Page 1

Model OFE-101

恒鹏(苏州)设备有限公司

开口炸锅操作指导书

型号: OFE-101

Henny Penny

Open Fryer

OPERATOR’S MANUAL

FM07-170-E

02-28-11

Page 2

Model OFE-101

This manual and Wiring diagram should be retained in a convenient location for future reference.

The Model OFE-101 open fryer cannot be operated without electric power. The unit will automatically

return to normal operation when power is restored.

本操作手册和接线图一定要妥善保管.以备将来参考

OFE-101 可以连续工作在有电源供应的状况下,中途停电不影响其功能, 恢复供电后该炸锅可自

动恢复正常。

Improper installation, adjustment, alteration, service, or maintenance can cause property damage,

injury, or death. Read the installation, operating, and maintenance instructions thoroughly before

installing or servicing this equipment.

不正确的安装, 调整, 服务和维护可能财产损失和人身伤害, 甚至死亡。 请您在安装和维护维

修该机器前仔细阅读安装, 操作和维护说明。

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. FIRE OR

EXPLOSION COULD RESULT.

不要在该设备附近存放汽油或任何易燃易爆物品, 负责可能引起火灾或爆炸。

Page 3

Model OFE-101

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION 介绍 ................................................................................................................. 1-1

1-1. Introduction 介绍 ............................................................................................................... 1-1

1-2. Features 特点 ..................................................................................................................... 1-1

1-3. Proper Care 保养................................................................................................................ 1-1

1-4. Assistance 协助 .................................................................................................................. 1-1

1-5. Safety 安全 ........................................................................................................................ 1-2

Section 2. INSTALLATION 安装 .................................................................................................................. 2-1

2-1. Introduction 介绍 ............................................................................................................... 2-1

2-2. Unpacking 拆箱 ................................................................................................................ 2-1

2-3. Leveling the Open Fryer 水平安装炸锅 ............................................................................ 2-2

2-4. Ventilation of Open Fryer 保证通风 ................................................................................. 2-2

2-5. Electrical Requirements OFE-101 供电要求..................................................................... 2-2

Section 3. OPERATION 操作规范 ................................................................................................................. 3-1

3-1. Operating Components- C1000 Controls操作组成 .......................................................... 3-1

3-2. Filling or Adding Shortening 注油和增加油 .................................................................... 3-3

3-3. C1000 Operations and Procedures 基本操作和程序 ........................................................ 3-4

3-4. C1000 Programming Instructions ...................................................................................... 3-5

3-5. Special Program Instructions ............................................................................................. 3-6

3-6. Care of Shortening 注油操作注意事项 ............................................................................. 3-8

3-7. Filtering of Shortening 滤油 .............................................................................................. 3-9

3-8. Filter Pump Problem Prevention 过滤泵问题防范 ........................................................... 3-12

3-9. Filter Pump Motor Protector - Manual Reset 过滤泵手工复位 ........................................ 3-12

3-10. Changing the Filter Envelope 更换滤纸套 ........................................................................ 3-14

3-11. Cleaning the Frypot 清洗锅筒 ........................................................................................... 3-15

3-12. Regular Maintenance 定期保养 ......................................................................................... 3-18

3-13. Wiring diagram 接线图 ...................................................................................................... 3-19

Section 4. PART LIST 零件清单

4-1. OPEN FRYER OFE-101 开口炸锅组件清单 ........................................................................ 4-1

4-2. FRAME ASSY 框架组件 .................................................................................................. 4-2

4-3. FILTER SYSTEM ASSY-DRAIN PAN 过滤系统-滤油盆 ............................................. 4-4

4-4. FILTER SYSTEM ASSY-TUBE 过滤系统-管路 ............................................................ 4-5

4-5.

4-6. ACCESSORIES 附件 ........................................................................................................ 4-7

4-7. POT ASSY 锅筒组件 ........................................................................................................ 4-8

Section 5. TROUBLESHOOTING ................................................................................................................ 5-1

5-1. Troubleshooting Guide ...................................................................................................... 5-1

5-2. Error Codes ........................................................................................................................ 5-2

FILTER MOTOR AND PUMP 马达和泵 ........................................................................ 4-7

Page 4

Model OFE-101

SECTION 1. INTRODUCTION 介绍

1-1. INTRODUCTION 介绍 The Henny Penny Open Fryer is a basic unit of food

equipment designed to cook foods better and easier.

This unit is used only in institutional and commercial food

service operations.

恒鹏公司的炸锅可使烹炸食品更好更方便, 该炸锅仅做

商业用途

1-2. FEATURES

• 55 lb-65lb. (24.94-29.47 kg.) shortening capacity

• 2 Half size baskets per well(option) 2 个炸蓝(可选)

• Stainless steel construction 不锈钢结构

• Manual reset high limit control 高温极限可手动恢复

• Filter is option 可选滤油系统

1-3. PROPER CARE 保养 As in any unit of food servicing equipment, the open fryer

does require care and maintenance. Requirements for the

1-4. ASSISTANCE 协助

1-1

特点 • Easily cleaned 易清洗

55-65 磅(24.94-29.47 公斤)炸油

maintenance and cleaning are contained in this manual and

must become a regular part of the operation of the unit at all

times. 和其他食品设备一样, 开口炸锅需要维护和保

养。维护和清洁是日常维护工作的一部分。

Should you require outside assistance, call your local

independent Henny Penny distributor in your area, call

Henny Penny Corp. at 0512-89180268 , or go to

Henny Penny online at www.hennypenny.com

您有任何需要协助的问题请与我们的代理商联系, 或者

打 0512-89180268,或者访问我们的网站 www.

hennypenny.com

.

Page 5

Model OFE-101

1-5. SAFETY 安全 The Henny Penny Open Fryer has many safety features

incorporated. However, the only way to ensure safe

operation is to fully understand the proper installation,

operation, and maintenance procedures. The instructions in

this manual have been prepared to aid you in learning the

proper procedures. Where information is of particular

importance or is safety related, the words DANGER,

WARNING, CAUTION, or NOTE are used. Their usage is

described on the next page:安全是我们产品的重要特征。

然而正确安装,操作和维护是保证安全的唯一途径。为

保证您正确理解,我们用了危险,警告,小心和注意字

样, 具体含义如下:

SAFETY ALERT SYMBOL is used with DANGER,

WARNING or CAUTION which indicates a personal injury

type hazard.用于危险,警告,小心的安全警告标记现实

可能会有人身伤害

NOTICE is used to highlight especially important

information. “注意”表明有特别重要的信息

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

造成财产损失

CAUTION used with the safety alert symbol indicates a

“小心”表明有潜在的危险, 忽视可能

potentially hazardous situation which, if not avoided, could

result in minor or moderate injury.

明有潜在的危险,

忽视可能造成小的中等的伤害。

加感叹号的“小心” 表

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury. “警告”表明存在潜在的危险情况,如果忽视可导

致严重的伤害。

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT AVOIDED,

WILL RESULT IN DEATH OR SERIOUS INJURY.“危

险” 表明存在潜在的严重的危险情况,如果忽视可导致严

重的伤害甚至死亡。

1-2

Page 6

Model OFE-101

ECTION 2. INSTALLATION 安装

2-1. INTRODUCTION 介绍 This section provides the installation instructions for

the Henny Penny Open Fryer.这章提供开口炸锅的安装方法

Installation of the unit should be performed only by a

qualified service technician.安装需由专业人员完成

Do not puncture the unit with any objects such as

drills or screws as component damage or electrical

shock could result. 不要用手枪钻或螺钉等在机器外壁钻

孔, 这样可能破坏结构或遭到电击

2-2. UNPACKING 拆箱 The Henny Penny Open Fryer has been tested, inspected, and

expertly packed to ensure arrival at its destination in the best

possible condition. The unit is banded to a wooden skid and

then packed inside a heavy cardboard carton with sufficient

padding to withstand normal shipping treatment.本开口炸锅经

过检查,测试,用木栈板和结实的包装箱及衬板进行包装

托运,经得起正常运输的颠簸

Any shipping damage should be noted in the presence

of the delivery agent and signed prior to his or her departure.

在拆包前发现任何损伤应当向托运者指出

2-1

Page 7

Model OFE-101

2-3. LEVELING THE OPEN For proper operation, the open fryer should be level from

FRYER 水平安装炸锅 side to side and front to back. Using a level placed on the

flat areas around the frypot collar, adjust the casters until the

unit is level. 为正确操作, 开口炸锅应水平安装, 调整脚

轮保证其安装水平。

2-4. VENTILATION OF OPEN The open fryer should be located with provision for venting

FRYER 保证通风 into an adequate exhaust hood or ventilation system. This is

essential to permit efficient removal of the steam exhaust and

frying odors. Special precaution must be taken in designing

an exhaust canopy to avoid interference with the operation of

the open fryer. We recommend you consult a local

ventilation or heating company to help in designing an

adequate system.开口炸锅应装有排气扇等通风设备, 保

证因烹炸食品所产生的异味及时排出并避免影响操作,

我们推荐您找专业的公司安装排风设备。

2-5. ELECTRICAL REQUIREMENTS

OFE-101 供电要求

电压 (V) 相数 功率 (KW) 电流(A)

380-415 3 14.4 20

Refer to the table below for supply wiring and fusing.

参考以下参数

To avoid electrical shock, this fryer must

adequately and safely grounded (earthed). Refer to

local electrical codes for correct grounding (earthing)

procedures or in absence of local codes, with The

National Electrical Code, ANSI/NFPA No. 70-(the

current edition).

为避免电击的发生,炸锅要充分接地, 请参考当地的相关标

准和文件

be

2-2

Page 8

Model OFE-101

SECTION 3. OPERATION

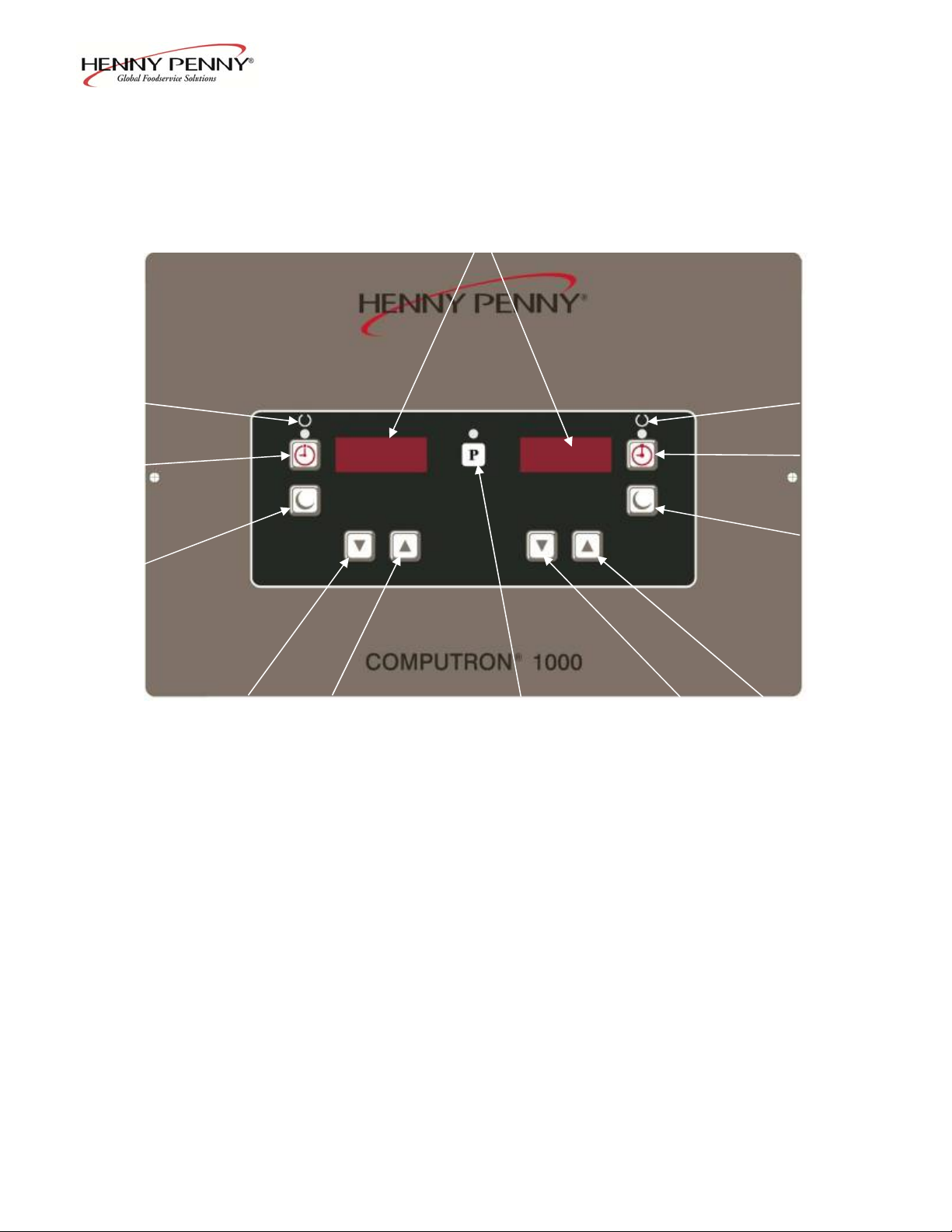

3-1. OPERATING COMPONENTS Reference Figure 3-1. 参考图 3-1

C1000 CONTROLS

Fig. Item Description Function

No. No.

3-1 1 Digital Display Shows the shortening temperature, the timer countdown in

数显屏 the Cook Cycle, and the selections in the Program Mode; the

temperature of the shortening can be shown by pressing

once, or twice to view set-point temperature;

if shortening temperature exceeds 425F (218C), the display

reads “E-5, FRYER TOO HOT”

用来显示油温,烹饪时间。可以通过 来设定设定油

温或者按两次来查设定温度。

3-1 2 This LED lights when the shortening temperature is within 5

of the setpoint temperature, signaling the operator that the

shortening temperature is now at the proper temperature for

dropping product into the frypot

准备就绪灯亮就表示现在油温在设定温度的正负 5 度范围

内,可以用来烹饪产品

3-1 3 The timer buttons are used to start and stop Cook Cycles

计时器按钮用来烹饪周期的开始和停止

3-1 4 The idle buttons are used to start an Idle Mode which reduces

the temperature of the shortening during non-use periods

空闲按钮用于在设备空闲时启动空闲模式,将温度保存

在一个较低的温度内以节省能源

3-1 5 The program button is used to access the Program Modes;

also, once in the Program Mode, it is used to advance to the

next parameter 程序按钮用来进入编程模式,可以修改一

些相关的参数

3-1 6 & 7 Used to adjust the value of the currently displayed setting

in the Program Mode and to change set-point temperature for

the left frypot, or basket

用来在编程模式下修改参数

3-1 8 & 9 Used to adjust the value of the currently displayed setting

in the Program Mode and to change set-point temperature for

the right frypot, or basket

用来在编程模式下修改参数

3-1

Page 9

Model OFE-101

Page 10

Model OFE-101

1

2

3

4

Figure 3-1

6 7 5 8 9

2

3

4

3-2

Page 11

Model OFE-101

3-2. FILLING OR

ADDING SHORTENING The shortening level must always be above the heating

注油或增加油 elements when the fryer is heating and at the frypot

level indicators on the rear of the frypot. Failure to

follow these instructions could result in a fire and/or

damage to the fryer. Less than level will caught fire.

烹炸产品时油必须在油位线之间,否则可能导致火灾

或人身伤害. 低于油位线有着火的危险。

When using solid shortening, it is recommended to melt

the shortening on an outside heating source before

placing it in the frypots. The heating element must be

completely submerged in shortening. Fire or damage

to the frypot could result.

当使用固体油时, 在融油时必须使油覆盖加热器。

否则可能导致火灾或人身伤害

1. It is recommended that a high quality frying shortening

be used in the open fryer. Some low grade shortenings

have a high moisture content and will cause foaming

and boiling over.

推荐用高质量的炸油, 一些低质量的油中含有水,

可引起过多的泡沫和飞溅

Wear gloves to avoid severe burns when pouring hot

shortening into frypot. Shortening and all metal

parts that are in contact with the shortening are

extremely hot, and take care to avoid splashing.

油和其接触的金属件很烫, 所以当把热油加入锅筒

时戴上手套,同时避免飞溅以防烫伤,

2. Cold shortening should be filled to the lower indicator

when the frypot has 2 indicator lines,

油位必须在两条油位线之间.

3-3

Page 12

Model OFE-101

3-3. C1000 OPERATIONS

The Computron 1000 controls are available on both split

AND PROCEDURES

electronic controls frypot and full frypot fryers. The following is a brief description

of the operating procedures for fryers with these controls.

无论是分体式的电控炸锅,还是合体式的电控炸锅,上面都配

有 C1000 控件。以上为带有此控件的炸锅,其操作规程如下:

1. Be sure the drain valve is in the closed position.

确定排水阀位于关闭的状态

2. Place basket support inside of frypot.

将炸篮支架放入炸锅内

3. Make sure frypot is filled with shortening to the proper

level. 确定加入炸锅里的油达到要求的油位线

4. Display shows “OFF” until power switch is turned to the

ON position. Display now shows the cook time and the unit

automatically goes into the Melt Cycle until the

shortening temperature reaches 230F (110C). The

control then automatically exits the Melt Cycle.

显示器在开关拨至“开”状态之前,一直显示为“OFF”

(关闭)。显示器开始显示烹制时间,设备开始自动地进

入到熔解程序,直至油温达到 250°F (121°C)。之后,控件

会自动地退出熔解程序.

The Melt Cycle may be bypassed, if desired, by pressing

and holding for 3 seconds.

如果需要的话,按此键

5. Once out of the Melt Cycle, the shortening is heated

until lights and the cook time is displayed.

Thoroughly stir shortening to stabilize the temperature

throughout the frypots.

熔解过程结束后,炸锅里的油便开始加热,直至

此时显示器上会显示出烹制时间;充分搅拌炸油以均衡锅缸

里的油温.

6. Before loading product into the baskets, lower baskets

into the hot shortening to keep the product from

sticking to the baskets.

在将食物装入炸篮之前,将炸篮放入热油内,以防止食物粘在

炸篮上。

7. Once the shortening temperature has stabilized at the

setpoint temperature, lower the basket with product into

the frypot.

等油温稳定后,将炸篮和食物一起放入炸锅的锅缸里

3秒钟可以略过熔解程序。

灯亮,

3-4

Page 13

Model OFE-101

3-3. C1000 OPERATIONS

AND PROCEDURES

(Continued)

Do not overload, or place product with extreme

moisture content into the basket. 12.5 lbs. (5.7 kg)

is the maximum amount of product per frypot

(6.25 lbs. (2.8 kg) maximum for the split frypot

fryers). Failure to follow these directions can result

in shortening overflowing the frypot. Serious burns

or damage to the unit could result. 不要在炸篮里放

入太多的食品,也不要在炸篮里放入水分含量过高的产品。每个炸锅锅缸的最大容量为 12.5

磅(5.7kg),而分体式炸锅锅缸的最大容量为 6.25 磅(2.8kg);如果不按以上要求进行操

作,可能会导致热油溢出,会对设备带来损伤

9. If the right basket was dropped into the shortening, then

press the right .

If the left basket was dropped, then press the left .

如果放入油里的是右边的炸篮,请按右边的 键;

如果放入油里的是左边的炸篮,请按左边的 键。

10. The timer on the appropriate side (right or left) starts

counting down. 这时左边(或右边)的计时器便开始

倒计时

The timing operation of the two sides of the control

is entirely independent of each other. One may be set,

started, or stopped without affecting the other.

两边的计时器操作是各自独立的。设定、启动、或关闭

任何一边不会影响另一边的正常操作

11. At the end of the Cook Cycle a tone will sound and the

display flashes “DONE”. Press button and lift the

basket from the shortening.

烹制过程结束之时,会有鸣叫声响起,此时显示器

显示“DONE”(完成)。按 键,将炸篮从油里

提起

Timer Programming

3-4. C1000 PROGRAMMNG

1. Anytime the cook time is displayed, press

INSTRUCTIONS

under the appropriate display to change the cook time.

1. 在显示烹制时间的情况下,按

键可以更改烹制时间

Set-Point Temperature Programming 设定预定好的温度

1. Press once to view the actual shortening

temperature and press again to view the setpointtemperatue.

3-5

Page 14

Model OFE-101

按一次 键,操作者将看到实际的油温,再按一

次 键,操作者将看到预先设定好的油温;

2. While the set-point temperature is in the display, press

to change the set-point temperature.

如果显示器上显示的是预先设定好的油温,按

键可以更改预先设定好的油温

If “LOCK” shows in display when pressing ,

the controls are locked and must be unlocked before

changing the time or set-point temperature. See C1000

Special Programming Section.

按 键,控件被锁定,这时显示器上显示 “LOCK”(锁定)

字样;如果要更换时间或设定温度,必须先解锁控件。见C1000特殊编程部分;

Special Programming is used to set the items below:

3-5. C1000 SPECIAL

特殊编程用于设定以下内容

PROGRAMMING

Fahrenheit or Celsius 华氏温度或摄氏温度

Initialize System 系统初始化

Lock or Unlock Controls 锁定或解锁控件

Fryer Type – Electric; Gas w/standing pilot;

Gas w/electronic ignition; Gas-Induced Draft

炸锅类型――电炸锅;配有常备点火设备的煤气炸

锅;配有电子点火设备的煤气炸锅;配有引风机的煤

气炸锅

Split or Full Vat (frypot) 分体式或合体式锅缸

1. To enter Special Programming, turn off power switch

(either side). Press and hold and turn the power

switch back on.

关掉任何一边的电源开关,进入到特殊编程。持续

按 键后将电源开关重新打开;

2. “SPEC” “PROG” followed by, “DEG” “°F” or “°C”.

Use to change to “°F” or “°C” or vice versa.

显示器上会显示“SPEC” “PROG”字样,随后会出现

DEG” “°F” 或 “°C”字样;按 键选择“°F” 或

“°C” ,反之亦然;

3. Press and “INIT” shows in the display.

Press and hold the right and display shows “In-3”,

“In-2”, “In-1” followed by “Init Sys” “DONE DONE”.

3-6

Page 15

Model OFE-101

The controls now are reset to factory parameters, the

time set to 0:00 and temperature 190°F or 88°C.

按 键,这时显示器上将显示 “INIT” 字样;

持续按右边的 键,显示器上将显示“In-3”,“In-

2”, “In-1”字样,接着会出现“Init Sys” “DONE

DONE”字样;此时控制器被重新设定回厂方设定的

参数,时间为0:00,温度为190°F 或 88°C;

4. Press and “LOCK” or “UNLOCK” shows in the

displays. Use to change from “LOCK” to

“UNLOCK, or vice versa.

按 键,显示器会显示“LOCK”(锁定)或

“UNLOCK”(解锁)字样; 按 键,在“LOCK”

(锁定)和“UNLOCK”(解锁)之间切换,反之亦然;

5. Press and “FRYR” shows in the display. Use

to change the fryer type: “ELEC” for

electric models; “GAS” for units with standing pilot;

SSI for units with solid state ignition; IDG for units

with induced draft gas burners.

按 键,显示器上显示“FRYR” (烹制)字样;通过

键,更换炸锅类型:“ELEC” 代表“电炸锅”;

“GAS” 代表“配有常备点火设备的煤气炸锅”;SSI

代表“配有固态点火设备的炸锅”;IDG 代表“配

有引风机的煤气炸锅”

6. Press and “VAT” shows in the display. Use

to change the vat (frypot) type from

“SPLIT” to “FULL” or vice versa.

按

键,显示器上显示 “VAT” 字样;通过 键,

将锅缸类型由“SPILT”切换成“FULL”,反之亦

然;应该设定为“FULL VAT”;

7. Press and hold to exit Special Programming at

any time. 任何时候持续按

键,退出特殊程序。

3-7

Page 16

Model OFE-101

3-6. CARE OF SHORTENING

注油操作注意事项

FOLLOW THE INSTRUCTIONS BELOW TO

AVOID SHORTENING OVERFLOWING THE

FRYPOT, WHICH COULD RESULT IN SERIOUS

BURNS, PERSONAL INJURY, FIRE, AND/OR

PROPERTY DAMAGE.

依照以下指示做以避免溢出锅筒而导致烫伤,人身伤

害,火灾和(或)财产损失

1. Maintain the shortening at the proper cooking level.

Add fresh shortening as needed.

保证加入新鲜的油, 并油在两个油位线之间

2 Discard any shortening which has a bad flavor or shows

signs of excessive foaming or boiling. Keep the frypot clean.

废弃有异味和测试不达标的油,保证炸锅清洁

WITH PROLONGED USE, THE FLASHPOINT OF

SHORTENING IS REDUCED. DISCARD SHORTENING IF IT SHOWS SIGNS OF EXCESSIVE

SMOKING OR FOAMING. SERIOUS BURNS,

PERSONAL INJURY, FIRE, AND/OR PROPERTY

DAMAGE COULD RESULT.

为延长油使用寿命, 减少闪点的发生,废弃冒烟和测试

不达标的油,否则可能导致烫伤,人身伤害,火灾和

(或)财产损失

3-8

Page 17

Model OFE-101

3-7. FILTERING OF

SHORTENING

过滤油注意事项

1. Turn the main switch to the OFF position. Remove and

clean the fry basket in soap and water. Rinse thoroughly.

关掉电源,把炸蓝放在肥皂水里,彻底漂洗。

normal frying temperature.在烹炸温度下过滤效果最好

2. Use a metal spatula to remove any build up from the sides

of the frypot. Do not scrape heating elements on electric

有专有的刮刀清洁锅筒内壁。 不要刮加热管

Best results are obtained when shortening is filtered at the

models.

,

Scraping the electric fryer elements

surfaces causing breading to stick and burn.

刮加热管可能导致管子爆裂

produces scratches in these

The filter drain pan must be placed all the way to the front of

the fryer. Be sure dairy union is connected .Failure to follow

these instructions causes splashing of shortening and could

result in personal injury. Surfaces of fryer and baskets will be

hot. Use care when filtering to avoid getting burned.

滤油盘必须从锅筒前面装在锅筒下。在打开泄油阀之前确认

滤油管连接好。滤油系统结构损坏可能导致油飞溅和人身伤

害。炸锅和炸蓝表面很热, 使用时务必小心,以免烫伤

3. Slowly turn drain valve handle a half turn. Leave for a few

minutes, then slowly, fully open drain valve. This prevents

much splashing of the hot shortening as it drains

DRAIN VALVE HANDLE FILTER VALVE HANDLE 小心打开泄油阀开关, 开始时只打开一半,过段时间后

在全部打开, 这样可以避免油飞溅。

4. As the shortening drains from the frypot, use brushes on the

heating elements. If the drain fills with breading, use

straight white brush to push excess breading into the filter

drain pan.

在油流入泄油盘的过程中清洗锅筒的四壁, 用黑刷清洗

加热器, 如果泄油阀里有面粉渣,用直白刷清洗使其流

入泄油盘里.

Figure 3-3

3-9

Page 18

Model OFE-101

3-7. FILTERING OF

SHORTENING

((Continued)(接上页)

过滤油注意事项

IF THERE ARE AIR BUBBLES COMING UP

IN THE SHORTENING BEFORE ALL

SHORTENING IS PUMPED UP, IT’S POSSIBLE

THAT THE FILTER CONNECTION AT THE

UNION ON THE FILTER TUBE IS NOT

TIGHTENED PROPERLY. IF SO, TURN

OFF THE PUMP AND WEAR PROTECTIVE

GLOVES OR CLOTH WHEN TIGHTENING

THE UNION. THIS UNION WILL BE HOT.

SEVERE BURNS COULD RESULT.

在油没有全部抽完之前如果有气泡从油中溢出, 可能

的原因是油管没有正确安装。 如果这样,请立即关闭

泄油阀。在连接活结时戴好防护手套,穿好防护衣,

因为活结很热, 可能会发生严重烧伤

5. Pump all of the shortening out of the filter drain pan and

back into the frypot. When the pump is pumping air only,

move the pump switch from PUMP to OFF

把油抽回锅筒,如果泵只抽空气请立即关闭

6 Check the level of the shortening in the frypot. Add fresh

shortening if necessary, until it reaches the bottom level

indicator line on the right wall of the frypot.

检查炸油是否达到锅筒内右侧的油位线,如果没有加入

新鲜的炸油

About 10 to 12 filterings can be made with one filter

paper envelope, depending on:

10-12 步可能需要更换滤纸, 是否更换取决于:

the quantity and type of product fried and filtered

烹炸和过滤的产品数量和类型

the type of breading used

面粉的类型

3-10

Page 19

Model OFE-101

3-7. FILTERING OF

SHORTENING

((Continued)(接上页)

过滤油注意事项

the amount of crumbs left inside the filter drain

pan. When the filter screen assembly and filter

paper become clogged, and the pumping flow

slows. Clean the filter screen assembly and

change the filter envelope.

留在滤油盘里的残渣数量,如果滤纸堵塞,泵流

速满,就要清理滤油管,更换滤纸。

7 To continue cooking, move the main POWER switch to

the ON position, and shortening reheats.

继续烹炸,打开电源,油开始回温。

3-11

Page 20

Model OFE-101

3-8. FILTER PUMP PROBLEM To help prevent filter pump problems: 正确安装滤纸:

PREVENTION 过滤泵问题防范

1. Properly install paper envelope over the filter screens.

Fold the open end of the envelope, and clamp with retaining

clips so that crumbs cannot enter. Figure 3-6.

如图 3-6 所示将滤纸正确的安装在滤网上并用夹子夹好

2. Pump shortening, until you see bubbles in the fry pot.

泵油,直到没有油泵出.

Figure 3-6

3-9. FILTER PUMP MOTOR In the event it overheats, the filter pump motor is equipped with a

PROTECTOR – MANUAL RESET

过滤泵手动复位

manual reset button located on the rear of the motor. After

waiting 5 minutes to allow the motor to cool, press the reset

button. It takes some effort to reset the motor. A screwdriver can

be used to help press reset button. Figure 3-7. 电机在过热后保护

功能启动, 电机不能启动。 等 5 分钟左右电机冷却之后, 按

马达后面的重启动按钮, 这个按钮可能需要按重一些才能有

效, 可以如图 3-7 所示用螺丝刀去按。

Figure 3-7

To prevent burns caused by splashing shortening, turn

the unit's filter PUMP switch to the OFF position

before resetting the filter pump motor’s manual reset

protection device. 为避免飞溅的油 引起火灾,所以手动

按泵的重起动按钮时将泵置于 OFF 状态

3-12

Page 21

Model OFE-101

3-10. CHANGING THE FILTER The filter envelope should be changed after 10-12 filterings or

ENVELOPE

当滤油 10-12 次后或者有杂物堵塞时应按以下步骤更换滤套。

whenever it becomes clogged with crumbs. Proceed as follows:

The filter union could be hot. Wear protective glove or

cloth, or severe burns could result.

滤油系统很热, 为避免烫伤请戴上手套

Use care to prevent burns caused by splashing of hot

shortening. 操作时小心炸油飞溅。

1. Move the main POWER switch to the OFF position.

关闭电源开关

2. Disconnect the filter union and remove the filter drain

pan from beneath the frypot.

3. Remove the filter screen assembly from the drain pan.

把滤盘从滤油盘里拿出

4. Wipe the shortening and crumbs from the filter drain pan.

Clean the drain pan with soap and water. Thoroughly rinse

with hot water.

擦去滤盘上的油,用肥皂水清洗,再用热水彻底漂洗

5. Unthread the standpipe from the filter screen assembly.

旋下滤盘上的直管

6. Remove the crumb catcher and clean with soap and water.

Rinse thoroughly with hot water.

拿出碎屑收集器,用肥皂水清洗,再用热水彻底漂洗

松开活结,把滤油盘从炸锅里移出

7. Remove the filter clips and discard the filter envelope.

拿下夹子和滤纸套

8. Clean the top and bottom filter screen with soap and water.

Rinse thoroughly with hot water.

用肥皂水清洗上下滤网,再用热水彻底漂洗

3-13

Page 22

Model OFE-101

3-10. CHANGING

THE

FILTERENVELOPE

更换滤纸套

Be sure that the filter screens, crumb catcher, filter clips

(接上页)

and the standpipe are thoroughly dry before assembly of the

filter envelope or water will dissolve the filter paper.

确保在安装滤纸套或滤纸淋湿之前滤网,碎屑收集器,

直管干燥

9. Assemble the top filter screen to the bottom filter screen.

安装上下滤网

10. Slide the screen into a clean filter envelope.

把滤网装入滤纸套

11. Fold the corners in and then double fold the open end.

折一次滤纸套角, 然后折两次滤纸套开口处。

12. Clamp the envelope in place with the two filter retaining

clips. 用两个夹子夹在滤纸套的折叠处

13. Replace the crumb catcher screen on top of the filter paper.

Screw on the standpipe assembly.

装上滤纸, 直管。

14. Place complete filter screen assembly back into filter drain

pan, slide pan back into place beneath the open fryer.

把滤网放进滤油盘, 连接到锅筒山上

15. Connect the filter union by hand. Do not use a wrench to

tighten. 用手连接活结,不要用扳手

16. The open fryer is now ready to operate.

现在更换完成, 可以操作

3-14

Page 23

Model OFE-101

3-11. CLEANING After the initial installation of the open fryer, as well as before

THE FRYPOT

清洗锅筒

cleaned as follows:

every change of shortening, the frypot should be thoroughly

如果新装锅筒或更换油,一定要彻底清洗锅筒。

1. Turn the main POWER switch off. 关闭电源

The filter drain pan must be as far back under fryer as it

will go. Failure to follow these instructions causes

splashing of shortening and could result in personal

injury.

确保滤油盘安装到位,否则可能导致油飞溅和人身伤害

Moving the fryer or filter drain pan while containing hot

shortening is not recommended. Hot shortening can

splash out and severe burns could result.

不推荐在有热油的情况下移动滤油盘,因为热油可能飞

溅出来而导致烧伤

Always wear chemical splash goggles or face shield and

protective rubber gloves when cleaning the frypot as the

cleaning solution is highly alkaline. Avoid splashing or

other contact of the solution with your eyes or skin.

Severe burns may result. Carefully read the instructions

on the cleaner. If the solution comes in contact with

your eyes rinse thoroughly with cool water and see a

physician immediately.

在清洗锅筒时一定要戴手套, 护眼套和防护服, 避免

油飞溅到你的眼睛和皮肤上而导致烧伤,仔细阅读操作

手册避免步行事的发生, 一旦有油飞溅到你的眼睛里或

皮肤上,请立即用冷水冲洗,然后去看医生

2. If hot shortening is present in the frypot, it must be drained by

Leave for a few minutes, then slowly open the valve to full

open position.

如果锅筒里有热油, 在打开泄油阀时一定先开一半让油慢

慢流出,过几分钟后在全部打开

3. Close the drain valve. Discard the shortening .

关闭泄油阀, 把油放在一边。

4 Remove the filter screen assembly from the filter drain pan.

把滤网从滤油盘里取出来

3-15

Page 24

3-11. CLEANING

THE FRYPOT 清洗锅筒

(Continued)(接上页)

cloth, or severe burns could result.

活结很烫,一定戴手套或用布衬着,否则可能烫伤

5. Fill the frypot to the level indicator with hot water. Add

4 ozs. (0.12 liters) of open fryer cleaner to the water and mix

thoroughly. The fry basket can be placed inside the frypot

for cleaning.

往锅筒里加热水到油位线,然后在加入 4盎司(0.12升)

开口炸锅清洁剂到水里混合均匀, 炸蓝 可以一起放在

锅筒里清洗

6. Turn the main POWER switch to the ON position and

set temperature to 195 F (90.5 C).

打开开关,将水加热到 195 F (90.5 C).

7. When the solution reaches 195 F (90.5 C), turn the main

POWER switch to the OFF position.

到达温度 195 F (90.5 C).后,关闭电源

8. Let the cleaning solution stand for 15 to 20 minutes with

the power off.

9. Using the open fryer brush (never use steel wool), scrub the

inside of the frypot.

用开口炸锅专用刷(不要用钢刷)擦洗锅筒内部

If the cleaning solution in the frypot starts to foam and

boil over, immediately turn the power switch to OFF

Do not

sanitizers containing chlorine, bromine, iodine or ammonia

chemicals, as these will deteriorate the stainless steel

material and shorten the life of the unit.

Do not

unit, or component damage could result.

Model OFE-101

The filter union could be hot. Wear protective glove or

关闭电源后 15 到 20分钟后开始清洗。不得用喷射水流

or damage to components could result.

如果加热时发现锅筒内的清洗剂起泡沫或溢出,立即

电源,否则可能会造成零件损坏

use steel wool, other abrasive cleaners or cleaners/

严禁使用钢刷,其他擦洗剂或包含氯,溴或氨水等化学物

质的食品杀菌剂,否则会损坏不朽钢表面和缩短其寿命

use a water jet (pressure sprayer) to clean the

严禁使用压力喷水式推进器清洗机器,否则导致零件损坏

3-16

Page 25

Model OFE-101

10. After cleaning, open the drain valve and drain cleaning

3-11. CLEANING

THE FRYPOT 清洗锅筒

(Continued)(接上页)

11. Replace the empty filter drain pan, close the drain valve, and

refill the frypot with plain hot water to the proper level.

放回空的滤油盘,关闭泄油阀,重新注入水到要求位置

14. Drain the vinegar rinse water and discard.

放掉含有蒸馏酒醋的水。

15. Rinse down the frypot using clean, hot water.

用热水再清洗一遍锅筒

solution from the frypot into the filter drain pan and discard.

洗完后打开泄油阀放掉水

12. Add approximately 8 ozs. (0.24 liters) of distilled vinegar

and bring the solution back up to 195 F (90.5 C).

加大约 8 盎司(0.24 升)蒸馏酒醋并加热到 195 F (90.5

C)

13. Using a clean brush, scrub the interior of the frypot. This

will neutralize the alkaline left by the cleaning compound.

用清洁刷清洗锅筒内部,这个步骤中和碱性的清洁剂

16. Thoroughly dry the filter drain pan and the frypot interior.

彻底清洗过滤器和炸锅内部

Make sure the inside of the frypot, the drain valve opening,

and all the parts that will come in contact with new

shortening are as dry as possible.

确保 在输入新油之前锅筒内部, 泄油阀和相关零件干燥

17. Replace the clean filter screen assembly in the drain pan,

and install filter drain pan under open fryer.

把过滤器装回到过滤盘, 把过滤盘放在锅筒下面

18. Refill the frypot with fresh shortening.注入新油

3-17

Page 26

Model OFE-101

3-12. REGULAR MAINTENANCE As in all food service equipment, the Henny Penny Open

Fryer does require care and proper maintenance. The table

定期保养 below provides a summary of scheduled maintenance

procedures to be performed by the operator.

Procedure Frequency

Filtering of shortening Daily (3-4 loads)3-4 次每天

滤油 See Filtering of Shortening

section详见滤油章节

Changing of shortening When shortening smokes,

换油 foams up violently, or tastes

bad 当油冒烟,泡沫很多,或

变味时

Changing the filter envelope After 10-12 filterings, or

换滤油纸袋 when envelope is clogged

with crumbs. See Changing

the Filter Envelope section

10-12 次滤油后,或纸袋阻塞

详见换滤油纸袋一节

清洁锅缸 See Cleaning the Frypot

section

每次换油后,详见清洁锅缸

一节

象其他食品设备一样“HennyPenny”压力炸锅需要维

护和正确的保养,下面提供了一个扼要的保养计划,接

下来的部分,为操作者提供了详尽的保养步骤

Cleaning the frypot Every change of shortening.

If moving fryer to perform preventive

maintenance:

定期维护后如果要移动炸锅时:

• Electrical supply should be unplugged or wall

circuit breaker turned off to avoid electrical

shock.

必须拔下电源插座或者关掉电源开关以避免电击

3-18

Page 27

3-13.Wiring diagram 接线图

Model OFE-101

78846_B

3-19

Page 28

4-1 OPEN FRYER OFE-101

开口炸锅组件清单

Model OFE-101

SECTION 4. PART LIST 零件清单

4-1

Page 29

4-2 FRAME ASSY 框架组件

Model OFE-101

16

4-2

Page 30

Model OFE-101

4-2 FRAME ASSY 框架组件

√

ITEM PN DESCRIBE

1 SC03-004 SCREW #8 X 3/4 PH PHD TEC C 2

2 SC03-005 SCREW SD #8 X 1/2 PH PHD 4

3 72562 SUPPORT-CONTROL PANEL 1

√

√

4 140138 KIT–C1000 CONTROL PANE L ASSY_OFE-101 1

5 SC03-005 SCREW SD #8 X 1/2 PH PHD 2

6 60718 BRACKET-DRAIN VALUE ROD 1

7 EF02-126 BUSHING-SNAP 1/2 ID X 5/8 OD PLASTIC 2

8 18227 MICRO SWITCH 1

9 SC01-058 SCREW #6-32 X 1 PH PHD C 2

10 SC03-005 SCREW SD #8 X 1/2 PH PHD 4

11 SC03-005 SCREW SD #8 X 1/2 PH PHD 4

12 SC03-004 SCREW #8 X 3/4 PH PHD TEC C 2

13 73341 PANEL SIDE-RIGHT 1

14 19707 BOX-JUNCTION 1

15 72558 PANEL SIDE-LEFT 1

16 ME70-005 SPEAKER-16 OHM-2 INCH 1

QUANTIT

Y

√Recommended Parts

4-3

Page 31

4-3 FILTER SYSTEM ASSY –

DRAIN PAN

过滤系统组件-滤油盆

Model OFE-101

√

√Recommended Parts

4-4

Page 32

Model OFE-101

4-4 FILTER SYSTEM ASSY –

TUBE

过滤系统组件-管路组件

4-5

ITEM PART NUMBER DESCRIBE QTY

1 67583 MOTOR-1/2 HP FILTER PUMP 1

√

2 64218 ASSY-FILTER PUMP-8 GPM 1

3 FP01-169 CON-90 MALE 3/4 TUBE 3/4 NPT 2

4 82327 ASSY-TUBE FILTER TO PUMP TUBE 1

5 FP01-170 CON-STR. MALE 3/4 TUBE 3/4 NPT 2

6 73801 VALVE-3/4 INCH 1

7 82328 ASSY-TUBE FILTER TO POT TUBE 1

8 83710 TUBE FILTER 1

9 69289 ASSY-FILTER UNION 1

10 83709 ASSY -TUBE FILTER TO PUMP 101 1

11 FP01-118 ELBOW-5/8 TUBE-1/2 NPT FEMALE 1

12 FP02-011 NIPPLE - 1/2 X 1 1/4 304 SS 1

13 FP01-185 BUSHING-3/4R1X1/2Rc 1

√Recommended Parts

Page 33

Model OFE-101

4-5. FILTER MOTOR AND PUMP 马达和泵

4-6

ITEM PART NUMBER DESCRIBE QTY

1 67583

√

√

2 17476 SEAL KIT 1

MOTOR-1/2 -50、60HZ

3 64218 ASSY-FILTER PUMP-8 GPM 2

4 SC01-132 1/4-20 X 5/8 SOC HD CAP SCREW 4

5 23470 CAP-8 GPM PUMP 1

6 23468 ROTOR-8 GPM PUMP 1

√

7 23469 ROLLER-8 GPM PUMP 5

8 17453 PUMP O RING GASKET 1

9 23467 BODY-8 GPM PUMP 1

10 17456 PUMP SHIELD 2

11 SC01-026 SCREW 5/16-18 X 3/4 HEX HD C 2

√Recommended Parts

1

Page 34

7

8

4-6 ACCESSORIES 附件

Model OFE-101

4

6

5

9

4-7

ITEM PART NUMBER DESCRIBE QTY

1 72568 BASKET FRY OFE-101 2

2 60747 SUPPORT - FRY BASKET, OFE 1

3 60744-3 HEATER-OFE32X, 230V 4800 WATT 3

√

4 19669 HTG ELEMENT HARDWARE KIT 1

√

5 SC01-055 SCREW #10-32 X 3/4 HEX HD S 8

6 LW02-005 LOCKWASHER 10 INTERNAL 8

7 51931 ASSY - SPREADER BAR, OE-100 4

8 SC01-053 SCREW #8-32 X 1/2 PH RHD S 2

9 40317 CLAMP-FRONT HI LIMIT 2

40315 CLAMP-REAR HI LIMIT 2

√Recommended Parts

Page 35

Model OFE-101

4-6 POT ASSY

4-8

锅筒组件

22

21

Page 36

筒组件

4-7 POT ASSY

锅

√

√

√

√

√

√

Model OFE-101

ITEM PN DESCRIBE QUANTITY

1 72618 INSULATION -SIDE CONTROL PANEL 1

2 72561 SHORD-COMPONENT-PANEL 1

3 EF02-006 FUSE HOLDER - 15A 300V 2

3 EF02-007 FUSE 15 AMP 2

4 EF02-004 BUSHING SNAP 3/4 IDX1 OD P 3

5 60730 GUARD - HEATER, OFE32X 2

6 29509 CONTACTOR KI T - 24 VAC 1

7 65073 CONTACTOR-SQUA RE D-24V 1

8 73475 INSULATION -FRONT POT 1

9 WA02-001 WASHER-INSULATION 1 1/2 X .015 8

10 17261 VALVE DRAIN BOD Y O NLY 1

11 17255 COTTER PIN 2

12 55142 COUPLING-DRAIN VALVE 1

13 72560 ROD-NORMALLY OPEN DRAIN 1

14 72565 SQUARE DRAIN ASSY 1

15 30321 BUSS BAR 2

16 60241 HIGH LIMIT-425 DEG CE SETTI NG 1

17 SC03-005 SCREW SD #8 X 1/2 PH PHD 5

18 SC01-113 SCREW #6-32 X 9/16 PH PHD BLAK 4

19 NS02-005 NUT HEX KEPS #6-32 C 4

20 SC04-003 SCREW #8-32 X 3/8 PH PHD S 6

21 60536 ASSY-TRANSFORMER, 24V/230V 1

√

22 14990 KIT-OFE32X/34X-C1000 FUL PROBE 1

√Recommended Parts

4-9

Page 37

Model OFE-101

SECTION 5. TROUBLESHOOTING 故障排除

5-1. TROUBLESHOOTING GUIDE 故障维修指导

Problem问题 Cause 原因 Correction 改正方案

POWER switch ON but fryer • Open circuit • Plug fryer in

completely inoperative 断路 检查插座有没有插好

电源打开不起作用 •Check breaker or fuse at supply box

检查断路器和保险器

Shortening will not • Open high limit • Reset high limit per 重起上限电路

heat but lights are on circuit上限电路断路 • Drain valve open 排油阀开

指示灯亮但炸油不热, • Turn drain valve handle to closed

Position 排油阀旋到关的位置

Foaming or boiling • Water in shortening • At end of cook cycle, drain

of shortening 油里有水 shortening and clean

油冒泡或沸腾 在烹饪周期后,排油并清洁

• Improper or bad • Use recommended shortening

shortening 油不好 使用推荐油

• Improper filtering • Refer to the procedure covering

过滤不好 filtering the shortening

参考油过滤程序

• Improper rinsing after • Clean and rinse the frypot, then

cleaning the fryer dry thoroughly 清洁炸锅,完全凉干

过滤后锅内有残渣

Shortening will not • Drain valve clogged • Open valve, force cleaning

drain from frypot with crumbs brush through drain

炸油不能排出 排油阀堵塞 打开排油阀并用刷子彻底清洗

Filter switch ON but • Motor therm

motor does not run protector tripped on Filter Pump Motor

过滤开关在 ON 电机热保护 Protector – Manual Reset

但电机不工作 参见过滤泵保护—说明书重起

Or detailed troubleshooting information is available in the Technical Manual, available at www.hennypenny.com,

or 0512-89180262 更多的维修信息可以从说明书获得,你也可以登陆我公司网站 www.hennypenny.com

电话 1-800-417-8405 , 1-937-456-8405

5-1

al • Reset thermal switch per section

重起过滤泵

或打

Page 38

Model OFE-101

5-2. ERROR CODES In the event of a control system failure, the digital display shows an error

message. The message codes are shown in the DISPLAY column below. A constant tone is heard

when an error code is displayed, and to silence this tone, press any button.

DISPLAY CAUSE PANEL BOARD CORRECTION

“E-4” Control board Turn switch to OFF position, then turn switch back to ON;

overheating if display shows “E-4”, the control board is getting too hot;

check the louvers on each side of the unit for obstructions

“E-5” Shortening Turn switch to OFF position, then turn switch back to ON;

overheating if display shows “E-5”, the heating circuits and temperature

probe should be checked

“E-6A” Temperature Turn switch to OFF position, then turn switch back to ON;

probe open if display shows “E-6A”, the temperature probe should be

checked; to replace, refer to Technical Manual

“E-6B” Temperature Turn switch to OFF position, then turn switch back to ON;

probe shorted if display shows “E-6B”, the temperature probe should be

checked; to replace, refer to Technical Manual

“E-10” High limit Reset the high limit by manually pushing up on the red

reset button; if high limit does not reset, high limit must be

replaced; refer to Technical Manual

“E-15” Drain switch Close drain, using the drain valve handle. If display still

failure shows “E-15”, check the drain microswitch; refer to

Technical Manual

“E-41”, “E-46” Programming Turn switch to OFF, then back to ON; if display shows any

failure of the error codes, try to reinitialize the control (Special

Program Mode section); if error code persists, replace the

control board; refer to Technical Manual

“E-31” Fan switch jumper Turn switch to OFF, then back to ON; if “E-31” persists,

wire missing or have jumper wires J2 & J4 on the 12-pin connectors on

disconnected the PC board; if jumpers are OK, have PC board replaced

“E-54” Faulty PC board Turn switch to OFF, then back to ON; if “E-54” persists,

component have PC board replaced

“E-70” Faulty power Have POWER switch checked, along with its wiring. Have

switch, or switch Input/Output board replaced if necessary

wiring; faulty

I/O board

5-2

Page 39

Model OFE-101

Loading...

Loading...