Page 1

HOME

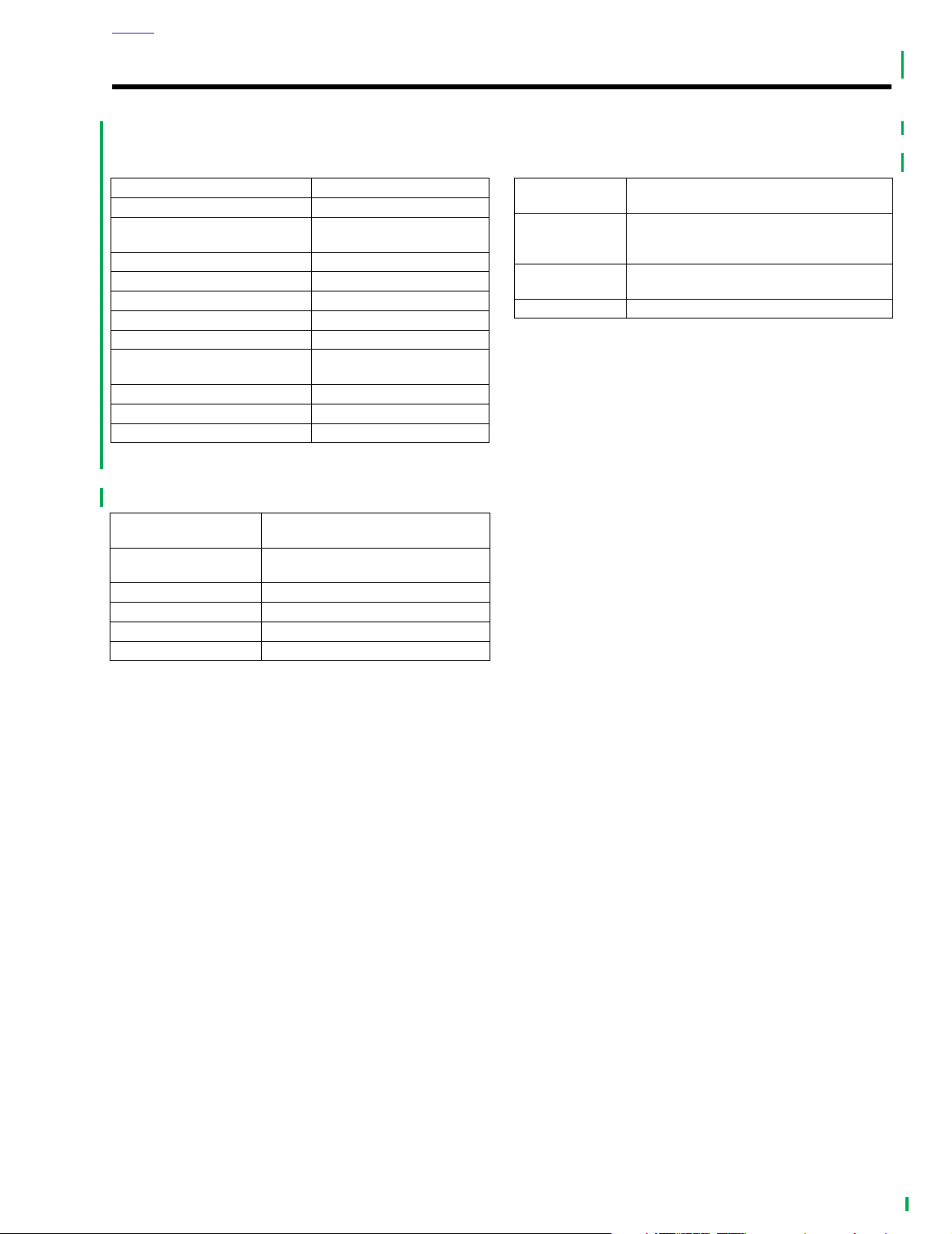

SPECIFICATIONS 3.1

Table 3-1. General

Number of cylinders 2

Ty pe 4-cycle, 45˚, air-cooled

To rque

Bore 3.875 in. (98.425 mm)

Stroke 4.375 in. (111.125 mm)

Piston displacement (approx.) 103 cu. in. (1690 cc)

Compression ratio 9.0:1

Combustion chamber Hemispherical

Cam system

Max. sustained engine speed 5800 RPM

Idle speed 1000 RPM ± 50

Weight 165 lbs (74.8 kg)

100 ft-lbs (138 Nm)

@ 3500 RPM

Tw in cams, chain driven with

spring loaded tensioners

Table 3-2. Ignition System

Ty pe

Ignition timing:

1050 RPM (hot idle)

Spark plug size 12 mm

Spark plug type Harley-Davidson 6R12

Spark plug gap 0.038-0.043 in. (0.97-1.09 mm)

Spark plug torque 12-18 ft-lbs (16.3-24.4 Nm)

Sequential, non waste spark,

MAP-N control

20˚-30˚

Table 3-3. Oiling System

Pump

Pressure

Filtration

Cooling Thermostat controlled oil cooler

Tw in gerotor, dual scavenge, crank mounted

and driven, internal oil pump, dry sump

30-38 psi (207-262 kN/m2) at

2000 RPM and normal operating temperature

of 230˚ F (110˚ C)

10 micron media,

filtered between pump and engine

2004 FLHTCSE: Engine 3-1

Page 2

HOME

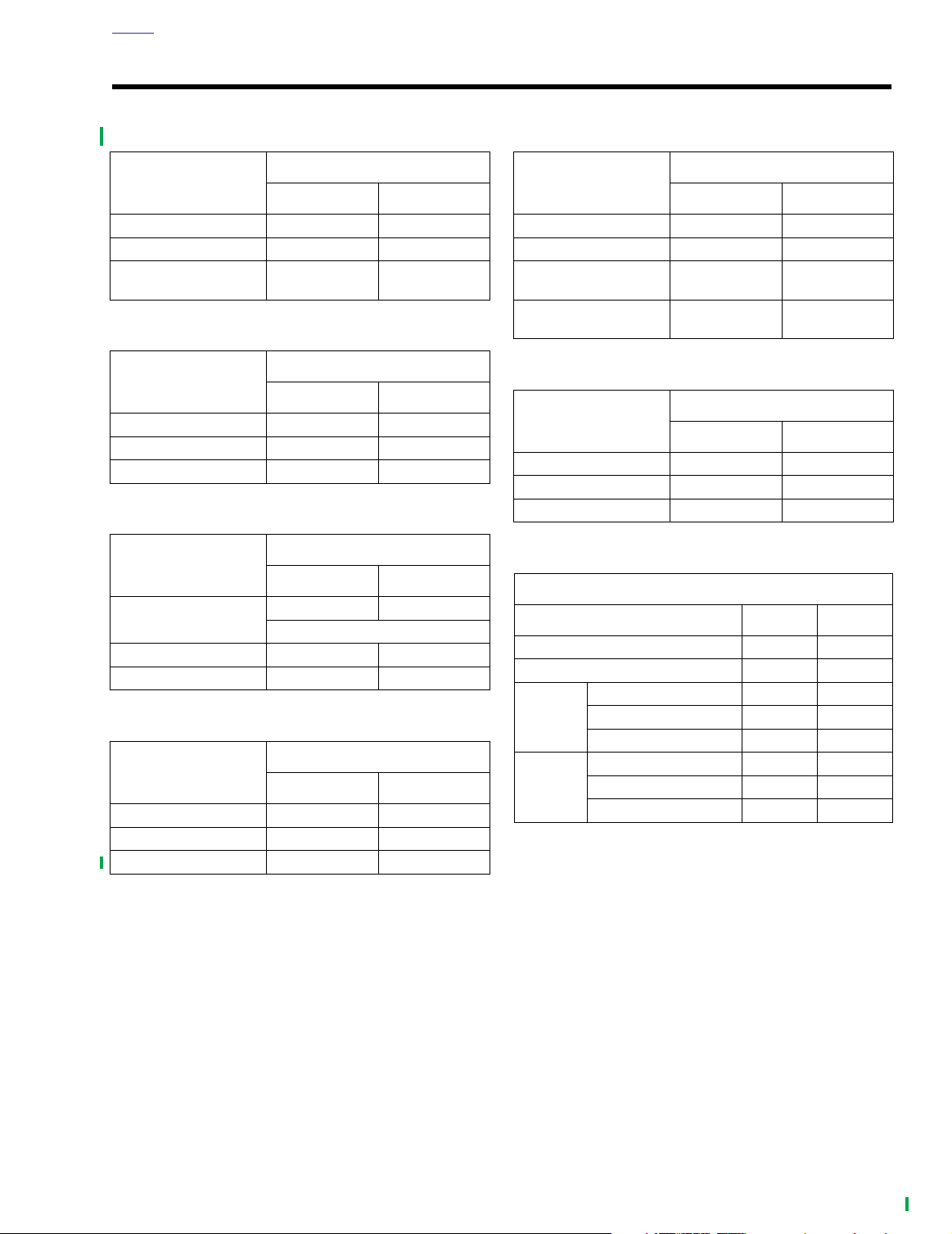

MANUFACTURING TOLERANCES 3.2

Table 3-4. Rocker Arms

IN.

Shaft fit in bushing

(loose)

End clearance 0.003-0.013 0.08-0.033

Bushing fit in rocker arm

(tight)

0.0005-0.0020 0.013-0.051

0.002-0.004 0.051-0.102

MM

Table 3-5. Rocker Arm Shaft

MM

Shaft fit in rocker arm

support plate (loose)

IN.

0.0007-0.0022 0.018-0.056

Table 3-6. Hydraulic Lifters

IN.

Fit in crankcase (loose) 0.0008-0.0020 0.02-0.05

MM

Table 3-7. Cylinder Heads

IN.

Valve guide in head (tight) 0.0020-0.0033 0.051-0.084

Valve seat in head (tight) 0.003-0.0045 0.076-0.114

Head gasket surface

(flatness)

0.006 0.0152

MM

Table 3-8. Valves

IN.

Fit in guide (exhaust) 0.0015-0.0033 0.038-0.084

Fit in guide (intake) 0.0008-0.0026 0.020-0.066

Seat width 0.040-0.062 1.02-1.58

Stem protrusion from

cylinder head boss

1.990-2.024 50.55-51.41

MM

Table 3-9. Valve Spring Assembly

PRESSURE

Closed 165 lbs (75 kg). 1.820 in (46.2 mm).

Open 416 lbs (189 kg) 1.290 in. (32.7 mm)

Free length n/a 2.210 in (56.1 mm)

DIMENSION

Table 3-10. Pistons

IN.

Fit in cylinder 0.0014-0.0025 0.036-0.064

Ring end gap:

To p compression ring

2nd compression ring

Oil control ring

Ring side clearance:

To p compression ring

2nd compression ring

Oil control ring

Piston pin fit (loose) 0.0002-0.0005 0.005- 0.013

0.010-0.020

0.014-0.024

0.010-0.050

0.0012-0.0037

0.0012-0.0037

0.0031-0.0091

MM

0.254-0.508

0.3556-0.6096

0.25-1.27

0.030-0.094

0.030-0.094

0.079-0.231

Table 3-11. Connecting Rods

IN.

Piston pin fit (loose) 0.0003-0.0007 0.008-0.018

Side play between

flywheels

Connecting rod to

crankpin (loose)

0.005-0.015 0.13-0.38

0.0004-0.0017 0.0102-0.0432

MM

Table 3-12. Flywheels

IN.

Runout

(flywheels at rim)

Runout

(shaft at flywheel)

End play 0.003-0.010 0.076-0.254

0.000-0.010 0.0-0.25

0.000-0.002 0.0-0.05

MM

Table 3-13. Crankshaft (Roller) Bearing

IN.

Roller bearing fit (loose) 0.0002-0.0015 0.005-0.038

Crankshaft runout 0.0-0.003 0.0-0.076

Bearing fit in

crankcase (tight)

Bearing inner race on

crankshaft (tight)

0.0038-0.0054 0.097-0.137

0.0001-0.0010 0.0025-0.0254

MM

3-2 2004 FLHTCSE: Engine

Page 3

HOME

SERVICE WEAR LIMITS 3.3

Table 3-14. Rocker Arm/Rocker Shaft

REPLACE IF WEAR EXCEEDS

IN. MM

Shaft fit in bushing (loose) 0.0035 0.089

End clearance 0.025 0.635

Shaft fit in rocker arm

support plate (loose)

0.0035 0.089

Table 3-15. Hydraulic Lifters

REPLACE IF WEAR EXCEEDS

IN. MM

Fit in crankcase 0.003 0.08

Roller fit 0.0015 0.038

Roller end clearance 0.015 0.38

Table 3-16. Cam Support Plate

REPLACE IF WEAR EXCEEDS

IN. MM

Cam chain

tensioner shoe

Warpage 0.010 0.25

Crankshaft bushing fit 0.0008-0.001 0.0203-0.0254

0.080-0.090 2.03-2.29

1/2 thickness of shoe

Table 3-17. Cylinder Heads

REPLACE IF WEAR EXCEEDS

IN. MM

Valve guide (tight) < 0.002 < 0.051

Valve seat (tight) < 0.002 < 0.051

Head warpage > 0.006 > 0.152

Table 3-18. Cylinders

REPLACE IF WEAR EXCEEDS

IN. MM

Ta per 0.002 0.051

Out of round 0.002 0.051

Warpage of gasket or

O-ring surfaces: top

Warpage of gasket or

O-ring surfaces: base

0.006 0.152

0.004 0.102

Table 3-19. Cylinder Bore

REPLACE IF WEAR EXCEEDS

IN. MM

Standard 3.877 98.48

0.005 in. oversize 3.882 98.60

0.010 in. oversize 3.887 98.73

Table 3-20. Pistons

REPLACE IF WEAR EXCEEDS

IN. MM

Fit in cylinder (loose) 0.003 0.076

Piston pin fit (loose) 0.0008 0.020

Ring

end gap

Ring

side

clearance

To p compression 0.030 0.762

2nd compression 0.034 0.863

Oil control ring rails 0.050 1.27

To p compression 0.0045 0.11

2nd compression 0.0045 0.11

Oil control ring rails 0.010 0.25

2004 FLHTCSE: Engine 3-3

Page 4

HOME

Table 3-21. Connecting Rods

REPLACE IF WEAR EXCEEDS

IN. MM

Piston pin fit (loose) 0.001 0.025

Side play between

flywheels

Fit on crankpin (loose) 0.002 0.05

0.020 0.51

Table 3-22. Flywheels

REPLACE IF WEAR EXCEEDS

IN. MM

Flywheel runout at rim 0.015 0.38

Shaft runout at flywheel 0.003 0.08

End play 0.010 0.254

Table 3-23. Crankshaft Sprocket

Shaft Bearing

IN.

Bearing fit (loose) 0.0015 0.038

Crankshaft runout 0.003 0.076

Bearing fit in

crankcase (tight)

Bearing inner race on

crankshaft (tight)

0.0038-0.0054 0.097-0.137

0.0001 0.0254

MM

3-4 2004 FLHTCSE: Engine

Page 5

HOME

TORQUE VALUES 3.4

ITEM TORQUE NOTES

Rocker housing bolts 120-168

Oil vent line crankcase fitting 130-150

Oil fittings 120-168

Chrome oil vent line nuts 60-80

Oil cooler to mounting backet 80-110

Tr ansfer passage cover 90-120

Oil filter mount 130-150

Thermostat plug 15-20 ft-lbs 20.4-27.1 Nm page 3-23

Oil filter adapter 12-16 ft-lbs 16.3-21.7 Nm page 3-23

Thermostat plug 15-20 ft-lbs 20.4-27.1 Nm page 3-24

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

13.6-18.9 Nm page 3-9

14.7-16.9 Nm page 3-17

13.6-19.0 Nm page 3-17

6.8-9.0 Nm page 3-17

9.1-12.4 Nm page 3-21

10.2-13.5 Nm page 3-23

14.7-16.9 Nm page 3-23

2004 FLHTCSE: Engine 3-5

Page 6

HOME

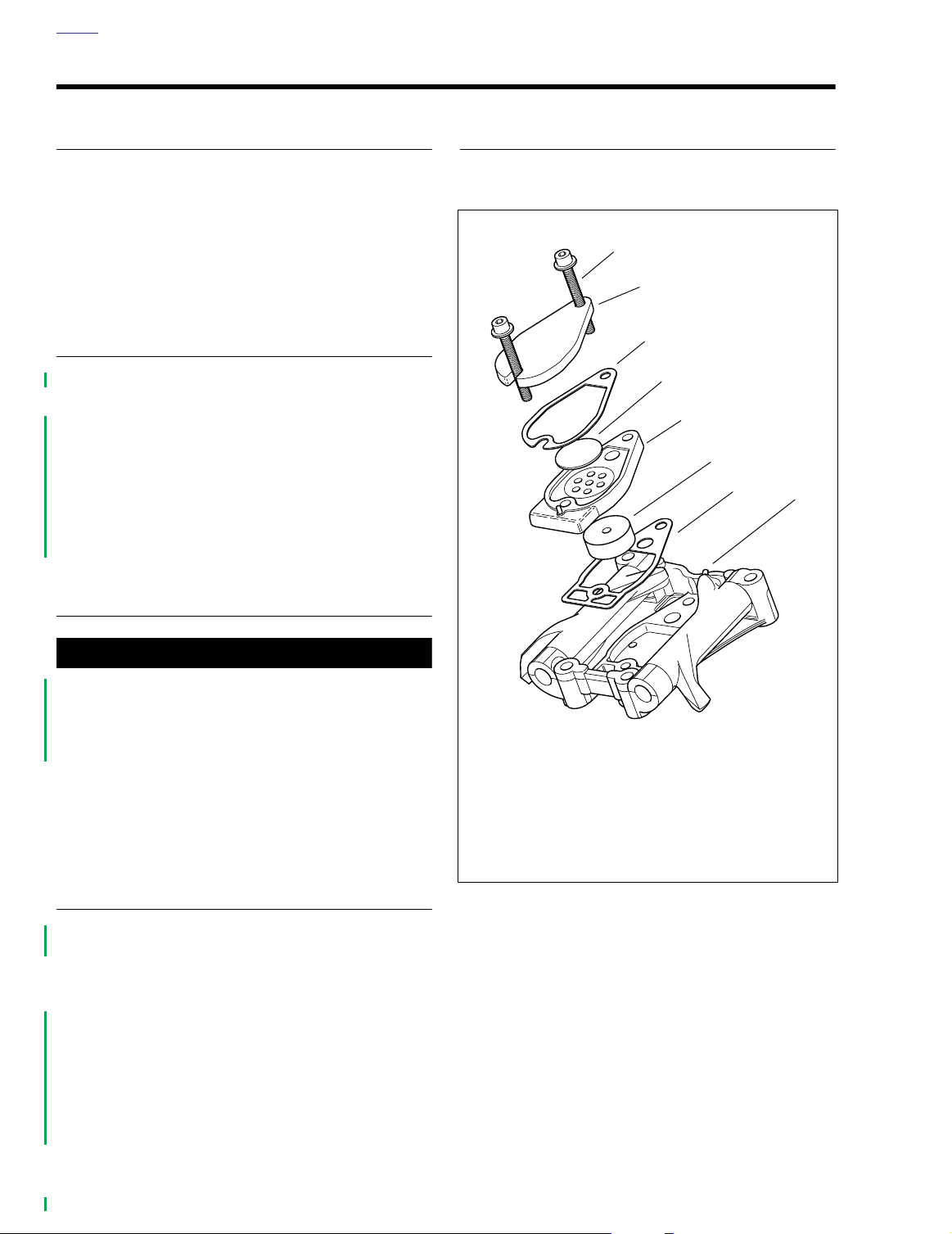

BREATHER ASSEMBLY 3.5

REMOVAL

See TOP END OVERHAUL in the Touring Models Service

Manual.

NOTE

If breather style is different from that illustrated, see

BREATHER ASSEMBLY under TOP END under SUBASSEMBLY SERVICE AND REPAIR, in the Touring Models Service Manual.

DISASSEMBLY

1. See Figure 3-1. Remove two fasteners from breather

assembly.

2. Remove breather cover and gasket. Discard cover gasket.

3. Remove the breather baffle and gasket. Discard gasket.

4. Pull filter element from bore on inboard side of breather

baffle. Discard filter element.

5. Pull stem of umbrella valve from hole at top of breather

baffle. Discard umbrella valve.

CLEANING AND INSPECTION

INSTALLATION

See TOP END OVERHAUL in the Touring Models Service

Manual.

f1531x4x

1

2

3

4

5

6

7

8

1WARNING1WARNING

Compressed air can pierce the skin and flying debris

from compressed air could cause serious eye injury.

Wear safety glasses when working with compressed air.

Never use your hand to check for air leaks or to determine air flow rates. (00061a)

1. Clean all parts in a non-volatile cleaning solution or solvent.

2. Thoroughly dry all parts with low pressure compressed

air.

ASSEMBLY

1. See Figure 3-1. Insert stem of

through center hole at top of breather baffle. Use denatured alcohol or glass cleaner to lubricate stem. Carefully pull rubber bead on stem through hole in baffle.

Verify that rubber bead is pulled completely through hole

and resides on bottom side of baffle.

2. Press

3. Place breather baffle gasket on a clean flat surface.

new

filter element into bore at bottom of baffle

Hole in filter element accommodates umbrella valve

stem.

Aligning holes, place breather baffle, cover gasket and

breather cover on top. Slide two screws through stackup

to keep assembly together until time of installation.

new

umbrella valve

1. Fastener

2. Breather cover

3. Cover gasket

4. Umbrella valve

5. Breather baffle

6. Filter element

7. Breather baffle gasket

8. Rocker arm support plate

Figure 3-1. Breather Components

3-6 2004 FLHTCSE: Engine

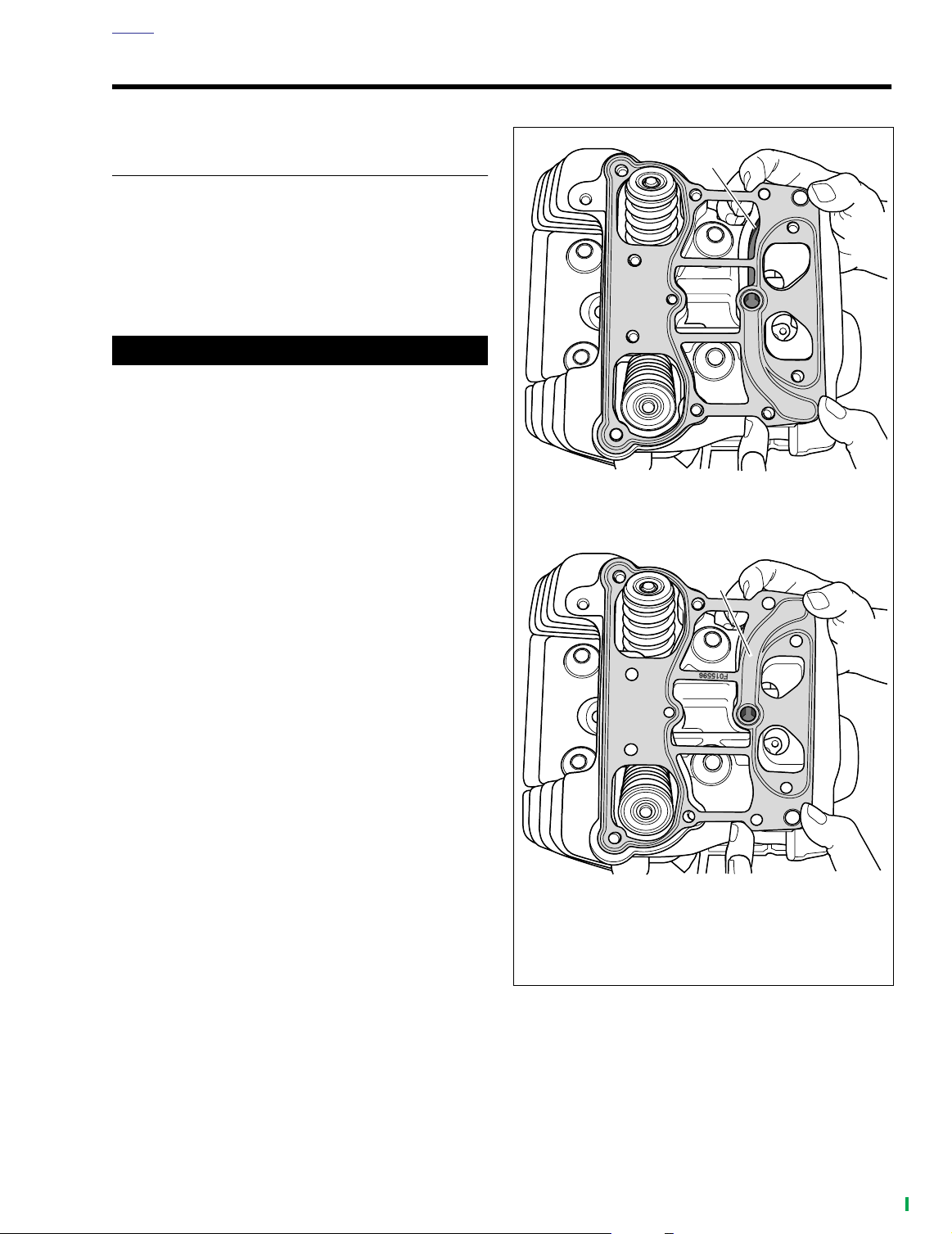

Page 7

HOME

f157x3x

1. Breather channel exposed (wrong)

2. Breather channel concealed (right)

f1576x3x

1

WRONG

RIGHT

2

ROCKER HOUSING 3.6

VALVE SPRING TO ROCKER HOUSING CLEARANCE

1. After torquing cylinder head bolts, continue top end overhaul by installing the rocker housings. See ASSEMBLY

under TOP END OVERHAUL in the Touring Models Service Manual.

2. Install a

flange.

Even though all bolt holes (rocker housing, rocker arm

support plate and breather assembly) may appear to be

in alignment, the rocker housing gasket may be installed

upside down. An upside down gasket will result in an

open breather channel causing an oil leak when the vehicle is started, possibly resulting in engine and/or property damage.

3. See Figure 3-2. Ver ify that the rocker housing gasket is

installed correctly by noting that the breather channel is

concealed.

4. With the indent facing forward, place the rocker housing

into position aligning the holes in the housing with those

in the gasket.

new

rocker housing gasket on the cylinder head

CAUTION

Figure 3-2. Rocker Housing Gasket

2004 FLHTCSE: Engine 3-7

Page 8

HOME

5. Apply a small dab of LOCTITE THREADLOCKER 243

(blue) (HD-99642-97) to threads of six rocker housing

bolts.

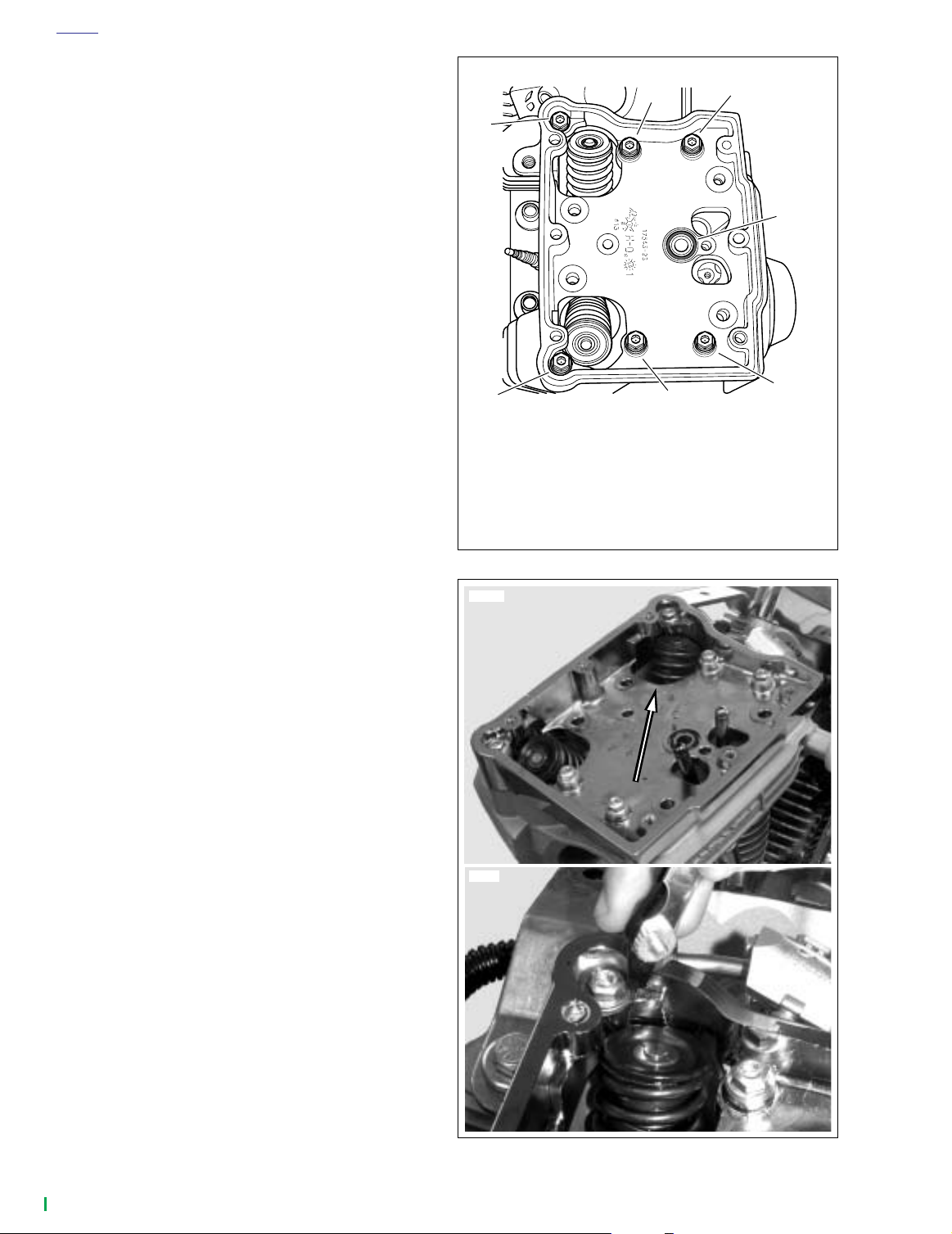

6. See Figure 3-3. Start the rocker housing bolts, two long

bolts on the left side of the engine, four intermediate

bolts in the interior.

NOTE

Rocker housing and rocker cover bolts have both an internal

and external hex, which allows the bolts to be installed with

either a short 3/16 inch allen wrench (tight spaces), or a 7/16

inch socket or open end/box wrench (open spaces). If the

engine is left in the chassis for service, the short 3/16 inch

allen wrench is indispensable when installing the rocker

housing and rocker cover bolts on the left side of the engine

(particularly the rear) where there is close proximity to the

frame.

7. From the cam cover side, press rocker cover diagonally

toward the intake valve.

8. See Figure 3-5. Snug bolts in torque sequence to hold

housing in position. Do not torque.

9. See Figure 3-4. Using a feeler gauge, check for clear-

ance around both valve spring assemblies and the

rocker housing.

f1578x3x

2

1

f1578x3x

7

1. Long bolt 1-3/4 in.

2. Intermediate bolt 1-1/4 in.

3. Intermediate bolt 1-1/4 in.

4. O-ring

5. Intermediate bolt 1-1/4 in.

6. Intermediate bolt 1-1/4 in.

7. Long bolt 1-3/4 in.

3

4

6

5

10. If spring assembly contacts rocker housing at any point

around springs, loosen rocker cover bolts and press on

side of cover opposite contact point to produced noticeable clearance between housing and valve assembly.

Figure 3-3. Rocker Housing Bolt Lengths

9977

8877

3-8 2004 FLHTCSE: Engine

Figure 3-4. Valve Spring to Rocker Housing Clearance

Page 9

HOME

3

1

2

4

5

6

f1578x3x

11. Tighten rocker housing bolts to 120-168

18.9 Nm) in the pattern shown in Figure 3-5.

NOTE

If the engine was left in the chassis for service, final tighten

the rear left rocker housing bolt (rear cylinder) using a torque

wrench with a 1/4 inch drive. Since this tool may not be available in foot-pounds, tighten the bolt to 120-168

12. Re-check clearance at both valve spring assemblies and

repeat until there is sufficient clearance between spring

assemblies and rocker housing with the bolts torqued.

CAUTION

O-rings that are missing, distorted, pinched or otherwise

damaged will result in either oil leakage or low oil pressure. Use of the wrong o-ring will have the same results.

Since many o-rings are similar in size and appearance,

always use ne

to avoid confusion.

13. Install

in rocker housing. Apply a thin film of clean SYN3 engine

oil to o-ring before installation.

w o-rings keeping them packaged until use

new

o-ring in groove around breather baffle hole

in-lbs

in-lbs

(13.6-

.

Figure 3-5. Rocker Housing Torque Sequence

14. Continue the top end overhaul by installing the hydraulic

lifters in the crankcase bores. See ASSEMBLY under

TOP END OVERHAUL in the Touring Models Service

Manual.

2004 FLHTCSE: Engine 3-9

Page 10

HOME

CYLINDER HEADS 3.7

GENERAL

Major components of the FLHTCSE engine differ from other

touring models in specification and appearance. However,

service procedures for the following components are the

same as those found in the Touring Models Service Manual.

See CYLINDER HEAD under SUBASSEMBLY SERVICE

AND REPAIR in the Touring Models Service Manual.

For service wear limits, refer to Ta bl e 3-17.

9975

2

1

1. Hemispherical combustion chamber

2. Machined relief

Figure 3-6. FLHTCSE

Front Cylinder Head

3-10 2004 FLHTCSE: Engine

Page 11

HOME

1. Oval opening

2. 4-5 inch micrometer

3. Spherical ball anvil adapters

f2109x3x

f2113x4x

11

3

2

PISTONS 3.8

GENERAL

Major components of the FLHTCSE engine differ from other

touring models in specification and appearance. However,

service procedures for the following components are the

same as those found in the Touring Models Service Manual.

See PISTON on SUBASSEMBLY SERVICE AND REPAIR in

the Touring Models Service Manual.

For service wear limits, refer to Ta bl e 3-20. and Table 3-19.

NOTE

The piston is measured on the bare aluminum to avoid measuring errors. An oval-shaped spot is present on each side of

the piston for proper placement of the micrometer. See upper

frame of Figure 3-8. Since the oval openings are too small for

a standard flat anvil micrometer, which would result in measuring errors, use a 4-5 inch micrometer with spherical ball

anvil adapters. See lower frame of Figure 3-8.

9974

Figure 3-8. FLHTCSE Piston Measurement

Figure 3-7. FLHTCSE Piston Orientation Arrow

(arrow points to front of engine)

2004 FLHTCSE: Engine 3-11

Page 12

HOME

BORING AND HONING CYLINDERS 3.9

CYLINDER BORE FINISHED SIZE

1. For cylinder removal, cleaning, inspection, boring and

honing and installation, see CYLINDER in the Touring

Models Service Manual.

2. Refer to Ta bl e 3-24. Bore the cylinder to 0.003 in. (0.08

mm) under the desired finished size. See BORING and

HONING CYLINDER in the Touring Models Service

Manual. Refer to Ta bl e 3-24.

CAUTION

An improper crosshatch pattern or too fine a hone will

result in insufficient oil retention and possible piston

seizure and/or high oil consumption.

3. Hone the cylinder to its finished size using a 280 grit

rigid hone followed by a 240 grit flexible ball hone. Honing must be done with the torque plates attached. All

honing must be done from the bottom (crankcase end of

the cylinder. Work for a 60˚ crosshatch pattern.

4. Stop frequently to examine the cylinder bore and/or take

measurements. Remember, a precise 60˚ cross hatch

pattern in the piston travel area is important.

Table 3-24. Oversize Pistons/Cylinder Bores

PISTON CYLINDER BORE FINISHED SIZE

5. Thoroughly wash the cylinder bore with liquid dish soap

and warm water to remove all abrasive particles and

residual girt. Continue cleaning until a clean cloth shows

no evidence or dirt or debris.

6. Immediately apply a thin film of clean engine oil to a

clean white paper towel and thoroughly wipe the inside

of the cylinder. This prevents the cylinder bore from rusting.

NOTE

After wiping the cylinder with a clean, oiled paper towel, the

towel will be dark with contamination. Repeat this process

using a new lightly oiled paper towel each time until the towel

remains white. The cylinder is now clean.

7. With the cylinder at room temperature, check the piston

clearance in the cylinder in which the piston will run. See

INSPECTION under PISTON in Touring Models Service

Manual.

8. For cylinder installation, see CYLINDER in Touring Models Service Manual.

TYPE SIZE MINIMUM MAXIMUM

Standard STD 3.8750 in. (98.4250 mm) 3.8755 in. (98.438 mm)

Oversize

0.005 in. (0.13 mm) 3.8800 in. (98.552 mm) 3.8805 in. (98.565 mm)

0.010 (0.25 mm) 3.8850 in. (98.679 mm) 3.8855 in. (98.692 mm)

3-12 2004 FLHTCSE: Engine

Page 13

HOME

CAMS AND TIMING MARKS 3.10

GENERAL

Major components of the FLHTCSE engine differ from other

touring models in specification and appearance. However,

service procedures for the following components are the

same as those found in the Touring Models Service Manual.

See Camshafts and Camshaft Bearings under CAM SUPPORT PLATE under SUBASSEMBLY SERVICE AND

REPAIR in the Touring Models Service Manual.

f1607a3x

1. Rear camshaft punch mark

2. Front camshaft punch mark

Figure 3-9. FLHTCSE

2

1

Cam Timing Marks

2004 FLHTCSE: Engine 3-13

Page 14

HOME

FLYWHEEL/CONNECTING ROD ASSEMBLY 3.11

GENERAL

For removal, inspection, and installation, see FLYWHEEL/

CONNECTING ROD ASSEMBLY under SUBASSEMBLY

SERVICE AND REPAIR in the Touring Models Service Manual.

For service wear limits, refer to Ta bl e 3-21. and Tab l e 3-22.

NOTE

If the flywheel or connecting rods need to be replaced, then

they must be replaced together as one assembly.

9978

SPROCKET SHAFT BEARING INNER RACE REPLACEMENT

PA RT NO. SPECIALTY TOOL

HD-44358 Flywheel support fixture

HD-95637-46A Wedge attachment

HD-34902B

HD-25070 Robinair heat gun

1. If reusing flywheel, remove bearing inner race and thrust

washer as follows:

a. Obtain FLYWHEEL SUPPORT FIXTURE (HD-

44358). See Figure 3-11. Install brass jaws or shop

towels around teeth of vise to prevent damage to

tool. Clamp tool in vise with the round hole topside.

b. Insert crankshaft end through hole resting flywheel

assembly on fixture. Slide knurled locating pin down

slot in tool to engage crank pin hole. Hand tighten

locating pin.

c. Slide hold-down clamp down slot to engage inboard

side of right flywheel half, and then hand tighten

knurled nut at bottom to secure. Repeat step to

secure hold-down clamp on opposite side of flywheel.

For proper clamping force, hold-down clamp must not be

tilted. Rotate hex on outboard stud until clamp is level.

d. Position WEDGE ATTACHMENT (HD-95637-46A)

on inboard side of thrust washer and turn hex nuts

an equal number of turns to draw halves of wedge

together.

Mainshaft bearing inner race

puller/installer

NOTE

Figure 3-10. FLHTCSE

Flywheel/Connecting Rod Assembly

3-14 2004 FLHTCSE: Engine

CAUTION

Install wedge attachment only so far as necessary to

ensure positive contact with thrust washer. Installing

tool with more contact than absolutely necessary will

result in damage to flywheel.

e. Obtain two 3/8-16 inch bolts 6-1/2 inches long (with

flat washers). Install flat washers on bolts. Obtain

bridge, forcing screw and hardened plug from

MAINSHAFT BEARING INNER RACE PULLER/

INSTALLER (HD-34902B).

f. Slide one bolt into channel on each side of bridge

so that flat washer is between bridge and bolt head.

Thread bolts into wedge attachment an equal number of turns.

g. Sparingly apply graphite lubricant to threads of forc-

ing screw to prolong service life and ensure smooth

operation. Start forcing screw into center hole of

bridge.

Page 15

1. Hold-down clamp

2. Locating pin

1

2

f1869x3d

1. Forcing screw

2. 3/8-16 Inch bolt with flat washer

3. Bridge

4. Hardened plug

5. Wedge attachment

6. Bearing inner race

7. Sprocket shaft

f2154x3x

1

2

3

4

5

6

7

HOME

CAUTION

Failure to use hardened plug may result in damage to

forcing screw and/or sprocket shaft.

h. Place cupped side of hardened plug against end of

sprocket shaft. Thread forcing screw into bridge until

the steel ball at the end of the screw makes firm

contact with hardened plug.

i. Using the ROBINAIR HEAT GUN (HD-25070), uni-

formly heat the bearing inner race for about 30 seconds using a circular motion.

NOTE

To facilitate removal without heat, apply a light penetrating oil

to shaft and leading edge of bearing inner race.

1WARNING1WARNING

Never use both heat and penetrating oil. Use only one or

the other. Excessive heat can cause the penetrating oil

to ignite resulting in flames or fire. Inadequate safety

precautions can result in death or serious injury.

j. Turn forcing screw until thrust washer and bearing

inner race move approximately 1/8 inch (3.2 mm).

k. Turn hex nuts an equal number of turns to separate

halves of WEDGE ATTACHMENT.

l. After bottoming thrust washer on shaft, reposition

WEDGE ATTACHMENT (HD-95637-46A) on

inboard side of bearing inner race. Turn hex nuts an

equal number of turns to draw halves of wedge

together.

CAUTION

Figure 3-11. Flywheel Support Fixture (Part No. HD-

44358)

Install wedge attachment only so far as necessary to

ensure positive contact with bearing inner race. Installing tool with more contact than absolutely necessary

will result in damage to flywheel.

m. Verify that the tool assembly is square, so that the

bearing inner race is not cocked during removal.

See Figure 3-12.

n. Using the ROBINAIR HEAT GUN (HD-25070), uni-

formly heat the bearing inner race for about 30 seconds using a circular motion.

To facilitate removal without heat, apply a light penetrating oil

to shaft and leading edge of bearing inner race.

o. Tu rn forcing screw until bearing inner race is pulled

free of sprocket shaft.

p. Remove thrust washer from sprocket shaft.

q. Discard thrust washer and bearing inner race.

NOTE

Figure 3-12. Remove Inner Race From Sprocket Shaft

2. Place new thrust washer over sprocket shaft with the ink

stamp facing outside (and the chamfer on the ID

inboard).

2004 FLHTCSE: Engine 3-15

Page 16

HOME

3. Place new bearing inner race on bench top. Using the

ROBINAIR HEAT GUN (HD-25070), uniformly heat

bearing inner race for about 60 seconds using a circular

motion.

4. Wearing suitable gloves to protect hands from burns,

place heated bearing inner race over sprocket shaft.

NOTE

To facilitate installation without heat, apply a light penetrating

oil to shaft and leading edge of bearing inner race.

1WARNING1WARNING

h9772-55b

Figure 3-13. Sprocket Shaft Timken Bearing

Cone Installer (Part No. HD-97225-55B)

Never use both heat and penetrating oil. Use only one or

the other. Excessive heat can cause the penetrating oil

to ignite resulting in flames or fire. Inadequate safety

precautions can result in death or serious injury.

5. See Figure 3-13. Obtain the SPROCKET SHAFT

TIMKEN BEARING CONE INSTALLER (HD-9722555B). Assemble tool as described below.

a. See Figure 3-14. Thread pilot shaft onto sprocket

shaft until contact is made with shoulder.

b. Sparingly apply graphite lubricant to threads of pilot

shaft to prolong service life and ensure smooth

operation.

c. Slide sleeve over pilot until it contacts bearing inner

race.

d. Slide Nice bearing and large flat washer over pilot

until contact is made with sleeve.

e. Thread handle onto pilot shaft. See upper frame of

Figure 3-14.

6. Rotate handle of tool in a clockwise direction until bearing inner race bottoms against thrust washer. See lower

frame of Figure 3-14.

f2152x3x

f2153x3x

1

4

3

2

5

7

6

7. Remove handle, flat washer, Nice bearing, sleeve and

pilot from sprocket shaft.

3-16 2004 FLHTCSE: Engine

1. Pilot shaft

2. Handle

3. Flat washer

4. Nice bearing

5. Sleeve

6. Inner race

7. Thrust washer

Figure 3-14. Press Inner Race Onto Sprocket Shaft

Page 17

HOME

1. Oil spout fitting

2. Hose

3. Oil vent line parallel to transmission cover

4. S-bend

5. Crankcase fitting nut

1

2

3

9968

4

5

OIL VENT LINE 3.12

REPLACEMENT

PA RT NO. SPECIALTY TOOL

HD-41137 Hose clamp pliers

IMPORTANT NOTE

Dispose of oil in accordance with local regulations.

1. See Figure 3-15. Back the chrome nut off of the crankcase oil fitting.

2. Using side cutters, cut the clamps on the short length of

hose at the oil spout end of the vent line.

3. Remove the oil vent line.

4. If necessary, remove both fittings and clean sealant from

threads in crankcase and oil fill.

Figure 3-15. Oil Vent Line (clamps removed)

NOTE

The spout fitting is a nipple styled fitting.

5. If removed, identify the crankcase end fitting and using

pipe sealant or TEFLON

threaded end of fitting. Thread fitting into crankcase and

tighten to 130-150 in-lbs (14.7-16.9 Nm).

6. If removed, identify oil spout fitting and using pipe sealant or TEFLON

of fitting. Thread fitting into oil spout and tighten to 130150 in-lbs (14.7-16.9 Nm).

7. Slide crankcase fitting nut and rubber ferrule on crankcase end of vent line.

8. Push new hose with new clamps on the oil spout end of

chrome vent line.

9. Orient s-bend in vent line toward crankcase and slide

chrome vent line into case fitting.

10. Push hose onto oil spout fitting.

11. Position line parallel with transmission cover and with

clearance to other components.

12. Push rubber ferrule into crankcase fitting. Thread

chrome nut over ferrule and hand tighten.

®

tape, prepare the tapered threaded end

®

tape, prepare the tapered

13. Tighten chrome nut to 60-80 in-lbs (6.8-9.0 Nm).

14. Using HOSE CLAMP PLIERS (HD-41137), crimp the

clamps on the hose.

15. Operate motorcycle and inspect for leaks.

2004 FLHTCSE: Engine 3-17

Page 18

HOME

OIL COOLER OPERATION 3.13

GENERAL

For engine oil flow through the engine, See ENGINE OIL

FLOW under GENERAL INFORMATION in Touring Models

Service Manual.

See Figure 3-16. The FLHTCSE

installed oil cooler controlled by a thermostat in the oil filter

mount.

Engine oil flows from the crankcase through the oil filter

mount to the oil cooler through a supply hose. The oil circulates through the finned tubes of the cooler to dissipate heat

and returns to the oil filter mount through a return hose.

Under pressure from the crankcase, engine oil enters the

lower port in the oil filter mount. A passage way directs oil to

flow to the oil filter. The oil circulates through the oil filter element and out the oil filter threaded fitting.

From the oil filter, the filtered oil flows in two directions:

1. From the oil filter adapter Into the thermostat chamber.

2. Through a side passage and out the supply oil fitting to

the oil cooler.

See Figure 3-18.The thermostat chamber is located in line

with the return port to the engine crankcase. The thermostat

assembly consists of a temperature sensitive plunger compressed between a spring-loaded piston, spring and an open

cage spreader.

While the engine oil temperature is below 180˚ F (82˚ C), the

thermostat is in its closed position. See Closed Thermostat

under 3.13 OIL COOLER OPERATION.

The filtered oil is circulated through the transfer passage

where it returns to the crankcase. At the same time, oil is

supplied under pressure to the oil cooler even though the oil

cooler return port is blocked.

is equipped with a factory

8871

2

1

3

3

4

5

6

7

1. Oil filter mount

2. Transfer passage cover

3. Thermostat plug

4. Oil return fitting

5. Oil supply fitting

6. Supply hose

7. Return hose

8. Oil cooler

Figure 3-16. Oil Cooler and Bracket

(chrome cover removed for photo clarity)

8

While the engine operates at average temperatures, approximately 195˚ F (91˚ C), the thermostat partially opens allowing

cooler oil from the cooler to mix with warmer oil from the oil

transfer passage as the oil returns to the crankcase. See Par-

tially Open Thermostat under 3.13 OIL COOLER OPERATION.

When the engine oil exceeds 210˚ F (99˚ C), the thermostat

is in its fully open position. See Fully Open Thermostat under

under 3.13 OIL COOLER OPERATION.

In this position, all the oil flows through the oil cooler and

back through the oil filter mount before returning to the crankcase.

NOTE

Regardless of whether the thermostat is closed, partially

open or fully open, oil is always pressurized in the transfer

passage, the oil cooler supply hose, the oil cooler and the oil

return hose.

The oil cooler should always be checked for dirt and debris to

maintain cooler efficiency at every service interval.

3-18 2004 FLHTCSE: Engine

Page 19

1. Oil filter adapter

2. Passage to oil filter element

3. Return to crankcase

4. Supply from crankcase

5. Return hose fitting

6. Supply hose fitting

7. Open passage from oil filter

8. Open passage to oil cooler supply

2

1

5

46

8

7

8872

8875

4

3

HOME

9980

1

2

4

3

1. Transfer passage cover

2. Thermostat plug

3. Return hose fitting

4. Supply hose fitting

Figure 3-17. Oil Filter Mount on Engine

9982

1

3

2

1. Open cage spreader

2. Thermostat plunger

3. Piston

4. Spring

5. O-ring

6. Thermostat plug

Figure 3-18. Thermostat Assembly

4

6

5

9931

1

1. Return port to crankcase (thermostat removed)

2. Supply port from crankcase

Figure 3-19. Oil Filter Mount Ports to Crankcase

2

Figure 3-20. Oil Filter Mount

2004 FLHTCSE: Engine 3-19

Page 20

HOME

Closed Thermostat

See Figure 3-21. While the engine oil is cool, the thermostat

is in its closed position. The spring holds the piston over the

return passage from the oil cooler. Even though oil pressure

is supplied to the oil cooler, oil is blocked from returning from

the oil cooler.

See Figure 3-22. When closed, the piston opens a port in the

transfer passage along the side of the thermostat chamber.

The filtered oil is circulated around the piston through the

transfer passage and into a port in the thermostat chamber

where it flows through the open cage spreader and returns to

the crankcase.

Partially Open Thermostat

As the engine oil exceeds 180˚ F (82˚ C), the thermostat

plunger begins to expand and compresses the spring pushing against the piston. The piston partially opens the return

passage from the oil cooler and partially closes the port from

the chamber to the transfer passage.

While the engine operates at an average temperature, 195˚ F

(91˚ C), the thermostat remains partially open allowing cooler

oil from the cooler to mix with warmer oil from the oil filter.

Fully Open Thermostat

See Figure 3-23. The thermostat fully opens when the engine

oil temperature exceeds 210˚ F (99˚ C). The piston fully

closes the port to the transfer passage and opens the return

passage from the oil cooler.

8876

1

1. Return passage from oil cooler

2. Open passage from oil filter

Figure 3-21. Thermostat Chamber

8874

1 2

2

3

In this position, all the oil flows from the oil filter through the

oil cooler and back through the return passage before returning to the crankcase. The oil from the oil cooler return will

back up under pressure in the transfer passage even though

the port from the oil filter is closed.

1. Port open from oil filter

2. Oil under pressure

3. Port open to crankcase return

Figure 3-22. Closed Thermostat

8873

1

1. Port open to oil cooler return

2. Oil under pressure

3. Port closed from oil filter

32

3-20 2004 FLHTCSE: Engine

Figure 3-23. Fully Open Thermostat

Page 21

HOME

1. Return hose clamp

2. Supply hose clamp

3. Oil cooler and guard

4. Bracket

8871

3

4

2

1

OIL COOLER 3.14

REMOVAL

1. Cover the front fender to protect finish.

IMPORTANT NOTE

Dispose of oil in accordance with local regulations.

2. Place a container under the motorcycle to catch excess

oil.

3. Remove the fasteners holding the oil cooler and cover to

mounting bracket.

4. Pull the cooler and cover forward and, using side cutters,

cut the clamps on the supply and return hoses.

5. Remove the oil cooler with cover.

NOTE

The oil cooler guard is held in place with adhesive tape.

6. If replacing the oil hoses, remove oil pressure switch to

gain access to clamps. Cut clamps at oil filter mount.

Remove oil hoses.

7. The oil cooler should be checked for dirt and debris.

INSTALLATION

PA RT NO. SPECIALTY TOOL

HD-41137 Hose clamp pliers

1. If replacing the hoses, install new hoses with clamps at

the oil filter mount. Using HOSE CLAMP PLIERS (HD-

41137), clamp the supply and return hoses at the oil filter mount.

2. Apply LOCTITE Thread Sealant to threads of oil pressure switch and install oil pressure switch. Tighten to 96144 in-lbs. (10.84-16.26 Nm).

3. Connect oil pressure switch wire lead.

4. Attach hoses to oil cooler. Using HOSE CLAMP PLIERS

(HD-41137), clamp the supply and return hoses at the

oil cooler.

5. Install oil cooler and cover to mounting bracket. Tighten

fasteners to 80-110 in-lbs (9.1-12.4 Nm).

6. Operate motorcycle and inspect for leaks.

Figure 3-24. Oil Cooler and Mount

(chrome cover removed for photo clarity)

2004 FLHTCSE: Engine 3-21

Page 22

HOME

OIL FILTER MOUNT 3.15

REMOVAL

9980

PA RT NO. SPECIALTY TOOL

HD-42311 or HD-44067 Oil filter wrench

1. Place a container under motorcycle to catch excess oil.

2. Bend a cardboard funnel and fit to motorcycle to route

fluid away from regulator and oil cooler to container.

3. Using OIL FILTER WRENCH (HD-42311 or HD-44067),

remove oil filter. Discard oil filter

IMPORTANT NOTE

Dispose of oil in accordance with local regulations.

4. If necessary, remove the threaded oil filter adapter and

oil pressure switch.

5. Using side cutters, cut the clamps and remove oil cooler

hoses.

6. If necessary, loosen but do not remove thermostat plug.

7. Bend tabs of the lockplate away from bolt heads.

8. Remove oil filter mount lockplate fasteners and flat

washers. Discard lockplate.

9. Remove middle bolt with flat washer and remove oil filter

mount.

Figure 3-25. Oil Filter Mount (engine removed from frame)

9931

DISASSEMBLY

1. If necessary, remove the thermostat. See 3.16 THER-

MOSTAT.

2. See Figure 3-26. Remove the o-rings in the oil filter

mount.

3. Remove the transfer passage cover.

4. Remove the transfer passage cover gasket.

5. Remove the two oil cooler line fittings.

6. Clean the oil passages in a cleaning solution or solvent.

7. Remove thread locking adhesive from the threads of the

oil filter adapter.

8. Inspect the oil passages and the oil filter mount.

Figure 3-26. Oil Filter Mount O-rings

(thermostat removed)

3-22 2004 FLHTCSE: Engine

Page 23

HOME

CAUTION

9983

ASSEMBLY

1. See Figure 3-27. Install a new gasket on the transfer

passage cover.

2. Install the transfer passage cover. Tighten to 90-120 in-

lbs (10.2-13.5 Nm).

3. Using pipe sealant or TEFLON tape, prepare the

tapered threaded end of oil supply and return fittings and

install fittings.

4. If removed, replace the thermostat components:

a. Replace the spreader.

b. Replace the thermostat plunger and piston.

c. Replace the spring.

d. Install a new o-ring and loosely install thermostat

plug.

INSTALLATION

PA RT NO. SPECIALTY TOOL

HD-41137 Hose clamp pliers

1. Install the oil cooler oil hoses to the filter mount with new

clamps.

2. Using HOSE CLAMP PLIERS (HD-41137), crimp the

clamps.

3. Place flat washers in recessed bolt holes at top and bottom of filter mount flange.

4. Align holes in lockplate with holes in flat washers.

5. Slide two fasteners through lockplate, flat washers and

filter mount flange. Apply LOCTITE 243 (blue) (HD99642-97) to threads of installed bolts.

6. See Figure 3-26. Install new o-rings into grooves in oil

filter mount.

To avoid cross threading tapped holes, exercise care

when starting hex head bolts in crankcase.

7. Align holes in filter mount flange with holes in crankcase

and tighten bolts until snug.

8. Install flat washer on remaining fastener, apply LOCTITE

to threads and install in middle hole of mount flange.

9. Starting at the top, alternately tighten the fasteners to

130-150 in-lbs (14.7-16.9) Nm.

10. Bend the ends of the lockplate to capture the top and

bottom fasteners.

11. If disassembled, tighten the Thermostat plug to 15-20 ftlbs (20.4-27.1 Nm).

12. Apply LOCTITE THREADLOCKER 243 (blue) to tapered

threads of oil filter adapter. Install oil filter adapter and

tighten to 12-16 ft-lbs (16.3-21.7 Nm).

13. Install a new oil filter. See SCHEDULED MAINTE-

NANCE in Touring Models Service Manual.

NOTE

If removed, install oil pressure switch using LOCTITE Thread

Sealant and tighten to 96-144 in-lbs (10.84-16.26 Nm).

Figure 3-27. Transfer Passage Cover and Gasket

2004 FLHTCSE: Engine 3-23

Page 24

HOME

THERMOSTAT 3.16

TEST PROCEDURE

1. Using an infrared thermometer, measure the temperature at the oil pan and at the oil cooler while operating

motorcycle.

2. Compare temperatures.

a. If the temperature of the oil cooler follows the tem-

perature of the oil pan at temperatures below 180˚ F

(82˚ C), then the thermostat may be stuck open.

Allow the engine to cool, remove the thermostat.

and proceed.

b. If the temperature of the oil cooler is less than that

of the oil pan below 180˚ F (82˚ C) but, above 180˚

F (82˚ C), follows the temperature of the oil pan, the

thermostat is operating correctly.

c. If the oil pan exceeds 210˚ F (99˚ C) and the oil

cooler is cooler, then the thermostat may be stuck

closed. Allow the engine to cool, remove the thermostat and proceed.

3. Verify that thermostat plunger is fully retracted.

4. Place thermostat plunger in a container of water with a

thermometer.

5. Refer to Ta bl e 3-25. Heat water to START TO OPEN

temperature. Verify that the plunger extends.

6. Heat water pass START TO OPEN temperature to FULL

OPEN temperature and verify that plunger is fully

extended.

7. If plunger does not extend per specifications, replace

thermostat assembly.

Table 3-25. Thermostat Operating Range

ITEM FAHRENHEIT CELSIUS

REMOVAL

1. Allow the motorcycle to cool.

2. Place a catch pan under motorcycle.

3. Bend a cardboard funnel and fit to motorcycle to route

fluid away from regulator and oil cooler to container.

IMPORTANT NOTE

Dispose of oil in accordance with local regulations.

4. See Figure 3-28. With a ball Allen wrench, loosen and

remove the thermostat plug.

5. Remove the spring.

6. Remove the thermostat plunger and piston with a pair of

needle nosed pliers.

7. Remove the open cage spreader with a pick.

INSTALLATION

1. See Figure 3-28. Insert the open cage spreader part

way into thermostat chamber.

2. Install the thermostat plunger and piston together.

3. Locate the plunger in the spreader and push in to bottom

of chamber.

4. Install the spring.

5. Fit a new o-ring and install thermostat plug. Tighten to

15-20 ft-lbs (20.4-27.1 Nm).

9982

1

3

4

2

6

5

START TO OPEN

(closed)

AVERAGE

(partially open)

FULL OPEN

(fully open)

3-24 2004 FLHTCSE: Engine

180˚ 82˚

195˚ 91˚

210˚ 99˚

1. Open cage spreader

2. Thermostat plunger

3. Piston

4. Spring

5. O-ring

6. Thermostat plug

Figure 3-28. Thermostat Components

Loading...

Loading...