Page 1

5

HOME

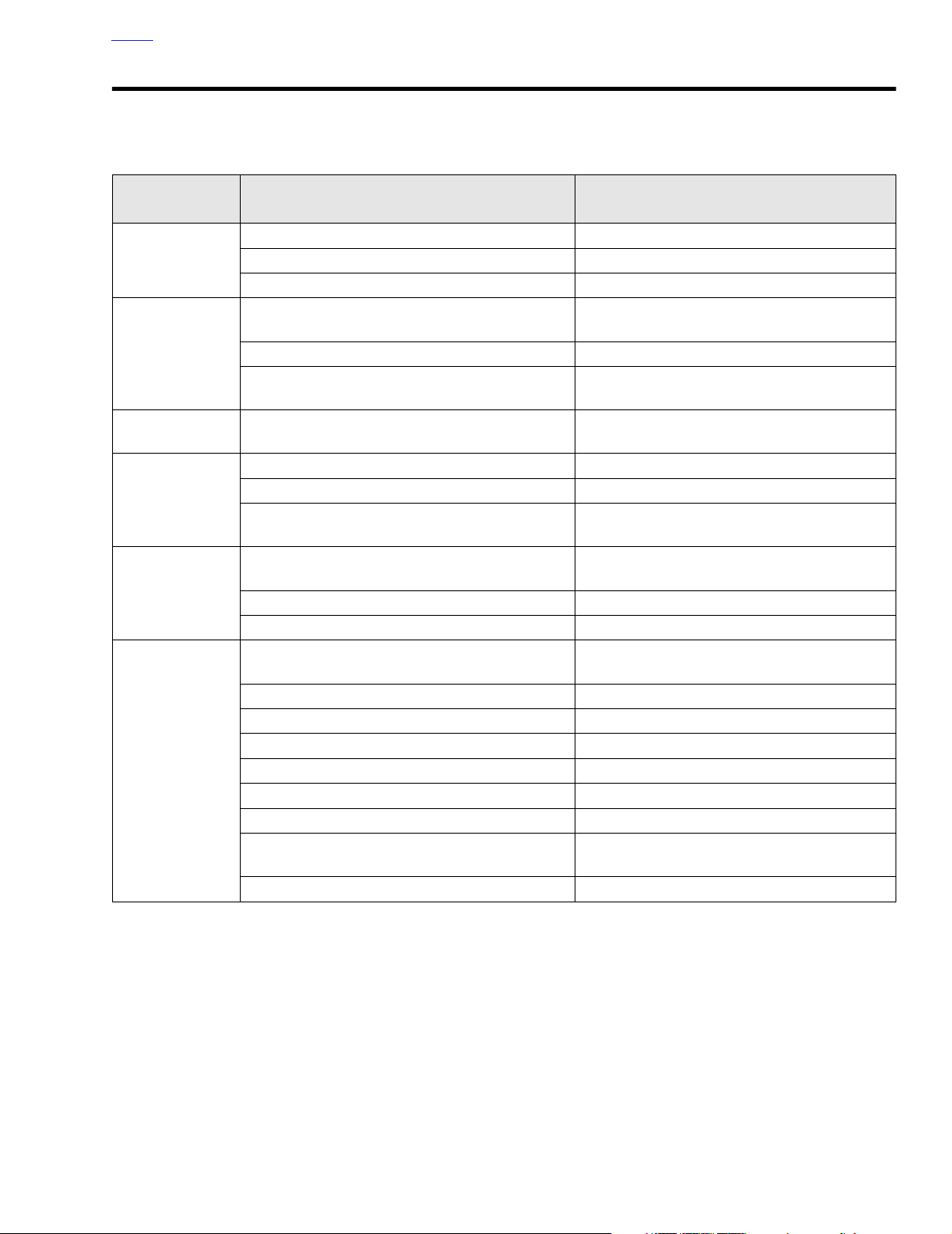

STARTER TROUBLESHOOTING 1.1

Table 1-1. Starter Does Not Run or Runs At Very Low Speeds

SOURCE OF

PROBLEM

Battery

Wiring

Handlebar

start switch

Starter relay

Solenoid

Starting motor

PROBABLE CAUSE SOLUTION

Voltage drop due to discharged battery. Charge battery.

Short-circuited or open between electrodes. Replace battery.

Poor contact condition of battery terminal(s). Clean and retighten.

Poor or no connection at either battery positive or

negative cable, at either end.

Cracked or corroded battery cable ends. Clean, tighten or replace cable(s) as needed.

Open wire(s) or poor connection at handlebar

switch or starter relay, especially relay ground wire.

Poor switch contacts or open switch. Replace switch.

Open coil winding. Replace relay.

Poor or no continuity at relay points. Replace relay.

TSM/TSSM has disabled starter relay.

Poor contact condition caused by burnt contact.

Pull-in winding open or short-circuited. Repair or replace solenoid assembly.

Hold-in winding open or short-circuited. Repair or replace solenoid assembly.

Brushes worn below specification.

Commutator burnt. Re-face or replace.

Commutator high mica. Correct by undercutting.

Field winding grounded. Replace.

Armature winding grounded or short-circuited. Replace.

Reduction gears damaged. Replace.

Insufficient brush spring tension. Replace.

Disconnected lead wire between solenoid and field

windings.

Ball bearing sticks. Replace bearing.

Repair or replace cable(s).

Tighten connections or repair or replace wire(s).

Check for open on wire to TSM/TSSM. Correct

lack of ground.

Polish contact surface or replace solenoid

assembly.

Check brush spring tension. Replace field frame

and holder.

Repair or replace lead wire.

2004 Touring: Starting & Charging 1-1

Page 2

HOME

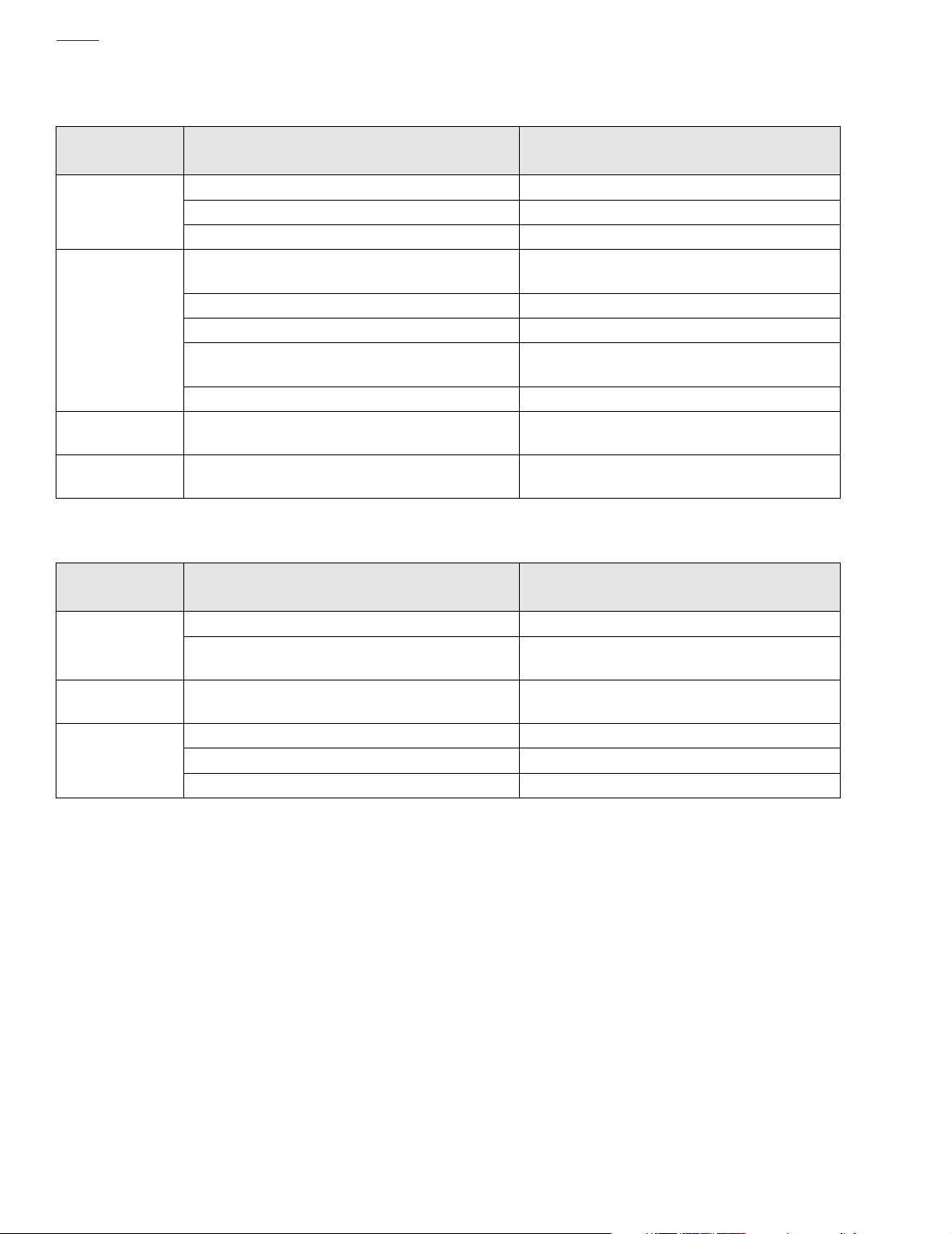

Table 1-2. Pinion Does Not Engage With Ring Gear

While Starter is Cranked or Engine Cannot Be Cranked

SOURCE OF

PROBLEM

Battery

Overrunning

clutch.

Jackshaft

assembly

Gear teeth on

clutch shell

SOURCE OF

PROBLEM

PROBABLE CAUSE SOLUTION

Voltage drop due to discharged battery. Charge battery.

Short-circuited or open between electrodes. Replace battery.

Poor contact condition of battery terminal(s). Clean and retighten.

Overrunning clutch malfunction (rollers or compres-

sion spring).

Pinion teeth worn out. Replace pinion.

Pinion does not run in overrunning direction. Replace overrunning clutch.

Poor sliding condition of spline teeth.

Reduction gears damaged. Replace overrunning clutch and idler gear.

Improper jackshaft parts assembly. Disassemble and assemble parts properly.

Excessively worn teeth. Replace clutch shell.

Replace overrunning clutch.

Remove foreign materials, dirt or replace overrunning clutch or pinion shaft.

Table 1-3. Starter Does Not Stop Running

PROBABLE CAUSE SOLUTION

Starting switch or

starter relay.

Gear teeth on

clutch shell

Solenoid.

Unopened contacts. Replace starting switch or starter relay.

Poor return caused by sticky switch

or relay contacts.

Excessively worn teeth. Replace clutch shell.

Return spring worn. Replace spring.

Coil layer shorted. Replace solenoid.

Contact plate melted and stuck. Replace solenoid.

Replace starting switch or starter relay.

1-2 2004 Touring: Starting & Charging

Page 3

HOME

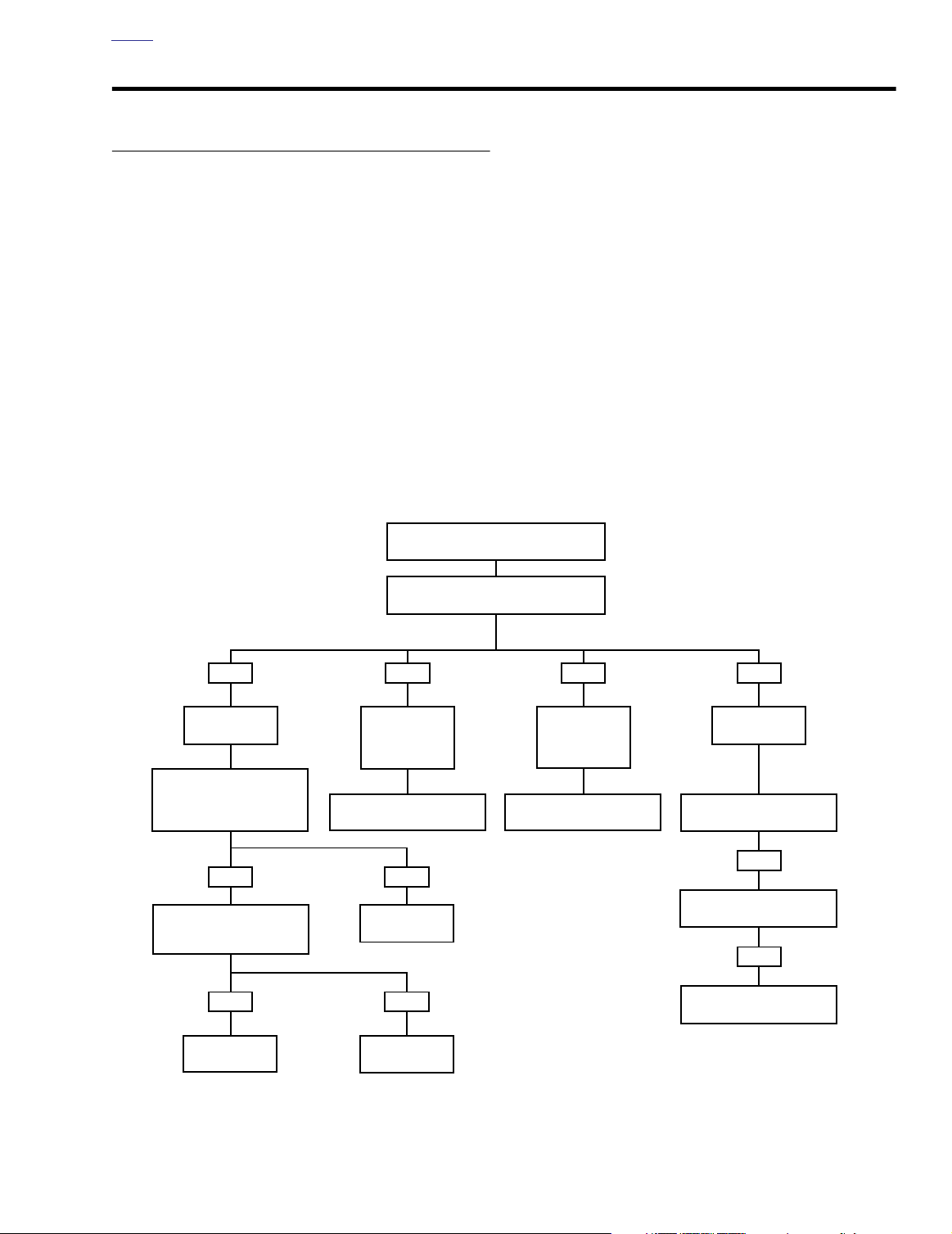

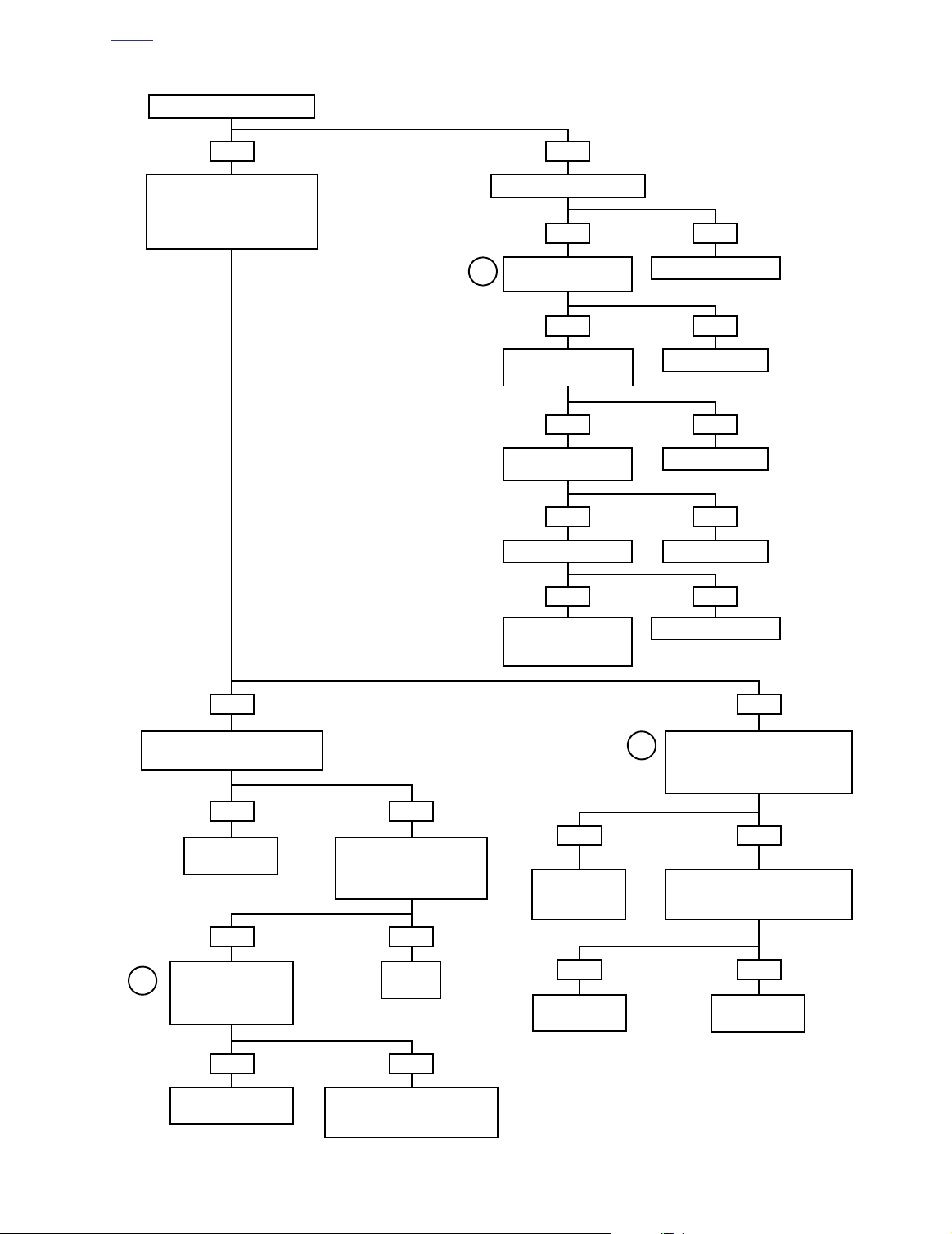

STARTING SYSTEM DIAGNOSIS 1.2

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the starter system flow charts.

1. See Section 1.4 DIAGNOSTICS/TROUBLESHOOTING,

VOLTAGE DROPS.

2. Remove starter motor. Connect jumper wires as

described under Section 1.6 TESTING ASSEMBLED

STARTER, FREE RUNNING CURRENT DRAW TEST.

3. Remove TSSM and use HARNESS CONNECTOR TEST

KIT (Part No. HD-41404) to short Pin 9 on connector [30]

to ground. If starter motor cranks, replace TSSM.

Starter Testing 1

Check battery using visual inspection,

voltage test and load test.

Check connections at battery and starter

components. Is system operational?

4. See Section 1.5 STARTER SYSTEM TESTING,

STARTER CURRENT DRAW TEST.

5. See Section 1.6 TESTING ASSEMBLED STARTER,

FREE RUNNING CURRENT DRAW TEST.

6. Connect BREAKOUT BOX (Part No. HD-42682) to TSM/

TSSM. See BREAKOUT BOX, TSM/TSSM.

7. Connect BREAKOUT BOX (Part No. HD-42682) (black)

and 6-pin Harness Adapters (Part no. HD-42962)

between wiring harness connector [22A] and Right Hand

Control harness connector [22B] (adapters not used on

FLHR/C/S models).

Job/Time Code Values

Dealership technicians filing warranty claims should use the

job/time code values printed in

appropriate repair.

5822

bold text

underneath the

YES

STARTER

RUNS ON.

Disconnect solenoid relay ter-

minal from solenoid. Is 12V

present on GN wire with starter

button not pressed?

YES

Is 12V present on starter relay

Terminal 86 with starter button

not pressed?

YES

Replace

starter button.

YES

STARTER

SPINS, BUT

DOES NOT

ENGAGE.

See Starter Testing 5: Starter

Spins, But Does Not Engage.

NO

Replace

solenoid.

5845

NO

Replace

starter relay.

58325818

YES

STARTER

STALLS OR

SPINS TOO

SLOWLY.

See Starter Testing 6: Starter

Stalls or Spins Too Slowly.

NO

Check for audible

clicking noise.

Solenoid clicks. See Starter

Testing 2: Solenoid Clicks.

OR

Relay clicks. See

Starter Testing 3: Relay Clicks.

OR

Nothing clicks. See Starter

Testing 4: Nothing Clicks.

2004 Touring: Starting & Charging 1-3

Page 4

HOME

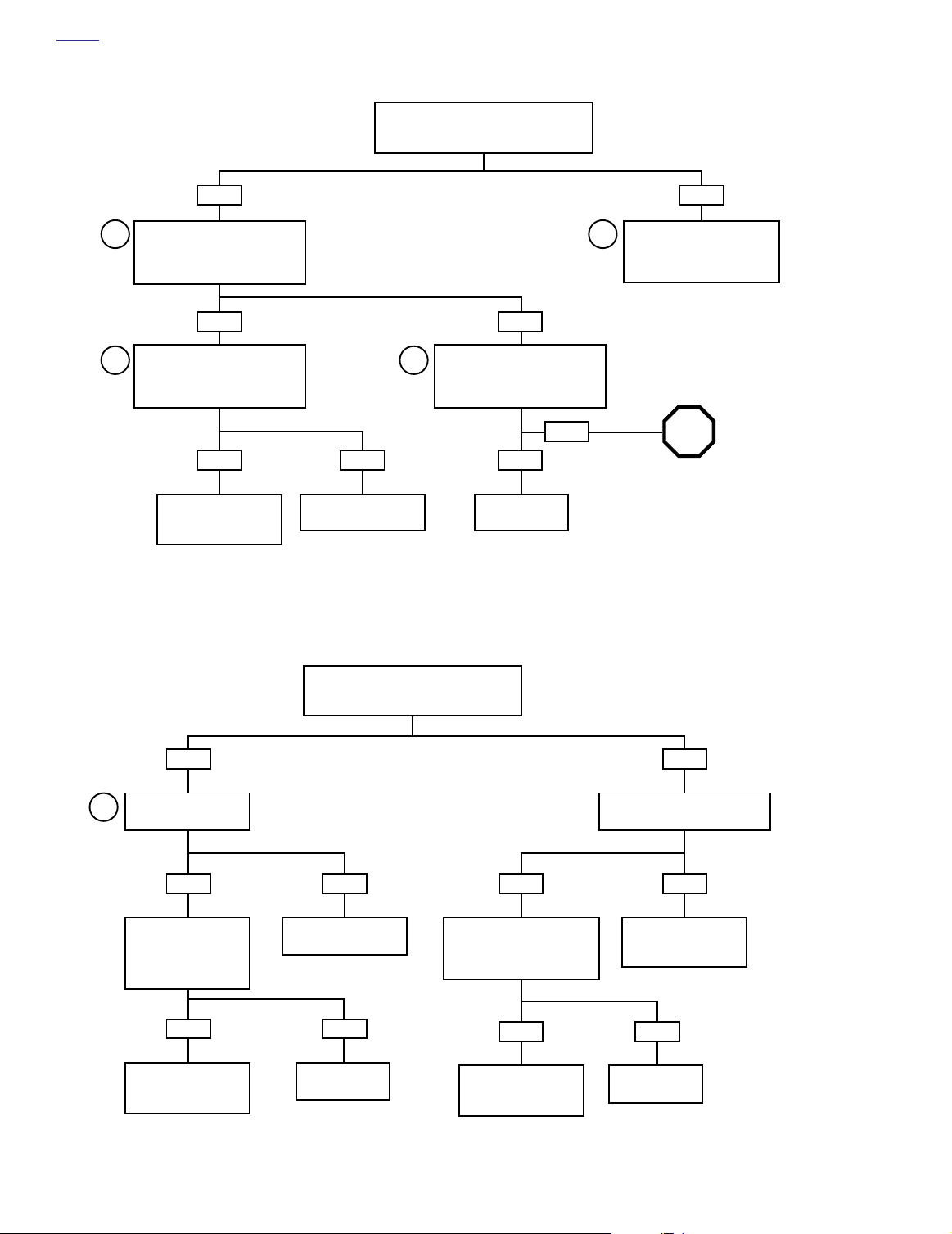

Starter Testing 2: Solenoid Clicks

Perform voltage drop tests between

battery and relay terminal on solenoid.

Less than 1.0 volt?

YES

Perform voltage drop tests from

1

battery positive to starter motor

terminal. Crank engine. Voltage

greater than 1 volt?

YES

Perform voltage drop tests from

1

battery positive to starter battery

terminal. Crank engine. Voltage

greater than 1 volt?

YES

Repair connection

between battery and

starter.

5824

Starter Testing 3: Relay Clicks

NO

Repair or replace

solenoid (contacts).

Perform voltage drop tests

1

between battery negative and

starter studs or bolts. Voltage

greater than 1 volt?

5845

NO

YES

Clean ground

connections.

5824

NO

Backtrack to pinpoint poor

1

connections or relay contact

problems using voltage drop

STOP

Go to Starter Testing 3:

Relay Clicks. Begin with

box marked with bold

asterisk.

NO

tests.

5823

Does starter motor

2

turn if jumped?

Perform solenoid

hold-in, pull-in tests. See

1.6 TESTING ASSEMBLED STARTER.

Solenoid OK?

Mechanical binding or

seal binding on jackshaft

(dirt or corrosion).

YES

YES

YES

5850

*

Test for voltage at solenoid relay terminal

on starter. Is 12V present when

starter button is pressed?

NO

Replace or repair

starter motor.

NO

Replace

solenoid.

5860

5817

Test for voltage from relay.

Is 12V present on relay

Terminal 87 when starter

button is pressed?

GN wire between relay

YES

YES

Repair open on

and solenoid.

Test for voltage to relay. Is 12V

present on relay terminal 30?

Repair open on R/BK

wire feeding Terminal 30

on starter relay.

NO

Replace

starter relay.

5827

NO

NO

5827

5832

1-4 2004 Touring: Starting & Charging

Page 5

HOME

Starter Testing 4: Nothing Clicks

Do turn signals work properly?

NOYES

With ignition switch ON and

starter button depressed, check

for battery voltage from starter

button to relay Terminal 86.

Battery voltage present?

Is Connector [30] fully mated?

YES

Continuity to ground on

6

Pin 12 of TSM/TSSM?

YES

Continuity on Pin 1 to

battery fuse?

YES NO

Continuity on Pin 2 to

Ignition fuse?

YES

Sidecar BAS installed?

YES NO

B1152, B1153.

NO

Mate Connector [30].

6792

NO

Repair open.

6805

Repair open.

6806

NO

Repair open.

6793

Replace TSM/TSSM.See 3.20 DTC B1151,

6791

YES

Check for ground at relay Terminal

85. Ground present?

YES

YES

Substitute good

relay or test relay.

5832

YES

Check for voltage on

3

TSM/TSSM Pin 9 with

key ON. Voltage

present?

YES

Locate and repair

short to voltage.

5830

NO

Check for continuity from relay

Te rminal 85 to Pin 9 on

TSSM connector [30].

Continuity present?

NO

Repair

open.

5828

NO

Replace TSM/TSSM. See 2004

Touring Models Service Manual

(Part Number 99483-04).

5838

YES

Repair wiring

from starter

button to relay.

YES

Replace

starter button.

NO

7

5831

5818 5831

Check for battery voltage from

starter button, terminal 6 (black). Bat-

tery voltage present with starter but-

Check for battery voltage to starter

button, terminal 4 (black). Battery volt-

ton pressed?

NO

age present?

NO

Repair wiring to

starter button.

2004 Touring: Starting & Charging 1-5

Page 6

HOME

Starter Testing 5: Starter Spins, But Does Not Engage

Remove and disassemble starter jackshaft

assembly. Is jackshaft properly assembled?

YES

Remove starter. Disassemble drive housing

assembly. Inspect for damage to armature

gear or idler gear. Damage present?

YES

Replace damaged idler

gear and armature.

5825

Starter Testing 6: Starter Stalls or Spins Too Slowly

Perform voltage drop tests from battery

1

positive to starter motor terminal. Crank

engine. Voltage greater than 1 volt?

YES

NO

Assemble jackshaft

properly.

NO

Starter clutch failure.

Replace starter clutch.

5850

5837

NO

Perform voltage drop tests

1

between battery positive to

starter battery terminal.

Crank engine.

Voltage greater than 1 volt?

Repair connection

between battery and

YES

starter.

5824

NO

Repair or replace

solenoid (contacts).

5845

Remove spark plugs while in

5th gear. Rotate rear wheel.

Check for engine, primary

and/or crankshaft bind.

YES

Clean ground

connections.

5835

YES

Use appropriate code

Perform voltage drop tests

between battery negative and

starter studs or bolts.

Voltage greater than 1 volt?

NO

Perform starter motor current

draw test (on vehicle).

Perform starter motor free draw

bench test.

Are test results within range?

NO

Replace or repair

starter motor.

5817

4

5

1-6 2004 Touring: Starting & Charging

Page 7

HOME

STARTER ACTIVATION CIRCUITS 1.3

s0593x8x

8

7

6

0.1A

20A

1

0.1A

ITEM A

2

0.1A

8

20A

1

0.1A

ITEM B

2

IDEAL CLOSED

CIRCUIT

7

20A

OV

20A

6

VDC

5

200A

200A

1

5

200A

200A

1

43

43

ITEM C ITEM D

0.1A

8

7

6

5

1. Start switch

2. Relay

3. Solenoid

4. Starter

0.1A

20A

12V OV

2

20A

0.1A

8

7

0.1A

20A 20A

VDC

6

VDC

43

200A

Figure 1-1. Typical Circuity. Refer to wiring diagrams for more information.

200A

5. Battery

6. Maxi fuse

7. Ignition switch

8. Ignition fuse

5

200A

2

GROUND CIRCUITOPEN CIRCUIT

43

200A

2004 Touring: Starting & Charging 1-7

Page 8

HOME

DIAGNOSTICS/TROUBLESHOOTING 1.4

GENERAL

The troubleshooting tables beginning on page 1-1 contain

detailed procedures to solve and correct problems. Follow the

1.2 STARTING SYSTEM DIAGNOSIS diagram to diagnose

starting system problems. The VOLTAGE DROPS procedure

below will help you to locate poor connections or components

with excessive voltage drops.

VOLTAGE DROPS

Check the integrity of all wiring, switches, circuit breakers and

connectors between the source and destination.

The voltage drop test measures the difference in potential or the

actual voltage dropped between the source and destination.

1. See ITEM A in Figure 1-1. Attach your red meter lead to

the most positive part of the circuit, which in this case

would be the positive post of the battery.

2. See ITEM B in Figure 1-1. Attach the black meter lead to

the final destination or component in the circuit (solenoid

terminal from relay).

3. Activate the starter and observe the meter reading. The

meter will read the voltage dropped or the difference in

potential between the source and destination.

4. An ideal circuit’s voltage drop would be 0 volts or no voltage dropped, meaning no difference in potential.

5. See ITEM C in Figure 1-1. An open circuit should read

12 volts, displaying all the voltage dropped, and the

entire difference in potential displayed on the meter.

NOTE

Open circuits on the ground side will read zero.

6. Typically, a good circuit will drop less than 1 volt.

7. If the voltage drop is greater, back track through the connections until the source of the potential difference is

found. The benefit of doing it this way is speed.

a. Your readings aren’t as sensitive to real battery volt-

age.

b. Your readings show the actual voltage dropped, not

just the presence of voltage.

c. This tests the system as it is actually being used. It

is more accurate and will display hard to find poor

connections.

d. This approach can be used on lighting circuits, igni-

tion circuits, etc. Start from most positive and go to

most negative (the destination or component).

8. See ITEM D in Figure 1-1. The negative or ground circuit

can be checked as well.

a. Place the negative lead on the most negative part of

the circuit (or the negative battery post). Remember,

there is nothing more negative than the negative

post of the battery.

b. Place the positive lead to the ground you wish to

check.

c. Activate the circuit. This will allow you to read the

potential difference or voltage dropped on the negative or ground circuit. This is very effective for identifying poor grounds due to powdered paint. Even the

slightest connection may cause an ohmmeter to give

a good reading. However, when sufficient current is

passed through, the resistance caused by the powdered paint will cause a voltage drop, or potential

difference in the ground circuit.

1-8 2004 Touring: Starting & Charging

Page 9

HOME

f2192x8x

NOTE

Check the wire tags for positive

identification of relays. Starter

relay can be positively identified

by heavy gauge Green wire.

FLTR, FLHT/C/U

85

O

86

30

87

87A

f1333x2x

Ohmmeter

Battery

Starter

Relay [123]

Ignition Keyswitch

Relay [126]

STARTER SYSTEM TESTING 1.5

GENERAL

Before removing the starter, perform one of the Starter Relay

Te sts which follow. If the relay is known to be good, perform

the STARTER CURRENT DRAW TEST in this section.

STARTER RELAY TEST 1

1. Remove relay. For FLHR/C/S models, see upper frame

of Figure 1-2. For all other models, see upper frame of

Figure 1-3.

2. Substitute a

Relay [123]

new

relay known to be good and verify operation. For convenience, use the brake light relay as a

temporary substitute on FLHR/C/S models, or use the

ignition keyswitch relay as a temporary substitute on

FLTR and FLHT/C/U models.

FLHR/C/S

Brake Light

Relay [124]

Starter

f2210x8x

Figure 1-3. Locate Relay Under Seat

STARTER RELAY TEST 2

f1741x5x

Battery

86

87A

87

30

Ohmmeter

85

Figure 1-2. Locate Relay Under Left Side Cover

The starter relay can be tested using the vehicle’s 12 volt battery and a continuity tester or ohmmeter (HD-35500B). Proceed as follows:

1. Remove relay. For FLHR/C/S models, see upper frame

O

of Figure 1-2. For all other models, see upper frame of

Figure 1-3.

2. To energize the relay, connect the battery leads to terminals 86 and 85. For FLHR/C/S models, see lower frame

of Figure 1-2. For all other models, see lower frame of

Figure 1-3.

3. Check for continuity between terminals 30 and 87.

2004 Touring: Starting & Charging 1-9

Page 10

HOME

4. If the tester lamp illuminates or there is a zero ohm reading on the ohmmeter, then continuity is present and the

relay is good. Replace the relay if continuity is not

present.

CAUTION

Relay terminal “85” must be connected to the negative

battery terminal to avoid damaging the diode connected

across the relay winding.

Induction

Ammeter

STARTER CURRENT DRAW TEST

Check the starter current draw with an inductive amp probe

(HD-39617) or induction ammeter. Before proceeding, be

sure that the battery is fully charged and that the engine temperature is stable and at room temperature.

1. Verify that the transmission is in neutral.

2. Disconnect the spark plug wires from the spark plug terminals.

3. Clamp induction ammeter over the positive battery cable.

See Figure 1-4.

4. With the ignition ON, turn the engine over by pressing

start switch while taking a reading on the ammeter. Disregard initial high current reading which is normal during

time the engine is first turned over.

a. Typical starter current draw will range between 160

and 200 amperes.

Battery

“Battery”

Terminal

Figure 1-4. Starter Current Draw Test

b. If the starter current draw exceeds 250 amperes, the

problem may be in the starter or starter drive.

5. Remove the starter for testing, if necessary. See the

2004 Touring Models Service Manual (Part Number

99483-04), STARTER, REMOVAL.

6. See Section 1.6 TESTING ASSEMBLED STARTER,

FREE RUNNING CURRENT DRAW TEST.

f1334x2x

1-10 2004 Touring: Starting & Charging

Page 11

HOME

b0161a5x

Relay

Terminal

Motor

Terminal

Battery

b0162a5x

Relay

Terminal

Motor

Terminal

Battery

TESTING ASSEMBLED STARTER 1.6

STARTER SOLENOID

1WARNING1WARNING

Wear eye protection during this series of tests. These

tests may produce flying sparks which could result in

death or serious injury.

NOTE

Do not disassemble solenoid. Before testing, disconnect field

wire from motor terminal as shown in Figure 1-5.

CAUTION

Each test should be performed for only 3-5 seconds to

prevent damage to solenoid.

NOTE

The solenoid Pull-in, Hold-in, and Return tests must be performed together in one continuous operation. Conduct all

three tests one after the other in the sequence listed.

SOLENOID PULL-IN TEST

1. See Figure 1-5. Using a 12 volt battery, connect three

separate test leads as follows:

a. Solenoid housing to negative battery post.

b. Solenoid motor terminal to negative battery post.

c. Solenoid relay terminal to positive battery post.

2. Observe starter shaft.

a. If starter shaft extends strongly, solenoid is working

properly.

b. If starter shaft does not extend strongly, replace the

solenoid.

Figure 1-5. Test 1: Pull-In Test

Figure 1-6. Test 2: Hold-In Test

2. Observe starter shaft.

a. If starter shaft remains extended, solenoid is work-

ing properly.

SOLENOID HOLD-IN TEST

1. See Figure 1-6. With test leads still connected in the

manner specified in the previous SOLENOID PULL-IN

TEST, disconnect solenoid motor terminal/battery nega-

tive test lead (B) at negative battery post only; reconnect

loose end of this test lead to positive battery post

instead.

b. If starter shaft retracts, replace the solenoid.

c. If starter shaft does not retract, replace the solenoid.

2004 Touring: Starting & Charging 1-11

Page 12

HOME

SOLENOID RETURN TEST

1. See Figure 1-7. With test leads still connected in the

manner specified at the end of the previous SOLENOID

HOLD-IN TEST, disconnect solenoid relay terminal/posi-

tive battery post test lead (C) at either end.

2. Observe starter pinion.

a. If starter shaft retracts, solenoid is working properly.

b. If starter shaft does not retract, replace the solenoid.

FREE RUNNING CURRENT

DRAW TEST

1. Place starter in vise, using a clean shop towel to prevent

scratches or other damage.

2. Connect a heavy jumper cable (6 gauge minimum) to

starter mounting flange as shown in Figure 1-8.

3. Connect other end to the negative (-) terminal of a fully

charged battery.

4. Connect a heavy jumper cable (6 gauge minimum) to the

positive (+) terminal of the battery.

5. Attach an inductive ammeter to positive cable and connect the other end of the positive cable to the “Battery”

terminal of the starter solenoid.

6. Use a smaller jumper cable (14 gauge) and connect to

the positive (+) terminal of the battery.

7. Connect other end of small jumper cable to the solenoid

“Relay” terminal.

8. Check ammeter reading. Ammeter should show 90 amps

maximum. If reading is higher, disassemble starter for

inspection.

NOTE

If starter current draw on vehicle was over 200 amps and the

starter FREE RUNNING CURRENT DRAW TEST was within

specification, there may be a problem with engine, primary

drive or starter jackshaft.

Relay

Motor

Terminal

Figure 1-7. Test 3: Return Test

b0439x5x

Terminal

1

5

4

1. Mounting flange

2. Battery

3. Induction ammeter

4. Battery terminal

5. Relay terminal

Figure 1-8. Free Running Current Draw Test

b0163a5x

Battery

2

3

1-12 2004 Touring: Starting & Charging

Page 13

HOME

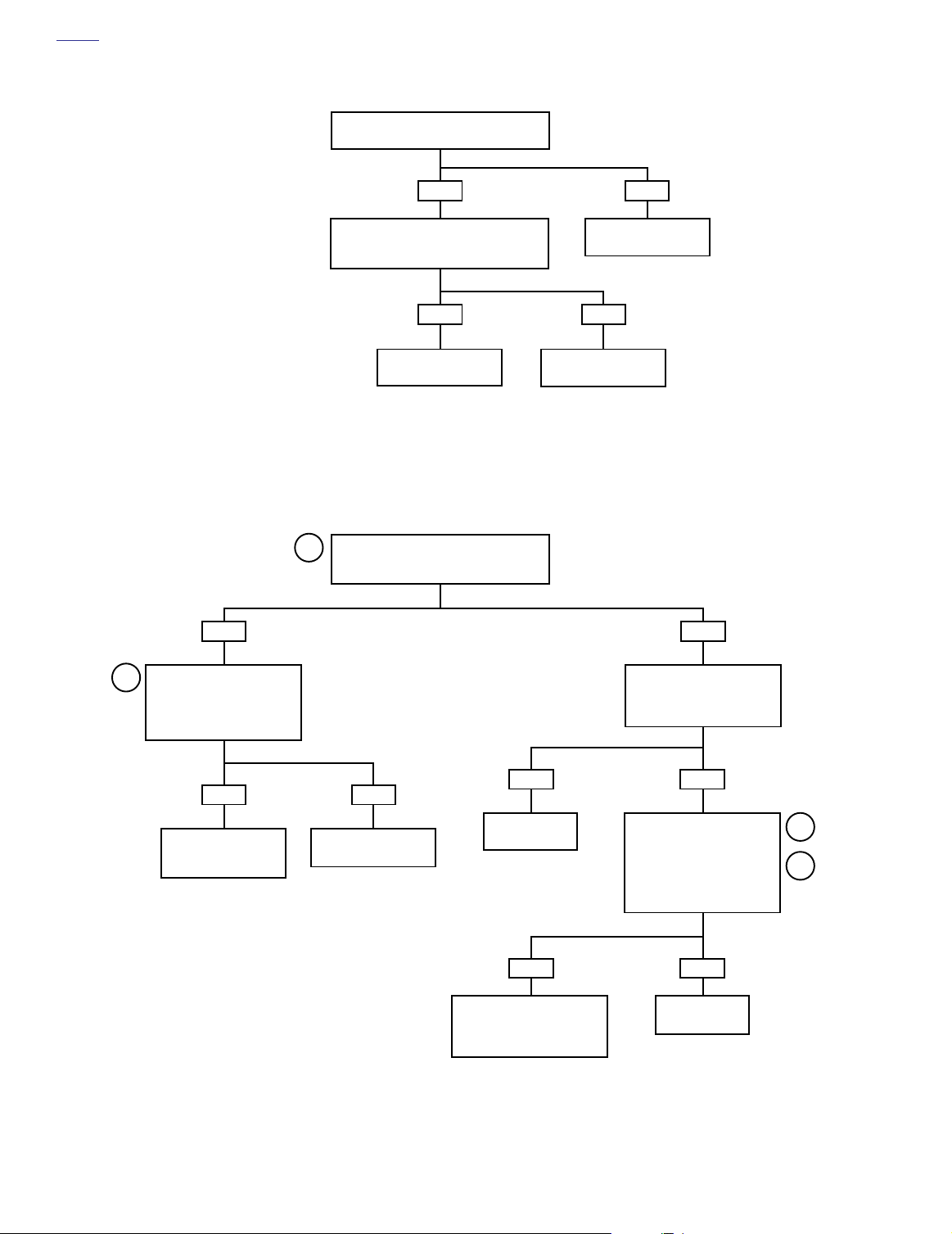

CHARGING SYSTEM 1.7

GENERAL

The charging system consists of the alternator and voltage

regulator. Charging system circuits are shown in Figure 1-9.

Alternator

The alternator consists of two main components: the rotor

which is mounted on the engine sprocket shaft, and the stator

which is bolted to the engine crankcase.

Voltage Regulator

A series regulator with a circuit that combines the functions of

rectifying and regulating.

TROUBLESHOOTING

When the charging system fails to charge or does not charge

at a satisfactory rate, it is recommended that the following

checks be made.

VOLTAGE

REGULATOR

+

DC AC

-

[46A]

BK

BK

Battery

Check for a weak or dead battery. Battery must be fully

charged in order to perform any electrical tests. Under certain

operating conditions, battery icon may illuminate if battery

voltage is out of range.

Wiring

See charging system circuit in Figure 1-9. Check for corroded

or loose connections.

Voltage Regulator Inspection

The regulator must have a clean, tight ground connection for

proper operation. Check by using an ohmmeter with one lead

on the battery ground cable and the other on the regulator

ground terminal (on right side transmission exhaust bracket)

Job/Time Code Values

Dealership technicians filing warranty claims should use the

job/time code values printed in

appropriate repair..

[46B]

A

A

B

B

BK

BK

bold text

STATOR

underneath the

BK

POWERTRAIN

GROUND

BK

MAXIFUSE

40 A

B A

[77B]

BK

BATTERY

[77A]

R

BK

STARTER

Figure 1-9. Charging System Circuit (Typical)

R

f2227p8x

2004 Touring: Starting & Charging 1-13

Page 14

HOME

Test 1.7 (Part 1 of 2)

SYMPTOM: BATTERY BECOMES DISCHARGED

Charge or replace as required.

See Voltage Regulator Inspection.

Test battery.

Inspect regulator.

PASS

Perform MILLIAMP DRAW

TEST (If applicable).

Perform TOTAL CURRENT

DRAW TEST.

Record measurement.

STOP

Go to Test 1.7

(Part 2 of 2).

FAIL

Correct as

required.

5306

FAILPASS

Isolate damaged

component or wiring.

5308

FAILPASS

Isolate damaged wiring or

excessive accessories.

5310

Whenever a charging system component fails a test and

is replaced, retest the system to be sure the problem has

been corrected.

1-14 2004 Touring: Starting & Charging

NOTE

Page 15

HOME

Test 1.7 (Part 2 of 2)

SYMPTOM: BATTERY BECOMES DISCHARGED

Perform CURRENT OUTPUT TEST. Record

measurement and compare with TOTAL CUR-

RENT DRAW TEST before proceeding.

From Test 1.7 (Part 1 of 2).

FAILPASS

Perform VOLTAGE

OUTPUT TEST.

System tests good up to this point. Suspect:

Accessories on for long periods when vehicle is

parked and not running.

Accessories on when vehicle is ridden very slowly

for long periods.

Battery self-discharge and/or accessory draw

because vehicle was not operated for a long

period.

FAILPASS

Replace

Regulator.

PASS

System

OK.

5316

Perform

AC OUTPUT CHECK.

Replace Regulator.

Perform CURRENT

OUTPUT TEST.

5315

FAIL

Damaged or

Slipping Rotor.

5319

Perform

STATOR CHECK.

PASS

Replace

Stator.

FAILPASS

Replace

Stator.

Inspect Rotor.

Replace

Rotor.

5312

FAILPASS

FAIL

53195314

NOTE

Whenever a charging system component fails a test and

is replaced, retest the system to be sure the problem has

been corrected.

2004 Touring: Starting & Charging 1-15

Page 16

HOME

TESTING

MILLIAMP DRAW TEST

NOTES

Be sure accessories are not wired so they stay on at all

●

times. Check for this by connecting ammeter between

negative battery terminal and battery.

●

TSM/TSSM will continue to draw 16-25 mA for 30 seconds after ignition is turned OFF. Any disruption and

reconnection of battery power, such as disconnecting the

battery to place a meter in series, will cause TSM/TSSM

to draw 16-25 mA for 30 seconds.

See Figure 1-10. Connect ammeter between negative battery

terminal and battery. With this arrangement, you will also pick

up any regulator drain.

The limits for these drains are listed in Table 1-4.

●

Any accessories must be considered and checked for

excessive drain.

TOTAL CURRENT DRAW TEST

If the battery runs down during use, the current draw of the

motorcycle components and accessories may exceed the

output of the charging system. To check for this condition,

place load tester induction pickup or current probe pickup

over battery negative cable as shown in Figure 1-11. Disconnect regulator from stator. Start engine and run at 3000 rpm.

With ignition and all continuously running lights and accessories turned on (headlamp on high beam), read the total current draw. Compare this reading to the reading obtained in

CURRENT OUTPUT TEST. The current output should

exceed current draw by 3.5 amps, minimum. If not, there may

be too many accessories for the charging system to handle.

Reconnect regulator when test is complete.

NOTE

Rider’s habits may require output test at lower RPM.

FLT0808A

AMP

●

This condition could drain battery completely if vehicle is

parked for a long time.

NOTES

●

A battery with surface discharge condition could cause a

static drain. Correct by cleaning battery case.

Any reading that exceeds the “Average Meter Reading”

●

values below indicates excessive current draw. Check for

bad radio, voltage regulator or a short in the interconnecting wiring. Alarms and customer accessories are

also prime suspects. Isolate problem by disconnecting

suspect components and observe change in meter reading.

Table 1-4. Milliampere Draw Test

COMPONENT

ECM (EFI models) 1.0

Speedometer 0.5

Ta chometer 0.5

TSM (no security) 0.5

TSSM (armed) 3.5

TSSM (disarmed) 3.0

TSSM (storage mode) 0.5

Voltage Regulator 2

Radio 4

DRAW IN MILLIAMPERES

Average Meter Reading

12v Battery

Battery

Negative Cable

Ignition “Off”

Figure 1-10. Milliamp Draw Test

Load

Tester

d0004x8x

Figure 1-11. Check Current Draw (Ignition Switch On)

1-16 2004 Touring: Starting & Charging

Page 17

HOME

f2251x8x

f2252x8x

CURRENT OUTPUT TEST

1. Connect load tester negative and positive leads to battery terminals and place load tester induction pickup over

positive regulator cable as shown in Figure 1-12.

2. Run the engine at 3000 rpm and increase the load as

required to obtain a constant 13.0 volts.

3. The current output should be as follows. Make note of

the measurement.

FLHR, FLHRI, FLHRCI,

FLHRS, FLHRSI, FLHT, FLHTC

38 amp (Low Output) .................... 34-40 amperes

FLHTI, FLHTCI, FLHTCUI,

FLTRI

45 amp (High Output) ................... 41-48 amperes

VOLTAGE OUTPUT TEST

See Figure 1-12. After removing the load, read the load tester

voltage meter. Voltage to the battery must be less than 15

volts. If voltage is higher, regulator is not functioning properly

or connections are loose or dirty.

CAUTION

Do not leave any load switch turned on for more than 20

seconds or overheating and tester damage are possible.

Load

Tester

Figure 1-13. Test for Grounded Stator

f1314x8x

Figure 1-12. Current and Voltage Output Test

To Circuit

Breaker

(DC Output)

To Voltage

Regulator

Figure 1-14. Check for Stator Resistance

STATOR CHECK

1. To check for a grounded stator, turn off ignition and disconnect the regulator from the stator.

2. See Figure 1-13. Connect an ohmmeter on the RX1

scale between primary cover bolt and either stator

socket. Use Harness Connector Test Kit (HD-41404), red

pin probes and patch cords. There should be no continuity (∞ ohms) across either test point. Any other reading

indicates a grounded stator which must be replaced.

3. See Figure 1-14. Check the resistance using an ohmme-

ter set on the RX1 scale. Resistance should be less than

0.5 ohms across the stator socket. If it is not, then the

stator is damaged and must be replaced.

2004 Touring: Starting & Charging 1-17

Page 18

HOME

AC OUTPUT CHECK

1. See Figure 1-15. To test AC output, disconnect the regulator and connect an AC voltmeter across both stator

sockets. Run the engine at 2000 RPM. The AC output

should be as follows.

FLHR, FLHRI, FLHRCI,

FLHRS, FLHRSI, FLHT, FLHTC

38 amp (Low Output) ...... 16-20 VAC per 1000 RPM

FLHTI, FLHTCI, FLHTCUI, FLTRI

45 amp (High Output) ..... 19-26 VAC per 1000 RPM

2. If the output is below specifications, charging problem

could be a faulty rotor or stator. Replace the rotor or stator.

3. Check the output again as described under CHARGING

SYSTEM OUTPUT TEST given earlier.

f2253x8x

Figure 1-15. Check AC Output

1-18 2004 Touring: Starting & Charging

Page 19

HOME

1WARNING1WARNING

CAUTION

VOLTS

AMPS

BATTERY

Induction

Pickup

Load

Tester

d0428x8x

BATTERY LOAD TEST 1.8

VOLTMETER TEST

See Ta ble 1-5. The voltmeter test provides a general indicator

of battery condition. Check the voltage of the battery to verify

that it is in a 100% fully charged condition. If the open circuit

(disconnected) voltage reading is below 12.6V, charge the

battery and then recheck the voltage after the battery has set

for one to two hours. If the voltage reading is 12.8V or above,

perform the LOAD TEST described in this section.

Table 1-5. Voltmeter Test

Voltage (OCV)

12.8 100%

12.6 75%

12.3 50%

12.0 25%

11.8 0%

State of Charge

LOAD TEST

The load test measures battery performance under full current load and is the best indicator of battery condition. To load

test the battery, proceed as follows:

1. Remove seat.

1WARNING1WARNING

Always disconnect the negative battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion which could result in death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

3. Unthread bolt and remove battery positive cable (red)

from battery positive (+) terminal.

4. Using a T-40 TORX drive head, loosen bolt to move lip of

hold-down clamp off edge of battery. Remove battery

from battery box.

Load testing a discharged battery can result in permanent battery damage.

5. Always fully charge the battery before testing or test

readings will be incorrect. Load testing a discharged battery can also result in permanent battery damage.

6. After charging, allow battery to stand for at least one

hour before testing.

CAUTION

Figure 1-16. Load Test Battery

Always turn the battery load tester OFF before connecting the tester cables to the battery terminals. Connecting

tester cables with the load tester ON could cause a spark

resulting in a battery explosion. A battery explosion may

rupture the battery case causing a discharge or spray of

sulfuric acid which could result in death or serious

injury.

7. Connect tester leads to battery posts and place induction

pickup over negative (black) cable. See Figure 1-16.

To avoid load tester and/or battery damage, do not leave

the load tester switch turned ON for more than 20 seconds.

8. Load battery at 50% of CCA rating using the load tester.

Voltage reading after 15 seconds should be 9.6V or more

at 70°F. (21°C).

Table 1-6. Battery Load Test

COLD CRANKING

AMPERAGE (CCA)

TOURING 300 150

100% 50%

2004 Touring: Starting & Charging 1-19

Page 20

HOME

1WARNING1WARNING

Always turn the battery load tester OFF before disconnecting the tester cables from the battery terminals. Disconnecting tester cables with the load tester ON could

cause a spark resulting in a battery explosion. A battery

explosion may rupture the battery case causing a discharge or spray of sulfuric acid which could result in

death or serious injury.

9. Place the fully charged battery into the battery box, terminal side forward.

CAUTION

Connect the cables to the correct battery terminals or

damage to the motorcycle electrical system will occur.

1WARNING1WARNING

Always connect the positive battery cable first. If the positive cable should contact ground with the negative cable

installed, the resulting sparks may cause a battery explosion which could result in death or serious injury.

10. Insert bolt through battery positive cable (red) into

threaded hole of battery positive (+) terminal. Tighten

bolt to 60-96

11. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

12. Apply a light coat of petroleum jelly or corrosion retardant

material to both battery terminals.

13. Rotate the hold-down clamp so that the lip (with rubber

pad) rests on the edge of the battery. Using a T-40 TORX

drive head, tighten the clamp bolt to 15-20 ft-lbs (20-27

Nm).

14. Install seat.

in-lbs

(6.8-10.9 Nm).

in-lbs

(6.8-10.9 Nm).

CAUTION

Overtightening bolts can damage battery terminals.

1-20 2004 Touring: Starting & Charging

Loading...

Loading...