Hilti DD 250, DD 200/HD 30, DD 200/ST 200 Operating Instruction

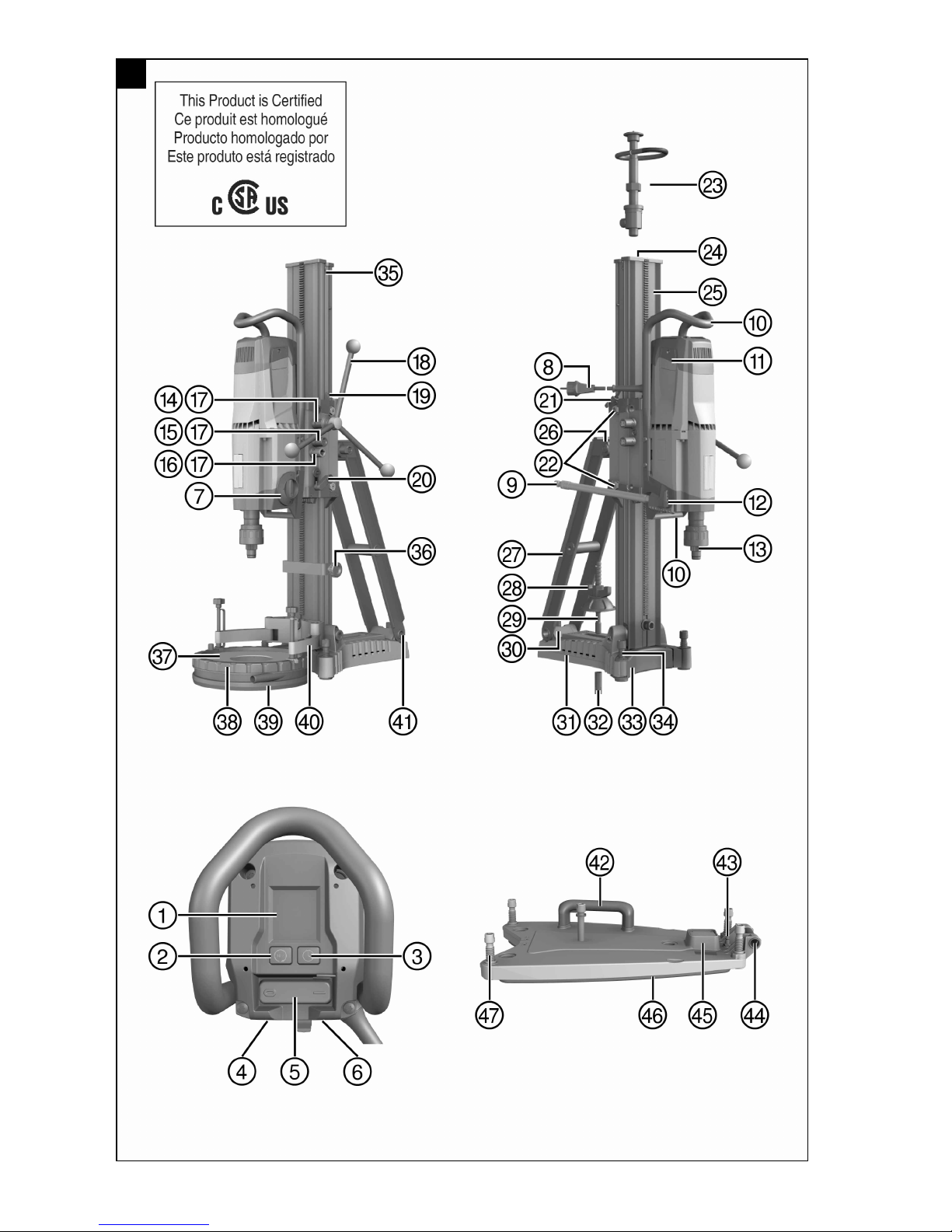

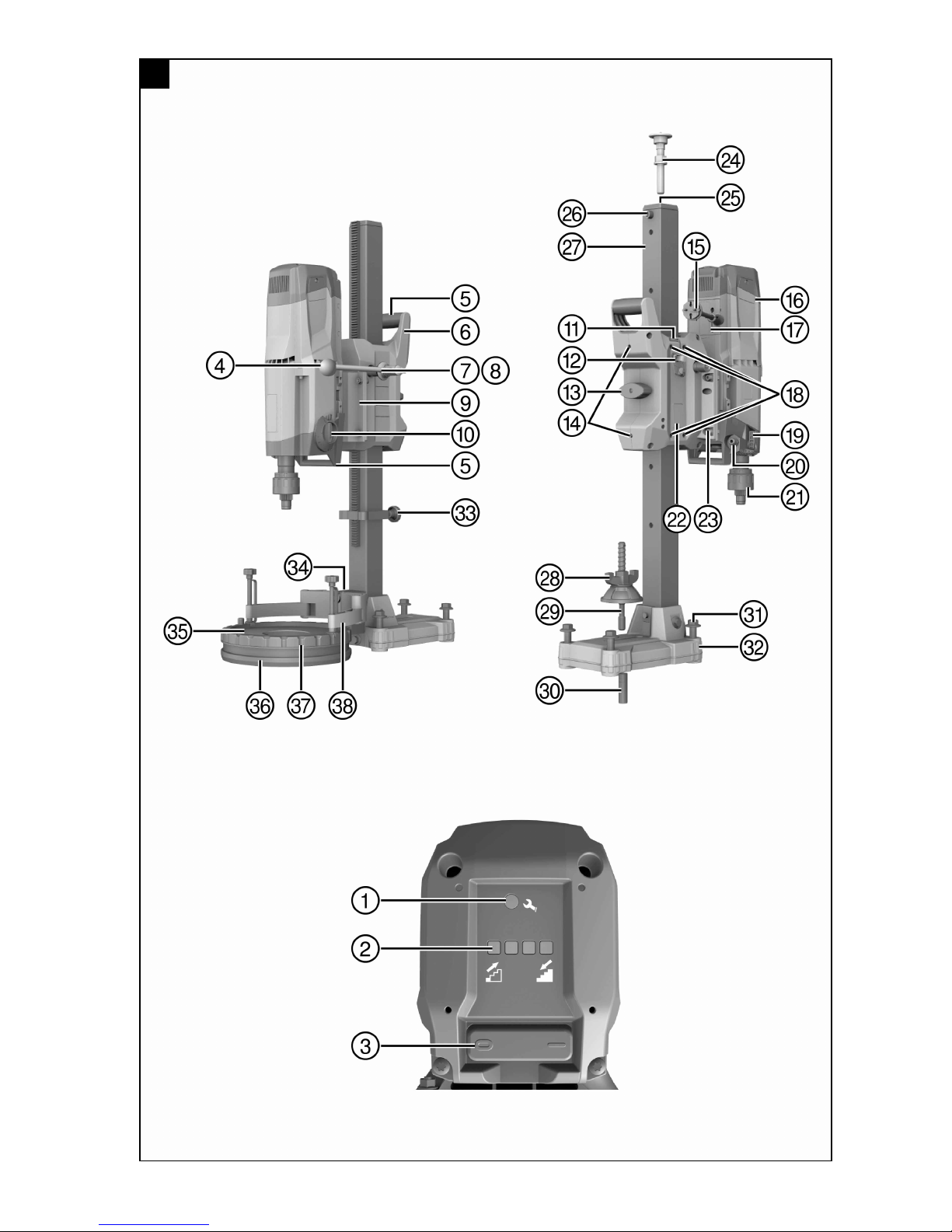

DD 250

DD 200/HD 30

DD 200/ST 200

English en

Français fr

Español es

Português pt

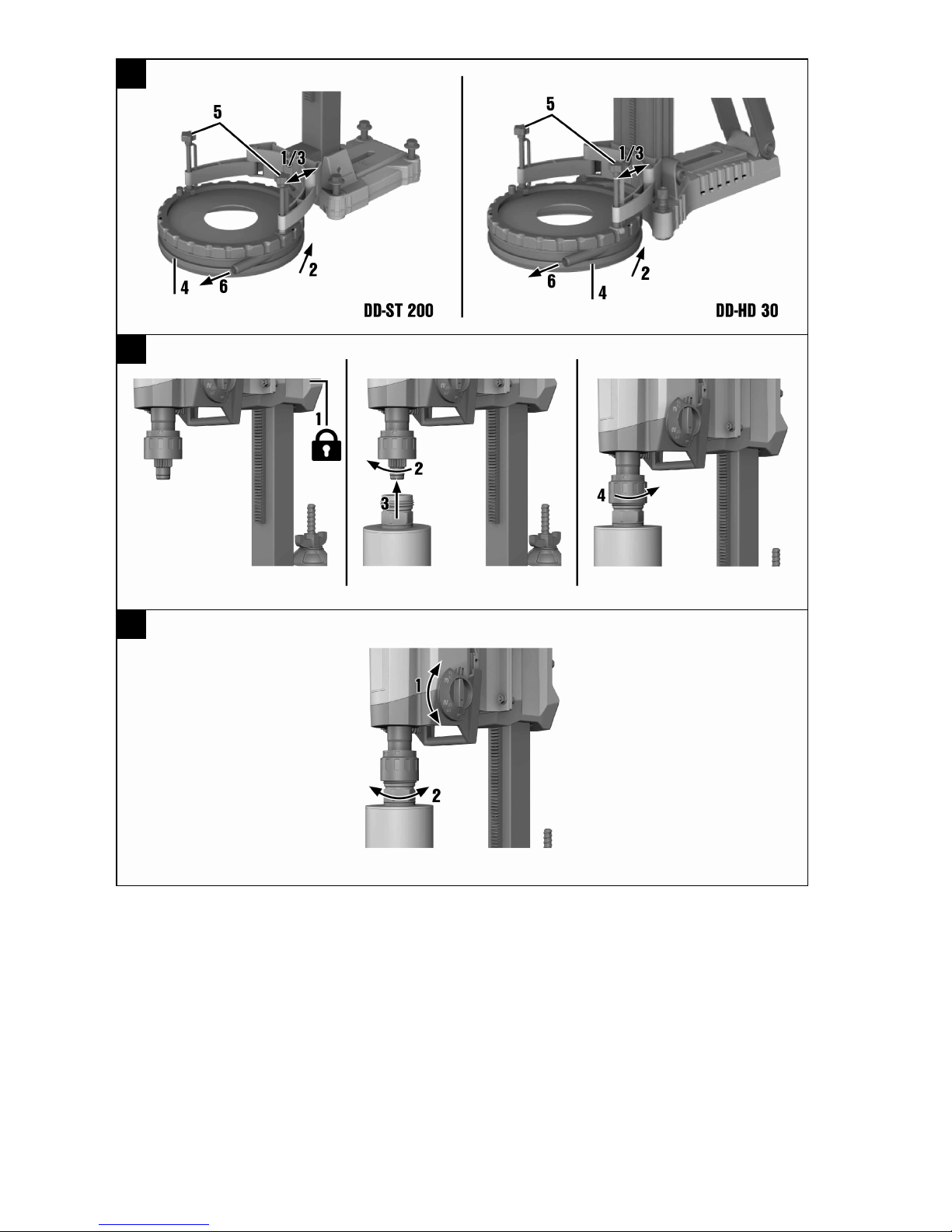

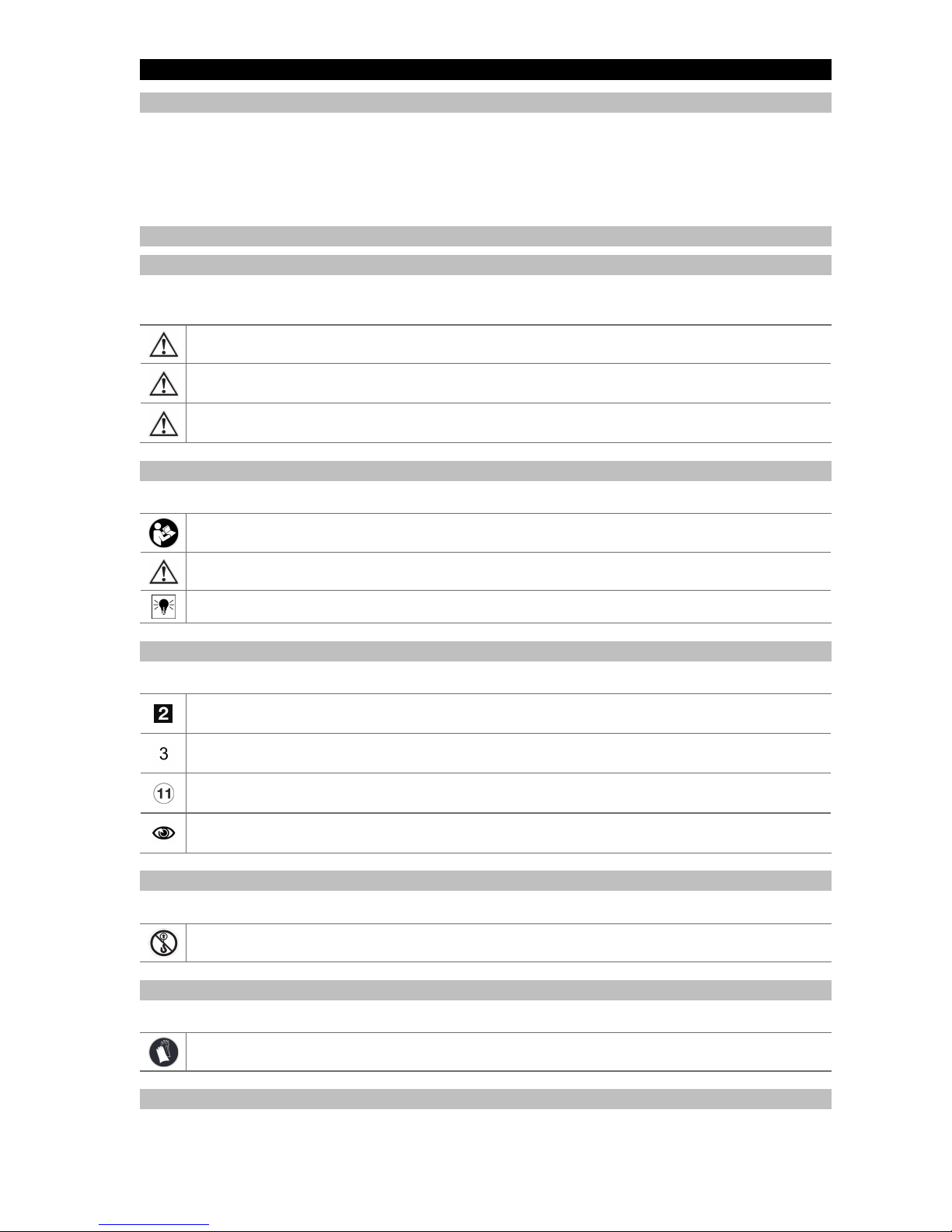

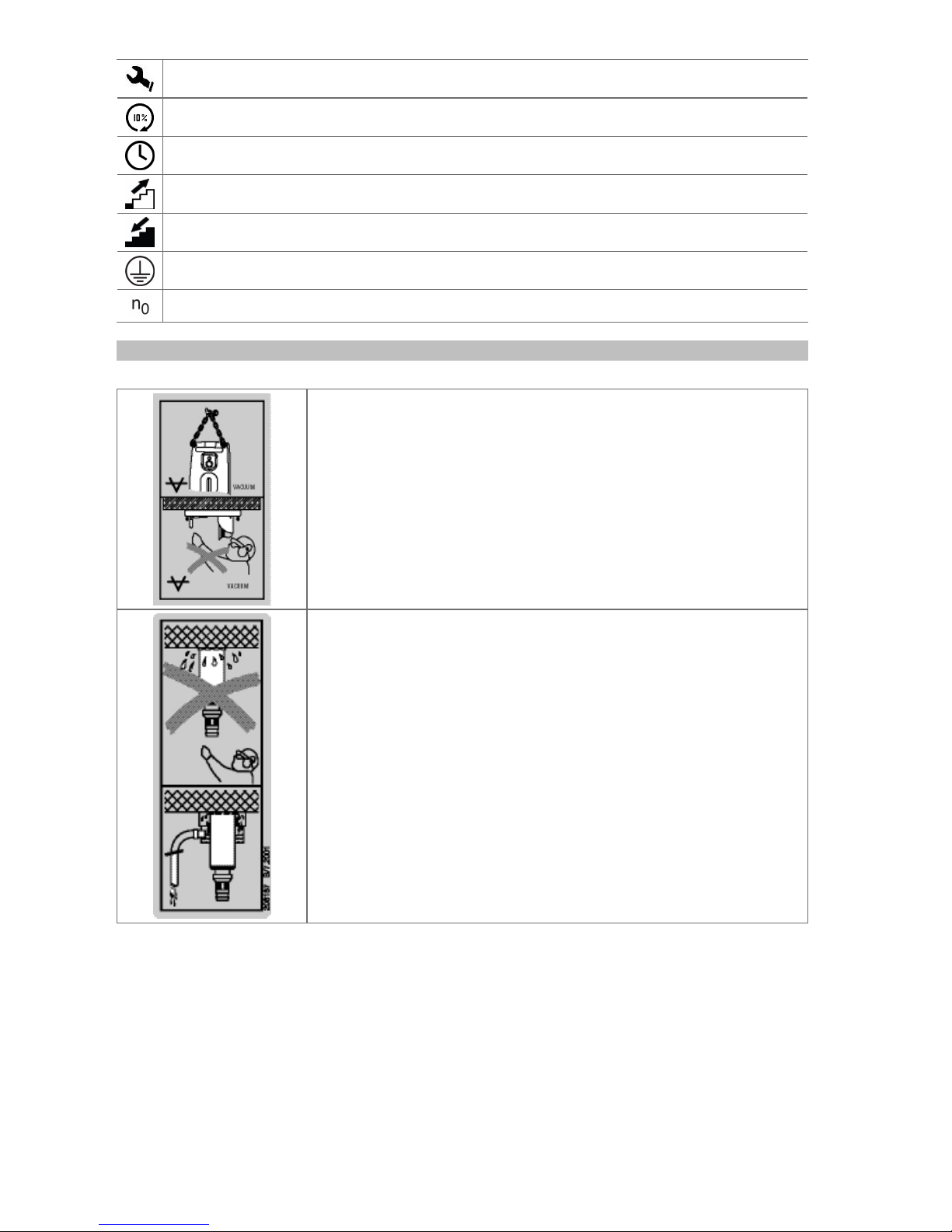

1

2

3

4

5

6

7

8

9

10

11

12

13

DD 250

DD 200/HD 30

DD 200/ST 200

en Original operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

fr Mode d'emploi original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

es Manual de instrucciones original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

pt Manual de instruções original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

1

1 Information about the documentation

1.1 About this documentation

• Read this documentation before initial operation or use. This is a is a prerequisite for safe, trouble-free

handling and use of the product.

• Observe the safety instructions and warnings in this documentation and on the product.

• Always keep the operating instructions with the product and make sure that the operating instructions

are with the product when it is given to other persons.

1.2 Explanation of signs used

1.2.1 Warnings

Warnings alert persons to hazards that occur when handling or using the product. The following signal words

are used in combination with a symbol:

DANGER! Draws attention to imminent danger that will lead to serious personal injury or fatality.

WARNING! Draws attention to a potential hazard that could lead to serious personal injury or

fatality.

CAUTION! Draws attention to a potentially dangerous situation that could lead to slight personal

injury or damage to the equipment or other property.

1.2.2 Symbols in the documentation

The following symbols are used in this document:

Read the operating instructions before use.

General warning

Instructions for use and other useful information

1.2.3 Symbols in the illustrations

The following symbols are used in illustrations:

These numbers refer to the corresponding illustrations found at the beginning of these operating

instructions.

The numbering reflects the sequence of operations shown in the illustrations and may deviate

from the steps described in the text.

Item reference numbers are used in the overview illustration and refer to the numbers used in

the product overview section.

These characters are intended to draw your special attention to certain points when handling the

product.

1.2.4 Prohibition signs

The following prohibition signs are used:

Transport by crane is not permissible

1.2.5 Mandatory signs

The following mandatory signs are used:

Wear protective gloves

1.2.6 Symbols on the product

The following symbols are used on the product:

2

Service indicator

Hole-starting mode

Runtime counter

Drilling performance indicator: Increase contact pressure

Drilling performance indicator: Reduce contact pressure

Protective earth

Rated speed under no load

1.3 Information notices

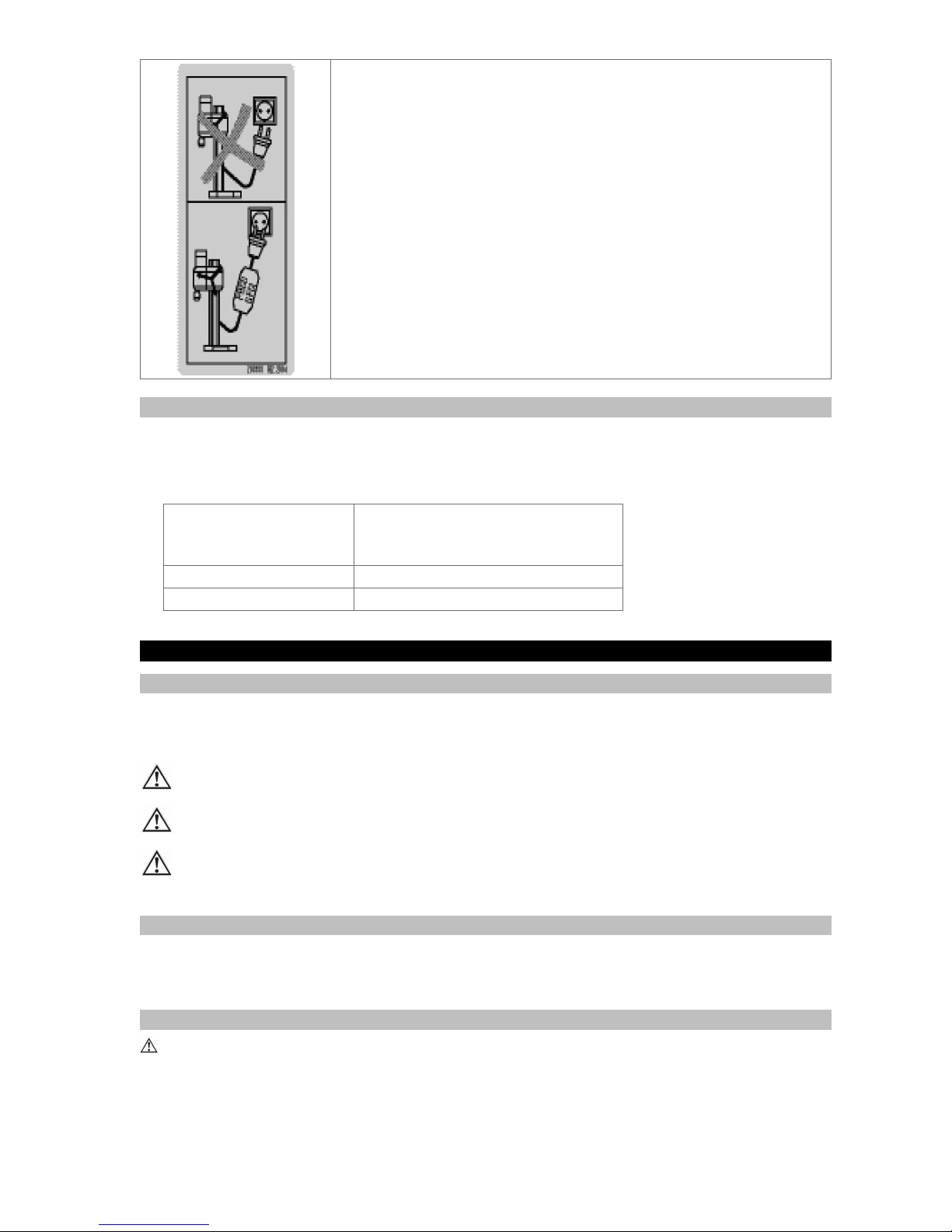

On the drill stand, base plate or diamond core drilling machine

On the vacuum base plate

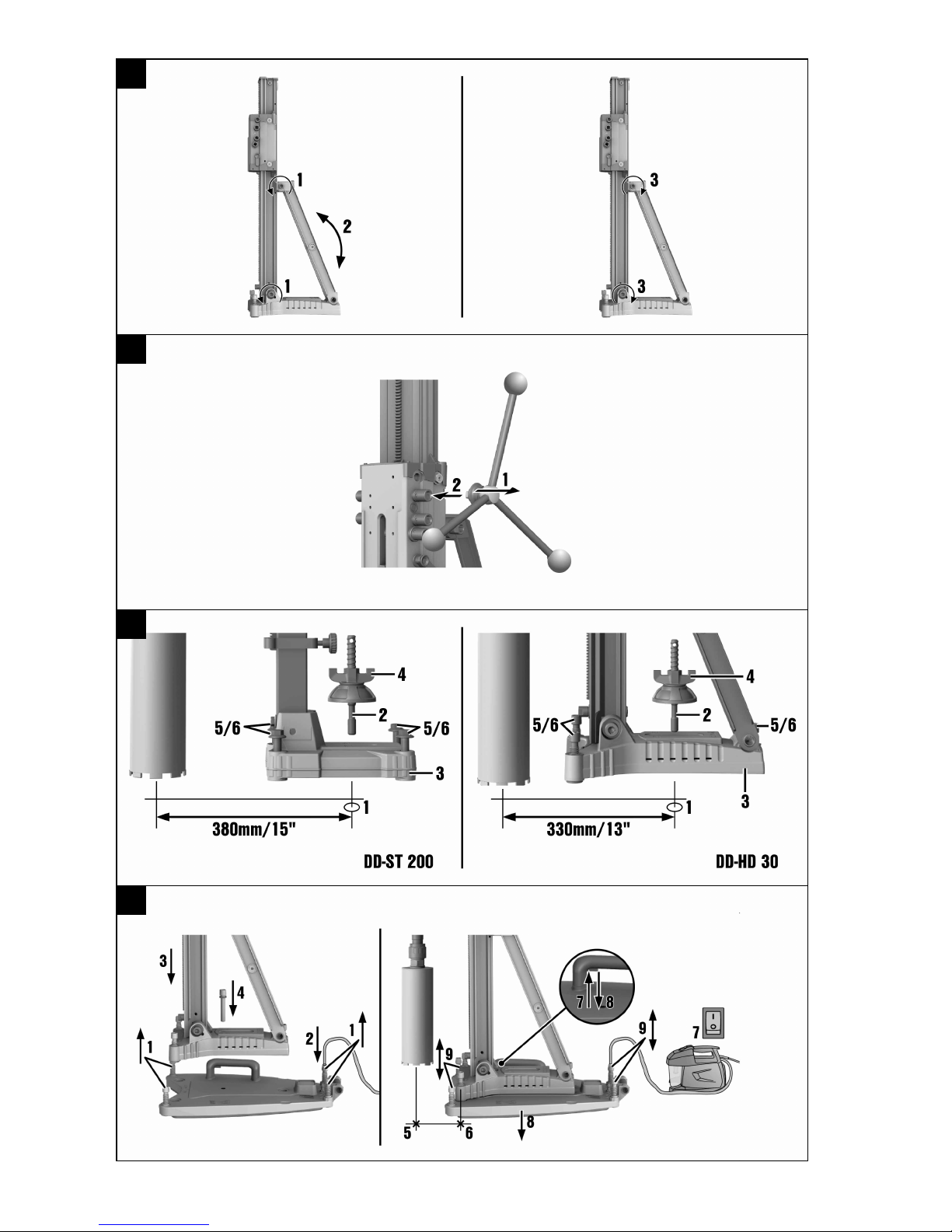

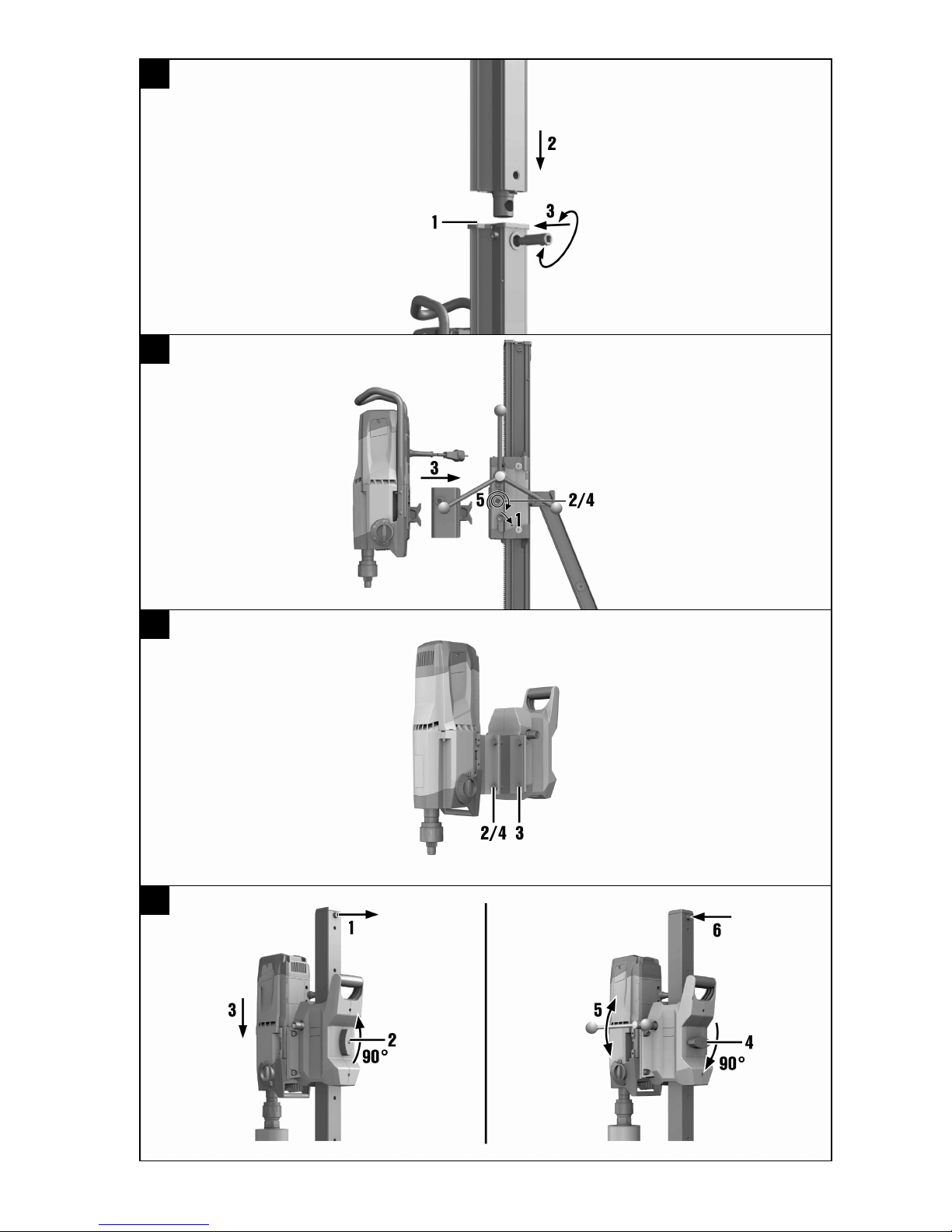

Upper half of the image: An additional means of securing the drill stand

must be employed when the machine is used for horizontal drilling with the

vacuum securing method.

Lower half of the image: Use of the vacuum securing method without

an additional means of securing is prohibited for drilling in an upward

direction.

On the diamond core drilling machine

Use of the water collection system in conjunction with a wet-type industrial

vacuum cleaner is a mandatory requirement for working overhead.

3

On the diamond core drilling machine

Operate the system only with a properly functioning PRCD.

1.4 Product information

▶ The type designation and serial number can be found on the rating plate on the product. Make a note of

this data in the following table and always refer to it when making an inquiry to your Hilti representative

or Hilti Service Center.

Product information

Diamond core drilling

machine

DD 250

DD 200/HD 30

DD 200/ST 200

Generation 02

Serial no.

2 Safety

2.1 Warnings

The purpose of warnings

Warnings alert persons to hazards that occur when handling or using the product.

Description of the key words used

DANGER

Draws attention to imminent danger that will lead to serious personal injury or fatality.

WARNING

Draws attention to a potentially dangerous situation that could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation that could lead to slight personal injury or damage

to the equipment or other property.

2.2 Safety precautions

The safety precautions given in the following section contain all general safety precautions for power tools

which, in accordance with the applicable standards, require to be listed in the operating instructions.

Accordingly, some of the rules listed may not be relevant to this power tool.

2.2.1 General safety precautions for power tools

WARNING Ensure that your read all safety precautions, instructions and technical data with which

this power tool is provided. Failure to follow the instructions below may result in electric shock, fire and/or

serious injury.

Keep all safety precautions and instructions for future reference.

The term “power tool” used in the safety precautions refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

4

Work area safety

▶ Keep your work area clean and well lit. Cluttered or dark work areas invite accidents.

▶ Do not operate the power tool in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

▶ Keep bystanders, children and visitors away while operating a power tool. Distractions can cause

you to lose control of the tool.

Electrical safety

▶ The plug on the supply cord of the power tool must match the power outlet. Do not change the

plug in any way. Do not use adapter plugs with earthed (grounded) power tools. Unmodified plugs

and matching power outlets reduce the risk of electric shock.

▶ Avoid body contact with earthed or grounded surfaces such as pipes, radiators, cookers, stoves

and refrigerators. There is an increased risk of electric shock if your body is grounded.

▶ Do not expose the power tool to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

▶ Do not abuse the supply cord. Never use the supply cord for carrying, pulling or unplugging the

power tool. Keep the supply cord away from heat, oil, sharp edges or moving parts. Damaged or

tangled supply cords increase the risk of electric shock.

▶ When operating a power tool outdoors, use only extension cords of a type suitable for outdoor

use. Use of an extension cord suitable for outdoor use reduces the risk of electric shock.

▶ If use of the power tool in a damp environment cannot be avoided, use a ground fault circuit

interrupter. Use of a ground fault circuit interrupter reduces the risk of electric shock.

Personal safety

▶ Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating the power tool may result in serious personal injury.

▶ Wear your personal protective equipment and always wear protective glasses. Depending on the

purpose for which the power tool is to be used, wearing safety equipment such as a dust mask, non-skid

safety shoes, hard hat, or hearing protection will reduce the risk of injury.

▶ Avoid accidental starting. Check that the power tool is switched off before you connect it to the

power supply and/or the battery and before picking it up or carrying it. Carrying power tools with

your finger on the switch or plugging in power tools that are already switched on invites accidents.

▶ Remove adjusting keys or switches before turning the power tool on. A tool or a key left attached to

a rotating part of the machine may result in personal injury.

▶ Avoid unaccustomed body positions. Maintain proper footing and balance at all times. This will

allow you to control the power tool better, even in unexpected situations.

▶ Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

▶ If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. The use of a dust removal system can reduce dust-related hazards.

▶ Do not lull yourself into a false sense of security and do not flout the safety rules for power tools,

even if you are familiar with the power tool after using it many times. Caress handling could cause

serious injury within fractions of a second.

Use of the power tool

▶ Do not overload the tool. Use the correct power tool for your application. The correct power tool

will do the job better and more safely within the performance range for which it is designed.

▶ Do not use a power tool if it has a faulty On/Off switch. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

▶ Disconnect the plug from the power outlet and/or remove a removable battery before making any

adjustments, changing accessories, or storing the tool. This precaution reduces the risk of the power

tool starting accidentally.

▶ Store idle power tools out of the reach of children . Do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

▶ Maintain power tools and accessories carefully. Check that moving parts operate satisfactorily

and do not jam, and whether any parts are broken or so damaged that the correct operation of the

power tool is adversely affected. If parts are damaged, have the parts repaired before using of the

tool. Many accidents are caused by poorly maintained power tools.

▶ Keep cutting tools sharp and clean. Properly maintained tools with sharp cutting edges are less likely

to bind and are easier to control.

5

▶ Use power tools, accessories, insert tools, etc. only as described in this manual. Take the working

conditions and the work to be performed into account. Use of the power tool for operations different

from those intended could result in a hazardous situation.

▶ Keep grips and gripping surfaces dry, clean and free from oil and grease. Slippery grips and gripping

surfaces do not allow the power tool to be safely operated and controlled in unforeseen situations.

Service

▶ Have your power tool repaired only by qualified,skilled personnel, using only genuine Hilti spare

parts. The safety of the power tool can thus be maintained.

2.2.2 Diamond drill safety warnings

▶ When performing drilling that requires the use of water, route the water away from the operator’s

work area or use a liquid collection device. Such precautionary measures keep the operator’s work

area dry and reduce the risk of electrical shock.

▶ Operate power tool by insulated grasping surfaces, when performing an operation where the

cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a “live”

wire may make exposed metal parts of the power tool “live” and could give the operator an electric

shock.

▶ Wear hearing protection when diamond drilling. Exposure to noise can cause hearing loss.

▶ When the bit is jammed, stop applying downward pressure and turn off the tool. Investigate and

take corrective actions to eliminate the cause of the bit jamming.

▶ When restarting a diamond drill in the workpiece check that the bit rotates freely before starting. If

the bit is jammed, it may not start, may overload the tool, or may cause the diamond drill to release from

the workpiece.

▶ When securing the drill stand with anchors and fasteners to the workpiece, ensure that the

anchoring used is capable of holding and restraining the machine during use. If the workpiece is

weak or porous, the anchor may pull out causing the drill stand to release from the workpiece.

▶ When securing the drill stand with a vacuum pad to the workpiece, install the pad on a smooth,

clean, non-porous surface. Do not secure to laminated surfaces such as tiles and composite

coating. If the workpiece is not smooth, flat or well affixed, the pad may pull away from the workpiece.

▶ Ensure there is sufficient vacuum before and during drilling. If the vacuum is insufficient, the pad

may release from the workpiece.

▶ Never perform drilling with the machine secured by the vacuum pad only, except when drilling

downwards. If the vacuum is lost, the pad will release from the workpiece.

▶ When drilling through walls or ceilings, ensure to protect persons and the work area on the other

side. The bit may extend through the hole or the core may fall out on the other side.

▶ When drilling overhead, always use the liquid collection device specified in the instructions. Do

not allow water to flow into the tool. Water entering the power tool will increase the risk of electric

shock.

2.2.3 Additional safety precautions

Personal safety

▶ Tampering with or modification of the machine is not permitted.

▶ The machine is not intended for use by inexperienced persons who have received no special

training.

▶ Keep the machine out of reach of children.

▶ Avoid touching rotating parts. Switch the machine on only after it is in position at the workpiece.

Touching rotating parts, especially rotating accessory tools, may lead to injury.

▶ Avoid skin contact with drilling slurry.

▶ Dust from materials, such as paint containing lead, some kinds of wood, concrete / masonry / stone

containing silica, and minerals as well as metal, may be injurious to health. Contact with or inhalation of

the dust may cause allergic reactions and/or respiratory or other diseases to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic such as oak and beech dust, especially in conjunction

with additives for wood conditioning (chromate, wood preservative). Material containing asbestos must

only be handled by specialists. Use a dust removal system that is as effective as possible. Accordingly,

use a suitable vacuum cleaner of the type recommended by Hilti for wood dust and/or mineral dust and

which is designed for use with this power tool. Ensure that the workplace is well ventilated. The use

of a dust mask suitable for the particular type of dust is recommended. Observe national regulations

applicable to the materials on which you intend to use the machine.

▶ The diamond core drilling machine and the diamond core bit are heavy pieces of equipment. There is a

risk of crushing parts of the body. The user and any other persons in the vicinity must wear suitable

Loading...

Loading...