Page 1

HOME

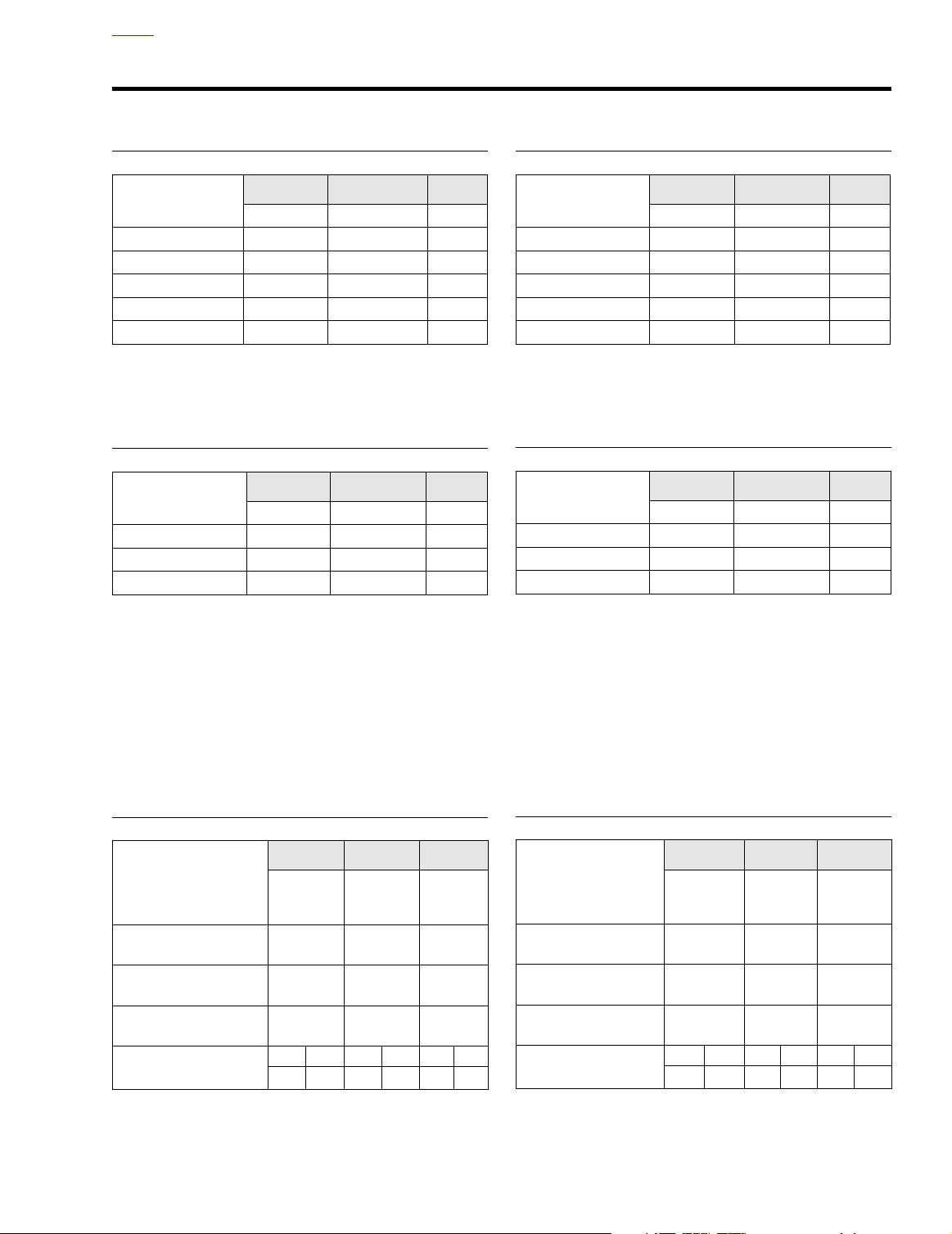

SPECIFICATIONS 2.1

DIMENSIONS (IN.)

FLHT/C/U

Wheel Base 63.5 63.5 63.5

Overall Length

Overall Width 39.0

Road Clearance 5.12

Overall Height 61.0

Saddle Height* 27.3

With 180 Lb. Rider

*

93.7/97.5/98.3

FLHR/C/S FLTR

93.7 93.7

34.45/34.45/39.40

5.12/5.12/4.70

55.06/55.06/46.40

27.3/26.9/26.1

35.75

WEIGHT (LBS.)

FLHT/C/U FLHR/C/S FLTR

DRY WEIGHT** 758/776/788 723/710/721 731

GVWR 1259 1259 1259

GAWR – Front 500 500 500

GAWR – Rear 827 827 827

As shipped from the factory

**

5.12

55.0

26.9

DIMENSIONS (MM)

FLHT/C/U

Wheel Base 1613 1613 1613

Overall Length

Overall Width 990

Road Clearance 130

Overall Height 1549

Saddle Height* 693

With 81.6 kg Rider

*

2380/2476/2497

FLHR/C/S FLTR

2380 2380

875/875/1001

130/130/119

1399/1399/1179

693/683/663

1397

WEIGHT (KG)

FLHT/C/U

DRY WEIGHT** 344/352/358 328/322/327 332

GVWR 571 571 571

GAWR – Front 227 227 227

GAWR – Rear 375 375 375

As shipped from the factory

**

FLHR/C/S FLTR

908

130

683

NOTE

Gross Vehicle Weight Rating (GVWR) (maximum allowable

loaded vehicle weight) and corresponding Gross Axle Weight

Ratings (GAWR) are given on a label located on the inside of

the right front frame downtube.

CAPACITIES (U.S.)

FLHT/C/U

Fuel Tank (gallons)

To tal***

Reserve

Oil Tank (quarts)

with filter 4 4 4

Tr ansmission

(Ounces, approximate) 20-24 20-24 20-24

Primary Chaincase

(Ounces, approximate) 32 32 32

Front Fork (Ounces)

***

Includes Reserve on Carbureted Models

0.9

Left Right Left Right Left Right

10.0 11.1 11.1 11.1 10.0 11.1

FLHR/C/S FLTR

5

5

0.9

5

0.9

CAPACITIES (METRIC)

FLHT/C/U

Fuel Tank (liters)

To tal***

Reserve

Oil Tank (liters)

with filter 3.78 3.78 3.78

Tr an smission

(Milliliters) 591-710 591-710 591-710

Primary Chaincase

(Milliliters) 946 946 946

Front Fork (Milliliters)

Includes Reserve on Carbureted Models

***

18.9

3.4

Left Right Left Right Left Right

295 328 328 328 295 328

FLHR/C/S FLTR

18.9

3.4

18.9

3.4

2004 Touring: Chassis 2-1

Page 2

HOME

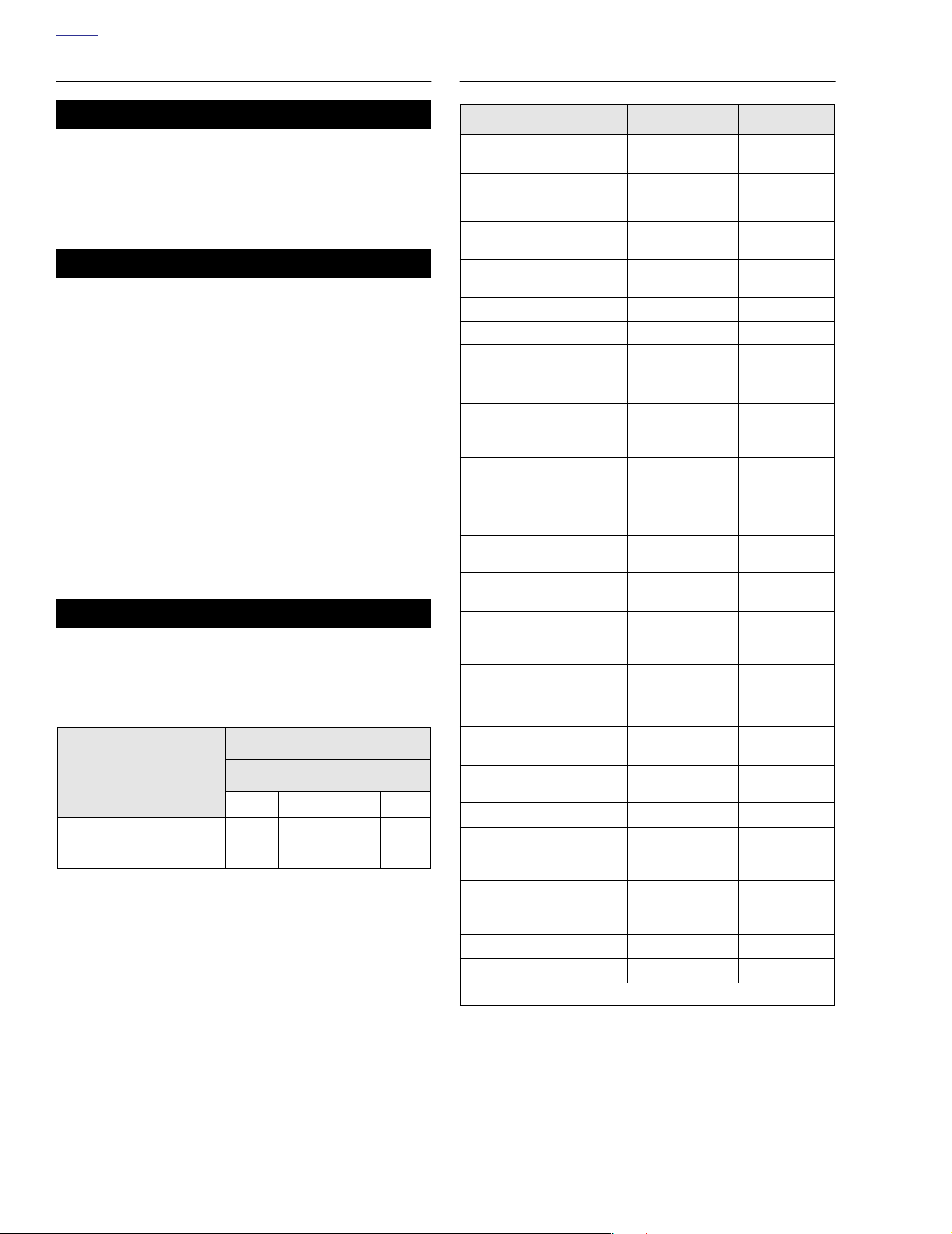

TIRE DATA

11WARNING1WARNING

Tires, rims and air valves must be correctly matched to

wheel rims. See your Harley-Davidson dealer for service.

Mismatching tires, tubes, rims and air valves may result

in damage to the tire bead during mounting or may allow

the tire to slip on the rim, possibly causing tire failure,

which could result in death or serious injury.

11WARNING1WARNING

Using tires in ways other than those specified below may

adversely affect motorcycle stability. Instability may lead

to loss of vehicle control, which could result in death or

serious injury.

Use tubeless tires on all Harley-Davidson cast and

●

disc wheels.

●

Tubeless tires fitted with the correct size inner tubes

also may be used on all Harley-davidson laced

wheels, but protective rubber rim strips must be

installed to prevent damage to the inner tubes.

●

Do not use inner tubes in radial tires. Do not use

radial tires on laced wheels.

Always use the correct size tires and tubes. Tire

●

sizes are molded on the tire sidewall. Tube sizes are

printed on the tube.

11WARNING1WARNING

Maximum inflation pressure must not exceed specification on tire sidewall. Exceeding inflation specifications

can adversely affect handling or result in tire failure,

which could result in death or serious injury.

Tire Pressure (Cold)

Dunlop Tires

Only

Front Rear

PSI BARS PSI BARS

Solo Rider 36 2.5 36 2.5

Rider & One Passenger 36 2.5 40 2.8

REAR WHEEL SPROCKET

All Models 70 teeth

TORQUE VALUES

Item

Front brake disc TORX

screws

Front axle nut

Front axle holder nuts

Front brake caliper

mounting bolts

Rear brake disc TORX

screws

Rear wheel sprocket bolts 55-65 ft-lbs

Rear axle cone nut 95-105 ft-lbs 129-142 Nm

Wheel spokes

Front engine mount to

frame bolts

Front engine mounting

bracket to rubber mount

bolt

Voltage regulator locknuts

Handlebar clamp to

master cylinder housing

TORX screws

Brake caliper bleeder

valve

Rear brake pedal shaft

locknut

Brake pedal/master

cylinder assembly to

mounting bracket hex nut

Banjo bolt to master

cylinder

Banjo bolt to brake caliper

Fairing lower U-bolt

retainer locknuts

Fairing lower to engine

guard clamp TORX screw

Fairing lower cap screws

Front brake master

cylinder reservoir cover

screws

Rear brake master

cylinder reservoir cover

screws

Brake caliper pad pins

Brake caliper bridge bolts

ft/in-lbs Nm

16-24 ft-lbs 22-33 Nm

50-55 ft-lbs

132-180

in-lbs

28-38 ft-lbs

30-45 ft-lbs

40-50

in-lbs

15-20 ft-lbs 20-27 Nm

15-20 ft-lbs 20-27 Nm

70-100

in-lbs

60-80

in-lbs

80-100

in-lbs

15-20 ft-lbs

30-40 ft-lbs 41-54 Nm

17-22 ft-lbs 23-30 Nm

17-22 ft-lbs 23-30 Nm

35-40

in-lbs

90-100

in-lbs

10-15

in-lbs

6-8

in-lbs

6-8

in-lbs

180-200

in-lbs

28-38 ft-lbs 38-52 Nm

68-75 Nm

14.9-20.3 Nm

37.9-51.5 Nm

41-61 Nm

75-88 Nm

4.5-5.6 Nm

7.9-11.3 Nm

6.8-9.0 Nm

9.0-11.3 Nm

20-27 Nm

4.0-4.5 Nm

10.2-11.3 Nm

1.1-1.7 Nm

0.7-0.9 Nm

0.7-0.9 Nm

20-23 Nm

Continued ...

2-2 2004 Touring: Chassis

Page 3

HOME

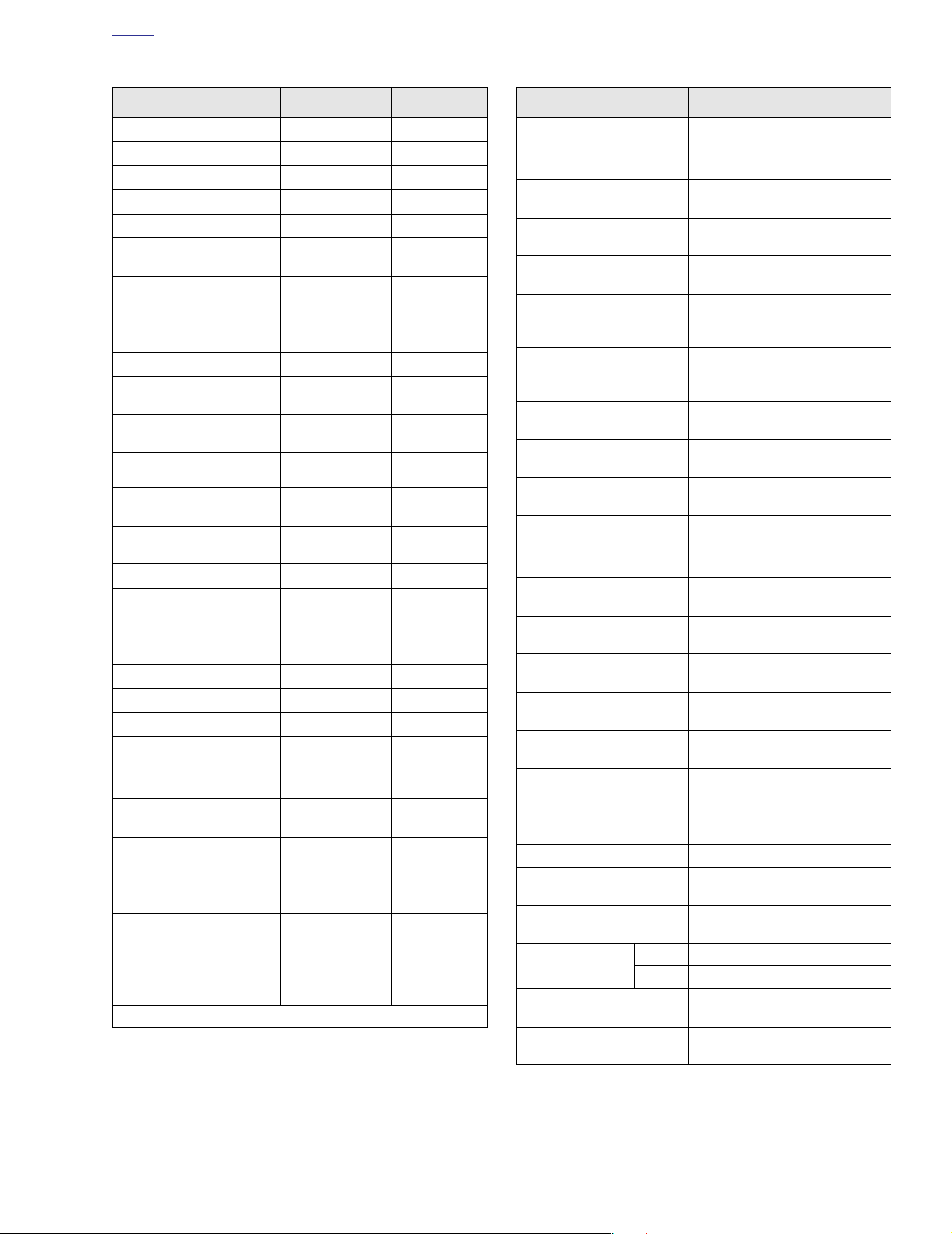

TORQUE VALUES (CONT.’D)

Item

Fork oil drain plugs

Fork pinch bolts

Fork stem nut

Fork tube plug

Fork cap bolt

Damper rod/cartridge

6mm screw

Damper rod locknut

(cartridge type fork)

Shock bottom mounting

bolt

Shock top mounting bolt

Rear swingarm bracket

bolts

Rear swingarm pivot shaft

locknut

Handlebar switch

housing TORX screws

Handlebar clamp to clutch

lever bracket screws

Clutch release cover

socket head screws

Clutch cable fitting 36-60

Tr ansmission lubricant

drain plug

Tr ansmission filler plug/

dipstick

Battery cable bolt

Tour-Pak mounting bolts

Inner fairing screws

Outer fairing screws

(below windshield)

Fairing cap TORX screws

Speedometer/tachometer

bracket socket screws

2 inch diameter gauge

nuts

Passing lamp bracket fork

bracket TORX bolts

Windshield wellnut

screws (FLTR)

Front turn signal lamp

bracket stud acorn nuts

(FLTR)

ft/in-lbs Nm

72-96

30-35 ft-lbs

60-80 ft-lbs

22-58 ft-lbs

50-60 ft-lbs

132-216

13-20 ft-lbs

35-40 ft-lbs

33-35 ft-lbs

34-42 ft-lbs

40-45 ft-lbs

35-45

60-80

120-144

14-21 ft-lbs

25-75

60-96

96-120

20-30

25-30

25-30

10-20

10-20

15-20 ft-lbs 20-27 Nm

6-13

40-50

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

8-11 Nm

41-48 Nm

81-109 Nm

30-79 Nm

68-81 Nm

14.9-24.4 Nm

18-27 Nm

47-54 Nm

45-48 Nm

46-57 Nm

54-61 Nm

4-5 Nm

6.8-9.0 Nm

13.6-16.3 Nm

4-7 Nm

19-28 Nm

2.8-8.5 Nm

6.8-10.9 Nm

10.8-13.5 Nm

2.3-3.4 Nm

2.8-3.4 Nm

2.8-3.4 Nm

1.1-2.3 Nm

1.1-2.3 Nm

0.7-1.5 Nm

4.5-5.7 Nm

Continued ...

Item

Short fairing screws

(FLTR)

Long fairing screws (FLTR)

Instrument bezel TORX

screws (FLTR)

Instrument nacelle to fork

bracket TORX bolts (FLTR)

Fairing bracket/steering

head thru bolt (FLTR)

Radio bracket/inner fairing

to fairing bracket stud locknuts (FLTR)

Headlamp nacelle handlebar clamp shroud Phillips

screw

Headlamp nacelle trim

strip flange nut

Passing lamp bracket fork

bracket stud acorn nuts

Front fender mounting

bolts

Rear fender TORX bolts

Jiffy stand leg stop flange

nut

Intake flange adapter

screws

Exhaust flange adapter

nuts

Exhaust pipe TORCA

clamps

Heat shield worm drive

clamps

Tr ansmission exhaust

bracket clamp bolt

Passenger footboard/

footrest socket screws

Rider footboard

pivot bolt nut

Air valve mount hex nut 40-50

Handlebar upper clamp

screws

Handlebar lower clamp

bolts (risers)

Ignition switch

nut

Speaker box to

Tour-Pak bolts

Throttle cable J-clamp

screw to wellnut (FLHR/C)

DOM 50-70

HDI 125-150

ft/in-lbs Nm

6-12

10-15

25-35

15-20 ft-lbs 20-27 Nm

20-30 ft-lbs 27.1-40.7 Nm

96-144

10-20

15-20

72-108

16-20 ft-lbs 22-27 Nm

15-20 ft-lbs 20-27 Nm

43-53 ft-lbs 58-72 Nm

96-144

100-120

45-60 ft-lbs 61-81 Nm

20-40

60-96

15-18 ft-lbs 20-24 Nm

84-108

12-16 ft-lbs 16.3-21.7 Nm

30-40 ft-lbs 40.7-54.2 Nm

25-35

9-18

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

0.7-1.4 Nm

1.1-1.7 Nm

2.8-4.0 Nm

10.9-16.3 Nm

1.1-2.3 Nm

1.7-2.3 Nm

8.1-12.2 Nm

10.9-16.3 Nm

11.3-13.6 Nm

2.3-4.5 Nm

6.8-10.8 Nm

9.5-12.2 Nm

4.5-5.6 Nm

5.7-7.9 Nm

14.1-16.9 Nm

2.8-4.0 Nm

1.0-2.0 Nm

2004 Touring: Chassis 2-3

Page 4

HOME

NOTES

2-4 2004 Touring: Chassis

Page 5

HOME

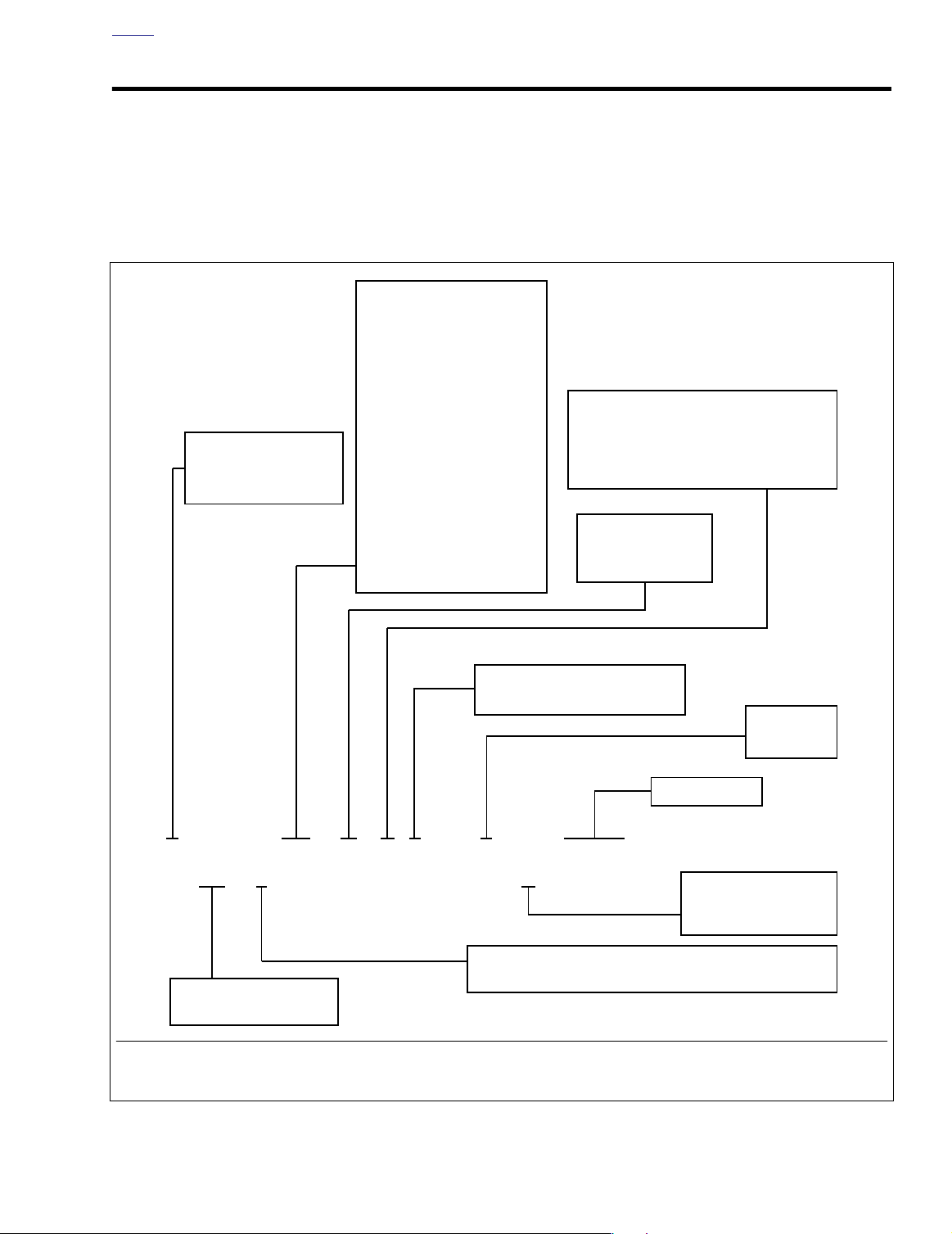

VEHICLE IDENTIFICATION NUMBER (VIN) 2.2

A 17-digit serial number, or Vehicle Identification Number

(VIN), is stamped on the right side of the frame backbone at

the rear of the steering head (and under the main harness

conduit). A label bearing the VIN code is also affixed to the

left side of the steering head. An abbreviated VIN is stamped

between the front and rear cylinders on the left side of the

crankcase.

Model Designation

DD – FLHT

DJ – FLHTC

FB – FLHRI

FC – FLHTCUI

FD – FLHR

FF – FLHTCI

FG – FLHTCUI W/SC

FH – FLHPI

Market Designation

1 = Domestic

5 = International (HDI)

FK – FLHTCI Shrine

FL – FLHTCUI Shrine

FM – FLHTPI

FR – FLHRCI

FS – FLTRI

FT – FLHPEI

FV – FLHTI

FW – FLHRI Shrine

FX – FLHRS

FY – FLHRSI

NOTE

Always give the complete VIN when ordering parts or making

an inquiry about your motorcycle.

Introduction Date and Special Models

1 = Regular introduction date

2 = Mid-year introduction date

3 = California model

4 = Anniversary model

Engine Type

V = Carbureted

W = Fuel Injected

VIN Check Digit

Var ies; can be 0 through 9, or X.

1HD 1DJ V 13 4 Y 500001

Motorcycle Type

1 = Heavyweight (901 cc and larger engine displacement)

Manufacturer and Make

Harley-Davidson

Sample VIN as it appears on the steering head –1HD1DJV134Y500001

Sample abbreviated VIN as it appears on the engine crankcase– DJV4500001

Figure 2-1. Vehicle Identification Number (VIN)

Model Year

4 = 2004

Serial Number

Assembly Plant

Y = York, PA

K = Kansas City, MO

2004 Touring: Chassis 2-5

Page 6

HOME

FRONT WHEEL 2.3

GENERAL

Maximum tire mileage and good handling qualities are

directly related to care given wheels and tires. Wheels and

tires should be regularly inspected for wear. If handling problems occur, see Section 1.1 TROUBLESHOOTING, HAN-

DLING, for possible causes.

Always keep tires inflated to the recommended pressure and

balance the wheel whenever a tire or tube is replaced.

PRELIMINARY INSPECTION

1. Measure brake disc thickness for excessive wear. Minimum acceptable thickness is stamped on side of disc.

Also replace discs if warped or badly scored. Obtain

new

T40 TORX screws if brake discs were removed.

2. Whenever the wheel is removed for tire replacement or

any other purpose, inspect the wheel bearings as follows:

a. Insert finger into wheel bearing and rotate the inner

race in both directions. Repeat step on opposite

side of wheel.

b. Replace the wheel bearings if there is rough rota-

tion, abnormal noise or anything unusual. Always

replace wheel bearings as a set. Never replace just

one wheel bearing.

2. Remove both the upper and lower mounting bolts from

lugs of front fork leg to release brake caliper assembly.

3. Lift caliper upward to remove from brake disc. Allow the

caliper to hang loose.

4. Repeat steps 1 thru 3 to release caliper on opposite side

of wheel.

NOTE

Do not operate the front brake hand lever with the front wheel

removed or the caliper pistons may be forced out. Reseating

pistons requires disassembly of the caliper.

5. Insert screwdriver or steel rod through hole in axle on

right side of vehicle. While holding axle stationary,

remove the axle nut, lockwasher and flat washer on the

left side.

6. Loosen the two axle holder nuts at bottom of right side

fork leg.

7. With soft mallet, tap axle toward right side of vehicle until

loose. Catching external spacers on left and right side,

pull axle from hub while supporting wheel.

8. Move wheel to bench area and inspect bearings. See

PRELIMINARY INSPECTION on this page.

REMOVAL

1. Use shop rag or tape to protect fender area adjacent to

caliper, as incidental contact can occur during caliper

removal.

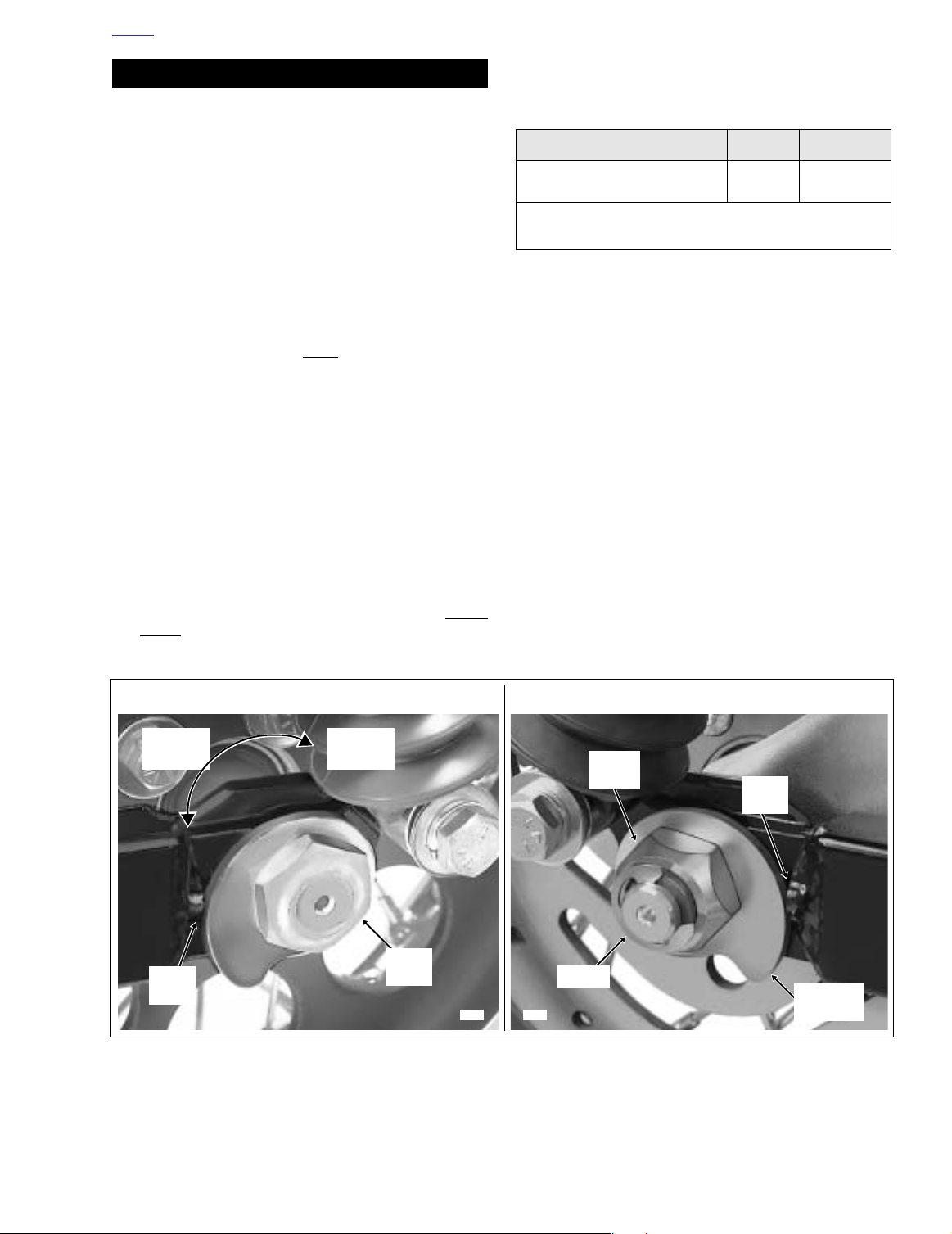

9428

Figure 2-2. Inspect Wheel Bearings

DISASSEMBLY

1. If wheel bearing replacement is necessary, proceed as

follows:

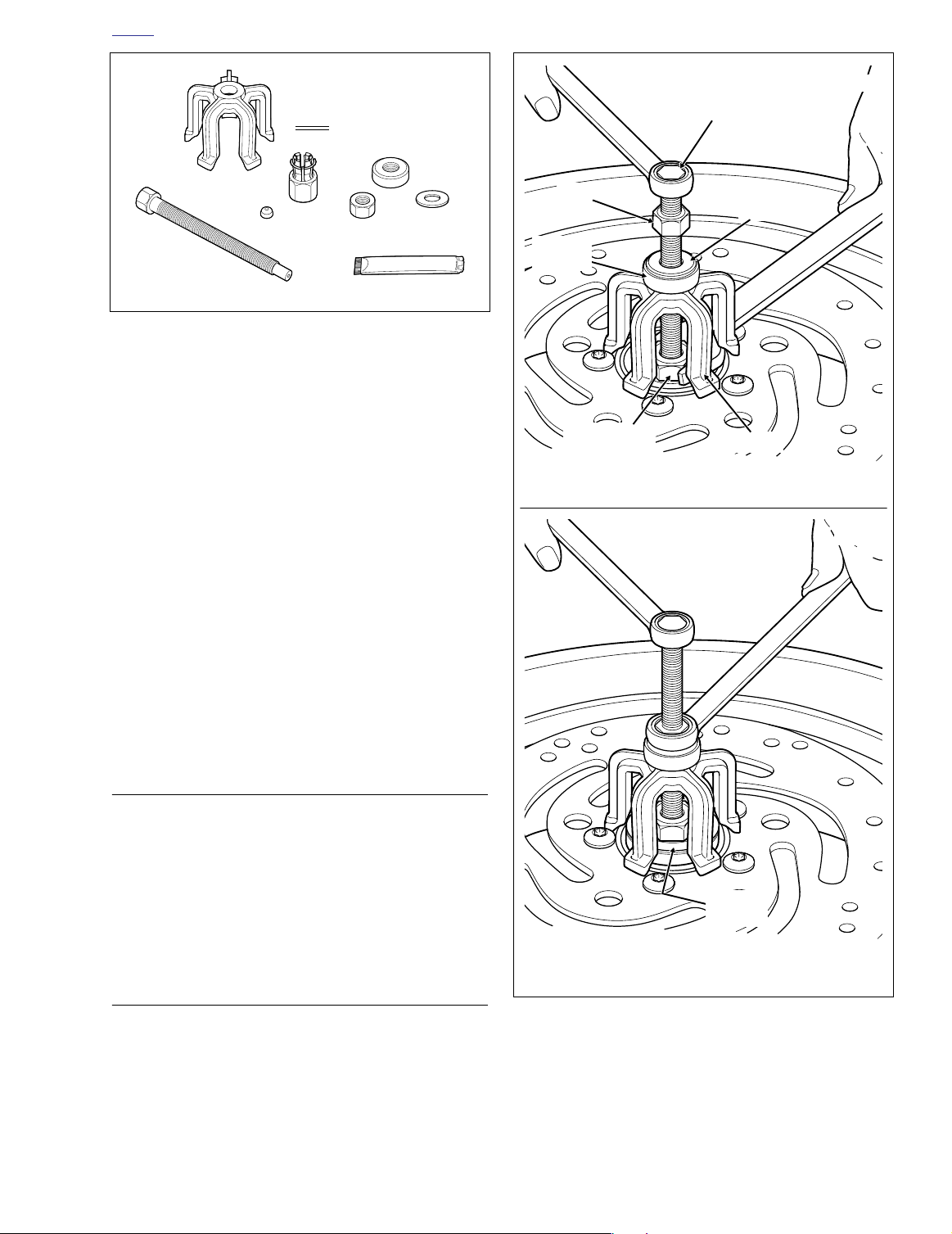

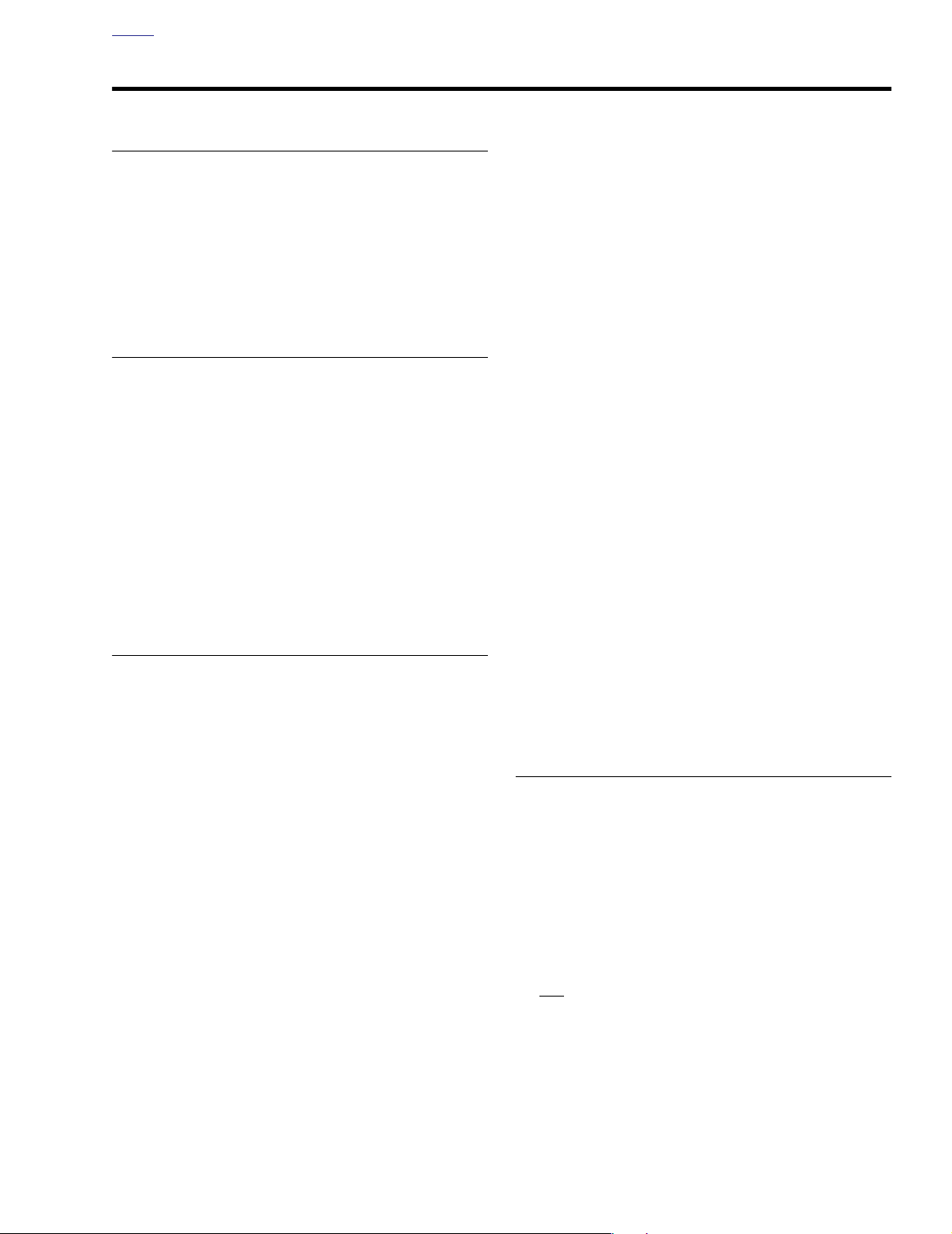

a. Obtain the WHEEL BEARING REMOVER/IN-

STALLER (HD-44060). Pick out the wheel bearing

remover tools for the front wheel. See Figure 2-3.

b. To prolong service life and ensure smooth opera-

tion, sparingly apply graphite lubricant to threads of

forcing screw.

c. Install hex nut, flat washer and Nice bearing on forc-

ing screw. Insert end of forcing screw through hole

in bridge.

d. Install steel ball inside

end of forcing screw.

e. Insert collet into bearing ID. Feel for inside edge of

bearing using lip at end of collet and then back off

slightly.

f. Holding forcing screw to prevent rotation, turn hex

on collet until lip makes firm contact with inside

edge of bearing. See upper frame of Figure 2-4.

lar

collet. Install collet at

ger

2-6 2004 Touring: Chassis

Page 7

HOME

f1775x2x

Wheel

Bearing

f1774x2x

Nice

Bearing

Hex

Nut

Forcing

Screw

Flat

Washer

Bridge

Collet Hex

with Ball Bearing

Hold Forcing Screw and Turn Hex on Collet to Expand.

Hold Forcing Screw and Turn Hex Nut to Pull Out Bearing.

Bridge

ger Collet

Lar

1 Inch

Steel Ball

Forcing Screw

Figure 2-3. Front Wheel Bearing Remover Tools

(Part No. HD-44060)

g. Holding forcing screw, turn hex nut until bearing is

free. See lower frame of Figure 2-4.

h. Remove spacer sleeve from wheel hub.

i. Repeat procedure to remove bearing on opposite

side of wheel. Discard bearings.

2. If brake disc replacement is necessary, use a T40 TORX

drive head and remove five screws securing brake disc

to hub. Discard TORX screws. Repeat procedure to

remove disc on opposite side of wheel. If the wheel is to

be assembled with the same discs, mark both the wheel

and discs, so that they can be installed in their original

positions.

3. If tire replacement is necessary, see Section 2.8 TIRES

AND TUBES.

4. If the wheel is laced, and hub, spoke or rim replacement

is necessary, loosen all spoke nipples and disassemble

hub from rim.

Nice Bearing

Hex Nut

Graphite Lubricant

f1769x2x

Flat Washer

CLEANING AND INSPECTION

1. Thoroughly clean all parts in solvent.

2. Inspect all parts for damage or excessive wear.

3. Always replace bearing assemblies as a complete set.

4. Inspect brake discs. Replace discs if warped or badly

scored. Measure disc thickness for excessive wear. Minimum acceptable thickness is stamped on side of disc.

ASSEMBLY

1. On laced wheels, if the hub and rim were disassembled,

assemble the hub, spokes and rim. See Section 2.6

WHEEL LACING - 16 INCH RIM.

Figure 2-4. Remove Sealed Wheel Bearings

2004 Touring: Chassis 2-7

Page 8

HOME

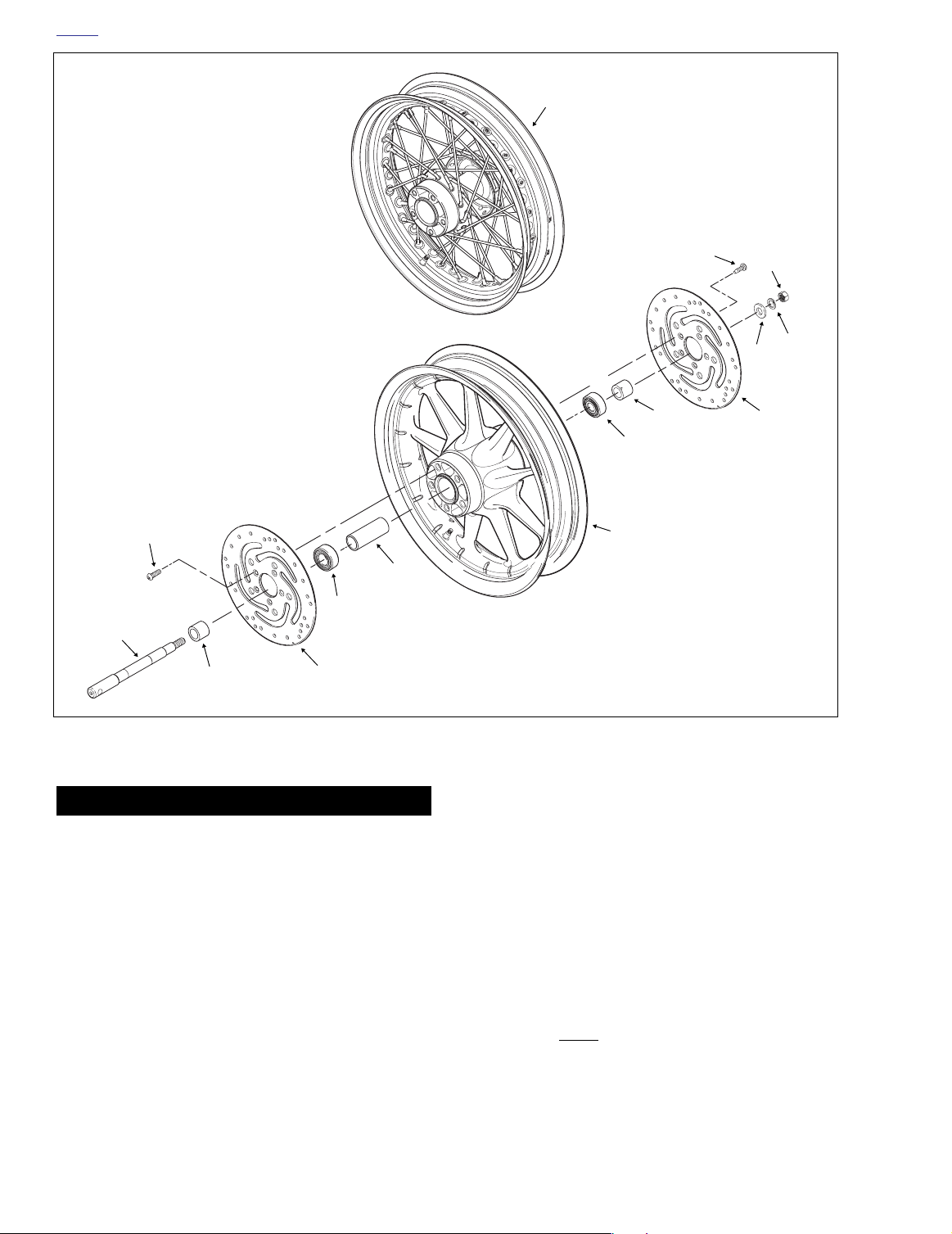

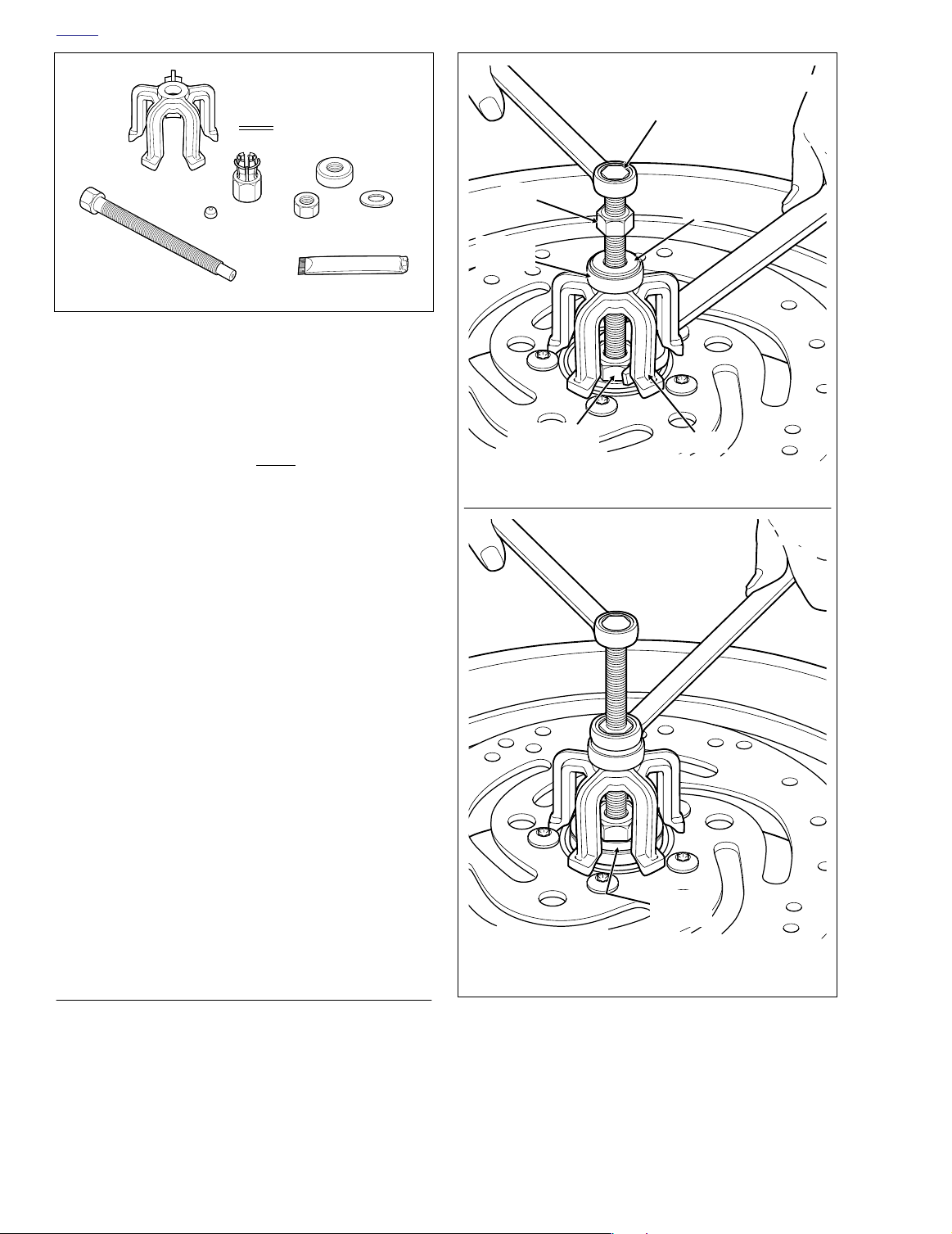

1. Axle Nut

2. Lockwasher

3. Flat Washer

4. T40 Torx Screw (10)

5. Brake Disc (Left Side)

6. External Spacer (Long)

7. Sealed Bearing (2)

8. Cast Wheel

9. Spacer Sleeve

10. Brake Disc (Right Side)

11. External Spacer (Short)

12. Axle

13. Laced Wheel

13

Left Side

4

1

2

3

Right Side

4

9

7

12

11

10

Figure 2-5. Front Wheel (Exploded View)

11WARNING1WARNING

Do not allow brake fluid or other lubricants to contact

the brake disc. Such contact can adversely affect braking ability, which could result in death or serious injury.

2. Using a T40 TORX drive head, install brake discs on hub

using

new

screws. Be sure to install discs in their original positions. Alternately tighten screws to 16-24 ft-lbs

(22-33 Nm).

3. Install

Always install first of two bearings on the left side (opposite

the valve stem side of the wheel).

new

wheel bearings as follows:

NOTE

6

5

7

8

f2042x2x

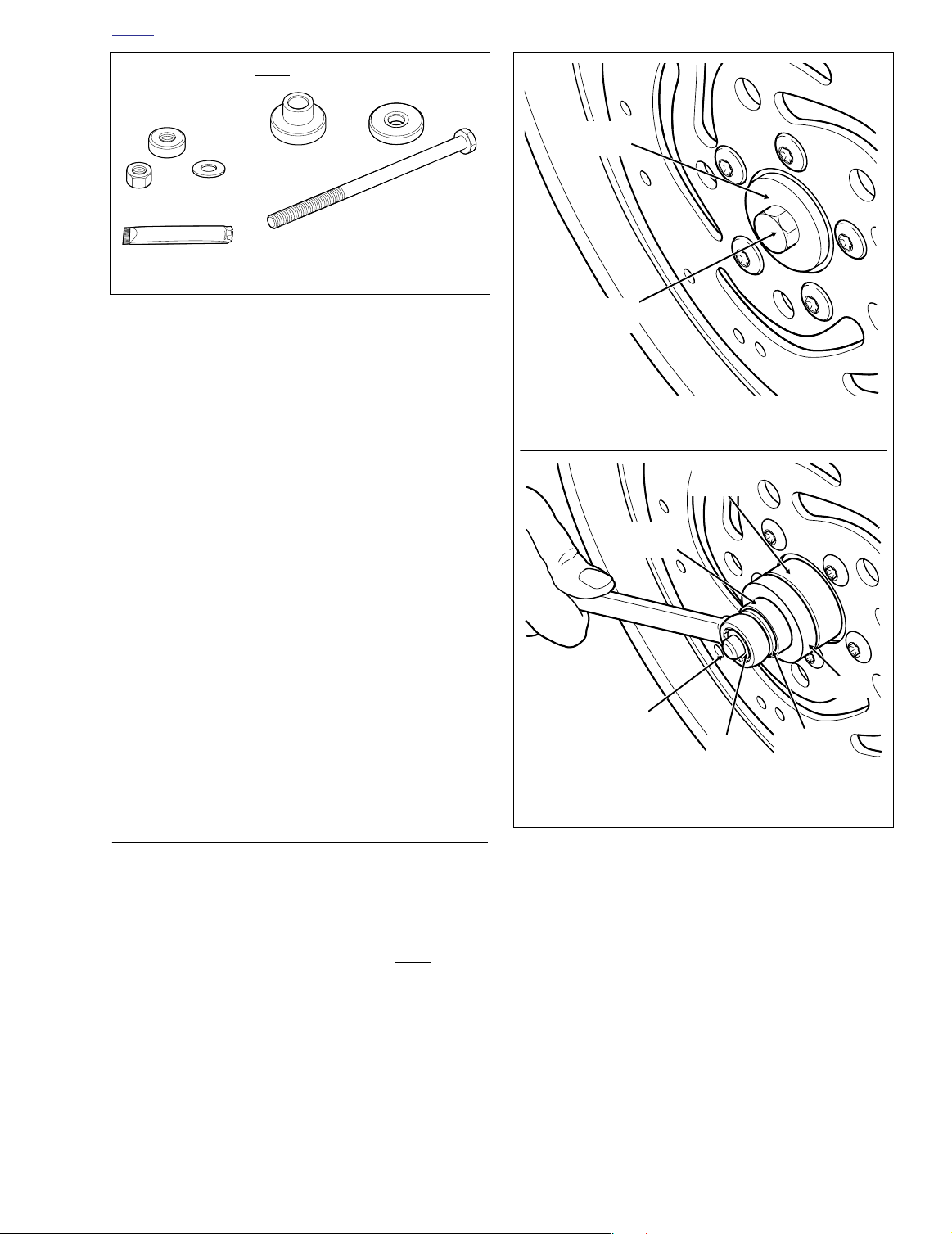

a. Obtain the WHEEL BEARING REMOVER/IN-

STALLER (HD-44060). Pick out the wheel bearing

installer tools for the front wheel. See Figure 2-6.

b. To prolong service life and ensure smooth opera-

tion, sparingly apply graphite lubricant to threads of

threaded rod.

c. Slide support plate onto threaded rod. Slide rod

through hub on the valve stem side of the wheel.

See upper frame of Figure 2-7.

d. On opposite side of wheel, slide bearing onto

threaded rod with lettered side facing outboard.

e. Install

lar

pilot, Nice bearing, flat washer and

ger

hex nut onto rod.

2-8 2004 Touring: Chassis

Page 9

HOME

f1777x2x

Support

Plate

Threaded

Rod

f1773x2x

Nice

Bearing

Hex

Nut

Threaded

Rod

Flat

Washer

Wheel

Bearing

Pilot

Slide Threaded Rod (with Support Plate) Through Hub.

Hold Threaded Rod and Turn Hex Nut to Push In Bearing.

Nice Bearing

Larger Pilot

1 Inch

Support Plate

Hex Nut

Graphite Lubricant

Flat Washer

Threaded Rod

f1771x2x

Figure 2-6. Front Wheel Bearing Installer Tools

(Part No. HD-44060)

f. Holding threaded rod on opposite side of wheel to

prevent rotation, turn hex nut to install bearing. See

lower frame of Figure 2-7. Bearing is fully seated

when it makes firm contact with the counterbore.

g. Disassemble and remove tool, but leave support

plate on threaded rod.

h. Slide threaded rod through installed wheel bearing

and hub of wheel.

i. On the valve stem side of the wheel, slide spacer

sleeve down threaded rod until it contacts installed

wheel bearing.

j. Repeat steps 3(d) through 3(g) to complete installa-

tion of second wheel bearing. Bearing is fully seated

when hex nut can no longer be turned.

4. Verify that wheel is true. See CHECKING CAST RIM

RUNOUT or TRUING LACED WHEEL, whichever

applies.

5. Install rim strip on wheel rim, if applicable. Install tube

and tire, if applicable. Verify that wheel is balanced.

INSTALLATION

1. Place wheel into position between forks with the valve

stem on the right side of the vehicle.

2. Coat the axle with ANTI-SIEZE LUBRICANT.

right fork leg. Push axle through fork,

spacer and wheel hub until it begins to emerge from left

side.

3. Supporting wheel, insert threaded end of axle through

4. With the three notches on the bearing side, push axle

through

long

external spacer and left fork leg until axle

shoulder contacts external spacer on right fork side.

shor

t

external

Figure 2-7. Install Sealed Wheel Bearings

5. Install flat washer, lockwasher and axle nut.

6. Insert screwdriver or steel rod through hole in axle on

right side of vehicle. While holding axle stationary,

tighten axle nut to 50-55 ft-lbs (68-75 Nm).

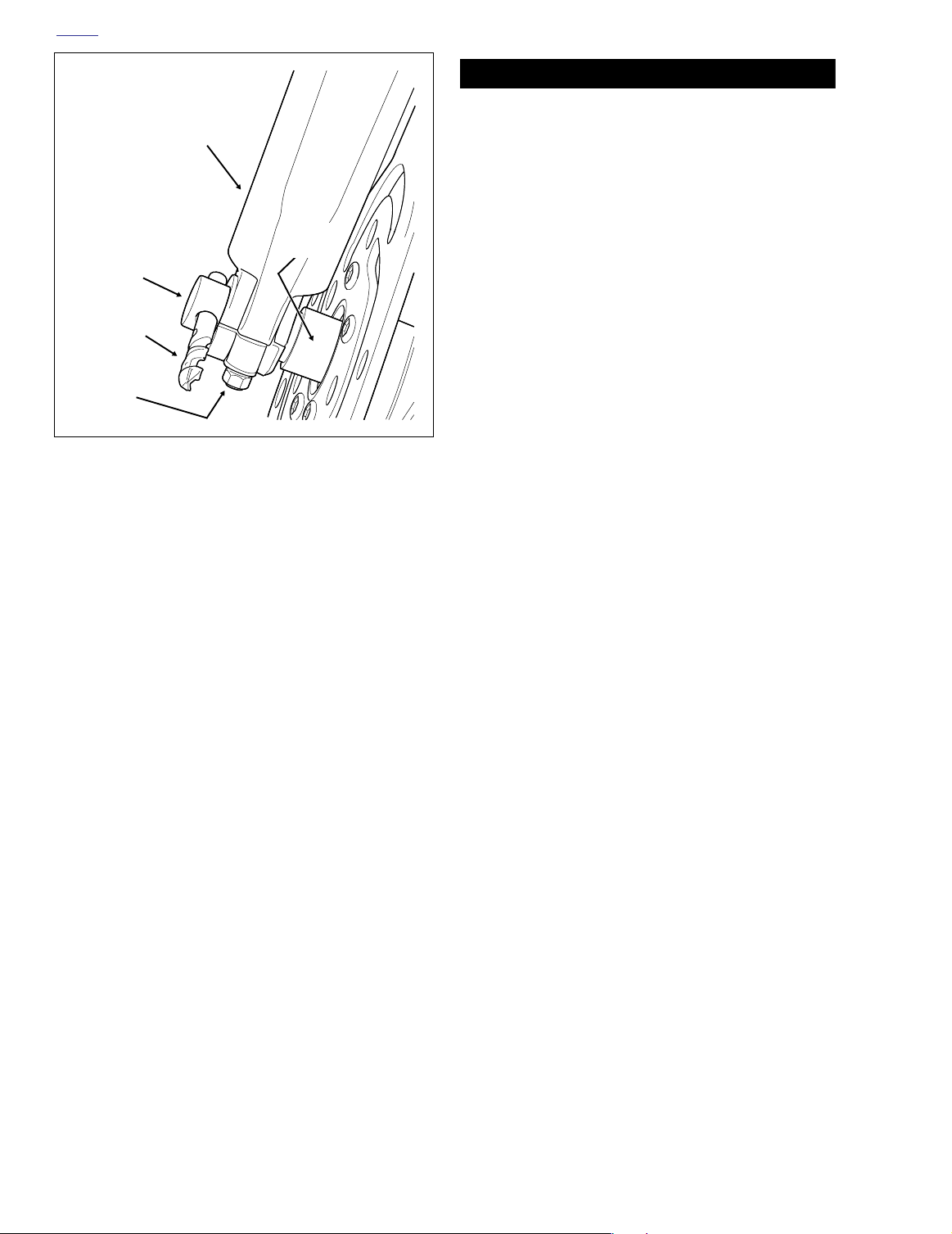

7. Insert 7/16 inch drill bit into hole in axle. See Figure 2-8.

8. Pull fork leg so that it just contacts drill bit, and then

tighten axle holder nuts to 132-180

in-lbs

(14.9-20.3

Nm).

2004 Touring: Chassis 2-9

Page 10

HOME

f1783x2x

Fork Leg

Right Side

Axle

Drill Bit

Axle Holder

Nuts

Figure 2-8. Align Front Wheel

9. Remove drill bit from axle hole.

10. Install brake caliper as follows:

Short

Spacer

11WARNING1WARNING

After installation of calipers and BEFORE moving motorcycle, pump front brake hand lever until pistons push

pads against the brake discs. If fluid pressure is not

pumped up, the brake will not be available the first time it

is used, a situation that could result in death or serious

injury.

11. Depress front brake hand lever several times to set

brake pads to proper operating position within caliper.

a. Use shop rag or tape to protect fender area adja-

cent to caliper, as incidental contact can occur during caliper installation.

b. With the bleeder valve topside, position caliper so

that brake disc is situated between friction pads. Pry

inner and outer brake pads back for additional clearance, if necessary.

c. Align upper mounting hole in caliper with upper

mounting lug on fork leg. Loosely install long caliper

mounting bolt into upper lug of fork leg.

d. Install short caliper mounting bolt into lower lug of

fork leg. Tighten lower mounting bolt to 28-38 ft-lbs

(37.9-51.5 Nm).

e. Tighten upper caliper mounting bolt to 28-38 ft-lbs

(37.9-51.5 Nm).

f. Repeat step 10 to install caliper on opposite side of

wheel.

2-10 2004 Touring: Chassis

Page 11

HOME

REAR WHEEL 2.4

GENERAL

Maximum tire mileage and good handling qualities are

directly related to care given wheels and tires. Wheels and

tires should be regularly inspected for wear. If handling problems occur, see Section 1.1 TROUBLESHOOTING, HAN-

DLING, for possible causes.

Always keep tires inflated to the recommended pressure and

balance the wheel whenever a tire or tube is replaced.

PRELIMINARY INSPECTION

1. Measure brake disc thickness for excessive wear. Minimum acceptable thickness is stamped on side of disc.

Also replace disc if warped or badly scored.

2. Whenever the wheel is removed for tire replacement or

any other purpose, inspect the wheel bearings as follows:

a. Insert finger into wheel bearing and rotate the inner

race. Repeat step on opposite side of wheel.

b. Replace the wheel bearings if there is rough rota-

tion, abnormal noise or anything unusual. Always

replace wheel bearings as a set. Never replace just

one wheel bearing.

c. Loosen TORCA clamp between rear header pipe

and muffer.

d. Remove two bolts (with lockwashers) to detach muf-

fler from the lower saddlebag support rail.

e. Remove bungee cord to release muffler from lower

saddlebag support rail.

3. Standing on right side of vehicle, remove E-clip from

groove at end of axle.

4. Remove cone nut and adjuster cam from axle.

5. Using a soft mallet, gently tap end of axle towards left

side to loosen. Catching external spacers on right and

left side of hub, pull axle free of wheel and rear

swingarm.

6. Pull wheel to release brake disc from caliper. Pry inner

and outer brake pads back for additional clearance, if

necessary. Use a putty knife with a wide thin blade to

avoid scoring or scratching the brake disc.

7. Remove caliper from anchor weldment on rear swingarm, and carefully hang over lower saddlebag support

rail.

8. Move wheel forward and slip belt off sprocket.

9. Move wheel to bench area and inspect bearings. See

PRELIMINARY INSPECTION on this page.

REMOVAL

1. Remove saddlebags. See Section 2.25 SADDLEBAG,

REMOVAL.

2. Remove both mufflers as follows:

Left Side

a. Open worm drive clamps to remove heat shield

from crossover pipe.

b. Using a bungee cord, tie the muffler to the lower

saddlebag support rail.

c. Loosen TORCA clamp between crossover pipe and

muffer.

d. Remove two bolts (with lockwashers) to detach muf-

fler from the lower saddlebag support rail.

e. Remove bungee cord to release muffler from lower

saddlebag support rail.

Right Side

a. Open worm drive clamps to remove heat shield

from rear header pipe.

b. Using a bungee cord, tie the muffler to the lower

saddlebag support rail.

NOTE

Do not operate the rear brake pedal with the rear wheel

removed or the caliper pistons may be forced out. Reseating

pistons requires disassembly of the caliper.

DISASSEMBLY

1. If wheel bearing replacement is necessary, proceed as

follows:

a. Remove five bolts (with flat washers) securing belt

sprocket to hub.

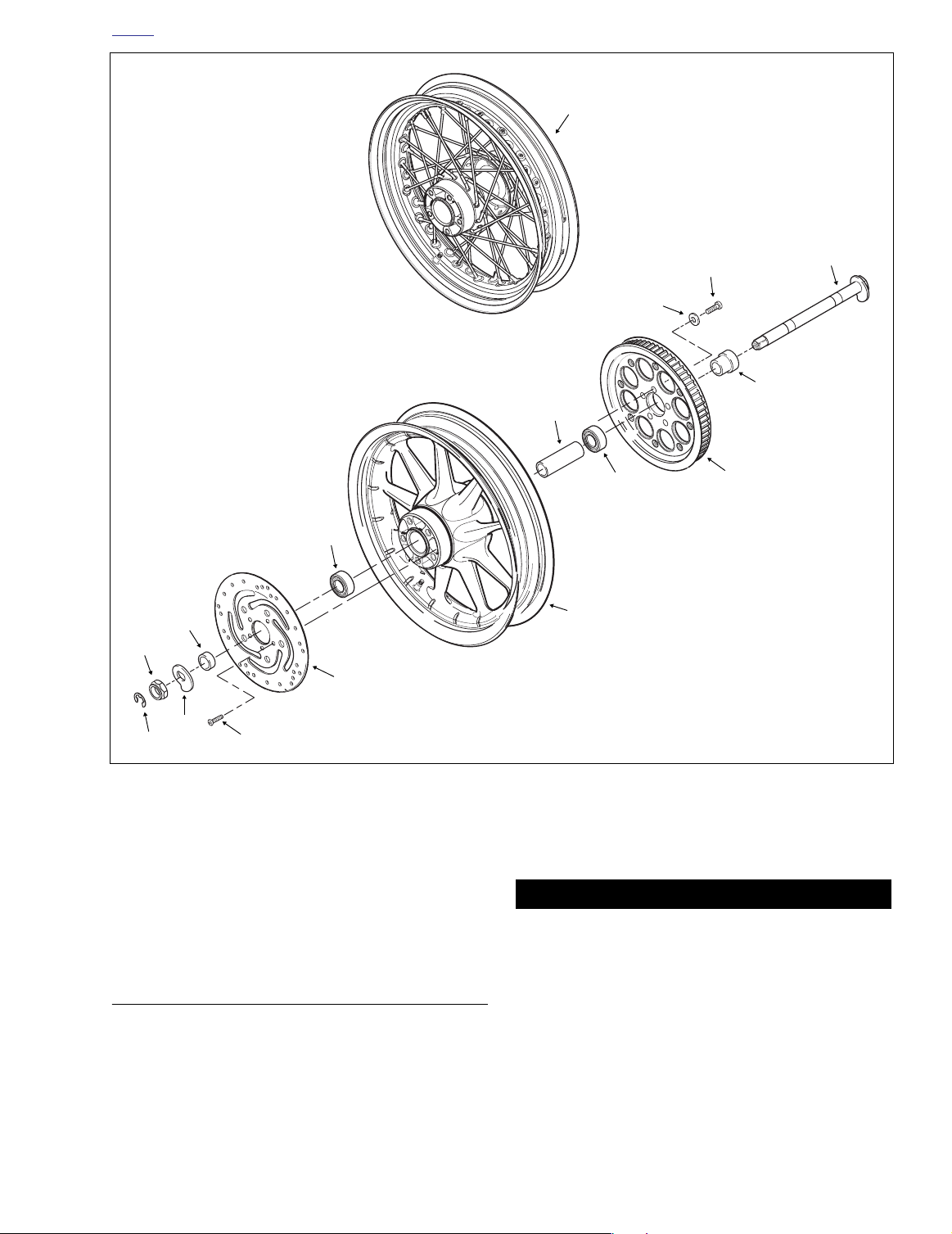

b. Obtain the WHEEL BEARING REMOVER/IN-

STALLER (HD-44060). Pick out the wheel bearing

remover tools for the rear wheel. See Figure 2-9.

NOTE

The smaller 3/4 inch collet (and pilot) is only used to replace

the rear

wheel bearings on 2000-01 Touring models.

c. To prolong service life and ensure smooth opera-

tion, sparingly apply graphite lubricant to threads of

forcing screw.

2004 Touring: Chassis 2-11

Page 12

HOME

Bridge

Forcing Screw

Steel Ball

ger Collet

Lar

1 Inch

Hex Nut

Graphite Lubricant

f1769x2x

Nice Bearing

Flat Washer

Figure 2-9. Rear Wheel Bearing Remover Tools

(Part No. HD-44060)

d. Install nut, flat washer and Nice bearing on forcing

screw. Insert end of forcing screw through hole in

bridge.

e. Install steel ball inside

lar

collet. Install collet at

ger

end of forcing screw.

f. Insert collet into bearing ID. Feel for inside edge of

bearing using lip at end of collet and then back off

slightly.

Forcing

Screw

Hex

Nut

Flat

Washer

Nice

Bearing

Collet Hex

with Ball Bearing

Hold Forcing Screw and Turn Hex on Collet to Expand.

Bridge

f1774x2x

f1775x2x

g. Holding forcing screw to prevent rotation, turn hex

on collet until lip makes firm contact with inside

edge of bearing. See upper frame of Figure 2-10.

h. Holding forcing screw, turn hex nut until bearing is

free. See lower frame of Figure 2-10.

i. Remove spacer sleeve from wheel hub.

j. Repeat procedure to remove bearing on opposite

side of wheel. Discard bearings.

2. If brake disc replacement is necessary, use a T45 TORX

drive head and remove five screws securing brake disc

to hub. If the wheel is to be assembled with the same

disc, mark both the wheel and disc, so that it can be

installed in its original position.

3. Remove tire, if necessary. Remove tube from the rim, if

applicable. See Section 2.8 TIRES AND TUBES.

4. If it is necessary to remove the hub from a laced wheel,

loosen all spoke nipples and remove the rim and spokes.

CLEANING AND INSPECTION

1. Thoroughly clean all parts in solvent.

Wheel

Bearing

Hold Forcing Screw and Turn Hex Nut to Pull Out Bearing.

Figure 2-10. Remove Sealed Wheel Bearings

2. Inspect all parts for damage or excessive wear.

2-12 2004 Touring: Chassis

3. Always replace bearings as a complete set.

Page 13

HOME

11WARNING1WARNING

1. Axle

2. External Spacer (Large)

3. Bolt (5)

4. Flat Washer (5)

5. Belt Sprocket

6. Sealed Bearing (2)

7. Spacer Sleeve

8. Cast Wheel

9. Brake Disc

10. T45 TORX Screw (5)

11. External Spacer (Small)

12. Adjuster Cam

13. Cone Nut

14. E-Clip

15. Laced Wheel

Right Side

15

Left Side

3

1

4

2

7

6

11

13

9

12

14

4. Inspect brake disc. Replace disc if warped or badly

scored. Measure disc thickness for excessive wear. Minimum acceptable thickness is stamped on side of disc.

5. Check the belt sprocket for wear, tooth damage, cracks

or pitting. Replace if necessary.

6. On laced wheels, replace spokes, rim or hub if damaged.

10

Figure 2-11. Rear Wheel (Exploded View)

ASSEMBLY

1. On laced wheels, if the hub and rim were disassembled,

assemble the hub, spokes and rim. See Section 2.6

WHEEL LACING - 16 INCH RIM.

6

5

8

f2044x2x

2. Verify that wheel is true. See Section 2.5 CHECKING

RIM RUNOUT or Section 2.7 TRUING LACED WHEEL,

whichever applies.

Do not allow brake fluid or other lubricants to contact

the brake disc. Such contact can adversely affect braking ability, which could result in death or serious injury.

3. Using a T45 TORX drive head, install five screws (and

locknuts on laced wheels) to secure brake disc to hub.

Always install brake disc in its original position. Use

screws after three use cycles. Alternately tighten screws

to 30-45 ft-lbs (41-61 Nm).

new

2004 Touring: Chassis 2-13

Page 14

HOME

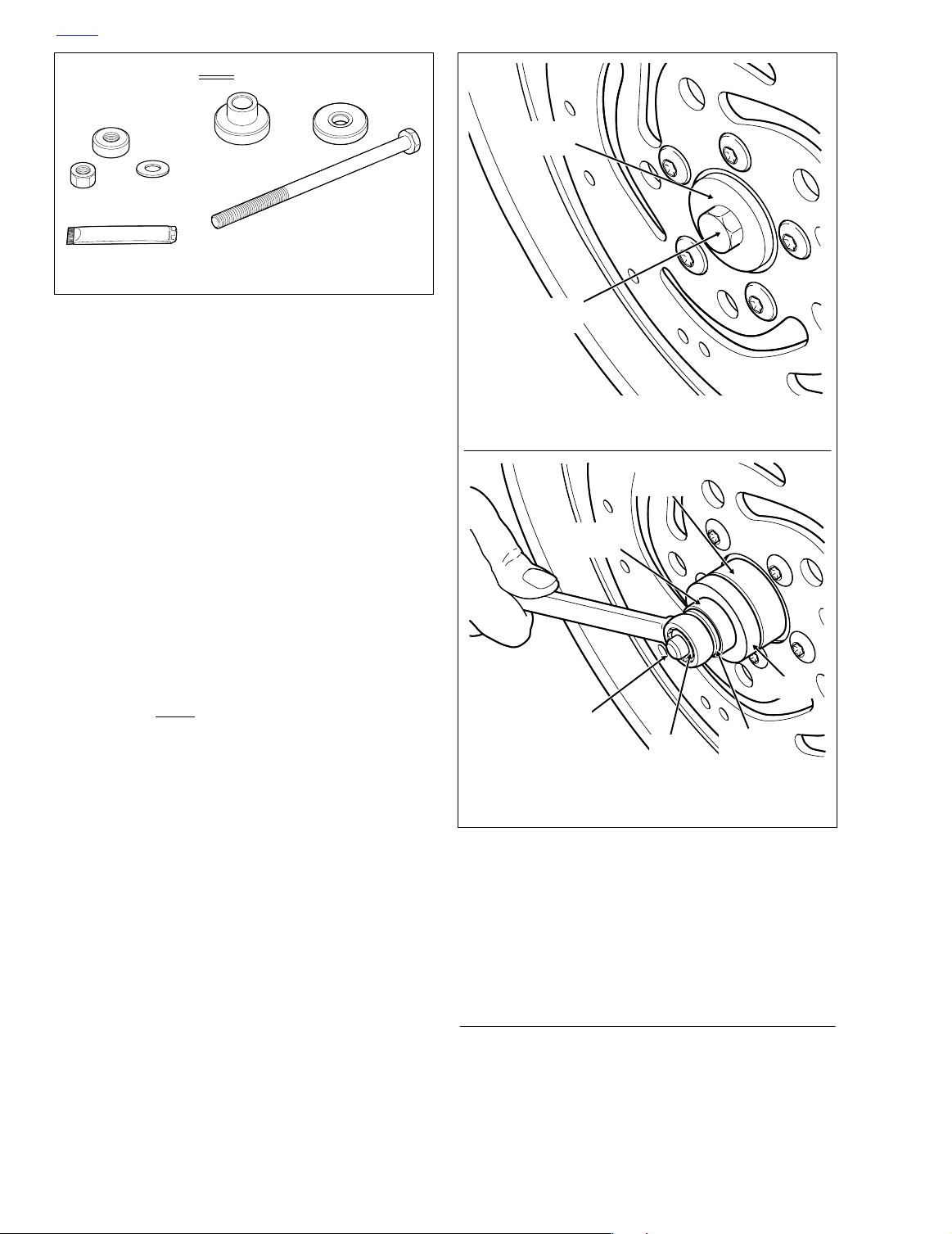

Nice Bearing

Larger Pilot

1 Inch

Support Plate

Support

Plate

Hex Nut

Graphite Lubricant

Flat Washer

Threaded Rod

f1771x2x

Figure 2-12. Rear Wheel Bearing Installer Tools

(Part No. HD-44060)

4. Install

new

wheel bearings as follows:

NOTE

Always install first of two bearings on the right side (the valve

stem side of the wheel).

a. Obtain the WHEEL BEARING REMOVER/IN-

STALLER (HD-44060). Pick out the wheel bearing

installer tools for the rear wheel. See Figure 2-12.

b. To prolong service life and ensure smooth opera-

tion, sparingly apply graphite lubricant to threads of

threaded rod.

c. Slide support plate onto threaded rod. Slide rod

through hub on the sprocket side of the wheel. See

upper frame of Figure 2-13.

d. On the valve stem side of the wheel, slide bearing

onto threaded rod with lettered side facing outboard.

e. Install

lar

pilot, Nice bearing, flat washer and

ger

hex nut onto rod.

f. Holding threaded rod on opposite side of wheel to

prevent rotation, turn hex nut to install bearing. See

lower frame of Figure 2-13. Bearing is fully seated

when it makes firm contact with the counterbore.

g. Disassemble and remove tool, but leave support

plate on threaded rod.

h. Slide threaded rod through installed wheel bearing

and hub of wheel.

i. On the other side of the wheel, slide spacer sleeve

down threaded rod until it contacts installed wheel

bearing.

j. Repeat steps 4(d) through 4(g) to complete installa-

tion of second wheel bearing. Bearing is fully seated

when hex nut can no longer be turned.

5. Install rim strip on wheel rim, if applicable. Install tube

and tire, if applicable. Verify that wheel is balanced.

Threaded

Rod

f1777x2x

Slide Threaded Rod (with Support Plate) Through Hub.

Wheel

Bearing

Nice

Bearing

Pilot

Threaded

Rod

f1773x2x

Hold Threaded Rod and Turn Hex Nut to Push In Bearing.

Hex

Nut

Flat

Washer

Figure 2-13. Install Sealed Wheel Bearings

6. Apply two drops of Loctite High Strength Threadlocker

271 (red) to threads of five belt sprocket bolts. Always

use

new

bolts after three use cycles. Install bolts with

flat washers to secure sprocket to hub. Alternately

tighten bolts to 55-65 ft-lbs (75-88 Nm).

INSTALLATION

1. Place wheel in rear swingarm. Slide wheel far enough

forward to slip belt over sprocket and then slide the

wheel back.

2-14 2004 Touring: Chassis

Page 15

HOME

CAUTION

lbs. (4.5 kg) of force at the midpoint of the bottom belt

strand. Belt deflection should be as follows:

Do not bend or fold belt backward or into loops smaller

than 5 inches (127 mm) in diameter. Sharp bending can

weaken the belt and cause premature failure.

2. Seat caliper on anchor weldment of rear swingarm. Position wheel in swingarm, so that brake disc is centered

between brake pads.

3. Coat the axle with ANTI-SIEZE LUBRICANT.

4. With the larger OD on the outboard side, hold external

spacer between rear swingarm and belt sprocket. Slide

axle through left side of rear swingarm, external spacer,

and belt sprocket into wheel hub.

5. When axle emerges from hub on brake disc side of

wheel, push axle through

shor

external spacer, caliper

t

bracket and right side of rear swingarm.

6. Rotate axle so that the flat on the threaded end is topside. With the thumb down and the cam forward, install

adjuster cam on end of axle.

7. Apply a thin film of ANTI-SIEZE LUBRICANT to the

inboard side of the cone nut avoiding contact with

threads. Install cone nut on axle, but finger tighten only.

8. Verify that adjuster cam just contacts weld nub on both

sides of rear swingarm. If necessary, push wheel forward slightly to achieve the desired result. Snug the

cone nut to 15-20 ft-lbs (20-27 Nm). See Figure 2-14.

9. Check deflection at the loosest spot in the belt. Use

BELT TENSION GAUGE (HD-35381A), or install narro

saddle (HD-35381-3) on existing gauge, and apply 10

Table 2-1. Belt Deflection in the Air

Orientation

Motorcycle Upright

With Rear Wheel in the Air

See Section 6.4 SECONDARY DRIVE BELT AND SPROCKETS

for belt deflection specification with motorcycle on jiffy stand.

NOTE

10. If belt is too tight, move to step 11 to increase belt

deflection. If belt is too loose, reduce belt deflection as

described below:

a. Rotate weld nut on left side of axle in a clockwise

direction.

b. Check belt deflection. Apply 10 lbs. (4.5 kg) of force

at the midpoint of the bottom belt strand. Belt

deflection should be within the range specified in

Ta bl e 2-1.

c. If belt is still too loose, repeat steps 10(a) through

10(b). If belt is now too tight, move to step 11.

11. If belt is too tight, increase belt deflection as follows:

a. Rotate weld nut on left side of axle in a counter-

clockwise direction.

b. Push wheel forward slightly so that adjuster cam

w

just contacts weld nub on both sides of rear swingarm. See Figure 2-14.

Inches Millimeters

3/16 - 1/4 4.8 - 6.4

Increase

Belt

Deflection

Weld

Nub

Reduce

Belt

Deflection

Cone

Nut

Weld

Nub

Weld

Nut

8398

E-Clip

8407

Figure 2-14. Move Rear Wheel Forward Until Adjuster Cams Just Contact Weld Nubs

RIGHT SIDELEFT SIDE

Adjuster

Cam

2004 Touring: Chassis 2-15

Page 16

HOME

c. Check belt deflection. Apply 10 lbs. (4.5 kg) of force

at the midpoint of the bottom belt strand. Belt

deflection should be within the range specified in

Ta bl e 2-1.

d. If belt is still too tight, repeat steps 11(a) through

11(c). If belt is now too loose, move to step 10.

12.

Holding

right side to 95-105 ft-lbs (128.8-142.4 Nm).

If the axle moves during tightening of the cone nut, then the

the belt deflection procedure must be restarted.

13. Recheck belt deflection to verify that it is still within specification.

If the belt deflection is not within specification, loosen

cone nut and then snug to 15-20 ft-lbs (20-27 Nm)

before returning to step 10.

14. With the flat side out, install

side of axle.

15. Install both mufflers as follows:

TORCA muffler clamps have eliminated the need for silicone

or graphite tape during assembly. To ensure sealing integrity

of muffler clamps and prevent the possibility of leakage, Harley-Davidson recommends that TORCA clamp assemblies be

discarded and replaced each time they are removed.

weld nut on left side of axle, tighten cone nut on

NOTE

new

E-clip in groove on right

NOTE

Left Side

a. Slide

b. Using a bungee cord, tie muffler to lower saddlebag

c. Tighten the two bolts (with lockwashers) to fasten

new

TORCA clamp onto free end of crossover

pipe.

support rail. Install muffler on crossover pipe. Place

TORCA clamp into position between crossover and

muffler.

the muffler to the lower saddlebag support rail.

CAUTION

CAUTION

Verify that the heat shields do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

g. Remove bungee cord from muffler.

Right Side

a. Slide

b. Using a bungee cord, tie muffler to lower saddlebag

c. Tighten the two bolts (with lockwashers) to fasten

Verify that the exhaust pipes do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

d. Verify that exhaust pipes are in alignment and do

e. Tighten the TORCA clamp to 45-60 ft-lbs (61-81

f. Open worm drive clamps and install heat shield on

Verify that the heat shields do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

g. Remove bungee cord from muffler.

new

TORCA clamp onto free end of rear

header pipe.

support rail. Install muffler on rear header pipe.

Place TORCA clamp into position between rear

header pipe and muffler.

the muffler to the lower saddlebag support rail.

CAUTION

not contact the vehicle frame or mounted components.

Nm).

rear header pipe. Position clamp so that screw is on

the outboard side in the most accessible position.

CAUTION

Verify that the exhaust pipes do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

d. Verify that exhaust pipes are in alignment and do

not contact the vehicle frame or mounted components.

e. Tighten the TORCA clamp to 45-60 ft-lbs (61-81

Nm).

f. Open worm drive clamps and install heat shield on

crossover pipe. Position clamp so that screw is on

the outboard side in the most accessible position.

2-16 2004 Touring: Chassis

11WARNING1WARNING

After installation of caliper and BEFORE moving motorcycle, pump rear brake pedal until pistons push pads

against the brake disc. If fluid pressure is not pumped

up, the rear brake will not be available the first time it is

used, a situation that could result in death or serious

injury.

16. Depress rear brake pedal several times to set brake

pads to proper operating position within caliper.

17. Install saddlebags. See Section 2.25 SADDLEBAG,

INSTALLATION.

Page 17

HOME

f1379x2x

Gauge

Radial

Runout

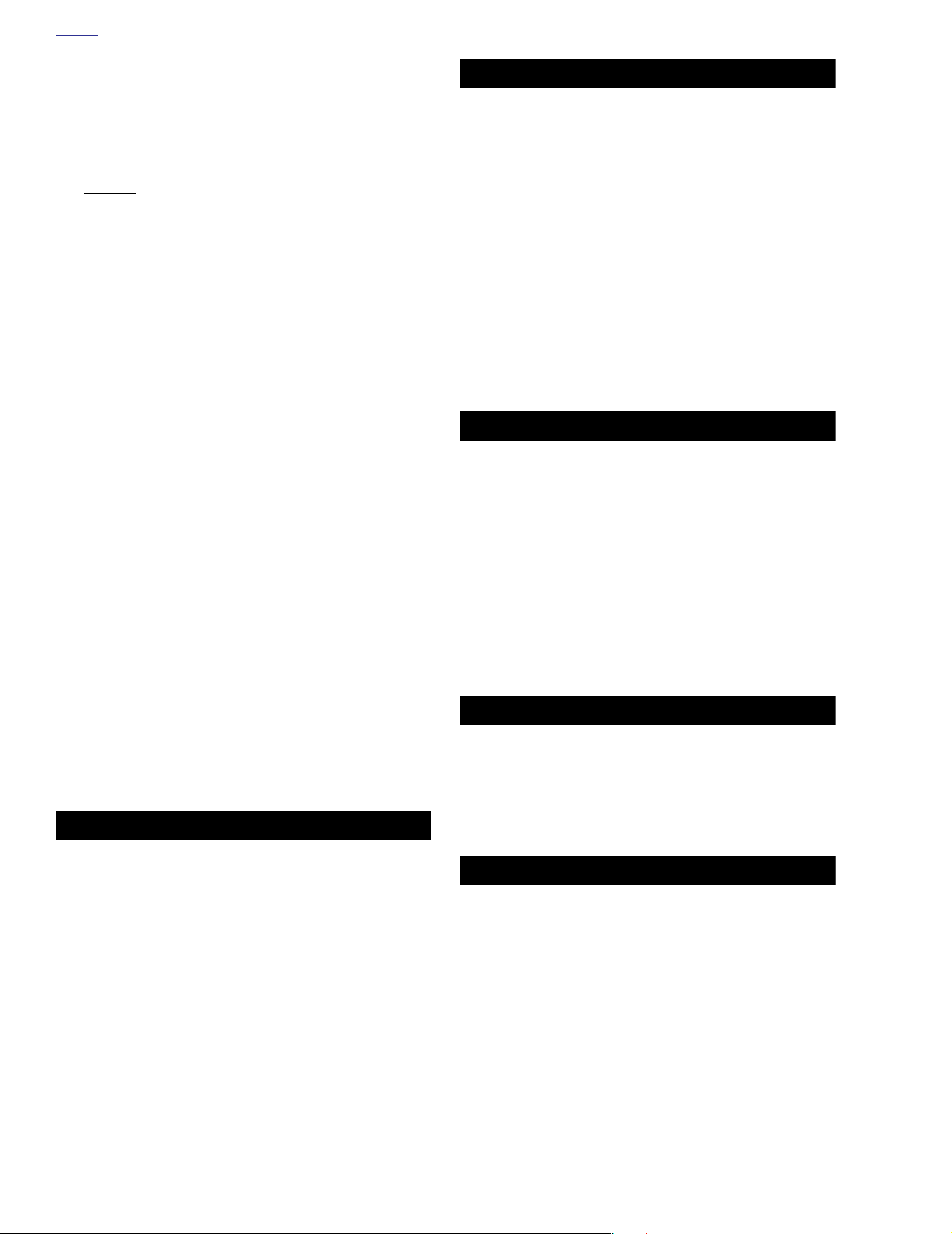

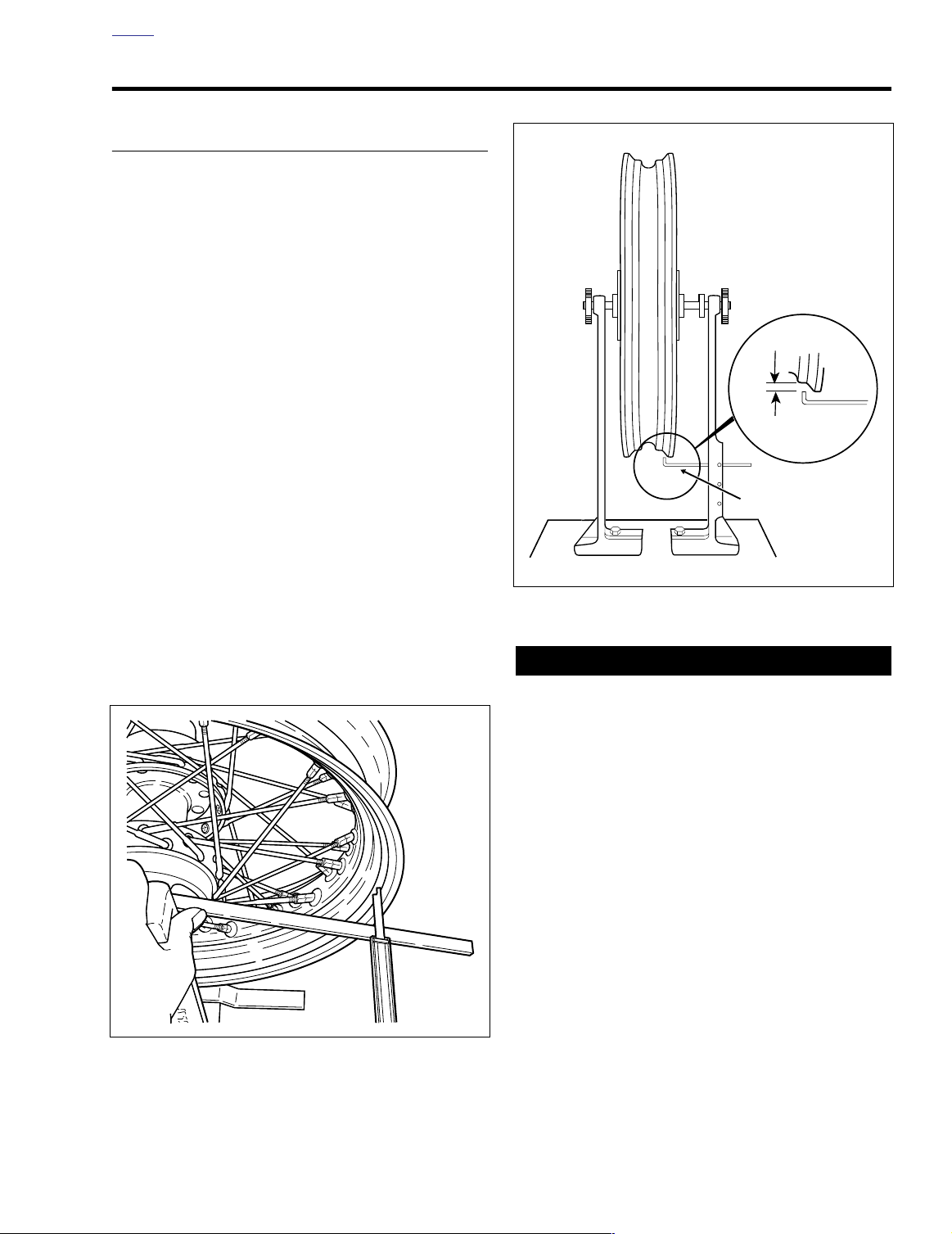

CHECKING RIM RUNOUT 2.5

INSPECTION

Check wheels for lateral and radial runout before installing a

new tire or tube.

1. Install truing arbor in wheel hub and place wheel in

WHEEL TRUING STAND, Part No. HD-99500-80.

2. See Figure 2-15. To check rim lateral runout, place a

gauge rod or dial indicator near the rim bead. If lateral

runout exceeds 0.040 inch (1.02 mm), replace the wheel

if cast. Retrue the wheel if laced.

3. See Figure 2-16. Check the rim radial runout as shown.

If radial runout exceeds 0.030 inch (0.76 mm), replace

the wheel if cast. Retrue the wheel if laced.

NOTE

Rim lateral and radial runout is adjustable on laced wheels.

See Section 2.7 TRUING LACED WHEEL.

f1378x2x

Lateral

Runout

Gauge

Figure 2-15. Checking Rim Lateral Runout

Figure 2-16. Checking Rim Radial Runout

4. If working with a laced wheel, proceed to Section 2.7

TRUING LACED WHEEL to check the wheel offset

dimension.

2004 Touring: Chassis 2-17

Page 18

HOME

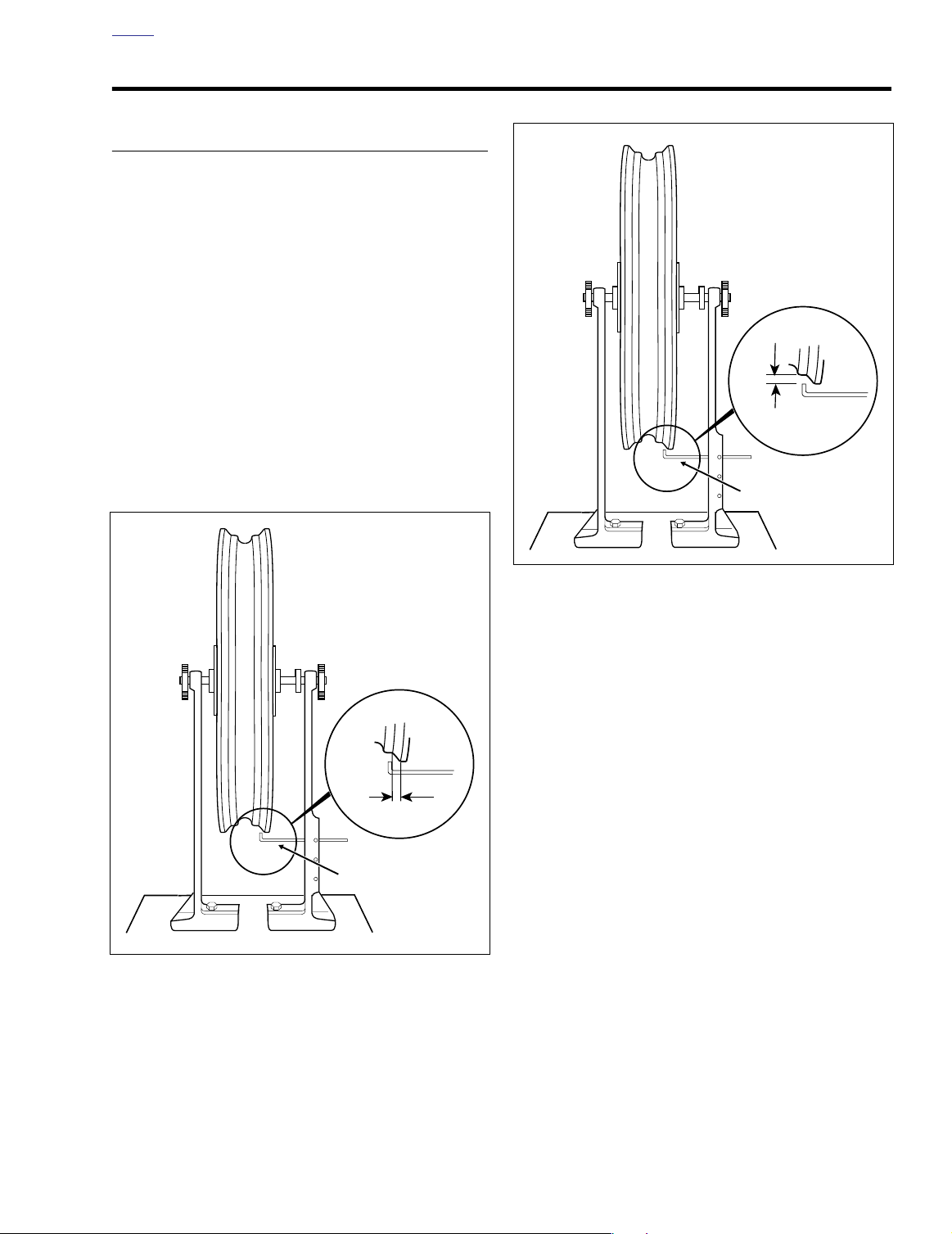

WHEEL LACING - 16 INCH RIM 2.6

GENERAL

The 16 inch wheel uses only one type of spoke, rather than

the separate inner and outer spokes (with differing head

angles) seen in the old style.

Exercise caution to avoid mixing old and new parts. The head

angle of the spoke is closer to 90 degrees, which makes it

very difficult to differentiate from the outer spoke of the old

style.

The nipple fitting of the spoke uses a TORX style fastener

(instead of the straight slotted) and requires a special T-30

I.P. (TORX Plus) driver (HD-42135) for removal and installation. See A of Figure 2-17. Use of a standard T-30 TORX bit

will result in nipple damage.

The 16 inch hub can be easily identified by its aluminum

construction. The 16 inch rim can be quickly identified by the

shape of the flat around the valve stem. The flat is tombstone

shaped on the rim (square shaped on the old style rim). See

B and C of Figure 2-17.

A

f1150a2x

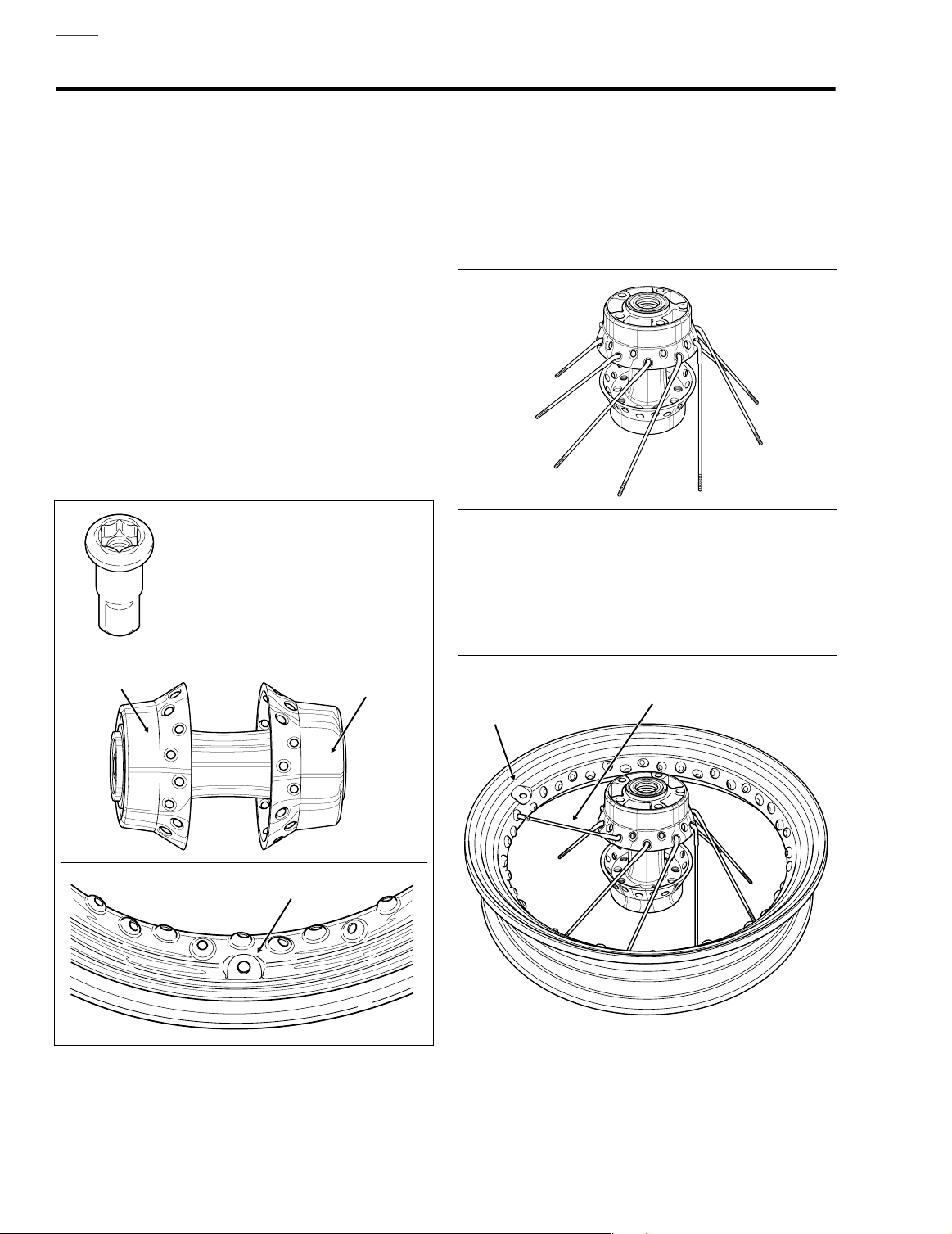

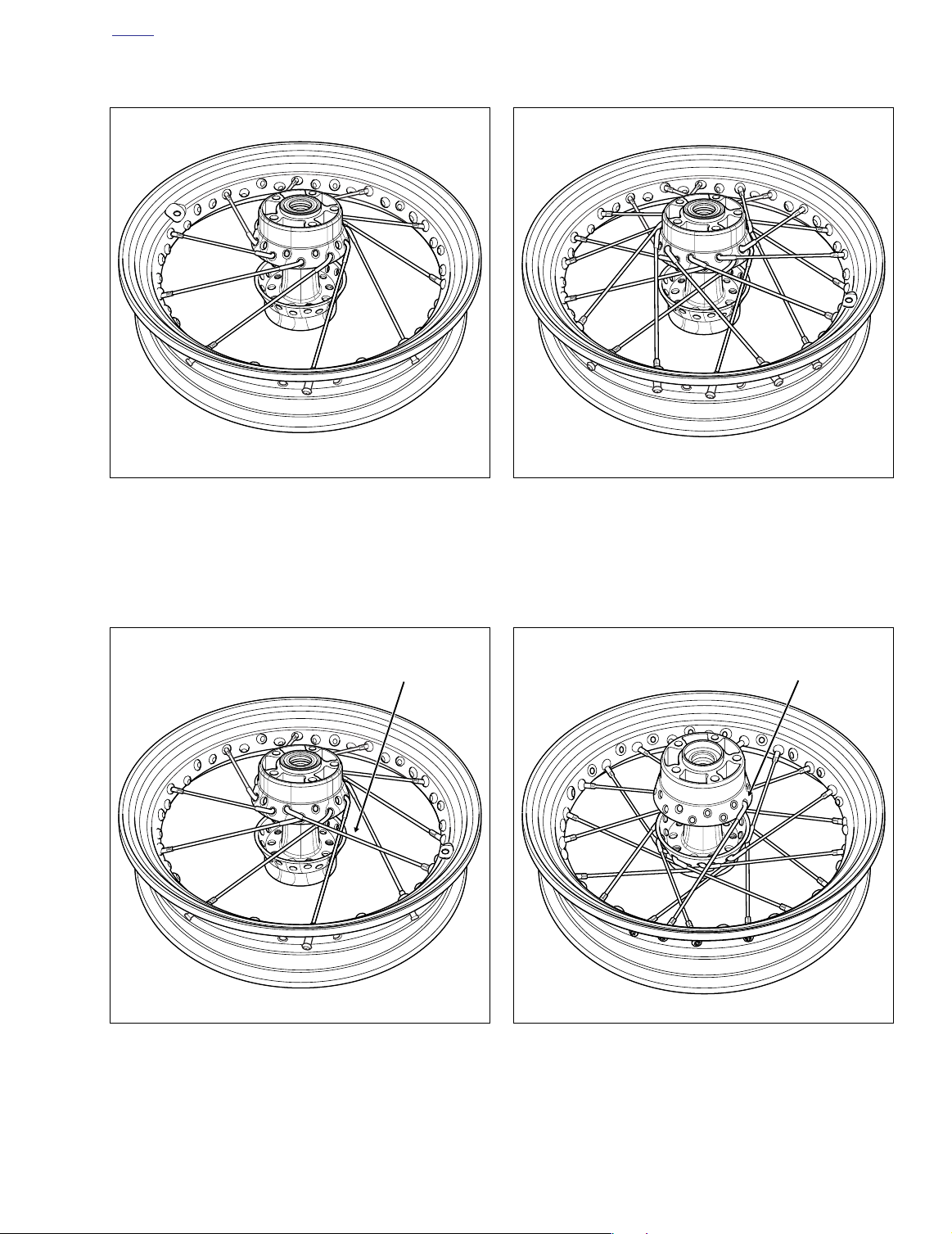

WHEEL LACING

1. If front wheel, place the hub on a table with the wider

flange side up. If rear wheel, place hub so that brake

disc side is up. Insert a spoke in each hole of the lower

row as shown below. Angle the spokes in a clockwise

direction .

f1150d2x

Figure 2-18.

2. Place the rim on the table with the valve stem side up.

Using any lower row spoke, place the first spoke into the

rim hole to the left of the valve stem hole on the upper

half of the rim centerline.

Narrow Flange

Belt Sprocket Side

f1150c2x

Figure 2-17. Parts Identification

B

Valve Stem Flat

Tombstone Shaped

C

Wide Flange

f1150b2x

First

Lower Row Spoke

Valve Stem Hole

f1150e2x

Figure 2-19.

2-18 2004 Touring: Chassis

Page 19

HOME

f1150h2x

f1150i2x

First

Lower Row Spoke

3. Install the rest of the lower row spokes in every fourth

hole.

f1150f2x

Figure 2-20.

5. Install the nine remaining upper row spokes into every

fourth hole remaining above the rim centerline.

Figure 2-22.

4. Place the first upper row spoke into the hub as shown

below. Angle the spoke counterclockwise crossing four

lower row spokes. The spoke must enter the hole to the

left of the valve stem hole.

First

Upper Row Spoke

1

2

4

3

f1150g2x

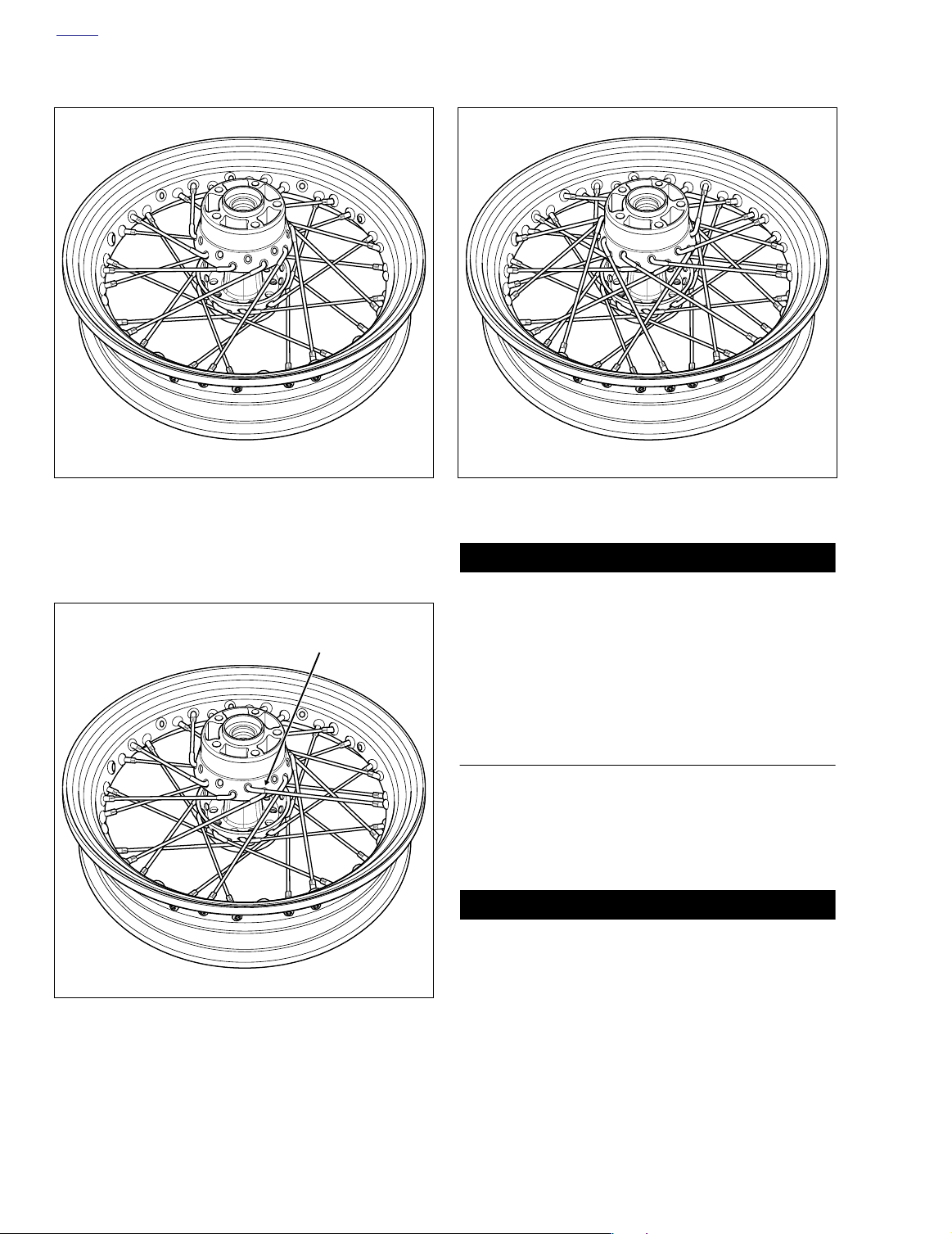

6. Turn the wheel over. Place any lower row spoke into the

hub. Angle the spoke clockwise and place into rim hole

angled to accept it.

Figure 2-21.

Figure 2-23.

2004 Touring: Chassis 2-19

Page 20

HOME

7. Angled clockwise, place the nine remaining lower row

spokes into hub and rim.

f1150j2x

Figure 2-24.

9. Install the nine remaining upper row spokes into hub and

rim.

f1150l2x

Figure 2-26.

8. Insert any upper row spoke into the hub and angle spoke

counterclockwise. Place spoke into appropriate rim hole

crossing four lower row spokes.

First

Upper Row Spoke

4

1

3

2

f1150k2x

Figure 2-25.

CAUTION

The hub is made of aluminum alloy and should not be

clamped in a vise or gripped with pliers, or the hub material may be damaged.

10. Verify that wheel is true. See Section 2.7 TRUING

LACED WHEEL for truing procedure and spoke torque

specification.

SPOKE TIGHTNESS

At the 1000 mile (1600 km) service interval, the 5000 mile

(8000 km) service interval, and then every 15,000 mile

(24,000 km) service interval thereafter, inspect spoke tightness, if applicable. Proceed as follows:

1. Raise wheel off the ground.

CAUTION

If nipples require more than one full turn to tighten

spoke, remove tire to check that spoke protrusion has

not damaged tube.

2. Lightly tap each spoke with a spoke wrench. Loose

spokes will sound dull and must be tightened. Tighten

spokes to 40-50 in-lbs (4.5-5.6 Nm). If more than a few

spokes are loose, true the entire wheel following the procedure on the next page.

2-20 2004 Touring: Chassis

Page 21

HOME

CAUTION

f1379x2x

Gauge

Radial

Runout

TRUING LACED WHEEL 2.7

PROCEDURE

1. Divide the wheel spokes into ten groups of four and

mark the center of each group with a piece of tape. The

groups should be directly across from one another and

approximately 90

four groups finger tight, leaving all others loose.

2. See Figure 2-28. Install truing arbor in wheel hub and

place wheel in WHEEL TRUING STAND, Part No. HD99500-80. Tighten arbor nuts so hub will turn on its bearings.

3. Lay a straightedge across the hub brake disc flange

(valve stem side of dual disc front wheel) and one of the

marked spoke groups. Measure the distance from the

straightedge to the edge of the rim as shown in Figure 2-

27. Be sure to subtract the thickness of the straightedge.

The offset dimension must be as follows:

● Front Wheel: 1.555- 1.575 inches (39.5- 40.0 mm).

● Rear Wheel: 1.472- 1.492 inches (37.4- 37.9 mm).

ο

apart. Tighten the spokes in these

If the dimension is not correct, tighten the four spokes

accordingly. Use the special T-30 I.P. (TORX Plus) driver

(HD-42135). For example, If the measurement on the right

rim edge side is less than it should be, loosen the two spokes

attached to the hub right side and tighten the two spokes

attached to the hub left side. Turn all four spokes an equal

number of turns until offset dimension is correct.

f1155b2x

Figure 2-28. Truing Rim Radially

Always loosen the appropriate spokes before tightening

the other two. Reversing this procedure will cause the

rim to become out-of-round.

4. Repeat Step 3 for all four groups on the wheel.

5. See Figure 2-28. After rim has been trued sideways it

must be checked and trued radially. Adjust truing stand

gauge to the rim's tire bead seat as shown. The rim

should be trued within 1/32 inch (0.79 mm).

6. Spin the rim slowly. If the rim contacts the gauge on or

near a marked group of spokes, loosen the spokes in the

marked group on the opposite side of the rim. Now

tighten the spokes in the group where the rim makes

contact. Loosen and tighten spokes an equal number of

turns.

7. If the rim contacts the gauge between two marked

groups, loosen the spokes in both opposite groups and

tighten the spoke groups on the side of the rim that

makes contact.Figure 2-27. Checking Laced Hub Offset Dimension

2004 Touring: Chassis 2-21

Page 22

HOME

8. When the wheel is centered and trued, start at the valve

stem hole and tighten the rest of the spoke nipples one

turn at a time until they are snug. Repeat step tightening

each spoke nipple to 40-50 in-lbs (4.5-5.6 Nm).

11WARNING1WARNING

Do not tighten spokes too tight, or nipples may be drawn

through rim, or hub flanges may be distorted. If spokes

are left too loose, they will continue to loosen when

wheel is put into service. This could adversely affect

handling, or cause spoke breakage, possibly leading to

loss of vehicle control, which could result in death or

serious injury.

9. File or grind off ends of spokes protruding through nipples to prevent puncturing tube when tire is mounted.

10. Check the rim lateral and radial runout as described

under Section 2.5 CHECKING RIM RUNOUT.

NOTE

After installation of front wheel, visually check the relationship of the front wheel to the fork fender bosses. The front

wheel should be approximately centered between the

bosses.

2-22 2004 Touring: Chassis

Page 23

HOME

1634

TIRES AND TUBES 2.8

GENERAL

Tires should be inspected for punctures, cuts, breaks and

wear at least weekly.

Whenever a tube type tire is replaced, the tube should also

be replaced. Inner tubes should be patched only as an emergency measure. Replace a damaged tube as soon as possible. Inner tubes must be used on all Harley-Davidson laced

wheels.

11WARNING1WARNING

Excessively worn tires are more susceptible to penetrations. Always remove tires from service before they

reach the tread wear indicator bars, which indicates that

1/32 inch (0.79 mm) tread pattern depth remains. Worn/

unworn tire combinations and worn tires used in wet

conditions can ad-versely affect handling and lead to

loss of vehicle control, which could result in death or

serious injury.

11WARNING1WARNING

Tubeless tires may be repaired in the tread area only and

then the puncture must be 1/4 inch (6.4 mm) or smaller.

Never repair a tire with less than 1/16 inch (1.6 mm) tread

depth. All repairs must be made from inside the tire. Use

of faulty or defective tires can adversely affect handling

and lead to loss of vehicle control, which could result in

death or serious injury.

NOTE

Acceptable repair methods include a patch and plug combination, chemical or hot vulcanizing patches or head-type

plugs.

When repairing tubeless tires, use TIRE SPREADER, Part

No. HD-21000 to spread the tire sidewalls.

11WARNING1WARNING

Always check both tire sidewalls for arrows indicating

proper forward tire rotation. Some tires require different

tire rotation depending on whether tire is used on front

or rear wheel. Improper mounting can result in poor tire

mileage. In wet weather, improper mounting can adversely affect handling and lead to loss of vehicle control, which could result in death or serious injury.

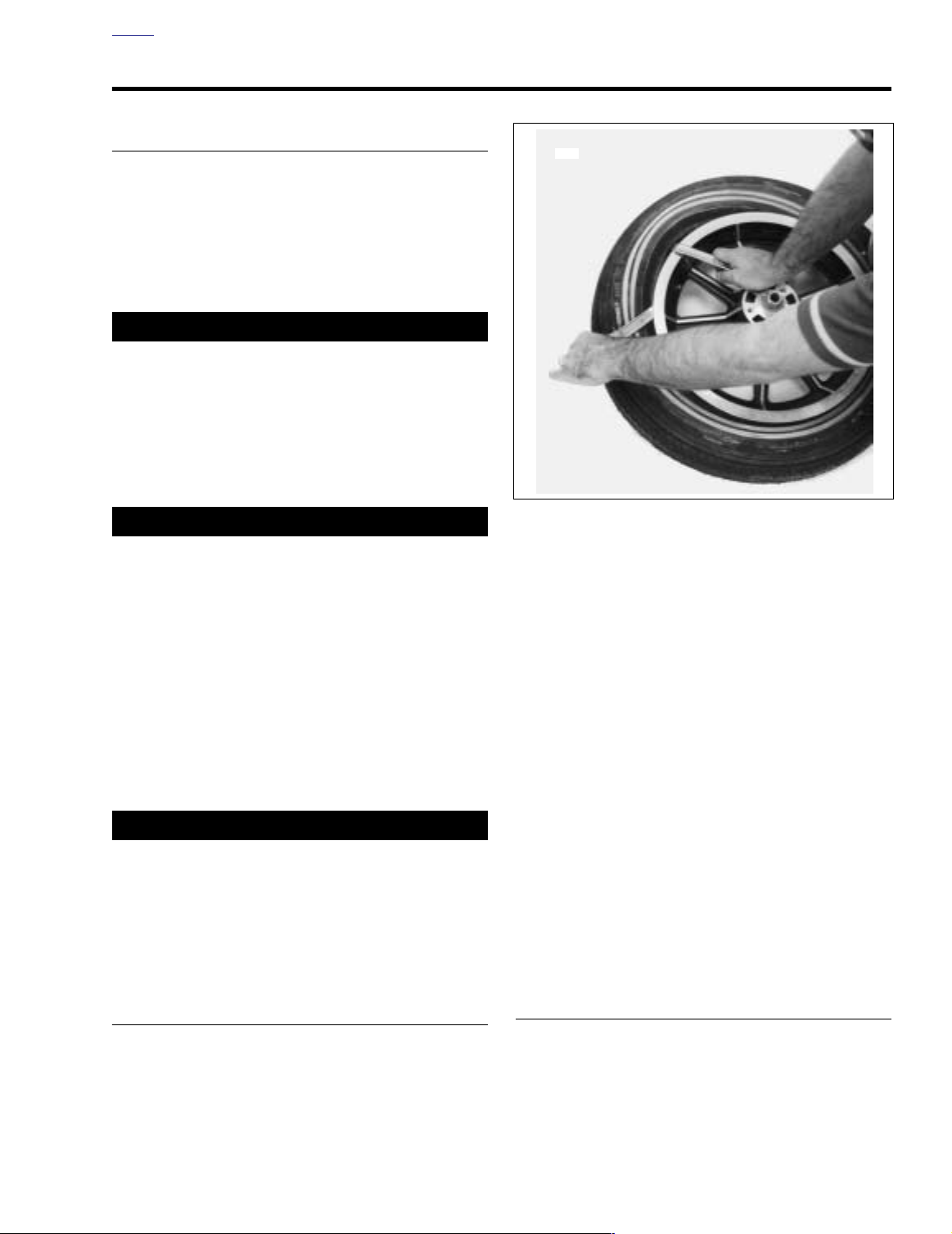

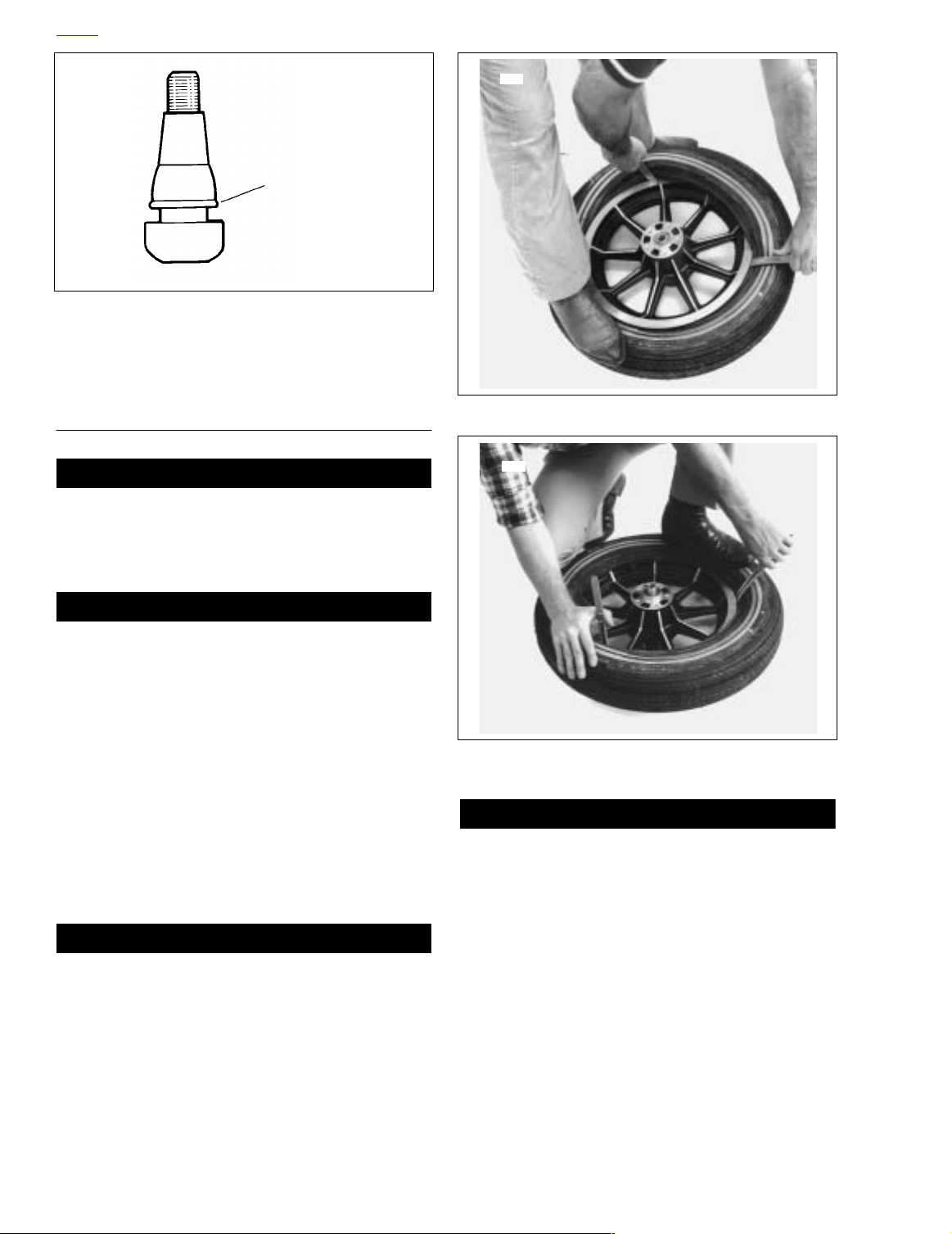

Figure 2-29. Starting Bead Off Rim

2. Loosen both tire beads from rim flange. See Figure 2-29.

In most cases, a bead breaker machine will be required

to loosen the bead from the rim.

3. Using tire tools (not sharp instruments), and RIM PROTECTORS, Part No. HD-01289, start upper bead over

edge of rim at valve. Do not use excessive force when

starting bead over rim. Bead wires may be damaged

ruining the tire. Repeat all around rim until first bead is

over rim. Remove the tube.

NOTE

It is not necessary to use tools to remove tubeless tires.

Make sure beads are well lubricated before removing from

rim.

4. Push lower bead into rim well on one side and insert tire

tool underneath bead from opposite side. Pry bead over

rim edge. Remove tire from rim.

NOTE

It is not always necessary to completely remove tire from rim.

Removing one side allows the tube to be replaced and allows

for inspection of tire.

REMOVAL

1. Remove wheel from motorcycle. Let the air out of the

tube or tire.

CLEANING AND INSPECTION

1. Clean the inside of tire, rim and tube. If rim is dirty or

rusty, clean with a stiff wire brush.

2004 Touring: Chassis 2-23

Page 24

HOME

Indicator

Ring

Figure 2-30. Snap-in Tubeless Tire Valves

2. Inspect the tire and tube for wear.

1635

INSTALLATION

11WARNING1WARNING

Use the correct inner tube and tire. See TIRE DATA in

SPECIFICATIONS. Use of incorrect tires or tubes can

adversely affect handling or result in tire failure, which

could result in death or serious injury.

11WARNING1WARNING

Do not interchange tire valves from one type to another.

Always replace valves with the same type as originally

furnished, either the threaded valve stem or snap-in

type. The rim configuration is designed to fit one type

only. Use of the wrong valve can lead to tire failure,

which could result in death or serious injury.

1. On tubeless wheels, damaged or leaking valves must be

replaced. To replace a snap-in type valve proceed as follows:

a. See Figure 2-30. Moisten the valve with water and

insert valve stem through rim hole.

b. Thread plug tool on valve stem and pull valve

through rim until all of the indicator ring is visible.

11WARNING1WARNING

Only install original equipment tire valves and valve

caps. A valve, or valve and cap combination, that is too

long may strike adjacent components, damage the valve

and cause rapid tire deflation. Rapid tire deflation can

cause loss of vehicle control, which could result in death

or serious injury.

Figure 2-31. Starting Bead on Rim

1636

Figure 2-32. Starting Second Bead on Rim

11WARNING1WARNING

Aftermarket valve caps that are heavier than the original

equipment cap may have clearance at slow speeds, but

at high speed the valve/cap will be moved outward by

centrifugal force. This movement could cause the valve/

cap to strike adjacent components, damage the valve

and cause rapid tire deflation. Rapid tire deflation can

cause loss of vehicle control, which could result in death

or serious injury.

2. On laced wheels, install a rim strip into the rim well.

Make sure no spokes protrude through nipples and be

sure to align the valve stem hole in rim strip with hole in

rim.

2-24 2004 Touring: Chassis

Page 25

HOME

f1386b2x

Gauge

Tire Radial Runout

f1386a2x

Gauge

Tire Lateral

Runout

3. Thoroughly lubricate the rim flanges and both beads of

the tire with tire lubricant. Install RIM PROTECTORS,

Part No. HD-01289 to prevent scarring rims.

4. See Figure 2-31. Starting at the valve stem, start the first

bead into the rim well. Work the bead on as far as possible by hand. Use the tire tool to pry the remaining bead

over the rim flange. If tire has colored dot on sidewall, it

is a balance mark and should be located next to valve

stem hole.

5. Inflate tube just enough to round it out. Lubricate thoroughly 360˚ around the tube base. Insert tube in tire with

valve stem in hole.

6. See Figure 2-32. Starting 180˚ from valve stem, start the

second bead onto the rim. Work the bead onto the rim

with tire tools, working toward valve in both directions.

Remove the valve core from the rim hole before prying

the remaining bead over the rim flange.

Make sure inner tube valve stem moves in and out freely,

then inflate the tire to recommended pressure to seat the

bead. See TIRE DATA at the beginning of this section.

Then deflate tire to allow inner tube to smooth out.

Inflate again to recommended pressure to seat the

bead.

7. Use the BEAD EXPANDER (Part No. HD-28700) to seat

beads on tubeless tires.

Figure 2-33. Checking Tire Radial Runout

11WARNING1WARNING

Do not inflate tire over 40 psi (2.8 bars) to seat beads.

Inflating tire beyond this point can cause the tire rim

assembly to burst, which could result in death or serious

injury. If the beads fail to seat, deflate and relubricate the

bead and rim. Reinflate to seat beads, but do not exceed

40 psi (2.8 bars).

CAUTION

When mounting tire and tube on the rim, use extreme

care so the inner tube is not pinched.

Checking Tire Radial Runout

1. Check runout by turning wheel on axle, measuring

amount of radial displacement from a fixed point near

the tire. See Figure 2-33.

2. Tire tread runout should be no more than 0.090 inch

(2.28 mm) If tire tread runout exceeds this specification,

remove tire from rim and check rim runout to see if rim is

at fault. (See Section 2.5 CHECKING RIM RUNOUT).

Make sure bead is properly seated on rim. Deflate and reseat

tire if necessary.

3. If rim runout is less than 1/32 inch (0.79 mm), tire is at

fault and should be replaced. If rim runout exceeds this

specification, correct by replacing cast wheel or truing

laced wheel.

NOTE

Figure 2-34. Checking Tire Lateral Runout

Checking Tire Lateral Runout

1. Check runout by turning wheel on axle, measuring tread

runout. See Figure 2-34.

2. Tire tread runout should be no more than 0.080 inch

(2.03 mm). If tire tread runout exceeds this specification, remove tire from rim and check rim bead runout to

see if rim is at fault (see Section 2.5 CHECKING RIM

RUNOUT).

NOTE

Make sure bead is properly seated on rim. Deflate and reseat

tire if necessary.

2004 Touring: Chassis 2-25

Page 26

HOME

3. If rim bead runout is less than 1/32 inch (0.79 mm), tire

is at fault and should be replaced. If rim bead runout

exceeds this specification, correct by replacing cast

wheel or truing laced wheel.

Wheel Balancing

Wheel balancing is recommended to improve handling and

reduce vibration, especially at high road speeds. Cast aluminum wheels require special self-adhesive weights. Gold

Color – 1 oz. (28g) weight, 1/2 oz. (14g) weight, Silver Color

1/2 oz. (14g) and 1/4 oz. (7g), and Black 1/4 oz. (7g) weight.

Laced wheels use balance weights which press over the

spoke nipples. 1 oz. (28g), 3/4 oz. (21g) and 1/2 oz. (14g)

weights are available.

1. Self adhesive wheel weights should be applied to the flat

surface of the rim. Make sure that area of application is

completely clean, dry and free of oil and grease.

NOTE

If 1 oz. (28g) or more weight must be added at one location,

split the amount so that half is applied to each side of the rim.

2. Remove paper backing from weight and apply three

drops of Loctite SUPERBONDER 420 to the adhe-

sive side of the weight. Place the weight on rim, press

firmly in place and hold for 10 seconds. Full adhesive

cure takes 8 hours.

3. In most cases, static balancing using WHEEL TRUING

STAND, Part No. HD-99500-80, will produce satisfactory

results. However, dynamic balancing, utilizing a wheel

spinner, should be used to produce finer tolerances for

best high and low speed handling characteristics. Follow

the instructions supplied with the balance machine you

are using. Wheels should be balanced to within 1/2 oz.

(14g) at 60 mph (96 km/h). The maximum permissible

weight to accomplish balance is 3-1/2 oz. (99g) total.

2-26 2004 Touring: Chassis

Page 27

HOME

f2117x2x

f2118x2x

Alignment

Screw

Pilot

Alignment

Fixture

VEHICLE ALIGNMENT 2.9

11WARNING1WARNING

Vehicle alignment is very important to ensure proper

handling and vibration control. Follow this procedure

carefully and in the sequence given. Failure to do so may

lead to loss of vehicle control, which could result in

death or serious injury.

METHOD A

NOTE

Use this procedure to realign the powertrain to the frame

whenever major disassembly or engine replacement occurs.

For acceptable results, a careful inspection should be

performed (wheel and tire runout, laced wheel offset, rubber

mount condition, etc.) to ensure that it is conducted with

serviceable components. See INSPECTION for more infor-

mation.

1. Place the motorcycle on a hydraulic center stand or

place blocking under the frame to support the vehicle

and lift the rear wheel off the ground. Be sure the motorcycle is positioned as level as possible.

2. Remove socket screw with lockwasher to remove left

passenger footboard from rear swingarm bracket.

Tighten both rear swingarm bracket bolts to 34-42 ft-lbs

(46-57 Nm). Repeat step on right side of motorcycle.

3. Remove the decorative chrome plug from both rear

swingarm brackets. While holding the left side pivot shaft

locknut, tighten the right side locknut to 40-45 ft-lbs (5461 Nm). Then hold the right side pivot shaft locknut and

tighten the left side locknut to 40-45 ft-lbs (54-61 Nm).

4. Verify that belt deflection is within specification and that

adjuster cams are tight against rear swingarm weld

nubs. Holding

nut on right side to 95-105 ft-lbs (128.8-142.4 Nm).

5. Remove seat. See Section 2.24 SEAT, REMOVAL.

6. Partially remove fuel tank to gain access to top engine

mounting bracket and stabilizer link. See Section 4.7

FUEL TANK (CARBURETED), PA RTIAL REMOVAL,

FLHT/C, or FLHR/S. For fuel injected models, see Sec-

tion 9.4 FUEL TANK (FUEL INJECTED), PA R TIAL

REMOVAL, FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

7. Top Engine Mount:

a. On left side of motorcycle, tighten the two top

engine mounting bracket to front and rear cylinder

head bolts to 35-40 ft-lbs (48-54 Nm). See A of Fig-

ure 2-37.

b. Moving to right side of motorcycle, tighten the top

stabilizer link eyelet to frame weldment bolt to 18-22

ft-lbs (24-30 Nm). See C of Figure 2-37.

weld nut on left side of axle, tighten cone

Figure 2-35. Vehicle Alignment Tool

(Part No. HD-46247)

Figure 2-36. Install Vehicle Alignment Tool (Left Side)

c. Loosen both top stabilizer link jam nuts.

d. Remove the top stabilizer link eyelet to top engine

mounting bracket bolt. See B of Figure 2-37.

8. Front Engine Mount:

a. Remove flange locknuts from studs on lower frame

crossmember. Remove voltage regulator from studs

and allow to hang by cables at front of motorcycle.

b. Tighten two engine to front engine mounting bracket

bolts to 33-38 ft-lbs (45-52 Nm). See H of Figure 2-

37.

c. Tighten front stabilizer link eyelet bolt to block on

front engine mounting bracket to 18-22 ft-lbs (24-30

Nm). See E of Figure 2-37.

d. Loosen both front stabilizer link jam nuts.

e. Remove front stabilizer link eyelet to frame weld-

ment bolt. See D of Figure 2-37.

f. Remove the center front engine mounting bracket to

rubber mount bolt (with washers and nut). See F of

Figure 2-37.

2004 Touring: Chassis 2-27

Page 28

HOME

B

C

A

LEFT SIDE RIGHT SIDE

Top Stabilizer Link and Engine Mounting Bracket

f2111x2xf2181x2x

H

Front Engine

Mounting Bracket

T

op

ATop Engine Mounting Bracket to Cylinder Heads

BEyelet to Top Engine Mounting Bracket

CEyelet to Frame Weldment

F

Front Stabilizer Link and Engine Mounting Bracket

Jam Nut

E

D

Front

Stabilizer Link

G

Bottom

DEyelet to Frame Weldment

EEyelet to Front Engine Mounting Bracket

FFront Engine Mounting Bracket to Rubber Mount

GFront Engine Mount to Frame Crossmember

H Engine to Front Engine Mounting Bracket

f1303x2x

Figure 2-37. Engine Mounting Bracket Bolts

9. Obtain Vehicle Alignment Tool (HD-46247). See Figure

2-35. Proceed as follows:

2-28 2004 Touring: Chassis

a. Back off alignment screws and pilot so that no con-

tact is made with pivot shaft during initial installation.

Page 29

HOME

b. Position alignment fixture so that pilot begins to

engage hole in rear swingarm bracket and then

start 5/16 allen head screw (with flat washer) into

lower hole of passenger footboard mount. Leave fixture loosely installed. Repeat step on other side of

motorcycle.

NOTE

Alignment fixtures are stamped L(eft) and R(ight) for easy

identification. When installing alignment fixture on right side

of motorcycle, first remove hex screw to free brake hose Pclamp from rear swingarm bracket. The relief in right side fixture accommodates hex screw boss.

c. Holding alignment fixture tight against rear swing-

arm bracket, use knurling to rotate pilot until it bottoms in rear swingarm bracket. Without disturbing

setting of pilot, tighten allen head screw to passenger footboard mount to 18-22 ft-lbs (24-30 Nm).

Repeat step on other side of motorcycle.

d. Hand turn alignment screw until it bottoms against

end of pivot shaft. Repeat step on other side of

motorcycle.

e. Tighten alignment screw to 60-80 in-lbs (6.8-9.0

Nm). Repeat step on other side of motorcycle. See

Figure 2-36.

10. Adjust each stabilizer link as follows:

a. Install bolts removed under steps 7(d) and 8(e), and

using the center hex to maintain equal thread

engagement at both eyelets, adjust stabilizer links

so that bolts thread in without any stress or engine

movement. See B and D of Figure 2-37.

b. Alternately tighten bolts to 18-22 ft-lbs (24-30 Nm).

c. Holding the stabilizer link adjuster and mounting

eyelets to prevent movement or binding, tighten jam

nuts on top and front stabilizer links.

11. Remove vehicle alignment tool from rear swingarm

brackets.

12. Snap the chrome plugs back into the rear swingarm

brackets.

13. Install socket screw with lockwasher to fasten passenger

footboard to rear swingarm bracket. Tighten screw to 1518 ft-lbs (20-24 Nm). Repeat step on other side of

motorcycle.

14. Verify that front rubber mount is centered under the front

mounting plate bolt hole and has not been bound by the

plate dragging across the isolator.

a. If the front rubber mount is centered and free of

binding, proceed as follows:

•Tighten the two front engine mount to frame cross-

member bolts to 15-20 ft-lbs (20-27 Nm). See G of

Figure 2-37.

•Install center front engine mounting bracket to rub-

ber mount bolt (with washers and nut) and tighten to

15-20 ft-lbs (20-27 Nm). See F of Figure 2-37.

b. If centering or relaxation of the mount is required,

proceed as follows:

• Loosen the two front engine mount to frame crossmember bolts. See G of Figure 2-37.

• Push on the rubber mount to center it with the thru

bolt hole in the mounting plate. It may be necessary

to bounce or wiggle the engine to unload any

binding of the rubber mount on the mounting plate.

•After the mount is centered, tighten the two front

engine mount to frame crossmember bolts to 15-20

ft-lbs (20-27 Nm). See G of Figure 2-37.

•Install center front engine mounting bracket to rubber mount bolt (with washers and nut) and tighten to

15-20 ft-lbs (20-27 Nm). See F of Figure 2-37.

15. Slide voltage regulator over studs on lower frame crossmember at front of vehicle. Install flange locknuts on

studs and tighten to 70-100 in-lbs (7.9-11.3 Nm).

16. Install fuel tank. For carbureted models, see Section 4.7

FUEL TANK (CARBURETED), INSTALLATION (AFTER

PA RTIAL REMOVAL), FLHT/C, or FLHR/S. For fuel

injected models, see Section 9.4 FUEL TANK (FUEL

INJECTED), INSTALLATION (AFTER PARTIAL

REMOVAL), FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

17. Verify minim

the following frame mounted components:

a. Top Engine/Horn Mounting Bracket to Fuel Tank:

0.328 inch (8.3 mm).

b. Rocker Covers to Fuel Tank: 0.375 inch (9.5 mm).

c. Carburetor Top Cover to Fuel Tank: 0.375 inch (9.5

mm).

d. Rear Spark Plug Boot to Fuel Valve: 0.250 inch (6.4

mm).

e. To p Stabilizer Link to Induction Module: 0.375 inch

(9.5 mm).

f. Front Stabilizer Link to Voltage Regulator: 0.375

inch (9.5 mm).

g. Inner Primary Chaincase to Lower Frame Tube:

0.187 inch (4.8 mm).

h. Exhaust Crossover Pipe to Primary Housing: 0.125

inch (3.2 mm).

i. Tire to Rear Fender: 0.100 inch (2.5 mm).

j. Perform the procedure under Method B to trouble-

shoot clearance problems and to identify offending

component(s).

18. Install seat. See Section 2.24 SEAT, INSTALLATION.

19. Test ride the motorcycle.

Vehicle leads that require more than 2-lbs pull to correct

need further diagnosis. Perform the procedure under Method

B in this section.

um clearance between the powertrain and

NOTE

2004 Touring: Chassis 2-29

Page 30

HOME

METHOD B

NOTE

Use this procedure to determine the cause of vehicle misalignment and to locate clearance problems, or as an

alternative to use of the Vehicle Alignment Tool (HD-46247)

described under Method A. For acceptable results, a careful

inspection should be performed (wheel and tire runout, laced

wheel offset, rubber mount condition, etc.) to ensure that it is

conducted with serviceable components. See INSPECTION

for more information.

1. Place the motorcycle on a hydraulic center stand or

place blocking under the frame to support the vehicle

and lift the rear wheel off the ground. Be sure the motorcycle is positioned as level as possible.

2. Remove socket screw with lockwasher to remove left

passenger footboard from rear swingarm bracket.

Tighten both rear swingarm bracket bolts to 34-42 ft-lbs

(46-57 Nm). Repeat step on right side of motorcycle.

3. Remove the decorative chrome plug from both rear

swingarm brackets. While holding the left side pivot shaft

locknut, tighten the right side locknut to 40-45 ft-lbs (5461 Nm). Then hold the right side pivot shaft locknut and

tighten the left side locknut to 40-45 ft-lbs (54-61 Nm).

4. Verify that belt deflection is within specification and that

adjuster cams are tight against rear swingarm weld

nubs. Holding

nut on right side to 95-105 ft-lbs (128.8-142.4 Nm).

5. Remove seat. See Section 2.24 SEAT, REMOVAL.

6. Partially remove fuel tank to gain access to top engine

mounting bracket and stabilizer link. See Section 4.7

FUEL TANK (CARBURETED), PA RTIAL REMOVAL,

FLHT/C, or FLHR/S. For fuel injected models, see Sec-

tion 9.4 FUEL TANK (FUEL INJECTED), PA R TIAL

REMOVAL, FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

7. Top Engine Mount:

a. On left side of motorcycle, tighten the two top

engine mounting bracket to front and rear cylinder

head bolts to 35-40 ft-lbs (48-54 Nm). See A of Fig-

ure 2-37.

b. Moving to right side of motorcycle, tighten the top

stabilizer link eyelet to frame weldment bolt to 18-22

ft-lbs (24-30 Nm). See C of Figure 2-37.

c. Loosen both top stabilizer link jam nuts.

d. Remove the top stabilizer link eyelet to top engine

mounting bracket bolt. See B of Figure 2-37.

8. Front Engine Mount:

a. Remove flange locknuts from studs on lower frame

crossmember. Remove voltage regulator from studs

and allow to hang by cables at front of motorcycle.

b. Tighten two engine to front engine mounting bracket

bolts to 33-38 ft-lbs (45-52 Nm). See H of Figure 2-

37.

weld nut on left side of axle, tighten cone

c. Tighten front stabilizer link eyelet to frame weldment

bolt to 18-22 ft-lbs (24-30 Nm). See D of Figure 2-

37.

d. Tighten front stabilizer link eyelet bolt to block on

front engine mounting bracket to 18-22 ft-lbs (24-30

Nm). See E of Figure 2-37.

e. Remove the center front engine mounting bracket to

rubber mount bolt (with washers and nut). See F of

Figure 2-37.

9. To verify alignment, install alignment bars or other suitable device on both the left and right side of motorcycle.

Proceed as follows:

NOTE

If the front tire is wider than the rear, then the alignment bars

must either be shimmed out equally at the points of contact

on the rear tire, notched at the front to clear the front tire, or

attached to the front tire with all measurements performed at

the rear. For explanatory purposes, the following procedure

assumes the alignment bars are secured to the rear tire.

a. Place a set of straightedges on both the left and

right sides of the motorcycle alongside the front and

rear tires.

b. Ve rify that both alignment bars firmly contact the

rear wheel at two points. Use clamp or bungee

cords to hold the bars in place. Tension should be

equal to avoid spreading or pinching the bars.

c. Verify that the bars are straight by matching the

width measurements at both ends.

d. Straighten the front end and verify that the

measurements from the front wheel to the bar on

one side of the motorcycle are equal at two points,

both fore and aft.

e. Measure the front wheel to the bar on the other side

of the motorcycle, both fore and aft, and compare

the results to the measurements obtained under

step 9(d). Measurements from left to right should be

equal +/- 0.030 inch (0.76 mm).

f. Loosen jam nuts, and using the center hex, adjust

the front stabilizer link as required to obtain equal

measurements at all four points (+/- 0.030 inch or

0.76 mm). See Figure 2-38.

NOTE

After each adjustment, unload any binding of the front rubber

mount and verify that the alignment bars and front wheel are

still correctly positioned.

g. Holding the front stabilizer link adjuster and

mounting eyelets to prevent movement or binding,

tighten both jam nuts.

h. Verify that the front rubber mount is centered under

the thru bolt hole in the mounting plate.

2-30 2004 Touring: Chassis

Page 31

HOME

FLT0240

To Correct:

Adjust top stablizer link.

Chassis

Powertrain

Chassis

Powertrain

To Correct:

Adjust front stablizer link.

FLT0239

Figure 2-38. Horizontally Misaligned

i. If the front rubber mount is centered and free of

binding, proceed as follows:

•Tighten the two front engine mount to frame crossmember bolts to 15-20 ft-lbs (20-27 Nm). See G of

Figure 2-37.

•Install center front engine mounting bracket to rubber mount bolt (with washers and nut) and tighten to