Page 1

Flextight X1 and Flextight X5

Page 2

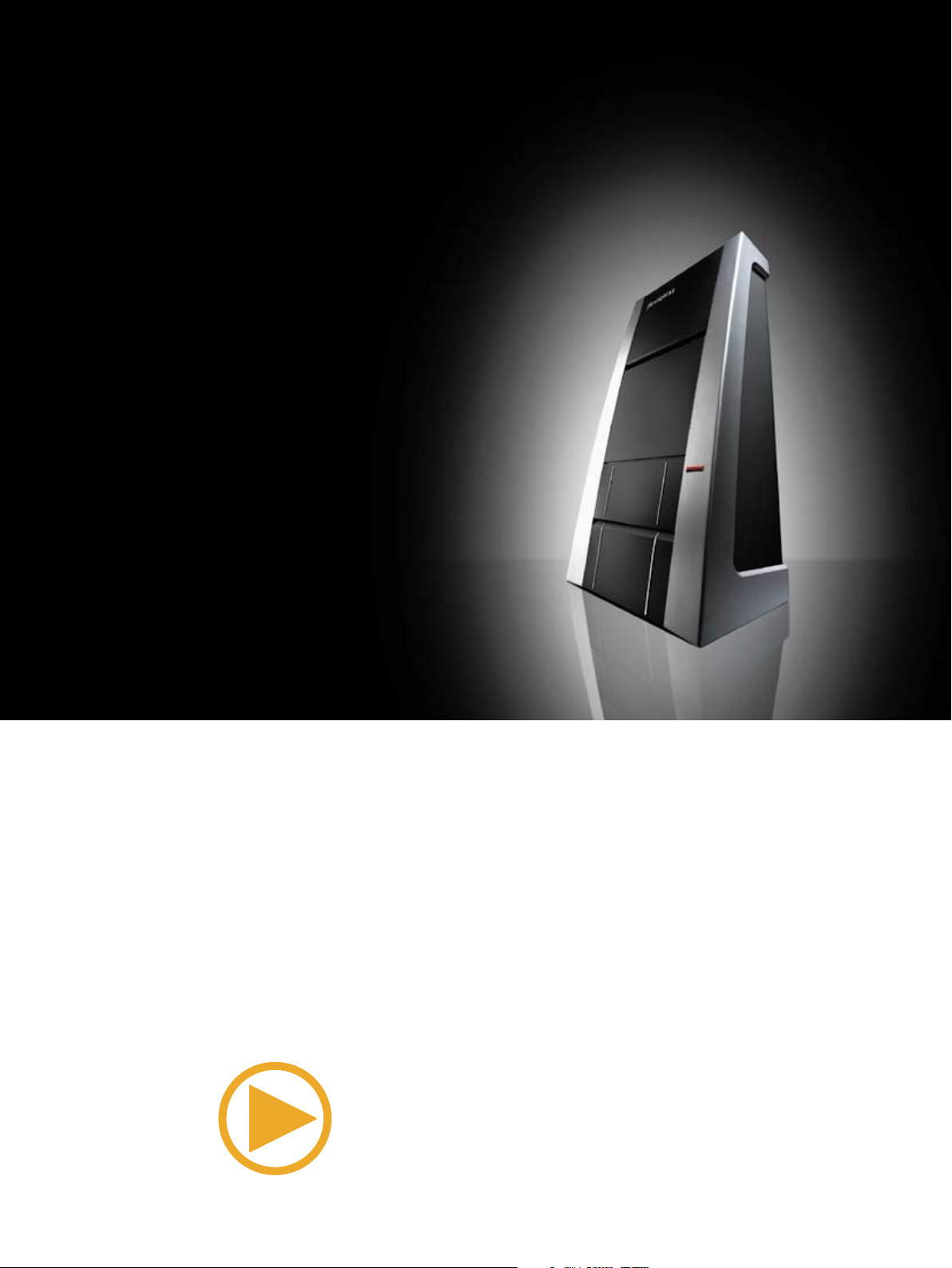

The Flextight X5 is the top model in the

Flextight scanner series providing the

best of all worlds. Ease of use, incomparable quality, unique, batch scanning

facilities all packed in a classical and

characteristic design.

Flextight X5

Key features:

- 8000dpi maximum resolution

- Up to 300MB/min.

- Optional feeders for maximum

productivity

- Hardware and software based

dust removal facility

- Simplified workflow with

3F Auto Scan button

Same, same, but different

The new generation of Hasselblad scanners, the Flextight X1 and X5, are both

built around the same foundation. A

vertical optical system allows the CCD

to face downwards, creating a glassfree optical path between the original

and the lens. The patented virtual drum

solution produces optimal focusing

across the entire original and the flexible holder guarantees easy mounting

and safe and secure handling of your

originals. The components used in both

Flextight scanners are basically the

same, meaning that whichever solution

you choose, the quality level is virtually

identical. Differences between the

models are more a matter of features

and capabilities, especially with regards

to productivity.

Hasselblad scanners:

freedom from choice

The freedom not to have to choose

between digital or film, for instance. The

freedom to use whatever capture medium

works best for a particular shoot or situation. And whether you choose to shoot

film because the elements are against

you or for creative reasons, with the new

generation of Hasselblad scanners you

know that you’ll be able to get your images safely into the digital world – wherever

they began – with ever y subtle detail

embedded in your negs and chromes

accurately reproduced.

Productivity

Naturally, the extraordinary scanning

speed of the Flextight X5 plays a key

part in increasing your productivity.

The benefits don’t stop there, however.

Various feeding devices, for example,

can be attached; the Batch Feeder for

mixed originals and the Slide Feeder for

scanning of mounted slides. Using these

devices together with the 3F workflow

produces a throughput that has to be

seen to be believed.

Page 3

The Flextight X1 model should serve

most photographers’ needs. Quality is

unsurpassed, it is fast and it can take

care of most kinds of originals. And, as

with any other scanner in this family, it

is easy to use.

Key features:

- 6300 maximum resolution of 6300dpi

- Up to 60 MB/min.

- Batch scanning capabilities

- Software based dust removal facility

- Simplified workflow with

3F Auto Scan button

Flextight X1

Even though you can find scanners with

larger sensors you will not find better

clarity and detail rendition when scan ning photographic film. That is due to

the electronic handling of the sensor,

the mechanical precision as well as

the quality of filters and the resolving

power of the Rodenstock lens. The

Flextight scanners are not only a piece

of art seen from the outside the entire

machiner y is saturated with excellent

solutions.

Keeping it cool

Heat reduction solutions are another

example of features not found on lower

range scanners. By removing the power

supply outside the scanner and using a

cold cathode light tube, which produces

very little infrared waves, Hasselblad

scanners eliminate two common

sources of heat-related noise. Our X5

scanner even has active sensor cooling,

which means that an electronic cooling

device is placed directly on the CCD,

which increases signal to noise ration

by 1 to 2 bits.

The new Fl extigh t scanne rs make it

poss ible to ca rry out t he fines t qualit y

scans w ith a sing le click o f a button .

We have plac ed a contr ol butt on on the

scanne r itse lf, that enab les one -tou ch

scanni ng with all p erso nal sett ings

intact . High qu ality s canning h as never

been ea sier!

The Unique 3F WorkflowSharpness and resolution

When selecting the 3F file format in automatic scan mode, images are scanned

at a specified resolution of 16 bits per

color. In this way the full color range of

the original is extracted from the scan.

The 3F file is never altered but acts as

a sort of "preview scan" when you open

it later, enabling you to re- do all operations or change any parameter you wish.

Consider it like re-scanning, but without

the film original present.

Furthermore – every time you save a

file from the 3F format, your action history is embedded in the 3F file, which

enables you to repeat these actions

whenever you like. The 3F workflow also

allows you to produce final TIFF images,

cropped and corrected, with a single

click of a button.

Page 4

The Flextight movie

Scanning, whether from transparencies,

negatives or reflectives was once an

occupation on its own. Nowadays more

and more photographers are finding

the need to include this activity in their

workflow.

Maintaining control to maintain quality

is an attractive concept to many photographers wanted to deliver the optimum

to their clients. That’s why Hasselblad

offers professional-level scanners that

are easy to use while still retaining the

quality inherent in the original.

On ww w.hasselblad.com you can watch

the Flextight movie and see for yourself

why the Flextight Scanners are the

professionals choice.

Scanners

Scanners

Flextight X1

Flextight X5

Max res

6300dpi

8000dpi

Technical specifications

Flextight X1/Flextight X5

Optical sensor: CCD (3x80 00)

Original type: X 1: Neg /Pos X5: Neg/Pos/Prints

Color depth: 16 bit

Auto frame detection: Yes

Auto focu s: Yes

Batch sc anning: Ye s

Batch- and slide feeder compatibility:

X1: No X5: Ye s

Interface: Firewire

Platform: PC/Ma c

Dmax:

X1: 4,6 X5: 4,9

Max speed

60MB/min

300MB/min

Film format: 100x245mm

Reflection:

X1: No X5: A4

Active cooling:

X1: No X5: Ye s

Flextouch: Ye s

3F scan initiated directly on scanner: Yes

Light condensator:

X1: No X5: Ye s

Dimensions: 230x390x650mm

Weight: 20,5k g

Dust removal

Soft ware based

Hard- & software

Reection Scan

No

Yes

Max optical res olution:

35mm 60 mm 4”x5”

X1: 6300dpi 3200dpi 2040dpi

X5: 8000dpi 3200dpi 204 0dpi

Max file size:

35mm 60 mm 4”x5”

X1: 450MB 370MB 460MB

X5: 580MB 370MB 460MB

Max scan speed:

35mm 60 mm 4”x5”

X1: 7.15 min 6.02 min 5.08 min

X5: 1.55 min 1.10 min 1.23 min

Active Cooling

No

Yes

Feeder

No

Yes

09.08 - UK v3 - 8 0500 378

www.hasselblad.com

Loading...

Loading...