Page 1

DD130

Bedienungsanleitung 1–12

Operating instructions 13–24

*370458*

370458

D

GB

F

I

NL

P

E

DK

SF

N

S

TR

EST

LV

LT

Page 2

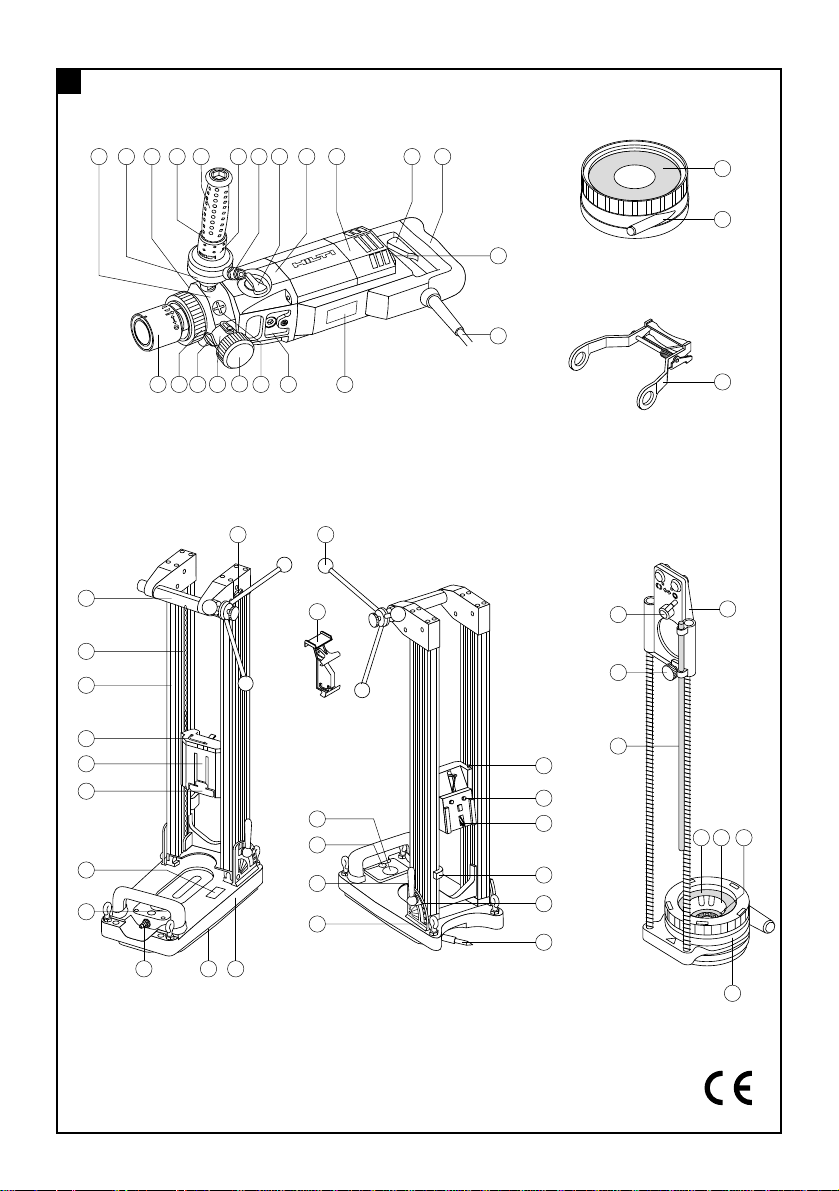

35

39

34

3231 33

53 52 51

50

38

37

40

36

28

29

27

25

26

24

23

30

41

42

43

46

57

56

55

54

45

44

47

48

49

DD 130

12

13

14

113

15

1617

18

21 1922

1098652 41 7

20

1

Page 3

DD 130

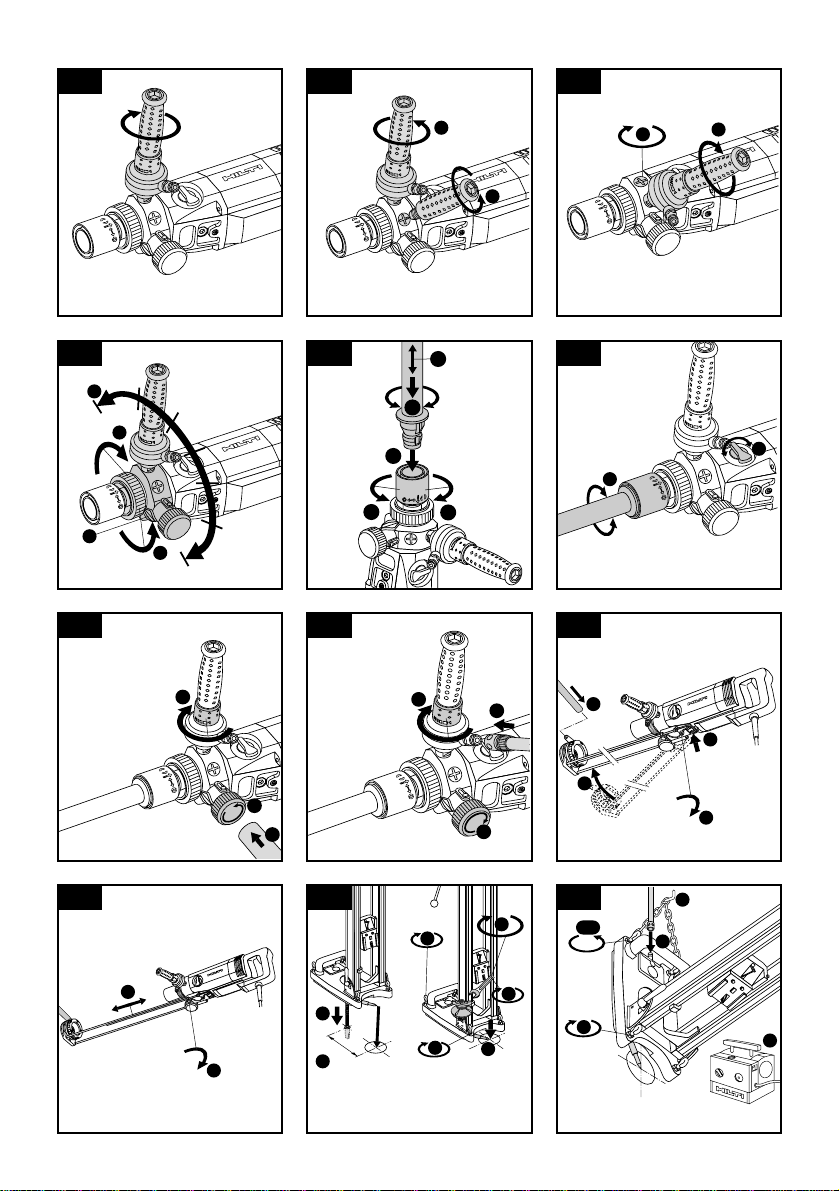

6.1.1

DD 130

1

4

3

2

15∞

15∞

15∞

15∞

15∞

15∞

6.1.3

1

2

3

6.4.1

DD 130

1

2

6.6.2

DD 130

1

1

6.1.2

1

4

2

5

3

6.2

2

3

1

6.5.1

1

2

4

3

7

5

6

6.7.1

DD 130

2

3

6.1.2

1

1

6.3

DD 130

4

1

3

2

6.6.1

2

6

3

1,4

5

6.7.2

Page 4

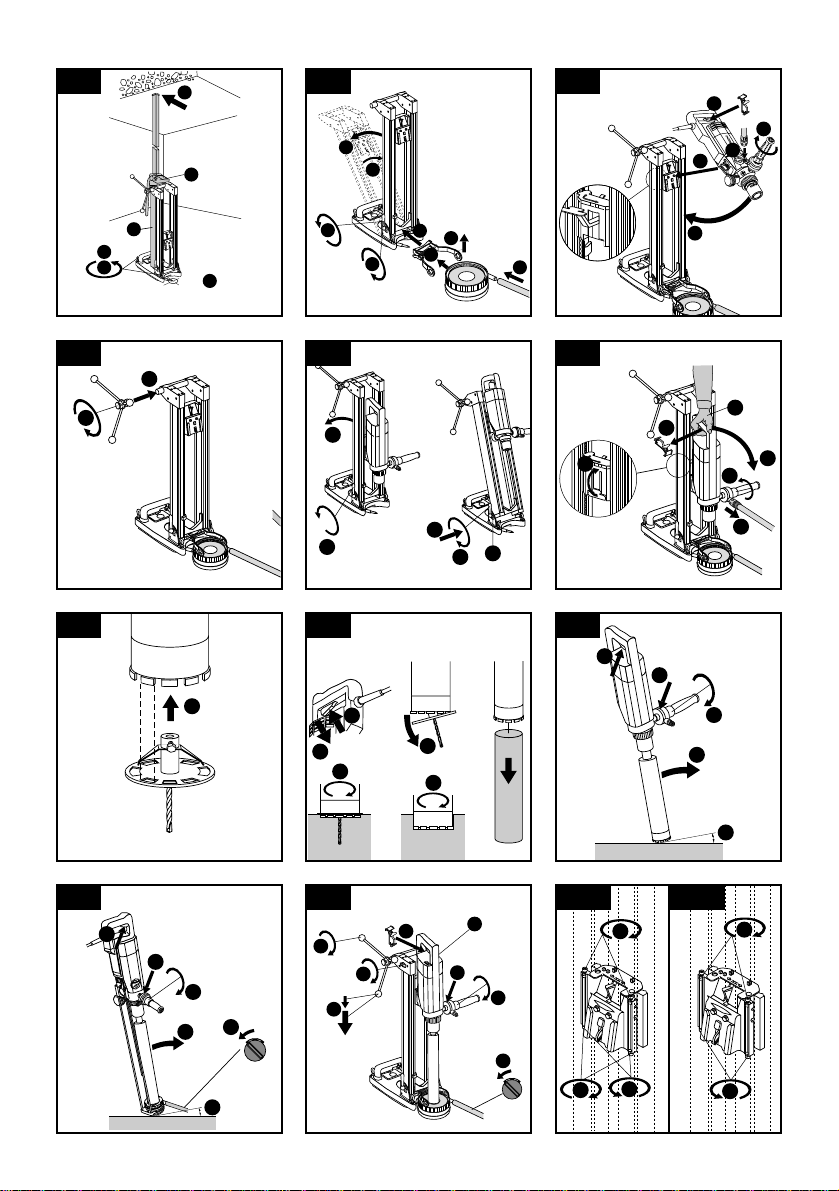

1

2

6

4

5

3

6.7.3

1

2

6.10

1

7.2.1

1

5

4

90˚

0

1

2

2

3

7.4

1

5

2

4

3

6

6

7

6.8

4

5

3

1

2

6.11

1

2

4

3

4

7.2.2

1

0

1

2

3

7

2

4

5

6

7.5

1

DD 130

2

3

5

4

6.9

2

3

4

5

4

1

6.12

3

4

1

1

90˚

2

7.3

3

2

1

2

1

8.5.1.1

2

1

8.5.1.2

Page 5

13

It is essential that the operating

instructions are read before the

tool is operated for the first time.

Always keep these operating

instructions together with the tool.

Ensure that the operating instructions are with the tool when it is

given to other persons.

Contents Page

1. General information 14

2. Description 14

3. Tools and accessories 14

4. Technical data 15

5. Safety precautions 15

6. Before use 17

7. Operation 20

8. Care and maintenance 21

9. Troubleshooting 22

10. Disposal 23

11. Warranty 23

12. Declaration of conformity see cover

DD1 30 diamond core drilling machine

Parts of the DD130

Core drilling machine

Water swivel / extraction head

Water flow indicator

Level indicator

Screwdriver (side handle)

Side handle

Water flow regulator

Water hose connector

Gear selector

Gearing section

Motor

On / off switch

Grip

Overload indicator

Supply cord with PRCD

Rating plate

Interface plate

Screw plugs (water swivel / extraction head)

Cover (water swivel / extraction head)

Extraction connector

Water swivel lock

Locking ring (water swivel / extraction head)

Chuck

Drill stand

Grip

Chain

Columns

Hex. wrench

Carriage

Release lever

Specification plate

Vacuum release valve

Vacuum hose connector

Vacuum pad

Baseplate

Chain arrestor

Hand wheel

On / off switch lock

Pressure gauge

Level indicator

Adjusting lever

Levelling screws

Hole centre indicator

Locating lugs

Depth gauge

Locking mechanism

Mounting pins

Chain tensioner

Water collector for hand-held use

Securing knob

Clamping screw

Depth gauge

Water collector cup

Centring ring

Centring ring adaptor

Seal

Mounting plate

Water collector for use with the drill stand

Holder

Water collector cup

Seal

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

Page 6

14

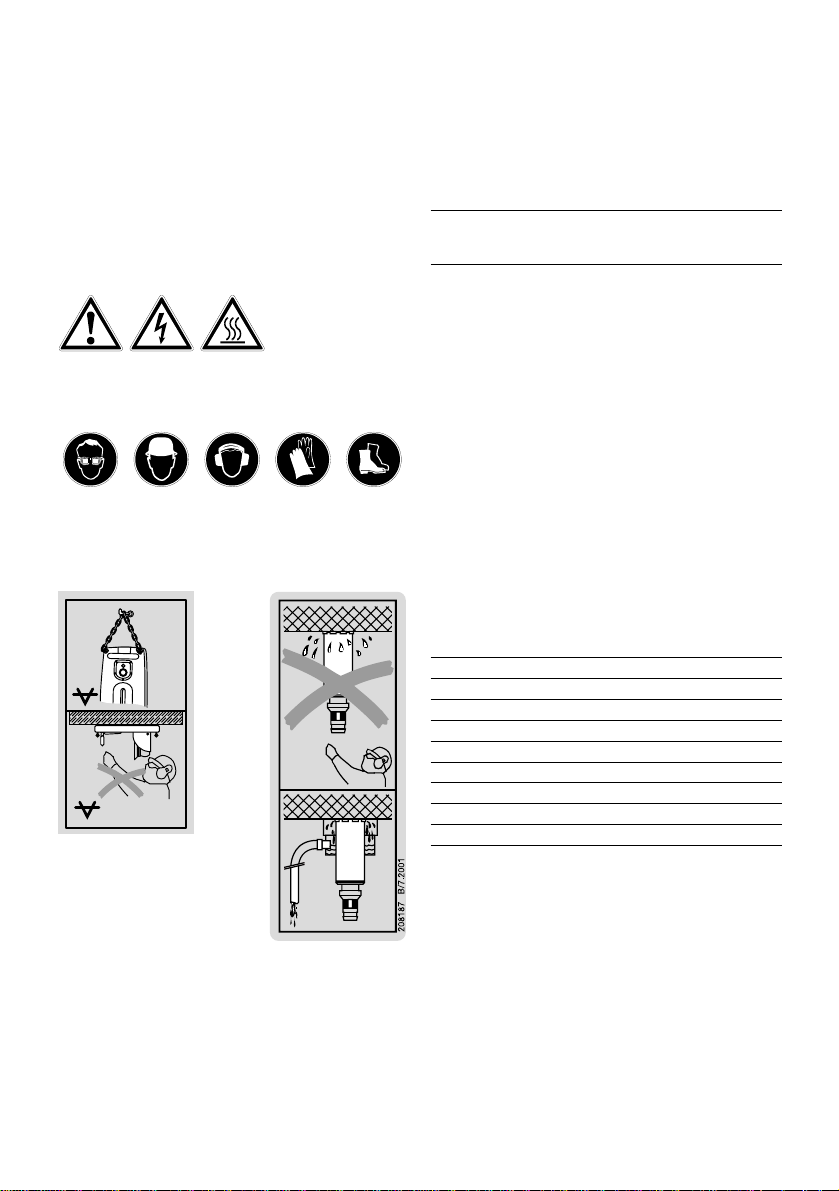

General

warning

Warning:

electricity

Warning: hot

surface

Obligation signs

Symbols

On the drill stand On the tool

Wear eye

protection

Wear a safety

helmet

Wear ear

protection

Wear safety

gloves

Wear safety

boots

1. General information

1.1 Indication of danger

-CAUTION-

Used to draw attention to a potentially dangerous situation which could lead to minor personal injury or damage to the equipment or other property when the given

safety precautions are not observed.

1.2 Pictograms

Warning signs

VACUUM

VACUUM

Top

An additional means of securing the drill stand must be

employed when used for horizontal drilling with vacuum

attachment.

Bottom

The drill stand must be fastened by means of an anchor

or quick-release brace when

used for overhead drilling.

Use of the water collector

system in conjunction with a

wet-type vacuum cleaner is

mandatory when working

overhead on ceilings.

Location of identification data on the tool

The type designation and serial number can be found

on the rating plate on the tool. Make a note of this data

in your operating instructions and always refer to it when

making an enquiry to your Hilti representative or service department.

Type: DD130

Serial no.:

2. Description

The DD 130 is an electrically powered diamond core

drilling machine designed for hand-held use or for mounting on a drill stand. It is suitable for wet or dry core

drilling.

Items supplied

The items supplied are: core drilling machine and operating instructions.

3. Accessories

Designation Item no.

Vacuum pump 47034

Quick-release brace 9870

Water collector system for hand-held use 370462

Water collector system for drill stand use 370460

Drill stand 370461

Wheel assembly 232228

DD-CS M12S-SM clamping spindle 251830

DD-CN SML clamping nut 251834

These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover pages. Keep these pages open while studying the

operating instructions.

In these operating instructions, the DD 130 core drilling

machine is referred to as "the tool".

Page 7

15

4. T echnical data

Nominal voltage: * 110 V 120 V 220 V 230 V 240 V

Nominal power: 1700 W 1800 W 1900 W 1900 W 1900 W

Nominal current: * 16 A 15 A 9.1 A 8.7 A 8.3 A

Frequency 50/60 Hz 50/60 Hz 50/60Hz 50/60Hz 50/60Hz

Nominal no-load speed 1

st

gear 780 r.p.m.

2

nd

gear 1400 r.p.m.

3

rd

gear 2600 r.p.m.

(Change gear only when rotation has stopped.)

Max. permissible water supply pressure: 6 bar (In the event of higher water pressure, a

pressure reduction valve must be fitted at the building

site connection.)

Dimensions (L×W×H): 515×114×170 mm

Weight (basic tool): approx. 7.1 kg

Radio and television interference suppression as per EN 55014-1

Interference immunity: as per EN 55014-2

Protection class as per EN 50144 and IEC 60745: Protection class I (earthed)

Drilling depth: max. 430 mm (730 mm with extension)

Noise and vibration information (measured in accordance with EN 50144):

Typical A-weighted noise power level (L wA): 89 dB (A)

Typical A-weighted noise emission pressure level (LpA): 102 dB (A)

Wear ear protection!

Typical weighted vibration at the grips: < 2.5 m/s

2

Information for the user in accordance with EN 61000-3-11:

Switching on the tool may cause a brief voltage drop. Under unfavourable conditions in the mains supply, this

may cause interference to other appliances. No interference is to be expected when the mains supply has an

impedance of < 0.15 ohms.

* The tool is available in versions for various nominal voltages. Please refer to the rating plate for information on

the nominal voltage and nominal current rating of the applicable tool.

Right of technical changes reserved

5. Safety precautions

5.1 Basic safety information

In addition to the safety precautions listed in the individual sections of these operating instructions, the following

points must be strictly observed at all times:

5.2 Use as intended

The DD 130 is designed for drilling through holes and blind holes in mineral materials.

Applications:

With / without drill stand Core bit diameter Drilling direction

Hand-held / dry With dust extraction, 12–162 mm dia. All directions

Hand-held / wet Without water collection system, 12– 62 mm dia. Not upwards

Hand-held / wet With water collection system, 12– 62 mm dia. All directions

Drill stand / wet Without water collection system, 12–152 mm dia. Not upwards

Drill stand / wet With water collection system 12–132 mm dia. All directions

When drilling in an upwards direction, a wet-type vacuum cleaner must be connected to the water collection system.

16

Page 8

5.3 Avoiding incorrect use

● Horizontal drilling with vacuum attachment is permissible only when an additional means of securing the

drill stand is employed. The drill stand may be used for

overhead drilling only when fastened by an anchor or

by means of a quick-release brace.

●Drilling into materials containing asbestos is not permissible.

●Changes or modifications to the tool are not permissible.

●To avoid the risk of injury , use only original Hilti accessories and additional equipment.

● Observe the information printed in the operating

instructions concerning operation, care and maintenance.

5.4 State of the art

●The tool is designed and manufactured according to

the state of the art.

●The tool and its accessories may, nevertheless, present hazards when used incorrectly by untrained personnel or when used not as directed.

5.5 Proper arrangement and organisation of the workplace

● Do not wear loose clothing, loose long hair or jewellery which could become caught up in moving parts.

Wear a hair net if you have long hair.

●Wear non-slip safety boots or shoes and always work

from a secure stance.

●Do not work from a ladder.

●Avoid unfavourable body positions.

●Do not expose the tool to rain or snow and do not use

it in damp or wet areas or where there is a risk of fire or

explosion.

●Ensure that the workplace is well lit.

●Objects which could cause injury should be removed

from the working area.

●Always lead the supply cord, extension cord and extraction hose away to the rear of the tool (away from rotating parts) when working.

●Take care to avoid tripping over the supply cord, exten sion cord or extraction hose.

●Keep other persons, children in particular, outside the

area affected while you are working.

●Concealed electric cables or gas and water pipes present a serious hazard if damaged while you are working. Accordingly, check the area in which you were working beforehand (e.g. using a metal detector). External

metal parts of the tool may become live, for example,

when an electric cable is drilled into inadvertently .

●Avoid contact between your body and earthed / grounded objects such as pipes or radiators.

● When drilling holes through ceilings or floors from

above, secure the area below as the core may fall out,

presenting a risk of injury or damage.

5.6 General safety precautions

●Operate the tool only as directed and only when it is

in faultless condition.

●Use a vice or clamp to secure loose workpieces.

● The tool may be operated only when held in both

hands or when mounted on the drill stand.

●Keep the grips dry, clean and free from oil and grease.

●Never leave the tool unsupervised.

●Ensure that the tool is switched off (remove the switch

lock insert) before switching on at the PRCD (ground

fault interrupter).

●Test the PRCD each time before use (see 7.1).

● Do not keep your finger on the on / off switch while

carrying the tool when connected to the mains supply.

●Disconnect the supply cord plug from the socket when

the tool is not in use (e.g. during breaks), before main-

tenance and before changing core bits.

●When not in use, the tool must be stored in a dry place,

locked up or out of reach of children.

●Avoid skin contact with drilling slurry.

5.6.1 Mechanical hazards

●Observe the instructions concerning care and main-

tenance and the replacement of core bits in good time.

●Ensure that core bits used are equipped with the cor-

rect connection end system and properly fitted and

secured in the chuck (see section 6.2).

●Always use the side handle for hand-held operation.

Ensure that it is fitted correctly and properly secured

(see 6.1.1 and 6.1.2).

● Ensure that the water swivel / extraction head (side

handle mount) is properly secured in position and that

the locking ring is tightened (see 6.1.3).

●Ensure that the tool is securely attached when mount-

ed on the drill stand (see 6.9).

●Do not touch rotating parts.

5.6.2 Electrical hazards

● Check the condition of the tool including the supply

cord and extension cord as well as the plug connections.

Do not operate the tool if damage is found, if the tool is

not complete or if its controls cannot be operated faultlessly.

●Never carry the tool by the supply cord.

●Grip the plug and not the cable when pulling it out of

the socket.

● Do not expose the supply cord to heat, oil or sharp

edges.

● Do not touch the supply cord in the event of it suf-

fering damage while working. Disconnect the supply

cord plug from the socket.

Page 9

17

- CAUTION-

■ The tool, the diamond core bit and the

drill stand are heavy.

■ There is a risk of pinching parts of the

body.

■ Wear a safety helmet, safety gloves and

safety boots.

●When working outdoors, use only extensin cords that

are approved and correspondingly marked for this application.

●Do not touch the supply cord in the event of it becoming damaged while working. Disconnect the supply cord

plug from the socket.

● Do not operate the tool when it is dirty or wet. Dust

or dampness on the surface of the tool make it more difficult to hold and, under unfavourable conditions, may

lead to electric shocks.

5.6.3 Thermal hazards

●The core bit may become hot during use. Wear safety gloves when changing core bits.

5.7 Requirements to be met by users

●The tool is intended for professional use.

●The tool may be operated, serviced and repaired only

by authorised, trained personnel. This personnel must

be informed of any special hazards that may be encountered.

● Always concentrate on the job you are doing. Proceed carefully and do not use the tool if your full attention is not on the job.

5.8 Personal protective equipment

The user and any other persons in the vicinity must wear

suitable safety goggles, a safety helmet, ear protection,

safety gloves and safety boots while the tool is in operation.

5.9 Protective equipment

Never use the tool without the applicable protective

equipment:

●Never operate the tool without the water swivel / extraction head.

●An additional means of securing the drill stand must

be employed when used for horizontal drilling with vacuum attachment.

●The drill stand must be fastened by means of an anchor

or quick-release brace when used for overhead drilling.

●Use of the water collector system in conjunction with

a wet-type vacuum cleaner is mandatory when carrying

out wet overhead drilling.

6. Before use

It is essential that the safety precautions printed in these

operating instructions are read and observed.

-CAUTION-

Disconnect the tool from the mains supply .

If extension cables are used: Only extension cables of a

type approved for the intended use and of adequate cross

section may be used. Failure to observe this point may

result in reduced performance and could cause the cable

to overheat. Damaged extension cables must be replaced.

The recommended cable cross-sections and maximum

lengths are:

Conductor cross-section

Mains voltage 1.5 mm22.0 mm22.5 mm23.5 mm

2

100 V 20 m 40 m

110–120 V 20 m 40 m

220–230 V 50 m 80 m

6.1 Side handle

6.1.1 Fitting the side handle

1. Screw the side handle onto the tool and tighten it

securely.

6.1.2 Fitting the side handle in a different position

1. Remove the screw plug at the position where the side

handle is to be fitted (e.g. for left-handed use). The

grip at the end of the side handle can be unscrewed

and used as a screwdriver .

2. Screw the side handle onto the tool at the desired

position and tighten it securely.

3. Insert the screw plug in the exposed threaded hole.

6.1.3 Adjusting the extraction head / water swivel (and

side handle)

1. Press the water swivel lock out of the gap between

the locking ring and the water swivel/extraction head.

2. Release the locking ring between the chuck and side

handle.

Page 10

18

Note

Use only original Hilti core bits and accessories!

1. Open the chuck by turning it counter-clockwise (as

seen from the front end of the chuck).

2. Insert the diamond core bit in the chuck.

3. Push the diamond core bit into the chuck and rotate

the core bit until it engages.

4. Close the chuck by turning it clockwise (as seen from

the front end of the chuck).

5. Check that the core bit it is securely seated by gripping it and attempting to pull it away from the chuck.

6.3 Selecting the drilling speed (gear selector posi-

tions 1-2-3)

-CAUTION-

Do not operate the gear selector while the tool is running. Wait until rotation has stopped.

Hand-held use

,

278663

4 3/4" - 6 1/2"

2

5

/8" - 4 1/4"

1

/2" - 2 1/2"

I

II

III

1

5

/8" - 2 1/2"

1

/2" - 1 1/2"IIIII

122 - 162

67 - 112

12 - 62

40 - 62

12 - 37

mm

Inch

Drill-stand use

1. Select the gear according to the table on the tool.

2. Move the gear selector to the desired setting while

rotating the core bit.

6.4 Dry drilling

6.4.1 Connecting the extraction system

1. Unscrew the cover from the water swivel / extraction

head.

2. Insert the extraction hose in the extraction connection.

3. Close the water valve in the side handle.

6.5 Hand-held wet drilling

6.5.1 Connecting the water supply

1. Close the water valve in the side handle.

2. Close the cover on the dust extraction connection.

3. Connect the water supply hose (hose connector).

6.6 Hand-held wet drilling with the water collection

system

6.6.1 Fitting the water collection system

Use of the water collection system permits water to be

drained away from the core bit thus avoiding soiling the

surrounding area. Best results are achieved in conjunction with a wet-type vacuum cleaner .

-CAUTION-

■ The core bit may become hot during

use or during sharpening.

■ It may burn your hands.

■ The cutting edges (segments) may cause

injury.

■ Wear safety gloves when changing the

core bit.

3. Move the side handle into the desired position (15°

increments).

4. Tighten the locking ring securely until the teeth and

the water swivel lock engage.

6.2 Fitting the diamond core bit

Page 11

19

Use of the water collection system in conjunction with

a wet-type vacuum cleaner is mandatory for overhead

drilling. Position the side handle and water swivel / extraction head so that the water collection system can be fitted without obstruction. The centering ring and seal

must be of a size suitable for the core bit diameter used.

1. From below the tool, position the water collection sys-

tem on the two mounting pins.

2. Swing the water collection system towards the front.

3. Secure the water collection system by turning the

knob.

4. Connect a wet-type vacuum cleaner to the front of the

water collection system. Alternatively, the water can

be allowed to flow away through a length of hose

attached to the connector (not permissible for overhead drilling).

6.6.2 Adjusting the depth gauge

1. Set the depth gauge to the desired depth.

2. Use the clamping screw to secure the depth gauge.

6.7 Using the drill stand

6.7.1 Using an anchor (HKD-D M12) to secure the

drill stand

1. Place the anchor at a distance of 200 mm (ideal dis-

tance) from the centre of the hole to be cored.

2. Screw the quick-release spindle into the anchor.

3. Place the drill stand over the quick-release spindle

and use the hole centre indicator to bring the drill

stand into alignment.

4. Fit the nut to the quick-release spindle but do not tight-

en it fully.

5. The four levelling screws should then be used to lev-

el the baseplate. The spirit level on the baseplate serves

as a levelling aid.

6. Use the locknuts to prevent further movement of the

levelling screws.

7. Tighten the nuts securely with an open-end wrench.

6.7.2 Securing the drill stand with the vacuum pad

A vacuum release valve is incorporated in the baseplate

grip.

Overhead drilling with the drill stand attached only by

vacuum is not permissible.

1. Unscrew the four levelling screws until they project

approx. 5 mm beneath the baseplate.

2. Connect the hose between the vacuum connector on

the baseplate and the vacuum pump.

3. Switch on the vacuum pump and extend the hole centre indicator. While pressing the vacuum release valve

and observing the hole centre indicator, bring the

baseplate into the desired position. When positioned

correctly, press the baseplate against the work surface and remove your finger from the vacuum release

valve. Before beginning drilling and during operation,

it must be ensured that the pressure gauge pointer

remains within the green area.

4. The four levelling screws should then be used to level the baseplate. The spirit level on the baseplate serves

as a levelling aid.

5. Tighten the lock nuts to prevent further movement of

the levelling screws.

6. An additional means of securing the drill stand must

be employed when drilling horizontally (e.g. a chain

attached to an anchor , ...)

6.7.3 Securing the drill stand with a quick-release

brace (e.g. between floor and ceiling)

1. Extend the hole centre indicator and then use it as an

aid to bring the drill stand into alignment with the centre point of the hole to be cored.

2. Position the end of the quick-release brace carefully

in the inner oval of the baseplate (not on the level indicator or pressure gauge).

3. Secure the baseplate by applying slight pressure with

the quick-release brace.

4. The four levelling screws should then be used to level the baseplate. The spirit level on the baseplate serves

as a levelling aid.

5. Tighten the lock nuts to prevent further movement of

the levelling screws.

6. Tighten the quick-release brace securely .

VACUUM

VACUUM

Page 12

20

6.8 Water collection system for use with the drill stand

Use of the water collection system permits water to be

drained away from the core bit thus avoiding soiling the

surrounding area. Best results are achieved in conjunction with a wet-type vacuum cleaner .

Use of the water collection system in conjunction with

a wet-type vacuum cleaner is mandatory for overhead

drilling. The drill stand must be set up at 90°to the work

surface.

The water collector sleeve and seal must be of a size

suitable for the core bit diameter used.

1. Slacken the column adjusting lever until the locating

lugs are disengaged.

2. Tilt the frame.

3. Fit the water collector holder .

4. Bring the frame back to the vertical position.

5. Close the adjusting levers until the locating lugs are

fully engaged and the frame is again secured.

6. Lift the holder and push the water collector cup under

the retainer as far as it will go.

7. Connect a wet-type vacuum cleaner to the water collector cup or connect a length of hose through which

the water can flow away.

6.9 Mounting the tool on the drill stand

The release lever on the drill stand must be in the open

position and the carriage should be at the top of its travel.

The drilling advance mechanism must be locked (chain

arrestor engaged).

1. Fit the tool interface plate onto the two mounting pins

on the drill stand.

2. Pivot the tool towards the drill stand until it engages.

3. Insert the switch lock in the grip opening. The switch

lock is used to hold the switch in the ON position during sustained operation.

4. Close the water valve in the side handle.

5. Connect the water supply .

6.10 Fitting the hand wheel

1. Fit the hand wheel onto the axle.

2. Secure the hand wheel by tightening the screw knob.

3. The hand wheel may be fitted on either side of the drill

stand.

6.11 Adjusting the drill stand drilling angle

(In increments of 7.5°; adjustable to max. 45°)

1. Slacken the column adjusting levers until the locating lugs are disengaged.

2. Bring the columns into the desired position.

3. Engage the locating lugs.

4. Move the adjusting levers until the locating lugs are

fully engaged and the frame is again secured.

5. Press in and pivot the adjusting levers to return them

to the vertical position.

6.12 Removing the tool from the drill stand

-CAUTION-

The tool must be disconnected from the electric mains

supply.

The drilling advance mechanism must be locked (chain

arrestor engaged).

1. Close the water valve in the side handle.

2. Disconnect the water supply .

3. Remove the switch lock from the grip.

4. Hold the tool with one hand on the grip and release

the lever on the drill stand.

5. Pivot the tool away from the drill stand.

7. Operation

7.1 Connect the tool to the electric mains supply

The voltage given on the rating plate must correspond

to the voltage provided by the mains supply .

1. Check that the tool is switched off or, respectively,

remove the switch lock.

2. Insert the supply cord plug in the mains socket.

3. Press the "ON" button on the PRCD ground fault interrupter (the lamp must light).

4. Press the "TEST" button on the PRCD ground fault

interrupter (the lamp must not

light).

5. Press the "ON" button on the PRCD ground fault interrupter (the lamp must light).

-CAUTION-

■ The tool and the coring operation create noise.

■ Excessive noise may damage the hearing.

■ Wear ear protection.

-CAUTION-

■ The coring operation may cause hazardous fragments to fly off.

■ Flying fragments may cause injury to

the eyes or other parts of the body.

■ Wear eye protection and a safety helmet.

7.2 Dry drilling

7.2.1 Fitting the hole-starting aid

A different hole-starting aid is required for each diamond

core bit diameter .

1. Fit the hole-starting aid into the front end of the diamond core bit.

7.2.2 Vacuum cleaner with power socket for electric

tools

The vacuum cleaner starts automatically after switching on the electric tool. Switching off the electric tool

Page 13

21

also causes the vacuum cleaner to be switched off after

a short delay.

Switching on

1. Press the on / off switch on the tool.

2. With the hole-starting aid fitted, begin drilling and

continue until the projecting segments have established a kerf in the base material.

3. Switch the tool off.

4. Remove the hole-starting aid and continue drilling.

Switching off

1. Switch the tool off.

2. Remove the core if necessary.

7.2.3 Vacuum cleaner without power socket for elec-

tric tools

Switching on

1. Switch the vacuum cleaner on.

2. Press the on / off switch on the tool.

Switching off

1. Switch the tool off.

2. Allow the vacuum cleaner to run for a short time in

order to remove remaining dust before switching off.

7.3 Hand-held wet drilling

Switching on

1. Open the water valve in the side handle until the desired

water volume flows. The water flow volume can be

observed at the indicator on the hand grip.

2. Press the on / off switch

3. When starting a hole, hold the tool at a slight angle

to the work surface. This makes hole-starting easier.

4. Once the hole has been started, bring the tool into the

90°position and continue drilling.

Switching off

1. Switch the tool off.

2. Close the water valve on the side handle.

7.4 Hand-held wet drilling using the water collection

system

The crosshair marks at the front end of the water collection system serve as an accurate positioning aid.

Switching on

1. Switch on the water extraction system (if used).

2. Open the water valve on the side handle slowly until

the desired water volume flows. Use the indicator on

the side handle to check the water flow rate.

3. Press the on / off switch.

4. Hold the tool at a slight angle to the work surface

when starting a hole. This makes hole-starting easier.

5. After starting the hole, bring the tool into the 90°position and continue drilling.

Switching off

1. Switch the tool off.

Caution: When drilling overhead, any water remain-

ing in the core bit must not be allowed to run down

over the tool.

2. Close the water valve on the side handle.

3. Switch off the vacuum cleaner (if used).

4. Remove the core if necessary.

7.5 Wet drilling using the drill stand

Switching on

1. Switch on the (wet) vacuum cleaner (if used).

2. Open the water valve at the side handle slowly until

the desired volume of water flows. The indicator at

the side handle can be used to check the water flow

rate.

3. Use the switch actuator to run the tool in sustained

operation mode.

4. Release the chain arrestor .

5. Bring the core bit into contact with the work surface

by turning the hand wheel.

6. Apply only slight pressure to the core bit when beginning drilling and then increase pressure once the core

bit has become centred.

7. Keep an eye on the overload indicator while drilling.

Pressure on the core bit must be reduced if the overload indicator lights.

Switching off

1. Close the water regulation valve at the side handle.

2. Pull the core bit out of the hole.

3. Engage the chain arrestor .

4. Switch the tool off.

5. Switch off the vacuum cleaner (if used).

6. Remove the core if necessary.

7. Switch the tool off.

Caution: When drilling overhead, any water remaining in the core bit must not be allowed to run down

over the tool.

8. Ensure stability of the drill stand by lowering the tool

and core bit to the baseplate.

8. Care and maintenance

Disconnect the supply cord plug from the socket.

8.1 Care of core bits

Remove any dirt adhering to the core bits and protect

their surfaces from corrosion by rubbing them with an

oily cloth from time to time. Always keep the connection end clean and slightly greased.

8.2 Care of the tool

Check that the supply cord plug is disconnected.

Never operate the tool if its ventilation slots are blocked.

Clean the ventilation slots carefully with a dry brush. Do

not allow foreign objects to enter the interior of the tool.

Clean the outside surfaces of the tool with a damp cloth

at regular intervals. Do not use a spray, steam cleaning

Page 14

22

equipment or running water for cleaning. This could

negatively affect the electrical safety of the tool. Always

keep the grip surfaces of the tool free from oil and grease.

Do not use cleaning agents which contain silicone.

Clean the chuck and the clamping segments with a cloth

at regular intervals and lubricate these parts with Hilti

lubricant spray. Remove any dirt and fragments from

the chuck.

Remove the filter in the water intake at the side handle

from time to time and rinse the filter sieve under running water in the direction opposite to the normal water

flow.

If the water flow indicator has become dirty, remove and

clean the parts. Do not use abrasive agents or sharp

objects to clean the sight glass. This may negatively

affect functionality of the water flow indicator .

8.3 Maintenance of the tool

Check all external parts of the tool for damage at regular intervals and check that all operating controls function faultlessly. Do not operate the tool when parts are

damaged or when operating controls do not function

faultlessly. The tool should be repaired at a Hilti service

centre.

Repairs to the electrical section of the tool may be carried out by trained electrical specialists only .

8.4 Care of the drill stand

8.4.1 Care of the chain

Check the chain guides to ensure they remain clean and

free from drilling slurry. The chain must always be protected by a film of grease.

8.5 Maintenance of the drill stand

8.5.1 Adjusting the movement

Movement should be easy but without play .

The movement can be adjusted by way of screws (2 at

the top and 2 at the bottom).

8.5.1.1 Stiffer movement

1. Release the lower screw.

2. Tighten the upper screw as far as necessary .

3. Tighten the lower screw as far as it will go.

8.5.1.2 Easier movement

1. Release the upper screw.

2. Tighten the lower screw as far as it will go.

8.5.2 Adjusting the chain tension

When the carriage is in the end position, the chain should

sag only slightly when running horizontally . Chain tension can be adjusted by way of two screws (chain symbol on the cover).

●Turning in a clockwise direction increases chain tension.

● Turning in a counter-clockwise direction decreases

chain tension.

Both chains must be tensioned equally.

Page 15

23

9. T roubleshooting

Fault Possible cause Remedy

The tool doesn't start. Fault in mains supply Plug in another electric appliance

and check whether it works.

Supply cord or plug defective The cord should be checked and

replaced if necessary by an

electrical specialist.

Switch defective The switch should be checked and

replaced if necessary by an

electrical specialist.

Motor runs but the core bit Gearing defective The tool should be repaired at a

doesn't rotate. Hilti service centre.

Rate of drilling progress decreases. Water pressure / water flow rate too Regulate the water flow rate at the

high side handle.

Core bit defective Check the core bit for damage and

replace it if necessary.

Gearing defective The tool should be repaired at a

Hilti service centre.

Core bit segments polished Resharpen the core bit on a sharp-

ening plate under water flow.

Motor cuts out. Tool stops running. Guide the tool straight.

Tool has overheated. The motor's Ease the load on the tool and allow

thermal overload protection has been it to run up to full speed by pressactivated. ing the switch several times.

Electronics defective The tool should be repaired at a

Hilti service centre.

Cooling fan defective The tool should be repaired at a

Hilti service centre.

Water does not flow. Filter or water flow indicator blocked Remove the filter or water flow

indicator and flush it through.

Water escapes at the gear housing. Shaft seal / water swivel / extraction The tool should be repaired at a

head defective Hilti service centre.

The core bit cannot be inserted in Connection end or chuck dirty or Clean the connection end and

the chuck. damaged chuck. Replace parts if necessary.

Water escapes at the chuck. Connection end or chuck dirty Clean the connection end and

chuck.

Chuck seal defective Check the seal and replace it if

necessary.

Excessive play in the drilling Excessive play at the guides Readjust the guides.

system. Chain inadequately tensioned Tension the chain.

Pivot mechanism loose Tighten the pivot mechanism

adjusting lever (6.11).

Page 16

24

10. Disposal

Most of the materials from which Hilti power tools are manufactured can be recycled. The materials must be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for taking

back your old electric tools for recycling. Please ask your Hilti customer service department or Hilti sales representative for further information.

Should you wish to return the electric tool yourself to a disposal facility for recycling, proceed as follows: Dismantle

the tool as far as possible without the need for special tools. Use absorbent paper to wipe oily parts clean and collect any oil that runs out. This paper should also be disposed of correctly. On no account should oil be allowed

to enter the waste water system or find its way into the ground.

Separate the individual parts as follows:

Part / assembly Main material Recycling

Transport box Plastic* Plastics recycling

Motor housing Plastic* / synthetic rubber Plastics recycling

Grip, side handle Plastic* Plastics recycling

Drill stand, complete Steel / aluminium / magnesium alloy / plastic* Scrap metal / plastics recycling

Motor (rotor / stator) Steel / copper Scrap metal

Gearing parts Steel Scrap metal

Screws, small parts Steel Scrap metal

Supply cord Copper / synthetic rubber Scrap metal

Drilling slurry **

**Plastic parts carry a mark indicating the material from which they are made.

** With regard to environmental aspects, allowing drilling slurry to flow directly into rivers, lakes or the sewerage

system without suitable pre-treatment is problematical. Ask the local authorities for information about applicable regulations.

We recommend the following pre-treatment:

●Collect the drilling slurry (e.g. use an industrial vacuum cleaner).

●Allow the slurry to settle and dispose of the solid material at a construction waste disposal site (the addition of

a flocculent may accelerate the settling process).

●Water from the drilling slurry (alkaline, ph value < 7) should be neutralised by adding an acidic neutralising agent

or large quantity of water before it is allowed to flow into the sewerage system.

11. Warranty

Hilti warrants that the tool supplied is free of defects in material and workmanship.This warranty is valid as long as the

tool is operated and handled correctly,cleaned and serviced

properly and in accordance with the Hilti Operating Instructions,all warranty claims are made within 12 months from

the date of the sale (invoice date),and the technical system

is maintained.This means that only original Hilti consumables,components and spare parts may be used in the tool.

This warranty provides the free-of-charge repair or replacement of defective parts only.Parts requiring repair or replacement as a result of normal wear and tear are not covered

by this warranty.

Additional claims are excluded,unless stringent national rules prohibit such exclusion.In particular ,Hilti is not

obligated for direct,indirect,incidental or consequential damages,losses or expenses in connection with,

or by reason of,the use of, or inability to use the tool

for any purpose.Implied warranties of merchantability or fitness for a particular purpose are specifically

excluded.

For repair or replacement,send tool and/or related parts

immediately upon discovery of the defect to the address of

the local Hilti marketing organization provided.

This constitutes Hilti’s entire obligation with regard to warranty and supersedes all prior or contemporaneous comments and oral or written agreements concerning warranties.

Page 17

12. EG-Konformitätserklärung

Bezeichnung: Diamantbohrgerät

Typenbezeichnung: DD130

Konstruktionsjahr: 2001

Wir erklären in alleiniger Verantwortung, dass dieses

Produkt mit den folgenden Richtlinien und Normen

übereinstimmt: EN 50144-2-1, EN 61029-1, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-311, 73/23/EWG, 89/336/EWG, 98/37/EG

Hilti Corporation

Ivo Celi Dr . Martin Goedickemeier

Head of Business Unit Diamond Head of Development

Business Unit Diamond Business Unit Diamond

December 2001 December 2001

12. EC declaration of conformity

Designation: Diamond drilling machine

Type: DD130

Year of design: 2001

We declare, on our sole responsibility, that this prod-

uct complies with the following standards or standardisation documents: 73/23/EEC low voltage directive (EU), 89/336/EEC EMC directive (EU), 98/37/EU

machine directive (EU), EN 50144-2-1, 61029-1, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-11.

Page 18

Hilti Corporation

FL-9494 Schaan

Tel.:+423/2342111

Fax: +423/2342 965

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 2690 0102 10-Pos. 1 1 Printed in Liechtenstein © 2002

Right of technical and programme changes reserved S. E. & O.

370458

Loading...

Loading...