Page 1

DD200

*305560*

305560

Bedienungsanleitung de

Operating instructions en

Mode d’emploi fr

Istruzioni d’uso it

Gebruiksaanwijzing nl

Manual de instruções pt

Manual de instrucciones es

Οδηγιες χρησεως

el

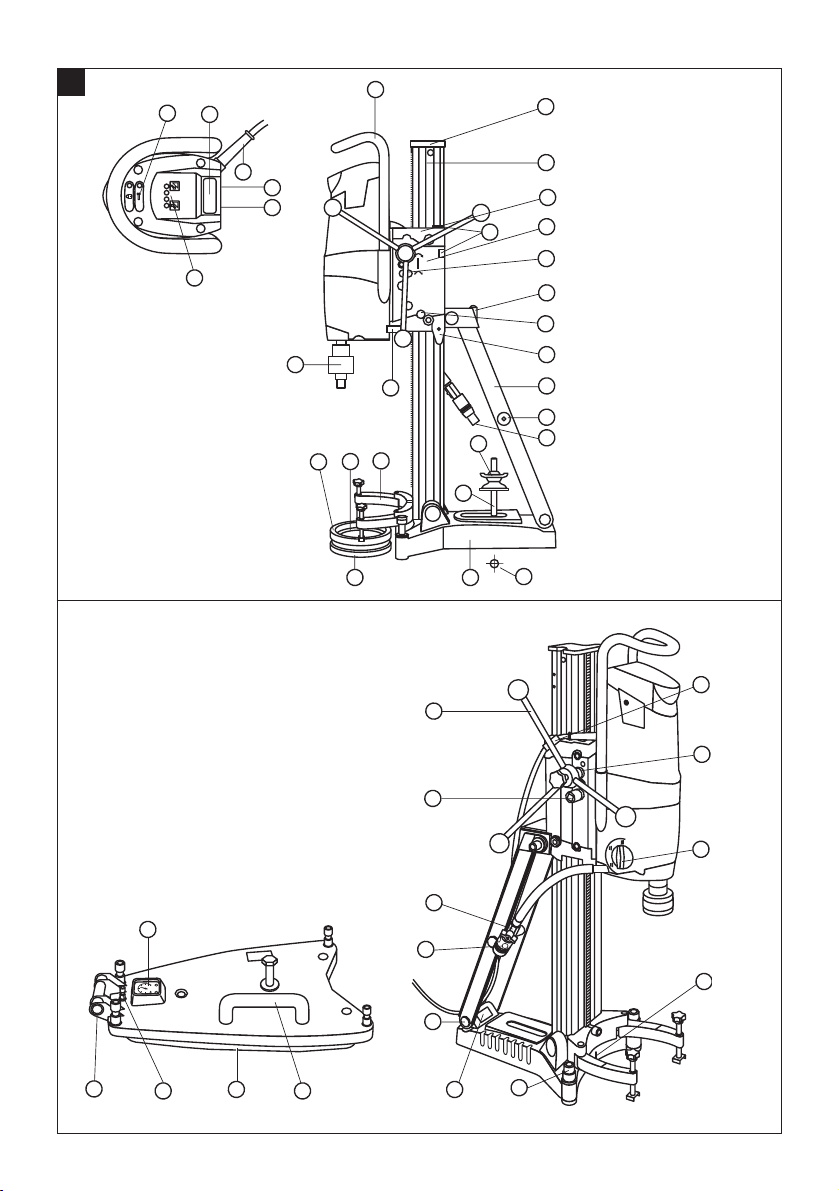

Page 2

1

9

32

13

14

22

23

28

7

9

26

14

15

28

41

42

40

43

16

18

17

31

39

19

29

27

25

29

24

21

20

30

33

10

6

5

2

4

8

3

11

12

34

38

37

36

35

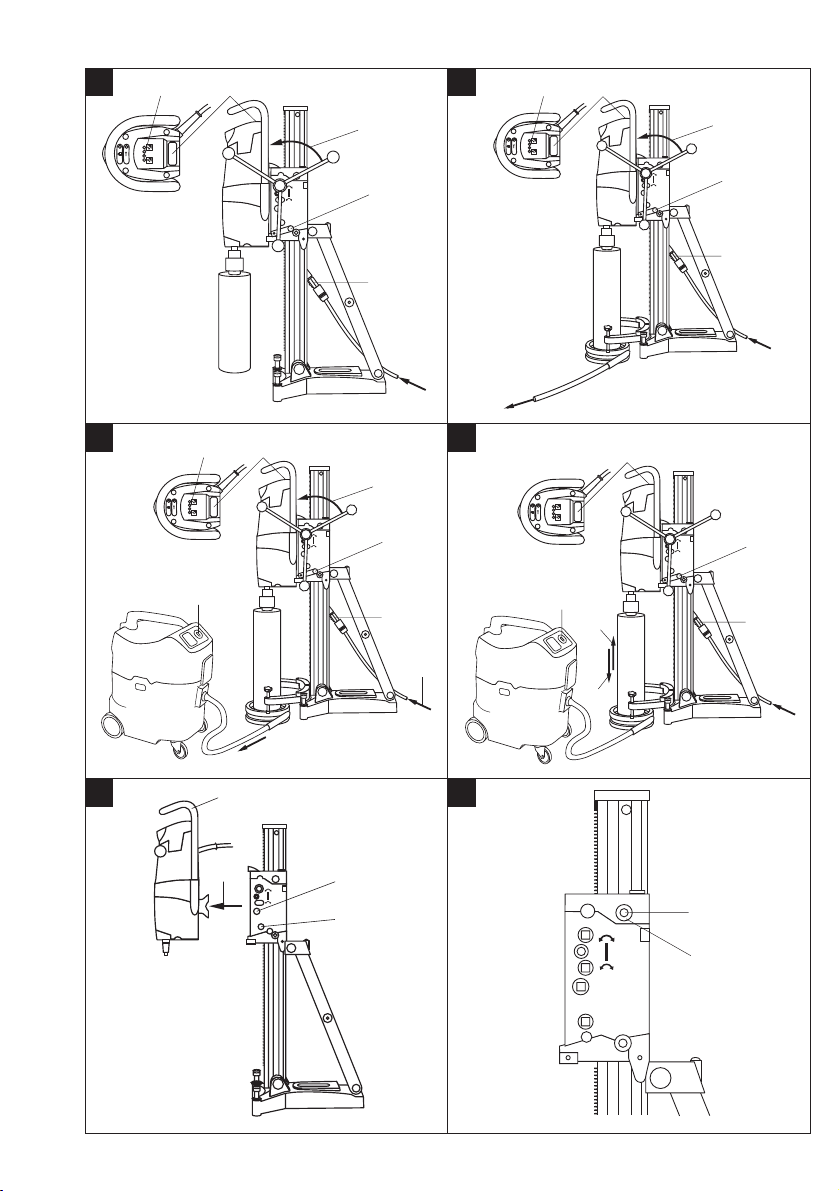

Page 3

2

2

4

6

3

5

7

3

3

2

1/3

1

2

1

4/6

2

5

3

1

2

5

6

8

8

7

9

6

5

1/12

11

3

10

42

6

3/5

4

1

4

2

1/3

2

1/3

Page 4

8

10

12

9

11

13

3

1

2

3

5

2/4

1

3

5

2/4

1

5

1/3

4

6

2

1

2/4

3

1

2

Page 5

14

16

18

15

17

19

6

4/5

2

3

1

6

2

4/5

3

1

8

1

4

6/7

5

3

2

5

2

6

4

3

1

2

5

3/4/6

1

1/3

2

Page 6

15

en

It is essential that the operating instructions

are read before the machine is operated for

the first time.

Always keep these operating instructions

together with the machine.

Ensure that the operating instructions are

with the machine when it is given to other

persons.

DD200 diamond core drilling system

1. General information

1.1 Safety notices and their meaning

-DANGER-

Draws attention to imminent danger that could lead to

serious bodily injury or fatality.

-CAUTION-

Draws attention to a potentially dangerous situation that

could lead to slight personal injury or damage to the

equipment or other property.

-NOTE-

Draws attention to instructions and other useful information that help the user to employ the product efficiently.

Contents Page

1. General information 15

2. Description 17

3. Tools and accessories 17

4. Technical data 17

5. Safety precautions 18

6. Before use 20

7. Operation 23

8. Care and maintenance 25

9. Troubleshooting 26

10. Disposal 27

11. Warranty 28

12. EC declaration of conformity 28

Operating controls, parts and indicators

Drilling rig (drive unit and drill stand)

Drive unit

; Service indicator

= Drilling performance indicator

% On / off switch

& Gear selector switch

( Water flow regulator

) Chuck

+ Supply cord with PRCD

§ Carrying grips (2)

/ Water hose connector

: Type plate

· Interface

Drill stand

$ Column

£ End cap

| Strut

¡ Base plate

Q Clamping spindle

W Clamping nut

E Anchor

R Leveling screws

T Hole center indicator

Z Carriage

U Drive unit (eccentric) locking bolt

I Direct drive

O Reduction gear

P Carriage locking mechanism

Ü Hand wheel

[ Carrying grip

] Supply cord guide

Æ Type plate

º Leveling indicators (2)

• End stop

A Wheel assembly mounting point

ACCESSORIES

Vacuum base plate

S Pressure gauge

D Vacuum release valve

F Vacuum seal

G Vacuum hose connector

H Wheel assembly mounting point

Water flow indicator

J Water flow indicator

Water collector system

K Water collector holder

L Water collector

Ö Seal

Ä Seal

Column extension

† Eccentric bolt

Depth gauge

Spacer

ΠDrive unit locking mechanism

Wheel assembly

Å Set of wheels

Page 7

16

en

Prohibition signs

Transport by

crane is not

permissible.

1.2 Pictograms

Warning signs

General

warning

Recycle

waste

material

Warning:

electricity

Warning: hot

surface

Read the operating

instructions before

use.

Symbols

On the vacuum baseplate On the tool

VACUUM

VACUUM

Top:

An additional means of

securing the drill stand must

be employed when used for

horizontal drilling with

vacuum attachment.

Below:

Use of only the vacuum baseplate to secure the drill stand

for overhead drilling is not

permissible.

Use of the water collector

system in conjunction with a

wet-type vacuum cleaner is

mandatory when working

overhead on ceilings.

These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover pages. Keep these pages open while studying the

operating instructions.

In these operating instructions, the designation "the

machine" refers to the DD 200 core drilling machine.

Location of identification data on the machine

The type designation and serial number can be found

on the rating plate on the machine. Make a note of this

data in your operating instructions and always refer to

it when making an enquiry to your Hilti representative

or service department.

Type: DD 200

Serial no.:

Type: DD-HD 30

Serial no.:

Use of a correctly functioning PRCD

circuit breaker is mandatory.

PRCD

GFCI

208188 B/2.2004

Page 8

17

en

2. Description

2.1 Use of the equipment as intended

The DD 200 and DD HD-30 form a drilling rig designed

for wet core drilling in mineral materials using diamond

core bits (hand-held use is not permissible).

The drive unit must always be mounted on the drill stand

when in use and the drill stand secured adequately by

means of an anchor, vacuum base plate or quick-release

brace.

Manipulation or modification of the drive unit, drill stand

or accessories is not permissible. To avoid the risk of

injury, use only original Hilti accessories and insert tools.

Observe the information printed in the operating instruc-

tions concerning operation, care and maintenance.

Observe the safety precautions and operating instructions for the accessories used.

Do not use a hammer or other heavy object when making adjustments to the baseplate.

The drive unit, drill stand, accessories and insert tools

may present hazards when used incorrectly by untrained

personnel or not as directed.

The machine may be operated only when connected to

an adequately rated electric supply equipped with an

earth / ground conductor.

3. Accessories

Water flow indicator 305939

Depth gauge 305535

Water collector holder 305536

Column extension 305537

Vacuum base plate 305538

Vacuum pump 332158; 92053 (USA)

Spacer 305539

Wheel assembly 305541

Clamping spindle 305940

Clamping nut 251834

Quick-release brace 9870

Water collector 25-162 232221

Water collector 92-250 232243

Water collector 8-87 232204

Equipment Core bits Drilling direction

System with water collector and wet-type vacuum cleaner 25–250 mm dia. All directions

System without water collector and wet-type vacuum cleaner 25–400 mm dia. Not upwards

System with water collector 25–250 mm dia. Not upwards

Use of the water collector system in conjunction with a

wet-type vacuum cleaner is mandatory when working

overhead on ceilings.

Use of the quick-release brace is not permissible for working on ceilings.

Horizontal drilling in conjunction with the vacuum base

plate (accessory) is permissible only when an additional means of securing the drill stand is employed.

Drilling into materials hazardous to the health (e.g.

asbestos) is not permissible.

4. Technical data

Drive unit DD 200

Rated voltage* 100 V 110 V 220 V 230 V 230 V 240 V

Rated power input* 2300 W 2500 W 2600 W 2600 W

Rated current* 15 A

Rated frequency 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

Nominal speed under no load (r.p.m.) 380/640/1300 320/550/1120

Max. permissible water supply

pressure 6 bar

Page 9

18

en

Dimensions (LxWxH) 630×150×173 mm

Weight (drive unit) 12.7 kg

Weight (drill stand) 17.9 kg

Drilling depth max. 500 mm without extension

Protection class as per EN/IEC 61029 protection class I (earthed)

Noise and vibration information (measured in accordance with EN 61029-1):

Typical A-weighted noise power level (LwA): 105 dB (A)

Typical A-weighted noise emission pressure level (LpA): 92 dB (A)

Wear ear protection

Typical weighted vibration at the hand wheel: < 2,5 m/s

2

Interference immunity as per EN 55014-2

Radio and television interference suppression as per EN 55014-1

* The machine is available in several versions with different voltage ratings. Please refer to the type plate for the voltage rating and input power

rating of your machine.

5. Safety precautions

CAUTION: The following basic safety precautions must

always be observed when using electric machines in

order to avoid the risk of electric shock, injury or fire.

Read all of these instructions before using this machine

and keep this list of safety precautions for future reference.

5.1 The necessary safety precautions at the workplace

● Approval must be obtained from the site engineer or

architect prior to beginning drilling work. Drilling work

on buildings and other structures may influence the

statics of the structure, especially when steel reinforcing bars or load-bearing components are cut through.

● Ensure that the workplace is well lit.

● Ensure that the workplace is well ventilated.

● Keep the workplace tidy. Objects which could cause

injury should be removed from the working area. Untidiness at the workplace can lead to accidents.

● When drilling through-holes, the area below the ceil-

ing, floor or behind the wall where the drilling is taking place must be secured as the drilled-out core may

fall out.

● Use clamps or a vice to secure the workpiece. The

workpiece is thus held more securely than by hand and

both hands remain free to operate the machine.

● Use protective equipment. Wear eye protection.

● Wear breathing protection if the work creates dust.

● Wear suitable working clothing. Do not wear loose

clothing, loose long hair or jewelry as it can become

caught up in moving parts. Wear suitable headgear if

you have long hair.

● It is recommended that rubber gloves and non-slip

shoes are worn when working outdoors.

● Keep children and other persons away from the work-

ing area.

● Do not allow other persons to tamper with the machine

or the supply cord.

● Avoid unfavorable body positions. Work from a secure

stance and stay in balance at all times.

● To avoid tripping and falling when working, always lead

the supply cord, extension cord and water hose away

to the rear.

● Keep the supply cord, extension cord, water hose and

vacuum hose away form rotating parts of the machine.

● CAUTION: Before beginning drilling, check that there

are no live electric cables located in the area where

the hole is to be made.

● Concealed electric cables or gas and water pipes pre-

sent a serious hazard if damaged while you are working. Accordingly, check the area in which you are working beforehand (e.g. using a metal detector). External

metal parts of the machine may become live, for example, when an electric cable is drilled into inadvertently.

● Do not work from a ladder.

Page 10

19

en

5.2 General safety precautions

● Use the right machine for the job. Do not use the

machine for purposes for which it was not intended.

Use the machine only as directed and when it is in

faultless condition.

● Use only the original accessories or ancillary equip-

ment listed in the operating instructions. Use of other insert tools or accessories may present a risk of

personal injury.

● Take the influences of the surrounding area into account.

Do not expose the machine to rain or snow and do

not use it in damp or wet conditions. Do not use the

machine where there is a risk of fire or explosion.

● Keep the grips dry, clean and free from oil and grease.

● Do not overload the machine. It will work more effi-

ciently and more safely within its intended performance range. The side handle must be fitted for all

types of work.

● Never leave the machine unattended.

● When not in use, the machine must be stored in a dry

place, locked up or out of reach of children.

● Avoid unintentional starting. Check that the on / off

switch is in the "off” position before plugging the supply cord into the electric socket.

● Unplug the machine from the electric supply when it

is not in use, during pauses between work, before

maintenance and when changing core bits.

● Check the PRCD each time before use.

● Take care of your core bits. You will be able to work

more efficiently and more safely if the core bits are

kept sharp and clean.

● Check the machine for possible damage. Protective

devices and any parts that may have suffered slight

damage should be checked for correct operation and

functionality before further use. Check that moving

parts function correctly without sticking and that no

parts are damaged. All parts must be fitted correctly

and fulfill all conditions necessary for correct operation of the machine. Damaged safety devices or other damaged parts must be replaced or repaired properly by an authorized repair workshop unless otherwise indicated in the operating instructions.

● Avoid skin contact with drilling slurry.

● Wear respiratory protection when the work creates

dust, e.g. during dry drilling. Connect a vacuum cleaner to the drilling system. Drilling into materials that

present a health hazard (e.g. asbestos) is not permissible.

5.2.1 Mechanical hazards

● Follow the instructions concerning care and mainte-

nance.

● Check that the insert tools used are compatible with

the chuck system and that they are secured in the

chuck correctly.

● Make sure that the machine is correctly and securely

attached to the drill stand.

● Do not touch rotating parts.

● Make sure that all clamping screws are tightened cor-

rectly.

● After detaching the column extension, the end cap

(with built-in, safety-relevant end stop function) must

be refitted to the drill stand.

5.2.2 Electrical hazards

● Protect yourself against electric shock. Avoid body

contact with earthed / grounded objects, e.g. pipes,

radiators, cookers and fridges.

● Check the condition of the supply cord and its plug

connections and have it replaced by a qualified electrician if damage is found. Check the condition of the

extension cord and replace it if damage is found.

● Check the condition of the machine and its acces-

sories. Do not operate the machine or its accessories

if damage is found, if the machine is incomplete or if

its controls cannot be operated faultlessly.

● Do not touch the supply cord in the event of it suffer-

ing damage while working. Disconnect the supply cord

plug from the socket.

● Damaged or faulty switches must be replaced at a Hilti

service center. Do not use the machine if it cannot be

switched on and off correctly.

● Have the machine repaired only by a trained electri-

cal specialist (Hilti service center) using original Hilti

spare parts. Failure to observe this point may result

in risk of accident to the user.

● Do not use the supply cord for purposes for which it

is not intended. Never carry the machine by the supply cord and never pull the plug out of the socket by

pulling the supply cord.

● Do not expose the supply cord to heat, oil or sharp

edges.

● When working outdoors, use only extension cords

that are approved and correspondingly marked for

this application.

● In the event of a power failure, switch the machine off

and unplug the supply cord.

● Avoid using extension cords with multiple sockets

and the simultaneous use of several machines connected to one extension cord.

● Never operate the machine when it is dirty or wet. Dust

(especially dust from conductive materials) or dampness adhering to the surface of the machine may,

under unfavorable conditions, cause an electric shock

to be received. Dirty or dusty machines should thus

be checked at a Hilti service center at regular intervals, especially used frequently for working on conductive materials.

Page 11

20

en

5.2.3 Thermal hazards

● The core bit may become hot during use. Wear pro-

tective gloves when changing core bits.

5.3 Requirements to be met by users

● The machine is intended for professional use.

● The machine may be operated, serviced and repaired

only by authorized, trained personnel. This personnel

must be informed of any special hazards that may be

encountered.

● Always concentrate on the job you are doing. Proceed

carefully and do not use the machine if your full attention is not on the job.

● Excercise your fingers during pauses between work

to improve blood circulation in your fingers.

5.4 Personal protective equipment

● The user and any other persons in the vicinity must

wear suitable eye protection, a hard hat, ear protection, protective gloves and safety footwear while the

machine is in use.

6. Before use

-NOTE-

The mains voltage must correspond with the information printed on the type plate. Ensure that the machine

is disconnected from the electric supply.

6.1 Use of extension cords

Use only extension cords of a type approved for the

application and with conductors of adequate cross section. Recommended minimum conductor cross section

and max. cable lengths

Mains voltage Conductor cross section

mm

2

AWG

Conductor cross section

1.5 2.0 2,.5 3.5 14 12

100 V not per- not per- not per- 25 m not per- –

missible missible missible missible

110–120 V not per- not per- 20 m – not per-

missible missible missible 75 ft

220–240 V 30 m – 50 m – – –

Do not use extension cords with 1.25 mm2 or 16 AWG

conductor cross sections.

6.2 Use of a generator or transformer

This machine may be powered by a generator or transformer which fulfils the following conditions:

– AC voltage, output power at least 4000 VA

– The operating voltage must be within +5% and –15%

of the rated voltage at all times.

– Frequency range 50 – 60 Hz, never above 65Hz

– Automatic voltage regulation with starting boost

Never operate other machines or appliances from the

generator or transformer at the same time. Switching

other machines or appliances on and off may cause

undervoltage and / or overvoltage peaks, resulting in

damage to the machine.

6.3 Preparations

6.3.1 Setting up the drill stand

-NOTE-

If the drill stand has been folded up to facilitate transport, proceed as follows:

1. Release the screws at the top end of the strut and at

the column pivot.

2. Pivot the column into the vertical position (as far as

it will go).

3. Tighten the screw at the top end of the strut and at

the column pivot securely.

-NOTE-

The end cap must be fitted on the end of the column. It

serves as a protector and as the end stop.

Wear a hard

hat

Wear ear

protection

Wear

protective

gloves

Wear safety

boots

Wear eye

protection

-CAUTION-

– The machine, the diamond core bit and the drill stand

are heavy. There is a risk of pinching parts of the body.

Wear a hard hat, protective gloves and safety boots.

Page 12

21

en

6.3.2 Fitting the hand wheel

-NOTE-

The hand wheel can be fitted on the left or right side of

the carriage, on either of the two axles. The upper axle

drives the carriage directly while the lower axle drives

the carriage by way of reduction gearing.

1. Fit the hand wheel to one of the two axles on either

the left or right side of the carriage.

2. Secure the hand wheel with the screw provided.

6.3.3 Fastening the drill stand with an anchor

1. Set an HKD-E M16 metal anchor 330 mm / 13" (the

ideal distance) from the center of the hole to be drilled.

2. Screw the clamping spindle (accessory) into the anchor.

3. Position the drill stand over the spindle and bring it

into alignment with the aid of the hole center indicator. When the spacer is used (accessory), the hole

center indicator cannot be used to align the drill stand.

4. Screw the clamping nut onto the spindle but do not

tighten it.

5. Level the base plate by way of the three leveling screws.

The two level indicators on the carriage serve as a leveling aid.

6. Use a 27 mm AF open-end wrench to tighten the

clamping nut on the spindle. Alternatively, the rear

leveling screws can be tightened. The strut can be pivoted out of the way to facilitate access.

7. Check that the drill stand is fastened securely.

6.3.4 Fastening the drill stand with the vacuum

base plate (accessory)

-CAUTION-

Suitable for use only with core

bits of up to 300 mm diameter

and without use of a spacer.

-NOTE-

The hand grip on the vacuum

base plate is equipped with a vacuum valve which can be used to

release the vacuum.

1. Turn the four leveling screws back until they project

approx. 5 mm beneath the vacuum base plate.

2. Connect the hose between the vacuum base plate and

the vacuum pump.

3. Position the drill stand on the vacuum base plate.

4. Fit the screw and washer provided.

5. Mark the center point of the hole to be drilled.

6. Draw a line approximately 800 mm in length from the

center mark toward the approx. position at which the

drill stand is to be secured.

7. Make a mark on the 800 mm line at a distance of

165 mm (6

1

⁄2") from the hole center mark.

Overhead drilling with the drill stand secured

only by the vacuum base plate is not permissible.

8. Bring the marks on the vacuum base plate into alignment with the 800 mm line.

9. Position the center of the front edge of the vacuum

base plate on the line at the 165 mm (6

1

⁄2") mark.

-NOTE- Before using the vacuum pump, make your-

self familiar with the information contained in its operating instructions and observe these instructions.

10. Switch on the vacuum pump and press the vacuum

release valve.

11. Once the drill stand has been positioned correctly,

remove your finger from the vacuum release valve

and press the base plate against the work surface.

-CAUTION- Ensure that the pressure gauge pointer

remains within the green area before beginning drilling

and during the drilling operation.

12. Use the four leveling screws to level the vacuum

base plate. The 2 built-in level indicators on the carriage serve as leveling aids. Note: Do not attempt to

level the anchor base plate on the vacuum base plate.

This is not permissible.

13. An additional means of securing the drill stand must

be employed when drilling horizontally (e.g. a chain

attached to an anchor, ...)

14. Check that the drill stand is fastened securely.

6.3.5 Securing the drill stand with a quick-release brace

(acces.: e.g. for use between floor and ceiling)

1. Extend the hole center indicator and then use it as an

aid to bring the drill stand into alignment with the center point of the hole to be drilled.

2. Position the end of the quick-release brace carefully

between the two struts on the baseplate.

3. Secure the baseplate provisionally by applying slight

pressure with the quick-release brace.

4. Level the baseplate by way of the 3 leveling screws.

The 2 spirit levels on the carriage plate serve as leveling aids.

5. Tighten the quick-release brace securely.

6.3.6 Adjusting the angle of the drill stand

(adjustable to max. 45°)

-CAUTION-

Take care to avoid pinching your fingers at the pivot.

Wear protective gloves.

1. Release the screw at the pivot at the lower end of the

column and at the strut at the top end.

2. Bring the column into the desired position. The angle

scale on the rear serves as an adjustment aid.

3. Retighten the two screws securely.

6.3.7 Using the column extension (accessory)

1. Remove the end cap (with built-in end stop) from the

top end of the column and refit it to the end of the

column extension.

2. Fit the cylindrical section of the column extension into

the end of the column on the drill stand.

Page 13

22

en

3. Secure the column extension by tightening the eccentric locking bolt.

4. A depth gauge (accessory) may be fitted on the column as an additional end stop.

5. The end cap (with built-in end stop) must be refitted

to the column on the drill stand when the column

extension is subsequently removed. The end stop is

a safety-relevant part and must always be used.

6.3.8 Fitting the spacer (accessory)

-NOTE-

The distance between the drilling axis and the drill stand

must be increased by fitting the spacer when diamond

core bits with a diameter greater than 300 mm are to be

used. The hole center indicator cannot be used in conjunction with the spacer.

These instructions presume that the drive unit is not

already fitted.

1. Lock the carriage in position on the column (activate

the carriage locking mechanism).

2. Release the drive unit locking bolt.

3. Pull out the locking bolt.

4. Fit the spacer onto the carriage.

5. Push the locking bolt into the carriage as far as it will

go.

6. Tighten the locking bolt securely.

6.3.9 Mounting the drive unit on the drill stand

-NOTE-

Ensure that the drive unit is disconnected from the electric supply.

1. Lock the carriage in position on the column (activate

the carriage locking mechanism).

2. Pull out the drive unit locking bolt.

3. Fit the drive unit onto the carriage or spacer.

4. Push the locking bolt into the carriage or spacer as

far as it will go.

5. Tighten the locking bolt securely.

6. Clip the supply cord into the supply cord guide on the

carriage cover.

7. Check that the drive unit is mounted securely.

6.3.10 Connecting the water supply

1. Close the water flow regulator on the drive unit.

2. Connect the water supply hose to the hose connector.

-NOTE-

A water flow indicator (accessory) can be connected

between the water supply hose and the hose connector

on the drive unit.

-CAUTION-

Check the hoses for damage at regular intervals and

ensure that the maximum permissible water supply pressure of 6 bar is not exceeded.

6.3.11 Fitting the water collector system

(accessory)

-NOTE-

Use of the water collection system permits water to be

drained away from the core bit thus avoiding soiling the

surrounding area. We recommend use of the water collector system with core bits of up to 250 mm. diameter.

Best results are achieved in conjunction with a wet-type

vacuum cleaner.

Use of the water collection system in conjunction with

a wet-type vacuum cleaner is mandatory for overhead

drilling. The drill stand must be set up at 90° to the ceiling.

The water collector seal must be of a size suitable for

the core bit diameter used.

1. Release the screw on the drill stand (at the front lower end of the column).

2. Slide the water collector holder into place behind the

screw from below.

3. Tighten the screw securely.

4. Fit the water collector between the two moveable arms

of the water collector holder.

5. Secure the water collector by way of the two screws

on the water collector holder.

6. Connect the water collector to a wet-type vacuum

cleaner. Alternatively, the water can be allowed to flow

away through a length of hose attached to the connector.

6.3.12 Adjusting the depth gauge (accessory)

1. Turn the hand wheel until the core bit contacts the

material in which the hole is to be drilled.

2. Set the desired drilling depth by adjusting the distance

between the carriage and the depth gauge.

3. Secure the depth gauge by tightening the clamping

screw.

Page 14

23

en

6.3.13 Fitting a diamond core bit

(drive unit with Hilti BL chuck)

– The core bit may become hot during use or during

sharpening. It may burn your hands. Wear protective

gloves when changing the core bit.

1. Lock the carriage in position on the column (activate

the carriage locking mechanism) and check that the

drill stand is fastened securely.

2. Open the chuck by turning it in the direction of the

"open” symbol (open brackets).

3. Push the connection end of the diamond core bit into

the chuck on the drive unit from below until it engages

with the gear teeth.

4. Close the chuck by turning it in the direction of the

"closed” symbol (closed brackets).

5. Check that the diamond core bit it is held securely

(check by hand for play and try to pull it away from

the chuck).

6.3.14 Selecting drilling speed

-CAUTION-

Do not change gear while the motor is running. Wait

until rotation has stopped.

1. Select the gear according to the core bit diameter to

be used.

2. Move the gear selector switch to the desired setting

while rotating the core bit by hand.

6.4 Transport

-CAUTION-

Transport the drive unit, drill stand and diamond core

bit as separate units.

Use the wheel assembly (accessory) to facilitate transport.

7. Operation

7.1 Switching on and checking the PRCD ground

fault interrupter

(use an isolating transformer with the GB version)

1. Plug the drive unit supply cord into an electric socket with earth connection.

2. Press the "ON" button on the PRCD ground fault interrupter (the indicator must light).

3. Press the "TEST" button on the PRCD ground fault

interrupter (the indicator must go out).

4. Press the "ON" button on the PRCD ground fault interrupter (the indicator must light).

7.2 Core bit diameters and corresponding

gears

Gear Core bit diameter Speed under no load

1 202–400 mm / 8" – 16" 320 r.p.m.

2 102–182 mm / 4" – 7" 550 r.p.m.

3 25– 97 mm / 1" – 33/4"1120 r.p.m.

7.3 Operating the drilling machine without the water

collector system and wet vacuum cleaner

-NOTE-

The water flows away in uncontrolled fashion. Overhead

drilling is not permissible!

-CAUTION-

Do not allow water to come into contact with the drive

unit.

7.3.1 Switching on

1. Open the water flow regulator slowly until the desired

volume of water is flowing.

2. Press the on / off switch on the drive unit (switch position " I ”).

3. Release the carriage lock.

4. Turn the hand wheel until the core bit comes into contact with the material in which the hole is being drilled.

5. Apply only light pressure until the core bit has become

centered and then gradually increase the pressure.

-CAUTION-

– The machine and the core drilling operation emit noise.

Excessive noise may damage the hearing. Wear ear

protection.

– The core drilling operation may cause hazardous frag-

ments to fly off. Flying fragments may cause injury to

the eyes or other parts of the body. Wear eye protection and a hard hat.

Page 15

24

en

6. Regulate the pressure applied to the core bit by observing the drilling performance indicator (optimum drilling

performance is achieved when the green lamps in the

display light).

7.4 Operating the drilling machine with the water

collector system (accessory)

-NOTE-

The water is allowed to flow away through a length of

hose. Overhead drilling is not permissible!

-CAUTION-

Do not allow water to come into contact with the drive

unit.

7.4.1 Switching on

1. Open the water flow regulator slowly until the desired

volume of water is flowing.

2. Press the on / off switch on the drive unit (switch position " I ”).

3. Release the carriage lock.

4. Turn the hand wheel until the core bit comes into contact with the material in which the hole is being drilled.

5. Apply only light pressure until the core bit has become centered and then gradually increase the pressure.

6. Regulate the pressure applied to the core bit by observing the drilling performance indicator (optimum drilling

performance is achieved when the green lamps in the

display light).

7.5 Operating the drilling machine with the water

collector system and wet-type vacuum cleaner

(accessories)

-NOTE-

Drilling at an angle in an upwards direction is not permissible (the water collector is not functional).

The core bit fills with water during overhead drilling.

-CAUTION-

Water must not be allowed to run over the drive unit.

-NOTE-

The wet-type vacuum cleaner must be switched on manually before beginning drilling and switched off manually at the end of the drilling operation.

7.5.1 Switching on

1. Switch on the wet-type vacuum cleaner. Do not use

automatic mode.

2. Ensure that the water supply is connected and ready

for use.

3. Open the water flow regulator.

4. Press the on / off switch on the drive unit (switch position “I”).

5. Release the carriage lock.

6. Turn the hand wheel until the core bit comes into contact with the material in which the hole is being drilled.

7. Apply only light pressure until the core bit has become

centered and then gradually increase the pressure.

8. Regulate the pressure applied to the core bit by observing the drilling performance indicator (optimum drilling

performance is achieved when the green lamps in the

display light).

7.6 Switching off

1. Close the water flow regulator.

2. Withdraw the diamond core bit from the hole.

Caution: The core bit fills with water during overhead

drilling. After overhead drilling, the water must first

be allowed to drain from the core bit. This is done by

disconnecting the water supply hose from the connector on the drive unit and then opening the water

flow regulator valve (do not allow the water to flow

back through the water flow indicator). The water

must not be allowed to run over the drive unit.

3. Engage the carriage lock.

4. Switch off the drive unit.

5. Switch off the vacuum cleaner, if used.

6. To ensure that the drill stand remains in balance, lower the core bit until in contact with the working surface or fold out the hole center indicator (this is not

effective if using the vacuum baseplate).

7. If necessary, remove the core from the core bit.

7.7 Removing the drive unit from the drill stand

-NOTE-

Ensure that the machine is disconnected from the mains

supply.

1. Secure the carriage on the column by engaging the

carriage lock.

2. Hold the drive unit securely with one hand on the carrying grip. -CAUTION- The drive unit may otherwise

fall from the drill stand!

3. Release the drive unit eccentric locking bolt with the

other hand.

4. Pull out the eccentric locking bolt.

5. Remove the drive unit from the carriage.

6. Push the eccentric locking bolt back into the carriage

as far as it will go.

7.8 Disposing of drilling slurry

see Section 10 “Disposal”.

Page 16

25

en

8. Care and maintenance

Disconnect the supply cord plug from the socket.

Care of insert tools and metal parts

Remove any dirt adhering to the core bits and protect

their surfaces from corrosion by rubbing them with an

oily cloth from time to time.

8.1 Care of the machine

The outer casing of the drive unit is made from impactresistant plastic.

Never operate the drive unit when the ventilation slots

are blocked. Clean the ventilation slots carefully using

a dry brush. Do not permit foreign objects to enter the

interior of the drive unit. Clean the outside of the drive

unit at regular intervals with a cloth. Do not use a spray,

steam pressure cleaning equipment or running water

for cleaning. This may negatively affect the electrical

safety of the drive unit.

8.2 Maintenance

Check all external parts of the machine for damage at

regular intervals and check that all controls operate faultlessly. Do not operate the machine if parts are damaged

or when the controls do not function faultlessly. If necessary, the machine should be repaired at a Hilti repair

center.

Repairs to the electrical section of the machine may be

carried out only by trained electrical specialists.

8.3 Replacing the carbon brushes

The indicator lamp with the wrench symbol lights when

the carbon brushes require to be replaced.

Failure to observe the following instructions may present a possibility of coming into contact with a dangerous high voltage. The machine may be operated, serviced and repaired only by authorized, trained personnel. This personnel must be informed of any special hazards that may be encountered.

1. Disconnect the drive unit from the electric supply.

2. Remove the covers from the right and left sides of the

drive unit.

3. Remove the used carbon brushes from the drive unit.

Note how the brushes are fitted.

4. Fit the new carbon brushes exactly as the old carbon brushes (Spare part no.: 100–127 V: 279526;

220–240 V: 280097).

5. Screw the covers back on to the right and left sides

of the machine.

8.4 Adjusting play between the column and the

carriage

The play between the column and the carriage can be

adjusted by way of 4 eccentrically-mounted rollers.

The 4 rollers shown in the illustration can be adjusted.

First remove the drive unit from the drill stand and run

the carriage up to the top of the column by turning the

hand wheel. The 4 rollers can then be adjusted as follows:

1. Use a 5 mm AF hex. socket wrench to unscrew the

locking screw slightly (do not remove the screw).

2. Use a 19 mm AF open-end wrench to turn the eccentric axle, thus pushing the roller slightly toward the

column.

3. Tighten the locking screw.

8.5 Checking the equipment after care and maintenance

All functions must be checked after care and maintenance.

Page 17

26

en

9. Troubleshooting

Fault Possible cause Remedy

The machine Fault in the electric supply Plug in another electric appliance and check

doesn’t start whether it works. Check the plug connections,

electric supply, PRCD and mains fuse.

Supply cord or plug defective Have it checked by a trained electrical

specialist and replaced if necessary.

Switch defective Have it checked by a trained electrical

specialist and replaced if necessary.

Machine switched off by the automatic Have it checked by a trained electrical

cut-out carbon brushes specialist and replaced if necessary.

The motor runs Gearing defective Have the machine repaired at a Hilti service

but the core bit center.

doesn’t rotate Gear selector switch not engaged Move the gear selector switch until it is felt to

engage.

Rate of drilling Water pressure / water flow rate too high Reduce the flow with the water flow

progress decreases regulator.

Core sticks inside the diamond core bit Remove the core.

Maximum drilling depth reached Remove the core and use a core bit

extension.

Diamond core bit defective Check the core bit for damage and replace it

if necessary.

Gearing defective Have the machine repaired at a Hilti service

center.

Diamond core bit segments polished Sharpen the core bit on a sharpening plate

with water running.

Diamond core bit segments polished The wrong core bit specification has been

used. Seek advice from Hilti.

The slip clutch releases prematurely or Have the machine repaired at a Hilti service

slips permanently center.

The motor cuts out The machine stops running Reduce the pressure applied.

Electronics defective Have the machine repaired at a Hilti service

center.

Electric power failure Check the plug connections, electric supply,

PRCD and mains fuse.

Cooling fan defective Have the machine repaired at a Hilti service

center.

Carbon brushes worn Have the machine repaired at a Hilti service

center.

Water leakage at Shaft seal defective Have the machine repaired at a Hilti service

the water swivel or center.

gear housing Water pressure too high Reduce the water pressure.

The diamond core Chuck or connection end dirty or damaged Clean the connection end / chuck or replace if

bit cannot be fitted necessary.

into the chuck

Water leakage at Chuck or connection end dirty Clean the connection end / chuck.n

the chuck during

operation Core bit not screwed securely into the Tighten it securely.

chuck

Chuck seal or core bit connection end Check the seal and replace it if necessary.

defective

Page 18

27

en

Excessive play in Screw at the top end of the strut and / or Tighten the screws.

the drilling system at the column pivot point is loose

Core bit not screwed securely into the Tighten it securely.

chuck

Drive unit locking mechanism loose Tighten the drive unit locking mechanism.

Leveling screws or clamping spindle Retighten the leveling screws clamping

not tightened spindle.

Excessive play at the carriage Adjust the play at the carriage guide rollers.

Excessive play at the chuck Check that the chuck runs true and replace it

if necessary.

Connection end defective Check the connection end and replace it if

necessary.

10. Disposal

Most of the materials from which Hilti tools or machines are manufactured can be recycled. The materials must

be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for

taking back your old machines or tools for recycling. Please ask your Hilti customer service department or Hilti

sales representative for further information.

Disposal of drilling slurry

With regard to environmental aspects, allowing drilling slurry to flow directly into rivers, lakes or the sewerage

system without suitable pre-treatment is problematical. Ask the local authorities for information about applicable regulations.

We recommend the following pre-treatment:

Collect the drilling slurry (e.g. use a wet-type industrial vacuum cleaner).

Allow the slurry to settle and dispose of the solid material at a construction waste disposal site (the addition of

a flocculent may accelerate the settling process).

Water from the drilling slurry (alkaline, ph value > 7) should be neutralized by adding an acidic neutralizing agent

or large quantity of water before it is allowed to flow into the sewerage system.

Only for EU countries

Do not dispose of electric tools together with household waste material!

In observance of European Directive 2002/96/EC on waste electrical and electronic equipment

and its implementation in accordance with national law, electric tools that have reached the

end of their life must be collected separately and returned to an environmentally compatible

recycling facility.

Page 19

28

en

12. EC declaration of conformity

We declare, on our sole responsibility, that this product

complies with the following standards or standardization documents: 98/37/EC, 89/336/EEC, EN 55014-1,

EN 55014-2, EN 61000-3-2, EN 61000-3-3, EN 61029-1.

Designation: Diamond drilling system

Type: DD 200

Year of design: 2003

Hilti Corporation

Dr. Ivo Celi Dr. Heinz-Joachim Schneider

Senior Vice President Executive Vice President

Business Unit Diamond Business Area Electric Tools & Accessories

12/2004 12/2004

11. Warranty

Hilti warrants that the product supplied is free of defects

in material and workmanship. This warranty is valid as

long as the product is operated and handled correctly,

cleaned and serviced properly and in accordance with

the Hilti operating instructions, all warranty claims made

within 6 months (machine) or 12 months (other items

of equipment) from the date of the sale (invoice date),

unless other mandatory national regulations prescribe

a longer minimum period, and the technical system is

maintained. This means that only genuine Hilti consumables, components and spare parts may be used

with the product.

This warranty provides the free-of-charge repair or

replacement of defective parts only. Parts requiring repair

or replacement as a result of normal wear and tear are

not covered by this warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular, Hilti is

not obligated for direct, indirect, incidental or consequential damages, losses or expenses in connection

with, or by reason of, the use of, or inability to use the

product for any purpose. Implied warranties of merchantability or fitness for a particular purpose are

specifically excluded.

Send the product and/or related parts immediately upon

discovery of a defect to the local Hilti marketing organization for repair or replacement.

This constitutes Hilti's entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

Page 20

Hilti Corporation

FL-9494 Schaan

Tel.: +423/ 234 2111

Fax: +423 /2342965

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 2936 0105 50-Pos. 1 1 Printed in Liechtenstein © 2005

Right of technical and programme changes reserved S. E. & O.

305560 / D

Loading...

Loading...