Page 1

HOM

CAUTION

6906

E

PISTON

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-11 and 15-29.

Disassembly

Piston Rings, Removal

1WARNING1WARNING

Always wear proper eye protection when removing the

compression rings. Slippage may propel the ring with

enough force to cause eye injury.

1. Carefully remove first and second compression rings

using the proper piston ring expander (Snap-On PRS8).

2. Using your fingers, remove the top and bottom oil rails

from the third ring groove. Remove the expander spring.

3. Discard the piston rings.

Cleaning and Inspection

Cleaning

CAUTION

Do not sand blast or glass bead blast pistons. Bead

blasting rounds off ring lands and will result in oil contamination leading to accelerated wear.

1. To remove all carbon and combustion deposits, soak the

pistons in a special detergent that will not corrode aluminum. Maintain the temperature of the cleaning solution

well below 212

2. Thoroughly rinse the pistons and dry with moisture free

compressed air.

3. Clean the oil drain holes leading from the oil control ring

groove to the underside of the piston crown. Run a small

bristle brush through the passageways to ensure their

cleanliness, but be careful not to damage or enlarge the

holes. Do not use a wire brush.

4. Verify that all other oil holes are clean and open.

o

F. (100o C.).

6. Using Magnaflux Dye Penetrant, inspect the piston for

surface cracks. Pay special attention to the area around

the pin bores, ring lands and oil drain holes beneath the

piston crown. If no cracks are found, thoroughly wash

piston to remove traces of dye.

Inspection

1. Lightly oil a good piston pin and insert it into the piston

pin bore to feel for the proper interference fit. The pin

should slide in and out without binding, but also without

pivoting or rocking. Replace piston and/or pin if clearance exceeds 0.0008 in. (0.020 mm).

2. Carefully inspect the pistons for damage or excessive

wear. Discard pistons with cracked, broken or bent ring

lands. Check the piston skirt for cracks, gouges, deep

scratches or heavy scoring. Check the piston heads for

evidence of burning, etching or melting. Look for marks

or imprints caused by contact with valves. Pistons with

superficial wear marks, minor scratching or mild scoring

may continue to be used.

3. Run your index finger around the edge of the piston

crown to feel for dings, nicks or burrs. Lightly file the

edge of the crown to remove any defects.

Worn ring grooves result in high oil consumption and

blow-by of exhaust gases. Blow-by of exhaust gases

contaminates the engine oil supply with acids and

leaves sludge in the crankcase. It also reduces engine

efficiency by weakening the combustion seal necessary

for efficient transfer of energy to the piston.

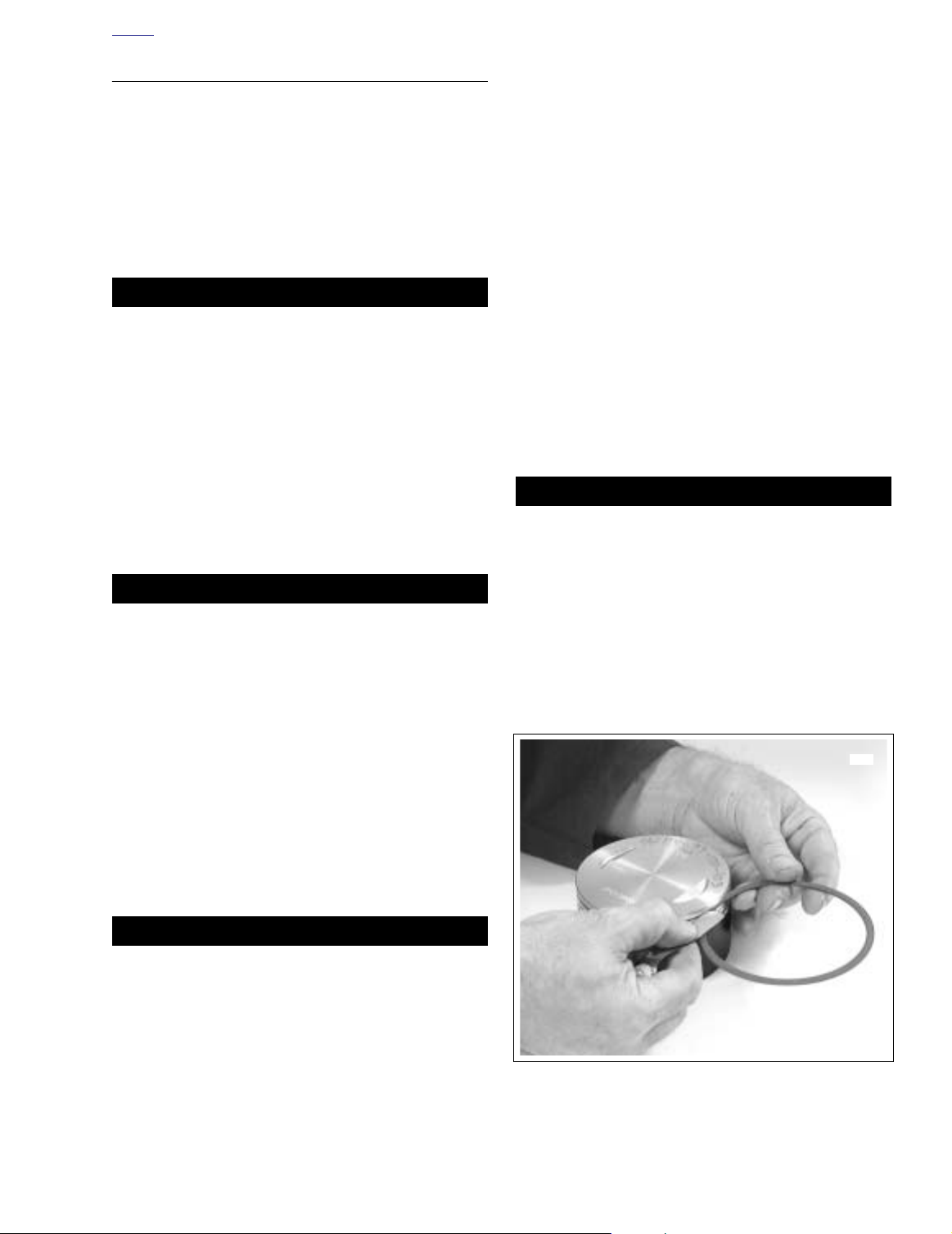

4. Measure the piston ring side clearance as follows:

a. Insert the edge of a new ring into the piston ring

groove. Insert a feeler gauge between the upper

surface of the ring and the ring land. See Figure 3-

88.

CAUTION

Exercise care to avoid scratching the sides of the piston

ring grooves.

5. Thoroughly clean the three piston ring grooves of all carbon deposits. A broken compression ring properly

ground to a sharp chisel-like edge may be used for this

purpose.

Figure 3-88. Measure Piston Ring Side Clearance

2004 Touring: Engine 3-77

Page 2

HOM

E

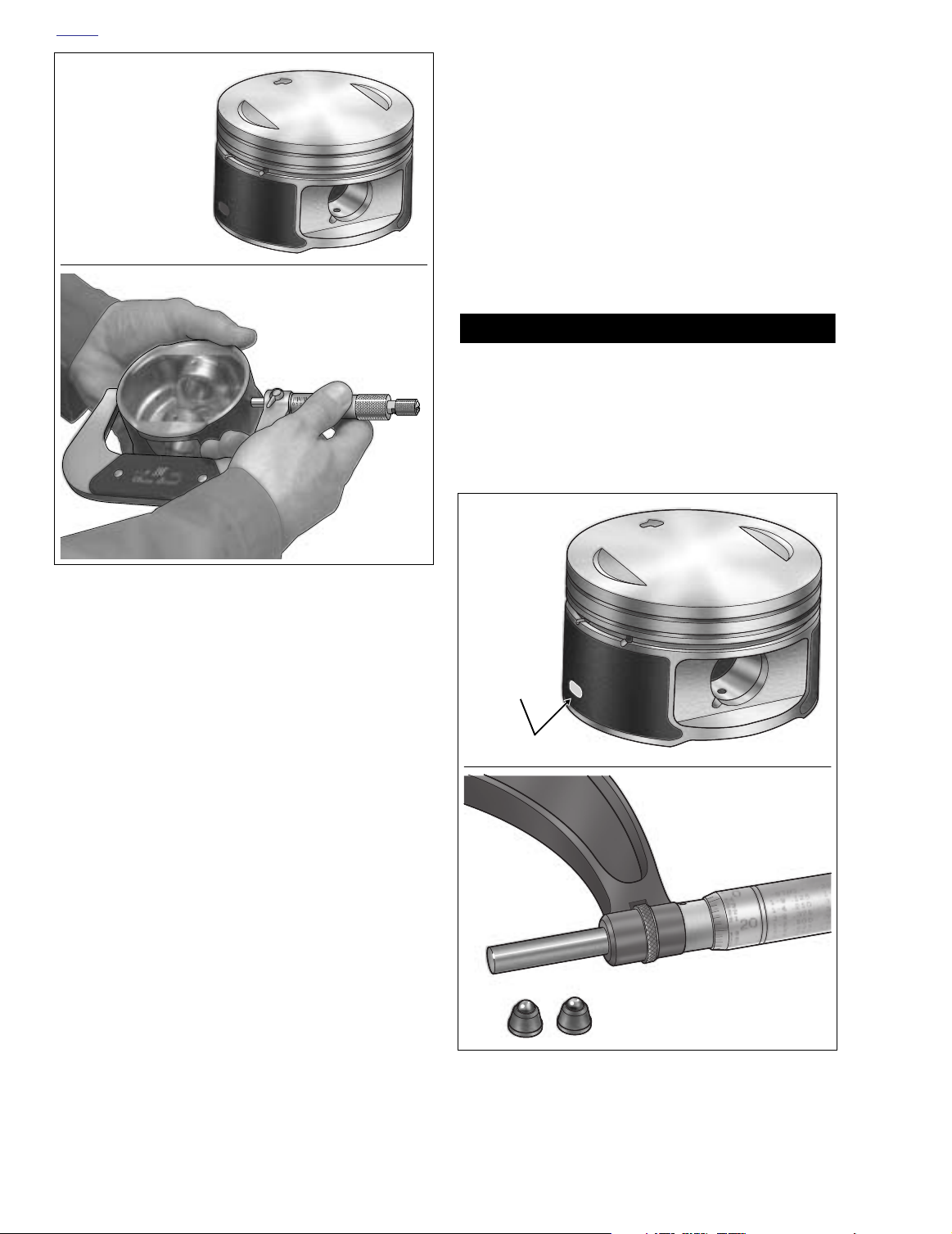

EARLY STYLE

FULLY COATED

No Bare

Aluminum

f2114x3x

NOTE

On late style pistons, the measurement is taken on the bare

aluminum to avoid measuring errors. An oval-shaped opening is present on each side of the piston for proper placement

of the micrometer. See upper frame of Figure 3-90. Since the

oval openings are too small for a standard flat anvil micrometer, which would result in measuring errors, use a 3-4 inch

blade or ball anvil style micrometer, or a 4-5 inch micrometer

with spherical ball anvil adapters. See lower frame of Figure

3-90.

c. Using a grease pencil, mark the top, middle and

bottom of the piston ring travel zone in the cylinder

bore. Measure at markings in cylinder parallel and

perpendicular to crankshaft.

CAUTION

Do not check piston running clearance immediately after

honing or deglazing cylinder. Since heat will cause measurements to vary by as much as 0.0002 inch (0.005 mm),

both piston and cylinder must be at room temperatures.

d. Replace piston and/or cylinder if running clearance

exceeds 0.003 in. (0.076 mm).

f1685x3x

Figure 3-89. Measure Early Style Piston for

Running Clearance

b. Since the grooves wear unevenly, repeat this check

at several locations around the piston groove circumference.

c. Discard the piston if the side clearance of either

compression ring exceeds 0.0045 in. (0.11 mm).

Discard the piston if the oil control ring side clearance exceeds 0.010 in. (0.25 mm).

5. Measure the running clearance on fully coated early

style pistons as follows:

NOTE

Check the piston clearance in the cylinder in which the piston

will run. The torque plates must be installed on the cylinder

and it must be deglazed and suitable for continued service.

a. Holding outside micrometer, measure piston skirt

diameter across the thrust faces (perpendicular to

pin bore). Start below the bottom ring land and

move micrometer towards bottom of skirt. Micrometer will be loose, then tight (about 1/2 inch from bottom), and then loose again. See lower frame of

Figure 3-89.

b. Measure the piston skirt at the tightest spot and

then transfer that measurement to the dial bore

gauge.

LATE STYLE

Bare

Aluminum

f2113x3x

4-5 Inch

Micrometer

Spherical Ball

Anvil Adapters

f2109x3x

Figure 3-90. Measure Late Style Piston for

Running Clearance

3-78 2004 Touring: Engine

Page 3

HOM

REAR

2

4

1

3

FRONT

4

2

3

1

1. Expander spring

2. Bottom oil rail

3. Top oil rail

4. Second compression ring

5. Top compression ring

5

5

f2066x3x

E

6905

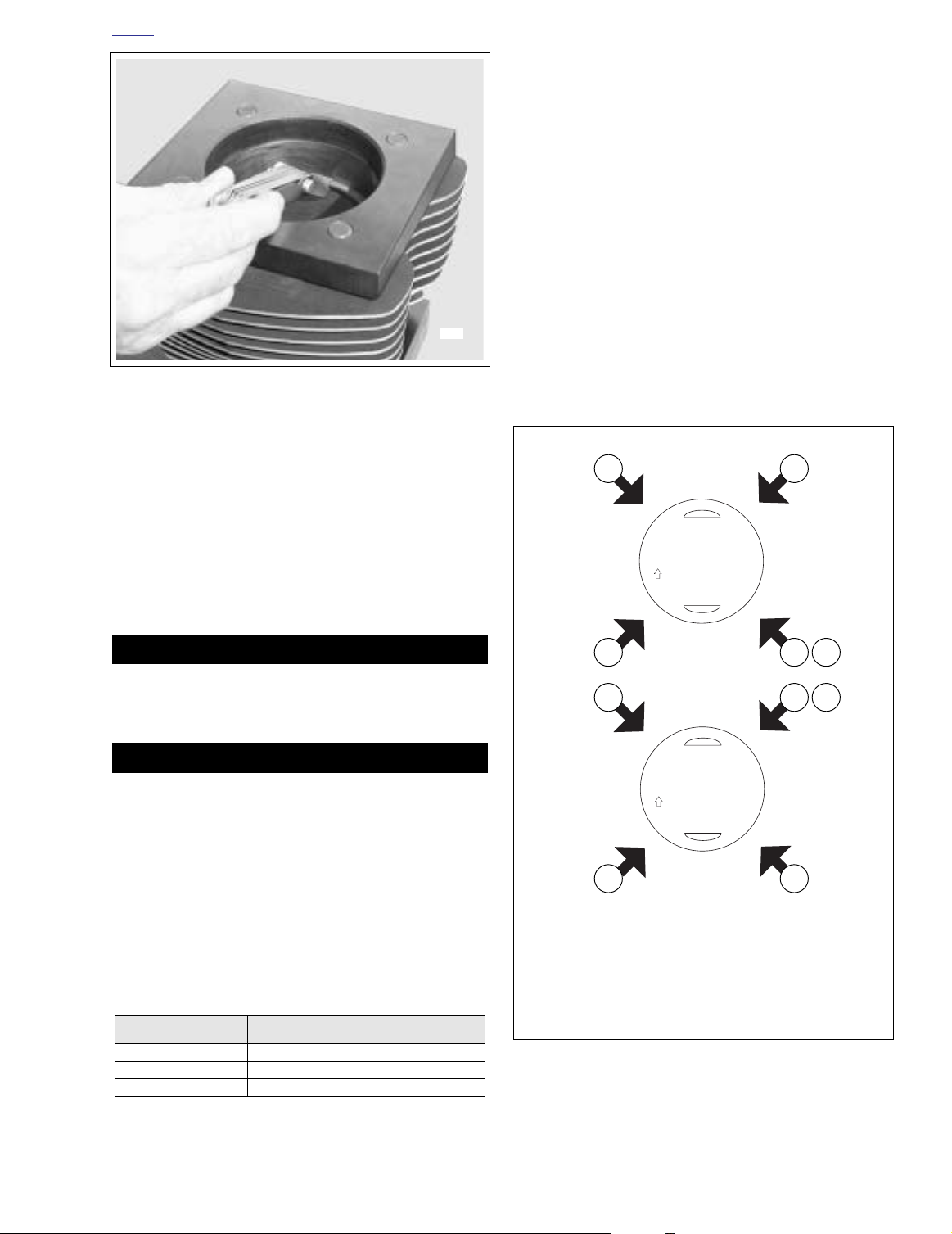

Figure 3-91. Measure Ring End Gap

Assembly

Piston Rings, Installation

NOTE

Always use

and must not be reused if the engine has been operated.

Always deglaze (or hone) the cylinder before installing new

rings. Ring sets are available to fit oversize pistons.

new

piston rings. Piston rings take a definite set

NOTE

Ring end gap dimensions also apply to oversize rings.

Replace ring if end gap exceeds specification. If end gap is

under specification, filing is permissible.

3. Use compressed air to remove any dirt or dust that may

have settled in the oil drain holes and piston ring

grooves.

4. Install piston rings as follows:

a. Apply clean H-D 20W50 engine oil to three piston

ring grooves.

b. Install expander spring into third ring groove. Spiral

bottom oil rail into space below expander spring

positioning the gap 90 degrees from the gap in the

expander spring. Spiral top oil rail into space above

expander spring positioning gap 180 degrees from

the gap in the bottom oil rail.

1. Before placing each ring on the piston, perform the following check.

CAUTION

Insufficient ring end gap may cause the ends to abut at

engine operating temperatures, resulting in ring breakage, cylinder scuffing and/or piston seizure.

Excessive ring end gap results in high oil consumption

and blow-by of exhaust gases. While blow-by contaminates the oil supply and leaves sludge in the crankcase,

it also reduces engine efficiency by weakening the combustion seal necessary for efficient transfer of energy to

the piston.

2. Insert the new ring into the cylinder, square it in the bore

using the top of the piston and measure the ring end gap

with a feeler gauge. See Figure 3-91. Do not use the ring

if the end gap does not fall within the following specifications.

CAUTION

Table 3-8. Ring End Gap

Ring Type

Top compression ring 0.010 in. (0.25 mm) - 0.020 in. (0.51 mm)

2nd compression ring 0.014 in. (0.36 mm) - 0.024 in. (0.61 mm)

Oil control ring

rails

0.010 in. (0.25 mm) - 0.050 in. (1.27 mm)

Ring End Gap

Figure 3-92. Piston Ring Gap Alignment

2004 Touring: Engine 3-79

Page 4

HOM

E

CAUTION

Use the proper piston ring spreader to prevent excessive

ring twist and expansion. Over expansion may cause the

ring to crack opposite the ring gap. Damaged or distorted rings result in blow-by of exhaust gases,

increased oil consumption and lower service life on

valves and other components.

CAUTION

Installing the second compression ring upside down will

cause oil to be scraped up into the combustion chamber

resulting in excessive oil consumption and low service

life on valves and other components.

c. Using the proper piston ring expander (Snap-On

PRS8), carefully install the second compression

ring making sure that the dot (punch mark) near the

ring gap faces the piston crown. Rotate the ring so

the gap is 90 degrees from the gap in the top oil rail.

d. Carefully install the top compression ring using the

proper piston ring expander (Snap-On PRS8).

Rotate the ring so the gap is 180 degrees from the

gap in the second compression ring.

e. Rotate the three piston rings using the palms of

both hands. The rings must rotate freely without

sticking.

f. Verify that the ring gaps are still properly staggered.

See Figure 3-92.

Installation

1. See Section 3.9 TOP END OVERHAUL, ASSEMBLY,

steps 1-23 and 28-37.

3-80 2004 Touring: Engine

Page 5

HOM

E

NOTES

2004 Touring: Engine 3-81

Page 6

HOM

E

UPPER CONNECTING ROD

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-11 and 15-29.

Disassembly/Assembly

NOTE

Service of connecting rods is limited to replacement of the

upper bushing. Damage to connecting rods or lower bushing

service requires replacement of the flywheel assembly.

Upper Connecting Rod Bushing

Removal

NOTE

Replace the upper rod bushing if the piston pin to rod bushing clearance exceeds 0.002 inch (0.051 mm).

CAUTION

Place clean shop towels in and around the crankcase

bore to prevent chips and shavings from falling into the

crankcase.

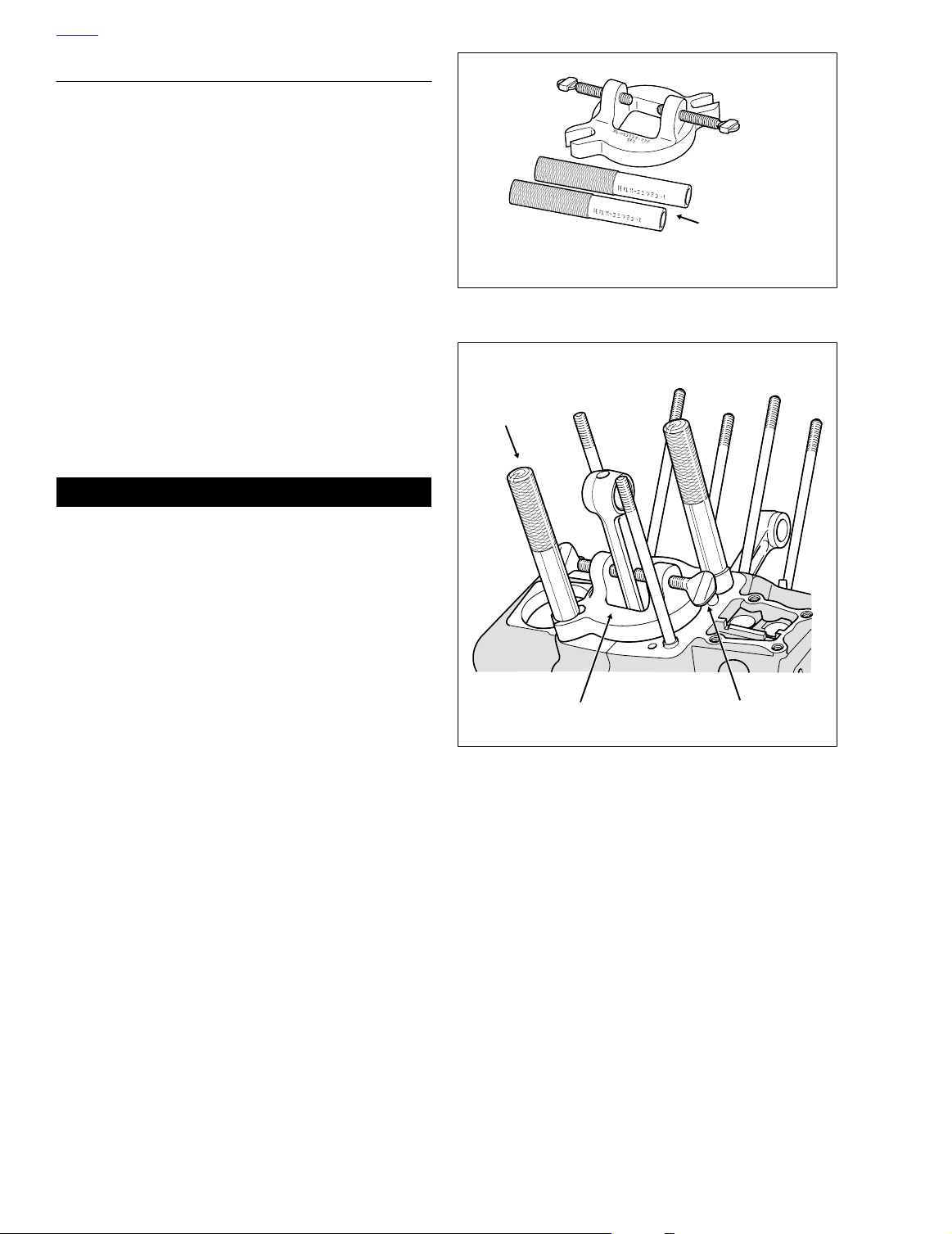

1. Obtain the CONNECTING ROD CLAMPING TOOL (HD95952-33B) and proceed as follows:

a. Slide clamp over connecting rod so that slots

engage cylinder head studs. See Figure 3-94. Exercise caution to avoid scratching or bending studs.

b. With the knurled side up, install threaded cylinders

(HD-95952-1) onto studs to secure position of

clamp.

c. Alternately turn each clamp thumbscrew a few turns

to gradually fix position of connecting rod. Turning

only one thumbscrew will move rod off-center, while

tightening second thumbscrew can cause rod to flex

or bend.

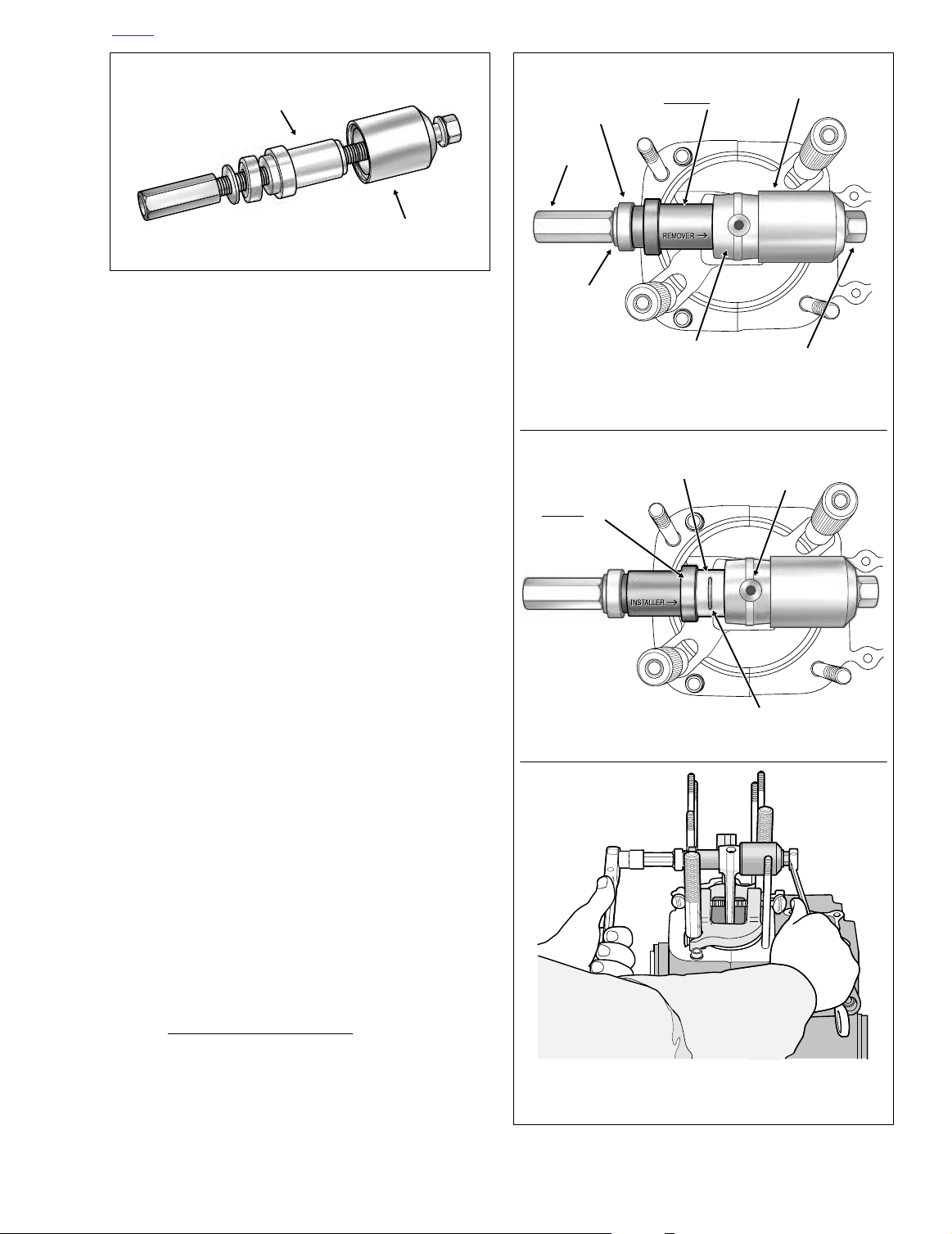

2. Obtain the CONNECTING ROD BUSHING REMOVER/

INSTALLER (HD-95970-32D) and proceed as follows:

a. Sparingly apply graphite lubricant to threads of rod

to prolong service life and ensure smooth operation.

b. Slide receiver cup (HD-95984-99) onto threaded rod

with the closed side facing hex nut.

c. Insert threaded rod through upper rod bushing.

d. Slide remover side of driver (HD-95986-99) down

threaded rod. The driver is stamped to ensure

proper orientation.

e. Slide Nice bearing and flat washer down threaded

rod until it contacts driver.

Threaded

Cylinders

Part No. HD-95952-1

Figure 3-93. Connecting Rod Clamping Tool

(Part No. HD-95952-33B)

f1597x3x

Threaded

Cylinder

ThumbscrewClamp

Figure 3-94. Install Connecting Rod Clamping Tool

f. Thread the hex cylinder onto rod until assembly is

snug. See upper frame of Figure 3-96.

g. Holding nut at end of threaded rod with a 5/8 inch

box wrench, turn hex cylinder with a 5/8 inch socket

until bushing is free.

h. Unthread hex cylinder from rod. Remove flat

washer, Nice bearing and driver. Remove threaded

rod from bushing bore.

i. Remove bushing from receiver cup and discard.

Installation

1. Obtain the CONNECTING ROD BUSHING REMOVER/

INSTALLER (HD-95970-32D) and proceed as follows:

3-82 2004 Touring: Engine

Page 7

HOM

f1601x3x

f1602x3x

f1598x3x

Driver

Installer Side

Slot

Oil Hole

Upper Rod

Bushing

Connecting

Rod

Threaded

Rod

Flat

Washer

Hex

Cylinder

Nice

Bearing

Receiver

Cup

Driver

Remover Side

Remover Stackup

Installer Stackup

Hold hex nut on threaded rod with 5/8 inch box.

Turn cylinder hex with 5/8 inch socket.

E

Driver

Part No. HD-95986-99

Figure 3-95. Connecting Rod Bushing Remover/Installer

a. Slide receiver cup (HD-95984-99) onto threaded rod

b. Insert threaded rod through upper rod bushing bore.

c. Slide

d. Slide installer side of driver (HD-95986-99) down

e. Slide Nice bearing and flat washer down threaded

f. Thread the hex cylinder onto rod until assembly is

g. Holding nut at end of threaded rod with a 5/8 inch

h. Unthread hex cylinder from rod and remove flat

Receiver Cup

Part No. HD-95984-99

(Part No. HD-95970-32D)

with the closed side facing hex nut.

new

bushing down threaded rod. Start bushing into bore. Verify that center of slot in bushing is

aligned with oil hole at top of rod. Also, be sure that

bushing is square in bore and not cocked. See center frame of Figure 3-96.

threaded rod until shoulder contacts bushing. The

driver is stamped to ensure proper orientation.

rod until it contacts driver.

snug.

box wrench, turn hex cylinder with a 5/8 inch socket

until collar on driver bottoms against connecting

rod. See lower frame of Figure 3-96.

washer, Nice bearing and driver. Remove threaded

rod from bushing bore, but exercise caution to avoid

scratching or gouging bushing.

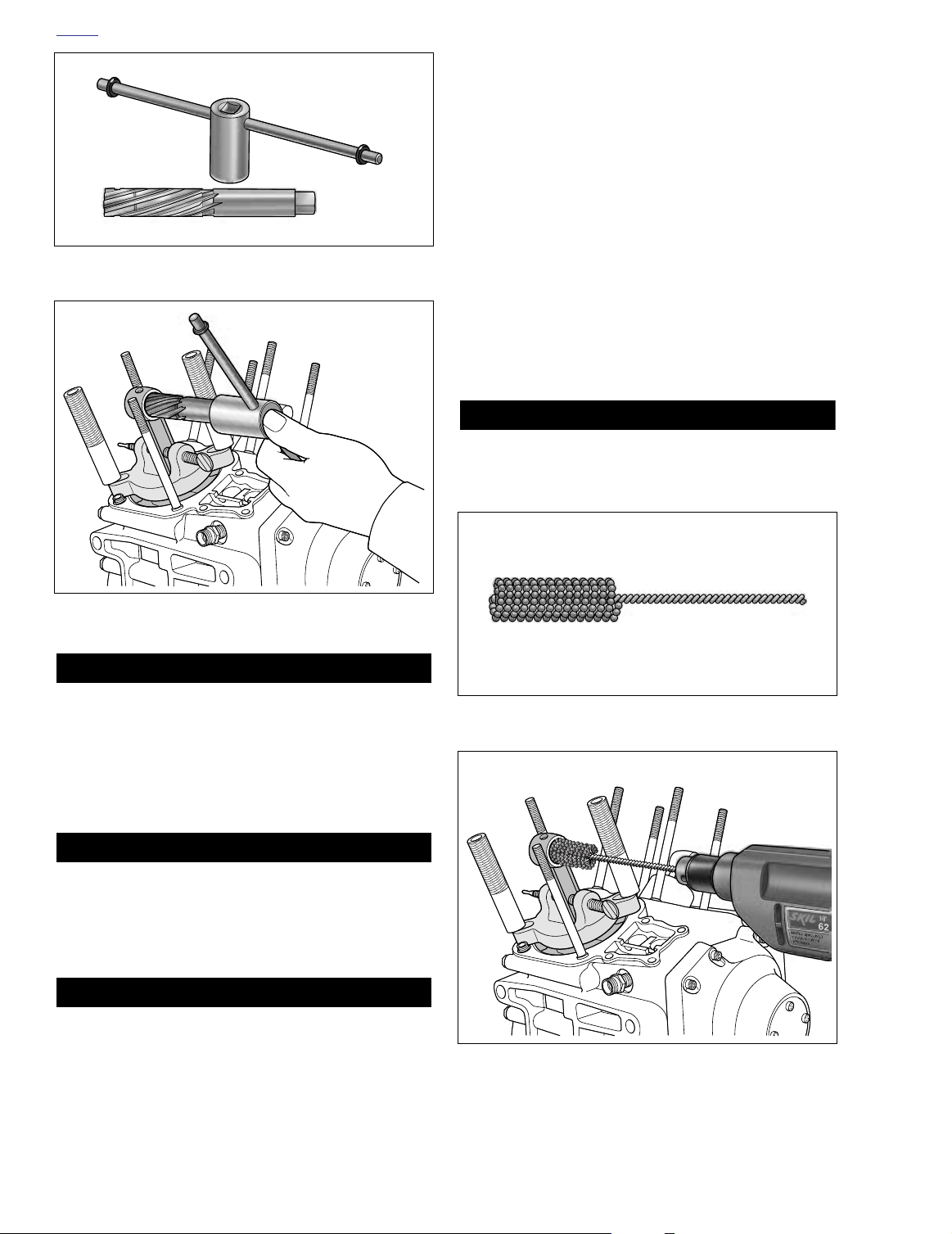

Reaming Upper Rod Bushing

1. Obtain the CONNECTING ROD BUSHING REAMER

(HD-42318) and REAMER HANDLE/DRIVE SOCKET

(HD-43645). Proceed as follows:

a. Carefully insert bit of reamer into upper connecting

rod bushing. Do not apply lubricant to reamer or

bushing. Ream the bushing dry or cut will not be

accurate.

b. Install handle/drive socket on reamer lug. See Fig-

ure 3-98.

c. Placing thumb on dr

ive socket, apply slight pressure

on reamer while rotating handle/drive socket in a

clockwise direction.

Figure 3-96. Remove/Install Connecting Rod Bushing

2004 Touring: Engine 3-83

Page 8

HOM

E

Handle/Drive Socket

Reamer

Figure 3-97. Connecting Rod Bushing Reamer (Part No.

HD-42318) and Handle/Drive Socket (Part No. HD-43645)

f1642x3x

2. Using contact cleaner or cleaning solvent, thoroughly

wipe upper connecting rod and bushing of any metal

shavings or debris.

Honing Upper Rod Bushing

1. Obtain the CONNECTING ROD BUSHING HONE (HD-

42569) and REAMER LUBRICANT (HD-39964). Proceed as follows:

a. Install hone in a high speed electric drill.

b. Apply reamer lubricant to finishing stones of hone

and inside of upper connecting rod bushing.

c. Start finishing stones of hone into bushing.

d. Activating the drill, move the entire length of the fin-

ishing stone arrangement forward and backward

through the bushing bore for 10 to 12 complete

strokes. See Figure 3-100. Work for a crosshatch

pattern of approximately 60˚.

CAUTION

Abrasive particles can damage machined surfaces and

plug oil passageways possibly resulting in engine failure.

Figure 3-98. Ream Connecting Rod Bushing

CAUTION

For best results, do not push on reamer or apply pressure to the reamer handle. While excessive pressure

results in a rough cut, bushing bore will be tapered if

pressure is not centrally applied.

d. Continue rotating handle/drive socket until entire bit

has passed through bushing and shank of reamer

rotates freely in the bore.

CAUTION

Never back reamer out of connecting rod or bushing will

be damaged.

e. Remove handle/drive socket, and carefully pulling

on bit, draw shaft of reamer out of connecting rod

bushing.

CAUTION

Abrasive particles can damage machined surfaces and

plug oil passageways possibly resulting in engine failure.

Figure 3-99. Connecting Rod Bushing Hone

(Part No. HD-42569)

f1643x3x

Figure 3-100. Hone Connecting Rod Bushing

3-84 2004 Touring: Engine

Page 9

HOM

E

2. Using contact cleaner or cleaning solvent, thoroughly

wipe upper connecting rod and bushing of any metal

shavings or debris. Continue wiping until a clean cloth

shows no evidence of dirt or debris.

3. Lightly oil a good piston pin and insert it into the upper

connecting rod bushing bore to feel for the proper interference fit. The pin should slide in and out of the bushing

without binding, but also without pivoting or rocking.

4. Remove shop towels exercising caution that shavings,

chips and other debris do not fall into crankcase.

Installation

See Section 3.9 TOP END OVERHAUL, ASSEMBLY, steps

1-24 and 29-39.

2004 Touring: Engine 3-85

Page 10

HOM

E

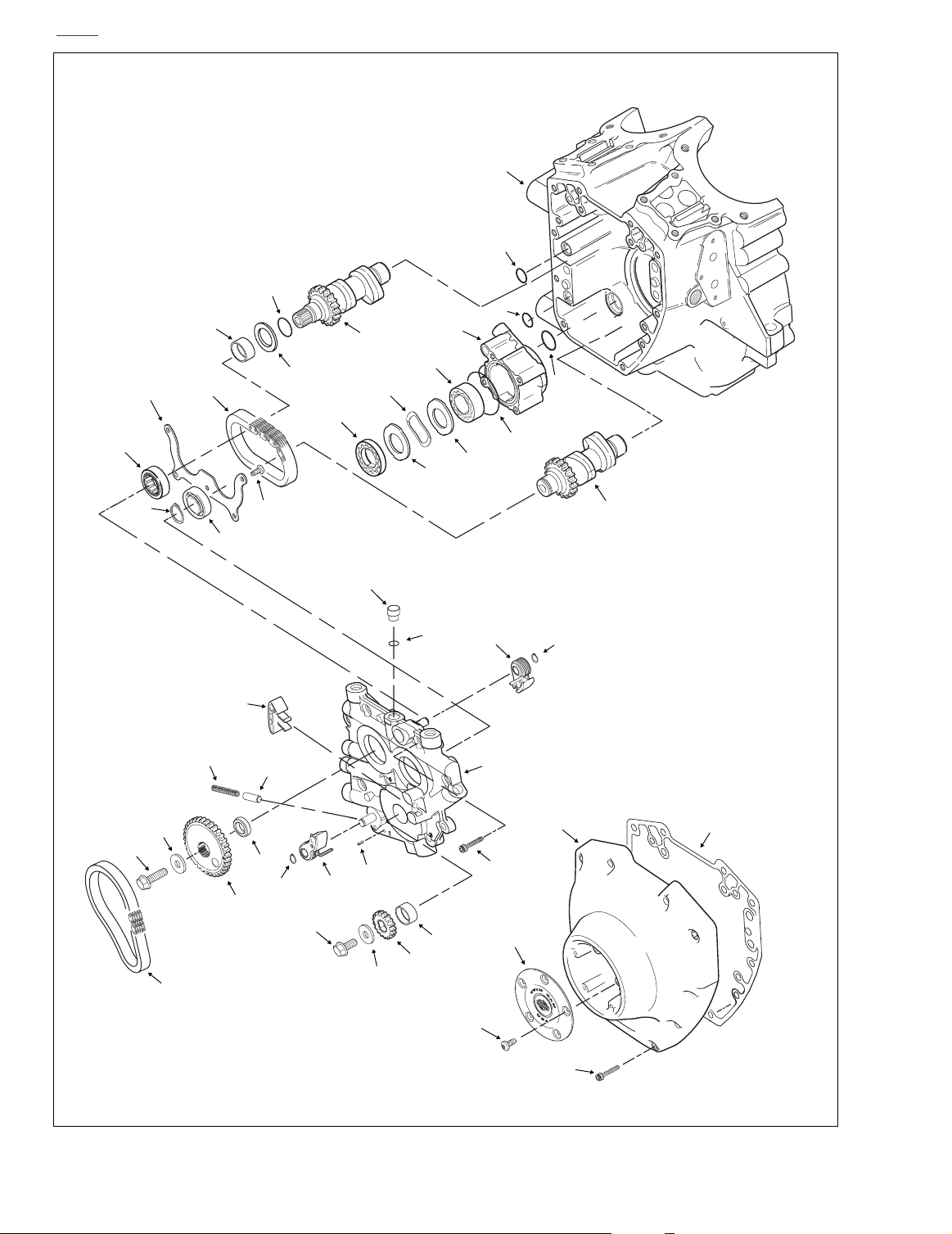

Legend:

1. T20 TORX Screw

2. Cam Position Sensor Cover

3. Screw

4. Cam Cover

5. Cam Cover Gasket

6. Primary Cam Chain

7. Flange Bolt

8. Flat Washer

9. Primary Cam Sprocket

10. Spacer

11. Retaining Ring

12. Primary Cam Chain Tensioner

13. Flange Bolt

14. Flat Washer

15. Crank Sprocket

16. Crankshaft Bushing

33

30

32

28

17. Roll Pin

18. Oil Pressure Relief Valve Piston

19. Valve Spring

20. Chain Guide

21. Screw

22. Cam Support Plate

23. Secondary Cam Chain Tensioner

24. Retaining Ring

25. O-Ring

26. Cleaning Plug

27. Retaining Ring

35

36

41

34

40

38

39

47

46

45

43

44

42

39

29

20

31

10

18

11

12

26

17

25

23

22

21

37

28. Rear Cam (Roller) Bearing

29. Front Cam (Ball) Bearing

30. Bearing Retainer Plate

31. T20 TORX Screw

32. Secondary Cam Chain

33. Roller Bearing Inner Race

34. Thrust Washer

24

4

35. O-Ring

36. Rear Camshaft

37. Front Camshaft

38. Feed Gerotor Set

39. Separator Plate

40. Wave Washer

41. Scavenge Gerotor Set

42. O-Ring

43. Oil Pump Housing

44. O-Ring (Scavenge Port Stub)

45. O-Ring (Oil Feed Hole)

46. O-Ring (Blind Hole)

47. Right Crankcase Half

5

27

19

8

7

9

13

16

15

6

14

2

f2143x3x

Figure 3-101. Cam Support Plate/Oil Pump Assemblies (Exploded View)

3-86 2004 Touring: Engine

1

3

Page 11

HOM

CAUTION

f1596x3x

f1595x3x

Wireform

Wireform

Binder Clip

E

BOTTOM END

CAM SUPPORT PLATE

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-11.

NOTE

When removing the cam support plate, it is not necessary to

disturb the lifter assemblies if a method is devised to prevent

the hydraulic lifters from dropping into the cam compartment.

One such method is provided in the following step. Leaving

the lifter assemblies intact simplifies the procedure, since the

lifter cover, gasket, anti-rotation pin and hydraulic lifters can

be left in place.

2. Fashion lifter holding tool as follows:

a. Obtain a large binder clip (available at any office

supply store). Squeeze wireforms to remove from

binder clip. See upper frame of Figure 3-102.

b. Compress wireform slightly and insert free ends into

outer and inner lifter cover bores so that legs

engage walls of both hydraulic lifter sockets. See

lower frame of Figure 3-102.

3. See Section 3.10 BOTTOM END OVERHAUL, DISAS-

SEMBLY, steps 1-14.

2. Center support tube under ram of arbor press.

3. Center crankshaft bushing in cam support plate over

support tube. Be sure that the primary cam chain side of

the cam support plate is facing upward.

If the crankshaft bushing is pressed out the primary cam

chain side, the bore will be damaged by the knurled edge

of the bushing. Damage to the bore requires replacement of the cam support plate.

4. Insert remover side of driver into crankshaft bore so that

shoulder on tool is seated on edge of bushing. See

upper frame of Figure 3-104.

5. Press on driver until collar of tool contacts cam support

plate. Remove bushing from support tube and discard.

Installation

1. Obtain the CRANKSHAFT BUSHING REMOVER/

INSTALLER (HD-42315).

2. Center support tube under ram of arbor press.

Disassembly/Assembly

1CAUTION

Do not pull the retention pins from the primary or secondary cam chain tensioners with the chains and

sprockets removed. With 35-40 pounds of spring pressure behind the tensioner, allowing it to accelerate

through its full length of travel will cause spring stretching and/or cracking of the tensioner shoe, damage which

requires replacement of the assembly. Furthermore, if

the tensioner should contact fingers or other parts of the

hand, minor or moderate injury may occur.

If the retention pins interfere with cleaning or service procedures, hold the retracted cam chain tensioner with the CAM

CHAIN TENSIONER UNLOADER (HD-42313), pull the

retention pin and ease the assembly into the unloaded position.

Crankshaft Bushing

Removal

1. Obtain the CRANKSHAFT BUSHING REMOVER/

INSTALLER (HD-42315).

NOTE

Figure 3-102. Fashion Tool to Hold Hydraulic Lifters

2004 Touring: Engine 3-87

Page 12

HOM

E

Remover

Side

Installer

Side

Support

Tube

Driver

Figure 3-103. Crankshaft Bushing Remover/Installer

(Part No. HD-42315)

3. Turn cam support plate over so that secondary cam

chain side is facing upward.

4. Start

new

bushing into bore with the knurled edge top-

side. Be sure that hole in b

ushing is aligned with oil hole

in bushing bore.

CAUTION

If the crankshaft bushing is pressed in from the primary

cam chain side, or from the secondary cam chain side

with the knurled edge of the bushing down, the bushing

bore will be damaged. Damage to the bore requires

replacement of the cam support plate.

Driver

Remover Side

Down

Support

Tube

Driver

Installer Side

Down

Ram

REMOVE

CRANKSHAFT

BUSHING

Crankshaft

Bushing

Knurled Side Up

f1599x3x

f1600x3x

5. Center crankshaft bushing bore over support tube.

6. Insert installer side of driver into bushing. See lower

frame of Figure 3-104.

7. Press on driver until collar of tool makes firm contact

with cam support plate.

8. Ream the crankshaft bushing following the directions

below.

Reaming Crankshaft Bushing

NOTE

A

new

crankshaft bushing must be reamed for proper size

and alignment. If crankcase halves are not split, ream the

bushing using a spare right case half to avoid further engine

disassembly.

1. Slide cam support plate onto two ring dowels in crank-

case flange.

2. Install six allen head socket screws (1/4 x 1 inch) to

secure cam support plate to crankcase flange. Alternately tighten screws until snug.

3. Obtain the CRANKSHAFT BUSHING REAMER (HD-

42316) and REAMER HANDLE/DRIVE SOCKET (HD-

43645). Proceed as follows:

Ensure Oil

Hole Alignment

INSTALL

CRANKSHAFT

BUSHING

Figure 3-104. Remove/Install Crankshaft Bushing

in Cam Support Plate

a. From flywheel compartment side, carefully insert

tapered end of reamer pilot into crankshaft bearing

until it stops. See left frame of Figure 3-106.

b. Slide reamer through pilot starting bit into crank-

shaft bushing in cam support plate. Do not apply

lubricant to reamer or bushing. Ream the bushing

dry or cut will not be accurate.

c. Install handle/drive socket on reamer lug. See right

frame of Figure 3-106.

d. Placing thumb on dr

ive socket, apply slight pressure

on reamer while rotating handle/drive socket in a

clockwise direction.

3-88 2004 Touring: Engine

Page 13

HOM

CAUTION

f1611x3x

Handle/

Drive Socket

Install handle/drive socket on reamer.

E

Handle/Drive Socket

Pilot

Reamer

Figure 3-105. Crankshaft Bushing Reamer (Part No. HD-

42316) and Handle/Drive Socket (Part No. HD-43645)

CAUTION

f. Remove handle/drive socket, and carefully pulling

on bit, draw shaft of reamer out of bushing on cam

side of crankcase.

g. Remove pilot from crankshaft bearing. Tap on pilot

using a soft rubber mallet, if necessary.

4. Remove the allen head socket screws to release the

cam support plate from the crankcase flange.

Abrasive particles can damage machined surfaces and

plug oil passages possibly resulting in engine failure.

5. Using a small screwdriver, carefully pry cleaning plug

from top of cam support plate. Thoroughly flush right

crankcase half and cam support plate in cleaning solvent to remove any metal shavings or debris. Blow dry

with compressed air. Install cleaning plug in cam support

plate replacing O-ring if torn or damaged.

For best results, do not push on reamer or apply pressure to the reamer handle. While excessive pressure

results in a rough cut, bushing bore will be tapered if

pressure is not centrally applied.

e. Continue rotating handle/drive socket until entire bit

has passed through bushing and shank of reamer

rotates freely in the bore.

Never back reamer out flywheel side of crankcase or

crankshaft bushing will be damaged.

Install pilot and reamer from flywheel side of case.

Reamer

CAUTION

Right Crankcase

Half

Camshafts/Camshaft Bearings

Removal

1. Place cup of CAM CHAIN TENSIONER UNLOADER

(HD-42313) over spring coil of secondary cam chain tensioner positioning finger on tool between tensioner and

shoe. See Figure 3-107. Rotate tool in a counterclockwise direction inserting retention pin through hole in

boss on

Pin engages hooks on tensioner to hold it in the

retracted position. For best results, place cam support

plate in a vise using brass jaw inserts to prevent casting

damage.

primar

y cam chain side

of cam support plate.

Pilot

Crankshaft

Bearing

f1619x3x

Figure 3-106. Ream Crankshaft Bushing

2004 Touring: Engine 3-89

Page 14

HOM

E

Finger

Tensioner

Unloader

Shoe

Retention

f1637x3x

Pin

Figure 3-107. Retract Secondary Cam Chain Tensioner

1WARNING1WARNING

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

2. Remove retaining ring from groove at end of front camshaft. Discard retaining ring.

3. Remove four T20 TORX screws to free bearing retainer

plate from inboard side of cam support plate.

4. Using a colored marker, mark one of the links of the secondary cam chain. Maintaining the original direction of

rotation during assembly may prolong service life of

chain.

5. With the primary cam chain side facing upward, place

cam support plate on parallel blocks under ram of arbor

press.

6. Obtain the CAMSHAFT/CAMSHAFT BEARING REMOVER/INSTALLER (HD-43644). See Figure 3-108.

Press out camshafts (with bearings).

Ram

Remove bearing from front camshaft.

Forcing

Screw

3/8-16 Inch

with Flat Washer

Bearing

Camshaft

Driver

Parallel

Blocks

f1623x3x

Bolt

Bridge

Hardened

Plug

Wedge

Attachment

Support Block

Camshaft Driver Bearing Pilot/Driver

Figure 3-108. Camshaft/Camshaft Bearing

Remover/Installer (Part No. HD-43644)

3-90 2004 Touring: Engine

Front

Camshaft

f1611x3x

Figure 3-109. Remove Camshafts/Front Cam Bearing

CAUTION

Since the bearing fit to the camshafts is tighter than its

fit in the support plate, any attempt to remove the camshafts without

the bearings will result in damage to the

cam support plate and bearing retainer plate, if installed.

Page 15

HOM

E

f1806x3x

Pull Bearing Inner Race and Thrust Washer

Fr

Thrust

A

Washer

om Rear Cam. Remove O-Ring if Present.

Box Wrench

5/8 Inch

Inner

Race

Shop

Box Wrench

9/16 Inch

Rag

NOTE

Although the vane has been eliminated

from the cam sprocket on production

motorcycles, the service part retains the

vane to retrofit earlier models having a

camshaft position sensor.

Inner

Race

Thrust

Washer

Shop

Rag

Install O-Ring and Thrust Washer.

B

f1807x3x

Cam bearings may be a loose fit in the cam support

plate. To avoid possible damage, be aware that camshaft

and bearing assemblies may drop out at start of press

procedure.

7. Fit cups of camshaft driver over ends of front and rear

camshafts, so that contact is made with the bearing

inner races. Centering driver under ram at a point midway between the camshafts, simultaneously press both

Press Bearing Inner Race Onto Rear Cam.

Figure 3-110. Remove/Install Bearing Inner Race (With O-Ring and Thrust Washer) Onto Rear Camshaft

CAUTION

camshafts (with attached bearings) from the cam support plate. See upper frame of Figure 3-109.

8. Remove secondary cam chain from cam sprockets.

9. If reusing front camshaft, remove bearing as follows:

a. Position WEDGE ATTACHMENT (HD-95637-46A)

on inboard side of front camshaft bearing and turn

hex nuts an equal number of turns to draw halves of

wedge together.

2004 Touring: Engine 3-91

Page 16

HOM

E

b. Obtain two 3/8-16 inch bolts 3-1/2 inches long (with

flat washers). Install flat washers on bolts. Obtain

bridge, forcing screw and hardened plug from

MAINSHAFT BEARING INNER RACE PULLER/

INSTALLER (HD-34902B).

c. Slide one bolt into channel on each side of bridge

so that flat washer is between bridge and bolt head.

Thread bolts into wedge attachment an equal number of turns.

d. Sparingly apply graphite lubricant to threads of forc-

ing screw to prolong service life and ensure smooth

operation. Start forcing screw into center hole of

bridge.

CAUTION

Failure to use hardened plug may result in damage to

forcing screw and/or camshaft.

e. Place cupped side of hardened plug against end of

camshaft. Thread forcing screw into bridge until the

steel ball at the end of the screw makes firm contact

with hardened plug.

f. Verify that the tool assembly is square so that the

bearing is not cocked during removal. See lower

frame of Figure 3-109. Turn forcing screw until bearing is pulled free of camshaft. Discard bearing.

10. If reusing rear camshaft, remove roller bearing assembly

as follows:

a. Slide roller bearing from end of rear camshaft.

Since bearing is a loose fit on cam, no pressing

tools are required.

b. Install tools as you would to remove the bearing

from the front camshaft, but position cup of wedge

inboard of the thrust washer.

c. Wrap a shop rag around camshaft to get a firm grip

and also to protect hand from sharp edges of

sprocket.

d. Using a 5/8 inch box wrench, turn forcing screw until

bearing inner race and thrust washer are pulled free

of camshaft. See A of Figure 3-110. A light interference fit allows the parts to be removed with little

effort. Discard inner race and thrust washer.

e. If present, remove O-ring from grinding relief groove

in camshaft. Groove is on the splined end between

the machined area and the secondary cam

sprocket. Discard O-ring.

NOTE

Since the O-ring is not used in production, it will only be

found if the cams were serviced at the dealer level.

Installation

1. Obtain new rear cam roller bearing kit (Part No. 8983).

See Figure 3-111.

O-Ring

Thrust Washer

Bearing Inner Race

Roller Bearing

f1805x3x

Figure 3-111. Rear Cam Roller Bearing Kit (P/N 8983)

2. Install O-ring, thrust washer and bearing inner race onto

rear camshaft as follows:

a. To properly locate thrust washer, first install O-ring

in grinding relief groove. Groove is on the splined

end between the machined area and the secondary

cam sprocket. Exercise caution to avoid stretching

or breaking the O-ring. Since the O-ring is not sold

separately, damage will require purchase of a new

roller bearing kit.

CAUTION

The thrust washer will be offset to one side if the O-ring

is not installed in the grinding relief groove. Damage to

the bearing cage can occur if the thrust washer is not

properly centered.

b. Slide thrust washer down rear camshaft until cen-

tered over O-ring in grinding relief groove.

c. Slide bearing inner race down rear camshaft until

contact is made with shoulder of machined area.

d. Install primary cam sprocket spacer and sprocket

on camshaft and secure using thic

and long

flange bolt.

ker flat washer

NOTE

If not enough of the splined shaft is exposed to install the

sprocket, leave out the spacer and proceed to step 2(e).

Once the bearing inner race has been started onto the

machined area, remove the flange bolt, washer and sprocket,

and then reassemble using the spacer. Repeat step 2(e) to

fully install bearing inner race.

e. Wrap a shop rag around camshaft to get a firm grip

and also to protect hand from sharp edges of

sprocket. Using a 9/16 inch box wrench, turn flange

bolt in a clockwise direction. Bearing inner race is

fully installed when it makes firm contact with the

thrust washer. See B of Figure 3-110.

3-92 2004 Touring: Engine

Page 17

HOM

f2067x3x

Rear

Camshaft

Front

Camshaft

Pin Stamped

Timing Lines

E

Roller Bearing

Rear Cam

f1804x3x

Ball Bearing

Front Cam

Figure 3-112. Cam Bearings

f. Verify that the thrust washer is locked in place and

cannot be rotated

. If necessary, install shaft in vise

using brass jaw inserts, and further tighten flange

bolt until the desired result is achieved.

g. Remove flange bolt, flat washer, sprocket and

spacer.

7. Apply a small dab of Loctite Medium Strength Threadlocker 243 (blue) to threads of four bearing retainer plate

screws. Using a T20 TORX drive head, secure bearing

retainer plate to cam support plate. Tighten screws to

20-30

in-lbs

(2.3-3.4 Nm) in a crosswise pattern. Verify

that hole in retainer plate is properly aligned with secondary cam chain oiler.

8. Place cam support plate back on support block, if

removed. Block properly supports inner races of bearings as camshafts are installed.

9. Align pin stamped timing lines on teeth of secondary

cam sprockets (outboard faces). See Figure 3-113.

Using a colored marker, carefully mark the timing line

locations on the inboard side of the sprocket teeth.

These marks are needed to observe proper orientation

of the camshafts when they are pressed into the bearings.

10. Place the secondary cam chain around the sprockets of

both the front and rear camshafts. To maintain the original direction of rotation, be sure that the colored mark

placed on the chain link during disassembly is facing

opposite the cam support plate during installation.

CAUTION

Always install new bearings. Only use genuine HarleyDavidson bearings. Reusing old bearings or using bearings from a supplier other than Harley-Davidson will

result in engine damage.

3. Obtain the CAMSHAFT/CAMSHAFT BEARING REMOVER/INSTALLER (HD-43644).

4. With the secondary cam chain side facing upward, place

cam support plate on support block, so that outer races

of bearings are properly supported. Note that one corner

of the support block is contoured to accommodate the

chain guide blocks cast into the front of the support

plate.

5. Center

new

bearing over bearing bore with the lettered

side up. Slide pilot shaft of bearing driver through

bearing into hole of support block.

NOTE

Be aware that the front and rear cam bearings are not interchangeable. The rear bearing is the roller type, while the front

is the ball bearing kind. See Figure 3-112.

6. Center bearing driver under ram of arbor press. Press

on driver until bearing makes firm contact with counterbore in cam support plate. See upper frame of Figure 3-

114. Repeat steps to install second bearing.

NOTE

Bearings may be a press to loose fit. If deemed necessary,

clean bearing OD and apply Loctite Low Strength Threadlocker 243 (Blue) before installation, but exercise caution to

avoid getting compound on rollers or bearing ID.

11. Orient the camshafts so that they are positioned on

opposite ends of the chain, and then verify that the colored marks placed on the inboard side of the sprocket

teeth are still in alignment.

12. Maintaining the position of the camshafts on the chain

with the colored marks in alignment, place the sprocket

ends of the camshafts into the bearings.

Figure 3-113. Align Timing Lines on Teeth

of Camshaft Sprockets

2004 Touring: Engine 3-93

Page 18

HOM

E

Press bearings into cam support plate.

Bearing

Pilot/Driver

Bearing

Support

Block

f1618x3x

Center front camshaft under ram. Start front camshaft into cam bearing.

Ram

Camshaft

Driver

Front

Support

Camshaft

Block

NOTE

Do not mix camshafts during the press procedure. The rear

camshaft, which can be identified by the splined shaft, must

go into the roller bearing at the rear of the cam support plate.

13. Place cup of camshaft driver over end of front camshaft

only.

CAUTION

Verify that splined end of rear camshaft has been started

into support block. Damage to the camshaft and/or support block can occur if end of camshaft catches top of

block during the press procedure.

NOTE

To r educe the likelihood of such contact occuring, use 7/8

inch drill bit to enlarge rear cam bore in support block. For

best results, radius top inside edge of bore after drilling.

CAUTION

Be sure that the tensioner shoe is clear of the secondary

cam chain during the press procedure. Contact can

result in damage that requires replacement of the tensioner assembly.

14. Center end of front camshaft under ram and slo

t

pressure to driver just to

front camshaft into bear-

star

wly apply

ing ID. See center frame of Figure 3-114.

f1822x3x

While applying pressure to front camshaft, wiggle

rear camshaft to guide inner race between bearing

rollers.

Rear

Camshaft

f1821x3x

Figure 3-114. Install Cam Bearings/Camshafts

CAUTION

If rear camshaft is not properly aligned, edge of installed

inner race can catch on bearing rollers. Bearing damage

can result if contact occurs during the press procedure.

15. Slowly apply pressure to driver on front camshaft, while

wiggling rear camshaft as necessary to guide inner race

between bearing rollers. See lower frame of Figure 3-

114.

16. When inner race on rear cam is started into roller bearing, apply pressure to driver until front camshaft is fully

seated. If necessary, keep finger pressure at top of rear

camshaft to ensure that assembly remains square and

inner race moves to installed position in roller bearing.

17. Since the pin stamped timing lines on the secondary

sprockets cannot be observed once the camshafts are

pressed into the bearings, note that the outboard ends of

the shafts have a second set of timing lines (although

they may be somewhat difficult to see). Using a straightedge, verify that these timing lines are in alignment. See

Figure 3-115. If they are not, then the camshafts must be

removed and reinstalled (with a new bearing set).

3-94 2004 Touring: Engine

Page 19

HOM

1CAUTION

1WARNING1WARNING

E

Rear

Camshaft

Pin Stamped

Timing Lines

Figure 3-115. Verify Alignment of Timing Lines

on Ends of Camshafts

Front

Camshaft

f2068x3x

1WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

18. With the sharp edge out, install

groove at end of front camshaft.

new

retaining ring in

Cam Chain Tensioners

Removal

Do not pull the retention pins from the primary or secondary cam chain tensioners with the chains and

sprockets removed. With 35-40 pounds of spring pressure behind the tensioner, allowing it to accelerate

through its full length of travel will cause spring stretching and/or cracking of the tensioner shoe, damage which

requires replacement of the assembly. Furthermore, if

the tensioner should contact fingers or other parts of the

hand, minor or moderate injury may occur.

1. If retracted, hold the cam chain tensioner with the CAM

CHAIN TENSIONER UNLOADER (HD-42313), pull the

retention pin and ease the assembly into the unloaded

position.

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

2. Remove retaining ring from groove in tensioner post.

Discard retaining ring.

3. Slide cam chain tensioner assembly from post disengaging spring pin from hole in cam support plate.

Installation

1. Slide cam chain tensioner assembly onto post inserting

spring pin into hole in cam support plate.

f1676x3x

Acceptable Wear Unacceptable Wear Unacceptable Wear

Continue use of the tensioner shoe

assembly (and chain) if worn to a depth

that is less than half the thickness of the

shoe material.

Replace the tensioner shoe assembly

(and chain) if worn to a depth that is

equal to or greater than half the thickness of the shoe material.

Figure 3-116. Cam Chain Tensioner Shoe Wear

Replace the tensioner shoe assembly

(and chain) if there is any evidence of

melting, burning or cracking.

2004 Touring: Engine 3-95

Page 20

HOM

E

6908

Figure 3-117. Oil Pressure Relief Valve Assembly

3. Slide spring into bypass port until seated in open side of

piston.

4. Start

new

roll pin into hole in cam support plate. Com-

press spring using the blade of a small screwdriver.

5. Holding spring compressed, tap roll pin into cam support

plate until it approaches pin hole on opposite side.

6. Remove screwdriver to release spring. Verify that spring

is straight and square in bore.

7. Using a 1/8 inch punch with a small hammer, carefully

tap roll pin until flush with casting.

8. Install primary cam chain tensioner assembly. See CAM

CHAIN TENSIONERS, INSTALLATION, in this section.

Cam Needle Bearings

1WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

2. With the sharp edge out, install

groove of post. Verify that the ring is fully seated in the

groove.

3. If retracted prior to disassembly, place cup of CAM

CHAIN TENSIONER UNLOADER (HD-42313) over

spring coil of cam chain tensioner assembly. Retract the

tensioner inserting a retention pin through hole in boss

on the

primar

y cam chain side

Oil Pressure Relief Valve

Removal

1. Before removal, see CLEANING AND INSPECTION in

this section.

2. Remove primary cam chain tensioner assembly. See

CAM CHAIN TENSIONERS, REMOVAL.

3. Secure the cam support plate in a vise with access to

the roll pin. Be sure to install a pair of brass jaw inserts in

the vise to avoid damage to the casting.

4. Using a 1/8 inch punch with a small hammer, carefully

tap roll pin from pin hole in cam support plate. Discard

roll pin.

5. Remove spring and piston from bypass port.

Installation

1. Secure the cam support plate in a vise. Install a pair of

brass jaw inserts to avoid damage to the casting.

2. Lubricate piston with clean H-D 20W50 engine oil. Slide

piston into bypass port with the open side facing outward.

new

retaining ring in

of cam support plate.

Removal

1. Obtain the CAMSHAFT NEEDLE BEARING REMOVER/INSTALLER (HD-42325).

2. Remove four button fasteners from threaded holes in

support plate, if installed. See Figure 3-118.

3. Sparingly apply graphite lubricant to threads of collet to

prolong service life and ensure smooth operation.

4. Slide collet through support plate so that threaded end

exits stamped side of plate.

5. Aligning two large holes in support plate with needle

bearing bores, hang right side of plate on ring dowel in

crankcase flange.

f1303x2x

Hex Nut

Nice

Bearing

Pilot

Flat

Washer

Collet

Threaded End

Figure 3-118. Camshaft Needle Bearing Remover/Installer

Graphite

Lubricant

Installer

Shaft

(HD-42325)

Button

Fastener (4)

Support

Plate

Collet

Expandable End

3-96 2004 Touring: Engine

Page 21

HOM

f1586x3x

f1587x3x

f1588x3x

Support

Plate

Button

Fastener

Hex

Nut

Flat

Washer

Nice

Bearing

Ring Dowel

Hole

Collet

Threaded End

Hex

Flat

Holding flat, turn hex in a

clockwise direction to expand collet.

Turn hex n

ut in a clockwise direction

to remove bearing.

Install support plate with collet.

Install Nice bearing, flat washer and hex nut.

E

6. Align four holes at corners of support plate with threaded

holes in crankcase flange. Install button fasteners in

these holes to secure support plate to crankcase. See

upper frame of Figure 3-119.

7. Center expandable end of collet in bearing bore and

slide Nice bearing and flat washer on threaded end.

Start hex nut on threaded end.

8. Push expandable end of collet through bearing bore into

flywheel compartment. Feel for inside edge of needle

bearing using end of collet and then back off slightly.

9. Holding collet to prevent lateral movement, finger tighten

hex nut until Nice bearing contacts support plate.

10. Using a 7/16 inch open end wrench, hold flat on collet to

prevent rotation. Using a second 7/16 inch open end

wrench, expand collet by turning hex at end of shaft in a

clockwise direction. See center frame of Figure 3-119.

Expandable end of collet makes contact with needle

bearing ID.

11. Using a 15/16 inch open end wrench, turn hex nut in a

clockwise direction until bearing is free. If necessary,

hold flat on collet to prevent rotation. See lower frame of

Figure 3-119.

12. Remove four button fasteners and pull support plate

from crankcase.

13. Holding flat on collet, turn hex at end of shaft in a counterclockwise direction to close collet. Remove and discard needle bearing.

14. Remove hex nut, flat washer and Nice bearing from

threaded end of collet. Pull collet from support plate.

15. Return to step 1 to remove second needle bearing.

Installation

1. Obtain the CAMSHAFT NEEDLE BEARING RE-

2. Sparingly apply graphite lubricant to threads of installer

3. Thread installer shaft into stamped side of support plate

4. Install pilot at end of installer shaft.

5. Place

6. Aligning two large holes in support plate with needle

7. Align four holes at corners of support plate with threaded

8. Using 15/16 inch open end wrench, turn hex at end of

9. Turn end of installer shaft in a counterclockwise direction

MOVER/INSTALLER (HD-42325).

shaft to prolong service life and ensure smooth operation.

until threads begin to emerge from opposite side.

new

needle bearing on pilot with lettered side fac-

ing shoulder.

bearing bores, hang right side of plate on ring dowel in

crankcase flange.

holes in crankcase flange. Install button fasteners in

these holes to secure support plate to crankcase. See

upper frame of Figure 3-120.

installer shaft in a clockwise direction until resistance is

felt. See lower frame of Figure 3-120.

until pilot is free of needle bearing bore.

Figure 3-119. Remove Cam Needle Bearing

2004 Touring: Engine 3-97

Page 22

HOM

E

Install support plate with installer shaft (and pilot).

Support

Plate

Button

Fastener

Ring Dowel

Hole

Installer

Shaft

f1589x3x

Turn hex on installer shaft in a clockwise direction

to install bearing.

a. Measure distance from edge of cam support plate

to inboard side of piston. Insert straight stiff wire into

unplugged hole outboard of roll pin until it bottoms,

and then mark and measure wire. With piston fully

seated in the bore, depth should be approximately

2.25 inches (57.15 mm). If it is not, continue with

step 1(b).

b. Remove oil pressure relief valve. See OIL PRES-

SURE RELIEF VALVE, REMOVAL, in this section.

c. Inspect spring for stretching, kinking or distortion.

d. Inspect piston and bore for burrs, scoring or other

damage. Look for steel particles or aluminum chips.

Replace cam support plate and piston if any of

these conditions are found.

e. Install piston in bore and measure running clear-

ance. If running clearance exceeds 0.003 inch

(0.076 mm), install new piston and remeasure.

Replace cam support plate if running clearance still

exceeds specification.

2. Clean cam support plate as follows:

a. Using a small screwdriver, carefully pry cleaning

plug from cam support plate. See Figure 3-121.

b. Thoroughly flush cam support plate with a non-vola-

tile cleaning solution or solvent and then blow dry

with low pressure compressed air.

c. Reinstall cleaning plug replacing O-ring if damaged

or deteriorated.

d. Verify that all oil holes are clean and open.

f1590x3x

Figure 3-120. Install Cam Needle Bearing

10. Remove four button fasteners and pull support plate and

installer shaft from crankcase.

11. Remove pilot from installer shaft. Unthread installer

shaft from support plate.

12. Return to step 1 to install second needle bearing.

13. Thread four button fasteners into threaded holes in support plate to prevent loss.

Cleaning and Inspection

1. Inspect oil pressure relief valve as follows:

NOTE

If diagnosing low oil pressure, start with step 1(a). If diagnosing high oil pressure, then begin with step 1(b).

CAUTION

Exercise caution to avoid enlarging the oil holes or oil

pressure will be adversely affected.

Installation

1. See Section 3.10 BOTTOM END OVERHAUL, ASSEM-

BLY, steps 12-29.

2. Remove wireforms to release hydraulic lifters.

3. See Section 3.9 TOP END OVERHAUL, ASSEMBLY,

steps 29-39.

6891

Figure 3-121. Remove Cleaning Plug

3-98 2004 Touring: Engine

Page 23

HOM

f1563x3x

Wear

Limit

Inner Gerotor Outer Gerotor

E

OIL PUMP

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-11.

NOTE

When removing the cam support plate, it is not necessary to

disturb the lifter assemblies if a method is devised to prevent

the hydraulic lifters from dropping into the cam compartment.

One such method is provided in the following step. Leaving

the lifter assemblies intact simplifies the procedure, since the

lifter cover, gasket, anti-rotation pin and hydraulic lifters can

be left in place.

2. Fashion lifter holding tool as follows:

a. Obtain a large binder clip (available at any office

supply store). Squeeze wireforms to remove from

binder clip. See upper frame of Figure 3-102.

b. Compress wireform slightly and insert free ends into

outer and inner lifter cover bores so that legs

engage walls of both hydraulic lifter sockets. See

lower frame of Figure 3-102.

3. See Section 3.10 BOTTOM END OVERHAUL, DISAS-

SEMBLY, steps 1-15.

Cleaning and Inspection

1. Clean all parts in a non-volatile cleaning solution or solvent.

Narrow

Gerotor Set

(Feed)

Wave

Washer

Oil Pump

Housing

Wide

Gerotor Set

(Scavenge)

O-Ring

O-Ring

Figure 3-123. Measure Gerotor Sets for Wear

2. Thoroughly dry all parts with low pressure compressed

air. Verify that all oil passages are clean and open.

3. Look for scoring, gouging or cracking caused by foreign

material that may have passed through the oil pump.

4. Look for grooves or scratches on the cam support plate,

which serves as the outboard side of the oil pump.

5. Check for excessive wear or damage on lobes of outer

gerotors and between lobes on inner gerotor.

6. Mesh pieces of one gerotor set together as shown in

Figure 3-123. Use a feeler gauge to determine clear-

ance between tips of lobes on inner and outer gerotors.

The maximum allowable clearance is 0.004 inch

(0.10 mm). Replace gerotor set if clearance exceeds

specification. Inspect second gerotor set in the same

manner.

7. Measure thickness of inner gerotor of one set with a

micrometer. Measure the outer gerotor of the same set.

Replace the gerotor set if the difference exceeds 0.001

inch (0.025 mm). Inspect second gerotor set in the same

manner.

8. Assemble the oil pump. Verify that feed gerotors stand

proud of the oil pump surface 0.080-0.090 inch (2.03-

2.29 mm). If measurement is less than 0.080 inch (2.03

mm), remove feed gerotor set and reassemble using

new

wave washer. Repeat measurement and replace oil

pump body if still not within specification.

Separator

Plate

Separator

Plate

Figure 3-122. Oil Pump Assembly

f1530b3x

Installation

1. See Section 3.10 BOTTOM END OVERHAUL, ASSEM-

BLY, steps 11-29.

2. Remove wireforms to release hydraulic lifters.

3. See Section 3.9 TOP END OVERHAUL, ASSEMBLY,

steps 29-39.

2004 Touring: Engine 3-99

Page 24

HOM

E

Legend:

1. Crankshaft Bearing

2. Ring Dowel

3. Cam Needle Bearing

4. Oil Inlet Fitting

5. Oil Outlet Fitting

6. Crankcase Breather Fitting

7. Right Crankcase Half

8. O-Ring

9. Piston Jet

10. T20 TORX Screw

11. Lock Ring

12. Sprocket Shaft Bearing

13. O-Ring

14. Ring Dowel

15. Plug

16. O-Ring

17. Oil Filter Mount

18. Oil Filter Adapter

19. Flat Washer

20. Bolt

21. Lockplate

22. Oil Filter

23. Crankcase Bolt

24. Ring Dowel

25. O-Ring

26. Left Crankcase Half

27. Thrust Washer

28. Oil Seal

29. Sprocket Shaft Spacer

f2070x3x

28

27

29

26

25

24

6

7

12

10

11

9

5

8

23

4

3

2

14

13

19

20

21

1

18

15

16

22

17

3-100 2004 Touring: Engine

Figure 3-124. Crankcase Assembly (Exploded View)

Page 25

1. Ram

2. Pilot/Driver

3. Support Tube

3

1

2

“A”

End Up

f2126x3x

HOM

E

CRANKCASE

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-29.

2. See Section 3.10 BOTTOM END OVERHAUL, DISAS-

SEMBLY, steps 1-18.

Disassembly/Assembly

RIGHT CRANKCASE HALF

Crankshaft Bearing

Removal

1CAUTION

Never move or lift the crankcase by grasping the cylinder studs. The crankcase is too heavy to be carried in

this manner and may be dropped. Dropping the crankcase may result in parts damage and minor or moderate

injury.

1. See Figure 3-125. Obtain CRANKSHAFT/SPROCKET

SHAFT BEARING REMOVER/INSTALLER PILOT/

DRIVER (B-45655) and CRANKSHAFT/SPROCKET

SHAFT BEARING REMOVER/INSTALLER SUPPORT

TUBE (HD-42720-5).

2. Place support tube on hydraulic press table with the “A”

end up. The ends of the support tube are stamped “A”

and “B” to ensure proper orientation.

3. With the outboard side of the right crankcase half facing

upward, position crankshaft bearing bore over support

tube.

Support Tube

Part No. HD-42720-5

Figure 3-126. Remove Crankshaft Bearing

4. Slide pilot/driver through bearing into support tube.

5. Center pilot/driver under ram of press. Apply pressure to

pilot/driver until bearing is free. See Figure 3-126.

6. Remove right crankcase half, pilot/driver and bearing

from support tube. Discard bearing.

Installation

1. See Figure 3-125. Obtain CRANKSHAFT/SPROCKET

SHAFT BEARING REMOVER/INSTALLER PILOT/

DRIVER (B-45655) and CRANKSHAFT/SPROCKET

SHAFT BEARING REMOVER/INSTALLER SUPPORT

TUBE (HD-42720-5).

Pilot/Driver

Part No. B-45655

Figure 3-125. Crankshaft/Sprocket Shaft Bearing

Pilot/Driver and Support Tube

d0687x3x

2. Turn support tube over so that the “B” end is up. The

ends of the support tube are stamped “A” and “B” to

ensure proper orientation.

3. With the outboard side of the right crankcase half facing

upward, position crankshaft bearing bore over support

tube.

4. Obtain new crankshaft bearing and apply a thin film of

clean engine oil to O.D.

2004 Touring: Engine 3-101

Page 26

HOM

E

1. Ram

2. Pilot/Driver

3. Support Tube

4. Crankshaft Bearing

1

2

4

“B”

End Up

3

f2127x3x

Installation

CAUTION

O-rings that are missing, distorted, pinched or otherwise

damaged will result in either oil leakage or low oil pressure. Use of the wrong O-ring will have the same results.

Since many O-rings are similar in size and appearance,

always use ne

use to avoid confusion.

1. Install new O-ring in groove of jet mounting flange. Apply

a very thin film of clean H-D 20W50 engine oil to O-ring

before installation.

2. Apply Loctite Low Strength Threadlocker 222 (purple) to

threads of two T20 TORX screws.

3. With the jet pointed upward, install TORX screws to

secure piston jet to crankcase. Tighten screws to 25-35

in-lbs (2.8-4.0 Nm).

w O-rings keeping them packaged until

LEFT CRANKCASE HALF

Sprocket Shaft Bearing

Removal

Figure 3-127. Install Crankshaft Bearing

5. Start crankshaft bearing into bore with the lettered side

up. Lubricate leading edge of bearing before placement.

6. Slide pilot/driver through bearing into support tube.

7. Center pilot/driver under ram of press. Apply pressure to

pilot/driver until resistance is felt and bearing bottoms in

support tube. See Figure 3-127.

8. Remove pilot/driver and right crankcase half from support tube.

Piston Jets

Removal

1. Remove two T20 TORX screws to free piston jet from

crankcase.

2. Remove O-ring from groove in mounting flange of jet.

Discard O-ring.

1CAUTION

Never move or lift the crankcase by grasping the cylinder studs. The crankcase is too heavy to be carried in

this manner and may be dropped. Dropping the crankcase may result in parts damage and minor or moderate

injury.

1WARNING1WARNING

Do NOT rotate left crankcase half in the engine stand so

the stator mount flange (sprocket shaft side) is facing up

or the flywheel assembly will drop to the floor. Dropping

the flywheel assembly may result in parts damage and

minor or moderate injury.

1. Holding flywheel assembly so that it does not drop out of

left crankcase half, rotate cradle so that engine is upright

and crankshaft and sprocket shaft are horizontal.

2. Carefully slide flywheel assembly out of left crankcase

half.

3. Remove left crankcase half from engine stand and move

to bench area. Remove thrust washer from outboard

side of crankcase by pulling it past the oil seal. Set thrust

washer aside for inspection or reuse.

4. Using a suitable drift, tap oil seal from bearing bore. Discard oil seal.

3-102 2004 Touring: Engine

Page 27

HOM

1CAUTION

3

1. Ram

2. Pilot/Driver

3. Support Tube (“A” end up)

4. Sprocket Shaft Bearing

1

4

f2132x3x

f2129x3x

2

3

E

f2136x3x

1

2

3

f2129x3x

1. Ram

2. Pilot/Driver

3. Support Tube (“A” end up)

Figure 3-128. Remove Sprocket Shaft Bearing

5. See Figure 3-125. Obtain CRANKSHAFT/SPROCKET

SHAFT BEARING REMOVER/INSTALLER SUPPORT

TUBE (HD-42720-5) and CRANKSHAFT/SPROCKET

SHAFT BEARING REMOVER/INSTALLER PILOT/

DRIVER (B-45655).

6. Place left crankcase half on work bench with inboard

side of facing upward.

7. Using the tip of a flat blade screwdriver, carefully lift end

of lock ring out of groove in bearing bore. Working the

screwdriver around the edge, lift the lock ring up and out

of the groove. Be careful not to damage the lip of the

groove during removal.

8. Place support tube on hydraulic press table with the “A”

end up. The ends of the support tube are stamped “A”

and “B” to ensure proper orientation.

9. With the outboard side of the left crankcase half facing

upward, position sprocket shaft bearing bore over support tube. See Figure 3-128.

10. Slide pilot/driver through bearing into support tube.

11. Center pilot/driver under ram of press. Apply pressure to

pilot/driver until bearing is free.

12. Remove left crankcase half, pilot/driver and bearing from

support tube. Discard bearing.

3

Figure 3-129. Install Sprocket Shaft Bearing

Installation

Never move or lift the crankcase by grasping the cylinder studs. The crankcase is too heavy to be carried in

this manner and may be dropped. Dropping the crankcase may result in parts damage and minor or moderate

injury.

1. See Figure 3-125. Obtain CRANKSHAFT/SPROCKET

SHAFT BEARING REMOVER/INSTALLER SUPPORT

TUBE (HD-42720-5) and CRANKSHAFT/SPROCKET

SHAFT BEARING REMOVER/INSTALLER PILOT/

DRIVER (B-45655).

2. Place support tube on hydraulic press table with the “A”

end up. The ends of the support tube are stamped “A”

and “B” to ensure proper orientation.

3. With inboard side of the left crankcase half facing

upward, position sprocket shaft bearing bore over support tube.

4. See Figure 3-129. Obtain new sprocket shaft bearing

and apply a thin film of clean engine oil to O.D.

5. Start sprocket shaft bearing into bearing bore with the

lettered side down. Lubricate leading edge of bearing

before placement.

2004 Touring: Engine 3-103

Page 28

HOM

E

6. Slide pilot/driver through bearing into support tube.

7. Center pilot/driver under ram of press. Apply pressure to

pilot/driver until bearing lightly bottoms in the bore.

8. Remove left crankcase half and pilot/driver from support

tube.

9. Place left crankcase half on work bench with inboard

side of facing upward.

10. Obtain new lock ring and work into groove in bearing

bore. Be careful not to damage the lip of the groove during installation. Verify that lock ring is fully seated in the

groove.

NOTE

If lock ring will not fit into groove, bearing bore may not have

been properly cleaned and/or bearing may not be fully

seated in the bore.

Sprocket Shaft Bearing Inner Race

Removal

1. If reusing flywheel, remove bearing inner race and thrust

washer as follows:

a. Obtain FLYWHEEL SUPPORT FIXTURE (HD-

44358). See Figure 3-130. Install brass jaws or

shop towels around teeth of vise to prevent damage

to tool. Clamp tool in vise with the round hole topside.

b. Insert crankshaft end through hole resting flywheel

assembly on fixture. Slide knurled locating pin down

slot in tool to engage crank pin hole. Hand tighten

locating pin.

c. Slide hold-down clamp down slot to engage inboard

side of right flywheel half, and then hand tighten

knurled nut at bottom to secure. Repeat step to

secure hold-down clamp on opposite side of flywheel.

NOTE

For proper clamping force, hold-down clamp must not be

tilted. Rotate hex on outboard stud until clamp is level.

d. Position WEDGE ATTACHMENT (HD-95637-46A)

on inboard side of thrust washer and turn hex nuts

an equal number of turns to draw halves of wedge

together.

CAUTION

Install wedge attachment only so far as necessary to

ensure positive contact with thrust washer. Installing

tool with more contact than absolutely necessary will

result in damage to flywheel.

e. Obtain two 3/8-16 inch bolts 6-1/2 inches long (with

flat washers). Install flat washers on bolts. Obtain

bridge, forcing screw and hardened plug from

MAINSHAFT BEARING INNER RACE PULLER/

INSTALLER (HD-34902B).

Hold-Down

Clamp

Locating Pin

Figure 3-130. Flywheel Fixture (Part No. HD-44358)

f2154x3x

1

2

3

7

6

1. Forcing Screw

2. 3/8-16 Inch Bolt

with Flat Washer

3. Bridge

Figure 3-131. Remove Inner Race From Sprocket Shaft

f. Slide one bolt into channel on each side of bridge

so that flat washer is between bridge and bolt head.

Thread bolts into wedge attachment an equal number of turns.

4. Hardened Plug

5. Wedge Attachment

6. Bearing Inner Race

7. Sprocket Shaft

4

5

3-104 2004 Touring: Engine

Page 29

HOM

CAUTION

f2152x3x

f2153x3x

1. Install Thrust Washer and Bearing Inner Race On

Sprocket Shaft. Assemble Tool.

2. Press Bearing Inner Race Onto Sprocket Shaft.

1. Pilot Shaft

2. Handle

3. Flat Washer

4. Nice Bearing

5. Sleeve

6. Inner Race

7. Thrust Washer

2

1

3

5

6

7

4

E

f2265x3x

Figure 3-132. Sprocket Shaft Timken Bearing

Cone Installer (Part No. HD-97225-55B)

g. Sparingly apply graphite lubricant to threads of forc-

ing screw to prolong service life and ensure smooth

operation. Start forcing screw into center hole of

bridge.

Failure to use hardened plug may result in damage to

forcing screw and/or sprocket shaft.

h. Place cupped side of hardened plug against end of

sprocket shaft. Thread forcing screw into bridge until

the steel ball at the end of the screw makes firm

contact with hardened plug.

i. Using the Robinair Heat Gun (HD-25070), uniformly

To faciliate removal without heat, apply a light penetrating oil

to shaft and leading edge of bearing inner race.

heat the bearing inner race for about 30 seconds

using a circular motion.

CAUTION

NOTE

1WARNING1WARNING

Never use both heat and penetrating oil. Use only one or

the other. Excessive heat can cause the penetrating oil

to ignite resulting in flames or fire. Inadequate safety

precautions can result in death or serious injury.

j. Turn forcing screw until thrust washer and bearing

inner race move approximately 1/8 inch (3.2 mm).

k. Turn hex nuts an equal number of turns to separate

halves of WEDGE ATTACHMENT.

Figure 3-133. Press Inner Race Onto Sprocket Shaft

l. After bottoming thrust washer on shaft, reposition

WEDGE ATTACHMENT (HD-95637-46A) on

inboard side of bearing inner race. Turn hex nuts an

equal number of turns to draw halves of wedge

together.

Install wedge attachment only so far as necessary to

ensure positive contact with bearing inner race. Installing tool with more contact than absolutely necessary

will result in damage to flywheel.

2004 Touring: Engine 3-105

Page 30

HOM

f2266x3x

E

9

8

7

2

3

1

Figure 3-134. Sprocket Shaft Bearing Assembly

m. Verify that the tool assembly is square, so that the

bearing inner race is not cocked during removal.

See Figure 3-131.

n. Using the Robinair Heat Gun (HD-25070), uniformly

heat the bearing inner race for about 30 seconds

using a circular motion.

NOTE

To faciliate removal without heat, apply a light penetrating oil

to shaft and leading edge of bearing inner race.

o. Tu rn forcing screw until bearing inner race is pulled

free of sprocket shaft.

p. Remove thrust washer from sprocket shaft.

2. Discard thrust washer and bearing inner race.

Installation

1. Place new thrust washer over sprocket shaft with the ink

stamp facing outside (and the chamfer on the ID

inboard).

2. Place new bearing inner race on bench top. Using the

Robinair Heat Gun (HD-25070), uniformly heat bearing

inner race for about 60 seconds using a circular motion.

3. Wearing suitable gloves to protect hands from burns,

place heated bearing inner race over sprocket shaft.

5

6

4

5. Bearing

1. Flywheel Assembly

2. Thrust Washer

3. Inner Race

4. Lock Ring

To faciliate installation without heat, apply a light penetrating

oil to shaft and leading edge of bearing inner race.

6. Left Crankcase Half

7. Thrust Washer

8. Oil Seal

9. Spacer

NOTE

1WARNING1WARNING

Never use both heat and penetrating oil. Use only one or

the other. Excessive heat can cause the penetrating oil

to ignite resulting in flames or fire. Inadequate safety

precautions can result in death or serious injury.

4. Obtain the SPROCKET SHAFT TIMKEN BEARING

CONE INSTALLER (HD-97225-55B). See Figure 3-132.

Assemble tool as described below.

a. Thread pilot onto sprocket shaft until contact is

made with shoulder.

b. Sparingly apply graphite lubricant to threads of pilot

shaft to prolong service life and ensure smooth

operation.

c. Slide sleeve over pilot until it contacts bearing inner

race.

d. Slide Nice bearing and large flat washer over pilot

until contact is made with sleeve.

e. Thread handle onto pilot shaft. See upper frame of

Figure 3-133.

3-106 2004 Touring: Engine

Page 31

HOM

E

5. Rotate handle of tool in a clockwise direction until bearing inner race bottoms against thrust washer. See lower

frame of Figure 3-133.

6. Remove handle, flat washer, Nice bearing, sleeve and

pilot from sprocket shaft.

Cylinder Studs

Removal

1. Thread a 3/8”-16 nut onto cylinder stud.

2. Thread a second nut onto stud until it contacts the first.

3. Placing wrench on first nut installed, remove stud from

cylinder deck.

Installation

1. Hand start stud in cylinder deck with the collar side

down.

2. Install steel ball bearing into unused cylinder head bolt.

Position head bolt on end of stud.

3. Using an air gun, tighten stud until collar almost contacts

cylinder deck.

4. Leaving cylinder head bolt installed, hand tighten stud to

10-20 ft-lbs (14-27 Nm).

5. Check ring dowels for looseness, wear or damage.

Replace as necessary.

6. Use a file to carefully remove any nicks or burrs from

machined surfaces.

7. Clean out tapped holes and clean up damaged threads.

8. Check the top of the crankcase for flatness with a

straightedge and feeler gauge. Replace if warped.

Installation

1. See Section 3.10 BOTTOM END OVERHAUL, ASSEM-

BLY, steps 1-29.

2. See Section 3.9 TOP END OVERHAUL, ASSEMBLY,

steps 1-39.

Pipe Plug and Oil Fittings

Removal

1. Turn hex on oil fittings in a counterclockwise direction

until free.

2. Turn pipe plug in a counterclockwise direction until free.

Installation

1. Apply Loctite Pipe Sealant with Teflon 565 to threads.

2. Turn hex on oil fittings in a clockwise direction until snug.

Tighten fittings to 120-168 in-lbs (13.6-18.9 Nm).

3. Install pipe plug. Tighten pipe plug to 120-168 in-lbs

(13.6-18.9 Nm).

Cleaning and Inspection

1. Scrape old gasket material from the crankcase flanges.

Old gasket material left on mating surfaces will cause

leaks.

2. Clean all parts in a non-volatile cleaning solution or solvent.

3. Thoroughly dry all parts with low pressure compressed

air.

4. Verify that all oil holes and passageways are clean and

open.

2004 Touring: Engine 3-107

Page 32

HOM

E

FLYWHEEL/CONNECTING ROD ASSEMBLY

Removal

1. See Section 3.9 TOP END OVERHAUL, DISASSEM-

BLY, steps 1-29.

2. See Section 3.10 BOTTOM END OVERHAUL, DISAS-

SEMBLY, steps 1-18.

3. See Section 3.11 SUBASSEMBLY SERVICE AND

REPAIR, CRANKCASE, LEFT CRANKCASE HALF,

SPROCKET SHAFT BEARING, REMOVAL.

Inspection

1. Replace the flywheel/connecting rod assembly if any of

the following conditions are noted: