Page 1

DCH 300

Operating instructions en

Mode d’emploi fr

Manual de instrucciones es

Manual de instruções pt

Page 2

1

This Product is Certified

Ce produit est homologué

Producto homologado por

Este produto está registrado

CUS

Page 3

2

3

Page 4

4

1

"#

2

"“

"[

"Ç

"]

3

Page 5

5

Page 6

DCH 300 Diamond cutter

It is essential that the operating instructions

are read before the machine is operated for

the first time.

Always keep these operating instructions

together with the machine.

Ensure that the operating instructions are

with the machine when it is given to other

persons.

Contents Page

1. General information 1

2. Description 2

3. Accessories, consumables 5

4. Technical data 5

5. Safety instructions 6

6. Before use 11

7. Operation 13

8. Care and maintenance 15

9. Troubleshooting 15

10. Disposal 16

11. Manufacturer’s warranty 17

1 These numbers refer to the corresponding illustrations. The illustrations can be found on the fold‐out

cover pages. Keep these pages open while studying

the operating instructions.

In these operating instructions, the designation “the

power tool” always refers to the DCH 300 diamond

cutter.

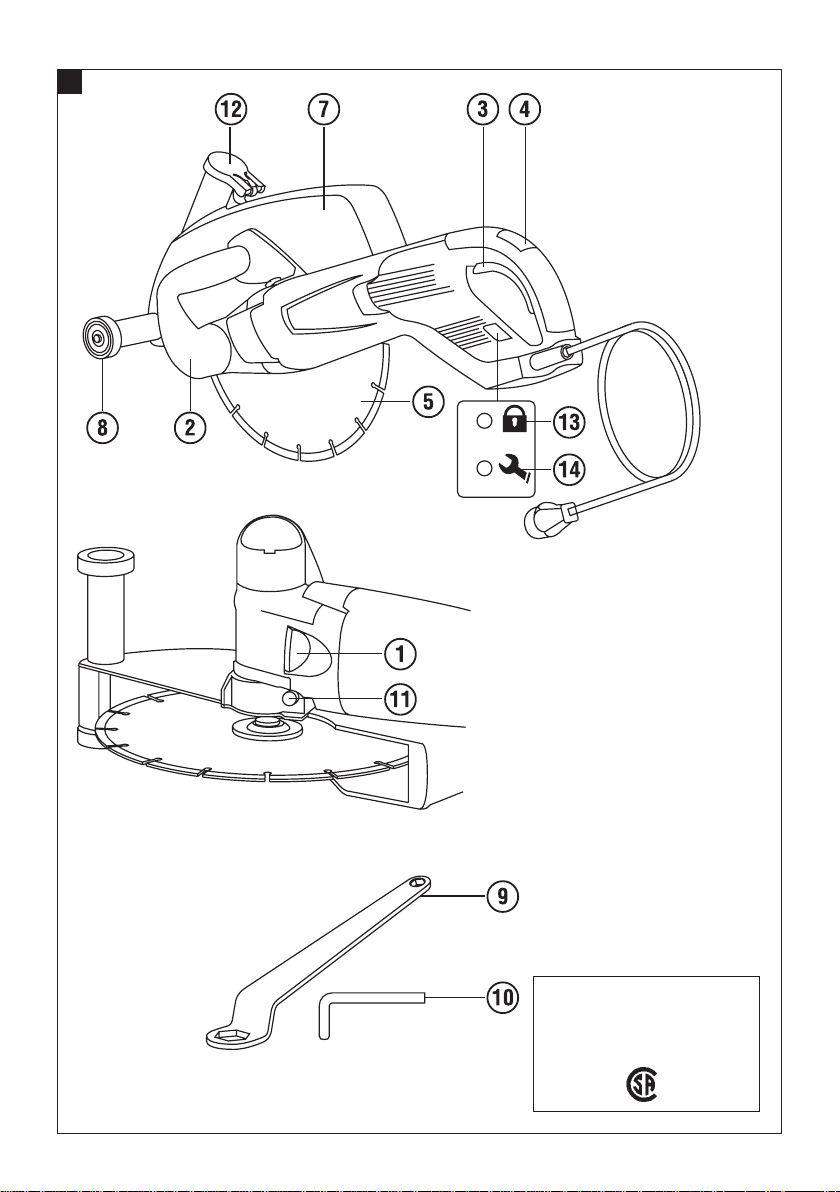

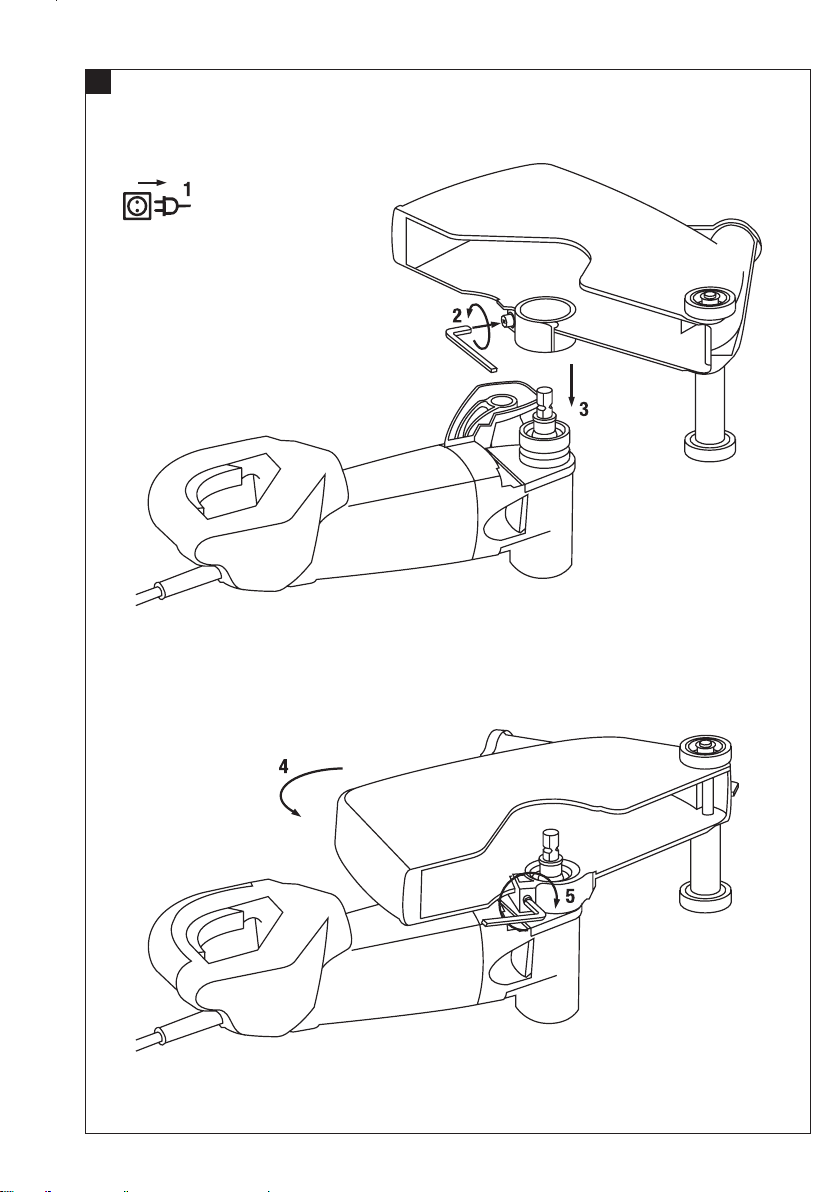

Operating controls and indicators 1

Spindle lockbutton

@

Front grip

;

On / off switch

=

Switch‐on interlock release button

%

Diamond cutting disc

&

Spindle

(

Guard (hood)

)

Guide wheels

+

Clamping nut wrench, 24 mm AF / 10 mm AF

§

Hex. socket wrench, 6 mm AF

/

Guard (hood) clamping screw

:

Dust removal connector cap

·

Service indicator

$

Theft protection indicator (option)

£

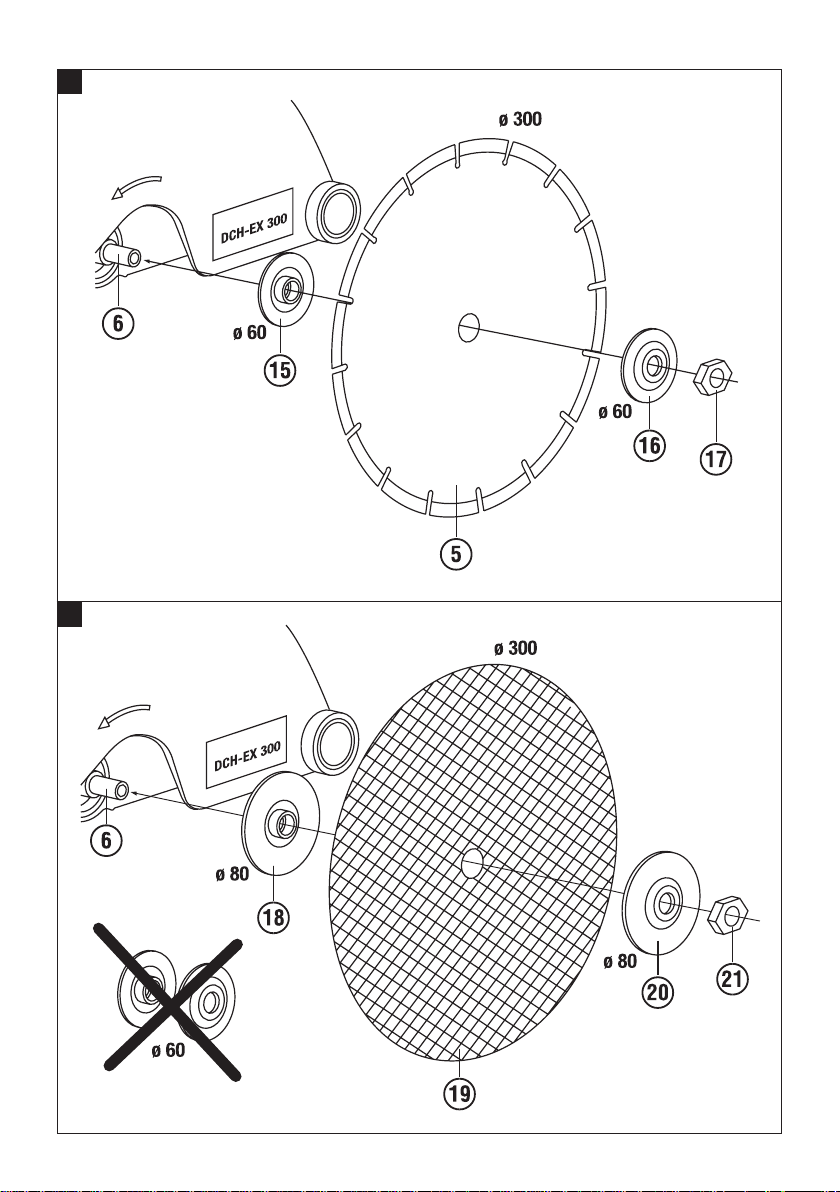

DCH 300 mounting system for diamond cutting

discs 2

Reversible flange 60 mm dia.

|

Clamping flange, 60 mm dia.

¡

Clamping nut, M16 x 1.5

Q

DCH 300 mounting system for synthetic resin‐

bonded fiber‐reinforced abrasive cutting discs (optional) 3

Reversible flange 80 mm dia.

W

Synthetic resin‐bonded fiber‐reinforced cutting

E

discs with a diameter of 300 mm (12")

Clamping flange, 80 mm dia.

R

Clamping nut, M16 x 1.5

T

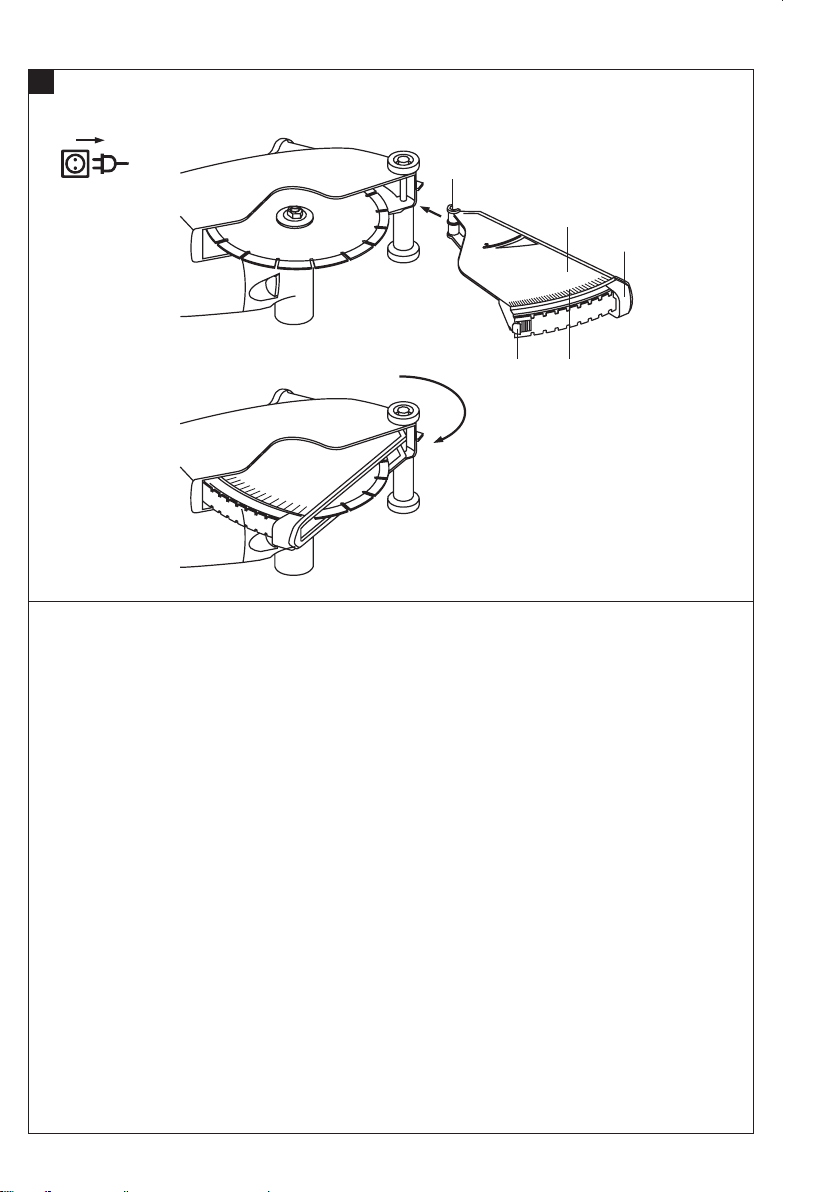

Hood extension with depth gauge (optional) 4

Hood extension

Z

Hook

U

Stop

I

Cutting depth sliding indicator

O

Cutting depth scale

P

en

1. General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that could lead

to serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation

that could lead to serious personal injury or fatality.

1

Page 7

CAUTION

Draws attention to a potentially dangerous situation

that could lead to slight personal injury or damage to

the equipment or other property.

NOTE

en

Draws attention to an instruction or other useful

information.

1.2 Explanation of the pictograms and other

information

Warning signs

Symbols

Read the

operating

instructions

before use.

Alternating

current

Return waste

material for

recycling.

Revolutions

per minute

Amps Volts

Diameter Nominal speed

under no load

General

warning

Obligation signs

Warning:

electricity

Double

insulated

Location of identification data on the machine

The type designation and serial number can be found

on the type identification plate on the machine. Make

Wear a hard

hat.

Wear eye

protection.

Wear ear

protection.

Wear

protective

gloves.

a note of this data in your operating instructions and

always refer to it when making an enquiry to your

Hilti representative or service department.

Type:

Wear safety

shoes.

Wear

breathing

protection.

Serial no.:

2. Description

2.1 Use of the product as directed

The DCH 300 is an electrically powered diamond cutter for professional use in the construction industry.

It is designed for cutting mineral materials with diamond discs without use of water.

A vacuum cleaner with the appropriate filter, e.g. Hilti VCD 50 vacuum cleaner, must be used when cutting

mineral materials.

In order to avoid electrostatic effects, a vacuum cleaner equipped with an antistatic hose should be used.

Use only diamond cutting discs with a maximum permissible peripheral speed of at least 80 m/sec (16000

ft/min).

The power tool is to be used exclusively in pushing mode (counter rotation).

The use of liquids, e.g. to cool the disc or suppress dust, is not permissible.

Do not use the power tool for cutting with cutting tools of a type not specified in these operating instructions

(e.g. circular saw blades) or for grinding.

When equipped with synthetic resin‐bonded fiber‐reinforced abrasive cutting discs, the power tool can also

be used for cutting metals. When doing so, use only synthetic resin‐bonded fiber‐reinforced abrasive cutting

discs with a maximum permissible peripheral speed of at least 80 m/sec (16000 ft/min).

2

Page 8

The working environment may be as follows: construction site, workshop, renovation, conversion or new

construction.

To avoid the risk of injury, use only genuine Hilti accessories and cutting tools.

Observe the safety rules and operating instructions for the accessories used.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

The machine is designed for professional use and may be operated, serviced and maintained only by trained,

authorized personnel. This personnel must be informed of any special hazards that may be encountered. The

machine and its ancillary equipment may present hazards when used incorrectly by untrained personnel or

when used not as directed.

The machine may be used only in a dry environment.

The machine may be operated only when connected to a power supply providing a voltage and frequency in

compliance with the information given on its type identification plate.

Do not use the machine where there is a risk of fire or explosion.

Working on materials hazardous to the health (e.g. asbestos) is not permissible.

Modification of the machine or tampering with its parts is not permissible.

2.2 Switches

On/off switch with switch‐on interlock

2.3 Starting current limitation

The starting current drawn by the power tool is several times higher than its rated current. The electronic

starting current limiter reduces the starting current drawn by the power tool and thus prevents the mains fuse

blowing. It also allows the power tool to start smoothly, without a jolt.

2.4 Restart interlock

The power tool does not restart by itself after an interruption in the electric supply. The switch must first be

released and then pressed again after approx. 1 second.

en

2.5 TPS theft protection system (optional)

The power tool may be optionally equipped with the TPS theft protection system. If equipped with this feature,

the power tool can be unlocked and made ready for operation only through use of the corresponding TPS key.

2.6 LED indicators

Service indicator LED (see section “Care and maintenance”)

Theft protection system indicator (optional) (see section “Operation”)

2.7 Guard (hood) with guide wheels

Cutting and slitting work on stone may be carried out only when the power tool is equipped with a dust hood

with wheels.

2.8 Electronic overload protection

The electronic overload protection system monitors current input and thus protects the power tool from

overload.

If the motor is overloaded through application of excessive working pressure, the power tool’s performance

drops noticeably or it may come to a complete standstill. A standstill should be avoided.

Permissible overload cannot be given as a specific value as it depends on the temperature of the motor.

If the power tool has been overloaded, release the pressure applied and then allow it to run under no load for

approx. 30 seconds.

3

Page 9

2.9 Using extension cords

Use only extension cords of a type approved for the application and with conductors of adequate gauge. The

power tool may otherwise lose performance and the extension cord may overheat. Check the extension cord

for damage at regular intervals. Replace damaged extension cords.

Recommended minimum conductor gauge (cross section) and max. cable lengths

en

Conductor cross section 14 AWG 12 AWG

Mains voltage 110‐120 V

Do not use extension cords with 16 AWG conductor cross section.

2.10 Using extension cords outdoors

When working outdoors, use only extension cords that are approved and correspondingly marked for this

application.

2.11 Using a generator or transformer

This tool may be powered by a generator or transformer when the following conditions are fulfilled: The unit

must provide a power output in watts of at least twice the value printed on the type identification plate on

the power tool. The operating voltage must remain within +5% and ‐15% of the rated voltage at all times,

frequency must be in the 50 – 60 Hz range and never above 65 Hz, and the unit must be equipped with

automatic voltage regulation and starting boost.

Never operate other power tools or appliances from the generator or transformer at the same time. Where

applicable, use a generator or transformer designed for simultaneous power tool and vacuum cleaner operation.

Switching other power tools or appliances on and off may cause undervoltage and / or overvoltage peaks,

resulting in damage to the power tool.

2.12 Hood extension with depth gauge (optional)

The power tool can be fitted with an optional hood extension with depth gauge. This improves dust removal

performance for cutting mineral materials. The maximum cutting depth can be set with the aid of the cutting

depth scale on the hood extension.

‐

125 ft

2.13 The items supplied as standard include:

1 Power tool with DCH‑EX 300 hood

1 Reversible flange 60 mm dia.

1 Clamping flange, 60 mm dia.

1 Clamping nut, M16 x 1.5

1 Clamping nut wrench, 24 mm AF / 10 mm

AF

1 Hex. socket wrench, 6 mm AF

1 Cardboard box

1 Operating instructions

2.14 Cutting disc specifications

Diamond cutting discs in compliance with the requirements of ANSI B7.1 are to be used with the power tool.

Synthetic resin‐bonded fiber‐reinforced cutting discs in compliance with ANSI B7.1 (cutting‐off wheels of

the straight, not offset type) may also be used with this power tool for working on metals. In this case, the

appropriate DCH 300 ABR disc mount (see accessories) must be used with the power tool.

The mounting instructions issued by the disc manufacturer must also be observed.

4

Page 10

3. Accessories, consumables

DCH 300 ABR disc mount 212259, Reversible flange

Ø80 mm, clamping flange

Ø80 mm, clamping nut M16 x 1.5

Depth gauge for the DCH 300

Vacuum cleaner

Antistatic hose, complete

Hilti toolbox

DCH 300

Disc type Specification Material

Diamond cutting disc

Diamond cutting disc

Diamond cutting disc

Diamond cutting disc

Diamond cutting disc

VCD 50

DCH‑D 12" C1 Concrete

DCH‑D 12" C2

DCH‑D 12" M1

DCH‑D 12" C10 Concrete (Economy Line

DCH‑D 12" M10

212131

Length 5 m (16.4 ft), Ø36

Hard concrete

Masonry, sand‐lime block

disc)

Masonry (Economy Line

disc)

4. Technical data

Right of technical changes reserved.

Other information about the power tool DCH 300

Rated voltage 120 V

Rated current input 20 A

Mains frequency

Dimensions 705 mm (27.76 in) x 240 mm (9.45 in) x 235 mm

Drive spindle thread M 16 X 1.5

Disc arbor size 25.4 mm (1")

Cutting disc

Cutting disc thickness

Weight of the power tool

Protection class Protection class I (grounded) or protection class II

Rated speed under no load Max. 4,900/min

Clamping nut tightening torque M16 x 1.5: 40…50 Nm (30…37 lb/ft)

60 Hz

(9.25 in)

Ø Max. 305 mm (12")

Max. 3.5 mm (¹⁄₈")

9.4 kg (20.72 lb)

(double insulated). See type identification plate.

en

5

Page 11

5. Safety instructions

5.1 General power tool safety warnings

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions

en

may result in electric shock, fire and/or serious injury. Save all warnings and instructions for future

reference. The term “power tool” in the warnings

refers to your mains‐operated (corded) power tool or

battery‐operated (cordless) power tool.

5.1.1 Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while oper-

ating a power tool. Distractions can cause you to

lose control.

5.1.2 Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet con-

ditions. Water entering a power tool will increase

the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

5.1.3 Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non‐skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will

reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch

is in the off‐position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on

the switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

Do not overreach. Keep proper footing and bal-

e)

ance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust ‐related hazards.

5.1.4 Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

6

Page 12

or storing power tools. Such preventive safety

measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the

hands of untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

5.1.5 Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

5.2 Safety instructions for all operations

5.2.1 Safety warnings for abrasive cutting‐off

operations

a) This power tool is intended to function as a

cut‐off tool. Read all safety warnings, instructions, illustrations and specifications provided

with this power tool. Failure to follow all instruc-

tions listed below may result in electric shock, fire

and/or serious injury.

b) Operations such as grinding, sanding, wire

brushing or polishing are not recommended to

be performed with this power tool. Operations for

which the power tool was not designed may create

a hazard and cause personal injury.

c) Do not use accessories which are not specif-

ically designed and recommended by the tool

manufacturer. Just because the accessory can be

attached to your power tool, it does not assure

safe operation.

d) The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and fly apart.

e) The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

f) The arbour size of wheels, flanges, backing

pads or any other accessory must properly fit the

spindle of the power tool. Accessories with arbour

holes that do not match the mounting hardware

of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

g) Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, wire brush for

loose or cracked wires. If power tool or accessory is dropped, inspect for damage or install

an undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no‐load speed for one minute. Damaged acces-

sories will normally break apart during this test

time.

h) Wear personal protective equipment. Depending

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece

fragments. The eye protection must be capable

of stopping flying debris generated by various

operations. The dust mask or respirator must be

capable of filtrating particles generated by your

operation. Prolonged exposure to high intensity

noise may cause hearing loss.

i) Keep bystanders a safe distance away from

work area. Anyone entering the work area must

wear personal protective equipment. Fragments

of workpiece or of a broken accessory may fly

away and cause injury beyond immediate area of

operation.

j) Hold power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring or

its own cord. Cutting accessory contacting a “live”

wire may make exposed metal parts of the power

tool “live” and shock the operator.

en

7

Page 13

k) Position the cord clear of the spinning accessory.

If you lose control, the cord may be cut or snagged

and your hand or arm may be pulled into the

spinning accessory.

l) Never lay the power tool down until the acces-

sory has come to a complete stop. The spinning

en

accessory may grab the surface and pull the power

tool out of your control.

m)Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

n) Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

o) Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

p) Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

5.2.2 Further safety instructions for all

operations

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel. Pinching or snagging causes rapid

stalling of the rotating accessory which in turn causes

the uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point

of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel that

is entering into the pinch point can dig into the surface

of the material causing the wheel to climb out or kick

out. The wheel may either jump toward or away from

the operator, depending on direction of the wheel’s

movement at the point of pinching. Abrasive wheels

may also break under these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and can

be avoided by taking proper precautions as given

below.

b) Never place your hand near the rotating acces-

sory. Accessory may kickback over your hand.

c) Do not position your body in the area where

power tool will move if kickback occurs. Kickback

will propel the tool in direction opposite to the

wheel’s movement at the point of snagging.

d) Use special care when working corners, sharp

edges, etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent

kickback and loss of control.

5.2.3 Safety warnings specific for abrasive

cutting‐off operations

a) Use only wheel types that are recommended for

your power tool and the specific guard designed

for the selected wheel. Wheels for which the

power tool was not designed cannot be adequately

guarded and are unsafe.

b) The guard must be securely attached to the power

tool and positioned for maximum safety, so the

least amount of wheel is exposed towards the

operator. The guard helps to protect operator from

broken wheel fragments and accidental contact

with wheel.

c) Wheels must be used only for recommended

applications. For example: do not grind with

the side of cut‐

are intended for peripheral grinding, side forces

applied to these wheels may cause them to shatter.

d) Always use undamaged wheel flanges that are of

correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing the possibility of wheel breakage. Flanges

for cut‐off wheels may be different from grinding

wheel flanges.

e) Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and

may burst.

off wheel. Abrasive cut‐off wheels

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to resist

kickback forces. Always use auxiliary handle,

if provided, for maximum control over kickback

or torque reaction during start‐up. The operator

can control torque reactions or kickback forces, if

proper precautions are taken.

8

5.2.4 Additional safety warnings specific for

abrasive cutting‐off operations

a) Do not “jam” the cut‐off wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases the

loading and susceptibility to twisting or binding of

Page 14

the wheel in the cut and the possibility of kickback

or wheel breakage.

b) Do not position your body in line with and behind

the rotating wheel. When the wheel, at the point

of operation, is moving away from your body, the

possible kickback may propel the spinning wheel

and the power tool directly at you.

c) When wheel is binding or when interrupting a

cut for any reason, switch off the power tool

and hold the power tool motionless until the

wheel comes to a complete stop. Never attempt

to remove the cut‐off wheel from the cut while

the wheel is in motion otherwise kickback may

occur. Investigate and take corrective action to

eliminate the cause of wheel binding.

d) Do not restart the cutting operation in the work-

piece. Let the wheel reach full speed and carefully reenter the cut. The wheel may bind, walk

up or kickback if the power tool is restarted in the

workpiece.

e) Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their

own weight. Supports must be placed under the

workpiece near the line of cut and near the edge of

the workpiece on both sides of the wheel.

f) Use extra caution when making a “pocket cut”

into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause kickback.

5.3 Safety instruction for all operations

5.3.1 Safety instructions for all operations

a) Do not use wheels that require liquid coolants.

Using water or other liquid coolants may result in

electrocution or shock.

b) Use only wheel types that are recommended for

your power tool and the specific guard designed

for the selected wheel. Wheels for which the

power tool was not designed cannot be adequately

guarded and are unsafe.

5.3.2 Personal safety

a) Always hold the machine securely with both

hands on the grips provided. Keep the grips dry,

clean and free from oil and grease.

b) Breathing protection must be worn if the power

tool is used without a dust extraction system for

work that creates dust. Close the cap over the

dust removal connector.

c) Improve the blood circulation in your fingers by

relaxing your hands and exercising your fingers

during breaks between working.

d) Avoid touching rotating parts. Switch the power

tool on only after bringing it into position at

the workpiece. Touching rotating parts, especially

rotating drill bits, discs or blades, etc. may lead to

injury.

e) Always lead the supply cord and extension cord

away from the power tool to the rear while

working. This helps to avoid tripping over the cord

while working.

f) The guard must always be fitted when the power

tool is used for cutting metals. Close the cap

over the dust removal connector.

g) If the work involves breaking right through, take

the appropriate safety measures at the opposite

side. Parts breaking away could fall out and / or

fall down and injure other persons.

h) Children must be instructed not to play with the

appliance.

i) The appliance is not intended for use by chil-

dren, by debilitated persons or those who have

received no instruction or training.

j) Do not use the power tool if it starts with a jolt.

This may be an indication that the electronic control

unit is defective. Have the power tool repaired by

Hilti Service immediately.

k) WARNING: Some dust created by grinding, sand-

ing, cutting and drilling contains chemicals

known to cause cancer, birth defects, infertility

or other reproductive harm; or serious and permanent respiratory or other injury. Some exam-

ples of these chemicals are: lead from lead‐based

paints, crystalline silica from bricks, concrete and

other masonry products and natural stone, arsenic

and chromium from chemically‐treated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

exposure to these chemicals, the operator and

bystanders should work in a well‐ventilated area,

work with approved safety equipment, such as

respiratory protection appropriate for the type of

dust generated, and designed to filter out microscopic particles and direct dust away from

the face and body. Avoid prolonged contact with

dust. Wear protective clothing and wash exposed areas with soap and water. Allowing dust

to get into your mouth, nose, eyes, or to remain

en

9

Page 15

on your skin may promote absorption of harmful

chemicals.

5.3.3 Power tool use and care

a) Cutting discs must be stored, handled and fitted

carefully in accordance with the manufacturer’s

en

instructions.

b) If use of a spacer ring or other intermediate

part is specified and the part is supplied with

the cutting disc, check to ensure that the part is

fitted.

c) Secure the workpiece. Use clamps or a vice

to secure the workpiece. The workpiece is thus

held more securely than by hand and both hands

remain free to operate the machine.

d) Before use, check that the cutting disc has been

fitted correctly and the clamping nut tightened.

Then allow the power tool to run for 30 seconds

under no load while holding it in a secure position. Switch off the power tool immediately if

significant vibration or any other faults are noticed. Should this occur, check the entire system

in order to determine the cause.

e) Take steps to ensure that flying sparks from

the power tool do not present a hazard, i.e.

by striking yourself or other persons. Adjust the

position of the disc guard accordingly.

f) Slits cut in loadbearing walls of buildings or other

structures may influence the statics of the structure, especially when steel reinforcing bars or

load‐bearing components are cut through. Con-

sult the structural engineer, architect, or person

in charge of the building project before beginning

the work.

g) Guide the power tool carefully and make straight

cuts in order to avoid jamming the cutting disc.

Cutting curves is not permissible.

h) Guide the power tool evenly and do not apply

lateral pressure to the cutting disc. Always bring

the power tool into contact with the workpiece

at right angles. Do not attempt to alter the line

of cut by applying lateral pressure or by bending

the cutting disc while cutting is in progress. This

presents a risk of damaging or breaking the cutting

disc.

5.3.4 Electrical safety

a) Before beginning work, check the working area

(e.g. using a metal detector) to ensure that no

concealed electric cables or gas and water pipes

are present. External metal parts of the machine

may become live, for example, when an electric

cable is damaged accidentally. This presents a

serious risk of electric shock.

b) Check the machine’s supply cord at regular inter-

vals and have it replaced by a qualified specialist

if found to be damaged. Check extension cords

at regular intervals and replace them if found

to be damaged. Do not touch the supply cord or

extension cord if it is damaged while working.

Disconnect the supply cord plug from the power

outlet. Damaged supply cords or extension cords

present a risk of electric shock.

c) Dirty or dusty machines which have been used

frequently for work on conductive materials

should be checked at regular intervals at

a Hilti Service Center. Under unfavorable

circumstances, dampness or dust adhering to

the surface of the machine, especially dust from

conductive materials, may present a risk of

electric shock.

d) When working outdoors with a power tool check

to ensure that the tool is connected to the electric

supply by way of a ground fault circuit interrupter

(GFCI) with a rating of max. 30 mA (tripping

current). Use of a ground fault circuit interrupter

reduces the risk of electric shock.

e) Use of a ground fault circuit interrupter (GFCI)

with a maximum tripping current of 30 mA is

recommended.

5.3.5 Work area safety

Ensure that the workplace is well ventilated. Ex-

posure to dust at a poorly ventilated workplace may

result in damage to the health.

10

Page 16

5.3.6 Personal protective equipment

The user and any other persons in the vicinity must

wear ANSI Z87.1‐approved eye protection, a hard

6. Before use

WARNING

The supply cord must be disconnected from the

electric supply and the cutting disc or drive spindle

must have come to a complete stop before attempting to change or adjust discs, parts of the tool or its

accessories.

CAUTION

The mains voltage must comply with the specification given on the type identification plate. Ensure

that the power tool is disconnected from the electric

supply.

CAUTION

Wear protective gloves, especially when changing

discs, adjusting the guard (hood) and when fitting

the hood extension with depth gauge.

6.1 Guard (hood)

WARNING

Never use the power tool without the guard (hood).

NOTE

If the guard (hood) clamping force is found to be

inadequate, this can be increased by tightening the

clamping screw slightly.

6.1.1 Fitting and adjusting the guard (hood) 5

1. Disconnect the supply cord plug from the power

outlet.

2. Use the hex. socket wrench to release the clamping screw.

hat, ear protection, protective gloves and breathing

protection while the machine is in use.

en

3. Fit the guard (hood) onto the collar on the gearing

section.

4. Rotate the guard (hood) into the desired position.

5. Use the hex. socket wrench to tighten the clamping screw.

6.1.2 Removing the guard (hood)

1. Disconnect the supply cord plug from the power

outlet.

2. Use the hex. socket wrench to release the clamping screw.

3. Rotate the guard (hood) and pull it away from the

tool.

6.2 Depth gauge (optional)

DANGER

The hood extension with depth gauge is to be

used exclusively for cutting mineral materials with

diamond discs.

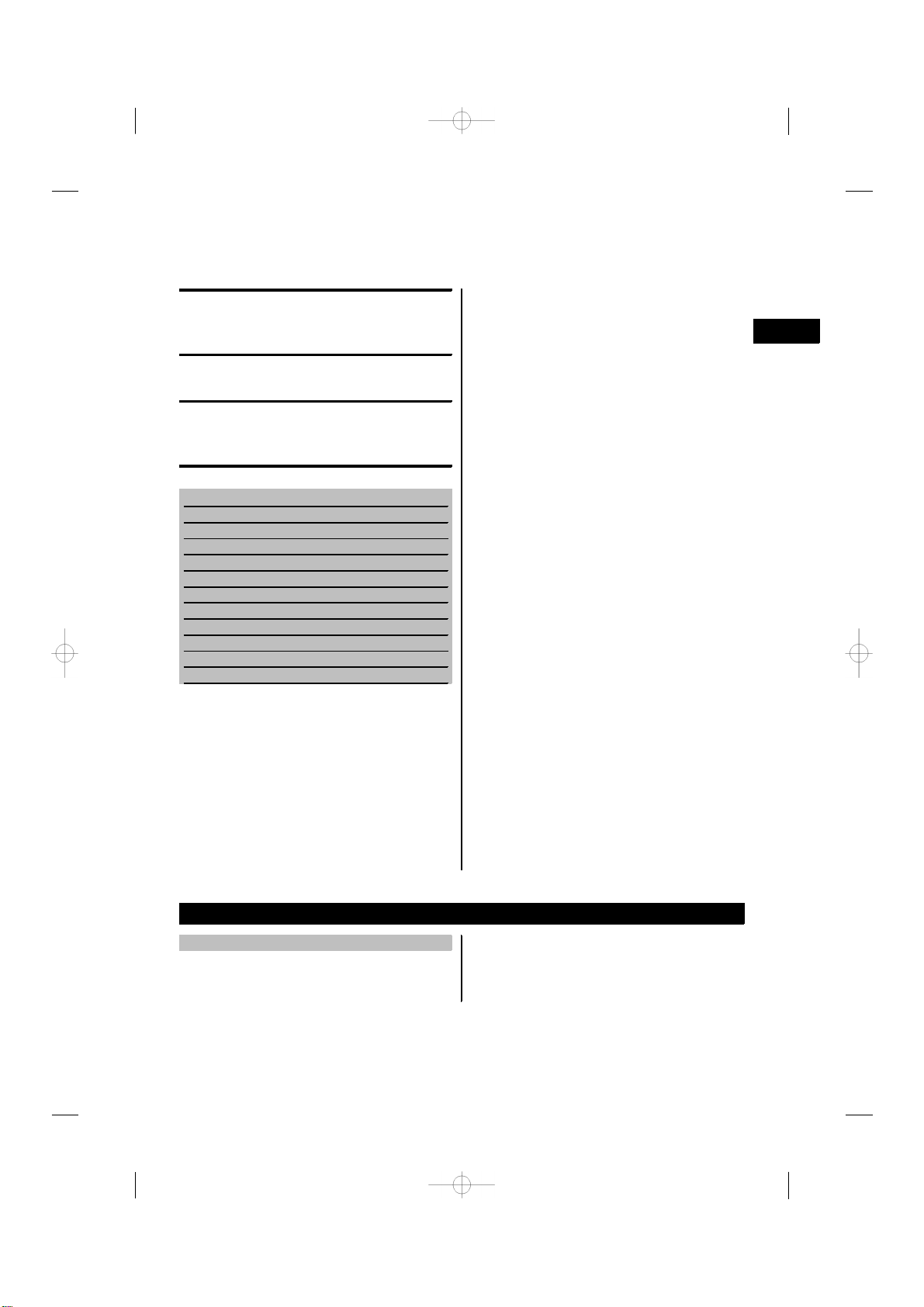

6.2.1 Fitting / removing the hood extension with

depth gauge 4

1. Disconnect the supply cord plug from the power

outlet.

2. Fit the hook over the guide wheel axle.

3. Pivot the hood extension into the hood until the

catch is heard to engage.

4. To remove the hood extension, press the catch

and pivot the hood extension down and away

from the hood.

6.2.2 Using the depth gauge to adjust cutting

depth

1. Press the cutting depth sliding indicator.

11

Page 17

2. Move the cutting depth sliding indicator to the

desired cutting depth.

6.3 Fitting a cutting disc

DANGER

en

Use only the metric‐size clamping flange and the

wrench supplied with the power tool.

CAUTION

Use only cutting tools with a rated maximum permissible speed which is at least as high as the

machine’s highest no‐load running speed.

CAUTION

Cutting discs which are damaged or out of round

(causing vibration) must not be used.

CAUTION

Do not use synthetic resin‐bonded fiber‐reinforced

cutting discs that have exceeded their use‐by date.

NOTE

Diamond cutting discs in compliance with the requirements of ANSI B7.1 are to be used with the

power tool. Synthetic resin‐bonded fiber‐reinforced

cutting discs in compliance with ANSI B7.1 (cutting‐off wheels of the straight, not offset type) may

also be used with this power tool for working on

metals. In this case, the appropriate DCH 300 ABR

disc mount (see accessories) must be used with the

power tool. The mounting instructions issued by the

disc manufacturer must also be observed.

6.3.1 Fitting diamond cutting discs

G

G

The width of the slot G between the segments must

not exceed 10 mm (³⁄₈"). The thickness of the disc

must not exceed 3.5 mm (¹⁄₈").

The 60 mm dia. interchangeable flange can be used

on one side for cutting discs with an inner diameter

of 22.2 mm (⁷⁄₈") or, on the other side, with cutting

discs with an inner diameter of 25.4 mm (1"). Check

which side of the flange fits the arbor hole in the

cutting disc. The flange must center the disc.

1. Disconnect the supply cord plug from the power

outlet.

2. Clean the clamping flange and the clamping nut.

3. Fit the 60 mm diameter reversible flange onto the

spindle the right way round, so that it is no longer

free to rotate.

4. Place the diamond cutting disc on the reversible

flange.

5. Fit the 60 mm diameter clamping flange and the

clamping nut.

6. CAUTION Do not press the spindle lockbutton

before the drive spindle has stopped rotating.

Press the spindle lockbutton and hold it in this

position.

7. Use the wrench to tighten the clamping nut securely and then release the spindle lockbutton.

8. Check to ensure that the spindle lockbutton has

disengaged.

6.3.2 Fitting synthetic resin‐bonded fiber‐

reinforced abrasive cutting discs (optional)

CAUTION

Never use flanges with a diameter of less than

80 mm with synthetic resin‐bonded fiber‐reinforced

cutting discs.

The 80 mm dia. interchangeable flange can be used

on one side for cutting discs with an inner diameter

of 22.2 mm (⁷⁄₈") or, on the other side, with cutting

discs with an inner diameter of 25.4 mm (1"). Check

which side of the flange fits the arbor hole in the

cutting disc. The flange must center the disc.

1. Disconnect the supply cord plug from the power

outlet.

2. Clean the clamping flange and the clamping nut.

3. Fit the 80 mm diameter reversible flange onto the

spindle the right way round, so that it is no longer

free to rotate.

4. Place the diamond cutting disc on the reversible

flange.

5. Fit the 80 mm diameter clamping flange and the

clamping nut.

6. CAUTION Do not press the spindle lockbutton

before the drive spindle has stopped rotating.

Press the spindle lockbutton and hold it in this

position.

7. Use the wrench to tighten the clamping nut securely and then release the spindle lockbutton.

12

Page 18

8. Check to ensure that the spindle lockbutton has

disengaged.

6.4 Removing the cutting disc from the tool

To remove the cutting disc from the tool, follow the

instructions for fitting the disc but carry out the steps

in the reverse order.

7. Operation

Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with

a “live” wire will make exposed metal parts of the tool

“live” and shock the operator.

WARNING

Do not use the power tool if it starts with a jolt.

This may be an indication that the electronic control

unit is defective. Have the power tool repaired by Hilti

Service immediately.

CAUTION

The power tool and the cutting operation generate

noise. Wear ear protectors. Exposure to noise can

cause hearing loss.

CAUTION

The cutting operation may cause dangerous splinters.

Splintering material presents a risk of injury to the

eyes and body. Wear eye protection and a hard hat.

CAUTION

The direction of advance is important. The power

tool must always be advanced with the guide wheels

ahead and in contact with the material being cut.

There is otherwise a risk of kick‐back.

6.5 Storing and transporting cutting discs

CAUTION

Remove the cutting disc from the power tool after

use. The cutting disc may suffer damage if the power

tool is transported with the disc fitted.

CAUTION

Store the cutting disc in accordance with the manufacturer’s recommendations. Incorrect or careless

storage may damage the cutting disc.

WARNING

The electric supply voltage must comply with the

information given on the type identification plate

on the power tool.

CAUTION

The cutting disc and parts of the power tool may

get hot through use. There is a risk of burning your

hands. Wear protective gloves. Touch the power

tool only at the grips provided.

CAUTION

Use clamps or a vice to hold the workpiece securely.

WARNING

Slits cut in loadbearing walls of buildings or other

structures may influence the statics of the structure,

especially when steel reinforcing bars or load‐bearing

components are cut through. Consult the structural

engineer, architect, or person in charge of the

building project before beginning the work.

7.1 Working with the power tool

Take care to ensure that the closed side of the guard

is always positioned toward the operator’s body.

Adjust the position of the guard (hood) to suit each

cutting application.

7.2 TPS theft protection system (optional)

NOTE

The power tool may be equipped with the optional

theft protection system. If the power tool is equipped

with this feature, it can be unlocked and made ready

for operation only with the corresponding TPS key.

en

13

Page 19

7.2.1 Unlocking the power tool

1. Plug the supply cord into the power outlet. The

yellow theft protection indicator LED blinks. The

power tool is then ready to receive the signal from

en

the TPS key.

2. Hold the TPS key against the lock symbol. The

power tool is unlocked as soon as the yellow theft

protection indicator LED no longer lights.

NOTE If, for example, the electric supply is briefly

interrupted due to a power failure or disconnected

when moving to a different workplace, the power

tool remains ready for operation for approx. 20

minutes. In the event of a longer interruption, the

TPS key must be used again to unlock the power

tool.

7.2.2 Activation of the tool’s theft protection

system

NOTE

Further detailed information on activation and use

of the theft protection system can be found in the

operating instructions for the theft protection system.

7.3 Switching on

1. Plug the supply cord into the power outlet.

2. Always hold the tool securely with both hands on

the grips provided.

3. Unlock the on / off switch by pressing the

switch‐on interlock release button.

4. Press the on / off switch.

5. Reposition your thumb around the rear grip.

7.4 Switching off

Release the on / off switch.

The tool stops after the on / off switch is released.

The switch‐on interlock is re‐activated.

7.5 Working with cutting discs

DANGER

To reduce the risk of kick‐back, avoid bringing the

cutting tool into contact with the material in the

area indicated.

DANGER

Wherever possible, bring the wheels into contact

with the workpiece before starting the cut. Take

extra care in situations where this is not possible

or where the cutting disc is inserted in an existing

cut.

1. When cutting mineral materials, first bring the

tool’s guide wheels into contact with the object to

be cut.

2. Allow the power tool to reach full speed.

3. Apply pressure to the power tool so that the

cutting disc is pressed into the material slowly.

This ensures that particles and sparks generated

by the cutting operation are caught by the hood

and extracted by the dust removal system.

NOTE Apply moderate pressure, adjusting the

rate of advance to suit the material being cut.

NOTE The diamond disc may overheat and suffer

damage when cutting very hard mineral materials,

e.g. concrete with a high hard pebble content. A

trail of sparks right round the circumference of

the diamond cutting disc is a sure indication of

this. Should this occur, stop cutting and cool the

disc by allowing the tool to run under no load.

A drop in the rate of cutting progress can be an indication of “blunt” (polished) diamond segments.

The segments can be resharpened by making a

few cuts in an abrasive material (Hilti sharpening

plate or sand‐lime block).

7.6 Using a suitable vacuum cleaner for working

on mineral materials

NOTE

Please read the operating instructions for the vacuum

cleaner for information about disposal of the material

collected.

14

Dust can be kept to a minimum when working by

using a suitable vacuum cleaner (such as the Hilti

VCD 50). Use of a vacuum cleaner also helps to cool

the segments on the disc and thus reduces segment

wear. In order to avoid electrostatic effects, a vacuum

cleaner equipped with an antistatic hose should be

used.

Page 20

8. Care and maintenance

CAUTION

Disconnect the supply cord plug from the power

outlet.

8.1 Care of the power tool

DANGER

When working on metal under extreme conditions,

conductive dust may accumulate inside the power

tool. This may negatively affect the power tool’s

protective insulation. Under such conditions, the

tool should be plugged into a ground fault circuit

interrupter (GFCI) and use of a stationary dust

removal system and frequent cleaning of the tool’s

cooling air slots is recommended.

8.2 Service indicator

NOTE

The power tool is equipped with a service indicator.

The outer casing of the motor and the grips are made

from impact‐resistant plastic. Parts of the grips have

a synthetic rubber covering.

Never operate the power tool when the ventilation

slots are blocked. Clean the ventilation slots carefully

using a dry brush. Do not permit foreign objects to

enter the interior of the power tool. Clean the outside

of the power tool at regular intervals with a slightly

damp cloth. Do not use a spray, steam pressure

cleaning equipment or running water for cleaning.

This may negatively affect the electrical safety of the

power tool. Always keep the grip surfaces of the

power tool free from oil and grease. Do not use

cleaning agents which contain silicone.

en

LED indicators

8.3 Maintenance

WARNING

Repairs to the electrical section of the machine may

be carried out only by trained electrical specialists.

Check all external parts of the power tool for damage

at regular intervals and check that all controls operate

faultlessly. Do not operate the power tool if parts

Constant red light End of service interval ‐ servicing is due. After the

lamp lights for the first time, the power tool may

continue to be used for several hours (switched‐on

running time) before the automatic cut‐out is

activated. To ensure that the power tool is always

ready for use, it should be returned to Hilti for

servicing in good time.

Blinking red light

See section “Troubleshooting”.

are damaged or when the controls do not function

faultlessly. If necessary, the power tool should be

repaired by Hilti Service.

8.4 Checking the power tool after care and

maintenance

After carrying out care and maintenance, check that

all protective and safety devices are fitted and that

they function faultlessly.

9. Troubleshooting

Fault Possible cause Remedy

The power tool doesn’t start.

Interruption in the electric supply. Plug in another electric appliance

and check whether it works.

The supply cord or plug is defective.

Have checked by a trained electrical

specialist and replaced if necessary.

15

Page 21

Fault Possible cause Remedy

The power tool doesn’t start.

en

The power tool doesn’t achieve

full power.

The power tool doesn’t start

and the service indicator blinks

red.

The power tool doesn’t start

and the service indicator lights

red.

The power tool doesn’t start

and the theft protection system

indicator blinks yellow.

The power tool has not been

unlocked (tools with optional theft

protection system).

The on / off switch is defective. If necessary, the power tool should

The power tool has been overloaded

(application limits exceeded).

The overheating protection system

is active.

Other electrical fault.

The electronic restart interlock is

activated after an interruption in the

electric supply.

The extension cord’s conductor

cross section is inadequate.

A fault has occurred in the power

tool.

The carbon brushes are worn. Have checked by a trained electrical

The power tool has not been

unlocked (tools with optional theft

protection system).

Use the TPS key to unlock the power

tool.

be repaired by Hilti Service.

Use the right power tool for the job

(don’t use a low‐powered tool for

heavy work).

Allow the power tool to cool down.

Clean the ventilation slots.

Have it checked by a trained

electrical specialist.

Switch the power tool off and on

again.

Use an extension cord with an

adequate conductor cross section.

(Please refer to “Before use”.)

If necessary, the power tool should

be repaired by Hilti Service.

specialist and replaced if necessary.

Use the TPS key to unlock the power

tool.

10. Disposal

Most of the materials from which Hilti machines or appliances are manufactured can be recycled. The

materials must be correctly separated before they can be recycled. In many countries, Hilti has already made

arrangements for taking back old machines and appliances for recycling. Ask Hilti customer service or your

Hilti representative for further information.

16

Page 22

11. Manufacturer’s warranty

Hilti warrants that the tool supplied is free of defects

in material and workmanship. This warranty is valid

so long as the tool is operated and handled correctly,

cleaned and serviced properly and in accordance with

the Hilti Operating Instructions, and the technical

system is maintained. This means that only original

Hilti consumables, components and spare parts may

be used in the tool.

This warranty provides the free‐of‐charge repair or

replacement of defective parts only over the entire

lifespan of the tool. Parts requiring repair or replacement as a result of normal wear and tear are not

covered by this warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental or consequential damages, losses or expenses

in connection with, or by reason of, the use of,

or inability to use the tool for any purpose. Implied warranties of merchantability or fitness for a

particular purpose are specifically excluded.

For repair or replacement, send the tool or related

parts immediately upon discovery of the defect to

the address of the local Hilti marketing organization

provided.

This constitutes Hilti’s entire obligation with regard

to warranty and supersedes all prior or contemporaneous comments and oral or written agreements

concerning warranties.

en

17

Page 23

en

18

Page 24

*212019*

212019

Hilti Corporation

LI-9494 Schaan

Tel.:+423/2342111

Fax: +423/2342965

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 3407 0308 00-Pos. 3 1 Printed in Liechtenstein © 2008

Right of technical and programme changes reserved S. E. & O.

212019 / A

Loading...

Loading...