Page 1

HOME

f1641x3x

SCHEDULED MAINTENANCE PROCEDURES 1.5

BATTERY

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

battery as follows:

1. Battery top must be clean and dry. Dirt on the top of the

battery may cause the battery to self-discharge at a

faster than normal rate.

2. Inspect battery screws, clamps, and cables for breakage, loose connections and corrosion. Clean clamps.

Coat terminals with grease.

3. Inspect battery for discoloration, raised top, or warped

case which may indicate battery has been overheated or

overcharged.

4. Inspect the battery case for cracks or leaks.

NOTE

For charging information, see Section 8.10 BATTERY, BAT-

TERY CHARGING.

ENGINE OIL/ENGINE OIL FILTER

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, change the

engine oil and engine oil filter as follows:

NOTE

If the motorcycle is ridden hard, under dusty conditions, or in

cold weather, the oil and filter should be changed more often.

1. Ride vehicle until engine is at normal operating tempera-

ture.

2. Locate oil filler plug/dipstick on right side of vehicle at top

of transmission case. To remove the oil filler plug, pull

steadily while moving plug back and forth.

3. Locate oil drain plug at front left side of the oil pan.

Remove the oil drain plug and allow oil to drain completely.

4. Inspect the oil drain plug O-ring for cuts, tears or signs of

deterioration. Replace as necessary.

5. Remove the oil filter as follows:

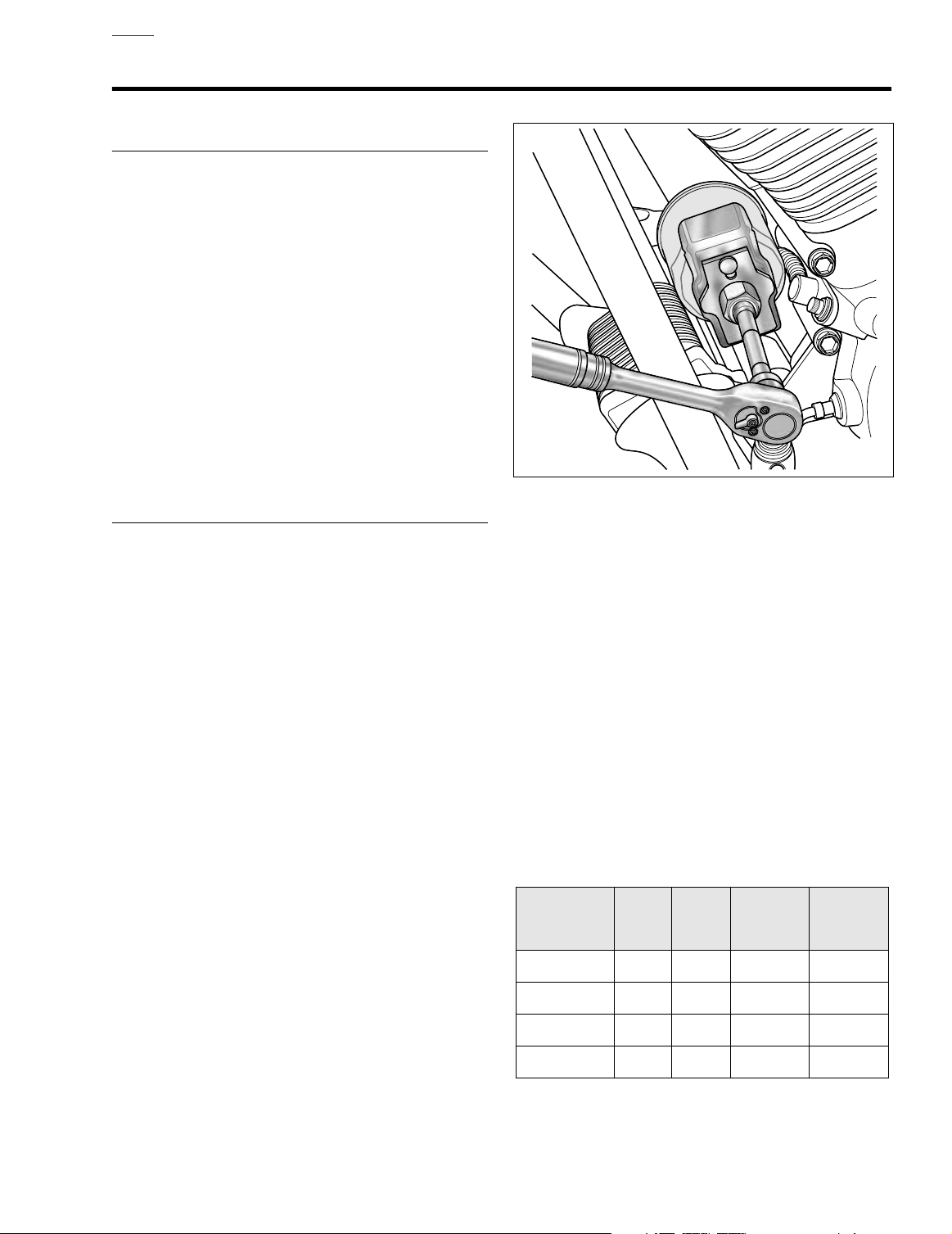

a. Obtain the OIL FILTER WRENCH (HD-42311). The

tool allows easy removal of the oil filter without risk

of damage to the crankshaft position sensor or

cable.

b. Place the jaws of the wrench over the oil filter with

the tool oriented vertically. See Figure 1-1.

c. Using a 3/8 inch drive with a 4 inch extension, turn

wrench in a counterclockwise direction. Do not use

with air tools.

NOTE

Use OIL FILTER WRENCH (HD-44067) if HD-42311 is not

available.

Figure 1-1. Remove Engine Oil Filter

6. Clean the oil filter mount flange of any old gasket material.

7. Lubricate gasket with clean engine oil and install

new

oil

filter on filter mount. Hand tighten oil filter 1/2-3/4 turn

after gasket first contacts filter mounting surface. Do

NOT

use OIL FILTER WRENCH for oil filter installation.

NOTE

Use of the Premium 10 micron synthetic media oil filter is

highly recommended, Part No. 63798-99 (Chrome) or 6373199 (Black).

8. Install engine oil drain plug and tighten to 14-21 ft-lbs

(19-28 Nm).

9. With vehicle resting on jiffy stand, add 3-1/2 quarts (3.3

liters) engine oil as specified in Ta bl e 1-1. Use the proper

grade of oil for the lowest temperature expected before

the next oil change.

Table 1-1. Recommended Engine Oils

Harley-Davidson

Type

HD Multi-grade

HD Multi-grade

HD Regular Heavy

HD Extra Heavy

Viscosity

SAE

10W40

SAE

20W50

SAE

50

SAE

60

Harley-

Davidson

Rating

HD 360

HD 360

HD 360

HD 360

Lowest

Ambient

Temperature

Below 40˚F

(4˚C)

Above 40˚F

(4˚C)

Above 60˚F

(16˚C)

Above 80˚F

(27˚C)

Cold Weather

Starts Below

50˚F (10˚C)

Excellent

Good

Poor

Poor

2004 Touring: Maintenance 1-15

Page 2

HOME

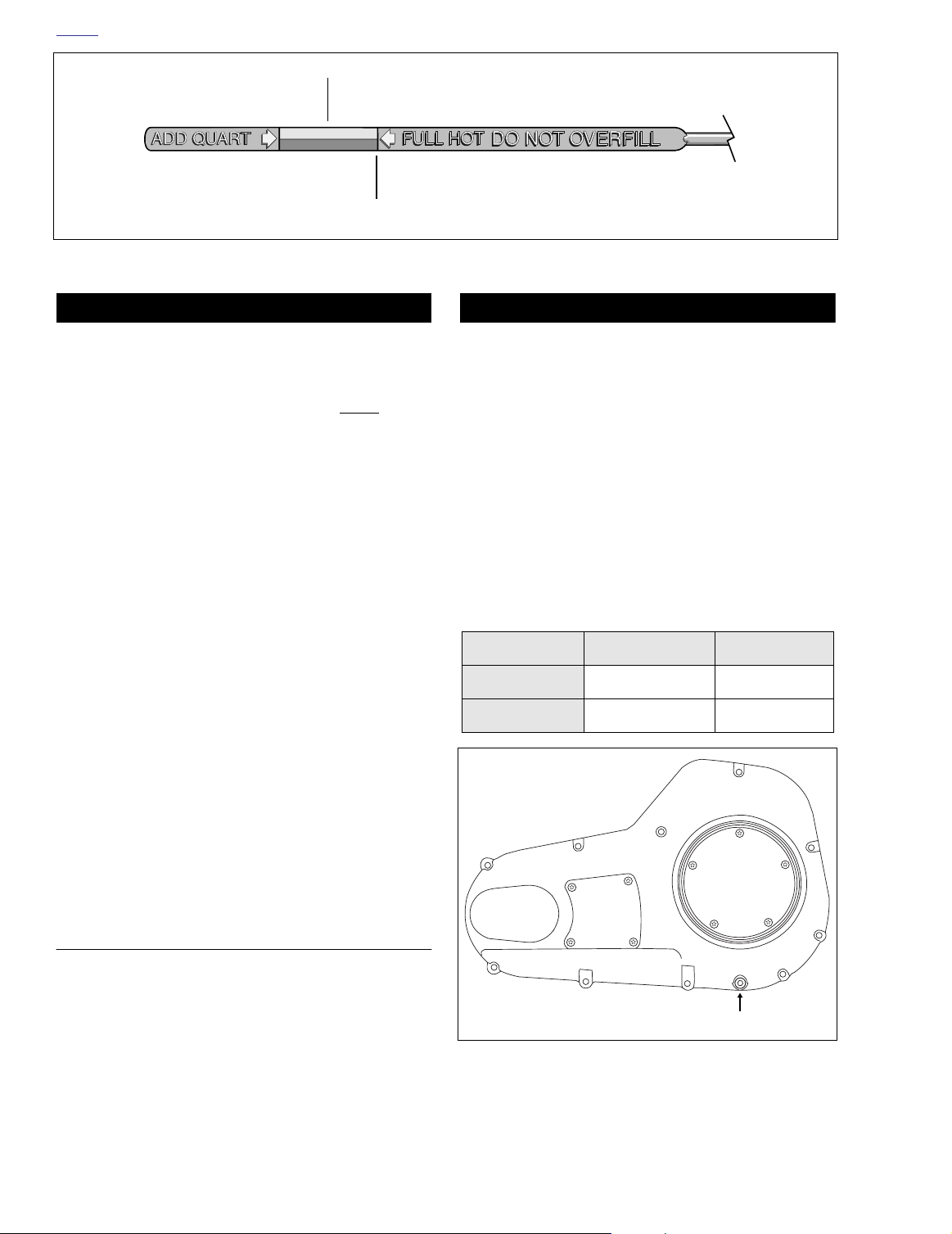

COLD CHECK

HOT CHECK

f1254b3x

Figure 1-2. Engine Oil Dipstick

CAUTION

Oil level cannot be accurately measured on a cold

engine. For preride inspection, with motorcycle leaning

on jiffy stand on level ground, oil should register on dipstick between arrows when engine is cold. Do NOT add

oil to bring the level to the FULL mark on a COLD

10. Perform engine oil level

COLD CHECK

as follows:

engine.

a. With the vehicle resting on the jiffy stand on level

ground, wipe off the dipstick and insert it back into

the oil pan with the plug pushed completely into the

fill spout.

b. Remove the dipstick and note the level of the oil. Oil

level should register between the two arrows on the

dipstick. See Figure 1-2. If oil level is at or below the

lower arrow, add only enough oil to bring the level

between the two arrows on the dipstick.

11. Perform engine oil level

HOT CHECK

as follows:

a. Ride vehicle until engine is at normal operating tem-

perature.

b. With the vehicle resting on the jiffy stand on level

ground, allow engine to idle for 1-2 minutes. Turn

engine off.

c. Wipe off the dipstick and insert it back into the oil

pan with the plug pushed completely into the fill

spout.

d. Remove the dipstick and note the level of the oil.

Add only enough oil to bring the level to the FULL

mark on the dipstick. See Figure 1-2. Do not overfill.

12. Start engine and carefully check for leaks around hoses,

drain plug and oil filter.

PRIMARY CHAIN

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

primary chain tension and adjust if necessary.

Proceed as follows:

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

11WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

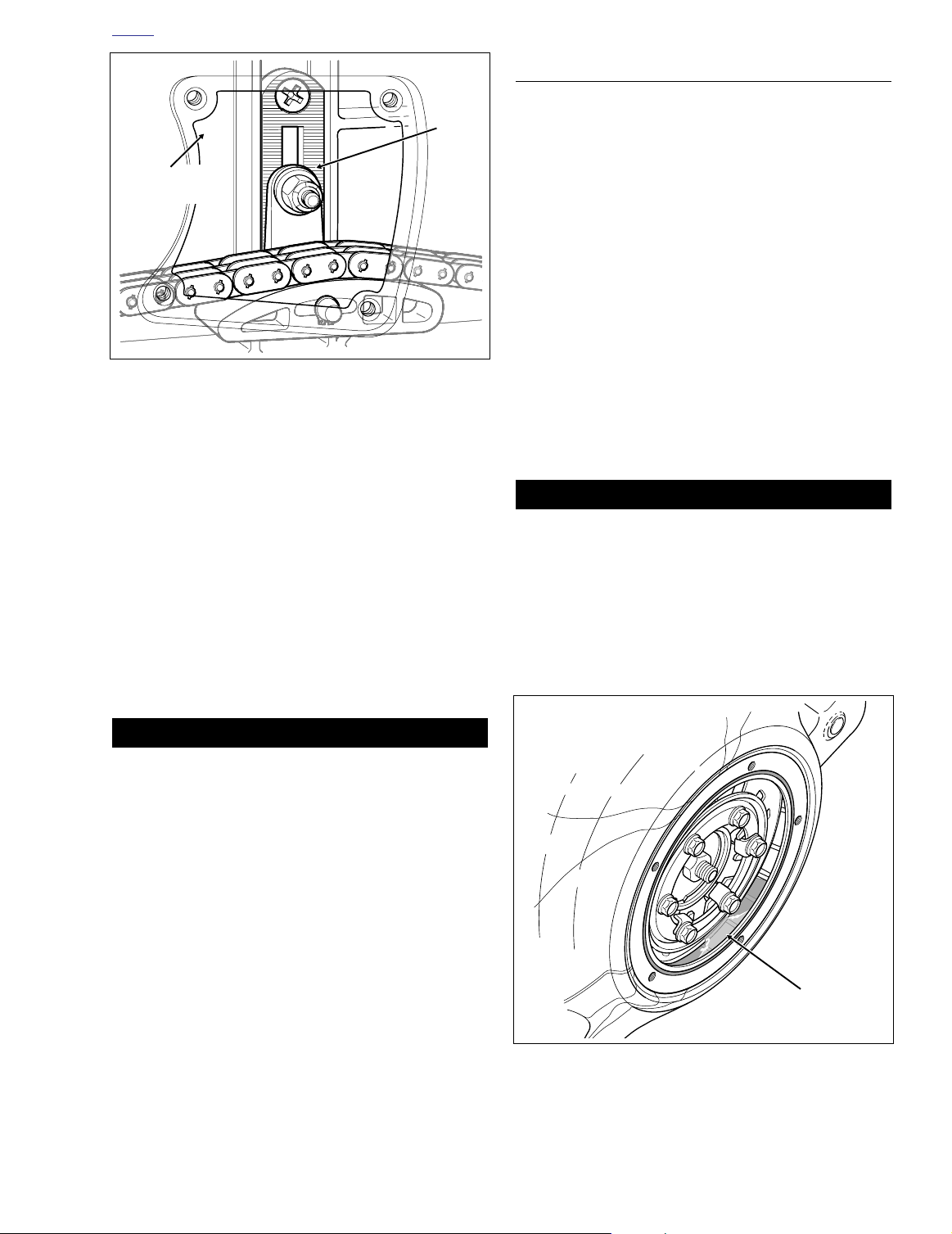

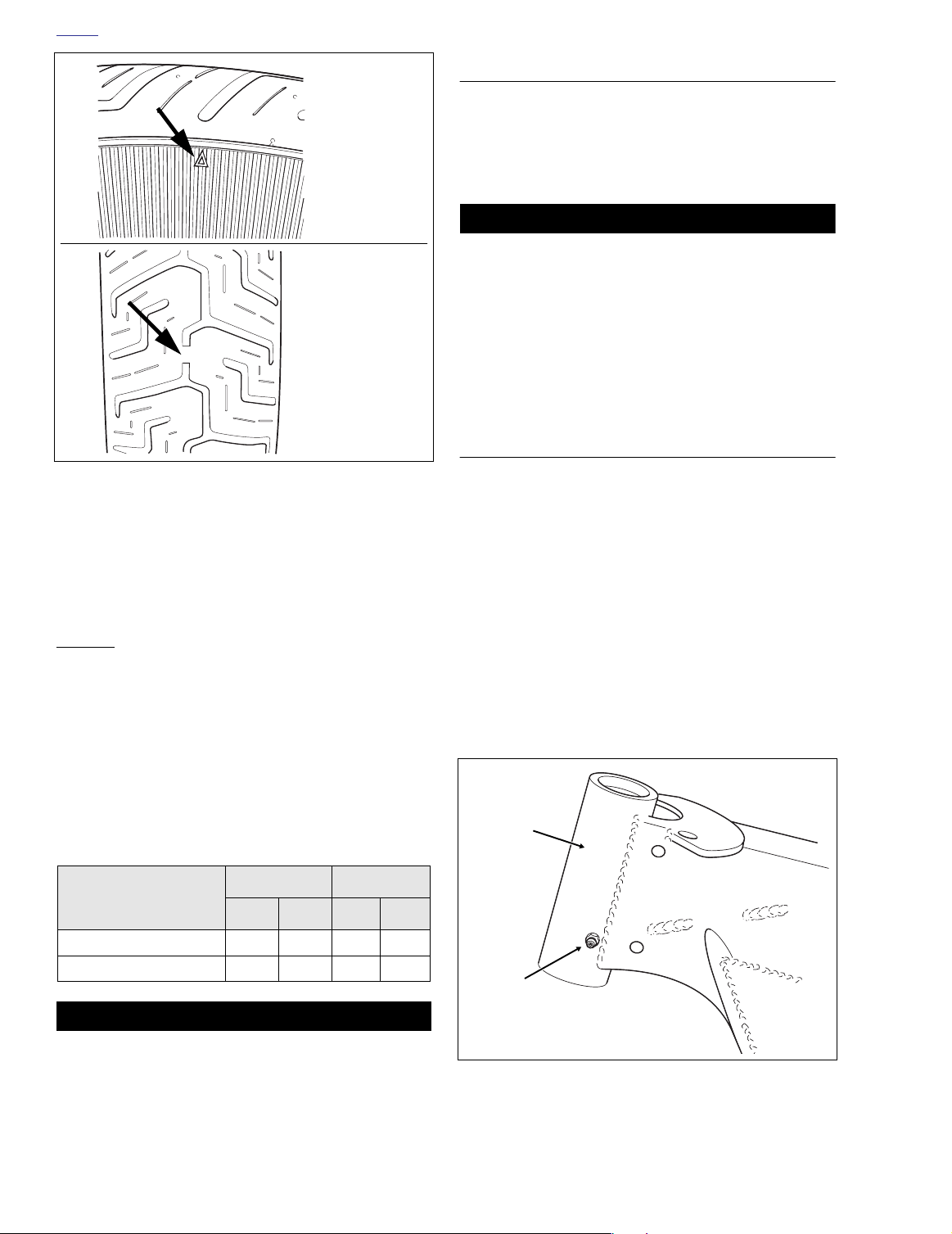

3. See Figure 1-3. Using a T27 TORX drive head, remove

four screws to free the primary chain inspection cover

from the primary chaincase cover.

4. Check the primary chain tension. Push on the upper

strand to verify that it has free up and down movement

midway between the engine compensating sprocket

(front) and the clutch sprocket (rear).

Table 1-2. Primary Chain Adjustment

(Free Play)

COLD ENGINE

HOT ENGINE

f1210x6x

4

Inspection

Figure 1-3. Primary Chaincase Cover

Inches Millimeters

5/8-7/8 inch 15.9-22.2 mm

3/8-5/8 inch 9.5-15.9 mm

1

43

Clutch

Inspection

Cover

2

Primary

Chain

Cover

1

32

Drain Plug

5

1-16 2004 Touring: Maintenance

Page 3

HOME

CAUTION

f1508b6x

Lubricant

Primary

Chaincase Cover

f1841x6x

Top

Center

Nut

Chain Inspection

Cover Opening

Figure 1-4. Primary Chaincase Cover

5. Measure the free play to be sure that it falls within the

range specified for a hot or cold engine. See Ta bl e 1-2.

6. If the chain is too tight or too loose, then adjust as follows:

a. Locate the chain tensioner assembly and loosen the

top center nut a maximum of two turns. See Figure

1-4.

b. Raise or lower the chain tensioner assembly as

necessary to obtain the specified free play.

NOTE

As chains stretch and wear, they run tighter at one spot than

another. Always adjust the free play at the tightest spot in the

chain. Replace the primary chain if it is worn to the point

where it cannot be properly adjusted.

PRIMARY CHAIN LUBRICANT

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, replace the

primary chain lubricant as follows:

1. Using a T27 TORX drive head, remove five screws (with

captive washers) to free clutch inspection cover from primary chaincase cover.

2. Remove magnetic drain plug at bottom of primary chaincase cover. Drain lubricant into suitable container. See

Figure 1-3.

3. Clean drain plug. If plug has accumulated a lot of debris,

inspect the condition of chaincase components.

4. Inspect drain plug O-ring for cuts, tears or signs of deterioration. Replace as necessary.

5. Install drain plug back into primary chaincase cover.

Tighten plug to 36-60

6. Pour 32 ounces (946 ml) of Harley-Davidson PRIMARY

CHAINCASE LUBRICANT through the clutch inspection

cover opening, Part No. 99887-84 (quart) or Part No.

99886-84 (gallon). See Figure 1-5.

Do not overfill the primary chaincase with lubricant.

Overfilling may cause rough clutch engagement, incomplete disengagement, clutch drag and/or difficulty in

finding neutral at engine idle.

7. Remove quad ring from groove in primary chaincase

cover. Wipe all lubricant from the quad ring and inspect

for cuts, tears or signs of deterioration. Replace as necessary.

in-lbs

(4.1-6.8 Nm).

CAUTION

Always keep the primary chain properly adjusted. Allowing the chain to run too tight or too loose will result in

excessive chain and sprocket wear.

c. Tighten the top center nut of the chain tensioner

assembly to 21-29 ft-lbs (29-39 Nm).

7. Align holes in

new

gasket with holes in the primary

chaincase cover. Using a T27 TORX drive head, install

four screws to secure primary chain inspection cover to

primary chaincase cover. Alternately tighten screws to

84-108

in-lbs

(10-12 Nm) in a crosswise pattern. See

Figure 1-3.

8. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

in-lbs

(6.8-10.9 Nm).

9. Install seat. See Section 2.24 SEAT, INSTALLATION.

Figure 1-5. Fill Primary Chaincase With Lubricant

2004 Touring: Maintenance 1-17

Page 4

HOME

f1440x6x

Rubber

Boot

Figure 1-6. Clutch Cable Adjuster Mechanism

Clutch

Cable

Ferrule

f1421x6x

Figure 1-7. Adjust Clutch Free Play

Jam

Nut

Cable

Adjuster

Adjust for 1/16-1/8 inch

(1.6-3.2 mm) gap

between ferrule

and bracket

Clutch Lever

Bracket

Cable

End

CLUTCH ADJUSTMENT

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, adjust the

clutch as follows:

CAUTION

Perform the clutch adjustment with the motorcycle at

room temperature. The clearance at the adjuster screw

will increase as the powertrain temperature increases. If

adjuster screw is adjusted while the powertrain is hot,

clearance at push rod bearing could be insufficient with

powertrain cold and clutch slippage could occur.

NOTE

Perform adjustment procedure whenever clutch components

are replaced during normal servicing. Repeat adjustment

after 500 miles (800 km) of use.

1. Stand vehicle upright and level.

2. Using a T27 TORX drive head, remove five screws (with

captive washers) to free clutch inspection cover from primary chaincase cover.

3. See Figure 1-6. Slide rubber boot off cable adjuster.

Holding cable adjuster with 1/2 inch wrench, loosen jam

nut using a 9/16 inch wrench. Back jam nut away from

cable adjuster. Move adjuster toward jam nut to introduce a large amount of free play at hand lever.

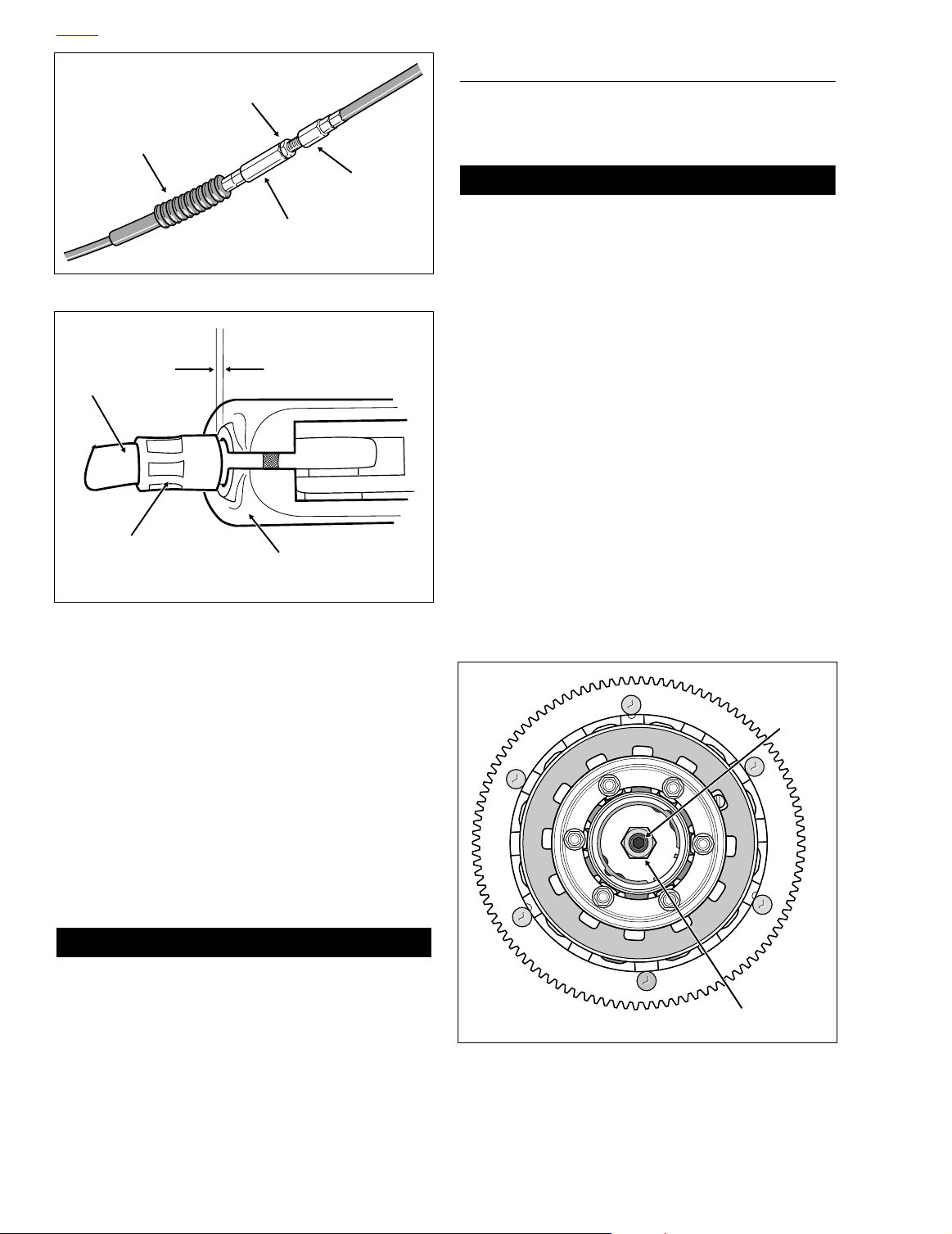

4. See Figure 1-8. Loosen locknut on clutch adjuster screw.

To take up all free play in push rods, turn screw inward

(clockwise) until lightly seated.

8. Swab all lubricant from the quad ring groove. Install

quad ring in primary chaincase cover with the nubs contacting the ring groove walls.

NOTE

If lubricant is not thoroughly removed from both the quad ring

and groove, compression of the ring during installation of the

clutch inspection cover can cause lubricant to be squeezed

to the outboard side of the ring groove, resulting in some

temporary weepage around the inspection cover.

9. Using a T27 TORX drive head, install five screws (with

captive washers) to secure clutch inspection cover to the

primary chaincase cover. Alternately tighten screws to

84-108

in-lbs

(10-12 Nm) in the pattern shown in Figure

1-3.

11WARNING1WARNING

When adding lubricant, do not allow dirt, debris or other

contaminants to enter the primary chaincase. Exercise

caution so that lubricant does not contact rear wheel,

tire and brake components. Such contact can adversely

affect traction and may lead to loss of vehicle control,

which could result in death or serious injury.

f1509b6x

Clutch

Adjuster

Screw

Locknut

Figure 1-8. Clutch Assembly

1-18 2004 Touring: Maintenance

Page 5

HOME

8496

Clutch

Release

Cover

Filler

Plug

OMF50

O-Ring

5. Back out adjuster screw 1/2 to 1 turn. While holding

adjuster screw with an allen wrench, tighten locknut to

72-120

in-lbs

(8-14 Nm).

6. Squeeze clutch lever to maximum limit three times to set

ball and ramp release mechanism.

7. Turn cable adjuster away from jam nut until slack is eliminated at hand lever. Pull clutch cable ferrule away from

clutch lever bracket to check free play. Turn cable

adjuster as necessary to obtain 1/16 to 1/8 inch (1.6 -

3.2 mm) free play between end of cable ferrule and

clutch lever bracket, as shown in Figure 1-7.

8. Hold adjuster with 1/2 inch wrench. Using 9/16 inch

wrench, tighten jam nut against cable adjuster. Cover

cable adjuster mechanism with rubber boot.

9. Remove quad ring from groove in primary chaincase

cover. Wipe all lubricant from the quad ring and inspect

for cuts, tears or signs of deterioration. Replace as necessary.

10. Swab all lubricant from the quad ring groove. Install

quad ring in primary chaincase cover with the nubs contacting the ring groove walls.

11. Using a T27 TORX drive head, install five screws (with

captive washers) to secure clutch inspection cover to the

primary chaincase cover. Alternately tighten screws to

84-108

in-lbs

(10-12 Nm) in the pattern shown in Figure

1-3.

Figure 1-9. Transmission Case (Right Side)

TRANSMISSION LUBRICANT

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, replace the

transmission lubricant as follows:

1. Remove the filler plug from the clutch release cover on

the right side of the transmission case. See Figure 1-9.

Check the O-ring for tears, cuts or general deterioration.

Replace as necessary. See Figure 1-10.

2. Locate transmission drain plug on the right side of the oil

pan. Remove the magnetic plug and drain the transmission lubricant into a suitable container.

3. Remove any foreign material from the drain plug. Check

the O-ring on the drain plug for tears, cuts or general

deterioration. Replace as necessary.

4. Install the transmission lubricant drain plug and tighten

to 14-21 ft-lbs (19-28 Nm).

11WARNING1WARNING

When adding lubricant, do not allow dirt, debris or other

contaminants to enter the transmission case. Exercise

caution so that lubricant does not contact rear wheel,

tire and brake components. Such contact can adversely

affect traction and may lead to loss of vehicle control,

which could result in death or serious injury.

Figure 1-10. Transmission Lubricant Filler Plug/Dipstick

5. Fill the transmission with 20-24 oz. (590-710 ml) of

transmission lubricant or until the lubricant level on the

dipstick of the filler plug is at the F(ULL) mark with the

motorcycle in a level, upright position and the filler plug

resting on the threads.

Use only Harley-Davidson SEMI-SYNTHETIC TRANSMISSION LUBRICANT: Part No.’s 99892-84 (quart),

98853-96 (case of quarts), 99891-84 (gallon), or 9885296 (case of gallons).

6. Install the transmission filler plug/dipstick in the clutch

release cover. Tighten the plug to 25-75

Nm).

in-lbs

(2.8-8.5

TIRES

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect both

the tire condition and pressure.

1. Inspect for wear as follows:

a. Locate the arrows on the tire sidewalls. The arrows

point to location of the tread wear indicator bars.

See upper frame of Figure 1-11.

2004 Touring: Maintenance 1-19

Page 6

HOME

o0250xox

Sidewall

Arrow

Indicator Bar on

Tread Surface

o0249xox

Figure 1-11. Tread Wear Indicator Bars

b. Immediately replace tires if any tread wear indicator

bar is on the tire tread surface, indicating that 1/32

inch (0.8 mm) or less of tire tread pattern remains.

See lower frame of Figure 1-11.

NOTE

Harley-Davidson recommends that the tires be replaced

BEFORE

surface.

2. Inspect for damage. Replace tires if:

3. Check tire pressure.

the tread wear indicator bars are on the tire tread

Cords or fabric become visible through cracked

●

sidewalls, snags or deep cuts.

Bump, bulge or split line is observed.

●

●

Puncture, deep cut or other damage is present that

is not repairable.

Table 1-3. Tire Pressure (Cold)

WHEEL SPOKES

At the 1000 mile (1600 km) service interval, the 5000 mile

(8000 km) service interval, and then every 15,000 mile

(24,000 km) service interval thereafter, inspect spoke tightness, if applicable. Proceed as follows:

1. Raise wheel off the ground.

CAUTION

If nipples require more than one full turn to tighten

spoke, remove tire to check that spoke protrusion has

not damaged tube.

2. Lightly tap each spoke with a spoke wrench. Loose

spokes will sound dull and must be tightened. Tighten

spokes to 40-50

spokes are loose, true the entire wheel following the procedure under Section 2.7 TRUING LACED WHEEL.

in-lbs

(4.5-5.6 Nm). If more than a few

STEERING HEAD BEARINGS

At the 1000 mile (1600 km) service interval, and at every

10,000 mile (16,000 km) service interval thereafter, grease

the steering head bearings using

Part No. 99857-97

grease fitting at the left side of the steering head. Connect

grease gun to fitting and inject grease until it exudes from top

and bottom of steering head. See Figure 1-12.

At every 25,000 mile (40,000 km) service interval, check the

swing-by following the procedure under Section 2.17

STEERING HEAD BEARINGS and adjust as necessary.

At every 50,000 mile (80,000 km) service interval, disassemble the steering head and inspect the bearings for brinelling,

scoring, or other damage. Replace and/or repack the bearings as required. See Section 2 for more information.

Steering

Head

. Tu rn handlebar full right to access the

Special Purpose Grease,

f2108x2x

DUNLOP TIRES ONLY

Solo Rider 36 2.5 36 2.5

Rider & One Passenger 36 2.5 40 2.8

FRONT REAR

PSI

BARS PSI BARS

11WARNING1WARNING

Do not inflate tires beyond the maximum inflation pressure specified on tire sidewall. Overinflation can lead to

tire failure while vehicle is in operation, which could

result in death or serious injury.

1-20 2004 Touring: Maintenance

Grease

Fitting

Figure 1-12. Steering Head Bearing Grease Fitting

Page 7

HOME

10 lbs. (4.5 kg)

of Force

f1652x6x

See Tabl e 1-4.

Transmission

Sprocket

Rear Wheel

Sprocket

Belt Tension Gauge Adapter

Part No. HD-35381-3

Belt Tension Gauge

Part No. HD-35381A

BRAKE FLUID

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

brake fluid condition and level. Proceed as follows:

CAUTION

To prevent dirt from entering the master cylinder reservoir, thoroughly clean the cover before removal.

1. Remove two Phillips screws from cover of master cylinder reservoir. Remove cover (with gasket).

2. Stand the vehicle upright so that the master cylinder reservoir is in a level position. Fluid level should be 1/ 8 inch

(3.2 mm) from the top. Add fluid as necessary.

NOTE

Use only D.O.T. 5 SILICONE HYDRAULIC BRAKE FLUID,

Part No. 99902-77 (12 oz.) or Part No. 99901-77 (gallon).

3. Install cover (with gasket) on the master cylinder reservoir. Install two Phillips screws and tighten to 6-8

(0.7-0.9 Nm).

in-lbs

11WARNING1WARNING

Whenever the brake system is serviced, it should be

tested on dry, clean pavement at slow speeds before putting the motorcycle into regular service. Improperly serviced brakes can lead to an accident that could result in

death or serious injury.

DRIVE BELT

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect drive

belt for damage and proper deflection. Proceed as follows:

1. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Check deflection at the loosest spot in the belt with the

transmission in neutral and the motorcycle cold. Use

BELT TENSION GAUGE (HD-35381A), or install narro

saddle (HD-35381-3) on existing gauge, and apply 10

lbs. (4.5 kg) of force at the midpoint of the bottom belt

strand. See Figure 1-13. Belt deflection should be as follows:

Table 1-4. Belt Deflection

Orientation

On Jiffy Stand

Without Rider or Luggage

10 psi (69 kPa) in Rear Shocks

Motorcycle Upright

With Rear Wheel in the Air

If belt deflection is within specification, install left side

saddlebag. If adjustment is necessary, move to step 3.

3. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

4. Remove right side muffler as follows:

Inches Millimeters

1/4 - 5/16 6.4 - 7.9

3/16 - 1/4 4.8 - 6.4

w

BRAKE PADS AND DISCS

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

brake pads and discs as follows:

Brake Pads

If brake pad friction material is worn to 0.04 inch (1.02 mm) or

less, replace the entire set of pads.

For correct and safe brake operation, brake pads must

be replaced in sets at the same time. Mismatched brake

pads could lead to an accident resulting in death or serious injury.

Brake Discs

The minimum brake disc thickness is stamped on the side of

the disc.

When checking the brake pads and discs, inspect the brake

lines and hoses for damage or leaks.

11WARNING1WARNING

Figure 1-13. Check and Adjust Belt Deflection

2004 Touring: Maintenance 1-21

Page 8

HOME

RIGHT SIDELEFT SIDE

Increase

Belt

Deflection

Reduce

Belt

Deflection

Weld

Weld

Nut

Nub

8398

Figure 1-14. Move Rear Wheel Forward Until Adjuster Cams Just Contact Weld Nubs

a. Open worm drive clamps to remove heat shield

from rear header pipe in front of muffler.

b. Using a bungee cord, tie the muffler to the lower

saddlebag support rail.

c. Loosen TORCA clamp between rear header pipe

and muffer.

d. Remove two bolts (with lockwashers) to detach muf-

fler from the lower saddlebag support rail.

e. Remove bungee cord to release muffler from lower

saddlebag support rail.

5. Standing on right side of vehicle, remove E-clip from

groove at end of axle. Loosen cone nut, and then snug

to 15-20 ft-lbs (20-27 Nm). See Figure 1-14.

6. If belt is too tight, move to step 7 to increase belt deflection. If belt is too loose, reduce belt deflection as

described below:

a. Rotate weld nut on left side of axle in a clockwise

direction.

b. Check belt deflection. Apply 10 lbs. (4.5 kg) of force

at the midpoint of the bottom belt strand. Belt

deflection should be within the range specified in

Ta bl e 1-4.

c. If belt is still too loose, repeat steps 6(a) through

6(b). If belt is now too tight, move to step 7.

7. If belt is too tight, increase belt deflection as follows:

a. Using a hydraulic center stand, raise motorcycle so

that the rear wheel is off the ground.

b. Rotate weld nut on left side of axle in a counter-

clockwise direction.

Cone

Nut

Weld

Nub

E-Clip

Adjuster

8407

Cam

c. Push wheel forward slightly so that adjuster cam

just contacts weld nub on both sides of rear swingarm. See Figure 1-14.

d. Check belt deflection. Apply 10 lbs. (4.5 kg) of force

at the midpoint of the bottom belt strand. Belt

deflection should be within the range specified in

Ta ble 1-4.

e. If belt is still too tight, repeat steps 7(b) through 7(d).

If belt is now too loose, move to step 6.

8.

Holding

weld nut on left side of axle, tighten cone nut on

right side to 95-105 ft-lbs (128.8-142.4 Nm).

NOTE

If the axle moves during tightening of the cone nut, then the

the belt deflection procedure must be restarted.

9. Recheck belt deflection to verify that it is still within specification.

If the belt deflection is not within specification, loosen

cone nut and then snug to 15-20 ft-lbs (20-27 Nm)

before returning to step 6.

10. With the flat side out, install

new

E-clip in groove on right

side of axle.

11. Install right side muffler as follows:

NOTE

TORCA muffler clamps have eliminated the need for silicone

or graphite tape during assembly. To ensure sealing integrity

of muffler clamps and prevent the possibility of leakage, Harley-Davidson recommends that TORCA clamp assemblies be

discarded and replaced each time they are removed.

a. Slide

new

TORCA clamp onto free end of rear

header pipe.

1-22 2004 Touring: Maintenance

Page 9

HOME

CAUTION

b. Using a bungee cord, tie muffler to lower saddlebag

support rail. Install muffler on rear header pipe.

Place TORCA clamp into position between rear

header pipe and muffler.

c. Tighten the two bolts (with lockwashers) to fasten

the muffler to the lower saddlebag support rail.

CAUTION

Verify that the exhaust pipes do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

d. Verify that exhaust pipes are in alignment and do

not contact the vehicle frame or mounted components.

e. Tighten the TORCA clamp to 45-60 ft-lbs (61-81

Nm).

f. Open worm drive clamps and install heat shield on

rear header pipe. Position clamp so that screw is on

the outboard side in the most accessible position.

CAUTION

Verify that the heat shields do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

g. Remove bungee cord from muffler.

12. Install saddlebags. See Section 2.25 SADDLEBAG,

INSTALLATION.

REAR SHOCK ABSORBERS

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

rear shock absorbers for signs of leakage or damage, and

replace if necessary. For adjustment of rear air suspension

pressures, see Section 2.18 REAR AIR SUSPENSION.

AIR CLEANER

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

air cleaner filter element, and clean or replace as necessary.

1. Remove large allen head socket screw in center of air

cleaner cover. Remove air cleaner cover with rubber

seal. See Figure 1-15.

2. Remove three T27 TORX screws to release cover

bracket from filter element.

Never run the engine with the filter element removed.

The filter prevents dirt and dust from entering the

engine.

3. Remove filter element pulling two breather tubes from

holes on inboard side.

4. Remove gasket from sleeve on inboard side of filter element. Discard gasket.

5. Remove breather tubes from fittings on two cylinder

head breather bolts.

6. Remove two cylinder head breather bolts from backplate

using a 7/16 inch deepwell socket.

Gasket

O-Ring

Cylinder Head

Breather Bolt

Backplate

Breather

Tube

Cover

Bracket

Gasket

Filter

Element

Figure 1-15. Air Cleaner Assembly

f1650x4x

T27 Torx

Screw

2004 Touring: Maintenance 1-23

Air Cleaner

Cover

Cover Screw

Page 10

HOME

7. Remove backplate from cylinder heads. On carbureted

California models, pull clean air inlet tube (to charcoal

canister) from hole on inboard side of backplate.

8. Remove two O-rings from grooves around breather bolt

holes on inboard side of backplate. Discard O-rings.

9. Remove gasket from inboard side of backplate. Discard

gasket.

10. Thoroughly clean air cleaner cover and backplate.

11. Replace the filter element if damaged or if filter media

cannot be adequately cleaned.

12. Wash the filter element and breather tubes in warm,

soapy water. To remove soot and carbon, soak element

for 30 minutes in warm water with mild detergent.

11WARNING1WARNING

Do not use gasoline or solvents to clean the filter element. Volatile or flammable cleaning agents may cause

an intake system fire, which could result in death or serious injury.

11WARNING1WARNING

Compressed air can pierce the skin and cause injury.

Never use your hand to check for leaks or to determine

air flow rates. Wear safety glasses to shield your eyes

from flying dirt and debris. Failure to comply could result

in death or serious injury.

13. Dry the filter element using low pressure compressed air

(32 psi/221 kPa maximum). Rotate the element while

moving air nozzle up and down the element interior. Do

not rap the element on a hard surface.

14. Hold the filter element up to a strong light source. The

element can be considered sufficiently clean if light is

uniformly visible through the media.

15. Inspect the breather tubes for cuts, tears, holes or signs

of deterioration. Replace as necessary. Direct compressed air through the breather tubes to verify that they

are not plugged.

16. Install

17. Aligning flat edge of gasket with molded tab, install

18. On California models, push clean air inlet tube (to char-

19. Align holes in backplate with those in cylinder heads and

20. Slide

new

O-rings in grooves around breather bolt

holes on inboard side of backplate.

new

gasket on inboard side of backplate. On California models, install gasket by aligning small holes with plastic

pins.

coal canister) into hole on inboard side of backplate.

install cylinder head breather bolts. Using a 7/16 inch

deepwell socket, alternately tighten bolts to 10-12 ft-lbs

(13.6-16.3 Nm).

new

gasket over sleeve on inboard side of filter

element. Be sure holes in gasket are aligned with those

in filter.

21. Insert breather tubes about 1/4 inch (6.4 mm) into holes

on inboard side of filter element.

22. Install breather tubes onto fittings of two cylinder head

breather bolts.

NOTE

Air cleaner mounting without installation of the breather

tubes allows crankcase vapors to be vented into the atmosphere in violation of legal emissions standards.

23. Place filter element onto backplate with the flat side

down, so that hole on inboard side of element fits over

molded boss in backplate.

24. Align holes in cover bracket with those in filter element

and start three T27 TORX screws. Stamp on cover

bracket points to downside. Alternately tighten screws to

20-40

in-lbs

(2.3-4.5 Nm) in a crosswise pattern.

25. Verify that rubber seal is properly seated around perime-

ter of air cleaner cover. Replace seal if cut, torn or shows

signs of deterioration.

26. Fit air cleaner cover into backplate. Apply a small dab of

Loctite Medium Strength Threadlocker 243 (blue) to

threads of large allen head socket screw. Install screw in

center of air cleaner cover. Tighten screw to 36-60

(4.1-6.8 Nm).

in-lbs

FUEL SYSTEM LINES AND FITTINGS

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

fuel system lines and fittings for leaks or damage.

FUEL TANK FILTER (CARBURETED)

At every 25,000 mile (40,000 km) service interval, remove

and inspect the fuel tank filter as follows:

11WARNING1WARNING

Gasoline is extremely flammable and highly explosive.

When servicing the fuel system, do not smoke or allow

open flame or sparks in the vicinity. Inadequate safety

precautions could result in death or serious injury.

1. Turn the handle of the fuel valve to OFF.

11WARNING1WARNING

A small amount of gasoline may drain from the carburetor fuel inlet hose when disconnected from the fuel valve

fitting. Thoroughly wipe up any spilled fuel immediately

and dispose of rags in a suitable manner. Gasoline is

extremely flammable and highly explosive. Inadequate

safety precautions could result in death or serious

injury.

1-24 2004 Touring: Maintenance

Page 11

HOME

11WARNING1WARNING

CAUTION

f1960x4x

Filter

Strainer

Carburetor

Fuel Inlet

Hose

Convoluted

Tubing

Figure 1-16. Vacuum Operated Fuel Valve

2. Using a side cutters, cut clamp and remove hose from

fuel outlet fitting at the front of the fuel valve. See Figure

1-16. Drain free end of hose into a suitable container.

3. Remove elbow of intake manifold vacuum tube from fitting on inboard side of the fuel valve.

4. Attach a length of fuel hose to the fuel outlet fitting. The

hose must be long enough to reach a suitable gasoline

container.

5. Turn the handle of the fuel valve to RES(ERVE).

6. Using the correct hose adapter, connect the Mity-Vac®

Hand Pump (HD-23738A) to the vacuum fitting.

To avoid damage to the diaphragm of the fuel valve, do

not apply a vacuum greater than 25 inches of Mercury

(Hg) to the vacuum fitting.

7. Gently apply a vacuum of 1-10 inches of Mercury (Hg) to

the vacuum fitting to get a good flow of gasoline through

the valve.

Clamp

Fuel

Outlet

Fitting

Hose

CAUTION

Jam

Nut

Gasket

Valve

Handle

Vacuum

Fitting

Atmospheric

Pressure

Port

8. When the fuel tank is completely drained, remove the

Mity-Vac® Hand Pump from the vacuum fitting.

9. Holding fuel tank adapter, turn the hex jam nut in a

clockwise direction to remove the fuel valve assembly.

10. Remove the fuel filter strainer from the valve head.

Clean or replace.

11. Remove the hex jam nut from the fuel valve.

12. Remove the gasket from the valve head. Discard the

gasket.

13. Install a

14. Install the fuel filter strainer fitting the internal tube into

the larger hole in the valve head.

15. Apply Loctite Pipe Sealant with Teflon 565 to threads of

fuel valve and fuel tank adapter.

16. With the hex side down, turn the jam nut two full turns in

a counterclockwise direction to thread onto fuel tank

adapter.

17. Insert fuel filter strainer into fuel tank. Holding the hex

jam nut to prevent rotation, turn the fuel valve two full

turns in a clockwise direction to thread onto hex jam nut.

Do not thread fuel valve onto hex jam nut more than two

turns or nut may “bottom” on valve, a condition which

may result in a gasoline leak. Any gasoline leak is a

potential fire hazard that could result in death or serious

injury.

18. Holding the fuel valve to prevent rotation, turn the hex

jam nut in a counterclockwise direction until snug.

Tighten the hex jam nut to 15-20 ft-lbs (20.3-27.1 Nm).

Do not allow dirt or fluids to get into the vacuum tube

that connects the fuel valve to the intake manifold. Contaminants can block the vacuum signal which could

cause the fuel valve to malfunction.

19. Connect elbow of intake manifold vacuum tube to fitting

on inboard side of the fuel valve.

20. Slide

hose. Install hose onto fuel outlet fitting at front of fuel

valve. Crimp clamp using HOSE CLAMP PLIERS (HD97087-65B).

21. Turn the handle of the fuel valve to OFF and fill the fuel

tank. Carefully inspect for leaks at fitting.

22. Turn the valve handle to ON and start engine. No priming or special procedures are required to start fuel flow.

Carefully inspect for leaks at fitting.

23. Stop engine and return the valve to the OFF position.

new

gasket on the valve head.

new

clamp onto free end of carburetor fuel inlet

2004 Touring: Maintenance 1-25

Page 12

HOME

f1438x4x

Enrichener

Knob

Knurled

Nut

Mounting

Bracket

Figure 1-17. Enrichener Control

Flat

Lockwasher

Hex

Nut

Enrichener

Cable

ENRICHENER CONTROL

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

enrichener control as follows:

The fuel enrichener knob should open, remain open and then

close without binding. The knurled plastic nut next to the

enrichener knob controls the ease at which the cable slides

within the conduit.

f1225x2x

Cardboard

Figure 1-18. Install Cardboard Insert

Ferrule

5/32 Inch

(4.0 mm)

Insert

Notch

Groove

If adjustment is needed, proceed as follows:

1. See Figure 1-17. Loosen hex nut at backside of mounting bracket.

2. Move cable assembly free of slot in mounting bracket.

3. Hold cable assembly at flat with adjustable wrench.

Hand turn knurled nut counterclockwise to reduce sliding

resistance until knob slides inward unaided.

4. Turn knurled nut clockwise to increase sliding resistance

until knob remains fully out without holding and then

closes with relative ease.

5. Slide enrichener cable into slot of mounting bracket.

With external tooth lockwasher and hex nut positioned

on the inboard side of the mounting bracket, tighten hex

nut to 20-35

Do not lubricate the cable or inside of conduit. The cable

must have sliding resistance to work properly.

in-lbs

(2.3-4.0 Nm).

CAUTION

THROTTLE CABLES

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect and

lubricate the throttle and clutch cables as follows:

Idle

Cable

f1474x2x

Figure 1-19. Remove Throttle/Idle Cables

Throttle

Grip

Throttle

Cable

Lubrication

CAUTION

Do not remove the switch housing assembly without first

placing the 5/32 inch (4.0 mm) cardboard insert between

the brake lever and lever bracket. Removal without the

insert may result in damage to the rubber boot and

plunger of the Front Stoplight Switch.

NOTE

Use the eyelet of an ordinary cable strap if the cardboard

insert is not available.

1. Place the cardboard insert between the brake lever and

lever bracket. See Figure 1-18.

1-26 2004 Touring: Maintenance

Page 13

HOME

f1376b2x

Throttle Control

Grip

Jam Nut

Throttle Cable

Adjuster

Idle Cable

Adjuster

Tension

Adjuster

Screw

Insert

Lubricant

Here

7958

Figure 1-20. Lubricate Throttle/Idle Cables

2. Using a T25 TORX drive head, remove the upper and

lower switch housing screws.

3. Using a T27 TORX drive head, loosen the upper screw

securing the handlebar clamp to the master cylinder

housing. Remove the lower clamp screw with flat

washer.

4. Remove the brass ferrules from the notches on the

inboard side of the throttle control grip. Remove the ferrules from the cable end fittings. See Figure 1-19.

NOTE

On non cruise equipped models, remove the friction shoe

from the end of the tension adjuster screw. The friction shoe

is a loose fit and may fall out or become dislodged if the lower

switch housing is turned upside down or shaken.

5. Remove the throttle control grip from the end of the han-

dlebar.

6. Move upper switch housing to the side in order to access

lower housing.

9. Apply a light coating of graphite to the handlebar.

10. Slide the throttle control grip over the end of the right

handlebar until it bottoms against the closed end. Rotate

the grip so that the ferrule notches are at the top. To prevent binding, pull the grip back about 1/8 inch (3.2 mm).

11. Position the lower switch housing beneath the throttle

control grip. Install the brass ferrules onto the cables so

that the end fittings seat in the ferrule recess. Seat the

ferrules in their respective notches on the throttle control

grip. Verify that the cables are captured in the grooves

molded into the grip. See Figure 1-19.

12. Position the upper switch housing over the handlebar

and lower switch housing. Verify that the wire harness

conduit runs in the depression at the bottom of the handlebar.

13. Start the upper and lower switch housing screws, but do

not tighten.

14. Position the brake lever/master cylinder assembly

inboard of the switch housing assembly engaging the

tab on the lower switch housing in the groove at the top

of the brake lever bracket.

15. Align the holes in the handlebar clamp with those in the

master cylinder housing and start the lower screw (with

flat washer). Position for rider comfort. Beginning with

the top screw, tighten the screws to 60-80

in-lbs

(6.8-9.0

Nm) torque using a T27 TORX drive head.

16. Using a T25 TORX drive head, tighten the lower and

upper switch housing screws to 35-45

in-lbs

(4-5 Nm).

NOTE

Always tighten the lower switch housing screw first so that

any gap between the upper and lower housings is at the front

of the switch assembly.

1CAUTION

Lubit-8 Tufoil Chain and Cable Lube contains detergents.

Avoid contact with eyes. Keep out of reach of children.

7. Obtain tube of Lubit-8 Tufoil Chain and Cable Lube (HD

Part No. 94968-85TV- 1/4 fl. oz.). Insert pin of tube

between throttle cable and cable housing inside lower

switch housing. Squeeze tube to squirt a quantity of

lubricant into cable housing moving pin around cable

OD. See Figure 1-20.

8. Repeat the procedure squirting a quantity of lubricant

between the idle cable and cable housing.

On non cruise equipped models, install the friction shoe with

the concave side up so that the pin hole is over the point of

the adjuster screw. The friction shoe is a loose fit and may fall

out or become dislodged if the lower switch housing is turned

upside down or shaken.

NOTE

Figure 1-21. Throttle Cable Assembly - Throttle Side

(FLHR/S)

2004 Touring: Maintenance 1-27

Page 14

HOME

Throttle

Cable Guide

Barrel End

Stop Plate

Figure 1-22. Throttle Cable Assembly - Carburetor Side

Throttle

Cam Stop

Throttle

Wheel

Idle

Cable Guide

Cable

Cable

Housing

Spring

f1381a2x

17. Remove the cardboard insert between the brake lever

and lever bracket.

18. Turn the Ignition/Light Key Switch to IGNITION and

apply brake lever to test operation of brake lamp.

Adjustment

NOTE

For throttle and idle cable adjustment on cruise equipped

models, see Section 8.30 CRUISE CONTROL (FLHRC,

FLTR, FLHTCU).

1. Slide rubber boot off throttle cable adjuster. See Figure

1-21. Holding cable adjuster with a 3/8 inch wrench,

loosen jam nut turning in a clockwise direction. Back jam

nut away from cable adjuster until it stops. Turn adjuster

clockwise until it contacts jam nut. Repeat procedure on

idle cable adjuster.

2. Point the front wheel straight ahead. Turn the throttle

control grip so that the throttle is wide open (fully counterclockwise) and then hold in position. Now turn the

throttle cable adjuster counterclockwise until the throttle

cam stop just touches the stop plate on the carburetor.

See Figure 1-22. Tighten jam nut against the throttle

cable adjuster and then release the throttle control grip.

Cover cable adjuster mechanism with rubber boot.

3. Turn the front wheel full right. Turn the idle cable adjuster

counterclockwise until the cable housing just touches

the spring in the longer cable guide. Work the throttle

grip to verify that the throttle cable returns to the idle

position when released. If the cable does not return to

idle, turn the adjuster clockwise slightly until the correct

response is achieved. Tighten jam nut against the idle

cable adjuster and cover cable adjuster mechanism with

rubber boot.

4. Verify that the throttle control operates freely without

binding. With the tension adjuster screw backed off, the

throttle control grip must freely return to the closed (idle)

position. The throttle control also must open and close

freely when the front wheel is turned to both the right

and left fork stops.

If the throttle grip does not return to the idle position

freely, check the adjuster screw tension. If the adjuster

screw is backed off, inspect the cables for short bends.

SPARK PLUGS

Inspect the spark plugs at every 5000 mile (8,000 km) service interval. Replace the spark plugs at every 10,000 mile

(16,000 km) service interval. Proceed as follows:

1-28 2004 Touring: Maintenance

Page 15

HOME

f1381d2x

Throttle

Stop Screw

The HD-6R12 plug has a resistor element to reduce radio

interference originating in the motorcycle ignition system.

Only resistor type plugs should be used with the electronic

ignition system.

Table 1-5. Spark Plug Data

SIZE 12 mm

GAP 0.038-0.043 in. (0.97-1.09 mm)

TYPE HD-6R12 (No Substitute)

1. Remove plugs and examine immediately. The deposits

on the plug base are an indication of the plug efficiency

and are a guide to the general condition of rings, valves,

carburetor and ignition system.

a. A wet black and shiny deposit on plug base, elec-

trodes and ceramic insulator tip indicate an oil

fouled plug. The condition may be caused by worn

rings and pistons, loose valves, weak battery or

faulty ignition.

b. A dry fluffy or sooty black deposit indicates a too

rich carburetor air/fuel mixture or long periods of

engine idling.

c. An overheated plug can be identified by a light

brown, glassy deposit. This condition may be

accompanied by cracks in the insulator or by erosion of the electrodes. This condition is caused by

too lean an air/fuel mixture, a hot running engine,

valves not seating or improper ignition timing. The

glassy deposit on the spark plug is a conductor

when hot and may cause high speed misfiring. A

plug with eroded electrodes, heavy deposits or a

cracked insulator should be replaced.

d. A plug with a white, yellow or light tan to rusty brown

powdery deposit indicates balanced combustion.

The deposits may be cleaned off at regular intervals

if desired.

2. Set the spark plug gap using a wire-type gauge. Bend

the outside of the electrode so only a slight drag on the

gauge is felt when passing it between electrodes. Never

make adjustments by bending the center electrode. Set

gap on all plugs at 0.038-0.043 in. (0.97-1.09 mm)

3. Before installing spark plugs, check condition of threads

in cylinder head and on plug. If necessary soften deposits with penetrating oil and clean out with a thread

chaser.

4. Install spark plug finger tight and then torque to 12-18 ftlbs (16-24 Nm).

ELECTRICAL COMPONENTS

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

operation of all electrical components and switches.

Figure 1-23. Idle Speed Adjustment

ENGINE IDLE SPEED

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

engine idle speed as follows:

NOTES

●

The C.V. carburetor has an enrichener circuit that will

cause the engine to idle at approximately 1500 rpm with

the engine at normal operating temperature and the

enrichener knob pulled fully out.

The increase in idle speed is intended to alert the rider

●

that the engine is warmed up to normal operating temperature and the enrichener knob should be pushed all

the way in.

Continuing to use the enrichener when the engine is at

●

full operating temperature WILL CAUSE FOULED

PLUGS.

●

TECHNICIAN – Be sure the engine is warmed up to normal operating temperature and the enrichener knob is

pushed all the way in BEFORE adjusting engine idle

speed. Be aware that because there are variations in

individual components, it is possible for a properly

warmed up engine to idle at 2000 rpm with the

enrichener knob pulled PARTIALLY OUT.

1. See Figure 1-23. With the engine at normal operating

temperature and the enrichener all the way in

(enrichener valve closed) adjust the throttle stop screw

so the engine idles at 950-1050 rpm.

2004 Touring: Maintenance 1-29

Page 16

HOME

NOTE

To me asure engine rpm on models without tachometers, use

a test tachometer connected to the negative ignition coil terminal.

CRITICAL FASTENERS

At the 1000 mile (1600 km) service interval, and at every

10,000 mile (16,000 km) service interval thereafter, inspect

the tightness of all critical fasteners. Replace fastener if damaged or missing.

Table 1-6. Critical Fastener Torque

Axle

Front axle nut 50-55 ft-lbs 68-75 Nm

Rear axle cone nut 95-105 ft-lbs 129-142 Nm

Brakes

Banjo Bolts 17-22 ft-lbs 23-30 Nm

Front Brake Disc Mounting

Screws

Front Brake Caliper Mounting

Bolts

Brake Caliper Pad Pins 180-200 in-lbs 20-23 Nm

Rear Brake Disc Mounting

Screws

Rear Master Cylinder Mounting

Nut

Reservoir Cover Screws 6-8 in-lbs 0.7-0.9 Nm

Front Forks

Axle Holder Nuts 132-180 in-lbs 14.9-20.3 Nm

Hand Controls

Clutch Lever/Handlebar Clamp 60-80 in-lbs 6.8-9.0 Nm

Master Cylinder/Handlebar

Clamp Screws

Upper/Lower Switch Housing

Screws

Handlebars

Lower Clamp (Riser) Bolts 30-40 ft-lbs 40.7-54.2 Nm

Pivot Shaft

Locknuts 40-45 ft-lbs 54-61 Nm

Swingarm Bracket Bolts 34-42 ft-lbs 46-57 Nm

Fastener ft/in-lbs Nm

16-24 ft-lbs 22-33 Nm

28-38 ft-lbs 38-52 Nm

30-45 ft-lbs 41-61 Nm

30-40 ft-lbs 41-54 Nm

60-80 in-lbs 6.8-9.0 Nm

35-45 in-lbs 4-5 Nm

ENGINE MOUNTS

At every 10,000 mile (16,000 km) service interval, inspect the

condition and tightness of the stabilizer links and engine

mounts. Proceed as follows:

NOTE

Raise fuel tank to access top engine stabilizer bolts and jam

nuts. For carbureted models, see Section 4.7 FUEL TANK

(CARBURETED), PARTIAL REMOVAL, FLHT/C, or FLHR/S.

For fuel injected models, see Section 9.4 FUEL TANK (FUEL

INJECTED), PARTIAL REMOVAL, FLHT/C/U/I, FLTRI, or

FLHR/C/S/I.

Top

On left side of vehicle, tighten top engine mounting

●

bracket bolts to front and rear cylinder heads to 35-40 ftlbs (48-54 Nm). See A of Figure 1-24.

●

To p stabilizer link - tighten eyelet bolt to top engine

mounting bracket to 18-22 ft-lbs (24-30 Nm). See B of

Figure 1-24.

●

Moving to right side of vehicle, tighten eyelet bolt to

frame weldment to 18-22 ft-lbs (24-30 Nm). See C of Fig-

ure 1-24.

Verify tightness of jam nuts on top stabilizer link.

●

Bottom

●

Front stabilizer link - on left side of vehicle, tighten eyelet

bolt to frame weldment to 18-22 ft-lbs (24-30 Nm). See D

of Figure 1-24.

●

Moving to right side of vehicle, tighten eyelet bolt to

block on front engine mounting bracket to 18-22 ft-lbs

(24-30 Nm). See E of Figure 1-24.

●

Verify tightness of jam nuts on front stabilizer link.

● Tighten center front engine mounting bracket to rubber

mount bolt to 15-20 ft-lbs (20-27 Nm). See F of Figure 1-

24.

● Tighten the two front engine mount to frame crossmem-

ber bolts to 15-20 ft-lbs (20-27 Nm). See G of Figure 1-

24.

● Tighten two engine to front engine mounting bracket

bolts to 33-38 ft-lbs (45-52 Nm). See H of Figure 1-24.

● Tighten four engine to transmission bolts to 30-35 ft-lbs

(41-48 Nm).

NOTE

Install fuel tank. For carbureted models, see Section 4.7

FUEL TANK (CARBURETED), INSTALLATION (AFTER

PA RTIAL REMOVAL), FLHT/C, or FLHR/S. For fuel injected

models, see Section 9.4 FUEL TANK (FUEL INJECTED),

INSTALLATION (AFTER PARTIAL REMOVAL), FLHT/C/U/I,

FLTRI, or FLHR/C/S/I.

1-30 2004 Touring: Maintenance

Page 17

HOME

B

C

A

LEFT SIDE RIGHT SIDE

Top Stabilizer Link and Engine Mounting Bracket

f2111x2xf2181x2x

H

Front Engine

Mounting Bracket

T

op

ATop Engine Mounting Bracket to Cylinder Heads

BEyelet to Top Engine Mounting Bracket

CEyelet to Frame Weldment

F

Front Stabilizer Link and Engine Mounting Bracket

Jam Nut

E

D

Front

Stabilizer Link

G

Bottom

DEyelet to Frame Weldment

EEyelet to Front Engine Mounting Bracket

FFront Engine Mounting Bracket to Rubber Mount

GFront Engine Mount to Frame Crossmember

H Engine to Front Engine Mounting Bracket

f1303x2x

Figure 1-24. Engine Mounting Bracket Bolts

2004 Touring: Maintenance 1-31

Page 18

HOME

FRONT FORK OIL

Overhaul the front fork assembly and replace the fork oil at

every 50,000 mile (80,000 km) service interval. For detailed

instructions, see Section 2.15 FRONT FORKS.

ROAD TEST

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, perform a

road test after all work is complete.

1-32 2004 Touring: Maintenance

Loading...

Loading...