Page 1

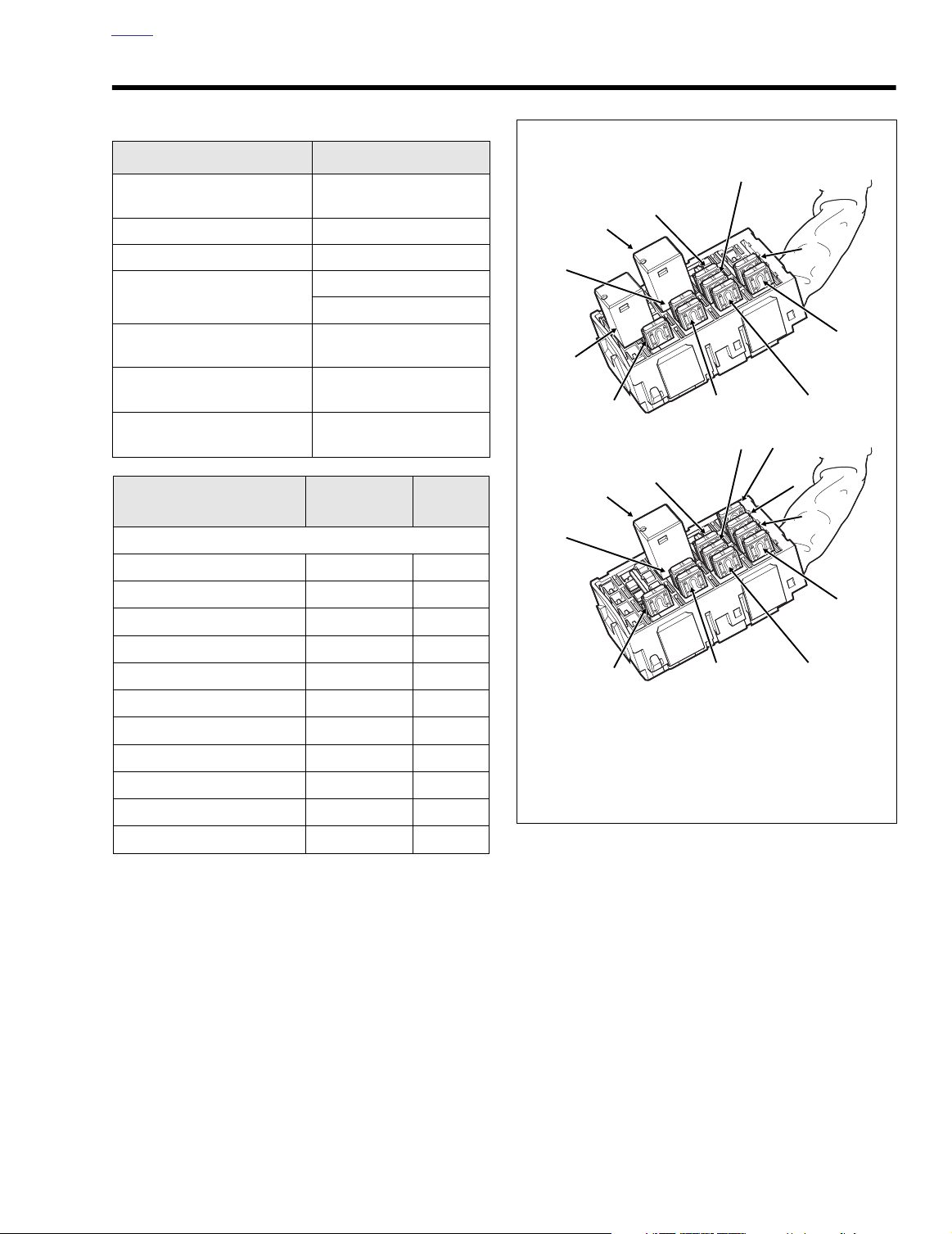

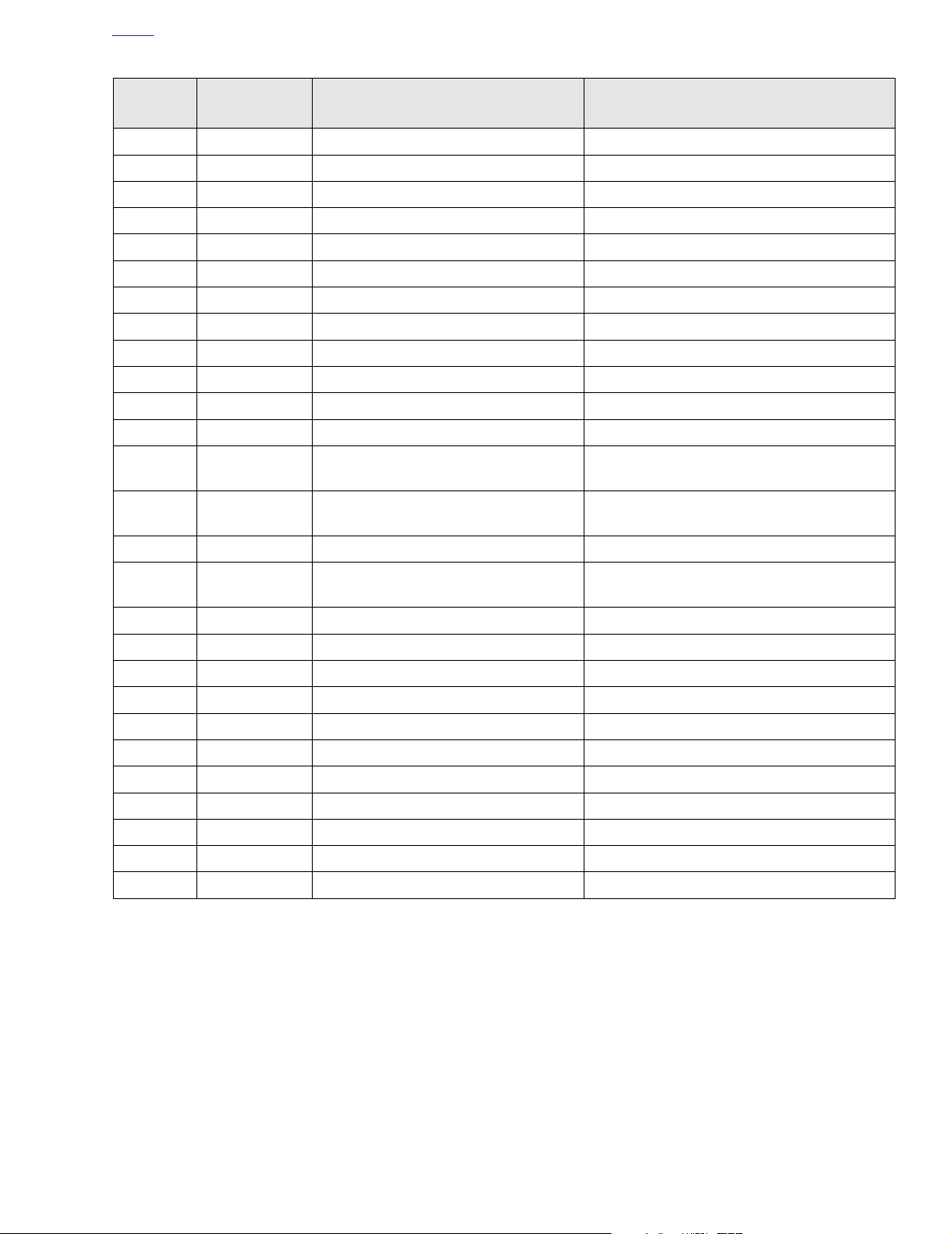

System Fuse Block (Under Left Side Cover)

11

10

9

1

8

5

4

3

2

FLHR/S

11

10

9

1

8

7

6

5

4

3

2

FLHT/C

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory

7. Radio Power

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

12. Starter Relay

12

f2210x8x

f2204x8x

7

HOME

SPECIFICATIONS 4.1

IGNITION

Spark timing advance

Idle speed 1000 ± 50 RPM

Spark plug size 12 mm

Spark plug gap

Spark plug type

Ignition coil primary

resistance

Ignition coil secondary

resistance

CIRCUIT

System Fuses

Maxi-Fuse 40 Orange

Headlamp 15 Blue

Ignition 15 Blue

Lighting 15 Blue

Instruments 15 Blue

Brakes/Cruise 15 Blue

Radio Memory 15 Blue

Radio Power 10 Red

Accessory 15 Blue

Battery 15 Blue

P & A 15 Blue

DATA

0°-50° BTDC (range)

30° BTDC@1000 RPM

0.038-0.043 in

0.97-1.09 mm

Harley-Davidson

No. 6R12 (no substitute)

0.5-0.7 ohms

5500-7500 ohms

RATING

(AMPERES)

COLOR

Figure 4-1. Fuse Locations

2004 Touring: Engine Management (Carbureted) 4-1

Page 2

HOME

0

N

DIAGNOSTIC INTRODUCTION 4.2

SYSTEM PROBLEMS

All system problems fall into at least one of three general categories.

No Start

The engine cranks over freely, but will not start. This does not

include situations where the engine will not crank, such as a

bad starter, dead battery, etc. This condition assumes that all

obvious checks (fuel in tank, etc.) have been made.

Poor Performance

The engine starts but there are performance problems. These

problems may include poor fuel economy, rough idle, engine

misfire, engine hesitation, severe spark knock, etc.

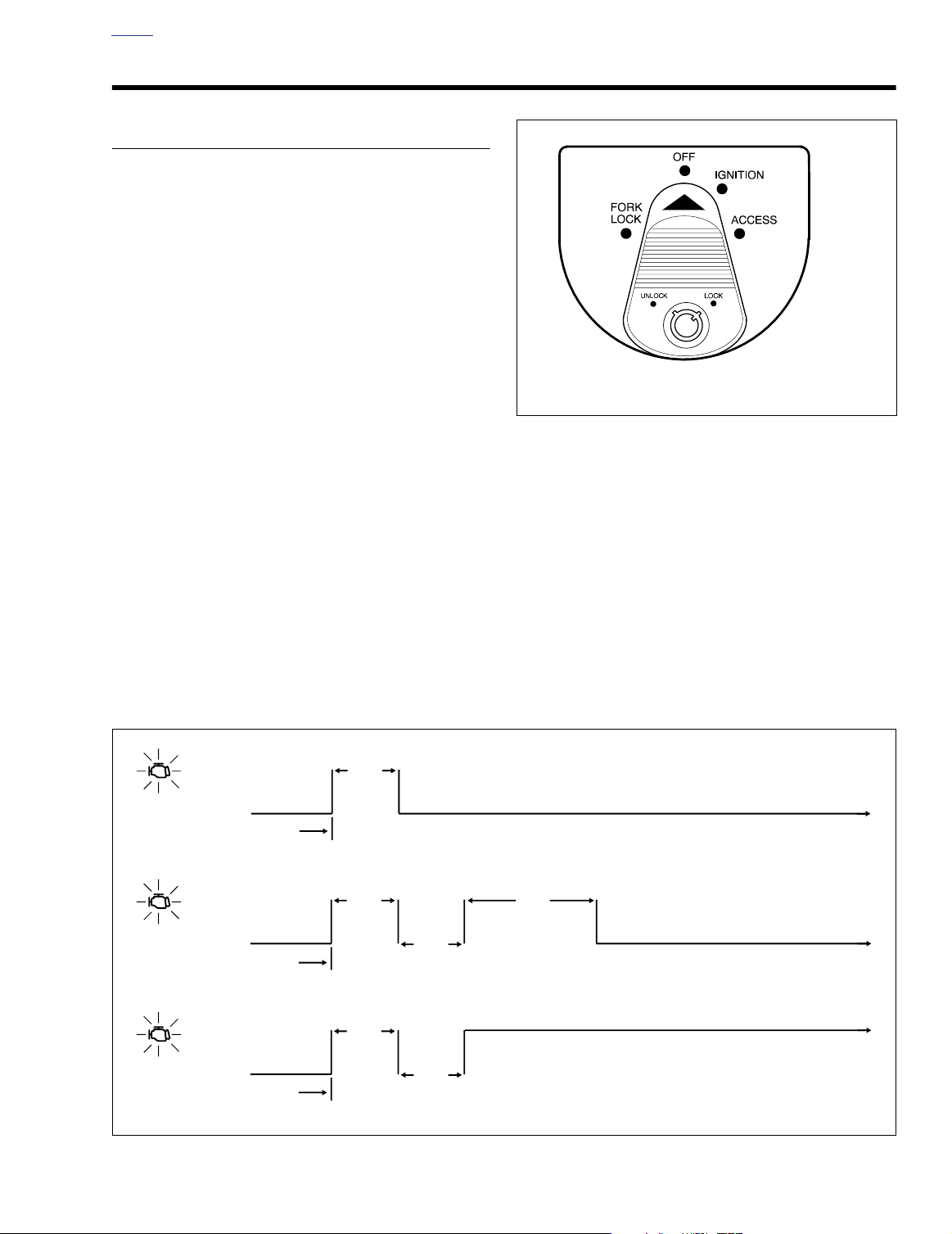

Check Engine Lamp

See Figure 4-2. The check engine lamp indicates the ignition

control module (ICM) has determined a fault condition exists.

There may also be starting or performance problems.

60

50

40

30

20

MPH

10

0

C

E

E

R

I

T

F

I

H

A

R

L

E

V

Y

-

A

D

Check Engine Lamp

Figure 4-2. Speedometer

70

80

90

100

110

120

D

N

O

S

D

I

20

10

0

H

30

A

RPM

R

L

E

40

x100

Y

-

A

D

f2160x8x

5

O

S

D

I

V

RESOLVING PROBLEMS

To resolve system problems, five basic steps are involved. In

order of occurrence, they are:

1. Check for diagnostic trouble codes (DTCs) by observing

check engine lamp. See 4.3 CHECKING FOR TROUBLE

CODES.

2. Retrieve DTCs using speedometer self diagnostics. See

4.5 SPEEDOMETER SELF DIAGNOSTICS.

3. Diagnose system problems. This involves using special

tools and the diagnostic flow charts in this section.

4. Correct problems through the replacement and/or repair

of the affected components.

5. After repairs are performed, the work must be validated.

This involves clearing the DTCs and confirming proper

vehicle operation as indicated by the behavior of the

check engine lamp.

4-2 2004 Touring: Engine Management (Carbureted)

Page 3

HOME

f1240x2x

CHECKING FOR TROUBLE CODES 4.3

CHECK ENGINE LAMP

To diagnose system problems, start by observing the behavior of the check engine lamp.

NOTE

●

See Figure 4-3. “Key ON” means that the ignition key is

turned to ON and the engine stop switch is set to RUN

(although the engine is

●

When the ignition switch is turned ON, the check engine

lamp will illuminate for approximately four seconds and

then turn off.

●

If the check engine lamp is not illuminated at key ON or if

it fails to turn OFF after the ititial four second period, then

see 4.5 SPEEDOMETER SELF DIAGNOSTICS.

●

If the check engine lamp comes on late (after 20 seconds), the problem is likely a serial data bus failure. Test

for codes using speedometer self diagnostics. See 4.5

SPEEDOMETER SELF DIAGNOSTICS.

●

If the check engine lamp fails to turn OFF after the initial

four second period, then a problem exists in the instrumentation. See 4.5 SPEEDOMETER SELF DIAGNOS-

TICS.

1. When the lamp turns off after being illuminated for the

first four second period, it will:

a. Remain off if there are no fault conditions or trouble

codes currently detected by the ignition control module. See A of Figure 4-4.

b. Come back on for an 8 second period if only historic

codes exist. See B of Figure 4-4.

not

running).

Figure 4-3. Ignition Switch (FLHT/C)

c. Come back on, and remain on, if a current trouble

code exists. See C of Figure 4-4.

2. See CODE TYPES which follows for a complete description of trouble code formats.

NOTE

Tr ouble codes relating to the ignition coil can only be fully

diagnosed during actuation. For example, a problem with the

ignition coil will be considered a current fault even after the

problem is corrected, since the ignition control module will not

know of its resolution until after the coil is exercised by vehicle

start sequence. In this manner, there may sometimes be a

false indication of the current trouble code.

ON

OFF

ON

OFF

ON

OFF

A

Key On

B

Key On

C

Key On

4 Sec.

Lamp OFF: No Current or Historic Trouble Codes

Lamp ON 8 Seconds:

Only Historic Trouble Codes Exist

4 Sec.

4 Sec.

8 Sec.

Lamp Remains ON: Current Trouble Code *

4 Sec.

4 Sec.

Figure 4-4. Check Engine Lamp Operation

*

Historic Trouble Codes May Also Exist

2004 Touring: Engine Management (Carbureted) 4-3

Lamp OFF

Page 4

HOME

CODE TYPES

There are two types of

current and historic. If a trouble code is stored, it can be read

using the speedometer self diagnostics. See 4.5 SPEEDOM-

ETER SELF DIAGNOSTICS.

All trouble codes reside in the memory of the ignition control

module (ICM) until cleared using the speedometer self diagnostics. See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

A trouble code is also cleared after a total of 50 trips has

elasped. A trip consists of a start and run cycle, the run cycle

lasting at least 30 seconds. After the 50 trip retention period,

the trouble code is automatically erased from memory providing that no subsequent faults of the same type are detected in

that period.

Current

Current trouble codes are those which presently disrupt

motorcycle operation. See the appropriate flow charts for

solutions.

Historic

If a particular problem happens to resolve itself, the active

status is dropped and it becomes a historic fault rather than a

current fault.

Historic trouble codes can only be retrieved using a computer

based diagnostic package called DIGITAL TECHNICIAN

(Part No. HD-44750).

Historic trouble codes are stored for a length of time to assist

in the diagnosis of intermittent faults.

diagnostic trouble codes (DTCs):

RETRIEVING DIAGNOSTIC TROUBLE CODES

The engine management system provides two levels of diagnostics.

●

The most sophisticated mode employs a computer

based diagnostic package called DIGITAL TECHNICIAN

(Part No. HD-44750).

The second mode requires using the speedometer self

●

diagnostics. Speedometer, tachometer (if equipped),

TSM/TSSM and ECM codes can be accessed and

cleared. See 4.5 SPEEDOMETER SELF DIAGNOS-

TICS.

MULTIPLE DIAGNOSTIC TROUBLE CODES

While it is possible for more than one fault to occur and set

more than one trouble code, there are several conditions

which may result in

Serial data codes (DTC U1016, U1064, U1097, U1255,

●

U1300 and U1301) may be accompanied by other

codes.

resolving the other codes.

For proper resolution to multiple trouble codes refer to diagnostic code priority chart (Table 4-5.)

one

fault setting

Always

correct the serial data codes before

multiple

trouble codes:

It is important to note that historic trouble codes may also be

present whenever the system indicates the existence of a

current fault. See MULTIPLE DIAGNOSTIC TROUBLE

CODES if multiple trouble codes are found.

Diagnostic charts are designed for use with current trouble

codes and as a result they frequently suggest part replacement.

4-4 2004 Touring: Engine Management (Carbureted)

Page 5

HOME

INITIAL DIAGNOSTIC CHECK: ICM 4.4

GENERAL

To locate faulty circuits or other system problems, follow the

diagnostic flow charts in this section. For a systematic

approach, always begin with INITIAL DIAGNOSTICS which

follows. Read the general information and then work your way

through the flow chart box by box.

Diagnostic Notes

If a numbered circle appears adjacent to a flow chart box,

then more information is offered in the diagnostic notes. Many

diagnostic notes contain supplemental information, descriptions of various diagnostic tools or references to other parts

of the manual.

Circuit Diagram/Wire Harness Connector Table

When working through a flow chart, refer to the illustrations,

the associated circuit diagram and the wire harness connector table as necessary. The wire harness connector table for

each circuit diagram identifies the connector number, description, type and general location.

In order to perform most diagnostic routines, a Breakout Box

and a DVOM are required. See 4.6 BREAKOUT BOX: ICM.

To perform the circuit checks with any degree of efficiency, a

familiarity with the various wire connectors is necessary.

Reprogramming ICM

Diagnostic charts frequently suggest ICM replacement. In the

event an ignition control module (ICM) needs to be replaced,

it must be reprogrammed using a computer based diagnostic

package called DIGITAL TECHNICIAN (Part No. HD-44750).

See your dealer. Password learn procedure must also be performed. See 3.24 PASSWORD LEARN.

INITIAL DIAGNOSTICS

General Information

The diagnostic check is an organized approach to identifying

a problem caused by an electronic control system malfunction. If no problems are found after completion of the diagnostic check, a comparison of running parameters may be used

to help locate intermittents and out-of-specification sensors.

See Ta ble 4-1.

Diagnostic Tips

If Speedometer reads “BUS Er” with the ignition key

●

turned ON (engine stop switch at RUN with the engine

off), check data bus for an open or short to ground

between data connector [91A] terminal 3 and ICM connector [10B] terminal 12, TSSM connector [30B] terminal

3, Speedometer connector [39B] terminal 2 or tachometer (if equipped) connector [108B] terminal 2.

Check for an open diagnostic test terminal between data

●

link connector [91A] terminal 3 and TSM/TSSM connector [30B] terminal 3. With ignition key turned ON, serial

data bus voltage should be typically 0.6-0.8 volts. The

range of acceptable voltage is 0-7.0 volts.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the diagnostic check flow charts. See page 4-10.

1. Compare engine behavior to symptoms tables in this

section.

a. Starts hard. See Ta ble 4-2.

b. Hesitates, stumbles, surges, misfires and/or slug-

gish performance. See Ta bl e 4-3.

c. Engine exhaust emits black smoke or fouls plugs.

See Ta bl e 4-4.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black socket probes and patch cord.

3. Connect BREAKOUT BOX (Part No. HD-42682) to igni-

tion control module. See 4.6 BREAKOUT BOX: ICM.

All diagnostic codes are listed in Ta bl e 4-5.

See 3.9 INITIAL DIAGNOSTIC CHECK: TSM/TSSM for any

codes related to the turn signal module (TSM) or turn signal

security module (TSSM).

See 2.5 BREAKOUT BOX: SPEEDOMETER for any codes

related to the speedometer.

2004 Touring: Engine Management (Carbureted) 4-5

Page 6

HOME

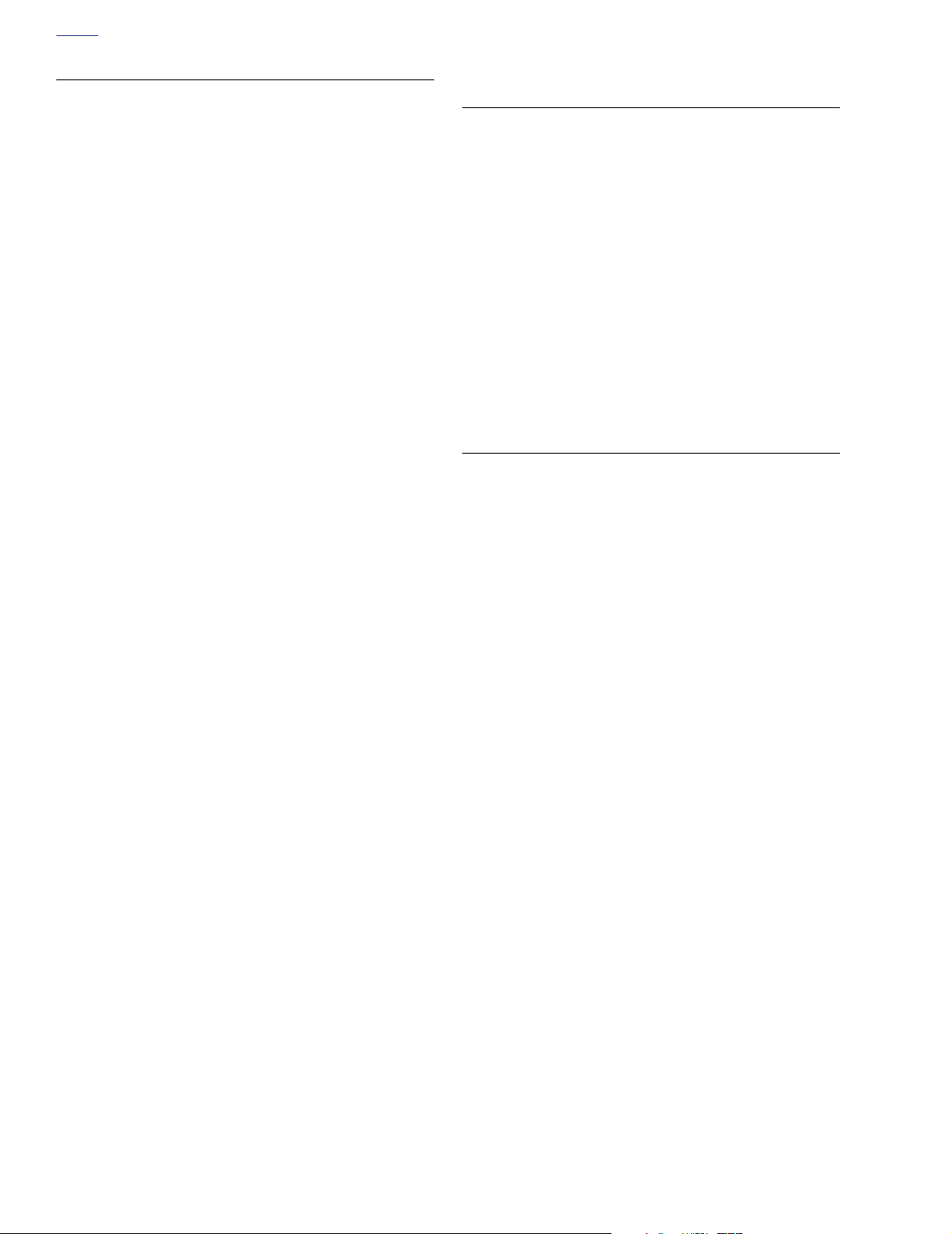

Table 4-1. Typical Running Values

ITEM

MAP sensor

RPM 0 5600 1000

Bank angle

sensor

MIN.

VALUE

0.1 V

(high

vacuum)

Run mode

0.45-1.1 V

MAX.

VALUE

4.96 V

(atmo-

spheric

pressure)

Disable

1.8-3.2 V

HOT

IDLE

1.5-3.0 V

Run mode

0.45-1.1 V

Table 4-2. Engine Starts Hard

SYMPTOM

Battery discharged

Spark plugs 4.12 MISFIRE.

Spark plug wires 4.12 MISFIRE

Ignition coil 4.12 MISFIRE.

Valve sticking

Water or dirt in fuel system Drain and refill with fresh fuel.

See charging system troubleshooting in this section.

See Section 3 in Touring Service Manual.

SOLUTION

Table 4-3. Engine Performance Problems

SYMPTOM

Perform intake leak test.

Manifold leak

MAP sensor plugged or not

operating properly

Water or dirt in fuel system

Spark plugs 4.12 MISFIRE.

EVAP hose disconnected

from induction module (CA)

Throttle plates not opening

fully

See 4.8 INTAKE LEAK

TEST.

4.13 DTC P0106, P0107,

P0108

Drain and refill with fresh

fuel.

Connect.

See throttle cable adjustment in Touring Service

Manual.

SOLUTION

Table 4-4. Engine Exhaust Emits

Black Smoke or Fouls Plugs

SYMPTOM

Clogged air filter

See Section 1 in Touring

Service Manual.

SOLUTION

4-6 2004 Touring: Engine Management (Carbureted)

Page 7

HOME

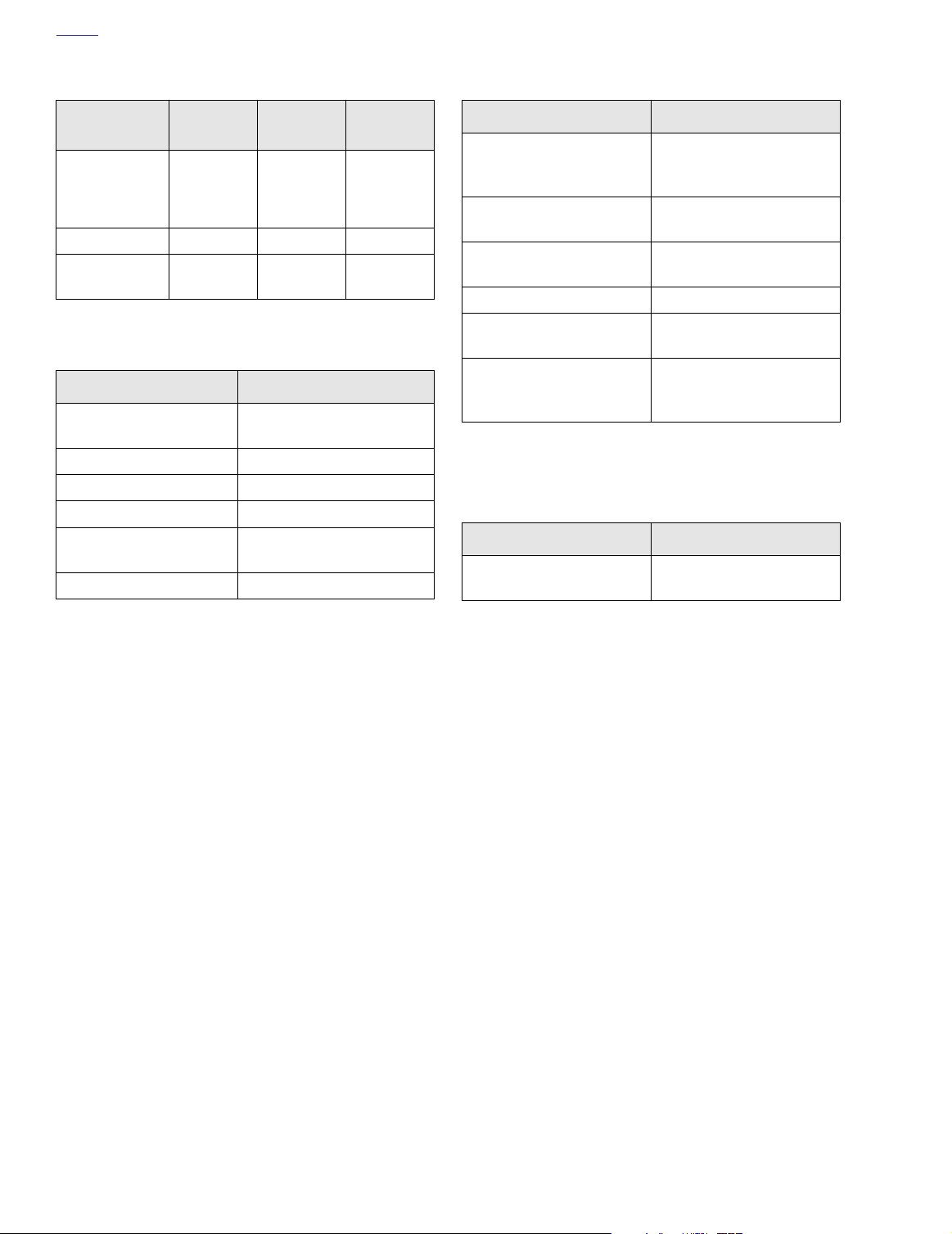

Table 4-5. Diagnostic Trouble Codes (DTC) and Fault Conditions

PRIORITY

RANKING

1 P0605 flash memory error 4.19 DTC P0602, P0603, P0604, P0605, P0607

2 P0603 EEProm memory error 4.19 DTC P0602, P0603, P0604, P0605, P0607

3 P0602 Flash memory error 4.19 DTC P0602, P0603, P0604, P0605, P0607

4 P0604 RAM memory error 4.19 DTC P0602, P0603, P0604, P0605, P0607

5 P0607 A to D error 4.19 DTC P0602, P0603, P0604, P0605, P0607

6“BUS Er” Serial data bus shorted low/open/high 4.10 STARTS, THEN STALLS

7U1300 serial data shorted low 4.10 STARTS, THEN STALLS

8U1301 serial data shorted high 4.10 STARTS, THEN STALLS

9U1064 lost TSM/TSSM communication 4.20 DTC U1064

10 U1097 lost speedometer communication 4.21 DTC U1097

11 U1255 Missing response at TSSM 4.20 DTC U1064

12 U1255 Missing response at speedometer 4.21 DTC U1097

13 P1009

14 P1010

15 P0373 crankshaft position sensor intermittent 4.17 DTC P0373, P0374

16 P0374

17 P0106 MAP sensor rate-of-change error 4.13 DTC P0106, P0107, P0108

18 P0107 MAP sensor failed open/low 4.13 DTC P0106, P0107, P0108

19 P0108 MAP sensor failed high 4.13 DTC P0106, P0107, P0108

21 P1351 Ignition coil driver front low/open 4.16 DTC P1351, P1352, P1354, P1355

20 P1354 Ignition coil driver rear low/open 4.16 DTC P1351, P1352, P1354, P1355

22 P1352 Ignition coil driver front high 4.16 DTC P1351, P1352, P1354, P1355

23 P1355 Ignition coil driver rear high 4.16 DTC P1351, P1352, P1354, P1355

24 P0562 system voltage low 4.14 DTC P0562, P0563

25 P0563 system voltage high 4.14 DTC P0562, P0563

26 P0501 VSS failed low 4.18 DTC P0501, P0502

27 P0502 VSS failed high/open 4.18 DTC P0501, P0502

DTC NO. FAULT CONDITION SOLUTION

TSM/TSSM disabled fuel due to bad

password

TSM/TSSM disabled fuel due to no password (starts then stalls)

crankshaft position sensor not detected/

cannot synchronize

4.15 DTC P1009, P1010

4.15 DTC P1009, P1010

4.17 DTC P0373, P0374

2004 Touring: Engine Management (Carbureted) 4-7

Page 8

HOME

[2A]

[2B]

f2208z8x

321654987121110

321654987121110

Speedometer

15A

Accessory

Fuse

321654987121110

321654987121110

Main to Interconnect

Harness

BK

LtGN/V

O

BN/GY

[39B]

[39A]

[108B]

[108A]

321654987121110

321654987121110

Tachometer

[1B] [1A]

123

123

Main to Interconnect

Harness

6

6

101112 78945

101112 78945

[156B] [156A]

6

6

5

5

4

4

3

3

2

2

1

1

BN/GY

Main to Interconnect

Harness

LtGN/V

GY

65

4

32

1

1

15A

Ignition

Fuse

6

5

4

32

GY

987

987

321654987121110

321654987121110

TSM/TSSM

BK

[8B]

121110

121110

[8A]

Ignition

Harness

1

2

3

4

Data Link

[91A]

BK

[30B]

[30A]

LtGN/V

15A

Battery

Fuse

[10B]

[10A]

Ignition Control Module

12

12

Serial data

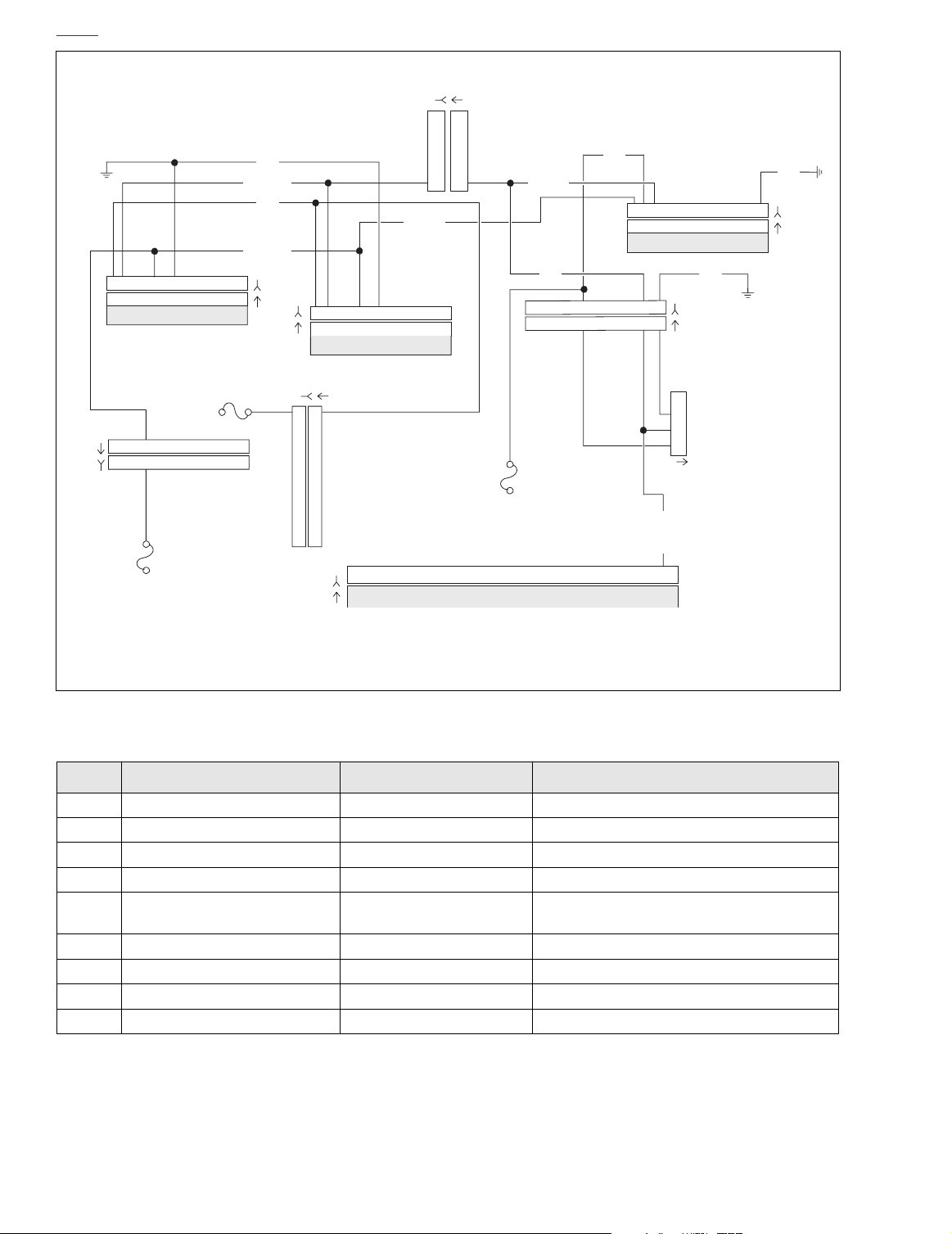

Figure 4-5. Diagnostic Check (FLHT/C)

Table 4-6. Wire Harness Connectors in Figure 4-5.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

4-8 2004 Touring: Engine Management (Carbureted)

Page 9

HOME

f2208y8x

BN/GY

BK

321654987121110

321654987121110

15A

Battery

Fuse

Speedometer

LtGN/V

BN/GY

O

15A

Accessory

Fuse

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

21

21

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

[8B]

[8A]

[91A]

Ignition

Harness

1

2

3

4

Data Link

987

6

54

3

98

7

654

3

121110

121110

LtGN/V

[10B]

[10A]

Ignition Control Module

12

12

Serial data

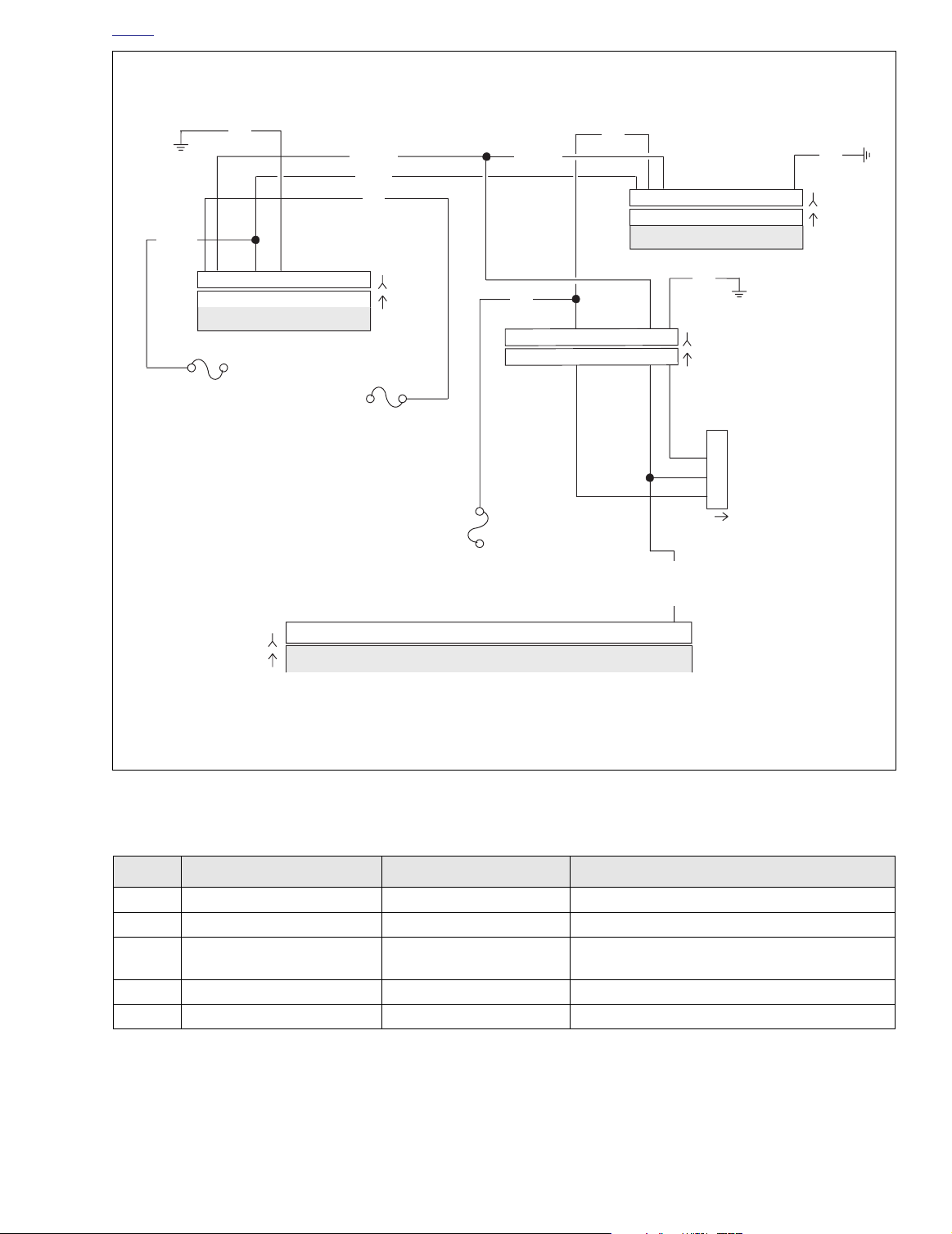

Figure 4-6. Diagnostic Check (FLHR/S)

Table 4-7. Wire Harness Connectors in Figure 4-6.

NO.

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

DESCRIPTION TYPE LOCATION

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2004 Touring: Engine Management (Carbureted) 4-9

Page 10

HOME

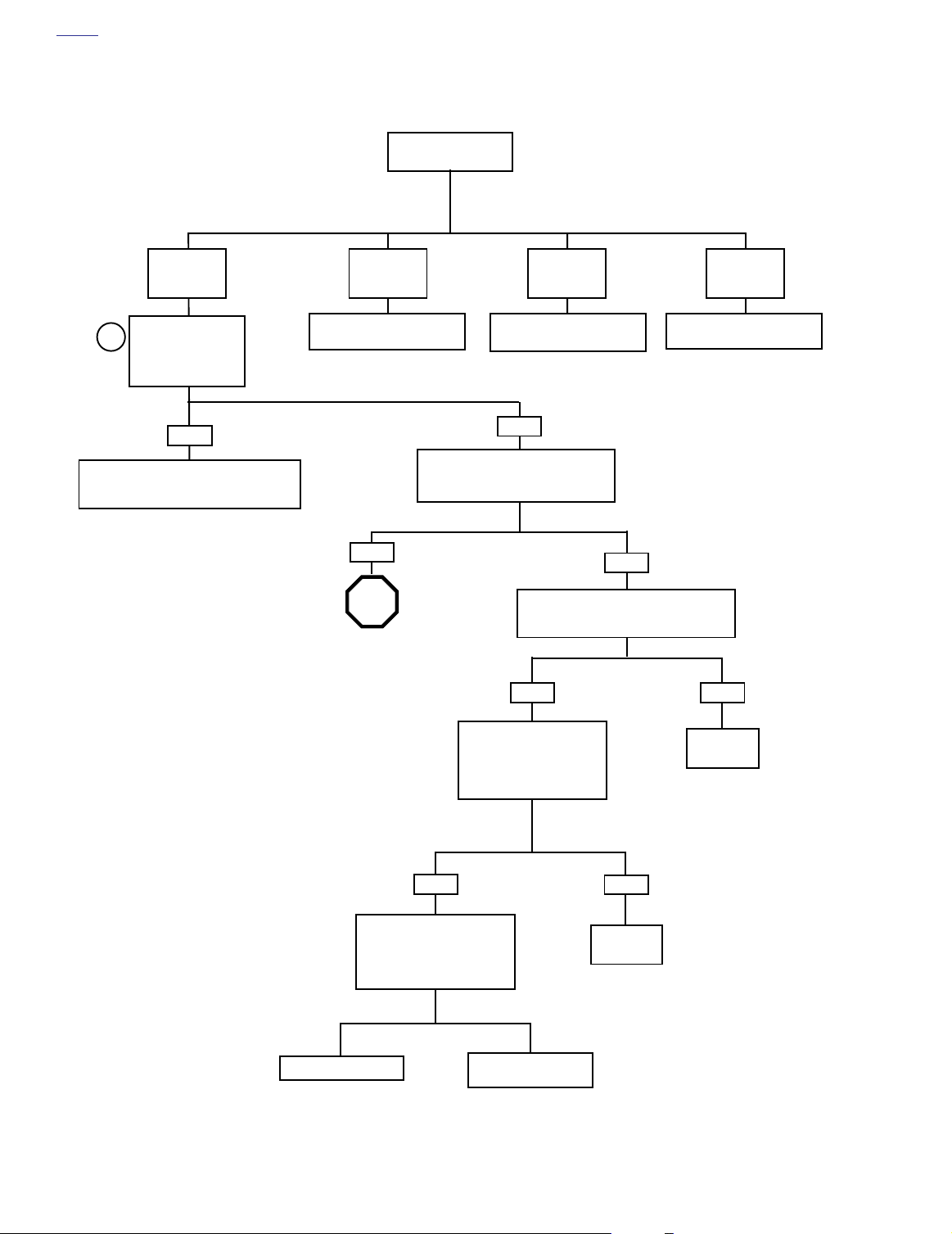

Initial Diagnostic Check (Part 1 of 2)

Does engine

start?

YES.

Starts and

runs.

Check for trouble

codes. See 4.5

1

SPEEDOMETER

SELF DIAGNOSTICS

Codes found?

YES

Refer to applicable trouble code priority chart.

All diagnostic codes are listed on page 4-7 in

Table 4-5. Codes are listed by priority.

YES.

Starts, then

stalls.

See 4.10 STARTS, THEN

STALLS.

YES

STOP

Go to Initial Diagnostic

Check (Part 2 of 2).

NO.

Cranks, but

will not start.

See 4.9 ENGINE CRANKS,

BUT WILL NOT START.

NO

With ignition switch OFF, press and

release odometer reset switch. Does

odometer display appear?

Check for continuity to ground on terminal 7

of speedometer. Wiggle harness during con-

tinuity check. Continuity present?

YES NO

Check for battery voltage at

terminal 5 of speedometer

while wiggling harness. Bat-

tery voltage continuously

present?

NO

NO.

Engine will not

crank.

See 1.2 STARTING SYSTEM

DIAGNOSIS.

Locate and

repair open.

Check continuity (with ignition

switch OFF) between terminals

8 and 11 on breakout box. Con-

tinuity present when speedome-

ter reset switch is depressed?

Replace speedometer.

4-10 2004 Touring: Engine Management (Carbureted)

YES

Replace speedometer

reset switch.

NO

Locate and

repair open.

Page 11

HOME

Initial Diagnostic Check (Part 2 of 2)

Continued from Initial Diagnostic

Check (Part 1 of 2).Turn ignition

switch ON, is odometer backlight

present?

YES

Turn key to ACC. Is

backlight present?

YES

No trouble found.

Is problem intermittent?

YES

Perform “wow” test. See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

1) backlight should illuminate

2) needle should sweep its full range of motion

3) LED’s should illuminate:

• check engine

• battery

• security (all models)

• low fuel (EFI models)

• cruise (even though not cruise equipped)

The following features should be functional

Are all features functional?

1

Check for battery voltage

at terminal 6. Battery volt-

age present?

YES

NO

NO

YES

Replace speedometer.

NO

Check for battery voltage at

terminal 1 of breakout box.

Battery voltage present?

YES

NO

Replace Speedometer.

NO

Is instrument

fuse blown?

NO

Replace speedometer.

YES

Repeat Diagnostic

Check while wiggling

harnesses.

Locate and repair open on

O/W wire between terminal 6

and accessory fuse.

Speedometer Inoperative

Remove and inspect vehi-

cle speed sensor. Debris

Remove debris. Reinstall

NO.

(no vehicle speed).

present?

YES

Vehicle speed sensor.

Locate and repair

source of fault.

Tachometer Inoperative

See Test 2.4 (Part 1 of 2)

under 2.4 SPEEDOMETER/

NO

Check for damaged wiring/

loose connection between

vehicle speed sensor and ICM.

Is wiring damage/loose

connection present?

YES

Locate and repair

source of fault.

Replace fuse.

NO.

(no engine speed).

TACHOMETER.

NO

Replace Speedometer.

Locate and repair open

between terminal 1 and

instrument fuse.

2004 Touring: Engine Management (Carbureted) 4-11

Page 12

HOME

SPEEDOMETER SELF DIAGNOSTICS 4.5

GENERAL

The speedometer is capable of displaying and clearing

speedometer, tachometer, TSM/TSSM, and ICM/ECM trouble

codes (diagnostic mode).

DIAGNOSTICS

Diagnostic Tips

For a quick check of speedometer function, a “wow” test

●

can be performed. Press and hold odometer reset switch

then turn ignition switch ON. Release reset switch. Background lighting should illuminate, speedometer needle

should sweep its full range of motion, and indicator

lamps [battery, security, low fuel (EFI models) check

engine and cruise] should illuminate. Some lamps may

illuminate even though they do not apply to the vehicle.

For example, the cruise lamp may illuminate even though

the motorcycle may not be cruise equipped.

●

If instrument module fails “wow” test, check for battery,

ground, ignition, speedometer reset switch and accessory to speedometer. If any feature in the speedometer is

non-functional, see 2.2 INITIAL DIAGNOSTIC CHECK:

SPEEDOMETER.

d0715x8x

1

1. Cruise On/Engaged

2. Check Engine

3. Low Fuel

2

Figure 4-7. Speedometer (FLHR/S)

3

4. Battery

5. Security

4

5

Diagnostic Notes

Use of speedometer self diagnostics assumes that DIGITAL

TECHNICIAN (Part No. HD-44750) is

The reference numbers below correlate with the circled numbers in the Speedometer Self Diagnostics (chart)

1. To exit diagnostic mode, turn ignition switch OFF.

2. To clear DTCs for selected module, press speedometer

reset switch for more than 5 seconds when code is displayed. This procedure will clear all codes for selected

module.

not

available.

4-12 2004 Touring: Engine Management (Carbureted)

Page 13

HOME

Speedometer Self Diagnostics (chart)

1

While holding odometer reset switch in,

turn ignition switch to IGN. Make sure

Run/Stop switch is in RUN position.

Release reset switch.

Does “diag” appear?

YES

”P” flashing.

To choose TSM/

TSSM, press and

release reset switch.

”S” flashing.

To choose Speedometer,

press and release reset

switch.

”SP” flashing.

To choose Tachometer,

press and release reset

switch.

”T” flashing.

To choose ICM, press and

release reset switch.

To display DTCs for the

ICM, press and hold

reset switch for more

than 5 seconds.

To display DTCs for

TSM/TSSM, press and

hold reset switch for

more than 5 seconds.

To display DTCs for

speedometer, press and

hold reset switch for more

than 5 seconds.

To display DTCs for

tachometer, press and

hold reset switch for more

than 5 seconds.

NO

See 2.2 INITIAL DIAGNOSTIC

CHECK: SPEEDOMETER.

Device

response?

YES

“none” displayed.

Press and release

reset switch. Part num-

ber of module will be

displayed.

DTC

2

displayed.

Press and release

reset switch.

Are more DTCs

displayed?

YES

NO

“no rsp” displayed.*

Tachometer malfunction.

2.4 SPEEDOMETER/

See

TACHOMETER.

* Models not equipped

with a tachometer will

display “no rsp” normally.

NO

“end” displayed.

To clear all DTCs for

selected module hold reset

switch for more than 5 seconds. If DTCs are not to be

cleared, Press and release

reset switch. Part number of

module will be displayed.

Press and release reset

switch again to continue to

next module.

Figure 4-8. Speedometer Self Diagnostics

2004 Touring: Engine Management (Carbureted) 4-13

Page 14

HOME

BREAKOUT BOX: ICM 4.6

GENERAL

The BREAKOUT BOX (Part No. HD-42682) splices into the

main harness. Used in conjunction with a DVOM, it allows circuit diagnosis of wiring harness and connections without having to probe with sharp objects.

INSTALLATION

1. Remove right saddlebag and side cover.

2. Depress latches on connector [10] to separate pin and

socket halves.

3. Attach Breakout Box as follows:

a. Mate black socket housing on Breakout Box with

ICM connector [10A].

b. Mate black pin housing on Breakout Box with har-

ness connector [10B].

REMOVAL

f2191x8x

Ignition Control Module

Connector [10]

Figure 4-9. Electrical Bracket (Under Right Side Cover)

1. Remove Breakout Box as follows:

a. Remove black socket housing on Breakout Box from

ICM connector [10A].

b. Remove black pin housing on Breakout Box from

harness connector [10B].

2. Mate pin and socket halves of ICM connector [10].

3. Install side cover and saddlebag.

f2001x8x

Connect Black Side

Only for Tests

f1998x9x

Figure 4-10. Breakout Box (Part No. HD-42682)

4-14 2004 Touring: Engine Management (Carbureted)

Page 15

HOME

hd39978

WIGGLE TEST 4.7

GENERAL

The wiggle test indicates the presence of intermittents in a

wiring harness.

PROCEDURE

1. See Figure 4-11. Connect DVOM (Part No. HD-39978) to

wiring harness between the suspect connections. When

diagnosing ignition module connections, a BREAKOUT

BOX (Part No. HD-42682) may be used to simplify the

procedure. See 4.6 BREAKOUT BOX: ICM.

2. Set DVOM to read voltage changes.

3. Start motorcycle engine and run at idle.

4. Shake or wiggle harness to detect intermittents. If intermittents are present, radical voltage changes will register

on the DVOM.

Figure 4-11. Fluke 78 Multimeter (DVOM)

(Part No. HD-39978)

2004 Touring: Engine Management (Carbureted) 4-15

Page 16

HOME

INTAKE LEAK TEST 4.8

GENERAL

1WARNING1WARNING

Propane is an extremely flammable liquid and vapor.

Vapor may cause flash fire. Keep away from heat, sparks

and flame. Keep container closed. Use only with adequate ventilation.

1WARNING1WARNING

Read all directions and warnings on propane bottle. Failure to follow all directions and warnings on bottle could

result in death or serious injury.

●

To prevent false readings, keep airbox cover installed

when performing test.

Do not direct propane into air cleaner, false readings will

●

result.

LEAK TESTER

Parts List

●

Standard 14 oz. propane cylinder.

9648

9649

Figure 4-12. Nozzle

1

3

2

4

5

6

Snap-on YA7148 Propane Enrichment Kit.

●

12 inches (304 mm) long-1/4 inch (6 mm) diameter cop-

●

per tubing.

Tester Assembly

1. Cut rubber hose from kit to 18 inches (457 mm) in length.

2. See Figure 4-12. Flatten one end of copper tube to form

a nozzle.

3. Insert round side of copper tube into end of tubing.

1. Nozzle

2. Copper tube

3. Hose

4. Valve

5. Knob

6. Propane bottle

Figure 4-13. Leak Tester

4-16 2004 Touring: Engine Management (Carbureted)

Page 17

HOME

10054

INTAKE LEAK TESTING

1. Start engine.

2. Warm engine to operating temperature.

3. See Figure 4-13. Tu rn knob counterclockwise to open

propane bottle.

1WARNING1WARNING

Propane is an extremely flammable liquid and vapor.

Vapor may cause flash fire. Keep away from heat, sparks

and flame. Keep container closed. Use only with adequate ventilation.

NOTE

Do not direct propane stream toward front of engine. If propane enters air cleaner, a false reading will be obtained.

4. See Figure 4-14. Aim nozzle toward possible sources of

leak such as fuel injectors and intake tract.

5. See Figure 4-13. Push valve opane enters source of

leak.

Figure 4-14. Checking for Leaks

2004 Touring: Engine Management (Carbureted) 4-17

Page 18

HOME

ENGINE CRANKS, BUT WILL NOT START 4.9

GENERAL

If starter will not crank engine, the problem is not ignition

related. Refer to SECTION 1-STARTING & CHARGING.

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.9 flow charts.

1. Check for trouble codes. See RETRIEVING DIAGNOS-

TIC TROUBLE CODES under 4.3 CHECKING FOR

TROUBLE CODES.

2. Check the condition of the battery. Perform a voltage test

and recharge if below 12.60V. Check battery connections

and perform load test. Replace the battery if necessary.

3. Remove spark plug cable from spark plug.

a. Visually check condition of plug.

d0273x8x

Figure 4-15. Spark Tester

7863

b. See Figure 4-15. Attach cable to SPARK TESTER

(Part No. HD-26792). Clip tester to cylinder head

bolt.

c. While cranking engine, look for spark. Repeat pro-

cedure on other spark plug cables.

NOTE

Engine will not spark with both spark plugs removed. When

checking for spark, use SPARK TESTER (Part No. HD-

26792) with both plugs installed.

4. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404) gray pin probes and patch cords.

5. See Figure 4-16. Plug IGNITION COIL CIRCUIT TEST

ADAPTER (Part No. HD-44687) and FUEL INJECTOR

TEST LAMP (Part No. HD-34730-2C) into Breakout Box.

Note that cranking the engine with test lamp in place of

the ignition coil can sometimes cause a DTC P1351,

P1352, P1354 or P1355. This condition is normal and

does not by itself indicate a malfunction. Clear codes

afterward.

6. Connect BREAKOUT BOX (Part No. HD-42682). See 4.6

BREAKOUT BOX: ICM.

Figure 4-16. Ignition Coil Circuit Test

7. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probe and patch cord.

8. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), brown socket probe and patch cord.

4-18 2004 Touring: Engine Management (Carbureted)

Page 19

HOME

Crankshaft

Position

Sensor

21

[79A]

[79B]

Ignition Control Module

R/BK To Ignition Switch

15 Amp

Ignition Fuse

To TSM/TSSM

[22B]

[22A]

Ignition

GY

[1B]

[1A]

GY

Engine Stop Switch

Coil

[83B]

A

B

C

W

\

B

K

56784321 9101112

56784321 9101112

FLHT/C Only

W \ BK

6-Place on FLHR/S

56784321 9101112

BK

R

Y \ BE

BE \ O

[8A]

[8B]

Ground Stud

BK

To

Data Link

W \ BK

[10B]

9

8

7

6

5

1

[10A]

Crank Sensor (-)

Crank Sensor (+)

Rear Coil

Front Coil

Ground

Key ON Power

Figure 4-17. Ignition Circuit

Table 4-8. Wire Harness Connectors in Figure 4-17.

NO.

[1]

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch (Black) Under Right Side Cover

[22]

[83] Ignition Coil All 3-Place Packard Below Fuel Tank (Left Side)

DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect

Harness

Interconnect to Right

Handlebar Switch Controls

FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

FLHT/C 12-Place Deutsch Inner Fairing- Right Fairing Support Brace

FLHR/S 6-Place Deutsch Inside Headlamp Nacelle

2004 Touring: Engine Management (Carbureted) 4-19

Page 20

HOME

Test 4.9 (Part 1 of 3)

ENGINE CRANKS, BUT WILL NOT START

Fresh fuel in tank?

Spark plug wires firmly

connected to proper coil

terminals?

Add fuel and

NO

YES

connect spark

plugs.

Check for trouble

1

Codes found?

See priority listing

in Table 4-5.

codes.

YES

NO

Check battery connections

and voltage. Is voltage

above 12.60?

2

YES

Does battery pass

load test?

YES

Check spark plug condition,

3

replace if fouled. Check

spark at both plugs while

cranking. Spark present?

YES

Check compression. If compression is

good, check fuel system.

NO

Recharge battery.

NO

Replace battery.

NO

Turn ignition ON and engine

stop switch to RUN.

Does check engine lamp

illuminate for 4 seconds?

immediately after Key ON?

Check battery voltage at

4

Terminal B of coil connector

[83B] using DVOM. Battery

voltage present?

4-20 2004 Touring: Engine Management (Carbureted)

YES

YES

STOP

Go to Test 4.9

(Part 2 of 3).

NO

4.11 NO SPARK/NO ICM

Locate and repair open on W/

See

POWER.

NO

BK wire to coil.

Page 21

HOME

Test 4.9 (Part 2 of 3)

ENGINE CRANKS, BUT WILL NOT START

Continued from Test 4.9 (Part 1 of 3).

Install Breakout Box and test light for the next

5

6

Front coil code: Check between

Terminals 1 and 6 on Breakout Box.

Terminals 1 and 7 on Breakout Box.

Does test lamp flash when engine is cranked?

inspection.

Rear coil code: Check between

YES

Check coil connections.

Connections OK?

YES

Test spark plug cable resis-

tance. See 4.12 MISFIRE.

Resistance OK?

YES

Plug wires in correct

coil towers?

YES NO

Replace

coil.

NO

Repair.

NO

Replace spark

plug cables.

Route

correctly.

NO

Connect Breakout Box. Check continuity

between socket A of connector [83B]

and terminal 7 (BK) on Breakout Box.

Measure resistance between socket C of

7

connector [83B] and terminal 6 (BK) on

Connect DVOM to terminals 8 and 9

(BK) of connector [10] on Breakout Box

and set it for AC volts. Crank engine.

Does DVOM read 1 VAC minimum?

Breakout Box.

Is resistance less than 1.0 ohm?

YES

YES

STOP

Go to Test 4.9

(Part 3 of 3).

NO

Poor connection at con-

nector [10B] or open in

harness between coil

and ICM. Repair open.

NO

Disconnect connector [79].

8

Check connector for moisture

and corrosion. Check wires for

chafing. Connect DVOM to ter-

minals 1 and 2 of connector

[79A]. Crank engine. Does

DVOM read 1 VAC minimum?

YES NO

Check for continuity between

socket 1 of connector [79B]

and terminal 8 of connector

[10] on Breakout Box.

Continuity present?

YES

Locate and repair open on

BK wire between socket 2 of

connector [79B] and socket 9

of connector [10B].

NO

Locate and repair open on

R wire between socket 1 of con-

nector [79B] and socket 8 of

connector [10B].

With meter still connected,

check for resistance.

Is resistance 600-1200 ohms?

YES

Remove and inspect CKP

sensor. Remove any debris on

sensor. Reinstall sensor.

NO

Replace CKP

sensor.

2004 Touring: Engine Management (Carbureted) 4-21

Page 22

HOME

Test 4.9 (Part 3 of 3)

ENGINE CRANKS, BUT WILL NOT START

Replace ignition control module (ICM). Reprogram and

perform password learn. Does vehicle start?

Continued from Test 4.9 (Part 2 of 3).

YES

System OK.

NO

Mechanical failure. Inspect for

sprocket gear, timing chain or

other mechanical failure.

4-22 2004 Touring: Engine Management (Carbureted)

Page 23

HOME

f2191x8x

Data Link

Connector [91]

STARTS, THEN STALLS 4.10

GENERAL

Diagnostic Trouble Codes U1300, U1301, P1009, P1010 or “BUS Er”

See Figure 4-18. The typical serial data voltage range is 0

volts (inactive) to 7 volts (active). Due to the short pulse, voltages will be much lower on a DVOM. In analog mode, a

DVOM reading serial data will show continuous voltage when

active, typically 0.6-0.8 volts. The range for acceptable operations is 0-7.0 volts.

NOTE

Problems in the fuel system or idle air control system may

also create this symptom.

Table 4-9. Code Description

DTC

U1300 Serial data low

U1301 Serial data open/high

DESCRIPTION

DIAGNOSTICS

Diagnostic Tips

If serial data is shorted, these codes will automatically

●

trip the check engine light. The odometer will read “Bus

Er” in this condition.

DTCs P1009 and P1010 may accompany DTCs U1300

●

and U1301.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.10 flow charts.

1. Check for trouble codes. See RETRIEVING DIAGNOS-

TIC TROUBLE CODES under 4.3 CHECKING FOR

TROUBLE CODES.

2. Connect BREAKOUT BOX (Part No. HD-42682) as fol-

lows:

a. Mate black socket housing on Breakout Box with

ICM connector [10A].

b. Mate black pin housing on Breakout Box with har-

ness connector [10B].

c. Mate gray socket housing on Breakout Box with

TSM/TSSM connector [30A].

d. Mate gray pin housing on Breakout Box with har-

ness connector [30B].

Figure 4-18. Electrical Bracket (Under Right Side Cover)

3. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black socket probes and patch cord.

4. Historic code U1300 would have been set. Clear historic

codes.

2004 Touring: Engine Management (Carbureted) 4-23

Page 24

HOME

[2A]

[2B]

f2208z8x

321654987121110

321654987121110

Speedometer

15A

Accessory

Fuse

321654987121110

321654987121110

Main to Interconnect

Harness

BK

LtGN/V

O

BN/GY

[39B]

[39A]

[108B]

[108A]

321654987121110

321654987121110

Tachometer

[1B] [1A]

123

123

Main to Interconnect

Harness

6

6

101112 78945

101112 78945

[156B] [156A]

6

6

5

5

4

4

3

3

2

2

1

1

BN/GY

Main to Interconnect

Harness

LtGN/V

GY

65

4

32

1

1

15A

Ignition

Fuse

6

5

4

32

GY

987

987

321654987121110

321654987121110

TSM/TSSM

BK

[8B]

121110

121110

[8A]

Ignition

Harness

1

2

3

4

Data Link

[91A]

BK

[30B]

[30A]

LtGN/V

15A

Battery

Fuse

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 4-19. Serial Data Circuit (FLHT/C)

Table 4-10. Wire Harness Connectors in Figure 4-19.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

4-24 2004 Touring: Engine Management (Carbureted)

Page 25

HOME

f2208y8x

BN/GY

BK

321654987121110

321654987121110

15A

Battery

Fuse

Speedometer

LtGN/V

BN/GY

O

15A

Accessory

Fuse

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

21

21

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

[8B]

[8A]

[91A]

Ignition

Harness

1

2

3

4

Data Link

987

6

54

3

98

7

654

3

121110

121110

LtGN/V

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 4-20. Serial Data Circuit (FLHR/S)

Table 4-11. Wire Harness Connectors in Figure 4-20.

NO.

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

DESCRIPTION TYPE LOCATION

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2004 Touring: Engine Management (Carbureted) 4-25

Page 26

HOME

Test 4.10 (Part 1 of 2)

ASTARTS, THEN STALLS: DTC U1300, U1301,

P1009, P1010 or “BUS Er”

1

Check for DTCs using 4.5 SPEEDOMETER

Is there fresh

fuel in tank?

SELF DIAGNOSTICS.

Any DTCs found?

NOYES

Add fuel.

YES.

DTC P1009,

P1010 found. See

4.15 DTC P1009,

P1010.

YES.

DTC U1300 or

U1301 are found.

YES.

BUS Er present.

Speedometer will not

communicate with other

modules.

STOP

Go to Test 4.10

(Part 2 of 2).

Replace intake

manifold seals.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

NO.

No DTCs found.

Inspect intake manifold for

leaks using intake leak test.

See 4.8 INTAKE LEAK TEST.

Are leaks present (runs longer

when propane is present)?

YES

Reprogram and learn

NO

Replace ICM.

password.

4-26 2004 Touring: Engine Management (Carbureted)

Page 27

HOME

Test 4.10 (Part 2 of 2)

STARTS, THEN STALLS: DTC U1300, U1301, P1009,

P1010 or “BUS Er”

2

Continued from Test 4.10 (Part 1 of 2)

Test the four data connector terminals for continuity.

Leave ICM disconnected

at connector [10]. Does

speedometer display TSM/

YES

Replace ICM. Reprogram

and learn password.

YES

TSSM data?

4

3

NO

Disconnect connector [30]. Check for

continuity to ground at terminal 3 of con-

nector [91A]. Continuity to ground?

DIAGNOSTIC LINK

CONNECTOR [91A]

Terminal Wire Color Terminal

1 N/A N/A

2BK 5

3 Lt. GN/V 12

4GYGY terminal on left

Continuity present in all three circumstances?

NO

Inspect terminals

for damage or repair

opens as necessary.

BREAKOUT BOX

(BLACK)

side of ignition fuse

Locate and repair short

to ground.

Locate and repair short

to voltage.

NOYES

Check for voltage at

terminal 3 of connector

[91A]. Voltage present?

Replace TSM/TSSM. Repro-

gram and learn password.

YES

System

OK.

NOYES

System OK?

NO

Disconnect connector

[39]. System OK?

YES NO

Replace

speedometer.

Replace

tachometer if

equipped.

2004 Touring: Engine Management (Carbureted) 4-27

Page 28

HOME

NO SPARK/NO ICM POWER 4.11

GENERAL

The ignition control module turns on when power is applied to

Pin 1 of [10], the black connector. The ignition control module

goes through an initialization sequence every time power is

removed and re-applied to Pin 1. The only visible part of this

sequence is the check engine lamp. Upon starting, the check

engine lamp will illuminate for 4 seconds and then (if parameters are normal) go out.

R/BK To Ignition Switch

[83B]

A

B

C

15 Amp

Ignition Fuse

Ignition

GY

Coil

W

\

B

K

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.11 flow chart.

1. See FUSES in the Touring Service Manual.

2. Connect BREAKOUT BOX (Part No. HD-42682). See 4.6

BREAKOUT BOX: ICM.

3. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

4104), black pin probe and patch cord.

4. Remove headlamp assembly on FLHR/S models or

outer fairing on FLHT/C.

Ignition Control Module

Y \ BE

BE \ O

BK

7

6

5

Rear Coil

Front Coil

Ground

To TSM/TSSM

[22B]

[22A]

[1B]

[1A]

GY

Engine Stop Switch

56784321 9101112

56784321 9101112

FLHT/C Only

W \ BK

6-Place on FLHR/S

56784321 9101112

[8A]

[8B]

Ground Stud

Figure 4-21. Ignition Control Module Power Circuit

To

Data Link

W \ BK

[10B]

1

[10A]

Key ON Power

4-28 2004 Touring: Engine Management (Carbureted)

Page 29

HOME

Test 4.11

NO SPARK/NO ICM POWER

1

Check Ignition

Fuse. Is Fuse

OK?

NO

Replace Fuse

and Find

Source of Fault.

YES

Replace ICM.

YES

2

Connect Breakout Box. With Igni-

tion ON, Place Multimeter Red

3

Wire to Terminal 1 of Connector

[10] on Breakout Box, Multimeter

Black Wire to Terminal 5 of Con-

nector [10] on Breakout Box. Is

Voltage 12V± 1.0V.?

3

Check Continuity Between Terminal

5 of Connector [10] on Breakout Box

and Ground. Continuity Present in

NO

Repair Open in BK

Wire (Pin 5) to

Ground.

NO

Both Places?

3

4

3

YES

Check Continuity Between Pin

4 (W/BK) of Connector [22A]

and Terminal 1 of Connector

[10] on Breakout Box.

Is Continuity Present?

YES

Check Continuity

Between Sockets 4

(W/BK) and 3 (GY) of

Connector [22B]. With

Engine Stop Switch

ON, Is Continuity

Present?

NO

Locate and Repair

Open in W/BK Wire

Between Connectors

[22] and [10].

YES

Locate and Repair

Open in GY Wire

Between Connector

[22A] and Fuse Block.

NO

Replace

Engine Stop

Switch.

Table 4-12. Wire Harness Connectors in Figure 4-21.

NO. DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect

[1]

Harness

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch (Black) Under Right Side Cover

Interconnect to Right

[22]

Handlebar Switch Controls

FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

FLHT/C 12-Place Deutsch Inner Fairing- Right Fairing Support Brace

FLHR/S 6-Place Deutsch Inside Headlamp Nacelle

2004 Touring: Engine Management (Carbureted) 4-29

Page 30

HOME

MISFIRE 4.12

GENERAL

Misfire at Idle or Under Load

● Battery condition and connections may also cause mis-

fires.

● Fuel system problems may also cause misfires. Refer to

Ta bl e 4-3.

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.12 flow chart.

1WARNING1WARNING

Any open spark around gasoline or other combustibles

may result in fire or explosion. Thoroughly wipe up any

spilt fuel and dispose of rags in a suitable manner. Inadequate safety precautions could result in death or serious

injury.

d0273x8x

Figure 4-22. Spark Tester

c. Compare resistance values to Ta b le 4-13. Replace

cables not meeting specifications. Reinstall and

repeat procedure on other spark plug cable.

Table 4-13. Spark Plug Cables

LOCATION LENGTH RESISTANCE

Front/Rear 20.2 inch (513 mm) 4975-11960

1. See Figure 4-22. Use the SPARK TESTER (Part No. HD-

26792) to verify adequate secondary voltage (25,000

volts) at the spark plug.

a. Turn Ignition/Light Key Switch to IGNITION.

b. Remove spark plug cable from spark plug. Visually

check plug condition.

c. Attach cable to SPARK TESTER. Clip tester to cylin-

der head bolt.

d. While cranking engine, watch for spark to jump

tester gap on leads.

IMPORTANT NOTE

Spark will not be present when cranking with both spark

plugs removed. When checking for spark, use SPARK

TESTER with both spark plugs installed and one plug

wire connected to SPARK TESTER.

e. Reinstall and repeat procedure on other spark plug

cable.

2. Perform spark plug cable resistance test.

a. Remove spark plug cable from spark plug and igni-

tion coil. For best results, use a needle nose pliers

for removal/installation on coil. Gently grasp cable

as close to terminals as possible.

b. Using an ohmmeter, touch probes to terminals on

each end plug wire.

3. This test can also be performed by substituting a known

good coil for one causing the no spark condition. The coil

does not require full installation to be functional. Verify

faulty coil by performing resistance test.

4. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probe and patch cord to the coil connector [83B].

5. Inspect for corrosion at battery terminals, maxi fuse terminals, ignition fuse terminals GY and R/BK, right handlebar switch controls connector [22], and ignition coil

connector [83].

4-30 2004 Touring: Engine Management (Carbureted)

Page 31

HOME

R/BK To Ignition Switch

15 Amp

Ignition Fuse

To TSM/TSSM

[22B]

[22A]

Ignition

GY

[1B]

[1A]

GY

Engine Stop Switch

Coil

[83B]

A

B

C

W

\

B

K

56784321 9101112

56784321 9101112

FLHT/C Only

W \ BK

6-Place on FLHR/S

56784321 9101112

Y \ BE

BE \ O

[8A]

[8B]

Ground Stud

Ignition Control Module

BK

W \ BK

[10B]

To

Data Link

7

6

5

1

[10A]

Rear Coil

Front Coil

Ground

Key ON Power

Figure 4-23. Ignition Coil Circuit

Table 4-14. Wire Harness Connectors in Figure 4-23.

NO. DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect

[1]

Harness

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch (Black) Under Right Side Cover

Interconnect to Right

[22]

Handlebar Switch Controls

[83] Ignition Coil All 3-Place Packard Below Fuel Tank (Left Side)

FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

FLHT/C 12-Place Deutsch Inner Fairing- Right Fairing Support Brace

FLHR/S 6-Place Deutsch Inside Headlamp Nacelle

2004 Touring: Engine Management (Carbureted) 4-31

Page 32

HOME

Test 4.12

MISFIRE AT IDLE OR UNDER LOAD

Is fuel contaminated?

YES

Replace

intake seals.

YES

Drain and flush

tank. Refill with

fresh fuel.

YES

Inspect intake manifold for leaks.

See 4.8 INTAKE LEAK TEST.

Leaks present?

Turn Ignition Switch OFF.

Disconnect one spark plug lead at a time

1

and install Spark Tester (HD-26792). See

Crank engine to induce spark. Observe

spark tester during test.

Spark should jump tester lead gap during

• Faulty, worn or cracked spark plug(s).

• Plug fouling due to engine

mechanical fault.

• Faulty or poor connection at plug.

NO

Figure 4-22.

test. Did it?

YES

Check for:

NO

Remove air cleaner cover. Start engine.

Open throttle quickly. Does slide move up

and down with throttle opening?

NO

Inspect CV carburetor diaphragm for leaks. Replace

or repair as necessary.

NO

Check resistance of each spark plug

2

cable that did not fire the spark tester.

Also, check for faulty plug wire connections.

Are wires OK?

YES

Original ignition coil

is faulty. Replace.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

4-32 2004 Touring: Engine Management (Carbureted)

YES

Switch coil with unit

known to be good.

3

Perform spark test.

Did spark jump gap

during engine cranking?

4

5

Replace ignition control

module. Reprogram and

Replace

faulty wires.

NO

Remove test coil. Disconnect negative bat-

tery cable. Measure resistance between bat-

tery positive and coil connector [83B]

Terminal B (W/BK). Wiggle harness. Is resis-

tance continuously less than 1.0 ohm?

YES

Find source of

learn password.

intermittent and repair.

NO

NO

Loading...

Loading...