Page 1

Maintenance and Lubrication

Safe Operating Maintenance

Perform the service and maintenance operations as indicated in the regular service interval table.

Lack of regular maintenance at the recommended intervals can affect the safe operation of your

motorcycle, which could result in death or serious injury. (00010a)

Good maintenance leads to a safe operating machine. A careful check of certain equipment must be made after

periods of storage and frequently between the regular service intervals to determine if additional maintenance is

necessary.

Check the following items:

1. Tires for correct pressure, excessive wear or any signs of tire damage.

2. Drive belt for proper tension.

3. Brakes, steering and throttle for responsiveness.

4. Brake fluid level and condition. Hydraulic lines and fittings for leaks. Also, check brake pads and discs for

wear.

5. Throttle cables for fraying or crimping and free operation.

6. Engine oil level.

7. Engine coolant level.

8. Clutch fluid level.

9. Headlamp, tail lamp, brake lamp and directional lamp operation.

Break-in Maintenance

NOTE:

The performance of new motorcycle initial service is required to keep your new motorcycle warranty in force and for

proper emissions system operation.

After a new motorcycle has been ridden its first 1000 mi 1600 km , it should be taken to an authorized HarleyDavidson dealer for initial service operations. Refer to Regular Service Intervals: 2012 VRSC Models.

Engine Lubrication

Prolonged or repeated contact with used motor oil may be harmful to skin and could cause skin

cancer. Promptly wash affected areas with soap and water. (00358b)

If swallowed, do not induce vomiting. Contact a physician immediately. In case of contact with eyes,

immediately flush with water. Contact a physician if irritation persists. (00357c)

Page 2

Do not switch lubricant brands indiscriminately because some lubricants interact chemically when

mixed. Use of inferior lubricants can damage the engine. (00184a)

Engine oil is a major factor in the performance and service life of the engine. Always use the proper grade of oil for

the lowest temperature expected before the next scheduled oil change. Your authorized dealer has the proper oil to

suit your requirements. Refer to Recommended Engine Oils.

This motorcycle was originally equipped with Genuine H-D 360 Multi-Grade 20W50 engine oil, and is the preferred

oil under normal operating conditions. If operation under extreme cold or heat are expected, refer to

Recommended Engine Oils for alternative choices.

If it is necessary to add oil and Harley-Davidson oil is not available, use an oil certified for diesel engines.

Acceptable diesel engine oil designations include: SH, CH-4, CI-4 and CJ-4.

The preferred viscosities for the diesel engine oils in descending order are: 20W50, 15W40 and 10W40.

At the first opportunity, see an authorized dealer to change back to 100 percent Harley-Davidson oil.

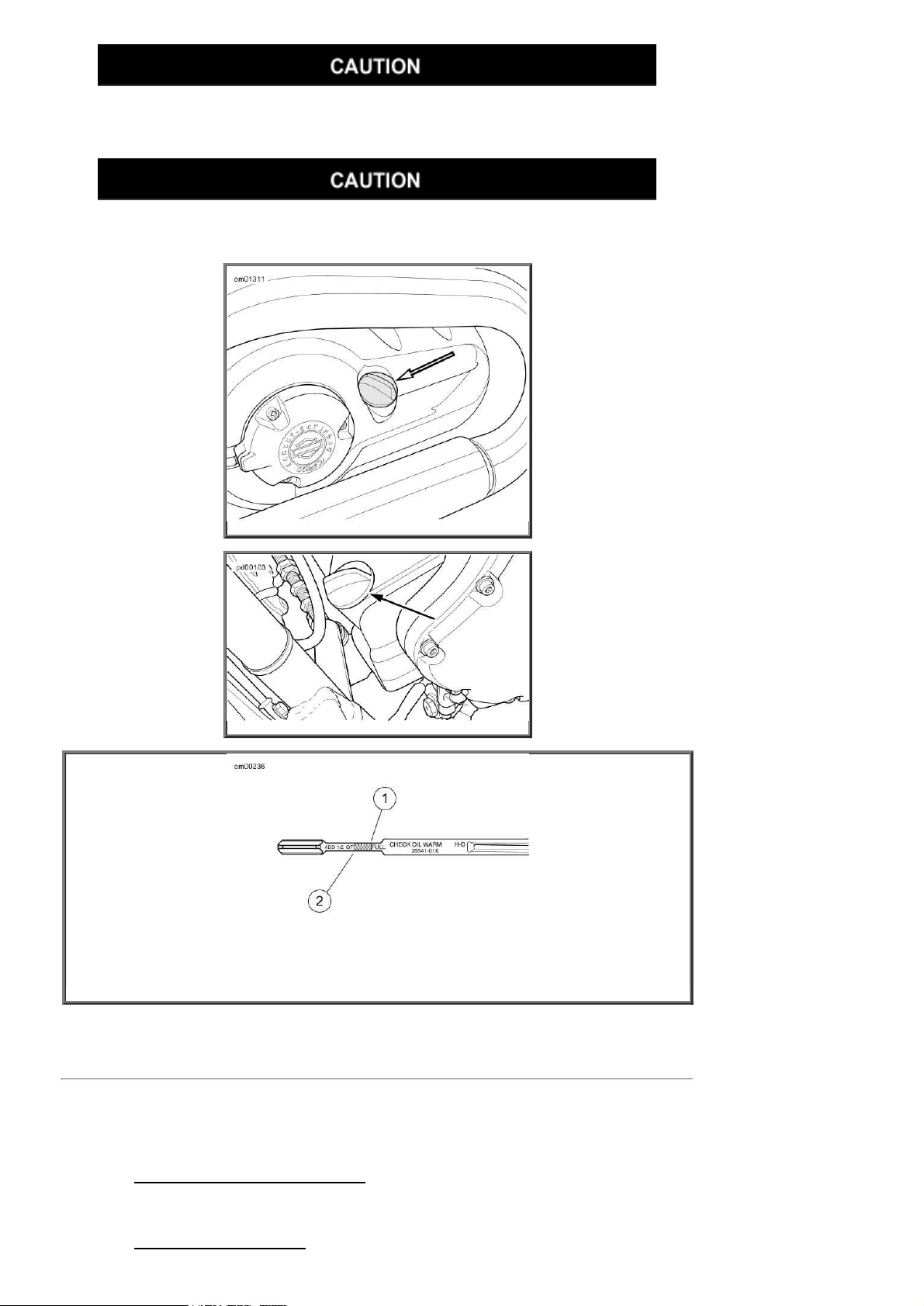

Recommended Engine Oils

TYPE VISCOSITY RATING LOWEST AMBIENT

TEMPERATURE

COLD WEATHER

STARTS BELOW

50 °F 10 °C

Screamin' Eagle SYN3 Synthetic

Motorcycle Lubricant

SAE

20W50

HD 360 Above 40 °F 4 °C Excellent

Screamin' Eagle Synthetic Blend

Motorcycle Lubricant

SAE

20W50

HD 360 Above 40 °F 4 °C Good

Genuine H-D 360 Multi-grade SAE

20W50

HD 360 Above 40 °F 4 °C Good

Multi-grade (oil certified for use in

diesel engines)

SAE

10W40

SH, CH4,

CI-4, CJ4

Below 40 °F 4 °C Excellent

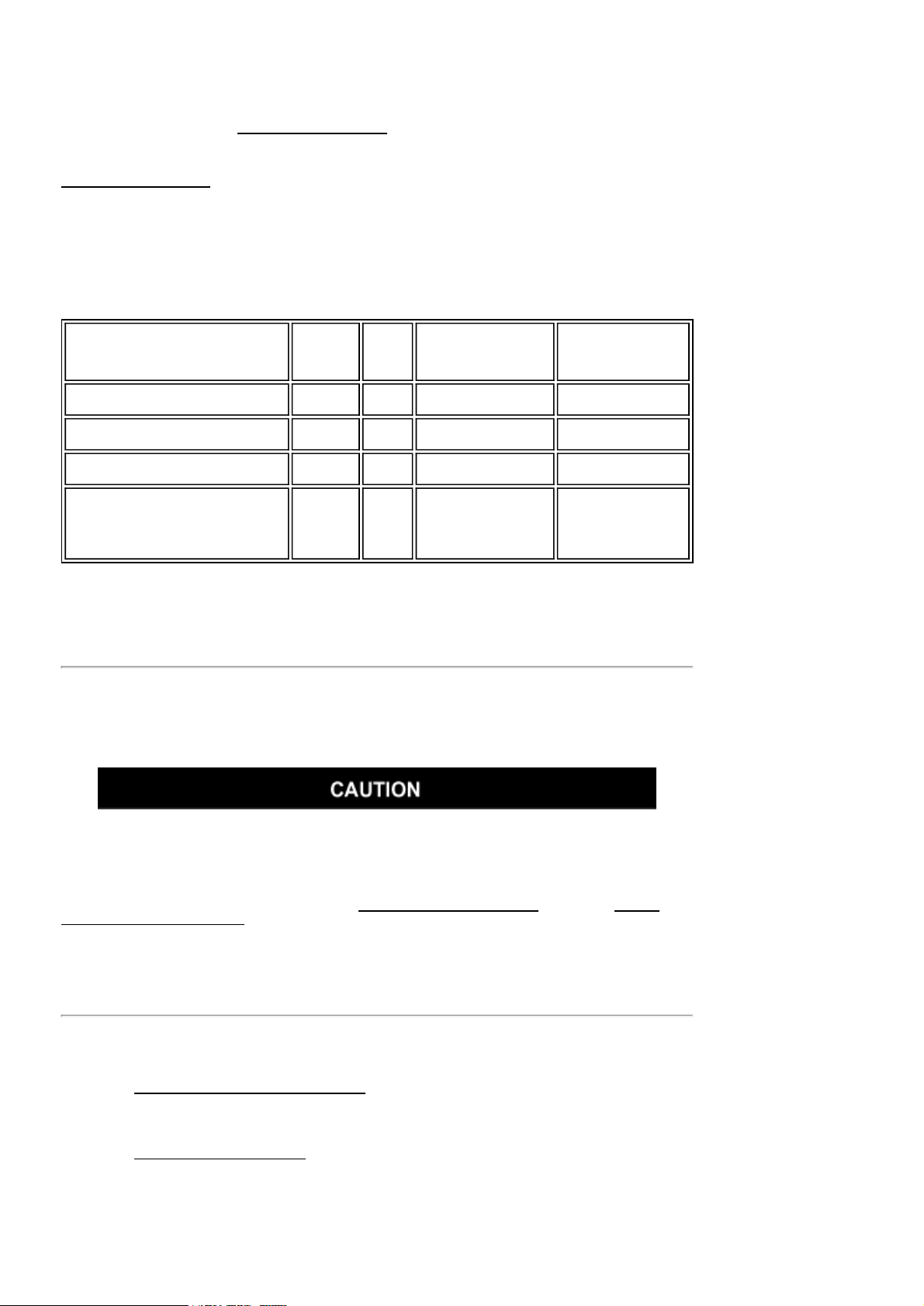

Checking Oil Level

NOTE:

This engine has a wet sump, an integral transmission, gear driven primary drive and wet clutch. This design allows

engine oil in the sump to be used to lubricate the engine, transmission and primary drive. The clutch and primary

drive are housed on the right side of the engine.

Oil level cannot be accurately measured on a cold engine. For pre-ride inspection with the

motorcycle upright (not leaning on jiffy stand) on level ground, the oil should register approximately

at the midpoint of the cross-hatch area on the dipstick when the engine is cold. Do not add oil to

bring the level to the full mark on a cold engine. (00186b)

Check engine oil level at each complete fuel refill. See Dipstick Location: VRSCF Model (VRSCF) and Dipstick

Location: VRSCDX/VRSCDX ANV (other models). On VRSCF model, the dipstick is located on the right side in the

clutch cover. On other models, the dipstick is located on left side at front of engine.

Cold Engine Oil Level Check

Check the oil level with the engine COLD as follows:

1. Stand the motorcycle upright (not leaning on the jiffy stand) on a level surface.

2. See Dipstick Location: VRSCDX/VRSCDX ANV. Unscrew the oil filler cap (with attached dipstick) by

turning the filler cap counterclockwise. Remove the filler cap and dipstick and wipe the dipstick clean.

3. Screw the filler cap into the engine. Make sure the cap is fully seated on the crankcase.

4. See Engine Oil Level: VRSC Models. Remove the filler cap again and check the oil level on the dipstick.

5. If the oil level is below the midpoint of the cross-hatch area on the dipstick, add enough Harley-Davidson

oil to bring the level up to the midpoint of the cross-hatch area shown.

Page 3

Do NOT operate the engine when the oil level is below the add mark on the dipstick at operating

temperature. Engine damage could result. (00493b)

To avoid over-filling the oil sump, wait approximately three minutes after adding oil before checking

the oil level with the dipstick. An over-filled sump can cause engine damage. (00188a)

Dipstick Location: VRSCF Model

Dipstick Location: VRSCDX/VRSCDX ANV

1. Full mark

2. Add mark. Do NOT operate the engine when the oil level is below the add mark at operating temperature.

Engine Oil Level: VRSC Models

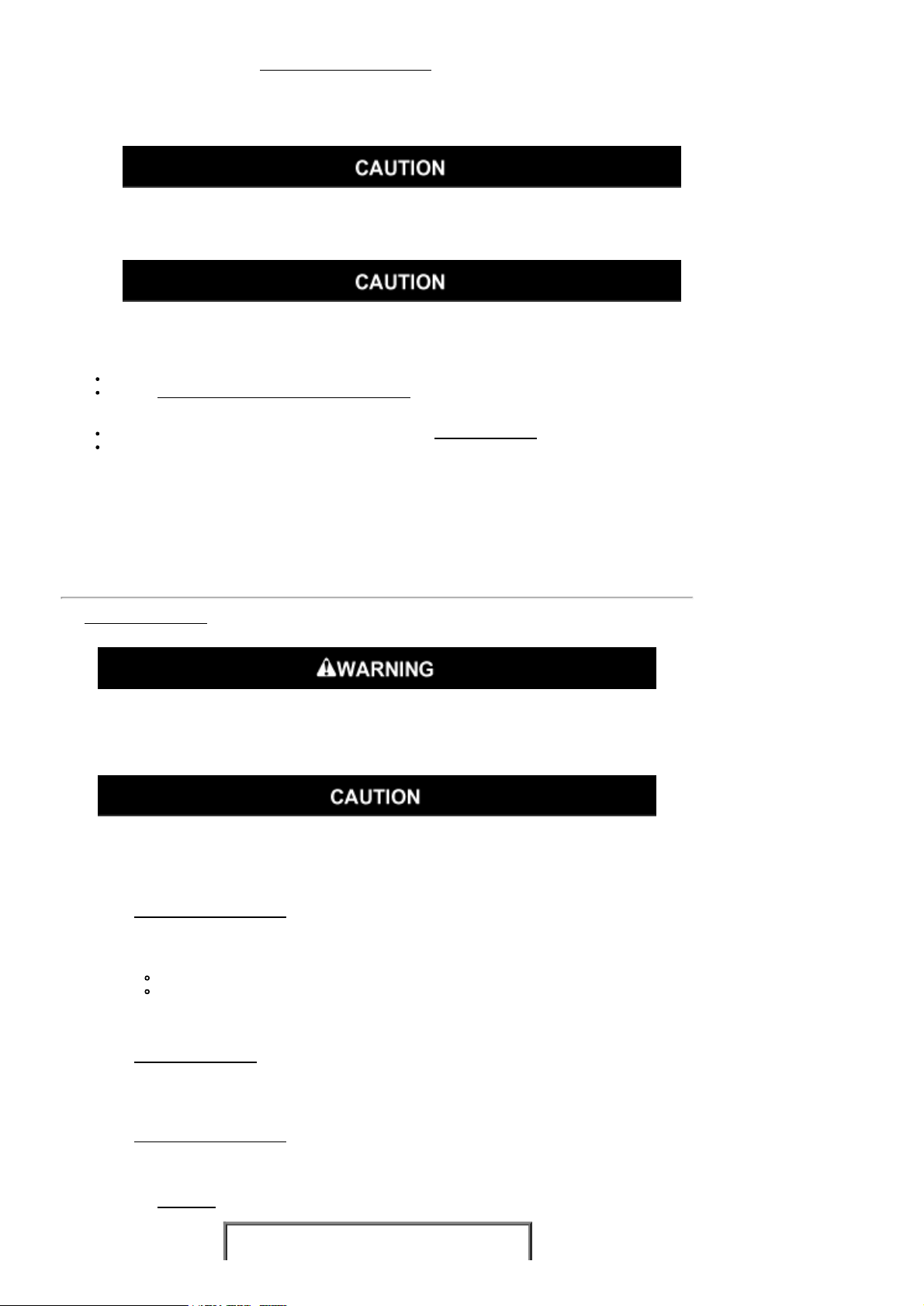

Hot Engine Oil Level Check

Check the oil level with the engine at normal operating temperature as follows:

1. Stop the engine and allow the oil to drain into the sump for about two minutes.

2. Stand the motorcycle upright (not leaning on the jiffy stand) on a level surface.

3. See Dipstick Location: VRSCDX/VRSCDX ANV. Unscrew the oil filler cap (with attached dipstick) by

turning the filler cap counterclockwise. Remove the filler cap and dipstick and wipe the dipstick clean.

4. Screw the filler cap into the engine. Make sure the cap is fully seated on the crankcase.

5. See Engine Oil Level: VRSC Models. Remove the filler cap again and check the oil level on the dipstick.

Page 4

6. If the oil level is below the FULL mark on the dipstick, add enough Harley-Davidson oil to bring the level up

to the FULL mark shown in Engine Oil Level: VRSC Models.

NOTE:

The engine will require a longer warm-up period in colder weather.

Do not allow hot oil level to fall below Add/Fill mark on dipstick. Doing so can result in equipment

damage and/or equipment malfunction. (00189a)

Do not overfill oil sump. Doing so can result in oil carryover to the air cleaner leading to equipment

damage and/or equipment malfunction. (00191a)

Check the engine oil supply at each complete fuel refill.

Refer to Regular Service Intervals: 2012 VRSC Models. The oil should be changed according to the

Regular Service Intervals in the Maintenance Schedule in normal service at warm or moderate

temperatures.

Oil change intervals should be shorter in cold weather. See Winter Lubrication.

The oil ADD mark is 1/2 quart (0.473 liters) to full.

Refer to the vehicle's service manual or see a Harley-Davidson dealer for proper procedures on draining the oil.

NOTE:

Dispose of oil in accordance with local regulations.

Changing Oil and Oil Filter

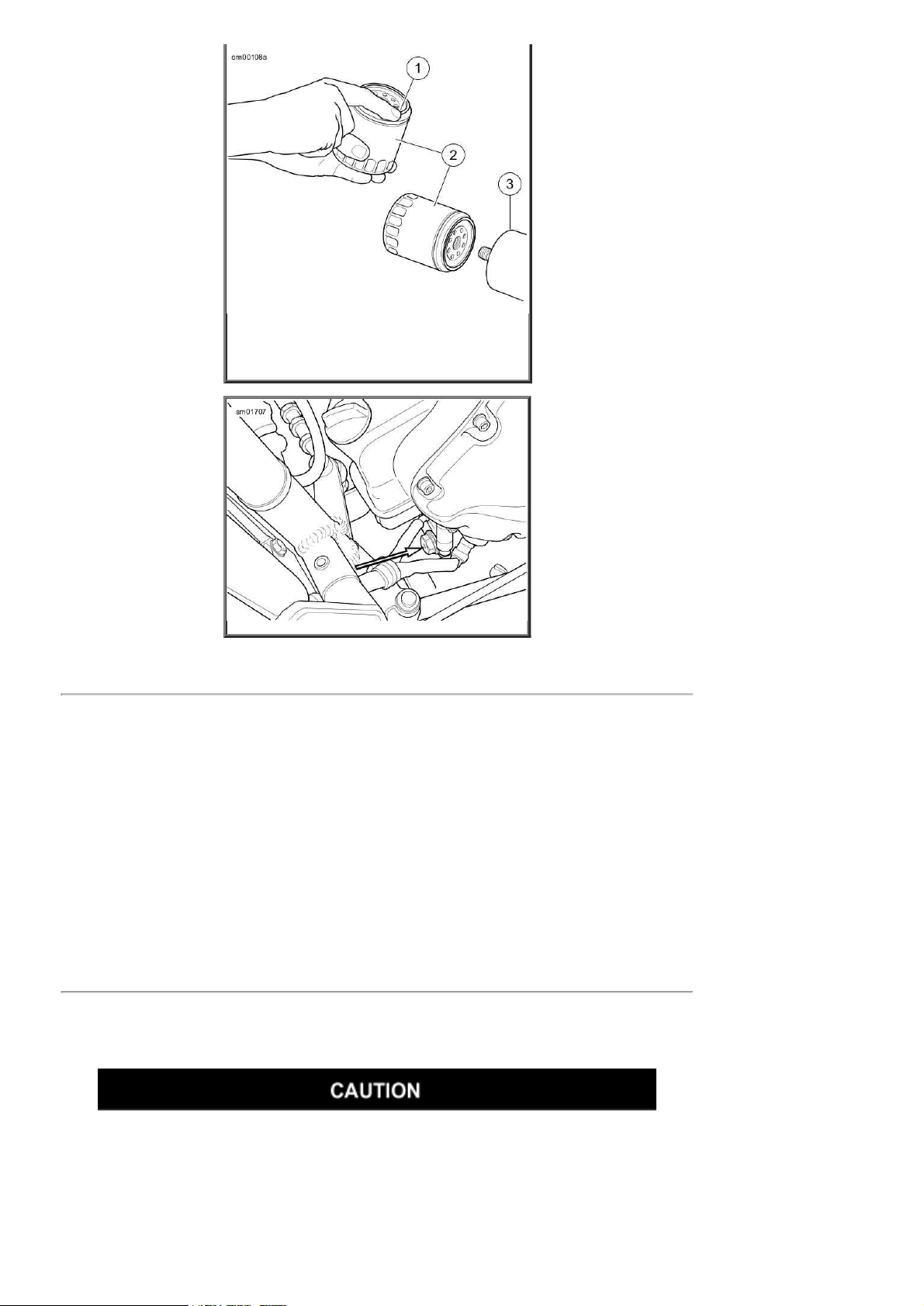

See Applying Thin Oil Film. The oil filter is located on an oil filter mount in front of the engine.

Be sure that no lubricants or fluids get on tires, wheels or brakes when changing fluid. Traction can

be adversely affected, which could result in loss of control of the motorcycle and death or serious

injury. (00047d)

Do not switch lubricant brands indiscriminately because some lubricants interact chemically when

mixed. Use of inferior lubricants can damage the engine. (00184a)

VRSC vehicles require a premium oil filter (Part No. 63793-01K).

1. See Oil Drain Plug: VRSC Model. Loosen the oil drain plug and completely drain the oil.

2. Remove the oil filter using an OIL FILTER WRENCH HD-42311 .

NOTES:

Removal of lower radiator support may make oil filter access easier.

Dispose of oil and oil filter in accordance with local regulations.

3. Clean the filter gasket contact surface on the mounting plate (the surface should be smooth and free of

any debris or old gasket material).

4. See Applying Thin Oil Film. Apply a thin film of oil to the gasket contact surface on the mounting plate,

gasket and new oil filter.

5. Screw the filter onto the adapter until the gasket contacts the plate surface, then apply another 2/3-1 full

turn.

6. See Oil Drain Plug: VRSC Model. Install the engine oil drain plug. Tighten the drain plug to 22-30 ft-lbs (3040 Nm).

7. Install lower radiator support if removed. Tighten fasteners to 15-19 ft-lbs 20-26 Nm .

8. Refer to Capacities. Fill the engine with the recommended amount of oil.

Page 5

1. Thin film of oil ONLY

2. Oil filter

3. Mounting plate

Applying Thin Oil Film

Oil Drain Plug: VRSC Model

Winter Lubrication

In colder climates, the engine oil should be changed often. If motorcycle is frequently used for trips less than 15 mi

24 km , in ambient temperatures below 60 °F 16 °C , reduce oil change intervals to 1500 mi 2400 km .

NOTE:

The further below freezing the temperature drops, the shorter the oil change interval should be.

Water vapor is a normal by-product of combustion in any engine. During cold weather operation, some of the water

vapor condenses to liquid form on the cool metal surfaces inside the engine. In freezing weather this water will

become slush or ice and, if allowed to accumulate too long, may block the oil lines and cause damage to the

engine.

If the engine is run frequently and allowed to thoroughly warm up, most of this water will become vapor again and

will be blown out through the crankcase breather.

If the engine is not run frequently and allowed to thoroughly warm up, this water will accumulate, mix with the

engine oil and form a sludge that is harmful to the engine.

Coolant Level

GENUINE HARLEY-DAVIDSON EXTENDED LIFE ANTIFREEZE & COOLANT (Part No. 99822-02) provides protection

to -34° F -36.7° C . In climates where the temperature falls below -34° F -36.7° C , consult a local Harley-Davidson

dealer for the proper mixture.

Use only Genuine Harley-Davidson Extended Life Antifreeze and Coolant. Use of other

coolants/mixtures may lead to engine damage. (00179b)

If you find yourself in a location where Genuine Harley-Davidson Extended Life Antifreeze & Coolant is not available,

you may use a 50-50 mixture of de-ionized water and Ethylene Glycol-based Antifreeze.

Page 6

De-ionized water must be used with the antifreeze in the cooling system. Hard water can cause

scale accumulation in water passages which reduces cooling system efficiency, leading to

overheating and engine damage. (00195a)

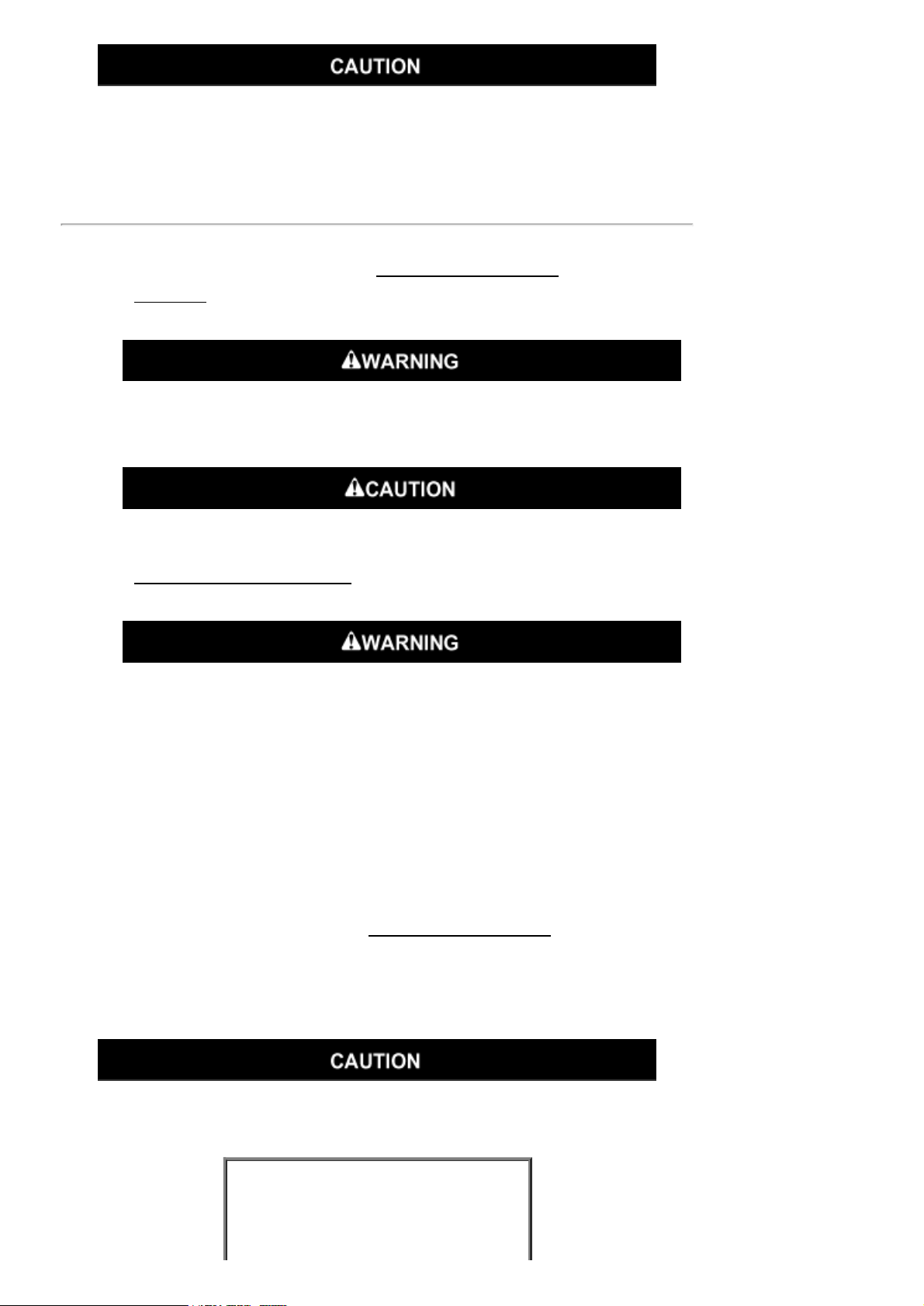

Checking Coolant Level in Expansion Tank

1. Open the seat.

2. On VRSCF model, remove front side covers. See Front Side Covers: VRSCF Model.

3. See Airbox Cover. Remove the airbox cover by turning the bailhead fastener 1/4 turn counterclockwise.

Pull the airbox cover away from the front locating holes.

Do not remove radiator filler cap when engine is hot. The cooling system is under pressure and hot

coolant and steam can escape, which could cause severe burns. Allow engine to cool before

servicing the cooling system. (00091a)

At operating temperature, the radiator and oil cooler contain hot fluids. Contact with the radiator or

oil cooler can result in minor or moderate burns. (00141a)

4. See Coolant Expansion Tank: VRSC Models. Check coolant level in expansion tank with coolant cold and

motorcycle on jiffy stand.

Coolant mixture contains toxic chemicals, which may be fatal if swallowed. If swallowed, do not

induce vomiting; call a physician immediately. Use in a well ventilated area. Irritation to skin or eyes

can occur from vapors or direct contact. In case of skin or eye contact, flush thoroughly with water

and go to hospital, if necessary. Dispose of used coolant according to federal, state and local

regulations. (00092a)

5. If level is below "COLD FULL" line on tank, remove cap from expansion tank by using pull tab and add

Harley-Davidson Extended Life Antifreeze & Coolant until fluid level reaches the "COLD FULL" line.

NOTE:

Genuine Harley-Davidson Extended Life Antifreeze & Coolant is pre-diluted and ready to use full-strength. Do

NOT add water.

6. Replace the cap on the expansion tank.

7. Install the airbox cover. Secure the cover by turning the bailhead fastener 1/4 turn clockwise.

8. On VRSCF model, install front side covers. See Front Side Covers: VRSCF Model.

NOTE:

If the coolant expansion tank is empty when the engine is cold, it is possible that air has been drawn into the

cooling system. The system must be purged of any trapped air and refilled with coolant. See the VRSC

service manual for instructions on the correct procedure.

Clean the inlet surface of the radiator regularly. Leaves and other debris can collect on the radiator

surface and degrade radiator performance which could lead to engine overheating and engine

damage. (00197c)

Page 7

1. Airbox cover

2. Bailhead fastener

Airbox Cover

1. Cold full line

2. Expansion tank cap

Coolant Expansion Tank: VRSC Models

Drive Belt

The inner tooth surface of the secondary belt has a thin coating of polyethylene lubricant. During initial operation,

this coating will wear off as it is burnished into the belt fabric. This is a normal condition and not an indication of

belt wear.

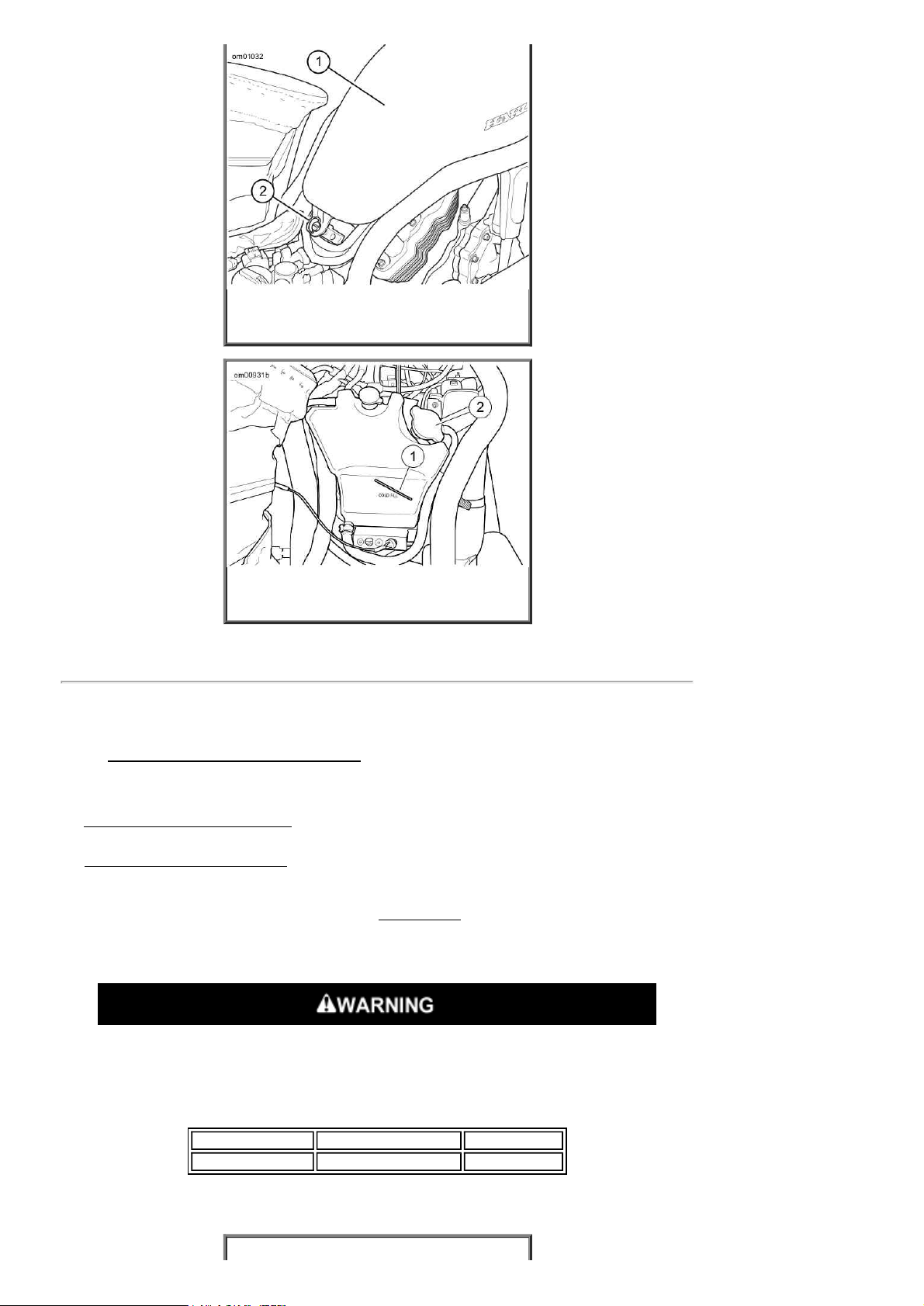

Refer to Regular Service Intervals: 2012 VRSC Models. Belt tension is set at the factory and should be checked

after the first 1000 miles 1600 kilometers and at regular intervals thereafter.

NOTE:

See Belt Deflection Window: VRSC Models. Belt deflection window on the debris deflector is graduated in 2.0 mm

increments.

See Check Belt Deflection: VRSC Models. Check belt tension with motorcycle cold, standing upright, transmission

in neutral and no rider on the motorcycle. Use the BELT TENSION GAUGE HD-35381 to apply 10 lbs. 4.5 kg of force

at the midpoint of the bottom belt strand.

Belt deflection should be within specification as shown in Belt Deflection. If belt tension adjustment is necessary,

see a Harley-Davidson dealer or follow the instructions given in the applicable Service Manual.

Check rear brake caliper position on rear brake disc. Disc should run true within brake caliper.

Be sure wheel and brake caliper are aligned. Riding with a misaligned wheel or brake caliper can

cause the brake disc to bind and lead to loss of control, which could result in death or serious injury.

(00050a)

Belt Deflection

MODELS IN MM

All Models 15/64-13/32 6.0-10.0

Page 8

1. Transmission sprocket

2. Rear wheel sprocket

3. Force of 10 lbs (4.5 kg)

4. Belt deflection

Check Belt Deflection: VRSC Models

1. Rear drive belt

2. Deflection graduations in 2.0 mm increments

Belt Deflection Window: VRSC Models

Chassis Lubrication

Refer to Regular Service Intervals: 2012 VRSC Models for all maintenance schedules.

NOTE:

Use recommended SPECIAL PURPOSE GREASE for steering head bearings. Use a multipurpose chassis grease for

other applications.

1. Remove and lubricate handlebar throttle control grip sleeve with fresh graphite.

2. Lubricate throttle control cables and clutch control cable with HARLEY LUBE.

3. Lubricate front brake hand lever and clutch control hand lever only if necessary.

4. Inspect rear fork pivot shaft bearings.

5. Pack the steering head bearings with SPECIAL PURPOSE GREASE at recommended service intervals.

6. Lubricate the jiffy stand mechanism with SILVER GRADE ANTI-SEIZE.

NOTE:

For model specific information regarding the chassis lubrication, refer to the appropriate Service Manual or see a

Harley-Davidson dealer.

Oil Applications

Refer to Regular Service Intervals: 2012 VRSC Models for all control connections and parts. Vehicle should be

oiled at regular intervals, particularly after washing motorcycle or driving in wet weather.

Front Fork Oil

Page 9

Refer to Regular Service Intervals: 2012 VRSC Models. Have a Harley-Davidson dealer drain the front fork oil and

refill at proper intervals. If fork does not appear to be working properly or an appreciable amount of oil leakage

should develop, see a Harley-Davidson dealer. If there is insufficient oil in either side of fork, the rebound action will

be incorrect.

Fuel Filter

A fuel filter is attached to the fuel pump. See a service manual or Harley-Davidson dealer for fuel filter

maintenance.

Hydraulic Clutch

Squeezing the left hand lever causes the clutch master cylinder to actuate and apply pressure to the clutch

actuation cylinder mounted in the engine right side cover. The actuation cylinder piston extends and contacts the

clutch release bearing to release the clutch.

Clutch fluid level should be checked periodically. Refer to Regular Service Intervals: 2012 VRSC Models. Check the

fluid level as follows:

1. Stand the motorcycle upright (not leaning on the jiffy stand) on a level surface, and turn handlebar so the

top of the clutch master cylinder is level.

2. See Clutch Reservoir Sight Glass. View reservoir sight glass and verify fluid level is at or above the Min

line. If fluid level is low, proceed to next step.

D.O.T. 4 brake fluid will damage painted and body panel surfaces it comes in contact with. Always

use caution and protect surfaces from spills whenever brake work is performed. Failure to comply

can result in cosmetic damage. (00239b)

3. Clean all dirt and debris from the clutch master cylinder cover. Remove the two clutch master cylinder

cover screws and remove the cover.

4. Verify the fluid level in the clutch master cylinder reservoir is at the FILL LEVEL mark at the top of the

ledge on the rear inside wall of the reservoir. If the fluid level is low, add D.O.T. 4 HYDRAULIC BRAKE

FLUID (Part No. 99953-99A) approved for clutch system use and available from a Harley-Davidson dealer.

NOTE:

Do not overfill the clutch master cylinder reservoir. As the clutch friction discs wear, the piston in the clutch

cylinder will force fluid back into the reservoir which could cause fluid overflow. If clutch fluid level is over

full, the clutch can be damaged.

D.O.T. 4 hydraulic brake fluid is used in the hydraulic clutch. Do not use other types of fluids as they

are not compatible and could cause equipment damage. (00353a)

Do not allow dirt or debris to enter the master cylinder reservoir. Dirt or debris in the reservoir can

cause improper operation and equipment damage. (00205c)

Direct contact of D.O.T. 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of

eye contact flush with large amounts of water and get medical attention. Swallowing large amounts

of D.O.T. 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use

in well ventilated area. KEEP OUT OF REACH OF CHILDREN. (00240a)

5. Inspect the clutch master cylinder cover gasket for rips, cuts, cracks, or other signs of damage. Replace

the gasket if necessary. Carefully place the cover and cover gasket on the master cylinder reservoir and

secure with the two cover screws. Tighten the screws to 6-8 in-lbs (0.7-0.9 Nm).

NOTE:

If the fluid level in the clutch master cylinder reservoir is correct but the clutch does not operate properly,

refer to the service manual or see a Harley-Davidson dealer for service.

Page 10

Clutch Reservoir Sight Glass

Steering Head Bearings

Adjustments to steering head bearings should be performed by a Harley-Davidson dealer.

Improperly adjusted bearings can adversely affect handling and stability, which could result in death

or serious injury. (00051b)

Check for proper steering head bearing adjustment and lubricate bearings using SPECIAL PURPOSE GREASE at

proper intervals. Refer to Regular Service Intervals: 2012 VRSC Models Service Intervals.

With motorcycle front end raised off the floor, be sure front fork turns freely without any binding or interference and

that there is no appreciable front to rear fork shake indicating excessive bearing looseness. Steering head bearings

should be adjusted according to service manual procedure, if necessary.

Brakes

Brake Fluid

D.O.T. 4 brake fluid will damage painted and body panel surfaces it comes in contact with. Always

use caution and protect surfaces from spills whenever brake work is performed. Failure to comply

can result in cosmetic damage. (00239b)

Direct contact of D.O.T. 4 brake fluid with eyes can cause irritation. Avoid eye contact. In case of

eye contact flush with large amounts of water and get medical attention. Swallowing large amounts

of D.O.T. 4 brake fluid can cause digestive discomfort. If swallowed, obtain medical attention. Use

in well ventilated area. KEEP OUT OF REACH OF CHILDREN. (00240a)

Do not allow dirt or debris to enter the master cylinder reservoir. Dirt or debris in the reservoir can

cause improper operation and equipment damage. (00205c)

Clean filler cap before removing. Use only D.O.T. 4 brake fluid from a sealed container.

Contaminated fluid can adversely affect braking, which could result in death or serious injury.

(00504c)

1. Stand the motorcycle upright (not leaning on the jiffy stand) on a level surface, and turn handlebar so the

top of the brake master cylinder is level.

Page 11

2. See Front Brake Fluid Sight Glass and Rear Brake Reservoir Gauge. Look through the sight glass on the

front brake fluid reservoir and at the marks on the side of the rear brake fluid reservoir to check the brake

fluid level. If necessary, shine a flashlight on the rear brake fluid reservoir to view the level.

The level in the sight glass or reservoir is the brake fluid level.

If the fluid level is below the minimum mark or not present, see a Harley-Davidson dealer.

NOTES:

If the brake system is not leaking, there should never be a need to add fluid. If the fluid level is low, the pads

are probably worn and need to be replaced. By replacing the pads, the fluid level will rise.

Use only DOT 4 BRAKE FLUID and replace the brake fluid every two years. See a Harley-Davidson dealer.

3. Verify that the front brake lever and the rear brake pedal have a firm feel when applied. If brakes are not

firm, the brake system must be bled. See a Harley-Davidson dealer.

1. Front brake sight glass

2. Rear brake reservoir gauge (behind right side radiator cover trim)

Front Brake Fluid Sight Glass and Rear Brake Reservoir Gauge

Brake Pads

Inspect brake pads for wear at service maintenance intervals. If you ride under adverse conditions

(steep hills, heavy traffic, etc.), inspect more frequently. Excessively worn brake pads can lead to

brake failure, which could result in death or serious injury. (00052a)

Always replace brake pads in complete sets for correct and safe brake operation. Improper brake

operation could result in death or serious injury. (00111a)

Brakes are a critical safety component. Contact a Harley-Davidson dealer for brake repair or

replacement. Improperly serviced brakes can adversely affect brake performance, which could

result in death or serious injury. (00054a)

Perform routine scheduled brake maintenance. Lack of maintenance at recommended intervals can

adversely affect brake performance, which could result in death or serious injury. (00055a)

Harley-Davidson has equipped your new motorcycle with the optimum brake pad friction material available. It is

selected to give the best performance possible under dry or wet conditions and at high operating temperatures. It

exceeds all regulatory requirements currently in effect. However, during some braking conditions you may

experience noise. This is normal for this friction material.

1. Check the rear brake disc as it spins. The disc should run true in the brake caliper.

Page 12

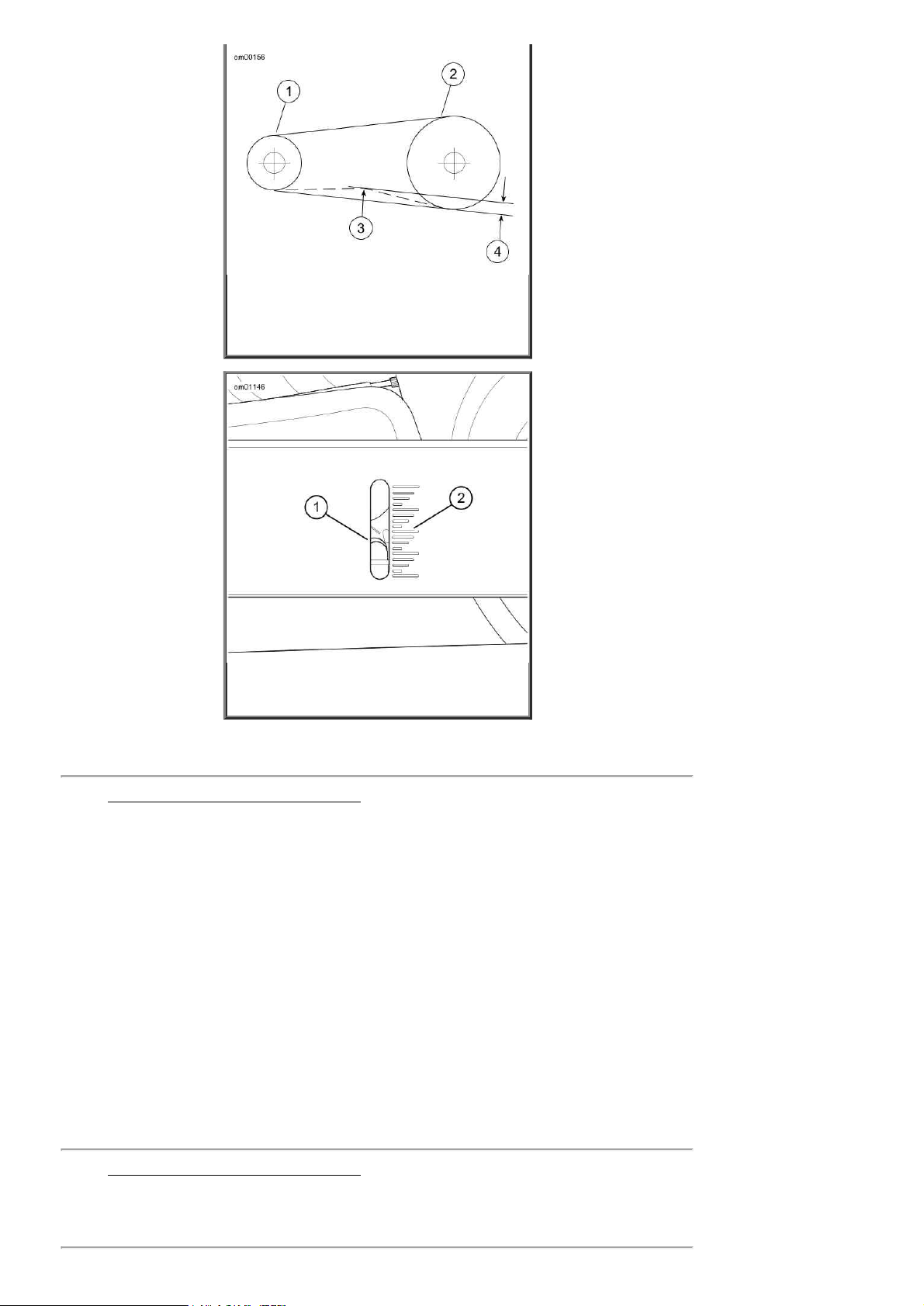

2. See Brake Friction Material. Using a thin plastic ruler, measure the thickness of the brake pad friction

material. For rear brakes, place the ruler against the brake disc through the space alongside the caliper.

3. If the brake pad friction material is at the minimum thickness or less, replace the pads. Always replace

brake pads in pairs. See a Harley-Davidson dealer. Refer to Minimum Brake Pad Friction Material

Thickness.

Be sure wheel and brake caliper are aligned. Riding with a misaligned wheel or brake caliper can

cause the brake disc to bind and lead to loss of control, which could result in death or serious injury.

(00050a)

Minimum Brake Pad Friction Material Thickness

in mm

0.040 1.02

1. Front brake

2. Rear brake

Brake Friction Material

Tires

See Specified Tires, Specifications for tires and pressures.

Maintain correct tire pressure.

Follow tire data for correct cold tire inflation pressure.

Check before riding when tires are cold.

NOTE:

The VRSC features performance-oriented tires. These tires require more frequent inspection and may require more

frequent replacement than Harley-Davidson touring model tires.

Be sure tires are properly inflated, balanced, undamaged, and have adequate tread. Inspect your

tires regularly and see a Harley-Davidson dealer for replacements. Riding with excessively worn,

unbalanced, improperly inflated, overloaded or damaged tires can lead to tire failure and adversely

affect stability and handling, which could result in death or serious injury. (00014b)

Use only Harley-Davidson specified tires. Refer to Specified Tires. Other tires may not fit correctly and could

adversely affect stability, handling and performance.

Match tires, tubes, rim strips or seals, air valves and caps to the correct wheel. Contact a HarleyDavidson dealer. Mismatching can lead to tire damage, allow tire slippage on the wheel or cause tire

failure, which could result in death or serious injury. (00023c)

Check tires for correct pressure, excessive wear or any signs of tire damage at least weekly if in daily use. Check

before each trip if only used occasionally.

Page 13

Tires are a critical safety component. Contact a Harley-Davidson dealer for tire repair or

replacement. Improper tire service can adversely affect stability and handling, which could result in

death or serious injury. (00057a)

Replace punctured or damaged tires. In some cases, small punctures in the tread area may be

repaired from within the removed tire by a Harley-Davidson dealer. Speed should NOT exceed 50

mph (80 km/h) for the first 24 hours after repair, and the repaired tire should NEVER be used over

80 mph (130 km/h). Failure to follow this warning could lead to tire failure and result in death or

serious injury. (00015b)

Striking an object, such as a curb or pothole can cause internal tire damage. If an object is struck,

have the tire inspected immediately inside and out by a Harley-Davidson dealer. A damaged tire can

fail while riding and adversely affect stability and handling, which could result in death or serious

injury. (00058b)

Tire Replacement

Inspection

Be sure tires are properly inflated, balanced, undamaged, and have adequate tread. Inspect your

tires regularly and see a Harley-Davidson dealer for replacements. Riding with excessively worn,

unbalanced, improperly inflated, overloaded or damaged tires can lead to tire failure and adversely

affect stability and handling, which could result in death or serious injury. (00014b)

Replace tire immediately with a Harley-Davidson specified tire when wear bars become visible or

only 1/32 in (0.8 mm) tread depth remains. Riding with a worn tire could result in death or serious

injury. (00090c)

Harley-Davidson tires are equipped with wear bars that run horizontally across the tread. When a tire is worn to the

point the tread wear indicator bars become visible on the tread surfaces, or 1/32 in 0.8 mm tread depth remains,

the tire can:

Be more easily damaged leading to tire failure.

Provide reduced traction.

Adversely affect stability and handling.

See Tire Sidewall: VRSC Models. Arrows on the tire sidewalls pinpoint location of wear bar indicators.

See Tread Surface Wear Bar (Typical): VRSC Models. Always replace tires before the tread wear indicator bars

appear.

When To Replace Tires

Use only Harley-Davidson specified tires. See a Harley-Davidson dealer. Using non-specified tires

can adversely affect stability, handling or braking, which could result in death or serious injury.

(00024b)

Page 14

New tires are needed if any of the following conditions exist (refer to Specified Tires for the specified replacement

tires):

1. Tread wear indicator bars become visible on the tread surfaces.

2. Tire cords or fabric become visible through cracked sidewalls, snags or deep cuts.

3. Bumps, bulges or slits in the tire.

4. Punctures, cuts, or other damage to the tire that cannot be repaired.

When installing tires on rims, do not rely on tread design to determine direction of rotation. Always be sure the

rotational arrows molded into the sidewalls point in the direction of rotation when the vehicle is moving forward.

Tire Sidewall: VRSC Models

Tread Surface Wear Bar (Typical): VRSC Models

Spark Plugs/Coils: VRSC Models

Refer to Regular Service Intervals: 2012 VRSC Models. Check the spark plugs at proper mileage intervals.

Do NOT pull on any electrical wires. Pulling on electrical wires may damage the internal conductor

causing high resistance, which may result in minor or moderate injury. (00168a)

Before installing spark plugs, the gap should be checked and adjusted if necessary to 0.035 in. (0.89 mm).

Be sure your motorcycle has the correct spark plug. Use a 10R12A spark plug.

Spark plugs must be tightened to the torque specified for proper heat transfer. Tighten spark plugs to 17 ft-lbs (23

Nm) per spark plug.

NOTES:

If a torque wrench is not available, tighten the spark plugs finger tight; then tighten an additional one quarter

turn with a spark plug wrench.

The VRSC is equipped with plug-top coils. To inspect the spark plugs, the coils must be removed. Consult

the VRSC Service Manual for the proper service procedure.

Shock Absorbers

Page 15

Inspect shock absorbers for leaks and rubber bushings for bushing deterioration at proper intervals.

Ignition

The engine in your motorcycle has been designed specifically to achieve optimum fuel economy within exhaust

emission controls. Factory programmed ignition characteristics provide maximum engine performance and

driveability.

Front Side Covers: VRSCF Model

Removal

1. See Front Side Cover Screws: VRSCF Model. Remove five screws from front side cover.

2. Lift side cover slightly to disengage mounting pin from bottom of side cover. Pull side cover from frame.

Installation

1. See Front Side Cover Screws: VRSCF Model. Orient the air inlet toward the front of the vehicle and align

grommet in side cover with the mounting pin on frame. Press side cover to engage mounting pin.

2. Install five screws with washers and tighten to 36.3-60.2 in-lbs (4.1-6.8 Nm).

Front Side Cover Screws: VRSCF Model

Air Cleaner

Refer to Regular Service Intervals: 2012 VRSC Models. The engine air cleaner is a paper/wire mesh air filter

element. Inspect the filter element. Inspect more often under dusty conditions. Remove the air cleaner as follows:

1. Open seat.

2. On VRSCF model, remove front side covers. See Front Side Covers: VRSCF Model.

3. See Airbox Cover. Remove the airbox cover by turning the bailhead fastener 1/4 turn counterclockwise.

Pull the airbox cover away from the front locating holes.

4. See Airbox Top: VRSC Models. Remove electrical connector (3) by pushing down on bail wire to unlock.

The airbox top is retained by eight clips, three per side, one at the rear and one in the front under the

snorkel. Release the clips and remove the airbox top.

Page 16

1. Airbox cover

2. Bailhead fastener

Airbox Cover

1. Airbox top

2. Mounting clips

3. Electrical connector

Airbox Top: VRSC Models

5. See Air Cleaner Assembly: VRSC Models. Unscrew the wing nut securing the air cleaner cap. Remove the

air cleaner cap and paper/wire mesh air filter element.

To prevent objects from falling down the velocity stacks, temporarily reinstall the air cleaner cap.

(00208a)

6. Wash the paper/wire mesh air filter element in luke warm water with a mild detergent. Rinse thoroughly.

Compressed air can pierce the skin and flying debris from compressed air could cause serious eye

injury. Wear safety glasses when working with compressed air. Never use your hand to check for air

leaks or to determine air flow rates. (00061a)

7. Allow the filter element to either air dry or blow it dry from the inside with low pressure air.

8. Hold the filter element up to a strong light source. If light is uniformly visible through the element, it is

sufficiently clean. Replace the filter element if it is damaged or if the filter media cannot be adequately

cleaned.

NOTE:

Do not use air cleaner filter oil on Harley-Davidson paper/wire mesh air filter elements.

9. Remove the air cleaner cap. Place the air filter element in the bottom tray of the airbox. Install the air

cleaner cap over the air filter element and secure with the wing nut.

Install air filter before running engine. Failure to do so can draw debris into the engine and could

result in engine damage. (00207a)

Page 17

10. Position the airbox top over the air filter assembly and fasten the clips along each side and the clip at the

rear.

11. See Front Airbox Clip. The front clip under the snorkel is attached to the airbox top. Fasten the clip over

the lip on the airbox bottom.

12. See Airbox Cover. Position the airbox cover with the locating pins in the holes on the frame tabs.

13. Turn the bailhead fastener 1/4 turn clockwise to secure the airbox cover to the motorcycle.

14. On VRSCF model, install front side covers. See Front Side Covers: VRSCF Model.

15. Close seat.

1. Air filter element

2. Air cleaner cap

3. Wing nut

Air Cleaner Assembly: VRSC Models

Front Airbox Clip

Headlamp Bulb Replacement

Bulb Removal

When replacement is required, use only the specified sealed beam unit or bulb, available from a

Harley-Davidson dealer. An improper wattage sealed beam or bulb, can cause charging system

problems. (00209a)

1. Remove the main fuse. See Fuses and Relays.

2. See Headlamp Assembly (VRSCF shown). Reach behind the headlamp bucket and grasp the low beam (1)

or high beam (2) bulb socket connector.

3. Squeeze the release latches to remove the connector from the headlamp bulb.

Handle bulb carefully and wear eye protection. Bulb contains gas under pressure, which, if not

handled carefully, could cause serious eye injury. (00062b)

Page 18

4. Twist the bulb 45 degrees counterclockwise and carefully pull the bulb from the housing. Discard bulb.

Bulb Installation

Never touch the quartz bulb. Fingerprints will etch the glass and decrease bulb life. Handle the bulb

with paper or a clean, dry cloth. Failure to do so could result in bulb damage. (00210b)

1. Insert new headlamp bulb into the housing and align tabs on the bulb with the slots in the housing.

2. Twist the bulb clockwise approximately 45 degrees until it stops.

3. Install the connector to the headlamp bulb.

4. Install the main fuse.

Be sure that all lights and switches operate properly before operating motorcycle. Low visibility of

rider can result in death or serious injury. (00316a)

5. Turn ignition on and check for proper operation.

6. Align the headlamp if necessary. See Headlamp Alignment.

1. Bulb (low beam)

2. Bulb (high beam)

3. Position bulb (international only)

Headlamp Assembly (VRSCF shown)

Headlamp Alignment

The automatic-on headlamp feature provides increased visibility of the rider to other motorists. Be

sure headlamp is on at all times. Poor visibility of rider to other motorists can result in death or

serious injury. (00030b)

NOTE:

Adjust the headlamps of motorcycles with multiple beam headlamps to converge into one pattern.

1. Make sure that front and rear tire inflation pressures are correct. See Specifications.

2. Make sure suspension is adjusted to the weight of the principal rider.

3. Fill fuel tank or add ballast to equal the weight of the fuel needed.

NOTE:

See Headlamp Alignment: VRSC Models. To aid in properly placing the motorcycle, a perpendicular line (1)

can be drawn on the floor. For best results, choose an area with minimum light.

Page 19

4. Draw a vertical line (2) on the wall.

5. Position motorcycle so that front axle is 25 ft 7.6 m from wall.

NOTE:

As the weight of the rider will compress the suspension slightly, have a person whose weight is

approximately the same as that of the principal rider sit on the motorcycle.

6. With the vehicle laden and upright, point the front wheel straight forward at wall and measure the distance

(4) from the floor to the center of the HIGH BEAM bulb.

7. Draw a horizontal line (5) through the vertical line on the wall that is 2.1 in 53.3 mm lower than the

measured bulb centerline.

8. Verify headlamp alignment. With the motorcycle on, set the headlamp switch to HIGH beam.

a. The center of the hot spot (brightest area of light beam) should be centered where the two lines

intersect.

b. Adjust headlamp alignment if necessary.

1. Perpendicular line

2. Vertical line

3. 7.6 meters (25 feet)

4. High beam bulb centerline

5. Horizontal line 53.3 mm (2.1 in.) lower than bulb centerline

Headlamp Alignment: VRSC Models

Headlamp Adjustment

1. See Headlamp Alignment Fastener (typical) Loosen fasteners slightly so headlamp is still snug.

2. Move headlamp assembly to adjust vertical alignment.

3. Tighten fasteners to 40-66 in-lbs (4.5-7.5 Nm).

Headlamp Alignment Fastener (typical)

LED Lamps

The following lamps are LED assemblies with no replaceable bulbs. See an authorized Harley-Davidson dealer or

service manual for assembly replacement.

VRSCDX, VRSCDX ANV: Tail lamp

VRSCF: Front turn signals, tail/rear turn signal assembly

Turn Signal Bulb Replacement: Bullet Style

Page 20

1. See Lens Cap Notch. Insert a coin or the blade of a small screwdriver into the notch at the bottom of the

lens cap. Carefully twist until the lens cap pops out of the lamp housing.

2. Push bulb in and rotate counterclockwise. Pull bulb from socket.

3. Inspect condition of electrical contacts in socket. If necessary, clean with a small wire brush and electrical

contact cleaner.

4. Coat base of new bulb with ELECTRICAL CONTACT LUBRICANT.

5. Align pins on bulb with pin guides in bulb socket. Push new bulb in and turn clockwise to lock in place.

6. Snap lens cap back into the lamp holder. Rotate lens to position notch at bottom of lamp.

Be sure that all lights and switches operate properly before operating motorcycle. Low visibility of

rider can result in death or serious injury. (00316a)

7. Turn ignition on and test for proper operation.

Lens Cap Notch

Alternator/Voltage Regulator

Charging Rate

The alternator output is controlled and changed to direct current by the voltage regulator.

The voltage regulator increases charging rate when battery is low or lamps are lit.

The voltage regulator decreases charging rate when battery charge is up.

It is possible to overload your vehicle's charging system by adding too many electrical accessories.

If the combined electrical accessories operating at any one time consume more electrical current

than the vehicle's charging system can produce, the electrical consumption can discharge the

battery and cause damage to the vehicle's electrical system. See an authorized Harley-Davidson

dealer for advice about the amount of current consumed by additional electrical accessories or for

necessary wiring changes. (00211c)

NOTES:

This unit requires no interval attention. If any electrical system trouble is experienced that might be

traceable to the alternator or voltage regulator, the motorcycle should be taken to a Harley-Davidson dealer

who has the necessary electrical testing equipment to give the required attention.

For model specific information regarding the voltage regulator, refer to the appropriate Service Manual or

see a Harley-Davidson dealer.

Battery: General

Page 21

Type

Your motorcycle uses a permanently sealed, maintenance-free, lead/calcium and sulfuric acid battery. All batteries

are shipped precharged and ready to be put into service. Do not attempt to open the battery for any reason.

Antidotes for Battery Acid

CONTACT TREATMENT

External Flush with water.

Internal Drink large quantities of milk or water, followed by milk

of magnesia, vegetable oil or beaten eggs. Get

immediate medical attention.

Eyes Flush with water. Get immediate medical attention.

Batteries contain sulfuric acid, which could cause severe burns to eyes and skin. Wear a protective

face shield, rubberized gloves and protective clothing when working with batteries. KEEP

BATTERIES AWAY FROM CHILDREN. (00063a)

Explosive hydrogen gas, which escapes during charging, could cause death or serious injury.

Charge battery in a well-ventilated area. Keep open flames, electrical sparks and smoking materials

away from battery at all times. KEEP BATTERIES AWAY FROM CHILDREN. (00065a)

Batteries, battery posts, terminals and related accessories contain lead and lead compounds, and

other chemicals known to the State of California to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling. (00019e)

Never remove warning label attached to top of battery. Failure to read and understand all

precautions contained in warning, could result in death or serious injury. (00064a)

1. Contents are corrosive

2. Wear safety glasses

3. Contents are explosive

4. Keep flames away

5. Read instructions

6. Keep away from children

Battery Warning Label

Page 22

Battery Warning Label

Voltmeter Test

The voltmeter test provides a general indicator of battery condition. Check the voltage of the battery to verify that it

is in a 100 percent fully-charged condition. If the open circuit (disconnected) voltage reading is below 12.6 V,

charge the battery and then re-check the voltage after the battery has set for one to two hours. Refer to Voltmeter

Test.

Voltmeter Test

READING IN VOLTS PERCENT OF CHARGE

12.7 100

12.6 75

12.3 50

12.0 25

11.8 0

Cleaning and Inspection

Battery top must be clean and dry. Dirt and electrolyte on top of the battery can cause battery to self-discharge.

1. Clean battery top.

2. Clean cable connectors and battery terminals using a wire brush or fine grit sandpaper to remove any

oxidation.

3. Inspect and clean the battery screws, clamps and cables. Check for breakage, loose connections and

corrosion.

4. Check the battery posts for melting or damage caused by overtightening.

5. Inspect the battery for discoloration, a raised top or a warped or distorted case. This might indicate that

the battery has been frozen, overheated or overcharged.

6. Inspect the battery case for cracks or leaks.

Charging

Never charge a battery without first reviewing the instructions for the charger being used. In addition to the

manufacturer's instructions, follow these general safety precautions.

Charge the battery if any of the following conditions exist:

Vehicle lamps appear dim.

Electric starter sounds weak.

Battery has not been used for an extended period of time.

Page 23

Explosive hydrogen gas, which escapes during charging, could cause death or serious injury.

Charge battery in a well-ventilated area. Keep open flames, electrical sparks and smoking materials

away from battery at all times. KEEP BATTERIES AWAY FROM CHILDREN. (00065a)

Batteries contain sulfuric acid, which could cause severe burns to eyes and skin. Wear a protective

face shield, rubberized gloves and protective clothing when working with batteries. KEEP

BATTERIES AWAY FROM CHILDREN. (00063a)

1. Perform a voltmeter test to determine the state of charge. If battery needs to be charged, proceed to the

next step.

2. Place the battery on a level surface.

Unplug or turn OFF battery charger before connecting charger cables to battery. Connecting cables

with charger ON can cause a spark and battery explosion, which could result in death or serious

injury. (00066a)

Connect positive (+) battery cable first. If positive (+) cable should contact ground with negative (-)

cable connected, the resulting sparks can cause a battery explosion, which could result in death or

serious injury. (00068a)

Disconnect negative (-) battery cable first. If positive (+) cable should contact ground with negative

(-) cable connected, the resulting sparks can cause a battery explosion, which could result in death

or serious injury. (00049a)

Do not reverse the charger connections described in the following steps or the charging system of

the motorcycle could be damaged. (00214a)

NOTES:

The figures in 19 Amp-Hour Battery Charging Rates/Times (Approximate) show typical charging

times. Charge times may vary. When using automatic chargers, allow the charger to determine

when charging is complete.

Do not use chargers with excessively high voltage designed for flooded batteries or excessively

high current designed for much larger batteries. Charging should be limited to no more than 5

amps at no more than 14.6 volts.

3. Connect the red battery charger lead to positive (+) terminal of the battery.

4. Connect the black battery charger lead to negative (-) terminal of the battery.

NOTE:

If the battery is still in the vehicle, connect the negative lead to the chassis ground. Make sure that the

ignition and all electrical accessories are turned off.

5. Step away from the battery and turn on the charger.

Unplug or turn OFF battery charger before disconnecting charger cables from battery.

Disconnecting clamps with charger ON can cause a spark and battery explosion, which could result

in death or serious injury. (00067a)

6. After the battery is fully charged, turn OFF the charger and disconnect the black battery charger lead to the

Page 24

negative (-) terminal of the battery.

7. Disconnect the red battery charger lead to the positive (+) terminal of the battery.

8. Mark the charging date on the battery.

19 Amp-Hour Battery Charging Rates/Times (Approximate)

READING

(VOLTS)

PERCENT

OF CHARGE

5 AMP

CHARGER

2 AMP

CHARGER

1.5 AMP

CHARGER

0.75 AMP

CHARGER

12.7 100 - - - -

12.6 75 2 hours 3 hours 24 minutes 4 hours 12 minutes 7 hours 18 minutes

12.3 50 2 hours 54 minutes 5 hours 48 minutes 7 hours 18 minutes 13 hours 42 minutes

12.0 25 3 hours 54 minutes 8 hours 6 minutes 10 hours 30 minutes 20 hours

11.8 0 4 hours 48 minutes 10 hours 30 minutes 13 hours 42 minutes 26 hours 18 minutes

Storage

If the motorcycle will not be operated for several months, such as during the winter season, remove the battery

from the motorcycle and fully charge.

If the motorcycle is to be stored with the battery installed, it will be necessary to connect a battery tender to

maintain charge. See an authorized dealer for more information.

A battery that is removed from the vehicle is affected by self-discharge. A battery that is stored in the vehicle is

affected by both self-discharge and, more significantly, parasitic loads. Parasitic loads occur from things like diode

leakage and maintaining computer memory with the vehicle off.

Batteries self-discharge at a faster rate at higher ambient temperatures.

To reduce the self-discharge rate, store battery in a cool, dry place.

Charge the battery once per month if stored in the vehicle.

Charge the battery every three months if stored out of the vehicle.

1. Capacity

2. Months of non-use

3. Measured at 105 °F (40 °C)

4. Measured at 77 °F (25 °C)

Effective Rate of Temperature on Battery Self-

discharging Rate

Battery

Disconnection and Removal

Before you can inspect or disconnect the battery you must read the section containing information about air

cleaner removal.

1. If equipped with security system siren, turn the ignition switch ON with the hands-free fob present to

disarm the security system.

2. Remove the main fuse. See Fuses and Relays.

Page 25

3. Remove the air cleaner. See Air Cleaner.

4. See Velocity Stacks. Disconnect rear breather hose (2).

5. Slide the o-ring (4) up each velocity stack (1) body to reveal the three retaining fasteners (5). Unscrew the

fasteners and lift off the velocity stacks.

6. Carefully lift up the airbox bottom tray. The front has a grommet which is pressed on to a brass bullet. The

rear has a breather hose which was disconnected in a previous step. Disengage the front grommet and

slide the rear breather hose out through the hole in the rear of the airbox tray.

Cover the throttle body bores with duct tape to prevent objects from falling down the injector bores.

Do NOT use shop cloths or objects that could damage the throttle plates. (00212d)

7. See Covering Injector Intakes. Cover injector intakes.

1. Velocity stacks

2. Rear breather hose

3. Air-oil separator

4. O-rings

5. Retaining fasteners (6)

Velocity Stacks

Covering Injector Intakes

Disconnect negative (-) battery cable first. If positive (+) cable should contact ground with negative

(-) cable connected, the resulting sparks can cause a battery explosion, which could result in death

or serious injury. (00049a)

8. See Battery Installed. Remove the battery negative cable from the negative (-) terminal of the battery.

9. Remove the battery positive cable from the positive (+) terminal of the battery.

10. Stretch battery hold down strap and remove from tab to release tension on strap. Battery hold down strap

will become free from lower tab and can be completely removed.

11. Firmly pull battery out and slightly upward to remove battery from battery caddy.

Page 26

1. Positive battery teminal hold down bolt (located under boot)

2. Negative battery terminal bolt

3. Hold down strap

4. Tabs (strap anchor points, one located under battery tray)

5. Throttle cables

Battery Installed

Installation and Connection

1. Connect hold down strap to bottom of battery caddy.

2. See Battery Installed. Slide the fully charged battery into battery caddy, terminal side up, negative (-)

battery terminal toward the right side of the motorcycle.

NOTES:

Battery must sit flat on bottom of tray pad. Verify that battery does not sit on front edge of pad.

3. See Battery Installed. Verify proper routing of throttle cable.

4. Stretch hold down strap over top of battery. Latch hold down strap to tab on top of battery.

Never route throttle cable over the battery. Fire due to short circuit could occur and cause death or

serious injury. (00494c)

Connect the cables to the correct battery terminals. Failure to do so could result in damage to the

motorcycle electrical system. (00215a)

Connect positive (+) battery cable first. If positive (+) cable should contact ground with negative (-)

cable connected, the resulting sparks can cause a battery explosion, which could result in death or

serious injury. (00068a)

Do not over-tighten bolts on battery terminals. Use recommended torque values. Over-tightening

battery terminal bolts could result in damage to battery terminals. (00216a)

5. Insert a battery terminal bolt through the battery positive cable (+) (red), into the threaded hole of the

battery positive (+) terminal.

6. Tighten the bolt to 60-70 in-lbs (6.8-7.9 Nm).

7. Insert the other battery terminal bolt through the battery negative cable (black), into the threaded hole of

the battery negative (-) terminal.

8. Tighten the bolt to 60-70 in-lbs (6.8-7.9 Nm).

Page 27

Keep battery clean and lightly coat terminals with petroleum jelly to prevent corrosion. Failure to do

so could result in damage to battery terminals. (00217a)

9. Apply a light coat of petroleum jelly or corrosion retardant material to both battery terminals.

10. Remove the covering from the injector intakes.

11. See Air Cleaner Gasket and Alignment Pins. Inspect the gasket on the bottom of the airbox tray. The

gasket is located by the three alignment pins on the mating surface.

NOTE:

Replace the gasket if it is torn or damaged in any way.

12. Place the airbox tray over the injectors. Make sure the taller slanted lip of the tray faces the front of the

motorcycle. Slide the rectangular hole in the tray down over the threaded mounting stud.

13. See Velocity Stacks. Insert rear breather hose through hole in rear of tray. Pull until hose seals properly.

14. Align the front grommet on the airbox tray with the brass bullet and press the airbox tray down firmly.

Make sure the tray sits flush on top of the injectors.

NOTE:

In the next step, you will install the velocity stacks. Each velocity stack has an index mark. Align the index

mark on the velocity stack with the corresponding index mark on the airbox tray.

15. See Air Cleaner Gasket and Alignment Pins. Align the index marks and install the velocity stacks, the

longest stack toward the front of the motorcycle. Start all fasteners by hand first, making sure none are

cross-threaded. Tighten the three fasteners on each velocity stack to 53 in-lbs (6 Nm).

16. Slide the o-ring down each velocity stack until it contacts the three fasteners. Slide the breather hose onto

the rear breather hose fitting.

17. Install the air filter element, air cleaner cap, wing nut, airbox top, electrical connector on airbox, and airbox

cover. Lower the seat down.

18. Install the main fuse. See Fuses and Relays.

Air Cleaner Gasket and Alignment Pins

1. Velocity stack index mark

2. Airbox tray index mark

Velocity Stack and Airbox Tray Index Marks

Jump Starting

Jump starting a motorcycle is typically not recommended. However, there may be circumstances when it is

necessary to do so. If a jump-start is necessary, use the following procedure.

Page 28

Be sure jumper cables touch only appropriate battery terminals or ground. Allowing jumper cables

to touch each other can result in sparks and a battery explosion, which could result in death or

serious injury. (00072a)

Explosive hydrogen gas, which escapes during charging, could cause death or serious injury.

Charge battery in a well-ventilated area. Keep open flames, electrical sparks and smoking materials

away from battery at all times. KEEP BATTERIES AWAY FROM CHILDREN. (00065a)

Be sure both vehicles have the same battery voltage when jump starting. Connecting vehicles with

different system voltages can result in vehicle damage. (00220c)

NOTES:

This procedure presumes the BOOSTER battery is in another vehicle. DO NOT jump start from a running

booster vehicle. The high output charging systems on some vehicles can damage the electrical components

on the motorcycle.

Make sure the motorcycle and the BOOSTER vehicle are not touching one another.

1. Turn off all unnecessary lamps and accessories.

Positive Cable

2. See Jump Start Cable Connections. Connect one end of a jumper cable to the DISCHARGED battery

positive (+) terminal (1).

3. Connect the other end of the same cable to the BOOSTER battery positive (+) terminal (2).

Negative Cable

Do not connect negative (-) cable to or near the discharged battery negative (-) terminal. Doing so

could cause a spark and explosion, which could result in death or serious injury. (00073a)

4. Connect one end of a jumper cable to the BOOSTER battery negative (-) terminal (3).

Do not connect the negative (-) cable to painted or chrome parts. Doing so could result in

discoloration at the attachment point. (00221a)

5. Connect other end of the same cable (4) to a safe ground, (away from the DISCHARGED battery).

6. Start motorcycle.

7. Disconnect cables in reverse order of Steps 2, 3, 4, 5; that is: Steps 5, 4, 3, 2.

Page 29

1. Discharged battery positive (+) terminal

2. Booster battery positive (+) terminal

3. Booster battery negative (-) terminal

4. Ground

Jump Start Cable Connections

Fuses and Relays

VRSC models have a rear fuse block under the seat and a front fuse block behind the steering head under the right

side cover.

For electrical problems, it is best to see a Harley-Davidson dealer who has the necessary parts and equipment to

perform electrical services.

Fuses do not reset. A blown fuse must be replaced with a fuse of the same rating.

NOTE:

Use only automotive type ATO fuses as replacements.

Front Fuse Block

1. Make sure the ignition is turned OFF.

2. Remove the front right side cover.

a. For VRSCF model, see Front Side Covers: VRSCF Model.

b. For other models, remove the fastener from the front right side cover and carefully lift the side

cover off the mounting tabs.

3. See Front Fuse Block and Main Fuse: VRSC Models. The front fuse block is mounted on the top right side

of the battery box. Pull the tabs out from the sides of the fuse block cover. Remove cover.

4. See Front Fuse Block: VRSC Models. Remove the suspect fuse and inspect the element. Replace the fuse

if the element is burned or separated.

5. Install the fuse block cover. Carefully press the cover until tabs snap into place.

6. Install the right front side cover.

a. For VRSCF model, see Front Side Covers: VRSCF Model.

b. For other models, install front side cover on the mounting tabs. Line up the hole on the cover with

the threaded hole in the frame tab and install the fastener. Tighten the fastener to 36.3-60.2 inlbs (4.1-6.8 Nm).

Page 30

1. Front fuse block (cover removed)

2. Main fuse

Front Fuse Block and Main Fuse: VRSC Models

1. Spare (15 amp.)

2. Start relay

3. ABS fuse (ABS-equipped models only, 30 amp.)

4. Battery (15 amp.)

5. Ignition (15 amp.)

6. Fan relay

Front Fuse Block: VRSC Models

Rear Fuse Block

1. Make sure the ignition is turned OFF.

2. Open the seat.

3. See Rear Fuse Block Location: VRSC Models. The rear fuse block is located on frame crossmember

behind fuel filler cap. Slide the fuse block to the left side of vehicle to remove from mount.

4. See Rear Fuse Block: VRSC Models. Remove the suspect fuse and inspect the element. Replace the fuse

if the element is burned or separated.

5. Slide fuse block onto the mount. Close the seat.

Rear Fuse Block Location: VRSC Models

Page 31

1. Spare (15 amp.)

2. Security (15 amp.)

3. Accessory (15 amp.)

4. P&A Ignition (2 amp. max)

5. Lights (15 amp.)

6. ECM power (15 amp.)

7. Fuel pump (15 amp.)

8. System relay

Rear Fuse Block: VRSC Models

Main Fuse

All VRSC models have a main fuse to protect the motorcycle wiring. This 40-amp main fuse provides main battery

power to the motorcycle. It is located in a rubber-coated fuse holder behind the motorcycle's right side cover.

1. Remove the front right side cover.

a. For VRSCF model, see Front Side Covers: VRSCF Model.

b. For other models, remove the fastener from the front right side cover and carefully lift the side

cover off the mounting tabs.

2. If equipped with security system siren, turn the ignition switch ON with the hands-free fob present to

disarm the security system.

3. Grasp the fuse holder in one hand, the plastic body of the main fuse in the other, and pull the main fuse

straight out of the fuse holder.

4. Insert the prongs of the new main fuse in the fuse holder slots. Push the main fuse firmly down into the

fuse holder.

5. Install the right front side cover.

a. For VRSCF model, see Front Side Covers: VRSCF Model.

b. For other models, install front side cover on the mounting tabs. Line up the hole on the cover with

the threaded hole in the frame tab and install the fastener. Tighten the fastener to 36.3-60.2 inlbs (4.1-6.8 Nm).

Inserting Main Fuse (typical)

Seat

Opening

Seat is hinged on the left side. Grasp lower edge of right side and lift.

NOTE:

See Seat Lanyard. The lanyard will hold the seat in position on the motorcycle frame.

Page 32

Closing

Rotate seat down to close seat.

Seat Lanyard

Motorcycle Storage

Placing Motorcycle in Storage

Proper storage is important for the trouble-free operation of your motorcycle. See your Owner's

Manual for storage recommendations or see a Harley-Davidson dealer. Improper storage

procedures can lead to equipment damage. (00046a)

If the motorcycle will not be operated for several months, such as during the winter season, there are several tasks

which should be performed. These steps will protect parts against corrosion, preserve the battery and prevent the

build-up of gum and varnish in the fuel system.

Do not store motorcycle with gasoline in tank within the home or garage where open flames, pilot

lights, sparks or electric motors are present. Gasoline is extremely flammable and highly explosive,

which could result in death or serious injury. (00003a)

NOTE:

Make a list of everything you do and fasten it to a handgrip. When you take the motorcycle out of storage, this list will

be your reference/checklist to get your motorcycle in operating condition.

1. Fill fuel tank and add a gasoline stabilizer. Use one of the commercially available gasoline stabilizers and

follow the manufacturer's instructions.

2. Warm motorcycle to operating temperature. Change oil and turn engine over to circulate the new oil.

3. Adjust the belt.

4. Check tire pressure, refer to Specified Tires for specified pressure.

5. Prepare battery for winter storage. See Battery: General.

Explosive hydrogen gas, which escapes during charging, could cause death or serious injury.

Charge battery in a well-ventilated area. Keep open flames, electrical sparks and smoking materials

away from battery at all times. KEEP BATTERIES AWAY FROM CHILDREN. (00065a)

6. If the motorcycle is to be stored with security system armed, it will be necessary to connect a Battery

Tender to maintain battery charge. If security system will not be armed and a Battery Tender is not

available, remove the Maxi-fuse.

Page 33

Use only Genuine Harley-Davidson Extended Life Antifreeze and Coolant. Use of other

coolants/mixtures may lead to engine damage. (00179b)

7. Check and fill the cooling system.

8. To protect the vehicle's body panels, engine, chassis and wheels from corrosion, follow the cosmetic care

procedures described in the Accessory Maintenance section of this owner's manual prior to storage.

9. If motorcycle is to be covered, use a material such as light canvas that will breathe. Plastic materials that

do not breathe promote the formation of condensation.

Removing Motorcycle From Storage

The clutch failing to disengage can cause loss of control, which could result in death or serious

injury. Prior to starting after extended periods of storage, place transmission in gear and push

vehicle back and forth several times to assure proper clutch disengagement. (00075a)

1. See Battery: General for proper battery care. Charge and install the battery.

2. Start the engine and run until it reaches normal operating temperature. Turn off engine.

3. Check the oil.

4. Check the clutch fluid level.

5. Check controls to be sure they are operating properly. Operate the front and rear brakes, throttle, clutch

and shifter.

6. Check steering for smoothness by turning the handlebars through the full operating range.

Coolant mixture contains toxic chemicals, which may be fatal if swallowed. If swallowed, do not

induce vomiting; call a physician immediately. Use in a well ventilated area. Irritation to skin or eyes

can occur from vapors or direct contact. In case of skin or eye contact, flush thoroughly with water

and go to hospital, if necessary. Dispose of used coolant according to federal, state and local

regulations. (00092a)

7. Check the radiator connections and coolant level.

Be sure tires are properly inflated, balanced, undamaged, and have adequate tread. Inspect your

tires regularly and see a Harley-Davidson dealer for replacements. Riding with excessively worn,

unbalanced, improperly inflated, overloaded or damaged tires can lead to tire failure and adversely

affect stability and handling, which could result in death or serious injury. (00014b)

8. Check tire pressure, refer to Specified Tires for specified pressure.

9. Check overall tire condition, see the tire replacement section.

10. Check all electrical equipment and switches including the stop lamp, turn signals and horn for proper

operation.

11. Check for any fuel, oil, coolant or brake fluid leaks.

Loading...

Loading...