Page 1

HOM

CAUTION

f1603x3x

E

TOP END OVERHAUL 3.9

DISASSEMBLY

1. Use low pressure spray to thoroughly clean exterior surfaces of engine prior to disassembly. Dirt caked on cooling fins and other areas can fall into crankcase bore or

stick to subassemblies as parts are removed. Abrasive

particles can damage machined surfaces or plug oil passageways.

NOTE

Rocker cover and rocker housing bolts have both an internal

and external hex, which allows the bolts to be removed with

either a short 3/16 inch allen wrench (tight spaces), or a 7/16

inch socket or open end/box wrench (open spaces). See Fig-

ure 3-20. The internal hex is necessary if the engine is left in

the chassis for service. In these cases, the short 3/16 inch

allen wrench is indispensable when removing the rocker

cover and rocker housing bolts on the left side of the engine

(particularly the rear) where there is close proximity to the

frame. A dimple or cavity cast into the left side of the upper

frame crossmember also aides in removing the rocker arm

support plate assembly.

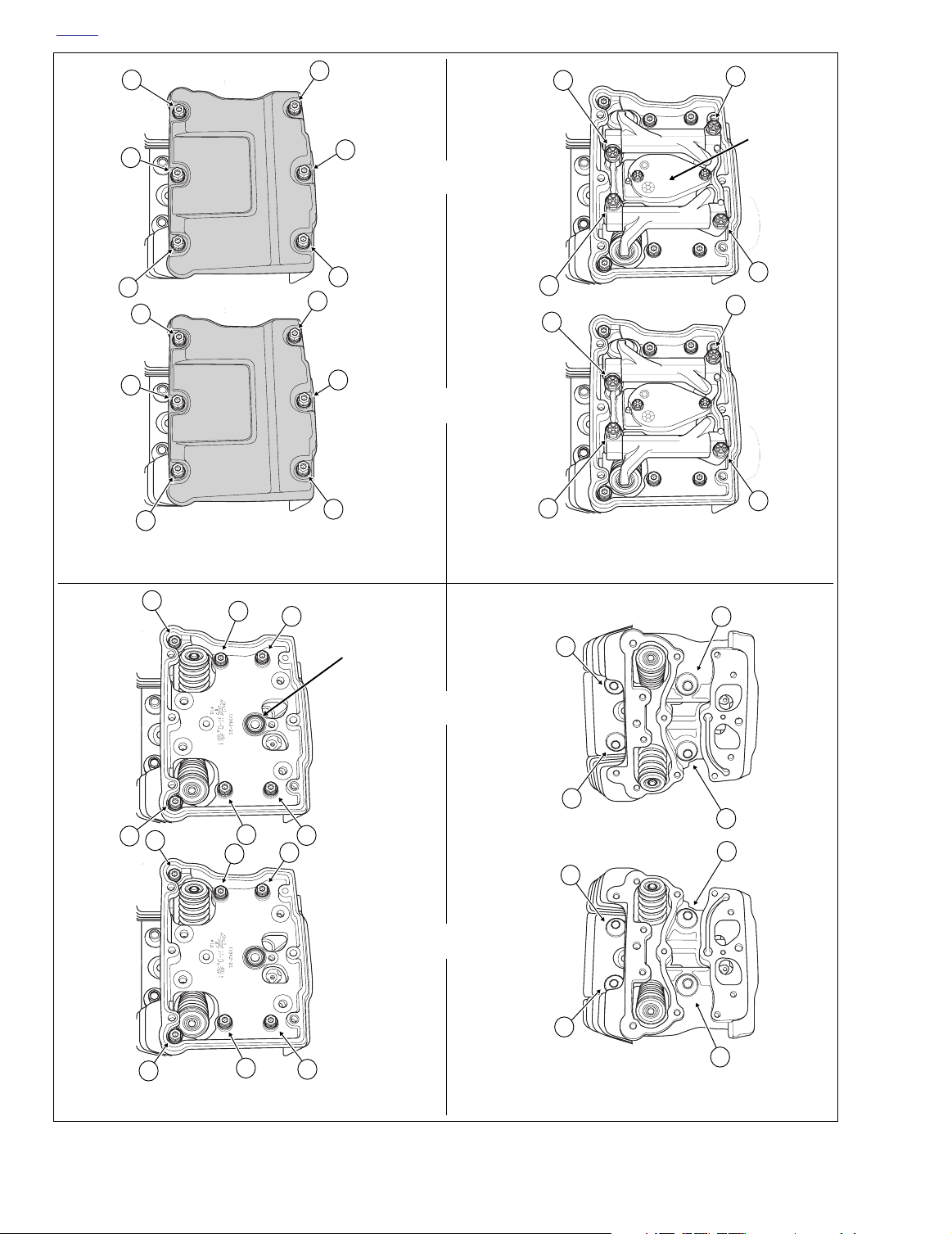

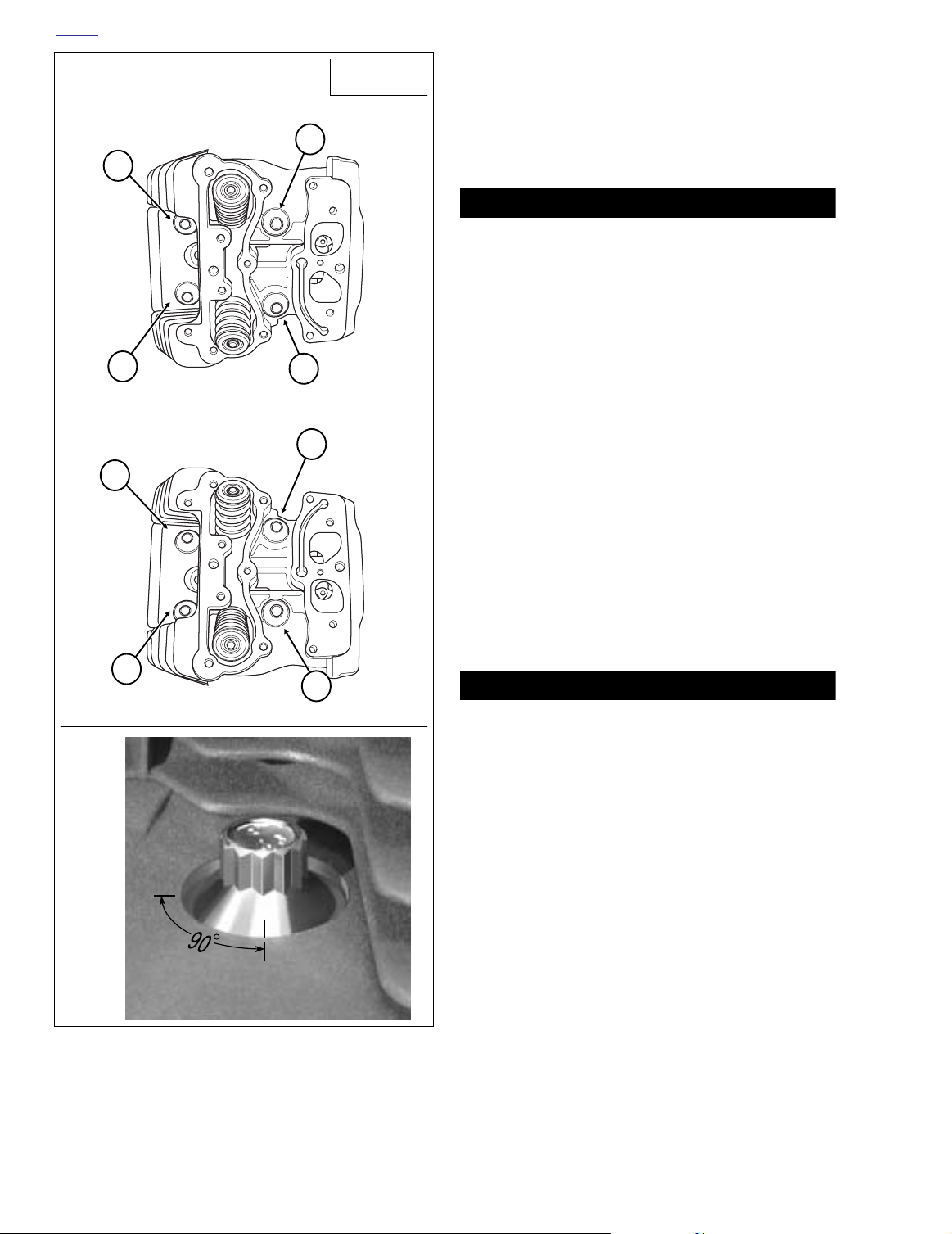

2. Alternately loosen the six rocker cover bolts following the

pattern shown in A of Figure 3-22. Remove the rocker

cover bolts.

NOTE

It is assumed that each step performed on one cylinder is

automatically repeated on the other.

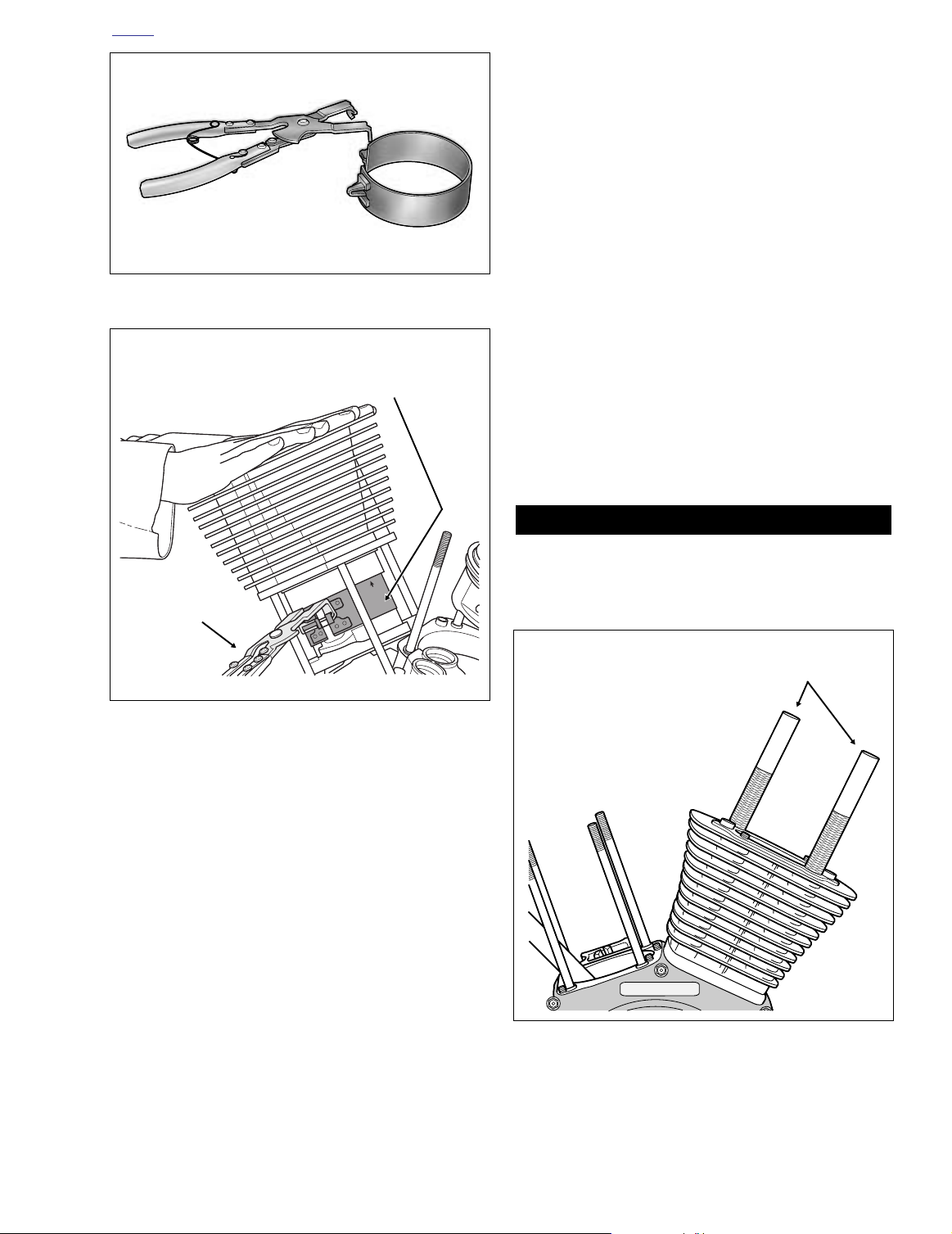

4. Insert the blade of a small screwdriver into cast loop of

5. Collapse upper and lower push rod covers.

6. To remove the rocker arm support plate,

Figure 3-21. Remove Spring Cap Retainer

spring cap retainer (at top of upper push rod cover), and

while pushing down on spring cap, rotate bottom of

screwdriver toward outboard side to remove. See Figure

3-21. Repeat step on second push rod cover.

both

lifters of

the cylinder being serviced must be on the base circle

(or lowest position) of the cam.

3. Remove the rocker cover and gasket. Discard the gasket.

Internal Hex

3/16 Inch Allen Wrench

External Hex

7/16 Inch Open End Wrench

Figure 3-20. Rocker Cover Bolt (1-1/4 Inch)

Captive

Washer

Lock Patch

f1570x3x

Removing the rocker arms with the valve train loaded

can result in bent push rods, damaged bushings or

warped support plate.

To find the base circle, it is first necessary to rotate the

engine. Based on the level of disassembly required,

three methods of engine rotation are presented below.

a. With pr

b. With pr

imary cover installed - With vehicle on center

stand, place the transmission in 5th gear and rotate

rear wheel in a clockwise direction (as viewed from

right side) until the base circle is found. See step

6(d) to find the base circle.

imary cover removed - Remove primary

cover. Place the transmission in neutral. Fit a 1-1/2

inch socket on the compensating sprocket shaft nut.

Rotate nut in a counterclockwise direction until the

base circle is found. See step 6(d) to find the base

circle.

2004 Touring: Engine 3-33

Page 2

HOM

E

f2164x3x

A

5

1

3

3

1

5

Loosen Six Rocker Cover Bolts.

4

6

3

1

2

f2163x3x

Breather

Assembly

FRONT

6

2

4

4

2

2

REAR

4

B

1

Remove Two Breather Assembly Bolts.

Alternately Loosen Four Rocker Arm Bolts

1/4 Turn in Pattern Shown.

3

f2165x3x

2

6

4

O-Ring

2

4

f2166x3x

FRONT

1

3

3

3

5

5

1

1

1

3

REAR

2

2

Loosen Six Rocker Housing Bolts.

CD

6

4

Alternately Loosen Four Cylinder Head

Bolts 1/4 Turn in Pattern Shown.

4

3-34 2004 Touring: Engine

Figure 3-22. Top End Disassembly

Page 3

HOM

CAUTION

E

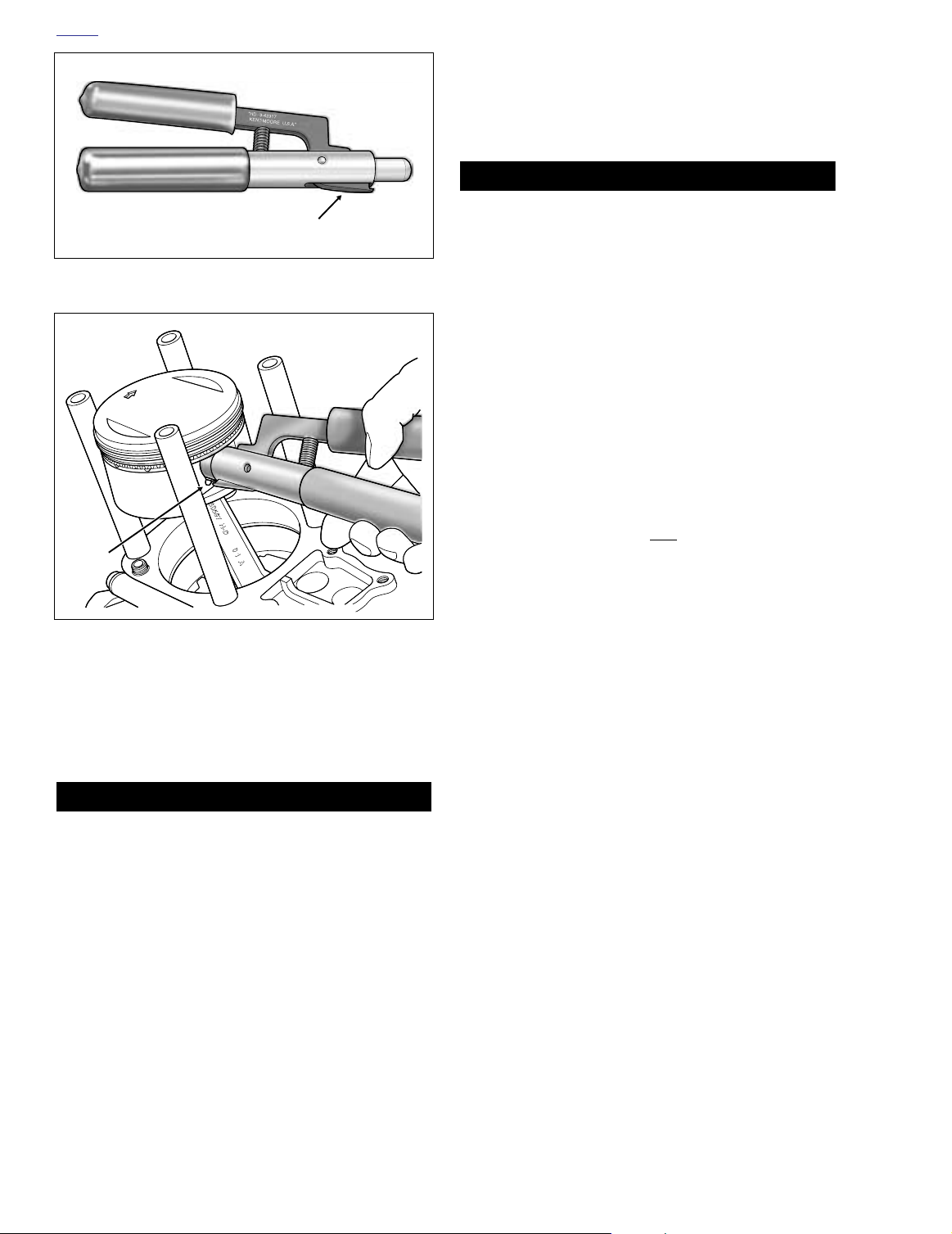

f1527x3x

Figure 3-23. Sprocket Shaft Engine Rotation Tool

CAUTION

Do not attempt to rotate engine by removing cam cover

and placing socket on crank or primary cam sprocket

flange bolt. Head of flange bolt can break off possibly

resulting in damage to flywheel or camshaft.

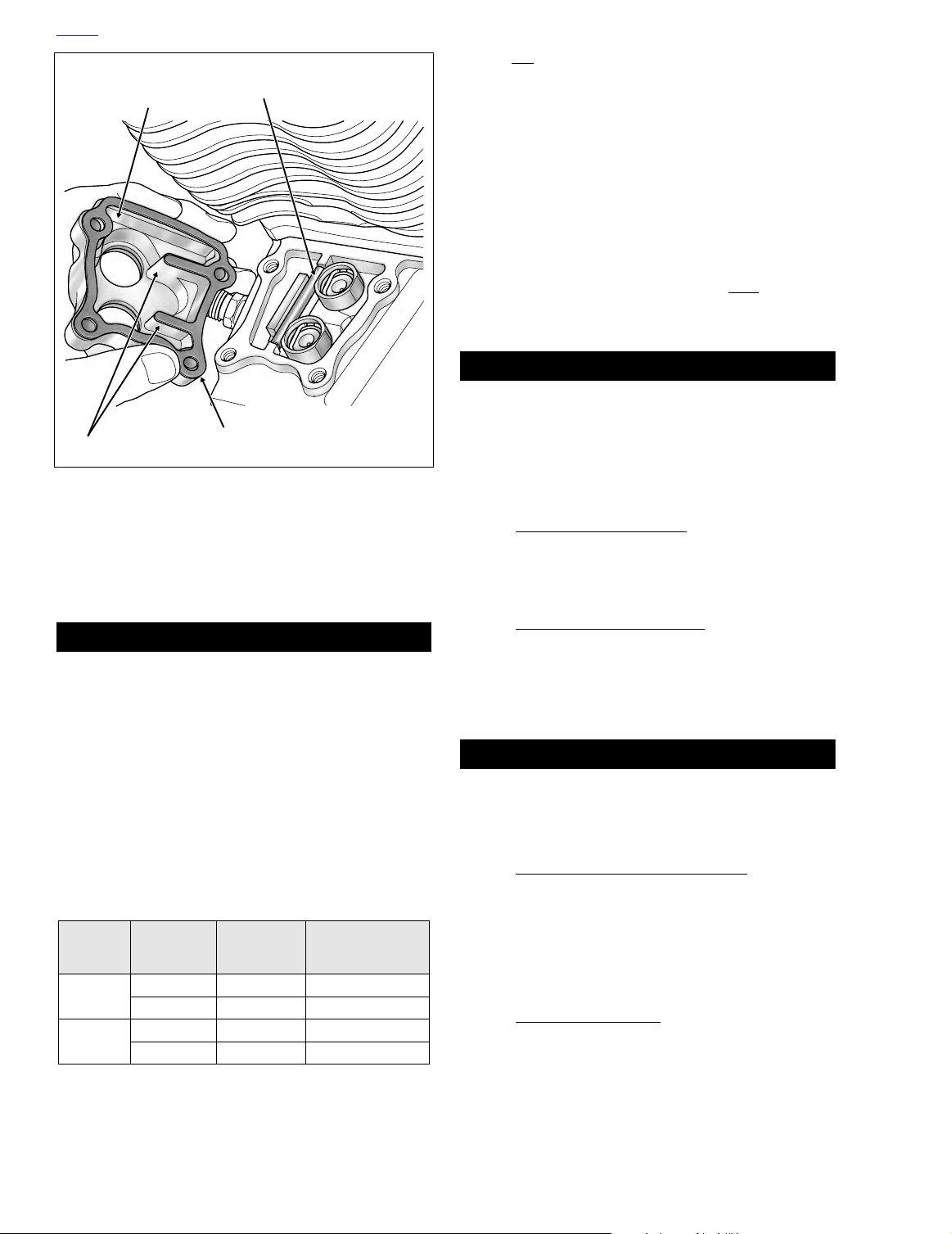

c. With engine mounted in engine stand

- Fashion tool

as follows: Obtain used or discarded compensating

sprocket shaft extension (HD-40266-85). Weld a 13/

16 inch socket with a 1/2 inch drive to outboard side

of extension. See Figure 3-23. Install tool on

sprocket shaft and rotate in a counterclockwise

direction until the base circle is found. See step 6(d)

to find the base circle.

d. Finding the base circle

: Using one of the methods

above, rotate engine until piston is at Top Dead

Center (TDC) of compression stroke. To accomplish

this, first raise lower push rod cover to access intake

lifter (inside hole of lifter cover). Place index finger

on top of the intake lifter. While rotating engine, feel

lifter rise (valve open) and fall (valve closed). Now

place finger tightly over spark plug hole and rotate

engine again. In the compression stroke, air will be

forced out against your finger until the piston

reaches the TDC position. Stop engine rotation

when the flow of air through the spark plug hole

stops. Direct the beam of a small flashlight into

spark plug hole to verify piston is at TDC. Both

intake and exhaust valves are now closed and the

push rods are in the unloaded position (and should

turn freely).

7. Remove two bolts to release breather assembly from the

rocker arm support plate. See B of Figure 3-22. See

Section 3.11 SUBASSEMBLY SERVICE AND REPAIR,

BREATHER ASSEMBLY.

8. Alternately loosen each of the four rocker arm support

plate bolts just 1/4 turn following the pattern shown in B

of Figure 3-22. Continue turning the bolts in these

increments until loose.

9. When the rocker arm support plate bolts are free of the

cylinder head, lift the support plate assembly from the

rocker housing. See Section 3.11 SUBASSEMBLY SER-

VICE AND REPAIR, ROCKER ARM ASSEMBLY.

NOTE

Always service each cylinder separately. After the first cylinder is serviced the engine must be rotated to find the base

circle on the second cam. Service on the remaining cylinder

can then proceed.

10. Remove the intake and exhaust push rods. Tag the push

rods as they are removed, so that they can be installed

in their original locations. Also take note of their orientation to be able to discern top from bottom at time of

installation.

11. Remove push rod covers from cylinder head and lifter

cover bores. Remove three O-rings from push rod covers and discard. If O-ring is missing from upper push rod

cover, be sure to dislodge it from the cylinder head bore.

12. Using a crosswise pattern, remove the four allen head

socket screws to release the lifter cover. Remove the

lifter cover and gasket. Discard the gasket.

13. Remove the anti-rotation pin. Remove the hydraulic lift-

ers. Tag lifters as they are removed, so that they can be

installed in their original locations. Also take note of their

orientation (by observing location of the oil hole) to be

able to discern front from rear at time of installation.

14. Place the lifters in clean plastic bags to keep out dust,

dirt and debris. See Section 3.11 SUBASSEMBLY SER-

VICE AND REPAIR, PUSH RODS/LIFTERS/COVERS.

15. Remove O-ring from groove around breather baffle hole

in rocker housing. Discard the O-ring.

16. Alternately loosen the six rocker housing bolts following

the pattern shown in C of Figure 3-22. Remove the

rocker housing bolts.

17. Remove the rocker housing and gasket. Discard the

gasket.

To prevent distortion of the cylinder head, cylinder and

cylinder studs, gradually loosen the cylinder head bolts

in the specified pattern.

18. Alternately loosen each of the four cylinder head bolts

just 1/4 turn following the pattern shown in D of Figure 3-

22. Continue turning the bolts in these increments until

loose. Remove the cylinder head bolts.

NOTE

Save the cylinder head gasket if not damaged. The gasket is

needed to install the CYLINDER TORQUE PLATES (HD42324A) when measuring, boring or honing of the cylinder is

required.

19. Remove cylinder head and head gasket. See Section

3.11 SUBASSEMBLY SERVICE AND REPAIR, CYLIN-

DER HEAD.

2004 Touring: Engine 3-35

Page 4

HOM

E

23. Remove O-ring seal from the bottom of the cylinder liner.

Discard O-ring seal. See Section 3.11 SUBASSEMBLY

SERVICE AND REPAIR, CYLINDER.

24. Remove O-ring from ring dowel on “downside” of cylinder deck. Discard the O-ring.

1CAUTION

Always wear proper eye protection when removing cir-

Claw

clips. Slippage may propel the ring with enough force to

cause eye injury.

Figure 3-24. Piston Pin Circlip

Remover/Installer (Part No. HD-42317A)

f1635x3x

Slot

Figure 3-25. Remove Piston Pin Circlip

20. Raise the cylinder just enough to place clean shop towels under the piston. This will prevent any dirt or debris,

such as broken ring pieces, from falling into the crankcase bore.

25. Verify that clean shop towels are properly positioned

over the crankcase bore to prevent the piston pin circlip

from falling into the crankcase.

26. Remove the piston pin circlip as follows:

a. Insert the PISTON PIN CIRCLIP REMOVER/

INSTALLER (HD-42317A) into the piston pin bore

until claw on tool is positioned in slot of piston

(directly under circlip). See Figure 3-25.

b. Squeeze the handles of the tool together and pull

from bore. In the event that the circlip should fly out,

hold a shop towel over the bore during removal.

Remove circlip from claw and discard.

NOTE

It is not necessary to remove both

piston removal. Leave the second circlip in the pin bore.

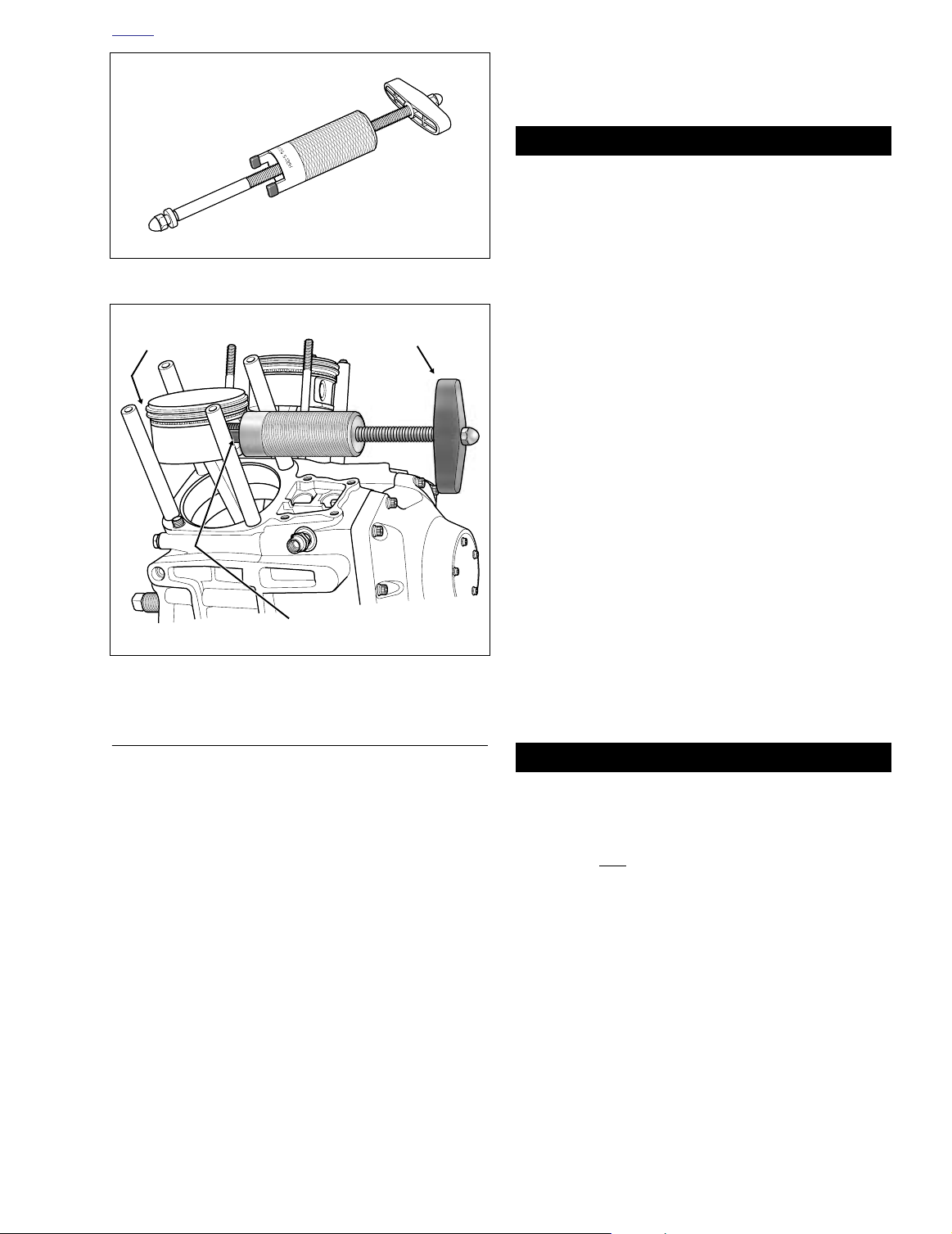

27. Remove the piston pin. If piston pin is difficult to remove,

use PISTON PIN REMOVER (HD-42320A). See Figure

3-26. Proceed as follows:

a. Remove acorn nut and spacer from rod end of tool.

b. Slide rod end through piston pin. Install spacer and

acorn nut to end of rod.

c. Position rubber-coated tips of tool on flat each side

of pin bore.

d. Turn handle in a clockwise direction until piston pin

is pulled free of bore. See Figure 3-27.

piston pin circlips during

CAUTION

Exercise caution to avoid bending the cylinder studs.

Even a slight bend or nick can cause a stress riser leading to stud failure.

21. Carefully remove the cylinder to avoid bending the cylinder studs. As the piston becomes free of the cylinder,

hold it upright to prevent it from striking the studs or

dragging across the stud thread area. Mark the cylinder

“F(ront)” or “R(ear)” to identify location.

22. Slide plastic tubing, rubber hose or conduit over each

cylinder stud. Material approximately 6 inches (152 mm)

long with an I.D. of 1/2 inch (12.70 mm) will protect cylinder studs and piston from damage.

3-36 2004 Touring: Engine

28. Remove the piston. Be sure to hold the rod shank

upright to prevent it from striking the crankcase. Place a

piece of foam-type water pipe insulation around each

rod (about 3 inches long with a 2-1/4 inch O.D. and a 1

inch I.D.) to prevent damage if contact should occur.

29. Turn the piston over and mark the pin boss with the

letters “F(ront)” or “R(ear)” to identify location. See Section 3.11 SUBASSEMBLY SERVICE AND REPAIR,

PISTON and UPPER CONNECTING ROD.

30. If performing a top end overhaul only, see Section 3.11

SUBASSEMBLY SERVICE AND REPAIR, TOP END,

before proceeding to Section 3.9 TOP END OVERHAUL,

ASSEMBLY, which follows. If performing a complete

engine overhaul, see Section 3.10 BOTTOM END

OVERHAUL, DISASSEMBLY.

Page 5

HOM

CAUTION

CAUTION

E

5. Insert piston pin through pin bore and upper connecting

rod bushing. Push pin until it contacts circlip installed in

opposite pin boss.

Do not reuse piston pin circlips. The circlips may weaken

during removal causing them to break or dislodge during engine operation, a condition that will result in

engine damage.

Figure 3-26. Piston Pin Remover (Part No. HD-42320A)

Spacer and

Acorn Nut

f1640x3x

Rubber Coated Tip

Figure 3-27. Remove Piston Pin

Handle

ASSEMBLY

6. Place clean shop towels over the cylinder and lifter

bores to prevent the piston pin circlip from falling into the

crankcase. Verify that the circlip groove is clean and free

of dirt and grime.

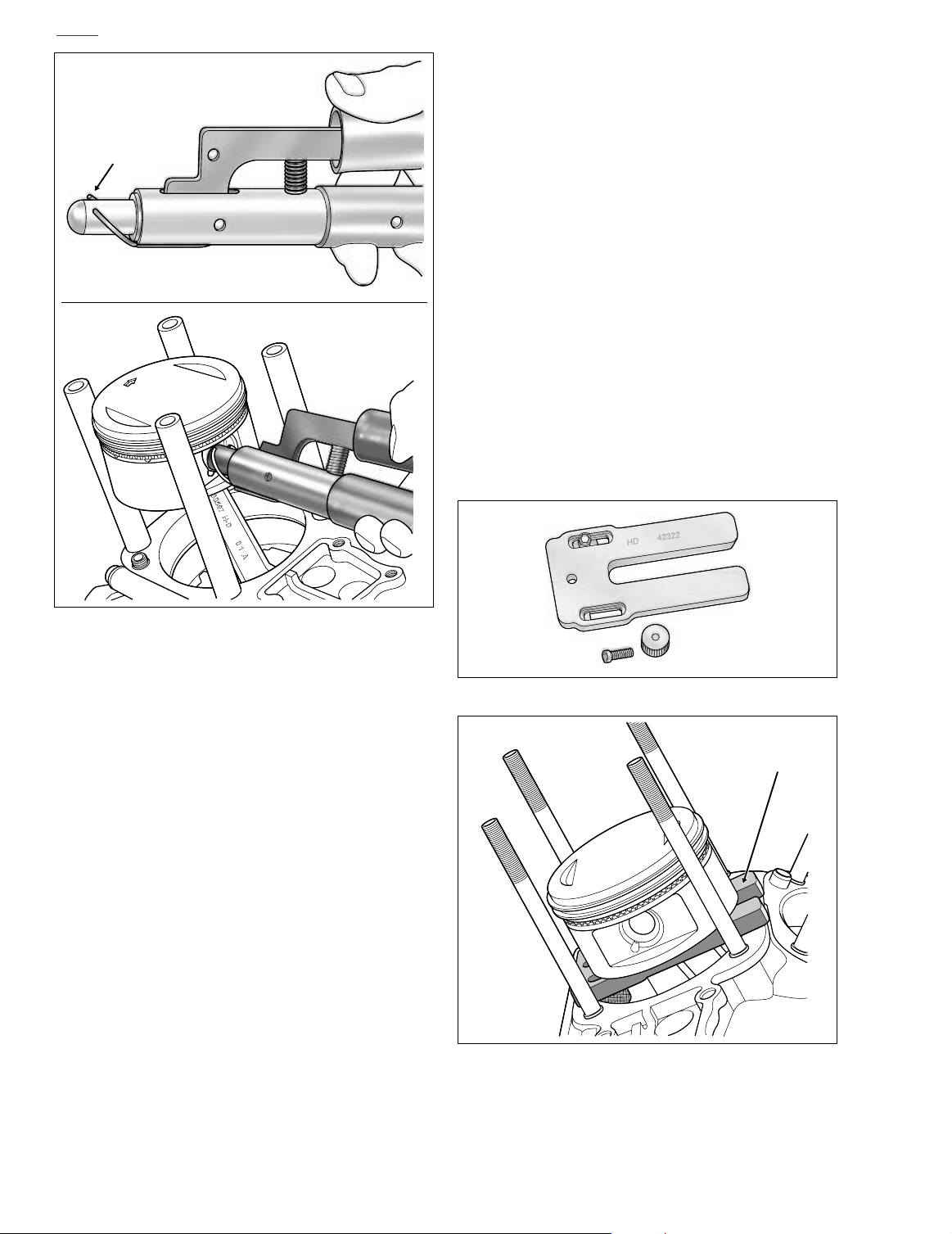

7. Install

new

piston pin circlip with the PISTON PIN CIRCLIP REMOVER/INSTALLER (HD-42317A). Proceed as

follows:

a. Slide circlip down nose of tool until it contacts claw.

Lightly squeeze handles of tool to capture circlip in

claw.

b. Releasing pressure on handles, rotate circlip so that

the end gap is centered at top of tool and then

recapture in claw.

c. Tilt the circlip forward until the end gap contacts

nose of tool. See upper frame of Figure 3-28.

d. Insert the tool into the piston pin bore until claw is

aligned with slot in piston.

e. Firmly push the tool into the piston pin bore until it

bottoms. Release handles and remove tool.

f. Inspect the circlip to verify that it is fully seated in

the groove.

NOTE

It is assumed that each step performed on one cylinder is

automatically repeated on the other.

1. Slide plastic tubing, rubber hose or conduit over each

cylinder stud, if removed. Material approximately 6

inches (152 mm) long with an I.D. of 1/2 inch (12.70 mm)

will protect cylinder studs and piston from damage.

2. Apply clean H-D 20W50 engine oil to piston pin, piston

bosses and upper connecting rod bushing.

3. Remove water pipe insulation from rod shank.

4. Place piston over rod end so that the arrow stamped at

the top of the piston points toward the front of the

engine.

O-rings that are missing, distorted, pinched or otherwise

damaged will result in either oil leakage or low oil pressure. Use of the wrong O-ring will have the same results.

Since many O-rings are similar in size and appearance,

always use ne

use to avoid confusion.

8. Install

dowel (that is, rear dowel on rear cylinder, front dowel on

front cylinder). Apply a very thin film of clean H-D 20W50

engine oil to O-ring before installation. Verify that O-ring

is properly seated in groove.

9. Install

Apply a very thin film of clean H-D 20W50 engine oil to

O-ring before installation.

w O-rings keeping them packaged until

new

O-ring over “downside” cylinder deck ring

new

O-ring seal at the bottom of the cylinder liner.

2004 Touring: Engine 3-37

Page 6

HOM

E

f1564x3x

f1636x3x

Circlip

b. With the forked end of the tool pointing towards the

center of the engine and the adjustable knobs facing downward, capture shank of connecting rod in

fork. Lay tool on cylinder deck so that adjustable

knobs contact wall of cylinder bore.

c. Rotate engine until piston skirt is centered and

firmly seated on top of support plate. See Figure 3-

30.

14. Install cylinder as follows:

a. Obtain the PISTON RING COMPRESSOR (HD-

96333-51C).

b. Fit tabs on pliers into slots of ring compressor band

(HD-96333-103). The arrow stamped on the band

indicates the side that faces up, so disregard the

word “bottom.” Place band around piston. Press the

lever on the right side of the pliers to open the jaws

for band expansion.

c. Orient tool so that the top of the band is positioned

between the top compression ring and the piston

crown. Tightly squeeze handles of tool to compress

piston rings. The racheting action of the tool allows

release of the handles after the rings are compressed.

Figure 3-28. Install Piston Pin Circlip

NOTE

Excessive lubrication of cylinder sleeve O-ring seal will result

in oil weepage between cylinder and crankcase as engine is

run, a condition that may be incorrectly diagnosed as an oil

leak.

10. Verify that the piston ring end gaps are properly staggered. If necessary, see Section 3.11 SUBASSEMBLY

SERVICE AND REPAIR, PISTON.

11. Apply clean H-D 20W50 engine oil to piston, piston rings

and cylinder bore.

12. Remove plastic tubing or rubber hose from cylinder

studs. Rotate engine until piston is at top dead center. If

necessary, see step 31 for methods of engine rotation.

13. Install the PISTON SUPPORT PLATE (HD-42322). Proceed as follows:

a. Slide both adjustable knobs on tool down slots away

from forked end. Tighten knobs when contact is

made with flats at end of slots.

Figure 3-29. Piston Support Plate (Part No. HD-42322)

Piston

Support Plate

f1612x3x

Figure 3-30. Install Piston Support Plate

3-38 2004 Touring: Engine

Page 7

HOM

CAUTION

f1518b3x

Threaded

Cylinder

E

h. Carefully set the cylinder over the two ring dowels in

the cylinder deck. Push down on the cylinder until it

is fully seated in the crankcase bore.

NOTE

To hold the first cylinder in position while installing the second, install threaded cylinders (HD-95952-1) from CONNECTING ROD CLAMPING TOOL (HD-95952-33B) onto

cylinder studs with the knurled side down. This will prevent

the piston rings from raising the cylinder as the engine is

rotated to bring the other piston into position for installation of

the second cylinder. See Figure 3-33.

Figure 3-31. Piston Ring Compressor

(Part No. HD-96333-51C)

f1613x3x

Ring Compressor Band

(3-5/8 - 3-7/8 Inches)

Part No. HD-96333-103

B

OT

TO

M

Pliers

Figure 3-32. Install Cylinder

d. Note that the cylinders should have been marked

with the letters “F(ront)” or “R(ear)” to identify

location. With the indent in the cooling fins facing

the right side of the engine, gently slide cylinder

over the cylinder studs and the piston crown resting

it on the top of the ring compressor band.

e. Place the palms of both hands at the top of the cyl-

inder. Push down on the cylinder with a sharp, quick

motion to pass the piston ring area. See Figure 3-

32.

f. Rotate the engine slightly to raise piston off support

plate. Remove pliers from band and then remove

band from around shank of connecting rod. Remove

piston support plate.

g. Remove shop towels from around the crankcase

bore exercising caution to keep out any dirt or

debris.

15. With the part number topside, place the head gasket

over the two ring dowels in the upper flange of the cylinder.

16. Note that the word “Front” or “Rear” is cast into the top of

the cylinder head to ensure proper installation. With the

indent in the cooling fins facing the right side of the

engine (for accommodation of the push rods and covers), carefully set the cylinder head over the two cylinder

ring dowels. To avoid damage to machined surfaces or

ring dowels, lower the cylinder head at an angle that

closely approximates the angle of the crankcase.

Thoroughly clean and lubricate the threads of the cylinder head bolts before installation. Friction caused by dirt

and grime will result in a false torque indication.

Figure 3-33. Install Threaded Cylinders to Studs

(Part No. HD-95952-1)

2004 Touring: Engine 3-39

Page 8

HOM

E

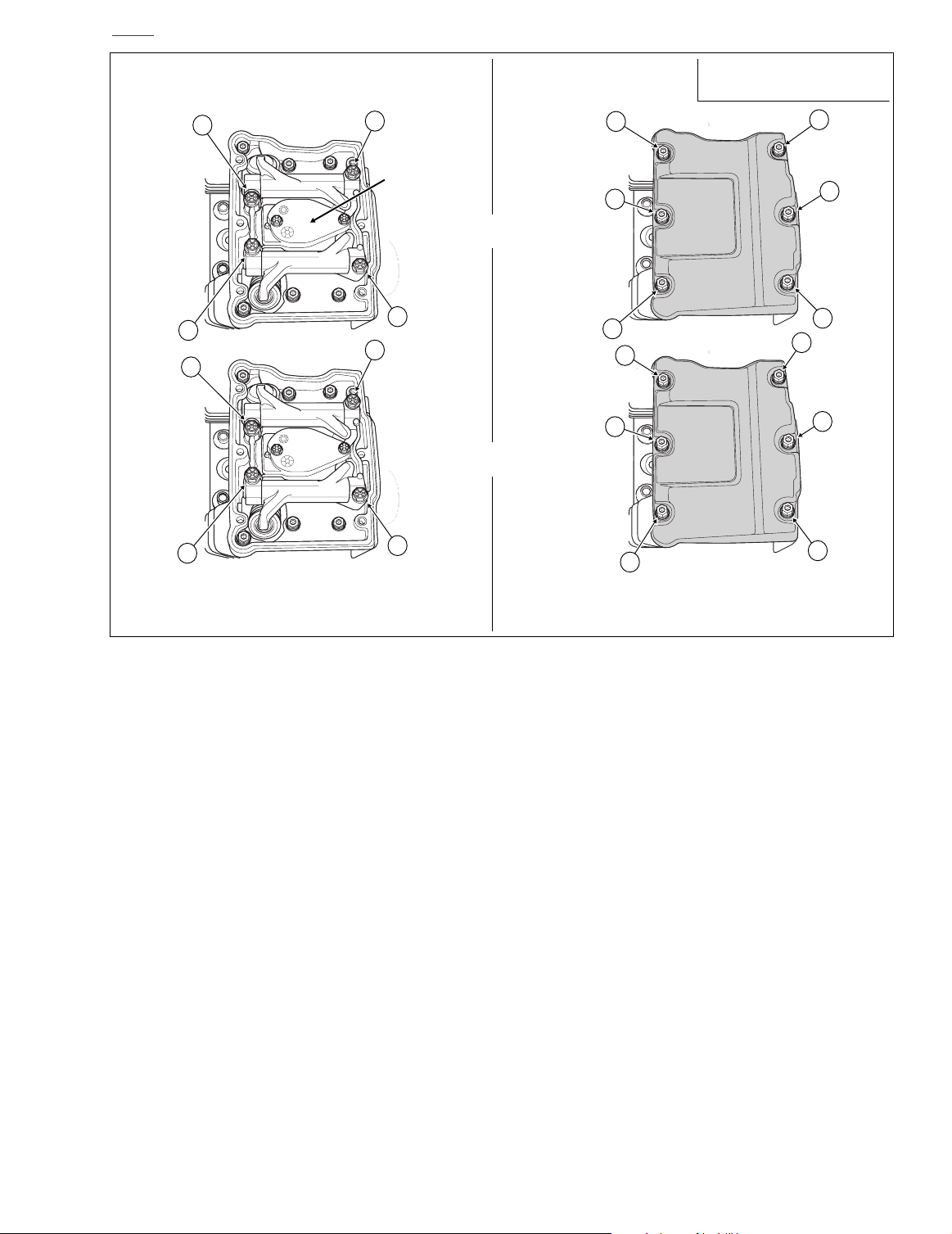

A

S

S= Short Bolt

FRONT

L= Long Bolt

L

S

4

2

1

S

REAR

3

L

L

3

1

17. Lightly oil threads and shoulders of cylinder head bolts

with clean H-D 20W50 engine oil.

18. Start the cylinder head bolts onto the cylinder studs, two

short bolts on the left side of the engine, two long bolts

on the right.

19. Tighten the four cylinder head bolts as follows:

CAUTION

Improperly tightened cylinder head bolts may result in

gasket leaks, stud failure and distortion of the cylinder

and/or cylinder head.

a. Alternately turn each cylinder head bolt until finger

tight.

b. Tighten the cylinder head bolts to 120-144

(13.6-16.3 Nm) in the sequence shown in A of Fig-

ure 3-34.

c. Following the same sequence, tighten each bolt to

15-17 ft-lbs (20.3-23.1 Nm).

d. Using a grease pencil, mark a straight line on the

cylinder head bolt continuing the line over onto the

cylinder head. Using the marks as a guide, turn

each bolt 1/4 turn or 90 degrees. See B of Figure 3-

34. Be sure to tighten the cylinder head bolts in the

sequence shown in A of Figure 3-34.

in-lbs

2

S

4

L

B

f1583x3x

Figure 3-34. Cylinder Head Torque Sequence

and Bolt Size

f2166x3x

NOTE

For best results, obtain Snap-on® Torque Angle Gauge

TA360.

20. Install a

flange.

Even though all bolt holes (rocker housing, rocker arm

support plate and breather assembly) may appear to be

in alignment, the rocker housing gasket may be installed

upside down. An upside down gasket will result in an

open breather channel causing an oil leak when the vehicle is started, possibly resulting in engine and/or property damage.

21. Verify that the rocker housing gasket is installed correctly by noting that the breather channel is concealed.

See Figure 3-35.

22. With the indent facing forward, place the rocker housing

into position aligning the holes in the housing with those

in the gasket.

23. Apply a small dab of Loctite Medium Strength Threadlocker 243 (blue) to threads of six rocker housing bolts.

Start the rocker housing bolts, two long bolts on the left

side of the engine, four intermediate bolts in the interior.

Alternately tighten the bolts to 120-168

Nm) in the pattern shown in Figure 3-36.

new

rocker housing gasket on the cylinder head

CAUTION

in-lbs

(13.6-18.9

3-40 2004 Touring: Engine

Page 9

HOM

S= Short Bolt, 1 In.

I = Intermediate Bolt, 1-1/4 In.

L = Long Bolt, 1-3/4 In.

2

4

3

1

6

5

3

1

2

4

5

6

f2165x3x

Install Six Rocker Housing Bolts.

Tor que: 120-168 in-lbs

L

I

L

L

L

I

I

I

I

I

I

I

FRONT

REAR

O-Ring

E

Breather Channel Concealed Breather Channel Exposed

CORRECT WRONG

Figure 3-35. Install Rocker Housing Gasket (Rear Cylinder Shown)

NOTE

Rocker housing and rocker cover bolts have both an internal

and external hex, which allows the bolts to be installed with

either a short 3/16 inch allen wrench (tight spaces), or a 7/16

inch socket or open end/box wrench (open spaces). If the

engine is left in the chassis for service, the short 3/16 inch

allen wrench is indispensable when installing the rocker

housing and rocker cover bolts on the left side of the engine

(particularly the rear) where there is close proximity to the

frame.

NOTE

If the engine was left in the chassis for service, final tighten

the rear left rocker housing bolt (rear cylinder) using a torque

wrench with a 1/4 inch drive. Since this tool may not be available in foot-pounds, tighten the bolt to 120-168

f1577x3x f1576x3x

in-lbs

.

O-rings that are missing, distorted, pinched or otherwise

damaged will result in either oil leakage or low oil pressure. Use of the wrong O-ring will have the same results.

Since many O-rings are similar in size and appearance,

always use ne

w O-rings keeping them packaged until

use to avoid confusion.

24. Install

new

O-ring in groove around breather baffle hole

in rocker housing. Apply a thin film of clean H-D 20W50

engine oil to O-ring before installation. See Figure 3-36.

25. Install the hydraulic lifters in the crankcase bores with

the flats facing forward and rearward. To preserve existing wear patterns, orientation of the oil hole (inboard or

outboard) should have been noted during disassembly.

To avoid damage, do not drop lifters onto cam lobes.

CAUTION

Figure 3-36. Rocker Housing Torque Sequence

and Bolt Size

2004 Touring: Engine 3-41

Page 10

HOM

E

Lifter Cover

Anti-Rotation

Pin

Do

not

install the spring cap retainers at this time. To

ensure proper installation, take note of Ta bl e 3-3.

30. Install the push rods in their original positions. Be sure to

remove any tags that may have been used for marking

location and orientation. To ensure proper installation,

take note of Ta bl e 3-3. For example, if reassembling the

rear cylinder, slide the intake push rod (silver) through

the front hole in the rocker housing engaging the lifter

socket in the inside hole of the lifter cover. Slide the

exhaust push rod (black) through the rear hole in the

rocker housing engaging the lifter socket in the outside

hole of the lifter cover.

Ribs

Gasket

f1606x3x

Figure 3-37. Install Lifters and Lock Position

With Anti-Rotation Pin

26. Place anti-rotation pin on the machined flat between the

blocks cast into the crankcase. See Figure 3-37.

27. Install a

new

lifter cover gasket aligning the holes in the

gasket with those in the cover.

CAUTION

Movement or loss of the anti-rotation pin can result in

lifter rotation causing catastrophic engine damage.

28. Install the lifter cover and start the four allen head socket

screws (1/4 x 1 inch). During installation, verify that the

anti-rotation pin is held in place by the ribs cast into the

inboard side of the lifter cover. See Figure 3-37. Tighten

the lifter cover screws to 90-120

in-lbs

(10.2-13.6 Nm) in

a crosswise pattern.

29. Hand compress the push rod cover assembly and fit the

O-ring end of the lower push rod cover into the lifter

cover bore. Expanding the assembly, fit the O-ring end of

the upper push rod cover into the cylinder head bore.

Table 3-3. Push Rod/Cover Locations

Cylinder

Front

Rear

*

Push Rods Are Color Coded - Intake (Silver), Exhaust (Black)

Cover and

Push Rod*

Intake Inside Rear

Exhaust Outside Front

Intake Inside Front

Exhaust Outside Rear

Lifter Cover

Bore

Cylinder Head/

Rocker Housing

Bore

31. To install the rocker arm support plate,

both

lifters of the

cylinder being serviced must be on the base circle (or

lowest position) of the cam.

CAUTION

Installing the rocker arms and rotating the engine with

the valve train loaded can result in bent push rods and/

or valve damage.

To find the base circle, it is first necessary to rotate the

engine. Based on the level of disassembly, three methods of engine rotation are presented below.

a. With pr

imary cover installed - With vehicle on center

stand, place the transmission in 5th gear and rotate

rear wheel in a clockwise direction (as viewed from

right side) until the base circle is found. See step

31(d) to find the base circle.

b. With pr

imary cover removed - Remove primary

cover. Place the transmission in neutral. Fit a 1-1/2

inch socket on the compensating sprocket shaft nut.

Rotate nut in a counterclockwise direction until the

base circle is found. See step 31(d) to find the base

circle.

CAUTION

Do not attempt to rotate engine by removing cam cover

and placing socket on crank or primary cam sprocket

flange bolt. Head of flange bolt can break off possibly

resulting in damage to flywheel or camshaft.

c. With engine mounted in engine stand

- Fashion tool

as follows: Obtain used or discarded compensating

sprocket shaft extension (HD-40266-85). Weld a 13/

16 inch socket with a 1/2 inch drive to outboard side

of extension. See Figure 3-23. Install tool on

sprocket shaft and rotate in a counterclockwise

direction until the base circle is found. See step

31(d) to find the base circle.

d. Finding the base circle

: Using one of the methods

above, rotate engine until piston is at Top Dead

Center (TDC) of compression stroke. To accomplish

3-42 2004 Touring: Engine

Page 11

HOM

E

f2163x3x

Rocker Arm Torque:

18-22 ft-lbs

1

4

4

3

Breather

Assembly

Tor que: 90-120 in-lbs

FRONT

2

2

REAR

f2164x3x

Tor que: 15-18 ft-lbs

S= Short Bolt, 1 In.

I = Intermediate Bolt, 1-1/4 In.

L = Long Bolt, 1-3/4 In.

5

S

1

S

3

S

3

S

1

S

4

L

2

L

6

L

6

L

2

L

1

AB

Alternately Tighten Four Rocker Arm Bolts

3

5

S

Install Six Rocker Cover Bolts.

4

L

1/4 Turn in Pattern Shown.

Figure 3-38. Rocker Arm/Rocker Cover Torque Sequence and Bolt Size

this, first raise lower push rod cover to access intake

lifter (inside hole of lifter cover). Place index finger

on top of the intake lifter. While rotating engine, feel

lifter rise (valve open) and fall (valve closed). Now

place finger tightly over spark plug hole and rotate

engine again. In the compression stroke, air will be

forced out against your finger until the piston

reaches the TDC position. Stop engine rotation

when the flow of air through the spark plug hole

stops. Direct the beam of a small flashlight into

spark plug hole to verify piston is at TDC. Both

intake and exhaust valves are now closed and the

push rods are in the unloaded position.

32. Place the rocker arm support plate assembly into the

rocker housing. Start the four rocker arm support plate

bolts into the cylinder head.

33. Place breather assembly at top of rocker arm support

plate. Apply a small dab of Loctite Medium Strength

Threadlocker 243 (blue) to threads of two breather

assembly bolts. Start bolts into cylinder head.

34. Alternately tighten each of the four rocker arm support

plate bolts just 1/4 turn following the pattern shown in A

of Figure 3-38. Continue turning the bolts in these

increments until snug. Following the same numerical

sequence, tighten the bolts to 18-22 ft-lbs (24.4-29.8

Nm).

35. Alternately tighten the two breather assembly bolts to

90-120

in-lbs

(10.2-13.6 Nm).

NOTE

If the engine was left in the chassis for service, final tighten

the rocker arm support plate bolt on the rear left side of the

rear cylinder using a 3/8 inch drive torque wrench with a 1/2

inch flank drive “dog bone” torque adapter (Snap-On

FRDH161). Since any extension can act as a torque multiplier, the torque wrench must be perpendicular to the torque

adapter when the bolt is tightened. The 90 degree orientation

between the tools cancels the multiplier effect and prevents

the bolt from being over-tightened. If the adapter is kept inline

with the torque wrench, the multiplier effect is in force and

distortion of the rocker housing will occur.

2004 Touring: Engine 3-43

Page 12

HOM

E

f1604x3x

Figure 3-39. Install Spring Cap Retainer

36. Lift up lower push rod covers and verify that both push

rods spin freely.

39. Apply a small dab of Loctite Medium Strength Threadlocker 243 (blue) to threads of six rocker cover bolts.

Start the rocker cover bolts, three short bolts on the left

side of the engine, three long bolts on the right. Tighten

the bolts to 15-18 ft-lbs (20.3-24.4 Nm) in the pattern

shown in B of Figure 3-38.

NOTE

If the engine was left in the chassis for service, final tighten

the three rocker cover bolts on the left side of the rear cylinder using a 3/8 inch drive torque wrench with a 7/16 inch

flank drive “dog bone” torque adapter (Snap-On FRDH141).

Since any extension can act as a torque multiplier, the torque

wrench must be perpendicular to the torque adapter when

the bolts are tightened. The 90 degree orientation between

the tools cancels the multiplier effect and prevents the bolts

from being over-tightened. If the adapter is kept inline with

the torque wrench, the multiplier effect is in force and distortion of the rocker cover will occur.

40. If engine was left in the chassis for service, see Section

3.6 ASSEMBLING MOTORCYCLE AFTER STRIPPING.

If engine was removed for service, see Section 3.8

INSTALLING ENGINE IN CHASSIS.

NOTE

Always service each cylinder separately. After the first cylinder is serviced the engine must be rotated to find the base

circle on the second cam. Service on the remaining cylinder

can then proceed.

37. Complete installation of the push rod covers as follows:

a. Verify that the O-ring ends of the upper and lower

push rod covers fit snugly into the cylinder head and

lifter cover bores.

b. Lodge the upper edge of spring cap retainer into the

cylinder head bore leaving the bottom edge free.

c. Insert blade of small screwdriver between bottom

edge of spring cap retainer and top of spring cap.

d. While simultaneously depressing spring cap with tip

of screwdriver, use forefinger to slide bottom edge

of spring cap retainer down shaft towards tip of

screwdriver blade. As spring cap reaches its full

length of travel, spring cap retainer should be in

approximate position against upper push rod cover.

See Figure 3-39.

NOTE

For best results, be sure that screwdriver, spring cap and

spring cap retainer are free of grease and oil.

e. Verify that spring cap retainer is seated tightly

against upper push rod cover.

38. Install a

new

rocker cover gasket on the rocker housing

flange. Place the rocker cover into position aligning the

holes in the cover with those in the gasket.

3-44 2004 Touring: Engine

Page 13

HOM

E

BOTTOM END OVERHAUL 3.10

DISASSEMBLY

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY. If only servicing cam compartment components,

see steps 1-11. If performing a complete engine overhaul, reference steps 1-29.

NOTE

The cam support plate, lifter cover and crankshaft position

sensor mount all use the same short allen head socket screw

(1/4 x 1 inch). Only the cam cover uses the longer screw (1/4

x 1-1/4 inches). For ease of assembly, do not mix short and

long screws. Store long screws inside cam cover to avoid

confusion. The short screws are interchangeable.

2. Remove the ten allen head socket screws to release the

cam cover. Remove and discard the cam cover gasket.

Flange Bolt and

Right

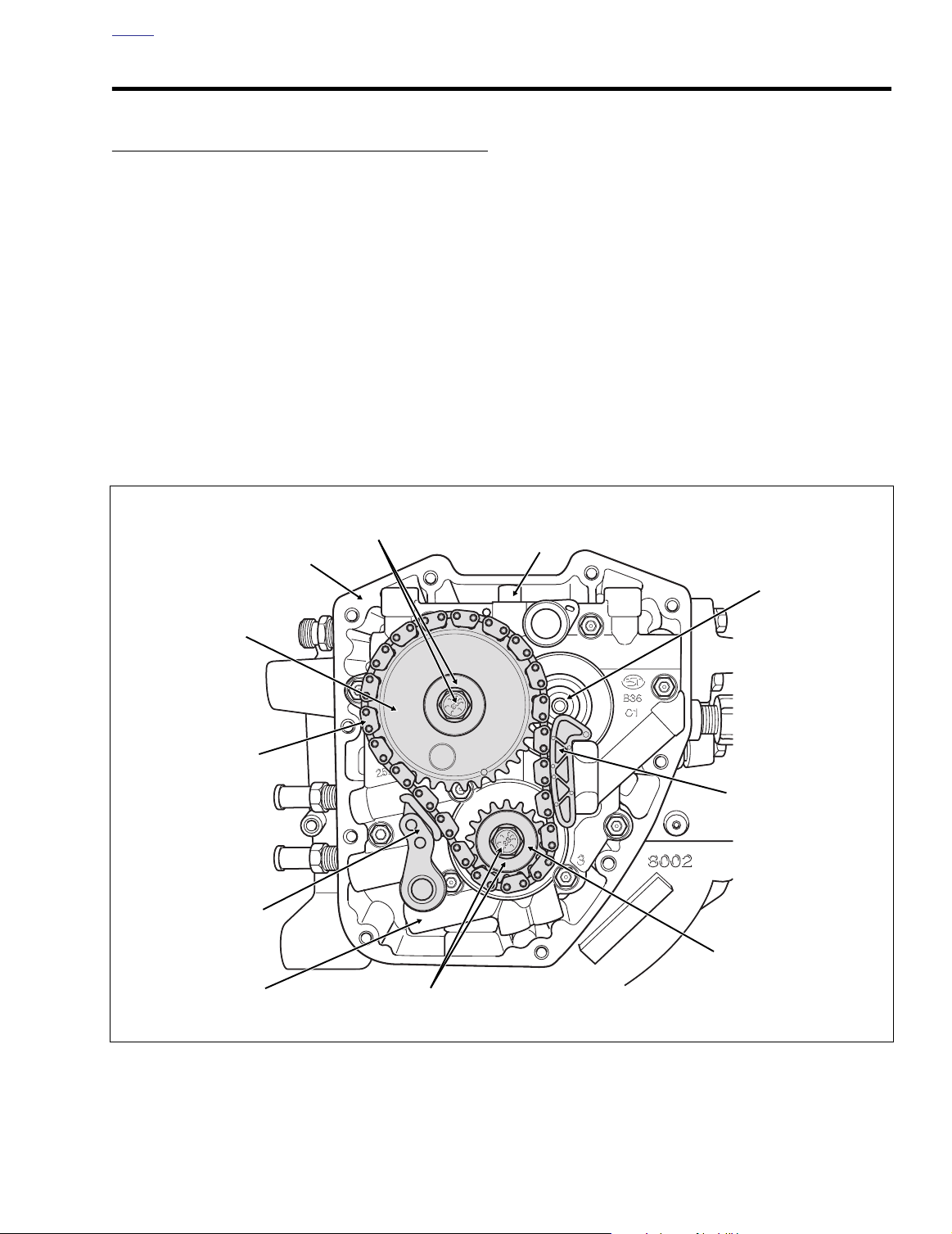

Crankcase Half

Flat Washer

3. Using a colored marker, mark the crank sprocket and

one of the links of the primary cam chain. Maintaining

the original direction of rotation during assembly may

prolong service life.

4. Remove the flange bolt and flat washer from the crank

sprocket. See Figure 3-40.

5. Remove the flange bolt and flat washer from the primary

cam sprocket.

NOTE

If too much loctite, or perhaps the wrong loctite, was used to

install the primary cam sprocket flange bolt, it may be very

difficult to remove. In these cases, break down loctite using

heat from a small propane torch. Apply flame evenly around

bolt head in a circular motion, but not for so long as to turn

bolt blue. Do not direct heat at chain tensioner assembly and

other components or damage will result. Other methods of

removal, such as use of a large breaker bar, also may result

in damage to chain drive and other components.

Cleaning

Plug

Camshaft

Front

Primary Cam

Sprocket

Primary

Cam Chain

Primary Cam Chain

Tensioner

Oil Pressure

Relief Valve

Flange Bolt and

Flat Washer

Figure 3-40. Cam Support Plate Assembly

Michalski

Chain Guide

Crank

Sprocket

f2141x3x

2004 Touring: Engine 3-45

Page 14

HOM

E

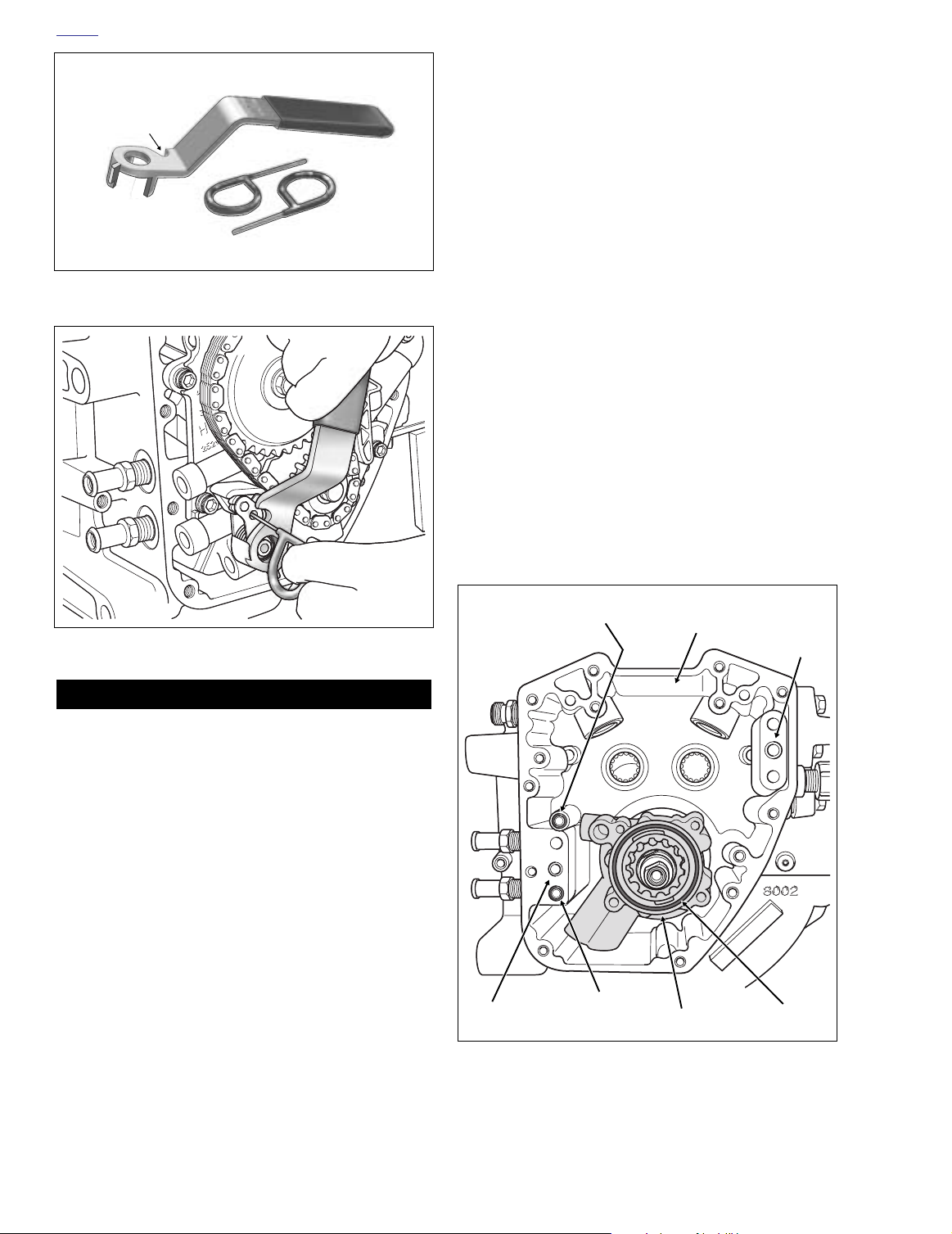

Tensioner

Unloader

Slot

Figure 3-41. Cam Chain Tensioner Unloader

with Retention Pins (Part No. HD-42313)

Retention Pins

7. Insert small pry bar (seal remover) between inboard side

of primary cam sprocket and cam support plate. Working

around its circumference, carefully ease primary cam

sprocket off splines of rear camshaft until loose.

8. Ease off crank sprocket with a slightly smaller pry bar

(seal remover). Remove the primary cam sprocket, primary cam chain and crank sprocket.

9. Remove the primary cam sprocket spacer from the rear

camshaft.

10. Squeeze tabs to remove chain guide from between

blocks cast into cam support plate.

11. Release the cam support plate from the oil pump flange.

Alternately loosen and then remove the four allen head

socket screws following the pattern shown in B of Figure

3-50.

12. Release the cam support plate from the crankcase

flange. Alternately loosen and then remove the six allen

head socket screws following the pattern shown in A of

Figure 3-50.

13. Two ring dowels in crankcase flange locate cam support

plate (lower rear, upper front). See Figure 3-43. Insert

small pry bar (seal remover) between inboard side of

cam support plate and crankcase flange in area adjacent to ring dowels. Alternately work each side free and

then carefully ease cam support plate from end of crankshaft. See Section 3.11 SUBASSEMBLY SERVICE AND

REPAIR, CAM SUPPORT PLATE.

f2140x3x

Figure 3-42. Retract Primary Cam Chain Tensioner

1WARNING1WARNING

Use extreme caution when operating propane torch.

Read the manufacturers instructions carefully before

use. Do not direct open flame or heat toward any fuel

system component. Extreme heat can cause fuel ignition

and explosion. Inadequate safety precautions could

result in death or serious injury.

6. Using the CAM CHAIN TENSIONER UNLOADER (HD-

42313), retract the primary cam chain tensioner as follows:

a. With the handle pointing toward the front of the cam

support plate, place cup of tool over spring coil. Correctly positioned, the slot in the tool should be adjacent to the hole in the tensioner. See Figure 3-42.

b. Rotate the handle of the tool in a counterclockwise

direction until the hole in the tensioner is aligned

with the hole in the boss of the cam support plate.

c. Insert a retention pin through the hole in the ten-

sioner and into the hole in the cam support plate.

f1573b3x

Ring

Dowel

O-Ring

Blind Hole

O-Ring

Oil Feed Hole

Right

Crankcase Half

Oil Pump

Figure 3-43. Oil Pump Assembly

Ring

Dowel

O-Ring

3-46 2004 Touring: Engine

Page 15

f1644x3x

f1645a3x

Crankshaft

Guide

Water Pipe

Insulation

Crankshaft

Guide

Left

Crankcase Half

Right

Crankcase Half

Crankshaft

Bearing

HOM

E

1CAUTION

Do not pull the retention pin from the primary cam chain

tensioner after removal of the cam support plate. With

35-40 pounds of spring pressure behind the tensioner,

allowing it to accelerate through its full length of travel

will result in spring stretching and/or cracking of the tensioner shoe. Furthermore, if the tensioner should contact fingers or other parts of the hand, minor or

moderate injury may occur.

14. Remove O-ring from groove around oil feed hole in

crankcase flange (directly below rear ring dowel).

Remove O-ring from groove around blind hole in boss

(directly above oil return hole in crankcase flange). Discard O-rings. See Figure 3-43.

15. Pull oil pump from crankshaft. Remove O-ring from outboard side of oil pump housing. Remove O-ring from

scavenge port stub. Discard O-rings. See Section 3.11

SUBASSEMBLY SERVICE AND REPAIR, OIL PUMP.

1WARNING1WARNING

Be sure that stator mount flange (sprocket shaft side) is

NOT facing up when the case halves are separated or the

flywheel assembly will drop to the floor. Dropping the flywheel assembly may result in parts damage and minor

or moderate injury.

16. Rotate crankcase in the engine stand so that the cam

cover flange is facing upward. Remove the nine crankcase bolts in the left case half. Follow the sequence

shown in Figure 3-46.

Figure 3-44. Crankshaft Guide (Part No. HD-42326A)

1CAUTION

Never move or lift the crankcase by grasping the cylinder studs. The crankcase is too heavy to be carried in

this manner and may be dropped. Dropping the crankcase may result in parts damage and minor or moderate

injury.

17. Using pry points, loosen case halves. Lift right crankcase half off end of crankshaft.

18. Remove O-rings from two ring dowels in split line face of

right case half. Discard the O-rings.

19. See Section 3.11 SUBASSEMBLY SERVICE AND

REPAIR, CRANKCASE.

ASSEMBLY

1. If removed, install left crankcase half in engine stand so

that the split line face is vertical.

2. To prevent damage to the sprocket shaft bearing, slide

CRANKSHAFT GUIDE (HD-42326A) over end of

sprocket shaft. Install flywheel assembly into left case

half. Remove tool.

Figure 3-45. Install Crankshaft Guide to Protect

Crankshaft Bearing

2004 Touring: Engine 3-47

Page 16

HOM

E

7. Rotate crankcase in the engine stand so that the stator

1

5

7

4

8

2

3

mount flange (sprocket shaft side) is facing upward.

Install service thrust washer on sprocket shaft with the

ink stamp facing outside (and the chamfer inboard). If

using OE part without markings, orient as required to

preserve existing wear pattern.

8. To install

Nice bearing, large flat washer and handle from

SPROCKET SHAFT TIMKEN BEARING CONE

INSTALLER (HD-97225-55B) and proceed as follows:

a. Verify that seal lip garter spring is in place on both

b. Thread pilot onto sprocket shaft until contact is

c. With the lettering facing outside, slide oil seal over

d. Slide SPROCKET SHAFT OIL SEAL INSTALLER

new

oil seal into bearing bore, obtain pilot,

sides of seal.

made with shoulder.

pilot until it contacts bearing bore.

(HD-39361A) over pilot until it contacts oil seal. See

Figure 3-47.

f1585x3x

O-rings that are missing, distorted, pinched or otherwise

damaged will result in either oil leakage or low oil pressure. Use of the wrong O-ring will have the same results.

Since many O-rings are similar in size and appearance,

always use ne

use to avoid confusion.

3. Install

of right case half.

4. Apply a small

(1.4 mm) wide to the split line face. For best results, use

High-Performance Sealant (gray), Part No. HD-99650-

02.

5. To prevent damage to the crankshaft bearing, place

CRANKSHAFT GUIDE (HD-42326A) over end of crankshaft. Mate case halves sliding bearing in right crankcase half over end of crankshaft. Remove tool. See

Figure 3-45.

6. Start the nine crankcase bolts and tighten as follows:

a. Alternately turn each crankcase bolt until finger

b. Tighten the crankcase bolts to 10 ft-lbs (13.6 Nm) in

c. Following the same sequence, tighten each bolt to

9

Figure 3-46. Crankcase Torque Sequence

(Left Side View)

CAUTION

w O-rings keeping them packaged until

new

O-rings over two ring dowels in split line face

bead of sealant approximately 0.056 inch

tight.

the sequence shown in Figure 3-46.

15-19 ft-lbs (20.3-25.8 Nm).

6

Figure 3-47. Sprocket Shaft Oil Seal Installer

(Part No. HD-39361A)

f1882x3x

Sprocket Shaft

Oil Seal Installer

Figure 3-48. Install Oil Seal In Bore

3-48 2004 Touring: Engine

Page 17

CAUTION

f2068x3x

Rear

Camshaft

Front

Camshaft

Pin Stamped

Timing Lines

HOM

E

e. Slide Nice bearing and large flat washer over pilot

until contact is made with seal installer.

f. Thread handle onto pilot shaft.

g. Rotate handle in a clockwise direction until oil seal

installer makes firm contact with crankcase stator

mount. See Figure 3-48.

h. Remove handle, flat washer, Nice bearing, seal

installer and pilot from sprocket shaft.

9. Slide sprocket shaft spacer over end of sprocket shaft.

Push spacer into oil seal until seated against bearing

race.

10. Rotate crankcase in the engine stand so that the cam

cover flange is facing upward.

11. Install oil pump as follows:

CAUTION

O-rings that are missing, distorted, pinched or otherwise

damaged will result in either oil leakage or low oil pressure. Use of the wrong O-ring will have the same results.

Since many O-rings are similar in size and appearance,

always use ne

w O-rings keeping them packaged until

use to avoid confusion.

a. Install

new

O-ring on scavenge port stub of oil

pump housing. Apply a very thin film of clean H-D

20W50 engine oil to O-ring before installation.

b. Slide oil pump housing onto crankshaft fitting O-ring

on scavenge port stub into crankcase bore at back

of cam compartment. Firmly push on scavenge port

stub with thumb to be sure that it is snug in bore.

Inspect O-ring on stub to verify that it is not pinched

or distorted.

c. Separate the gerotor gears into two sets, one wide

(scavenge) and the other narrow (feed).

NOTE

Lubricate parts with clean H-D 20W50 engine oil during

assembly.

d. Fit the smaller of the

larger. Slide the wide gerotor set down the crank-

wide

gerotor gears into the

shaft until it bottoms in the oil pump housing.

e. Slide the first of two separator plates down the

crankshaft until it contacts the wide gerotor set.

Install wave washer and second separator plate.

f. Fit the smaller of the

narrow

gerotor gears into the

larger. Slide the narrow gerotor set down the crankshaft until it contacts the separator plate.

Figure 3-49. Verify Alignment of Timing Lines

on Front and Rear Camshafts

O-rings that are missing, distorted, pinched or otherwise

damaged will result in either oil leakage or low oil pressure. Use of the wrong O-ring will have the same results.

Since many O-rings are similar in size and appearance,

always use ne

w O-rings keeping them packaged until

use to avoid confusion.

g. Install

new

O-ring in groove on outboard side of oil

pump housing. See Figure 3-43. Apply a very thin

film of clean H-D 20W50 engine oil to O-ring before

installation.

12. Install

new

O-ring in groove around oil feed hole in

crankcase flange (directly below rear ring dowel). Install

new

O-ring around blind hole in boss (directly above oil

return hole in crankcase flange). Apply a thin film of H-D

20W50 engine oil to O-rings before installation.

13. If not retracted, place cup of CAM CHAIN TENSIONER

UNLOADER (HD-42313) over spring coil of secondary

cam chain tensioner positioning finger on tool between

tensioner and shoe. Rotate tool in a counterclockwise

direction inserting retention pin through hole in boss on

primar

y cam chain side

of cam support plate. Pin

engages hooks on tensioner to hold it in the retracted

position. For best results, place cam support plate in a

vise using brass jaw inserts to prevent casting damage.

14. Lubricate cam needle bearings with clean H-D 20W50

engine oil.

2004 Touring: Engine 3-49

Page 18

HOM

E

3

6

2

5

4

2

4

1

1

CAM SUPPORT PLATE OIL PUMP

AB

Figure 3-50. Cam Support Plate/Oil Pump Torque Sequence

f1581b3x

3

f1581b3x

15. Using a straightedge, verify that the pin stamped timing

lines on the ends of the front and rear camshafts are in

alignment (although they may be somewhat difficult to

see). See Figure 3-49. If necessary, rotate camshafts in

order to make this observation.

16. Aligning bushing in cam support plate with end of crankshaft, slide cam support plate over crankshaft onto two

ring dowels in crankcase flange. Use a rubber mallet to

fully seat cam support plate on ring dowels.

17. Install the six allen head socket screws (1/4 x 1 inch) to

secure the cam support plate to the crankcase flange.

Tighten screws to 90-120

pattern shown in A of Figure 3-50.

18. Secure the cam support plate to the oil pump flange as

follows:

a. Start two allen head socket screws (1/4 x 1 inch)

into holes 3 and 4. See B of Figure 3-50.

b. Obtain two ALIGNMENT TOOLS used to install lifter

guides on Evolution engines (HD-33443). Loosely

install alignment tools in holes 1 and 2.

c. While rotating the engine, alternately snug and then

tighten the alignment tools to 40-45

Nm).

For methods of engine rotation, see Section 3.9 TOP END

OVERHAUL, DISASSEMBLY, step 7.

NOTE

in-lbs

(10.2-13.6 Nm) in the

in-lbs

(4.5-5.1

d. Alternately snug and then tighten the screws in

holes 3 and 4 to 40-45

e. Remove the alignment tool from hole 1. Install the

allen head socket screw and tighten to 40-45

(4.5-5.1 Nm).

f. Repeat step 18(e) to replace alignment tool in hole

2 with allen head socket screw.

g. Final tighten all four screws to 90-120

13.6 Nm). Use the pattern shown in B of Figure 3-

50. Numbers cast adjacent to the bolt holes also

indicate the oil pump torque sequence.

If only realigning the oil pump, first loosen all screws following

the pattern shown in B of Figure 3-50. Remove screws from

holes 1 and 2 and then follow the alignment procedure starting at step 18(b).

19. Pull retention pin from hole in cam support plate to

release secondary cam chain tensioner.

20. Squeeze tabs and install chain guide between blocks

cast into cam support plate.

21. Install primary cam sprocket spacer onto rear camshaft.

22. If using the original cam support plate, camshafts, primary cam sprocket, crank sprocket and flywheel assembly, then move to step 23. However, if any of these parts

have been replaced, then proceed as follows:

NOTE

in-lbs

(4.5-5.1 Nm).

in-lbs

in-lbs

(10.2-

3-50 2004 Touring: Engine

Page 19

HOM

f2142x3x

E

a. Install primary cam sprocket onto splines of rear

camshaft. Install long

flange bolt with thicker flat

washer to secure sprocket to end of camshaft.

b. Install crank sprocket onto crankshaft. Install shor

flange bolt with smaller diameter flat washer (that is,

washer from bulk inventory) to secure sprocket to

end of crankshaft.

NOTE

Use of smaller diameter flat washer with crank sprocket

flange bolt allows room on sprocket face for placement of

straightedge under step 22(e).

c. To prevent rotation, position the CRANKSHAFT/

CAMSHAFT SPROCKET LOCKING TOOL (HD-

42314) between the crank and primary cam sprock

ets. See Figure 3-52. The handle of the tool is

stamped “Crank” and “Cam” to ensure proper orientation. Tighten the crank and primary cam sprocket

flange bolts to 15 ft-lbs (20.3 Nm). Remove the

sprocket locking tool.

d. Push on rear camshaft to remove end play.

Figure 3-51. Crankshaft/Camshaft Sprocket Locking Tool

(Part No. HD-42314)

t

-

Figure 3-53. Check Alignment of Crank and

Primary Cam Sprocket Faces

e. Place a straightedge across the crank and primary

cam sprocket faces. Try to insert a 0.010 inch feeler

gauge between the straightedge and each sprocket

face. See Figure 3-53. If the feeler gauge does not

fit at either location, then proceed to step 22(f).

On the other hand, if the crank sprocket is “proud”

(that is, rises above the face of the primary cam

sprocket) more than 0.010 inch, remove the flange

bolt and primary cam sprocket, and noting the part

number stamped on the existing spacer, replace it

with the next larger size. See spacer sizes listed in

Ta bl e 3-4. Replace the spacer with the next smaller

size only if the primary cam sprocket is “proud”

(rises above the face of the crank sprocket) more

than 0.010 inch. Return to step 21 to repeat the

check with the new spacer installed.

Sprocket

Locking Tool

f2139x3x

Figure 3-52. Lock Crank and Primary Cam Sprockets

Before Tightening Flange Bolts

Table 3-4. Primary Cam Sprocket Spacers

Spacer Size

0.287 25722-00

0.297 25723-00

0.307 25721-00

0.317 25719-00

0.327 25717-00

0.337 25725-00

f. Remove both crank and primary cam sprockets.

Discard smaller diameter flat washer obtained from

bulk inventory.

23. Install the primary cam chain and sprocket assembly as

follows:

H-D Part Number

2004 Touring: Engine 3-51

Page 20

HOM

E

Crank

Primary Cam

Sprocket

Punch Marks

Figure 3-54. Verify Alignment of Crank and

Primary Cam Sprocket Punch Marks

a. Place the primary cam sprocket in the cam chain.

Hold the sprocket allowing the chain to hang loose.

Rotate the sprocket so that the punch mark on the

sprocket root faces straight downward.

NOTE

To maintain the original direction of rotation, verify that the

colored mark placed on the chain link and crank sprocket is

facing away from the cam support plate during installation.

b. Place the crank sprocket in the opposite end of the

chain with the punch mark on the sprocket tooth facing straight upward.

c. Maintaining the position of the sprockets on the

chain with the punch marks in alignment, start the

primary cam sprocket onto the splines of the rear

camshaft. Apply a thin film of clean H-D 20W50

engine oil to the splines before installation.

d. Maintaining the position of the crank sprocket on the

chain, rotate the primary cam sprocket in a clockwise direction until the flat on the crank sprocket is

aligned with the flat on the crankshaft. Install the

crank sprocket.

24. Rotate the primary cam sprocket in a clockwise direction

until the punch mark on the root is aligned with the

punch mark on the crank sprocket tooth. Lay a straightedge across the centerline of the crank and primary cam

sprocket flange bolt holes to verify that the punch marks

are in alignment. See Figure 3-54.

Sprocket

f2138x3x

NOTE

If the punch marks are not in alignment, then the sprockets

must be removed and reinstalled. The vehicle will not run

properly if the sprockets are misaligned by even one tooth.

NOTE

Both crank and primary cam sprocket flange bolts are specially hardened, while the flat washers are of a special diameter and thickness. Therefore, use only genuine HarleyDavidson parts when replacement is necessary. The crank

and primary cam sprocket flange bolts and flat washers are

NOT

interchangeable.

25. Install crank sprocket and primary cam sprocket flange

bolts and flat washers as follows:

NOTE

Exercise caution to avoid mixing oil on washer with threadlocker on bolt or sealing integrity may be compromised.

a. Apply a thin film of clean H-D 20W50 engine oil to

both sides of flat washers.

b. Install thinner

c. Install thic

d. Apply Loctite Primer 7649 (P/N 98968-99) to

threads of flange bolts.

e. Apply one drop

locker 262 (red) to threads of flange bolts.

f. Install shor

secure crank sprocket to end of crankshaft.

g. Install long

secure primary cam sprocket to end of camshaft.

h. Position CRANKSHAFT/CAMSHAFT SPROCKET

LOCKING TOOL (HD-42314) between the crank

and primary cam sprockets to prevent rotation. See

Figure 3-52. The handle of the tool is stamped

“Crank” and “Cam” to ensure proper orientation.

i. Alternately tighten the crank and primary cam

sprocket flange bolts to 15 ft-lbs (20.3 Nm).

j. Loosen each flange bolt one full turn.

k. Tighten the crank sprocket flange bolt to 24 ft-lbs

(32.5 Nm).

l. Tighten the primary cam sprocket flange bolt to 34

ft-lbs (46.1 Nm).

m. Remove the sprocket locking tool.

flat washer on short flange bolt.

ker flat washer on long flange bolt.

of Loctite High Strength Thread-

t flange bolt with thinner flat washer to

flange bolt with thicker flat washer to

1CAUTION

Ease the primary cam chain tensioner into the unloaded

position using the proper tool. Do not pull the retention

pin to unload the tensioner or the pin may be damaged.

Furthermore, if the tensioner should contact fingers or

other parts of the hand, minor or moderate injury may

occur.

3-52 2004 Touring: Engine

Page 21

HOM

CAUTION

E

Tor que: 125-155 in-lbs

1

9

26. Hold the retracted primary cam chain tensioner with the

7

6

4

10

CAM CHAIN TENSIONER UNLOADER (HD-42313),

pull retention pin from hole in cam support plate and

ease the assembly into the unloaded position.

27. Apply clean H-D 20W50 engine oil to crank and primary

cam sprockets.

Before cam cover installation, verify cleanliness of blind

holes in the crankcase flange. Tightening screws with

dirt, water or oil in the holes can cause the casting to

crack or break. Damage to the casting requires replacement of the right crankcase half.

5

3

Figure 3-55. Cam Cover Torque Sequence

2

f1616b3x

28. Align holes in

crankcase flange.

8

29. Install the cam cover using ten allen head socket screws

(1/4 x 1-1/4 inches). Alternately tighten screws to 125155

in-lbs

Figure 3-55.

30. If performing a complete engine overhaul, see Section

3.9 TOP END OVERHAUL, ASSEMBLY, steps 1-39. If

only cam compartment components were serviced, just

see steps 28-37.

new

cam cover gasket with those in the

(14.1-17.5 Nm) following the pattern shown in

2004 Touring: Engine 3-53

Page 22

HOM

E

Legend:

1. Bolt

2. Bolt

3. Rocker Cover

4. Rocker Cover Gasket

5. Breather Bolt

6. Breather Cover

7. Breather Cover Gasket

8. Umbrella Valve

9. Breather Baffle

10. Filter Element

11. Breather Baffle Gasket

12. Rocker Arm Bolt

13. Rocker Arm Support Plate

14. Rocker Arm Bushing

15. Rocker Arm

16. Rocker Arm Shaft

17. Rocker Arm

18. Breather Baffle O-Ring

19. Rocker Housing Bolt

20. Rocker Housing Bolt

21. Rocker Housing

22. Rocker Housing Gasket

23. O-Ring

23

14

15

24. Upper Push Rod Cover

25. Spring Cap Retainer

2

1

3

5

26. Spring Cap

27. Spring

28. Flat Washer

29. O-Ring

30. Lower Push Rod Cover

31. O-Ring

32. Lifter Cover Screw

33. Lifter Cover

34. Anti-Rotation Pin

35. Lifter Cover Gasket

36. Hydraulic Lifter

37. Push Rod

4

7

6

14

12

9

8

11

10

13

12

19

37

25

32

27

29

24

35

26

28

16

30

17

18

20

16

21

22

31

33

34

36

Figure 3-56. Rocker Arm/Breather/Lifter Assemblies (Exploded View)

3-54 2004 Touring: Engine

f2239x3x

Page 23

HOM

f2176x3x

1. Bolt

2. Breather Cover

3. Cover Gasket

4. Umbrella Valve

5. Breather Baffle

6. Filter Element

7. Breather Baffle Gasket

1

2

3

4 5

6

7

E

SUBASSEMBLY SERVICE AND REPAIR 3.11

TOP END

BREATHER ASSEMBLY

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-8.

Disassembly

1. Remove two bolts and lift breather assembly from rocker

arm support plate. See Figure 3-57.

2. Remove the breather cover and gasket. Remove the

breather baffle and gasket. Discard gaskets.

3. Pull filter element from bore on inboard side of breather

baffle. Pull stem of umbrella valve from hole at top of

breather baffle. Discard both filter element and umbrella

valve.

Cleaning and Inspection

1. Clean all parts in a non-volatile cleaning solution or solvent.

2. Thoroughly dry all parts with low pressure compressed

air.

3. Set a straightedge diagonally across the length of the

breather cover intersecting the opposite corners of the

gasket surface. Slide a feeler gauge beneath the

straightedge to check the breather cover for warpage.

Repeat the step checking the opposite diagonal. Discard

the breather cover if any low spot exceeds 0.005 inch

(0.13 mm).

4. Repeat step 3 to inspect the gasket surface of the

breather baffle for flatness. Discard the breather baffle if

any low spot exceeds 0.005 inch (0.13 mm).

Assembly

1. Insert stem of

top of breather baffle. Carefully pull rubber bead on stem

through hole in baffle. Use denatured alcohol or glass

cleaner to lubricate stem, if necessary. Verify that rubber

bead is pulled completely through hole and resides on

bottom side of baffle.

2. Press

Hole in filter element accommodates umbrella valve

stem.

new

umbrella valve through center hole at

new

filter element into bore at bottom of baffle.

Figure 3-57. Breather Assembly

3. Place breather baffle gasket on a clean flat surface.

Aligning holes, place breather baffle, cover gasket and

breather cover on top. Slide two screws through stackup

to keep assembly together until time of installation.

Installation

1. See Section 3.9 TOP END OVERHAUL, ASSEMBLY,

steps 31-39.

2004 Touring: Engine 3-55

Page 24

HOM

E

ROCKER ARM ASSEMBLY

3. Remove the rocker arms from the rocker arm support

plate. Mark the rocker arms to indicate location.

Removal

Cleaning and Inspection

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-9.

Disassembly

1. Remove the four bolts from the rocker arm support plate.

If necessary, slightly wiggle the two bolts on the push rod

side (right) to disengage them from the notches in the

rocker arm shafts.

2. Using a hammer and brass drift, tap left side of rocker

arm shafts so that the notched ends exit the rocker arm

support plate first. Mark the shafts so that they are

installed in their original locations at time of assembly.

1. Clean all parts in a non-volatile cleaning solution or solvent. Thoroughly dry with low pressure compressed air.

2. Check rocker arms for uneven wear or pitting where contact is made with the valve stem tips. Check for concave

wear where rocker arms contact the push rod ends.

Replace rocker arm if excessive wear is found at either

location.

3. Verify that oil holes in rocker arms and rocker arm support plate are clean and open.

4. Inspect rocker arm shafts for scratches, burrs, scoring or

excessive wear. Replace as necessary.

A B

C D

Figure 3-58. Measure Rocker Arm Assembly for Wear

3-56 2004 Touring: Engine

Page 25

HOM

6916

Remove Bushings.

9/16”-18 Tap

Driver

Discarded Shaft

6923

Ream Bushings.

Bushing Reamer

Part No. HD-94804-57

6922

Driver

Install Bushings.

E

5. Measure the inside diameter of the rocker arm support

plate bore. See A of Figure 3-58. Measure the outside

diameter of the rocker arm shaft where it fits in the bore.

See B of Figure 3-58. Repeat the measurement on

opposite side of support plate and shaft. Replace the

shaft or support plate if any measurement equals or

exceeds 0.0035 inch (0.089 mm).

6. Measure the inside diameter of the rocker arm bushing.

See C of Figure 3-58. Measure the outside diameter of

the rocker arm shaft where it rides in the bushing. See D

of Figure 3-58. Repeat the measurement on opposite

side of rocker arm and shaft. Replace the shaft or bushings if any measurement equals or exceeds 0.0035 inch

(0.089 mm).

7. To replace rocker arm bushings, proceed as follows:

NOTE

Remove, install and ream one bushing at a time.

a. Obtain a 9/16”-18 (14.29 mm) tap. Turn tap into

bushing until tight. Place rocker arm under ram of

arbor press with tap at bottom. Slide a discarded

rocker arm shaft through open end of rocker arm

until contact is made with tap. Using shaft as driver

(and untapped bushing as pilot), press against shaft

until both tap and bushing are free. See upper

frame of Figure 3-59.

b. Using a suitable driver, press

new

bushing into side

of rocker arm until flush with casting. See center

frame of Figure 3-59. Be sure to orient bushing so

that split line faces top of rocker arm.

Never back reamer out of rocker arm or new bushing will

be damaged.

Assembly

1. Place the rocker arms into position on the rocker arm

2. Push the un-notched ends of the rocker arm shafts into

CAUTION

c. Lock rocker arm in a vise using brass jaw inserts or

shop towels to prevent casting damage. Insert

tapered end of ROCKER ARM BUSHING REAMER

(HD-94804-57) into old bushing in rocker arm. Note

that old bushing on drive side of reamer serves as

pilot. See lower frame of Figure 3-59. Rotate reamer

until new bushing on far side is reamed, and then

continuing in the same direction, draw drive side of

reamer from new bushing.

d. Repeat steps 7(a) thru 7(c) to remove, install and

ream second bushing.

support plate.

the right side of the support plate and then into the

rocker arms. As they approach their fully installed positions, rotate the shafts so that the notches are aligned

with the bolt holes in the support plate.

Figure 3-59. Replace Rocker Arm Bushings

2004 Touring: Engine 3-57

Page 26

HOM

E

3. To check for proper end play, insert a feeler gauge

between the rocker arm and support plate. See Figure 3-

60. Repeat measurement on other rocker arm. Replace

the rocker arm, rocker arm support plate, or both if end

play exceeds 0.025 inch (0.635 mm).

4. Install the four bolts in the rocker arm support plate. For

proper assembly, remember that the two bolts on the

push rod side (right) must engage the notches in the

rocker arm shafts.

Installation

1. See Section 3.9 TOP END OVERHAUL, ASSEMBLY,

steps 31-39.

6917

Figure 3-60. Check End Play

3-58 2004 Touring: Engine

Page 27

CAUTION

f1584x3x

Flat

Washer

Spring Cap

Spring

Spring Cap

Retainer

Upper

Push Rod

Cover

O-Ring

Small

O-Ring

Intermediate

O-Ring

Large

Lower

Push Rod

Cover

Flared End

HOM

E

PUSH RODS/LIFTERS/COVERS

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-14.

Disassembly

1. With the exception of the lifter covers, all parts should

have been disassembled and marked during the

removal procedure. Disassemble the lifter covers as follows:

a. Separate upper and lower push rod covers.

b. Remove O-ring from seat at bottom of lower push

rod cover. Discard O-ring.

c. Remove O-ring from seat at top of upper push rod

cover. Slide O-ring, flat washer, spring and spring

cap from body of upper push rod cover. Discard Orings.

Cleaning and Inspection

1. Scrape old gasket material from the lifter cover flange.

Old gasket material left on mating surfaces will cause

leaks.

2. With the exception of the hydraulic lifters, clean all parts

in a non-volatile cleaning solution or solvent. Verify that

the O-ring seats and contact surfaces of the push rod

covers are completely clean.

3. Thoroughly dry all parts with low pressure compressed

air. Verify that all oil holes are clean and open.

4. Verify that the hydraulic lifter rollers turn freely and are

free of flat spots, scuff marks and pitting. If flat spots

exist, examine the cam lobe on which the lifter operates.

5. Inspect the lifter socket for signs of wear. Verify that the

plunger of the hydraulic lifter is fully extended up against

the C-clip. Use index finger to pump plunger to verify

lifter operation.

6. Examine the push rods. Replace any push rods that are

bent, dented, broken or discolored. Replace the rod if

the ball ends show signs of excessive wear or damage.

7. Cover all parts with a clean plastic sheet to protect them

from dust and dirt.

Assembly

1. With the exception of the lifter covers, all parts will be

assembled during the installation procedure. Assemble

the lifter covers as follows:

Figure 3-61. Push Rod Cover Assembly

O-rings that are missing, distorted, pinched or otherwise

damaged will result in either oil leakage or low oil pressure. Use of the wrong O-ring will have the same results.

Since many O-rings are similar in size and appearance,

always use ne

use to avoid confusion.

w O-rings keeping them packaged until

2004 Touring: Engine 3-59

Page 28

HOM

E

a. Obtain three new o-rings- small, intermediate and

large.

b. Install small O-ring on seat at the top of the upper

push rod cover.

NOTE

Apply a very thin film of clean H-D 20W50 engine oil to Orings before installation.

c. Slide the spring cap, spring, flat washer and inter-

mediate size O-ring onto the body of the upper push

rod cover. Move parts up body until spring cap contacts upper O-ring seat.

d. Fit the straight end of the upper push rod cover into

the flared end of the lower push rod cover.

e. Install large O-ring on seat at bottom of lower push

rod cover.

Installation

1. See Section 3.9 TOP END OVERHAUL, ASSEMBLY,

steps 25-39.

3-60 2004 Touring: Engine

Page 29

HOM

E

NOTES

2004 Touring: Engine 3-61

Page 30

HOM

E

Legend:

1. Tapered Keepers

2. Spring Retainer

3. Inner Spring

4. Outer Spring

5. Valve Stem Seal

6. Spring Seat

7. Valve Guide

8. Cylinder Head Bolt

9. Cylinder Head Bolt

10. Cylinder Head

11. Valve Seat

12. Valve

13. Cylinder Head Gasket

14. Cylinder

15. Ring Dowel

16. O-Ring Seal

17. Cylinder Stud

18. Piston

19. Piston Pin

20. Circlip

21. Top Compression Ring

22. Second Compression Ring

23. Oil Rail

24. Oil Rail Spacer

10

1

2

3

8

4

5

9

6

7

11

20

22

24

19

21

23

23

13

12

15

14

20

18

16

17

Figure 3-62. Cylinder Head/Cylinder/Piston Assemblies (Exploded View)

3-62 2004 Touring: Engine

f21332x3x

Page 31

HOM

f1648x3x

E

CYLINDER HEAD

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-11 and 15-19.

Disassembly

1. Before proceeding with the disassembly procedure,

determine if cylinder head reconditioning is necessary.

Proceed as follows:

a. Raise valve ports of cylinder head to strong light

source. If light is visible around edges of seats, then

move to step 2 to recondition cylinder head.

b. Fill ports at top of cylinder head with solvent. Wait

ten full seconds and then check for leakage into

combustion chamber. If solvent leakage into combustion chamber is evident, then move to step 2 to

recondition cylinder head.

14mm End

Figure 3-65. Valve Spring Compressor

(Part No. HD-34736B)

12mm End

Figure 3-63. Cylinder Head Holding Fixture

(Part No. HD-39786)

f1658x3x

Cylinder Head

Holding Fixture

Figure 3-64. Install Cylinder Head Holding Fixture in Vise

Figure 3-66. Compress Valve Springs

2. Obtain the CYLINDER HEAD HOLDING FIXTURE (HD-

39786) and proceed as follows:

a. Note that both ends of the fixture are threaded, one

end at 14mm and the other at 12mm. Thread the

12mm end of the tool into the spark plug hole of the

cylinder head.

b. Clamp tool in vise at a 45 degree angle (or one that

offers a comfortable working position). See Figure

3-64.

3. Obtain the VALVE SPRING COMPRESSOR (HD34736B) and proceed as follows:

a. Place tool over cylinder head so that the blunt end is

centered on the valve head and adapter at end of

forcing screw is seated on the valve spring retainer.

See Figure 3-66.

b. Rotate forcing screw to compress valve springs.

c. If spring retainer has not broken free of tapered

keepers, give head of tool a sharp tap with a soft

mallet. Using magnetic rod or small screwdriver,

remove the keepers from the valve stem groove.

2004 Touring: Engine 3-63

Page 32

HOM

E

d. Rotate forcing screw to release the valve spring

compression.

4. Remove the spring retainer and inner and outer valve

springs.

5. Slide the valve from the valve guide.

6. Using pliers, twist and remove the valve stem seal from

the top of the valve guide. Discard the valve stem seal.

7. Remove the spring seat from the cylinder head.

8. Mark the bottom of the valve “F(ront)” or “R(ear)” to indicate the cylinder head from which it was removed. Also,

separate and tag tapered keepers, valve springs, spring

retainers and spring seats so that they are installed on

the same valve at time of assembly.

9. Repeat steps 3-8 to remove the other valve components.

10. Release the cylinder head holding fixture from the vise

and then remove the tool from the spark plug hole.

Cleaning and Inspection

Cleaning

1. Remove old gasket material from cylinder head. Gasket

material left on sealing surfaces will cause leaks.

2. Remove all carbon deposits from combustion chamber