Page 1

7351

7

HOME

DTC P0106, P0107, P0108 4.13

GENERAL

MAP Sensor

See Figure 4-24. The manifold absolute pressure sensor

(MAP sensor) is supplied 5 volts from the ignition control

module and sends a signal back to the ignition control module. This signal varies in accordance with engine vacuum and

atmospheric barometric pressure. Changes in barometric

pressure are influenced by weather and altitude.

Table 4-15. Code Description

DTC

P0106 MAP sensor rate-of-change error

P0107 MAP sensor failed open/low

P0108 MAP sensor failed high

DESCRIPTION

DIAGNOSTICS

Diagnostic Tips

DTC P0106 will set if the MAP sensor signal fluctuates

●

faster than normal operation.

With the MAP sensor disconnected, the ignition control

●

module should recognize a low voltage. If low voltage is

observed, the ignition control module and harness are

not at fault.

●

Gently place a jumper wire across MAP Sensor connector [80B] Terminals B and C using HARNESS CONNECTOR TEST KIT (Part No. HD-41404), gray male probes

and patch cord. With the jumper in place, the ignition

control module should recognize a high voltage.

Figure 4-24. MAP Sensor

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.13 flow charts.

1. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and ignition control module. See

4.6 BREAKOUT BOX: ICM.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probes and patch cords.

MAP sensor output check. Using the VACUUM PUMP

●

(Part No. HD-23738A), apply a vacuum to the pressure

port of the MAP sensor. The signal voltage should lower

as the vacuum is applied.

2004 Touring: Engine Management (Carbureted) 4-33

Page 2

HOME

s0587a8x

To vehicle

speed sensor

(VSS)

Manifold

absolute

pressure

sensor

(MAP)

V/W

BK/W

[80A]

[80B]

R/W

R/W

BK/W

V/W

[10B]

[10A]

Ignition control module

Sensor power

Sensor ground

MAP signal

Figure 4-25. MAP Sensor Circuit

Table 4-16. Wire Harness Connectors in Figure 4-25.

NO.

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[80] Manifold Absolute Pressure Sensor (MAP) 3 - Place Packard Top of Intake Manifold

DESCRIPTION TYPE LOCATION

4-34 2004 Touring: Engine Management (Carbureted)

Page 3

HOME

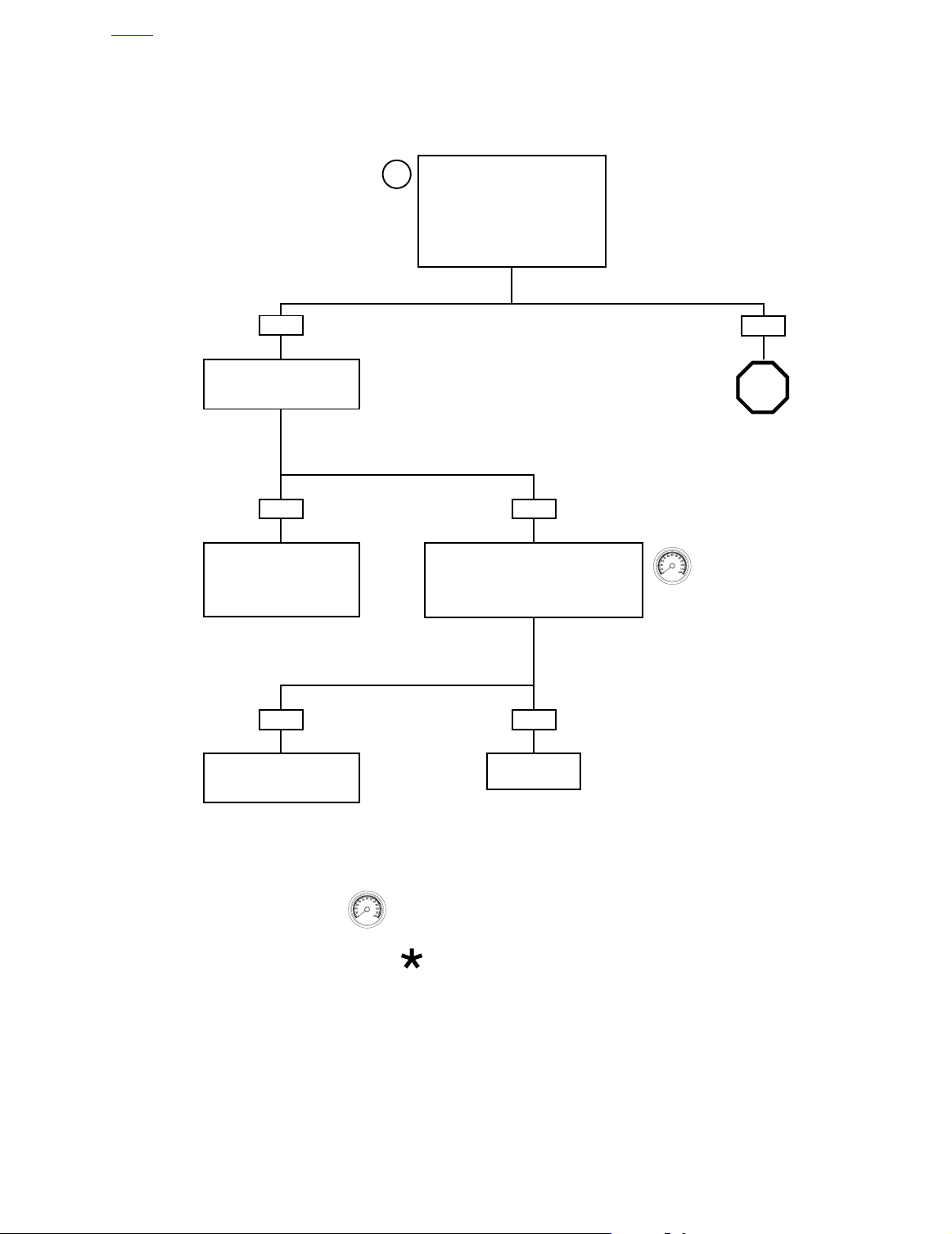

Test 4.13 (Part 1 of 2)

MAP SENSOR: DTC P0106, P0107, P0108

1

With ignition ON, measure voltage

between Breakout Box terminal 11 (+)

and terminal 4 (-). With key ON,

engine OFF, voltage must be between

4.2 and 4.95 volts. With key ON,

engine running, voltage must be

between 1.5-3.0 volts at hot idle.

Does voltage fit specifications?

YES

Perform 4.7 WIGGLE TEST

to check for intermittents.

Intermittents present?

YES

To identify the source of inter-

mittents, start with box marked

by Bold Asterisk under Test

4.13 (Part 2 of 2). Wiggle har-

ness while watching DVOM.

YES

Install original MAP sensor.

Replace ignition control module

and road test again to verify.

NO

Replace MAP sensor. See the Touring Service Manual. Clear diagnostic trouble codes.

See 4.5 SPEEDOMETER SELF DIAGNOS-

TICS. Road test. Did check engine lamp illu-

minate and set Code P0106, P0107 or

NO

System

now OK.

NO

STOP

Go to Test 4.13

(Part 2 of 2).

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

2004 Touring: Engine Management (Carbureted) 4-35

Page 4

HOME

Test 4.13 (Part 2 of 2)

MAP SENSOR: DTC P0106, P0107, P0108

2

Continued from Test 4.13 (Part 1 of 2).

Check the 5 volt reference supply at

the MAP sensor connector [80B]. With

ignition ON, measure voltage between

terminal C (R/W) and terminal A (BK/W).

Is voltage approximately 5.0 volts?

YES

Connect Breakout Box. Disconnect ignition

1

control module from Breakout Box.

OPEN CHECK: Measure resistance

between MAP connector [80B] Terminal B

2

and Breakout Box connector [10]

terminal 11. Is resistance less than 1 ohm?

YES

SHORT CHECK: Measure

2

resistance between MAP connector Terminal B and chassis

ground. Is resistance greater

than 1 meg ohm?

YES

Replace MAP sensor. See the

Touring Service Manual.

NO.

Greater

than 6V.

Locate short to 12 volts on R/W

wire in wire harness. Repair as

necessary.

NO

Locate and repair

open on V/W wire.

With MAP sensor connector

NO

Locate and repair

grounded V/W wire.

Disconnect ignition control module from

1

Check continuity between MAP connector

2

connector [10] terminal 3. Then measure

continuity between MAP connector [80B]

Te r minal A and Breakout Box connector [10]

YES

[80] disconnected, check

resistance between Break-

out Box terminal 3 and 5

(black). Is it greater than 1

megohm?

YES

NO.

Less

than 4.5V.

Breakout Box.

[80B] Terminal C and Breakout Box

terminal 4.

Continuity present?

NO

Repair

open wire.

NO

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

4-36 2004 Touring: Engine Management (Carbureted)

Replace ICM.

Reprogram and

learn password.

Locate and repair

short between

R/W wire and

ground.

Page 5

HOME

DTC P0562, P0563 4.14

GENERAL

Battery Voltage

The ignition control module monitors battery positive voltage.

The normal operating range is between 8-16 volts while

engine is running.

NOTE

When either a diagnostic trouble code P0562 or P0563 is set,

the battery icon in the speedometer will illuminate.

A DTC P0562 is set if the ignition module detects battery

●

positive voltage less than 8 volts while the engine is running.

A DTC P0563 is set if the ignition module detects battery

●

positive voltage greater than 16 volts.

Low voltage generally indicates a loose wire, corroded

●

connections and/or a charging system problem.

●

A high voltage condition may be caused by a faulty voltage regulator.

Table 4-17. Code Description

DTC

P0562 battery voltage low

P0563 battery voltage high

DESCRIPTION

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.14 flow charts.

1. Was battery allowed to discharge? Was battery drawn

down by a starting problem?

a.

Yes.

Charge battery.

b.

No.

See charging system troubleshooting.

2. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and ignition control module. See

4.6 BREAKOUT BOX: ICM.

3. The ignition control module is monitoring voltage at ignition control module connector [10] (black) Pin 1.

4. This checks for voltage drops in the ignition control module circuit.

a. Place (+) probe to battery positive terminal.

b. Place (-) probe to terminal 1 on Breakout Box.

5. Remove Breakout Box at ICM, reconnect ICM. Insert

Breakout Box at connector [22] (BK). On FLHR/S models

(6-place connector), install Breakout Box adapters (HD-

42962).

2004 Touring: Engine Management (Carbureted) 4-37

Page 6

HOME

R/BK To Ignition Switch

15 Amp

Ignition Fuse

To TSM/TSSM

[22B]

[22A]

Ignition

GY

[1B]

[1A]

GY

Engine Stop Switch

Coil

[83B]

A

B

C

W

\

B

K

56784321 9101112

56784321 9101112

FLHT/C Only

W \ BK

6-Place on FLHR/S

56784321 9101112

Y \BE

BE \ O

[8A]

[8B]

Ground Stud

Ignition Control Module

BK

W \ BK

[10B]

To

Data Link

7

6

5

1

[10A]

Rear Coil

Front Coil

Ground

Key ON Power

Figure 4-26. Battery Voltage Circuit

Table 4-18. Wire Harness Connectors in Figure 4-26.

NO.

[1] Main to Interconnect Harness FLHT/C 12-Place Deutsch Inner Fairing- Right Fairing Bracket

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch (Black) Under Right Side Cover

[22]

[83] Ignition Coil All 3 - Place Packard Below Fuel Tank (Left Side)

DESCRIPTION MODEL TYPE LOCATION

Interconnect to Right

Handlebar Switch Controls

FLHT/C 12-Place Deutsch

Right Fairing Support Brace

FLHR/S 6-Place Deutsch Inside Headlamp Nacelle

Inner Fairing-

4-38 2004 Touring: Engine Management (Carbureted)

Page 7

HOME

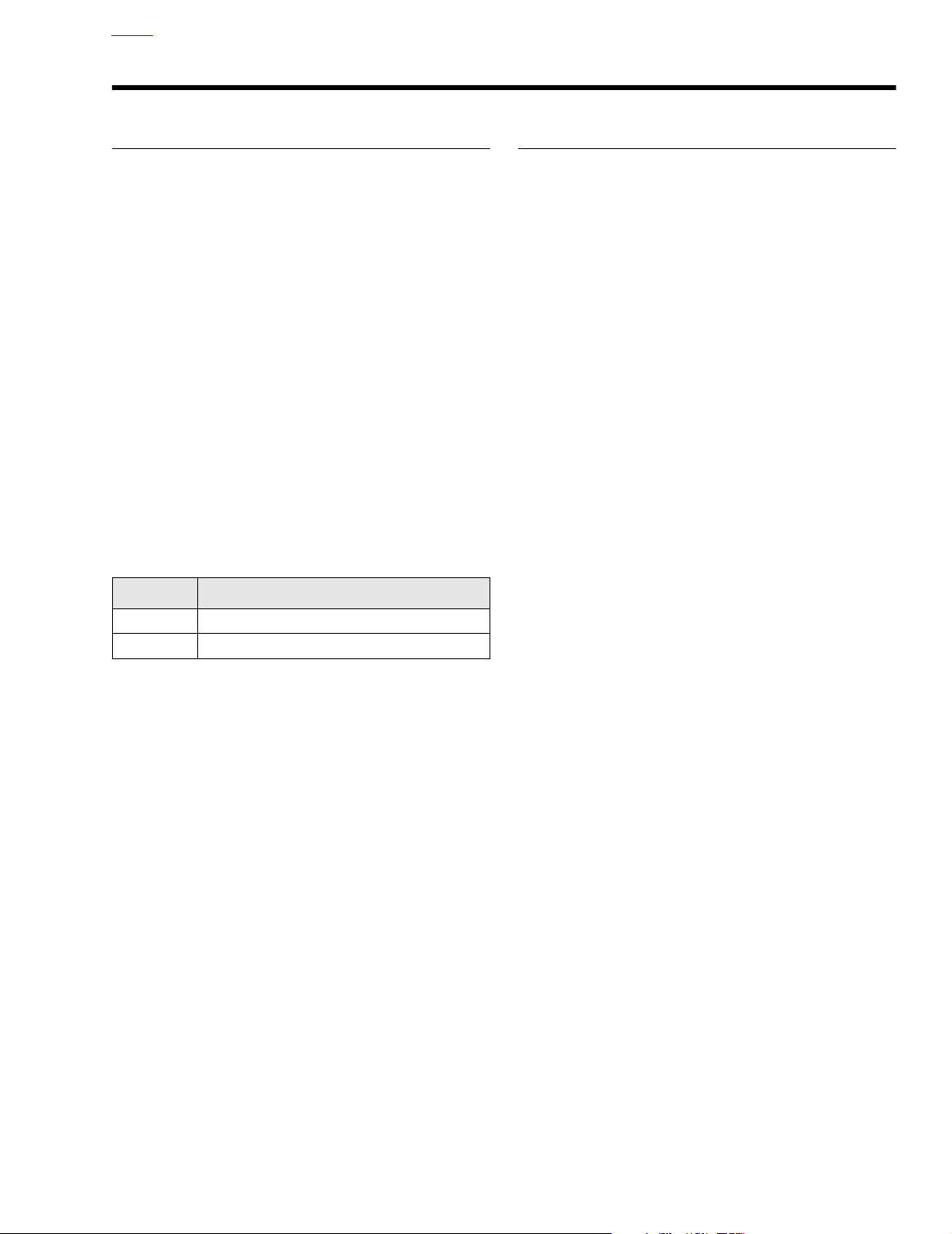

Test 4.14 (Part 1 of 2)

BATTERY VOLTAGE: DTC P0562, P0563

Perform charging system tests.

1

Charging system OK?

YES

With ignition ON, measure voltage drop

between battery positive (+) terminal

and connector [22A] Pin 3 (-). Is voltage

drop greater than 0.5 volt?

YES

2

With ignition ON, measure voltage drop

between battery positive (+) terminal

3

and Breakout Box connector [10] (black)

Pin 1 (-). Is voltage drop greater

4

With ignition ON, measure voltage drop

5

between battery positive (+) terminal

and connector [22A] Pin 4 (-). Is voltage

than 0.5 volt?

YES

drop greater than 0.5 volt?

NO

Repair or replace

W/BK wire or

terminals.

YES

Locate and repair

bad connection.

NO

Repair

charging system.

NO

Check for voltage drop between battery

negative (-) terminal and Pin 5 (+) on

connector [10B] (black) on Breakout Box.

Is voltage drop greater than 0.5 volt?

NO

Problem is intermittent.

Perform 4.7 WIGGLE

TEST.

YES

STOP

Go to Test 4.14

(Part 2 of 2).

NO

Inspect connector [22] for

corrosion or loose wires. If

above conditions are not

present, replace engine stop

switch.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (Carbureted) 4-39

Page 8

HOME

Test 4.14 (Part 2 of 2)

BATTERY VOLTAGE: DTC P0562, P0563

Continued from Test 4.14 (Part 1 of 2). With

ignition ON, measure voltage drop between

battery positive (+) terminal and GY terminal

on 15 amp ignition fuse (-). Is voltage

drop greater than 0.5 volt?

YES

With ignition ON, measure voltage drop

between battery positive (+) terminal and

R/BK terminal on 15 amp ignition fuse. Is

voltage drop greater than 0.5 volt?

YES

With ignition ON, measure voltage drop

between battery positive (+) terminal and

terminal A of maxi fuse (-).

Is voltage drop greater than 0.5 volt?

YES

With ignition ON, measure voltage drop

between battery positive (+) terminal and

terminal B of maxi fuse (-).

Is voltage drop greater than 0.5 volt?

NO

Repair or replace GY

wire or terminals.

NO

Replace fuse or

fuse terminals.

NO

Replace ignition

switch or terminals.

High resistance between maxi

fuse and battery. Replace wire or

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

4-40 2004 Touring: Engine Management (Carbureted)

YES

terminals.

NO

Replace maxi fuse.

Page 9

HOME

6924

3

2

1

4

1. Terminal 2: ground (BK)

2. Terminal 3: serial data (Lt GN/V)

3. Terminal 4: power (GY)

4. Protective cap

DTC P1009, P1010 4.15

GENERAL

Password Problem

The ICM and TSM/TSSM exchange passwords during operation. An incorrect password or missing password will set a

diagnostic code.

NOTE

If the TSM/TSSM is not connected to the wiring harness, the

vehicle will not start.

Table 4-19. Code Description

DTC

P1009 Incorrect password

P1010 Missing password

DESCRIPTION

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.15 flow charts.

1. DTC P1009 may be set if a recent ICM or TSM/TSSM

replacement did not follow the correct password assignment procedure. See 3.24 PASSWORD LEARN for

details.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black socket probes and patch cord.

3. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and ICM. See 4.6 BREAKOUT

BOX: ICM.

4. See the Touring Service Manual for TSM/TSSM replacement. See PASSWORD LEARNING under 3.24 PASS-

WORD LEARN for the password learning procedure.

Figure 4-27. TSM/TSSM

Figure 4-28. Data Link Connector

2004 Touring: Engine Management (Carbureted) 4-41

Page 10

HOME

[2A]

[2B]

f2208z8x

321654987121110

321654987121110

Speedometer

15A

Accessory

Fuse

321654987121110

321654987121110

Main to Interconnect

Harness

BK

LtGN/V

O

BN/GY

[39B]

[39A]

[108B]

[108A]

321654987121110

321654987121110

Tachometer

[1B] [1A]

123

123

Main to Interconnect

Harness

6

6

101112 78945

101112 78945

[156B] [156A]

6

6

5

5

4

4

3

3

2

2

1

1

BN/GY

Main to Interconnect

Harness

LtGN/V

GY

65

4

32

1

1

15A

Ignition

Fuse

6

5

4

32

GY

987

987

321654987121110

321654987121110

TSM/TSSM

BK

[8B]

121110

121110

[8A]

Ignition

Harness

1

2

3

4

Data Link

[91A]

BK

[30B]

[30A]

LtGN/V

15A

Battery

Fuse

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 4-29. Serial Data Circuit (FLHT/C)

Table 4-20. Wire Harness Connectors in Figure 4-29.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

4-42 2004 Touring: Engine Management (Carbureted)

Page 11

HOME

f2208y8x

BN/GY

BK

321654987121110

321654987121110

15A

Battery

Fuse

Speedometer

LtGN/V

BN/GY

O

15A

Accessory

Fuse

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

21

21

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

[8B]

[8A]

[91A]

Ignition

Harness

1

2

3

4

Data Link

987

6

54

3

98

7

654

3

121110

121110

LtGN/V

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 4-30. Serial Data Circuit (FLHR/S)

Table 4-21. Wire Harness Connectors in Figure 4-30.

NO.

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

DESCRIPTION TYPE LOCATION

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2004 Touring: Engine Management (Carbureted) 4-43

Page 12

HOME

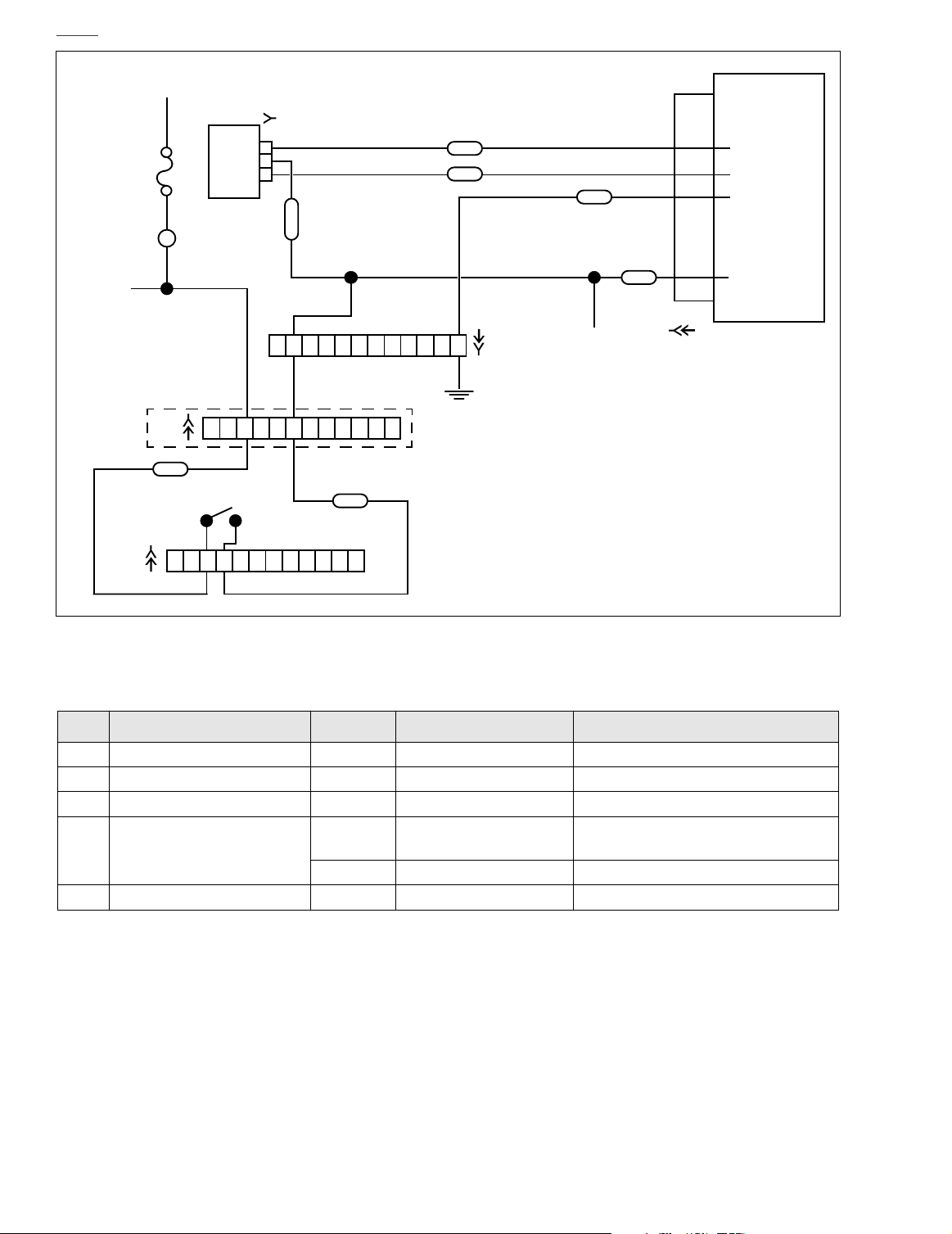

Test 4.15

PASSWORD PROBLEM: DTC P1009, P1010

Which diagnostic trouble

code was set?

1

4

4

DTC P1009.

Bad password.

Reprogram password.

See 3.24 PASSWORD

DTC P1009 still exist?

Replace TSSM and

relearn password.

System OK?

LEARN.

YES

YES

System

OK.

6702

NO

System

OK.

NO

Reinstall original TSSM.

5

Replace ICM.

Reprogram and relearn

password.

6701

6703

Troubleshoot

lowest U-code.

Repair short

to ground.

Repair short

to voltage.

6704

6705

DTC P1010.

No password.

Are there any

U-codes set?

NOYES

Remove ICM connector [10]. Check

for continuity to ground at data

connector [91A] Terminal 3.

Continuity present?

NOYES

Check for battery voltage on Pin 3.

Battery voltage present?

NOYES

Test data connector [91A]

Terminal 3 against Breakout Box Pin

12 for continuity. Continuity present?

2

2

3

YES

Replace TSM/TSSM and relearn

4

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

password. System OK?

YES

System

OK.

6707

4-44 2004 Touring: Engine Management (Carbureted)

Inspect terminals

for damage or repair

opens as necessary.

2

Reinstall original TSSM.

4

Replace ICM.

Reprogram and relearn

NO

6706

NO

password.

6708

Page 13

HOME

7863

s0592x8x

A

B

C

Coil tower

DTC P1351, P1352, P1354, P1355 4.16

GENERAL

Ignition Coil

Ignition coil codes will set if the ignition coil primary voltage is

out of range. This could occur if there is an open coil or loss of

power to the coil. If front and rear codes are set simultaneously, it is likely a coil power failure or a coil failure.

The coil receives power from the engine run/stop switch. The

ignition control module is responsible for turning on the coils

by providing the ground to activate the coils, which in turn

powers the coils.

Table 4-22. Code Description

DTC

P1351 Front ignition coil open/low

P1352 Front ignition coil high/shorted

P1354 Rear ignition coil open/low

P1355 Rear ignition coil high/shorted

DESCRIPTION

Figure 4-31. Ignition Coil Circuit Test

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.16 flow charts.

1. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probes and patch cord.

CAUTION

Gently connect test lamp to connector [83B]. Forcefully

inserting test lamp will result in ignition connector terminal damage.

2. See Figure 4-31. Plug IGNITION COIL CIRCUIT TEST

ADAPTER (Part No. HD-44687) and FUEL INJECTOR

TEST LAMP (Part No. HD-34730-2C) into Breakout Box.

Note that cranking the engine with test lamp in place of

the ignition coil can sometimes cause a DTC P1351,

P1352, P1354 or P1355. This condition is normal and

does not by itself indicate a malfunction. Codes must be

cleared if this condition occurs.

3. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and ICM. See 4.6 BREAKOUT

BOX: ICM.

Figure 4-32. Ignition Coil Connector Terminals

4. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray socket probes and patch cord.

Table 4-23. Coil Terminal Description

TERMINAL

A Rear coil Y/BE

BPowerW/BK

CFront coil BE/O

DESCRIPTION WIRE COLOR

2004 Touring: Engine Management (Carbureted) 4-45

Page 14

HOME

R/BK To Ignition Switch

15 Amp

Ignition Fuse

To TSM/TSSM

[22B]

[22A]

Ignition

GY

[1B]

[1A]

GY

Engine Stop Switch

Coil

[83B]

A

B

C

W

\

B

K

56784321 9101112

56784321 9101112

FLHT/C Only

W \ BK

6-Place on FLHR/S

56784321 9101112

Y \BE

BE \ O

[8A]

[8B]

Ground Stud

Ignition Control Module

BK

W \ BK

[10B]

To

Data Link

7

6

5

1

[10A]

Rear Coil

Front Coil

Ground

Key ON Power

Figure 4-33. Battery Voltage Circuit

Table 4-24. Wire Harness Connectors in Figure 4-33.

NO.

[1] Main to Interconnect Harness FLHT/C 12-Place Deutsch Inner Fairing- Right Fairing Bracket

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch (Black) Under Right Side Cover

[22]

[83] Ignition Coil All 3 - Place Packard Below Fuel Tank (Left Side)

DESCRIPTION MODEL TYPE LOCATION

Interconnect to Right

Handlebar Switch Controls

FLHT/C 12-Place Deutsch

Right Fairing Support Brace

FLHR/S 6-Place Deutsch Inside Headlamp Nacelle

Inner Fairing-

4-46 2004 Touring: Engine Management (Carbureted)

Page 15

HOME

Test 4.16 (Part 1 of 2)

IGNITION COIL: DTC P1351, P1352, P1354, P1355

Disconnect connector [83].

Measure voltage on Terminal B

of coil. Equal to battery voltage

1

after key ON?

YES

Use Breakout Box and test light for the

2

Front coil codes: Check between ICM Pin

3

Rear coil codes: Check between ICM Pin

Does test lamp flash when engine is

YES

4

YES

Measure coil resistance.

Front coil codes: Check between

coil Terminal B and Terminal C.

Rear coil codes: Check between

coil Terminal B and Terminal A.

Resistance 0.5-0.7 ohms?

NO

next inspection.

6 and ICM Pin 1.

7 and ICM Pin 1.

cranked?

connection on W/BK wire.

Replace ICM.

Reprogram and

perform password learn.

NO

Repair open wire or

NO

STOP

Go to Test 4.16

(Part 2 of 2).

Replace coil.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (Carbureted) 4-47

Page 16

HOME

Test 4.16 (Part 2 of 2)

IGNITION COIL: DTC P1351, P1352, P1354, P1355

Continued from Test 4.16 (Part 1 of 2).

Using Breakout Box, measure resistance between

ICM and coil terminals as follows.

YES NO

Perform 5.8 WIGGLE TEST

to check for intermittents.

Intermittents present?

YES NO

Repair

intermittent.

DTC COIL

P1351/

P1352C(BE/O wire)

1

P1353/

P1354A(Y/BE wire)

3

TERMINAL

Resistance less than 0.5 ohms?

Check for continuity to ground.

Front coil codes: Check

Breakout Box Pin 6.

Rear coil codes: Check

Breakout Box Pin 7.

Continuity present?

BREAK-

OUT BOX

TERMINAL

6

7

Repair open wire

or connection.

YES NO

Repair short

to ground.

YES

Repair short

to voltage.

Check for voltage.

Front coil codes: Check

Breakout Box Pin 6.

Rear coil codes: Check

Breakout Box Pin 7.

Voltage present?

Reprogram and

learn password.

4-48 2004 Touring: Engine Management (Carbureted)

NO

Replace ICM.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Page 17

HOME

f2256x8x

Crankshaft

Position Sensor

Connector [79]

Under Voltage Regulator

Stator

Connector [46]

DTC P0373, P0374 4.17

GENERAL

Crank Position Sensor

See Figure 4-34. A DTC P0373, P0374 will set if the crankshaft position sensor (CKP) signal is weak or absent.

Table 4-25. Code Description

DTC

P0373 Crankshaft position sensor intermittent

P0374

Crankshaft position sensor not detected or

cannot synchronize

DESCRIPTION

DIAGNOSTICS

Diagnostic Notes

1. Connect BREAKOUT BOX (Part No. HD-42682) to ignition control module wire harness only, leaving ignition

control module disconnected. See 4.6 BREAKOUT BOX:

ICM.

2. One megohm is very high resistance. Some meters will

read infinity, OL, etc.

3. Use HARNESS CONNECTOR TEST KIT (Part No. D-

41404), brown socket probes and patch cords.

4. For testing purposes, install sensor without running wiring along normal path. Disconnect and route wiring properly if system is now OK.

Figure 4-34. Voltage Regulator (Left Side View)

2004 Touring: Engine Management (Carbureted) 4-49

Page 18

HOME

Crankshaft

Position

Sensor

R

BK

f2208w8x

[10B]

[10A]

[79A]

[79B]

BK

Module Ground

12

R

BK

Crank Sensor (-)

Crank Sensor (+)

Ignition Control Module

Figure 4-35. Ignition Circuit

Table 4-26. Wire Harness Connectors in Figure 4-35.

NO.

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[79] Crankshaft Position Sensor 2 - Place Mini-Deutsch Bottom of Voltage Regulator

4-50 2004 Touring: Engine Management (Carbureted)

DESCRIPTION TYPE LOCATION

Page 19

HOME

Test 4.17

CRANK POSITION SENSOR: DTC P0373, P0374

Leaving ICM disconnected, connect Breakout

1

2

Box to harness only. Measure resistance

between Pins 8 and 5, and between Pins 9 and 5

on connector [10]. Is resistance more than 1

megohm?

YES

Check for intermittent connection, pinched

or damaged wires, and loose CKP sensor

fastener. Conditions found?

YES

Repair as

necessary.

YES

With DVOM still connected, check for

intermittents using 4.7 WIGGLE TEST.

Intermittents present?

YES

Repair as

necessary.

codes and retest.

NO

Replace CKP

sensor. Clear

Code P0373,

P0374 set?

NO

Connect DVOM to Terminals 8 and 9 at

connector [10] on Breakout Box.

Set DVOM to AC volts and crank engine.

Does DVOM read 1 VAC minimum

during cranking?

NO

Connect DVOM at Terminals 1

3

and 2 of connector [79A].

DVOM should read 1 VAC

minimum while cranking.

Does it?

YES

Check for continuity between

Pin 8 [10B] and Pin 1 [79B]. Is

continuity present?

4

NO

Disconnect connector [79]. Leaving ICM

disconnected, use Breakout Box to measure

resistance between Pins 8 and 5 on connector

[10]. Also measure resistance between Pins 9

and 5 on connector [10]. Is there still continuity to

ground (less than 1 megohm resistance)?

YES

Repair short to

ground on R or

BK wire between

connectors [10B]

and [79B].

NO

Replace CKP

sensor.

Replace CKP

sensor.

NO

YES

Reinstall CKP

sensor. Replace

ICM. Reprogram

and perform pass-

word learn.

NO

System

OK.

YES

Repair open on BK wire

between Pin 2 [79B] and Pin 9

on connector [10B].

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

between Pin 1 [79B] and Pin 8

2004 Touring: Engine Management (Carbureted) 4-51

NO

Repair open on R wire

on connector [10B].

Page 20

HOME

DTC P0501, P0502 4.18

GENERAL

Vehicle Speed Sensor

See Figure 4-36. The vehicle speed sensor is powered and

monitored by the ICM. The ICM processes the vehicle speed

signal and transmits this signal to the TSM/TSSM and speedometer through serial data.

NOTE

When the vehicle speed signal is greater than 0, the closed

loop idle speed control is inhibited.

Table 4-27. Code Description

DTC

P0501 VSS sensor low

P0502 VSS sensor high/open

DESCRIPTION

DIAGNOSTICS

Diagnostic Notes

7951

Speed

Sensor

Engine Oil Fill

Plug/Dipstick

Figure 4-36. Vehicle Speed Sensor Location

f2183x8x

The reference numbers below correlate with the circled numbers on the Test 4.18 flow charts.

1. The speedometer has a built-in diagnostic mode. See

4.5 SPEEDOMETER SELF DIAGNOSTICS.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black pin probe and patch cord.

3. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and ICM. See 4.6 BREAKOUT

BOX: ICM.

4. Jack up motorcycle and rotate rear wheel with transmission in neutral.

1

2

1. Vehicle Speed Sensor Connector [65]

2. P&A Security Siren Connector [142]

Figure 4-37. Electrical Bracket (Inboard Side)

4-52 2004 Touring: Engine Management (Carbureted)

Page 21

HOME

Vehicle Speed

Sensor

R

W

BK

A

B

C

[65A]

A

B

C

[65B]

R/W

W/GN

BK/W

R/W

BK/W

f2208x8x

W/GN

[10B]

[10A]

Ignition

Control

Module

3

10

VSS

5v Power

Sensor Ground

Figure 4-38. Vehicle Speed Sensor Circuit

Table 4-28. Wire Harness Connectors in Figure 4-38.

NO.

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[65] Vehicle Speed Sensor 3 - Place Deutsch Under Right Side Cover (Behind Electrical Bracket)

DESCRIPTION TYPE LOCATION

2004 Touring: Engine Management (Carbureted) 4-53

Page 22

HOME

Test 4.18 (Part 1 of 2)

VEHICLE SPEED SENSOR: DTC P0501, P0502

Remove and inspect vehicle speed sensor. Inspect

for debris and clean if necessary. Place speedometer

into diagnostic mode and clear ICM trouble codes.

Connect all circuits and ride motorcycle for

approximately 1.0 mile (1.6 km). Check for newly

1

logged codes. Codes present?

Check for continuity between socket

2

A of connector [65B] (R/W wire) and

YES

Repair short to ground.

Check for continuity between socket C

YES

YES

ground. Continuity present?

Check for continuity between socket A

2

of connector [65B] (R/W wire) and pin 3

[10] of breakout box. Continuity

3

YES

of connector [65B] (BK wire) and

ground. Continuity present?

NO

present?

NO

NO

System OK.

NO

Repair open on R/W wire

between connectors [10B]

and [65B].

Repair open on BK wire

STOP

Go to. Test 4.18

(Part 2 of 2)

between connector [65B]

4-54 2004 Touring: Engine Management (Carbureted)

and ground.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Page 23

HOME

Test 4.18 (Part 2 of 2)

VEHICLE SPEED SENSOR: DTC P0501, P0502

YES

Check for voltage on W/GN wire of connector

[65B] while connected. Meter should read 4-6

volts when gear tooth absent and 0-1 volts

4

when gear tooth is present. Does it?

YES NO

Replace ICM. Reprogram

and learn password.

2

3

Replace ICM. Reprogram

and learn password.

Continued from Test 4.18 (Part 1 of 2).

Check for continuity between socket B of connector

[65B] and Pin 10 [10] of breakout box. Continuity

4-6 volts present. 4-6 volts present but no

present?

fluctuation from 0-1 volts

Replace vehicle

speed sensor.

NO

Repair open on W/GN

wire between connectors

[10B] and [65B].

2004 Touring: Engine Management (Carbureted) 4-55

Page 24

HOME

DTC P0602, P0603, P0604, P0605, P0607 4.19

GENERAL

ICM Failure

All of the following codes indicate an internal failure which

requires replacement of the ignition control module. See the

To uring Service Manual for replacement procedures.

DTC P0602 - Calibration memory error

●

●

DTC P0603 - EE PROM failure

●

DTC P0604 - RAM failure

●

DTC P0605 - Program memory error

●

DTC P0607 - A to D converter error

DIAGNOSTICS

DTC P0607 Test

1. Power down the vehicle.

2. Clear codes using speedometer self-diagnostics.

3. Replace ICM if codes reappear.

DTC P0602, P0603, P0604, P0605 Test

1. Power down the vehicle.

2. Clear codes.

3. Using Digital Technician, reprogram ICM using the correct calibration. See your dealer.

4. Restart vehicle. If code reappears, replace ICM. Reprogram and perform password learn.

4-56 2004 Touring: Engine Management (Carbureted)

Page 25

HOME

6924

3

2

1

4

1. Terminal 2: ground (BK)

2. Terminal 3: serial data (Lt GN/V)

3. Terminal 4: power (GY)

4. Protective cap

DTC U1064 4.20

GENERAL

Loss of TSM/TSSM Serial Data

The serial data connector provides a means for the ICM and

TSM/TSSM to communicate their current status. When all

operating parameters on the serial data link are within specifications, a state of health message is sent between the components. A DTC U1064 indicates that the TSM/TSSM is not

receiving this state of health message.

Table 4-29. Code Description

DTC

U1064 Loss of TSM/TSSM serial data

DESCRIPTION

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.20 flow chart.

1. Connect BREAKOUT BOX (Part No. HD-42682) as follows:

a. Mate black socket housing on Breakout Box with

speedometer connector [39] using SPEEDOMETER

HARNESS ADAPTER (Part No. HD-46601).

b. Mate black pin housing on Breakout Box with speed-

ometer harness connector [39B] using SPEEDOMETER HARNESS ADAPTER (Part No. HD-46601).

c. Mate gray socket housing on Breakout Box with

TSM/TSSM connector [30A].

d. Mate gray pin housing on Breakout Box with har-

ness connector [30B].

Figure 4-39. TSM/TSSM

Figure 4-40. Data Link Connector

2004 Touring: Engine Management (Carbureted) 4-57

Page 26

HOME

[2A]

[2B]

f2208z8x

321654987121110

321654987121110

Speedometer

15A

Accessory

Fuse

321654987121110

321654987121110

Main to Interconnect

Harness

BK

LtGN/V

O

BN/GY

[39B]

[39A]

[108B]

[108A]

321654987121110

321654987121110

Tachometer

[1B] [1A]

123

123

Main to Interconnect

Harness

6

6

101112 78945

101112 78945

[156B] [156A]

6

6

5

5

4

4

3

3

2

2

1

1

BN/GY

Main to Interconnect

Harness

LtGN/V

GY

65

4

32

1

1

15A

Ignition

Fuse

6

5

4

32

GY

987

987

321654987121110

321654987121110

TSM/TSSM

BK

[8B]

121110

121110

[8A]

Ignition

Harness

1

2

3

4

Data Link

[91A]

BK

[30B]

[30A]

LtGN/V

15A

Battery

Fuse

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 4-41. Serial Data Circuit (FLHT/C)

Table 4-30. Wire Harness Connectors in Figure 4-41.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

4-58 2004 Touring: Engine Management (Carbureted)

Page 27

HOME

f2208y8x

BN/GY

BK

321654987121110

321654987121110

15A

Battery

Fuse

Speedometer

LtGN/V

BN/GY

O

15A

Accessory

Fuse

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

21

21

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

[8B]

[8A]

[91A]

Ignition

Harness

1

2

3

4

Data Link

987

6

54

3

98

7

654

3

121110

121110

LtGN/V

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 4-42. Serial Data Circuit (FLHR/S)

Table 4-31. Wire Harness Connectors in Figure 4-42.

NO.

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

DESCRIPTION TYPE LOCATION

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2004 Touring: Engine Management (Carbureted) 4-59

Page 28

HOME

Test 4.20

LOSS OF TSM/TSSM SERIAL DATA: DTC U1064

Can you read TSM/TSSM hardware P/N?

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

YES

Install Breakout Box on speedometer.

1

While wiggling harness, check for continuity

between terminal 3 (gray) and terminal 2

(black) of Breakout Box

Continuity present?

YES

Clear trouble codes.

Test Ride. Does U1064

return?

YES NO

Perform password learn

procedure.

NO

Repair intermittent

on LtGN/V wire.

No trouble found.Replace TSM/TSSM.

NO or “No Rsp”

Install Breakout Box on speedometer.

1

Check for continuity between terminal 3

(gray) and terminal 2 (black) of Breakout

YES

Replace TSM/TSSM.

Learn password.

Box

Continuity present?

NO

Repair open on

LtGN/V wire.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

4-60 2004 Touring: Engine Management (Carbureted)

Page 29

HOME

f2191x8x

Ignition Control Module

Connector [10]

6924

3

2

1

4

1. Terminal 2: ground (BK)

2. Terminal 3: serial data (Lt GN/V)

3. Terminal 4: power (GY)

4. Protective cap

DTC U1097 4.21

GENERAL

Loss of Speedometer Serial Data

The serial data connector provides a means for the speedometer, ICM and TSM/TSSM to communicate their current status. When all operating parameters on the serial data link are

within specifications, a state of health message is sent

between the components. A DTC U1097 indicates that the

speedometer is not capable of sending this state of health

message.

Table 4-32. Code Description

DTC

U1097

Loss of all speedometer serial data

(state of health)

DESCRIPTION

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the 4.21 flow chart.

1. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and speedometer using SPEEDOMETER HARNESS ADAPTER (Part No. HD-46601).

See 2.5 BREAKOUT BOX: SPEEDOMETER.

2. Connect BREAKOUT BOX (Part No. HD-42682) (black)

as follows:

a. Mate black socket housing on Breakout Box with

speedometer connector [39A] (at the back of the

speedometer) using INSTRUMENT HARNESS

ADAPTERS (Part No. HD-46601).

b. Mate black pin housing on Breakout Box with wire

harness connector [39B] using INSTRUMENT HARNESS ADAPTERS (Part No. HD-46601).

Figure 4-43. Electrical Bracket (Under Right Side Cover)

Figure 4-44. Data Link Connector

2004 Touring: Engine Management (Carbureted) 4-61

Page 30

HOME

[2A]

[2B]

f2208z8x

321654987121110

321654987121110

Speedometer

15A

Accessory

Fuse

321654987121110

321654987121110

Main to Interconnect

Harness

BK

LtGN/V

O

BN/GY

[39B]

[39A]

[108B]

[108A]

321654987121110

321654987121110

Tachometer

[1B] [1A]

123

123

Main to Interconnect

Harness

6

6

101112 78945

101112 78945

[156B] [156A]

6

6

5

5

4

4

3

3

2

2

1

1

BN/GY

Main to Interconnect

Harness

LtGN/V

GY

65

4

32

1

1

15A

Ignition

Fuse

6

5

4

32

GY

987

987

321654987121110

321654987121110

TSM/TSSM

BK

[8B]

121110

121110

[8A]

Ignition

Harness

1

2

3

4

Data Link

[91A]

BK

[30B]

[30A]

LtGN/V

15A

Battery

Fuse

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 4-45. Serial Data Circuit (FLHT/C)

Table 4-33. Wire Harness Connectors in Figure 4-45.

NO.

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

DESCRIPTION TYPE LOCATION

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

4-62 2004 Touring: Engine Management (Carbureted)

Page 31

HOME

f2208y8x

BN/GY

BK

321654987121110

321654987121110

15A

Battery

Fuse

Speedometer

LtGN/V

BN/GY

O

15A

Accessory

Fuse

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

21

21

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

[8B]

[8A]

[91A]

Ignition

Harness

1

2

3

4

Data Link

987

6

54

3

98

7

654

3

121110

121110

LtGN/V

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 4-46. Serial Data Circuit (FLHR/S)

Table 4-34. Wire Harness Connectors in Figure 4-46.

NO. DESCRIPTION TYPE LOCATION

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2004 Touring: Engine Management (Carbureted) 4-63

Page 32

HOME

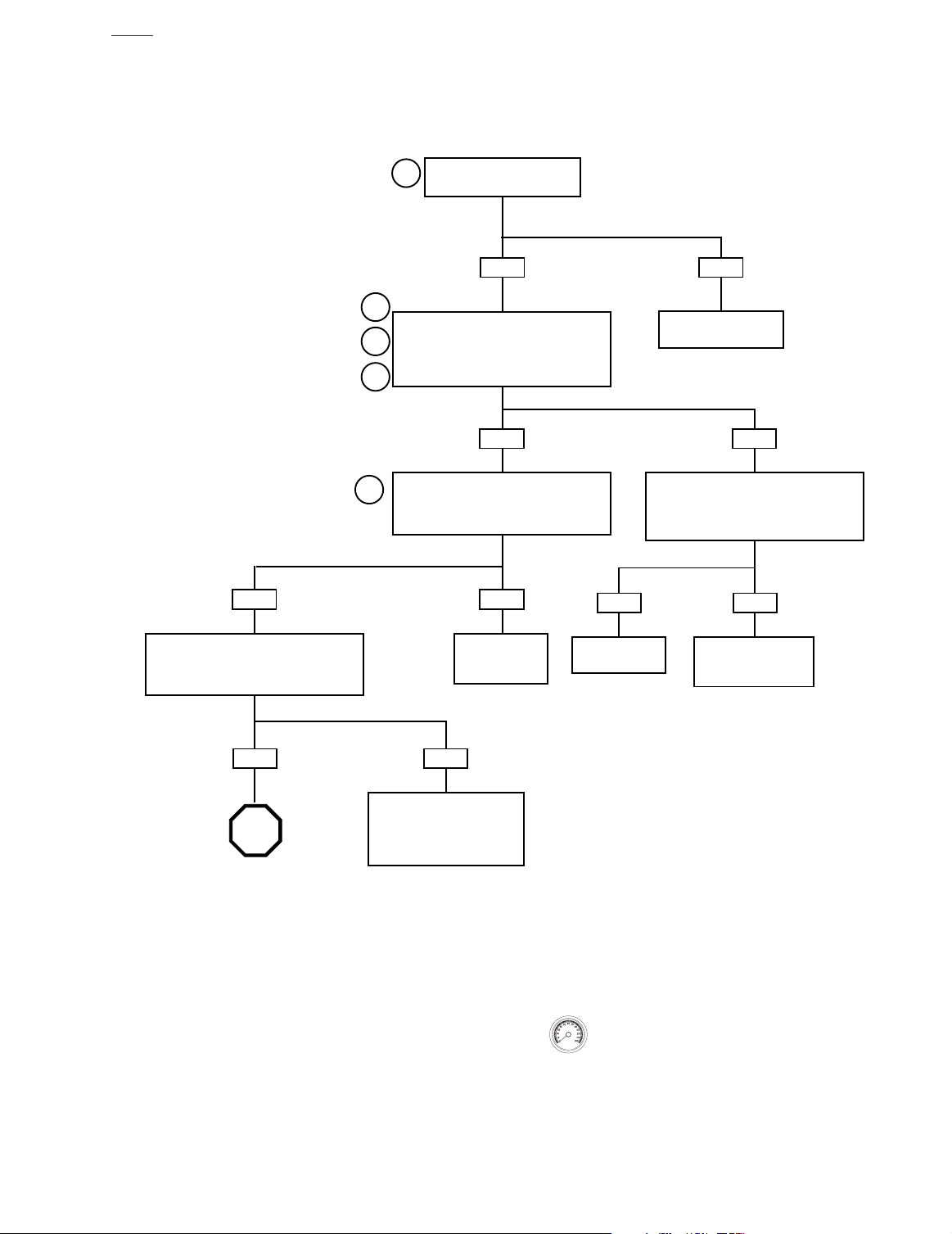

Test 4.21

LOSS OF SPEEDOMETER SERIAL DATA:

DTC U1097

Can you read ECM/ICM hardware part number?

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Install Breakout Box on speedometer.

While wiggling harness, check continuity

1

between terminal 2 (black) of Breakout

Box and terminal 12 of connector [10B].

2

YES

Clear codes. Test ride.

Does DTC U1097

return?

YES

Replace ICM.

Reprogram and learn

password.

YES

Continuity present?

NO

No trouble found.

NO

Repair intermittent

on LtGN/V wire.

NO or “No Rsp”

Install Breakout Box on speedometer. Check conti-

1

nuity between terminal 2 (black) of Breakout Box

and terminal 12 of connector [10B].

2

Replace speedometer.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Continuity present?

YES

NO

Repair open on

Lt GN/V wire.

4-64 2004 Touring: Engine Management (Carbureted)

Loading...

Loading...