brush covers on the left-hand and right-hand side of the motor.

3. Take note of how the carbon brushes are fitted and how the conductors are positioned. Remove

the worn carbon brushes from the diamond core drilling machine.

4. Fit the new carbon brushesso that they arepositioned exactly thesame as the oldones fitted previously.

Note

Take care to avoid damaging the insulation on the indicator lead as you insert the brushes.

5. Screw on the carbon brush covers on the left- and right-hand side of the motor.

6. Run in the carbon brushes by letting the machine run under no load for at least one minute without

interruption.

Note

After replacing the carbon brushes, the indicator lamp will go out after the machine has run for

approx. one minute.

If the minimum running-in time of oneminute is not observed, the life of thecarbon brushes will be

greatly reduced.

6.3 Transport and storage

CAUTION

Risk of personal injury and material damage Frost-damaged components may cause the tool to

stop working and present a risk of injury for the user.

▶ When temperatures drop below zero, check to ensure that no water remains in the power tool.

WARNING

Risk of injury Individual parts may become detached and fall off.

▶ Do not lift the diamond core drilling machine and/or the drill stand by crane.

22

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 31

Note

Transport the diamond core drilling machine, the drill stand and the core bit as separate units.

Use the wheel assembly (accessory) as an aid when transporting the equipment.

▶ Open the water flow regulator before putting the diamond core drilling machine into storage.

7 Troubleshooting

▶ If the trouble you are experiencing is not listed in this table or you are unable to remedy the problem by

yourself, please contact Hilti Service.

7.1 DD 200: The diamond core drilling machine is not in working order Malfunction Possible cause Action to be taken

The PRCD isn’t switched on. ▶ Check that the PRCD is

functioning and switch it on.

Interruption in the electric supply. ▶ Plug in another electric tool or

The service indicator shows

nothing.

appliance and check whether it

works.

▶ Check the plug connections,

supply cord, power supply line

and main supply fuse.

Water in the motor. ▶ Allow the diamond core drilling

machine to dry out completely

in a warm, dry place.

The carbon brushes are worn out. ▶ Replace the carbon brushes.

→ page 22

The service indicator lights.

The motor has overheated. ▶ Wait a few minutes until the

motor has cooled down or

allow the diamond core drilling

The service indicator blinks.

machine to run under no load in

order to speed up the cooling

process. Switch the diamond

core drilling machine off and

then on again.

7.2 DD 200: The diamond core drilling machine is in working order Malfunction Possible cause Action to be taken

The motor has overheated. The

diamond core drilling machine is

running in cooling mode.

The service indicator blinks.

▶ Wait a few minutes until the

motor has cooled down or

allow the diamond core drilling

machine to run under no load

in order to speed up the

cooling process. When normal

temperature is reached the

indication in the display goes

out and the diamond core

drilling machine activates the

restart interlock. Switch the

diamond core drilling machine

off and then on again.

The carbon brush wear limit has

almost been reached. The diamond

▶ Have the carbon brushes

replaced at thenext opportunity.

core drilling machine will continue

The service indicator lights.

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

to run for a few hours until it shuts

down automatically.

23

Page 32

Malfunction Possible cause Action to be taken

The carbon brushes have been

changed and must be run in.

▶ Run in the carbon brushes by

letting the machine run under

no load for at least 1 minute

The service indicator lights.

The drilling performance indicator does not light up.

The diamond core drilling

machine doesn’t achieve full

performance.

Communication error between

the motor electronics and LED

indicator.

Supply network fault – undervoltage occurred.

without interruption.

▶ The diamond core drilling

machine is capable of working

even without LED indicator.

▶ Bring the diamond core drilling

machine to Hilti at your earliest

convenience.

▶ Check whether other power

consumers are disrupting the

supply from the network or

generator.

▶ Check the length of the exten-

sion cord used.

The diamond core bit doesn’t

rotate.

The diamond core bit has become

jammed in the base material.

▶ Use an open-end wrench to

release the diamond core bit:

Disconnect thesupply cord plug

from the power outlet. Grip the

diamond core bit with a suitable

open-end wrench close to the

connection end and release the

diamond core bit by rotating it.

Stand-guided drilling

▶ Turn the handwheel and try to

release the diamond core bit

by moving the carriage up and

down.

The gear selector isn’t engaged. ▶ Operate the gear selector until

it engages.

The drilling speed is decreasing.

Maximum drilling depth has been

reached.

The core is stuck in the diamond

▶ Remove thecore and usea core

bit extension.

▶ Remove the core.

core bit.

Wrong core bit specification for the

base material.

High steel content (indicated by

clear water containing metal cut-

▶ Select a more suitable diamond

core bit specification.

▶ Select a more suitable diamond

core bit specification.

tings).

The diamond core bit is defective. ▶ Check the diamond core bit

for damage and replace it if

necessary.

Wrong gear selected. ▶ Select the right gear.

Contact pressure is too low. ▶ Increase the contact pressure.

The machine has too little power. ▶ Select the next lower gear.

The diamond core bit is polished. ▶ Sharpen the diamond core bit

by drilling into a sharpening

plate.

The water flow rate is too high. ▶ Reduce the water flow rate

by adjusting the water flow

regulator.

24

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 33

Malfunction Possible cause Action to be taken

The drilling speed is decreasing.

The water flow rate is too low. ▶ Check the water supply to

the diamond core bit or,

respectively, increase the water

flow by adjusting the water flow

regulator.

The carriage lock is engaged. ▶ Release the carriage locking

mechanism.

The handwheel can be turned

The shear pin is broken. ▶ Replace the shear pin.

without resistance.

The diamond core bit can’t be

fitted into the chuck.

The core bit connection end or

chuck is dirty or damaged.

▶ Clean and grease the connec-

tion end and/or the chuck or

replace these parts.

Water escapes at the water

swivel or gear housing.

Water escapes from the

chuck during operation.

The water pressure is too high. ▶ Reduce the water pressure.

The rotary shaft seal is worn out. ▶ Replace the rotary shaft seal.

The diamond core bit isn’t securely

tightened in the chuck.

▶ Tighten the diamond core bit

securely.

▶ Remove the core bit. Rotate the

diamond core bit approx. 90°

about its own axis. Refit the

diamond core bit.

The core bit connection end /

chuck is dirty.

The seal at the chuck or at the

connection end is defective.

▶ Clean and grease the connec-

tion end and/or the chuck.

▶ Check the seal and replace it if

necessary.

No water is flowing. The water channel is blocked. ▶ Increase the water pressure or

flush the water channel clear

from the opposite direction.

Clean the water inlet and outlet

aperture.

The drilling system has too

much play.

The diamond core bit isn’t securely

tightened in the chuck.

▶ Tighten the diamond core bit

securely.

▶ Remove the core bit. Rotate the

diamond core bit approx. 90°

about its own axis. Refit the

diamond core bit.

The core bit connection end /

chuck is defective.

▶ Check the connection end and

chuck and replace them if

necessary.

The connection between the diamond core drilling machine and the

carriage or spacers is loose.

▶ Check the connection and,

if necessary, refasten the

diamond core drilling machine.

The carriage has too much play. ▶ Adjust the play between the rail

and carriage.

Screws / bolts on the drill stand are

loose.

▶ Check the security of screws

/ bolts on the drill stand and

tighten them if necessary.

The drill stand is inadequately fastened.

▶ Fasten the drill stand more

securely.

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

25

Page 34

7.3 DD 250: The diamond core drilling machine is not in working order Malfunction Possible cause Action to be taken

The PRCD isn’t switched on. ▶ Check that the PRCD is

functioning and switch it on.

Interruption in the electric supply. ▶ Plug in another electric tool or

appliance and check whether it

works.

The multifunction display is

not showing anything.

▶ Check the plug connections,

supply cord, power supply line

and main supply fuse.

Water in the motor. ▶ Allow the diamond core drilling

machine to dry out completely

in a warm, dry place.

The carbon brushes are worn out. ▶ Replace the carbon brushes.

→ page 22

Water in the motor. ▶ Allow the diamond core drilling

machine to dry out completely

Service required.

The motor has overheated. The

cooling down process is complete.

Supply network fault – the power

supply has been interrupted.

in a warm, dry place.

▶ Switch the diamond coredrilling

machine off and then on again.

▶ Check whether other power

consumers are disrupting the

power supply from the network

Restart interlock.

or generator.

▶ Check the length of the exten-

sion cord used.

▶ Switch the diamond coredrilling

machine off and then on again.

Maximum running time with holestarting mode activated exceeded.

▶ Switch the diamond coredrilling

machine off and then on again.

Water in the motor. ▶ Allow the diamond core drilling

machine to dry out completely

in a warm, dry place.

The motor has overheated. ▶ Wait a few minutes until the

motor has cooled down or

allow the diamond core drilling

machine to run under no load in

order to speed up the cooling

Overheating.

process. Switch the diamond

core drilling machine off and

then on again.

26

Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 01Printed: 04.09.2017 | Doc-Nr: PUB / 5245926 / 000 / 03

Page 35

7.4 DD 250: The diamond core drilling machine is in working order Malfunction Possible cause Action to be taken

The motor has overheated. The

diamond core drilling machine is

running in cooling mode.

▶ Wait a few minutes until the

motor has cooled down or

allow the diamond core drilling

machine to run under no load

in order to speed up the

Overheating.

cooling process. When normal

temperature is reached the