Harmar Mobility AL500 User Manual

M

O

B

I

L

I

T

Y

M

O

B

I

L

I

T

Y

M

O

B

I

L

I

T

Y

MOB

I

L

I

T

Y

M

O

B

I

L

I

T

Y

M

O

B

I

L

I

T

Y

M

O

B

IL

IT

Y

M

O

B

I

L

I

T

Y

M

O

B

I

L

I

T

Y

TY

TY

I

I

L

L

I

I

OB

OB

M

M

Y

T

I

L

I

B

O

M

Y

T

I

L

I

OB

M

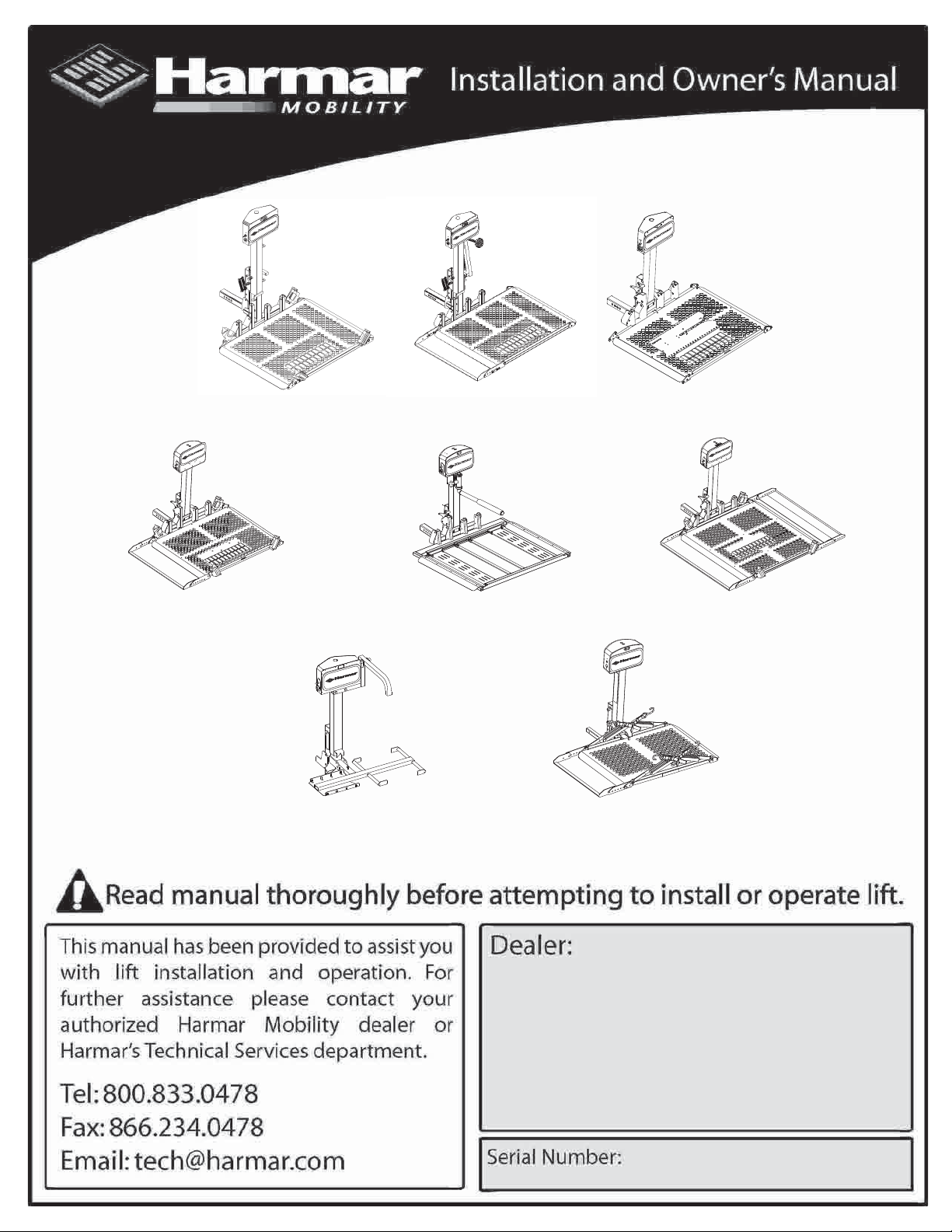

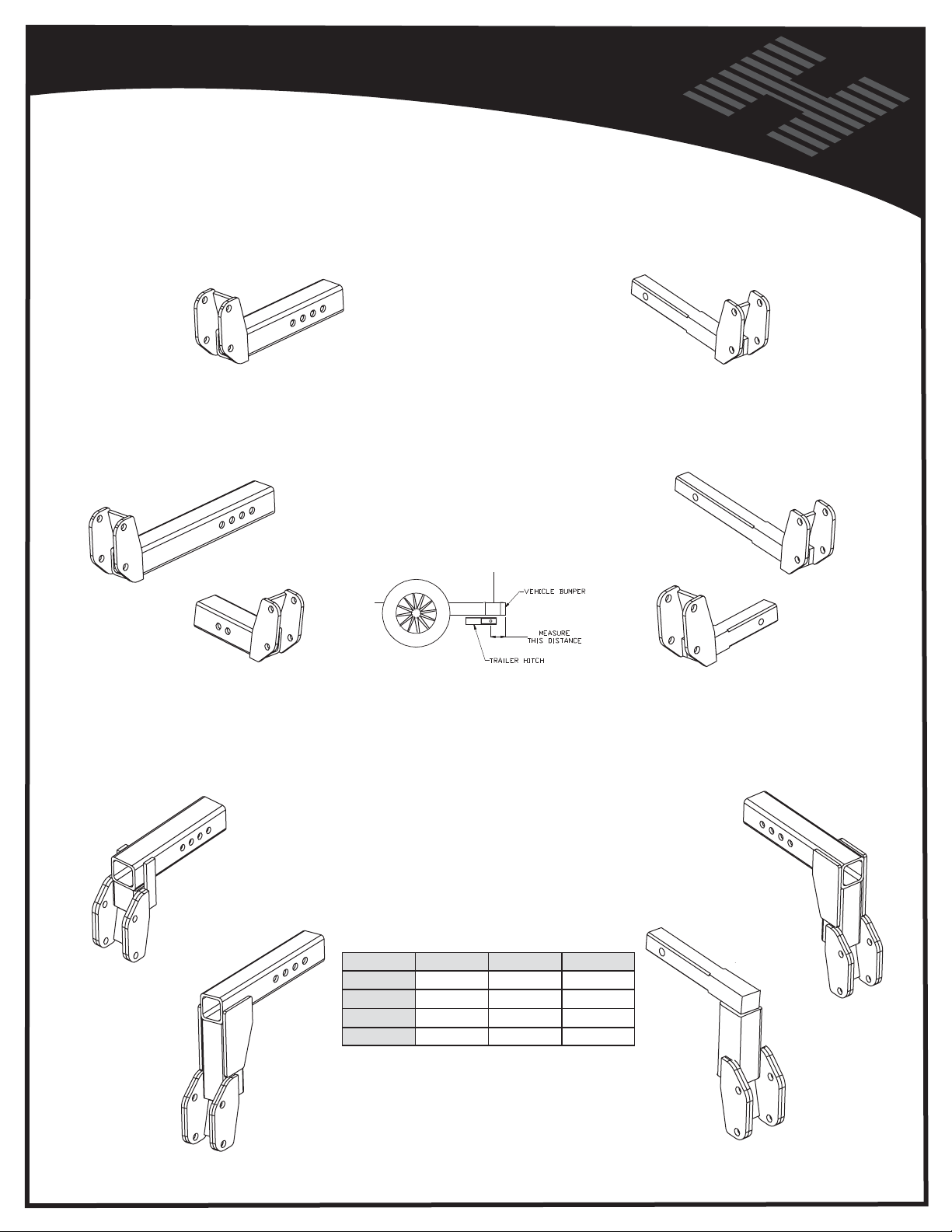

AL500 Universal Power Chair Lift

TY

I

L

I

B

O

M

AL300 Universal Power Chair /

Scooter Lift

Capacity: 350 lbs

Capacity: 350 lbs Capacity: 350 lbs Capacity: 350 lbs

AL 560 Auto Hold Down P.C. Lift

ITY

L

I

B

O

M

AL030 Power Tote for

Manual Wheelchairs

Capacity: 100 lbs

AL100 Universal Scooter Lift AL550 Automatic Power Chair Lift

Y

T

LI

I

B

O

M

Y

IT

IL

B

O

M

Outside Lift

Capacity: 350 lbs

AL301XL Extra Wide Power Chair /

Y

T

I

IL

B

O

M

AL010/050 Micro Power Chair /

Micro Scooter Lift

Capacity: 135 lbs

Scooter Lift

Capacity: 350 lbs

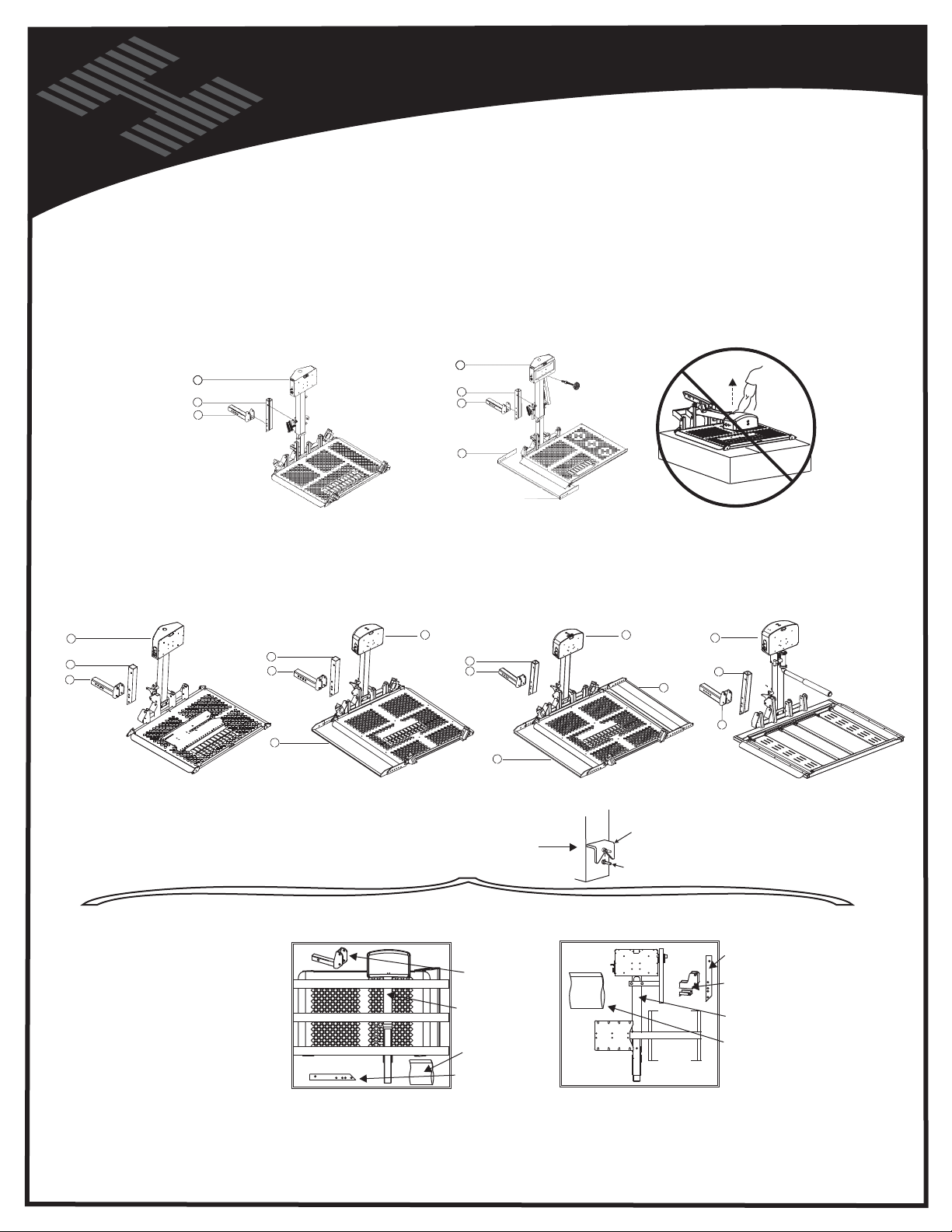

1

Unpacking the Lift

1 1

1

1

2

2

2

2

3

3

3

3

4

4

5

11

2

3

11

2

3

4

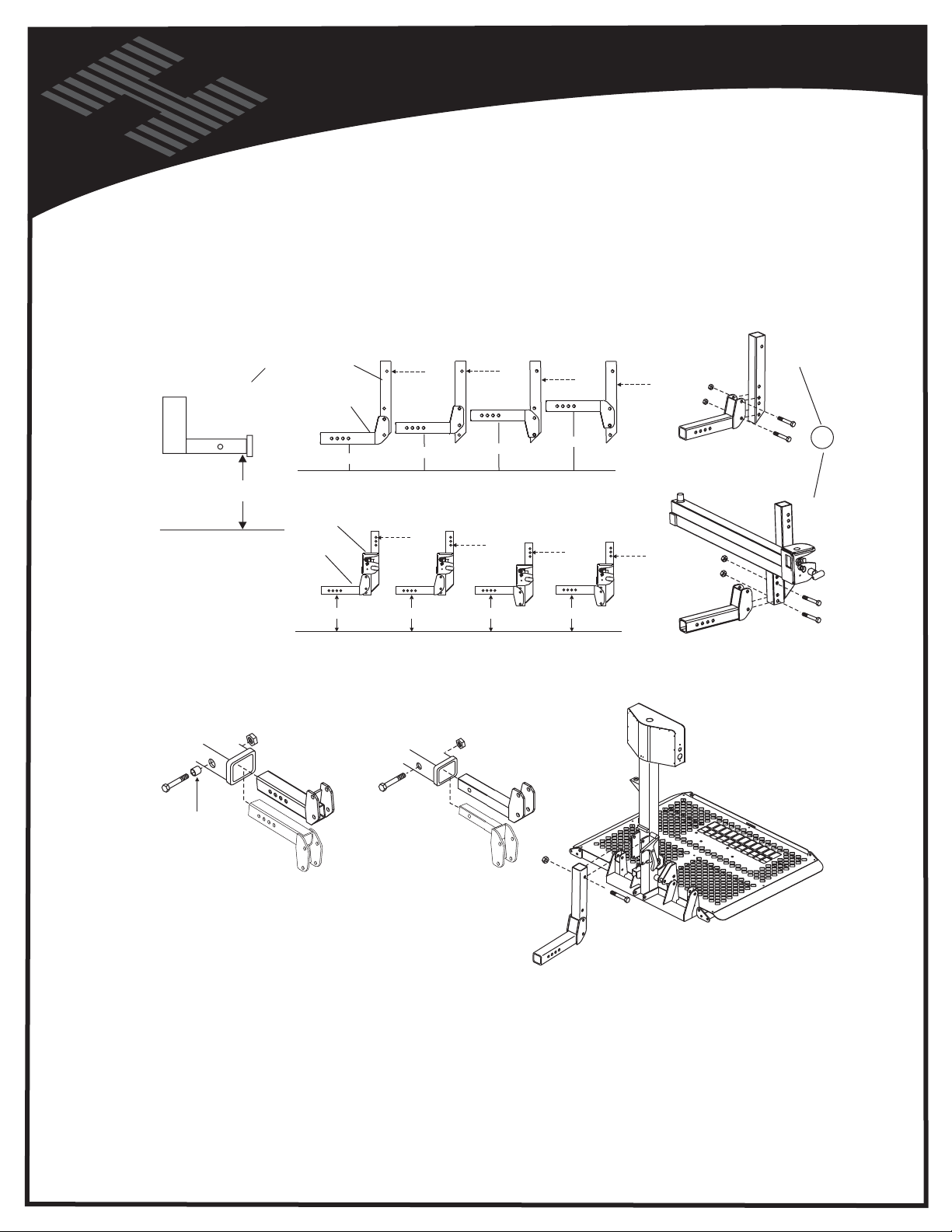

AL500

Package Check List Package Check List

Main lift body (# 1) Main lift body (# 1)

Hitch Post (# 2)

Hitch Adapter (# 3)

Anchor Plate

Hardware pack

AL100

Hitch Post (# 2)

Hitch Adapter (# 3)

Hardware pack

Spreader Bar (# 4)

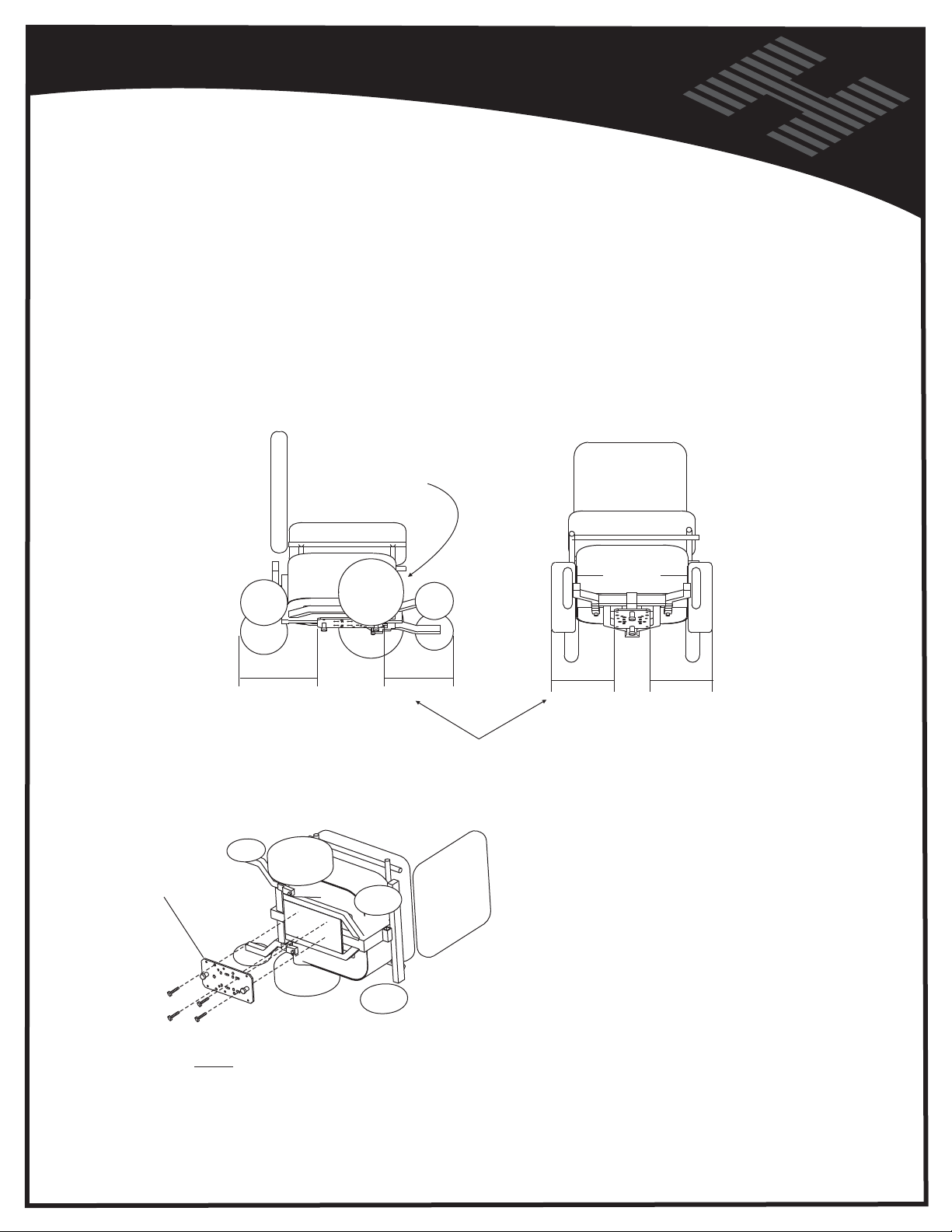

UNPACKING THE LIFT

Your Universal Outside Lift was factory preassembled to require little assembly before installation.

Box contents should include:

Hardware Package

Contents Include:

Vehicle Wiring Harness

Required Fasteners

Keys

Black tie wraps

Instruction Manual

DO NOT

LIFT

FROM

MOTOR

COVER

AL550

Package Check List

Main lift body (#1)

Hitch Post (#2)

Hitch Adapter (#3)

Hardware pack

THE AL010/050’s PLATFORM

HAS BEEN LEFT OFF

FOR A DECREASE IN PACKAGE

SIZE, ALLOWING NEXT DAY

SERVICE / NON-FREIGHT

SHIPPING. ATTACH TO LIFT

AT PIVOT BOLT (SEE

EXPLODED VIEW FOR

REFERENCE )

AL300

Package Check List

Main lift body (# 1)

Hitch Post (# 2)

Hitch Adapter (# 3)

Spreader Bar (# 4)

Hardware pack

Hardware pack

NOTE: THE PLATFORM WILL NOT

UNFOLD UNTIL THE LIFT HAS BEEN

LOWERED AT LEAST AN INCH

AL010/050 - Micro Scooter / Power Chair Lift

AL301XL

Package Check List

Main lift body (# 1)

Hitch Post (# 2)

Hitch Adapter (# 3)

Rear Wheel Craddle (# 4)

Front Wheel Craddle (# 5)

CLASS 2

Hitch Adapter

LIFT BODY

HARDWARE

PACK

HITCH POST

Hardware pack

LIFT

PLATFORM

KEEPER

WELDE

D TO

P

LATF

OR

M

AL030 - Manual Wheelchair Lift

Al560

Package Check List

Main lift body (# 1)

Hitch Post (# 2)

Hitch Adapter (# 3)

HITCH POST

HITCH ADAPTER

and Stabilizer

LIFT BODY

HARDWARE PACK

Be sure and check the contents of the box against the package check list to be sure that all parts are included with

the lift that are required for proper installation. If any parts are missing or if any damage is noted, immediately contact

the distributor from which you purchased your lift. DO NOT attempt to install or use the lift with any missing or

damaged parts.

2

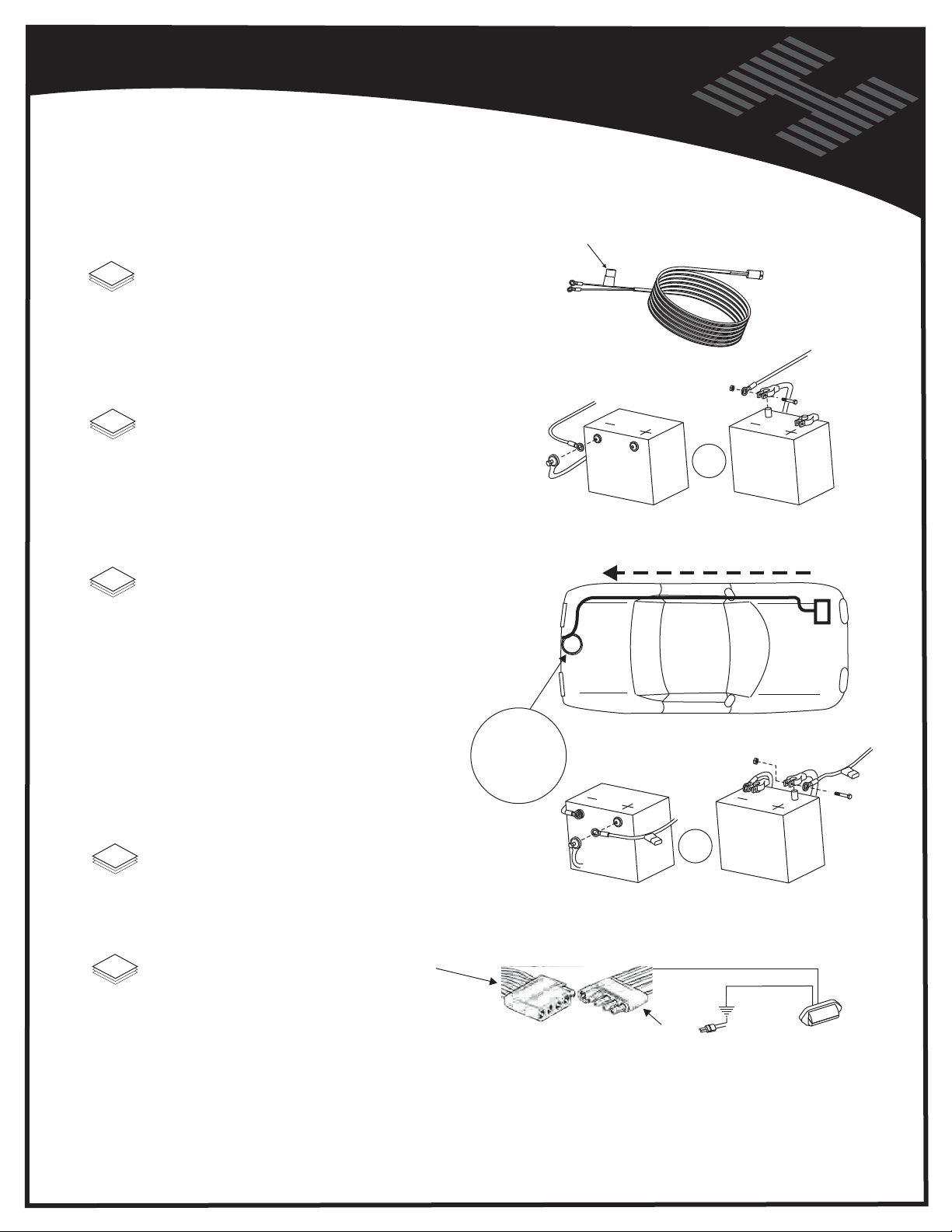

WIRING THE VEHICLE

Vehicle Wiring Harness

Installation Instructions

1

Unwind the harness and lay it flat. One end of the

harness has a black plug . This end of the harness

goes to the back of the vehicle.

2

BEGIN ROUTING THE VEHICLE

HARNESS AT THE BATTERY

Attach the black wire to the negative terminal on the battery.

Do not attach the red wire yet.

Self-resetting

Circuit Breaker

To vehicle's

battery

BLACK WIRE

OR

To back

of vehicle

BLACK WIRE

Run the wiring harness under, or when possible through

3

the vehicle, back to the trailer hitch. Always locate the wiring

harness where it can not be snagged by road debris and

away from the vehicle's gas tank.

If the harness is too long for the vehicle, coil the

excess wire and secure it to the vehicle frame with

cable ties.

Secure the plug about even with the end of

the hitch receiver tube.

Do not cut or shorten the harness.

COIL

EXCESS

WIRE

HERE

4

Attach the red wire to the positive terminal on the battery.

Wire in a Standard 4-contact female flat trailer

5

connector to the vehicles' taillights. This will

provide power for the motor cover light.

Important Reminder: Never attempt to attach the wire harness

to a secondary power source. The harness requires direct connection

to the battery.

Side mount

RED WIRE

Side mount

TRAILER PLUG

ON LIFT HARNESS

OR

BROWN WIRE

Ground for light is

provided by main

2 prong power

connector

Top mount

Top mount

MOTOR COVER

RED WIRE

LIGHT

Caution: Route the harness away from the exhaust system, brake lines, fuel lines, gas tank, pinch points,

and sharp edges. Locate the wiring harness where it can not be snagged by road debris.

3

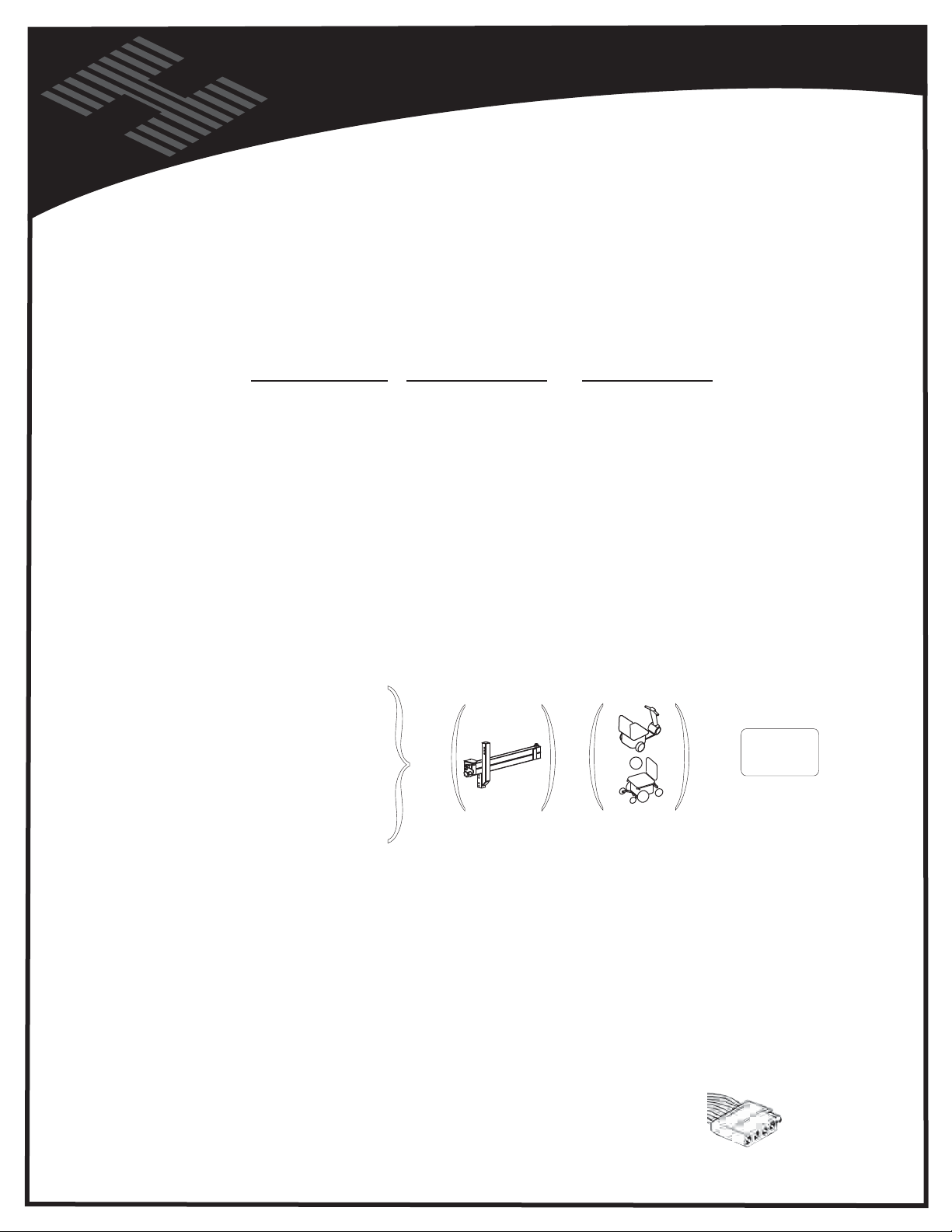

Vehicle Hitch

To install an Outside Lift on a vehicle, the vehicle must be capable of accepting a Class 2 or Class 3

hitch. If you are unsure about the vehicle and hitch compatibility, contact a local hitch installer or the

web sites below. The vehicle should also be wired with standard 4 post trailer wiring.

Listed below are three websites of hitch companies that can be used as a reference

www.hitch-web.com

, www.reeseprod.com, or

VEHICLE HITCH

www.draw-tite.com

Be sure to recommend a hitch installer that is reputable, insur

direct reflection on the customers perception of a properly installed mobility lift.

Impor

tant Note: Not every vehicle is capable of having a hitch installed

Remember: Calculate the weights of the lift, mobility d

option, being certain that the total weight does not exceed the recommended tongue weight of the

hitch. Different types of hitches are capable of bearing different amount of tongue weight.

The lift manufacturer suggests the installer observe the vehicles Gross Vehicle Weight Ratings and

Restrictions.

HITCH

PRODUCT:

AL 100

AL 500

AL 550

AL 300

AL 301XL

AL 010/050

AL 030

AL 560

CLASS:

2 or 3

2 or 3

2 or 3

2 or 3

2 or 3

2 or 3

1, 2 or 3

2 or 3

WEIGHT:

98 lbs

95

lbs

112

lbs

127

lbs

110

lbs

73

lbs

60

lbs

lbs

105

+

IF

USED

Not for

AL030

Swing

40 lbs

ed, and capable, as their work has a

evice, and where applicable the swing away

Chair /

Away

+

Scooter

OR

X lbs

Must NOT

Exceed Hitch

=

Manufacturer's

Max Tongue

Weight

lbs

Important Note: Some states have very strict license plate obstruction laws, so be sure to familiarize

yourself with the local and state laws.

Important Note: Assure the receiver tube of the hitch is parallel to the ground. This is not a

recommendation, but rather a requirement.

If the hitch is not installed properly, it will affect the functioning of the lift.

Some vehicles will require that the rear suspension be supplemented. The manufacturer

recommends the installer contact a suspension specialist for additional technical support.

A vehicle with a Class 3 (Class 2

wiring is ready for installation of the lift.

requires optional accessories) hitch and standard 4 post trailer

4

VEHICLE HITCH

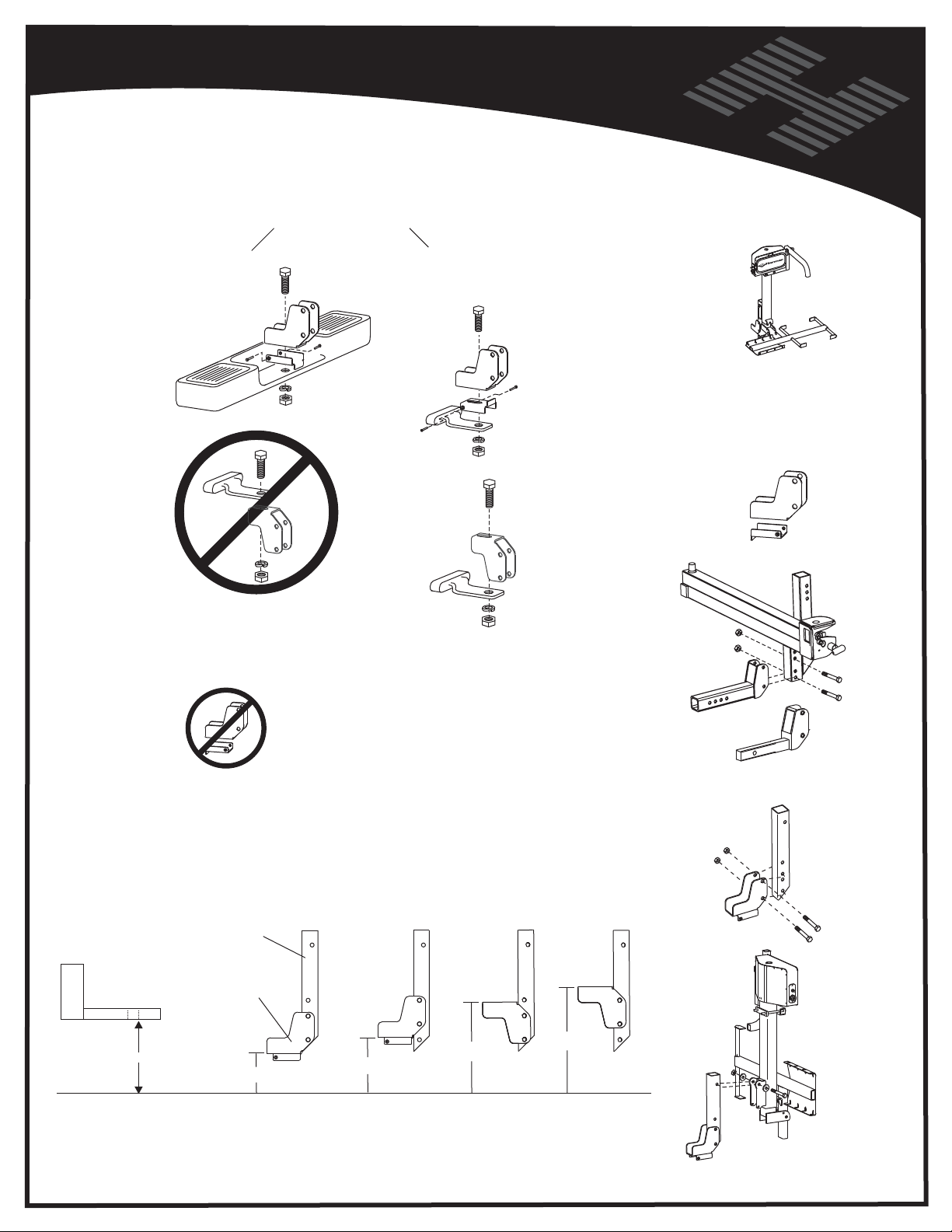

Hitch Adapters

AL123

Standard Class 3

AL125

Class 3 Extra long

H124

Class 3 Short

AL1232

2in Drop Class 3

A Hitch Adapter is the part of the lift

that plugs into a vehicle's trailer hitch.

Several hitch adapters are available

to fit the needs of differnet vehicles.

When selcting a Hitch Adapter you

should determine the hitch class and

measure the bumper distance.

Bumper distance is the length from the

trailer hitch's bolt hole to the rear most

point on the vehicle.

Hitch class is usually printed on the trailer hitch,

however it can also be determined by measuring

the inside of the receiver on the trailer hitch.

Class 2 hitches measure 1-1/4" x 1-1/4"

Class 3 hitches measure 2" x 2"

Once you have determined the hitch class

and bumper distance, refer to the diagram

below to select the proper hitch adapter.

As always, Harmar Mobility's trained personnel

will be glad to assist you in selecting the

proper hitch adapter.

AL126

Standard Class 2

AL127

Class 2 Extra long

H128

Class 2 Short

AL1235

5in Drop Class 3

AL1236

6in Drop Class 3

Hitch Class Bumper Distance Bumper Distance Bumper Distance

Class II 0”-7.5” 7.5”-10” 10”-13.5”

AL126 AL127

Class III AL123 AL125 AL125

AL1265

4in Drop Class 2

Shorter adapters available for

shallow hitches.

Drop adapters available for higher

than normal vehicles.

5

Vehicle Hitch

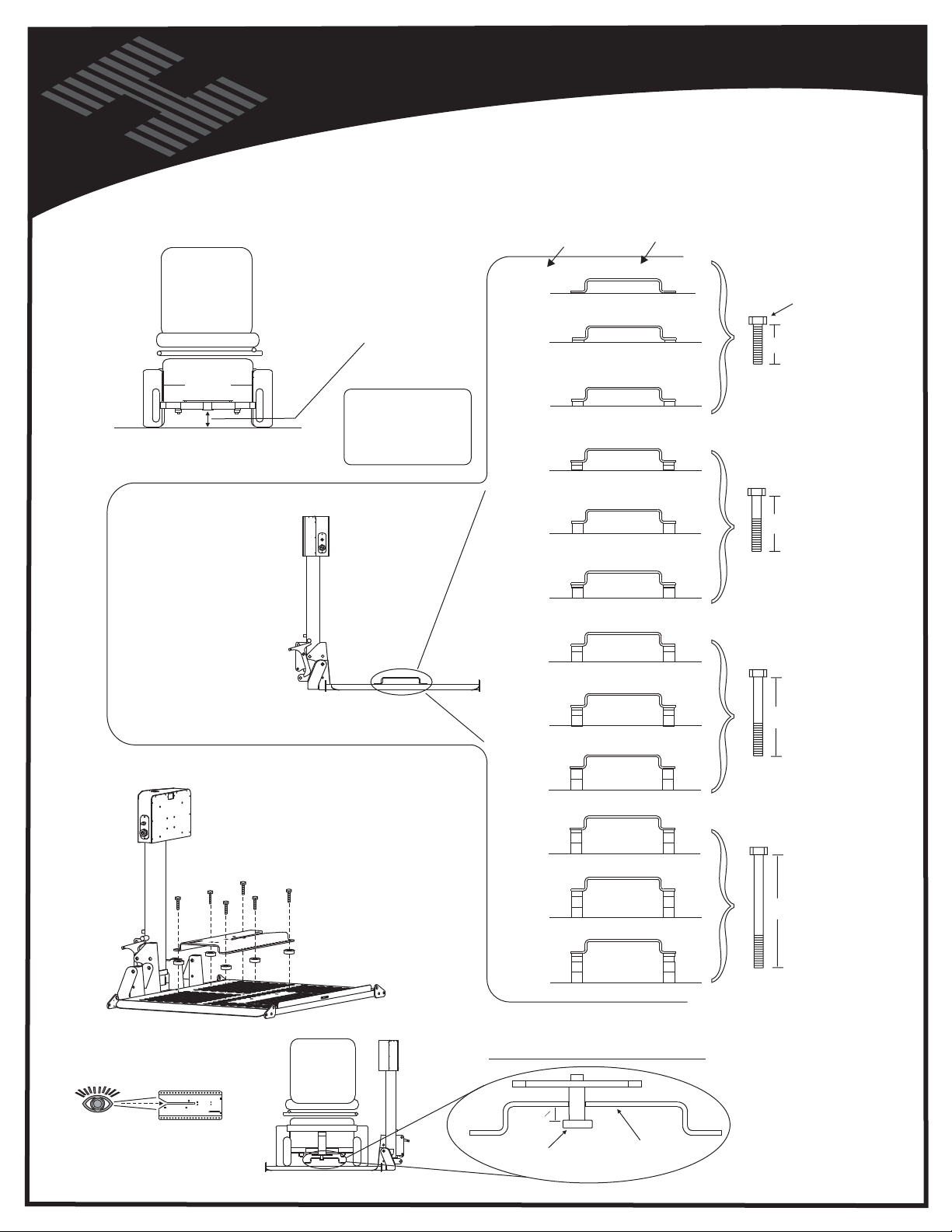

In order to determine how to assemble the Hitch Post and Hitch Adapter, the distance from the

bottom of the hitch to the ground must be measured.

together the Hitch Post and Hitch Adapter. Use the 1/2” x

Drawings below depict a Class 3 Hitch Adapter

The installation for a Class 2 is identical

HITCH

POST

INSTALLATION

Determine which set of holes to use to bolt

3-1/2” bolts and nuts provided and tighten.

Hitch

Post

Without Swing

Away Option

Measure from

Hitch Bar to ground

With Swing

Away Option

HITCH

ADAPTER

5-13"

SWING AWAY

HITCH

ADAPTER

4-12" 12-14"

13-15"

15-17"

14-16"

17-19"

16-17"

Once you have determined the proper adjustment for the Hitch Post or Swing Away

and have attached it to the Hitch Adapter, insert the adapter into the hitch receiver

and attach it using the 1/2" x 3-1/2" bolt, , Pinch Bolt Tube and lock nut.

CLASS 3

( 2 x 2 TUBE )

PINCH BOLT

TUBE

OR

CLASS 2

( 1.25 x 1.25 Solid Bar )

Pinch Bolt Tube

Not required, as

Class 2 is threaded

OR

OR

Swing

Away

NOTE: Pinch Bolt Tube is added to the Class 3 reciever

bolt to prevent the lift from moving side to side

Extremely Important Note:

Attach Lift to Hitch Post or Swing Away

DO NOT OVERTIGHTEN THIS BOLT!

It is a pivot point!

Valuable Installation Hint! (Using Caution), Once the lift is placed behind the vehicle, plug the

power cord into the harness that you have installed on the vehicle. Turn the key on an

toggle DOWN switch to raise the motor box. Continue to power the lift until the mounting holes in the

lift are even with the top hole in the Hitch Post. Attach the lift to the post using the supplied 1/2” bolt

with lock nut and washers. Using this method will allow you to attach the lift without physically having

to lift the unit and hold it while the bolt is inserted.

Route the lift power cord down the lift away from its moving parts and potential pinch points. The

cord should follow along the post and be secured with zip ties provided to allow the lift to operate

without disconnecting the power cord.

6

d use the

INSTALLATION

Bumper Mount

( Be sure to comply with

vehicle's bumper rating )

FOR AL030 ONLY

( Ball Mount

Hitch adapter )

Flat Bar Style

( Be sure to comply with

vehicle's bumper rating )

Y

T

I

L

I

B

O

M

For AL030 ONLY

Ball Mount Hitch

Adapter and

stabilizer

Do not attempt to

mount up from under

Ball Mount Hitch Adapter

can NOT be used when

installing a Swing Away

Drawings below depict a Ball Mount Hitch Adapter

The installation for a Class 2 or 3 Hitch

Adapter can be used and is identical

HITCH

POST

BALL MOUNT

HITCH

ADAPTER

Omit stabilizer

OMIT

STABILIZER

Only Class 3 or 2

Hitch Adapters

can be used with

a Swing Away

OMIT

STABILIZER

Swing

Away

OR

Measure from Hitch Bar to ground

5-13"

13-15"

15-17"

7

17-19"

Vehicle Hitch

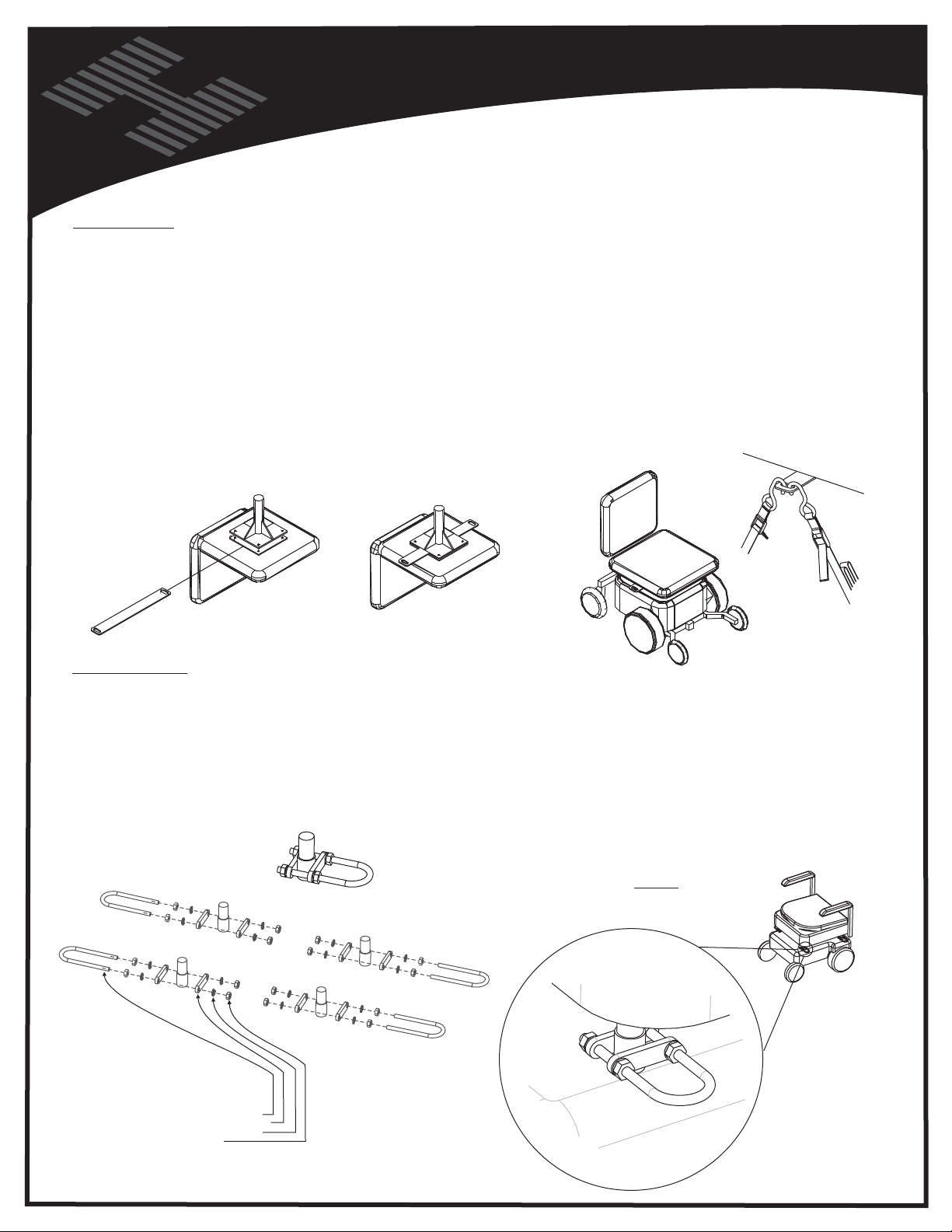

AL600 & AL690

ANCHOR PLATE:

THE ANCHOR PLATE IS A FLAT PLATE THAT IS 20” LONG WITH A SLOT IN EACH END.

THIS PLATE WILL WORK WITH ANY CHAIR OR SCOOTER THAT HAS A CENTER SEAT POST

AND ATTACHES TO THE BOTTOM OF THE SEAT.

ATTACH THE ANCHOR PLATE BY THE FOLLOWING STEPS:

THE ANCHOR PLATE SHOULD EXTEND ABOUT 1-1/2” OUT FROM THE SIDE OF THE CUSHION.

THIS WILL ALLOW THE USER TO ATTACH THE STRAP HOOKS TO THE ANCHOR PLATE TO SECURE

THE CHAIR TO THE LIFT.

1. REMOVE SEAT FROM THE CHAIR.

2. LOOSEN THE SCREWS THAT ATTACH THE PLATE TO THE BOTTOM OF THE SEAT. ALLOW ENOUGH ROOM

TO SLIDE THE ANCHOR PLATE BETWEEN THE SEAT AND SEAT PLATE.

3. ATTACH THE ANCHOR PLATE IN THE CENTER OF THE SEAT PLATE WITH THE HOLES ON EACH END

EXTENDING EVENLY ON EACH SIDE OF THE SEAT.

4. RE-TIGHTEN THE SCREWS THAT HOLD THE SEAT PLATE TO THE BOTTOM OF THE SEAT.

5. REPLACE THE SEAT ON THE CHAIR.

Power Chair or Scooter

CHAIR PREPARATION

Preparation

THERE ARE 2 OPTIONS ON HOW TO ATTACH

THE STRAP HOOKS TO THE CHAIR

THAT ARE INCLUDED WITH THE LIFT.

ANCHOR U-BOLTS:

THE U-BOLTS ARE TO BE USED WITH POWER CHAIRS OR SCOOTERS THAT DO NOT HAVE A CENTER SEAT POST.

ON THIS TYPE OF CHAIR, THE SEAT IS NORMALLY ATTACHED TO A TUBULAR FRAME. ATTACH THE U-BOLTS, TWO ON EACH SIDE,

TO THE FRAME AS SHOWN BELOW. MAKE SURE THAT THE LOOP EXTENDS TO THE OUTSIDE OF THE CHAIR TO ALLOW THE STRAP

HOOKS TO BE ATTACHED BY THE END USER.

EACH TYPE OF CHAIR WILL DIFFER SLIGHTLY AND THE PLACEMENT OF THE U-BOLTS WILL DIFFER BETWEEN DIFFERENT MODELS

AND MANUFACTURERS. PLACE THE ANCHOR U-BOLTS TOWARDS THE CENTER OF THE SEAT IF POSSIBLE. BECAUSE OF THE

DIFFERENT TYPES OF SEATS, YOU MAY BE FORCED TO ATTACH THE ANCHOR U-BOLTS MORE TOWARDS THE FRONT OR REAR OF

THE SEAT, BUT WE RECOMMEND ATTACHMENT AS CLOSE AS POSSIBLE TO THE CENTER OF THE SEAT.

SEAT

POST

SEAT

POST

KIT CONTAINS:

4 - 1/4-20 x 3-1/4” U-BOLTS

8 - U-BOLT BACKING PLATES

16 - SPLIT LOCK WASHERS

16 - 1/4-20 NUTS

SEAT

POST

SEAT

POST

ALA580

U-BOLT HARDWARE KIT

8

INSTALLATION

CHAIR PREPARATION

AL550 only

CHOOSING A LOCATION and MOUNTING THE DOCKING DEVICE PLATE

WARNING: Do not attempt to use this automatic lock down device

on any folding, or take apart chairs unless recommended

by Harmar.

The closer the plate is

positioned to the drive

wheels, the easier the

chair will be to engage

the Locking Device

DOCKING

DEVICE

PLATE

Drive

wheel

Find approximate

center of the chair

Use existing holes where ever possible.

If too little or no holes exist,

holes need to be drilled. Remove

power chair's batteries, and use

plate as a template.

Drill as required.

Attach to chair using supplied

hardware.

DO NOT USE SPACERS HERE

SPACERS BELONG UNDER THE

STATION ON THE PLATFORM

4---1/4-20 x 1.00" HHCS

4---1/4-20 Nylock Nut

ATTACHED TO PLATE

9

Vehicle Hitch

AL600 & AL690

CHAIR PREPARATION

AL550 only

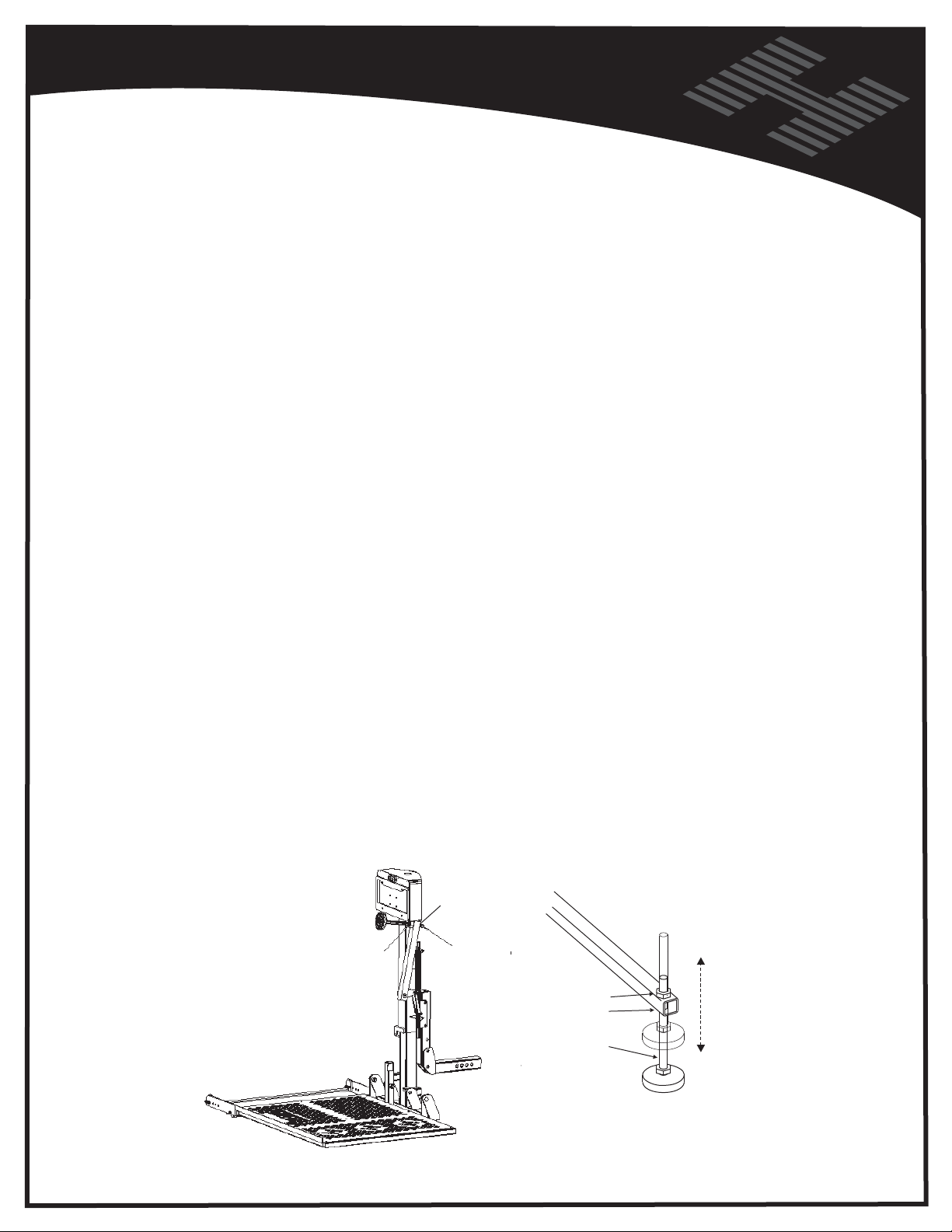

SETTING DOCKING DEVICE HEIGHT

Determine

number

of spacers

required for

your ground

clearance

Measure distance of

mounting surface

to ground

PRIOR TO MOUNTING

DOCKING PLATE TO CHAIR

Ground clearance

MUST be greater

than or equal to

1.75"

If ground

clearance =

1.75" - 2"

2.25"

2.5"

2.75"

3"

3.25"

3.5"

Then use:

No Spacers

.25" spacers

0.25" 0.25"

.5" spacers

.75" spacers

0.25"

0.50"

1" spacers

1.00" 1.00"

1" + .25" spacers

0.25" 0.25"

1.00" 1.00"

1" + .5" spacers

0.50" 0.50"

1.00" 1.00"

Hardware Used:

( from hardware pack )

Mounted on lift

from factory

1"

x6

0.50"0.50"

0.25"

0.50"

1.75"

x6

Drive Chair onto Lift

look down the entry

point of the

locking device

Remove Locking

Device and insert

appropriate number

of spacers.

Re-attach to platform.

( change to longer

screws if )

necessary

1"+ .5" + .25" spacers

0.25" 0.25"

3.75"

0.50" 0.50"

1.00" 1.00"

1"+ 1" spacers

4"

1.00" 1.00"

1.00" 1.00"

1"+ 1" + .25" spacers

0.25" 0.25"

4.25"

1.00" 1.00"

1.00" 1.00"

1"+ 1" + .5" spacers

0.50" 0.50"

4.5"

1.00" 1.00"

1.00" 1.00"

1"+ 1" + .5" + .25" spacers

0.25" 0.25"

0.50" 0.50"

4.75"

Verify the head of the shoulder bolt is

below the underside of the locking device.

UP TO A 1/4" OF SPACE IS ACCEPTABLE

1.00" 1.00"

1.00" 1.00"

1

4"

Shoulder

Bolt Head

Underside

of Locking

Device

2.5"

x6

3.25"

x6

Perform lock down test

on next page to assure

installation of Docking

Device Plate and Locking

Device are correct.

10

LIFT PREPARATION

AL100

SETTING HOLD DOWN FOOT HEIGHT

With platform on the ground, drive scooter onto platform, from left (driver's side ) to right, until the rear

wheels are located in the rear wheel spreader bar assembly. Stop when the rear tires contact the ramp

on the platform.

Raise the platform on either lift until the motor's clutch

is heard ( top of travel ). Loosen both nuts on hold down arm, and thread the Hold Down Foot down to

the scooter's deck. Lower Platform about 1-2 inches. Thread Hold Down Foot down once again to

scooter's deck. Raise Platform. Verify Hold Down Foot places adequate pressure on scooter.

DO NOT

adjust the leg so far down that the top of the threaded rod does not protrude through the top

of the pivot tube. Once the foot is adjusted to the proper position, tighten the jam nut to lock it in place.

Once the lift is properly adjusted, lower the platform to the ground and raise it back to the

transporting position. Repeat this several times to make sure all parts are operating properly and

that the scooter is properly secured. Next, remove the scooter from the lift and using the toggle

switch, cycle the lift completely up and down to make sure that all parts are in working order and the

lift fol ds up when it is empty.

Caution: On some scooters, it may be necessa ry to temporarily move the steering tiller forward to

clear the hold down arm as it lowers into the lock down position.

Caution: Some scooters have pneumatic (air inflated) tires. If your scooter has this type tire, be

sure the tires are properly inflated. Improper inflation of the tires will change the deck height of the

scooter and therefore change the amount of clamping force the hold down arm places on the

scooter. The scooter can fall off of the lift if not properly secured.

Caution: Be sure to instruct the end user not to enter steep driveways straight on. Enter and leave

at an angle to the street so that your lift platform does not drag on the ground.

NOTE: Drive the scooter off in REVERSE. When the scooter is clear of the platform, raise t

he

platform by pushing up on the UP/DOWN switch.

NUT

NUT

END OF THREADED ROD

MUST PROTRUDE

THROUGH TOP OF

TUBE AND NUT

Turn threaded rod

11

Loosen top nut

and bottom nut

to lengthen or

shorten foot

Loading...

Loading...