Page 1

DD-160 E

Diamond Core Coring System

Operating Instructions

2–8

Système de carottage au diamant

Mode d’emploi

9–15

Sistema de taladro con diamante

Manual de instrucciones

16–22

Sistema de perfuração com coroa diamantada

Manual de Instruções

23–29

*236036*

236036

Page 2

2

Safety precautions

Contents Page

1. DD-160 E

diamond coring system 2

2. DD-160 E

diamond coring rig 3

3. Safety 3

4. Technical data 4

5. Assembling the system

components 4

6. Selecting the method of

fastening the coring rig 5

7. Preparing the coring system

for use 5

8. Operating the system 8

9. Maintenance 8

10. Warranty 8

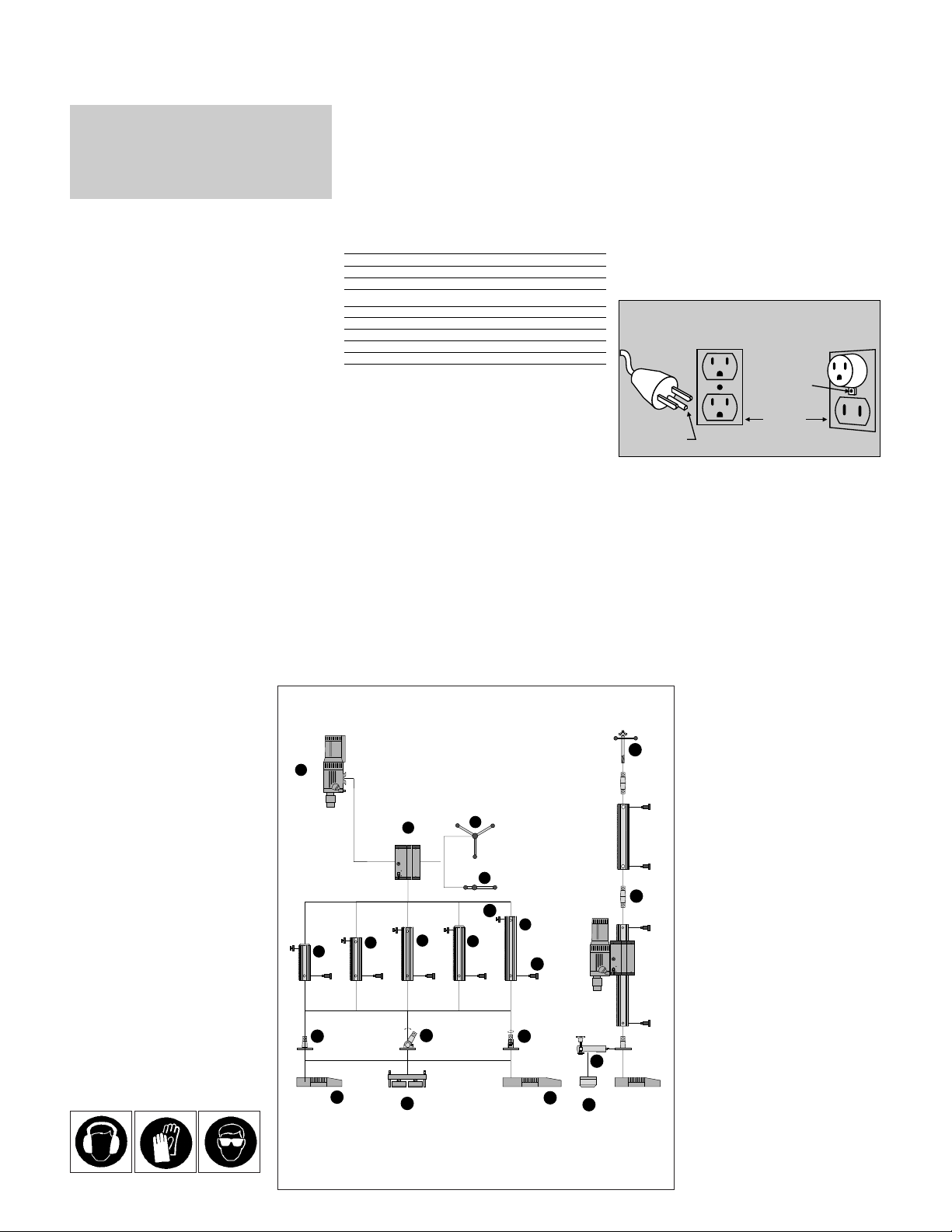

1. The DD-160 E diamond coringsystem

1.DD-160 E motor unit

2.DD-CA-S carriage

3.Handwheel DD-FH

1

/2’’

4.Ratchet

1

/2’’

5.DD-R 80-S rail

6.DD-R 100-S rail

7.DD-R 120-S rail

8.DD-R 65 F-S rail

9.DD-R 100 F-S rail

10.DD-CO-S taper

11.DD-EP-S eccentric pin

12.DD-SL-SML spindle

13.DD-CP-S stop

14.DD-BA-3 baseplate

15.DD-BAV-4 baseplate

16.DD-BV-P baseplate

17.DD-BCQ-S baseplate taper

18.DD-BCS-S baseplate taper

19.DD-BCR-S baseplate taper

20.DD-WC-SM water collector

21.DD-HSM-S holder

Do not use thisproduct in any

way other than asdirected by these

operating instructions.

Always wear ear

protectors.

Always wear

protective gloves.

Always wear safety

glasses.

for grounded tools

Read all instructions

Warning!

The following fundamental safety pr ecautions must

always be observed when using electric tools/machines

as protection against an electric shock, the risk of injury

and a fire hazard.Please readand takenote of these precautions before you use the tool/machine. Please read

and keep these safety precautions ina safe place!

1. Keep Work Area Clean. Cluttered areas and benches invite

injuries.

2. Consider Work Area Environment. Don’t expose power

tools to rain. Don’t usepowertoolsindamporwetlocations.Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

3. Guard Against Electric Shock. Prevent body contact with

grounded surfaces. For example; pipes, radiators, ranges, refrigerator enclosures.

4. Keep Children Away. Do not let visitors contact tool or extension cord. All visitors should be kept away from work area.

5. Store Idle Tools. When not in use, tools should be stored in

dry,and high or locked-up place – out of reach of children.

6. Don’t Force Tool. It will do the job better and safer at the rate

for which it was intended.

7. Use Right Tool. Don’t for ce small tool or attachment to do the

job of a heavy-duty tool. Don’t use tool forpurpose not intended –

for example – don’t use circular saw for cutting tree limbs or logs.

8. Dress Properly. Do not wear loose clothing or jewelry. They can

be caught in moving parts. Rubber gloves and non-skid footwear

are recommended when working outdoors. Wear protective hair

covering to contain long hair.

9. Use Safety Glasses. Also use face or dust mask if cutting operation is dusty.

10. Don’t Abuse Cord. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

11. Secure Work. Use clamps or a vise to hold work. It’s safer

than using your hand and it frees both hands to operate tool.

12. Don’t Overreach / Maintain Control. Keep proper footingand

balance at all times.

13. Maintain Tools With Care. Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect extension cords periodically and replace if damaged. Keep handles dry,

clean, and free from oil and grease.

14. Disconnect Tools. When not in use, before servicing and

when changing accessories, such as blades, bits, cutters.

15. Remove Adjusting Keys and Wrenches. Formhabit of checking to see that keys and adjusting wrenches are removed from tool

before turning it on.

16. Avoid Unintentional Starting. Don’t carry tool with finger on

switch. Be sure switch is off when plugging in.

16A. Extension Cords. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss

of power and overheating. The following table shows the correct

size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage

number,the heavler the cord.

Extension Cord Table

Volts TotalLengthofCordinFeet

120 V 0–25 26– 50 51–100 101–150

240 V 0–50 51–100 101–200 201–300

Ampere Rating AWG

More Than Not More Than

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Notrecommended

17. Outdoor Use Extension Cords. When tool is used outdoors,

use only extension cords intended for use outdoors and so

marked.

18. Stay Alert. Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

19. Check Damaged Parts. Before further useof the tool, aguard

or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center.Do not use tool if switch does not turn it on and off.

20. Only use accessories and attachments which are given in the

operating instructions or in the respective catalogue. The use of

accessories or insert tools or attachmentsother than those speci-

fied in the operating instructions can result in personal injury to

you.

21. Only have repairs carried out by recognized electrical specialists. This electric tool/machine complies with respective safety

regulations. Repairs may only be carried out by an electrical specialist otherwisean accident hazard for the operator can exist.

22. Wear ear protectors when using for extended periods.

23. Always use any supplied side handle, and keep it tightly

secured; use both hands during operation. Firmcontrol of the tool

is necessaryshould the tool bind.

24. Hold Tool by Handle(s) Provided. Do not touch uninsulated

parts of tool when drilling. Exposed metal surfaces may be made

live if the tool drills into electrical wiring.

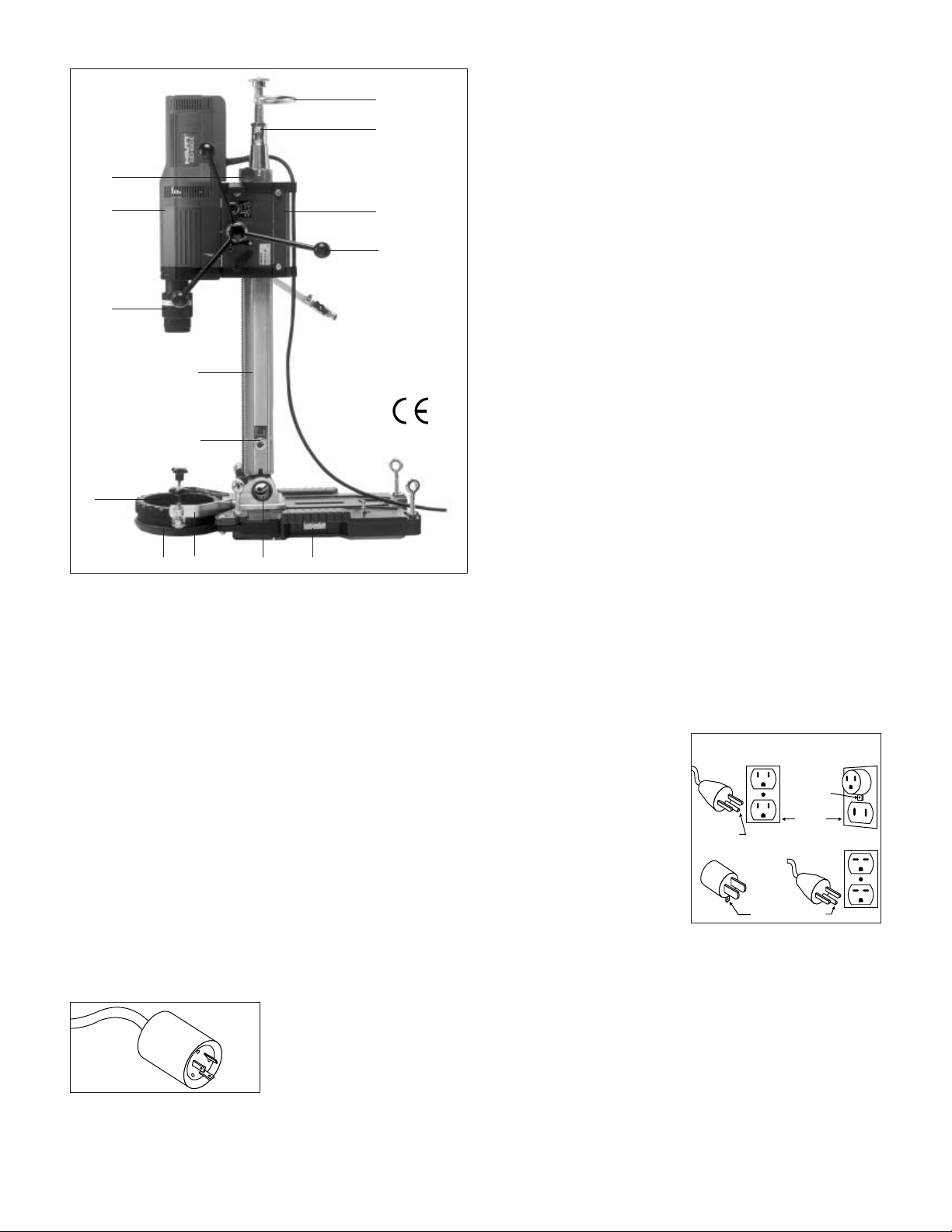

25. Grounding instructions. This tool should be grounded while in

use to protect the operator from electric shock. The tool is

equipped with a 3-conductor cord and 3-prong grounding type

plug to fit the proper grounding type receptacle. The green (or

green and yellow) conductor in the cord is the grounding wire.

Never connect the green (or green and yellow) wire to a live terminal. If your unit is for use on less than 150 V, it has a plug that

looks like that shown in sketch (A) in Figure «Grounding Methods». An adapter, see sketch (B), is available for connecting sketch

(A) type plugs to 2-prong receptacles. Thegreen-colored rigid ear,

lug, or the like, extending from the adapter must be connected in a

permanent ground, such as a properly grounded outlet box.

GROUNDING METHODS

metal screw

cover of grounded

grounding pin

26. Extension Cords. Use only 3-wire extension cords that have 3prong grounding-type plugs and 3-pole receptacles that accept the

tool’splug. Replace or repair damaged cords.

27. Replacement parts. When servicing use only identical

replacement parts.

Save these instructions.

(A)

outlet box

(B)

1

DD-160-E

2

DD-CA-S

DD-R 100-S

DD-BV-P

16

6

18

8

DD-R 65F-S

17

DD-BCQ-S DD-BCS-S DD-BCR-S DD-BCQ-S

DD-BA-3 DD-BAV-4

5

DD-R 80-S

14

DD-R 100F-S

3

DD-CP-S

9

12

4

13

7

11

DD-R 120-S

DD-EP-S

19

DD-HSM-S

10

DD-CO-S

DD-CA-S

21

DD-WC-SM

15

20

DD-BA-3

Page 3

3

2. DD-160 E diamondcoring rig

1.DD-160 E motor unit

2.DD-C-BU chuck

3.DD-CA-S carriage

4.DD-FH

1

/2” handwheel

5.DD-R 100-S rail

6.DD-CO-S taper

7 .DD-SL-SML spindle

8.DD-CP-S stop

9.DD-EP-S eccentric pin

10.DD-BCS-S baseplate taper

11.DD-BAV-4 baseplate

12.DD-HSM-S holder

13.DD-WC-SM water collector

14.DD-SW-SM sealing disc

3. Safety

3.1 Safety precautions onthe jobsite

Before beginning work withthe coring

system, read the operatinginstructions carefully and ensurethat the

safety precautions listed beloware

observed.

Please also note thatpermission to

begin coring work mustbe obtained

from the site engineeror other authorised person.

■ Ensure that no electriccables, gas

or water pipes etc.are situated

where holes are tobe drilled.

■ Cables, pipes or othersupply lines

situated in close proximityto where

holes are to bedrilled must be

switched off.

■ The coring work mustnot have a

negative effect on thestructural design of the building(coring through

steel reinforcement!).

■ Cordon off areas wherecoring work

is taking place, particularlybehind/

below walls or ceilingswhich are

being drilled through.

■ Wear a helmet, safetyshoes, gloves

and ear protectors.

■ Tidiness and good organisation

on the jobsite helpto prevent accidents.

■ Use only original Hilti parts.

■ Protect the motor unitfrom water

spray and rain.

■ For overhead coring, thewater col-

lector and water removalsystem

must be in goodorder and function

correctly.

쐃

쐇

쐄

쐎

쐉씈쐈쐅

쐊

쐏

쐋

쐂

쐆

씉

3.2a Grounding instructions

This tool should begrounded while

in use to helpprotect the operator

from electric shock. Thetool is equipped with a 3-conductorcord and

3-prong grounding type plugto fit the

proper grounding type receptacle.The

green (or green andyellow) conductor

in the cord isthe grounding wire.Never connect the green(or green and

yellow) wire to alive terminal.

If your unit isfor use onless than

150V, it hasa plug thatlooks likethat

shown in sketch (A)in Figure 1.If itis

for use on 150to 250 V,it hasa plug

that looks like thatshown in sketch

(D). An adapter, seesketches (B) and

(C), is available forconnecting sketch

(A) type plugs to2-prong receptacles.

The greencolored rigid ear,lug, or the

like, extending from theadapter must

be connected to apermanent ground,

3.2b Extension Cords

Use only 3-wire extension cords that

have 3-prong grounding-type plugs and

3-pole receptacles that accept the tool’s

plug. Replace or repair damaged cords.

such as a properlygrounded outlet

box. No adapter isavailable for aplug

as shown in sketch(D).

metal screw

cover of grounded

outlet box

grounding pin

grounding

means

grounding pin

GROUNDING METHODS

(A)

(B)

(C) (D)

For the DD-160Ea20Aplug is

demanded that looks likethat shown

in Figure 2.

Figure 2

Figure 1

■ The coring system mustonly be

operated with the built-inGFCI

ground fault circuit interruptor.

■ In order to ensuresafe, trouble-free

operation, the drilling systemmust

be kept clean.

(Do not clean usinga jet ofwater.)

■ Drilling work should onlybe carried

out by trained personnel.

■ When working with thevacuum

baseplate on walls anadditional

means of securing therig must be

employed (see section 7.2).

■ If leakage occurs inthe water

supply system, the equipmentmust

be serviced.

■ Do not touch rotating parts.

3.2 Electrical safety

The GFCI ground faultcircuit interruptor protects the operatorin case of

faults in the insulationof the motorunit

or supply cord (betweenthe GFCI and

the motor unit). Thisdevice also prevents the machine fromrestarting on

its own accord whenpower returns

after an interruption inthe power supply. The earth/ground connectionprotects the operator fromdangerously

high voltages in caseof coring intolive

cables. The protective functionof the

ground fault interrupter mustbe

checked at regular intervalsin accordance with regulations issuedby

national authorities (see section7.17).

3.3 Overload protection

Hilti diamond coring systemsare

equipped with mechanical, electronic

and thermal overload protectiondevices.

Mechanical clutch:

Protects the operator, motorand core

bit in case thecore bit suddenlysticks.

Electronic protection:

In case of overloadingcaused by

excessive coring feed pressure,motor

current is reduced automaticallyso

that the core bitthen only rotates

slowly. Motor current returnsto normal when coring feedpressure is

reduced, and the motorthen continues to run atfull power.

Protection against overheating:

The motor is protectedagainst overheating by a sensorwhich auto-matically reduces current inputin case of

sustained overloading and athigh

ambient temperatures. The machine

can be operated normallyafter the

temperature of the motorwindings

has dropped to asatisfactory level.

The motor windings canbe cooled

more quickly by allowingthe motor to

run without load.

Page 4

4

3.4 Instructions andprecautions for overhead coring

When coring overhead, forsafety

reasons, the following equipment

must be used:

1 .Baseplate, fastened tothe ceiling

using an HDI

1

/2˝ anchor.

2.Water collector complete with

appropriate sealing disc.

3.Hose strain-relief clamp.

4.Water removal hose.

5.Adaptor for vacuum cleaner.

6.6 mA GFCI groundfault circuit

interruptor

(integral part of supplycord).

7.Supply cord with earth/ground

conductor.

8.Vacuum cleaner suitable forwet

materials.

9.Three-way water connection.

10.Rail stop

Turn off the watersupply and drainthe

water from the corebit at thethreeway water connector beforewithdrawing the core bit.

Note: The life ofthe sealing discscan

be extended by applyinga little grease

(e.g. bearing grease) orHilti lubricant

spray.

4.Technical data

Voltage 115 V 230 V

Current input 18 A 9A

Power input 2000 W 2000 W

Frequency 50/60 Hz

Core bit diameter range 25 – 162 mm

Core bit diameter range: Speeds (no load):

1st speed: 500 r.p.m. 92 – 162mm dia.(3

5

/9”–63/8”)

2ndspeed: 1000 r.p.m. 40 – 102 mm dia.(1

1

/2” – 4”)

3rd speed: 2000 r.p.m. 25 – 52mm dia.(1” – 2”)

Weight (motor unit) 11.5 kg

Length of supply cord 5metres

Chuck DD-C-BU quick-release chuck

Electronic idling speed regulator

Overload current regulator

Optical service indicator

Built-in starting current regulator

Thermal motor overload protection

Mechanical slip clutch

Protection class I, withinternal class IIdesign (mainssupply with earth/ ground

connection required)

Ground fault circuit interruptor(GFCI) 6 mA 30 mA

Zero-voltage trip

Approved as per IEC1029

Noise and vibration

TechnicalA-weighted noiselevels of themachineare:

– Noise (pressure) level 89 dB (A)

– Noise (power) level 102 dB(A)

Ear protection must beworn.

Typical exposure of thehand/arm to vibrationis lessthan 2.5 m/s

2

.

Right of technical modificationsreserved.

5. Assembling the system components

5.1 Mounting thebaseplate taper on the baseplate

1. Baseplate

2. Baseplate taper

3. Mounting screws (4)

4. Wrench (supplied withthe

baseplate)

5.2 Fitting thewheel assembly to the baseplate

1. Baseplate

2. Wheel

3. Screw

4. 19 mm AFwrench

5.4 Changing thechuck

1. Drive shaft

2. Chuck

3. Screws (2)

4. 6 mmAF wrench

(supplied with the chuck)

5.3 Fitting thewater collector holder to thebaseplate taper

1. Baseplate taper

2. Holder

3. Screw

4. 8 mmAF wrench

(supplied with the holder)

This Product is UL listed and CSA certified

R

3

2

1

4

7

5

8

6

10

9

2

1

3

4

1

3

2

4

4

3

2

1

1

4

O

P

E

N

3

E

S

O

L

C

2

Page 5

5

6. Selecting the method offastening the coringrig

6.1 Anchor fastening

– Secure method of fasteningfor high

coring performance

– Versatile method

(Suitable for use onwall, ceiling

or floor)

– Can also be usedon unevenand

rough surfaces

Caution: The coring system must not

be operated before the rig hasbeen

secured rigidly in position!

6.3 Braching usingthe guide rail

– Quick method

– No need to drillanchor holes

– Very rigid

– Can be used inaddition toanchor

fastening or with thevacuum baseplate

Bracing using the guiderail is notsuitable for overhead applications.

Caution: The coring system must not

be operated before the rig hasbeen

secured rigidly in position!

– Quick method

– No need to drill anchorholes

Caution: Must be securedadditionally

for wall applications withchain, rope,

brace or support tosupport a loadof

at least 400 kg.

For ceiling applications isthe use ofa

vacuum baseplate not allowed.

The coring system mustnot be

assembled or operated beforethe rig

has been rigidly securedin position.

6.2 Fastening the unitusing the vacuumbaseplate

6.4 Bracing using thequick-release column

– Quick and simple method

– No need to drill anchorholes

– Can be used in additionto anchor

fastening and with thevacuum

baseplate

Bracing using the quick-releasecolumn is not suitablefor overhead applications.

Caution: The coring systemmust

not be operated beforethe righ has

been secured rigidly inposition!

7. Preparing thecoring system for use

7.1 Fastening the baseplate using ananchor andbracing spindle

7.1a Fasteningthe baseplateusing an anchorand bracingspindle

(continued)

1 .Tighten the levelling screws(in diag-

onal sequence) until thebaseplate

stands rigidly and securely.

7.2 Securing the vacuum baseplate

1. Vacuum pump

2. Vacuum connection

3. Vacuum plate

4. Hand grips

5. Release valve

6. Centre indicator

7. Vacuum gauge

(indicator must remain withingreen

area while baseplate isin use)

8. Levelling screws

9. Securing chain,rope, brace or

support (see section 6.2.)

Raise the levelling screwsand check

the seal for damagebefore positioning

the vacuum baseplate.

7.2a Securingthe vacuumbaseplate (continued)

1. After applyingthe vacuum, tighten

the levelling screws byhand, as far

as they will go,following a diagonal

sequence.

1. HDI1/2˝ internally-threaded

anchor (in concrete)

2. Bracing spindle

3. Baseplate

4. Hole-centre indicator

5. Bracing spindlenut

6. Open-end wrench

The coring rig ismost stable whenthe

anchor is positioned atthe front endof

the anchor slot (closestto column).

Recommended distance from anchor

to hole centre -approx. 300 mm.

Raise the levelling screwsbefore positioning the baseplate.

3

2

1

4

5

6

1

9

7

4

5

3

6

2

8 1

Page 6

6

7.3 Bracing the baseplate using thequick-release column

1. Baseplate

2. Quick-release column

3. Telescopie column

4. Bracing mechanism

7.4 Mounting a rail on thebaseplate

1. Connecting taper

2. Rail

3. Eccentric pin

4. Wrench

7.5 Mounting the carriage on therail

1. Carriage

2. Rail

3. Feed movementlocking device

The feed movement lockingdevice

must face the directionof coring.

7.6 Fittingthe stopon the rail

1. Rail

2. Steel bar

3. Engaging teeth

4. Clamping screw

The use of astop is mandatoryfor

coring overhead and onwalls.

7.7 Adjustingthe railangle

1. Baseplate

2. Baseplate taperfor angular coring

3. Clamping screw

4. Wrench

Secure the rig sothat it cannotfall

before releasing the clampingscrew.

Angular coring in anupwards direction

is not permitted (watercollector does

not function correctly).

7.8 Extending theguide rail

1. Rail

2. Rail extension

3. Taper

4. Eccentric pins(2)

5. Wrench

7.9 Fitting the bracing spindle

1. Rail

2. Eccentric pin

3. Wrench

4. Taper

5. Spindle

6. Locking nut

7.10 Mounting the motor unit on thecarriage

1. Motor unit

2. Motor unit mount

3. Carriage

4. Mounting surface

5. Eccentric clampingpin

6. Wrench

7. Supply cordsupport

8. Water hosesupport

Caution: Do not pinchthe supply

cord!

Removing the motor unit:Hold the

motor to prevent itfrom falling when

the eccentric clamping pinis pulled

out.

3

4

2

4

3

2

1

1

3

2

2

1

3 4

1

45˚

2

4

3

1

5

6

4

1

2

3

2

4

3

5

1

2

4

1

7

3

5

6

8

Page 7

7

7.11 Fitting the handwheel

1. Carriage

2. Connecting boss

3. Handwheel

4. Clamping screw

The handwheel can befitted on either

side.

7.12 Fitting a core bit

1. Chuck

2. Connection end

3. Core bit

4. Locking sleeve

5. Motor unit

7.13 Releasing a core bit

1. Chuck

2. Core bit

3. Locking sleeve

Hold the core bitbefore disengaging

the chuck.

When releasing the corebit, ensure

that the core doesnot fall outaccidentally.

After overhead coring, drainthe core

bit through the watersupply hose

before releasing it fromthe chuck (see

section 3.4).

7.14 Inserting a sealing disc in thewater collector

1. Water collector

2. Sealing disc

(select correct diameter)

3. Clamping ring

4. Hose connection

5. Sealing ring

6. Water removalhose

A water removal systemand a sealing

disc in new conditionmust always be

used for overhead coring.

Sealing discs of thecorrect diameter

are available from yourlocal Hilti

centre or representative.

7.15 Fitting the water collector

1. Baseplate

2. Water collector holder

3. Water collector

4. Clamping screws

Use the core bitto centre thewater

collector and then tightenthe clamping screws evenly.

Use of the watercollector is mandatory for overhead coringand recommended for all othercoring positions.

7.16 Connecting the water supply

1. Carriage

2. Hose support

3. Water hose

4. Water regulationvalve

5. Hose connector

6. External watersupply

The water supply pressuremust not

exceed 10 bar.

7.17 Connecting to the mains supply

(Mains socket with earth/ ground connectionrequired)

1. Plug – typedepends on country

2. GFCI groundfault circuit interruptor

3. ON-switch forGFCI

4. Test button

5. Indicator

6. Supply cord

7. Motor unitON / OFFswitch

The GFCI must betested for correct

operation each time beforebeginning

work.

1. Check that themotor is switched off.

2. Connectthe plug to the mains supply.

3. Press theON button. Thelamp

must light!

4. Press theTEST button. Thelamp

must extinguish!

5. Press theON button againbefore

beginning operation.

In the case ofa malfunction (test

failed), the unit mustbe checked by

an electrical specialist beforework

with the equipment continues!

After every fault orinterruption in the

mains supply, switch offthe motor unit

before resetting the GFCIinterruptor.

1

2

3

4

5

1

4

2

3

O

S

P

O

E

L

N

C

1

2

1

E

3

2

4

56

3

2

1

3

4

1

2

3

4

5

6

7

6

3

5

2

4

1

6

Page 8

8

8. Operation

1. Select thecorrect coring speed.

(Change speed only whenrotation

has stopped.)

2. Release thefeed movement locking

device.

3. Guide thecore bit intothe water

collector.

4. Open thewater supply valve.

5. Switch onthe motor.

(When using a vacuumbaseplate,

ensure that the vacuumindicator

remains within the greenarea.)

■ Reduce feed pressure whenstart-

ing holes in orderto avoid vibration.

■ If steel reinforcement iscontacted,

select lower coring speedif possible and reduce waterflow.

(Obtain permission from anauthorised person before cuttingthrough

steel reinforcement.)

■ The diamond segments canbe-

come polished (reduced cutting

performance) if coring feedpressure is too lowor if thewater flow

rate is excessive.

■ Insufficient water will causeover-

heating, resulting in seriousdamage to the corebit.

■ Reduce coring feed pressureif

the overload current regulatoris

activated.

■ Water flow rates

8 – 47mm dia. max. 1–1.5 l/min.

52 –132 mmdia. max.3 l/min.

142 –162 mmdia. max. 4l/min.

9 Maintenance

9.1 In orderto ensure trouble-free operation, thefollowing points must be

observed:

1 Motor unit

■ Keep the chuck cleanand well

lubricated.

■ Keep the ventilation slotsin the

motor housing free ofdirt and dust.

■ If the service indiciatorlights, the

carbon brushes must bereplaced

by a trained specialistas soon as

possible.

■ Check the system regularlyfor

water leakage.

2 Carriage

■ The guide rollers requireno mainte-

nance.

■ Keep the motor unitmounting sur-

face clean.

■ If movement is tooeasy, the guide

rollers should be adjustedby a

trained specialist.

3 Rails

■ Keep the rails clean

■ Internal tapers must bekept clean

and lightly oiled.

4 Baseplate

■ With the exception ofthe seals, the

baseplates require no maintenance.

9.2 Wearing parts

■ Seals for the DD-BAV-4and

DD-BV-P vacuum baseplates

■ Sealing discs for theDD-WC-SM

water collector

■ Sealing ring for theDD-WC-SM

water collector

Sealing discs of thecorrect diameter

are available from yourlocal Hilti centre or representative.

In case of technicalproblems

please contact the Hilticustomer

service department.

Tips

➌

➎

➌➍➊

➋

10. Warranty

Hilti warrants that the tool supplied is

free of defects in material and workmanship. This warranty is valid so

long as the tool is operated and handled correctly, cleaned and serviced

properly and in accordance with the

Hilti Operating Instructions, all warranty claims are made within

6 months for the motor unit and

1year for additional equipment and

accessories from the date of the sale

(invoice date), and the technical system is maintained. This means that

only original Hilti consumables, components and spare parts may be

used in the tool.

This warranty provides thefree-ofcharge repair or replacementof defective parts only. Partsrequiring repair or

replacement as a resultof normal

wear and tear arenot covered bythis

warranty.

Additional claims are excluded,

unless stringent national rulesprohibit such exclusion. Inparticular,

Hilti is not obligatedfor direct, indirect, incidental or consequential

damages, losses or expensesin

connection with, or byreason of,

the use of, orinability to usethe tool

for any purpose. Impliedwarranties

of merchantability or fitness for a

particular purpose are specifically

excluded.

For repair or replacement,send tool

and/or related parts immediatelyupon

discovery of the defectto the address

of the local Hiltimarketing organization

provided.

This constitutes Hilti’s entireobligation

with regard to warrantyand supersedes all prior orcontemporaneous

comments and oral orwritten agreements concerning warranties.

Page 9

USA

Hilti, Inc.

5400 South 122

nd

East Avenue

Tulsa, Oklahoma 74146

Telephone (918)252-6000

CANADA

Hilti (Canada) Limited /Limitée

6790 Century Avenue, Suite300

CDN - Mississauga, OntarioL5N2V8

Telphone (905) 8139200

LATIN AMERICA

Hilti Latin America, Ltd.

5400 South 122

nd

East Avenue

P.O. Box 21148

Tulsa, Oklahoma 74146

Telephone (918)252-6595

Hilti = registered trademark of Hilti Corp., Schaan W 1950 0802 10-Pos. 3 1 Printed in Liechtenstein © 2002

Right of technical and programme changes reserved S.E.&O.

236036/F

Loading...

Loading...