Page 1

2

HOME

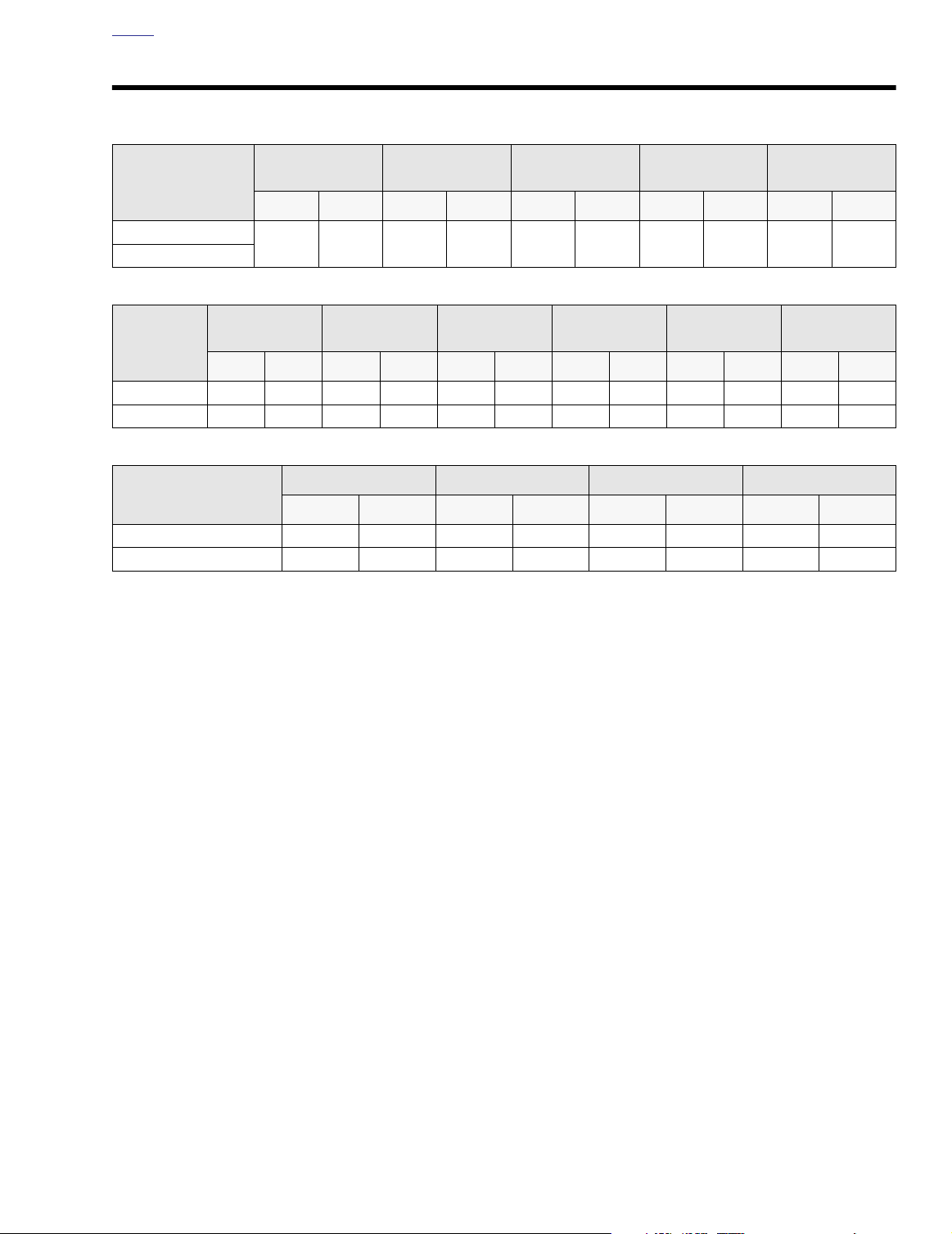

SPECIFICATIONS 2.1

FUEL TANK

MODEL

FLHTP

FLHP

WHEEL BASE

MODEL

in. mm in. mm in. mm in. mm in. mm in. mm

FLHTP 63.5 1612.9 93.70 2379.9 39.0 990.6 5.1 129.5 61.0 1549.4 27.3 693.4

FLHP 63.5 1612.9 93.70 2379.9 34.5 876.3 5.1 129.5 55.1 1399.5 27.3 693.4

MODEL

FLHTP 758.0 343.8 1200 544.3 500 226.8 770 349.3

FLHP 723.0 327.9 1200 544.3 500 226.8 770 349.3

Gross vehicle weight rating (GVWR) (maximum allowable

loaded vehicle weight) and corresponding gross axle weight

rating (GAWR) are printed on a label fixed to the bottom of

the right front frame downtube.

TOTAL

gal. liter gal. liter qt. liter oz. liter oz. liter

5.0 18.92 - - 4.0 3.79 24 0.71 32 0.95

OVERALL

LENGTH

DRY WEIGHT GVWR GAWR FRONT GAWR REAR

lb. kg lb. kg lb. kg lb. kg

NOTE

FUEL TANK

RESERVE

OVERALL

WIDTH

OIL TANK

W/FILTER

ROAD

CLEARANCE

See Section 2.3 TIRES for important information regarding

tire data and tire inflation.

TRANSMISSION

(APPROX.)

OVERALL

HEIGHT

NOTE

PRIMARY

CHAINCASE

SADDLE

HEIGHT (Laden)

2004 FLT Police: Chassis 2-1

Page 2

HOME

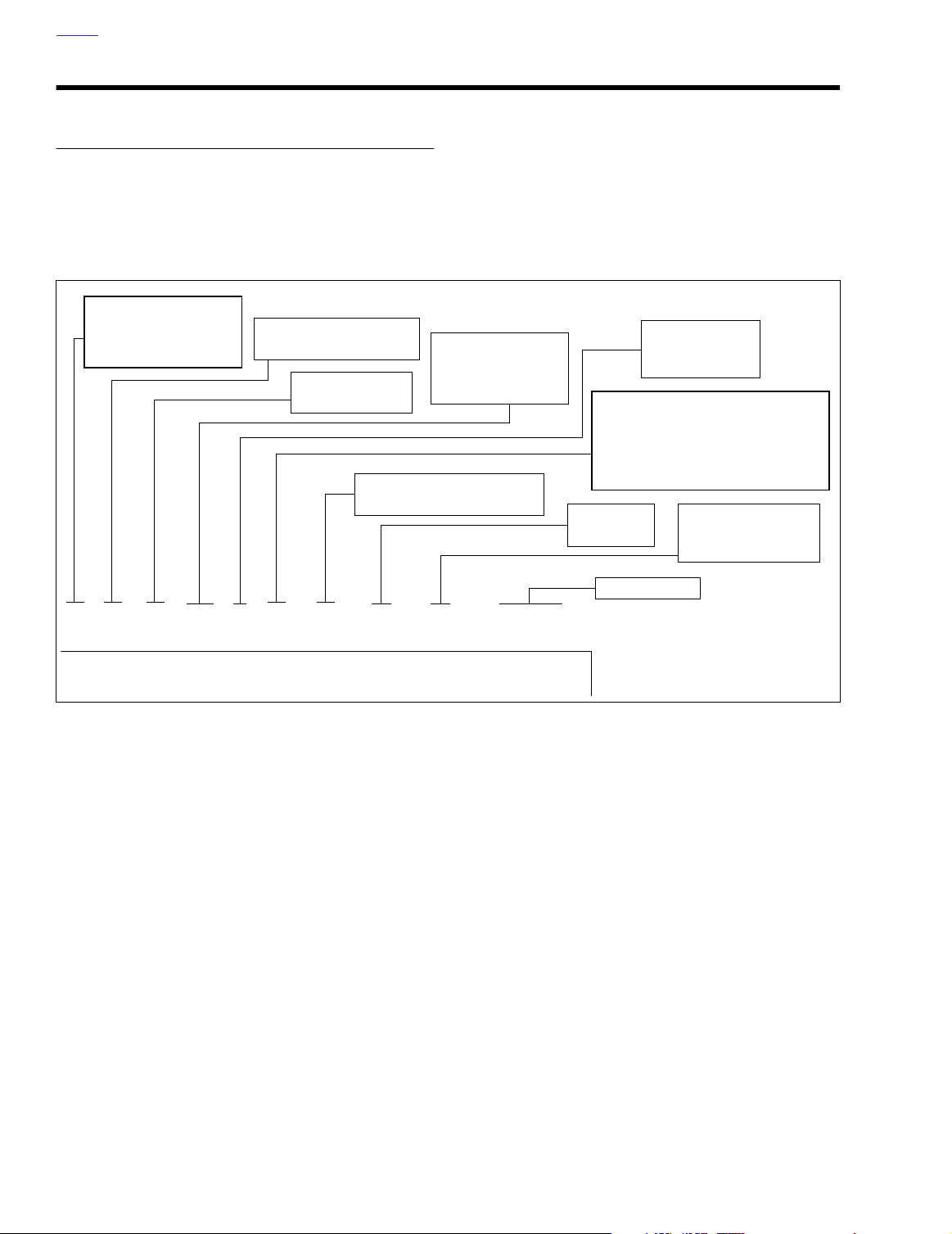

VEHICLE IDENTIFICATION NUMBER 2.2

GENERAL

A 17-digit serial number, or Vehicle Identification Number

(VIN), is stamped on the right side of the frame backbone at

the rear of the steering head (and under the main harness

conduit). A label bearing the VIN code is also affixed to the

left side of the steering head. An abbreviated VIN is stamped

Market Designation

1 = Domestic

5 = International (HDI)

Manufacturer and Make

Harley-Davidson

Motorcycle Type

1 - Heavyweight

Vin Check Digit

Varies; can be 0 thru 9, or X.

between the front and rear cylinders on the left side of the

crankcase.

NOTE

Always give the complete VIN when ordering parts or making

an inquiry about your motorcycle.

Model Designation

FH - FLHPI

FM - FLHTPI

FT - FLHPEI

Model Year

4 - 2004

Engine Type

V - Carbureted

W - Fuel Injected

Introduction Date/Special Models

1 = Regular introduction date

2 = Mid-year introduction date

3 = California model

4 = Anniversary model

Assembly Plant

Y - York, PA

K - Kansas City, MO

Serial Number

1HD 1 FM W 13 4 Y 110000

Sample VIN as it appears on the steering head - 1HD1FMW134Y110000

Sample abbreviated VIN as it appears on the engine - FMW4110000

Figure 2-1. Vehicle Identification Number (VIN)

2-2 2004 FLT Police: Chassis

Page 3

HOME

11WARNING1WARNING

TIRES 2.3

GENERAL

The rear tire on FL police motorcycles is fit for solo riding

only. If converted to a two-up bike, that is, configured for passenger use (with luggage), then the rear tire needs to be

changed to one with a higher weight rating. Since it has long

been Harley-Davidson policy not to mix different types of tires

on the same vehicle, we strongly recommend that both front

and rear tires be replaced. In order to alert the customer to

this safety issue, the following warning appears on a label fitted to the rear fender approximately 1/4 inch (6.4 mm) behind

the domestic seat mounting hole.

11WARNING1WARNING

This vehicle has tires with weight ratings for one person

operation. If this vehicle is modified to carry two people,

the tires must be changed. See your local Harley-Davidson dealer for the proper replacement tires. Failure to follow this warning could cause tire failure which could

result in death or serious injury. (00096a)

Table 2-1. Tire Data

MODEL

TIRE

LOCATION

SIZE

NOTE

Use the tires recommended for civilian/pleasure vehicles of

the same year and model family.

The Dunlop front and rear tires on Harley-Davidson

motorcycles are not interchangeable. DO NOT put a front

tire at the rear of the vehicle or a rear tire at the front.

Improper placement of tires can adversely affect motorcycle stability and handling, which may lead to loss of

vehicle control resulting in death or serious injury.

(00026a)

Tire size, manufacturer’s description and inflation pressure

are listed below.

MANUFACTURER’S

DESIGNATION

TIRE

PRESSURE

(Cold)

FLHTP/FLHP

Front MT90B1672H

Rear MT90B1671H

Dunlop

D402F PT

Dunlop

D402 PT

36 psi

(248 kPa)

36 psi

(248 kPa)

2004 FLT Police: Chassis 2-3

Page 4

HOME

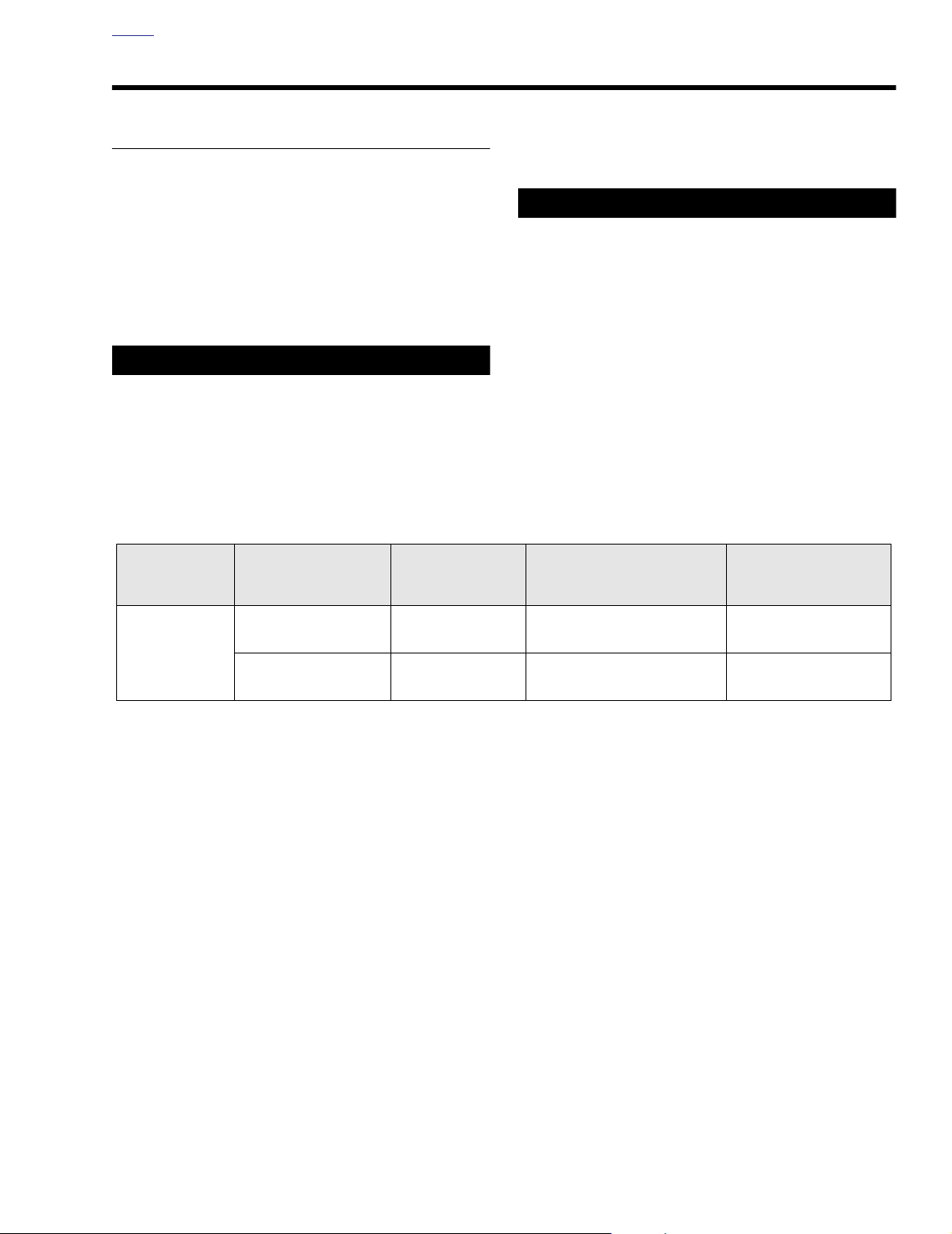

SEAT 2.4

OPERATION

CAUTION

Maximum seat air pressure is 100 psi (689 kPa). Normal

air pressure is between 30-45 psi (207-310 kPa). Minimum

air pressure is determined by rider weight. Do not operate with pressure so low that system bottoms out on

bumpy roads. (00167a)

NOTE

To set minimum air pressure, have rider sit on seat and

bounce to simulate riding conditions. Visually check for any

contact between air spring and frame components. Add air as

necessary.

1. Standing on left side of vehicle, press down on rear of

seat and pull quick release pin from hole in support post.

See Figure 2-2. Raise seat toward fuel tank console.

2. To lock seat in place, move seat down until support post

engages hole in rear seat bracket.

5872

Support

Post

Figure 2-2. Seat Latch

3. While pressing down on rear of seat, insert quick release

pin into hole of support post.

The seat does not adjust forward or backward.

Quick Release

Pin

Rear Seat

Bracket

NOTE

1. Air spring hose

2. Air spring

3. Screw (2) @ 36-60 in-lbs (4.1-6.8 Nm)

4. Trim panel

5. Seat faring

6. Screw

7. Rivnut (4)

8. Screw

9. Bushing

10. Seat support bracket

11. Nut @ 48-84 in-lbs (5.4-9.5 Nm)

12. Seat

13. Seat mount bracket (2)

14. Washer

15. Screw @ 60-120 in-lbs (6.8-13.6 Nm)

16. Screw (4) @ 15-20 ft-lbs (20.3-27.1 Nm)

17. Rubber bumper

18. Flange locknut (2) @ 96-144 in-lbs (10.9-16.3 Nm)

19. Quick release pin

20. Flange nut (2) @ 60-120 in-lbs (6.8-13.6 Nm)

21. Washer (2)

22. Rear seat bracket

23. Set screw (2)

24. Nut (2) @ 50-70 in-lbs (5.7-7.9 Nm)

25. Quick release fitting

6

5

10

11

9

8

13

16

15

14

19

7

12

17

18

20

4

3

2

23

1

25

21

22

24

p0047c2x

2-4 2004 FLT Police: Chassis

Figure 2-3. Air Seat Support

Page 5

HOME

Air

Reservoir

Air Valve

f1842x2x

Air Pressure

Gauge

AIR SEAT RESERVOIR

Removal

1. Remove luggage rack. See Section 2.6 LUGGAGE

RACK, REMOVAL, steps 1-5.

2. Alternately loosen screws on each side of motorcycle to

release ends of luggage rack from frame tube weldments. Continue loosening screws until luggage rack can

be raised high enough to remove air reservoir.

3. Remove two Phillips screws (with lockwashers) from luggage rack to release top of air reservoir bracket.

4. Remove two Phillips screws from license plate bracket to

free rear of air reservoir bracket. Be sure to hold reservoir as the last screw is removed or damage to fender

paint may occur when assembly is released.

5. Raise luggage rack and remove air reservoir from motorcycle.

6. Remove tee fittings from reservoir, if necessary.

Installation

1. Install tee fittings to air reservoir, if removed.

2. Position air reservoir beneath luggage rack exercising

caution to avoid scratching fender paint.

Figure 2-4. Air Seat Reservoir Air Valve

3. Slide Phillips screws through two holes in license plate

bracket and two holes in luggage rack engaging weld

nuts in air reservoir bracket. Alternately tighten screws

until snug.

4. Alternately tighten screws on each side of motorcycle to

secure ends of luggage rack to frame tube weldments.

5. Install luggage rack. See Section 2.6 LUGGAGE RACK,

INSTALLATION, steps 1-4 and 6-13.

1. Air seat reservoir and

bracket

2. Lockwasher (2)

3. Screw (2)

4. Air pressure gauge

5. Air tube

6. Compression fitting

7. Air valve

8. Protective cap

9. Tee fitting (2)

10. Screw (2)

6

8

3

5

7

2

4

9

1

Figure 2-5. Air Seat Reservoir

10

p0048b2x

2004 FLT Police: Chassis 2-5

Page 6

HOME

FOOTBOARDS 2.5

GENERAL

FLHTP and FLHP models are equipped with adjustable footboards.

ADJUSTMENT

Right Side

1. Loosen two allen head socket screws (with lockwashers

and flat washers) to release right side footboard brackets

from frame weldment. For best results, approach from

left side of vehicle using a 3/8 inch ball allen with extension.

2. Move the footboard to one of two positions. Alternately

tighten allen head socket screws to 30-35 ft-lbs (40.7-

47.5 Nm).

11WARNING1WARNING

Rear brake will not operate properly if brake pedal cannot be fully depressed. After adjusting right footboard,

check for minimum clearance of 2.25 inches (57 mm)

between bottom of brake pedal and top of footboard.

Failure to allow for proper clearance can lead to loss of

braking performance, which could result in death or serious injury.

4. At footboard rear bracket, slide upper hex bolt through

frame weldment, jiffy stand bracket and footboard

bracket thru hole. Install lockwasher and locknut. Slide

lower hex bolt (with lockwasher) through frame weldment

and jiffy stand bracket into threaded hole of footboard

bracket. Alternately tighten two hex bolts to 15-20 ft-lbs

(20.3-27.1 Nm).

NOTE

Perform a visual check to verify that both footboards are at

the same height.

Left Side

1. Loosen the allen head socket screw (with lockwasher

and flat washer) to release the footboard forward bracket

from frame weldment. For best results, approach from

opposite side of vehicle using a 3/8 inch ball allen.

2. To free footboard rear bracket from frame weldment and

jiffy stand bracket, remove lower hex bolt (with lockwasher) and upper hex bolt (with lockwasher and locknut).

3. Move the footboard to one of two positions. Alternately

tighten allen head socket screw to 30-35 ft-lbs (40.7-47.5

Nm).

2-6 2004 FLT Police: Chassis

Page 7

HOME

6046

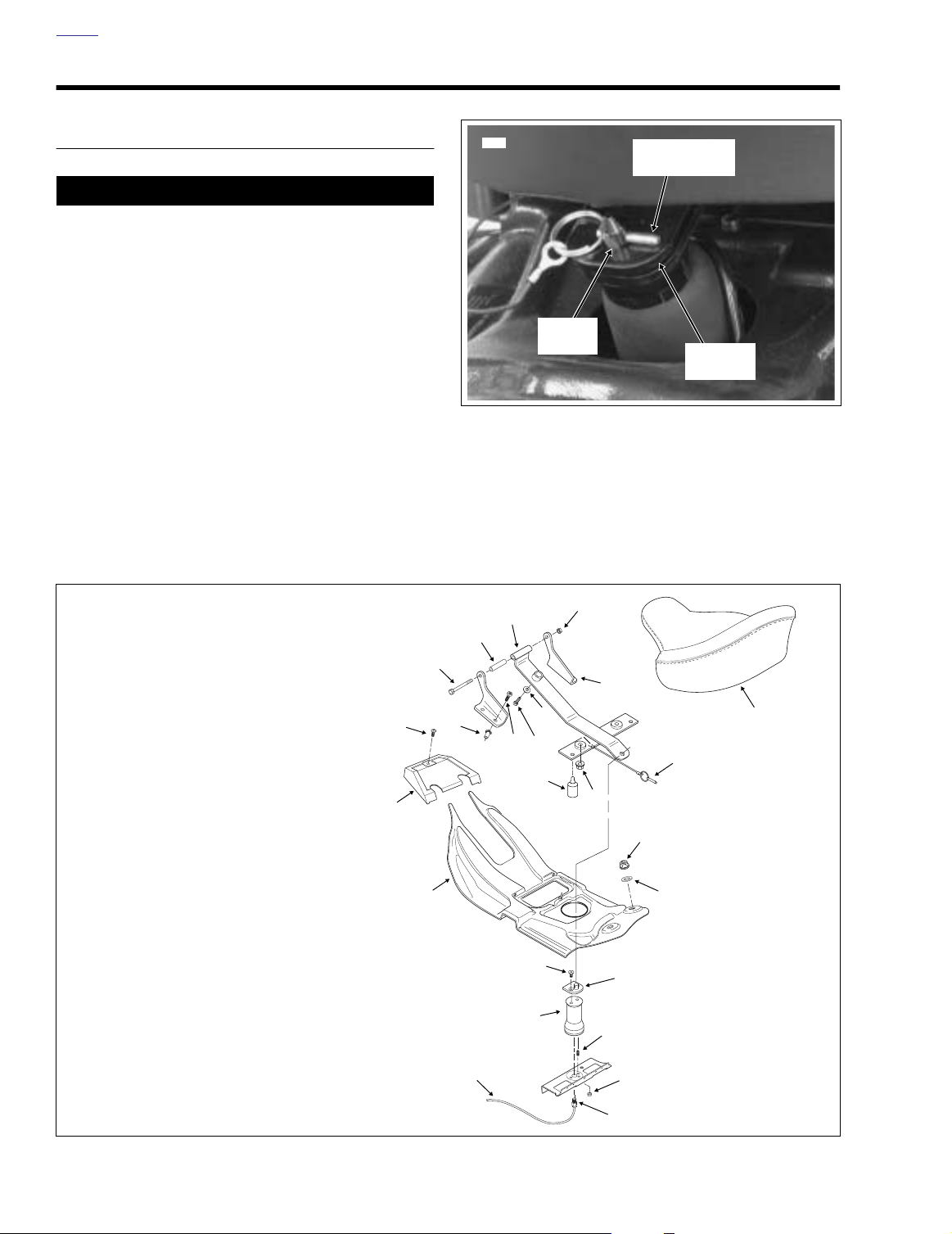

LUGGAGE RACK 2.6

REMOVAL

1. Remove both saddlebags.

2. On the right side of the motorcycle, locate the air seat

reservoir air valve under the luggage rack, and on the left

side, the rear shock air valve just below the chrome

frame cover. See Figure 2-6.

11WARNING1WARNING

Exercise caution when bleeding air from the air valves.

Moisture combined with lubricant (either from shock

assembly or drip oiler in the air compressor lines) may

be ejected onto the rear wheel, tire and/or brake components and adversely affect traction and/or braking efficiency, which could result in death or serious injury.

f1842x2x

f2018x2x

Air Seat

Reservoir

Air Valve

Rear Shock

Air Valve

Figure 2-7. Remove Luggage Rack

3. Remove protective cap from each air valve and depress

pin to bleed air from both reservoir and shocks. To purge

rear air suspension lines of any oil, add 3-5 psi (20.7-

34.5 kPa) before releasing air. Depress collar on each

compression fitting and pull out air tube.

4. Remove bolt (with flat washer) to remove saddlebag front

mounting bracket from chrome frame cover. Remove

Phillips screw and then remove frame cover. Repeat step

on opposite side of motorcycle.

5. Remove two bolts to free license plate bracket from bottom support tube.

6. Remove screws (with spacers) on each side of motorcycle to release ends of luggage rack from frame tube

weldments.

7. Remove pole lamp. See Section 8.5 POLE LAMP.

8. Slide luggage rack toward rear of motorcycle to clear

front bushings, and then rotate rack upward to clear

frame tubes. See Figure 2-7.

INSTALLATION

Figure 2-6. Air Valves

1. Place luggage rack into position inboard of frame tubes.

2004 FLT Police: Chassis 2-7

Page 8

HOME

2. Install screws (with spacers) on each side of motorcycle

to secure ends of luggage rack to frame tube weldments.

3. Install two bolts to fasten license plate bracket to bottom

support tube.

4. Position chrome frame cover on frame tube and install

Phillips screw. Install bolt (with flat washer) to install saddlebag front mounting bracket, but do not tighten. Repeat

step on opposite side of motorcycle.

5. Install pole lamp. See Section 8.5 POLE LAMP.

6. Depress collar on compression fitting of air seat reservoir, and insert air tube until it bottoms. Gently tug on

tube to verify that it is locked in place.

CAUTION

Maximum seat air pressure is 100 psi (689 kPa). Normal

air pressure is between 30-45 psi (207-310 kPa). Minimum

air pressure is determined by rider weight. Do not operate with pressure so low that system bottoms out on

bumpy roads. (00167a)

7. Fill air reservoir to desired pressure. Install protective

cap on air valve. See upper frame of Figure 2-6.

Table 2-2. Rear Air Suspension Pressures

Shock Loading

Solo rider up to 150 lbs. (68 kg) 0 0

Solo rider 150-200 lbs. (68-91 kg) 0-10 0-69

Solo rider 200-250 lbs. (91-113 kg) 5-15 35-103

Maximum GVWR (see Section 2.1

SPECIFICATIONS)

Recommended

Pressures

PSI

0-35

20-35 138-241

kPa

0-241

11WARNING1WARNING

Use this table as a starting point in determining suitable rear air suspension pressures. Do not exceed

maximum GVWR when loading vehicle and do not

pressurize system in excess of 35 psi (241 kPa).

Excessive load weight and/or air suspension pressure can adversely affect handling and lead to loss

of vehicle control, which could result in death or serious injury.

NOTE

To set minimum air pressure, have rider sit on seat and

bounce to simulate riding conditions. Visually check for any

contact between air spring and frame components. Add air as

necessary.

8. Observe air pressure gauge. If leakage occurs, then

remove tube and inspect end for burrs or damage. If

either condition is found, snip off end of tube and insert

back into fitting.

9. Depress collar on compression fitting of each shock and

insert air tube until it bottoms. Gently tug on tube to verify

that it is locked in place.

10. Fill shocks to desired pressure. See Ta ble 2-2.

CAUTION

All air components fill rapidly. Use a small hand or foot

operated air pump to avoid possible damage to shocks

or air suspension components.

NOTE

An AIR SUSPENSION PUMP AND GAUGE (Part No. HD-

34633) is available at your Harley-Davidson dealer.

11. Observe air pressure gauge while filling. If leakage

occurs, remove tubes and inspect ends for burrs or damage. If either condition is found, snip off end of tube and

insert back into fitting.

12. When air pressure remains constant, install protective

cap on air valve.

13. Install saddlebags. Using an open end/box wrench,

tighten saddlebag front mounting bracket bolts.

2-8 2004 FLT Police: Chassis

Page 9

HOME

1. Headlamp Nacelle

2. Nut

3. Flat Washer

4. Flange Nut

5. Chrome Strip

6. Phillips Screw (2)

7. Tachometer Bracket

8. Acorn Nut (2)

9. Fork Lock Plate

10. Handlebar Clamp Shroud

11. Stud Plate

f1458d2x

7

8

9

6

10

11

5

4

3

2

1

INSTRUMENT MOUNTING BRACKET: FLHP 2.7

GENERAL

The Instrument Mounting Bracket relocates the tachometer to

allow for the addition of a radio and speaker.

NOTE

The two rear holes in the handlebar clamp shroud allow the

rider to adjust the handlebars without having to remove the

shroud. To keep out moisture and debris, be sure to install

plastic plugs back into holes after handlebar adjustment.

INSTALLATION

1. Remove windshield. See Section 2.31 WINDSHIELD/

HEADLAMP NACELLE (FLHR/C/S), REMOVAL, in the

2004 Touring Models Service Manual (Part No. 99483-

04).

2. Remove Phillips screw at the bottom of the headlamp

door (chrome ring). Remove the headlamp door.

3. Remove the eight Phillips screws to free the headlamp

housing from the headlamp nacelle.

4. Squeeze the two external tabs (if present) to remove the

wire connector at the back of the headlamp bulb.

Remove headlamp housing assembly from the vehicle.

5. Reaching inside the headlamp nacelle, remove flange

nut to release the chrome strip at the top of the nacelle.

See Figure 2-8.

6. Carefully pry off the fork lock plate at the rear of the handlebar clamp shroud. Remove two Phillips screws

beneath the lock plate.

7. Loosen the Phillips screw from tab at the front of the handlebar clamp shroud (but do not remove).

8. Remove two acorn nuts from the left side fork studs.

Remove acorn nuts from the right side fork studs.

9. Cover front fender with suitable material to protect fender

paint. Remove the passing lamp bracket from the left and

right side fork studs and carefully set on front fender.

10. Remove grommets (and clutch cable clamp) from the left

and right side fork studs.

11. Reaching inside the headlamp nacelle, disconnect

tachometer connector [108], 3-place Deutsch.

12. Remove the handlebar clamp shroud from the vehicle,

while gently pulling the tachometer conduit and connector out of the headlamp nacelle. See Figure 2-9.

Figure 2-8. Headlamp Nacelle Assembly

13. Remove two acorn nuts and flat washers to release

tachometer bracket from the handlebar clamp shroud.

14. A peel and stick foam tape on the stud plate holds it in

place on the inboard side of the handlebar clamp shroud,

Place the instrument mounting bracket over the studs

and secure using hardware provided by manufacturer.

See upper frame of Figure 2-11.

2004 FLT Police: Chassis 2-9

Page 10

HOME

f1458e2x

Figure 2-9. Handlebar Clamp Shroud

1

2

5531

Install instrument mounting bracket on stud plate.

p0044x5x

5532

3

6

5

4

1. Acorn Nut

2. Instrument Mounting

Bracket

3. Handlebar Clamp Shroud

Figure 2-10. Instrument Mounting Bracket Assembly

15. Secure slotted tab of instrument mounting bracket to

front of handlebar clamp shroud using nut and bolt provided by manufacturer. See middle frame of Figure 2-11.

16. Place tachometer bracket over studs on instrument

mounting bracket and install two acorn nuts with flat

washers. See lower frame of Figure 2-11.

17. Part the halves of the headlamp nacelle slightly. With the

flat washer on the handlebar clamp shroud facing the

inside surface of the nacelle, slide the Phillips screw

down the gap until the shroud is in position at top of

nacelle. See Figure 2-9.

4. Stud Plate

5. Screw

6. Nut

Install instrument mounting bracket front bolt.

5530

Install tachometer bracket.

Figure 2-11. Install Instrument Mounting Bracket

18. Raising handlebar clamp shroud slightly, feed tachometer connector and conduit into the headlamp nacelle.

Install shroud over mating flange while routing tachometer conduit through opening for left side handlebar.

Reaching inside headlamp nacelle, mate pin and socket

halves of tachometer connector.

2-10 2004 FLT Police: Chassis

Page 11

HOME

19. With the halves of the nacelle mated, tighten the Phillips

screw in the tab of the handlebar clamp shroud to 10-20

in-lbs

(1.1-2.3 Nm). If necessary, temporarily install a

small cable strap into holes at the bottom of the nacelle

(headlamp housing flange) to hold the halves together.

20. Install two Phillips screws to fasten handlebar clamp

shroud to the fork lock mechanism. Install fork lock plate.

21. Inserting weld stud on chrome strip into hole at the top of

the headlamp nacelle, reach inside the nacelle to install

flange nut. Tighten flange nut to 15-20

in-lbs

(1.7-2.3

Nm).

22. Install grommets on the left and right side fork studs.

23. Slide passing lamp bracket onto the left and right side

fork studs. Verify that four grommets are positioned on

the inboard side of the passing lamp brackets.

24. Install acorn nuts on the fork studs and tighten to 72-108

in-lbs

(8.1-12.2 Nm). Be sure to capture the clutch cable

clamp on the upper left stud before installing the acorn

nut.

25. Install wire connector at the back of headlamp bulb.

26. Align holes in headlamp housing with those in headlamp

nacelle (headlamp door bracket at bottom). Install the

eight Phillips screws.

27. Fit the square-shaped portion of the headlamp door

spring into the slot at the top of the headlamp housing

and then snap the headlamp door (chrome ring) into

place. Install Phillips screw at the bottom of the headlamp door.

28. Install windshield. See Section 2.31 WINDSHIELD/

HEADLAMP NACELLE (FLHR/C/S), INSTALLATION, in

the 2004 Touring Models Service Manual (Part No.

99483-04).

2004 FLT Police: Chassis 2-11

Page 12

HOME

NOTES

2-12 2004 FLT Police: Chassis

Loading...

Loading...