Page 1

14 englisch

Safety precautions

■

1

Keep your place of work clean and tidy.

Disorder where you are working creates a potential risk of accidents.

■

2

Make allowance for influence from the surroundings. Don’t expose your electric tools/machines to rain. Don’t use electric tools/machines in damp or wet surroundings. Make

sure the work area is well lit. Don’t use electric tools/ machines near inflammable liquids

or gases.

■

3

Always protect yourself against electric

shock. Never touch grounding (earthing) parts

e.g. pipes, radiators, cookers, ovens, refrigerators.

■

4

Keep children away. Don’t let other persons touch the electric tool/machine or supply cord. Keep them away from your work

area.

■

5

Keep your electric tool/machine in a safe

place. Electric tools/machines not in use should

be kept in a dry locked-up place out of the

reach of children.

■

6

Don’t overload your electric tools/machines.

You will do your work better and safer in the

specified performance/rating range.

■

7

Always use the right electric tool/machine

for the job. Don’t use underpowered tools/machines or attachments for heavier duty jobs.

Don’t use electric tools/ machines for work

and purposes for which they are not intended, e.g. don’t use a hand-held circular saw to

cut down trees or cut up branches.

■

8

Wear suitable clothing. Don’t wear loose

clothing or jewellery – they could be caught

up in moving parts. When working outside,

the use of rubber gloves and non-slip shoes

is recommended. Wear a helmet or cap if you

have long hair.

■

9

Always wear protective goggles. If work

causes dust, wear a mask as well.

■

10

Don’t use the supply cord for any other

purpose. Don’t carry the electric tool/ machine

by the supply cord and don’t pull the plug out

of the socket/receptacle by pulling the supply cord. Protect the cable from heat, oil and

sharp edges.

■

11

Secure the workpiece. Use a clamping device or vice to hold the workpiece. It is secured more reliably in this way than in your

hand and you can then hold and operate your

electric tool/machine with both hands.

■

12

Don’t bend over too far when working.

Avoid an unusual stance. Make sure that you

are standing firmly and keep your balance at

all times.

■

13

Take good care of your electric tools/machines. Keep the drill bits, insert tools etc.

sharp and clean so that you can do your work

better, safer and more reliably. Observe the

cleaning and maintenance regulations and

the instructions for changing drill bits, insert

tools etc. Check the supply cord regularly and

have it renewed by a recognized specialist if

it is damaged. Check the extension supply

cord regularly and, if it is damaged, replace

it. Keep grips and side handles dry and free

from oil or grease.

■

14

Always pull out the plug from the mains if

the electric tool/machine is not in use, prior

to cleaning and maintenance work and when

changing a drill bit, saw blade or insert tools

of any kind.

■

15

Never leave a key in place. Always check

before switching on that the key or adjusting

tools have been removed.

■

16

Avoid any unintentional start-up. Never

carry a plugged-in electric tool/machine with

your finger on the switch. Always make sure

that the switch is off when plugging the electric tool/machine into the main electric supply.

■

17

If an extension supply cord is used outside, only use one which has been approved

for the purpose and is correspondingly marked.

■

18

Be attentive at all times. Keep your eye on

your work. Remain in a sensible frame of mind

and don’t use the electric tool/machine if you

cannot concentrate completely.

■

19

Check your electric tool/machine for damage. You must check the safety devices or

damaged parts carefully for perfect functioning in keeping with the intended purpose before using the electric tool/machine further.

Check whether the moving parts function

properly, whether they aren’t sticking, whether

any parts are broken, whether all other parts

work properly and are fitted correctly, and

make sure that all other conditions which can

influence operation and running of the electric tool/machine are as they should be. Damaged guards and protective devices and parts

must be repaired properly by an authorized

service workshop or replaced provided that

nothing else is stated in the operating instructions. Damaged switches must also be

replaced in the recognized service workshop.

Never use electric tools/machines which cannot be switched on and off by the switch.

■

20

Caution ! For your own safety’s sake, only use accessories and attachments which are

specified in the operating instructions or in

the respective catalogue. The use of accessories or insert tools or attachments other

than those specified in the operating instructions can result in personal injury to you.

■

21

Only have repairs carried out by recognized

electrical specialists. This electric tool/machine complies with respective safety regulations. Repairs may only be carried out by

an electrical specialist otherwise an accident

hazard for the operator can exist.

■

22

Connect dust extraction equipment. If devices are provided for the connection of dust

extraction and collection facilities ensure these

are connected and properly used.

Caution: The following fundamental safety

precautions must always be observed when

using electric tools/machines as protection

against electric shock, the risk of injury and

fire hazards.

Please read and take note of these precautions before you use the tool/machine.

Please keep these safety precautions in a

safe place.

Page 2

15

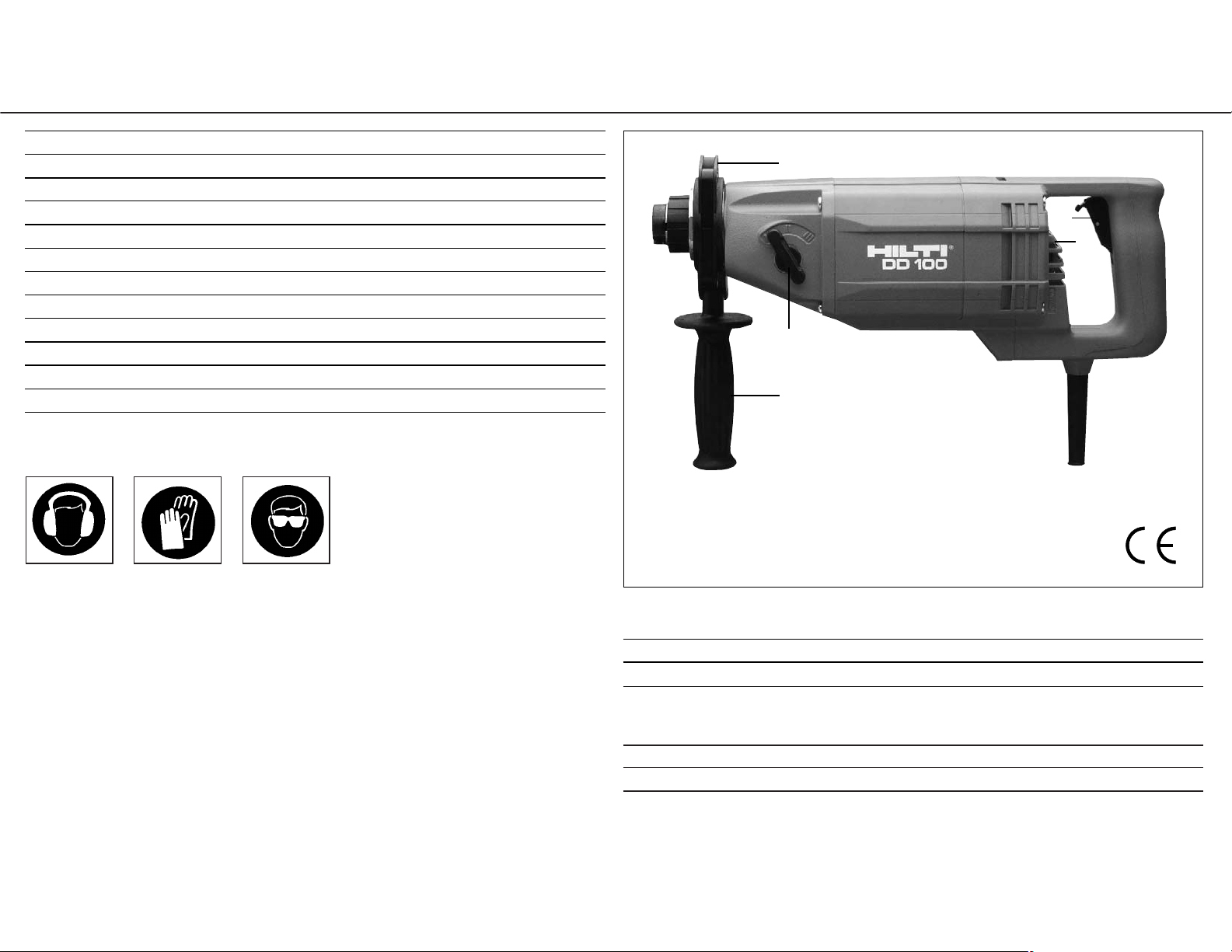

DD100 basic unitContents

DD100 basic unit 15

Versions with additional equipment 16

Assembly instructions/conversion 17

Drilling speeds 18

Water collector 18+19

Safety regulations 20

DD100 motor/technical data 21

Overload indicator 22

Aids for starting drilling 23

Accessories 23

Ground fault interruptor PRCD 24

Maintenance 24

➂

➄

➁

➀ Electronic switch (easy hole-starting)

➁ Side handle

➂ Depth gauge ( not fitted)

➃ Overload indicator

➄ Speed-change switch

➀

➃

Technical data

Weight (basic unit): Approx. 6,2 kg

Dimensions: Approx. 440=115 =155 mm

Drill bit size range: dry 16–152 mm dia.

wet 8– 42 mm dia. (hand held)

8– 82 mm dia. (drilling rig)

Chuck for core bits: Hilti quick-change DD-BI

Chuck for dry-cutting core bits: Key-type chuck

Before beginning work:

Please observe the enclosed safety precautions!

Noise and vibration

Typically the A-weighted noise levels of the tool are:

– sound pressure level: 89 dB (A)

– sound power level: 102 dB (A)

Wear ear protection.

The typical hand-arm-vibration is below is 2,5 m/s

2

.

Do not use this product in any way other than as directed by these operating instructions.

When working with the machine, it must be held with two hands.Always make sure that you

have a safe stance/ foothold.

Always wear ear

protectors.

Always wear protective gloves.

Always wear safety

glasses.

Page 3

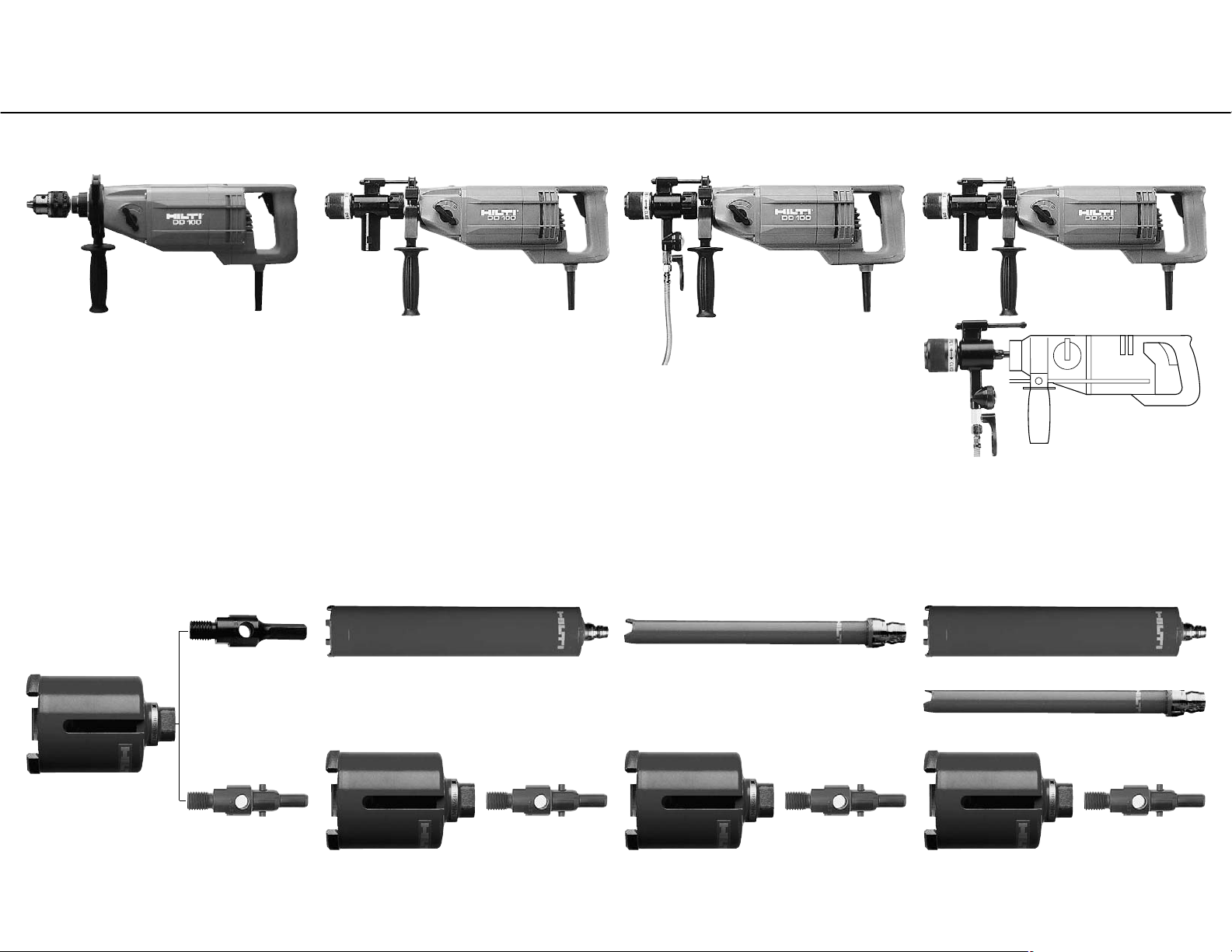

16

DD100 versions with additional equipment

DD100-B

Basic-version

DD100-D

Dry-drilling version

DD100-W

Wet-drilling version

DD100-M

Multi-purpose (wet/dry) version

Core bit for dry drilling Core bit for wet drilling

Core bit for wet drilling

Core bit for dry drilling

Socket cutters

DD100 adaptorDD100 adaptor

Universal

adaptor

DD100 adaptor DD100 adaptor

Equipment supplied

Insert tool programme

● Machine

● Key-type chuck

● Cardboard box

● Machine

● Extraction head with chuck

● Plastic case

● Machine with build-in ground fault interruptor

● Water swivel witch chuck

● Water collector

● Plastic case

● Machine with built-in ground fault interruptor

● Extraction head with chuck

● Water swivel with chuck

● Water collector

● Plastic case

Socket cutters Socket cutters Socket cutters

Page 4

17

DD100: Assembly and conversion

Re-equipping Key-type chuck Extraction head Water swivel

The water swivel is connected by way of a Gar-

dena coupling.

The water supply valve (➀) can be regulated

using the index finger (➁).The flow of water is

displayed by the flow indicator.

Note: If wet-drilling core bits are allowed to run

dry,they will become overheated, which could

lead to destruction of the diamond segments.

Connection to vacuum cleaner: If a Hilti vacuum cleaner is used, no additional adaptor is

necessary.Press the vacuum cleaner hose firmly into the extration head connection (➀). (See

page 23 for adaptor for other vacuum cleaners.)

Note: Drilling without dust removal could permanently damage or destroy the diamond core

bit.

Open the chuck as far as is necessary,and insert an insert tool with cylindrical, 3-flat or

hexagonal shank(13 mm or

1

/2w). After pushing in the insert tool as far as it will go, tighten the chuck using the key provided.

To remove the chuck, first turn the locking ring

(➀) until it clicks into place. When fitting the

chuck, the drive pin must be inserted into the

groove.

The chuck is secured by turning the locking

ring as far as it will go.

Important: Due to the keyed fit, the water

swivel cannot be fitted to the DD100-D.

Conversion of a DD100-D or DD100-B for

the first time, for wet drilling (DD100-W,

DD100-M) must be carried out by a Hilti service centre.

➀

➁

➀

Push the chuck rotation-prevention pin into the

opening provided.

➞

Insert the core bit into the chuck, possibly turning it slightly until the longitudinal groove can

be felt to lock in place. to remove the core bit,

first slide back the locking sleeve and then pull

out the core bit.

➀

Page 5

18

Speed-change switch

Recommended speeds for maximum drilling performance

Speed (r.p.m.) Wet (dia. in mm) Dry (dia. in mm)

3 (3900) 8–25 16– 42

2 (2400) 20–32 35– 67

1 (1200) 30–82 56–152

Important:

Wet and dry-drilling core bits are designed for

a drilling contact pressure of 250 N (25 kg). Insufficient pressure can lead to polishing of the

segments and a reduction of drilling performance. Polished/blunt core bits can be resharpened e.g. using the Hilti sharpening plate

(item no. 51343/3).

Water collector

Insert the centering ring (➀) for the appropriate

core bit diameter into the ring holder (➁).

Insert the water collector (➂) and press it down

firmly into the holder. Connect the water extraction hose.

Insert the guide pin (➀) on the water collector holder into the boss (➁) in the side handle

collar.Press the frame of the water collector

holder into its guide on the side handle collar

(➂).

If the sealing ring supplied with the diamond core bit begins to leak, it must be replaced. Reordering information: The diameter range is printed on the sealing disc.

Dry drilling Wet drilling

Extraction and Vacuum cleaner connection Water connection and

water supply water extraction

Power supply Electric supply as per Electric supply as per rating

rating plate plate

Safety device according to

national

approval for the use of this

hand-held electric tool

Speed selection Select correct speed Select correct speed

Hole-starting aid Use centering disc Use centering ring

Core bit Use DD100-D diamond core Use DD100-W core bits

bits

Caution:

DD-BI-HCW core bits (hand held) must be used for drilling anchor holes!

Page 6

19

O

P

E

N

C

L

O

S

E

1

3

2

O

P

E

N

C

L

O

S

E

5

Press the core bit through the water collector

(sealing disc, centering ring) onto the surface

to be drilled. Switch on the DD 100 by pressing the main switch.

Fitting a core bit

1. Chuck

2. Connection end

3. Core bit

4. Locking sleeve

5. Motor unit

The water supply valve can be regulated using the index finger.

Removing a core bit

1. Chuck

2. Core bit

3. Locking sleeve

Hold the core bit before disengaging the locking sleeve.

When the core bit is released, ensure that the

core does not accidentally fall out of the bit.

When drilling overhead, close the water supply valve and drain the core bit via the water

supply hose before releasing it from the chuck.

Important: First-time conversion of a dry-drilling machine (DD100-D, DD100-B) to a wet-drilling (DD100-W, DD100-M) can only be carried out by a Hilti service centre.

1

4

2

3

Page 7

20

Safety precautions on the jobsite

Preparations before beginning work Electrical safety

Before beginning work with the drilling system, read the operating instructions carefully and ensure that the saftety precautions listed below are observed.

Please also note that permission to begin drilling work must be

obtained from the site engineer or other authorised person.

● Ensure that no electric cables, gas or water pipes etc. are

situated where holes are to be drilled.

● Cables, pipes or other supply lines situated in close prox-

imity to where holes are to be drilled must be switched off.

● The drilling work must not have a negative effect on the

structural design of the building (drilling through steel reinforcement!).

● Cordon off areas where drilling work is taking place, partic-

ularly behind/below walls or ceilings which are being drilled

through.

● Wear a helmet, safety shoes,gloves and ear protectors.

● Tidiness and good organisation on the jobsite help to pre-

vent accidents.

● Use only original Hilti parts.

● Protect the motor unit from water spray and rain.

● For overhead drilling,the water collector and water removal

system must be in good order and function correctly.

● The wet drilling system must only be operated with the built-

in PRCD fault interruptor ( GB-with isolating transformer).

● In order to ensure safe, trouble-free operation, the drilling

system must be kept clean.(Do not clean using a jet of water.)

●Drilling work should only be carried out by trained person-

nel.

● If leakage occurs in the water supply system, the equipment

must be serviced.

In addition to the safety precautions, the following preparations

at the jobsite must be made.

– Make sure that a water connection or pressurized container with continuous water flow is available.

– Make preparations for the flow of water. If necessary, install

water extraction equipment.When drilling into hollow building

components, find out where the drilling water is likely to flow,

in order to avoid damage.

– A power supply with earth/ground connection must be available for use.

– Measure out and mark holes to be drilled.

– Safe electrical operation of the DD 100 can only be guaranteed as long as moisture is prevented from entering the motor. All electrical safety precautions can only reduce the consequences of allowing water to enter a DD 100 motor, but not

eliminate them. A DD 100 motor which has become wet must

be serviced by the electrical specialists at a Hilti centre.

Caution: When drilling overhead you have to use a proper water collector, replace a leaky water extraction device/sealing disc immediately (see page 19), if not your life

could be in danger.

Additional safety precautions:

– When drilling, make sure you have a secure position to work

from.

– Hold the DD 100 firmly with both hands.

– Pay attention and concentrate on the job when working.

The PRCD (DD 100 wet drilling machine) fault interruptor protects the operator in case of faults in the insulation of the motor unit or supply cord (between the PRCD and the motor unit).

This device also prevents the machine from restarting of its own

accord when power returns after an interruption in the power

supply.The earth/ground connection protects the operator from

dangerously high voltages in case of drilling into live cables.The

protective function of the ground fault interruptor must be checked

at regular intervals in accordance with regulations issued by

national authorities.

Page 8

21

DD100 motor Technical data

➄

➂

➁

➀ Quick-change coupling for rapid re-equipping with different chucks

➁ Adjustable side handle

➂ 3 speeds

➃ Overload indicator

➄ Switch with infinite speed adjustment (for hole-starting mode)

Caution:

Switch should be fully depressed when DD 100 is in continuous operation!

➀

➃

Voltages: 100/115V 230/240 V

Power input: 100V = 1400 W 1700 W

110 V = 1600 W

115 V = 1600 W

Current input: 15 A 8 A

Frequency: 50/60 Hz 50/60 Hz

No-load speed: 1

st

speed: 1200 r.p.m.

2

nd

speed: 2400 r.p.m.

3rdspeed : 3900 r.p.m.

(Operate speed-change switch only

when motor has stopped.)

Drill bit size range

Wet drilling, hand-held: 8– 42 mm dia.

Wet drilling with drilling rig: 8– 82 mm dia.

Dry drilling: 16–152 mm dia.

Drilling depth

Wet: Approx. 280 mm

Dry: Up to 400 mm (above 25 mm dia.)

Drilling rig stroke: Up to approx. 330 mm

Weight (basic unit without cord): 6,2 kg

Dimensions (unit without head): 440=115 =155 mm

Chuck for core bits : Hilti quick-change DD-BI

(Key-type chuck)

Depth gauge: Same as TE machines

Electronic speed regulator for constant no-load speed (nominal speed)

Overload current regulator and integrated starting current regulator

Thermal/mechanical motor protection/safety clutch

Electrical protection class1 (electric supply with earth/ground connection necessary)

Radio and television interference suppression in accordance with EN 55014 (CISPR. PUBL.

14)

See EN 60555, parts 2 and 3 for implications for electric supply (mains)

Ground fault interruptor (PRCD) 6 mA 10 mA

Zero-voltage trip

Please refer to the respective regulations of your trade association and the enclosed safety precautions.

Before beginning work: Please observe the enclosed safety precautions!

Please keep these operating instructions in a safe place.

Right of technical modifications reserved!

Page 9

22

Overload protection Dry/wet vacuum removal

The DD100 is equipped with

mechanical,electronic and thermal overload

protection devices.

Mechanical

This protects the operator, motor and core bit

if the core bit suddenly sticks (safety clutch)

Electronic

If the machine is overloaded due to excessive pressure being applied, the current is

reduced so that the core bit only rotates slowly.After releasing pressure on the core bit,

full current is again supplied to the motor and

the drilling speed returns to normal.

Thermal

The motor is protected additionally against continuous overloading by a temperature sensor

which automatically reduces current input.The

DD 100 can be made to operate at normal speed

by pressing the switch after the temperature

of the motor windings has dropped sufficiently.

Cooling of the motor windings can be assisted by allowing the machine to run without load.

The motor speed necessary for effective cooling can be reached more quickly by depressing the switch several times.

Overload indicator TDA-VC 60

If the overload indicator (➀) lights up, it is an

indication that you are approaching the limit

of thermal overload. It is recommended that

the DD100 is operated in such a way that the

overload indicator lamp does not light up(if the

indicator remains on, the thermal motor protection will be activated).After the machine has

been allowed to cool, work can continue normally (cooling at no-load speed approx. 20 seconds).

Caution: In order to avoid overheating and

damage to the core bit, drilling dust must be

removed continuously,allowing ventilation of

the cutting edge.

If suction is poor (low drilling progress), clean

the contaminated filter (operate shaker after

drilling each hole). Clean the extraction head

and core bit. It may be necessary to use a vacuum cleaner with greater suction capacity.

Empty the dust container regularly.

Note:

The TDA-VC60 must be used when a large

number of consecutive holes are being

drilled! The TDA-VC40 is suitable only for

occasional use.

When drilling overhead, wet vacuum removal

is absolutely essential. A dust removal system

must be used for dry drilling.

Wet vacuum removal: See page 23 for adaptor.

➀

Page 10

23

Hole starting aids Accessories

Wet (centering ring) Adhesive plate Drilling rig Adaptor

Hole-starting aid for wet drilling: A centering

ring is available for each core bit diameter (8–32

mm).It can be used with the water dam holder and adhesive plate (see accessories)

Dry (centering disc)

Hole-starting aid for dry drilling:Use the appropriate

disc for each core bit diameter.Apply the selfadhesive disc where the hole is to be drilled

after removing the protective foil. Nails can be

used if the adhesive is not effective. The selfadhesive centering disc can be used only once.

An adhesive plate for drilling individual holes.

– Apply double-sided adhesive foil to the adhesive plate.

– Position adhesive plate in the desired position, or use nails if the adhesive is not effective.

– Insert the appropriate centering ring.

– Insert the the water collector incl. appropriate

sealing disc into the adhesive plate, ensuring

it is held firmly in place.

– Connect the water supply hose.

– The adhesive plate can be re-used after

replacing the adhesive foil.

A drilling rig for semi-stationary use with core

bit diameters up to 82 mm.

– For use only with M12 anchors.

– Drilling overhead is only allowed when using the water collector.

Wet adaptor for connecting the water extraction hose to a water extractor (hose diameter

12 and 20 mm, item no.213149/8).

Dry adaptor for connecting other types of vacuum cleaner to the DD 100 extraction head

(35-50 mm connections, item no.213148/0).

Page 11

24

DD100 ground fault interruptor (PRCD) Maintenance Warranty

1

6

2

4

6

3

5

7

1. Plug - type depends on country

2. PRCD ground fault interruptor

3. ON-switch for PRCD (ON)

4. Test button (TEST)

5. Indicator

6. Supply cord (three wire grounded)

7. Monitor unit ON/OFF switch

The PRCD interruptor must be tested for correct operation each time before beginning work.

1. Check that the motor is switched off.

2. Connect the plug to the mains supply.

3. Press the ON button. The lamp must light!

4. Press the TEST button. The lamp must extinguish!

5. Press the ON button again before beginning

operation.

In the case of a malfunction (test failed),

the unit must be checked by an electrical

specialist before work with the equipment

continues!

To avoid damage to the system and to ensure trouble-free operation, the following parts

must be cleaned and oiled or greased after finishing work:

– Rods on water collector holder

– Chuck

– Extraction head/water swivel

– Thread on side handle

Keep the ventilation slots on the motor housing and side handle clean.

Ensure that the extraction head and water swivel interfaces are kept clean.Lubricate with Hilti

spray.

Keep the chuck clean – use Hilti spray.

In case of technical problems, please contact

the Hilti customer service.

Repairs to the electrical parts of the DD100

must be carried out by an electrical specialist.

Hilti warrants that the tool supplied is free of

defects in material and workmanship. This warranty is valid as long as the tool is operated and

handled correctly,cleaned and serviced properly and in accordance with the Hilti Operating

Instructions, all warranty claims are made within 12 months from the date of the sale (invoice

date), and the technical system is maintained.

This means that only original Hilti consumables,

components and spare parts may be used in

the tool.

This warranty provides the free-of-charge

repair or replacement of defective parts only.

Parts requiring repair or replacement as a result

of normal wear and tear are not covered by this

warranty.

Additional claims are excluded, unless

stringent national rules prohibit such exclusion. In particular, Hilti is not obligated for

direct, indirect, incidental or consequential

damages, losses or expenses in connection

with, or by reason of, the use of, or inability

to use the tool for any purpose. Implied warranties of merchantability or fitness for a

particular purpose are specifically excluded.

For repair or replacement, send tool and/or

related parts immediately upon discovery of the

defect to the address of the local Hilti marketing organization provided.

This constitutes Hilti’s entire obligation with

regard to warranty and supersedes all prior or

contemporaneous comments and oral or written agreements concerning warranties.

Warning : This appliance must be earthed

As the colours of the wires in the mains lead of this tool may not correspond with the coloured

maekings identifying the terminals in your plug, proceed as follows:

–The wire that is coloured green and yellow must be conected to the terminal in the plug that

is marked with the letter E or by the earth symbol or coloured green or green and yellow.

–The wire that is coloured blue must be connected to the terminal that is marked with the

letter N or coloured black.

–The wire that is coloured brown must be connected to the teminal that is marked with the letter L or coloured red.

Loading...

Loading...