Page 1

H

Spare

ECM Power

f2223x9x

EFI System

Relay

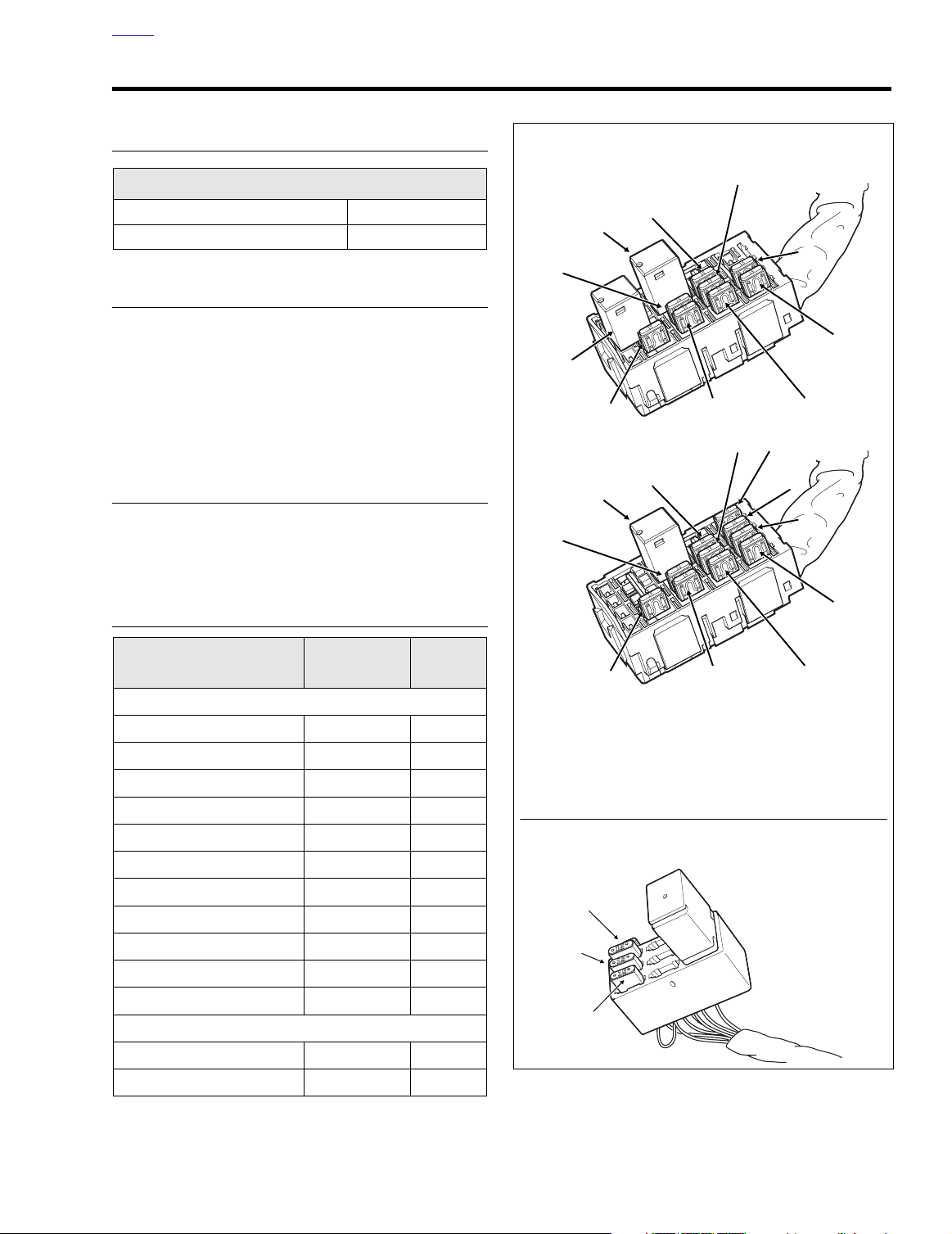

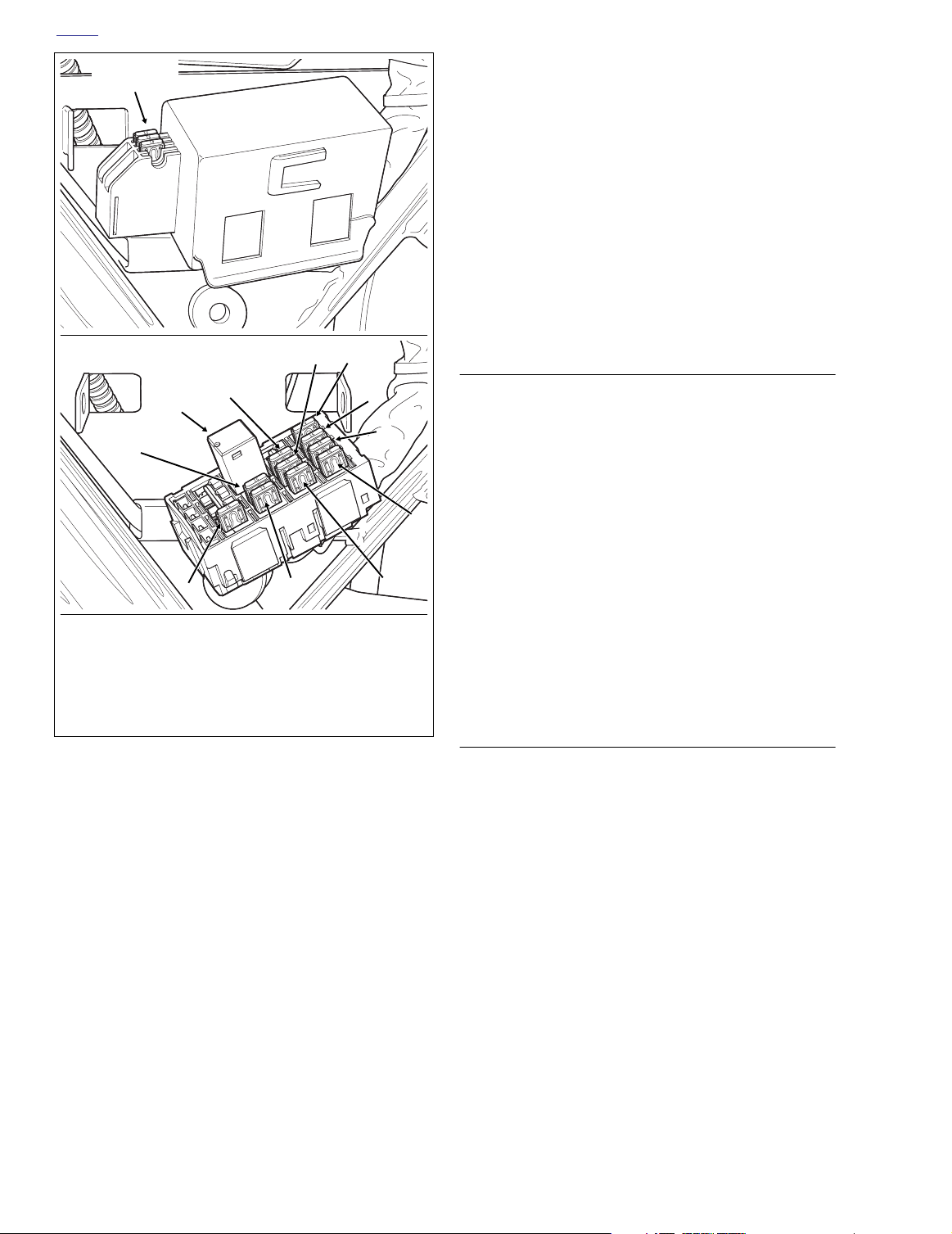

System Fuse Block (Under Left Side Cover)

EFI Fuse Block (Under Right Side Cover)

11

10

9

1

8

5

4

3

2

FLHR/C/S

11

10

9

1

8

7

6

5

4

3

2

FLTR, FLHT/C/U

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory

7. Radio Power

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

12. Starter Relay

12

f2210x8x

f2204x8x

Fuel Pump

OME

SPECIFICATIONS 8.1

IGNITION TIMING

ALL FL Models

RANGE TDC - 50˚ BTDC

START

ALTERNATOR SYSTEM

TDC

Output Voltage @ 3600 rpm 14.3-14.7

38 Amp:

FLHR, FLHRI, FLHRCI, FLHRS, FLHRSI, FLHT, FLHTC

45 Amp:

FLHTI, FLHTCI, FLHTCUI, FLTRI

BATTERY

Voltage 12V

Amperes – 28 AH @ 20 Hour Rate

FUSES

System Fuses

Maxi-Fuse 40 Orange

Headlamp 15 Blue

Ignition 15 Blue

Lighting 15 Blue

Instruments 15 Blue

Brakes/Cruise 15 Blue

Radio Memory 15 Blue

Radio Power 10 Red

Accessory 15 Blue

Battery 15 Blue

P & A 15 Blue

EFI Fuses

Fuel Pump 15 Blue

ECM Power 15 Blue

Circuit

Rating

(Amperes)

Color

Figure 8-1. Fuse Locations

2004 Touring: Electrical 8-1

Page 2

H

OME

SPARK PLUG

Part No.

32317-86A 6R12 12 mm

Be sure spark plugs are gapped to specification before installation.

No. Size Gap

0.038-0.043 in.

0.97-1.09 mm

NOTE

TORQUE VALUES

Item

Ignition module socket

head screws

MAP sensor TORX screw 25-35

Ignition coil bracket

socket screws

Spark plug 12-18 ft-lbs 16-24 Nm

Stator to crankcase TORX

screws

Battery cable bolt 60-96

Voltage regulator locknuts 70-100

Battery hold-down clamp

TORX bolt

Headlamp door screw 9-18

Passing lamp bracket fork

bracket TORX bolts

Passing lamp bracket fork

bracket stud acorn nuts

Ta il lamp lense screws 20-24

Ta il lamp circuit board/

plastic bracket

Rear fender tip lamp nuts 20-25

Front fender tip lamp nuts 20-25

Front fender trim strip tee

bolt nuts

Ignition switch to upper

fork bracket

Fairing cap TORX screws 25-30

Ignition switch button

head screws

Ignition switch

nut

DOM 50-70

HDI 125-150

ft/in-lbs Nm

50-60

in-lbs

in-lbs

84-144

in-lbs

55-75

in-lbs

in-lbs

in-lbs

15-20 ft-lbs 20-27 Nm

in-lbs

15-20 ft-lbs 20-27 Nm

72-108

in-lbs

in-lbs

40-48

in-lbs

in-lbs

in-lbs

10-15

in-lbs

36-60

in-lbs

in-lbs

18-23

in-lbs

in-lbs

in-lbs

5.7-6.8 Nm

2.8-4.0 Nm

9.5-16.3 Nm

6.2-8.5 Nm

6.8-10.9 Nm

7.9-11.3 Nm

1.0-2.0 Nm

8.1-12.2 Nm

2.3-2.7 Nm

4.5-5.4 Nm

2.3-2.8 Nm

2.3 - 2.8 Nm

1.1-1.7 Nm

4.1-6.8 Nm

2.8-3.4 Nm

2.0-2.6 Nm

5.7-7.9 Nm

14.1-16.9 Nm

Continued ...

Item

Fork lock to upper fork

bracket (FLHR/C/S)

Ignition switch screws

(FLHR/C/S)

Instrument bezel TORX

screws

Handlebar clamp to

master cylinder housing

screws

Lower and upper handlebar switch housing TORX

screws

Handlebar clamp to

clutch lever bracket TORX

screws

Neutral switch 120-180

Horn stud flange nut

(10mm)

Horn bracket acorn nut to

rubber mount stud

2 inch diameter gauge

nuts

Tachometer bracket

socket screws

Speedometer speed

sensor screw

Speedometer bracket

socket screws

Console mounting bolt

acorn nut (FLHR/C/S)

Console pod Phillips

screws

Fuel tank canopy TORX

screws

Cruise module locknuts 60-96

Radio to support bracket

socket screws

Upper fairing speaker

lower TORX screw

Upper fairing speaker

upper TORX screws

Throttle cable J-clamp

screw to wellnut

(FLHR/C/S)

Ground post flange nuts 50-90

ft/in-lbs Nm

36-60

20-30

25-35

60-80

35-45

60-80

80-100

80-100

10-20

10-20

84-108

10-20

50-90

6-11

18-24

35-45

22-28

35-50

9-18

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

4.1-6.8 Nm

2.3-3.4 Nm

2.8-4.0 Nm

6.8-9.0 Nm

4-5 Nm

6.8-9.0 Nm

13.6-20.3 Nm

9.0-11.3 Nm

9.0-11.3 Nm

1.1-2.3 Nm

1.1-2.3 Nm

9-12 Nm

1.1-2.3 Nm

5.7-10.2 Nm

0.7-1.2 Nm

2.0-2.7 Nm

6.8-10.9 Nm

4.0-5.1 Nm

2.5-3.2 Nm

4.0-5.7 Nm

1.0-2.0 Nm

5.7-10.2 Nm

8-2 2004 Touring: Electrical

Page 3

H

OME

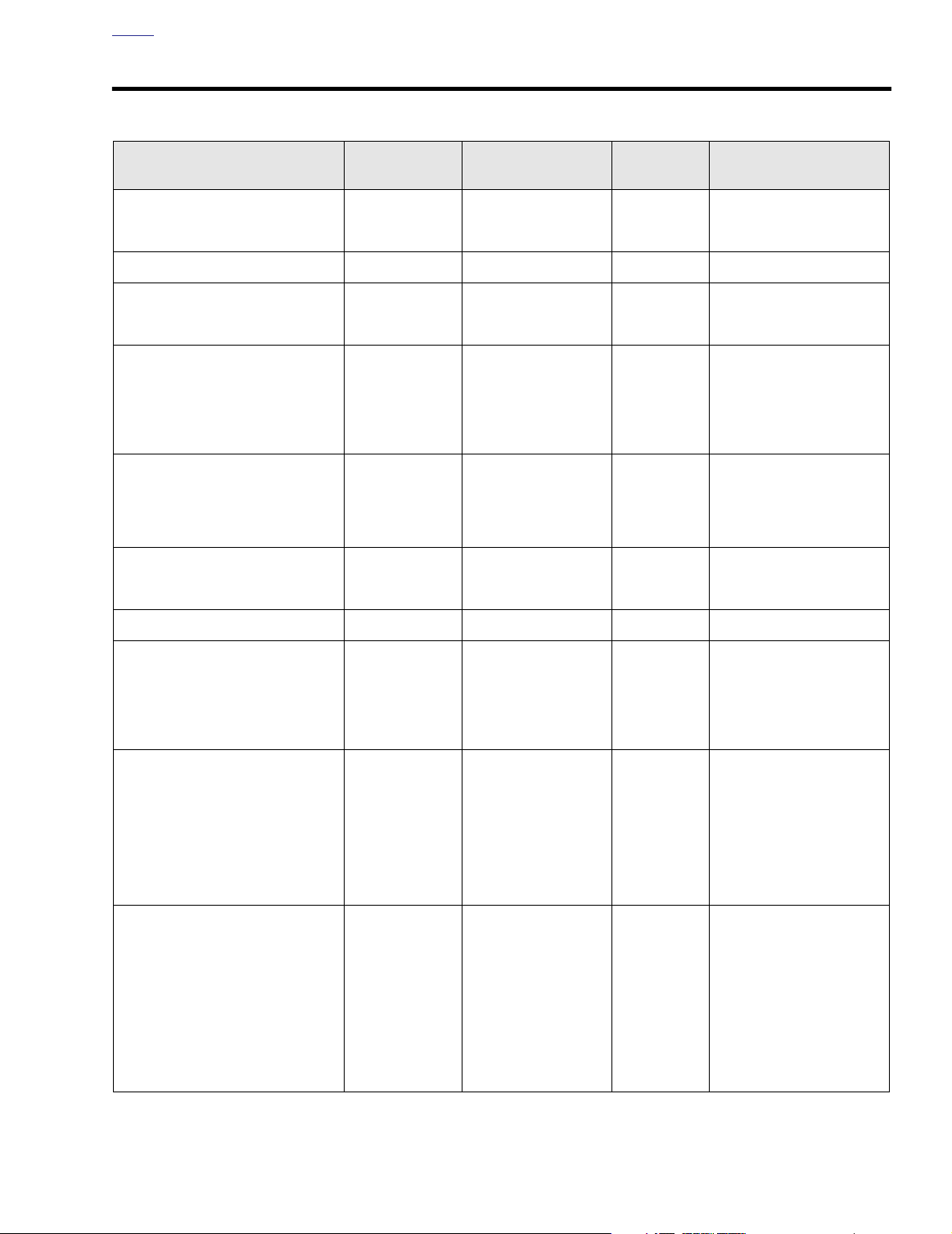

BULB CHART 8.2

Lamp Description,

All Lamps 12V

HEADLAMP

FLHT/C/U, FLHR/C/S 1 4.58/5 55/60 68329-03

FLTR

POSITION LAMP (HDI)

PASSING LAMPS

(DOM) 2 2.50 30 68674-69B

(HDI)

TAIL AND STOP LAMP

Tail Lamp 0.59 6 68167-88

Stop Lamp 2.10 24 68167-88

Tail Lamp (HDI) 0.59 6 68167-88

Stop Lamp(HDI) 2.10 24 68167-88

License Plate (HDI)

TURN SIGNAL LAMP

Front/Running 2 2.25/.59 27/7 68168-89

Front (HDI) 2 1.75 21 68163-84

Rear 2 2.25 27 68572-64B

Rear (HDI)

TOUR-PAK

Side Marker Lamps * 4 0.3 3.7 53439-79

Tail/Brake Lamps (Ultra)

FENDER TIP LAMPS *

Number of

Bulbs

24.58/5 55/60 68329-03

10.323.9 53438-92

22.923568847-98A

1

10.375.2 53436-97

21.75 21 68163-84

20.59768168-89A

2 0.3 3.7 53439-79

Current Draw

(Amperage)

Wattage

Harley-Davidson

Part No.

INSTRUMENT PANEL LAMPS

FLHT/C/U, FLTR

High Beam 1 0.15 2.1 68024-94

Oil Pressure 1 0.15 2.1 68024-94

Neutral 1 0.15 2.1 68024-94

Turn Signal

GAUGE LAMPS

FLHT/C/U, FLTR

Speedometer **

Tachometer **

Voltmeter 1 0.24 3.4 67445-00

Oil Pressure Gauge 1 0.24 3.4 67445-00

Air Temperature Gauge 1 0.24 3.4 67445-00

Fuel Gauge 1 0.24 3.4 67445-00

Engine **

INSTRUMENT PANEL/

GAUGE LAMPS

FLHR/C/S

High Beam **

Oil Pressure **

Neutral **

Turn Signal **

Fuel Gauge **

Speedometer **

Odometer **

Engine **

* Not Applicable to HDI

** LED Illuminated. LEDs are not repairable. Assembly must be replaced if LED fails.

20.152.1 68024-94

2004 Touring: Electrical 8-3

Page 4

H

OME

NOTES

8-4 2004 Touring: Electrical

Page 5

H

Maxi-Fuse

f2207x8x

OME

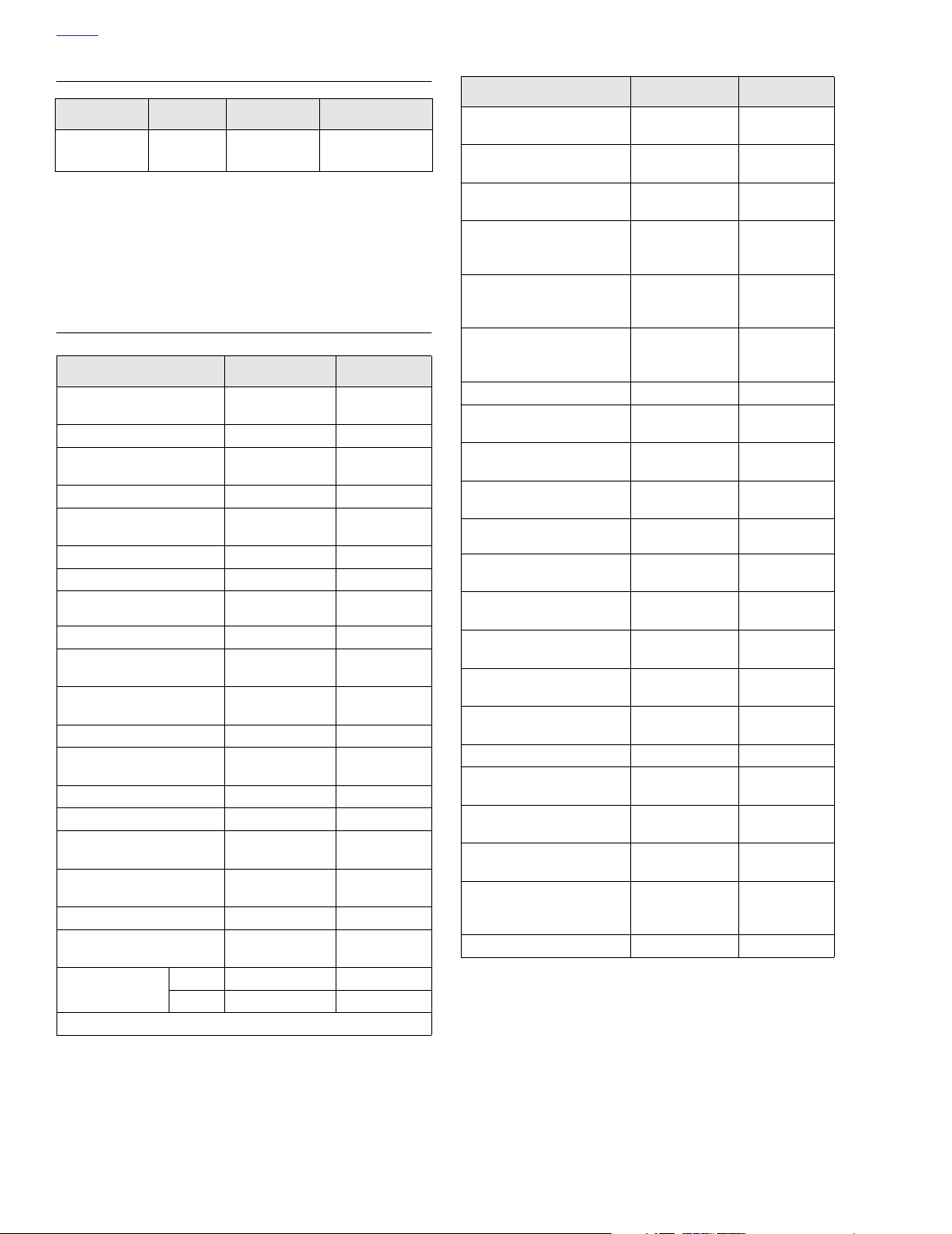

SYSTEM FUSES 8.3

MAXI-FUSE

REMOVAL

1. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Gently pull side cover from frame downtubes (no tools

required).

3. Depress latches on maxi-fuse holder and then slide

cover rearward to disengage tongue from groove in fuse

block cover. See Figure 8-2.

4. Pull maxi-fuse from maxi-fuse holder. See Figure 8-3.

Figure 8-3. Remove Maxi-Fuse

INSTALLATION

1. Insert maxi-fuse into maxi-fuse holder. See Figure 8-3.

2. Slide cover forward to engage tongue in groove of fuse

block cover and then insert maxi-fuse holder into cover

until latches engage. See Figure 8-2.

3. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

4. Install left side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

Fuse

Block

f2206x8x

Figure 8-2. Remove Left Side Cover

Maxi-Fuse

Cover

MAXI-FUSE HOLDER

REMOVAL

1. Remove maxi-fuse. See MAXI-FUSE, REMOVAL, in this

section.

2. Remove socket terminals from maxi-fuse holder. See

Section B.3 PACKARD ELECTRICAL CONNECTORS,

800 METRI-PACK SERIES.

INSTALLATION

3. Install socket terminals into maxi-fuse holder. See

Section B.3 PACKARD ELECTRICAL CONNECTORS,

800 METRI-PACK SERIES.

4. Install maxi-fuse. See MAXI-FUSE, INSTALLATION, in

this section.

SYSTEM FUSES/RELAYS

REMOVAL

1. Remove maxi-fuse. See MAXI-FUSE, REMOVAL, in this

section.

2. Pull fuse block from tabs on mounting bracket. Tabs on

bracket fit into slots on each side of fuse block cover.

2004 Touring: Electrical 8-5

Page 6

H

OME

Spare Fuse

Holder

f2203x8x

11

10

Fuse Block

Cover

9

INSTALLATION

1. Install system fuse/relay in fuse block. See lower frame

of Figure 8-4.

NOTE

For FLHR/C/S configuration, see upper frame of Figure 8-1 in

Section 8.1 SPECIFICATIONS.

2. Slide cover over fuse block until slots fully engage tabs

on block. See upper frame of Figure 8-4.

3. Slide fuse block into position on mounting bracket. Tabs

on bracket fit into slots on each side of fuse block cover.

4. Install maxi-fuse. See MAXI-FUSE, INSTALLATION, in

this section.

f2209x8x

7

8

6

5

FUSE BLOCK

REMOVAL

1. Remove system fuses and relay(s). See SYSTEM

FUSES/RELAYS, REMOVAL, in this section.

5. Remove socket terminals from fuse block. See Section

B.3 PACKARD ELECTRICAL CONNECTORS, 280

4

METRI-PACK SERIES.

1

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory

Figure 8-4. Fuse Block (FLTR, FLHTC/U)

NOTE

The fuse block cover also serves as the spare fuse holder.

One spare 10 amp and 15 amp fuse are provided.

3. Remove the fuse block cover. Raise lipped side slightly

to disengage slots from tabs on fuse block. See upper

frame of Figure 8-4.

4. Remove system fuse/relay from fuse block. Replace

fuse if the element is burned or broken. Automotive type

ATO fuses are used. See lower frame of Figure 8-4.

NOTE

For FLHR/C/S configuration, see upper frame of Figure 8-1 in

Section 8.1 SPECIFICATIONS.

2

7. Radio Power

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

3

INSTALLATION

1. Install socket terminals into fuse block. See Section B.3

PA CKARD ELECTRICAL CONNECTORS, 280 METRIPA CK SERIES.

2. Install system fuses and relay(s). See SYSTEM FUSES/

RELAYS, INSTALLATION, in this section.

EFI FUSES

See Section 9.2 ELECTRICAL BRACKET ASSEMBLY, EFI

FUSES.

8-6 2004 Touring: Electrical

Page 7

H

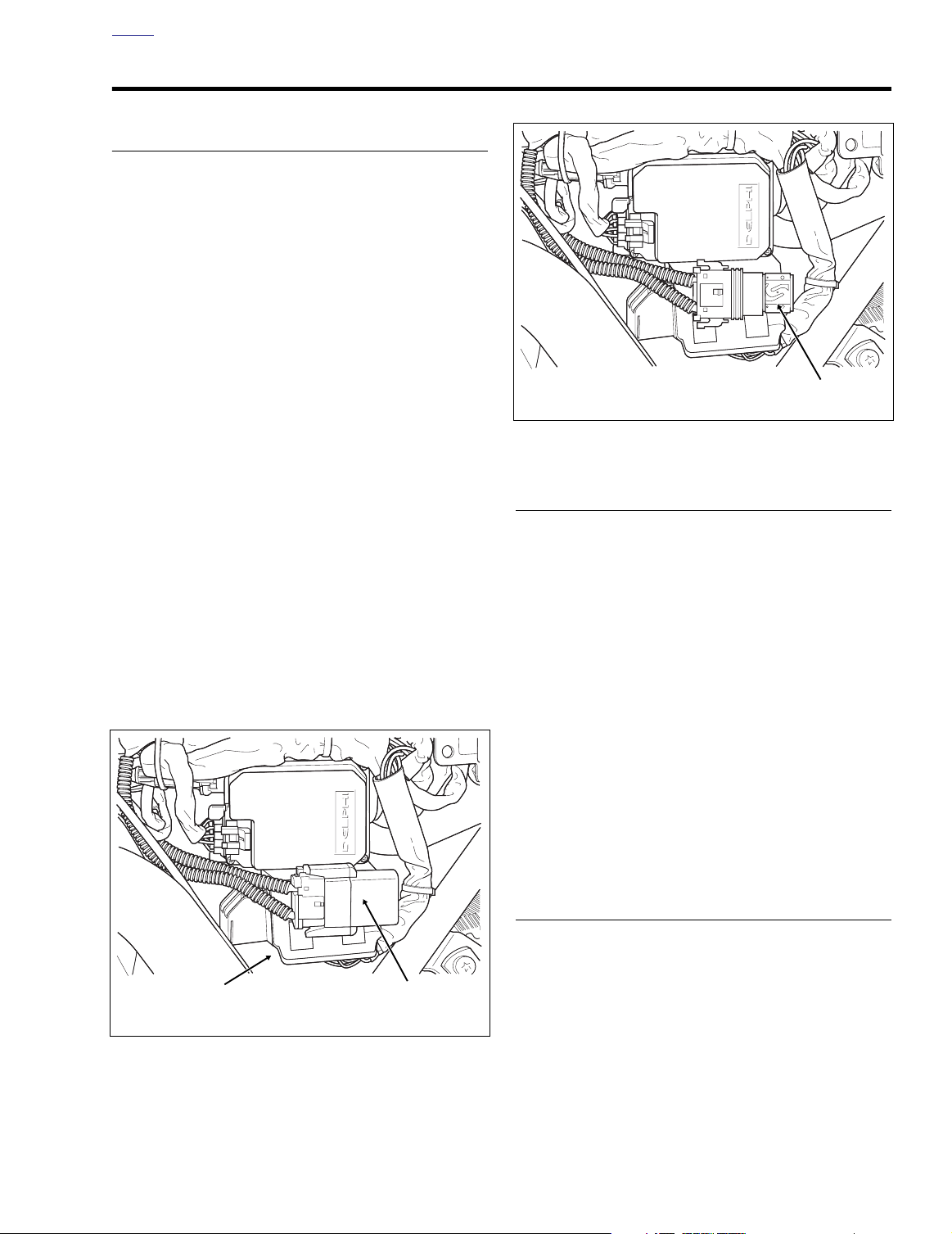

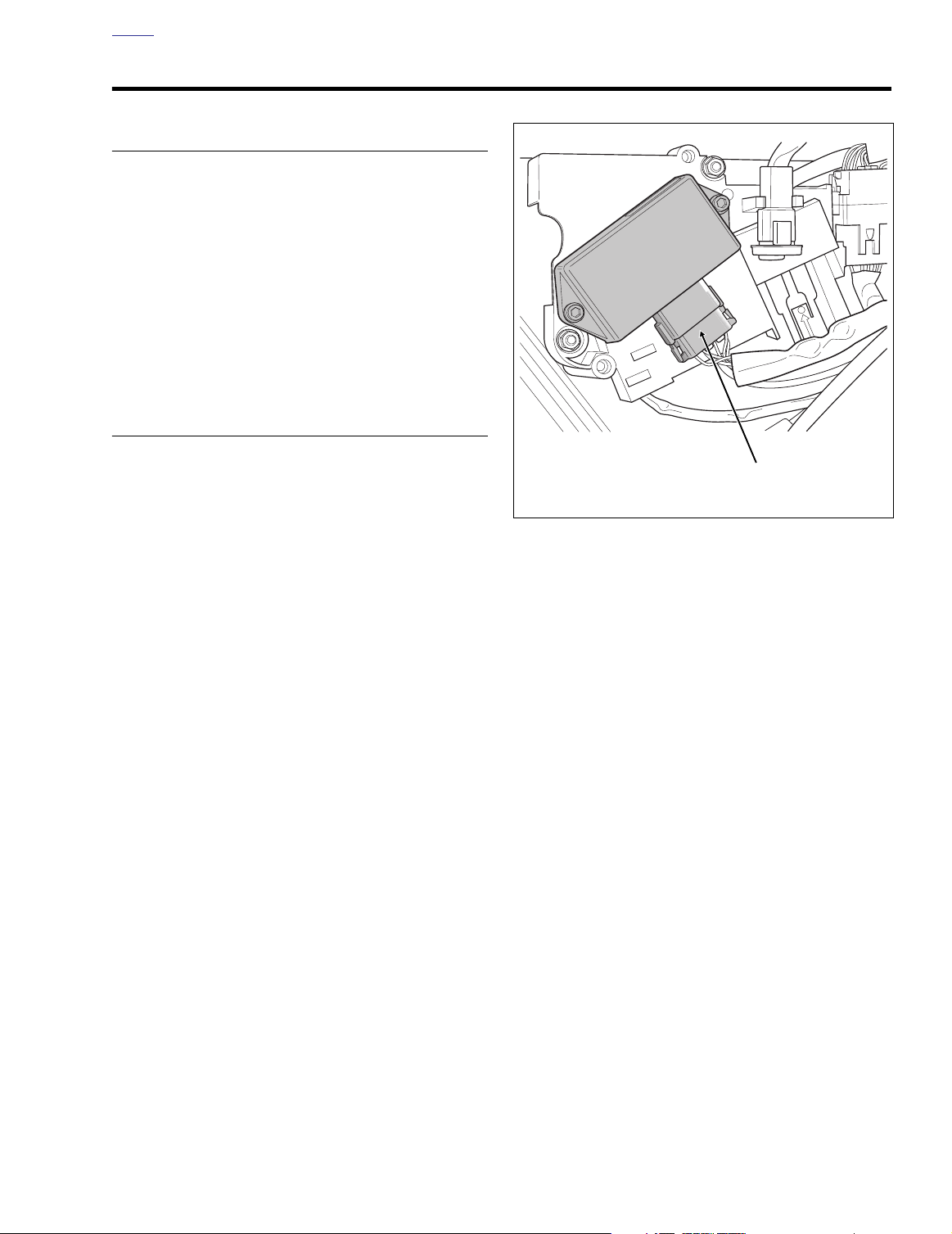

f2191x8x

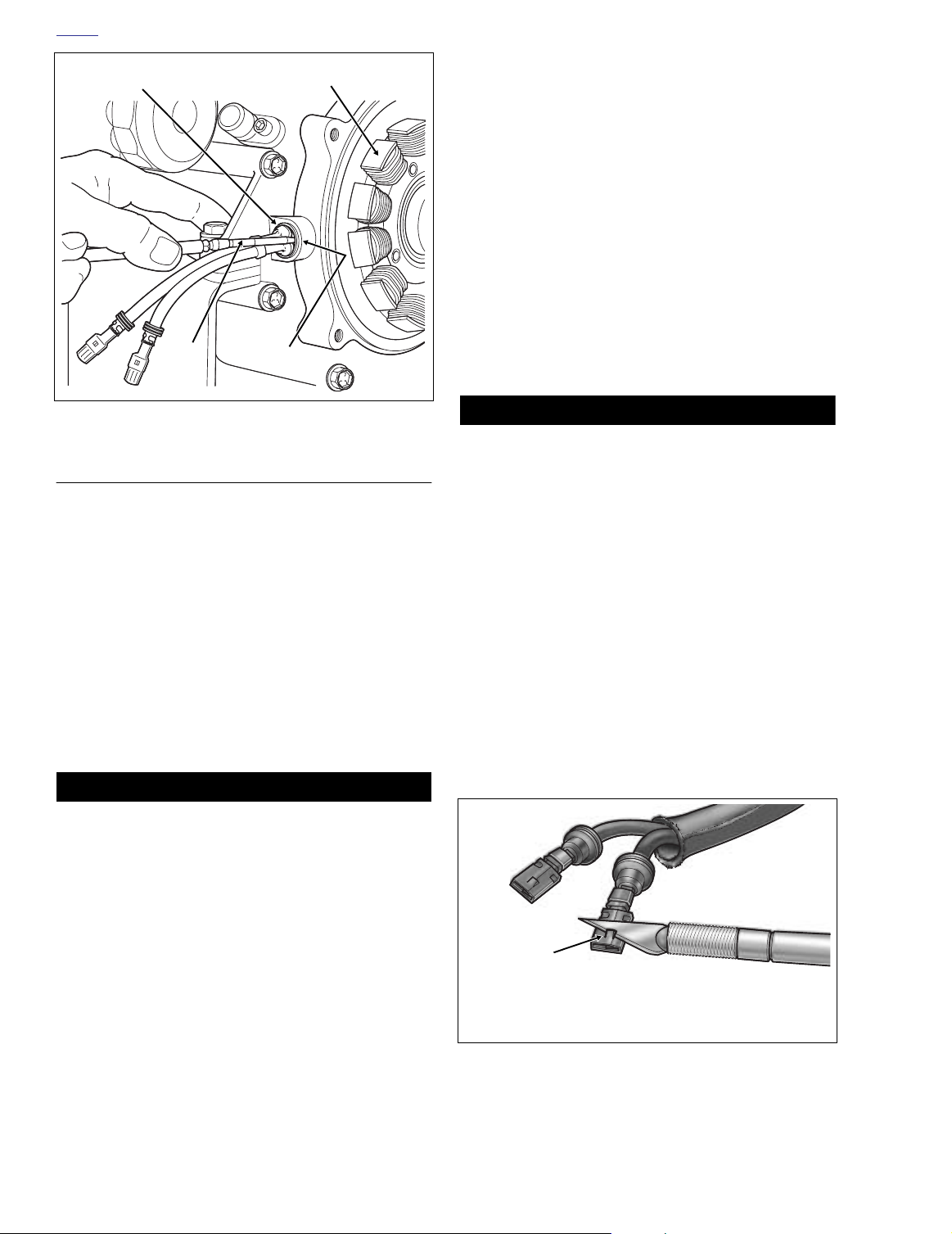

Ignition Control Module

Connector [10]

OME

IGNITION CONTROL MODULE (CARBURETED) 8.4

REMOVAL

1. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Gently pull side cover from frame downtubes (no tools

required).

3. Depress external latches and use a rocking motion to to

remove electrical connector. See Figure 8-5.

4. Remove two socket screws to detach ignition control

module from electrical bracket.

INSTALLATION

1. Align holes in ignition control module with those in electrical bracket. Install two socket screws and tighten to

50-60

in-lbs

(5.7-6.8 Nm).

2. Align tabs on socket housing with grooves on pin housing and push connector halves together until latches

click.

3. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools required).

Figure 8-5. Electrical Bracket (Under Right Side Cover)

4. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

2004 Touring: Electrical 8-7

Page 8

H

OME

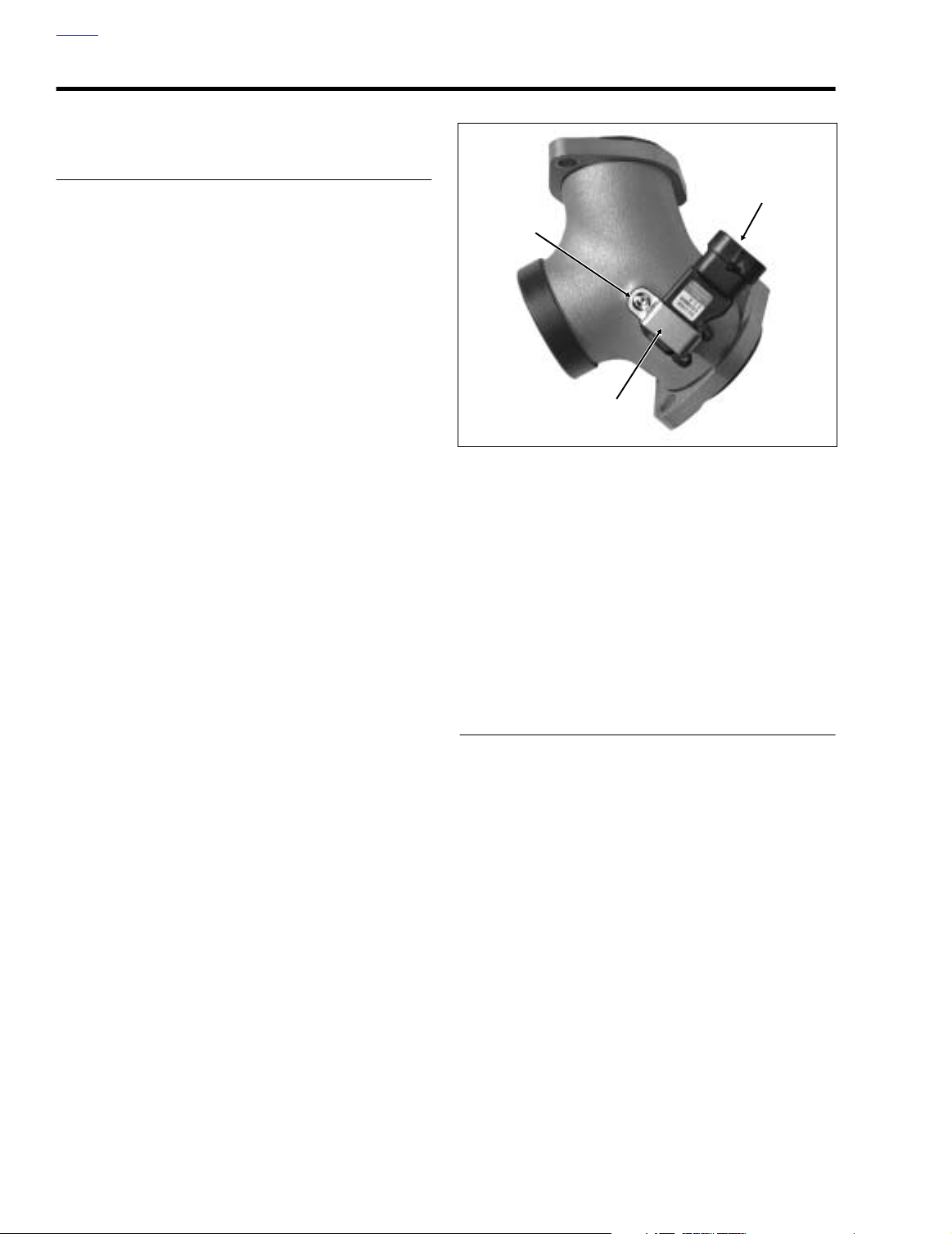

SENSORS (CARBURETED) 8.5

MANIFOLD ABSOLUTE PRESSURE SENSOR

MAP Sensor

Removal

1. Partially remove fuel tank. See Section 4.7 FUEL TANK

(CARBURETED), PA RTIAL REMOVAL, FLHT/C, or

FLHR/S.

2. Pull external latch outward and use rocking motion to

remove electrical connector.

3. Remove T20 TORX screw to release retaining clip from

intake manifold. See Figure 8-6.

T20 TORX

Screw

4. Carefully pull pressure port (enveloped in rubber seal)

from hole in intake manifold.

5. If reusing sensor, inspect condition of rubber seal.

Replace the seal if it is cut, torn or shows signs of deterioration.

Installation

1. Install rubber seal on pressure port, if removed.

2. With port side down, slide end of retaining clip in slot at

side of sensor. Aligning hole in retaining clip with

threaded hole in intake manifold, carefully press pressure port into bore,

Retaining

Clip

Figure 8-6. Intake Manifold

3. Install T20 TORX screw and tighten to 25-35

4.0 Nm). See Figure 8-6.

4. Align latch on socket housing with locking tab on pin

housing and push connector halves together until latch

clicks.

5. Install fuel tank. See Section 4.7 FUEL TANK (CARBU-

RETED), INSTALLATION (AFTER PARTIAL REMOVAL),

FLHT/C, or FLHR/S.

in-lbs

(2.8-

CRANKSHAFT POSITION SENSOR

See Section 9.3 SENSORS, CRANKSHAFT POSITION

SENSOR.

8-8 2004 Touring: Electrical

Page 9

H

8316

f1925x8x

Front

Rear

OME

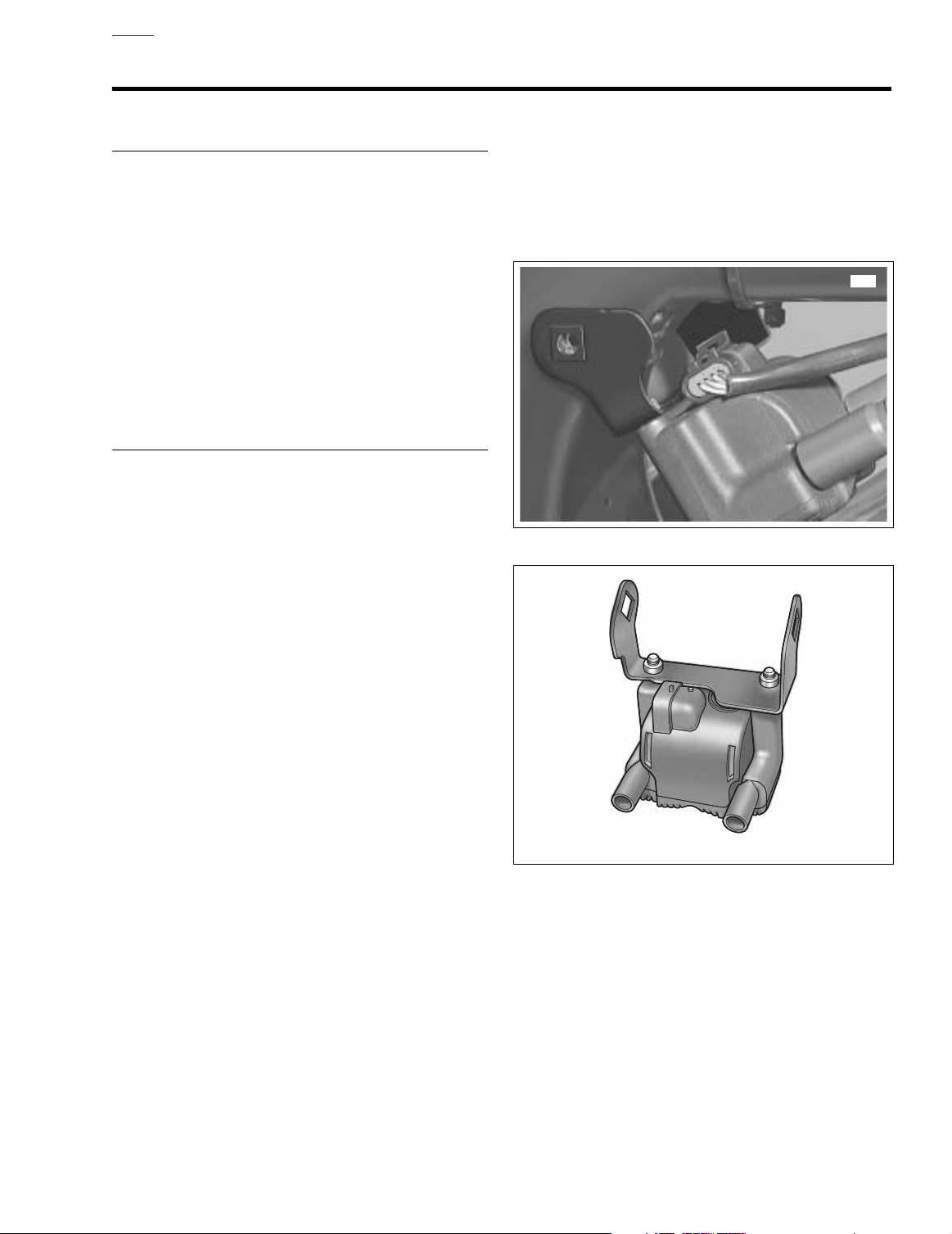

IGNITION COIL 8.6

REMOVAL

1. Partially remove fuel tank. For carbureted models, see

Section 4.7 FUEL TANK (CARBURETED), PA RT IAL

REMOVAL, FLHT/C or FLHR/S. For fuel injected mod-

els, see Section 9.4 FUEL TANK (FUEL INJECTED),

PA RTIAL REMOVAL, FLHT/C/U/I, FLTRI or FLHR/C/S/I.

2. Unplug spark plug cables from ignition coil towers.

3. Pull external latch outward and use rocking motion to

remove electrical connector from left side of ignition coil.

4. Pull sides of ignition coil bracket outward to remove from

bosses of front fuel tank mount. See Figure 8-7.

5. Remove two socket screws to free ignition coil from

bracket.

INSTALLATION

1. Align holes in

Properly positioned, connector pin housing should be

positioned at cut in bracket. Install two socket screws

and tighten to 84-144

8-8.

2. With the coil towers facing rear of vehicle, hold ignition

coil and bracket at bottom of frame backbone. Pull sides

of bracket outward and install on bosses of front fuel

tank mount. See Figure 8-7.

3. Install electrical connector on left side of ignition coil.

Align latch on socket housing with locking tab on pin

housing and push connector halves together until latch

clicks.

4. Install spark plug cable to front cylinder onto left side coil

tower. Verify that spark plug cable is captured in doublesided cable clip at bottom left side of frame backbone.

Install

new

See Figure 8-10.

5. Install spark plug cable to rear cylinder onto right side

coil tower. Verify that spark plug cable is captured in two

single-sided cable clips at bottom left side of frame backbone. Install

missing. See Figure 8-10.

new

ignition coil with holes in bracket.

in-lbs

(9.5-16.3 Nm). See Figure

cable clip on T-stud if damaged or missing.

new

cable clips on T-studs if damaged or

6. Install fuel tank. For carbureted models, see Section 4.7

FUEL TANK (CARBURETED), INSTALLATION (AFTER

PA RTIAL REMOVAL), FLHT/C or FLHR/S. For fuel

injected models, see Section 9.4 FUEL TANK (FUEL

INJECTED), INSTALLATION (AFTER PARTIAL

REMOVAL), FLHT/C/U/I, FLTRI or FLHR/C/S/I.

Figure 8-7. Remove Ignition Coil Bracket From Vehicle

Figure 8-8. Install Bracket to Ignition Coil

2004 Touring: Electrical 8-9

Page 10

H

OME

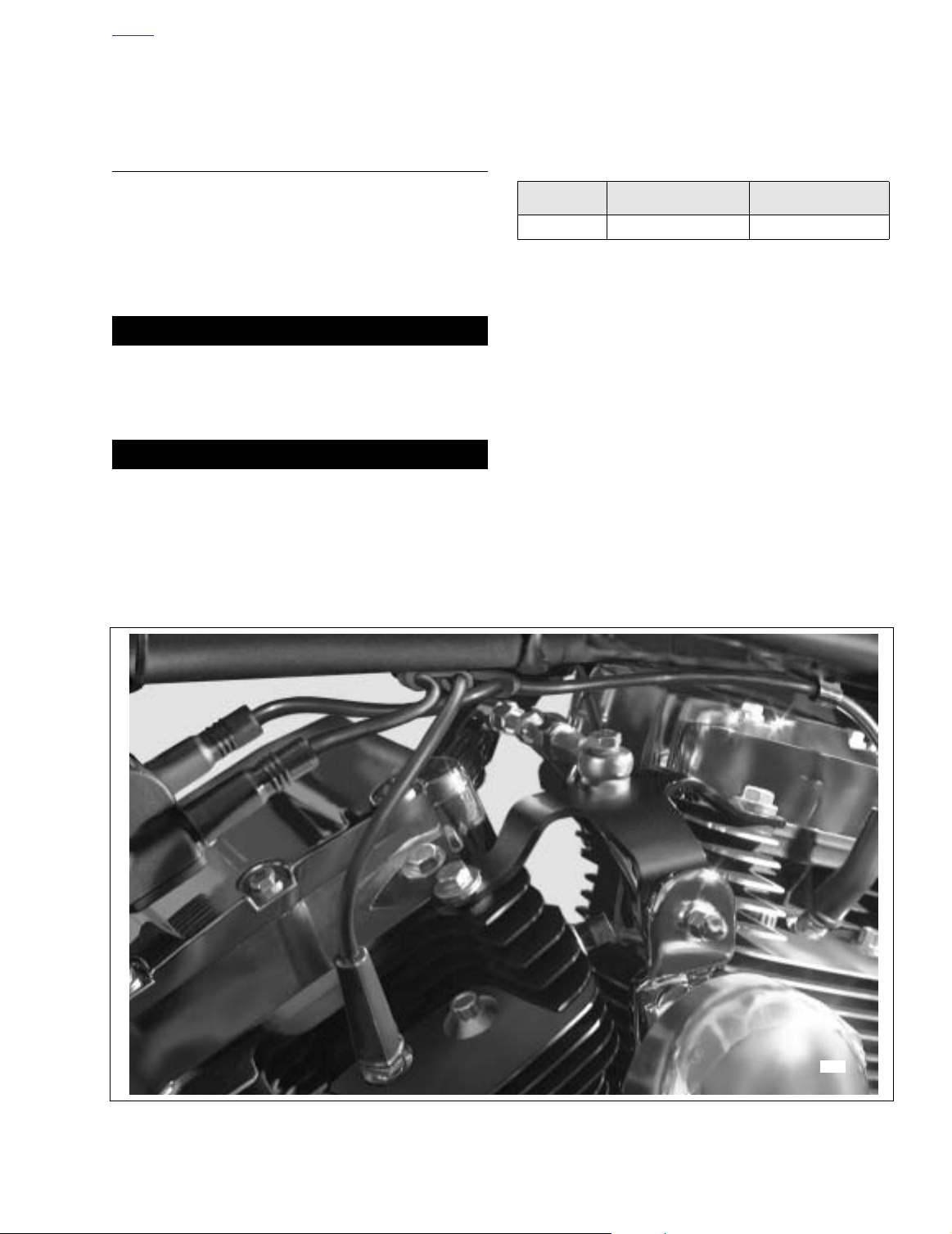

SPARK PLUGS/SPARK PLUG CABLES 8.7

SPARK PLUGS

Inspect spark plugs at 5000 miles (8,000 km) and replace at

10,000 miles (16,000 km).

The number 6R12 plug is supplied as original equipment and

is the only plug that should be used. The resistor plug

reduces radio interference created by the ignition system and

will not adversely affect performance or fuel economy.

REMOVAL

1. Remove spark plug cables. See SPARK PLUG CABLES

on the next page.

2. Remove spark plug using a 5/8 inch spark plug socket.

INSPECTION

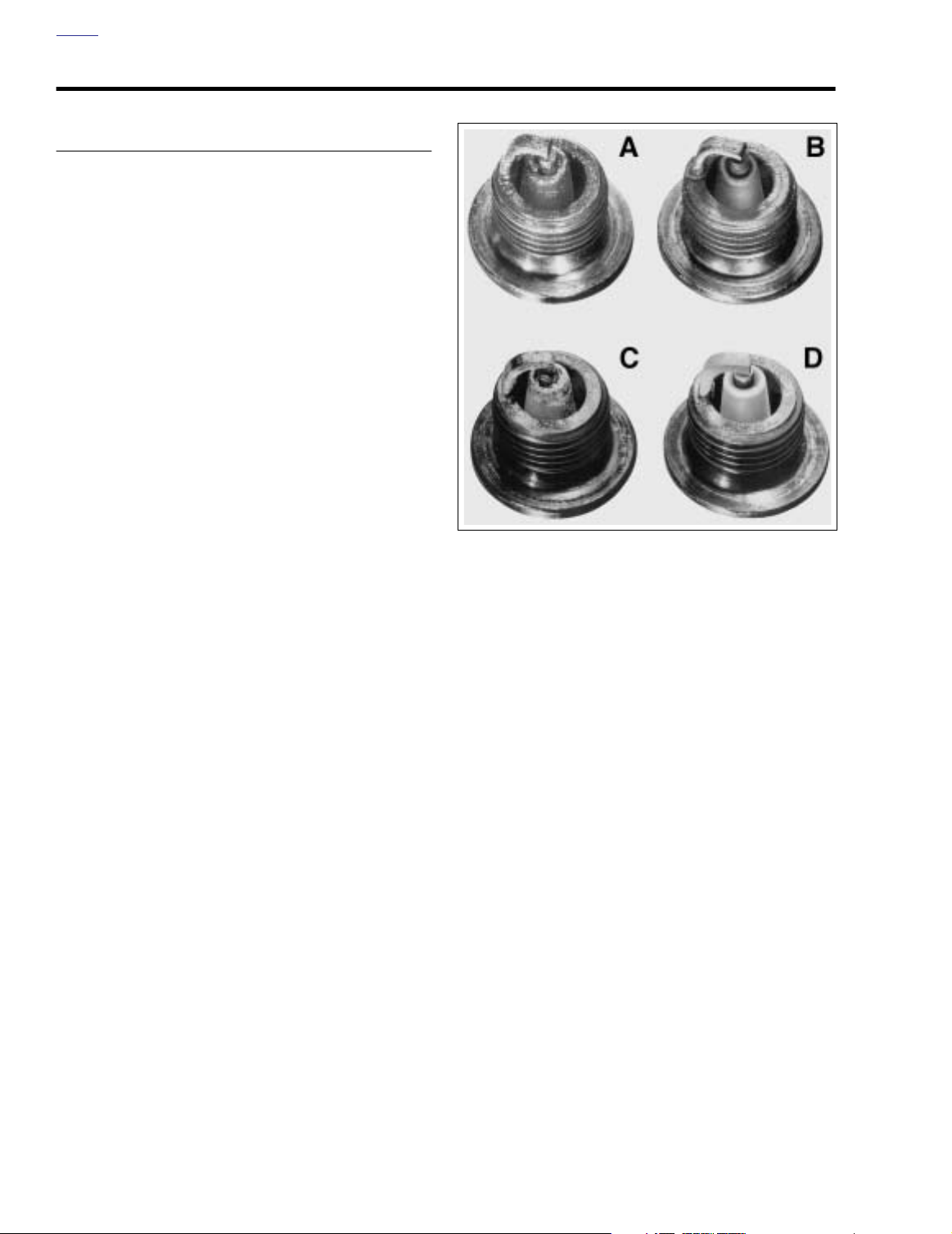

See Figure 8-9. Examine plugs as soon as they have been

removed. The deposits on the plug base are an indication of

the plug efficiency and are a guide to the general condition of

rings, valves, carburetor and ignition system.

a. A wet black and shiny deposit on plug base, elec-

trodes and ceramic insulator tip indicate an oil

fouled plug. The condition may be caused by worn

rings and pistons, loose valves or seals, weak battery or faulty ignition.

b. A dry fluffy or sooty black deposit indicates a too

rich carburetor air-fuel mixture or long periods of

engine idling. Excessive use of the enrichener may

also cause this condition.

c. An overheated plug can be identified by a light

brown, glassy deposit. This condition may be

accompanied by cracks in the insulator or by erosion of the electrodes. This condition is caused by

too lean an air-fuel mixture, a hot running engine,

valves not seating or improper ignition timing. The

glassy deposit on the spark plug is a conductor

when hot and may cause high speed misfiring. A

plug with eroded electrodes, heavy deposits or a

cracked insulator should be replaced.

d. A plug with white, yellow or light tan to rusty brown

powdery deposit indicates balanced combustion.

The deposits may be cleaned off at regular intervals

if desired.

CLEANING

Figure 8-9. Types of Plug Base Deposits

2. Use a thin file to flatten spark plug electrodes. A spark

plug with sharp edges on its electrodes requires 25%40% less firing voltage than one with rounded edges.

3. Adjust spark plug gap. See ADJUSTMENT below.

ADJUSTMENT

Use only a wire-type gauge. Bend the outside electrode so

only a slight drag on the gauge is felt when passing it

between electrodes. Never make adjustments by bending the

center electrode. Set gap on all plugs at 0.038-0.043 in.

(0.97-1.09 mm).

INSTALLATION

1. Before installing spark plugs, check condition of threads

in cylinder head and on plug. If necessary soften deposits with penetrating oil and clean out with a thread

chaser.

2. Apply a very light coating of ANTISEIZE LUBRICANT to

spark plug threads. Install spark plug. Tighten spark plug

to 12-18 ft-lbs (16-24 Nm).

1. Degrease firing end of spark plug using ELECTRICAL

CONTACT CLEANER. Dry spark plug with compressed

air.

8-10 2004 Touring: Electrical

If a torque wrench is not available, finger-tighten spark

plug and then using a spark plug wrench, tighten plug an

additional 1/4-turn.

Page 11

H

OME

3. Connect spark plug cables to spark plugs. Make sure

boots/caps are secured properly.

4. Check engine idle speed, and adjust if necessary.

SPARK PLUG CABLES

Resistor-type high-tension cables have a carbon-impregnated fabric core (instead of solid wire) for radio noise suppression and improved reliability of electronic components.

Use the exact replacement cable for best results.

REMOVAL

1WARNING1WARNING

Never disconnect a spark plug cable with the engine running. Doing so will result in an electric shock from the

ignition system that could result in death or serious

injury.

CAUTION

When disconnecting a spark plug cable from the spark

plug terminal, always grasp and pull on the rubber boot

at the end of the cable assembly (as close to the spark

plug terminal as possible). Pulling on the cable portion

will damage the carbon core.

1. Disconnect spark plug cables from ignition coil and

spark plug terminals.

INSPECTION

1. Check cables for cracks or loose terminals.

2. Check spark plug cable resistance with an ohmmeter.

Resistance must be as follows:

Table 8-1. Spark Plug Cable Resistance

Position

Front /Rear 20 Inches (508 mm) 5,000 - 11,666

3. Replace cables that are worn or damaged, or that do not

meet resistance specifications.

4. Check cable boots/caps for cracks or tears. Also check

for loose fit on ignition coil and spark plugs. Replace

boots/caps if defects are noted.

Cable Length Resistance (Ohms)

INSTALLATION

1. Connect spark plug cables to spark plugs.

2. Install spark plug cable to front cylinder onto left side coil

tower. Verify that spark plug cable is captured in doublesided cable clip at bottom left side of frame backbone.

Install

new

cable clip on T-stud if damaged or missing.

See Figure 8-10.

3. Install spark plug cable to rear cylinder onto right side

coil tower. Verify that spark plug cable is captured in two

single-sided cable clips at bottom left side of frame backbone. Install

missing. See Figure 8-10.

new

cable clips on T-studs if damaged or

Figure 8-10. Spark Plug Cable Clips (Left Side View)

8497

2004 Touring: Electrical 8-11

Page 12

H

OME

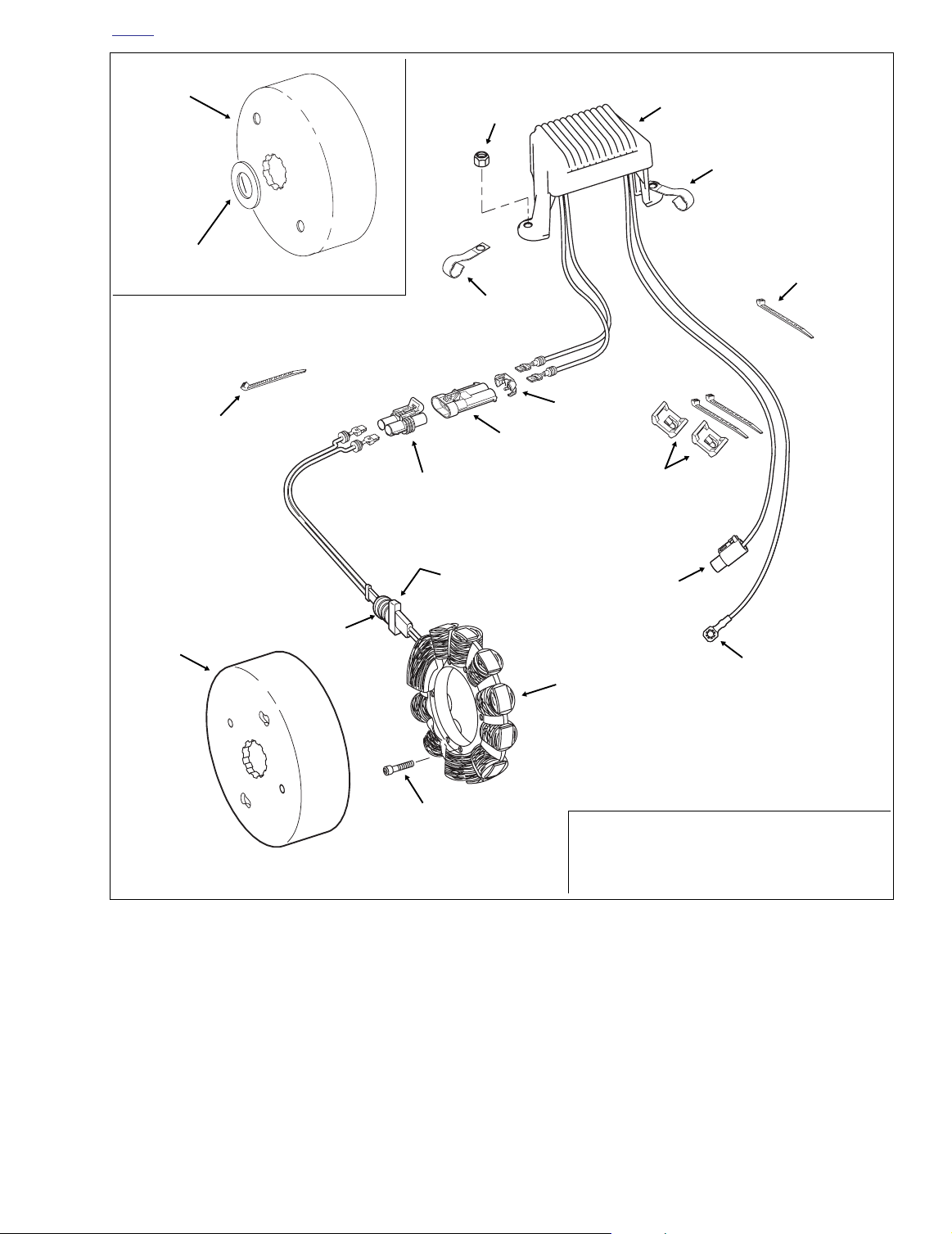

ALTERNATOR/STATOR 8.8

REMOVAL

Rotor

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

1WARNING1WARNING

f2120x8x

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

3. Remove the primary chaincase cover. Remove the

clutch, primary chain, compensating sprocket and shaft

extension as a single assembly. See Section 6.5 PRI-

MARY CHAINCASE, REMOVAL, steps 3-15.

4. Remove the alternator rotor spacer, if present.

1CAUTION

The high-output rotor is used on fuel injected vehicles,

FLHR/C/S/I excepted. Since the high-output rotor contains magnets that are considerably more powerful than

those used on low-output rotors, the ROTOR REMOVER/

INSTALLER and SHAFT PROTECTOR SLEEVE (HD-

41771) must be used to prevent parts damage and possi-

ble hand injury during removal and installation.

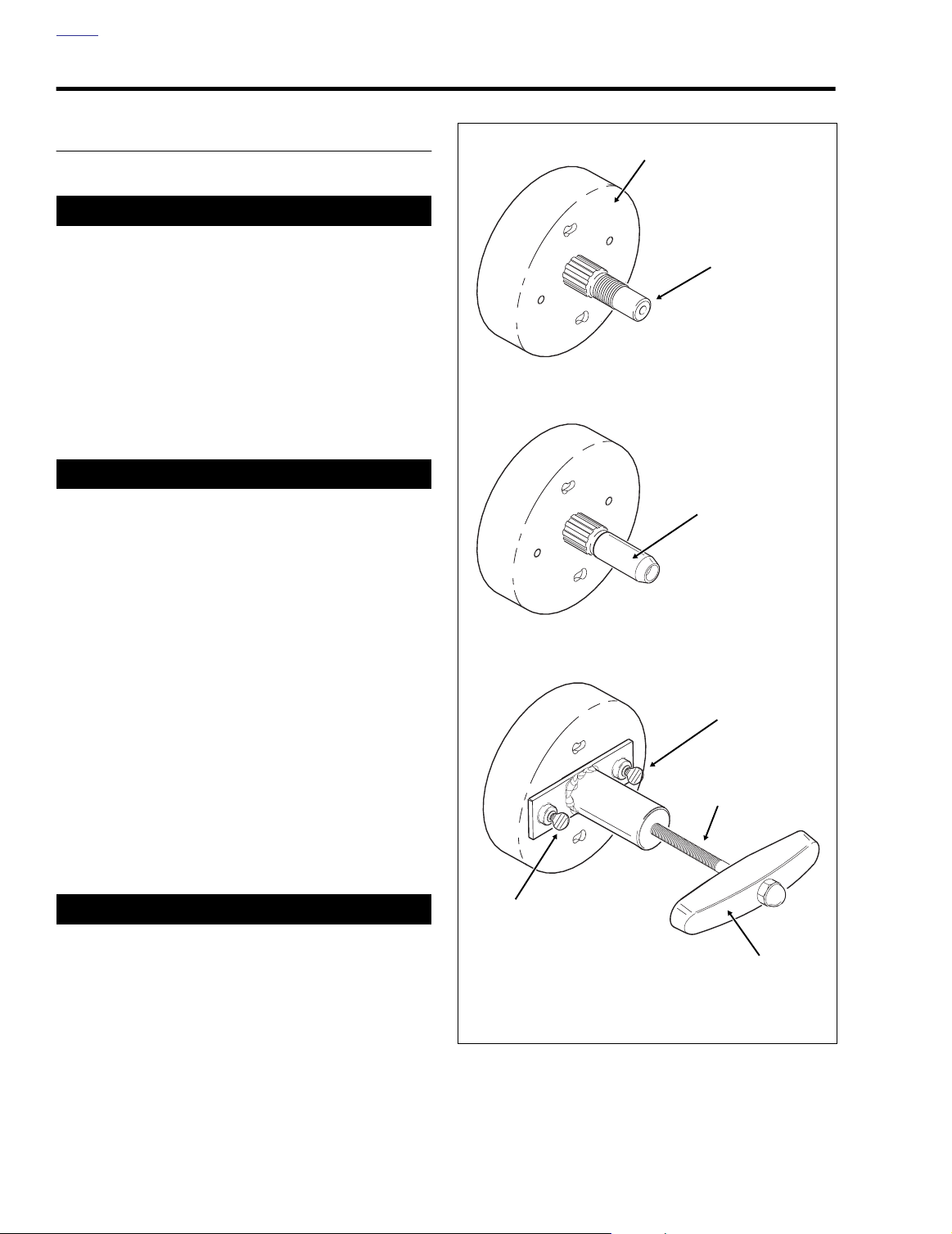

5. Remove the rotor as follows:

High Output Rotor - 45 Amp

a. Verify that threads of engine sprocket shaft are

clean, especially of old Loctite material. Thread the

Shaft Protector Sleeve onto the shaft. See Figure 8-

11.

b. Tu rn thumbscrews of Rotor Remover/Installer into

threaded holes in rotor face.

c. Rotate handle of forcing screw in a clockwise direc-

tion to remove rotor from shaft.

Engine

Sprocket Shaft

1. Clean Sprocket Shaft Threads.

Shaft Protector

Sleeve

2. Install Shaft Protector Sleeve.

Thumbscrew

Forcing Screw

Low Output Rotor - 38 Amp

CAUTION

Do not strike or drop rotor. Damage to magnet adhesive

may result in rotor failure.

a. Fabricate wire hooks or use the ends of two allen

wrenches to carefully pull rotor at holes in rotor

face.

b. Pull rotor from stator. Magnets in rotor cause some

resistance during removal.

8-12 2004 Touring: Electrical

Thumbscrew

Handle

3. Install Rotor Remover/Installer.

Rotate Handle in a Clockwise Direction.

Figure 8-11. Remove Rotor from Engine Sprocket Shaft

Page 13

H

OME

Stator

Connector [46]

12. Using a T27 TORX drive head, remove four screws to

free stator from crankcase. Discard screws.

13. Using point of awl, carefully lift capped rib on grommet

away from crankcase and then insert into bore between

grommet and casting. See Figure 8-14. Tilt awl slightly

squirting isopropyl alcohol or glass cleaner into opening.

Repeat this step at one or two other locations around

grommet.

14. While pushing on capped rib from outside of crankcase,

draw grommet through bore by pulling on cable stop with

needle nose pliers. Rock grommet back and forth to

facilitate removal, if necessary. Exercise caution to avoid

damaging ribs on grommet if stator is to be reused.

15. Draw stator cables and socket terminals through crankcase bore. For best results, feed one cable and socket

terminal through at a time.

f2256x8x

Figure 8-12. Voltage Regulator (Left Side View)

6. Locate stator connector [46], 2-place Packard, fixed to

bracket at bottom of voltage regulator. Cut small cable

strap and slide connector toward left side of motorcycle

to release groove from tongue on bracket. Raise the

external latch and separate pin and socket halves. See

Figure 8-12.

7. Remove locknut from left side leg of voltage regulator.

Loosen right side locknut. Raise voltage regulator as

necessary to free left side leg from stud on lower frame

crossmember.

8. Remove P-clip from stud. Remove P-clip from cable conduit.

9. Draw cable conduit and connector to rear of front engine

stabilizer link and then up to area in front of primary

chaincase.

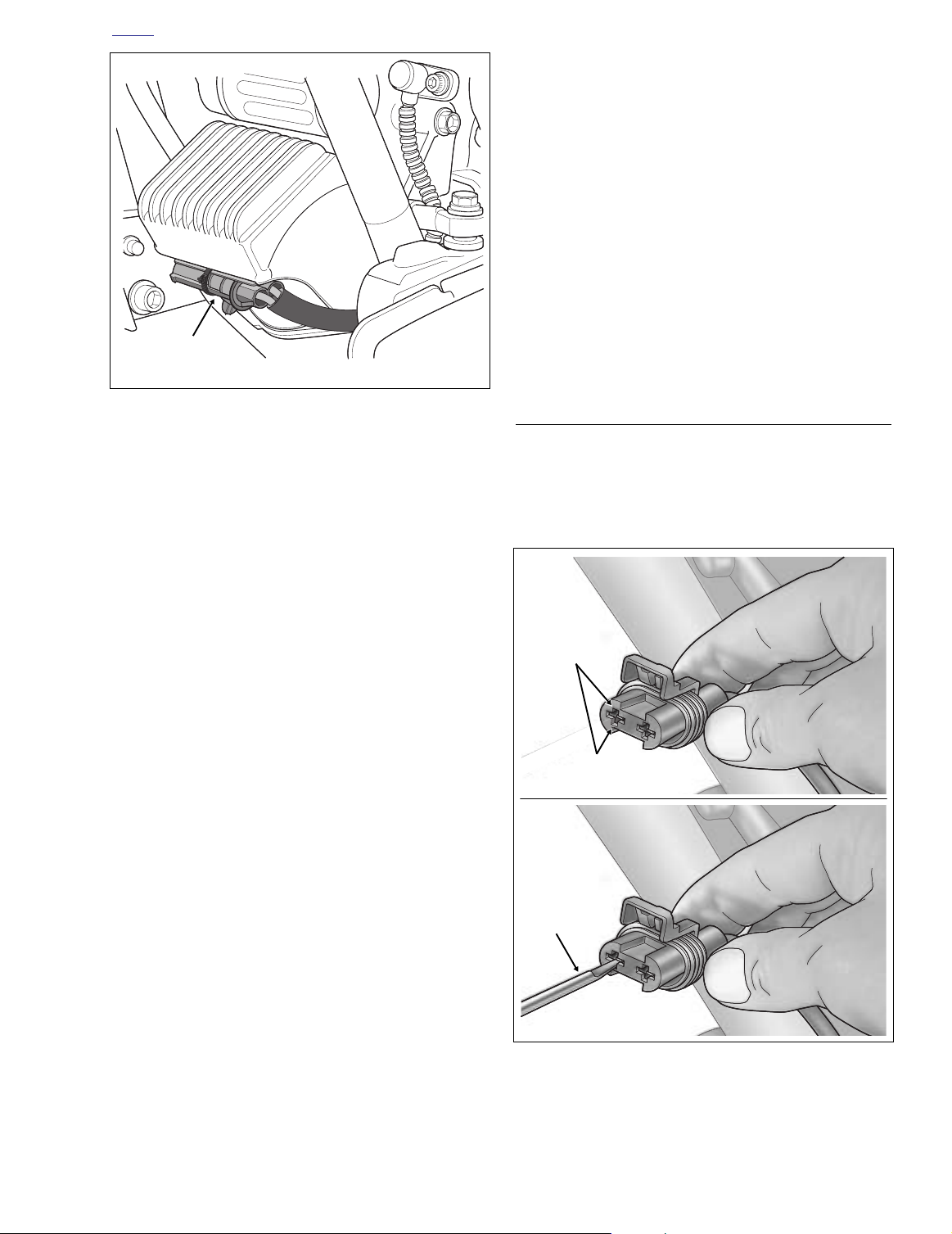

10. Depress tangs inside socket housing and back out sockets through wire end of connector. Proceed as follows:

a. Looking into the socket housing, take note of the

cavity on each side of the terminal. See upper frame

of Figure 8-13.

b. Gently insert pick (Snap-On TT600-3) into the cavity

about 1/4 inch (6.4 mm) or until it stops, and pivot

the side of the pick toward the terminal body.

Repeat step on other cavity. See lower frame of Fig-

ure 8-13.

c. Gently tug on cable to pull terminal from chamber. If

terminal is still locked, one or both tangs are not

fully depressed. Repeat steps 10(b) and 10(c) as

necessary.

d. Repeat procedure to release second terminal.

CLEANING AND INSPECTION

1. Check inside of rotor and remove any metal fragments

captured by magnets.

2. Clean the rotor using a petroleum solvent. Clean the stator and grommet by wiping it with a clean cloth.

f1912x8x

Cavity

Terminal A

f1911x8x

Pick

11. Remove conduit from cables. For best results, pull one

cable and socket terminal through conduit at a time.

Figure 8-13. Remove Socket Terminals

2004 Touring: Electrical 8-13

Page 14

H

OME

Capped

Rib

Awl

Figure 8-14. Remove Grommet From Crankcase

Opening

Stator

f1634x8x

INSTALLATION

1. From inside crankcase, feed socket terminals and stator

cables through hole in crankcase. For best results, feed

one cable and socket terminal through at a time.

2. Thorougly lubricate grommet with isopropyl alcohol or

glass cleaner. Ribs of grommet must be clean and free

of dirt and oily residue.

3. Carefully grasp cable stop behind grommet with a needle nose pliers. Push grommet into crankcase bore while

carefully pulling on outside cable. Installation is complete when cable stop contacts casting and capped rib of

grommet exits crankcase bore.

4. If necessary, carefully run awl around edge of capped rib

so that it rests flat against seating surface on crankcase.

NOTE

The Shaft Protector Sleeve not only protects the threads from

the splines of the rotor, but acts as a guide to ensure that the

rotor is properly centered.

b. Center ball on forcing screw in recess at end of

engine sprocket shaft. Rotate the handle of the tool

in a counterclockwise direction to ease rotor into

position over stator.

c. Loosen thumbscrews and remove Rotor Remover/

Installer. Remove Shaft Protector Sleeve.

d. Install the shaft extension on the engine sprocket

shaft. (No alternator rotor spacer is provided.)

Low Output Rotor - 38 Amp

a. Slide rotor over stator with the concave side

inboard.

1CAUTION

When installing rotor, keep fingers away from edge that

mates with crankcase. Since rotor is magnetized, as it

nears the crankcase it may be pulled in with considerable force, resulting in pinched fingers or other hand

injury.

b. See inset of Figure 8-16. Install the 0.020 inch

(0.508 mm) thick alternator rotor spacer and the

shaft extension on the engine sprocket shaft.

7. Install conduit onto cables. For best results, feed one

socket terminal and cable through conduit at a time.

8. Install sockets into stator/voltage regulator connector as

follows:

a. Using a fingernail or a thin flat blade, like that on an

X-Acto knife, carefully bend the tangs outward away

from each terminal body. See Figure 8-15.

b. Feed each socket into wire end of stator/voltage

regulator connector until it “clicks” in place.

CAUTION

Do not reuse T27 TORX screws. The threads of the

screws contain a locking compound in pellet form. When

the screw is started, the pellet breaks releasing the compound.

5. Using a T27 TORX drive head, install four

fasten stator to crankcase. Alternately tighten screws to

55-75

in-lbs

(6.2-8.5 Nm).

6. Install the rotor as follows:

new

screws to

High Output Rotor - 45 Amp

a. Install the Shaft Protector Sleeve and Rotor

Remover/Installer, if removed. See Figure 8-11.

8-14 2004 Touring: Electrical

X-Acto Knife

Tang

f1913x8x

Figure 8-15. Bend Tangs Outward

Page 15

H

OME

Rotor

Alternator Rotor Spacer

0.020 Inch (0.508 mm) Thick

f2221x8x

Cable Strap

Stator Connector

f2119x8x

38 AMP

Connector [46]

Stator

Socket

Housing

Flange

Locknut

P-Clamp

Pin

Housing

Secondary

Lock

Cable Straps

and Anchors

Lower Frame Tube

Voltage

Regulator

P-Clamp

Anchored

Cable Strap

Brake Pedal

Weldment

Cable Stop

Grommet

Rotor

T27 TORX

Screw

NO

Alternator Rotor Spacer

Figure 8-16. Stator/Voltage Regulator Assemblies - 45 AMP

c. Verify that sockets will not back out of chambers. A

slight tug on each cable will confirm that it is locked.

9. Feed connector and cable conduit under front engine

stabilizer link and then forward along outboard side of

voltage regulator leg. See Figure 8-12.

Voltage Regulator

Connector [77]

Stator

38 Amp:

FLHR, FLHRI, FLHRCI, FLHRS, FLHRSI, FLHT, FLHTC

45 Amp:

FLHTI, FLHTCI, FLHTCUI, FLTRI

Ring Terminal

10. Install P-clip on cable conduit approximately five inches

(127 mm) from socket housing. Slide P-clip over left side

stud on lower frame crossmember. Properly oriented, Pclip is positioned at front of stud with the open side up

and angled so that it is inline with the lower rail of the

engine guard.

2004 Touring: Electrical 8-15

Page 16

H

OME

11. Raise voltage regulator as necessary to install left side

leg onto stud. Install locknut and tighten to 70-100

in-lbs

(7.9-11.3 Nm).

12. Tighten right side locknut to 70-100

in-lbs

(7.9-11.3

Nm).

13. Mate pin and socket halves of stator connector [46], 2-

place Packard. At bottom of voltage regulator, slide connector toward right side of motorcycle until groove fully

engages tongue on bracket. Install

new

cable strap capturing bracket, connector and cable loop at rear of connector. See Figure 8-12.

14. Install the clutch, primary chain, compensating sprocket

and shaft extension as a single assembly. Install the primary chaincase cover. See Section 6.5 PRIMARY

CHAINCASE, INSTALLATION, steps 9-33.

15. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

in-lbs

(6.8-10.9 Nm).

16. Install seat. See Section 2.24 SEAT, INSTALLATION.

8-16 2004 Touring: Electrical

Page 17

H

f2220x8x

Left

Side

Right

Side

Ring Terminal

Stator

Connector [46]

Voltage Regulator

Connector [77]

Anchored

P-Clip

OME

VOLTAGE REGULATOR 8.9

REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Moving to right side of motorcycle, remove socket head

screw (with captive washer) to release ring terminal from

weld nut at front of transmission exhaust bracket.

3. Locate voltage regulator connector [77], 1-place Deutsch, just below the transmission exhaust bracket.

Depress external latch to separate pin and socket housings.

4. Cut cable strap to free voltage regulator cables from

front anchor installed on T-stud at top of lower frame

tube.

5. Cut cable strap to free voltage regulator cables from

inboard side of rear brake pedal weldment.

6. Draw voltage regulator cables forward allowing ring terminal and Deutsch socket housing to hang at rear of

lower frame crossmember.

7. Locate stator connector [46], 2-place Packard, fixed to

f2256x8x

bracket at bottom of voltage regulator. Cut small cable

strap and slide connector toward left side of motorcycle

to release groove from tongue on bracket. Raise the

external latch and separate pin and socket halves. See

Figure 8-17.

Stator

Connector [46]

Figure 8-17. Voltage Regulator (Left Side View)

Crankshaft

Position Sensor

Connector [79]

Figure 8-18. Voltage Regulator (Rear View)

8. Locate crankshaft position sensor connector [79], 2place Mini-Deutsch, also fixed to bracket at bottom of

voltage regulator. Push connector toward right side of

motorcycle to disengage small end of slot on attachment

clip from T-stud on bracket. Lift connector off T-stud.

9. Remove locknuts from studs on lower frame crossmember. Lift voltage regulator off studs to remove from

motorcycle. Note that right side P-clip is anchored to leg

of voltage regulator. See Figure 8-18.

2004 Touring: Electrical 8-17

Page 18

H

OME

Crankshaft Position Sensor Connector

[79] and Cable Strap Not Shown

Front Cable Strap

Anchor

Stator

Connector [46]

Figure 8-19. Voltage Regulator Cable Routing (Right Side View)

NOTE

For instructions on removing and installing wire terminals in

stator connector [46], 2-place Packard, see Section 8.8

ALTERNATOR/STATOR, REMOVAL and INSTALLATION,

steps 10 and 8, respectively. To remove and install cable in

voltage regulator connector [77], 1-place Deutsch, see Section B.1 DEUTSCH ELECTRICAL CONNECTORS, 1-PLACE

CABLE CONNECTOR.

Rear Brake Pedal

Weldment

f2281x8x

INSTALLATION

1. If removed, slide P-clip over left side stud on lower frame

crossmember. Properly oriented, P-clip is positioned at

front of stud with the open side up and angled so that it

is inline with the lower rail of the engine guard.

2. Slide voltage regulator over studs feeding two cables

downward at rear of lower frame crossmember. Allow

ring terminal and Deutsch socket housing to hang

beneath motorcycle.

8-18 2004 Touring: Electrical

Page 19

H

OME

3. Install locknuts on studs and tighten to 70-100

(7.9-11.3 Nm).

4. Locate crankshaft position sensor connector [79], 2place Mini-Deutsch, at rear of voltage regulator. Place

large end of slot on attachment clip over T-stud on

bracket at bottom of voltage regulator. Push connector

toward left side of motorcycle to engage small end of

slot.

5. Mate pin and socket halves of stator connector [46], 2place Packard. At bottom of voltage regulator, slide connector toward right side of motorcycle until groove fully

engages tongue on bracket. Install

turing bracket, connector and cable loop at rear of connector.

6. Route voltage regulator cables rearward following

inboard side of lower frame tube. Capturing voltage regulator cables and lower frame tube, install

strap through opening in rear brake pedal weldment.

See Figure 8-19. Cut any excess cable strap material.

NOTE

Cable strap also captures branch of main harness leading to

oil pressure sender and crankshaft position sensor connectors.

7. Position voltage regulator cables over front anchor

installed on T-stud at top of lower frame tube. Thread

new

cable strap through eyelets in anchor to capture

cables. Cut any excess cable strap material.

new

cable strap cap-

new

in-lbs

cable

8. Mate pin and socket housings of voltage regulator connector [77], 1-place Deutsch, just below the transmission

exhaust bracket.

9. Install socket head screw (with captive washer) to fasten

ring terminal to weld nut at front of transmission exhaust

bracket. Tighten screw to 20-35

10. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

11. Load test charging system.

in-lbs

(2.3-4.0 Nm).

NOTE

Cable strap anchor also captures rear brake line and branch

of main harness leading to oil pressure sender and crankshaft position sensor connectors.

2004 Touring: Electrical 8-19

Page 20

H

OME

BATTERY 8.10

GENERAL

All batteries are permanently sealed, maintenance-free,

valve-regulated, lead/calcium and sulfuric acid batteries. The

batteries are shipped pre-charged and ready to be put into

service. Do not attempt to open these batteries for any reason.

1WARNING1WARNING

All batteries contain electrolyte. Electrolyte is a sulfuric

acid solution that is highly corrosive and can cause

severe chemical burns. Avoid contact with skin, eyes,

and clothing. Avoid spillage. Always wear protective face

shield, rubberized gloves and protective clothing when

working with batteries. A warning label is attached to the

top of the battery. See Figure 8-20. Never remove warning label from battery. Failure to read and understand all

precautions contained in warning label before performing any service on batteries could result in death or serious injury. See Figure 8-21.

Table 8-2. Antidote

External - Flush with water

Internal - Drink large quantities of milk or

water, followed by milk of magnesia, vegetable oil or beaten eggs.

Call doctor immediately.

Eyes - Flush with water, get immediate

medical attention.

Warning

Label

r

o

d without charge

ls

a

f

i

r

o

e

t

e

e

t

a

t

a

a

m

d

d

n

i

m

m

o

e

o

r

ll be replac e

v

r

f

6

i

f

t

r

s

c

e

s

e

h

e

h

t

h

t

f

t

f

t

n

e

f

n

A

o

d

o

o

.

e

e

m

s

m

s

b

WARRANTY AND ADJUSTMENT POLICY

h

2

a

t

6

o

1

h

n

t

r

battery will

c

o

p

o

r

i

d

d

u

m

This battery wi

h

n

e

e

p

s

s

u

g

2

a

n

r

r

o

1

f

a

e

a

h

t

f

c

e

h

i

m

n

r

c

h

k

t

u

u

r

r

o

p

e

n

o

c

i

s

e

-

rchase , the

w

l

h

a

e

t

c

n

i

h

i

h

r

t

c

h

w

u

-

r

t

e

t

r

u

f

e

v

e

u

r

p

o

v

b

f

o

e

s

,

o

h

f

s

h

t

t

e

o

h

t

n

d

m

n

o

,

i

n

e-counter pu

t

o

s

a

m

r

e

m

f

d

MADE IN USA

-th

e

c

t

a

a

l

over

p

e

e

c

r

i

r

u

e

p

n

b

r

e

a

h

l

t

u

nly for the period of ownership based on

r

g

o

e

e

v

r

e

d

h

t

e

h

t

t

y

a

r

b

t

o

d

y

r

l

e

p

o

d

r

i

t

rranty. This wa rran ty

o

c

v

e

l

wa

s

e

i

r

d

e

n

p

a

o

D

r

-

p

Y

m

i

E

E

L

K

I

R

U

E

A

A

D

A

H

W

M

IL

M

o

h

t

o

t

a

r

n

e

.

e

s not transferable

b

i

e

v

s

u

m

j

u

e

b

r

a

f

r

o

o

e

t

s

c

u

e

l

e

g

N

e

1

n

O

,

e

0

S

2

D

3

I

1234567890

V

5

I

A

.

A

.

W

,

S

.

E

U

N

JA FE MA AP MY JU JY AU SE OC NO DE

.

O

N

T

R

PA

f1730x8x

Figure 8-20. Maintenance-Free Battery

VOLTMETER TEST

See Ta b l e 8-3. The voltmeter test provides a general indicator of battery condition. Check the voltage of the battery to

verify that it is in a 100% fully charged condition. If the open

circuit (disconnected) voltage reading is below 12.6V, charge

the battery and then recheck the voltage after the battery has

set for one to two hours. If the voltage reading is 12.8V or

above, perform the LOAD TEST described in this section.

Contents

are Corrosive.

Wear

Safety Glasses.

8-20 2004 Touring: Electrical

Contents

are Explosive.

Keep

Flames Away.

Figure 8-21. Battery Warning Label

Read

Instructions.

Keep Away

From Children.

f2180x3x

Page 21

H

1WARNING1WARNING

CAUTION

OME

Table 8-3. Voltmeter Test

Voltage (OCV) State of Charge

12.8 100%

12.6 75%

12.3 50%

12.0 25%

11.8 0%

DISCONNECTION AND REMOVAL

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

1WARNING1WARNING

Always disconnect the negative battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion which could result in death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

3. Unthread bolt and remove battery positive cable (red)

from battery positive (+) terminal.

4. Using a T-40 TORX drive head, loosen bolt to move lip of

hold-down clamp off edge of battery. Remove battery

from battery box.

BATTERY CHARGING

SAFETY PRECAUTIONS

Never charge a battery without first reviewing the instructions

for the charger being used. In addition to the manufacturer’s

instructions, follow these general safety precautions:

Always wear proper eye, face and hand protection.

●

●

Always charge batteries in a well-ventilated area.

Turn the charger “OFF” before connecting the leads

●

to the battery to avoid dangerous sparks.

●

Never try to charge a visibly damaged or frozen battery.

● Connect the charger leads to the battery; red posi-

tive (+) lead to the positive (+) terminal and black

negative (–) lead to the negative (–) terminal. If the

battery is still in the vehicle, connect the negative

lead to the chassis ground. Be sure that the ignition

and all electrical accessories are turned off.

● Make sure that the charger leads to the battery are

not broken, frayed or loose.

● If the battery becomes hot, or if violent gassing or

spewing of electrolyte occurs, reduce the charging

rate or turn off the charger temporarily.

● Always turn the charger “OFF” before removing

charger leads from the battery to avoid dangerous

sparks.

CHARGING BATTERY

CLEANING AND INSPECTION

1. Battery top must be clean and dry. Dirt and electrolyte

on top of the battery can cause battery to self-discharge.

Clean battery top with a solution of baking soda (sodium

bicarbonate) and water (5 teaspoons baking soda per

quart or liter of water). When the solution stops bubbling,

rinse off the battery with clean water.

2. Clean cable connectors and battery terminals using a

wire brush or sandpaper. Remove any oxidation.

3. Inspect the battery screws, clamps and cables for breakage, loose connections and corrosion. Clean clamps.

4. Check the battery posts for melting or damage caused

by overtightening.

5. Inspect the battery for discoloration, raised top or a

warped or distorted case, which might indicate that the

battery has been frozen, overheated or overcharged.

6. Inspect the battery case for cracks or leaks.

Charge the battery if any of the following conditions exist:

● Vehicle lights appear dim.

● Electric starter sounds weak.

● Battery has not been used for an extended period of

time.

Always charge the battery in a well ventilated area.

Explosive hydrogen gas escapes from the battery during

charging. Keep open flames, electrical sparks and smoking materials away from the battery at all times. Failure

to do so could result in death or serious injury.

If the battery releases an excessive amount of gas during charging, decrease the charging rate. If the battery

gets hotter than 110˚F. (43˚C) during charging, discontinue charging and allow the battery to cool. Overheating

may result in plate distortion, internal shorting, dryout or

other damage.

2004 Touring: Electrical 8-21

Page 22

H

OME

Table 8-4. Battery Charging Rates/Estimated Times

Battery

Amp-Hour

TOURING

28

The figures listed above assume that the battery is charging at room temperature. If warmer than room temperature, use a slightly shorter

charging time. If colder, use a slightly longer charging time.

The use of constant current chargers to charge sealed maintenance-free batteries is not recommended. Any overcharge will cause dryout and premature battery failure. If a constant current charger is the only type available, do not exceed the charge times listed above and

do not continue charging the battery if it gets hot. When charging, never exceed 15 volts for more than 30 minutes.

1. Perform a voltmeter test to determine the state of

charge. See VOLTMETER TEST in this section. If battery needs to be charged, proceed to step 2.

Always remove the battery from the motorcycle before

charging. Accidental electrolyte leakage will damage

motorcycle parts.

2. Remove the battery from the motorcycle. See DISCON-

NECTION AND REMOVAL in this section. Place the bat-

tery on a level surface.

Always unplug or turn OFF the battery charger before

connecting the charger clamps to the battery. Connecting clamps with the charger ON could cause a spark

resulting in a battery explosion. A battery explosion may

rupture the battery case causing a discharge or spray of

sulfuric acid which could result in death or serious

injury.

Do not reverse the charger connections described in the

following steps or the charging system of the motorcycle

could be damaged.

Voltage Reading % of Charge

State of Charge

12.8 V100% ----

12.6 V 75% 2.5 hours 1.25 hours 45 minutes 25 minutes

12.3 V 50% 5 hours 2.5 hours 1.5 hours 50 minutes

12.0 V 25% 7.5 hours 3.75 hours 2.25 hours 70 minutes

11.8 V 0% 10 hours 5 hours 3 hours 1.5 hours

CAUTION

3

Amp Charger6Amp Charger10Amp Charger20Amp Charger

NOTE

If the battery is still in the vehicle, connect the negative lead

to the chassis ground. Be sure that the ignition and all electrical accessories are turned off.

5. Step away from the battery and turn on the charger. See

the charging instructions in Ta bl e 8-4.

1WARNING1WARNING

Always unplug or turn OFF the battery charger before

disconnecting the charger clamps from the battery. Disconnecting clamps with the charger ON could cause a

spark resulting in a battery explosion. A battery explo-

1WARNING1WARNING

CAUTION

sion may rupture the battery case causing a discharge

or spray of sulfuric acid which could result in death or

serious injury.

6. After the battery is fully charged, disconnect the black

battery charger lead to the negative (–) terminal of the

battery.

7. Disconnect the red battery charger lead to the positive

(+) terminal of the battery.

8. Mark the charging date on the battery.

9. Perform a load test to determine the condition of the battery. See LOAD TEST on this page.

LOAD TEST

3. Connect the red battery charger lead to the positive (+)

terminal of the battery.

4. Connect the black battery charger lead to the negative

(–) terminal of the battery.

The load test measures battery performance under full current load and is the best indicator of battery condition. To

load test the battery, proceed as follows:

8-22 2004 Touring: Electrical

Page 23

H

CAUTION

1WARNING1WARNING

1WARNING1WARNING

CAUTION

OME

CAUTION

Load testing a discharged battery can result in permanent battery damage.

1. Always fully charge the battery before testing or test

readings will be incorrect. See CHARGING BATTERY, in

this section. Load testing a discharged battery can also

result in permanent battery damage.

2. After charging, allow battery to stand for at least one

hour before testing.

1WARNING1WARNING

Always turn the battery load tester OFF before connecting the tester cables to the battery terminals. Connecting

tester cables with the load tester ON could cause a spark

resulting in a battery explosion. A battery explosion may

rupture the battery case causing a discharge or spray of

sulfuric acid which could result in death or serious

injury.

3. Connect tester leads to battery posts and place induction pickup over negative (black) cable. See Figure 8-22.

Load

Tester

To avoid load tester and/or battery damage, do not leave

the load tester switch turned ON for more than 20 seconds.

4. Referencing Table 8-4, load battery at 50% of CCA rating using the load tester. Voltage reading after 15 seconds should be 9.6V or more at 70°F. (21°C).

Table 8-5. Battery Load Test

COLD CRANKING

AMPERAGE (CCA)

TOURING 300 150

Always turn the battery load tester OFF before disconnecting the tester cables from the battery terminals. Disconnecting tester cables with the load tester ON could

cause a spark resulting in a battery explosion. A battery

explosion may rupture the battery case causing a discharge or spray of sulfuric acid which could result in

death or serious injury.

5. Install the battery on the motorcycle. See INSTALLA-

TION AND CONNECTION below.

100% 50%

Induction

Figure 8-22. Load Test Battery

Pickup

BATTERY CABLE ROUTING

Hole on left side of frame crossmember is used for

cruise cable routing only. Use of the hole for battery

cable routing can result in contact with hot exhaust pipe

causing melting or burning of the cable insulation, damage that can lead to driveability problems or fire hazard,

conditions which could result in death or serious injury.

Route all battery cables through opening between tray of battery box and bottom of frame cross member. Cables should

be positioned as shown in Figure 8-23.

INSTALLATION AND CONNECTION

1. Place the fully charged battery into the battery box, terminal side forward.

f1731x8x

Connect the cables to the correct battery terminals or

damage to the motorcycle electrical system will occur.

2004 Touring: Electrical 8-23

Page 24

H

OME

1WARNING1WARNING

Always connect the positive battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion which could result in death or serious injury.

CAUTION

Overtightening bolts can damage battery terminals.

1. Insert bolt through battery positive cable (red) into

threaded hole of battery positive (+) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

2. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

3. Apply a light coat of petroleum jelly or corrosion retardant material to both battery terminals.

4. Rotate the hold-down clamp so that the lip (with rubber

pad) rests on the edge of the battery. Using a T-40 TORX

drive head, tighten the clamp bolt to 15-20 ft-lbs (20-27

Nm).

5. Install seat. See Section 2.24 SEAT, INSTALLATION.

f2268x8x

Frame

Cross Member

Frame Hole

Cruise Cable

Routing Only

f1732x8x

Effect of Temperature on

Battery Self-Discharge Rate

100%

C

A

75%

50%

P

A

C

I

T

Y

0

at 105°F

MONTHS OF STAND

3691215

at 77

°

F

Figure 8-24. Battery Self-Discharge Rate

STORAGE

1WARNING1WARNING

Store the battery out of the reach of children. Inadequate

safety precautions could result in death or serious

injury.

CAUTION

The electrolyte in a discharged battery will freeze if

exposed to freezing temperatures. Freezing may crack

the battery case and buckle battery plates.

If the motorcycle will not be operated for several months,

such as during the winter season, remove the battery from

the motorcycle and fully charge. See CHARGING BATTERY

in this section.

Positive

Battery Cable

Negative

Battery Cable

Main Power

To Maxi-Fuse

Figure 8-23. Battery Cable Routing (Right Side View)

Self-discharge is a normal condition and occurs continuously

at a rate that depends on the ambient temperature and the

battery’s state of charge. Batteries discharge at a faster rate

at higher ambient temperatures. To reduce the self-discharge

rate, store battery in a cool (not freezing), dry place. See Fig-

ure 8-24.

Charge the battery every month if stored at temperatures

below 60˚ F. (16˚ C). Charge the battery more frequently if

stored in a warm area above 60˚ F. (16˚ C).

NOTE

The GLOBAL BATTERY CHARGER (Part No. 99863-01)

may be used to maintain battery charge for extended periods

of time without risk of overcharging or boiling.

When returning a battery to service after storage, refer to the

instructions under CHARGING BATTERY in this section.

8-24 2004 Touring: Electrical

Page 25

1WARNING1WARNING

f1268x2x

Wider

Ear

Wire Form

Loop

Bulb

Socket

Wire Form

Loop

Hinge

Slots

Lense

Backplate

H

OME

HEADLAMP (FLHR/C/S, FLHT/C/U) 8.11

HEADLAMP ASSEMBLY

REMOVAL

1. Remove the Phillips screw at the bottom of the headlamp door (chrome ring). Remove the headlamp door.

2. Proceed as follows:

FLHT/C/U: Remove the four TORX screws to free the

headlamp housing from the fairing.

FLHR/C/S: Remove the eight Phillips screws to free the

headlamp housing from the headlamp nacelle.

3. Squeeze the two external tabs (if present) to remove the

wire connector at the back of the headlamp bulb.

Remove the headlamp housing assembly from the vehicle.

INSTALLATION

1. Install the wire connector at the back of headlamp bulb.

2. Proceed as follows:

FLHT/C/U: Align holes in headlamp housing with those

in fairing (headlamp door bracket at bottom). Install the

four TORX screws.

FLHR/C/S: Align holes in headlamp housing with those

in headlamp nacelle (headlamp door bracket at bottom).

Install the eight Phillips screws.

3. Fit the square-shaped portion of the headlamp door

spring into the slot at the top of the headlamp housing

and then snap the headlamp door (chrome ring) into

place. Install Phillips screw at the bottom of the headlamp door and tighten to 9-18 in-lbs (1.0-2.0 Nm).

5372

Retaining

Ring Screws

Figure 8-26. Headlamp Lense/Bulb Assembly

(Rear View)

HEADLAMP BULB REPLACEMENT

The headlamp is a replaceable bulb (and not a sealed

beam). Made of quartz glass filled with Halogen gas, the bulb

is very delicate and must be handled with care.

NOTE

When replacement is required, use only the specified bulb

available from your Harley-Davidson dealer. Improper wattage or bulb may cause charging system problems.

1. Remove the Phillips screw at the bottom of the headlamp door (chrome ring). Remove the headlamp door.

2. Remove the three Phillips screws to free the retaining

ring from the headlamp housing. See Figure 8-25. Carefully remove the lense and bulb assembly.

3. Squeeze the two external tabs (if present) to remove the

wire connector at the back of the headlamp bulb.

Remove the lense and bulb assembly from the vehicle.

4. Remove the rubber boot at the back of the lense.

5. Push down on loops of wire form to free ends from slots

on lense insert. See Figure 8-26. Use hinge to swing

wire form out of the way.

Figure 8-25. Remove Retaining Ring Screws

(FLHT/C/U Model Shown)

The bulb contains Halogen gas under pressure. Wear

adequate eye protection and handle the bulb carefully.

Inadequate safety precautions could result in death or

serious injury.

2004 Touring: Electrical 8-25

Page 26

H

OME

f1285b2x

A

Figure 8-27. Check Headlamp Alignment

6. Remove and discard bulb.

CAUTION

Never touch the quartz bulb with your fingers. Fingerprints will etch the glass and cause premature bulb failure. Always wrap the bulb in paper or a clean dry cloth

during handling.

7. Install new bulb in lense. Rotate bulb as necessary so

that backplate makes full contact with lense insert.

NOTE

Wider ear on backplate should point toward the top of the

lense. The top can be determined by the position of the headlamp door bracket, which is at the bottom (on the opposite

side).

8. Use hinge to place wire form over socket at back of bulb.

Press down on loops so ends of wire form engage slots

on lense insert.

9. Install rubber boot at back of lense tucking outer edge

into headlamp housing.

10. Install the wire connector at the back of headlamp bulb.

11. Fit lense and bulb assembly into headlamp housing.

Align holes in retaining ring with those in headlamp

housing. Install the three Phillips screws.

12. Fit the square-shaped portion of the headlamp door

spring into the slot at the top of the headlamp housing

and then snap the headlamp door (chrome ring) into

place. Install Phillips screw at the bottom of the headlamp door and tighten to 9-18 in-lbs (1.0-2.0 Nm).

25 ft.

(7.62m)

5374

Headlamp

Door

Slot

5372

Vertical

Adjuster Screw

Horizontal

Adjuster Screw

(Headlamp Door Removed for Illustration Purposes)

Figure 8-28. Adjust Headlamp Alignment

(FLHT/C/U Model Shown)

A

HEADLAMP ADJUSTMENT

Check headlamp beam for proper height and lateral alignment.

8-26 2004 Touring: Electrical

Page 27

H

OME

1WARNING1WARNING

DO NOT modify the ignition/light key switch wiring to

disable the automatic-on headlamp feature. High visibility is an important safety consideration for motorcycle

riders. Ensure that the headlamp is on at all times. Failure to do so could result in death or serious injury.

1. Verify correct front and rear tire inflation pressure.

2. Place the motorcycle on a level floor or pavement in an

area with minimum light.

3. See Figure 8-27. Point the front of the motorcycle toward

a screen or wall which is 25 feet (7.62 m) from where

patch of front tire contacts floor (i.e. - directly below front

axle).

4. Draw a horizontal line on screen or wall that is exactly

the same height above the floor as the headlamp center.

5. Have a person whose weight is roughly the same as that

of the principal rider sit on the motorcycle seat. The

weight of the rider will compress the vehicle suspension

slightly.

6. Stand the motorcycle upright with both tires resting on

the floor and with the front wheel held in straight alignment (directly forward).

7. Turn the Ignition/Light Key Switch to IGNITION. Set the

Light Switch on the left handlebar to Hi(gh) beam.

8. Check the light beam for proper height alignment. The

center of the main beam of light should be even with the

horizontal line on the screen or wall.

9. Check the light beam for proper lateral alignment. The

main beam of light should be directed straight ahead

(i.e., equal area of light to right and left of center).

NOTE

The headlamp adjustment can be performed without removing the headlamp door (chrome ring).

10. If the headlamp alignment requires adjustment, use slots

in headlamp door to insert Phillips screw driver between

headlamp housing and rubber gasket. Turn the vertical

adjuster screw as necessary to adjust the headlamp vertically. Turn the horizontal adjuster screw to adjust the

headlamp horizontally. See Figure 8-28.

2004 Touring: Electrical 8-27

Page 28

H

OME

HEADLAMP (FLTR) 8.12

HEADLAMP ASSEMBLY

REMOVAL

1. Remove the outer fairing. See Section 2.30 UPPER

FAIRING/WINDSHIELD (FLTR), OUTER FAIRING,

REMOVAL.

2. Move outer fairing assembly to bench area.

3. Squeeze two external tabs to disconnect headlamp harness connectors from bulb contacts.

CAUTION

Wrap electrical tape around blade of screwdriver to prevent damage to tabs of transparent lense cover.

4. From inboard side of outer fairing, release top of transparent lense cover from slots in fairing by gently

depressing two tabs with blade of screwdriver. Depress

two bottom tabs and remove lense cover from fairing.

5. Depress mounting clips on three hex adjuster studs and

pull headlamp assembly out front of outer fairing. See

Figure 8-29.

Plastic

Boss

Hex Adjuster

Stud

Bulb

Housing

Figure 8-30. Remove Retainer to Release Bulb

Plastic

Retainer

f1546x8x

INSTALLATION

1. Align hex adjuster studs with plastic bosses on inboard

side of outer fairing. Push headlamp assembly into position until mounting clips engage bosses.

2. Carefully snap bottom tabs of transparent lense cover

into bottom slots of outer fairing. Carefully snap upper

tabs of lense cover into upper slots of fairing.

3. Install headlamp harness connectors onto bulb contacts.

4. Install the outer fairing. See Section 2.30 UPPER FAIR-

ING/WINDSHIELD (FLTR), OUTER FAIRING, INSTAL-

LATION.

Mounting

Clip

Figure 8-29. Depress Mounting Clips

8-28 2004 Touring: Electrical

f1544x8x

HEADLAMP BULB REPLACEMENT

The headlamp is a replaceable bulb (and not a sealed

beam). Made of quartz glass filled with Halogen gas, the bulb

is very delicate and must be handled with care.

NOTE

When replacement is required, use only the specified bulb

available from your Harley-Davidson dealer. Improper wattage or bulb may cause charging system problems.

REMOVAL

1. Remove the outer fairing. See Section 2.30 UPPER

FAIRING/WINDSHIELD (FLTR), OUTER FAIRING,

REMOVAL.

2. Move outer fairing assembly to bench area.

Page 29

H

CAUTION

1WARNING1WARNING

OME

f1545x8x

Wider

Ear

Slot

Tabs

Figure 8-31. Install New Bulb in Bulb Housing

3. Squeeze two external tabs to disconnect headlamp harness connector from bulb contacts.

4. Remove rubber boot at back of bulb housing.

5. Rotate plastic retainer in a counter-clockwise direction to

remove from bulb housing flange. See Figure 8-30.

INSTALLATION

Never touch the quartz bulb with your fingers. Fingerprints will etch the glass and cause premature bulb failure. Always wrap the bulb in paper or a clean dry cloth

during handling.

1. Install new bulb in bulb housing. Orient bulb so that

wider ear on backplate is topside and then push bottom

of backplate so that tabs on outboard side fit snugly in

slot of bulb housing. See Figure 8-31.

2. Place plastic retainer over bulb housing flange and

rotate in a clockwise direction until tight. See Figure 8-

30.

3. Install rubber boot over retainer until flush with base of

bulb socket.

4. Connect headlamp harness connector to bulb contacts.

5. Install the outer fairing. See Section 2.30 UPPER FAIR-

ING/WINDSHIELD (FLTR), OUTER FAIRING, INSTAL-

LATION.

HEADLAMP ADJUSTMENT

Check headlamp beam for proper height and lateral alignment.

1WARNING1WARNING

The bulb contains Halogen gas under pressure. Wear

adequate eye protection and handle the bulb carefully.

Inadequate safety precautions could result in death or

serious injury.

6. Remove and discard bulb.

6421 6420

Hex Adjuster

LEFT SIDE RIGHT SIDE

DO NOT modify the ignition/light key switch wiring to

disable the automatic-on headlamp feature. High visibility is an important safety consideration for motorcycle

riders. Ensure that the headlamp is on at all times. Failure to do so could result in death or serious injury.

Hex Adjuster

Figure 8-32. Headlamp Adjustment (FLTR)

2004 Touring: Electrical 8-29

Page 30

H

OME

1. Verify correct front and rear tire inflation pressure.

2. Place the motorcycle on a level floor or pavement in an

area with minimum light.

3. See Figure 8-27. Point the front of the motorcycle toward

a screen or wall which is 25 feet (7.62 m) from where

patch of front tire contacts floor (i.e. - directly below front

axle).

4. Draw a horizontal line on screen or wall that is exactly

the same height above the floor as the headlamp center.

5. Have a person whose weight is roughly the same as that

of the principal rider sit on the motorcycle seat. The

weight of the rider will compress the vehicle suspension

slightly.

6. Stand the motorcycle upright with both tires resting on

the floor and with the front wheel held in straight alignment (directly forward).

7. Turn the Ignition/Light Key Switch to IGNITION. Set the

Light Switch on the left handlebar to Hi(gh) beam.

8. Check the light beam for proper height alignment. The

center of the main beam of light should be even with the

horizontal line on the screen or wall.

9. Check the light beam for proper lateral alignment. The

main beam of light should be directed straight ahead

(i.e., equal area of light to right and left of center).

10. Locate the hex adjusters near the bottom edge of the

inner fairing. See Figure 8-32. Tu rning the adjusters

causes the double headlamp housing to pivot around its

upper mount.

11. Using a 4.5 mm, 1/4 inch drive socket (Snap-On

TMM4.5) and flexible driver (Snap-On TM62B), adjust

the headlamp horizontally by turning either the left or

right side adjuster. Turn both adjusters equally to adjust

the headlamp vertically. Adjuster rotation moves the

headlamp beam as follows:

Table 8-6. FLTR Hex Adjuster Rotation

Hex Adjuster Rotation

Left Only CW

Right Only CCW

Left Only CCW

Right Only CW

Left and Right Equally CW Upward

Left and Right Equally CCW Downward

CW= Clockwise CCW= Counter-Clockwise

Beam

Movement

To t he Right

To the Left

8-30 2004 Touring: Electrical

Page 31

H

Lamp

Index Tab

Nesting Ring

Index Tab

f2272x8x

OME

PASSING LAMPS 8.13

ADJUSTMENT

1. Using a long shank ball end socket (Snap-on® FABL5),

remove two screws to release turn signal lamp from

mounting bracket. See Figure 8-33. Use hole in passing

lamp bracket to access inboard screw.

2. Insert flare nut socket (Snap-on® FRX181) at bottom of

turn signal mounting bracket and loosen locknut on stud.

3. Move lamp and swivel block to obtain the desired position.

NOTE

Passing lamps should shine straight ahead with the center of

the main light beam even with a horizontal line drawn on a

wall 25 feet (7.6 m) away. The line on the wall should be at

the same height as the center of the passing lamps with the

rider mounted.

4. Using flare nut socket, tighten locknut to 18 ft-lbs (24.4

Nm).

Passing

Lamp

8820

Door

Figure 8-34. Install Nesting Ring at Back of

Passing Lamp Bulb

5. Using long shank ball end socket, start two screws to

secure turn signal lamp to mounting bracket. Verify that

conduit fits in slot at back of bracket and is not pinched

as screws are tightened.

Bracket

Screw

Mounting

Bracket

Conduit

Turn Signal

Lamp

Figure 8-33. Passing Lamp and Turn Signal

Door

Screw

PASSING LAMP BULB

REMOVAL

1. Loosen passing lamp door screw as required to pull

lamp door from lip of lamp housing. See Figure 8-33.

2. Pull socket terminals from spade contacts at back of

lamp.

3. Remove nesting ring and discard lamp.

INSTALLATION

1. Place nesting ring at back of new lamp with the concave

side up. See Figure 8-34.

2. Install socket terminals onto spade contacts at back of

lamp.

3. Install lamp fitting nesting ring over edge of lamp housing. Rotate nesting ring so that index tab is aligned with

slot at bottom of lamp housing.

2004 Touring: Electrical 8-31

Page 32

H

OME

Figure 8-35. Inner Fairing (FLHT/C/U)

f2212x8x

Passing Lamp

Connector [73]

f2238x8x

PASSING LAMP

REMOVAL

1. Proceed as follows:

FLHT/C/U: Remove the outer fairing. See Section 2.29

UPPER FAIRING/WINDSHIELD (FLHT/C/U), OUTER

FAIRING/WINDSHIELD, REMOVAL. Locate passing

lamp connector (white 2-place Multilock) below upper

fork bracket. See Figure 8-35.

FLHR/C: Remove the Phillips screw at the bottom of the

headlamp door (chrome ring). Remove the headlamp

door. Remove the eight Phillips screws to free the headlamp housing from the headlamp nacelle. Squeeze the

two external tabs to remove the wire connector at the

back of the headlamp bulb. Remove the headlamp housing assembly from the vehicle. Locate passing lamp connector (white 2-place Multilock). See Figure 8-36.

2. Depress the button on the socket terminal side of the

connector and pull apart the pin and socket halves.

3. Remove terminal of Gray/Black wire from socket housing.

NOTE

For instructions on properly removing wire terminals, see

APPENDIX B.2 AMP MULTILOCK ELECTRICAL CONNEC-

TORS, REMOVING SOCKET/PIN TERMINALS.

Passing Lamp

Switch Connector [109]

Passing Lamp

Connector [73]

Figure 8-36. Headlamp Nacelle (FLHRC)

4. Holding nesting ring in place, rotate lamp so that dot on

lense is at the bottom and index tabs at back engage

slots in nesting ring.

5. Verify that two adhesive foam strips are present on

inboard side of lamp door. Install new foam strips if deteriorated or missing.

6. Install lamp door over lip of lamp housing. Rotate lamp

door so that screw is centered at bottom, and then

tighten door screw until snug.

4. Using a long shank ball end socket (Snap-on® FABL5),

remove two screws to release turn signal lamp from

mounting bracket. See Figure 8-33. Use holes in pass-

ing lamp bracket to access inboard screw.

5. Obtain length of strong flexible wire for use as mechanics wire. Feed wire through opening in socket terminal

and then loop back twisting end until tightly coiled

around longer strand as shown in Figure 8-37.

Mechanics Wire

Socket Terminal

f1418x2x

Figure 8-37. Fix Mechanics Wire to Socket Terminals

8-32 2004 Touring: Electrical

Page 33

H

OME

NOTE

Be sure that mechanics wire is of sufficient strength to pull

terminal through conduit without breaking. Wire length must

also be long enough so that free end is not lost in conduit

when pulled.

6. Carefully pull wire to draw socket terminal through conduit.

7. Unravel mechanics wire to release socket terminal.

8. Insert flare nut socket (Snap-on® FRX181) at bottom of

turn signal mounting bracket and remove locknut from

stud. Remove the turn signal mounting bracket and

clamp block.

9. Remove passing lamp (with Belleville washer and swivel

block) from the passing lamp bracket.

INSTALLATION

1. Lay old passing lamp next to new passing lamp and cut

Gray/Black wire to length.

2. Strip 3/16 inch (4.8 mm) of insulation off new lamp wire

and crimp on new socket terminal.

NOTE

For instructions on crimping wire terminals, see APPENDIX

B.2 AMP MULTILOCK ELECTRICAL CONNECTORS,

CRIMPING INSTRUCTIONS.

3. If removed, slide swivel block and Belleville washer down

Gray/Black wire onto passing lamp stud. Be sure that

rounded side of swivel block and concave side of

Belleville washer face passing lamp.

4. Feed Gray/Black wire of passing lamp through slot at top

of passing lamp bracket and insert threaded stud into

forward slot. Slide clamp block (rounded side up), turn

signal mounting bracket and locknut up Gray/Black wire

onto passing lamp stud at bottom of bracket.

5. Using flare nut socket (Snap-on® FRX181), tighten locknut to 18 ft-lbs (24.4 Nm).