Page 1

HOME

1WARNING1WARNING

CAUTION

Mainshaft

Plug

9411

JAPANESE MAINSHAFT/COUNTERSHAFT D.1

NOTE

Check the eight digit number stamped on the transmission

case just above the side door. If the third digit is “9,” then the

transmission was built for Japan only. If the digit is “0,” then it

was built for all countries except Japan. See the instructions

which follow if servicing a Japanese transmission. For all

other transmissions, see Section 7.6 MAINSHAFT/COUN-

TERSHAFT.

DISASSEMBLY

NOTES

●

Perform all steps if completely overhauling the transmission assembly.

●

Perform steps 1-11 and 17-18 if replacing only

tershaft or one or more countershaft gears.

Perform steps 1-5 and 12-18 if replacing only

●

shaft or one or more mainshaft gears.

the coun-

the main-

Figure D-2. Press Out Countershaft

Perform steps 1-6, 12, and 17-18 if replacing only

●

side door bearings.

1. Position the side door assembly on a bench with the

shafts pointing straight up, the mainshaft on the left hand

side. The mainshaft is the longer of the two shafts. See

Figure D-3.

2. Slide off the mainshaft 2nd gear (spur).

NOTE

To facilitate reassembly, label each gear as it is removed.

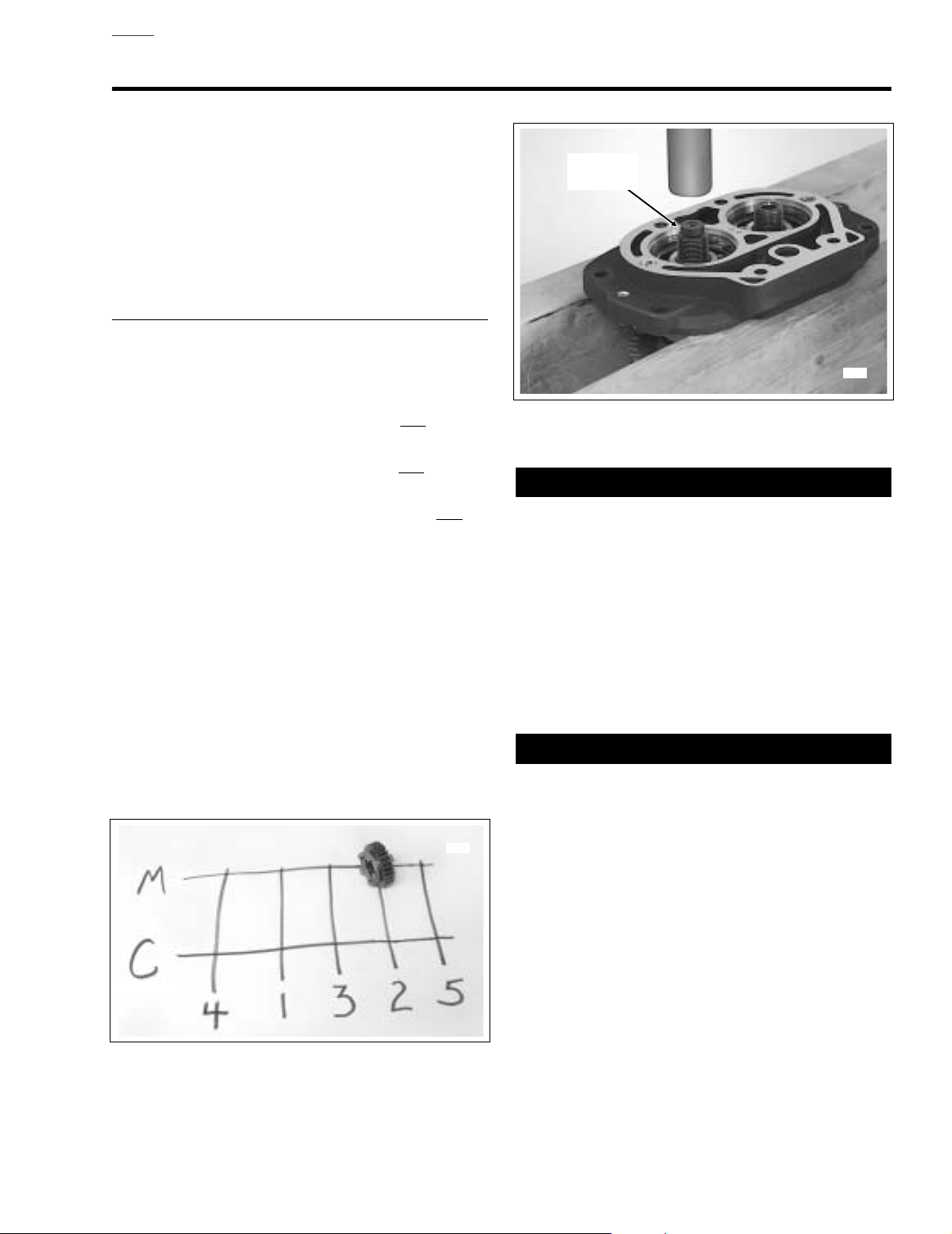

See Figure D-1.

3. Obtain the TRANSMISSION SHAFT RETAINING RING

PLIERS, Part No. J-5586.

the

9412

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

4. Locate retaining ring just above the mainshaft 3rd gear

(spur). Move the retaining ring up approximately 3/8 inch

(9.5 mm) towards the free end of the shaft. Turn side

door assembly upside down and verify that mainshaft

3rd gear is still partially engaged with countershaft 3rd

gear.

Failure to move the retaining ring on the mainshaft can

cause countershaft 1st gear to contact mainshaft 3rd

gear when the countershaft is pressed out. On the other

hand, if the retaining ring is moved too far, loss of

engagement between mainshaft 3rd gear and countershaft 3rd gear can result in hard contact between these

two gears. Any hard contact can result in gear tooth

damage.

5. With the outboard side up, rest side door on parallel

blocks under ram of arbor press. Be sure that assembly

is flat and does not rest on dowel on inboard side.

Figure D-1. Note Gear Location During Disassembly

6. Center countershaft under ram. Install mainshaft plug

into hole at end of countershaft. Slowly apply pressure

until countershaft is free. See Figure D-2. Remove main-

shaft plug.

Appendix D D-1

Page 2

HOME

9413

1 10

11

3

2

4

126

4

3

6

5

4

13

3

4

3

7

146

3

4

4

3

68

9

15

16

1. Mainshaft

2. 2nd Gear

3. Retaining Ring

4. Thrust Washer

5. 3rd Gear

6. Split Cage Bearing

7. 1st Gear

8. 4th Gear

7. Slide blue spacer and countershaft 4th gear (helical) off

threaded end of countershaft.

D-2 Appendix D

9. Gold Spacer

10. Countershaft

11. 5th Gear

12. 2nd Gear

13. 3rd Gear

14. 1st Gear

15. 4th Gear

16. Blue Spacer

Figure D-3. Fully Assembled Side Door

8. Secure countershaft in a vise with the threaded end top-

side. Be sure to install a pair of aluminum or brass jaw

inserts in vise to avoid parts damage. See Figure D-4.

Page 3

HOME

9415

Mainshaft

1st Gear

9416

17. Set the side door on a bench with the outboard side up.

Remove retaining ring from the bearing bore.

Countershaft

1st Gear

Aluminum

Jaws

Figure D-4. Disassemble/Assemble Countershaft

9. Remove retaining ring just above the countershaft 1st

gear (spur with single row of indents on teeth). Remove

thrust washer and countershaft 1st gear. Gently pull

apart the split cage bearing and remove. Remove second thrust washer.

NOTE

Depending upon whether one or both shafts were removed,

replace one or both side door bearings. Always replace the

bearing if the shaft was pressed out.

18. Turn side door over so that the inboard side is up and

place on flat plate under ram of arbor press. Apply pressure to outer race to press bearing from bore.

CLEANING AND INSPECTION

1. Clean all parts in cleaning solvent and blow dry with

compressed air.

2. Check gear teeth for damage. Replace the gears if they

are pitted, scored, rounded, cracked or chipped.

3. Inspect the engaging dogs on the gears. Replace the

gears if the dogs are rounded, battered or chipped.

4. Inspect the side door bearings. Bearings must rotate

freely without drag. Replace the bearings if pitted,

grooved, or if the shafts were removed.

10. Remove retaining ring above the countershaft 3rd gear

(spur). Remove countershaft 3rd gear.

11. Remove retaining ring just above the countershaft 2nd

gear (spur). Remove thrust washer and countershaft

2nd gear. Gently pull apart the split cage bearing and

remove.

12. Center mainshaft under ram of arbor press. Install mainshaft plug into hole at end of mainshaft. Slowly apply

pressure until mainshaft is free. Remove mainshaft plug.

13. Slide gold spacer, mainshaft 4th gear (helical), split cage

bearing and thrust washer off end of mainshaft.

14. Secure the mainshaft in a vise with the longer splined

end at the top. Be sure to install a pair of aluminum or

brass jaw inserts in vise to avoid parts damage. See Fig-

ure D-5.

15. Remove retaining ring above the mainshaft 1st gear

(spur with double row of indents on teeth). Remove

mainshaft 1st gear.

16. Remove retaining ring just above the mainshaft 3rd gear

(spur). Remove the thrust washer and mainshaft 3rd

gear. Gently pull apart the split cage bearing and

remove. Remove the second thrust washer. Remove the

last retaining ring, which was moved out of the groove

before the countershaft was pressed out.

Figure D-5. Disassemble/Assemble Mainshaft

Appendix D D-3

Page 4

HOME

ASSEMBLY

NOTES

Perform all steps if the transmission assembly was com-

●

pletely overhauled.

Perform steps 1-5 and 12-24 if only

●

one or more countershaft gears were replaced.

●

Perform steps 1-11 and 20-24 if only the mainshaft or

one or more mainshaft gears were replaced.

●

Perform steps 1-4, 11, and 18-24 if only the side door

bearings were replaced.

1. With the outboard side up, place side door on flat plate

under ram of arbor press.

NOTE

Note the two drill points between the bearing bores on the

side door. See Figure D-7. Two drill points indicate that the

side door must be fitted with the new style 12mm wide bearings. Installation of the old style 14mm wide bearings would

cover the retaining ring grooves.

2. Position

topside.

3. Applying pressure to outer race, press bearing into bore

until firm contact is made with the counterbore.

new

bearing over bore with the number stamp

the countershaft or

1WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

4. With the flat side in towards the bearing (beveled side

out), install

Depending upon the level of disassembly, replace one or

both side door bearings. Always replace the bearing if the

shaft was pressed out.

5. Obtain the TRANSMISSION SHAFT RETAINING RING

PLIERS, Part No. J-5586.

new

retaining ring in bearing bore.

NOTE

1WARNING1WARNING

Always use new retaining rings when assembling the

mainshaft and countershaft. Reusing retaining rings can

cause the transmission to become “locked” during

motorcycle operation, a situation which could result in

death or serious injury.

9417

Figure D-6. Press In Countershaft

6. Secure the mainshaft in a vise with the longer splined

end at the top. Be sure to install a pair of aluminum or

brass jaw inserts in vise to avoid parts damage.

7. Install

8. Slide thrust washer down mainshaft until it contacts

9. With the fork groove up, slide mainshaft 1st gear (spur

Verify that the mainshaft 1st gear has the doub

indents on teeth. Using a gear with a single row of

indents will result in transmission damage.

10. Slide thrust washer down the mainshaft until it contacts

11. With the inboard side up, place side door on flat plate

new

retaining ring approximately 3/8 inch (9.5

mm) below the bottom retaining ring groove.

retaining ring. Lightly coat split cage bearing with oil and

install in race just above thrust washer. Install mainshaft

3rd gear (spur) with the shifter dogs down. Install second

thrust washer. Install

above the bearing race.

with double row of indents on teeth) down mainshaft until

it contacts retaining ring. Install

groove above the gear. See Figure D-5.

the retaining ring. Lightly coat the split cage bearing

(double roller) with oil and install in race above the thrust

washer. Install mainshaft 4th gear (helical) over the

bearing with the shifter dogs down. Install gold spacer.

under ram of arbor press. Holding mainshaft assembly

together, remove from vise and position over bearing

bore in side door. Install mainshaft plug into hole at end

of mainshaft. Supporting inner race of bearing, press

mainshaft into bearing bore. Remove mainshaft plug.

new

retaining ring in groove just

CAUTION

Mainshaft

Plug

new

retaining ring in

le row of

D-4 Appendix D

Page 5

HOME

Mainshaft

Locknut

Countershaft

Locknut

Two Drill

Points

9414

Figure D-7. Install Mainshaft/Countershaft Locknuts

12. Secure the countershaft in a vise with the threaded end

topside. Be sure to install a pair of aluminum or brass

jaw inserts in vise to avoid parts damage.

21. Return side door assembly to bench. Position with the

shafts pointing straight up, the mainshaft on the left hand

side.

22. Move partially installed retaining ring into groove just

above the mainshaft 3rd gear.

23. Install mainshaft 2nd gear (spur) with the fork groove

down.

The final assembly appears as shown in Figure D-3.

24. Install spacer and locknut on the threaded end of each

shaft and tighten the nuts until finger tight. See Figure D-

7.

NOTE

For final tightening of the locknuts and installation of the side

door, see Section 7.6 MAINSHAFT/COUNTERSHAFT,

INSTALLATION.

13. Lightly coat split cage bearing with oil and install in race

next to the countershaft 5th gear.

14. Install countershaft 2nd gear (spur) over the bearing with

the shifter dogs up. Install thrust washer and

new

retain-

ing ring.

15. Install countershaft 3rd gear (spur) with the fork groove

down. Install

new

retaining ring in groove above the

gear.

16. Slide the thrust washer down the countershaft until it

contacts the retaining ring. Lightly coat the split cage

bearing with oil and install in the race just above the

thrust washer. Install countershaft 1st gear (spur with

single row of indents on teeth) with the taper up. Install

second thrust washer and

new

retaining ring. See Fig-

ure D-4.

17. Install countershaft 4th gear (helical) with the sleeve

down. Install blue spacer with the taper up.

18. With the inboard side up, place side door on flat plate

under ram of arbor press. Support inner race of bearing.

19. Holding countershaft assembly together, remove from

vise. Raising mainshaft 3rd gear until it contacts partially

installed retaining ring, position countershaft over bearing bore. Verify that taper on blue spacer is facing

towards the bearing.

20. Place mainshaft plug at end of countershaft. Be sure

that mainshaft and countershaft gears mesh and that

assembly is square. Press countershaft into bearing

bore. Remove mainshaft plug. See Figure D-6.

Appendix D D-5

Page 6

HOME

NOTES

D-6 Appendix D

Loading...

Loading...