Page 1

HOME

SPECIFICATIONS 9.1

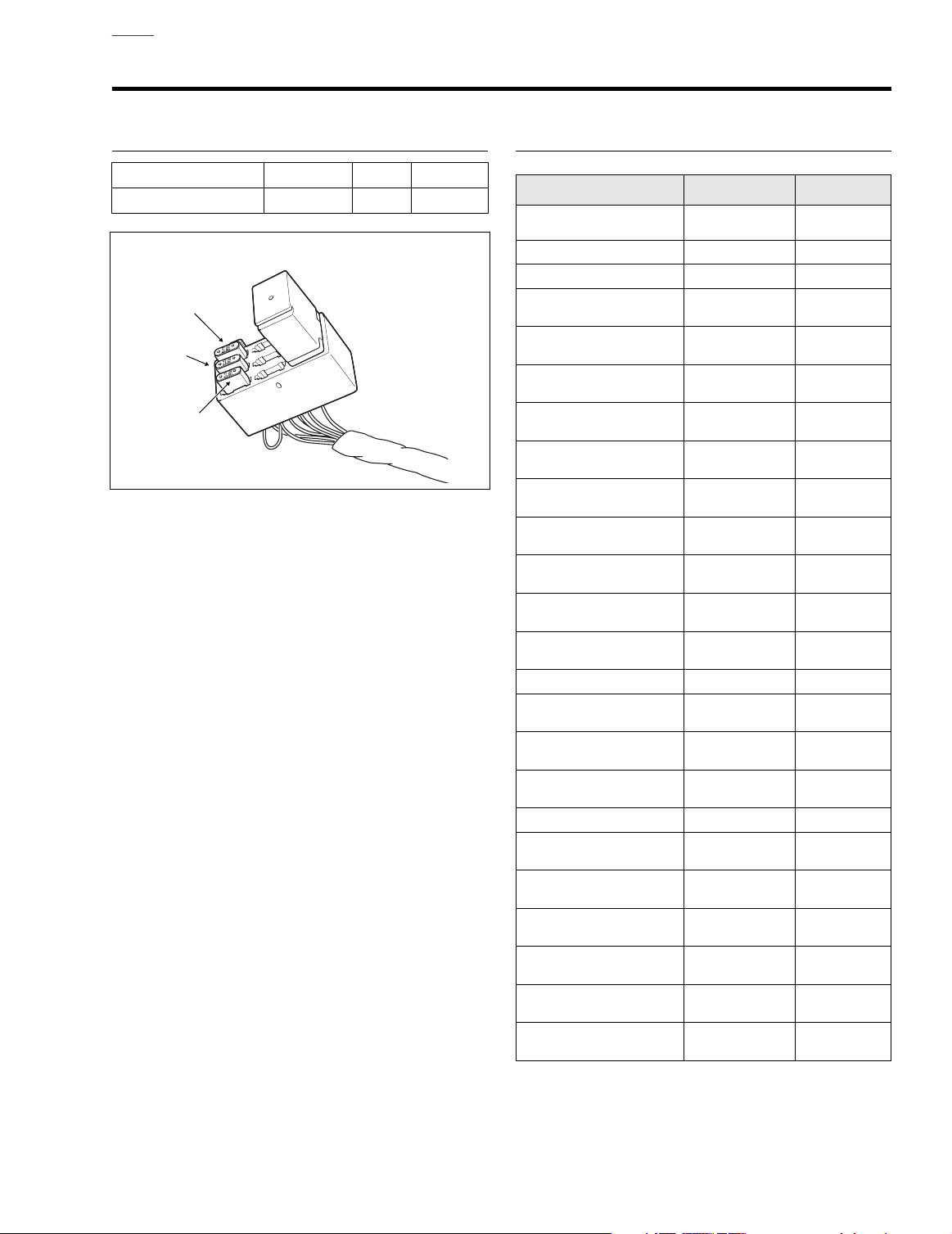

EFI FUSES

Fuel Pump 15 Blue Blade

ECM Power 15 Blue Blade

Spare

Fuel Pump

ECM Power

EFI System

Relay

Figure 9-1. EFI Fuses (Under Right Side Cover)

f2223x9x

TORQUE VALUES

Item

Battery hold-down clamp

TORX bolt

Battery cable bolt 60-96

ECM socket screws 50-60

Electrical bracket flange

nuts

Crank position

sensor screw

Engine sensor harness

clip screws to crankcase

Engine temperature

sensor

Fuel tank rear mounting

bolt

Fuel tank front mounting

bolts

Fuel tank canopy TORX

screws

Fuel level sender TORX

screw

Fuel supply line

quick-connect fitting

Fairing lower U-bolt

retainer locknuts

Fairing lower cap screws

Intake manifold to throttle

body TORX screws

Intake flange adapter

screws

Exhaust flange adapter

screws

Fuel rail TORX screws

Fuel supply tube clamp

TORX screw

Intake air temperature

sensor TORX screws

Throttle position sensor

TORX screws

Throttle cable bracket

side TORX screw

Idle air control flange

screws

Console mounting bolt

acorn nut

ft/in-lbs Nm

15-20 ft-lbs

in-lbs

in-lbs

36-48

in-lbs

90-120

in-lbs

25-35

in-lbs

120-180

in-lbs

15-20 ft-lbs 20-27 Nm

15-20 ft-lbs 20-27 Nm

18-24

in-lbs

25-35

in-lbs

22-26 ft-lbs 29.8-35.3 Nm

35-40

in-lbs

10-15

in-lbs

27-33

in-lbs

96-144

in-lbs

60-80

in-lbs

27-33

in-lbs

27-33

in-lbs

12

in-lbs

27-33

in-lbs

27-33

in-lbs

25

in-lbs

50-90

in-lbs

20-27 Nm

6.8-10.9 Nm

5.7-6.8 Nm

4.1-5.4 Nm

10.2-13.6 Nm

2.8-4.0 Nm

13.6-20.3 Nm

2.0-2.7 Nm

2.8-4.0 Nm

4.0-4.5 Nm

1.1-1.7 Nm

3.1-3.7 Nm

10.9-16.3 Nm

6.8-9.0 Nm

3.0-3.7 Nm

3.0-3.7 Nm

1.4 Nm

3.0-3.7 Nm

3.0-3.7 Nm

2.8 Nm

5.7-10.2 Nm

2004 Touring: Fuel Injection 9-1

Page 2

HOME

NOTES

9-2 2004 Touring: Fuel Injection

Page 3

HOME

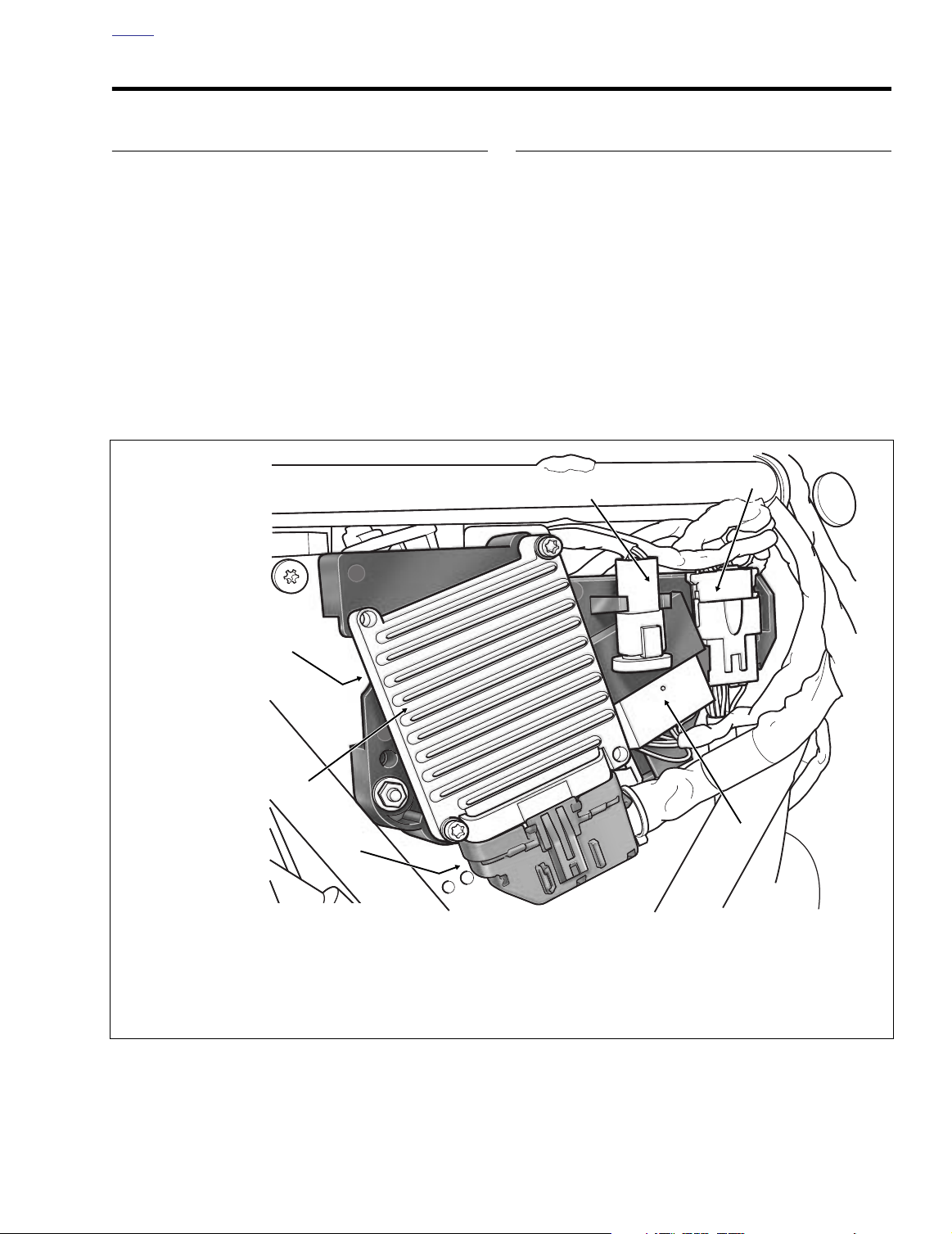

ELECTRICAL BRACKET ASSEMBLY 9.2

GENERAL

See Figure 9-2. The electrical bracket assembly is mounted

beneath the side cover on the right side of the vehicle. The

electrical bracket assembly carries the following components:

●

Data Link Connector

●

Main Harness to EFI Harness Connector

●

ECM Power Fuse/Fuel Pump Fuse

●

EFI System Relay

●

Electronic Control Module (ECM)

●

Vehicle Speed Sensor Connector

Optional Security Siren Connector

●

DATA LINK CONNECTOR

SETTING ENGINE IDLE SPEED

NOTE

Engine idle speed can only be set using DIGITAL TECHNICIAN (Part No. HD-44750). Do not tamper with the throttle

stop screw as it will not permanently change idle speed.

1. Turn the ignition/light key switch to OFF.

2. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

3. Gently pull side cover from frame downtubes (no tools

required).

1

2

6,7

5

4

1. Data Link Connector [91]

2. Main Harness Connector [8]

3. Fuse Block (ECM Power Fuse, Fuel Pump

Fuse, EFI System Relay)

4. Electronic Control Module Connector [78]

Figure 9-2. Electrical Bracket Assembly

3

f1917x9x

5. Electronic Control Module (ECM)

6. Vehicle Speed Sensor Connector [65]

(Under Bracket)

7. P&A Security Siren Connector [142] (Under Bracket)

2004 Touring: Fuel Injection 9-3

Page 4

HOME

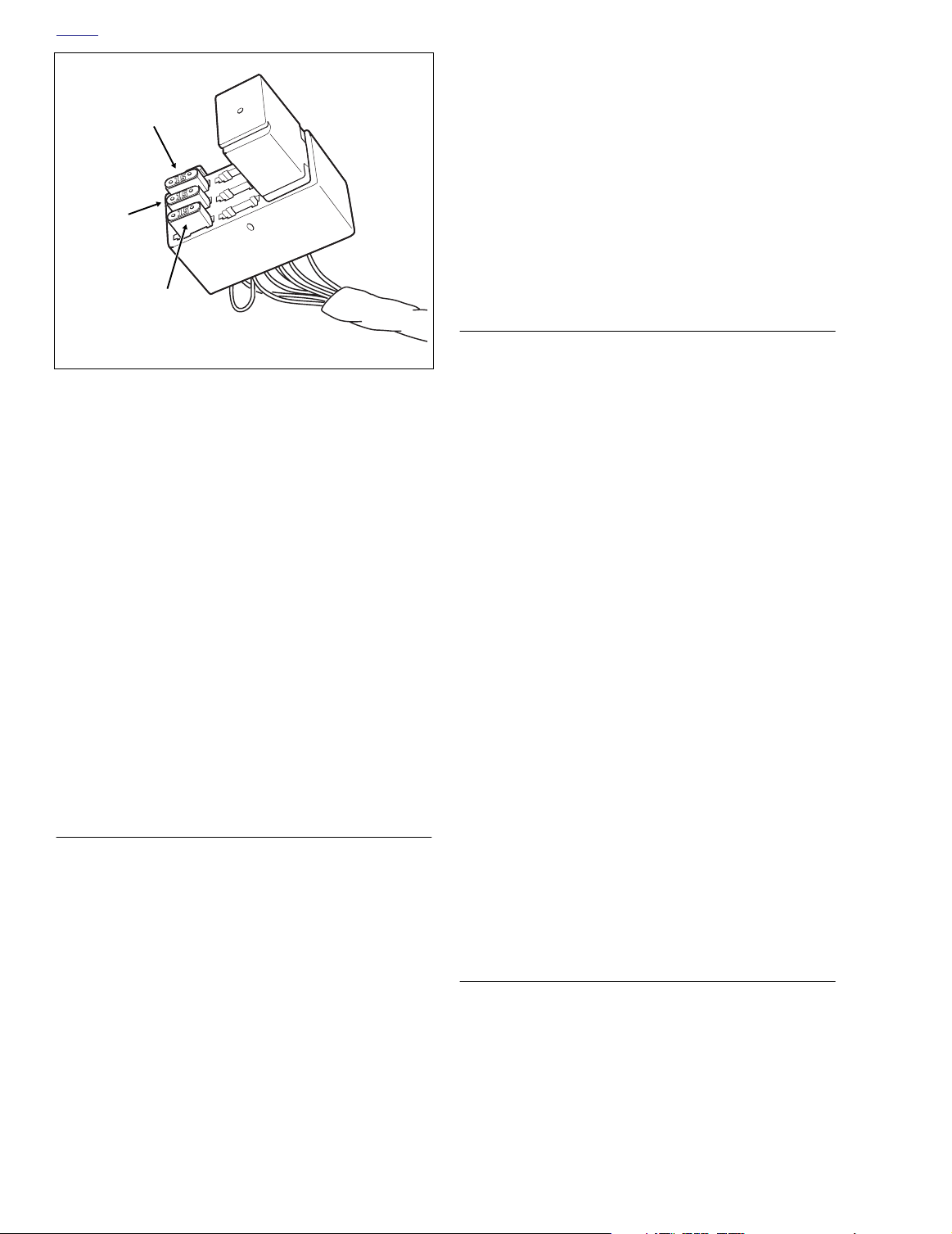

Fuel

Pump

Spare

EFI System Relay

f2223x9x

INSTALLATION

1. Install relay in slots of fuse block. See Figure 9-3.

2. Engage tabs on fuse block with slots in bracket. Slide

fuse block up into cavity. Gently tug on conduit to verify

that fuse block is locked in place.

3. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

4. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

ECM Power

Figure 9-3. EFI Fuse Block

4. Gently pull on data link connector [91] to disengage from

arms on electrical bracket. See Figure 9-2.

5. Remove rubber protective plug from data link connector.

6. See DIGITAL TECHNICIAN (Part No. HD-44750) or the

2004 ELECTRICAL DIAGNOSTIC MANUAL (Part No.

99497-04) to use the data link connector for system

diagnosis and electrical troubleshooting.

7. Install protective plug in data link connector.

8. With the plug side down and in contact with tab, position

connector between arms on electrical bracket.

9. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

10. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

EFI SYSTEM RELAY

REMOVAL

1. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Gently pull side cover from frame downtubes (no tools

required).

3. Locate painted white dot on inboard side of fuse block.

Pressing on dot, gently tug on conduit to release tabs on

fuse block from slots in bracket.

4. Pull relay from slots in fuse block. See Figure 9-3.

EFI FUSES

REMOVAL

1. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Gently pull side cover from frame downtubes (no tools

required).

3. Locate painted white dot on inboard side of fuse block.

Pressing on dot, gently tug on conduit to release tabs on

fuse block from slots in bracket.

4. Pull fuses from slots in fuse block and inspect for damage. Replace fuse if the element is burned or broken.

Automotive type ATO fuses are used. See Figure 9-3.

NOTE

While a spare 15 amp fuse is located in the EFI fuse block,

one extra 10 amp and 15 amp fuse are also located in the

system fuse block cover. See Section

for more information.

8.3 SYSTEM FUSES

INSTALLATION

1. Insert fuse in the appropriate slot. See Figure 9-3.

2. Engage tabs on fuse block with slots in bracket. Slide

fuse block up into cavity. Gently tug on conduit to verify

that fuse block is locked in place.

3. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

4. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

ELECTRONIC CONTROL MODULE

REMOVAL

1. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

9-4 2004 Touring: Fuel Injection

Page 5

HOME

1. Vehicle Speed Sensor [65]

2. P&A Security Siren [142]

1

2

f2183x8x

2. Gently pull side cover from frame downtubes (no tools

required).

3. Depress external latch and use rocking motion to

remove ECM connector [78]. See Figure 9-2.

4. Remove two socket screws to detach ECM from electrical bracket.

INSTALLATION

1. Align holes in ECM with those in electrical bracket.

Install two socket screws and tighten to 50-60

(5.7-6.8 Nm). See Figure 9-2.

2. Install ECM connector [78]. Push connector halves

together until latch clicks.

3. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

4. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

in-lbs

Figure 9-4. Electrical Bracket (Inboard Side)

SECURITY SIREN CONNECTOR

REMOVAL

1. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Gently pull side cover from frame downtubes (no tools

required).

3. Remove two flange nuts to release electrical bracket

from studs on side of battery box. See Figure 9-4.

INSTALLATION

1. Install security siren connector [142] and vehicle speed

sensor connector [65] on inboard side of electrical

bracket as shown in Figure 9-4. Be sure that conduit and

cables are properly routed or wires may be pinched during installation.

2. Slide electrical bracket onto studs at side of battery box.

3. Install flange nuts on studs and tighten to 36-48

(4.1-5.4 Nm).

4. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

in-lbs

EFI HARNESS

For removal and installation instructions, see Section 8.32

WIRING HARNESSES AND CABLES, EFI HARNESS

(FUEL INJECTED).

5. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

2004 Touring: Fuel Injection 9-5

Page 6

HOME

SENSORS 9.3

GENERAL

Six sensors inform the ECM of the environmental and engine

operating factors influencing fuel and spark requirements.

The sensors are as follows:

Intake Air Temperature Sensor

●

Throttle Position Sensor

●

Manifold Absolute Pressure Sensor

●

●

Bank Angle Sensor (Internal to TSM/TSSM)

●

Crankshaft Position Sensor

Engine Temperature Sensor

●

INTAKE AIR TEMPERATURE SENSOR

See Section 9.5 INDUCTION MODULE ASSEMBLY,

INTAKE AIR TEMPERATURE SENSOR.

THROTTLE POSITION SENSOR

See Section 9.5 INDUCTION MODULE ASSEMBLY,

THROTTLE POSITION SENSOR.

MANIFOLD ABSOLUTE PRESSURE

SENSOR

f2256x8x

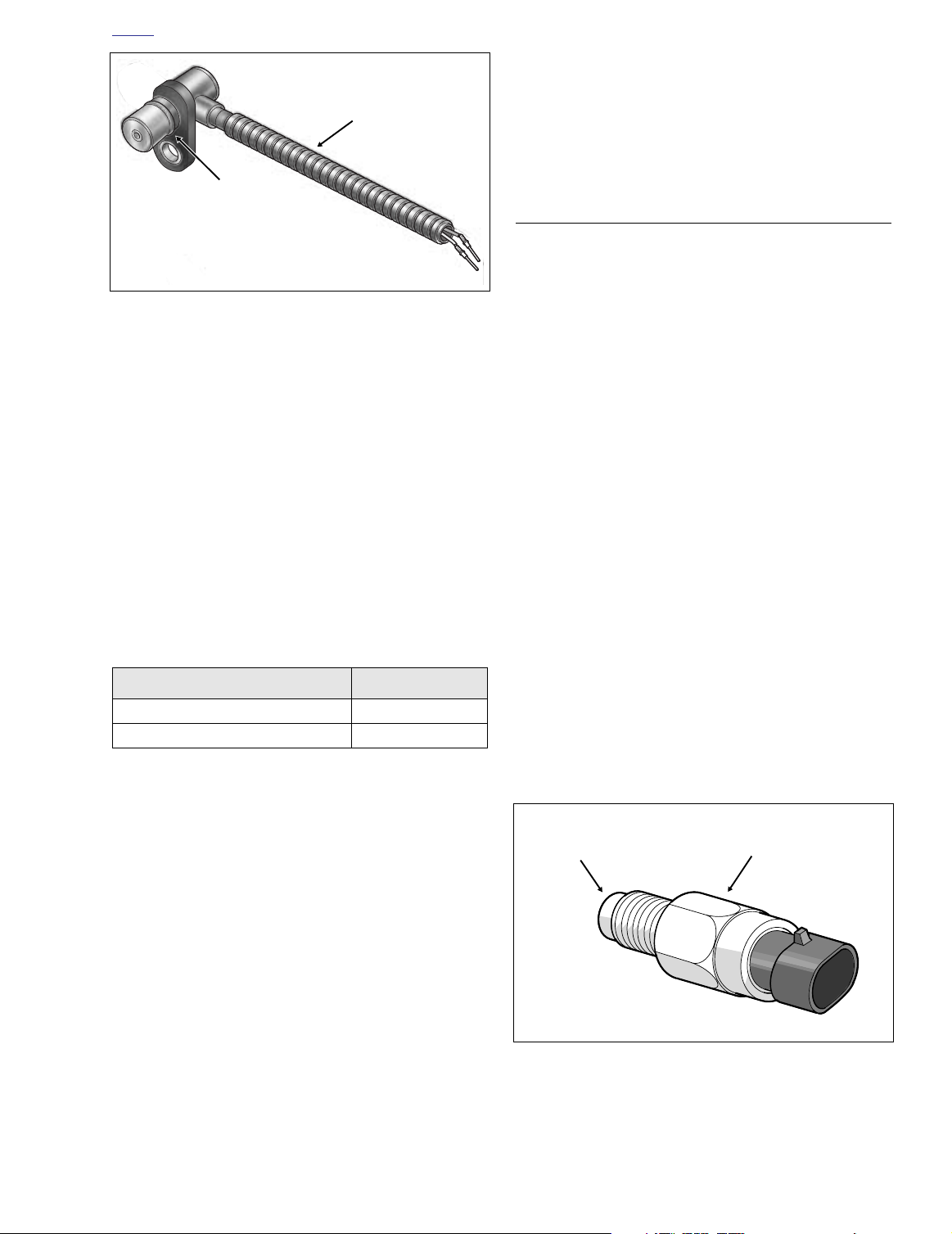

Stator

Connector [46]

Crankshaft

Position Sensor

Connector [79]

Figure 9-5. Voltage Regulator (Left Side View)

f2217x8x

Socket Screw

See Section 9.5 INDUCTION MODULE ASSEMBLY, MANI-

FOLD ABSOLUTE PRESSURE SENSOR.

BANK ANGLE SENSOR

See Section 8.17 TURN SIGNAL/SECURITY MODULE.

CRANKSHAFT POSITION SENSOR

REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Locate crankshaft position sensor connector [79], 2place Mini-Deutsch, fixed to bracket at bottom of voltage

regulator. See Figure 9-5.

3. Push connector toward right side of motorcycle to disengage small end of slot on attachment clip from T-stud on

bracket. Lift connector off T-stud.

4. Depress button on socket terminal side and pull apart

pin and socket halves.

Figure 9-6. Remove Sensor Mount Socket Screw

5. Remove allen head socket screw to free crankshaft position sensor mount from front left side of crankcase. Pull

sensor from bore. See Figure 9-6.

6. Pull sensor to draw convoluted tubing and connector out

from under voltage regulator.

7. Remove terminals from pin housing. See Figure 9-7.

9-6 2004 Touring: Fuel Injection

Page 7

HOME

f1699x9x

Sensor

Body Hex

Thermistor

O-Ring

Convoluted

Tubing

7. Place large end of slot on attachment clip over T-stud on

bracket. Push connector toward left side of motorcycle to

engage small end of slot.

8. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

ENGINE TEMPERATURE SENSOR

f2218x8x

Figure 9-7. Crankshaft Position Sensor

NOTE

For instructions on properly removing wire terminals, see

APPENDIX B.1 DEUTSCH ELECTRICAL CONNECTORS,

REMOVING/INSTALLING PINS.

8. Remove convoluted tubing from crankshaft position sensor cable.

INSTALLATION

1. Install convoluted tubing onto crankshaft position sensor

cable. See Figure 9-7.

2. Referencing the following table, install terminals into pin

housing.

Table 9-1. Crankshaft Position Sensor [79]

Wire Color

Red 1

Black 2

NOTE

For instructions on properly installing wire terminals, see

APPENDIX B.1 DEUTSCH ELECTRICAL CONNECTORS,

REMOVING/INSTALLING PINS.

Chamber Number

REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. On left side of motorcycle, pull back boot at back of front

cylinder to reveal engine temperature sensor connector

[90], 2-place Packard.

3. Pull external latch outward and use rocking motion to

remove connector.

4. Slide a 3/4 inch deepwell socket over the sensor body

hex and turn counter-clockwise to loosen. See Figure 9-

8. When sensor turns easily, pull out the deepwell socket

and remove sensor by hand.

INSTALLATION

1. Hand start threaded end of

cylinder head bore.

2. Slide 3/4 inch deepwell socket over sensor body hex and

tighten to 120-180

3. Install engine temperature sensor connector [90], 2place Packard, at back of front cylinder.

4. Pull boot over sensor to keep out dirt and debris.

5. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

in-lbs

new

temperature sensor into

(13.6-20.3 Nm).

3. Install

4. Push sensor into bore aligning hole in sensor mount with

5. Route connector and convoluted tubing under front

6. Mate pin and socket halves of crankshaft position sensor

new

O-ring in groove on sensor body. Apply a thin

film of clean H-D 20W50 engine oil to O-ring before

installation.

hole in spot face. Install allen head socket screw and

tighten to 90-120

engine stabilizer link to underside of voltage regulator.

connector [79]. See Figure 9-5.

in-lbs

(10.2-13.6 Nm). See Figure 9-6.

Figure 9-8. Engine Temperature Sensor

2004 Touring: Fuel Injection 9-7

Page 8

HOME

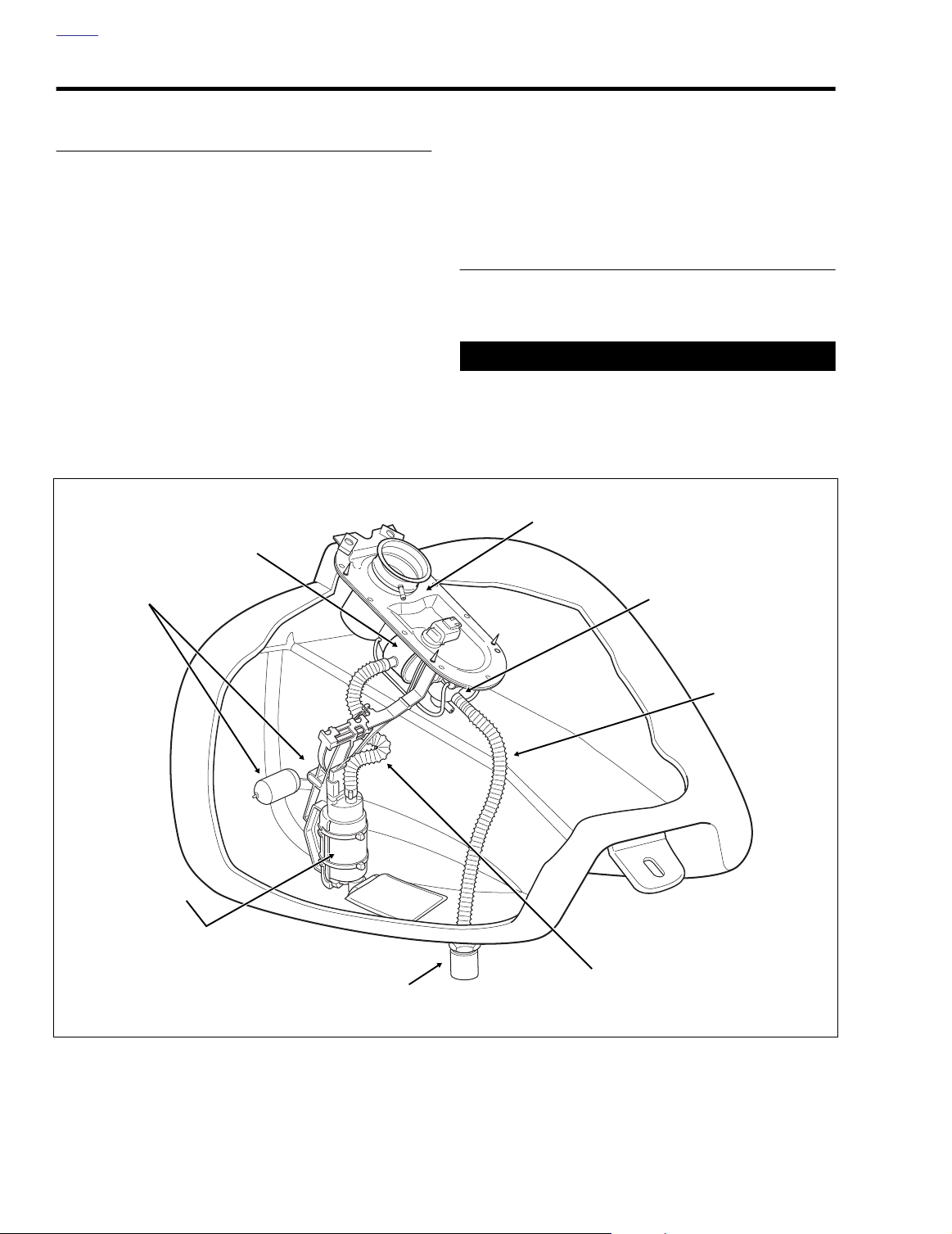

FUEL TANK (FUEL INJECTED) 9.4

Fuel Level Sender

GENERAL

See Figure 9-9. The fuel pump, fuel filter canister, fuel pressure regulator, and fuel level sender are attached to the canopy for easy removal and installation. The act of raising the

canopy automatically removes these items, thereby eliminating those tasks which used to be performed by reaching

inside the fuel tank. This arrangement minimizes the possibility of dropping or losing parts inside the tank, or adding contaminants (such as grease and oil) to the fuel supply.

The fuel tank assembly consists of the following components:

Fuel Tank

●

●

Canopy

●

Fuel Pump

Fuel Pressure Regulator

●

●

Fuel Filter Canister

●

Low Fuel Level Warning Lamp

●

Fuel Supply Check Valve

●

COMPLETE REMOVAL

FLHT/C/U/I, FLTRI

1WARNING1WARNING

Gasoline is extremely flammable and highly explosive.

When servicing the fuel system, do not smoke or allow

open flame or sparks in the vicinity. Inadequate safety

precautions could result in death or serious injury.

Fuel Level

Sender

and Float

Fuel Pump

Fuel Filter

Canister

Supply Fitting

(Check Valve)

Canopy

Fuel Pressure

Regulator

In-tank Tubing

(Fuel Pump to Filter Canister)

In-tank Tubing

(Fuel Pressure Regulator

to Supply Fitting)

f1969x9x

Figure 9-9. Fuel Tank Assembly (FLHT/C/U/I, FLTRI)

9-8 2004 Touring: Fuel Injection

Page 9

HOME

1WARNING1WARNING

1WARNING1WARNING

1WARNING1WARNING

Fuel

Pump

f2223x9x

Figure 9-10. EFI Fuse Block

1WARNING1WARNING

Gasoline will drain from the crossover hose when disconnected from the fuel tank. Thoroughly wipe up any

spilled fuel immediately. Dispose of rags in a suitable

manner. Gasoline is extremely flammable and highly

explosive. Inadequate safety precautions could result in

death or serious injury.

CAUTION

Do not kink crossover hose or crimp shut using pliers or

similar tool. Damage to the rigid inner lining will occur.

1. Drain fuel tank as follows:

Obtain a short section of hose with a 5/16 inch (7.9 mm) I.D.

Insert bolt in one end of hose and install hose clamp to

ensure that end is securely plugged. Using a side cutters, cut

clamp from one end of crossover hose beneath fuel tank.

Quickly replace crossover hose on fuel tank fitting with open

end of short hose while directing flow of gasoline from free

end of crossover hose into suitable container.

2. Remove seat. See Section 2.24 SEAT, REMOVAL.

1WARNING1WARNING

a. Remove the 15 amp fuel pump fuse. See Figure 9-

10. If necessary, see Section 9.2 ELECTRICAL

BRACKET ASSEMBLY, EFI FUSES, REMOVAL.

b. Start the engine and allow the vehicle to run.

c. When the engine stalls, operate starter for 3 sec-

onds to remove remaining fuel from fuel lines.

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

4. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

5. Carefully cut anchored cable strap securing main harness bundles, console pod conduit (Ultra models only),

fuel level sender/fuel pump conduit, and fuel vapor vent

tube to left side of frame backbone.

6. Open fuel door on console. Remove two Allen head

screws inboard of rubber bumpers. These screws secure

console to clip nuts on the canopy bracket.

7. Remove Allen head screw to detach flange at rear of

console from clip nut on fuel tank weldment.

8. Lay a clean shop towel on forward part of rear fender.

9. Remove filler cap from neck of fuel tank. Remove console and lay upside down on shop towel. Reinstall filler

cap.

10. Depress button on socket side and remove fuel level

sender/fuel pump connector [141], 3-place Mini-Deutsch, at top of canopy.

11. Gently pry fuel vapor vent tube from fitting on filler neck

of fuel tank. Exercise caution to avoid pulling fitting from

filler neck.

A small amount of gasoline may drain from the fuel supply line when disconnected from the fuel tank. Thoroughly wipe up any spilled fuel immediately. Dispose of

rags in a suitable manner. Gasoline is extremely flammable and highly explosive. Inadequate safety precautions

could result in death or serious injury.

The gasoline in the fuel supply line downstream of the

fuel pump is under high pressure (58 psi). To avoid an

uncontrolled discharge or spray of gasoline, always

purge the system of high pressure gas before the fuel

supply line is disconnected. Gasoline is extremely flammable and highly explosive. Inadequate safety precautions could result in death or serious injury.

3. Purge the fuel supply line of high pressure gas. Proceed

as follows:

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

12. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and pull down on fuel supply line

fitting to disconnect. See Figure 9-11.

2004 Touring: Fuel Injection 9-9

Page 10

HOME

Fuel

Tank

Chrome

Sleeve

Figure 9-11. Fuel Supply Line Fitting

13. Remove two fuel tank front mounting bolts (with flat

washers) from left and right side of frame. Remove bolt

(with flat washer) to free rear of fuel tank from frame

backbone.

NOTE

The fuel tank mounting bolts have both an internal TORX

recess and an external hex, which allows them to be

removed with either a T40 TORX bit or a 1/2 inch open end/

box wrench. Use of the external hex allows the front mounting bolts to be removed without having to loosen or remove

the fairing lowers, if installed.

14. Remove fuel tank from vehicle.

f2021x9x

FLHR/C/S/I

CAUTION

When removing instrument console, exercise caution to

avoid damaging speedometer unit. Wrap console in a

clean, dry shop towel to prevent damage.

6. Secure instrument console to top of rear fender using

bungee cords.

7. Remove console mounting bolt from slot at top of canopy.

8. Gently pry fuel vapor vent tube from fitting.

9. At bottom left side of fuel tank, gently pull on convoluted

tubing to draw fuel gauge connector [117], 4-place Multilock, out of tunnel. Depress button on socket terminal

side and pull apart pin and socket halves.

1WARNING1WARNING

A small amount of gasoline may drain from the fuel supply line when disconnected from the fuel tank. Thoroughly wipe up any spilled fuel immediately. Dispose of

rags in a suitable manner. Gasoline is extremely flammable and highly explosive. Inadequate safety precautions

could result in death or serious injury.

1WARNING1WARNING

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

10. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and pull down on fuel supply line

fitting to disconnect. See Figure 9-11.

11. Remove fuel tank from vehicle.

1. See Section 9.4 FUEL TANK (FUEL INJECTED), COM-

PLETE REMOVAL, FLHT/C/U/I, FLTRI, steps 1-4.

2. Remove two fuel tank front mounting bolts (with flat

washers) from left and right side of frame. Remove bolt

(with flat washer) to free rear of fuel tank from frame

backbone. On FLHRSI models, removal of rear bolt also

releases instrument console bracket.

3. Carefully cut anchored cable strap securing main harness bundle, instrument console conduit, and fuel vapor

vent tube to left side of frame backbone.

4. Remove acorn nut from instrument console. If present,

also remove Phillips screw and large flat washer (absent

on FLHRSI models).

5. Raise instrument console and bend back flexible clamp

on canopy to release main harness conduit. Depress

button on socket side and remove fuel level sender/fuel

pump connector [141], 3-place Mini-Deutsch.

9-10 2004 Touring: Fuel Injection

INSTALLATION (AFTER COMPLETE REMOVAL)

FLHT/C/U/I, FLTRI

CAUTION

Exercise caution to avoid pinching the wiring harness

between the fuel tank and vehicle frame. Wire damage

may result in electrical problems.

1. Work fuel tank into position aligning front flange holes

with those in frame.

2. Slide

new

clamp onto free end of crossover hose. Running hose beneath frame backbone, install hose onto fitting at bottom front of fuel tank (after removing

temporary plug). Crimp clamp.

Page 11

HOME

1WARNING1WARNING

1WARNING1WARNING

Fuel

Tank

Fuel Pump,

Fuel Level

Sender Conduit

Main

Harness

Bundle

Console

Pod Conduit

Console

Pod

Fuel Vapor

Vent Tube

(To Vapor Valve)

Anchored

Cable Strap

FLHTCUI

f2007x9x

Fuel

Overflow

Hose

Main

Harness

Bundle

3. Start fuel tank front mounting bolts (with flat washers)

into left and right side of frame.

4. Install bolt (with flat washer) to secure rear of fuel tank to

frame backbone. Tighten bolt to 15-20 ft-lbs (20-27 Nm).

5. Tighten fuel tank front mounting bolts to 15-20 ft-lbs (2027 Nm).

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

6. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and insert neck of fuel supply line

fitting. While pushing up on bottom of fitting, pull down

on chrome sleeve until it “clicks” into the locked position.

To avoid an uncontrolled discharge or spray of gasoline,

always be sure the quick-connect fitting is properly

mated. A slight tug on the fuel supply line fitting will verify this condition. Gasoline is extremely flammable and

highly explosive. Inadequate safety precautions could

result in death or serious injury.

Fuel

Tank

Console

Fuel Pump,

Fuel Level

Sender Conduit

Fuel Vapor

Vent Tube

(To Vapor Valve)

Main

Harness

Bundle

Anchored

Cable Strap

FLHT/C/I, FLTRI

Figure 9-12. Console Pod Cable/Hose Routing

(Top View)

f1739b9x

Fuel

Overflow

Hose

Main

Harness

Bundle

7. Connect fuel vapor vent tube to nipple on filler neck of

fuel tank.

8. Install fuel level sender/fuel pump connector [141], 3place Mini-Deutsch, at top of canopy.

9. Remove filler cap. Position console on canopy. Route

cables from beneath console as shown in Figure 9-12.

Be sure that hoses and wires are not pinched by the

console during installation. Reinstall filler cap.

10. Install Allen head screw to fasten rear flange of console

to clip nut on fuel tank weldment. Tighten screw to 25-30

in-lbs

(2.8-3.4 Nm).

11. Open fuel door on console. Install two Allen head screws

to secure front of console to clip nuts on canopy bracket.

Alternately tighten screws to 25-30

12. Snap anchor of

frame backbone. Tighten cable strap capturing main harness bundles, console pod conduit (Ultra models only),

fuel level sender/fuel pump conduit, and fuel vapor vent

tube. See Figure 9-12. Cut any excess cable strap material.

Route fuel overflow hose inboard of wire bundles on right

side of frame, but do not capture in cable straps.

13. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

new

cable strap into hole on left side of

NOTE

in-lbs

(6.8-10.9 Nm).

in-lbs

(2.8-3.4 Nm).

2004 Touring: Fuel Injection 9-11

Page 12

HOME

14. Install the 15 amp fuel pump fuse. See Figure 9-10. If

necessary, see Section 9.2 ELECTRICAL BRACKET

ASSEMBLY, EFI FUSES, INSTALLATION.

15. Install seat. See Section 2.24 SEAT, INSTALLATION.

FLHR/C/S/I

1. Work fuel tank into position aligning front flange holes

with those in frame.

Convoluted

Tubing

2. Slide

new

clamp onto free end of crossover hose. Running hose beneath frame backbone, install hose onto fitting at bottom front of fuel tank (after removing

temporary plug). Crimp clamp.

1WARNING1WARNING

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

3. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and insert neck of fuel supply line

fitting. While pushing up on bottom of fitting, pull down

on chrome sleeve until it “clicks” into the locked position.

1WARNING1WARNING

To avoid an uncontrolled discharge or spray of gasoline,

always be sure the quick-connect fitting is properly

mated. A slight tug on the fuel supply line fitting will verify this condition. Gasoline is extremely flammable and

highly explosive. Inadequate safety precautions could

result in death or serious injury.

4. Connect fuel vapor vent tube to fitting at top of canopy.

5. Slide head of console mounting bolt into slot at top of

canopy.

6. Moving instrument console toward installed position,

install fuel level sender/fuel pump connector [141], 3place Mini-Deutsch, at top of canopy. Bend flexible

clamp to capture main harness conduit.

7. Align hole in instrument console with console mounting

bolt and place into position on fuel tank.

8. Star

9. Install bolt (with flat washer) to secure rear of fuel tank to

10. Tighten fuel tank front mounting bolts to 15-20 ft-lbs (20-

t fuel tank front mounting bolts (with flat washers)

into left and right side of frame.

frame backbone. On FLHRSI models, capture instrument console bracket during installation. Tighten bolt to

15-20 ft-lbs (20-27 Nm).

27 Nm).

8870

Figure 9-13. Fuel Gauge (FLHR/C/S)

11. Install acorn nut at top of instrument console and tighten

to 50-90

Phillips screw and large flat washer (absent on FLHRSI

models). Tighten screw to 36-60

12. Connect fuel gauge to main harness. Route pin housing

and convoluted tubing forward and then inboard

between front of crossover hose fitting and bottom of fuel

tank. Mate pin and socket halves of fuel gauge connector [117], 4-place Multilock. Feed connector into tunnel

of fuel tank. See Figure 9-13.

13. Snap anchor of

frame backbone. Tighten cable strap capturing main harness bundle, instrument console conduit, and fuel vapor

vent tube. Cut any excess cable strap material. See Fig-

ure 9-12.

14. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

15. Install the 15 amp fuel pump fuse. See Figure 9-10. If

necessary, see Section 9.2 ELECTRICAL BRACKET

ASSEMBLY, EFI FUSES, INSTALLATION.

16. Install seat. See Section 2.24 SEAT, INSTALLATION.

in-lbs

(5.7-10.2 Nm). If present, also install

in-lbs

(4.1-6.8 Nm).

new

cable strap into hole on left side of

in-lbs

(6.8-10.9 Nm).

PARTIAL REMOVAL

FLHT/C/U/I, FLTRI

1WARNING1WARNING

Gasoline is extremely flammable and highly explosive.

When servicing the fuel system, do not smoke or allow

open flame or sparks in the vicinity. Inadequate safety

precautions could result in death or serious injury.

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

9-12 2004 Touring: Fuel Injection

Page 13

HOME

1WARNING1WARNING

CAUTION

1WARNING1WARNING

The gasoline in the fuel supply line downstream of the

fuel pump is under high pressure (58 psi). To avoid an

uncontrolled discharge or spray of gasoline, always

purge the system of high pressure gas before the fuel

supply line is disconnected. Inadequate safety precautions could result in death or serious injury.

2. Purge the fuel supply line of high pressure gas. Proceed

as follows:

a. Remove the 15 amp fuel pump fuse. See Figure 9-

10. If necessary, see Section 9.2 ELECTRICAL

BRACKET ASSEMBLY, EFI FUSES, REMOVAL.

b. Start the engine and allow the vehicle to run.

c. When the engine stalls, operate starter for 3 sec-

onds to remove remaining fuel from fuel lines.

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

3. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

4. Carefully cut anchored cable strap securing main harness bundles, console pod conduit (Ultra models only),

fuel level sender/fuel pump conduit, and fuel vapor vent

tube to left side of frame backbone.

5. Open fuel door on console. Remove two Allen head

screws inboard of rubber bumpers. These screws secure

console to clip nuts on the canopy bracket.

6. Remove Allen head screw to detach flange at rear of

console from clip nut on fuel tank weldment.

7. Lay a clean shop towel on forward part of rear fender.

8. Remove filler cap from neck of fuel tank. Remove console and lay upside down on shop towel. Reinstall filler

cap.

9. Depress button on socket side and remove fuel level

sender/fuel pump connector [141], 3-place Mini-Deutsch, at top of canopy.

10. Gently pry fuel vapor vent tube from fitting on filler neck

of fuel tank. Exercise caution to avoid pulling fitting from

filler neck.

1WARNING1WARNING

A small amount of gasoline may drain from the fuel supply line when disconnected from the fuel tank. Thoroughly wipe up any spilled fuel immediately. Dispose of

rags in a suitable manner. Gasoline is extremely flammable and highly explosive. Inadequate safety precautions

could result in death or serious injury.

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

11. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and pull down on fuel supply line

fitting to disconnect. See Figure 9-11.

12. Remove two fuel tank front mounting bolts (with flat

washers) from left and right side of frame. Remove bolt

(with flat washer) to free rear of fuel tank from frame

backbone.

NOTE

The fuel tank mounting bolts have both an internal TORX

recess and an external hex, which allows them to be

removed with either a T40 TORX bit or a 1/2 inch open end/

box wrench. Use of the external hex allows the front mounting bolts to be removed without having to loosen or remove

the fairing lowers, if installed.

13. Raise the fuel tank approximately 2 inches. Move the

fuel tank crossover hose to the rear of the ignition coil,

so that the tank can be raised an additional 2-3 inches.

Move fuel tank straight back and rest on frame backbone.

14. Obtain several 1 x 2 inch wooden blocks. Raise front and

rear of fuel tank off the frame backbone by placing

blocks in tunnel at bottom of tank.

FLHR/C/S/I

1. See Section 9.4 FUEL TANK (FUEL INJECTED), PAR-

TIAL REMOVAL, FLHT/C/U/I, FLTRI, steps 1-3.

2. Remove two fuel tank front mounting bolts (with flat

washers) from left and right side of frame. Remove bolt

(with flat washer) to free rear of fuel tank from frame

backbone. On FLHRSI models, removal of rear bolt also

releases instrument console bracket.

3. Carefully cut anchored cable strap securing main harness bundle, instrument console conduit, and fuel vapor

vent tube to left side of frame backbone.

4. Remove acorn nut from instrument console. If present,

also remove Phillips screw and large flat washer (absent

on FLHRSI models).

5. Raise instrument console and bend back flexible clamp

on canopy to release main harness conduit. Depress

button on socket side and remove fuel level sender/fuel

pump connector [141], 3-place Mini-Deutsch.

When removing instrument console, exercise caution to

avoid damaging speedometer unit. Wrap console in a

clean, dry shop towel to prevent damage.

2004 Touring: Fuel Injection 9-13

Page 14

HOME

6. Secure instrument console to top of rear fender using

bungee cords.

7. Remove console mounting bolt from slot at top of canopy.

8. Gently pry fuel vapor vent tube from fitting at top of canopy.

9. At bottom left side of fuel tank, gently pull on convoluted

tubing to draw fuel gauge connector [117], 4-place Multilock, out of tunnel. Depress button on socket terminal

side and pull apart pin and socket halves. See Figure 9-

13.

1WARNING1WARNING

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

5. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and insert neck of fuel supply line

fitting. While pushing up on bottom of fitting, pull down

on chrome sleeve until it “clicks” into the locked position.

1WARNING1WARNING

A small amount of gasoline may drain from the fuel supply line when disconnected from the fuel tank. Thoroughly wipe up any spilled fuel immediately. Dispose of

rags in a suitable manner. Gasoline is extremely flammable and highly explosive. Inadequate safety precautions

could result in death or serious injury.

1WARNING1WARNING

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

10. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and pull down on fuel supply line

fitting to disconnect. See Figure 9-11.

11. Raise the fuel tank approximately 2 inches. Move the

fuel tank crossover hose to the rear of the ignition coil,

so that the tank can be raised an additional 2-3 inches.

Move fuel tank straight back and rest on frame backbone.

12. Obtain several 1 x 2 inch wooden blocks. Raise front and

rear of fuel tank off the frame backbone by placing

blocks in tunnel at bottom of tank.

INSTALLATION (AFTER PARTIAL REMOVAL)

FLHT/C/U/I, FLTRI

1. Remove wooden blocks and move fuel tank toward its

installed position. While positioning fuel tank, move

crossover hose in front of ignition coil. Work fuel tank

into position aligning front flange holes with those in

frame.

2. Star

3. Install bolt (with flat washer) to secure rear of fuel tank to

4. Tighten fuel tank front mounting bolts to 15-20 ft-lbs (20-

t fuel tank front mounting bolts (with flat washers)

into left and right side of frame.

frame backbone. Tighten bolt to 15-20 ft-lbs (20-27 Nm).

27 Nm).

1WARNING1WARNING

To avoid an uncontrolled discharge or spray of gasoline,

always be sure the quick-connect fitting is properly

mated. A slight tug on the fuel supply line fitting will verify this condition. Gasoline is extremely flammable and

highly explosive. Inadequate safety precautions could

result in death or serious injury.

6. Connect fuel vapor vent tube to fitting on filler neck of

fuel tank.

7. Install fuel level sender/fuel pump connector [141], 3place Mini-Deutsch, at top of canopy.

8. Remove filler cap. Position console on canopy. Route

cables from beneath console as shown in Figure 9-12.

Be sure that hoses and wires are not pinched by the

console during installation. Reinstall filler cap.

9. Install Allen head screw to fasten rear flange of console

to clip nut on fuel tank weldment. Tighten screw to 25-30

in-lbs (2.8-3.4 Nm).

10. Open fuel door on console. Install two Allen head screws

to secure front of console to clip nuts on canopy bracket.

Alternately tighten screws to 25-30 in-lbs (2.8-3.4 Nm).

11. Snap anchor of new cable strap into hole on left side of

frame backbone. Tighten cable strap capturing main harness bundles, console pod conduit (Ultra models only),

fuel level sender/fuel pump conduit, and fuel vapor vent

tube. Cut any excess cable strap material. See Figure 9-

12.

NOTE

Route fuel overflow hose inboard of wire bundles on right

side of frame, but do not capture in cable straps.

12. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

13. Install the 15 amp fuel pump fuse. See Figure 9-10. If

necessary, see Section 9.2 ELECTRICAL BRACKET

ASSEMBLY, EFI FUSES, INSTALLATION.

14. Install seat. See Section 2.24 SEAT, INSTALLATION.

9-14 2004 Touring: Fuel Injection

Page 15

HOME

1WARNING1WARNING

CAUTION

1WARNING1WARNING

FLHR/C/S/I

1. Remove wooden blocks and move fuel tank toward its

installed position. While positioning fuel tank, move

crossover hose in front of ignition coil. Work fuel tank

into position aligning front flange holes with those in

frame.

1WARNING1WARNING

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

2. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and insert neck of fuel supply line

fitting. While pushing up on bottom of fitting, pull down

on chrome sleeve until it “clicks” into the locked position.

1WARNING1WARNING

To avoid an uncontrolled discharge or spray of gasoline,

always be sure the quick-connect fitting is properly

mated. A slight tug on the fuel supply line fitting will verify this condition. Gasoline is extremely flammable and

highly explosive. Inadequate safety precautions could

result in death or serious injury.

3. Connect fuel vapor vent tube to fitting at top of canopy.

4. Slide head of console mounting bolt into slot at top of

canopy.

5. Moving instrument console toward installed position,

install fuel level sender/fuel pump connector [141], 3place Mini-Deutsch, at top of canopy. Bend flexible

clamp to capture main harness conduit.

6. Align hole in instrument console with console mounting

bolt and place into position on fuel tank.

7. Star

8. Install bolt (with flat washer) to secure rear of fuel tank to

9. Tighten fuel tank front mounting bolts to 15-20 ft-lbs (20-

10. Install acorn nut at top of instrument console and tighten

11. Connect fuel gauge to main harness. Route pin housing

t fuel tank front mounting bolts (with flat washers)

into left and right side of frame.

frame backbone. On FLHRSI models, capture instrument console bracket during installation. Tighten bolt to

15-20 ft-lbs (20-27 Nm).

27 Nm).

to 50-90 in-lbs (5.7-10.2 Nm). If present, also install

Phillips screw and large flat washer (absent on FLHRSI

models). Tighten screw to 36-60 in-lbs (4.1-6.8 Nm).

and convoluted tubing forward and then inboard

between front of crossover hose fitting and bottom of fuel

tank. Mate pin and socket halves of fuel gauge connector [117], 4-place Multilock. Feed connector into tunnel

of fuel tank. See Figure 9-13.

12. Snap anchor of new cable strap into hole on left side of

frame backbone. Tighten cable strap capturing main harness bundle, instrument console conduit, and fuel vapor

vent tube. Cut any excess cable strap material. See Fig-

ure 9-12.

13. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

14. Install the 15 amp fuel pump fuse. See Figure 9-10. If

necessary, see Section 9.2 ELECTRICAL BRACKET

ASSEMBLY, EFI FUSES, INSTALLATION.

15. Install seat. See Section 2.24 SEAT, INSTALLATION.

CONSOLE POD/CANOPY

FLHT/C/U/I, FLTRI

REMOVAL

Gasoline will drain from the crossover hose when disconnected from the fuel tank. Thoroughly wipe up any

spilled fuel immediately. Dispose of rags in a suitable

manner. Gasoline is extremely flammable and highly

explosive. Inadequate safety precautions could result in

death or serious injury.

Do not kink crossover hose or crimp shut using pliers or

similar tool. Damage to the rigid inner lining will occur.

1. Drain fuel tank as follows:

Obtain a short section of hose with a 5/16 inch (7.9 mm)

I.D. Insert bolt in one end of hose and install hose clamp

to ensure that end is securely plugged. Cut clamp from

one end of crossover hose beneath fuel tank. Quickly

replace crossover hose on fuel tank fitting with open end

of short hose while directing flow of gasoline from free

end of crossover hose into suitable container.

2. Remove seat. See Section 2.24 SEAT, REMOVAL.

The gasoline in the fuel supply line downstream of the

fuel pump is under high pressure (58 psi). To avoid an

uncontrolled discharge or spray of gasoline, always

purge the system of high pressure gas before the fuel

supply line is disconnected. Inadequate safety precautions could result in death or serious injury.

3. Purge the fuel supply line of high pressure gas. Proceed

as follows:

2004 Touring: Fuel Injection 9-15

Page 16

HOME

f1955x9x

Convoluted

Tube

Figure 9-14. Raise Canopy and Remove Tube

(FLHT/C/U/I, FLTRI)

a. Remove the 15 amp fuel pump fuse. See Figure 9-

10. If necessary, see Section 9.2 ELECTRICAL

BRACKET ASSEMBLY, EFI FUSES, REMOVAL.

b. Start the engine and allow the vehicle to run.

c. When the engine stalls, operate starter for 3 sec-

onds to remove remaining fuel from fuel lines.

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

4. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

5. Carefully cut anchored cable strap securing main harness bundle, console pod conduit (Ultra models only),

fuel level sender/fuel pump conduit, and fuel vapor vent

tube to left side of frame backbone.

6. Open fuel door on console. Remove two Allen head

screws inboard of rubber bumpers. These screws secure

console to clip nuts on the canopy bracket.

7. Remove Allen head screw to detach flange at rear of

console from clip nut on fuel tank weldment.

8. Lay a clean shop towel on forward part of rear fender.

9. Remove filler cap from neck of fuel tank. Remove console and lay upside down on shop towel. Reinstall filler

cap.

10. Depress button on socket side and remove fuel level

sender/fuel pump connector [141], 3-place Mini-Deutsch, at top of canopy.

11. Gently pry fuel vapor vent tube from fitting on filler neck

of fuel tank. Exercise caution to avoid pulling fitting from

filler neck.

12. Using a T20 TORX bit, remove ten screws around the

outer edge of the canopy. Discard screws.

13. Raise canopy slightly to access top fitting (inlet port) at

back of fuel pressure regulator. Using a side cutters, cut

hose clamp and remove convoluted tube. Exercise caution to avoid cutting or damaging tube or dropping

pieces of cut clamp into fuel tank. See Figure 9-14.

14. Remove canopy from fuel tank (with attached fuel pressure regulator, fuel filter canister, fuel pump and fuel

level sender).

A spring-loaded hinge on the fuel pump bracket facilitates removal of the assembly. For best results, press

down on top of fuel pump with index finger or end of

screwdriver, and after raising canopy slightly, rotate on

hinge in a counterclockwise direction. When canopy is at

a 45˚ angle to top of fuel tank, carefully pull assembly

from left side lobe of fuel tank. See Figure 9-16.

15. Remove and discard canopy gasket. Verify that sealing

devices from screws are not lodged in canopy holes.

Remove and discard devices if present.

INSTALLATION

1. Obtain new canopy gasket. With the locator bump on the

gasket OD toward the front, position gasket at bottom of

canopy. Start four nubs on gasket into holes in canopy.

Moving to top of canopy, alternately grasp each nub and

pull through hole.

CAUTION

Exercise care to avoid bending float rod of fuel level

sender during installation. Be sure to position float rod

to the right of the fuel gauge drain tube or it will be bent

during installation of the canopy. A bent float rod will

result in erroneous gauge readings.

2. While holding fuel pump stationary, raise canopy slightly

and rotate on hinge 90˚ in a counterclockwise direction.

3. Holding assembly so that canopy is at a 45˚ angle to top

of fuel tank, insert assembly into left side lobe of fuel

tank. The spring-loaded hinge on the fuel pump bracket

automatically returns assembly to its installed position

inside fuel tank.

CAUTION

Carefully inspect end of convoluted tube for cuts, tears,

holes or other damage. Replace tube if any damage is

found. Even the smallest hole can cause a reduction in

fuel pressure.

4. Raise canopy slightly and slide new hose clamp onto

free end of convoluted tube. Install tube onto top fitting

(inlet port) at back of fuel pressure regulator. Crimp

clamp. See Figure 9-14.

9-16 2004 Touring: Fuel Injection

Page 17

HOME

f1957x9x

f1956x9x

Sealing

Device

1

79

63

5

4

810

f1963x9x

10. Open fuel door on console. Install two Allen head screws

to secure front of console to clip nuts on canopy bracket.

Alternately tighten screws to 25-30 in-lbs (2.8-3.4 Nm).

11. Snap anchor of new cable strap into hole on left side of

frame backbone. Tighten cable strap capturing main harness bundles, console pod conduit (Ultra models only),

fuel level sender/fuel pump conduit, and fuel vapor vent

tube. See Figure 9-12. Cut excess cable strap material.

12. Slide new clamp onto free end of crossover hose. Running hose beneath frame backbone, install hose onto fitting at bottom front of fuel tank. Crimp clamp.

13. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

f2011x9x

2

Figure 9-15. Canopy Sealing Screws and Torque

Sequence

1WARNING1WARNING

Always use new screws when installing the canopy.

Reusing old screws may compromise sealing integrity

resulting in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

NOTE

Check canopy screws for proper sealing devices. Screws

must have a bonded seal on underside of head. Replace

screws if seal is missing or damaged. See Figure 9-15.

5. While pushing down on the canopy, align holes in can-

opy with those in fuel tank. Hand start ten new T20

TORX screws in perimeter of canopy. Tighten screws to

18-24 in-lbs (2.0-2.7 Nm) using the pattern shown in

Figure 9-15.

6. Connect fuel vapor vent tube to fitting on filler neck of

fuel tank.

7. Install fuel level sender/fuel pump connector [141], 3place Mini-Deutsch, at top of canopy.

8. Remove filler cap. Position console on canopy. Route

cables from beneath console as shown in Figure 9-12.

Be sure that hoses and wires are not pinched by the

console during installation. Reinstall filler cap.

9. Install Allen head screw to fasten rear flange of console

to clip nut on fuel tank weldment. Tighten screw to 25-30

in-lbs (2.8-3.4 Nm).

Figure 9-16. Remove Canopy From Vehicle (FLHR/C/S/I)

2004 Touring: Fuel Injection 9-17

Page 18

HOME

14. Install the 15 amp fuel pump fuse. See Figure 9-10. If

necessary, see Section 9.2 ELECTRICAL BRACKET

ASSEMBLY, EFI FUSES, INSTALLATION.

15. Install seat. See Section 2.24 SEAT, INSTALLATION.

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

INSTRUMENT CONSOLE/CANOPY

FLHR/C/S/I

REMOVAL

1WARNING1WARNING

Gasoline will drain from the crossover hose when disconnected from the fuel tank. Thoroughly wipe up any

spilled fuel immediately. Dispose of rags in a suitable

manner. Gasoline is extremely flammable and highly

explosive. Inadequate safety precautions could result in

death or serious injury.

CAUTION

Do not kink crossover hose or crimp shut using pliers or

similar tool. Damage to the rigid inner lining will occur.

1. Drain fuel tank as follows:

Obtain a short section of hose with a 5/16 inch (7.9 mm)

I.D. Insert bolt in one end of hose and install hose clamp

to ensure that end is securely plugged. Cut clamp from

one end of crossover hose beneath fuel tank. Quickly

replace crossover hose on fuel tank fitting with open end

of short hose while directing flow of gasoline from free

end of crossover hose into suitable container.

2. Remove seat. See Section 2.24 SEAT, REMOVAL.

1WARNING1WARNING

The gasoline in the fuel supply line downstream of the

fuel pump is under high pressure (58 psi). To avoid an

uncontrolled discharge or spray of gasoline, always

purge the system of high pressure gas before the fuel

supply line is disconnected. Inadequate safety precautions could result in death or serious injury.

3. Purge the fuel supply line of high pressure gas. Proceed

as follows:

a. Remove the 15 amp fuel pump fuse. See Figure 9-

10. If necessary, see Section 9.2 ELECTRICAL

BRACKET ASSEMBLY, EFI FUSES, REMOVAL.

b. Start the engine and allow the vehicle to run.

c. When the engine stalls, operate starter for 3 sec-

onds to remove remaining fuel from fuel lines.

4. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

5. Carefully cut anchored cable strap securing main harness bundle, instrument console conduit, and fuel vapor

vent tube to left side of frame backbone.

6. Remove acorn nut from instrument console. If present,

also remove Phillips screw and large flat washer (absent

on FLHRSI models).

7. On FLHRSI models only, remove bolt (with flat washer)

to free rear of fuel tank from frame backbone. Removal

of rear bolt also releases instrument console bracket.

8. Raise instrument console and bend back flexible clamp

on canopy to release main harness conduit. Depress

button on socket side and remove fuel level sender/fuel

pump connector [141], 3-place Mini-Deutsch.

CAUTION

When removing instrument console, exercise caution to

avoid damaging speedometer unit. Wrap console in a

clean, dry shop towel to prevent damage.

9. Secure instrument console to top of rear fender using

bungee cords.

10. Remove console mounting bolt from slot at top of canopy.

11. Gently pry fuel vapor vent tube from fitting at top of canopy.

12. Using a T20 TORX bit, remove ten screws around the

outer edge of the canopy. Discard screws.

13. Raise canopy slightly to access top fitting (inlet port) at

back of fuel pressure regulator. Using a side cutters, cut

hose clamp and remove convoluted tube. Exercise caution to avoid cutting or damaging tube or dropping

pieces of cut clamp into fuel tank. See Figure 9-14.

14. Remove canopy from fuel tank (with attached fuel pressure regulator, fuel filter canister, fuel pump and fuel

level sender).

A spring-loaded hinge on the fuel pump bracket facilitates removal of the assembly. For best results, press

down on top of fuel pump with index finger or end of

screwdriver, and after raising canopy slightly, rotate on

hinge in a counterclockwise direction. When canopy is at

a 45˚ angle to top of fuel tank, carefully pull assembly

from left side lobe of fuel tank. See Figure 9-16.

15. Remove and discard canopy gasket. Verify that sealing

devices from screws are not lodged in canopy holes.

Remove and discard devices if present.

9-18 2004 Touring: Fuel Injection

Page 19

HOME

INSTALLATION

1. Obtain new canopy gasket. With the locator bump on the

gasket OD toward the front, position gasket at bottom of

canopy. Start four nubs on gasket into holes in canopy.

Moving to top of canopy, alternately grasp each nub and

pull through hole.

CAUTION

Exercise care to avoid bending float rod of fuel level

sender during installation. Be sure to position float rod

to the right of the fuel gauge drain tube or it will be bent

during installation of the canopy. A bent float rod will

result in erroneous gauge readings.

2. While holding fuel pump stationary, raise canopy slightly

and rotate on hinge 90˚ in a counterclockwise direction.

3. Holding assembly so that canopy is at a 45˚ angle to top

of fuel tank, insert assembly into left side lobe of fuel

tank keeping the float rod positioned to the right of the

fuel gauge drain tube. The spring-loaded hinge on the

fuel pump bracket automatically returns assembly to its

installed position inside fuel tank.

CAUTION

Carefully inspect end of convoluted tube for cuts, tears,

holes or other damage. Replace tube if any damage is

found. Even the smallest hole can cause a reduction in

fuel pressure.

8. Moving instrument console toward installed position,

install fuel level sender/fuel pump connector [141], 3place Mini-Deutsch, at top of canopy. Bend flexible

clamp to capture main harness conduit.

9. Align hole in instrument console with console mounting

bolt and place into position on fuel tank.

10. Install acorn nut at top of instrument console and tighten

to 50-90 in-lbs (5.7-10.2 Nm). If present, also install

Phillips screw and large flat washer (absent on FLHRSI

models). Tighten screw to 36-60 in-lbs (4.1-6.8 Nm).

11. On FLHRSI models only, install bolt (with flat washer) to

secure rear of fuel tank and instrument console bracket

to frame backbone. Tighten bolt to 15-20 ft-lbs (20-27

Nm).

12. Snap anchor of new cable strap into hole on left side of

frame backbone. Tighten cable strap capturing main harness bundle, instrument console conduit, and fuel vapor

vent tube. Cut any excess cable strap material.

13. Slide new clamp onto free end of crossover hose. Running hose beneath frame backbone, install hose onto fitting at bottom front of fuel tank. Crimp clamp.

14. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

15. Install the 15 amp fuel pump fuse. See Figure 9-10. If

necessary, see Section 9.2 ELECTRICAL BRACKET

ASSEMBLY, EFI FUSES, INSTALLATION.

16. Install seat. See Section 2.24 SEAT, INSTALLATION.

4. Raise canopy slightly and slide new hose clamp onto

free end of convoluted tube. Install tube onto top fitting

(inlet port) at back of fuel pressure regulator. Crimp

clamp. See Figure 9-14.

1WARNING1WARNING

Always use new screws when installing the canopy.

Reusing old screws may compromise sealing integrity

resulting in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

NOTE

Check canopy screws for proper sealing devices. Screws

must have a bonded seal on underside of head. Replace

screws if seal is missing or damaged. See Figure 9-15.

5. While pushing down on the canopy, align holes in can-

opy with those in fuel tank. Hand start ten new T20

TORX screws in perimeter of canopy. Tighten screws to

18-24 in-lbs (2.0-2.7 Nm) using the pattern shown in

Figure 9-15.

6. Connect fuel vapor vent tube to fitting at top of canopy.

7. Slide head of console mounting bolt into slot at top of

canopy.

FUEL FILTER CANISTER

Replace the fuel filter canister every 25,000 miles (40,000

km) . Proceed as follows:

REMOVAL

1. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

REMOVAL, or INSTRUMENT CONSOLE/CANOPY,

FLHR/C/S/I, REMOVAL.

2. Release fuel filter canister as follows:

a. Pull wireform to release from slots on fuel filter can-

ister bracket. See A of Figure 9-17.

b. Use hinge to swing wireform out of the way. Move

canister bracket forward to disengage tab from slot

on canopy weldment. See B of Figure 9-17.

c. Pull fitting on canister from fuel pressure regulator

assembly. See C of Figure 9-17.

3. Using a side cutters, cut hose clamp and remove convoluted tube from inlet port at side of fuel filter canister.

Exercise caution to avoid cutting or damaging tube. Discard fuel filter canister.

2004 Touring: Fuel Injection 9-19

Page 20

HOME

INSTALLATION

A

f1940x9x

Pull wireform from slots in canister bracket.

B

CAUTION

Do not replace tubes inside of fuel tank with ordinary

bulk hose. All internal lines must be replaced with the

special original equipment convoluted nylon tubes. Bulk

hose will degrade when immersed in gasoline (particularly stale gasoline), resulting in contamination of the

fuel supply. Use of contaminated fuel will cause starting

and driveability problems and possible vehicle damage.

1. If present, remove and discard plastic caps from fittings

of new fuel filter canister.

2. Slide new hose clamp onto free end of convoluted tube

(from fuel pump). Install tube onto inlet port at side of

fuel filter canister. If necessary, use a little isopropyl

alcohol or glass cleaner to aid installation. Crimp clamp.

3. Install fuel filter canister as follows:

a. Install new O-ring onto fitting of fuel filter canister.

Insert fitting into fuel pressure regulator assembly,

so that inlet port is on fuel pump side. See C of Fig-

ure 9-17.

b. Slide tab on canister bracket into slot of canopy

weldment until bump on bracket engages depression at side of canister. See B of Figure 9-17.

c. Use hinge to rotate wireform over canister bracket.

Press on wireform until it fully engages slots on canister bracket. See A of Figure 9-17.

f1945x9x

Pull canister bracket from canopy weldment.

C

f1944x9x

Pull canister from fuel pressure regulator.

Figure 9-17. Remove Fuel Filter Canister (FLHR/C/S/I)

CAUTION

Carefully inspect end of convoluted tube for cuts, tears,

holes or other damage. Replace tube if any damage is

found. Even the smallest hole can cause a reduction in

fuel pressure.

4. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

INSTALLATION, or INSTRUMENT CONSOLE/CANOPY, FLHR/C/S/I, INSTALLATION.

FUEL PRESSURE REGULATOR

REMOVAL

1. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

REMOVAL, or INSTRUMENT CONSOLE/CANOPY,

FLHR/C/S/I, REMOVAL.

2. See FUEL FILTER CANISTER, REMOVAL, step 2.

3. Slide fuel pressure regulator assembly forward to free

arms from catches on canopy weldment. See Figure 9-

18.

9-20 2004 Touring: Fuel Injection

Page 21

HOME

CAUTION

Screwdriver

8399

f1943x9x

Figure 9-18. Remove Fuel Pressure Regulator

(FLHR/C/S/I)

5. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

INSTALLATION, or INSTRUMENT CONSOLE/CANOPY, FLHR/C/S/I, INSTALLATION.

FUEL PUMP

REMOVAL

1. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

REMOVAL, or INSTRUMENT CONSOLE/CANOPY,

FLHR/C/S/I, REMOVAL.

2. Depress external latch and remove electrical connector

at top of fuel pump.

3. Using a side cutters, cut hose clamp and pull convoluted

tube from fuel pump outlet port. Exercise caution to

avoid cutting or damaging tube (and cracking or breaking outlet port).

4. Remove T15 TORX screw and pull fuel level sender from

post on fuel pump bracket.

5. Release end of return spring from hook on fuel pump

bracket.

Housing

f1931x9x

Figure 9-19. Fuel Pressure Regulator Assembly

4. Remove fuel pressure regulator from housing. To overcome the resistance of two O-rings, insert blade of small

screwdriver into gap between regulator and housing and

gently pry regulator out. See Figure 9-19.

5. Inspect O-rings for cuts, tears or general deterioration.

Replace the O-rings if they have taken a definite set.

O-Ring

INSTALLATION

1. Apply a thin coat of clean engine oil to new O-rings.

Install O-rings in grooves of fuel pressure regulator. See

Figure 9-19.

2. Install fuel pressure regulator into housing.

3. Fit fuel pressure regulator assembly into canopy weldment engaging arms in catches. See Figure 9-18.

4. See FUEL FILTER CANISTER, INSTALLATION, step 3.

Be absolutely certain fuel pump is faulty before removing hinge from support arm. Hinge is damaged during

removal and requires replacement of the fuel pump and

bracket assembly.

6. Insert flat tip screwdriver at location shown in Figure 9-

20. Carefully crack plastic webbing at top of hinge and

remove from support arm. Discard fuel pump and

bracket assembly.

7. Inspect the condition of the fuel pump wiring. If the wiring needs to be replaced, see FUEL PUMP/FUEL

LEVEL SENDER WIRING on the next page.

Figure 9-20. Crack Hinge to Remove From Support Arm

2004 Touring: Fuel Injection 9-21

Page 22

HOME

INSTALLATION

1. Obtain new fuel pump and bracket assembly. Install new

hinge at top of fuel pump bracket, so that opening of

support arm slot is on the fuel level sender mount side.

2. Slide end of support arm into slot at top of hinge. Pull on

hinge to verify that it is locked by pin on support arm.

Install free end of return spring onto hook on fuel pump

bracket.

CAUTION

Carefully inspect end of convoluted tube for cuts, tears,

holes or other damage. Replace tube if any damage is

found. Even the smallest hole can cause a reduction in

fuel pressure.

3. Slide new hose clamp onto free end of convoluted tube

(to fuel filter canister inlet). Install tube onto outlet port of

fuel pump. Crimp clamp, but exercise caution to avoid

cracking or breaking outlet port.

4. Install electrical connector at top of fuel pump. Gently

tug on connector to verify that external latch is locked

and connector will not come free of terminals.

5. Align two holes in fuel level sender with threaded hole

and post on fuel pump bracket. Install T15 TORX screw

in upper hole and tighten to 25-35 in-lbs (2.8-4.0 Nm).

6. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

INSTALLATION, or INSTRUMENT CONSOLE/CANOPY, FLHR/C/S/I, INSTALLATION.

f1946x9x

Push

Pull

To disengage tabs from windows, simultaneously

pull on one safety pin while pushing on the other.

Pull terminals from wire block and cut.

FUEL PUMP/FUEL LEVEL SENDER WIRING

CAUTION

Do not replace the special teflon coated fuel pump/fuel

level sender wiring with ordinary bulk wire. Ordinary

insulation materials may deteriorate when in contact

with gasoline.

NOTE

Damaged fuel pump and/or fuel level sender wiring requires

replacement of the fuel level sender unit. See FUEL LEVEL

SENDER on this page.

FUEL LEVEL SENDER

REMOVAL

1. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

REMOVAL, or INSTRUMENT CONSOLE/CANOPY,

FLHR/C/S/I, REMOVAL.

f1930x9x

Figure 9-21. Remove Wire Block and Cut Terminals

2. If present, cut cable strap to release wiring at bottom of

support arm.

3. Unwind spiral tubing from fuel pump and fuel level

sender wiring.

4. Depress external latch and remove electrical connector

at top of fuel pump.

5. At bottom of canopy, remove socket terminal from spade

contact on connector clip.

6. Remove T15 TORX screw and pull fuel level sender from

post on fuel pump bracket.

9-22 2004 Touring: Fuel Injection

Page 23

HOME

7. Remove socket terminals from 3-place Mini-Deutsch

connector on canopy. Proceed as follows:

NOTE

For additional clearance, pull wireform to release from slots

on fuel filter canister bracket, and then use hinge to swing

wireform out of the way. Move canister bracket forward to disengage tab from slot on canopy weldment. Remove socket

terminal from spade contact on connector clip.

a. At underside of canopy, take note of the rectangular

opening or window on each side of the connector

body. Now take note of the tab inside each window.

b. Obtain two safety pins. On each side of connector

body, insert a safety pin between body and wire

block until end of each pin appears in window. To

disengage tabs from windows, gently pull on one

safety pin while pushing on the other. See upper

frame of Figure 9-21. With tabs released, gently tug

on wires to release wire block from connector body.

c. Pull the wire socket terminals out of the wire block.

See lower frame of Figure 9-21. Cut off the socket

terminals and back the wires out of the wire block.

d. Insert wire block back into connector body until tabs

lock in windows. One corner of wire block and connector body is square to prevent improper installation.

INSTALLATION

1. Insert socket terminals of new wiring into wire block.

Ta ke note of the table below for wire locations.

Table 9-2. Fuel Level Sender/Fuel Pump

Connector [141], 3-Place Mini-Deutsch

Chamber Wire Color Function

1Orange Pump Power

2Yellow Sender Output

3Black Ground

NOTE

A series of dots are molded into the wire end of the block to

indicate wire location, one dot indicating chamber 1, two dots

chamber 2, three dots chamber 3. (Wire location numbers

are also stamped below the terminals inside the Mini-Deutch

pin housing.)

5. Install electrical connector at top of fuel pump. Gently

tug on connector to verify that external latch is locked

and connector will not come free of terminals.

6. Wind spiral tubing around fuel pump (and fuel level

sender) wiring.

7. Install new cable strap capturing wiring at bottom of support arm. Cut any excess cable strap material.

8. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

INSTALLATION, or INSTRUMENT CONSOLE/CANOPY, FLHR/C/S/I, INSTALLATION.

CANOPY CONNECTOR/O-RING

REMOVAL

1. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

REMOVAL, or INSTRUMENT CONSOLE/CANOPY,

FLHR/C/S/I, REMOVAL.

2. At bottom of canopy, remove socket terminal from spade

contact on connector clip.

3. Remove wire block from connector body as described

under FUEL LEVEL SENDER, REMOVAL, steps 7(a)-

7(b), on this page.

4. Slide connector clip from slots on connector body.

Remove connector body from canopy.

5. Remove O-ring from groove on connector body.

INSTALLATION

1. Apply a very thin film of clean H-D 20W50 engine oil to

O-ring. Install O-ring in groove of connector body.

2. Fit connector body into hole at top of canopy. At underside of canopy, install connector clip engaging slots in

connector body.

3. Insert wire block back into connector body until tabs lock

in windows. One corner of wire block and connector

body is square to prevent improper installation.

4. Install socket terminal onto spade contact on connector

clip.

5. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

INSTALLATION, or INSTRUMENT CONSOLE/CANOPY, FLHR/C/S/I, INSTALLATION.

2. Gently tug on wires to verify that they will not back out of

wire block.

3. Install socket terminal onto spade contact on connector

clip.

4. Align two holes in fuel level sender with threaded hole

and post on fuel pump bracket. Install T15 TORX screw

in upper hole and tighten to 25-35 in-lbs (2.8-4.0 Nm).

FUEL SUPPLY CHECK VALVE/TUBE

NOTE

The in-tank check valve is housed in the quick-connect fitting.

The check valve prevents the fuel tank from draining when

the external supply line is disconnected.

2004 Touring: Fuel Injection 9-23

Page 24

HOME

Convoluted

Tube

O-Ring

Body Hex

Chrome Sleeve

Figure 9-22. Supply Check Valve (Quick-Connect Fitting)

REMOVAL

1. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

REMOVAL, steps 1-13, or INSTRUMENT CONSOLE/

CANOPY, FLHR/C/S/I, REMOVAL, steps 1-12.

1WARNING1WARNING

SUPPLY CHECK VALVE/TUBE

3. Slide a 7/8 inch deepwell socket over chrome sleeve

engaging hex on quick-connect fitting. See Figure 9-22.

Looking down at top of fuel tank, rotate fitting in a cloc

wise direction until it turns easily. Remove the fitting by

hand drawing convoluted tube out through hole at bottom of fuel tank.

f2048x9x

k-

A small amount of gasoline may drain from the fuel supply line when disconnected from the fuel tank. Thoroughly wipe up any spilled fuel immediately. Dispose of

rags in a suitable manner. Gasoline is extremely flammable and highly explosive. Inadequate safety precautions

could result in death or serious injury.

1WARNING1WARNING

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

2. Locate quick-connect fitting on left side of fuel tank. Pull

up on chrome sleeve and pull down on fuel supply line

fitting to disconnect. See Figure 9-11.

1WARNING1WARNING

A small amount of gasoline may drain from the fuel tank

when the quick-connect fitting is removed. Thoroughly

wipe up any spilled fuel immediately. Dispose of rags in

a suitable manner. Inadequate safety precautions could

result in death or serious injury.

INSTALLATION

CAUTION

Carefully inspect convoluted tube for cuts, tears, holes

or other damage. Replace tube (with attached quick-connect fitting) if any damage is found. Even the smallest

hole can cause a reduction in fuel pressure.

1. Apply a very thin film of clean H-D 20W50 engine oil to

new O-ring. Slide O-ring down convoluted tube and into

groove of new quick-connect fitting. See Figure 9-22.

2. Feeding convoluted tube through hole at bottom of fuel

tank, hand thread quick-connect fitting into bore. Looking down at top of fuel tank, rotate fitting in a counterclockwise direction until snug.

3. Slide a 7/8 inch deepwell socket over chrome sleeve

engaging hex on quick-connect fitting. Tighten fitting to

22-26 ft-lbs (29.8-35.3 Nm).

9-24 2004 Touring: Fuel Injection

Page 25

HOME

1WARNING1WARNING

1WARNING1WARNING

Exercise caution to avoid twisting the fuel supply line fitting, as any cracks in the plastic construction of the line

can result in gas leaks. Gas leakage can cause fire or

explosion which could result in death or serious injury.

4. Pull up on chrome sleeve of quick-connect fitting and

insert neck of fuel supply line fitting. While pushing up on

bottom of fitting, pull down on chrome sleeve until it

“clicks” into the locked position.

To avoid an uncontrolled discharge or spray of gasoline,

always be sure the quick-connect fitting is properly

mated. A slight tug on the fuel supply line fitting will verify this condition. Gasoline is extremely flammable and

highly explosive. Inadequate safety precautions could

result in death or serious injury.

5. See CONSOLE POD/CANOPY, FLHT/C/U/I, FLTRI,

INSTALLATION, steps 4-15, or INSTRUMENT CONSOLE/CANOPY, FLHR/C/S/I, INSTALLATION, steps 4-

14.

2004 Touring: Fuel Injection 9-25

Page 26

HOME

NOTES

9-26 2004 Touring: Fuel Injection

Loading...

Loading...