Page 1

HOME

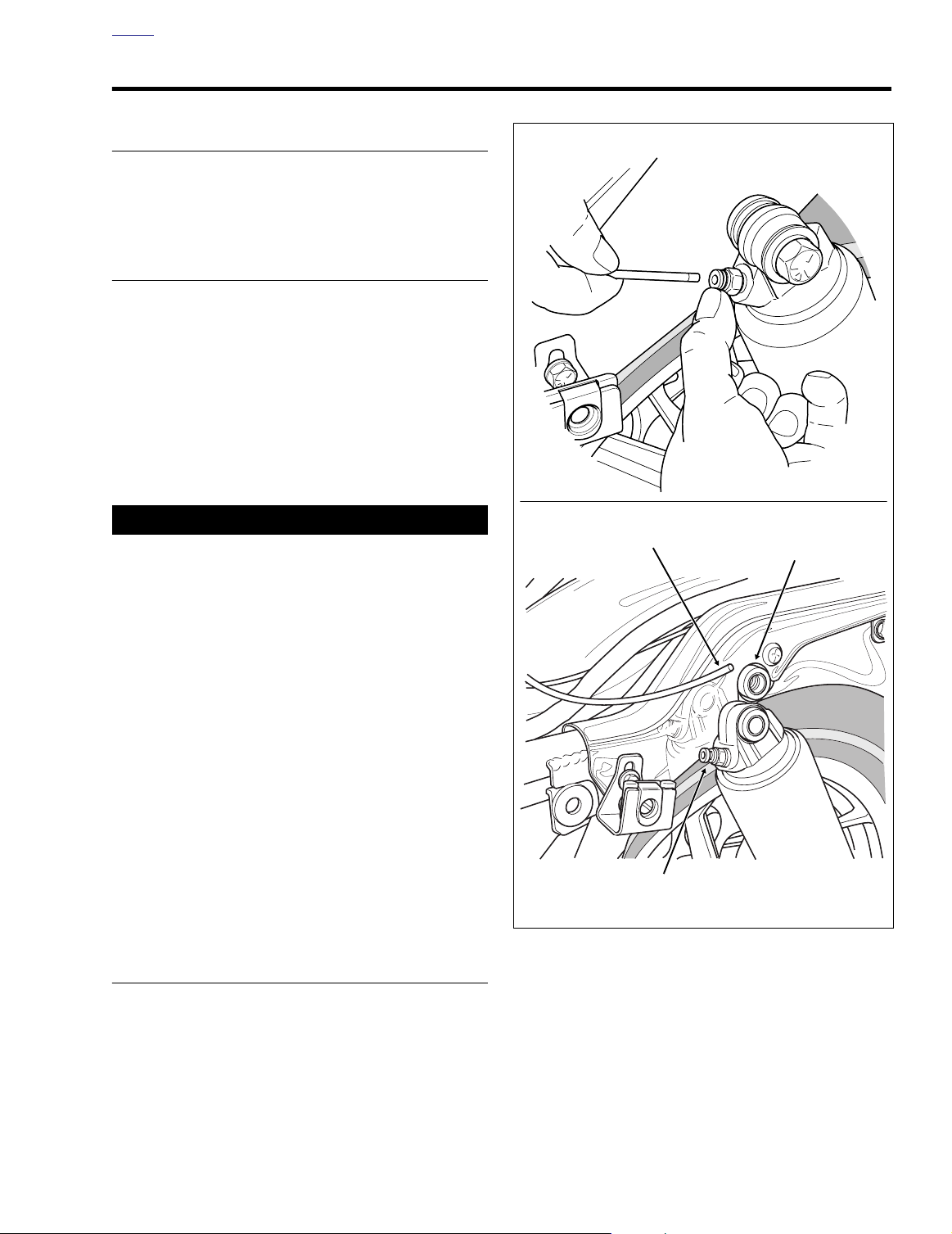

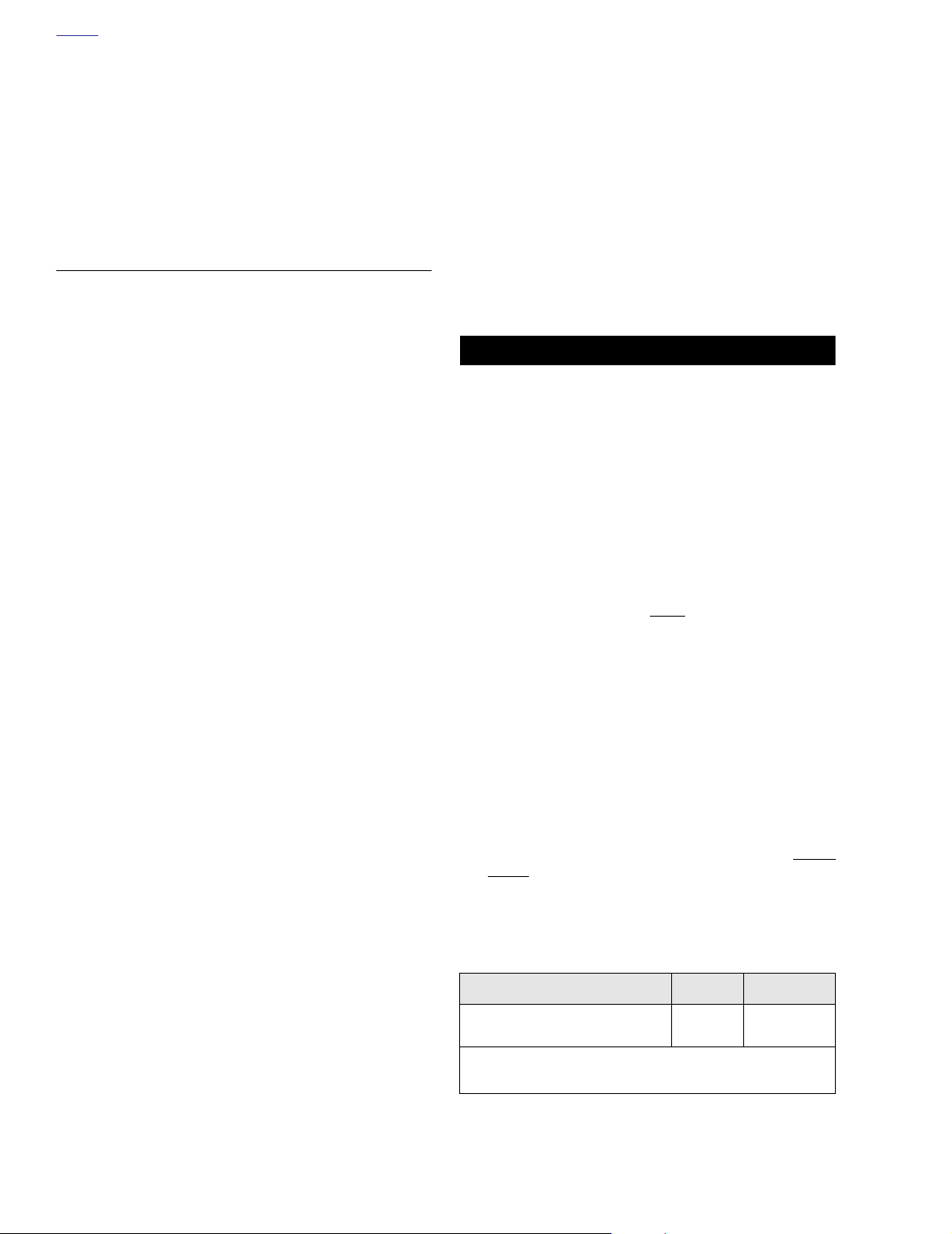

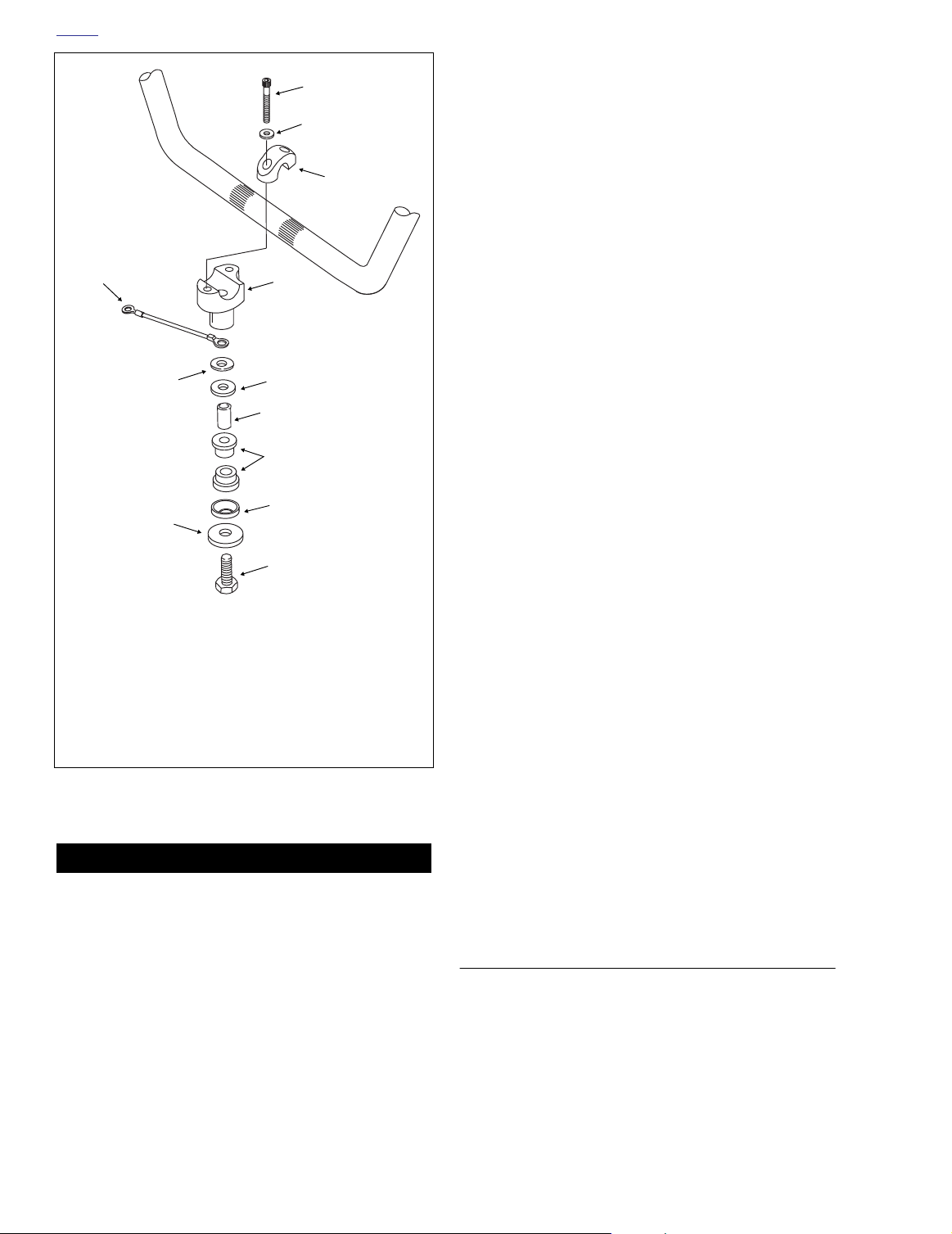

f2010x2x

f1449a2x

Frame

Boss

Air Inlet

Tube

Shock

Absorber

Compression

Fitting

Depress Collar on Fitting

and Pull Out Air Inlet Tube.

REAR SHOCK ABSORBERS 2.19

ADJUSTMENT

For the correct air pressure, see Section 2.18 REAR AIR

SUSPENSION.

REMOVAL

NOTE

If replacing both shock absorbers, remove and install one

shock at a time. Remove and install the second shock only

after the first shock is installed, but before the air suspension

system is pressurized.

1. Place the motorcycle on a hydraulic center stand with

the rear wheel raised off the ground.

2. Remove saddlebags. See Section 2.25 SADDLEBAG,

REMOVAL.

11WARNING1WARNING

Exercise caution when bleeding air from the air valve.

Moisture combined with lubricant (either from shock

assembly or drip oiler in the air compressor lines) may

be ejected onto the rear wheel, tire and/or brake components and adversely affect traction and/or braking efficiency, which could result in death or serious injury.

3. Remove protective cap from air valve. Using a no-loss

AIR SUSPENSION PUMP AND GAUGE (Part No. HD-

34633), add 3-5 psi (20.7-34.5 kPa) to purge lines of any

oil.

4. Depress pin in valve to bleed air from shocks.

5. Depress collar on compression fitting to release air tube.

See upper frame of Figure 2-96.

6. Remove the upper shock mounting bolt with lockwasher

and flat washer. See lower frame of Figure 2-96.

7. Remove the lower shock mounting bolt with lockwasher

and flat washer. Remove the shock absorber assembly

from the vehicle.

DISASSEMBLY

Figure 2-96. Remove Air Inlet Tube and

Upper Shock Mounting Bolt (Left Side View)

NOTE

Air shocks are not repairable. Replace the shocks if damaged or worn.

2004 Touring: Chassis 2-79

Page 2

HOME

CLEANING AND INSPECTION

1. Examine the rubber mounting bushings for cracks or

wear. Examine the shock for leaks. The unit should not

leak and should compress slightly easier than it extends.

Compare the action of the shock with a new one to judge

if it is worn. Replace the shock if necessary.

2. Clean and examine the shock mounting hardware.

Replace parts that are worn or damaged.

ASSEMBLY

NOTE

If the compression fittings were removed, apply PIPE SEALANT WITH TEFLON to the threads before assembly.

INSTALLATION

1. Install lockwasher and flat washer on the lower shock

mounting bolt. Insert bolt through the shock bottom

bushing.

2. Apply two or three drops of Loctite Medium Strength

Threadlocker 243 (blue) to threads.

3. Start bolt into rear swingarm mount. Tighten bolt to 3540 ft-lbs (47-54 Nm).

4. Install lockwasher and flat washer on the upper shock

mounting bolt. Insert bolt through the shock upper bushing

5. Apply two or three drops of Loctite Medium Strength

Threadlocker 243 (blue) to threads.

6. Start bolt into frame boss. Tighten bolt to 33-35 ft-lbs

(45-48 Nm).

7. Insert air tube into compression fitting until it bottoms.

Gently tug on tube to verify that it is locked in place.

NOTE

If replacing both shock absorbers, remove and install the

other shock at this time.

8. Pressurize rear air suspension system and check for

leaks. For the correct air pressure, see Section 2.18

REAR AIR SUSPENSION.

9. Install saddlebags. See Section 2.25 SADDLEBAG,

INSTALLATION.

2-80 2004 Touring: Chassis

Page 3

HOME

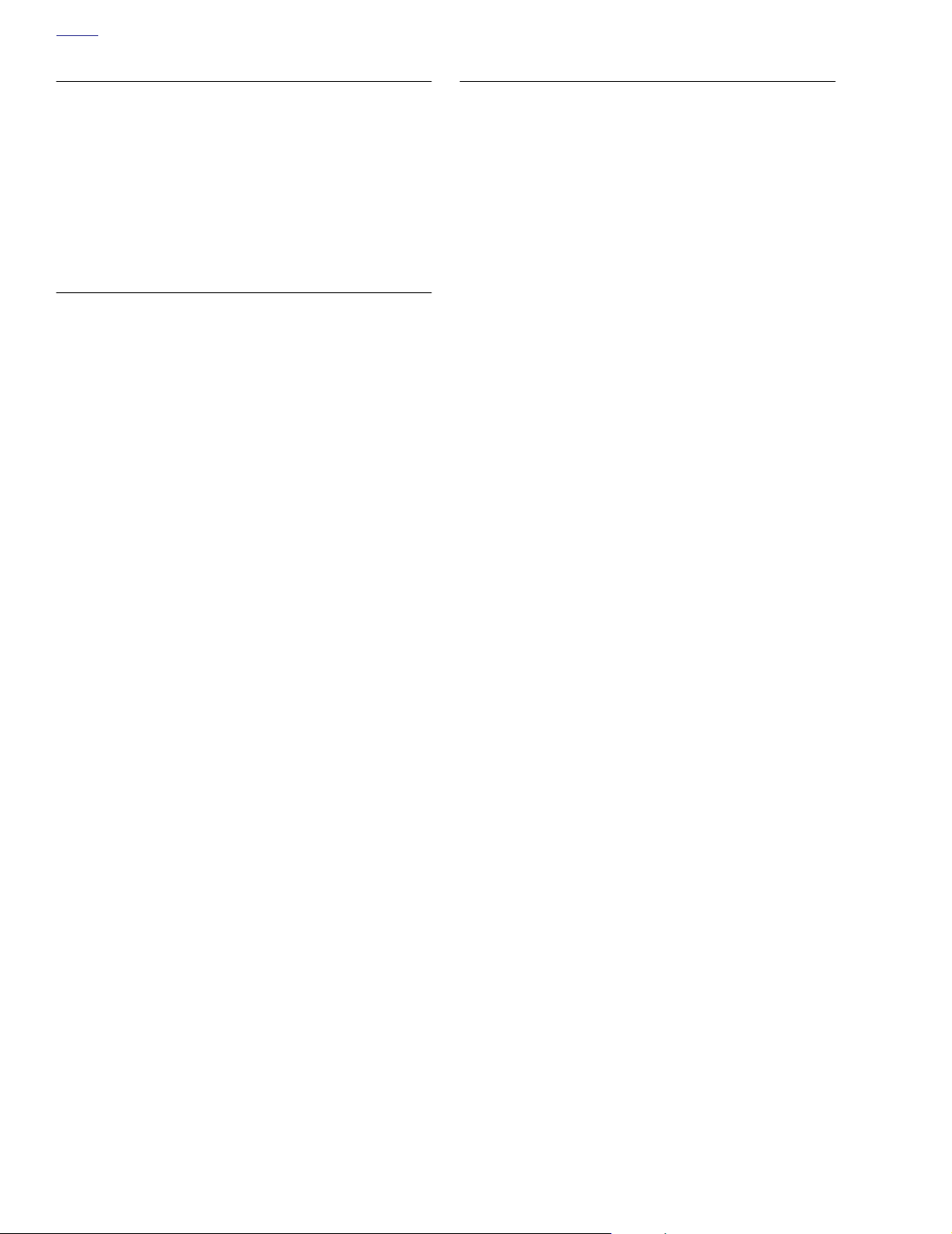

f2006x2x

Rear

Swingarm

Slot

Rubber

Mount

Pivot

Shaft

Locknut

REAR SWINGARM 2.20

REMOVAL

1. Remove saddlebags. See Section 2.25 SADDLEBAG,

REMOVAL.

2. Remove socket screw with lockwasher to remove passenger footboard from rear swingarm bracket. Repeat

step on opposite side of vehicle.

3. Remove both mufflers as follows:

Left Side

a. Open worm drive clamps to remove heat shield

from crossover pipe in front of muffler.

b. Using a bungee cord, tie the muffler to the lower

saddlebag support rail.

c. Loosen TORCA clamp between crossover pipe and

muffer.

d. Remove two bolts (with lockwashers) to detach muf-

fler from the lower saddlebag support rail.

e. Remove bungee cord to release muffler from lower

saddlebag support rail.

Right Side

a. Open worm drive clamps to remove heat shield

from rear header pipe in front of muffler.

b. Using a bungee cord, tie the muffler to the lower

saddlebag support rail.

c. Loosen TORCA clamp between rear header pipe

and muffer.

d. Remove two bolts (with lockwashers) to detach muf-

fler from the lower saddlebag support rail.

e. Remove bungee cord to release muffler from lower

saddlebag support rail.

4. Place the motorcycle on a hydraulic center stand. Slide

a block of wood beneath the oil pan to support the

weight of the transmission once the pivot shaft is

removed.

5. Standing on right side of vehicle, remove E-clip from

groove at end of axle.

6. Remove cone nut and adjuster cam from axle.

7. Using a soft mallet, gently tap end of axle towards left

side to loosen. Catching external spacers on right and

left side of hub, pull axle free of wheel and rear

swingarm.

8. Pull wheel to release brake disc from caliper. Pry inner

and outer brake pads back for additional clearance, if

necessary. Use a putty knife with a wide thin blade to

avoid scoring or scratching the brake disc.

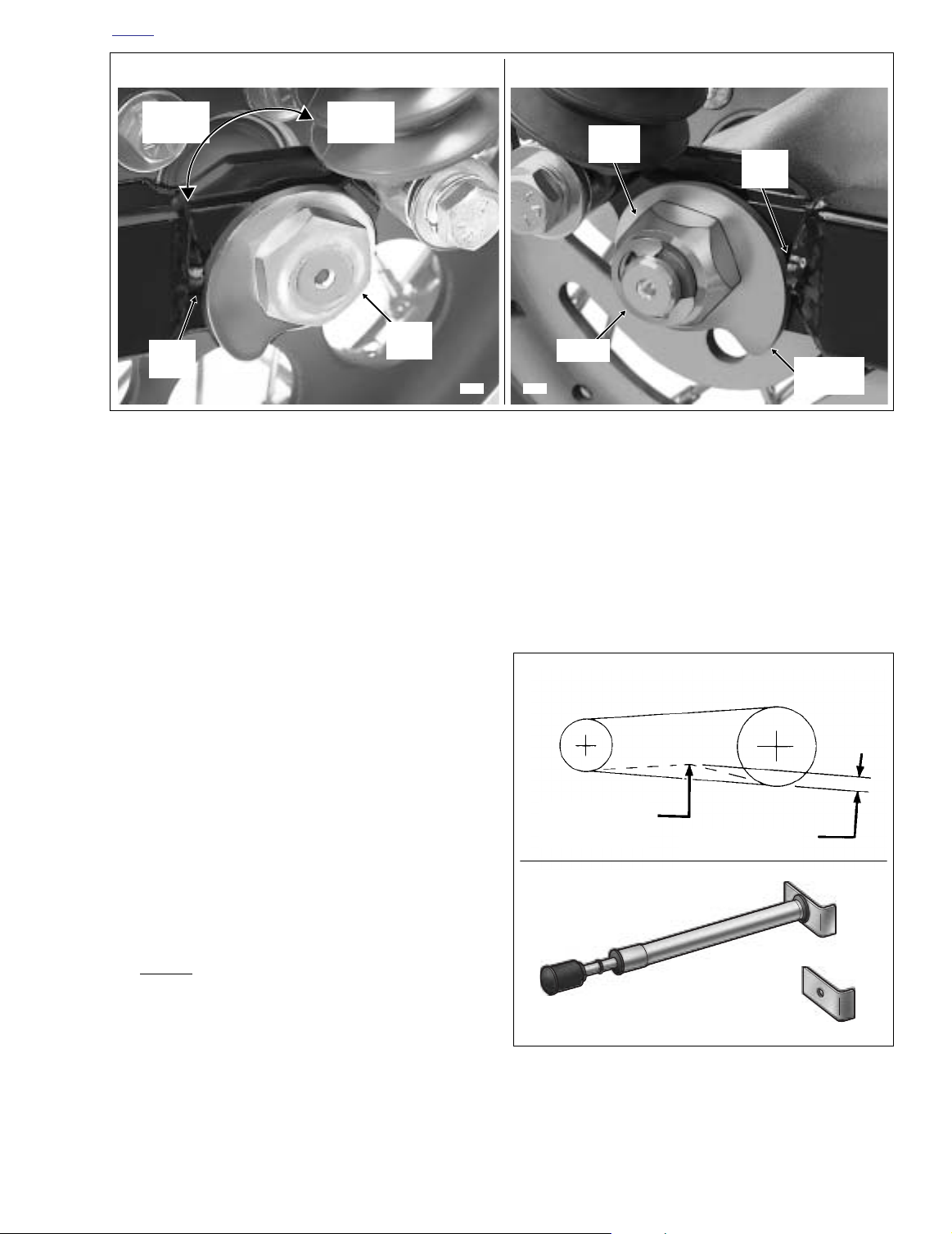

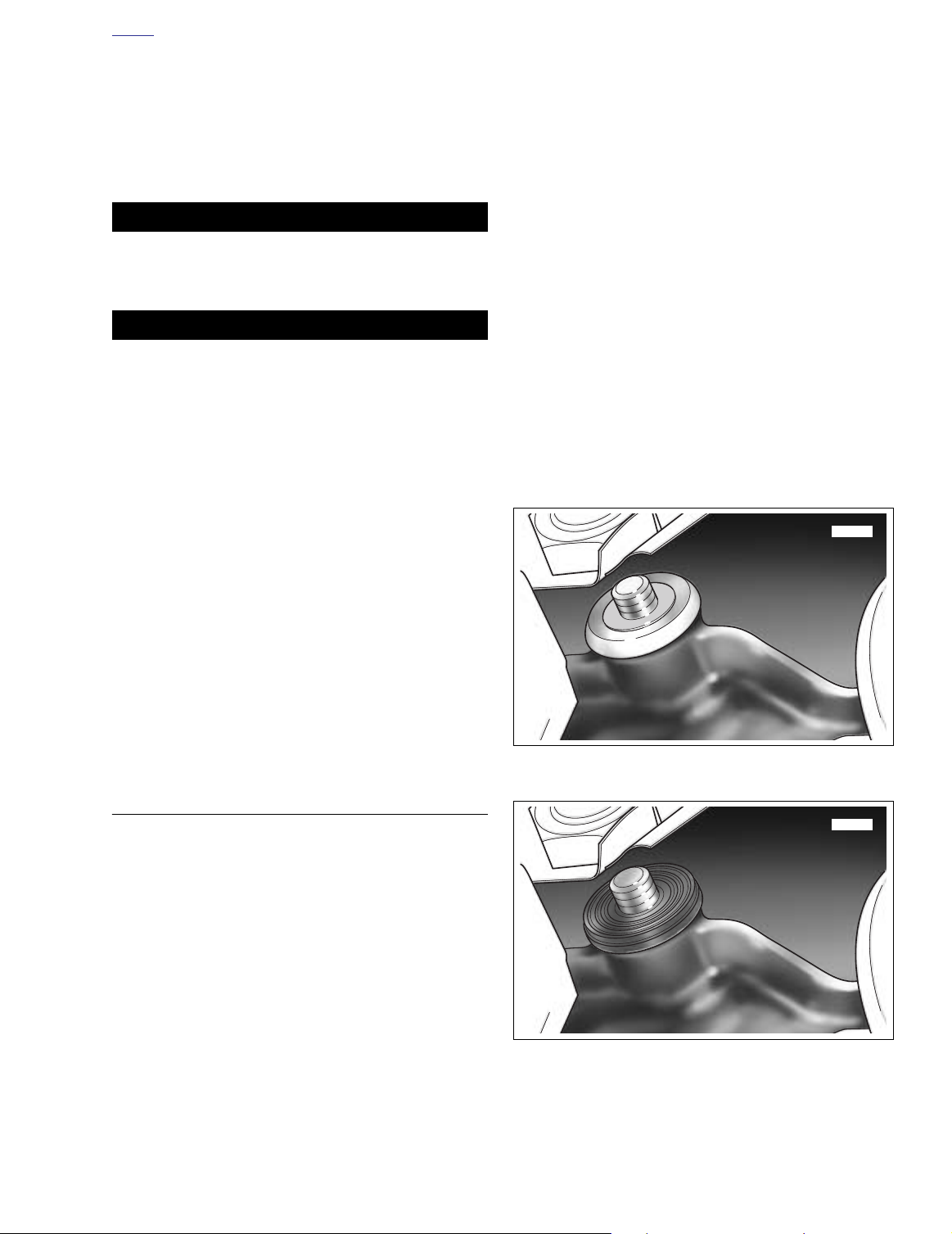

Figure 2-97. Remove Rear Swingarm Bracket

(Left Side View)

9. Remove caliper from anchor weldment on rear swingarm, and carefully hang over lower saddlebag support

rail.

10. Roll wheel forward and slip belt off sprocket. Move wheel

out from beneath rear fender.

11. Remove belt guard from bottom of left side swingarm.

First remove two rear screws, and then loosen front

screw. Push belt guard toward the front of the vehicle

until screw engages large end of slot, and then remove.

12. Remove lower shock mounting bolt (with lockwasher and

flat washer) to release shock absorber from rear swingarm mount. Repeat step on opposite side of vehicle.

13. Remove two bolts (with lockwashers) to free rear swingarm bracket from left side of vehicle frame. See Figure 2-

97.

14. Moving to right side of vehicle, leave rear swingarm

bracket installed, but remove decorative chrome plug.

15. Open two cable clips on T-studs at top of right side swingarm. Free rear brake line hose from cable clips.

NOTE

For best results, insert blade of small screwdriver into gap at

side of clip and gently rotate end of screwdriver to pop open.

2004 Touring: Chassis 2-81

Page 4

HOME

Ram

Socket

Extension

Socket

Figure 2-98. Press Out Drive Side Bearing

16. Holding left side nut within rubber mount, remove right

side locknut from end of pivot shaft. Remove cup

washer.

17. Using a suitable drift, tap pivot shaft toward left side of

vehicle.

18. Moving to left side, pull pivot shaft assembly (pivot shaft,

locknut, cup washer, rubber mount and outer spacer) out

of transmission mount and left side swingarm. See

Figure 2-102.

19. Standing at rear of vehicle, work rear swingarm free of

transmission mount and rear swingarm brackets.

20. Remove outer spacer from right side swingarm tube.

21. Remove rubber mount from behind right side swingarm

bracket.

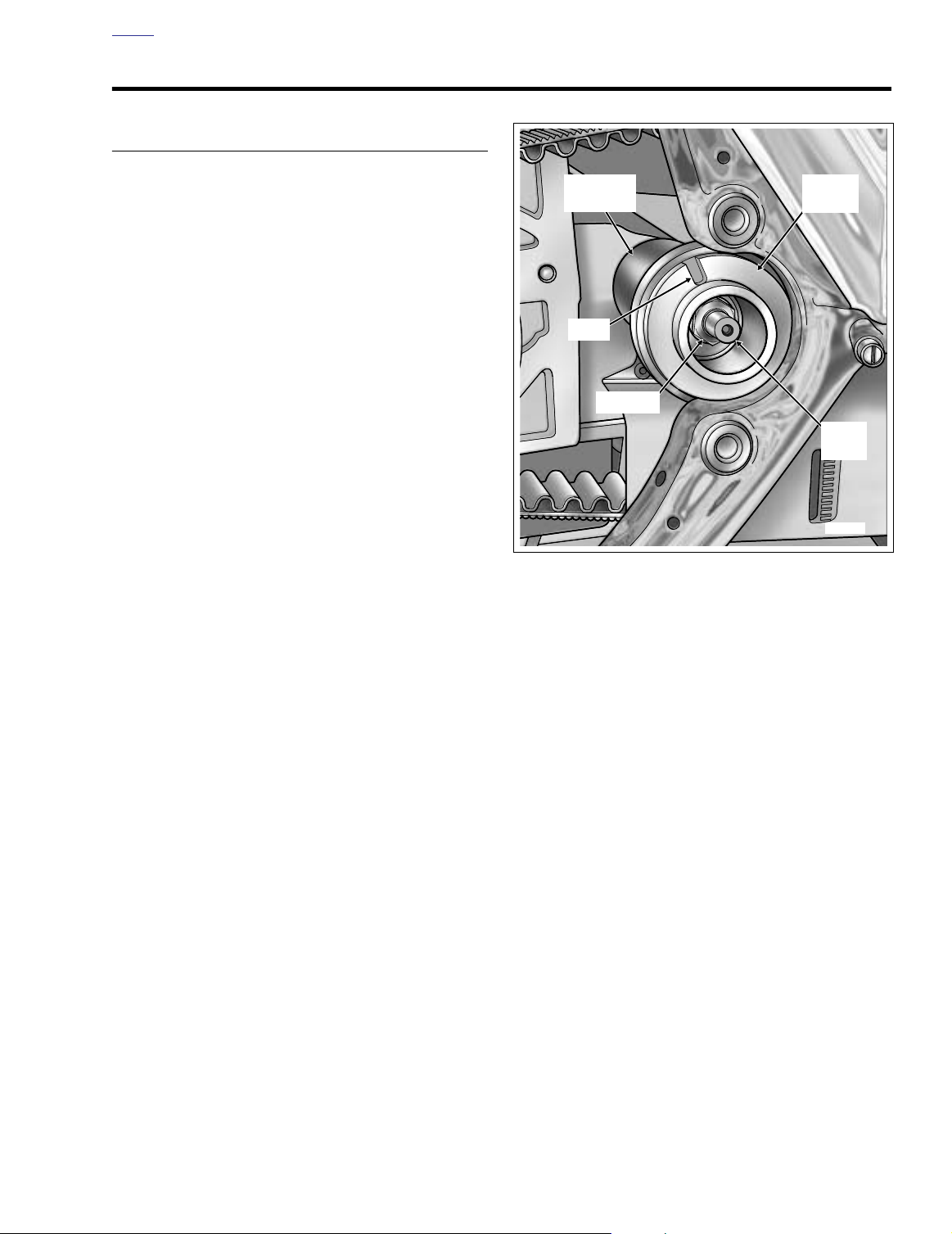

Socket

f1903x2x

Anchor

Weldment

Wood

Block

f1967x2x

Spacer

Bearing

DISASSEMBLY/ASSEMBLY

Bearing Removal

1. Move rear swingarm to an hydraulic press.

2. Place swingarm on its side, so that the brake side is on

top. The brake side is easily recognized by the anchor

weldment for mounting of the brake caliper.

3. Support the swingarm with a block of wood and a large

socket as shown in Figure 2-98. Ver ify that assembly is

square and the bearing bore is completely vertical.

2-82 2004 Touring: Chassis

Figure 2-99. Press Spacer Into Bearing

4. Slide driver handle (or long socket extension) through

the brake side swingarm tube and bearing until it contacts driver (or large socket) placed on inboard side of

drive side bearing.

5. Center driver handle (or long socket extension) under

ram and press drive side bearing from rear swingarm.

6. Remove tools from rear swingarm. Turn swingarm over

and repeat steps 3-5 to press out brake side bearing.

Page 5

HOME

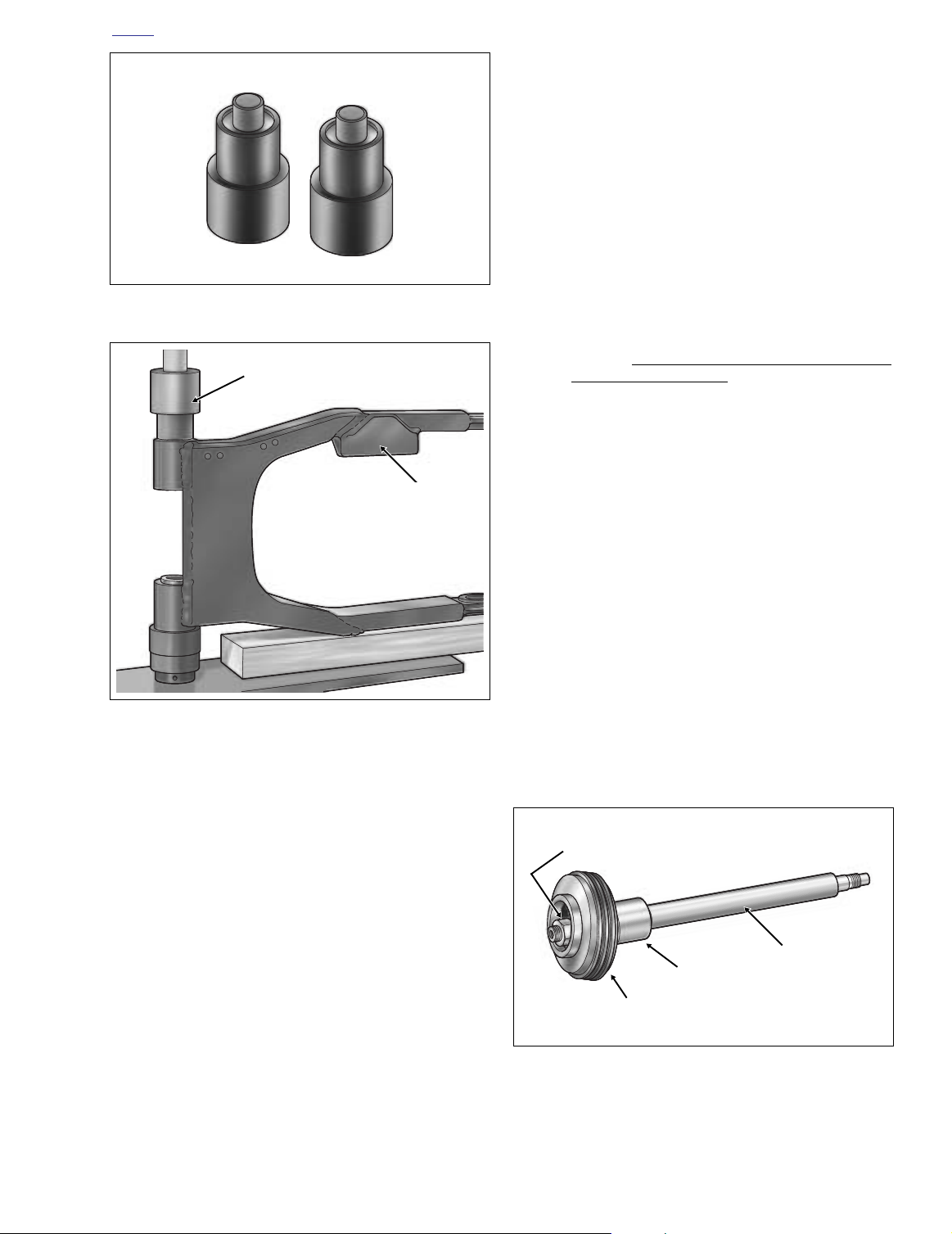

f1914x2x

Pivot

Shaft

Rubber

Mount

Locknut and

Cup Washer

Spacer

Right Side

Drive Side

Driver

Figure 2-100. Rear Swingarm Bearing Installer (HD-

45327)

Brake Side

Driver

Brake Side

Driver

Anchor

Weldment

f1909x2x

a. Place swingarm on its side, so that the brake side is

on top. The brake side is easily recognized by the

anchor weldment for mounting of the brake caliper.

b. With the spacer inboard, insert bearing into out-

board side of brake side swingarm tube.

c. Insert driver stamped “Brake Side” into swingarm

tube until it contacts installed bearing. Center driver

under ram and press on brake side bearing until

shoulder on tool makes contact with casting of swingarm. See Figure 2-101.

d. Remove tool and turn rear swingarm over. With the

spacer inboard, insert bearing into outboard side of

drive side swingarm tube.

e. Insert driver stamped “Drive Side” into swingarm

tube until it contacts installed bearing. Center driver

under ram and press on drive side bearing until it

bottoms. Shoulder on tool will

with casting of swingarm.

f. Remove tool from swingarm. Remove swingarm

from hydraulic press.

not

mak

e contact

Pivot Shaft Disassembly

1. Partially install locknut on right side of pivot shaft. Install

second locknut on right side until it contacts the first.

Holding first locknut to prevent rotation of shaft, remove

left side locknut. See Figure 2-102.

2. Remove cup washer, rubber mount and outer spacer.

3. Remove right side locknuts from pivot shaft.

Bearing Installation

1. Obtain

2. Install assembled bearings into rear swingarm. Proceed

Figure 2-101. Press In Brake Side Bearing

new

rear swingarm bearings. Bearings and spacers must be assembled before installation. Proceed as

follows:

a. Obtain REAR SWINGARM BEARING INSTALLER

(HD-45327). See Figure 2-100.

b. With the nose topside, center one of the drivers

under ram of hydraulic press.

c. Place bearing over nose of driver. With the collar

topside, place spacer over nose and into bearing.

See Figure 2-99.

d. Apply pressure to spacer until it bottoms in bearing.

e. Repeat step to assemble second swingarm bearing.

as follows:

Pivot Shaft Assembly

1. With larger OD outboard, slide outer spacer onto left

side of pivot shaft until counterbore contacts shoulder on

shaft.

2. Install rubber mount with the flat side inboard toward

outer spacer.

3. Install cup washer with the concave side facing in toward

the rubber mount.

Figure 2-102. Pivot Shaft Assembly

2004 Touring: Chassis 2-83

Page 6

HOME

4. Apply two drops of Loctite Medium Strength Threadlocker 243 (blue) to threads of left side locknut, and then

start on shaft.

5. Partially install locknut on right side of pivot shaft. Install

second locknut on right side until it contacts the first.

Holding second locknut to prevent rotation of shaft,

tighten left side locknut to 40-45 ft-lbs (54-61 Nm).

6. Remove right side locknuts from pivot shaft.

INSTALLATION

1. With the slot on the outboard side between the twelve

and one o’clock positions, install rubber mount behind

rear swingarm bracket on right side of vehicle. Be sure

that index tab cast on inboard side of bracket fully

engages slot in rubber mount.

2. Place outer spacer into right side swingarm tube.

3. With the belt on the inboard side of the left side swingarm, work the rear swingarm into position between the

transmission mount and the rear swingarm brackets.

Use a rubber mallet and carefully tap swingarm into

position, if necessary.

4. The pivot shaft secures the rear swingarm and transmission to the vehicle frame. See Figure 2-102. Install the

pivot shaft as follows:

a. Coat pivot shaft with Loctite ANTI-SEIZE LUBRI-

CANT.

b. From left side of vehicle, slide pivot shaft assembly

(pivot shaft, locknut, cup washer, rubber mount and

outer spacer) through left side swingarm and transmission mount. After exiting right side swingarm,

guide end of pivot shaft through holes in rubber

mount and right side swingarm bracket.

c. With the concave side inboard, slide cup washer

onto end of pivot shaft.

d. Install locknut on pivot shaft. Holding left side nut on

pivot shaft, tighten locknut to 40-45 ft-lbs (54-61 Nm).

Now hold right side nut and tighten left side locknut

using the same torque value.

e. Carefully raise swingarm up and down slightly to

verify movement (and that assembly is not in a

bind).

f. Install decorative chrome plug in right side rear

swingarm bracket.

g. Moving to left side of vehicle, rotate the rubber

mount so that the slot is between the eleven and

twelve o’clock positions. Install left side swingarm

bracket fitting index tab into rubber mount slot. See

Figure 2-97.

h. Install two bolts (with lockwashers) to secure left

side swingarm bracket to vehicle frame. Tighten

bolts to 34-42 ft-lbs (46-57 Nm).

5. Install lockwasher and flat washer on the lower shock

mounting bolt. Insert bolt through the shock bottom

bushing. Apply two or three drops of Loctite Medium

Strength Threadlocker 243 (blue) to threads. Start bolt

into rear swingarm mount. Tighten bolt to 35-40 ft-lbs

(47-54 Nm). Repeat step on opposite side of vehicle.

6. Install belt guard at bottom of left side swingarm. Push

belt guard toward the rear of the vehicle until front screw

engages small end of slot. Install two rear screws, and

then tighten front screw.

7. Capture rear brake line hose in two cable clips at top of

right side swingarm. Snap cable clips closed.

8. Place wheel in rear swingarm. Slide wheel far enough

forward to slip belt over sprocket and then slide the

wheel back.

CAUTION

Do not bend or fold belt backward or into loops smaller

than 5 inches (127 mm) in diameter. Sharp bending can

weaken the belt and cause premature failure.

9. Seat caliper on anchor weldment of rear swingarm. Position wheel in swingarm, so that brake disc is centered

between brake pads.

10. Coat the axle with Loctite ANTI-SIEZE LUBRICANT.

11. With the larger OD on the outboard side, hold external

spacer between rear swingarm and belt sprocket. Slide

axle through left side of rear swingarm, external spacer,

and belt sprocket into wheel hub.

12. When axle emerges from hub on brake disc side of

wheel, push axle through

bracket and right side of rear swingarm.

13. Rotate axle so that the flat on the threaded end is topside. With the thumb down and the cam forward, install

adjuster cam on end of axle.

14. Apply a thin film of ANTI-SIEZE LUBRICANT to the

inboard side of the cone nut avoiding contact with

threads. Install cone nut on axle, but finger tighten only.

15. Verify that adjuster cam just contacts weld nub on both

sides of rear swingarm. If necessary, push wheel forward slightly to achieve the desired result. Snug the

cone nut to 15-20 ft-lbs (20-27 Nm). See Figure 2-103.

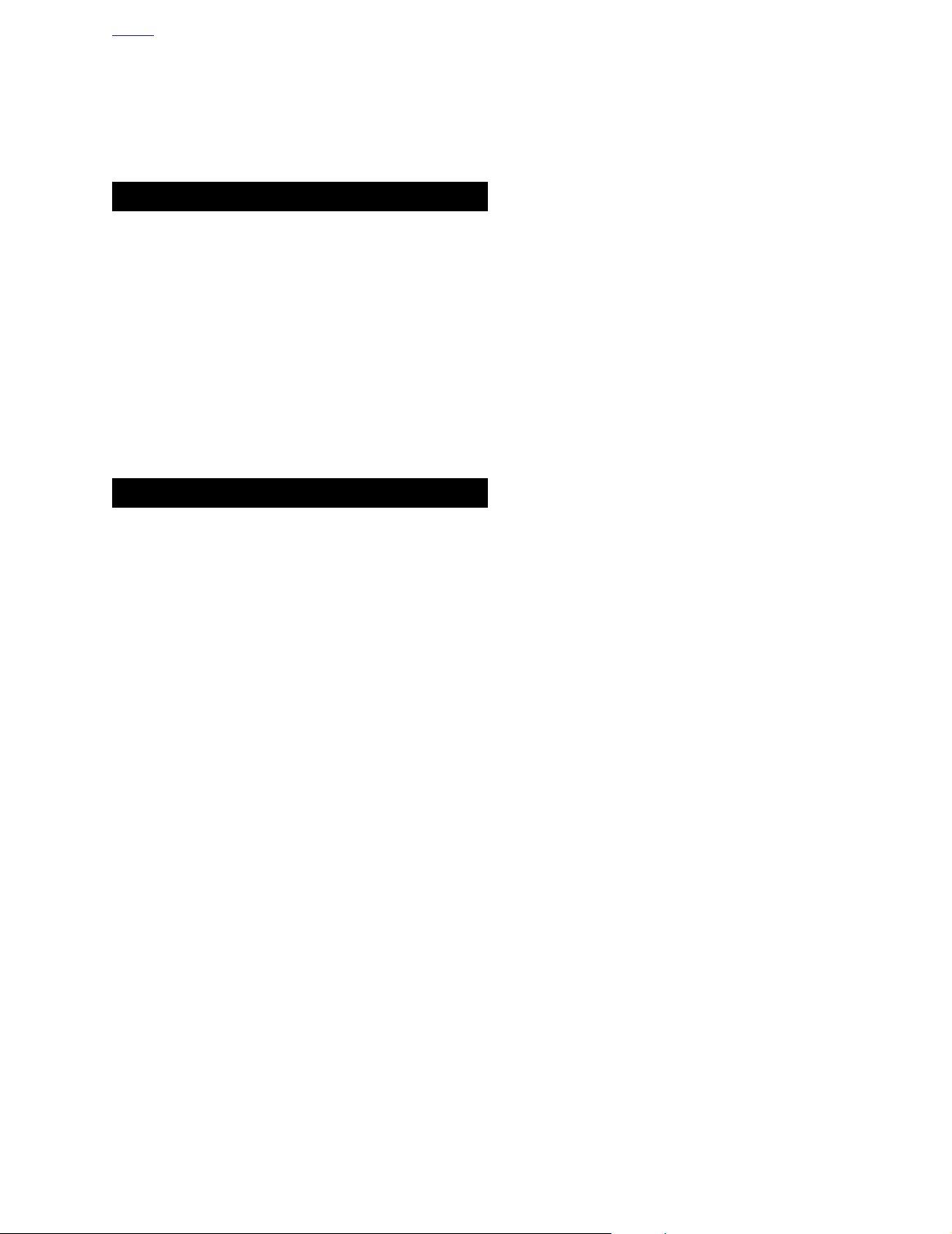

16. Check deflection at the loosest spot in the belt. Use

BELT TENSION GAUGE (HD-35381A), or install narro

saddle (HD-35381-3) on existing gauge, and apply 10

lbs. (4.5 kg) of force at the midpoint of the bottom belt

strand. See Figure 2-104. Belt deflection should be as

follows:

shor

t

external spacer, caliper

Table 2-4. Belt Deflection in the Air

Orientation

Motorcycle Upright

With Rear Wheel in the Air

See Section 6.4 SECONDARY DRIVE BELT AND SPROCKETS

for belt deflection specification with motorcycle on jiffy stand.

NOTE

Inches Millimeters

3/16 - 1/4 4.8 - 6.4

w

2-84 2004 Touring: Chassis

Page 7

HOME

10 lbs. (4.5 kg)

of Force

f1652x6x

See Tabl e 2-4.

Transmission

Sprocket

Rear Wheel

Sprocket

Belt Tension Gauge Adapter

Part No. HD-35381-3

Belt Tension Gauge

Part No. HD-35381A

RIGHT SIDELEFT SIDE

Increase

Belt

Deflection

Reduce

Belt

Deflection

Weld

Weld

Nut

Nub

8398

Figure 2-103. Move Rear Wheel Forward Until Adjuster Cams Just Contact Weld Nubs

17. If belt is too tight, move to step 18 to increase belt

deflection. If belt is too loose, reduce belt deflection as

described below:

a. Rotate weld nut on left side of axle in a clockwise

direction.

b. Check belt deflection. Apply 10 lbs. (4.5 kg) of force

at the midpoint of the bottom belt strand. Belt

deflection should be within the range specified in

Ta ble 2-4.

c. If belt is still too loose, repeat steps 17(a) through

17(b). If belt is now too tight, move to step 18.

Cone

Nut

Weld

Nub

E-Clip

Adjuster

8407

Cam

20. Recheck belt deflection to verify that it is still within specification.

If the belt deflection is not within specification, loosen

cone nut and then snug to 15-20 ft-lbs (20-27 Nm)

before returning to step 17.

21. With the flat side out, install

new

E-clip in groove on right

side of axle.

22. Depress rear brake pedal several times to set brake

pads to proper operating position within caliper.

18. If belt is too tight, increase belt deflection as follows:

19.

If the axle moves during tightening of the cone nut, then the

the belt deflection procedure must be restarted.

a. Rotate weld nut on left side of axle in a counter-

clockwise direction.

b. Push wheel forward slightly so that adjuster cam

just contacts weld nub on both sides of rear swingarm. See Figure 2-103.

c. Check belt deflection. Apply 10 lbs. (4.5 kg) of force

at the midpoint of the bottom belt strand. Belt

deflection should be within the range specified in

Ta ble 2-4.

d. If belt is still too tight, repeat steps 18(a) through

18(c). If belt is now too loose, move to step 17.

Holding

weld nut on left side of axle, tighten cone nut on

right side to 95-105 ft-lbs (128.8-142.4 Nm).

NOTE

Figure 2-104. Check and Adjust Belt Deflection

2004 Touring: Chassis 2-85

Page 8

HOME

11WARNING1WARNING

After installation of caliper and BEFORE moving motorcycle, pump rear brake pedal until pistons push pads

against the brake disc. If fluid pressure is not pumped

up, the rear brake will not be available the first time it is

used, a situation that could result in death or serious

injury.

23. Install both mufflers as follows:

NOTE

TORCA muffler clamps have eliminated the need for silicone

or graphite tape during assembly. To ensure sealing integrity

of muffler clamps and prevent the possibility of leakage, Harley-Davidson recommends that TORCA clamp assemblies be

discarded and replaced each time they are removed.

Left Side

a. Slide

b. Using a bungee cord, tie muffler to lower saddlebag

c. Tighten the two bolts (with lockwashers) to fasten

new

TORCA clamp onto free end of crossover

pipe.

support rail. Install muffler on crossover pipe. Place

TORCA clamp into position between crossover pipe

and muffler.

the muffler to the lower saddlebag support rail.

Passenger

Footboard

Bracket

Chrome

Plug

Rear

Swingarm

Bracket

f1787x2x

CAUTION

Verify that the exhaust pipes do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

d. Verify that exhaust pipes are in alignment and do

not contact the vehicle frame or mounted components.

e. Tighten the TORCA clamp to 45-60 ft-lbs (61-81

Nm).

f. Open worm drive clamps and install heat shield on

crossover pipe. Position clamp so that screw is on

the outboard side in the most accessible position.

CAUTION

Verify that the heat shields do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

g. Remove bungee cord from muffler.

Right Side

a. Slide

new

TORCA clamp onto free end of rear

header pipe.

Locknut

Pivot

Shaft

L(eft) Side

Casting Stamp

f2073x2x

Figure 2-105. Remove Chrome Plugs and Check

Pivot Shaft Locknut Torque (Left Side View)

2-86 2004 Touring: Chassis

Page 9

HOME

b. Using a bungee cord, tie muffler to lower saddlebag

support rail. Install muffler on rear header pipe.

Place TORCA clamp into position between rear

header pipe and muffler.

c. Tighten the two bolts (with lockwashers) to fasten

the muffler to the lower saddlebag support rail.

CAUTION

Verify that the exhaust pipes do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

d. Verify that exhaust pipes are in alignment and do

not contact the vehicle frame or mounted components.

e. Tighten the TORCA clamp to 45-60 ft-lbs (61-81

Nm).

f. Open worm drive clamps and install heat shield on

rear header pipe. Position clamp so that screw is on

the outboard side in the most accessible position.

CAUTION

Verify that the heat shields do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

25. Install saddlebags. See Section 2.25 SADDLEBAG,

INSTALLATION.

NOTE

Remove the decorative chrome plugs in the rear swingarm

brackets and check the torque on the pivot shaft locknuts

every 10,000 miles (16,000 km). See Figure 2-105. Holding

right side nut on the pivot shaft, tighten left side locknut to 4045 ft-lbs (54-61 Nm). Then hold left side nut and tighten right

side locknut using the same torque value.

g. Remove bungee cord from muffler.

24. Install socket screw with lockwasher to fasten passenger

footboard to rear swingarm bracket. Tighten screw to 1518 ft-lbs (20-24 Nm). Repeat step on opposite side of

vehicle.

2004 Touring: Chassis 2-87

Page 10

HOME

THROTTLE CABLES (NON-CRUISE) 2.21

ADJUSTMENT

NOTE

For throttle and idle cable adjustment or replacement on

cruise equipped models, see Section 8.30 CRUISE CON-

TROL (FLHRC, FLTR, FLHTCU).

The throttle control must operate freely without binding. With

the tension adjuster screw backed off, the throttle control grip

must freely return to the closed (idle) position. The throttle

control also must open and close freely when the front wheel

is turned to both the right and left fork stops. If the throttle

grip does not return to the idle position freely, check the

adjuster screw tension. If the adjuster screw is backed off,

inspect the cables for short bends.

11WARNING1WARNING

Do not overtighten the tension adjuster screw. An overtightened screw will prevent the engine from automatically returning to idle in an emergency situation. This

can lead to loss of vehicle control, which could result in

death or serious injury.

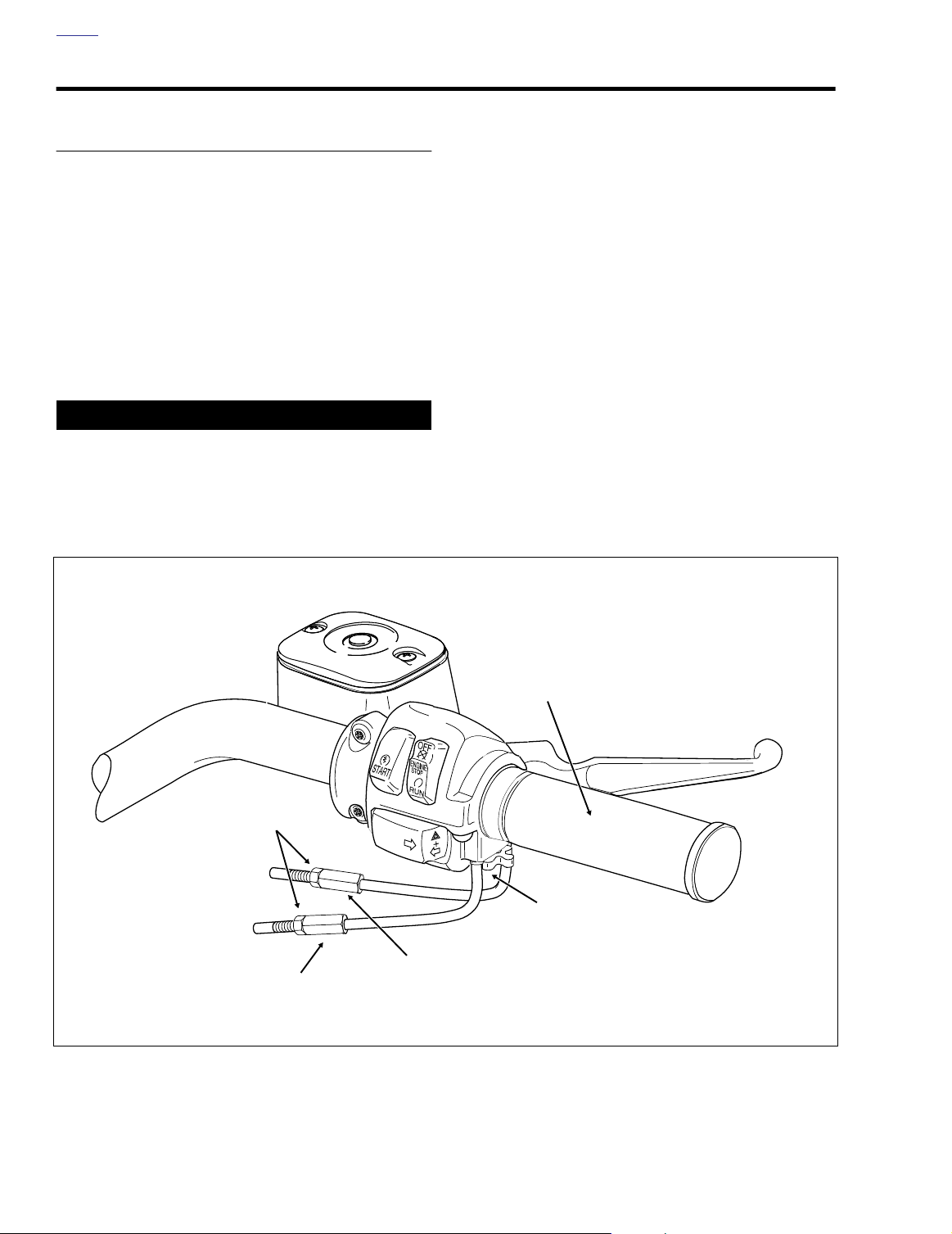

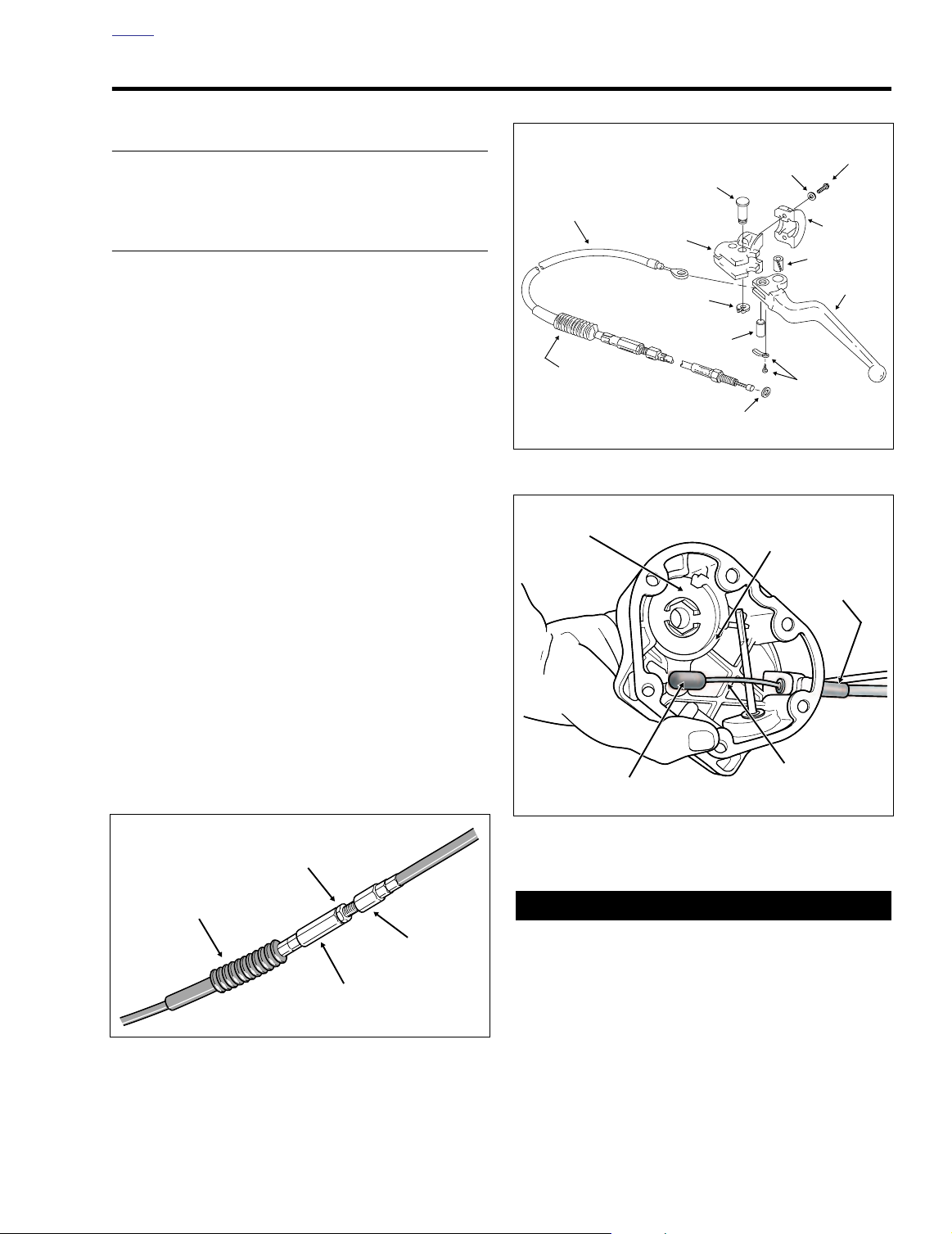

1. Slide rubber boot off throttle cable adjuster. See Figure

2-106. Holding cable adjuster with a 3/8 inch wrench,

loosen jam nut turning in a clockwise direction. Back jam

nut away from cable adjuster until it stops. Turn adjuster

clockwise until it contacts jam nut. Repeat procedure on

idle cable adjuster.

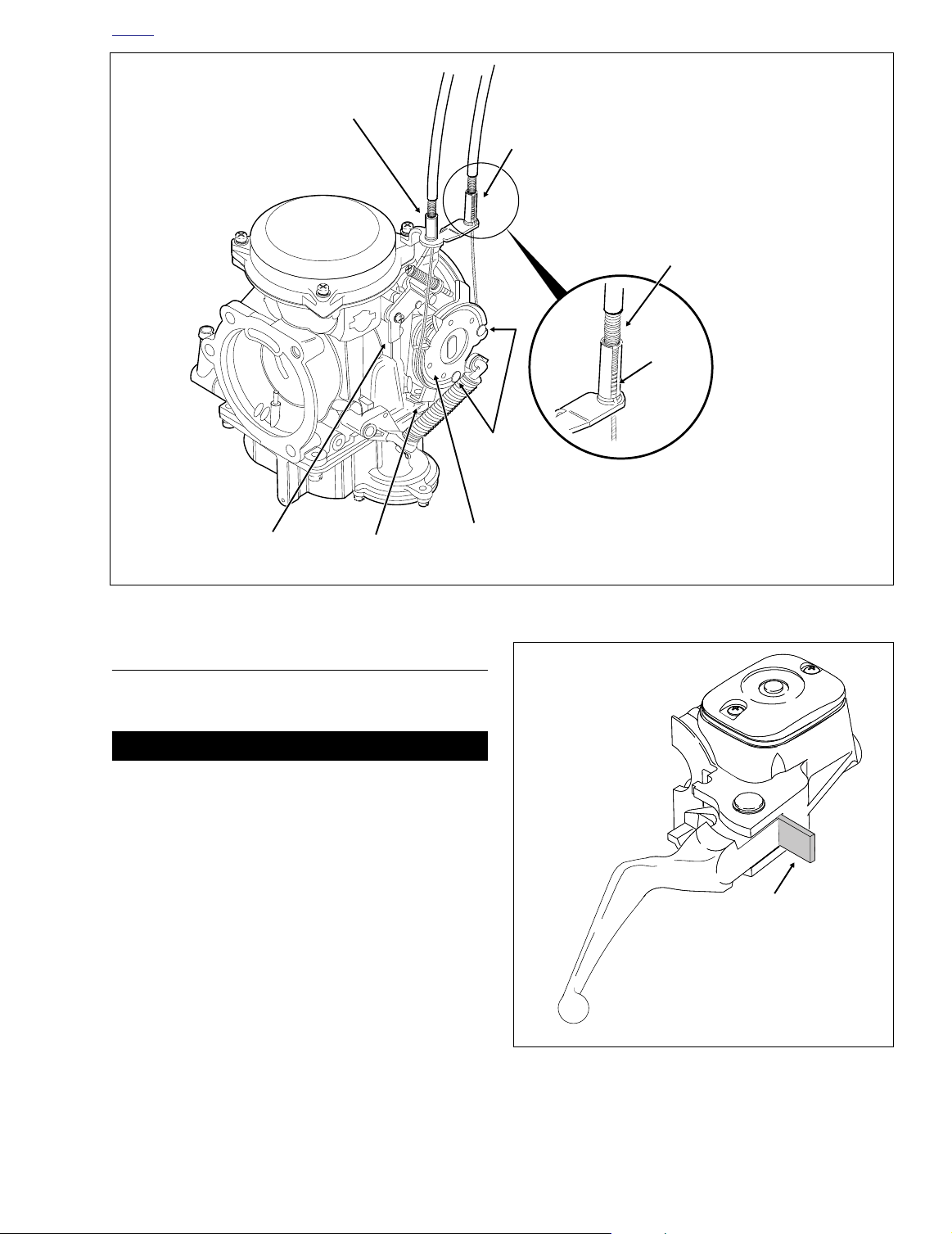

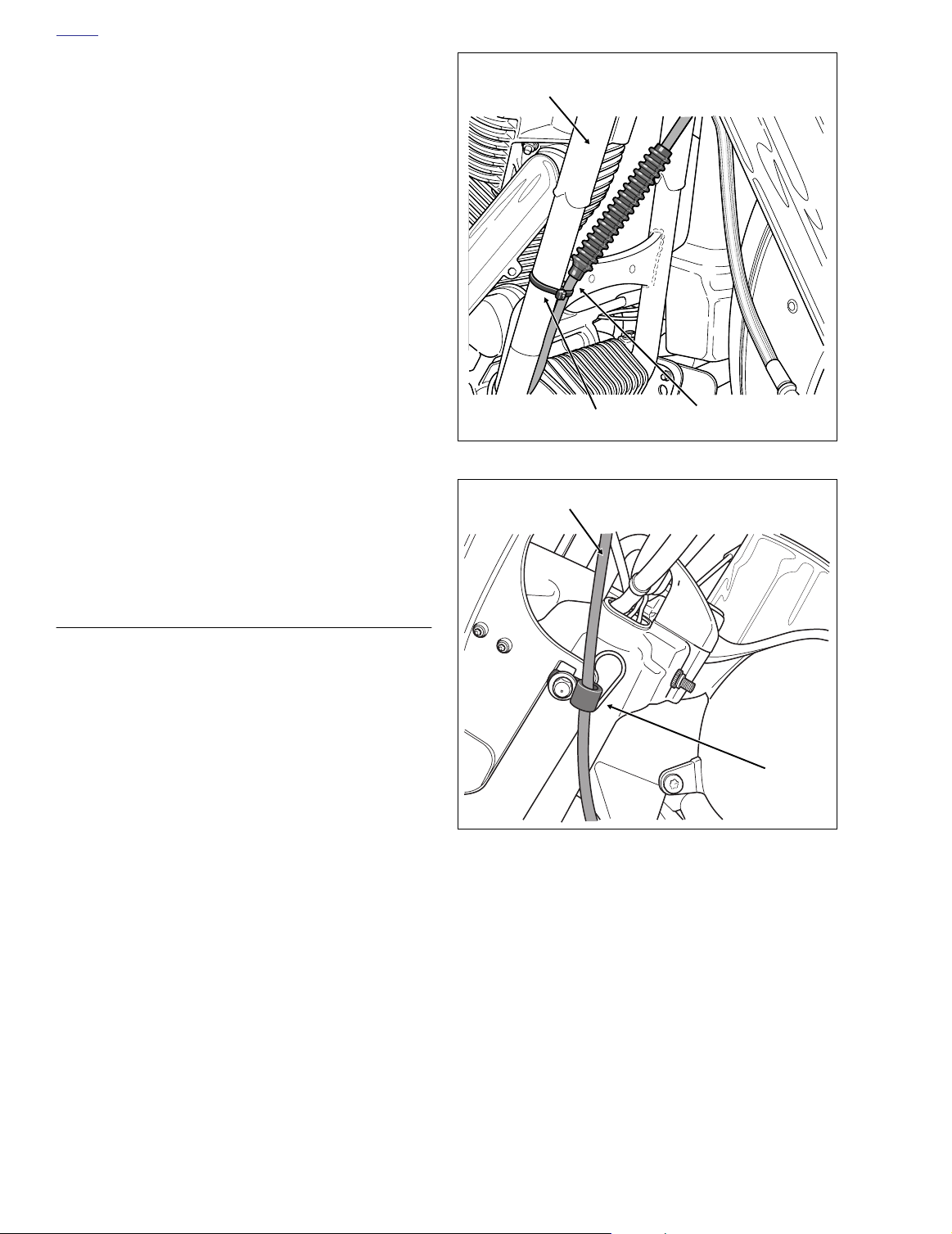

2. Point the front wheel straight ahead. Turn the throttle

control grip so that the throttle is wide open (fully counterclockwise) and then hold in position. Now turn the

throttle cable adjuster counter-clockwise until the throttle

cam stop just touches the stop plate. See Figure 2-107.

Release the throttle control grip and then tighten the jam

nut against the throttle cable adjuster. Cover cable

adjuster mechanism with rubber boot.

3. Turn the front wheel full right. Turn the idle cable adjuster

counterclockwise until the cable housing just touches

the spring in the cable guide (as seen through slot).

Work the throttle grip to verify that the throttle cable

returns to the idle position when released. If the cable

does not return to idle, turn the adjuster clockwise

slightly until the correct response is achieved. Tighten

jam nut against the idle cable adjuster and cover cable

adjuster mechanism with rubber boot.

Throttle Control

Grip

Jam Nut

Tension

Adjuster

Screw

Throttle Cable

Idle Cable

Adjuster

Figure 2-106. Throttle Cable Assembly - Throttle Side (FLHR)

Adjuster

f1376b2x

2-88 2004 Touring: Chassis

Page 11

HOME

f1225x2x

5/32 Inch

(4.0 mm)

Cardboard

Insert

Throttle

Cable Guide

Idle

Cable Guide

Cable

Housing

Spring

Cable

Barrel End

Stop Plate

Throttle

Cam Stop

Figure 2-107. Throttle Cable Assembly - Carburetor Side

Throttle

Wheel

REMOVAL

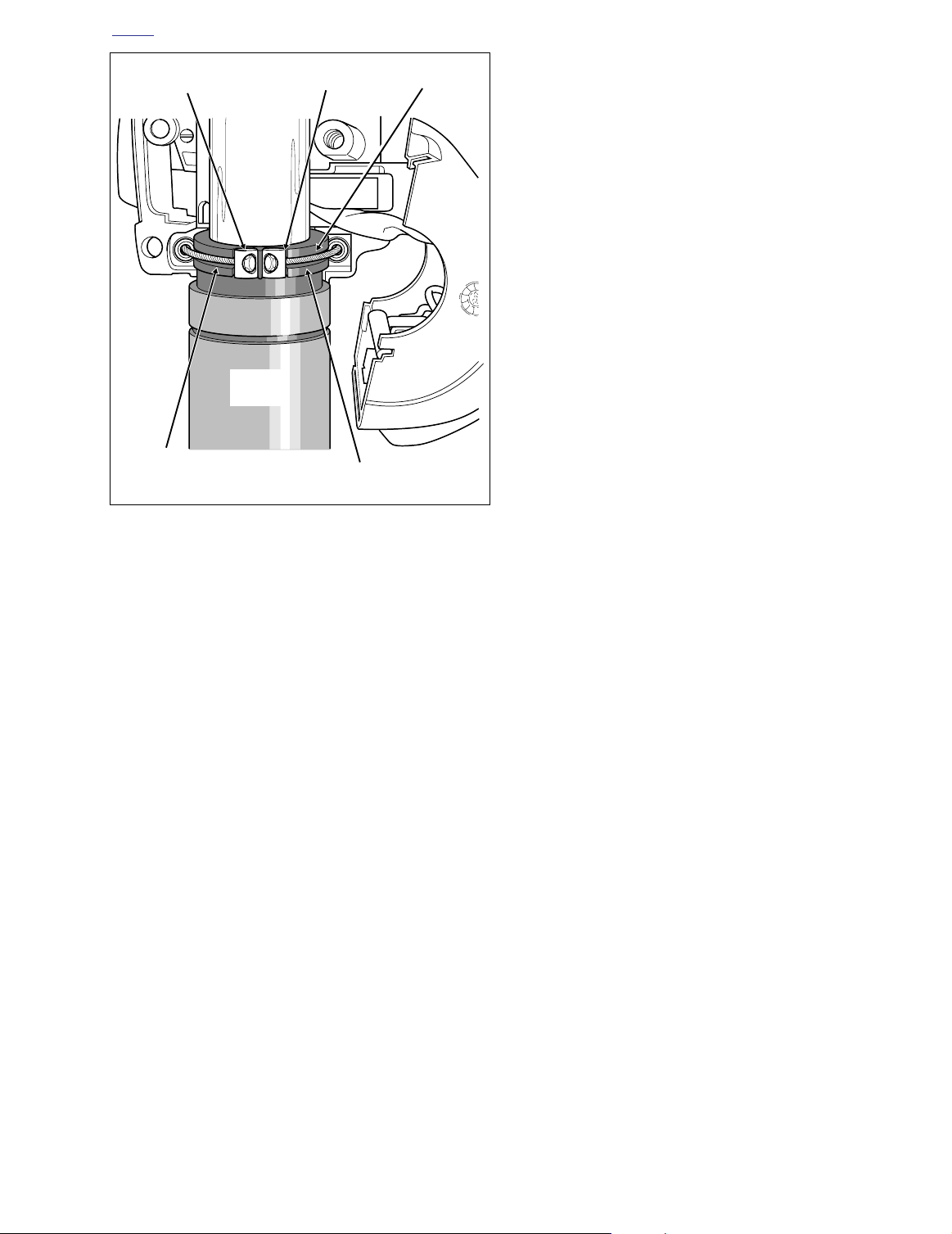

THROTTLE SIDE

CAUTION

Do not remove the switch housing assembly without first

placing the 5/32 inch (4.0 mm) cardboard insert between

the brake lever and lever bracket. Removal without the

insert may result in damage to the rubber boot and

plunger of the Front Stoplight Switch.

NOTE

Use the eyelet of an ordinary cable strap if the cardboard

insert is not available.

1. Place the cardboard insert between the brake lever and

lever bracket. See Figure 2-108.

2. Using a T25 TORX drive head, remove the upper and

lower switch housing screws.

3. Using a T27 TORX drive head, loosen the upper screw

securing the handlebar clamp to the master cylinder

housing. Remove the lower clamp screw with flat

washer.

f1381a2x

Figure 2-108. Install Cardboard Insert

2004 Touring: Chassis 2-89

Page 12

HOME

4. Remove the brass ferrules from the notches on the

inboard side of the throttle control grip. Remove the ferrules from the cable end fittings.

5. Remove the friction shoe from the end of the tension

adjuster screw.

NOTE

The friction shoe is a loose fit and may fall out or become dislodged if the lower switch housing is turned upside down or

shaken.

6. Remove the throttle control grip from the end of the handlebar.

7. Pull the crimped inserts at the end of the throttle and idle

cable housings from the lower switch housing.

For best results, use a rocking motion while pulling.

Place a drop of light oil on the retaining rings, if necessary. Remove the cables from the switch housing.

CARBURETOR/INDUCTION MODULE SIDE

1. Remove the air cleaner and backplate. See Section 4.5

AIR CLEANER, REMOVAL.

2. Raise fuel tank to access cables in area of frame backbone. For carbureted models, see Section 4.7 FUEL

TANK (CARBURETED), PA RTIAL REMOVAL, FLHT/C,

or FLHR/S. For fuel injected models, see Section 9.4

FUEL TANK (FUEL INJECTED), PARTIAL REMOVAL,

FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

3.

Carbureted:

idle cable barrel from upper inboard hole in throttle

wheel. Pull throttle cable barrel from remaining hole.

Release idle and throttle cables from guides in throttle

cable bracket. See Figure 2-107.

Induction Module:

pull idle cable barrel from upper hole in throttle wheel.

Pull throttle cable barrel from lower hole. Using slots,

release idle and throttle cables from guides in throttle

cable bracket. See Figure 2-111.

4. Free cables from J-clamp riveted to right side of frame

backbone.

5. If present, remove screw (with flat washer) to release Jclamp from wellnut in right side of steering head.

Remove J-clamp from cables.

Using a needle nose pliers, carefully pull

Using a needle nose pliers, carefully

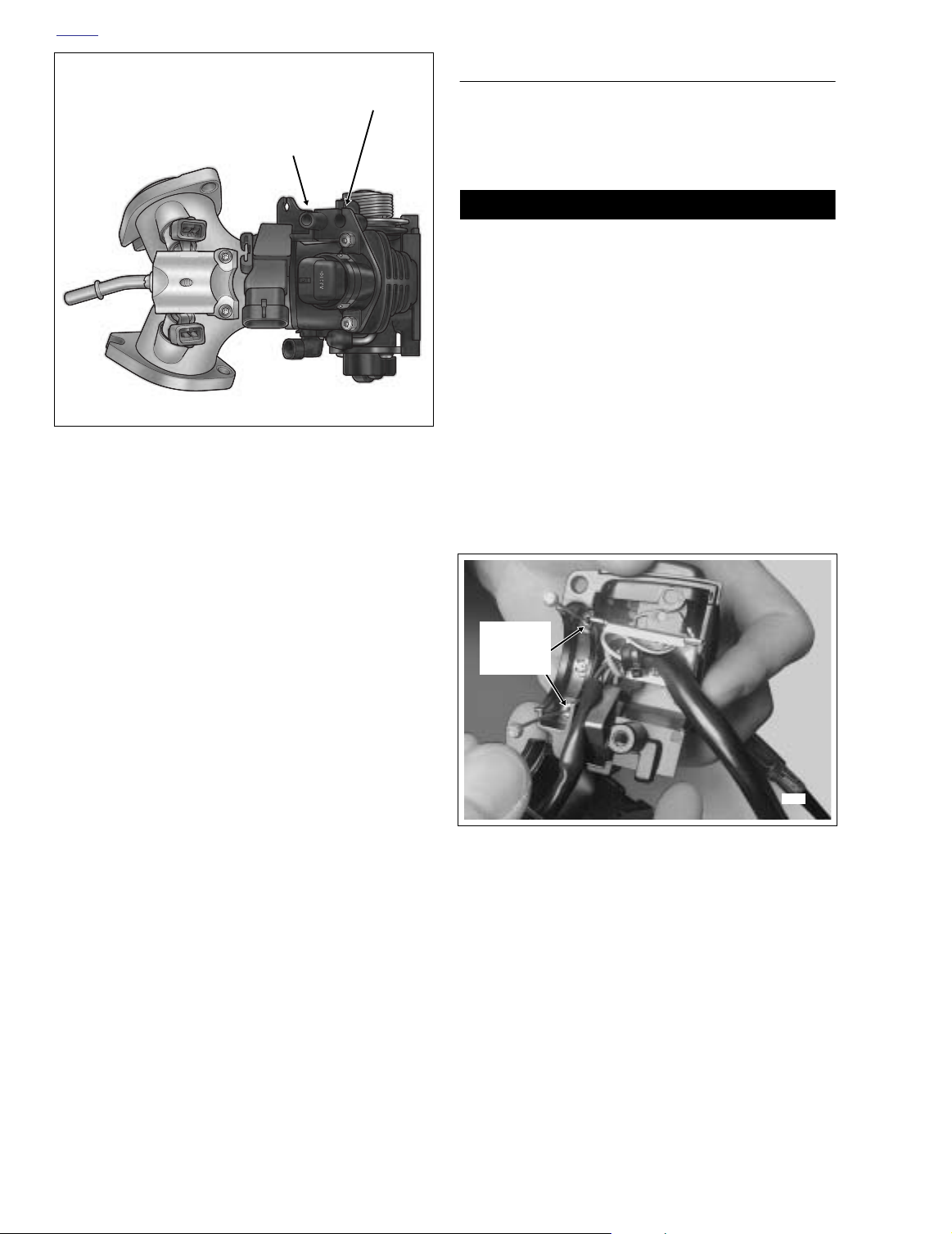

7961

Lower

Switch

Housing

Throttle

Cable Insert

(Silver)

Idle

Cable Insert

(Gold)

Figure 2-109. Install Throttle/Idle Cables

in Lower Switch Housing

2. Inspect the cables for damage or wear. Replace the

cables if frayed, kinked or bent.

3. Obtain tube of Lubit-8 Tufoil Chain and Cable Lube (HD

Part No. 94968-85TV- 1/4 fl. oz.). Insert pin of tube

between throttle cable and cable housing. Squirt a few

drops of lubricant into cable housing moving pin around

cable OD. Repeat the procedure squirting a few drops

between the idle cable and cable housing.

INSTALLATION

THROTTLE SIDE

1. Apply a light coating of graphite to the handlebar and

inside surface of the switch housings.

2. Push the throttle and idle cables into the lower switch

housing until they snap in place. See Figure 2-109. Proceed as follows:

Note the different diameter inserts crimped into the end

of the throttle and idle cable housings.

Push the larger diameter insert (silver) on the throttle

cable housing into the larger hole in front of the tension

adjuster screw.

Push the smaller diameter insert (gold) on the idle cable

housing into the smaller hole at the rear of the tension

adjuster screw.

CLEANING AND INSPECTION

1. Clean all parts in a non-flammable cleaning solvent and

blow dry with compressed air.

2-90 2004 Touring: Chassis

NOTE

To aid assembly, place a drop of light oil on the retaining

rings of the crimped inserts. Always replace the retaining

rings if damaged or distorted.

Page 13

HOME

Ferrule

Throttle

Grip

8. Position the brake lever/master cylinder assembly

GrooveNotch

inboard of the switch housing assembly engaging the

tab on the lower switch housing in the groove at the top

of the brake lever bracket.

9. Align the holes in the handlebar clamp with those in the

master cylinder housing and start the lower screw (with

flat washer). Position for rider comfort. Beginning with

the top screw, tighten the screws to 60-80

Nm) torque using a T27 TORX drive head.

10. Using a T25 TORX drive head, tighten the lower and

upper switch housing screws to 35-45

NOTE

Always tighten the lower switch housing screw first so that

any gap between the upper and lower housings is at the front

of the switch assembly.

11. Remove the cardboard insert between the brake lever

and lever bracket.

in-lbs

in-lbs

(6.8-9.0

(4-5 Nm).

Idle

Cable

Figure 2-110. Install Throttle/Idle Control Cables on

Throttle Control Grip

3. With the concave side facing upward, install the friction

shoe so that the pin hole is over the point of the adjuster

screw.

NOTE

The friction shoe is a loose fit and may fall out or become dislodged if the lower switch housing is turned upside down or

shaken.

4. Slide the throttle control grip over the end of the right

handlebar until it bottoms against the closed end. Rotate

the grip so that the ferrule notches are at the top. To prevent binding, pull the grip back about 1/8 inch (3.2 mm).

5. Position the lower switch housing beneath the throttle

control grip. Install the brass ferrules onto the cables so

that the end fittings seat in the ferrule recess. Seat the

ferrules in their respective notches on the throttle control

grip. Verify that the cables are captured in the grooves

molded into the grip. See Figure 2-110.

6. Position the upper switch housing over the handlebar

and lower switch housing. Verify that the wire harness

conduit runs in the depression at the bottom of the handlebar.

7. Start the upper and lower switch housing screws, but do

not tighten.

Throttle

Cable

f1474x2x

12. Turn the Ignition/Light Key Switch to IGNITION and

apply brake lever to test operation of brake lamp.

CARBURETOR/INDUCTION MODULE SIDE

1. Route the throttle and idle cables as follows:

FLHT/C:

line to the inner fairing. Pass the cables through the

inner fairing grommet and then loop them toward the

rear along the right side of the steering head.

FLHR/C:

handlebar to the handlebar clamp shroud. Pass the

cables through the opening in the shroud and then loop

them toward the rear along the right side of the steering

head. Capture cables in J-clamp and then start screw

(with flat washer) to fasten J-clamp to wellnut in right

side of steering head. Tighten screw to 9-18

2.0 Nm).

2. Route the throttle and idle cables rearward along the

right side of the frame backbone. After passing through

J-clamp riveted to frame backbone, route cables downward to carburetor/induction module.

3.

Carbureted:

shorter cable guide in throttle cable bracket. Drawing

throttle cable downward, fit barrel end into lower outboard hole in throttle wheel. Install sleeve and spring on

idle cable housing into longer cable guide inserting barrel end into upper inboard hole in throttle wheel. See

Figure 2-107.

Route the cables downward following the brake

Route the cables downward following the right

in-lbs

(1.0-

Install sleeve on throttle cable housing into

2004 Touring: Chassis 2-91

Page 14

HOME

f2162x9x

Throttle Cable

Guide

Figure 2-111. Throttle Cable Assembly -

Induction Module Side

Induction Module:

ing into shorter cable guide at top of throttle cable

bracket. Drawing throttle cable downward, fit barrel end

into lower hole in throttle wheel. Install sleeve and spring

on idle cable housing into longer cable guide at bottom

of throttle cable bracket inserting barrel end into upper

hole in throttle wheel. See Figure 2-111.

4. Tighten cables as necessary to keep barrel ends from

dislodging. Verify that cables are seated in channel of

throttle wheel. Verify operation by turning throttle grip

and observing cable action. Adjust throttle cables as

described under ADJUSTMENT.

Install sleeve on throttle cable hous-

Idle Cable

Guide

LUBRICATION

1. See REMOVAL, THROTTLE SIDE, in this section, steps

1-5.

2. Move upper switch housing to the side in order to access

lower housing.

1CAUTION

Lubit-8 Tufoil Chain and Cable Lube contains detergents.

Keep out of reach of children. Contact with eyes may

result in minor or moderate injury.

3. Obtain tube of Lubit-8 Tufoil Chain and Cable Lube (HD

Part No. 94968-85TV- 1/4 fl. oz.). Insert pin of tube

between throttle cable and cable housing inside lower

switch housing. Squeeze tube to squirt a quantity of

lubricant into cable housing moving pin around cable

OD. See Figure 2-112.

4. Repeat the procedure squirting a quantity of lubricant

between the idle cable and cable housing.

5. See INSTALLATION, THROTTLE SIDE, in this section,

steps 3-12.

6. Turn the Ignition/Light Key Switch to IGNITION and

apply brake lever to test operation of brake lamp.

Insert

Lubricant

Here

5. Install fuel tank. For carbureted models, see Section 4.7

FUEL TANK (CARBURETED), INSTALLATION (AFTER

PA RTIAL REMOVAL), FLHT/C, or FLHR/S. For fuel

injected models, see Section 9.4 FUEL TANK (FUEL

INJECTED), INSTALLATION (AFTER PARTIAL

REMOVAL), FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

6. Install the air cleaner assembly. See Section 4.5 AIR

CLEANER, INSTALLATION.

2-92 2004 Touring: Chassis

7958

Figure 2-112. Right Handlebar Lower Switch Housing

Page 15

HOME

11WARNING1WARNING

f1140axx

Flat

Washer

Retaining

Ring

Anchor

Pin

Handlebar

Clamp

Clutch

Lever

Bracket

Anti-Rattle

Spring

and Screw

Screw

Bushing

O-Ring

Rubber Boot

Pivot Pin

Hand Lever

Clutch Cable

f1896x7x

Inner

Ramp

Retaining

Ring

Cable

Fitting

Coupling

Clutch Cable

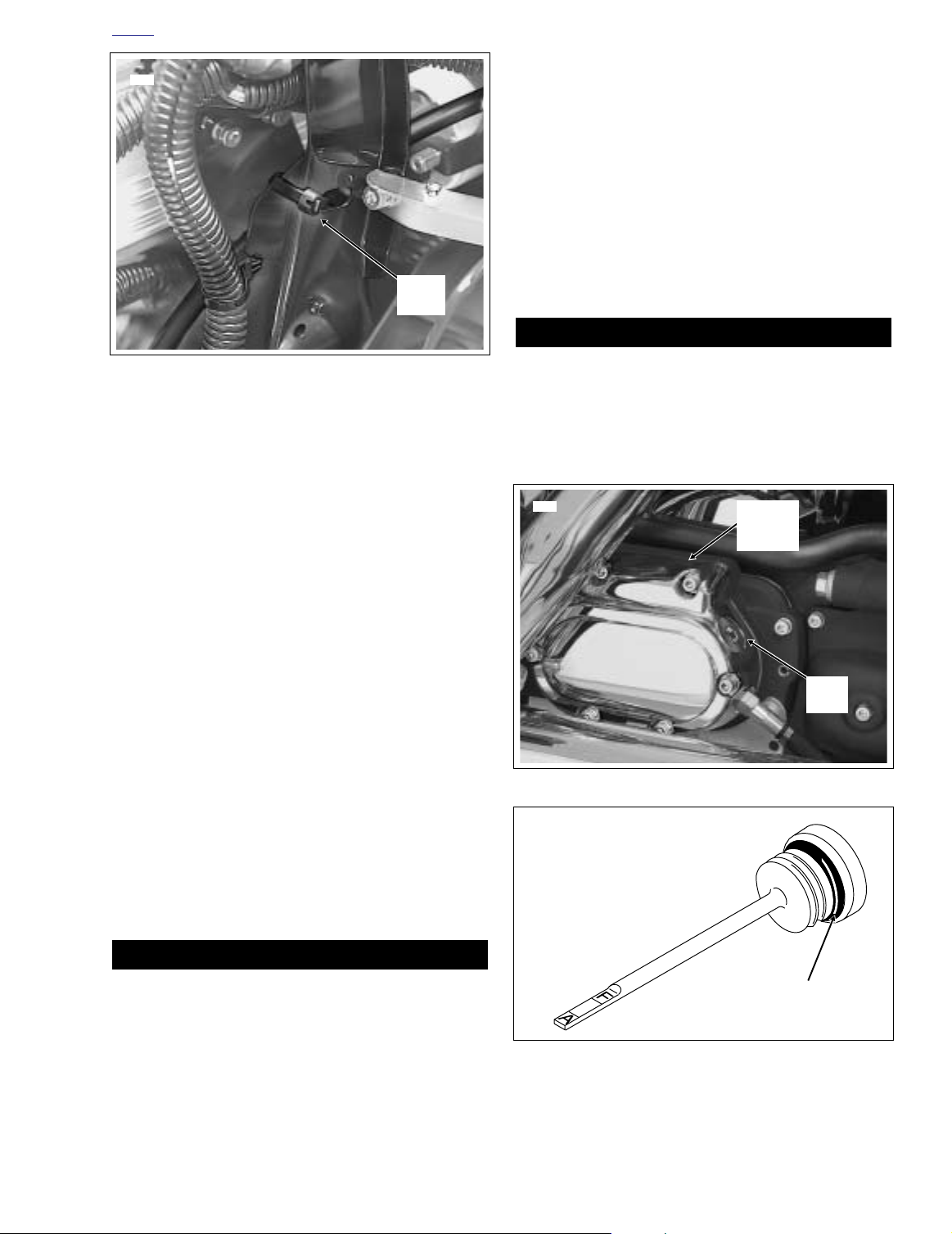

CLUTCH CABLE 2.22

ADJUSTMENT

See Section 6.3 CLUTCH, ADJUSTMENT.

REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. To access the clutch release cover assembly, remove

right side exhaust system. See Section 3.7 REMOVING

ENGINE FROM CHASSIS, steps 3-9.

3. Remove the magnetic drain plug at the bottom right side

of the oil pan and drain the transmission lubricant into a

suitable container. Remove the filler plug/dipstick.

4. Slide rubber boot off clutch cable adjuster. Holding cable

adjuster with 1/2 inch wrench, loosen jam nut using 9/16

inch wrench. Back jam nut away from cable adjuster.

Move adjuster toward jam nut to introduce free play at

hand lever. See Figure 2-113.

5. Remove retaining ring from pivot pin groove at bottom of

clutch lever bracket. Remove pivot pin.

6. Remove clutch hand lever from clutch lever bracket. If

necessary, use a T27 TORX drive head and remove two

screws (with flat washers) to release handelbar clamp

from clutch lever bracket.

7. Remove anchor pin and clutch cable eyelet from clutch

hand lever. See Figure 2-114.

8. Remove six socket head screws and washers to free

clutch release cover from transmission case. Remove

and discard gasket. See Figure 2-115.

f1440x6x

Jam

Nut

Rubber

Boot

Figure 2-114. Clutch Hand Lever Assembly

Figure 2-115. Clutch Release Cover Assembly

Figure 2-113. Clutch Cable Adjuster Mechanism

Cable

Adjuster

Cable

End

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

9. Remove retaining ring securing ball and ramp mechanism to clutch release cover.

2004 Touring: Chassis 2-93

Page 16

HOME

10. Lift inner ramp out of clutch release cover and turn the

assembly over so that ball sockets are facing outboard.

Remove hook of ramp from button on coupling. Remove

coupling from clutch cable end.

11. Remove balls from outer ramp sockets. Remove outer

ramp from clutch release cover.

12. Unscrew the cable fitting from the clutch release cover.

Remove clutch cable and fitting.

13. Cut cable strap in hole of crossbrace to free clutch cable

from right frame downtube. See Figure 2-116. Continue

as follows:

FLHR/C/S:

Remove T40 TORX screw with flat washer

(FLHRS) or acorn nut (FLHR/C) to release clutch cable

from P-clamp fastened to upper fork bracket. See Figure

2-117.

FLTR:

Release clutch cable from cable clip anchored in

hole on left side of instrument nacelle.

FLHT/C/U:

Remove the outer fairing. See Section 2.29

UPPER FAIRING/WINDSHIELD (FLHT/C/U), OUTER

FAIRING/WINDSHIELD, REMOVAL. Cut cable strap to

release clutch cable from left fairing bracket. See Figure

2-118.

14. Remove clutch cable from motorcycle.

NOTE

If ball and ramp or throwout bearing and clutch pushrod need

service, see Section 7.5 CLUTCH RELEASE COVER.

Right Frame

Downtube

Cable Strap

Clutch Cable

f1472b2x

Figure 2-116. Clutch Cable Routing (Right Side View)

Clutch Cable

f2257x2x

INSTALLATION

1. See Figure 2-114. Insert clutch cable eyelet into groove

of clutch hand lever aligning eyelet with hole without

bushing. Insert anchor pin through lever and eyelet.

2. Insert lever into groove of clutch lever bracket fitting

sleeve at end of cable housing into bore on inboard side

of bracket.

3. Align hole in hand lever with hole in bracket and install

pivot pin. Install retaining ring in pivot pin groove.

4. If removed, use a T27 TORX drive head and install two

screws (with flat washers) to secure handelbar clamp to

clutch lever bracket. See Figure 2-114. Starting with the

top screw, tighten screws to 60-80

5. Start clutch cable routing as follows:

FLHR/C/S:

Capture clutch cable in P-clamp and fasten

to upper fork bracket using T40 TORX screw with flat

washer (FLHRS) or acorn nut (FLHR/C). Orient P-clamp

as shown in Figure 2-117. On left side of steering head,

run cable downward between engine guard and front of

left frame downtube.

FLTR:

Capture clutch cable in cable clip and anchor clip

in hole on left side of instrument nacelle. Run cable forward and then rearward beneath instrument nacelle following left side of steering head. Run cable downward

between engine guard and front of left frame downtube.

in-lbs

(6.8-9.0 Nm).

Clamp

Figure 2-117. Clutch Cable Routing - FLHR/C

(Left Side View)

FLHT/C/U:

Feed clutch cable through grommet on left

side of inner fairing. Route cable on inboard side of left

fairing bracket between upper and lower wings of radio

(or storage box) support bracket. Cable strap clutch

cable to left fairing bracket using oblong hole at this location. See Figure 2-118. Run cable downward along left

side of steering head, and then between engine guard

and front of left frame downtube. Install the outer fairing.

See Section 2.29 UPPER FAIRING/WINDSHIELD

(FLHT/C/U), OUTER FAIRING/WINDSHIELD, INSTALLATION.

2-94 2004 Touring: Chassis

Page 17

HOME

CAUTION

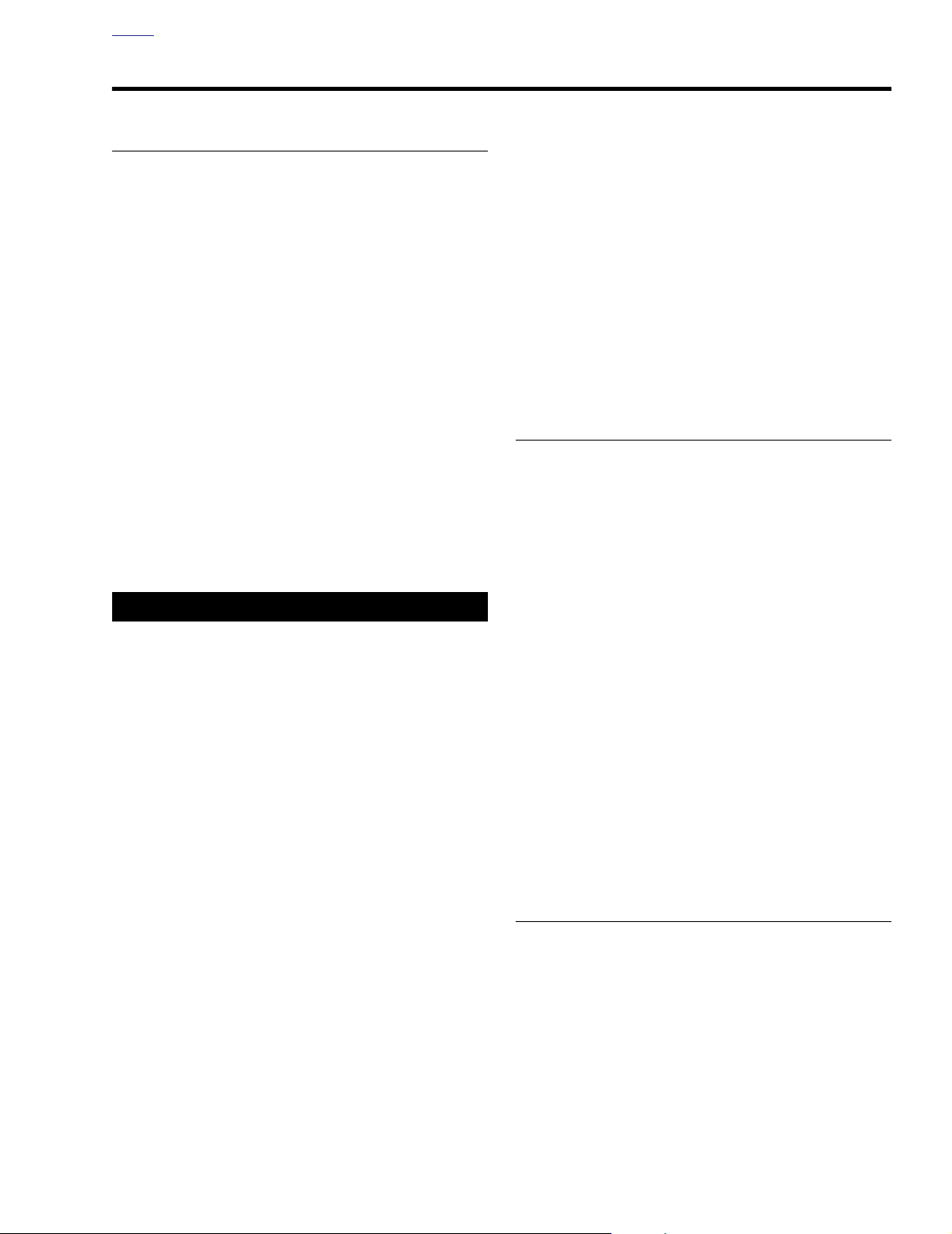

8496

Clutch

Release

Cover

Filler

Plug

OMF50

O-Ring

9421

Cable

Strap

12. Install the retaining ring so that the opening is to the right

of the outer ramp tang slot in the clutch release cover.

13. Verify that the two locating dowels are in place on the

right side of the transmission case. Hang a

new

gasket

on the dowels.

14. Holding the clutch release cover in position, install six

socket head screws. Tighten screws to 120-144

in-lbs

(13.6-16.3 Nm).

15. Tighten clutch cable fitting to 36-60

in-lbs

(4-7 Nm).

16.Check the O-ring on the transmission drain plug for

tears, cuts or general deterioration. Replace as necessary.

Figure 2-118. Secure Clutch Cable to Fairing Bracket

6. Complete clutch cable routing as follows:

All Models:

Continue downward progression while

crossing to right side of motorcycle and then run cable

between outboard side of voltage regulator and inboard

side of right frame downtube. Threading cable strap

through hole in crossbrace, secure clutch cable to downtube as shown in Figure 2-116. Following inboard side of

frame downtube, route cable between bottom of cam

cover and top of lower frame tube to area of clutch

release cover.

7. Inspect cable fitting O-ring and replace if damaged or

deformed. Install clutch cable fitting into clutch release

cover. See Figure 2-115. Do not tighten cable fitting at

this time.

8. Place outer ramp in clutch release cover recess with

tang in cover slot.

9. Apply a multi-purpose grease to the balls and outer

ramp sockets. Place a ball in each of three outer ramp

sockets.

10. Hold coupling with button facing outboard. Place cable

end in recess of coupling. With ball sockets facing outboard, place hook of inner ramp on button of couplng.

Holding inner ramp and coupling together, turn the

assembly over.

11. Place inner ramp (ball socket side down) over balls in

outer ramp sockets.

Do not overtighten filler plugs or drain plugs. Overtightening plugs can cause leaks.

17.Install transmission the drain plug. Tighten the plug to

14-21 ft-lbs (19-28 Nm).

Figure 2-119. Transmission Case (Right Side)

11WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

Figure 2-120. Transmission Lubricant Filler Plug/Dipstick

2004 Touring: Chassis 2-95

Page 18

HOME

18. Remove the filler plug from the clutch release cover, if

installed. See Figure 2-119. Check the O-ring for tears,

cuts or general deterioration. Replace as necessary.

See Figure 2-120.

19. Fill the transmission with 20-24 oz. (590-710 ml) of

transmission lubricant or until the lubricant level on the

dipstick of the filler plug is at the F(ULL) mark with the

motorcycle in a level, upright position and the filler plug

resting on the threads. Use only Harley-Davidson

TRANSMISSION LUBRICANT, Part No. 99892-84

(quart) or Part No. 99891-84 (gallon).

20. Install the transmission filler plug/dipstick in the clutch

release cover. Tighten the plug to 25-75

in-lbs

(2.8-8.5

Nm).

21. Adjust the clutch cable. See Section 6.3 CLUTCH,

ADJUSTMENT.

22. Install right side exhaust system. See Section 3.8

INSTALLING ENGINE IN CHASSIS, steps 46-52.

23. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

2-96 2004 Touring: Chassis

Page 19

HOME

HANDLEBARS 2.23

HANDLEBAR ADJUSTMENT

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2.

FLHR/C/S:

Section 2.31 WINDSHIELD/HEADLAMP NACELLE

(FLHR/C/S), NACELLE REMOVAL (FLHR/C), steps 1-

11, or NACELLE REMOVAL (FLHRS), steps 1-7.

FLTR:

UPPER FAIRING/WINDSHIELD (FLTR), BEZEL,

REMOVAL.

FLHT/C/U:

UPPER FAIRING/WINDSHIELD (FLHT/C/U), FAIRING

CAP, REMOVAL.

3. Loosen rear screws on the upper handlebar clamps. On

FLTR models, loosen the front screws instead.

4. Position handlebars for rider posture and comfort.

5. To be sure that the handlebars are centered, verify that

the knurled area on the outboard side of the left side

handlebar clamp is equal to that on the right side.

6. Snug upper handlebar clamp screws.

Remove the handlebar clamp shroud. See

Remove the instrument bezel. See Section 2.30

Remove the fairing cap. See Section 2.29

11WARNING1WARNING

Improperly aligned handlebars can contact the fuel tank

when turned to the left or right fork stops. Contact with

the fuel tank while riding can cause loss of vehicle control resulting in death or serious injury.

7. Slowly turn handlebars to the full right fork stop and then

the full left fork stop to be sure there is no contact with

the fuel tank. If contact occurs and handlebars are properly aligned, raise handlebars as necessary until the

proper clearance is obtained.

8. Tighten the upper handlebar clamp screws to 12-16 ftlbs (16.3-21.7 Nm).

9.

FLHR/C/S:

Section 2.31 WINDSHIELD/HEADLAMP NACELLE

(FLHR/C/S), NACELLE INSTALLATION (FLHR/C),

steps 3-15, or NACELLE INSTALLATION (FLHRS),

steps 5-13.

FLTR:

UPPER FAIRING/WINDSHIELD (FLTR), BEZEL,

INSTALLATION.

FLHT/C/U:

UPPER FAIRING/WINDSHIELD (FLHT/C/U), FAIRING

CAP, INSTALLATION.

Install the handlebar clamp shroud. See

Install the instrument bezel. See Section 2.30

Install the fairing cap. See Section 2.29

10. If necessary, adjust left and right handlebar switch controls as follows:

a. Using a T27 TORX drive head, loosen the two

screws securing the handlebar clamp to the clutch

lever bracket (left) or master cylinder housing

(right).

b. Position switch controls for rider posture and com-

fort.

c. Beginning with the top screw, tighten the screws to

60-80

in-lbs

(6.8-9.0 Nm).

11. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

HANDLEBAR REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Place blanket or protective cover over front of fuel tank to

protect against scratches or other damage.

3.

FLHR/C/S:

Section 2.31 WINDSHIELD/HEADLAMP NACELLE

(FLHR/C/S), NACELLE REMOVAL (FLHR/C), steps 1-

11, or NACELLE REMOVAL (FLHRS), steps 1-7.

FLTR:

UPPER FAIRING/WINDSHIELD (FLTR), INSTRUMENT

NACELLE, REMOVAL.

FLHT/C/U:

UPPER FAIRING/WINDSHIELD (FLHT/C/U), FAIRING

CAP, REMOVAL. Remove the radio (or storage box).

See Section 8.31 PREMIUM SOUND SYSTEM (FLHTC/

U, FLTR), RADIO (FLHTC/U), REMOVAL, steps 3-7.

4. Remove the left and right handlebar switch controls. See

Section 8.21 HANDLEBAR SWITCHES, REMOVAL.

5. Remove upper handlebar clamp screws (with flat washers). Remove upper handlebar clamps and handlebar.

Remove the handlebar clamp shroud. See

Remove the instrument nacelle. See Section 2.30

Remove the fairing cap. See Section 2.29

HANDLEBAR INSTALLATION

1. Place

2. To be sure that the handlebars are centered, verify that

3. Snug upper handlebar clamp screws.

new

handlebars on lower handlebar clamps.

Install upper handlebar clamps and loosely install clamp

screws (with flat washers).

the knurled area on the outboard side of the left side

handlebar clamp is equal to that on the right side.

2004 Touring: Chassis 2-97

Page 20

HOME

f2056x2x

1

2

3

*9

**10

4

5

6

7

5

**11

8

1. Screw

2. Flat washer

3. Upper clamp

4. Lower clamp

5. Cup washer

6. Spacer

7. Rubber bushing

8. Bolt

Figure 2-121. Handlebar Clamp Assemblies

*LEFT CLAMP ONLY

9. Ground cable

**RIGHT CLAMP ONLY

10. Flat washer

11. Large flat washer

11WARNING1WARNING

Improperly aligned handlebars can contact the fuel tank

when turned to the left or right fork stops. Contact with

the fuel tank while riding can cause loss of vehicle control resulting in death or serious injury.

5. Tighten upper handlebar clamp screws as follows:

a. Tighten front screws until upper and lower handle-

bar clamps make contact.

b. Tighten rear screws to 12-16 ft-lbs (16.3-21.7 Nm).

c. Tighten front screws to 12-16 ft-lbs (16.3-21.7 Nm).

NOTE

A slight gap will exist between the upper and lower clamps at

the rear of the handlebars after tightening.

6. Install the left hand grip. See LEFT HAND GRIP,

INSTALLATION, in this section.

7. Install the left and right handlebar switch controls. See

Section 8.21 HANDLEBAR SWITCHES, INSTALLA-

TION.

8.

FLHR/C/S:

Section 2.31 WINDSHIELD/HEADLAMP NACELLE

(FLHR/C/S), NACELLE INSTALLATION (FLHR/C),

steps 3-15, or NACELLE INSTALLATION (FLHRS),

steps 5-13.

FLTR:

UPPER FAIRING/WINDSHIELD (FLTR), INSTRUMENT

NACELLE, INSTALLATION.

FLHT/C/U:

UPPER FAIRING/WINDSHIELD (FLHT/C/U), FAIRING

CAP, INSTALLATION. Install the radio (or storage box).

See Section 8.31 PREMIUM SOUND SYSTEM (FLHTC/

U, FLTR), RADIO (FLHTC/U), INSTALLATION, steps 1-

6.

9. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

10. Turn the ignition/light key switch to IGNITION and test

each handlebar switch for proper operation.

11. Apply front brake hand lever to test operation of brake

lamp.

12. Adjust idle and throttle control cables as follows:

Non-Cruise:

(NON-CRUISE), ADJUSTMENT.

Cruise Equipped:

TROL (FLHRC, FLTR, FLHTCU), CABLE ADJUSTMENT.

Install the handlebar clamp shroud. See

Install the instrument nacelle. See Section 2.30

Install the fairing cap. See Section 2.29

See Section 2.21 THROTTLE CABLES

See Section 8.30 CRUISE CON-

LEFT HAND GRIP

4. Slowly turn handlebars to the full right fork stop and then

the full left fork stop to be sure there is no contact with

the fuel tank. If contact occurs and handlebars are properly aligned, raise handlebars as necessary until the

proper clearance is obtained.

2-98 2004 Touring: Chassis

REMOVAL

1. Remove the left handlebar switch controls. See Section

8.21 HANDLEBAR SWITCHES, REMOVAL.

Page 21

HOME

f2077x2x

f2076x2x

2. Use a sharp blade to carefully cut rubber and then peel

off handlebar.

3. Thoroughly clean handlebar to remove all residual adhesive.

INSTALLATION

11WARNING1WARNING

HARLEY-DAVIDSON ADHESIVE contains METHYL

ETHYL KETONE, a chemical known to the State of California to cause cancer or other reproductive harm.

11WARNING1WARNING

Use HARLEY-DAVIDSON ADHESIVE in well ventilated

areas only. Vapors are flammable and can be harmful to

breath. Avoid contact with eyes, mucous membranes, or

prolonged contact with skin. Keep out of reach of children.

1. Obtain a

ADHESIVE (Part No. 99839-95). Apply a coat of the

adhesive to the inside surface of the grip one inch (25.4

mm) from the open end. Apply a coat to the end of the

handlebar.

2. Immediately push grip completely onto end of handlebar

using a twisting motion. Do not hesitate when installing

grip or adhesive may dry before installation is complete.

If the left hand grip is patterned, align it with the pattern on

the right grip with the throttle in the fully closed position.

3. Let 6-8 hours elapse (at 70

cure.

4. Install the left handlebar switch controls. See Section

8.21 HANDLEBAR SWITCHES, INSTALLATION.

new

left hand grip and HARLEY-DAVIDSON

NOTE

°

F.) to allow adhesive to fully

Right Side

3. Holding lower handlebar clamp to prevent rotation, turn

bolt at bottom of upper fork bracket until free.

4. Remove lower handlebar clamp, flat washer and cup

washer at top of upper fork bracket. See Figure 2-122.

5. Pull bushing from fork bracket bore and discard. See

Figure 2-123.

6. Moving to bottom of upper fork bracket, remove bolt,

large flat washer and cup washer. See Figure 2-124.

7. Pull bushing and spacer from fork bracket bore. Remove

spacer from bushing. See Figure 2-125. Discard bushing.

Left Side

8. Holding lower handlebar clamp to prevent rotation, turn

bolt at bottom of upper fork bracket until free.

9. Remove lower handlebar clamp, ground wire ring terminal and cup washer at top of upper fork bracket.

RUBBER MOUNTS

NOTE

For complete disassembly of the handlebar clamp assemblies and/or to replace the rubber mounts, proceed as follows.

REMOVAL

General

1. Turn fork to left fork stop and loosen right side bolt at

bottom of upper fork bracket. Turn fork to right fork stop

and loosen left side bolt at bottom of upper fork bracket.

2. Remove handlebars. See HANDLEBAR REMOVAL in

this section.

Figure 2-122. Remove Flat Washer and

Upper Cup Washer (Right Side)

Figure 2-123. Remove Upper Bushing (Right Side)

2004 Touring: Chassis 2-99

Page 22

HOME

f2058x2x

Figure 2-124. Remove Bolt, Large Washer

and Lower Cup Washer (Right Side)

f2057x2x

Figure 2-125. Remove Spacer From Lower Bushing

5. Install cup washer over threaded end of bolt fitting concave side over collar of bushing. Install flat washer. See

Figure 2-122.

6. Apply two or three drops of Loctite Medium Strength

Threadlocker 243 (blue) to threads of bolt and start lower

handlebar clamp. Holding clamp to prevent rotation, turn

bolt at bottom of upper fork bracket until snug.

Left Side

7. Insert spacer into new bushing until flush with outboard

side of collar. See Figure 2-125.

8. Insert bushing into bore at bottom of upper fork bracket

fitting collar of bushing over lip of boss.

9. Install cup washer on bolt. Insert bolt into bushing fitting

concave side of cup washer over collar of bushing.

10. Moving to top of upper fork bracket, insert bushing into

bore fitting collar of bushing over lip of boss. See Figure

2-123.

11. Install cup washer over threaded end of bolt fitting concave side over collar of bushing. Install ground wire ring

terminal.

12. Apply two or three drops of Loctite Medium Strength

Threadlocker 243 (blue) to threads of bolt and start lower

handlebar clamp. Holding clamp to prevent rotation, turn

bolt at bottom of upper fork bracket until snug.

10. Pull bushing from fork bracket bore and discard. See

Figure 2-123.

11. Moving to bottom of upper fork bracket, remove bolt and

cup washer.

12. Pull bushing and spacer from fork bracket bore. Remove

spacer from bushing. See Figure 2-125. Discard bushing.

INSTALLATION

Right Side

1. Insert spacer into new bushing until flush with outboard

side of collar. See Figure 2-125.

2. Insert bushing into bore at bottom of upper fork bracket

fitting collar of bushing over lip of boss.

3. Install large flat washer and cup washer on bolt. See Fig-

ure 2-124. Insert bolt into bushing fitting concave side of

cup washer over collar of bushing.

4. Moving to top of upper fork bracket, insert bushing into

bore fitting collar of bushing over lip of boss. See Figure

2-123.

General

13. Install handlebars and upper handlebar clamps. See

HANDLEBAR INSTALLATION in this section, steps 1-5.

14. Turn fork to left fork stop and tighten right side bolt at

bottom of upper fork bracket to 30-40 ft-lbs (40.7-54.2

Nm). Turn fork to right fork stop and tighten left side bolt

to the same torque value.

15. Complete assembly of motorcycle. See HANDLEBAR

INSTALLATION in this section, steps 7-12.

2-100 2004 Touring: Chassis

Page 23

HOME

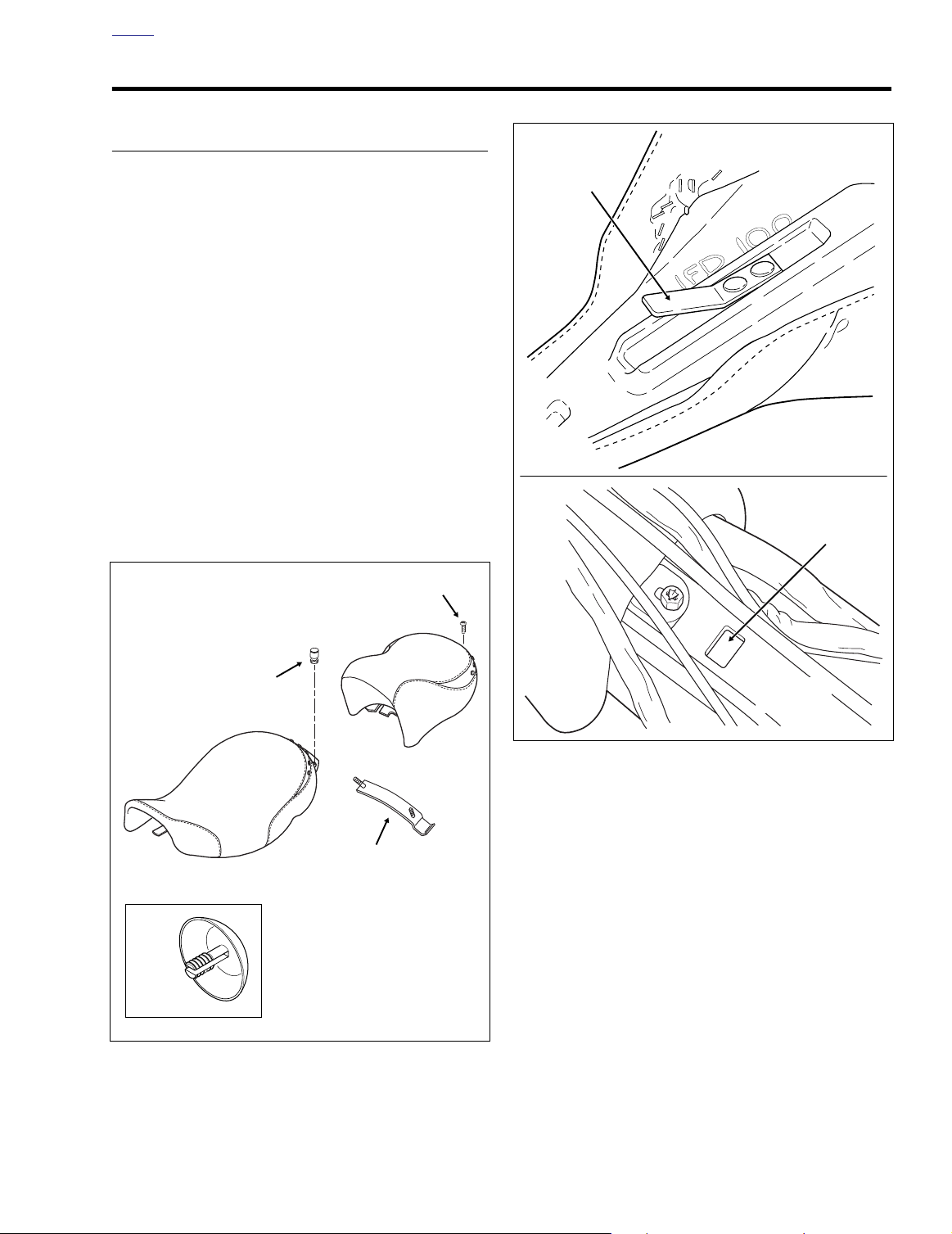

f1416x2x

f2171x2x

Tongue

Slot

Seat

Bottom

Frame

Backbone

SEAT 2.24

FLHR

REMOVAL

1. Remove Phillips screw to detach passenger seat mounting bracket from top of rear fender. See Figure 2-126.

Slightly lift up back of passenger seat and carefully slide

toward rear of vehicle to detach from front seat mounting

bracket nuts.

NOTE

The FLHR seat can be converted to a solo seat by removal of

the passenger section. When the solo seat configuration is

desired, turn the passenger seat upside down and locate the

chrome plug pressed into the seat frame hole. See inset of

Figure 2-126. Remove the plug and press into the seat reten-

tion nut hole using finger pressure only.

2. Using the 5/8 hex, remove two nuts from studs to free

front seat mounting bracket from rear fender.

3. Push front seat rearward to free tongue from slot in

frame backbone. See Figure 2-127.

f1091d2x

Nut

Front Seat

Passenger Seat

f1456x2x

Figure 2-126. Seat Assembly - FLHR

Retention Nut Plug

Passenger

Seat

Stud Plate

Screw

Figure 2-127. Seat Mounting

INSTALLATION

1. Position front seat on frame with mounting bracket at

rear.

2. Firmly push front of seat downward and rearward until

tongue engages slot in frame backbone. See Figure 2-

127. Push seat forward until studs are centered in slots

of mounting bracket.

3. Using the 5/8 hex, install two nuts on studs to secure

front seat mounting bracket to rear fender.

4. Install passenger seat fitting slots on passenger seat

front mounting bracket between rounded caps and hex

of front seat mounting bracket nuts.

2004 Touring: Chassis 2-101

Page 24

HOME

5. Push passenger seat forward until rear fender seat

retention nut is centered in hole of rear mounting

bracket. Install Phillips screw.

NOTE

If seat retention nut is damaged or lost, see SEAT RETEN-

TION NUT REPLACEMENT for instructions.

11WARNING1WARNING

Pull up on seat to verify that it is properly secured, front

and rear. A loose seat may shift during vehicle operation

and startle the rider, possibly causing loss of vehicle

control resulting in death or serious injury.

FLHRC

REMOVAL

f1550x2x

Slot

Figure 2-128. Route Passenger Seat Strap Through

Slots in Seat - FLHRC

1. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Remove bolt (with flat washer) to remove passenger

seat strap and saddlebag front mounting bracket from

chrome frame tube cover.

3. Using slots in seat, carefully pull passenger seat strap

from seat. See Figure 2-128.

4. Remove Phillips screw to detach seat mounting bracket

from top of rear fender.

5. Push seat rearward to free tongue at front of seat from

slot in frame backbone. See Figure 2-127.

6. Remove seat from frame.

INSTALLATION

1. Place seat on frame backbone.

2. Firmly push front of seat downward and rearward until

tongue engages slot in frame backbone. See Figure 2-

127.

3. Push seat forward until rear fender seat retention nut is

centered in hole of mounting bracket. Install Phillips

screw.

NOTE

If seat retention nut is damaged or lost, see SEAT RETEN-

TION NUT REPLACEMENT for instructions.

11WARNING1WARNING

Pull up on seat to verify that it is properly secured, front

and rear. A loose seat may shift during vehicle operation

and startle the rider, possibly causing loss of vehicle

control resulting in death or serious injury.

4. Using slots in seat, route free end of passenger seat

strap to right side of vehicle. See Figure 2-128.

5. Insert bolt with flat washer through passenger seat strap

and slotted hole of saddlebag front mounting bracket.

Insert bolt into forward hole in chrome frame tube cover.

Snug saddlebag front mounting bracket bolt, b

tighten.

6. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

7. Using an open end/box wrench, tighten saddlebag front

mounting bracket bolt.

ut do not

FLHRS, FLTR

REMOVAL

CAUTION

Removing seat without first removing passenger seat

strap will result in damage to rear fender paint.

1. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Remove bolt (with flat washer) to remove passenger

seat strap and saddlebag front mounting bracket from

chrome frame tube cover. Draw free end of passenger

seat strap to left side of vehicle.

3. Remove Phillips screw to detach seat mounting bracket

from top of rear fender.

4. Push seat rearward to free tongue at front of seat from

slot in frame backbone. See Figure 2-127.

5. Remove seat from frame.

2-102 2004 Touring: Chassis

Page 25

HOME

11WARNING1WARNING

11WARNING1WARNING

INSTALLATION

1. Place seat on frame backbone.

2. Firmly push front of seat downward and rearward until

tongue engages slot in frame backbone. See Figure 2-

127.

3. Push seat forward until rear fender seat retention nut is

centered in hole of mounting bracket. Install Phillips

screw.

NOTE

If seat retention nut is damaged or lost, see SEAT RETEN-

TION NUT REPLACEMENT for instructions.

11WARNING1WARNING

Pull up on seat to verify that it is properly secured, front

and rear. A loose seat may shift during vehicle operation

and startle the rider, possibly causing loss of vehicle

control resulting in death or serious injury.

4. Draw free end of passenger seat strap to right side of

vehicle. Insert bolt with flat washer through passenger

seat strap and slotted hole of saddlebag front mounting

bracket. Insert bolt into forward hole in chrome frame

tube cover. Snug saddlebag front mounting bracket bolt,

b

ut do not tighten.

5. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

6. Using an open end/box wrench, tighten saddlebag front

mounting bracket bolt.

Pull up on seat to verify that it is properly secured, front

and rear. A loose seat may shift during vehicle operation

and startle the rider, possibly causing loss of vehicle

control resulting in death or serious injury.

FLHTC/U

REMOVAL

1. Open Tour-Pak to move passenger seat backrest out of

the way.

NOTE

The Tour-Pak must be positioned to the rear to access the

seat mounting bracket screw. If the Tour-Pak is in the forward

position, remove Tour-Pak and install in rearward position.

See Section 2.26 TOUR-PAK for more information.

2. Remove Phillips screw to detach seat mounting bracket

from top of rear fender.

3. To protect finish of Tour-Pak, cover rear seat mounting

bracket with palm of hand.

4. While pushing seat forward, raise rear of seat until

bracket clears top of Tour-Pak. Push seat rearward

slightly to free tongue at front of seat from slot in frame

backbone. See Figure 2-127.

5. Remove seat from frame.

FLHT

REMOVAL

1. Remove Phillips screw to detach seat mounting bracket

from top of rear fender.

2. Push seat rearward to free tongue at front of seat from

slot in frame backbone. See Figure 2-127.

3. Remove seat from frame.

INSTALLATION

1. Place seat on frame backbone.

2. Firmly push front of seat downward and rearward until

tongue engages slot in frame backbone. See Figure 2-

127.

3. Push seat forward until rear fender seat retention nut is

centered in hole of mounting bracket. Install Phillips

screw.

NOTE

If seat retention nut is damaged or lost, see SEAT RETEN-

TION NUT REPLACEMENT for instructions.

INSTALLATION

1. Place seat on frame backbone.

2. To protect finish of Tour-Pak, cover rear seat mounting

bracket with palm of hand.

3. While raising rear of seat approximately 3 inches (76.2

mm), use other hand to firmly push front of seat downward and rearward until tongue engages slot in frame

backbone. See Figure 2-127.

4. Push seat forward until rear fender seat retention nut is

centered in hole of mounting bracket. Install Phillips

screw.

NOTE

If seat retention nut is damaged or lost, see SEAT RETEN-

TION NUT REPLACEMENT for instructions.

Pull up on seat to verify that it is properly secured, front

and rear. A loose seat may shift during vehicle operation

and startle the rider, possibly causing loss of vehicle

control resulting in death or serious injury.

2004 Touring: Chassis 2-103

Page 26

HOME

SEAT RETENTION NUT REPLACEMENT

1. Slide retention nut over tapered end of cable strap so

that larger OD of nut rests on cable strap eyelet. From

bottom of rear fender, feed cable strap up through fender

hole.

2. See Figure 2-129. With tab on retention nut seated in

notch of fender hole, pull up on cable strap to hold nut

snug against underside of rear fender. From the side

opposite the tab, slide on the retention washer to lock

the position of the retention nut. Remove cable strap.

Rear

Fender

Tab

f1897x2x

Retention

Washer

Retention

Nut

Figure 2-129. Seat Retention Nut and Washer

2-104 2004 Touring: Chassis

Page 27

HOME

f1553x2x

f1554x2x

Check Strap

Anchor Tabs

Anchor Brackets

Hinge

Latch

SADDLEBAG 2.25

OPENING

NOTE

Maximum recommended load for each saddlebag is 15 lbs.

FLHRC

1. Raise the decorative buckle and press tabs on both

sides of catch to release from receptacle. Repeat step to

release second catch. See upper frame of Figure 2-130.

2. Rotate hinge on outboard side of saddlebag to open lid.

FLHRS

1. Depress button on front inboard side of saddlebag, and

while holding button in, raise lid. See lower frame of Fig-

ure 2-130.

f1552x2x

f2228x3x

Catch

Receptacle

FLHRC

Button

FLHRS

Figure 2-130. Open Saddlebag (FLHRC/S)

Figure 2-131. Open Saddlebag (FLHR, FLTR, FLHT/C/U)

2. Rotate hinge on inboard side of saddlebag to open lid.

FLHR, FLTR, FLHT/C/U

1. Use key to unlock lid latch if locked.

2. Pull bottom of latch outward and then lift upward raising

outboard corners of saddlebag lid. See upper frame of

Figure 2-131.

3. With top of lid tilted toward motorcycle, carefully lift

inboard side of lid upward disengaging front and rear

anchor tabs from anchor brackets.

4. Pivot lid on latch hinge to open. A nylon check strap suspends the lid in the open position. See lower frame of

Figure 2-131.

2004 Touring: Chassis 2-105

Page 28

HOME

Rear

Mounting

Bracket

Quick-Release

Stud

Wire

Form

Flat

Bail

Wire

Figure 2-132. Saddlebag Quick-Release Fasteners

Washer

Spring

Plate

Mounting

CLOSING

FLHRC

Front

Bracket

f1075axx

f1451x2x

Front Mounting

Bracket Bolt

1. Rotate hinge on outboard side of saddlebag to close lid.

2. Insert catch into receptacle until tabs fully engage.

Repeat step to secure second catch. See upper frame of

Figure 2-130.

FLHRS

1. Rotate hinge on inboard side of saddlebag to close lid.

Lid latches automatically.

FLHR, FLTR, FLHT/C/U

1. Rotate lid to closed position engaging both anchor tabs

with bottom of anchor brackets. Press bottom of latch

inward until it snaps closed. See lower frame of Figure 2-

131.

2. Use key to lock lid latch.

REMOVAL

1. Open saddlebag. See OPENING in this section.

2. Grasp bail wire inside saddlebag and rotate each stud a

full 1/4 turn in a counter-clockwise direction. Remove

bail head studs with flat washers. See Figure 2-132.

f1450x2x

Figure 2-133. Saddlebag Mounting Bracket Bolts

(Right Side View)

NOTE

On some HDI vehicles, the bail wire has been removed from

the quick release stud. In these cases, turn the stud by

engaging the slotted end with a large screwdriver.

3. Remove saddlebag.

Rear Mounting

Bracket Bolt

INSTALLATION

1. Position saddlebag on vehicle.

2. Place flat washers on bail head studs.

2-106 2004 Touring: Chassis

Page 29

HOME

8863

8862

Rub Bar

8865

8864

Opening

3. With groove at end of stud held in a horizontal position,

insert stud through holes in saddlebag and front mounting bracket. When groove engages wire form of spring

plate on inboard side of bracket, turn stud clockwise a

full 1/4 turn until it snaps in place. Install rear bail head

stud in the same manner.

NOTE

On some HDI vehicles, the bail wire has been removed from

the quick release stud. In these cases, turn the stud by

engaging the slotted end with a large screwdriver.

NOTE

Molded rubber insert at bottom of saddlebag must fit snugly

on lower saddlebag support rail. If saddlebag is not fully

seated, use an open end/box wrench to loosen bolts securing mounting brackets to saddlebag support and frame. See

Figure 2-133. Alternately tighten bolts to 60-96 in-lbs (7-11

Nm) after seating saddlebag.

4. Close saddlebag. See CLOSING in this section.

LATCH SPRING REPLACEMENT (FLHR, FLTR, FLHT/C/U)

REMOVAL

1. Lay clean pad or blanket on work bench to protect

painted surfaces of saddlebag.

2. Remove saddlebag from motorcycle leaving lid open.

See REMOVAL in this section.

3. Lay saddlebag flat on pad with the inboard side facing

up and the lid closest to you.

4. Remove two T20 TORX screws to release check strap

from lid.

5. Remove two T15 TORX screws to release check strap

from saddlebag.

6. Remove two remaining T15 TORX screws to remove

latch from saddlebag. Move saddlebag back and out of

the way.

CAUTION

This procedure assumes that the latch is NOT removed

from the saddlebag lid. If there is doubt as to whether the

procedure can be accomplished without scratching

painted surfaces of the lid, then remove the five remaining T15 TORX screws to completely remove latch.

7. Position lid right side up with latch closest to you.

Figure 2-134. Lid Right Side Up With Latch on Near Side

8. Raise latch slightly and rotate hinge on inboard side so

that it is topside with the two plastic rub bars pointed

upward. See upper frame of Figure 2-134.

Figure 2-135. Lid Up Side Down With Latch on Far Side

2004 Touring: Chassis 2-107

Page 30

HOME

9. Rotate rub bar section of hinge to expose hinge pin and

spring. Using a flat tip screwdriver, carefully bend

crimped end link outward. See lower frame of Figure 2-

134.

NOTE

The end link on opposite side of hinge has a weld spot that

prevents pin removal.

10. Reposition lid so that it is upside down with the latch

farthest from you. Rotate hinge so that plastic rub bars

are positioned beneath latch and spring is topside.

11. Using a needle nose pliers, grasp pin through opening

just outboard of the spring and push toward the crimped

link side. Work pin in this manner until end can be seen

exiting crimped link. See upper frame of Figure 2-135. If

necessary, pry crimped link outward a little more to

achieve the desired result.

12. Grasping end with needle nose pliers, slowly pull pin

from links until spring can be slid off opposite end. Only

pull pin as far as necessary to remove spring. See lower

frame of Figure 2-135.

INSTALLATION

1. Slide new spring onto end of pin. Orient spring as shown

in lower frame of Figure 2-135.

2. Slide pin back through links. Using tapered end of

needle nose pliers, push end of pin into crimped link

3. Reposition lid so that it is right side up with latch closest

to you. As before, raise latch slightly and rotate hinge on

inboard side so that it is topside with plastic rub bars

pointing upward. Now rotate rub bar section of hinge to

expose hinge pin and spring. See Figure 2-134.

4. Holding lid down with elbow, if necessary, use a pliers to

bend crimped link back into its original position, so that