Henny Penny OFE-142 Operation Manual

Henny Penny

Open Fryer

Model OFE-142

FM05-066-A

05-26-11

This manual and Wiring diagram should be retained in a convenient location for future reference.

The Model OFE-142 open fryer cannot be operated without electric power.

The unit will automatically return to normal operation when power is restored.

Improper installation, adjustment, alteration, service, or maintenance can cause property

damage, injury, or death. Read the installation, operating, and maintenance instructions

thoroughly before installing or servicing this equipment.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. FIRE OR

EXPLOSION COULD RESULT.

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION

1-1. Introduction ........................................................................................................... 1

1-2. Features ............................................................................................................... 1

1-3. Proper Care .......................................................................................................... 1

1-4. Assistance ............................................................................................................ 1

1-5. Safety ................................................................................................................... 2

Section 2. INSTALLATION

2-1. Introduction ........................................................................................................... 3

2-2. Unpacking ............................................................................................................ 3

2-3. Leveling the Open Fryer ....................................................................................... 3

2-4. Ventilation of Open Fryer ..................................................................................... 3

2-5. Electrical Requirements OFE-142 ........................................................................ 4

Section 3. OPERATION

3-1. Operating Components- C1500 Controls ............................................................. 5

3-2. Filling or Adding Shortening ................................................................................. 11

3-3. Care of Shortening ............................................................................................... 12

3-4. Filtering of Shortening .......................................................................................... 12

3-5. Filter Pump Problem Prevention .......................................................................... 14

3-6. Filter Pump Motor Protector - Manual Reset ........................................................ 14

3-7. Changing the Filter Envelope ............................................................................... 15

3-8. Cleaning the Frypot .............................................................................................. 15

3-9. Regular Maintenance ............................................................................................ 18

3-10. Wiring Diagram ................................................................................................... 19

Section 4. PART LIST

4-1. OFE142.101_ GENERAL ASSY .......................................................................... 21

4-2. OFE142.101_FRONT SHROUD ASSY ................................................................ 23

4-3. OFE142.101_ASSY-DRAIN PAN ......................................................................... 24

4-3. OFE142.101_PIPING SYSTEM ........................................................................... 25

4-4. OFE142.101_ASSY-FRAME 2 WELL .................................................................. 27

4-5. OFE142.101_ASSY POT&CTOP ......................................................................... 29

4-6. OFE142.101_ASSY-LH DOOR ............................................................................ 30

4-7. OFE142.101_ASSY-RH DOOR ........................................................................... 31

4-8. OFE142.101_ASSY-FULL ELEMENT & HUB ...................................................... 32

Section 5. TROUBLESHOOTING

5-1. Troubleshooting Guide ......................................................................................... 34

5-2. Error Codes .......................................................................................................... 35

SECTION 1. INTRODUCTION

1-1. INTRODUCTION The Henny Penny Open Fryer is a basic unit of foo

equipment designed to cook foods better and easier.

This unit is used only in institutional and commercial

foodservice operations.

1-2. FEATURES • Easily cleaned

• 55 lb-65lb. (24.94-29.47 kg.) shortening capacity

• 2 Half size baskets per well(option)

• Stainless steel construction

• Manual reset high limit control

• Filter is option

1-3. PROPER CARE As in any unit of food servicing equipment, the open

fryer does require care and maintenance.

Requirements for the maintenance and cleaning are

contained in this manual and must become a regular

part of the operation of the unit at all times.

1-4. ASSISTANCE Should you require outside assistance, call your local

independent Henny Penny distributor in your area, call

Henny Penny Corp. at 0512-89180268 , or go to

Henny Penny online at www.hennypenny.com.

1-5. SAFETY The Henny Penny Open Fryer has many safety

features incorporated. However, the only way to

ensure safe operation is to fully understand the proper

installation, operation, and maintenance procedures.

The instructions in this manual have been prepared to

aid you in learning the proper procedures. Where

information is of particular importance or is safety

related, the words DANGER, WARNING, CAUTION, or

NOTE are used. Their usage is described on the next

page:

OFE142

1

1-5. SAFETY (continued)

SAFETY ALERT SYMBOL is used with DANGER,

WARNING or CAUTION which indicates a personal injury

type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could

result in minor or moderate injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT AVOIDED,

WILL RESULT IN DEATH OR SERIOUS INJURY.

OFE142

2

OFE142

SECTION 2. INSTALLATION

2-1. INTRODUCTION This section provides the installation instructions for

the Henny Penny Open Fryer.

Installation of the unit should be performed only by a

qualified service technician.

Do not puncture the unit with any objects such as

drills or screws as component damage or electrical

shock could result.

2-2. UNPACKING The Henny Penny Open Fryer has been tested, inspected, and

expertly packed to ensure arrival at its destination in the best

possible condition. The unit is banded to a wooden skid and

then packed inside a heavy cardboard carton with sufficient

padding to withstand normal shipping treatment.

Any shipping damage should be noted in the presence

of the delivery agent and signed prior to his or her departure.

2-3. LEVELING THE OPEN

For proper operation, the open fryer should be level from

side to side and front to back. Using a level placed on the

flat areas around the frypot collar, adjust the casters until the

unit is level.

2-4. VENTILATION OF OPEN FRYER

The open fryer should be located with provision for venting

into an adequate exhaust hood or ventilation system. This is

essential to permit efficient removal of the steam exhaust and

frying odors. Special precaution must be taken in designing

an exhaust canopy to avoid interference with the operation of

the open fryer. We recommend you consult a local

ventilation or heating company to help in designing an

adequate system.

3

2-5. ELECTRICAL REQUIREMENTS OFE-142

Refer to the table below for supply wiring and fusing.

VOLT (V) PH WATTS (KW) AMP(A)

380-415 3 14.4 20.6

To avoid electrical shock, this fryer must

be

adequately and safely grounded (earthed). Refer to

local electrical codes for correct grounding (earthing)

procedures or in absence of local codes, with The

National Electrical Code, ANSI/NFPA No. 70-(the

current edition).

OFE142

4

OFE142

SECTION 3. OPERATING

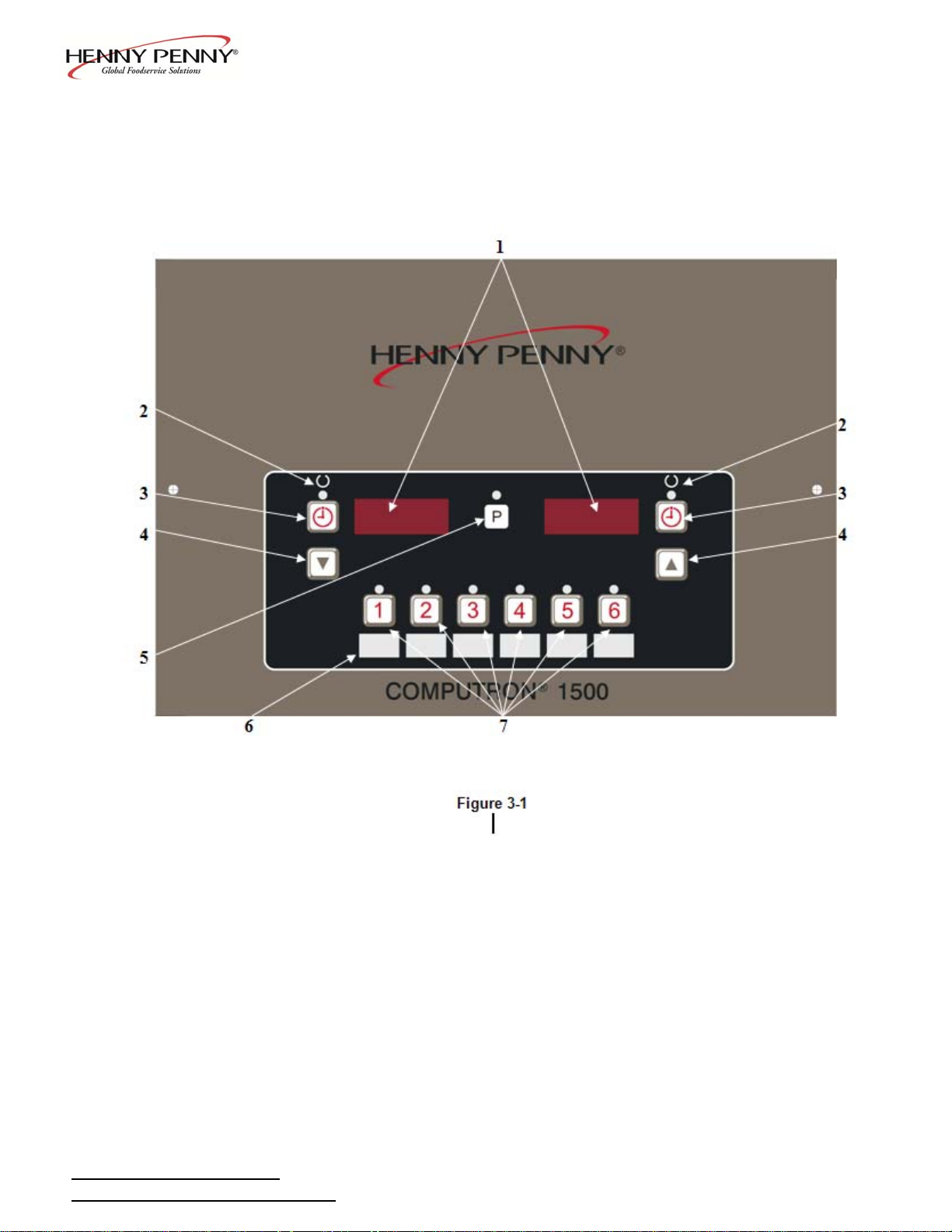

3-1. Operating Components- C1500 Controls

Reference Figure 3-1.

Fig. Item Description Function

No. No.

3-1 1 Digital Display Shows the shortening temperature, the timer countdown in

the Cook Cycle, and the selections in the Program Mode; the

temperature of the shortening can be shown by pressing

once, or twice to view set-point temperature;

if shortening temperature exceeds 425F (218C), the display

reads “E-5, FRYER TOO HOT”

3-1 2 This LED lights when the shortening temperature is within 5

of the set-point temperature, signaling the operator that the

shortening temperature is now at the proper temperature for

dropping product into the frypot

3-1 3 The timer buttons are used to start and stop Cook Cycles; exit

the Melt Cycle; press and hold in the “INIT” Special

Program Mode to re-initialize the controls

3-1 4 Used to adjust the value of the currently displayed setting

in the Program Mode

3-1 5 5 The program button is used to access the Program Modes and

used to advance to the next parameter; also, once in the

Program Mode the LED above the button is lit

3-1 6 Menu Card The name of the food product associated with each product

Window selection button; the menu card strip is located

behind the decal

3-1 7 Product Select Used to select the product for cooking and the LED above

Buttons the selected product is lit

5

OFE142

3-1.C1500 OPERATIONS

The Computron 1500 controls are available on both split frypot and

AND PROCEDURES(continued)

6

OFE142

c

full frypot fryers. The following is a brief description of the

operating procedures for fryers with these controls

1. Be sure the drain valve is in the closed position.

2. Place basket support inside of frypot.

3. Make sure frypot is filled with shortening to the proper level.

4. Display shows “OFF” until power switch is turned to the

ON position. Display shows the selected product as

“P-1”, “P-2”, “P-3”, etc, and the unit automatically starts

the Melt Cycle until the shortening temperature reaches

250

To assign a product to a timer button, press product button and

then the desired timer button. “XXXX” is displayed if the product doesn’t mat

(and set-point) press and hold the timer to choose the new set-

point. Once the new set-point is chosen, press the timer button to

start the cook cycle.

Full vat operation: Only products with the same set-point and

LED’s on, can be selected for cooking .

Split vat operation: Products with two different set-points and

LED’s on, can be chosen.

F (121C). The control automatically exits the Melt Cycle.

The OFG-140 series open fryer has several safety devices which

shuts-down the gas supply when they are activated. The above

procedures should be followed to restart the open fryer and if the

shut down is repeated, a qualified technician should be notified.

The Melt Cycle may be bypassed, if desired, by pressing

and holding for 3 seconds.

Do not bypass the Melt Cycle unless enough shortening has

melted to completely cover all of the burner tubes

on gas fryers and elements on electric fryers. If Melt

Cycle is bypassed before all burner tubes or elements

are covered, excessive smoking of the shortening, or a

fire will result.

3-1.C1500 OPERATIONS

AND PROCEDURES(continued)

Until lights and the selected product is displayed.

5. Once out of the Melt Cycle, the shortening is heated

7

OFE142

Thoroughly stir shortening to stabilize the temperature

throughout the frypots.

6. Before loading product into the baskets, lower baskets

into the hot shortening to keep the product from

sticking to the baskets.

7. Once the shortening temperature has stabilized at the

set-point temperature, lower the basket with product into

the frypot.

Do not overload, or place product with extreme

moisture content into the basket. 12.5 lbs. (5.7 kg)

is the maximum amount of product per frypot

(6.25 lbs. (2.8 kg) maximum for the split frypot

fryers). Failure to follow these directions can result

in shortening overflowing the frypot. Serious burns

or damage to the unit could result.

9. If the right basket was dropped into the shortening, then

press the right .

If the left basket was dropped, then press the left .

10. The timer on the appropriate side (right or left) starts

counting down.

11. At the end of the Cook Cycle a tone will sound and the

display flashes “DONE”. Press button and lift the

basket from the shortening.

3-1.C1500 OPERATIONS

AND PROCEDURES(continued)

If “LOCK” shows in the display when trying to change the

set-points or times, see Special Programming for unlocking

procedures.

8

OFE142

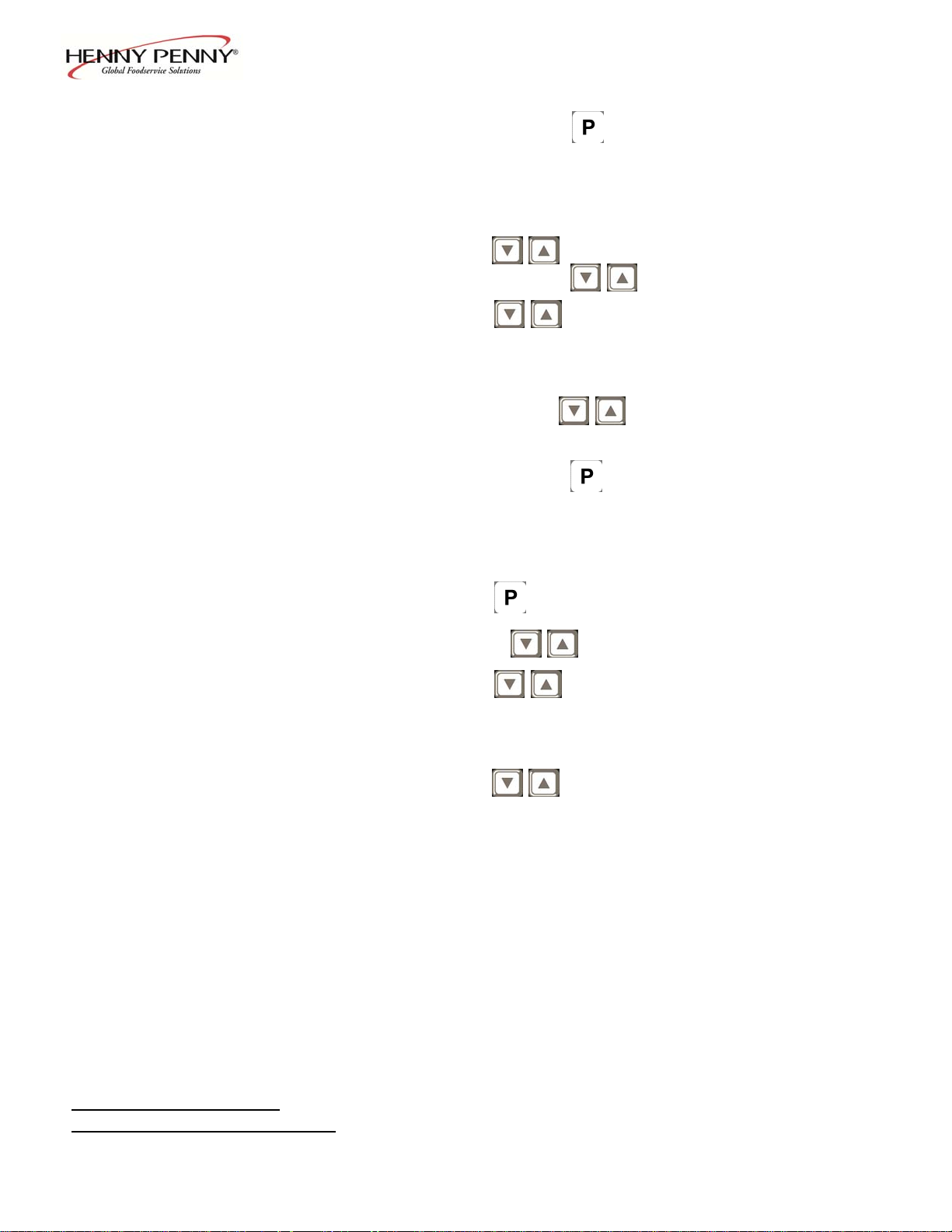

To Change Set-Point Temperatures

1. Press and hold until “PROG MODE” shows in

the display.

2. Press the desired product button and the LED above the

button is on and the set-point temperature flashes.

3. Press to change the set-point temperature.

Press and hold and the values increases by 5.

4. Once are released, the set-point is saved after

2 seconds.

5. To reset set-point temperature to default settings, press

and hold both simultaneously.

To change Product Cooking Times

1. Press and hold until “PROG MODE” shows in

the display.

2. Press the desired product button and the LED above the

button is on and the set-point temperature flashes.

3. Press and the cook time flashes.

4. Press to change the product cooking time.

5. Once are released, the time is saved after 2

seconds

6. To reset cooking time to default settings, press and hold

both simultaneously.

Special Programming

3-1.C1500 OPERATIONS

AND PROCEDURES(continued)

Fahrenheit or Celsius

Initialize System

Lock or Unlock Controls

Fryer Type – Open or Pressure

is used to set the items below:

9

Loading...

Loading...