Page 1

Page 2

(96.03

13

14

E)

Page 3

0

I

6 P*Fp€t3

6

dEd<3E,'8

Nsrsfu)@F@

F.EFEgEg

.C

.E

F

c

=

6

=

il rl el

zt>t6l

Hl

E.l

o'l

.g

a

E

Cg

6

c

(6

c

$19#l

rl !l tl

zF.

oEfr

o

O or5

9.;

o

=Ei'

EEd

6t5

O

:f

5lPl6l

slElEl

c

E

5

6)

o

a

slScl

bl

dl

ol

rh

E6-"

Y=

): 99

l,

Pd9.

=E-

E

lslEl

E

6

=E

O;9

oeO

R€p'oE

lolal

f

q)

tEt I

trpg

d

Itrt I

t6t I

(E

lsl I

+rBts

(E-E

o

lsl I

.E

OE:

o)

Il

o

tgt I

9'' e

o

lsl I

33

o,

ltl

t^tl

6

'tr

=l'l.l

.l|

A

;i

. ,il9A-9riic.Y O

oo-N<o$ro

.E os X F

!

vLvv)v)Lv)

.=-.lc-<

-

F-ii--

o

O

=

N

El9-;l

o

o

oJ-l=l

t@t I

o*

(*

E X o

lo

:<tNt-l

_.l,il I

t9 l

l;t I

rcl

gl

Y

:! }.E P Eg

Y'O

qt.=^-o

o

",

F i..n

"'f

i

.lJ

dlFt

I

I

m*

=

f=o=

x-

tst I

^

;u]

".6'8

6 E ?5.!2 d\ n

=-L

a

@

r)

=

619';l

:li.')lsl

||l

o

lpl=l

||l

@gg

o

PlKl-l

ottrt

I

tgl

Lttrt I

l9 l

It

#

$*=fi€f e *FtHEt

EEASA$

:fi:E

;E:E

F6

v

#p ii 9

E6:=o

$ @ro f(o

^O^XP

"ra

Hv did

A-

-i

;

€g

€

ffi E

eet*tE iu

e

B

EE$€

f;rte i€;i

gE

Efi* Hif

3

Eq H

F

_CX:U

d F rr

==E;x

* E49 E

vv

>;-;

eSF!

u

n, u

(e

c

L

I

Er**rcEF

P

gE$g

iEEttEF€

€g€* A

[E*E

E

^F;E€r

EEg

g;i

g

E

-

q.Y'F

P:.E

F P+E

hH 6:

5;

9

E

EEEEEiEE

e-93E n

9 6.g)

^s

X

u=

!6'-^F

Bf 9_c

'

o*

d

o.g

u=

H

HEE:€ffig fi€F*€EE5€ea*€3e"

s,n:f Es€n E;!frEEEgi::€Ef;E

f;+lffi

-$EeE

fstE

EEela

: sE;

g

ED=

eE,

-Yb

;g

6

c o

E

o .:h\"

.s99

_lDor3

B:>

i=

E;E FE;

i

sEI

.e

i

bE:

6ts

d

*EEIAEg

E

F.P:

€F

=

.d

p

Eb;

gieigi;

EEg€g :

Hi*Ic

:

i:q

8*'

€

s

E Ef;

E

PcX

tr

EE9

=

c-

Sq*

:;€,Fg; t rf EE€

ocEoo

FP:bc

.5

g

=6.o

.=E

E

P

'=-dl

o:-(E

gE;'

i

$ $8,

iEE

;F,E

s

$E s af

ggggE;gEfiB$$

giE€f;EEE*EfEIFf;

giFEBSFE€iifig€$_EEEi$EEEEg€€

;gEffE-ErciFH*

*I=*E;i

=fr$gg!

aeE*eE

HIIE*E

E

gF

it,E

gr

EE;gEE€$iiiEEggE

cBE

3fi

g

fi

iggiEIfEii9#

gi

€

€i *$

E Fi e

-gegEgEfi

Efi€ff*#E

€EFEF€EE

s

E €* E €

€

€=

iE=;

EF:a

g

iiE€EFE

#€EF5E

igfiEs€;,

IFEiEifi

EEEi$gfii

:ffeffEi

g€sEeEfiE

EE

g

5i*g;e

=$e€lE

:3 E :E

F'3 E aE

E#

;' E ,tAE EE ;:i=Effi*

$fff*;;

;

E^EEiFEfr

e,

:E;

-E

fiEE

lp E ftS€! E F

;

IE

g_i

u

E:€*5EES

q

s;sE B;€

;gEEHE="*

-

g!E

Page 4

SE$;;Et

ggE

ggEgEEl

g:EEEi$E:Egflfr

gEFiEIgE

AEE €FE EgE

Eg

g€

*gE

itE

fiHE

Efr

gg

ff;

i6€

ffeE

#

gE

€e"*;

€B-6

fi*=r

fr

Eg

o

B

E: .i

q

6f,!Ef

d'FiE€*:*9'FT

Usi'6c'Ec*r.i6!

\u

o),Y- I

8f€dF"E

-lt

v,Ya

c

E

fi

=

9

'i:

'=

.=

6

cl E8.E'*F'=:Eii€B

g

gXE$'EdX99o=

.E9-

EE

!= s=9838p E

.9d

=^xF6'd;3,

i'FI*,ooQ

3F--;.:3

e

p

o

o- 8,6

b ;E FeiE=E

O

Eq .@#7EP

EdSH+&

b

E ff E#EEE$

(U

iH. X€oES-

ad e'5€ fr5u

EE

EE !EIE",*

€; 5 9 E.e F 5

FE E€ffi*a

6-c - tr'i nr F 6

fE;E

T

gE

=

5E

Ps EEEc

?-a Y.4 a H

e'

ff:

*'n5* o

i'E.ee

8

b3.

fr

.o

."'=

lc+ Yrict

hX R

g

o,9

eL

E

iD

E

:U

=

O

-6

O7

E

O

5E

L

ai6

c.ri

y

>, H

EgiliggF

*$EE

acs

er

z

;3

oiFb* 6.c

o

EEE

o

tr-E

gx

E.6

R'>

=^

c=

oh

'E

6Foro6ts

4;

!{-E"+

H9rEe;h

i.e

HE F

=oi

=

d

!

o.6

gE

6X

5s,

dttgE

tA-y.

9.pF:6

* 9r= X

c

=:9

=-

.;

_E *

6

.c)

c

o

'9

EO>(s

w'-

c'= c

v

iE

ggg;Fg

-I

E-

o

(U

E

;(

E.s

o>

.= l=

o.oi:

p.Y

-o

e*

EgEEEE

I

c

a.

c

oEo

(g

o_

EEEE

E:

v+

-=

E E

'i

g

*

:

E

EEEfiE

I

OEf,:

o6*

E

_il

F66t

o=

F

IE

>.E=J

gs

fl

gglug

I

rr3,{ o

E_

oi9 F,

ts

oro:

9;s9)

(Ets!

o

E

ti;

E

L! C

d

[j'6 x6

H'n b_

€E$e#gs

--0)

6,*

o6o)

\ .^.!ll

G

:;9.89,

E-a!j

6',9

.\+E

g

i

PE E;;

toSri

9o)

oo)

c'=E

5P.,€E

Qa;ie

=

g;

i,5 E H:

g'lJ',

EE EqE

rffig

.!9 tr

PE

lo.l

;F

Y V n\'i

ao--o

or oS F

H

3E;

t!

-

g

H*B F

UE

3,9

.9

EE

:(u

!!

:

-.

>jJ

g

*E

o

.ooP

6_O

v

=

E 2E

E tt

so-

o'- o

< v';

:g

E

I ;E

dE

be

6i

-fr

g9b

9;,

..G

'=

n

Ptr;q6

o"r U

E

OF t!

ea

L(S

o,

OY

*

ET6Etr

$fEe

* E t E

FF#gEsg

E

o@o

q)

,9

E

.E

tt

ui

e

E

El

riEi

F3g5gg

F*

FF

E* E

E

eE:

jc

[:Hris5

gt€

;s {

F E;Ftf

^,e=E

a7

ra ;

EY

9!

€

E,

EE

Et+E

EA i

p

-

-s

r\5

EE

€

€

a

E

F

.=

5

9,

g

'*

€

Page 5

Initial operation

Switching on/off

The on/off switch consists of 2 control elements, the release button 10 and the

switch 11.

To switch on: 1. Press button 10

2. Press

depressed.

To switch off: Release switch 11.

switch

11

(to

switch on).

(to

The

release).

machine

runs

as

long

as switch 11

Permitted

at least.11,000

discs which

rype

is

fginforced

Always ob*ruettr-@e

types:

{isc

r.p.m.

are approved

qrindinq

discs

Use only

Use_only

for a

grinding

discs

which

synthetic resin-bonded,

peripheral

Ma.-

125

speed

mm

are

of B0 m/sec.

Md.

11500

approved for

fibie+einforced grinding

r.p.m.

disc tabet.

a speed

[/a.

g0

m/sec.

pqiphsa]

of

Testing new discs

Allow

it must

Keep discs free of

ments

Electronic

machine

the

replaced

be

of ANSI

run for

to

immediately.

grease

87.1

and

on the use and care of discs.

minute

one

protect

control

under no load.

lf

the disc

vibrates

from impact damage. Follow the require-

Starting current regulator

The starting curent required

nominal cunent inout.

The starting cunent regulator limits the

starting, helping

machine starts smoothly without

prevent

by the machine is several times higher

the

mains fuse from tripping. lt also ensures that the

jolt.

a

current drawn by

the

than

machine when

Constant-speed electronics

The constant-speed

constant under load or no-load conditions. This oermits materials to be oround

or cut optimally as

Protection

Thermal motor

The thermal

temperature. This

lf the motor is

restart when

permitted

The

temoerature.

Restart interlock

protection

This

interruption of the

connected by another

Even after the supply cord has

machine

machine must first be switched off before it

Seruice indicator

The service indicator LED 16 lights up or

before the

LED

have switched off the machine

The

can only be restarted by operating the on/off switch intentionally. The

automatic cut-out carbon brushes finally switch off the machine.

16 will no longer be light up once the automatic cut-out carbon brushes

machine must then be serviced bv Hilti.

electronic control system

result of the

a

constant disc speed.

devices

protection

motor orotection circuit monitors current consumotion and motor

prevents

overloaded while working, the machine will stop, and

pressure

overload is not

device

on the

power

person.

the machine

grinding

a certain specified

prevents

uncontrolled restading of the machine after

supply, e.

been

after

g.

this

keeps

the running speed almost

from overheating.

or

when the

reconnected to the mains

disc is reduced.

cutting

value,

but depends on motor

plug

mains

be restarted.

can

to flicker approximately 8 hours

begins

approx. 8 hour

is

period,

will

only

accidentally dis-

the

supply,

the

Operation

grinding

Rough

F91p9st

19^srlttq.with

of 30 to 40'to

Materials

Fire risk

where

Carc and

Always disconnect

the machine!

Keep the

out the motor

ot compressed

let

The machine

Should the

m.anufacturing

Hilti

service centre.

Accessories

Abrasive

Warrantv

Hilti

warranis

wod<manship.

correctly,

Operati,ng Instructions,

date of the

means that

used in

of defective

wear and

Under no

or consequential

reasolr

-specifically

padicular

for

a

For

repair

discovery

orovided.

This constitutes

prior

all

conceming

the workino

containing

Ensure that

sparks fly

when

maintenance

cooling

slots in

at regular

air.

requires

machine

and inspection

grinding

discs

that

This wananty

cleaned

(invoice

sale

only original

the tool.

This

parts

only.

tear are not

circumstances

oJ, the

or

damages,

_use

excludes

purpose,

or.replacement,.send

of the

defect

Hilti's

contemporaneous

warranties.

grinding

rough

surface.

asblestos

no flammable

cutting and

the mains

no other

develop

the tool

and

wananty

Parts requiring

covered

of, or inability

the implied

plug

the motor

intervals

maintenance.

a fault

procedures,

supplied

is

valid

serviced

all wananty

date),

Hilti

consumables,

provides

by

will

Hilti

losses

to the address

entire

obligation

bomments

(smoothing)

must

not

be

materials

grinding

from the

housing

(approx.

and the

this wananty.

every

despite

it

is free

so long

properly

claims bre

technical

componerits

the

repair

be ogligited

or expenses

to

use the

warranties

tool

and/or

of the local

with

discs, hotd

ground.

are located

metal.

mains

supply

clean

and free

four weeks),

having

should

as the tool

and in

free-of-charge

or replacemint

been

be repaired

of

defects in

is

accordance

made within

system

and spare

tor

direct, indirect

in

connection

tool for

of merchantaliiliry

parts

related

Hilii

regard to

and oral

wananty

or wriiten

the disc

within

before

of

obstructions.

possible,

if

subjected

by

operated

12 months

is

maintained.

repbir

or replacement

ds a resuli

purpos6.

any

immediately

marketing

and

at

an angte

a

wide area

working

clean

using

to careful

an authorised

material

with the Hilti

and

and handled

from

This

parts

may

of normal

incidental

irvitr,

or

Hilii

dnd fitress

upon

organizjtion

supersedes

agrbements

of

on

a

the

be

bv

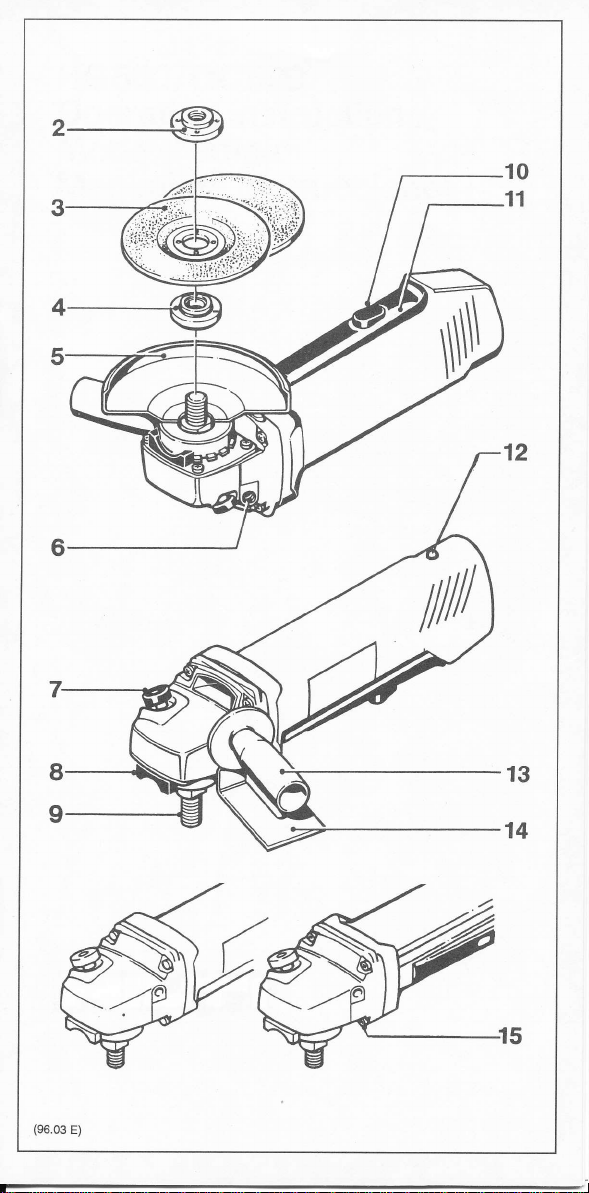

Changing discs

Alwayvdlsconnect the mains

machine!

Grinding discs: Lock the spindle by

le lockbutton

se the clamping nut 2 using the

flange

7 should only be

4 and clamping nut 2.

plug

pressed

pin

from the mains supply before working on the

pressing

the spindle lockbutton 7.

once spindle rotation has stopped. Relea-

wrench.

Clean

the

grinding

disc,

The

clamping

spind-

Loading...

Loading...