Hellwig Air 6110 User Manual

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

6110 Air Spring Kit

Ford F150 2/4WD

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THIS INSTRUCTION SHEET COMPLETELY BEFORE STARTING

YOUR INSTALLATION

IMPORTANT NOTES

DO NOT INFLATE ANY AIR SPRING ASSEMBLY UNLESS IT HAS BEEN

PROPERLY INSTALLED ON VEHICLE.

DO NOT INFLATE AIR SPRINGS OVER 50 PSI.

LOADS REQUIRING OVER 50 PSI WILL EXCEED THE GVW AND

DESIGN LIMITS OF THE VEHICLE AND MAY RESULT IN PERSONAL

INJURY AND/OR DAMAGE TO YOUR VEHICLE AND PROPERTY.

A MINIMUM OF 5-10 PSI MUST BE MAINTAINED IN AIR SPRINGS

AFTER INSTALLATION FOR WARRANTY TO BE VALID. FAILURE TO

KEEP MINIMUM PRESSURE IN AIR SPRINGS WILL VOID WARRANTY.

THIS UNIT IS DESIGNED TO INCREASE THE LEVEL LOAD CARRYING

CAPACITY OF YOUR VEHICLE. NEVER LOAD THE VEHICLE THIS

UNIT IS INSTALLED ON BEYOND THE MANUFACTURER’S MAXIMUM

GROSS VEHICLE WEIGHT RATING.

6110( R-6110) 01/24/2013

559-734-7451 800-367-5480 FAX 559-734-7460

BEFORE STARTING YOUR PROJECT

WHEN LIFTING A VEHICLE WITH A JACK, BE SURE TO SET THE PARKING BRAKE AND USE

SAFETY STANDS.

ENSURE THAT THE INSTALLATION OF COMPONENTS WILL NOT CRUSH OR DAMAGE

FUEL AND BRAKE LINES OR ELECTRICAL HARNESSES.

BEFORE DRILLING ANY HOLES, ENSURE THAT ALL ELECTRICAL WIRES, FUEL LINES,

BRAKE LINES, BRAKE HOSES AND ANY OTHER COMPONENTS ARE MOVED OR

PROTECTED TO AVOID DAMAGE FROM DRILLING ANY HOLES .

DO NOT ATTEMPT ANY MODIFICATIONS TO THE VEHICLE OTHER THAN THOSE

OUTLINED IN THIS INSTRUCTION SHEET. IF ANY INTERFERENCE WITH THE GAS TANK,

FUEL LINES, BRAKE LINES, EXHAUST PIPE, ETC. EXISTS, STOP YOUR INSTALLATION AND

CALL HELLWIG PRODUCTS FOR TECHNICAL HELP.

IF WHEELS ARE REMOVED FOR INSTALLATION OF KIT, CHECK MANUFACTURERS

SPECIFICATIONS FOR PROPER LUG NUT TORQUE BEFORE REINSTALLING WHEELS.

WHEN CUTTING AIR BRAKE TUBING, A SQUARE CUT IS REQUIRED AND THE HOSE END

MUST NOT BE DEFORMED OR LEAKAGE MAY RESULT.

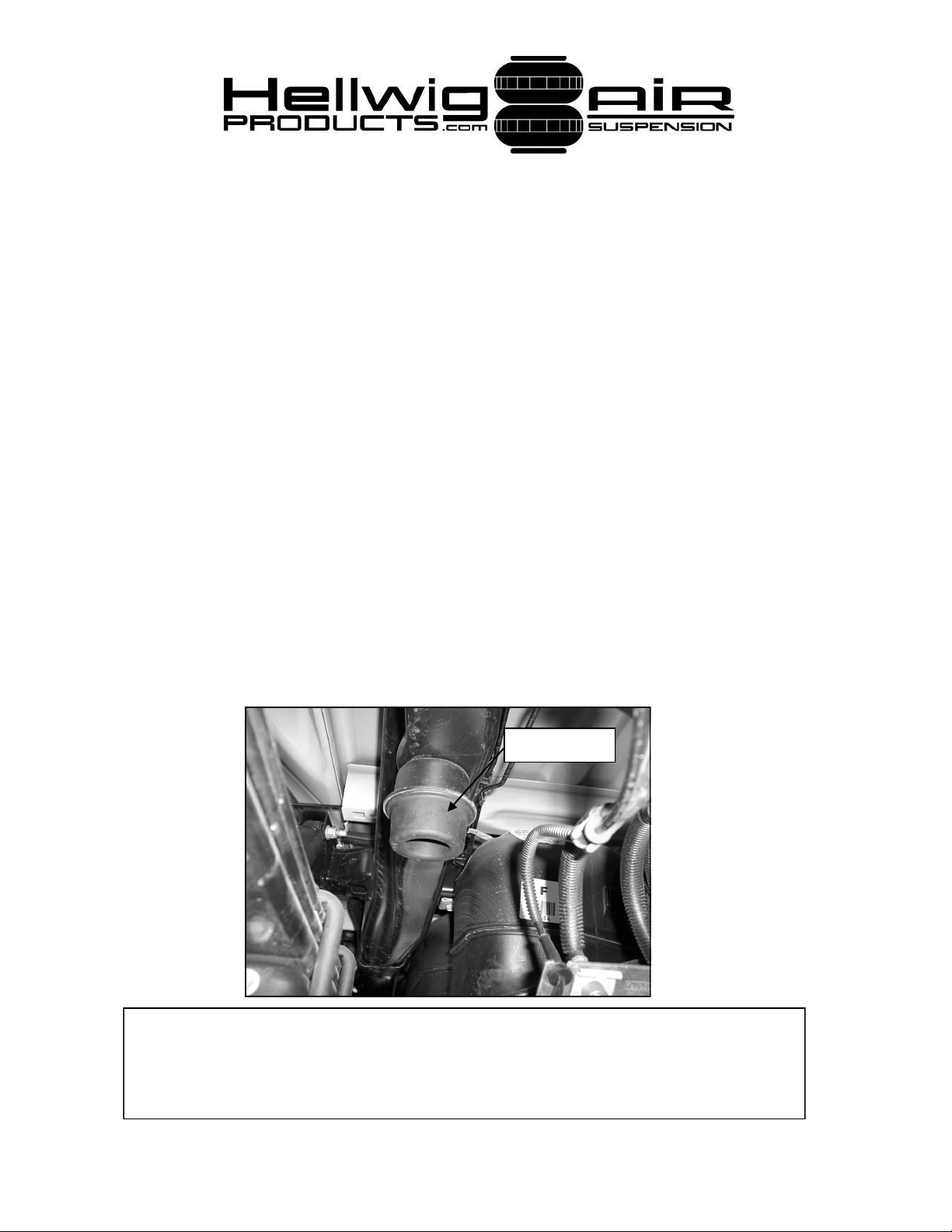

Bump Stop

1. Park vehicle securely and set parking brake and chock wheels. Remove

factory bump stops from vehicle by removing nuts from studs using a

13mm socket.

6110( R-6110) DO NOT INFLATE AIR SPRINGS OVER 50 PSI 01/24/2013

559-734-7451 800-367-5480 FAX 559-734-7460

M10-1.5 Flat head cap

screw. Torque to 25 ft-lb

2. Install frame adapter on frame using M10-1.5 flat head cap screw. Align bracket

so that the inboard holes are evenly spaced from the inside wall of the frame rail.

Torque to 25 ft-lb.

3. Install fitting in port of air spring. Torque fitting to approximately 20 ft-lb.

3/8” X 1” threaded stud

4. Install threaded studs into

frame adapter with countersunk

holes oriented as shown. Apply

loc-tite supplied in kit to threaded

studs before installation.

4

6110( R-6110) DO NOT INFLATE AIR SPRINGS OVER 50 PSI 01/24/2013

3/8” X 1-1/2” threaded stud

Loading...

Loading...