Page 1

XR-1000 HIGH PERFORMANCE DATA FOR CLOSED

Chamber

Comb

Vol

.

.

+

CIRCUIT RACING

General

This bulletin provides specification information and other data for

improved performance of the XR-1000 motorcycle for closed circuit

racing.

NOTE

Use of any of the Harley-Davidson part numbers listed in this

bulletin voids all warranty.

Table of Contents

SUBJECT PAGE

Engine 1-4

Transmission & Shifter 4-5

Clutch 6-8

Gearing 9

Ignition and Spark Plugs 9-10

Carburetion 11

Chassis 11

Exhaust Pipes 11

Fuel and Oil 12

Suppliers 12

Engine

The stock XR-1000 engine will produce approximately 71 HP at

5600 RPM. In modified condition, with "E" cams, racing

megaphones and high compression pistons installed, the engine

will produce approximately 93 HP at 6400 RPM

Max RPM stock Engine 6200

Max. RPM Modified Engine 7200

HIGH COMPRESSION PISTONS

DISPLACE (cc)

PART # BORE PER CYLINDER

22600-83R Std. 499

22603-83R +0.030 508

22605-83R +0.060 518

22606-83R +0.070 521

Piston to cylinder wall clearance: 0.0035 0.0045 in.

A break-in distance of 50 miles is required when new pistons are

installed and cylinder is bored for 0.0035 clearance.

COMPRESSION RATIO

Do not exceed 10.5:1. The formula for calculating the compression

ratio is:

ChamberCombVolCylVol

CR

=

To measure combustion chamber volume, do the followings

1. Coat cylinder wall with general-purpose grease. (This will

prevent the oil, used to measure combustion chamber

volume, from leaking past the upper piston ring.)

2. Install cylinder head and turn engine so piston is at top dead

center (TDC) and both valves closed.

3. Tilt engine so spark plug hole is level.

4. Fill a beaker, having cubic centimeter (cc) graduations, with

75cc of light oil.

5. Place a small funnel in spark plug hole and fill combustion

chamber with oil from the beaker. Continue filling until oil

covers bottom two threads of spark plug hole.

6. Check the amount of oil remaining in beaker and subtract that

amount from the original 75cc. The difference equals the

combustion chamber volume-

EXAMPLE:

75cc Oil in beaker

- 22cc Oil remaining in beaker

53cc = Volume of combustion chamber

Insert the above volume and the cylinder volume given with

high compression pistons into the compression ratio (CR)

formula:

...

Page 2

1:4.10

=

==

+

CR

NOTE

4.10

1

552

53

53499

53

=

CR

INTAKE AND EXHAUST PORTS

Although the XR-1000 ports are very efficient, additional porting

work can be done. Suppliers recommended are Branch

Flowmetrics or C. R. Axtell. Supplier’s addresses and phone

numbers are listed on the last page of this bulletin.

FLYWHEELS

Before assembling the flywheel, extreme care must be taken in the

cleaning of the tapers and the threads. After parts are cleaned in

solvent it is necessary that the deposits are washed away with

detergent and then rinsed in clean water. Clean tapers must not be

touched with the fingers

FLYWHEELS AND SHAFTS

Torque to 120 ft-Ibs. Leave them set overnight or a minimum of

four (4) hours. (Use grease sparingly on the threads while keeping

the tapers clean) When it is time to retorque, remove nuts, clean

thread (see above), and add Loctite.

If the procedures specify Loctite, use Loctite 620 RETAINING

COMPOUND.

Order part number 25480-83R for a complete set of "E” cams.

"E" Cam Timing at 0.060 in. Tappet Lift is as follows:

Intake opens at 33° BTDC

Intake closes at 54° ABDC

Exhaust opens at 65° BBDC

Exhaust closes at 24° ATDC

Full tappet lift 0.300 in.

Rocker arm ratio 1.48

Valve Lash:

"E” Cams with muffler 0.012 in.

'”E" Cams with open megs 0.006 in.

CAUTION

Valve to valve clearance (valves on seat) should measure

0.180 in. minimum.

Be sure to check clearance between cam lobes and the crankcase

(front intake and rear exhaust only).

See Figure 1 Install set screws in cam cover and cam bushing, as

bushings may tend to work their way out.

Locate in bushing of number 1, 2, 3 and 4 camshaft and pinion

shaft.

FLYWHEELS AND CRANKPIN

Torque to 100 ft-Ibs and true assembly (Use grease sparingly on

the threads while keeping the tapers clean.) Next torque to 175 ft –

Ibs, followed by the same waiting period and retorquing as for

flywheels and shafts. Recheck runout.

NOTES

Loctite as well as grease serves as a lubricant during the

tightening.

W-D 40 must not be used for lubricant as it will spread to the

tapers.

Solvents leave a powdery deposit, which serves as a lubricant.

If time does not permit the retorquing procedure to be followed, all

nuts should be assembled with Loctite immediately.

/f Loctite /s used on tapers take care that none is spilled into the

rod bearing (parts cannot be retorqued.)

Harley Davidson flywheels are made of cast iron. Forged steel

flywheels are available from S & S Cycle

CAM SHAFTS

For best performance use Harley-Davidson “E” cams.

Figure 1. Retaining Cam Cover Bushings

8-32 x 0.375 in. set screw

CYLINDER STUDS AND NUTS

Be sure the cylinder head nuts are torqued to 30 ft-Ibs.

CONNECTING RODS

Do not polish connecting rods, they are shot peened and polishing

will destroy their properties.

PISTON RINGS

End gap top and second compression ring: 0.012-0.014 in.

Before installing the cylinders and pistons, make sure that the ring

grooves for the compression rings, as well as the oil rings, are

machined deep enough.

Page 3

When rings are pushed against the bottom of the ring groove ring

must be a minimum of 0.015 in. below outside diameter of the

piston.

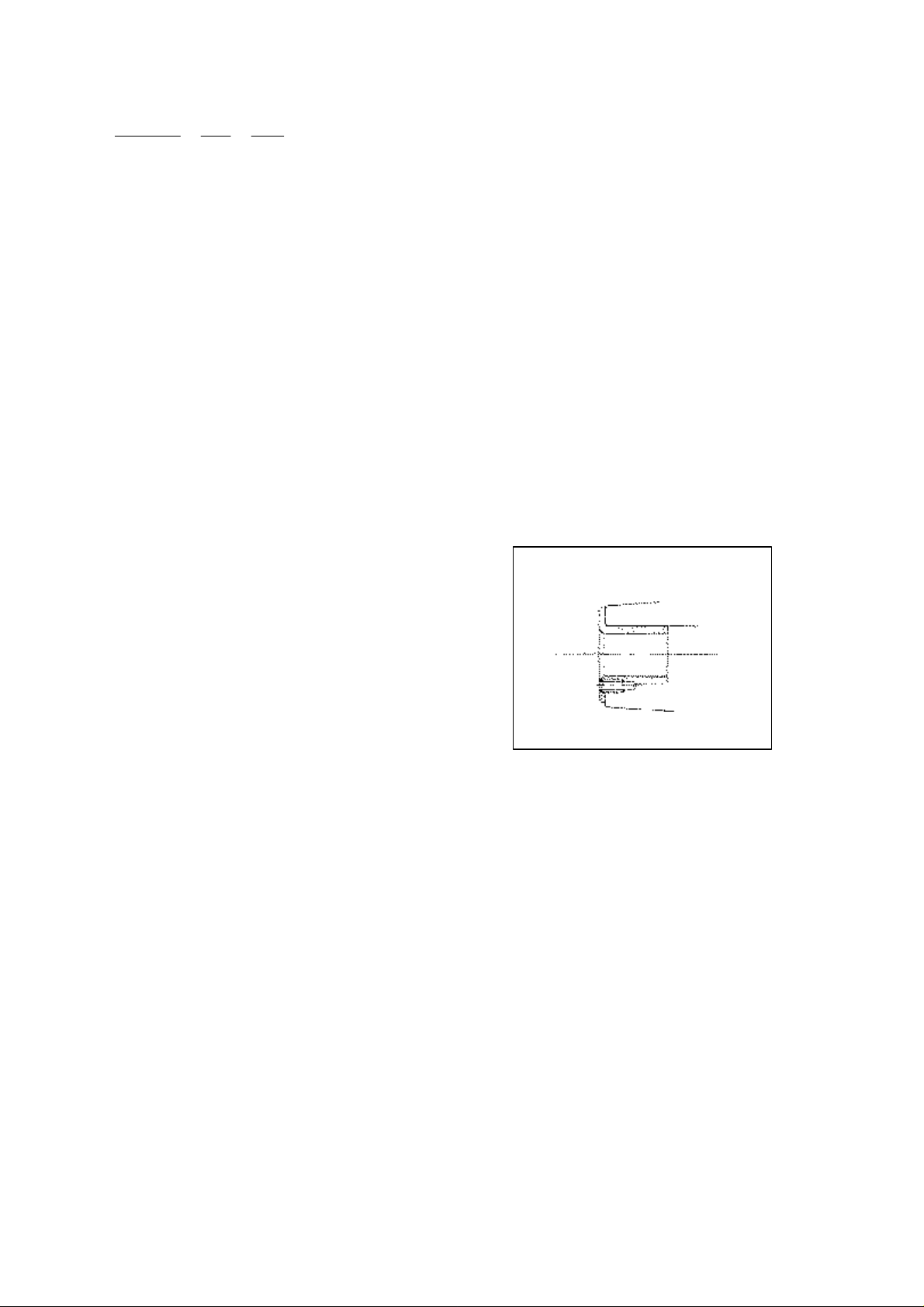

OILING SYSTEM See Figure 2 Add baffle plate to crankcase

sump as shown.

Figure 2. Oil System Modifications

Page 4

Change return oil line from rear cylinder head to drain directly into

sump For this a 1/8 in. taper pipe thread hose fitting has to he

installed in the right crankcase (see bottom view of Figure 2).

Locate this fitting with engine mounted in the frame.

CYLINDER BASE GASKET

Eliminate the gasket use Dow Corning 732 silicone sealant.

Proper placement will be above the lower frame tube and behind

the vertical crankcase boss for oil pick-up hole.

To reduce oil flow to the connecting rod bearing a restrictor

should be pressed into the pinion shaft One way to make this

would be to machine the thread off a carburetor main jet (A main

jet from an MX, SS or SX carburetor may have the following

dimensions.)

Pinion shaft hole size 0.19 ± 0.02 in.

Restrictor hole size 0.090 in.

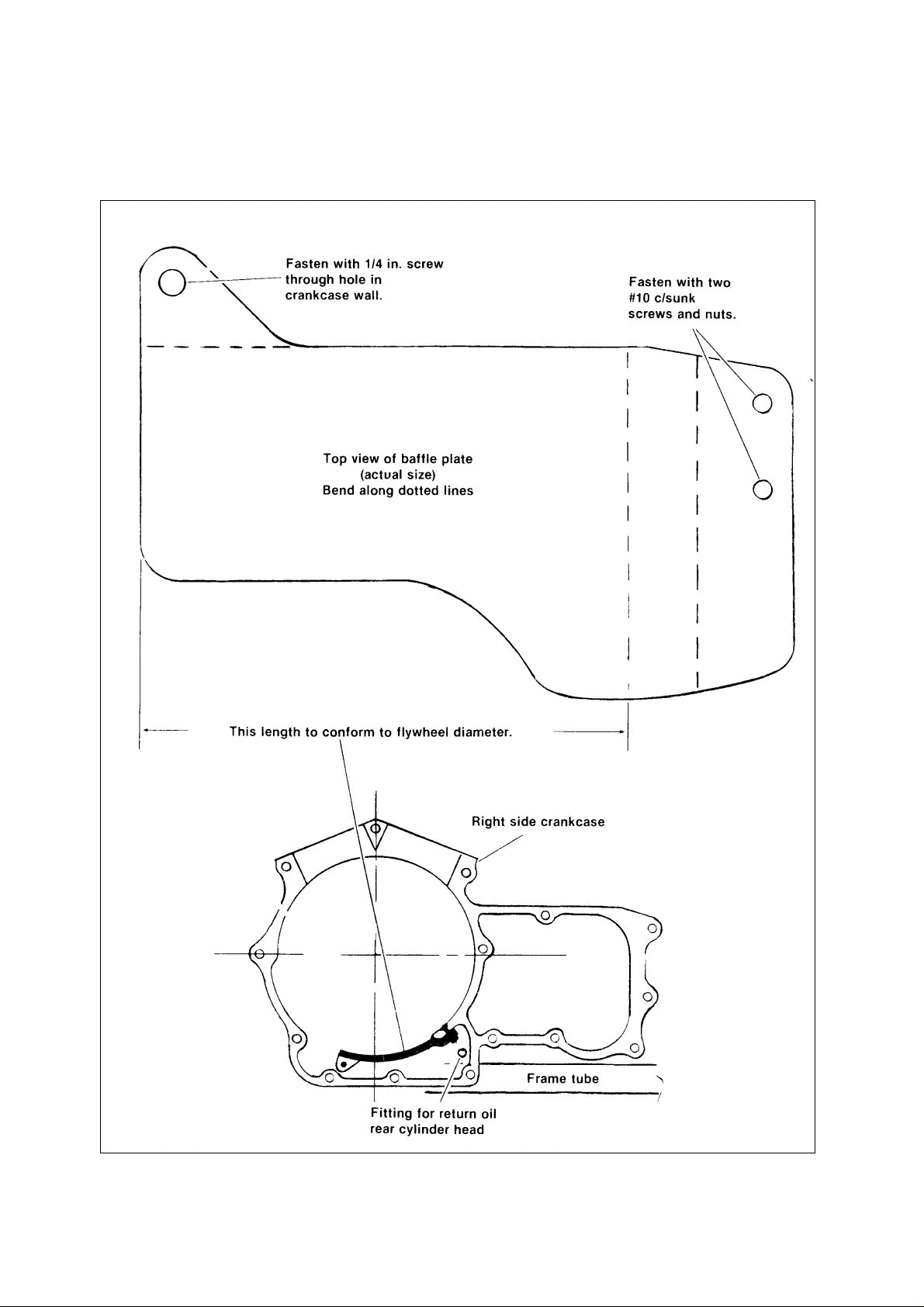

Transmission

In road racing 1st 2nd and 3rd gears are used more frequently

than in normal street use The bushing in the clutch gear is

subjected to higher speeds and must be packed in grease or in its

place a needle bearing (Torrington #B1010) can be installed. See

Figure 3. To allow use of the needle bearing the mainshaft must

be ground to dimensions shown Remove stock bushing and press

needle bearing into clutch gear as shown.

Figure 3. Transmission Modification

Page 5

SHIFTER MECHANISM

The shifter forks are subjected to heavy loads. This can be reduced

by carefully modifying the shifter cam plate. See Figure 4. The

removal of metal at the shaded areas of cam plate will allow more

engagement of the gears. In order to find out where and how much

material has to be removed, put transmission in each of the four

gears and recheck for each gear, what is required to make the

gears engage more completely. Figure 4 shows where metal must

be removed, if necessary.

Remove a little metal at a time and recheck engagement of gears.

Repeat until gears are fully engaged with one another.

Shifter forks should be free while holding gears together.

Shifter cam grooves and outside surface where plunger rides,

should be polished for smoother operation.

Remove countershaft oiler plug on transmission door to eliminate

the chance of it coming out.

A close ratio 3rd gear ("C" ratio) is available from Andrews

Products.

Figure 4. Shifter Plate Modification

Page 6

Clutch Modifications

To improve operation of the clutch, more oil must be allowed to

flow through. The following operations are recommended.

CLUTCH SHELL

See Figure 5. To sling oil out of the clutch, drill two 0.19 in.

diameter evenly spaced holes in each driving groove (24 holes

total). Drill three 0.38 in. diameter equally spaced holes in back

plate.

Figure 5. Clutch Shell Holes

Page 7

CLUTCH HUB

See Figure 6. Drill a diagonal pattern of six 0.09 in. diameter holes

all around hub while taking care that the

no. 3 and no. 5 holes do not run out into hub center plate. Seven

0.25 in. diameter holes must be drilled flush with inside diameter

(I.D.) of hub rim (where no. 4 holes break through).

Figure 6. Clutch Hub Holes

Page 8

Figure 7. Clutch Release Disc Modification

Modification, Clutch Release Disc

See figure 7. In order to circulate more oil through the clutch,

three scoops must be added to the clutch release disc.

Fabricate the scoops from light gauge steel sheet metal. Drill

three 0.375 in holes through the clutch release disc. Position the

scoops and weld them in place.

Page 9

Overall Gear Ratios

RANGE

HOT

N4C

R

*

1056

The overall qear ratios with various sprockets are listed in the

following chart.

Speed Formula

HourMiles

/ =

CS

*

REAR WHEEL

SPROCKET

(TEETH)

40 3.65 3.47 3.31

41 3.74 3.56 3.39

42 3.84 3.64 3.47

43 3.93 3.73 3.55

44 4.02 3.82 3.64

45 4.11 3.90 3.72

46 4.20 3.99 3.80

Transmission sprockets with 79 and 20 teeth require a

0.090 in. thick spacer.

PART HARLEY-DAVIDSON PART NUMBER

19 T Transmission Sprocket 35197-52

20 T Transmission Sprocket 35198-52

21 T Transmission Sprocket 35205-52A

TRANSMISSION

SPROCKET

(TEETH)

19 20 21

Overall Gear Ratios

NOTE

S = Engine RPM

C = Tire circumference (inches)

R = Overall Gear Ratio

Average gearing for Stock bikes 3.84

Ignition Timing

For Stock and Modified classes full advance ignition timing is 30°

BTDC above 2000 RPM.

Spark Plugs and Cables

If stock Magnavox ignition is used also use resistor spark plugs

and stock carbon core spark plug cables. This will prevent

problems with electronic ignition module and tachometer.

Champion resistor spark plugs are identified by the letter R in

front of spark plug type ie. RN6YC.

Spark plug gap should be closed up to 0.022 in (Stock and

Modified classes).

Since the heat range required for each cylinder may not be the

same it is necessary to take plug readings on both cylinders. See

spark plug chart for heat ranges.

HEAT

PROJECTED PROJECTED REGULAR FINE WIRE RETRACTED

RN7YC N7YC HEAT

N3C N87 RANGE

RN6YC N6YC

N2C N86 N62R G63R STOCK

N4YC &

N60 N84 N60R G61R MOD.

G59R

COLD N57 N82 N57R G58R

14 mm 10 mm

RACING HEAT RANGE CHART FOR CHAMPION

SPARK PLUGS

Page 10

See Figure 8. The engine will run cooler with an additional

spark plug installed on the right side of the cylinder head.

With two (2) plugs installed, make the following changes:

Ignition Timing 17-20° BTDC

Gap 14 mm Plug 0.018 in.

Gap 10mm Plug* 0.015 in.

*See spark plug chart for recommended 10 mm plugs.

Connect two coils in parallel to make all plugs fire at the same

time.

Figure 8. Installing Additional Spark Plug

Page 11

Carburetion

For best results jet both carburetors individually.

The accelerator pump should be disconnected by removing the

plastic lever (cam follower) from the carburetor cover.

If stock mufflers are repaced by megaphones the main jets

have to be increased by approximately two sizes.

D’Ellorto 36 mm 40 mm

Main Jet 140-155 145-160

Slide 50/3 60/5

Needle K27 K4

THROTTLE

The throttle should be lubricated with Bel Ray 6 in 1 oil. Do

not use dry slide lubricant.

FUEL VALVE

Remove stand pipe in fuel valve and turn knob to reserve for

maximum fuel flow.

IGNITION SWITCH

Pack wire on the back of switch in RT\/ silicon sealant to prevent it

from breaking.

REAR SET FOOTRESTS

Raise master cylinder 2½ in. and turn brake and shifter levers

around.

For the new location of the footrests use a rear footrest support

from a 1982 XL.

Needle Jet 262AB 265AB

Idle Jet 62-65 62-65

Suppliers for D’Ellorto carbs and parts is Cosmopolitan Motors.

Forty-one mm Lectron carburetors and tapered manifolds are

available from Branch Flowmetrics.

Specially modified flat slide Mikuni carburetors are available from

Storz Performance.

Chassis

Front fork: Use 20W fork oil. To check oil level in fork Iegs,

remove springs and bottom out the suspension. The distance

from the top of the fork to the oil level should be 5.8 in. with the

suspension bottomed out. Be sure spring is free from oil at the

time of installation.

See figure 9. To increase compression damping, one of the

two 0.24 in. diameter holes in the fork damper tube has to be

PART HARLEY-DAVIDSON PART NUMBER

Footrest Support (1) 52706-82

Footrest (2) 33048-72

Locknut (2) 7778

Bo!t (2) 4721

A rear swingarm mounted footrest kit is available for the XL

models and can also be used for the XR-1000. Order HarleyDavidson Part No. 49105-83.

HANDLEBARS, STOCK CLASS ONLY

Upside down mounted handlebars from a 1983 XLS, or HarleyDavidson Draqbike handlebars work very well. If the dragbike

bars are used, a notch must be made in the switch housing to

prevent the wires from being cut.

PART HARLEY-DAVIDSON PART NUMBER

XLS Handlebar 56082-83

Draqbike Handlebar 55963-77

REAR FENDER

Flatten rivets on bottom side of rear fender to prevent

interference with tire.

plugged.

F igure 9 Fork Damper Tube Modification

REAR SHOCKS

The following shocks and springs are recommended:

Shock: Koni #7610F-1283 (13½ in. Ig.)

Spring: Koni #250-15-21-28

Supplier - Parts Unlimited

KICK STAND

The kick stand must be removed.

Exhaust Pipes

The Harley-Davidson part number for the exhaust pipe kit is

80078-83.

To prevent cracking exhaust pipes must be mounted without

stress.

Modified class: Springs can be used to. mount header pipes and

hold joints together. Interconnector can have slip fit.

Page 12

Fuel

Stock Class: The use of racing gasoline is recommended.

However, a premium leaded or unleaded gasoline with a

minimum octane rating of 92 is satisfactory.

Modified Class: Use racing gasoline only.

Oil

Engine:

HD20W50 Power Blend. (Mineral Oil)

40W Racing Oil (Mineral Oil)

40W Castor Oil (Vegetable Oil)

Transmission: Racing automatic transmission fluid

(available at automotive performance shops).

OIL FILTER

The oil filter must be safety wired. A hose clamp secured to

the outside of the filter provides a means for safety wiring the

filter.

Suppliers

Andrews Products

5212 North Shapland Avenue Rosemont, IL 60018

312-992-4014

Branch Flowmetrics

5556 Corporate Drive Cypress, CA 90623

714-827-1463

C. R. Axtell

10949 Tuxford Street, #17

Sun Valley, CA 91352

213-768-5594

Cosmopolitan Motors

Jacksonville & Meadowbrook Roads

Hatboro, PA 19040

215-672-9100

Parts Unlimited

P. 0. Box 9238

Ashevilie, NC 28805

S & S Cycle

Route 2, County G

Viola, Wl 54664

608-627-1497

Storz Performance

1362 Tower Square, #2

Ventura, CA 93003

805-654-8816

Loading...

Loading...