Page 1

HOME

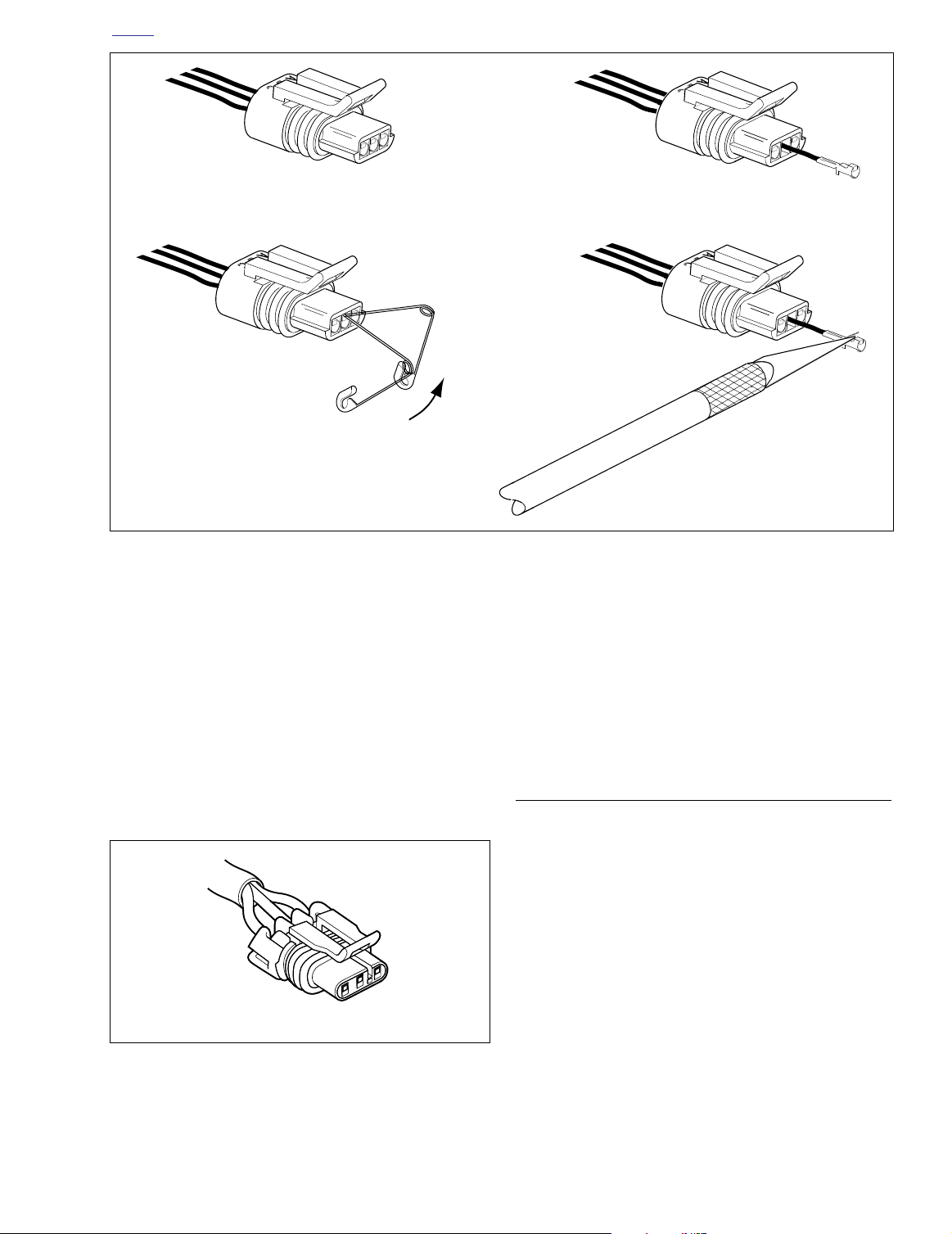

f1049a8x

DEUTSCH ELECTRICAL CONNECTORS B.1

GENERAL

Attachment clips are attached to the pin housings of some

connectors. The clips are then attached to T-studs on the

motorcycle frame. T-studs give positive location to electrical

connectors and wire harnesses. Consistent location reduces

electrical problems and improves serviceability.

To become familiar with the Deutsch connector, read the

parts description below while referencing the 12-place connector illustrated in Figure B-3.

Soc

ket housing: alignment tabs and/or external latch, sec-

ondary locking wedge, internal seal, wire seal, seal pin.

NOTE

Seal pins or plugs are installed in the wire seals of unused

chambers. If removed, seal pins must be replaced to maintain the integrity of the environmental seal.

Pin housing

secondary locking wedge, wire seal, seal pin.

: alignment grooves and/or external latch cover,

REMOVING/DISASSEMBLING

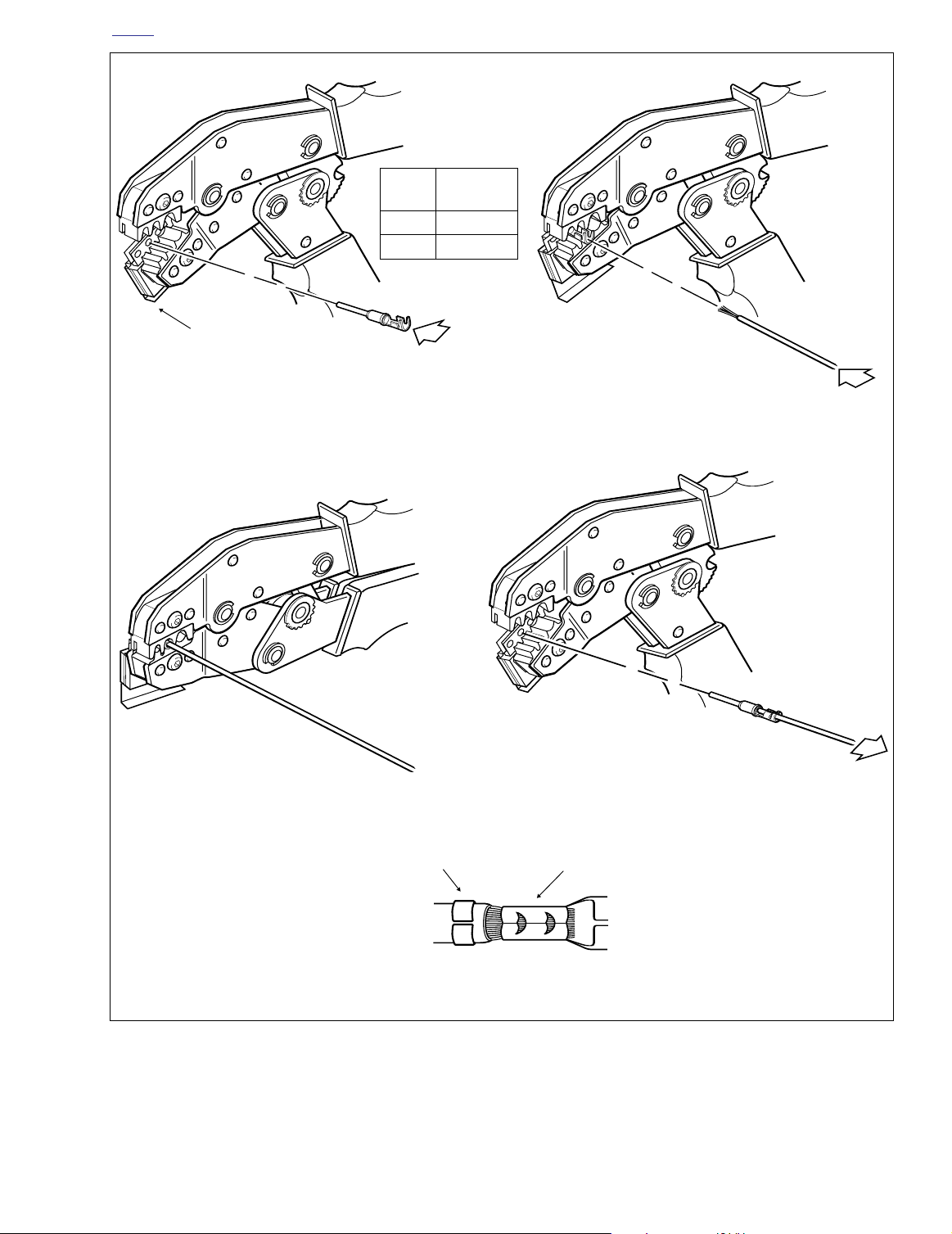

1. Push the connector to disengage small end of slot on

attachment clip fromT-stud. Lift connector off T-stud.

2. Depress the external latch(es) on the socket housing

side and use a rocking motion to separate the pin and

socket halves. Two-, three-, four- and six-place Deutsch

connectors have one external latch, while eight- and

twelve-place connectors have two, both of which must

be pressed simultaneously to separate the connector

halves.

4566

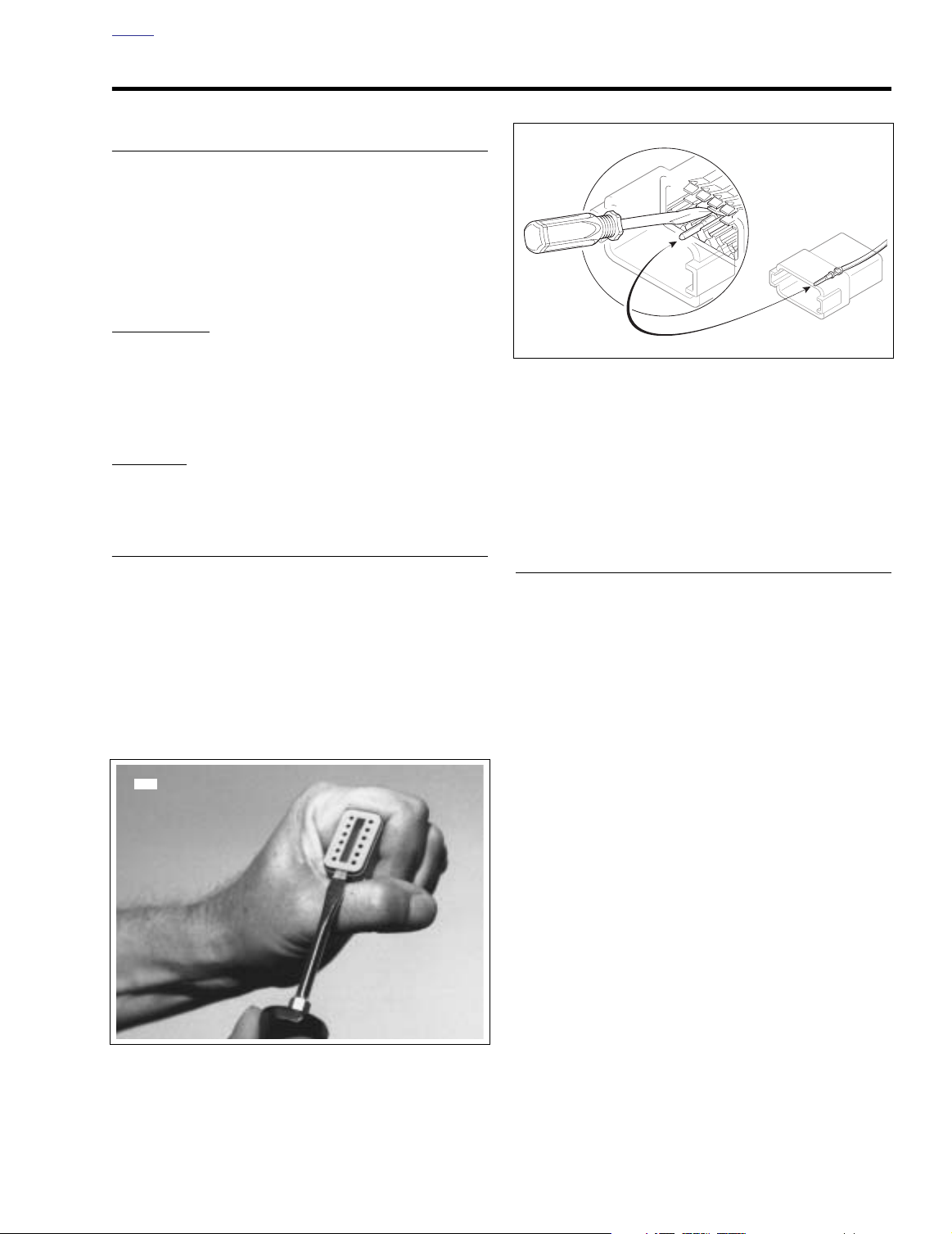

Figure B-2. Depress Terminal Latches/Back Out Pins

NOTE

With few exceptions, the socket housing can always be found

on the accessory side, while the pin side of the connector is

plumbed to the wiring harness.

REMOVING/INSTALLING SOCKETS

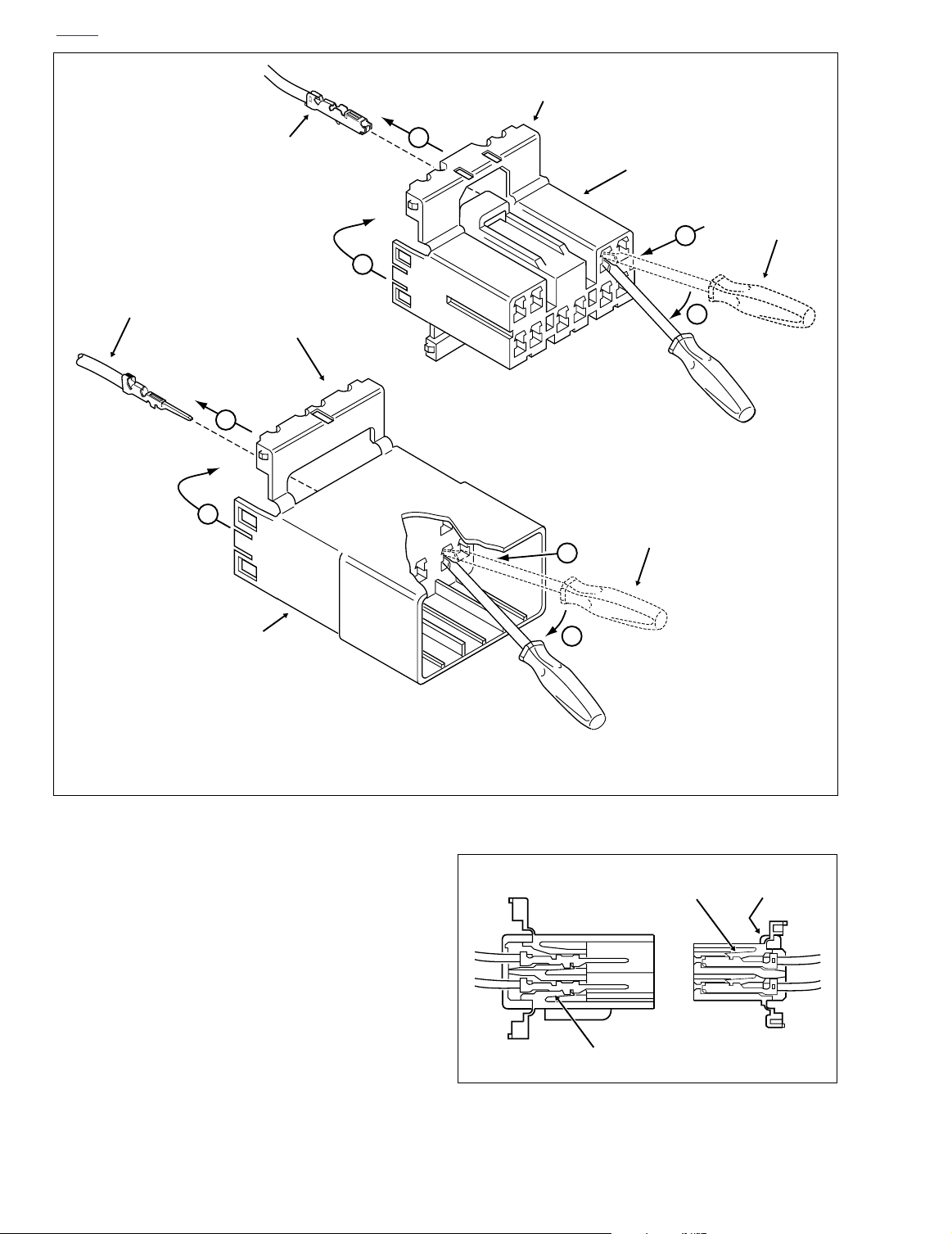

1. See Figure B-1. Remove the secondary locking wedge.

Insert the blade of a small screwdriver between the

socket housing and locking wedge inline with the groove

(inline with the pin holes if the groove is absent). Turn

the screwdriver 90 degrees to pop the wedge up.

2. Gently depress terminal latches inside socket housing

and back out sockets through holes in rear wire seal.

See Figure B-2.

NOTE

If new terminals must be installed, see CRIMPING

INSTRUCTIONS in this section.

Figure B-1. Remove Secondary Locking Wedge

3. Fit rear wire seal into back of socket housing, if removed.

Grasp socket approximately 1 inch (25.4 mm) behind the

contact barrel. Gently push sockets through holes in wire

seal into their respective chambers. Feed socket into

chamber until it “clicks” in place. Verify that socket will

not back out of chamber; a slight tug on the wire will confirm that it is properly locked in place.

4. Install internal seal on lip of socket housing, if removed.

Insert tapered end of secondary locking wedge into

socket housing and press down until it snaps in place.

The wedge fits into the center groove within the socket

housing and holds the terminal latches tightly closed.

Appendix B B-1

Page 2

HOME

Terminal

Pin

Latch Cover

Wire Seal

Alignment

Grooves

f1915x8x

Pin

Housing

Locking Wedge

(Pin Side)

Locking Wedge

(Socket Side)

Internal

Seal

Socket

Housing

Wire

Seal

NOTE

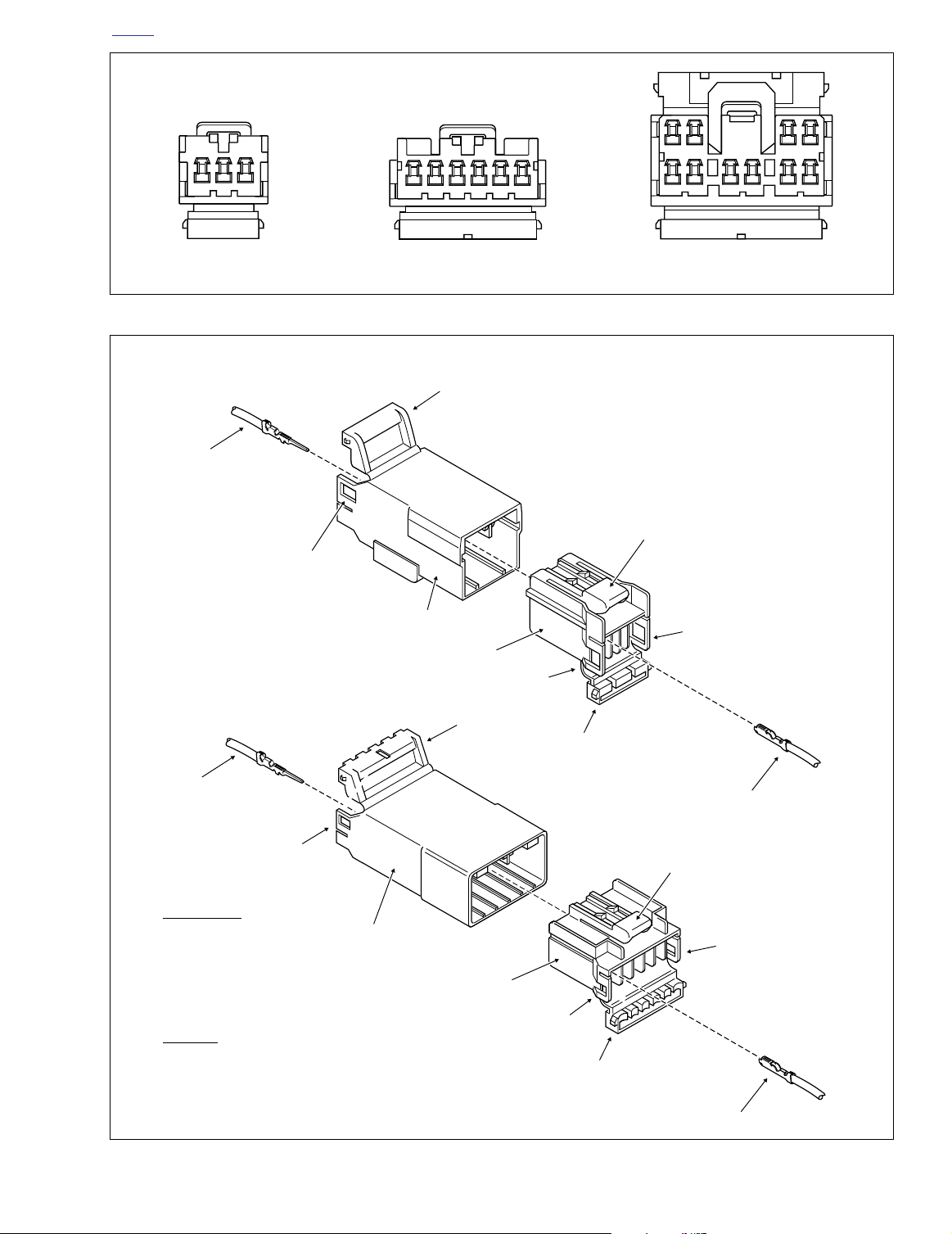

For exploded views of 2-place,

3-place and 4-place Deutsch

connectors, see Figure B-5.

Figure B-3. 12-Place Deutsch Connector (Exploded View)

NOTE

While rectangular wedges do not require a special orientation, the conical secondary locking wedge of the 3-place connector must be installed with the arrow pointing toward the

external latch. See Figure B-4.

NOTE

If the secondary locking wedge does not slide into the

installed position easily, verify that all terminals are fully

installed in the socket housing. The lock indicates when terminals are not properly installed by not entering its fully

installed position.

REMOVING/INSTALLING PINS

Alignment

Tabs

Housing

Socket

Housing

Seal

Pin

External

Latch

Socket

Terminal

Pin

Arrow Points to

External Latch

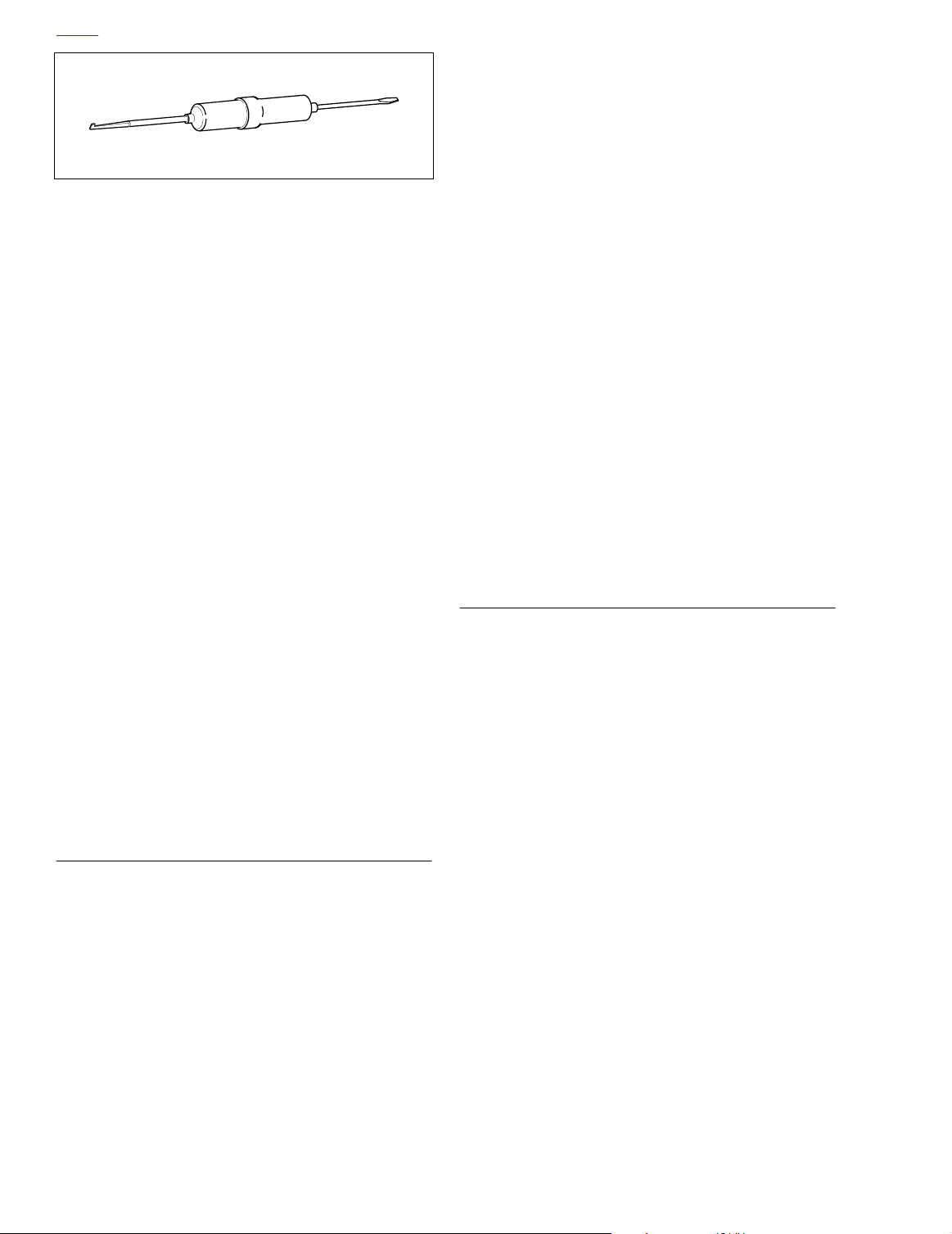

1. Remove the secondary locking wedge. Use the hooked

end of a stiff piece of mechanics wire, a needle nose pliers or a suitable pick tool (HD-41475-100). See Figure

B-6.

B-2 Appendix B

f1515x8x

Figure B-4. 3-Place Locking Wedge Orientation

Page 3

HOME

f1510x8x

11

11

10

8

7

6

5

9

2-Place Connector

4

2

3

10

8

1

7

6

9

5

3-Place Connector

4

11

Socket Side

1. Socket Terminal

2. Wire Seal

3. Socket Housing

4. External Latch

5. Internal Seal

6. Locking Wedge

DEUTSCH

9

10

Pin Side

7. Locking Wedge

8. Latch Cover

9. Pin Housing

10. Wire Seal

11. Pin Terminal

2

3

1

8

7

6

5

4-Place Connector

4

2

1

DEUTSCH

3

Figure B-5. 2-Place, 3-Place and 4-Place Deutsch Connectors

Appendix B B-3

Page 4

HOME

Figure B-6. Deutsch Connector Pick Tool

(Part No. HD-41475-100)

2. Gently depress terminal latches inside pin housing and

back out pins through holes in wire seal.

NOTE

If new terminals must be installed, see CRIMPING

INSTRUCTIONS on this page.

3. Fit wire seal into back of pin housing. Grasp crimped pin

approximately 1 inch (25.4 mm) behind the contact barrel. Gently push pins through holes in wire seal into their

respective numbered locations. Feed pin into chamber

until it “clicks” in place. Verify that pin will not back out of

chamber; a slight tug on the wire will confirm that it is

properly locked in place.

4. Insert tapered end of secondary locking wedge into pin

housing and press down until it snaps in place. The

wedge fits in the center groove within the pin housing

and holds the terminal latches tightly closed.

click (latch), press on one side of the connector until that

latch engages, then press on the opposite side to

engage the other latch.

NOTES

Deutsch connectors are colored coded for location pur-

●

poses. Those connectors associated with

accessories, such as the front and rear

are

gray

. All other connectors, including those associ-

ated with right side accessories, are black.

If it should become necessary to replace a plug or

●

receptacle, please note that the 8-place and 12-place

gray and black connectors are not interchangeable.

Since location of the alignment tabs differ between the

black and gray connectors, plugs or receptacles must be

replaced by those of the same color. If replacing both the

socket and pin halves, then the black may be substituted

for the gray, and vice versa. The socket and pin halves of

all other connectors are interchangeable, that is, the

black may be mated with the gray, since the alignment

tabs are absent and the orientation of the external latch

is the same.

2. Fit the attachment clip to the pin housing, if removed.

Place large end of slot on attachment clip over T-stud on

frame. Push assembly forward to engage small end of

slot.

left

turn signals,

left

side

NOTE

While rectangular wedges do not require a special orientation, the conical secondary locking wedge of the 3-place connector must be installed with the arrow pointing toward the

external latch. See Figure B-4.

NOTE

If the secondary locking wedge does not slide into the

installed position easily, verify that all terminals are fully

installed in the pin housing. The lock indicates when terminals are not properly installed by not entering its fully

installed position.

ASSEMBLING/INSTALLING

1. Insert socket housing into pin housing until it snaps in

place. Two-, three-, four- and six-place Deutsch connectors have one external latch on the socket half of the

connector. To fit the halves of the connector together, the

latch on the socket side must be aligned with the latch

cover on the pin side.

For those connectors with two external latches (8-place

and 12-place), a different system is used to prevent

improper assembly. Align the tabs on the socket housing

with the grooves on the pin housing. Push the connector

halves together until the latches “click.” If latches do not

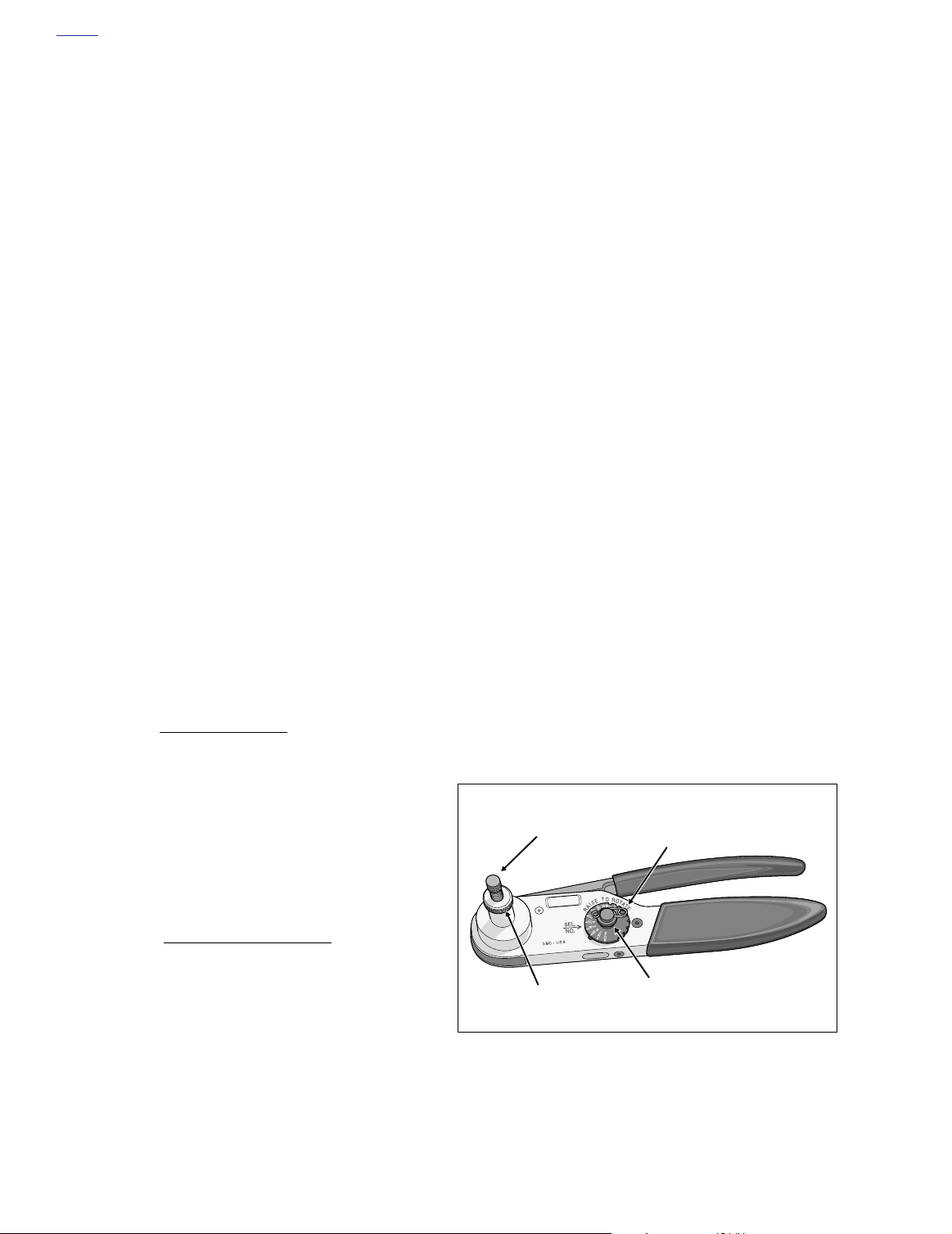

CRIMPING INSTRUCTIONS

Use the Deutsch Terminal Crimp Tool (HD-39965) to install

standard size terminals with crimp tails, as described under

STANDARD TERMINALS below. To install the mini-Deutsch

terminals with crimp tails, see MINI TERMINALS, which follows. To install those terminals without crimp tails, both standard and mini-Deutsch, use the Deutsch Solid Barrel Contact

Crimp Tool (HD-42879) as described under SOLID BARREL

CONTACTS.

NOTE

A Deutsch Connector Service Kit (HD-41475) contains a

selection of wire seals, internal seals, seal plugs, secondary

locking wedges, attachment clips and socket/pin terminals.

Also included is a compartmented storage box, carrying case

and pick tool (HD-41475-100) used for the removal of all

types of locking wedges.

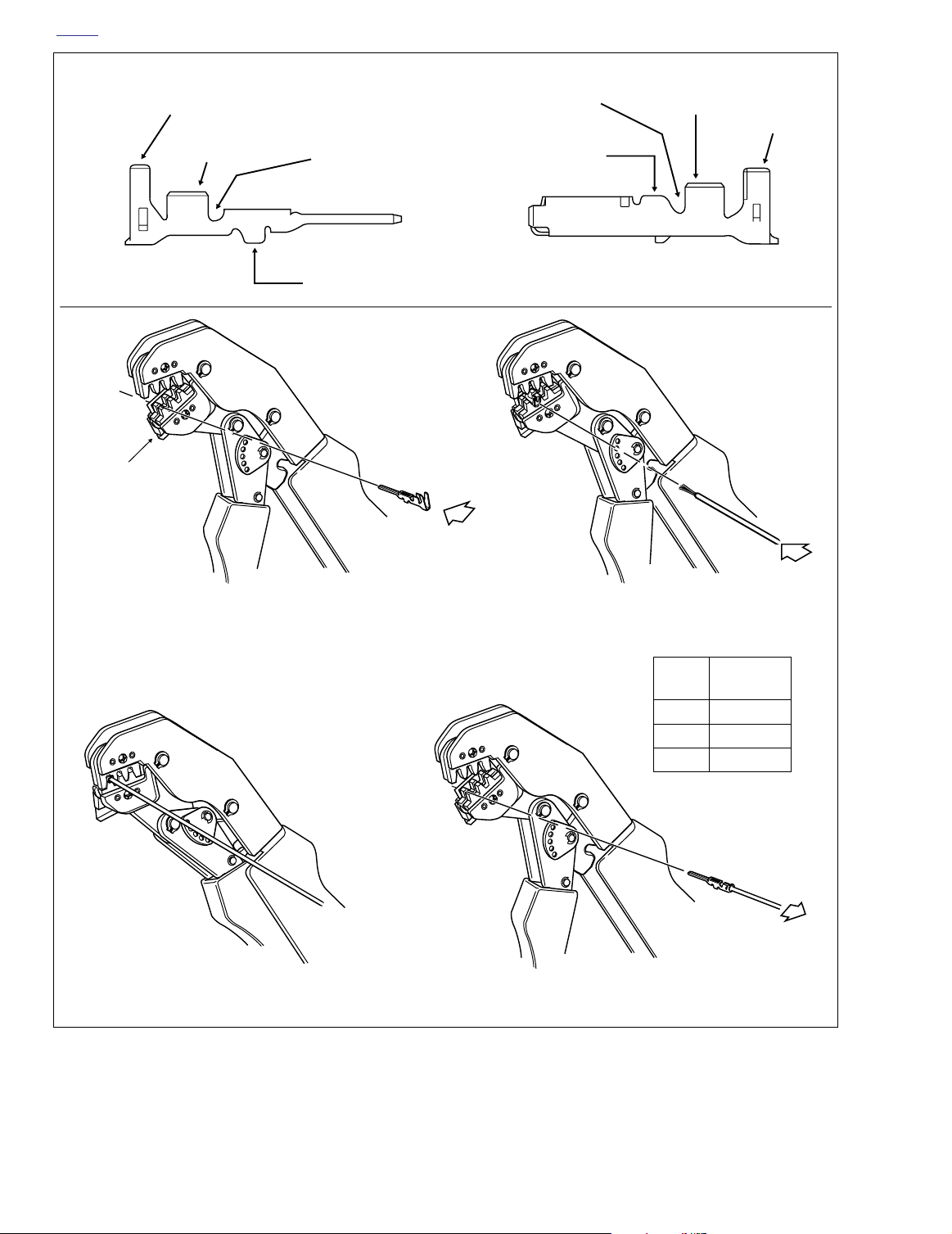

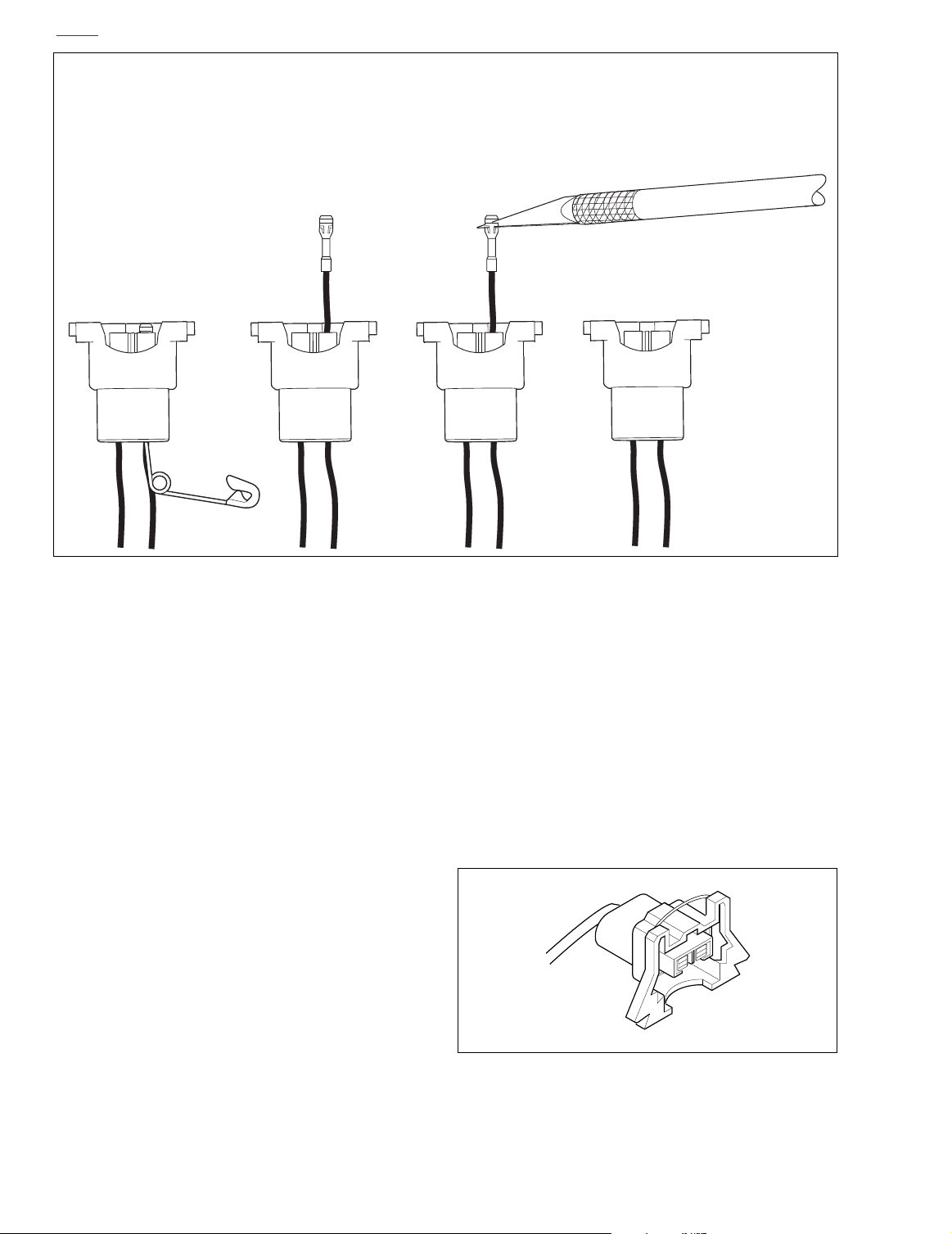

STANDARD TERMINALS

1. Obtain the DEUTSCH TERMINAL CRIMP TOOL (HD-

39965).

2. Squeeze the handles to cycle the crimp tool to the fully

open position. See Figure B-7.

B-4 Appendix B

Page 5

HOME

f1516x8x

2.1.

Gauge

Wire

20 Front

16-18 Middle

Locking

Bar

1. Insert contact through hole of locking bar

so that barrel rests on nest of crimp tool.

3.

Nest of

Crimp Tool

2. Insert stripped lead until it contacts

locking bar.

4.

3. Close and squeeze crimp tool. 4. Raise locking bar and remove contact.

Insulation crimp Core crimp

5.

5. Inspect quality of core and insulation crimps.

f1558x8x

Figure B-7. Deutsch Crimping Procedure

Appendix B B-5

Page 6

HOME

3. Raise the locking bar by pushing up on bottom flange.

With the crimp tails facing upward, insert contact

(socket/pin) through hole of locking bar, so that the

rounded side of the contact barrel rests on the nest (concave split level area) of the crimp tool. Use the middle

hole in the locking bar for 16-18 gauge wire, the front

hole for 20 gauge wire.

4. Release locking bar to lock position of contact. If the

crimp tails are slightly out of vertical alignment, the crimp

tool automatically rotates the contact so that the tails

face straight upward. When correctly positioned, the

locking bar fits snugly in the space between the contact

band and the core crimp tails.

5. Strip lead removing 5/32 inch (4.0 mm) of insulation.

Insert wires between crimp tails until ends make contact

with locking bar. Verify that wire is positioned so that

short pair of crimp tails squeeze bare wire strands, while

long pair folds over insulation material.

6. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete. Raise up locking bar and remove contact.

7. Inspect the quality of the core and insulation crimps. Distortion should be minimal.

MINI TERMINALS

1. Obtain the PACKARD TERMINAL CRIMP TOOL (HD38125-7).

2. Strip wire lead removing 5/32 inch (4.0 mm) of insulation.

3. Compress handles until ratchet automatically opens.

NOTE

Always perform core crimp before insulation crimp.

4. Position the core cr

sure the core crimp tails are facing the forming jaws.

5. Gently apply pressure to handles of tool until crimpers

just secure the core crimp tails.

6. Insert stripped wire between crimp tails. Verify that wire

is positioned so that short pair of crimp tails squeeze

bare wire strands, while long pair is positioned over the

insulation material.

7. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete.

8. Position the insulation cr

tool. Be sure the insulation crimp tails are facing the

forming jaws.

9. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete.

10. Inspect the quality of the core and insulation crimps. Distortion should be minimal.

imp on nest E of the crimping tool. Be

imp on nest C of the crimping

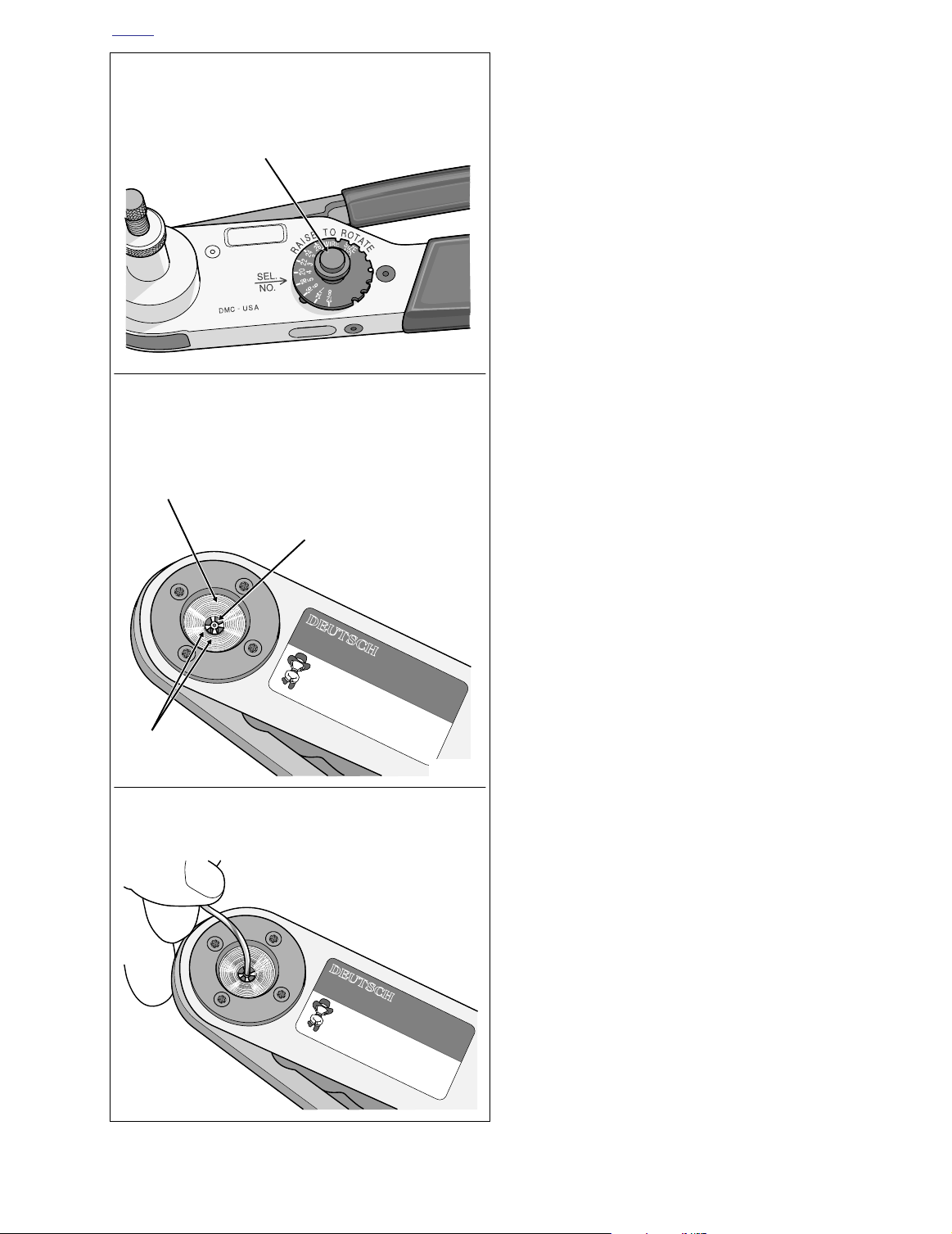

SOLID BARREL CONTACTS

For Size 20, 16 and 12 Contacts

Wire Range 26-12 AWG

1. Obtain the DEUTSCH SOLID BARREL CONTACT

CRIMP TOOL (HD-42879).

2. Squeeze the handles to cycle the crimp tool to the fully

open position.

3. Remove locking pin from selector knob. See Figure B-8.

4. Raise selector knob and rotate until selected wire size

stamped on wheel is aligned with “SEL. NO.” arrow. See

upper frame of Figure B-9.

5. Loosen knurled locknut and turn adjusting screw clockwise (in) until it stops.

6. Turn tool over and drop contact into indentor cover hole

with the wire end out.

7. Turn adjusting screw counterclockwise (out) until contact

is flush with bottom of depression in indentor cover.

Tighten knurled locknut.

8. Slowly squeeze handles of crimp tool until contact is

centered between indentor points. See middle frame of

Figure B-9.

9. Strip wire lead removing 1/4 inch (6.4 mm) of insulation.

10. Insert bare wire strands into contact barrel. See lower

frame of Figure B-9.

11. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete.

12. Remove crimped contact from indentor.

13. Inspect the quality of the crimp. Verify that all wire

strands are in crimp barrel.

Adjusting

Screw

t

o

n

t

s

u

m

l

o

o

t

D

N

A

H

s

i

h

T

d

e

r

e

w

o

p

y

n

a

n

i

d

e

s

u

e

b

y

b

d

e

n

i

f

e

d

s

a

'

'

S

S

E

R

)

P

6

"

4

(

1

1

2

.

0

1

9

1

R

F

C

A

H

S

O

Locknut

Figure B-8. Deutsch Solid Barrel Contact Crimp Tool

(Part No. HD-42879)

Locking

Pin

Selector

Knob

f1535x8x

B-6 Appendix B

Page 7

HOME

Rotate selector knob to align wire size on wheel

with arrow stamped in tool.

Selector

Knob

t

o

n

t

s

u

m

l

o

o

t

D

N

A

H

is

h

T

d

e

r

e

w

o

p

y

n

a

in

d

e

s

u

e

b

y

b

d

e

n

i

f

e

d

s

a

''

S

S

E

R

)

P

6

"

4

(

1

1

2

.

0

1

9

1

R

F

C

A

H

S

O

f1534x8x

Turn adjusting screw as described in text. When

contact is flush with bottom of depression in

indentor cover, squeeze handles to center contact

between indentor points.

Indentor

Cover

Contact

NOTE

Tool must be readjusted when changing contact size/type.

14. Install pin to lock position of selector knob.

HEMET RYAN AIRPORT, P.O. BOX 878

HEMET, CA. 92343-0161 (714) 929-1200

IN

D

U

S

T

R

IA

L

P

R

O

D

U

C

T

S

HDT - 48 - 00

D

JDG360-1

Indentor

Points

f1532x8x

Insert bare wire strands into contact barrel.

Squeeze handle of crimp tool until tightly closed.

HEMET RYAN AIRPORT, P.O. BOX 878

HEMET, CA. 92343-0161 (714) 929-1200

INDUSTRIAL PRODUCTS DIVISION

HDT - 48 - 00

JDG360-1

f1533x8x

I

V

IS

IO

N

Figure B-9. Deutsch Solid Barrel Contact

Crimping Procedure

Appendix B B-7

Page 8

HOME

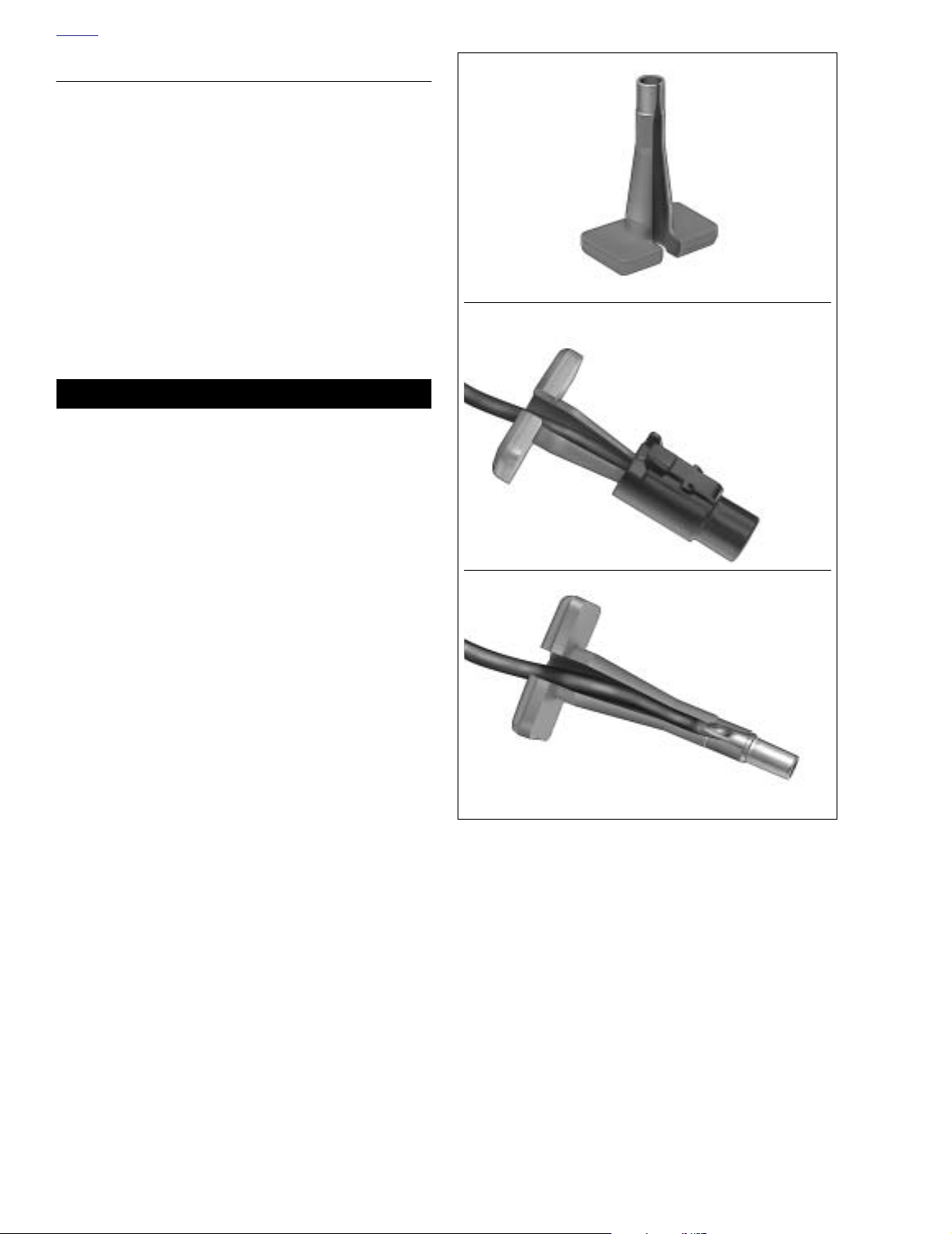

1-

PLACE

CABLE CONNECTOR

General

Use the following instructions to service the voltage regulator

cable connector.

Removal

1. Depress external latch and separate pin and socket

halves of connector.

2. Pull rear wire seal from back of housing and slide down

voltage regulator cable to move out of the way.

3. Obtain terminal pick tool (Deutsch® 114008) like that

shown in A of Figure B-10.

CAUTION

Rough handling or careless storage can result in tool

damage. Exercise care to avoid cracking or breaking the

thin plastic construction.

4. Install terminal pick tool onto voltage regulator cable so

that the tapered end is in the wire end of the housing.

See B of Figure B-10.

5. Push tool into wire end of housing until it bottoms. Gently tug on housing to pull from terminal. See C of Figure

B-10.

6. Remove tool from voltage regulator cable.

A

7786

B

7787

C

Installation

1. Insert terminal into wire end of housing until it “clicks” in

place. Verify that terminal will not back out of housing. A

slight tug on the voltage regulator cable will confirm that

it is properly locked in place.

2. Fit rear wire seal into back of housing.

3. Mate pin and socket halves of connector.

7788

Figure B-10. Remove Socket/Pin Housing

B-8 Appendix B

Page 9

HOME

AMP MULTILOCK ELECTRICAL CONNECTORS B.2

REMOVING SOCKET/PIN TERMINALS

1. Remove connector from the retaining device, either

attachment or rosebud clip.

2. Depress the button on the socket terminal side of the

connector (plug) and pull apart the pin and socket

halves. See Figure B-11.

3. Bend back the latch slightly and free one side of secondary lock, then repeat the step to release the other side.

Rotate the secondary lock outward on hinge to access

terminals in chambers of connector housing.

4. Looking in the terminal side of the connector (opposite

the secondary lock), take note of the cavity next to each

terminal.

5. See Figure B-12. With the flat edge against the terminal,

insert the pick (Snap-On TT600-3) into the cavity until it

stops. Pivot the end of the pick away from the terminal

and gently tug on wire to pull terminal from chamber. Do

not tug on the wire until the tang is released or the terminal will be difficult to remove. A “click” is heard if the tang

Secondary Lock

Open

Pin Terminal

is engaged but then inadvertently released. Repeat the

step without releasing the tang.

NOTE

An Electrical Terminal Crimp Tool (Part No. HD-41609) is

used to install Amp Multilock pin and socket terminals on

wires. If new terminals must be installed, see CRIMPING

INSTRUCTIONS in this section.

INSTALLING SOCKET/PIN TERMINALS

NOTE

For wire location purposes, numbers are stamped into the

secondary locks of both the socket and pin housings. See

Figure B-14.

1. From the secondary lock side of the connector, insert the

terminal into its respective numbered chamber until it

snaps in place. For proper fit, the slot in the terminal

must face the tang in the chamber.

NOTE

For exploded views of 3-place

and 6-place Amp Multilock

connectors, see Figure B-15.

Latch

f1292x2x

Pin Housing

Figure B-11. 10-Place Amp Multilock Connector (Exploded View)

Socket Housing

Latch

Button

Secondary Lock

Open

Secondary Lock

Open

Latch

Socket Terminal

Appendix B B-9

Page 10

HOME

Secondary Lock

Open

f1289x2x

Pin Terminal

Socket Terminal

Secondary Lock

Open

4

1

4

Socket Housing

2

Pick Tool

1

3

2

Pick Tool

Pin Housing

1. Open Secondary Lock.

2. Insert Pick into Cavity on Mating End of Connector.

3. Pivot End of Pick to Release Tang.

4. Gently Tug on Wire to Remove Terminal from Housing.

Figure B-12. Release Tang and Back Out Terminals

NOTE

The tang in the chamber engages the slot to lock the terminal

in position. On the pin side of the connector, tangs are positioned at the bottom of each chamber, so the slot in the pin

terminal (on the side opposite the crimp tails) must face

downward. On the socket side, tangs are at the top of each

chamber, so the socket terminal slot (on the same side as the

crimp tails) must face upward. Up and down can be determined by the position of the release button (used to separate

the pin and socket halves), the button always being the top of

the connector. See Figure B-13.

2. Gently tug on wire end to verify that the terminal is

locked in place and will not back out of chamber.

3

Pin Housing

f1428x8x

Figure B-13. Tang Location (Cross Sectional View)

Tang

Tang

Button

Socket Housing

B-10 Appendix B

Page 11

HOME

f1287x2x

– AMP

123

3-Place Connector 6-Place Connector 10-Place Connector

Figure B-14. Numbers Stamped on Secondary Locks for Wire Color Locations (Socket Housings Shown)

3-Place Connector

Secondary Locks Open

– AMP

123456

56 78 910

8

9

5

43 21

f1291x2x

7

6-Place Connector

9

7

Socket Side

12. Socket Terminal

13. Secondary Lock (Open)

14. Latch

15. Socket Housing

16. Button

Pin Side

17. Pin housing

18. Latch

19. Secondary Lock (Open)

20. Pin Terminal

6

3

4

3

8

2

1

5

6

3

4

3

2

1

f1288x2x

Figure B-15. 3-Place and 6-Place Amp Multilock Connectors

Appendix B B-11

Page 12

HOME

f1286x2x

PIN TERMINAL SOCKET TERMINAL

Insulation

Crimp Tail

Core

Crimp Tail

Locking Bar

Groove

Tang Slot

Locking Bar

Groove

Tang Slot

Crimp Tail

2.1.

Locking

Bar

Core

Insulation

Crimp Tail

f1290a2x

1. Raise locking bar and seat contact on

nest of crimp tool. Release locking bar.

3.

3. Close and squeeze crimp tool. 4. Raise locking bar and remove contact.

Figure B-16. Amp Multilock Crimping Procedure

4.

2. Insert stripped lead until it contacts

locking bar.

Gauge

Wire

20 Front

16 Middle

18 Rear

Nest of

Crimp Tool

B-12 Appendix B

Page 13

HOME

3. Rotate the hinged secondary lock inward until tabs fully

engage latches on both sides of connector.

4. Insert the socket housing (plug) into the pin housing

(receptacle) until it snaps in place.

5. Install connector on retaining device, either attachment

or rosebud clip.

CRIMPING INSTRUCTIONS

1. Squeeze the handles to cycle the crimp tool (Part No.

HD-41609) to the fully open position.

2. Raise locking bar by pushing up on bottom flange. With

the crimp tails facing upward, insert contact (socket/pin)

through locking bar, so that the closed side of the contact rests on the nest (concave split level area) of the

crimp tool). Use the front nest for 20 gauge wire, the

middle for 16 gauge and the rear for 18 gauge. See Fig-

ure B-16.

3. Release locking bar to lock position of contact. When

correctly positioned, the locking bar fits snugly in the

space at the front of the core crimp tails.

4. Strip lead removing 5/32 inch (4.0 mm) of insulation.

Insert wires between crimp tails until ends make contact

with locking bar. Verify that wire is positioned so that

short pair of crimp tails squeeze bare wire strands, while

long pair folds over insulation material.

5. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete. Raise up locking bar and remove contact.

6. Inspect the quality of the core and insulation crimps. Distortion should be minimal.

Appendix B B-13

Page 14

HOME

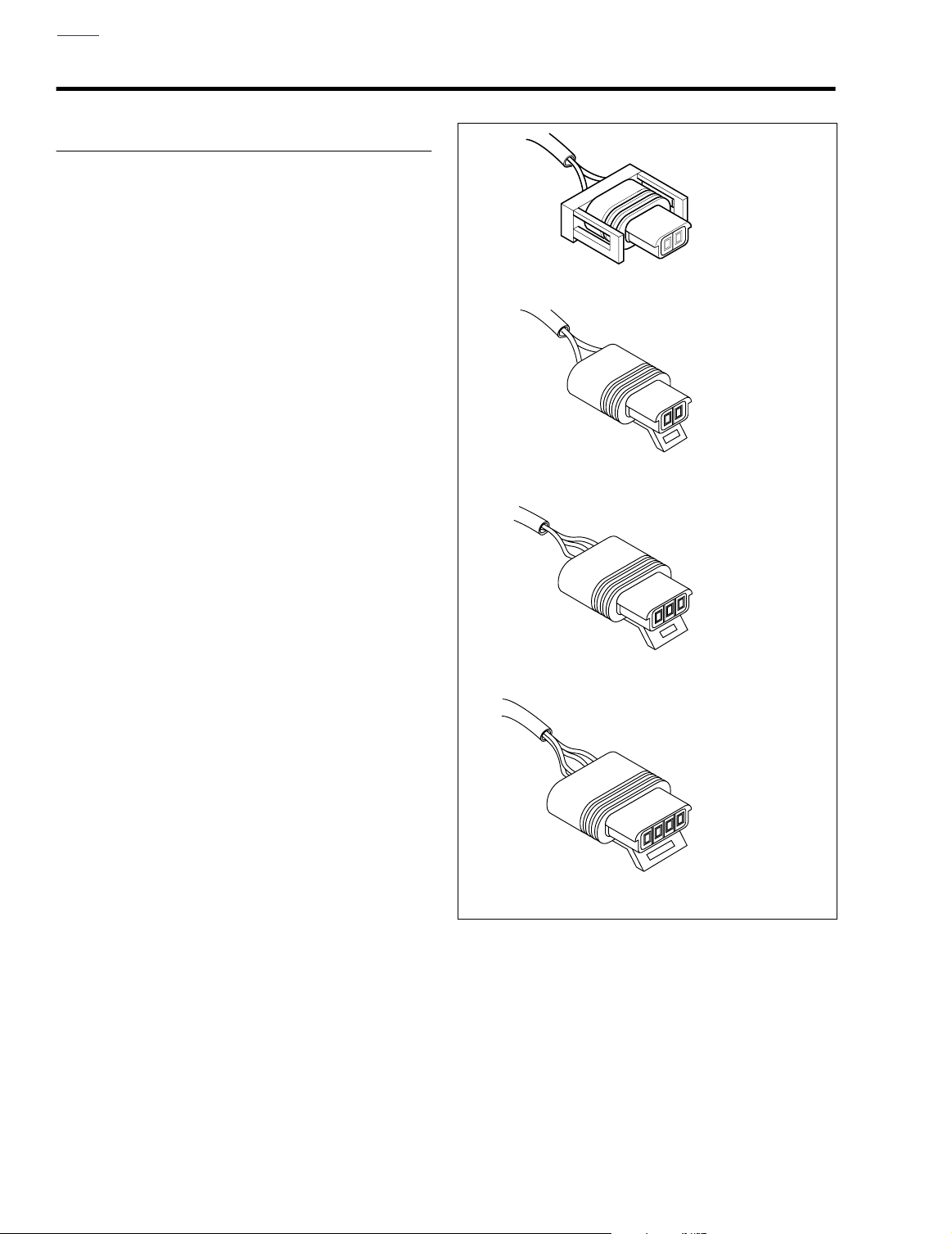

PACKARD ELECTRICAL CONNECTORS B.3

150 METRI-PACK SERIES

General

Use these instructions to service the following connectors:

●

MAP Sensor [80B]

Ignition Coil [83B/130B]

●

●

IAC Actuator [87B]

●

TP Sensor [88B]

ET Sensor [90B]

●

●

IAT Sensor [89B]

Disassembly

1. Remove the connector from the retaining device, if

present.

2. Bend back the external latch(es) slightly and separate

the pin and socket halves of the connector.

3. To free a pull-to-seat terminal from the connector housing, first look into the mating end of the connector to find

the locking tang. See A in Figure B-18. The tangs are

always positioned in the middle of the chamber and are

on the same side as the external latch. On those connectors with locking ears, the tang is on the side opposite the ear. See Figure B-19.

4. At a slight angle, gently insert the point of a one inch

safety pin down the middle of the chamber about 1/8

inch (3.2 mm), and pivot the end of the pin toward the

terminal body. When a click is heard, remove the pin and

repeat the procedure. See B in Figure B-18. The click is

the sound of the tang returning to the locked position as

it slips from the point of the pin. Pick at the tang in this

manner until the clicking stops and the pin seems to

slide in at a slightly greater depth than it had previously.

This is an indication that the tang has been depressed.

2-Place

AB

IAT Sensor Connector [89B]

2-Place

AB

ET Sensor Connector [90B]

3-Place

ABC

TP Sensor Connector [88B]

4-Place

ABCD

NOTE

On those terminals that have been extracted on a previous

occasion, no clicking sound may be heard when the pin is

pivoted to depress the tang, but proceed as if the clicking is

audible and then push on the wire end of the lead to check if

the terminal is free.

NOTE

When picking multiple terminals, the end of the pin may

become malleable. For best results, continue the procedure

with a new safety pin.

B-14 Appendix B

IAC Connector [87B]

Figure B-17. Packard External Latch Type Connectors

(Socket Sides)

5. Remove the pin and push on the wire end of the lead to

extract the terminal from the mating end of the connector. See C in Figure B-18. If necessary, pull back the

conduit and remove the wire seal at the back of the connector to introduce some slack in the wires.

Page 15

HOME

f1360x8x

A

Locate tang on latch side of chamber. Push on wire end of lead to remove terminal.

B

Pivot end of pin to depress tang.

Figure B-18. Depress Tang and Extract Terminal From Mating End of Connector

6. If necessary, crimp new terminals on wires. See Crimp-

ing Instructions at the end of this section.

Assembly

NOTE

For wire location purposes, alpha characters are stamped

into the socket housings.

C

D

Raise tang and re-install terminal.

2. Gently pull on the lead at the wire end of the connector

to draw the terminal back into the chamber. A click is

heard when the terminal is properly seated.

3. Push on the lead to verify that the terminal is locked in

place.

4. Push the pin and socket halves of the connector

together until the latches “click.”

1. Using a thin flat blade, like that on an X-Acto knife, carefully bend the tang outward away from the terminal body.

See D in Figure B-18.

C

AB

Figure B-19. Packard Pull-to-Seat Terminal Connector

With Locking Ear

280 METRI-PACK SERIES

General

Use these instructions to service the following:

Front/Rear Fuel Injectors [84B/85B]

●

System Fuse Block [64B]

●

Fuel Injectors

Disassembly

1. Depress the wireform and use a rocking motion to

detach the electrical connector.

2. Pry rubber seal from wire end of connector and move

seal down wires toward conduit.

Appendix B B-15

Page 16

HOME

A. Insert safety pin at wire end of

connector to depress tang.

B. Push on wire end of lead to

remove terminal.

A

BC D

C. Raise tang with blade of X-Acto

knife.

D. Pull on wire end of lead to draw

terminal back into chamber.

f2012x9x

Figure B-20. Extract/Install Socket Terminal at Mating End of Connector

3. Hold the connector so that the wireform is facing down,

and looking into the wire end of the connector, insert the

point of a safety pin between the top of the terminal and

the inside chamber wall.

4. Push safety pin completely into chamber while watching

terminal on mating end of connector. When terminal is

observed moving forward slightly, then tang is

depressed. See A in Figure B-20. Remove safety pin.

NOTE

Repeat steps 3 and 4 as necessary until the desired result is

achieved.

5. Push on wire end of the lead to extract the terminal from

the mating end of the connector. See B in Figure B-20.

6. If necessary, crimp new terminals on wires. See Crimp-

ing Instructions at the end of this section.

Assembly

NOTE

For wire color locations, see Section B.8 WIRING DIA-

GRAMS and then refer to Figure B-21.

1. Using a thin flat blade, like that on an X-Acto knife, carefully bend the tang outward away from the terminal body.

See C in Figure B-20.

2. Gently pull on the lead at the wire end of the connector

to draw the terminal back into the chamber. Be sure that

the tang faces opposite the wireform as it enters the

chamber. A “click” is heard when the terminal is properly

seated. See D in Figure B-20.

3. Push on lead to verify that terminal is locked in place.

4. Fit rubber wire seal back into wire end of connector.

5. Push the pin and socket halves of the connector

together until the latch “clicks.” The groove in the socket

housing must be aligned with the tab in the pin housing.

AB

Figure B-21. Fuel Injector Connector [84B/85B]

B-16 Appendix B

Page 17

HOME

1WARNING1WARNING

Lip of

Locking Wedge

f2205x8x

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory

7. Radio Power

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

11

10

9

1

8

7

6

5

4

3

2

f2204x8x

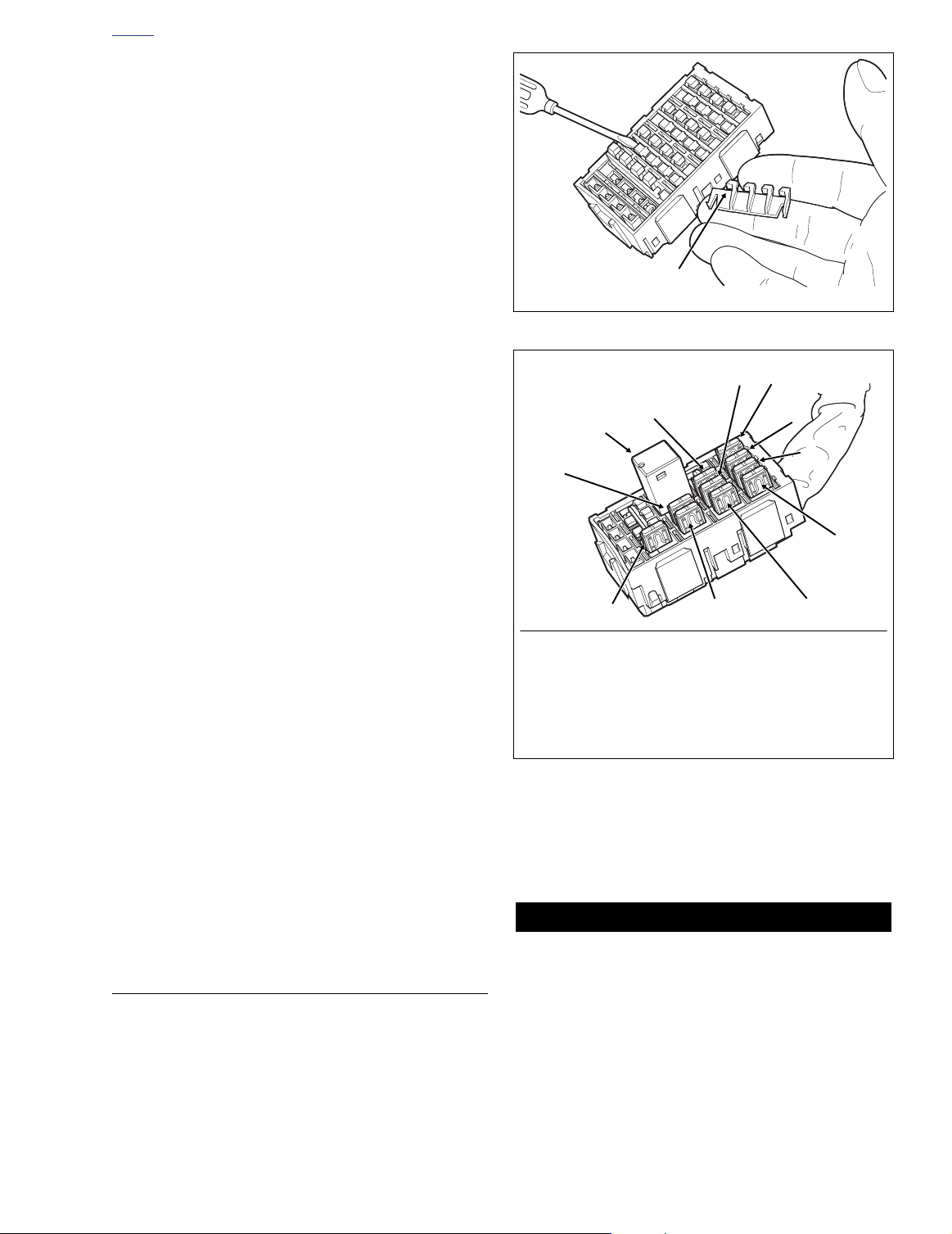

System Fuse Block

Disassembly

1. Remove system fuses and relay(s) from fuse block. See

Section 8.3 SYSTEM FUSES, SYSTEM FUSES/

RELAYS, REMOVAL.

2. Remove secondary locks as follows:

a. Insert end of small flat blade screwdriver under lip of

locking wedge and gently pry up secondary lock.

NOTE

For best results, start with locking wedge on outboard side of

secondary lock. See Figure B-22.

3. Remove socket terminals as follows:

a. Looking into chamber at top of fuse block, note the

tang next to each socket terminal.

b. Using a thin flat blade, like that on an X-Acto knife,

gently push tang away from terminal, and then tug

on wire to back terminal out wire end of chamber.

4. If necessary, crimp new terminals on wires. See Crimp-

ing Instructions at the end of this section.

Assembly

1. Install socket terminals as follows:

NOTE

See Section B.8 WIRING DIAGRAMS, MAIN HARNESS, for

wire colors and locations.

a. With the open side of the socket terminal facing the

tang, push lead into chamber at the wire end of the

fuse block. A click is heard when the terminal is

properly engaged.

b. Gently tug on the wire to verify that the terminal is

locked in place and will not back out of the chamber.

2. Install secondary locks as follows:

a. With the locking wedges positioned above the tangs

in each chamber, slide flat side of secondary lock

into slot (between rows), and push down until it bottoms. See Figure B-22.

3. Install system fuses and relay(s) in fuse block. See Section 8.3 SYSTEM FUSES, SYSTEM FUSES/RELAYS,

INSTALLATION.

480 METRI-PACK SERIES

General

Use the following instructions to service the B+ connector.

Figure B-22. Remove Secondary Locks From Fuse Block

Figure B-23. Fuse Block (FLTR, FLHTC/U)

Disassembly

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

Always disconnect the negative battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion, which could result in death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

Appendix B B-17

Page 18

HOME

f2250x8x

B+ Connector

Figure B-24. Remove Seat

3. Unthread bolt and remove battery positive cable (red)

from battery positive (+) terminal.

4. Using a T40 TORX drive head, loosen bolt to move lip of

hold-down clamp off edge of battery. Remove battery

from battery box.

5. Cut anchored cable strap to release accessory connector and B+ connector from left side of frame crossmember (in front of battery box). See Figure B-24.

6. Using small flat blade screwdriver, depress button on pin

housing (red wire) side of the connector and pull apart

the pin and socket halves. See A of Figure B-25.

7. Bend back the latch slightly and free one side of secondary lock, then repeat the step to release the other side.

Rotate the secondary lock outward on hinge to access

terminal in chamber of connector housing. See B of Fig-

ure B-25.

8. On the mating end of the connector, note the tang in the

square shaped opening centered next to the terminal.

Gently insert the point of a stick pin or large safety pin

into the opening between the tang and the chamber wall

until it stops. Pivot the end of the pin toward the terminal

body to depress the tang. Remove the pin and then pull

terminal out wire end of connector housing. See C of

Figure B-25.

9. If necessary, crimp new terminals on wires. See Crimp-

ing Instructions at the end of this section.

2. With the tang on the same side as the square shaped

opening in the mating end of the connector housing,

feed terminal into wire end of connector housing until it

“clicks” in place.

3. Verify that terminal will not back out of the chamber. A

slight tug on the cable will confirm that it is locked.

4. Rotate the hinged secondary lock inward until latches

fully engage tabs on both sides of connector housing.

5. Mate pin and socket halves of connector.

6. Install

7. Place battery in battery box, terminal side forward.

f2258x8x

f2259x8x

new

anchored cable strap in lower hole on left

side of frame crossmember (in front of battery box).

Tighten cable strap to capture conduit of both accessory

connector and B+ connector approximately one inch

from connector housings. See Figure B-25.

A

B

Assembly

1. Carefully bend the tang outward away from the terminal

body.

B-18 Appendix B

f2260x8x

Figure B-25. Remove Socket Terminal

C

Page 19

HOME

1WARNING1WARNING

Always connect the positive battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion, which could result in death or serious injury.

8. Insert bolt through battery positive cable (red) into

threaded hole of battery positive (+) terminal. Tighten

bolt to 60-96

9. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

10. Rotate hold-down clamp so that the lip (with rubber pad)

rests on the edge of the battery. Using a T40 TORX drive

head, tighten the clamp bolt to 15-20 ft-lbs (20-27 Nm).

11. Install seat. See Section 2.24 SEAT, INSTALLATION.

in-lbs

(6.8-10.9 Nm).

in-lbs

(6.8-10.9 Nm).

630 METRI-PACK SERIES

General

Use these instructions to service the following connectors:

●

Main to Interconnect Harness [15]

Ignition Light/Key Switch [33]

●

Assembly

NOTE

For wire location purposes, alpha characters are molded into

the secondary locks of each connector housing.

1. Using a thin flat blade, like that on an X-Acto knife, carefully bend the tang outward away from the terminal body.

2. With the tang facing the chamber wall, push the lead into

the chamber at the wire end of the connector. A click is

heard when the terminal is properly seated.

3. Gently tug on the wire end to verify that the terminal is

locked in place and will not back out of the chamber.

4. Rotate the hinged secondary lock inward until tabs fully

engage latches on both sides of connector.

5. Push the pin and socket halves of the connector

together until the latches “click.”

6. Install connector on barbed anchor or other retaining

device, if present.

800 METRI-PACK SERIES

General

Use the following instructions to service the maxi-fuse holder.

Disassembly

1. Remove connector from barbed anchor or other retaining device, if present.

2. Bend back the external latch slightly and separate pin

and socket halves of the connector.

3. Bend back the latch slightly and free one side of the secondary lock. Repeat the step to unlatch the other side.

4. Rotate the secondary lock outward on hinge to view the

terminals in the chambers of the connector housing. The

locking tang is on the side opposite the crimp tails and

engages a rib in the chamber wall to lock the terminal in

place.

5. Moving to the mating end of the connector, take note of

the small opening on the chamber wall side of each terminal.

6. Insert pick (Snap-on® TT600-3) into opening until it

stops. Pivot the end of the pick toward the terminal to

depress the locking tang.

7. Remove the pick and gently tug on the wire to pull the

terminal from the wire end of the connector. Repeat

steps if the terminal is still locked in place.

8. If necessary, crimp new terminals on wires. See Crimp-

ing Instructions at the end of this section.

Disassembly

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES.

MAXI-FUSE, REMOVAL.

2. Remove socket terminals as follows:

a. Gently pull sides of secondary lock away from

socket housing to disengage slots from tabs on

socket housing. See A of Figure B-26. Free secondary lock from cables and set aside.

b. Ta ke note of the opening on one side of the socket

terminal. Gently insert flat blade of pick (Snap-On

TT600-5) or small screwdriver into opening until it

stops. Pivot the pick toward the terminal body and

hold in position. See B of Figure B-26.

c. Tug on cable to pull socket from wire end of socket

housing. A firm tug is necessary to overcome the

resistance of the rubber seal.

d. Repeat steps 2(b) and 2(c) to remove remaining

socket terminal.

3. If necessary, crimp new terminals on wires. See Crimp-

ing Instructions at the end of this section.

Appendix B B-19

Page 20

HOME

A

B

Tab

f2245x8x

Secondary

Lock

f2244x8x

d. Repeat steps 1(a) thru 1(c) to install remaining

socket terminal.

e. Install secondary lock onto cables and then push

onto wire end of socket housing until slots engage

tabs on sides of socket housing.

2. Install maxi-fuse. See Section 8.3 SYSTEM FUSES.

MAXI-FUSE, INSTALLATION.

PACKARD MICRO 64

General

Use the following instructions to service the speedometer

and tachometer connectors.

Disassembly

1. Bend back the external latches slightly and separate the

pin and socket halves of the connector.

NOTE

To differentiate between the speedometer and tachometer

connectors, note that the speedometer connector has a second length of conduit leading to the odometer reset switch.

C

Figure B-26. Remove Socket Terminals

Assembly

1. Install socket terminals as follows:

a. Carefully bend tang outward away from the terminal

body. See C of Figure B-26.

b. Feed socket into wire end of socket housing until it

“clicks” in place. Verify that socket will not back out

of chamber. A slight tug on the cable will confirm

that it is locked.

c. Push rubber seal into wire end of socket housing.

f2246x8x

2. Locate the head of the secondary lockpin on one side of

the connector housing. See Figure B-28.

3. Insert the blade of a small screwdriver between the center ear of the lockpin and the connector housing and

gently pry out lockpin. When partially removed, pull lockpin from connector housing.

4. Obtain the Packard Micro 64 Terminal Remover (HD-

45928). See Figure B-27. Proceed as follows:

a. Locate small hole between terminals on mating end

of connector. See Figure B-28.

b. Push the adjacent terminals all the way into the con-

nector housing and then insert tool into hole until it

bottoms. See upper frame of Figure B-29.

Figure B-27. Packard Micro 64 Terminal Remover

(Part No. HD-45928).

B-20 Appendix B

Page 21

HOME

Small

f2202x8x

Hole

Secondary

1

6

Lockpin

23456

1

8

7

10

9

7

12

11

12

Figure B-28. Mating End of Connector

f2196x8x

f2197x8x

Figure B-29. Insert Tool and Remove Terminal

NOTE

For wire location purposes, the corners of the socket housing

are stamped with the numbers 1, 6, 7 and 12, representing

terminals 1-6 on one side, and 7-12 on the other. See Figure

B-28.

2. Bottom the terminal in the chamber and then gently tug

on the wire to verify that it is locked in place.

NOTE

Once the terminal is removed it may not lock in place when

first reinstalled. Until the lock engages, move the terminal

back and forth slightly while wiggling the lead.

3. Since the terminal remover tool releases two terminals

simultaneously, repeat step 2 on the adjacent terminal

even if it was not pulled from the connector housing.

4. With the center ear on the head of the secondary lockpin

facing the mating end of the connector, push lockpin in

until head is flush with the connector housing.

5. Push the pin and socket halves of the connector

together until the latches “click.”

Crimping Instructions

1. Strip lead removing 1/8 inch (3.0 mm) of insulation.

2. Obtain the Packard Micro 64 Terminal Crimper (HD-

45929). See Figure B-30.

3. Squeeze the handles to cycle the tool to the fully open

position.

4. Obtain

5. Raise locking bar and barrel holder by pushing up on

6. With the crimp tails facing upward, insert contact

7. Release locking bar to lock position of contact. When

new

contact (socket terminal). Verify that contact

and crimp tails are not bent or deformed.

bottom tab with index finger. See Figure B-31.

through locking bar into front hole in barrel holder (20-22

gauge wire).

correctly positioned, the locking bar fits snugly in the

space at the front of the core crimp tails and the closed

side of the terminal rests on the outer nest of the crimp

tool. See Figure B-32.

c. Leaving the tool installed, gently tug on wires to pull

either one or both terminals from wire end of connector. See lower frame of Figure B-29. Remove

tool.

5. If necessary, crimp new terminals on wires. See Crimp-

ing Instructions on this page.

Assembly

1. Insert terminal into its respective numbered chamber on

wire end of connector. No special orientation of the terminal is necessary.

Figure B-30. Packard Micro 64 Terminal Crimper

(Part No. HD-45929)

Appendix B B-21

Page 22

HOME

11. Inspect the quality of the core and insulation crimps. Distortion should be minimal.

PACKARD 100W

General

Use the following instructions to service the ECM connector.

f2198x8x

Figure B-31. Raise Locking Bar and Barrel Holder

f2199x8x

Locking

Bar

Figure B-32. Position Contact in Crimper

Barrel

Holder

Disassembly

1. Gently depress latch on each side of the clear plastic

secondary lock and remove. For best results, release

one side at a time, See Figure B-34.

2. Carefully cut cable strap to free strain relief collar from

conduit.

3. Using a thin blade, gently pry at seam at back of socket

housing to release three plastic pins from slots in housing. Separate and spread halves of socket housing. See

Figure B-35.

4. Push on selected wire to free terminal from chamber.

See Figure B-36.

5. If necessary, crimp new terminals on wires. See Crimp-

ing Instructions on the next page.

f2062x8x

1

2

7

3

f2201x8x

Figure B-33. Crimp Terminal Onto Wire

8. Insert wires between crimp tails until ends make contact

with locking bar. Verify that wire is positioned so that

wide pair of crimp tails squeeze bare wire strands, while

the narrow pair folds over the insulation material.

9. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete. See Figure B-33.

10. Raise locking bar and barrel holder to remove contact.

B-22 Appendix B

6

5

1. Latch

2. Rib

3. Secondary Lock

4. Strain Relief Collar

Figure B-34. Remove Secondary Lock

2

1

4

5. Conduit

6. Cable Strap

7. External Latch

Page 23

HOME

1-5 A-E F-G

Packard 270

(HD-38125-6)

Packard 271

(HD-38125-7)

Packard 115

(HD-38125-8)

Sealed

Terminals

Non-Sealed

Terminals

Non-Sealed

Terminals

Butt Splices*

*

See Appendix B.5 SEALED BUTT SPLICE CONNECTORS.

Packard Terminal Crimp Dyes (Nests)

Figure B-35. Separate Halves of Socket Housing

Pins

f2063x8x

Crimping Instructions

1. Strip wire lead removing 5/32 inch (4.0 mm) of insulation.

2. Compress handles until ratchet automatically opens.

NOTE

Always perform core crimp before insulation/seal crimp.

3. See Figure B-37. Determine the correct dye or nest for

the core crimp.

4. Position the core crimp on the appropriate nest. Be sure

the core crimp tails are facing the forming jaws.

5. Gently apply pressure to handles of tool until crimpers

just secure the core crimp tails.

6. Insert stripped wire between crimp tails. Verify that wire

is positioned so that short pair of crimp tails squeeze

bare wire strands, while long pair is positioned over the

insulation or seal material.

7. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete.

8. See Figure B-37. Determine the correct dye or nest for

the insulation/seal crimp.

Figure B-36. Push Wire to Extract Terminal

Assembly

1. From inside socket housing, gently pull on wire to draw

terminal into chamber. See Figure B-36.

2. Exercising caution to avoid pinching wires, press halves

of socket housing together until three plastic pins fully

engage slots in housing. See Figure B-35.

3. Install

4. With the two ribs on the secondary lock on the same

new

cable strap in groove of strain relief collar

capturing cable conduit. See Figure B-34.

side as the external latch, install over terminals until

latches lock in place.

f2064x8x

Figure B-37. Packard Terminal Crimp Tools

Appendix B B-23

Page 24

HOME

Seal

SEALED TERMINAL

Core Crimp

Seal Crimp

9. Position the insulation/seal crimp on the appropriate

nest. Be sure the insulation/seal crimp tails are facing

the forming jaws.

10. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete.

11. Inspect the quality of the core and insulation/seal

crimps. Distortion should be minimal. See Figure B-38.

f1006a8x

Insulation

Crimp

Core Crimp

f1005a8x

Insulation

NON-SEALED TERMINAL

Figure B-38. Inspect Core and Insulation/Seal Crimps

B-24 Appendix B

Page 25

HOME

8821

AUTOFUSE ELECTRICAL CONNECTOR B.4

General

Use these instructions to service the following connector:

●

HDI Ignition Light/Key Switch Jumper Harness [33D]

Disassembly

1. Obtain terminal pick (Snap-on® GA500A) like that

shown Figure B-39.

2. Insert smallest pair of pins into chamber on mating end

of socket housing to depress tangs on each side of terminal simultaneously.

3. Gently pull on wire to remove terminal from wire end of

socket housing.

4. If necessary, crimp new terminals on wires.

Figure B-39. Depress Tangs and Remove Terminal

Assembly

1. Using a thin flat blade, like that on an X-Acto knife, carefully bend tang on each side of terminal outward away

from terminal body.

2. With the open side of the terminal facing rib on wire end

of socket housing, insert terminal into chamber until it

locks in place.

Appendix B B-25

Page 26

HOME

SEALED BUTT SPLICE CONNECTORS B.5

PROCEDURE

Butt splicing may be a necessary procedure for the replacement of some components. Proceed as follows:

1. Strip 3/8 inch (9.5 mm) of insulation off the ends of the

wires.

2. Compress the handles of the Packard Crimp Tool (HD38125-8) until the ratchet automatically opens.

3. Since the size of the connectors vary with the gauge of

the wire, reference the following table to ensure properly

sealed splices are used.

Gauge

Wire

18-20 Red P/N 70585-93

14-16 Blue P/N 70586-93

10-12 Yellow P/N 70587-93

4. Determine the correct dye or nest for the crimping operation. Match the color or gauge wire marked on the butt

splice connector with the corresponding crimp cavity on

the crimp tool. See Figure B-40.

5. Gently apply pressure to the handles until the crimper

lightly secures one side of the metal insert inside the butt

splice connector. The connector must be crimped in two

stages, one side and then the other.

6. See Figure B-41. Feed the wire into the butt splice connector until the stripped end contacts the wire stop

inside the metal insert.

7. Squeeze the handles of the crimp tool until tightly

closed. The tool automatically opens when the crimping

se-quence is complete.

Connector

Color

Part

Number

8. Repeat steps 5-7 on the other side of the butt splice connector.

NOTE

If adjacent wires are being spliced, stagger the splices so

that the butt splice connectors are spaced at different positions along the length of the wires.

9. Using the UltraTorch UT-100 (HD-39969), Robinair Heat

Gun (HD-25070) with heatshrink attachment (HD-

41183) or other suitable radiant heating device, heat the

crimped splice to encapsulate the butt splice connection.

Apply heat from the center of the crimp out to each end

until the meltable sealant exudes out both ends of the

connector. See Figure B-41.

Red

Blue

Yellow

Figure B-40. Packard Crimp Tool (HD-38125-8)

Wire

Stop

Insert stripped wire

ends into connector

f1203b8x

B-26 Appendix B

Metal

Insert

Crimp wire ends

in connector

Figure B-41. Installing Sealed Butt Splice Connectors

Melted Sealant

Apply heat and allow

connector to cool

Page 27

HOME

1WARNING1WARNING

Use extreme caution when operating the UltraTorch UT100 or any other radiant heating device. Read the manufacturers instructions carefully before use. Always keep

hands away from tool tip area and heat shrink attachment. Avoid directing the heat toward any fuel system

component. Extreme heat can cause fuel ignition/explosion. Avoid directing heat toward any electrical system

component other than the connectors on which heat

shrink work is being performed. Be sure to turn the “ON/

OFF” switch to the “OFF” position after use. Inadequate

safety precautions could result in death or serious

injury.

NOTE

It is acceptable for the splice to rest against the heat shrink

tool attachment.

10. Heat the center of the splice until the crimp indentations

disappear and the tubing assumes a smooth cylindrical

appearance.

Appendix B B-27

Page 28

HOME

AMP ELECTRICAL CONNECTORS B.6

1-PLACE CONNECTOR

The 1-place Amp MATE-N-LOK connector can be found on

some Touring models.

SOCKET TERMINAL

Removal

1. Bend back the ears on the pin housing slightly and separate the pin and socket halves of the connector.

2. Grasp the lead on the wire end of the socket housing

and push the terminal forward toward the mating end of

the connector until it stops. This will disengage the locking tang from the groove in the connector.

3. Fit the barrel of the Amp Socket Terminal Remover (HD39621-27) over the socket, and while rotating the tool

slightly, push until it bottoms in the housing. Allow the

plunger to “back out” of the handle. See Figure B-42.

Install Socket Terminal Remover

A

4. Holding the socket housing while keeping the tool firmly

bottomed, depress the plunger. The terminal pops out

the wire end of the connector.

NOTE

If the terminal is not released from the socket housing, then

the terminal was not pushed forward far enough before

placement of the tool or the tool was not bottomed in the connector housing.

Installation

1. Note the lip at the middle of the socket housing. One

side of the lip is flat while the other side is tapered. Insert

the wire terminal into the socket housing on the flat lip

side.

2. Push the lead into the socket housing until it stops. A

click is heard when the terminal is properly seated.

3. Gently tug on the lead to verify that the terminal is locked

in place.

4. Push the pin and socket halves of the connector

together until the latches “click.”

Socket

Housing

Lip

Depress Plunger

B

Figure B-42. Remove Terminal from Amp Socket Housing

Amp Socket

Terminal Remover

(HD-39621-27)

Plunger

f1364x8x

PIN TERMINAL

Removal

1. Bend back the ears on the pin housing slightly and separate the pin and socket halves of the connector.

2. Grasp the lead on the wire end of the pin housing and

push the terminal forward toward the mating end of the

connector until it stops. This will disengage the locking

tang from the groove in the connector.

3. Fit the barrel of the Amp Pin Terminal Remover (HD39621-28) over the pin, and while rotating the tool

slightly, push until it bottoms in the housing. Allow the

plunger to “back out” of the handle. See Figure B-43.

4. Holding the pin housing while keeping the tool firmly bottomed, depress the plunger. The terminal pops out the

wire end of the connector.

NOTE

If the terminal is not released from the pin housing, then the

terminal was not pushed forward far enough before placement of the tool or the tool was not bottomed in the connector

housing.

B-28 Appendix B

Page 29

HOME

Installation

A

Install Pin Terminal Remover

Pin

Housing

Depress Plunger

B

Figure B-43. Remove Terminal from Amp Pin Housing

Amp Pin

Terminal Remover

(HD-39621-28)

Plunger

f1366x8x

1. Push the lead into the pin housing until it stops. A click is

heard when the terminal is properly seated.

2. Gently tug on the lead to verify that the terminal is locked

in place.

3. Push the pin and socket halves of the connector

together until the latches “click.”

Appendix B B-29

Page 30

HOME

ELECTRICAL CONNECTOR LOCATIONS B.7

FLHT/C/U WIRE HARNESS CONNECTORS

No. Description Type Location Fig.

[1] Main to Interconnect Harness 12 - Place Deutsch (Black) Inner Fairing - Right Fairing Bracket 44

[2] Main to Interconnect Harness 12 - Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace 44

[4] Accessory 4 - Place Deutsch Upper Frame Cross Member (Under Seat) 49

[5] Maxi-Fuse 2 - Place Packard Under Left Side Cover 46

[6] Audio to Interconnect Harness 3 - Place Deutsch (Black) Inner Fairing - Back of Radio 44

[7] Rear Fender Lights Harness 8 - Place Multilock Top of Rear Fender (Under Seat) 52

[8] Ignition Harness (EFI Harness on Fuel Injected Models) 12 - Place Deutsch (Gray) Under Right Side Cover 48,51

[10] Ignition Control Module **** 12 - Place Deutsch (Black) Under Right Side Cover 51

[12] Tour-Pak Lights 3 - Place Multilock Inside Tour-Pak 45

[13] Fuel Tank Harness 3 - Place Multilock Behind Fuel Tank (Under Seat) 55

[15] Main to Interconnect Harness 4 - Place Packard Inner Fairing - Bottom of Radio (Right Side) 44

[17] Cruise Control Module ** 10 - Place Packard Under Left Side Cover 46

[18] Left Rear Turn Signal 2 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[19] Right Rear Turn Signal 2 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[21] Indicator Lamps 10 - Place Multilock Inner Fairing - Above Radio 44

[22] Interconnect to Right Handlebar Switch Controls 12 - Place Deutsch (Black) Inner Fairing - Fork Stem Nut Lock Plate (Left Side) 44

[24] Interconnect to Left Handlebar Switch Controls 12 - Place Deutsch (Gray) Inner Fairing - Left Fairing Support Brace 44

[27] Radio * 23 - Place Amp (Black) Inner Fairing - Back of Radio (Right Side) 44

[28] Radio ** 23 - Place Amp (Gray) Inner Fairing - Back of Radio (Left Side) 44

[30] Turn Signal/Security Module 12 - Place Deutsch Cavity in Crossmember at Rear of Battery Box (Under Seat) 50

[31] Front Turn Signals 6 - Place Multilock Inner Fairing - Left Fairing Support Brace 44

[32] Front Fender Tip Lamp (DOM) 2 - Place Multilock (Black) Inner Fairing - Below Upper Fork Bracket (Left Side) 44

[33] Ignition/Light Key Switch 4 - Place Packard Inner Fairing - Bottom of Radio (Center) 44

[38] Headlamp Headlamp Connector Inner Fairing -

[39] Speedometer 12 - Place Packard Inner Fairing (Back of Speedometer) 44

[41] Rear Right Speaker/Passenger Controls ** 6 - Place Mini-Deutsch Inside Rear Right Speaker Box -

[42] Rear Left Speaker/Passenger Controls ** 6 - Place Mini-Deutsch Inside Rear Left Speaker Box -

[45] Rear Fender Tip Lamp (DOM) 3 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

Stator 2 - Place Packard Bottom of Voltage Regulator

[46]

[50] CB Antenna Cable ** - Inner Fairing - Back of Radio (Right Side) 44,45

[51] Radio Antenna Cable * - Inner Fairing - Back of Radio (Left Side) 44

[53] Console Pod ** 12 - Place Mini-Deutsch Rear of Battery Box (Under Seat) 50

[64] Fuse Block Packard Under Left Side Cover 46,47

[65] Vehicle Speed Sensor 3 - Place Deutsch Under Right Side Cover (Behind Electrical Bracket) 48

[73] Passing Lamps 2 - Place Multilock (White) Inner Fairing - Below Upper Fork Bracket (Left Side) 44

[75] Cruise Roll-Off Switch Spade Contacts Right Side of Steering Head -

[76] Passenger Headset 7 - Place DIN Below Rear Left Speaker Box -

[77] Voltage Regulator 1 - Place Deutsch Right Lower Frame Tube (Below Transmission Bracket) -

[78] Electronic Control Module (ECM) *** 36 - Place Packard Under Right Side Cover 48

[79] Crankshaft Position (CKP) Sensor 2 - Place Mini-Deutsch Bottom of Voltage Regulator 54

[80] Manifold Absolute Pressure (MAP) Sensor 3 - Place Packard Top of Intake Manifold/Induction Module -

[83] Ignition Coil 4 - Place Packard Below Fuel Tank (Left Side) -

[84] Front Injector *** 2 - Place Packard Below Fuel Tank (Left Side) -

[85] Rear Injector *** 2 - Place Packard Below Fuel Tank (Left Side) -

[87] Idle Air Control (IAC) *** 4 - Place Packard Below Fuel Tank (Right Side) -

[88] Throttle Position Sensor (TP Sensor) *** 3 - Place Packard Below Fuel Tank (Right Side) -

[89] Intake Air Temperature Sensor (IAT Sensor) *** 2 - Place Packard Below Fuel Tank (Right Side) -

54

Continued ...

B-30 Appendix B

Page 31

HOME

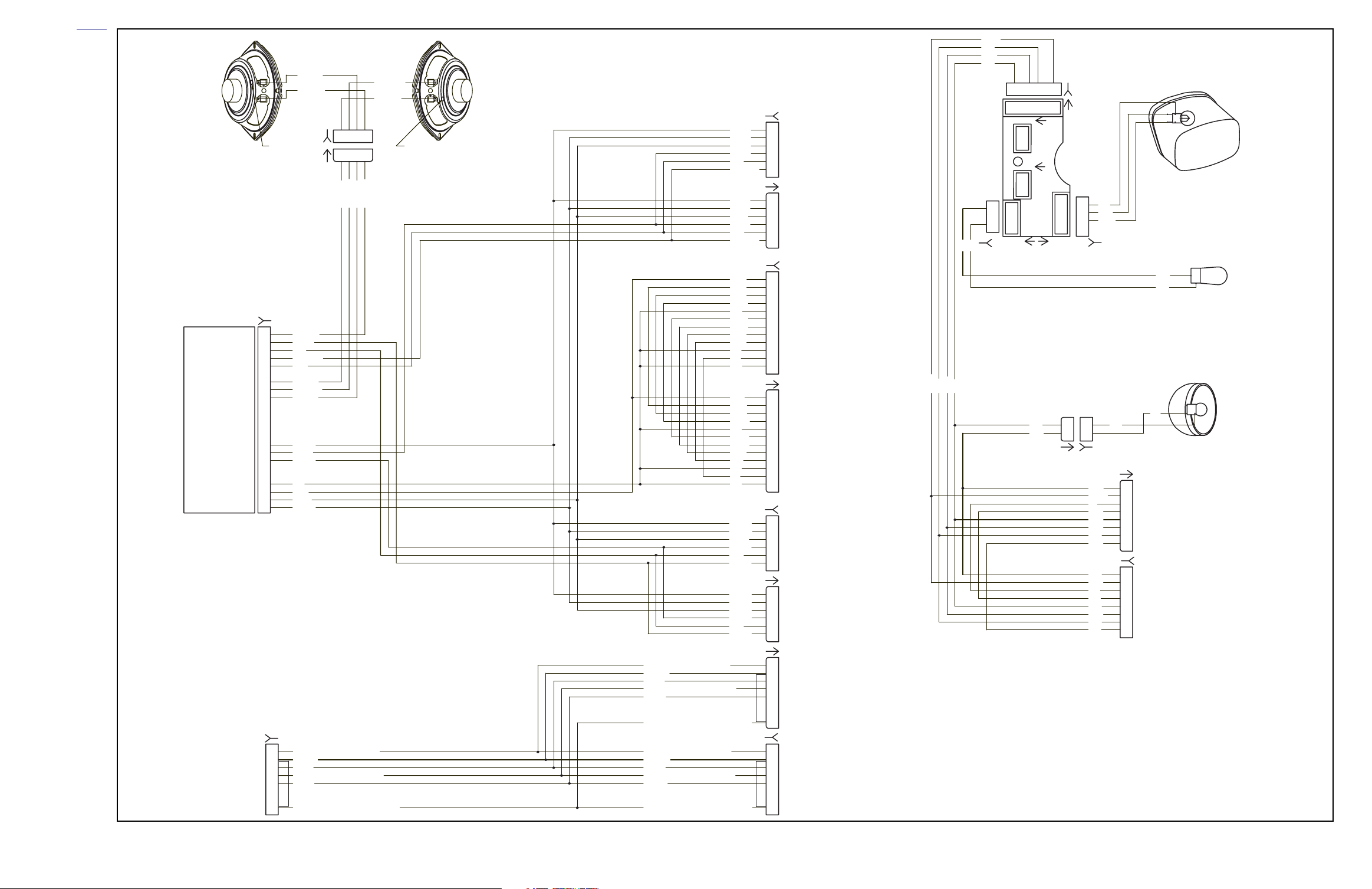

Main to Interconnect

Harness [156]

Main to Interconnect

Harness [15]

Lamps [21]

Tac hometer

Gauge [108]

Indicator

Speedometer

Gauge [39]

Ambient

Temperature

Sensor [107]

Left Handlebar

Switch Controls [24]

Main to Interconnect

Harness [2]

Main to Interconnect

Harness [1]

Radio [27]

Radio [28]

Front Turn

Signals [31]

Radio Antenna

Cable [51]

f2238x8x

Fairing Cap

Switches [105]

CB Antenna

Cable [50]

Ignition

Switch [33]

Right Handlebar

Switch Controls [22]

Lamp [73]

Figure B-44. Inner Fairing Connectors (FLHT/C/U)

Audio to Interconnect

Harness [6]

Front

Fender Tip [32]

Passing

Appendix B B-31

Page 32

HOME

FLHT/C/U WIRE HARNESS CONNECTORS (Continued)

No. Description Type Location Fig.

[90] Engine Temperature Sensor (ET Sensor) *** 2 - Place Packard Back of Front Cylinder (Left Side) -

[91] Data Link 4 - Place Deutsch Under Right Side Cover 48

[93] Tail Lamp 4 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[94] Rear Fender Lights Harness to Circuit Board 6 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[105] Fairing Cap Switches 12 - Place Multilock Inner Fairing - Above Upper Fork Bracket (Right Side) 44

[107] Ambient Air Temperature Sensor * 3 - Place Multilock Inner Fairing - Left Fairing Bracket (Outboard Side) 44

[108] Tachometer 12 - Place Packard Inner Fairing (Back of Tachometer) 44

[110] Voltmeter Lamp Spade Connector Inner Fairing -

[111] Voltmeter Spade Connector Inner Fairing -

[112] Oil Pressure Gauge Lamp Spade Connector Inner Fairing -

[113] Oil Pressure Gauge Spade Connector Inner Fairing -

[114] Air Temperature Gauge Lamp Spade Connector Inner Fairing -

[115] Air Temperature Gauge Spade Connector Inner Fairing -

[116] Fuel Gauge Lamp Spade Connector Inner Fairing -

[117] Fuel Gauge Spade Connector Inner Fairing -

[119] EFI Fuses *** Fuse Terminals Fuse Block (Under Right Side Cover) 48

[121] Rear Brake Light Switch Spade Terminals Beneath Transmission (Right Side) -

[122] Horn Spade Terminals Between Cylinders (Left Side) -

[123] Starter Relay Relay Connector Rear of Battery Box (Under Seat) - Left Side 50

[124] Brake Light Relay Relay Connector Fuse Block (Under Left Side Cover) 47

[126] Ignition Keyswitch Relay Relay Connector Rear of Battery Box (Under Seat) - Left Side 50

[128] Starter Solenoid Spade Terminals Top of Starter -

[129] Harness Grounds Ring Terminals Upper Frame Cross Member (Under Seat) 49

[131] Neutral Switch Post Terminals Transmission Top Cover -

[132] Cigarette Lighter * Spade Terminals Inner Fairing -

[135] EFI System Relay *** Relay Connector Fuse Block (Under Right Side Cover) 48

[139] Oil Pressure Sender 4 - Place Packard Front Right Crankcase -

[141] Fuel Level Sender (and Fuel Pump on EFI models) 3 - Place Mini-Deutsch Top of Canopy (Under Console) -

[142] Security Siren (Optional) 3 - Place Packard Under Right Side Cover (Behind Electrical Bracket) 48

[156] Main to Interconnect Harness 6 - Place Deutsch Inner Fairing - Right Fairing Support Brace 44

[160] B+ 1 - Place Packard Upper Frame Cross Member (Under Seat) 49

* Classic and Ultra ** Ultra Only *** Fuel Injected Models **** Carbureted Models

f1466a2x f1467b2x

Cavity

CB Antenna

Tour-Pak Lights

Connector [12]

LEFT SIDE

RIGHT SIDE

Cable Connector

[50C/D]

Figure B-45. Tour-Pak Connectors

B-32 Appendix B

Page 33

HOME

f1917x9x

*P&A

Security Siren

[142]

Data Link

[91]

Main Harness to

EFI Harness [8]

*Vehicle Speed

Sensor [65]

EFI Fuse

Block

* Under Bracket

Electronic

Control

Module [78]

f2206x8x

Cruise Module

Connector [17]

Spare Fuse

Holder

Cruise Cable

Connector

Fuse Block

Cruise Module

Maxi-Fuse

Holder [5]

f2203x8x

10

11

1

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory*

Figure B-46. Cruise Control Module (Under Left Side Cover)

7

8

9

6

5

4

2

7. Radio Power*

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

3

*Absent from FLHR/C/S models.

Figure B-47. Fuse Blocks - FLTR, FLHTC/U

(Under Left Side Cover)

Figure B-48. Electrical Bracket - Fuel Injected Models

(Under Right Side Cover)

Appendix B B-33

Page 34

HOME

f2250x8x

Main Harness

Ground Ring

Terminals (2)

Main Harness

Ground Ring

Terminals (2)

Chassis

Ground Cable

Fuel Tank Harness

Connector [13]

Not Present on FLHR/C/S

B+ Connector [160]

Starter

Relay [123]

Console Pod [53]

Figure B-49. Electrical Connectors - Upper Frame Cross Member (Under Seat)

Ignition Keyswitch

f2191x8x

Relay [126]

Accessory

Connector [4]

Battery

Positive Cable

Battery

Negative Cable

Turn Signal/Security

Module [30]

f2192x8x

Under Crossmember

Figure B-50. Electrical Connectors/Relays (Under Seat)

B-34 Appendix B

Ignition Control Module

Connector [10]

Figure B-51. Ignition Control Module - Carbureted Models

(Under Right Side Cover)

Page 35

HOME

Crankshaft

Position Sensor

Connector [79]

f2256x8x

Stator

Connector [46]

f1924x8x

Fuel Tank

Fuel Vapor

Vent Tube

To Vapor Valve

Fuel Tank Harness

Connector [13]

Not Present on FLHR/C/S

f2013x8x

Rear Fender

Lights Connector [7]

Fender Tip

Lamp [45]

Tail Lamp

[93]

Figure B-52. Rear Fender (Under Seat)

Right Turn

Signal Lamp

[19]

Left Turn

Signal Lamp

[18]

Fender Lights

Harness to

Circuit Board

Figure B-54. Voltage Regulator (Left Side View)

[94]

f2172x8x

Figure B-53. Rear Fender Lights Assembly

Figure B-55. Rear of Fuel Tank (Under Seat)

Appendix B B-35

Page 36

HOME

FLHR/C/S WIRE HARNESS CONNECTORS

No. Description Type Location Fig.

[4] Accessory 4 - Place Deutsch Upper Frame Cross Member (Under Seat) 49

[5] Maxi-Fuse 2 - Place Packard Under Left Side Cover 46

[7] Rear Fender Lights Harness 8 - Place Multilock Top of Rear Fender (Under Seat) 52

[8] Ignition Harness (EFI Harness on Fuel Injected Models) 12 - Place Deutsch (Gray) Under Right Side Cover 48,51

[10] Ignition Control Module **** 12 - Place Deutsch (Black) Under Right Side Cover 51

[18] Left Rear Turn Signal 2 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[19] Right Rear Turn Signal 2 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[21] Indicator Lamps 8 - Place Mini-Deutsch Under Console 57

[22] Right Handlebar Controls 6 - Place Deutsch Inside Headlamp Nacelle - Fork Stem Nut Lock Plate (Right Side) 56

[24] Left Handlebar Controls 6 - Place Deutsch Inside Headlamp Nacelle - Fork Stem Nut Lock Plate (Left Side) 56

[30] Turn Signal/Security Module 12 - Place Deutsch Cavity at Rear of Battery Box (Under Seat) 50

[31] Front Turn Signals 6 - Place Multilock Inside Headlamp Nacelle - Fork Stem Nut Lock Plate (Left Side) 56

[32] Front Fender Tip Lamp (DOM) 2 - Place Multilock (Black) Inside Headlamp Nacelle 56

[33] Ignition/Light Key Switch 3 - Place Packard Under Console 57

[38] Headlamp Headlamp Connector Inside Headlamp Nacelle 56

[39] Speedometer 12 - Place Packard Back of Speedometer (Under Console) 57

[45] Rear Fender Tip Lamp (DOM) 3 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

Stator 2 - Place Packard Bottom of Voltage Regulator

[46]

[64] Fuse Block Packard Under Left Side Cover 46,47

[65] Vehicle Speed Sensor 3 - Place Deutsch Under Right Side Cover (Behind Electrical Bracket) 48

[67] Accessory Switch 4 - Place Amp Inside Headlamp Nacelle 56

[73] Passing Lamps 2 - Place Multilock (White) Inside Headlamp Nacelle 56

[75] Cruise Roll-Off Switch ** Spade Contacts Right Side of Steering Head -

[77] Voltage Regulator 1 - Place Deutsch Right Lower Frame Tube (Below Transmission Bracket) -

Continued ...

54

f2212x8x

Right Handlebar

Controls [22]

Passing Lamps

Switch [109]

Used on FLHR/C Only

Cruise Set/Resume

Switch [159]

Used on FLHRC Only

Front Turn

Signals [31]

Passing Lamps [73]

Used on FLHR/C Only

Figure B-56. Headlamp Nacelle Connectors (FLHR/C/S)

Left Handlebar

Controls [24]

Cruise On/Off

Switch [158]

Used on FLHRC Only

Accessory

Switch [67]

Front Fender

Tip Lamp [32]

Used on FLHR Only

Headlamp [38]

B-36 Appendix B

Page 37

HOME

FLHR/C/S WIRE HARNESS CONNECTORS (Continued)

No. Description Type Location Fig.

[78] Electronic Control Module (ECM) *** 36 - Place Packard Under Right Side Cover 48

[79] Crankshaft Position (CKP) Sensor 2 - Place Mini-Deutsch Bottom of Voltage Regulator 54

[80] Manifold Absolute Pressure (MAP) Sensor 3 - Place Packard Top of Intake Manifold/Induction Module -

[83] Ignition Coil 4 - Place Packard Below Fuel Tank (Left Side) -

[84] Front Injector *** 2 - Place Packard Below Fuel Tank (Left Side) -

[85] Rear Injector *** 2 - Place Packard Below Fuel Tank (Left Side) -

[87] Idle Air Control (IAC) *** 4 - Place Packard Below Fuel Tank (Right Side) -

[88] Throttle Position Sensor (TP Sensor) *** 3 - Place Packard Below Fuel Tank (Right Side) -

[89] Intake Air Temperature Sensor (IAT Sensor) *** 2 - Place Packard Below Fuel Tank (Right Side) -

[90] Engine Temperature Sensor (ET Sensor) *** 2 - Place Packard Back of Front Cylinder (Left Side) -

[91] Data Link 4 - Place Deutsch Under Right Side Cover 48

[93] Tail Lamp 4 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[94] Rear Fender Lights Harness to Circuit Board 6 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[108] Optional Tachometer 1 - Place Amp Inside Headlamp Nacelle -

[109] Passing Lamps Switch 4 - Place Amp Inside Headlamp Nacelle 56

[117] Fuel Gauge 4 - Place Multilock Below Fuel Tank (Left Side) -

[119] EFI Fuses *** Fuse Terminals Fuse Block (Under Right Side Cover) 48

[120] Oil Pressure Switch Post Terminal Front Right Crankcase -

[121] Rear Brake Light Switch Spade Terminals Beneath Transmission -

[122] Horn Spade Terminals Between Cylinders (Left Side) -

[123] Starter Relay Relay Connector Fuse Block (Under Left Side Cover) -

[124] Brake Light Relay Relay Connector Fuse Block (Under Left Side Cover) 47

[126] Ignition Keyswitch Relay Relay Connector Rear of Battery Box (Under Seat) - Left Side 50

[128] Starter Solenoid Spade Terminals Top of Starter -

[129] Harness Grounds Ring Terminals Upper Frame Cross Member (Under Seat) 49

[131] Neutral Switch Post Terminals Top of Transmission -

[135] EFI System Relay *** Relay Connector Fuse Block (Under Right Side Cover) 48

[141] Fuel Level Sender (and Fuel Pump on EFI models) 3 - Place Mini-Deutsch Top of Canopy (Under Console) -

[142] Security Siren (Optional) 3 - Place Packard Under Right Side Cover (Behind Electrical Bracket) 48

[158] Left Handlebar Controls (Cruise Switches) ** 2 - Place Deutsch (Gray) Inside Headlamp Nacelle 56

[159] Right Handlebar Controls (Cruise Switches) ** 2 - Place Deutsch (Black) Inside Headlamp Nacelle 56

[160] B+ 1 - Place Packard Upper Frame Cross Member (Under Seat) 49

** FLHRC Only *** Fuel Injected Models **** Carbureted Models

Speedometer

Gauge [39]

f2095x8x

Ignition/Light

Key Switch [33]

Indicator Lights [21]

Figure B-57. Instrument Console Connectors (FLHR/C)

Appendix B B-37

Page 38

HOME

FLTR WIRE HARNESS CONNECTORS

No. Description Type Location Fig.

[1] Main to Interconnect Harness 12 - Place Deutsch (Black) Inner Fairing - Below Radio (Right Side) 59

[2] Main to Interconnect Harness 12 - Place Deutsch (Gray) Inner Fairing - Below Radio (Right Side) 59

[4] Accessory 4 - Place Deutsch Upper Frame Cross Member (Under Seat) 49

[5] Maxi-Fuse 2 - Place Packard Under Left Side Cover 46

[7] Rear Fender Lights Harness 8 - Place Multilock Top of Rear Fender (Under Seat) 52

[8] Ignition Harness (EFI Harness on Fuel Injected Models) 12 - Place Deutsch (Gray) Under Right Side Cover 48,51

[10] Ignition Control Module **** 12 - Place Deutsch (Black) Under Right Side Cover 51

[13] Fuel Tank Harness 3 - Place Multilock Behind Fuel Tank (Under Seat) 55

[15] Main to Interconnect Harness 4 - Place Packard Inner Fairing - Below Radio (Right Side) 59

[17] Cruise Control Module 10 - Place Packard Under Left Side Cover 46

[18] Left Rear Turn Signal 2 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[19] Right Rear Turn Signal 2 - Place Multilock Circuit Board Under Tail Lamp Assembly 53

[21] Indicator Lamps 10 - Place Multilock Inside Instrument Nacelle (Under Bezel) 58

[22] Interconnect to Right Handlebar Switch Controls 12 - Place Deutsch (Black) Inner Fairing - Left Side of Radio Bracket 59

[24] Interconnect to Left Handlebar Switch Controls 12 - Place Deutsch (Gray) Inner Fairing - Left Side of Radio Bracket 59

[27] Radio 23 - Place Amp (Black) Inner Fairing - Back of Radio (Right Side) 59

[30] Turn Signal/Security Module 12 - Place Deutsch (Gray) Cavity at Rear of Battery Box (Under Seat) 50

[31L] Front Turn Signals - Left Side 3 - Place Multilock Inner Fairing - Left Side 59