Henny Penny OFE- 291 User Manual

Model OFE- 291

SECTION 3. OPERA TION

3-1. OPERA TING COMPONENTS

Frypot This reservoir holds the cooking shortening, and is designed to

accommodate the heating elements, 6 head of product and an

adequate cold zone for collection of cracklings

Carrier This stainless steel carrier consists of five racks which contain

the food product during and after frying

Drain V alve A two-way ball valve, normally in the closed position; turn the

handle to drain the shortening from the frypot into the filter drain

pan

Drain Interlock Switch A microswitch that provides protection for the frypot in the event an

operator inadvertently drains the shortening from the frypot while

the main switch is in the COOK position; the switch is designed to

automatically shut off the heat when the drain valve is opened

Shortening Mixing System A shortening mixing capability to help ensure shortening is properly

mixed to prevent an accumulation of moisture and hence boiling

action in the pot; the filter pump is activated by the controls, at

preset intervals, to mix the shortening

Lid Latch A mechanical catch on the front of the lid which engages a bracket

on the front of the frypot, when lid is lowered

Air V alve Pumps air into the shortening, periodically , to keep the shortening at

a uniform temperature; this only functions when unit has been sitting

idle for a period of time, and when heating up from a cold start

703 3-1

Model OFE- 291

3-1. OPERA TING COMPONENTS

(Continued)

High Limit This high temperature control senses the temperature of the

shortening; if the temperature of the shortening exceeds

450°F (230°C), this control will open and shut off the heat

to the frypot; when the temperature of the shortening drops

to a safe operation limit, the control must be manually reset by

pressing the red reset button, located under the control panel, in the

right, front of the fryer

Figure 3-1

Filter Drain Pan The removable pan that houses the filter and catches the shortening

when it is drained from the frypot; also used to remove anddiscard

old shortening

When hot shortening is in this pan, use extreme care to

avoid burns.

Filter Union Connects the filter to the filter pump, and allows easy removal of the

filter and drain pan

Fuses A protective device which breaks the circuit when the current

exceeds the rated value

3-2. LID OPERA TION T o close lid:

1. Lower the lid until latch comes into contact with the pot.

T o open lid:

1. Unlatch the front lid latch.

2. Lift up on handle to raise lid.

3-2 703

Model OFE- 291

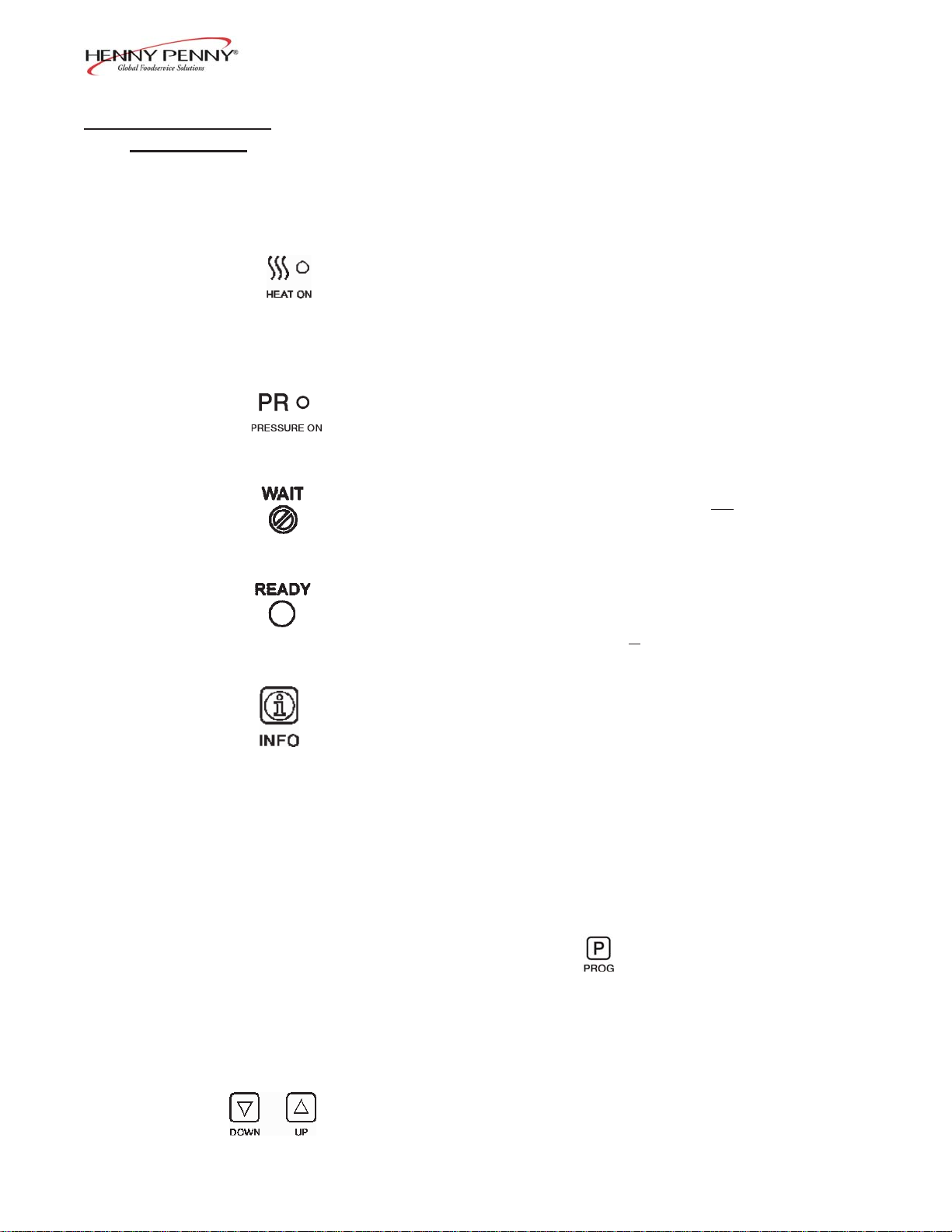

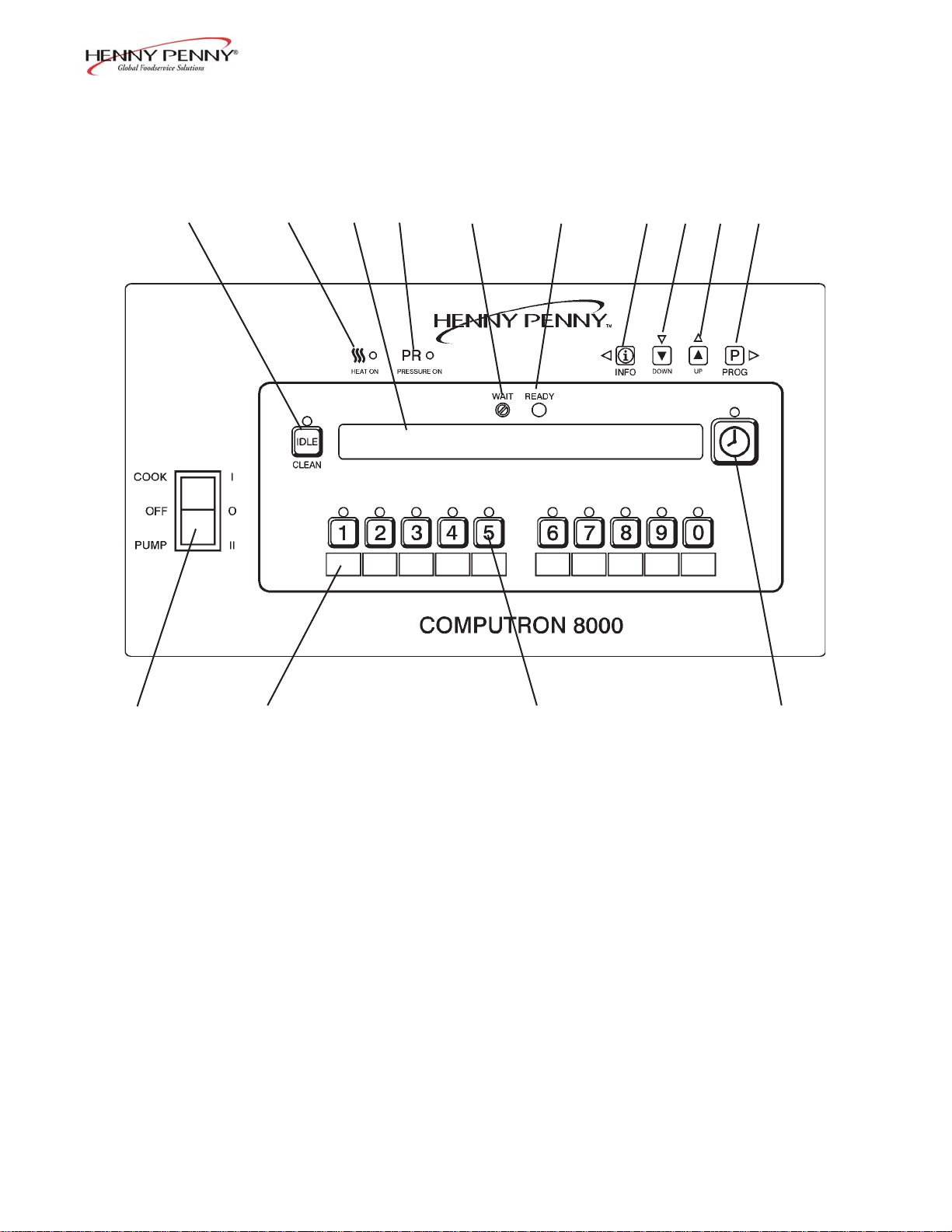

3-3. SWITCHES AND Refer to image at the end of this section.

INDICATORS

Fig. Item Description Function

No. No.

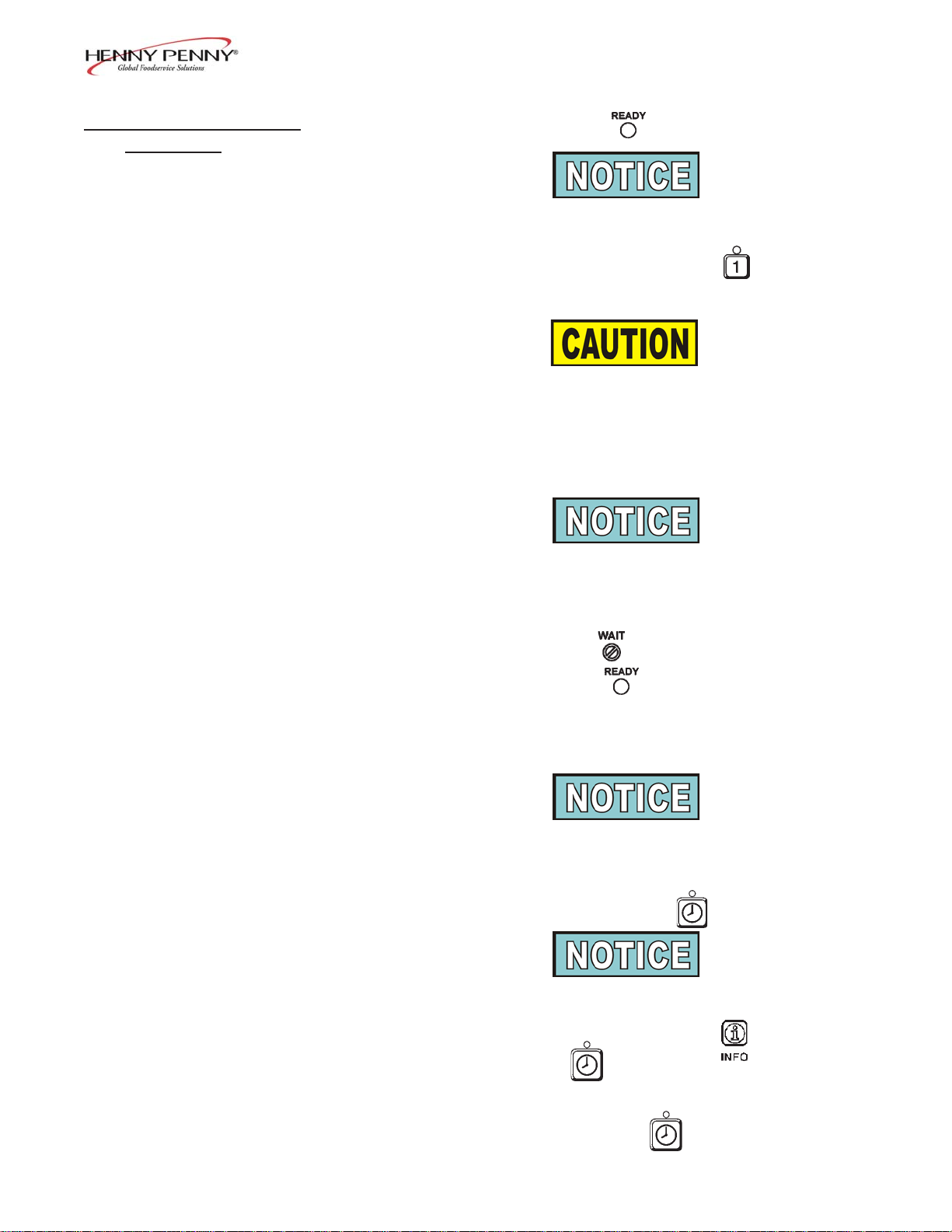

3-2 1 Lights when the control calls for heat; the elements come on and

heats the shortening

3-2 2 Digital Display Shows all the functions of the Cook Cycle, Program Modes,

Diagnostic Modes, and alarms

3-2 3 Only used on models that create pressure in the frypot; this

should not light

3-2 4 Flashes when the shortening temperature is

not at the

proper temperature for cooking product

3-2 5 Lights when the shortening temperature is 5° F below to

15° F above the cooking temperature, signaling the operator

that the shortening temperature

is at the proper temperature

for cooking product

3-2 6 Press to display the following fryer information and status:

a. The temperature of the shortening

b. The temperature setpoint

c. Filter status

d. The number of times filtered today

e. The average no. of filters per day

f . No. of times Cook Cycle was stopped early today

g . No. of times Cook Cycle was stopped early in past week

e. Oil Life Display (Only if “Change Oil” feature is enabled)

f . Date and time

If pressed in the Program Mode, shows previous settings.

Pressing this along with accesses the Information

Mode which has historic information on the operator and

fryer’s performance

3-2 7 & 8 Used to adjust the value of the currently displayed setting in

the Program Modes

1005 3-3

Model OFE- 291

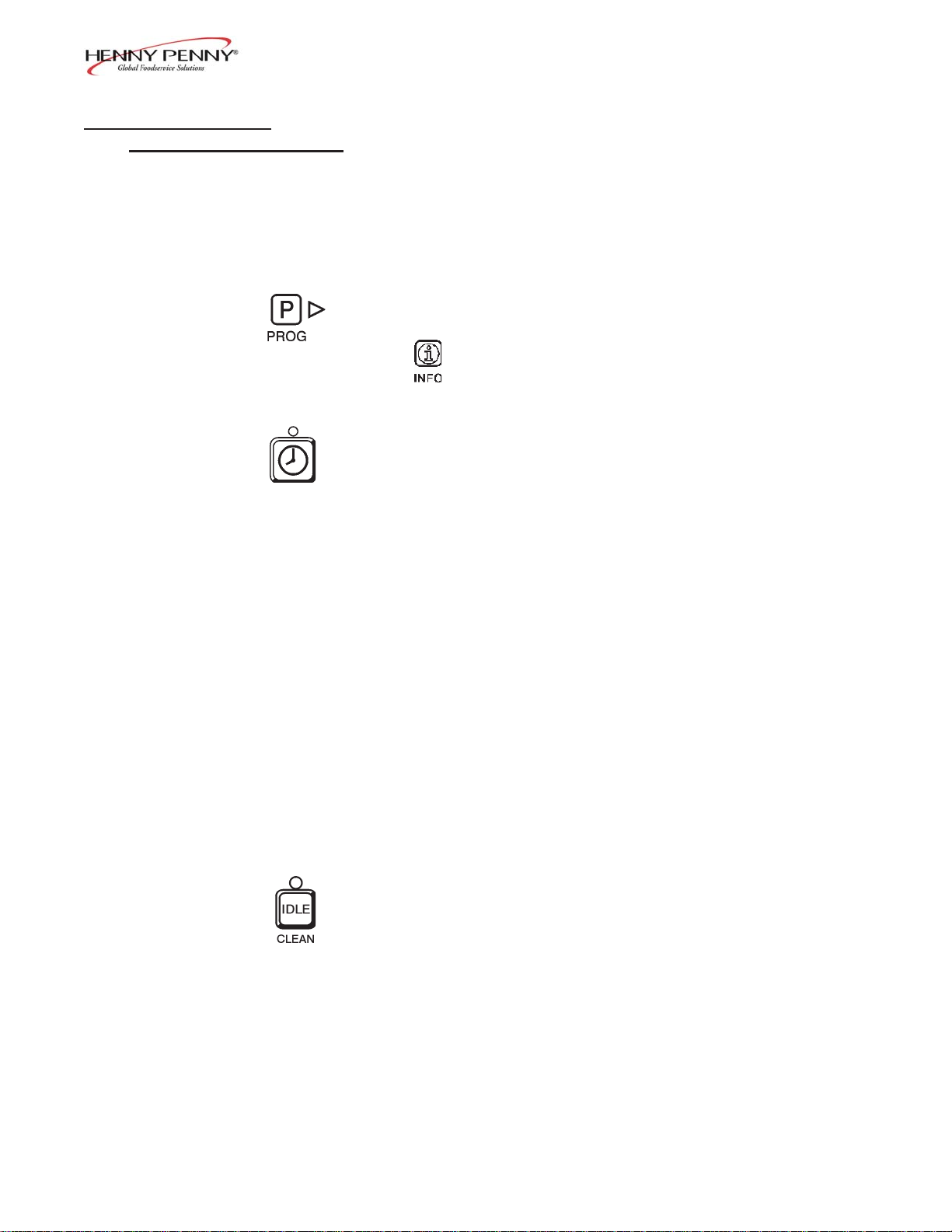

3-3. SWITCHES AND

INDICA TORS (Continued)

Fig. Item Description Function

No. No.

3-2 9 Press to access Program Modes; once in the Program Mode, it

is used to advance to the next setting; if pressed along with

it accesses the Information Mode which has historic

information on the operator and fryer’s performance

3-2 10 Used to start and stop Cook Cycles, and to stop the timer at

the end of a Holding Cycle

3-2 1 1 Menu Card The name of the food product associated with each product

W ind ow selection button; the menu card strip is located behind the

decal

3-2 12 Product Select Are used to select the product for cooking;

Buttons to use them to start Cook Cycles, see section 3, Special

Program Mode item SP-10

3-2 13 COOK/PUMP Switch A 3-way switch with a center OFF position turn the switch

to the COOK position to operate the fryer; turn the switch to

the PUMP position to operate the filter pump; certain

conditions must be met before operating the filter pump;

these conditions are covered later in the Filtering Section of

this manual

3-2 14 Used to manually enter an Idle Mode, or Clean-Out Mode

3-4 703

Model OFE- 291

14 1 2 3 4 5 6 7 8 9

13 11 12 10

Figure 3-2

403 3-5

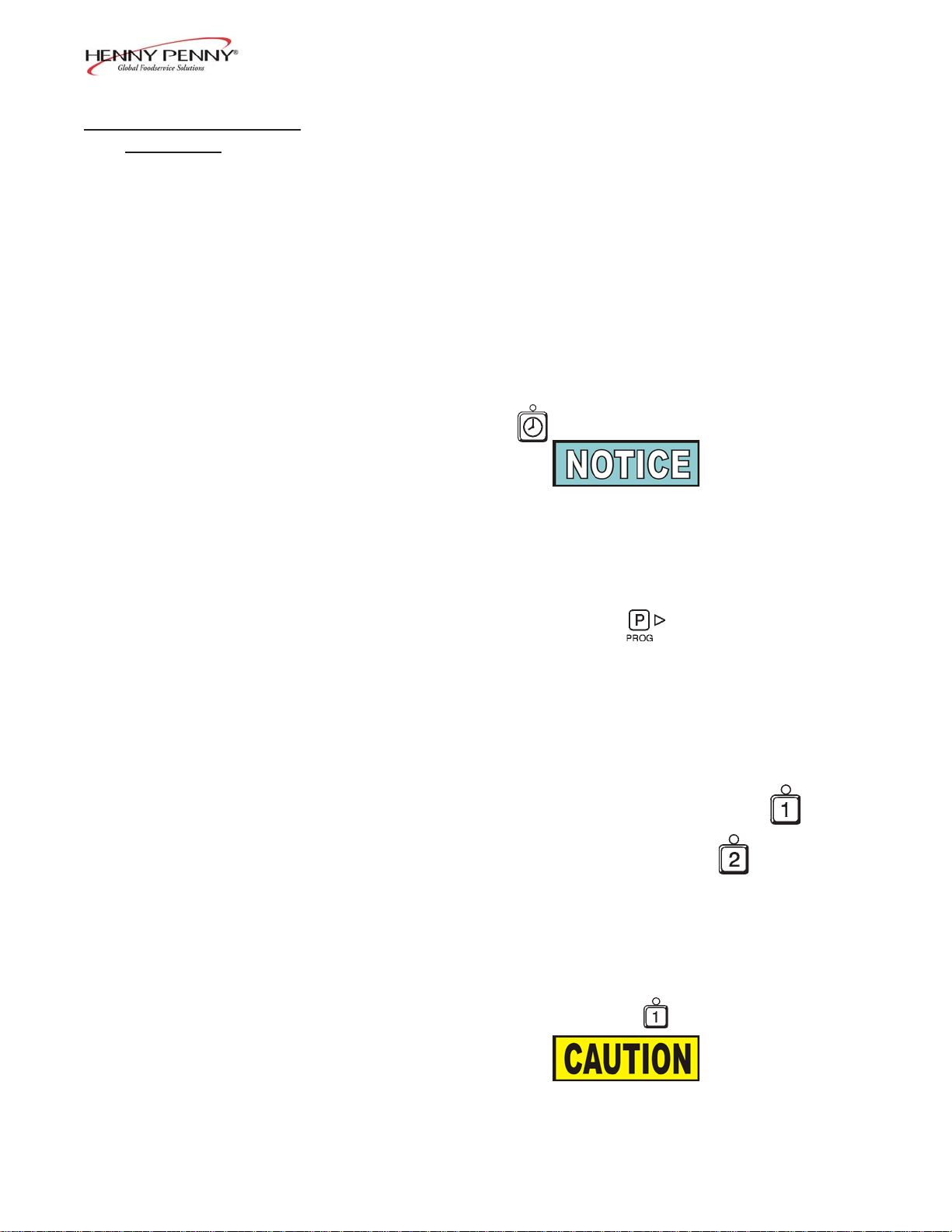

3-4. CLOCK SET

Model OFE- 291

Upon initial start-up, or PC board replacement, if

“CLOCK SET” automatically appears in the display ,

start with step 4.

1. Press and hold for 5 seconds until “LEVEL 2”

shows in display .

2. Press and “CLOCK SET”, “ENTER CODE”

shows in display .

3. Press .

4. “CS-1, SET, MONTH”, and the month flashes in the

display .

5. Press the to change the month.

6. Press and “CS-2, SET, DATE” shows in the

display , with the date flashing.

7. Press to change the date.

8. Press and “CS-3, SET , YEAR” shows in the

display , along with the year flashing.

9. Press to change the year .

10. Press and “CS-4, SET, HOUR” shows in the

display , with the hour and “AM” or “PM” flashing.

11 . Press to change the hour and AM/PM setting.

12. Press and “CS-5, SET , MINUTE” shows in the

display , with the minutes flashing.

13. Press to change the minutes.

3-6 403

Model OFE- 291

3-4. CLOCK SET 14. Press and “CS-6, CLOCK MODE” shows in the

(Continued)

display , along with “1.AM/PM”.

“1.AM/PM” is 12 hour time, “2.24-HR” is 24 hour

time. Press to change.

15. Press and “CS-7, DA YLIGHT SAVINGS ADJ”

shows in the display , along with “2.US”.

Press to change to the following:

a. “1.OFF” = No automatic adjustments for daylight

savings time.

b. “2.US” = Automatically applies United States

daylight savings time adjustment. DST activated

on the first Sunday in April. DST de-activated on

the last Sunday in October .

c. “3.EURO” = Automatically applies European (CE)

daylight saving time adjustment. DST activated

on the last Sunday in March. DST de-activated on

the last Sunday in October .

16. Press and “CS-8, BEGIN NEW DAY” shows in

display , along with “3:00AM”.

This setting indicates the time of day that statistics start

accumulating for a new day . If set to 3:00AM, for

example, then late night cook cycles and filter

operations from midnight to 3:00AM Tuesday morning,

are accumulated with Monday’s statistics.

The CS-8 value can be set from 12:00AM (midnight) to

8:00AM, in half hour increments (12:00 AM,

12:30 AM, 1:00 AM, 1:30 AM, etc.). The default value

for general market software is 3:00 AM.

Press to change the time the “new” day starts.

17. Clock Set is now complete. Press and hold to exit.

403 3-7

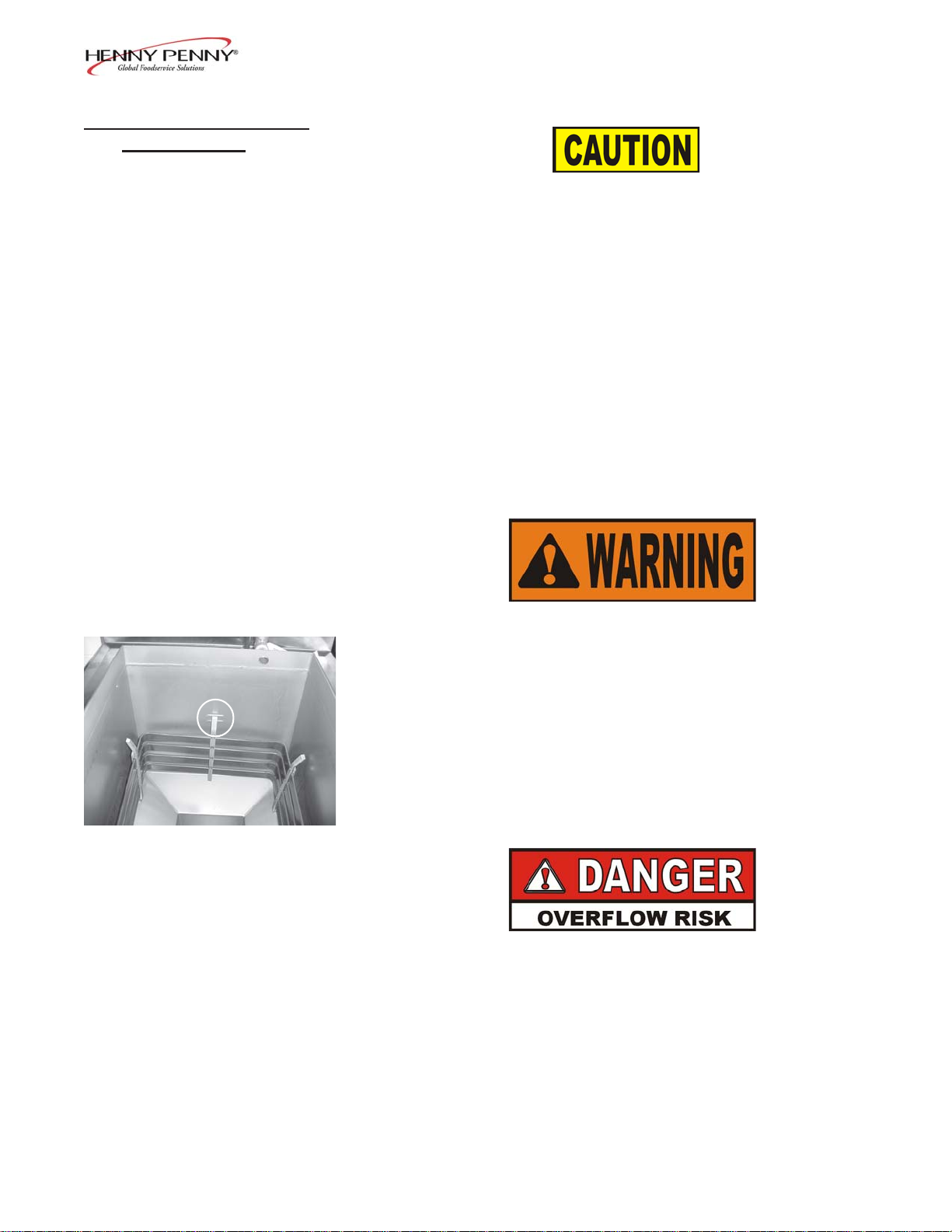

3-5. FILLING OR ADDING

SHORTENING

Model OFE- 291

The shortening level must always be above the heating

elements when the fryer is heating and at the frypot level

indicators on the rear of the frypot (Figure 3-3). Failure

to follow these instructions could result in a fire and/or

damage to the fryer.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source befor e placing it in the frypots. The burner tubes must be completely

submerged in shortening. Fire or damage to the frypot

could result.

1. It is recommended that a high quality frying shortening

be used in the open fryer . Some low grade shortenings have a

high moisture content and will cause foaming and boiling over .

Figure 3-3

T o avoid severe burns when pouring hot shortening

into frypot, wear gloves and take care to avoid

splashing.

2. The electric model requires 100 lbs. shortening (45 Kg.) The

frypot has two level indicator lines inscribed on the rear wall

of the frypot which show when the heated shortening is at the

proper level.

3. Cold shortening should be filled to lower indicator.

BE CERT AIN THE SHORTENING IS NEVER

ABOVE THE UPPER LEVEL INDICA TOR LINE.

FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESUL T IN SHOR TENING OVERFLOWING

THE FRYPOT CAUSING SERIOUS BURNS, PERSONAL INJUR Y , FIRE AND/OR PROPERTY

DAMAGE.

3-8 703

Model OFE- 291

3-6. PRODUCT RACKING

RECOMMENDATIONS The rack positions are referenced starting at the bottom:

4 _____________

3 _____________

2 _____________

1 _____________

The bottom position is to be avoided on small loads because it is

closer to the cold zone. (The oil is cooler at the bottom of the frypot

and hotter at the top.) W ith bigger loads, however, there is generally

enough turbulence in the oil that the bottom rack gets sufficient heat.

The top position is to be avoided on small loads because of

insufficient oil coverage. W ith bigger loads, the top rack has good

oil coverage because the volume of product on the lower racks

raises the overall oil level.

Cooking ONE rack Cooking TWO racks

(2-head load) (4-head load)

4 _____________ 4 _____________

3 _____________ 3 OOOOOOOOO

2 OOOOOOOOO 2 OOOOOOOOO

1 _____________ 1 _____________

Cooking THREE racks Cooking FOUR racks

(6-head load) (8-head load)

4 _____________ 4 OOOOOOOOO

3 OOOOOOOOO 3 OOOOOOOOO

2 OOOOOOOOO 2 OOOOOOOOO

1 OOOOOOOOO 1 OOOOOOOOO

503 3-9

Model OFE- 291

3-7. BASIC OPERA TION Follow the procedures below on the initial start-up of the fryer, and

each time the fryer is brought from a cold, or shut down condition,

back into operation. These are basic instructions.

1. Fill shortening to the proper level in the frypot; to the lower

level indicator

BE CERT AIN THE SHORTENING IS NEVER

ABOVE THE UPPER FRYPOT LEVEL INDICA TOR

LINE. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESUL T IN SHOR TENING OVERFLOWING THE FRYPOT WHICH COULD CAUSE

SERIOUS BURNS, PERSONAL INJUR Y , FIRE AND/

OR PROPERTY DAMAGE.

2. Turn the COOK/PUMP switch to the COOK position and

press the appropriate product button to select the amount of

product to be cooked. Unit automatically goes into the

Melt Cycle. When temperature reaches 250° F (121° C) the

controls goes into the Heat Cycle, and heats the shortening to

the setpoint temperature.

3. Stir the shortening as it’ s heating up from a “cold” start.

Be sure to stir down into the “cold zone”.

DO NOT STIR THE SHORTENING A T ANY OTHER

TIME EXCEPT A T MORNING ST ART-UP . FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESUL T IN SHOR TENING OVERFLOWING THE

FRYPOT WHICH COULD CAUSE SERIOUS

BURNS, PERSONAL INJUR Y , FIRE, AND/OR

PROPERTY DAMAGE

3-10 403

Model OFE- 291

3-7. BASIC OPERA TION 4. Allow fryer to heat until illuminates.

(Continued)

Bypass the melt cycle, if desired, by pressing a product

button and holding it for five seconds. The display shows

“EXIT MELT? 1=YES 2=NO”. Press to exit melt.

Do not bypass the Melt Cycle unless enough shortening

has melted to completely cover all of the heating elemets.

If the Melt Cycle is bypassed before all heating elements

are covered, excessive smoking of shortening, or a fire

could result.

The heat cycles on and off about 10 degrees before the

setpoint temperature, to help prevent overshooting the

setpoint temperature. (proportional control)

Once out of the Melt Cycle, flashes until 5° before setpoint

temperature is reached. Then illuminates and the selected

product shows in the display .

5. Slide racks of breaded product into carrier on the lid,

starting with the bottom rack, to prevent damaged product.

Before loading product onto the racks, lower the racks

into the hot shortening to prevent the product sticking to

the racks.

6. Lower and latch the lid, and press .

A different product can be selected during the first minute of

cooking, in case the wrong product button was pressed. T o

check the shortening temperature press or to stop a

Cook Cycle, press .

7. At the end of the cycle, an alarm sounds, while the display

shows “DONE”. Then press .

403 3-11

3-7. BASIC OPERA TION 8. Unlatch and raise the lid cautiously.

(Continued)

9. Using the rack handles, remove the racks of product from

the carrier, starting with the top rack, to prevent damaged

product.

10. If a Quality time (hold time) was programmed, the controller

automatically starts the hold timer. The display alternately

shows the product selected and the quality time remaining in

minutes. If a different product is selected during the Hold

Cycle, the display only shows the product selected.

1 1. At the end of the Hold Mode, a tone sounds, the display

flashes “QUALITY”, and the product it was timing. Press

and release .

In the Cook Mode, when “FILTER SUGGESTED”, shows in

the display , the operator has the option to filter at this time, or

to continue cooking. But, if the operator continues cooking, a

Filter Lockout occurs within the next Cook Cycle, or two.

Model OFE- 291

When “FILTER LOCKOUT” , then “YOU *MUST* FILTER

NOW........” shows in the display, is the only button that

functions, until the unit is filtered. Follow the filtering instructions in

this manual.

Once filtering is complete and the COOK/PUMP switch is turned

back on, “IS POT FILLED” shows in the display, followed by

“1=YES 2=NO”.

If shortening is at the proper level in the frypot, press and

the controls start a normal heating process.

If shortening is NOT at the proper level, press and “TURN

OFF UNTIL FILLED…” scrolls through the display. Turn the

COOK/PUMP switch to the OFF position, fill frypot to the proper

level, then turn the COOK/PUMP switch back to the COOK

position.

Again, “IS POT FILLED” shows in the display , followed by

“1=YES 2=NO”. This time press and unit resumes

normal heating process.

When the fryer is heating, the shortening level must always

be above the heating elements. Failure to follow these

instructions could result in a fire and/or damage to the

fryer.

3-12 403

Loading...

Loading...