Page 1

H

f2115x8x

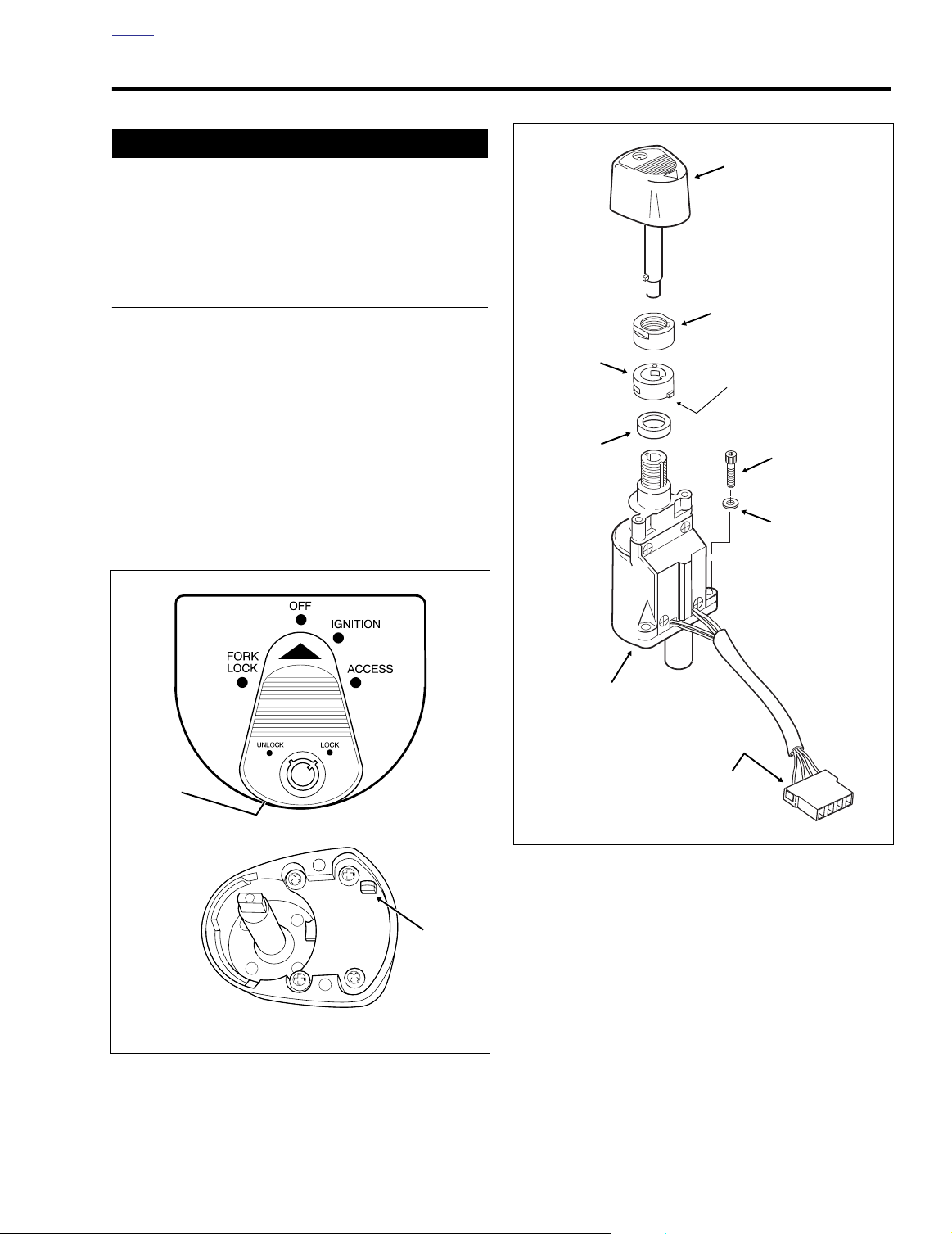

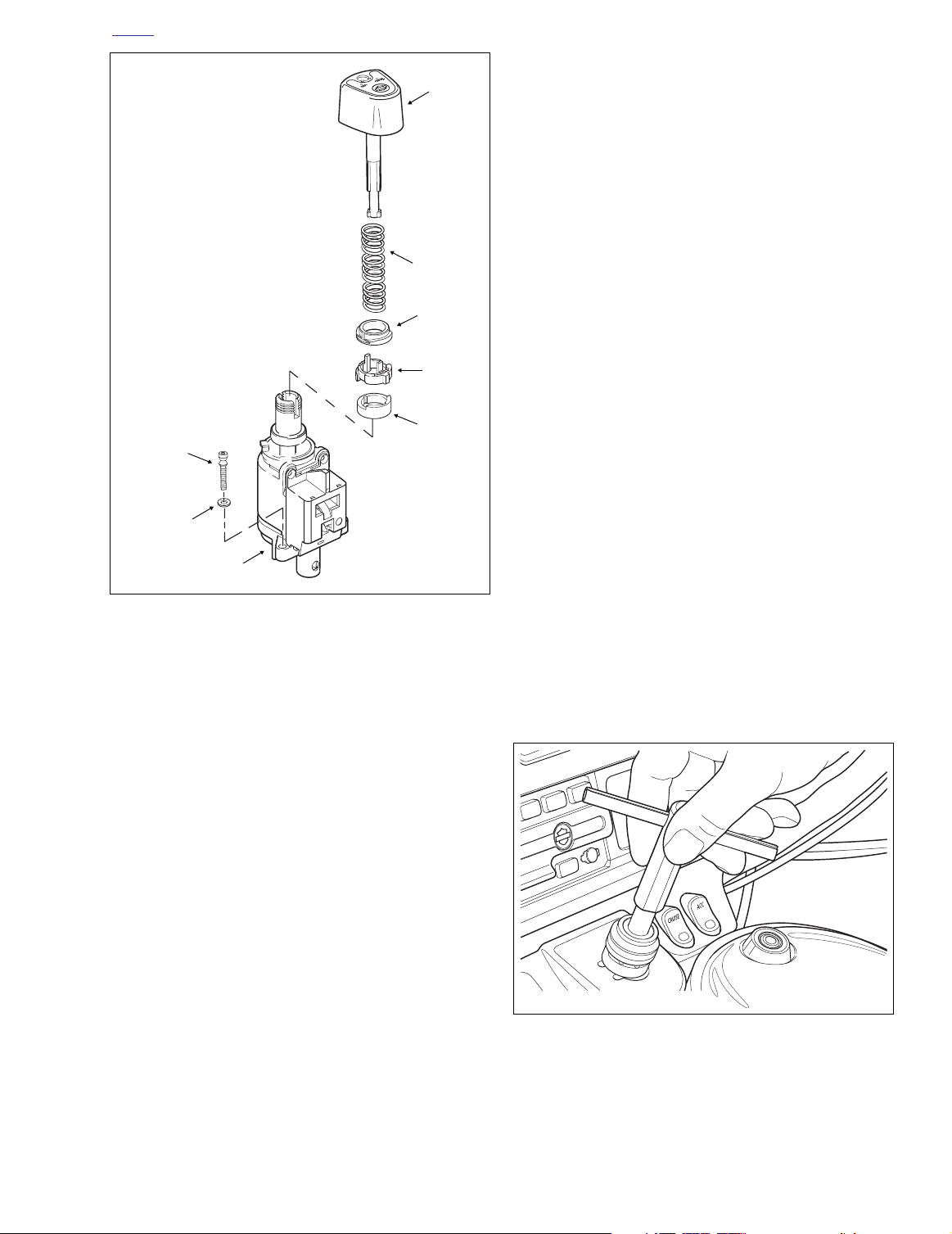

Socket

Screw

Flat

Washer

Switch

Housing

4-Place

Packard

Connector

Spacer

Collar

Nut

Knob

Tab

Down and Forward

OME

IGNITION/LIGHT KEY SWITCH AND FORK LOCK 8.18

1WARNING1WARNING

DO NOT modify the ignition/light key switch wiring to

disable the automatic-on headlamp feature. High visibility is an important safety consideration for motorcycle

riders. Ensure that the headlamp is on at all times. Failure to do so could result in death or serious injury.

FLHT/C/U, FLTR (DOMESTIC)

REMOVAL

1. Remove the outer fairing. See Section 2.29 UPPER

FAIRING/WINDSHIELD (FLHT/C/U), OUTER FAIRING/

WINDSHIELD, REMOVAL.

2. To remove the ignition switch knob, insert the Ignition

Switch key and turn to the UNLOCK position. Leaving

the key installed, rotate the knob to ACCESS. Depressing the release button at bottom (left side) with a small

screwdriver, push key down and turn an additional 60

degrees in a counter-clockwise direction. Lift and

remove knob. See Figure 8-61.

f1240x2x

Button

f1476x8x

Figure 8-61. Ignition Switch Knob Release Button

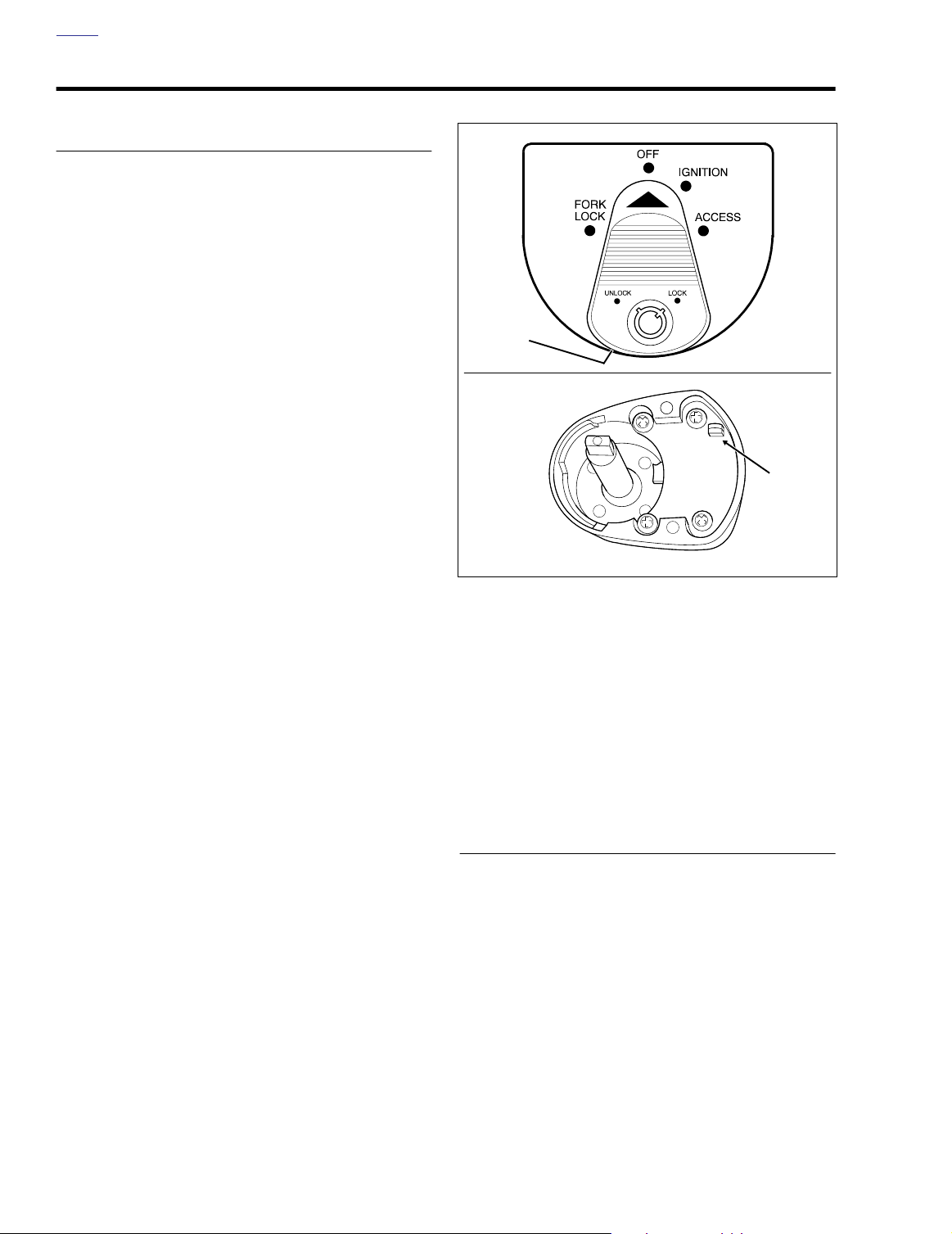

TOP VIEW

Button

BOTTOM VIEW

Figure 8-62. Ignition Switch Assembly (Domestic)

3. Using a 7/8 inch wrench on flats, loosen switch nut and

remove from threaded post of ignition switch housing.

Remove collar and spacer. See Figure 8-62.

4. Using a T27 TORX drive head, remove the two screws

(with flat washers) that secure fairing cap to left and right

sides of inner fairing.

5. Remove the switch position plate by pulling tabs from

slots in fairing cap. If necessary, raise the fairing cap

slightly to facilitate removal.

2004 Touring: Electrical 8-49

Page 2

H

OME

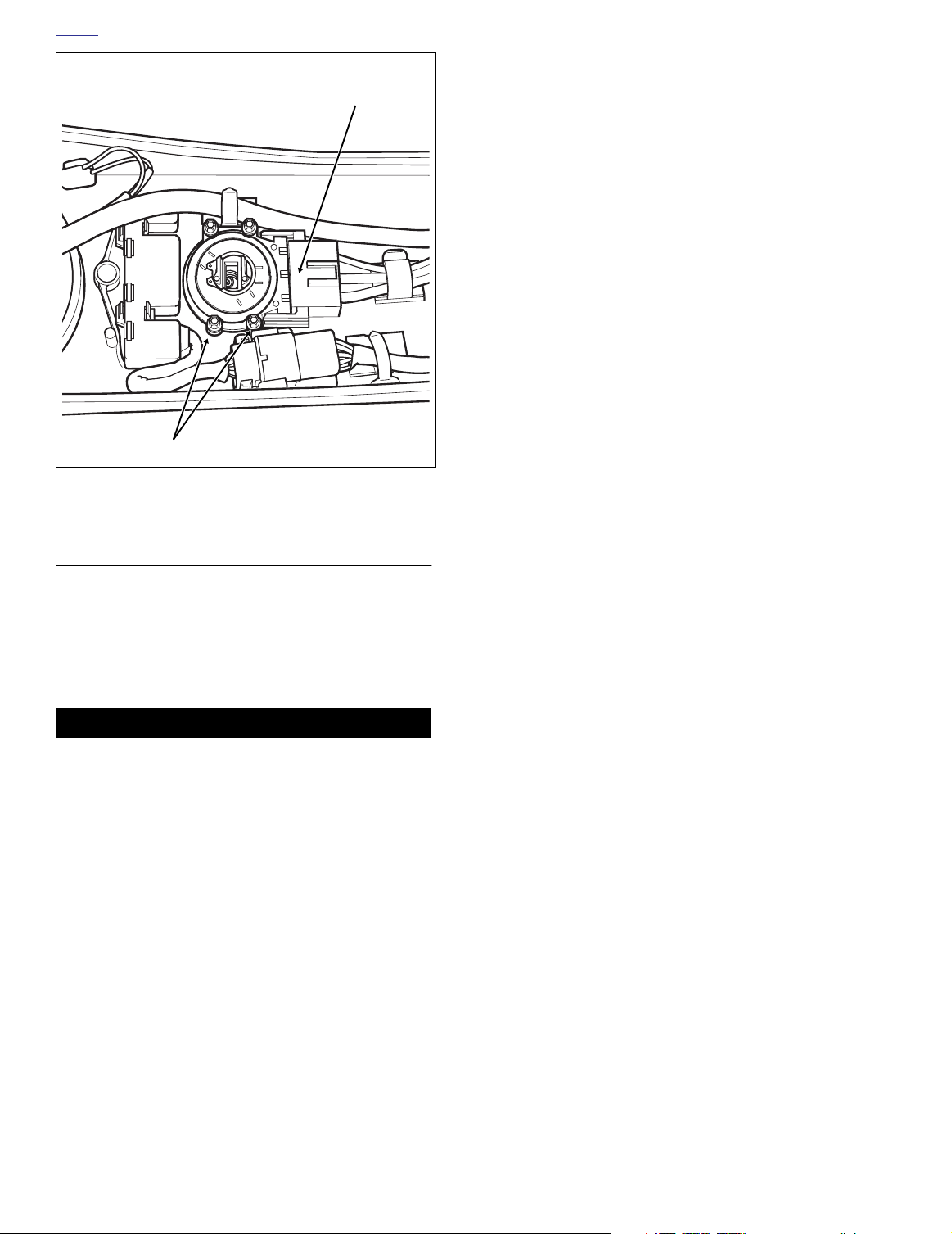

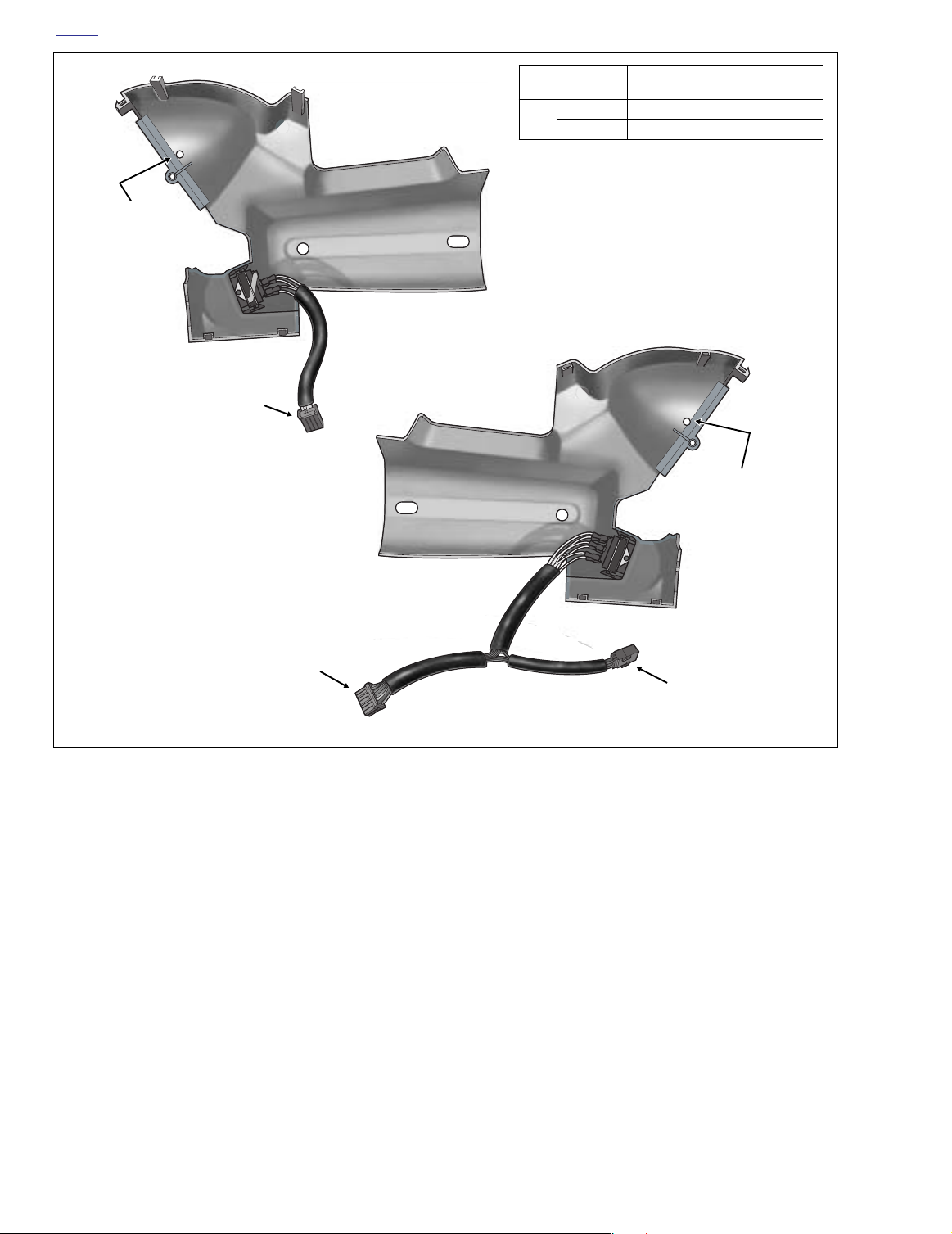

6. With the forks turned fully to the left, disconnect the Fairing cap switch connector [105], 12-place Multilock

(black), from behind right side of fairing cap. Depress the

button on the plug side of the connector to pull apart the

pin and socket halves.

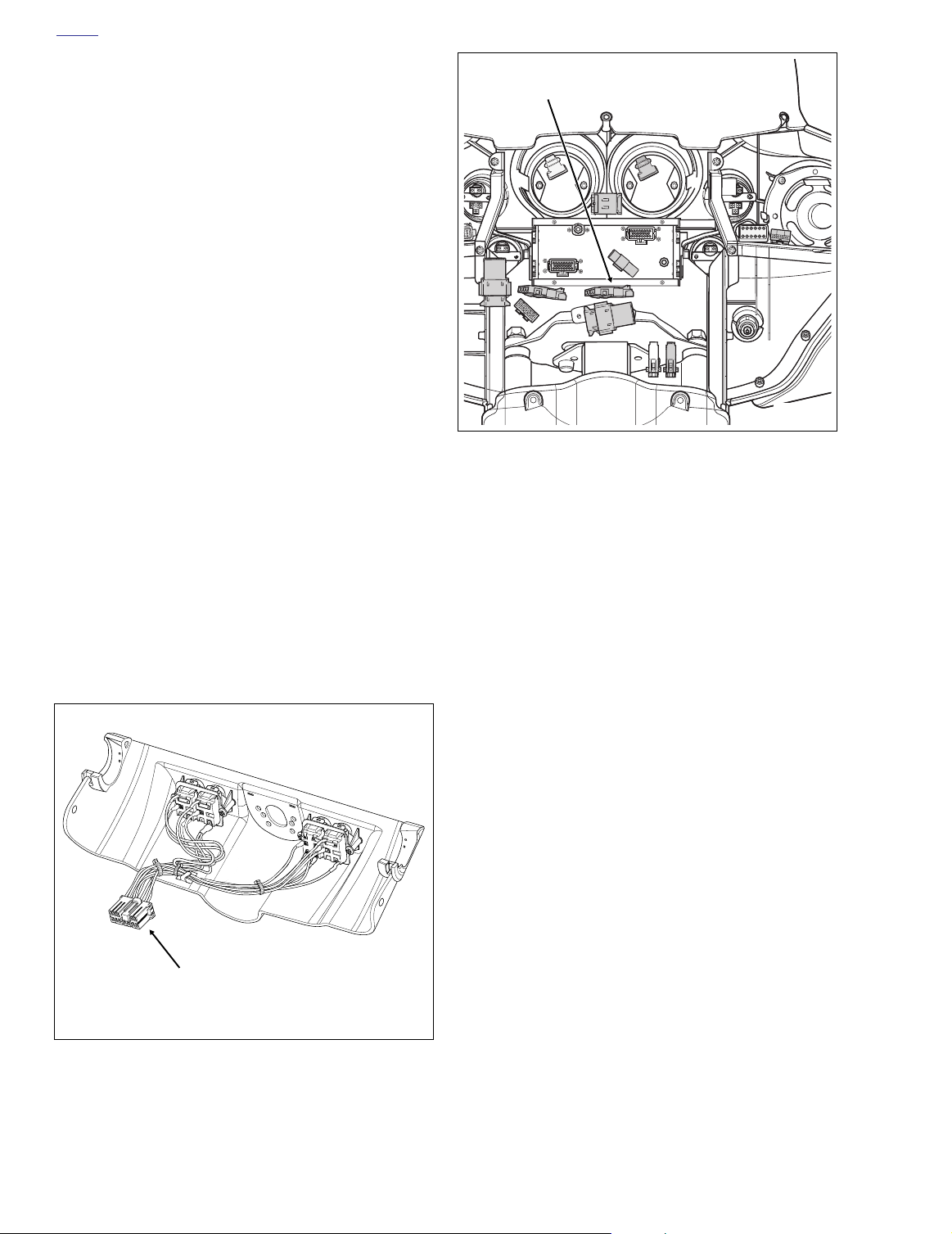

7. Remove the fairing cap from the motorcycle. See Figure

8-63.

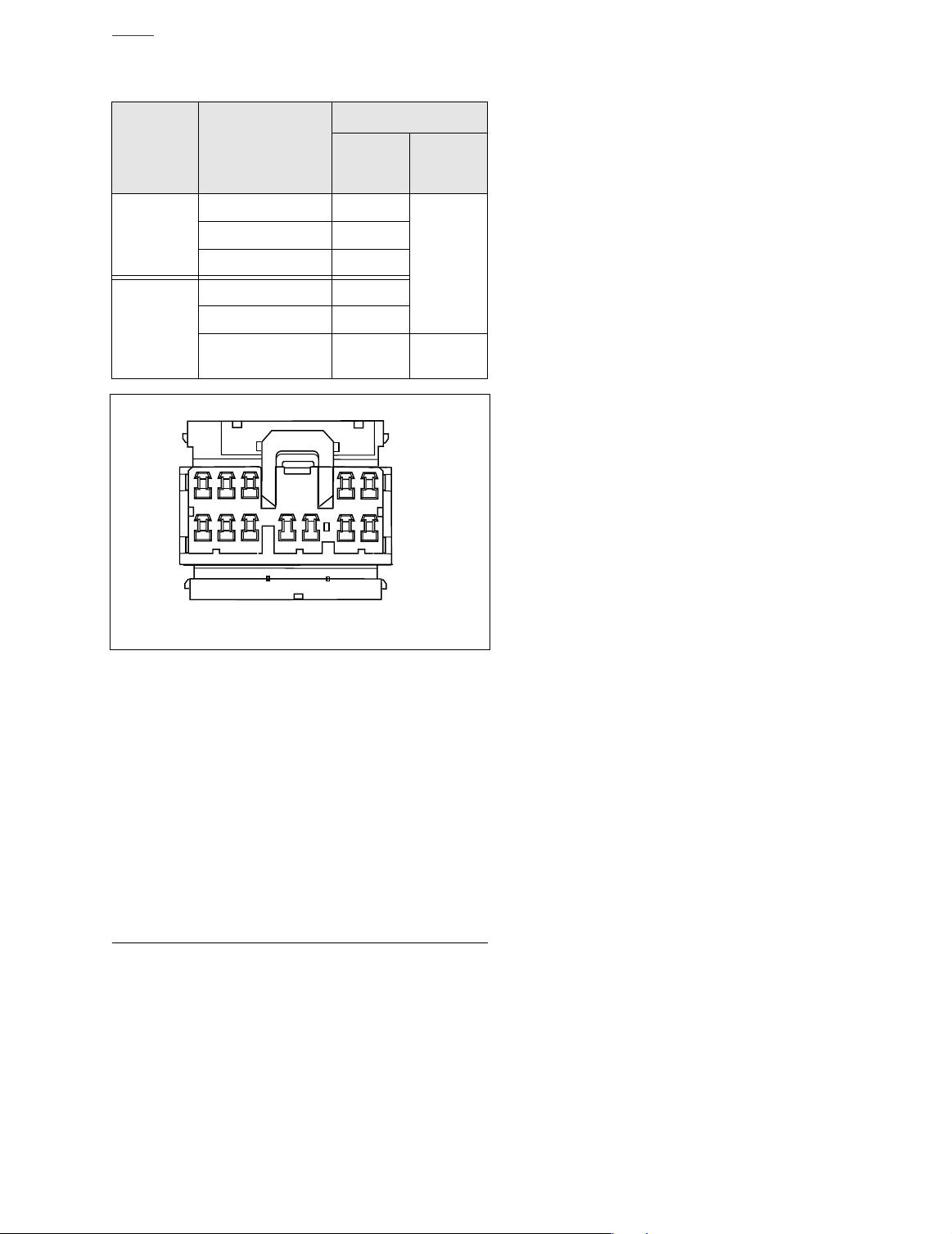

8. Locate the Ignition switch connector [33], 4-place Packard, at bottom of radio. Slide connector off anchor and

separate pin and socket halves. See Figure 8-64.

9. Remove the socket screws (with flat washers) and lift the

switch housing from the upper fork bracket bore. Route

the Ignition switch connector to rear of inner fairing and

remove switch housing from the vehicle.

INSTALLATION

1. Slide base of ignition switch into bore of upper fork

bracket. Install screws (with flat washers) and tighten to

36-60

in-lbs

(4.1-6.8 Nm).

2. Route the Ignition switch connector [33], 4-place Packard, to front of inner fairing. Mate pin and socket halves

of connector and install onto anchor at bottom of radio.

See Figure 8-64.

3. Verify that the rubber grommets are installed on each

side of the fairing cap. Barbs on cap fit into holes in

grommets.

4. Connect the Fairing cap switch connector [105], 12place Multilock (black), on the right side of fairing cap.

5. With the forks turned fully to the left, install fairing cap

over ignition switch housing.

f1305b2x

Ignition Switch

Connector [33]

f2238x8x

Figure 8-64. Ignition Switch Connector Location

(FLHT/C/U)

6. Install switch position plate fitting tabs in slots of fairing

cap. Plate snaps in place when properly installed. Exercise care to avoid breaking tabs. Replace plate if tabs

are broken.

7. Using a T27 TORX drive head, start two fairing cap

screws (with flat washers). Verify that grommets in fairing cap fully capture handlebar along with throttle and

clutch cables.

8. Slide spacer over threaded post of ignition switch housing until it contacts switch position plate. Slide collar over

post with the tab side down (and forward). Install nut,

and using a 7/8 inch wrench on flats, tighten to 50-70

lbs

(5.7-7.9 Nm).

in-

Fairing Cap

Switch Connector [105]

12-Place Multilock

Figure 8-63. Fairing Cap Assembly (FLHT/C/U)

8-50 2004 Touring: Electrical

9. With the red arrow pointing toward the ACCESS position, install the ignition switch knob. Turn key clockwise

to UNLOCK position and then turn knob to OFF.

10. Using a T27 TORX drive head, tighten two fairing cap

screws to 25-30

in-lbs

(2.8-3.4 Nm).

11. Verify operation of both the ignition switch and fork lock

assemblies.

12. Install the outer fairing. See Section 2.29 UPPER FAIR-

ING/WINDSHIELD (FLHT/C/U), OUTER FAIRING/

WINDSHIELD, INSTALLATION.

Page 3

H

f2086x8x

OME

FLHT/C/U, FLTR (INTERNATIONAL)

REMOVAL

1. Remove the ignition switch knob as follows:

a. Insert the ignition switch key and turn to the

UNLOCK position. Leave the key installed in the

ignition switch knob.

b. Tu rn the front forks to the left fork stop and rotate

the knob to FORK LOCK.

c. Depressing the release button at bottom (left side)

with a small screwdriver, push key down and turn 60

degrees in a counter-clockwise direction. See Fig-

ure 8-65.

d. Lift and remove knob. Be aware that spring will drop

out of bore at underside of knob when removed.

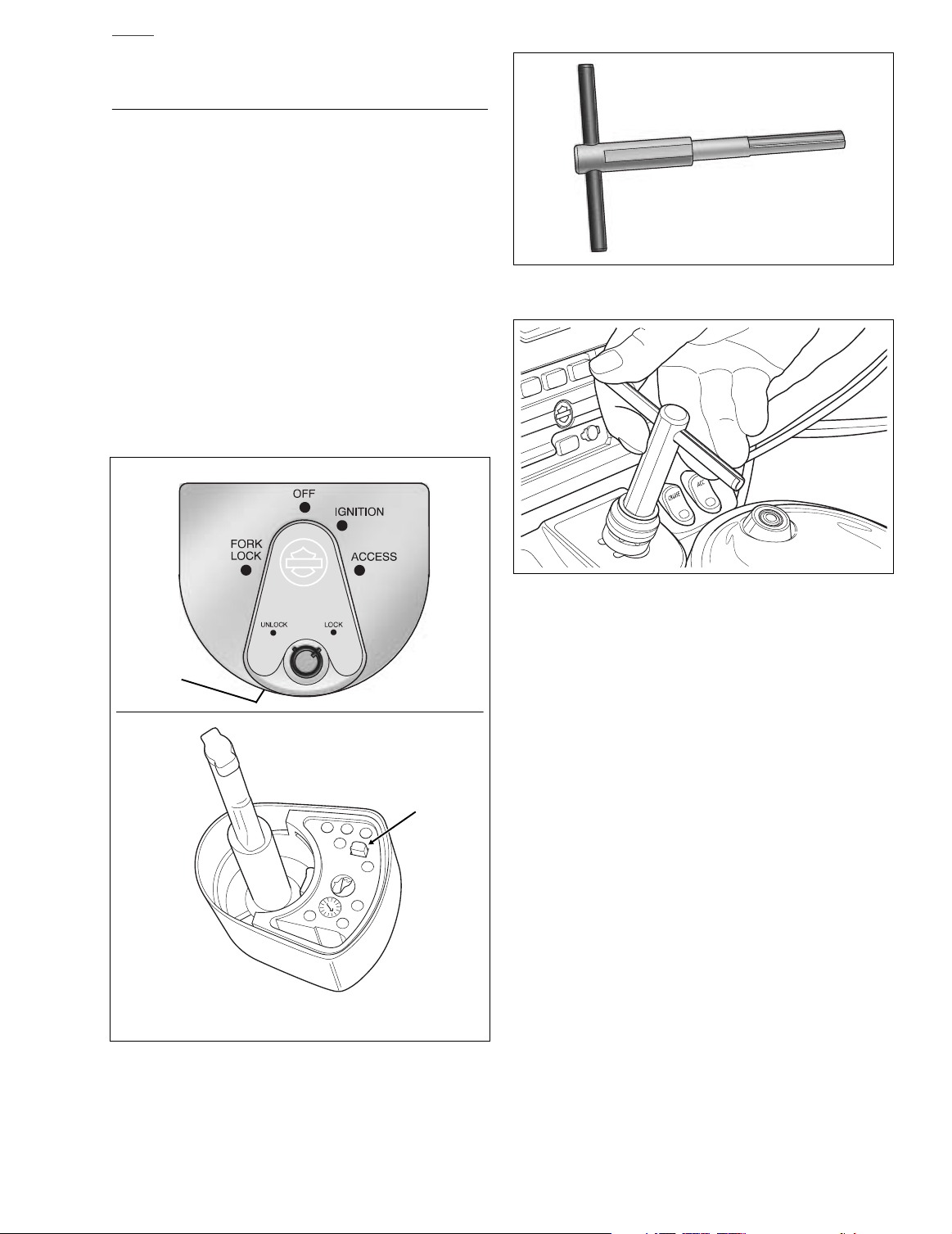

Figure 8-66. Ignition Switch Alignment Tool

(Part No. HD-45962)

f2080x8x

Button

f2097x8x

Figure 8-65. Ignition Switch Knob Release Button

TOP VIEW

Button

BOTTOM VIEW

Figure 8-67. Bottom Alignment Tool in Threaded Post

and Rotate to Desired Position

NOTE

After removal of the knob, the IGNITION SWITCH ALIGNMENT TOOL (HD-45962) may be used to move the switch to

other positions as required. Insert tool until bottom of handle

contacts top of threaded post, and then rotate handle in a

clockwise direction to the selected position. See Figure 8-67.

2. Turn the front forks to the right fork stop, and using a 7/8

inch open end wrench on flats, remove nut from

threaded post of ignition switch housing.

3. Pull collar and spacer from threaded post.

4. Remove the switch position plate by pulling tabs from

slots in fairing cap (FLHT/C/U) or instrument nacelle

(FLTR).

5.

FLTR:

Remove the instrument nacelle. See Section 2.30

UPPER FAIRING/WINDSHIELD (FLTR), INSTRUMENT

NACELLE, REMOVAL.

FLHT/C/U:

UPPER FAIRING/WINDSHIELD (FLHT/C/U), FAIRING

CAP, REMOVAL.

Remove the fairing cap. See Section 2.29

2004 Touring: Electrical 8-51

Page 4

H

OME

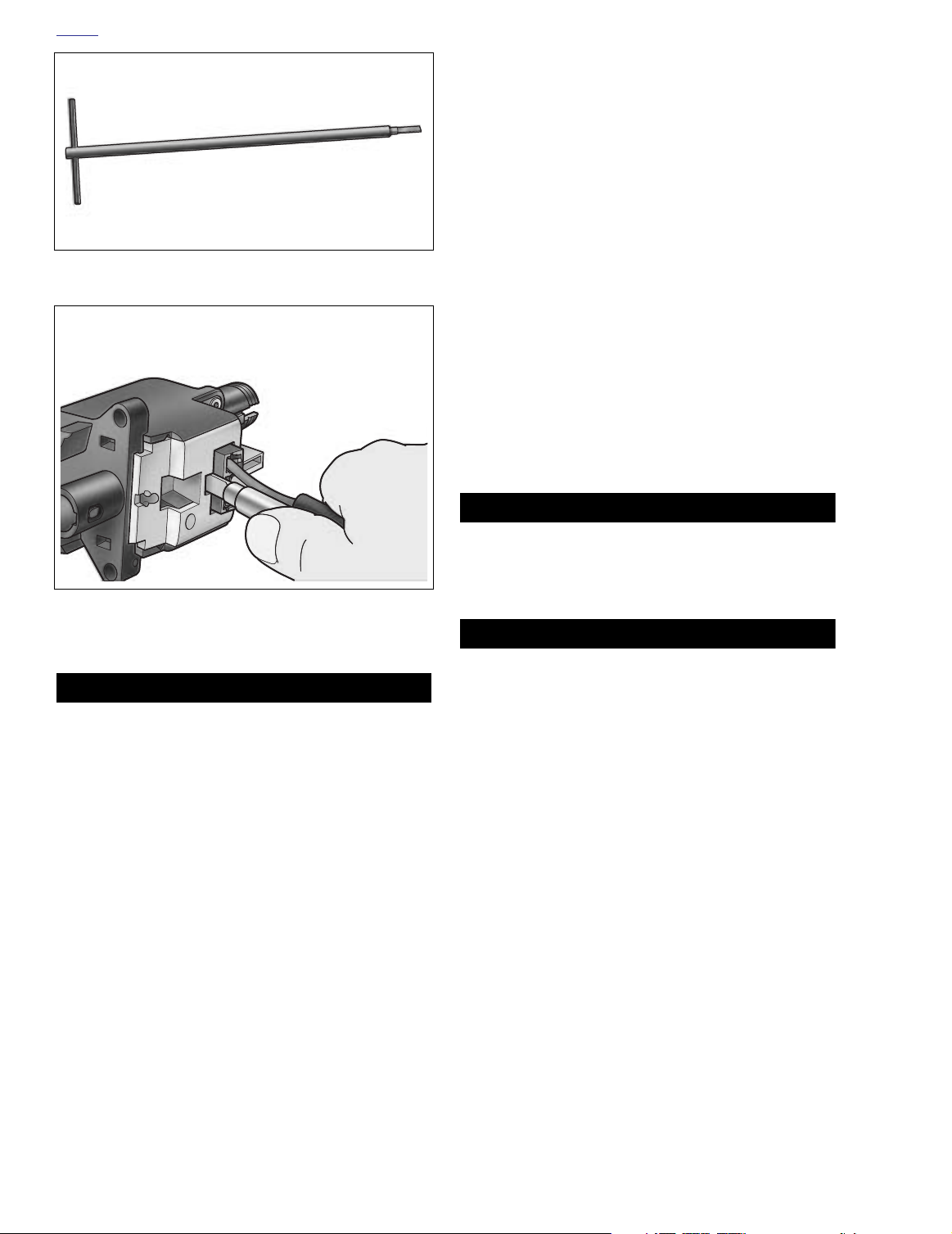

Figure 8-68. Ignition Switch Connector Remover

(Part No. HD-45961)

f2090x8x

8. Disconnect the ignition switch jumper harness connector

[33], 3-place Packard, at front of ignition switch housing.

Proceed as follows:

a. Obtain the IGNITION SWITCH CONNECTOR

REMOVER (HD-45961). See Figure 8-68.

b. Gently insert end of tool into slot in ignition switch

housing until it stops.

c. Grasping jumper harness conduit and tool, pull both

at the same time to release socket housing from

ignition switch housing. See Figure 8-69.

NOTE

For instructions on properly removing and installing jumper

harness terminals, see APPENDIX B.4 AUTOFUSE ELEC-

TRICAL CONNECTOR.

INSTALLATION

1. Install Ignition switch jumper harness connector [33], 3place Packard, at front of

2. Slide base of ignition switch housing into bore of upper

fork bracket.

new

ignition switch housing.

Figure 8-69. Pull Jumper Harness Conduit and Tool

to Release Socket Housing

1WARNING1WARNING

Always wear proper eye protection when drilling. Flying

debris may result in eye injury.

6. Remove the two break-away screws at the base of the

ignition switch housing. Proceed as follows:

a. Use a center punch to make a pilot hole at the top of

each break-away screw.

b. Install a 1/8 inch left handed bit in drill and set the

drill to Reverse. Positioning the bit in the pilot hole,

spin out the break-away screws.

NOTE

If the above method fails, use a 3/16 inch bit with long shank

to carefully drill off heads of break-away screws. Use a pliers

to unthread the shafts from the upper fork bracket.

7. Remove ignition switch housing from upper fork bracket

bore.

CAUTION

Verify that the threads in the upper fork bracket are clean

and in good condition. Dirty and/or damaged threads

may cause the heads of the break-away screws to snap

off before the switch housing is properly tightened.

CAUTION

Exercise care to avoid losing heads of break-away

screws in vehicle. Vibration may cause captured heads

to scratch finished surfaces, chafe wires or cause other

damage.

3. Install

4.

5. Install switch position plate fitting tabs in slots of fairing

6. Install spacer over threaded post of ignition switch hous-

new

break-away screws at base of ignition switch

housing. Turn screws in a clockwise direction until heads

snap off.

FLTR:

Install the instrument nacelle. See Section 2.30

UPPER FAIRING/WINDSHIELD (FLTR), INSTRUMENT

NACELLE, INSTALLATION.

FLHT/C/U:

UPPER FAIRING/WINDSHIELD (FLHT/C/U), FAIRING

CAP, INSTALLATION.

cap (FLHT/C/U) or instrument nacelle (FLTR). Plate

snaps in place when properly installed. Exercise care to

avoid breaking tabs. Replace plate if tabs are broken.

ing until it contacts switch position plate. Orient spacer

so that the widest side is forward and the inside tabs fit

in slots of post. See Figure 8-70.

Install the fairing cap. See Section 2.29

8-52 2004 Touring: Electrical

Page 5

H

f2087x8x

OME

1. Knob

2. Spring

3. Nut

4. Collar

5. Spacer

6. Break-Away Screw

7. Flat Washer

8. Switch Housing

12. Knob was removed in ACCESS or switch may have

1

2

3

been moved out of the FORK LOCK position. Proceed

as follows:

a. Insert alignment tool until bottom of handle contacts

top of threaded post, and holding front forks at the

left fork stop, rotate handle of tool in a counterclockwise direction until fork locks. See Figure 8-67.

b. Remove tool and repeat step 10.

c. If knob does not install properly, move to step 13.

13. Detent and switch position lugs are misaligned. This can

occur when the alignment tool (or ignition switch knob) is

rotated before it is properly bottomed in the ignition

switch housing. Proceed as follows:

4

5

6

7

8

Figure 8-70. Ignition Switch Assembly (International)

7. Slide collar over threaded post until it contacts spacer.

Orient collar so that the outside tab is forward and the

inside tabs fit in slots of post.

8. Thread nut onto post with the lipped side down and the

smaller OD topside. Turn the front forks to the right fork

stop, and using a 7/8 inch Open End Crow Foot on flats,

tighten nut to 125-150

9. Install spring into bore at underside of knob.

10. With the knob pointing toward the FORK LOCK position,

insert shaft into threaded post. Holding the knob down,

turn key clockwise to UNLOCK. An audible “click” should

be heard when knob and switch are properly engaged.

Release knob and then rotate through all four switch

positions to verify proper operation.

If knob will not install properly, move to step 11.

11. Proceed as follows:

a. Verify that button at bottom of knob is depressed

and key is turned 60 degrees beyond the UNLOCK

position. See Figure 8-65.

b. Repeat step 10.

c. If knob does not install properly, move to step 12.

in-lbs

(14.1-16.9 Nm).

f2116x8x

a. Reinstall knob inserting shaft into threaded post and

gently rotate knob until it drops into the partially

installed position. Take note of the position of the

knob, that is, whether it is pointing toward the rear,

or to ACCESS, IGNITION or OFF.

b. Remove knob and insert alignment tool so that the

bottom of the handle is approximately 1/2-3/4 inch

(12.7-19.1 mm) from the top of the threaded post,

and then hold. See Figure 8-71.

c. Rotate alignment tool in a counter-clockwise

direction the number of positions needed to get to

FORK LOCK. For example, if the knob dropped into

the partially installed position at IGNITION in step

13(a), rotate the alignment tool two positions in a

counter-clockwise direction. Or if the knob was

pointing toward the rear when it dropped, rotate the

alignment tool four positions in a counter-clockwise

direction or one position in a clockwise direction.

Repeat step 10.

Figure 8-71. Rotate Alignment Tool Without Bottoming

2004 Touring: Electrical 8-53

Page 6

H

OME

Ignition/Light

Key Switch Connector [33]

Screw

Figure 8-72. Instrument Console (FLHR/C)

f2095x8x

FLHR/C/S

IGNITION/LIGHT KEY SWITCH

Removal

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

3. Carefully cut anchored cable strap securing main harness bundle, instrument console conduit, and fuel vapor

vent tube to left side of frame backbone.

6. Raise instrument console and bend back flexible clamp

on canopy to release main harness conduit. Depress

button on socket side and remove fuel level sender/fuel

pump connector [141], 3-place Mini-Deutsch.

7. Lay a clean shop towel on forward part of rear fender.

Lift the instrument console from fuel tank and lay upside

down on shop towel.

8. Pull external latches outward to disconnect ignition/light

key switch connector [33], 3-place Packard. See Figure

8-72.

9. Remove four screws to release switch from console.

Installation

1. Align holes in

ure 8-72.

2. Start four screws and alternately tighten to 20-30

(2.3-3.4 Nm) in a crosswise pattern.

3. Connect ignition/light key switch connector [33], 3-place

Packard.

4. Slide head of console mounting bolt into slot at top of

canopy.

5. Moving instrument console toward installed position,

install fuel level sender/fuel pump connector [141], 3place Mini-Deutsch, at top of canopy. Bend flexible

clamp to capture main harness conduit.

6. Align hole in instrument console with console mounting

bolt and place into position on fuel tank.

7. Install acorn nut at top of instrument console and tighten

to 50-90

Phillips screw and large flat washer (absent on FLHRS

models). Tighten screw to 36-60

8. On FLHRS models only, install bolt (with flat washer) to

secure rear of fuel tank and instrument console bracket

to frame backbone. Tighten bolt to 15-20 ft-lbs (20-27

Nm).

9. Snap anchor of

frame backbone. Tighten cable strap capturing main harness bundle, instrument console conduit, and fuel vapor

vent tube. Cut any excess cable strap material.

10. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

11. Install seat. See Section 2.24 SEAT, INSTALLATION.

new

switch with those in console. See Fig-

in-lbs

(5.7-10.2 Nm). If present, also install

in-lbs

(4.1-6.8 Nm).

new

cable strap into hole on left side of

in-lbs

(6.8-10.9 Nm).

in-lbs

4. Remove acorn nut from instrument console. If present,

also remove Phillips screw and large flat washer (absent

on FLHRS models).

5. On FLHRS models only, remove bolt (with flat washer) to

free rear of fuel tank from frame backbone. Removal of

rear bolt also releases instrument console bracket.

8-54 2004 Touring: Electrical

FORK LOCK

Removal

1. Remove the handlebar clamp shroud. See Section 2.31

WINDSHIELD/HEADLAMP NACELLE (FLHR/C/S),

NACELLE REMOVAL (FLHR/C), steps 1-11, or

NACELLE REMOVAL (FLHRS), steps 1-7.

Page 7

H

OME

f2101x8x

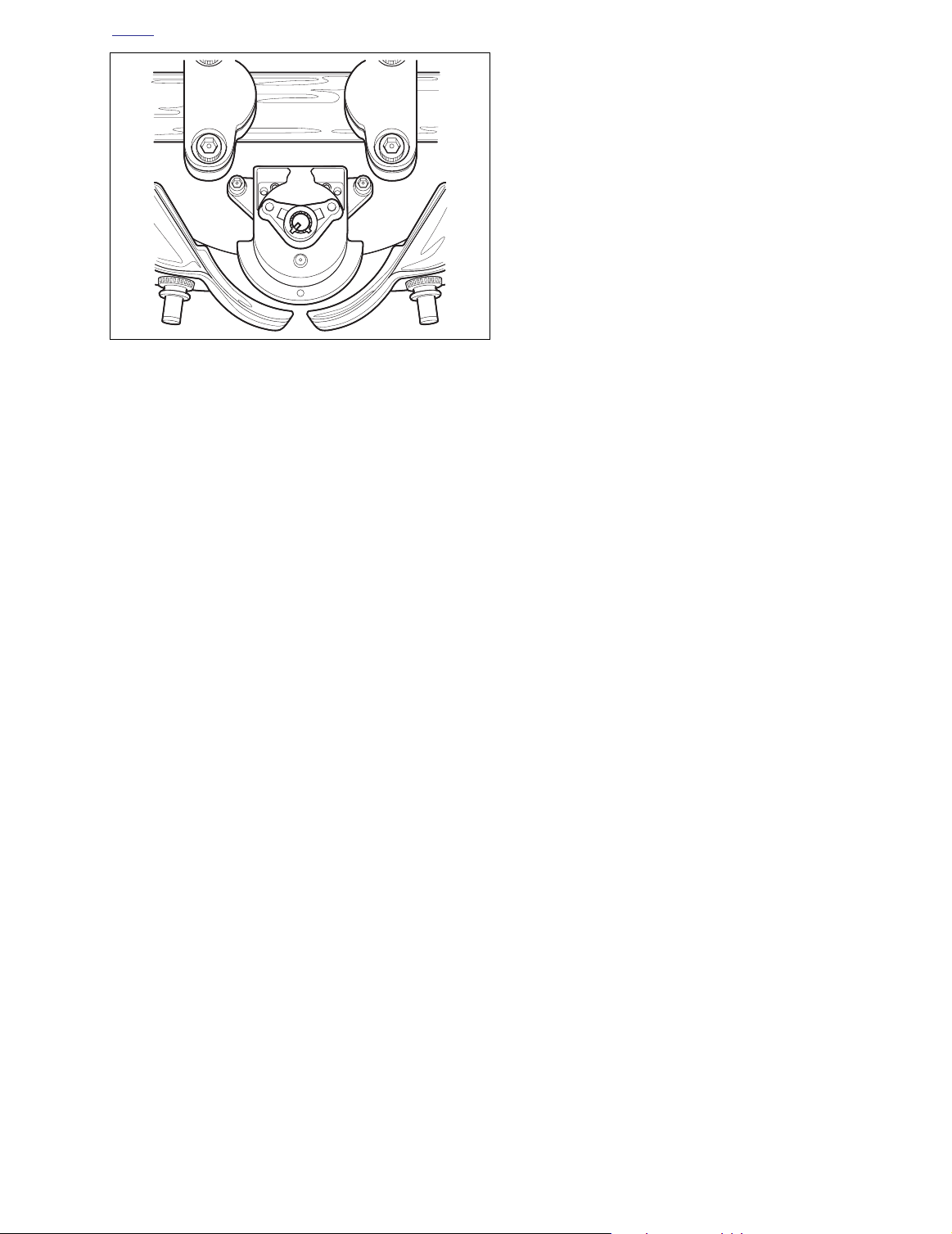

Figure 8-73. Fork Lock (FLHR/C/S)

2. Start acorn nuts on both the left and right side fork studs

to keep halves of headlamp nacelle on motorcycle.

3. Remove two allen head socket screws (with flat washers) and pull fork lock assembly from upper fork bracket

bore. See Figure 8-73.

3. Install the handlebar clamp shroud. See Section 2.31

WINDSHIELD/HEADLAMP NACELLE (FLHR/C/S),

NACELLE INSTALLATION (FLHR/C), steps 3-15, or

NACELLE INSTALLATION (FLHRS), steps 5-13.

NOTE

On HDI models, use a center punch to make a pilot hole at

the top of each break-away screw. Install a 1/8 inch left

handed bit in drill and set the drill to reverse. Positioning the

bit in the pilot hole, spin out the break-away screws.

Installation

1. Install

2. Install two allen head socket screws (with flat washers)

On HDI models, install

clockwise direction until heads snap off. Verify that threads in

upper fork bracket are clean and in good condition or heads

may break off before fork lock assembly is properly tightened.

Avoid losing heads of screws in vehicle as vibration may

cause captured heads to scratch finished surfaces, chafe

wires or cause other damage.

new

fork lock assembly into bore of upper fork

bracket. See Figure 8-73.

and alternately tighten to 36-60

NOTE

new

break-away screws and turn in a

in-lbs

(4.1-6.8 Nm).

2004 Touring: Electrical 8-55

Page 8

H

OME

FAIRING CAP SWITCHES (FLHTC/U) 8.19

REMOVAL

1. Partially disassemble domestic ignition switch as follows:

NOTE

For partial disassembly of HDI ignition switch, see Section

8.18 IGNITION/LIGHT KEY SWITCH AND FORK LOCK,

FLHT/C/U, FLTR (INTERNATIONAL), REMOVAL, steps 1-4.

a. See Figure 8-74. To remove the ignition switch

knob, insert the Ignition Switch key and turn to the

UNLOCK position. Leaving the key installed, rotate

the knob to ACCESS. Depressing the release button at bottom (left side) with a small screwdriver,

push key down and turn an additional 60 degrees in

a counter-clockwise direction. Lift and remove knob.

b. Using a 7/8 inch wrench on flats, loosen switch nut

and remove from threaded post of ignition switch

housing. Remove collar and spacer.

c. Gently remove the switch position plate by pulling

tabs from slots in fairing cap. If necessary, raise the

fairing cap slightly to facilitate removal.

2. Using a T27 TORX drive head, remove the two screws

(with flat washers) that secure fairing cap to left and right

sides of inner fairing.

3. With the forks turned fully to the left, disconnect the fairing cap switch connector [105], 12-place Multilock

(black), from behind right side of fairing cap. Depress the

button on the socket terminal side of the connector and

pull apart the pin and socket halves.

4. Remove the fairing cap from the motorcycle. See Figure

8-75.

5. Bend back the flexible clamp to release switch wires

from the inboard side of the fairing cap. Carefully cut

cable straps to free wires from bundles.

f1240x2x

Button

BOTTOM VIEW

f1476x8x

Figure 8-74. Ignition Switch Knob Release Button

10. Remove the appropriate terminals from the socket housing.

NOTE

For instructions on properly removing wire terminals, see

APPENDIX B.2 AMP MULTILOCK ELECTRICAL CONNEC-

TORS, REMOVING SOCKET/PIN TERMINALS.

TOP VIEW

Button

6. Using a T25 TORX drive head, remove two screws to

release switch bracket.

7. Gently pry two latches on bracket outward to release

tabs on switch. Remove switch from bracket. See Figure

8-76.

8. If replacing Cruise or Speaker Switch, cut Black/Green

wire lead halfway between Cruise and Speaker Switch

terminals.

9. Follow the wires of the faulty switch to the socket housing, or reference Figure 8-77 and Table 8-10 for the

applicable chamber numbers. For wire location purposes, numbers are stamped into the secondary locks of

both the pin and socket housings.

8-56 2004 Touring: Electrical

INSTALLATION

1. Feeding wires through bracket, place

position. Engage tabs on switch in slots of latches and

then gently bend tabs upward to lock position of switch

in bracket.

2. Install terminals into socket housing.

NOTE

For instructions on properly installing wire terminals, see

APPENDIX B.2 AMP MULTILOCK ELECTRICAL CONNEC-

TORS, INSTALLING SOCKET/PIN TERMINALS.

new

switch into

Page 9

H

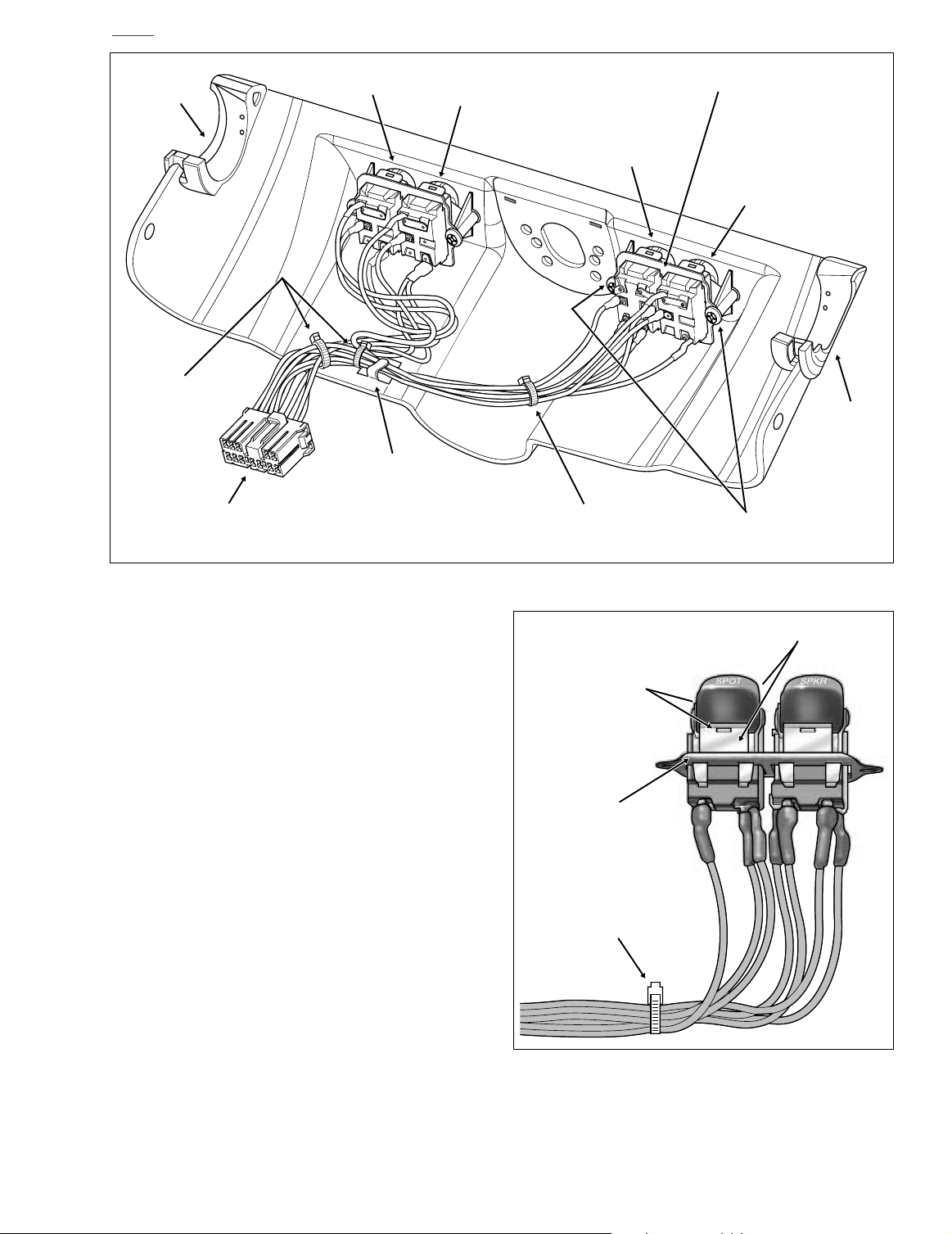

f1304b2x

Cable

Strap

Switch

Bracket

Tab

Latch

OME

Grommet

Cable

Strap

Socket Housing

12-place Multilock

Fairing Cap Switch Connector [105]

Accessory

Switch

Flexible

Clamp

Cruise

Switch

Speaker

Cable

Strap

Switch

Switch

Bracket

Spotlight

Switch

Switch Bracket

TORX Screws

f1305b2x

Grommet

Figure 8-75. Fairing Cap (Inboard Side) - Ultra Model Shown

3. If Cruise or Speaker Switch was replaced, butt splice

Black/Green wire lead between Cruise and Speaker

Switch terminals.

NOTE

For detailed butt splicing information, see APPENDIX B.5

SEALED BUTT SPLICE CONNECTORS.

4. Using a T25 TORX drive head, install two screws to

secure switch bracket to fairing cap.

5. Install

new

cable straps to capture wire bundles and

then secure switch wires to the fairing cap using the flexible clamp. Route the wires as shown in Figure 8-75.

6. Verify that the rubber grommets are installed on each

side of the fairing cap. Barbs on cap fit into holes in

grommets.

7. Connect the fairing cap switch connector [105], 12-place

Multilock (black), on the right side of fairing cap.

8. With the forks turned fully to the left, install fairing cap

over ignition switch housing. Verify that grommets in fairing cap fully capture handlebar along with throttle and

clutch cables.

9. Start two fairing cap screws (with flat washers). Using a

T27 TORX drive head, alternately tighten screws to 2530

in-lbs

(2.8-3.4 Nm).

Figure 8-76. Bend Latches Outward to Release Tabs

2004 Touring: Electrical 8-57

Page 10

H

OME

10. Assemble domestic ignition switch as follows:

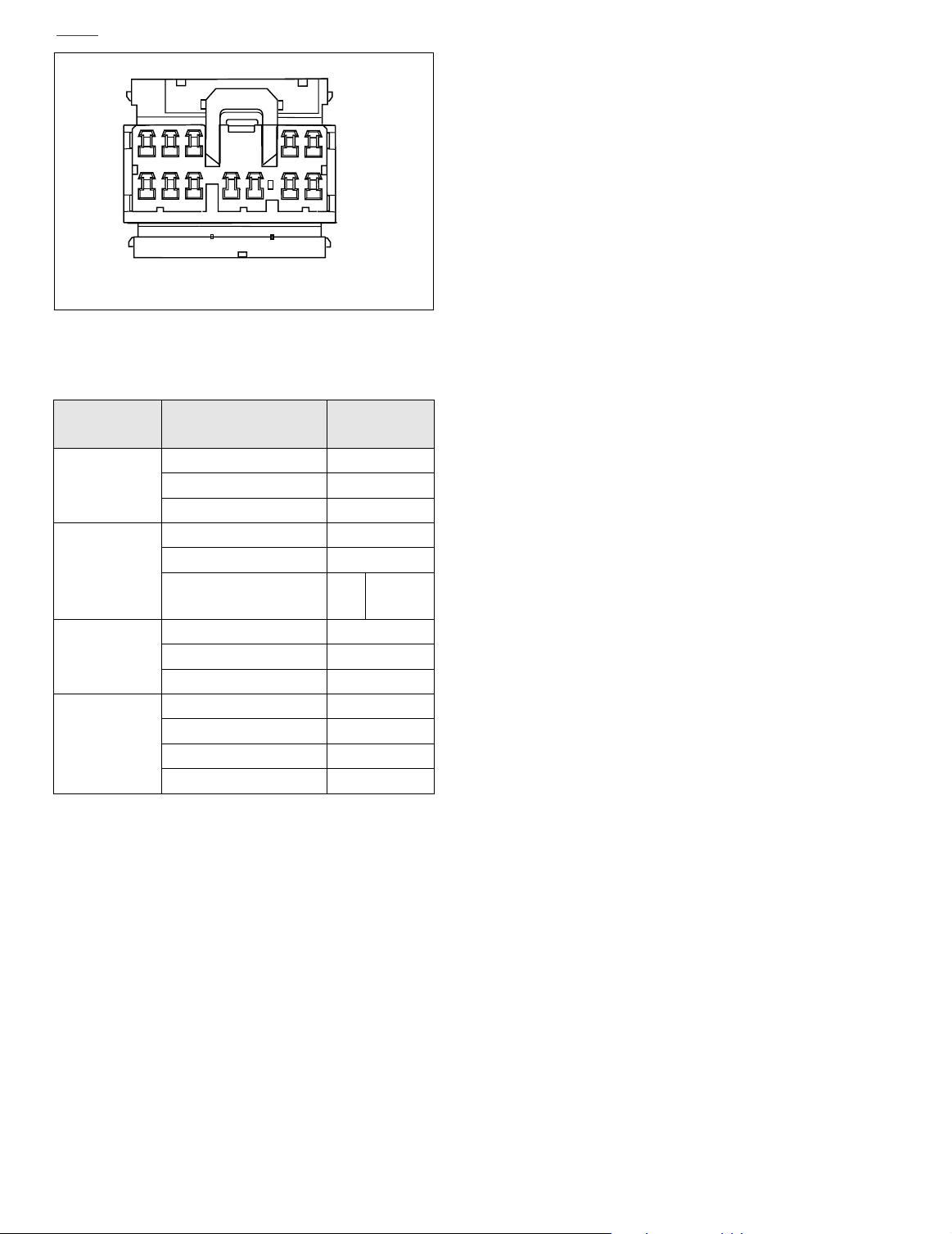

3

1

2

– AMP

7910

8

6

Secondary Locks Open

4

5

5

12

11

f1287b2x

Figure 8-77. Numbers Stamped on Secondary Locks

(Socket Housing Shown)

Table 8-10. Fairing Cap Switches [105]

Switch

Accessory

Cruise

Ultra Only

Spot

Speaker

Ultra Only

Wire Color

Orange/Red 1

Orange 2

Black 3

Orange/Violet 4

Red/Green 5

Black/Green

(Double Lugged)

Ye llow 6

Gray/Black 7

Black 8

Orange/Blue 9

Violet/Orange 10

Brown/Orange 11

Black/Green

Chamber

Number

To

Speaker

12

Switch

To Cruise Switch

NOTE

For assembly of HDI ignition switch, see Section 8.18 IGNI-

TION/LIGHT KEY SWITCH AND FORK LOCK, FLHT/C/U,

FLTR (INTERNATIONAL), INSTALLATION, steps 5-10.

a. Install switch position plate fitting tabs in slots of fair-

ing cap. Plate snaps in place when properly

installed. Exercise care to avoid breaking tabs.

Replace plate if tabs are broken.

b. Slide spacer over threaded post of ignition switch

housing until it contacts switch position plate.

c. Slide collar over post with the tab side down (and

forward).

d. Install nut, and using a 7/8 inch wrench on flats,

tighten to 50-70

in-lbs

(5.7-7.9 Nm).

e. With the red arrow pointing toward the ACCESS

position, install the ignition switch knob. Turn key

clockwise to UNLOCK position and then turn knob

to OFF.

8-58 2004 Touring: Electrical

Page 11

H

OME

INSTRUMENT NACELLE SWITCHES (FLTR) 8.20

REMOVAL

1. Using a T25 TORX drive head, remove screw on left and

right side of instrument bezel.

2. Use thumbs to push tab at rear of bezel from slot in front

of ignition switch. Gently raise free side of bezel until

tabs at front of instrument nacelle become disengaged

from slot at front of bezel (concealed behind decorative

adhesive strip).

3. Raising bezel slightly, remove anchor on ambient temperature sensor from hole in bottom inboard ear of

speedometer bracket.

4. See Figure 8-78. Disconnect instruments and indicator

lamps from interconnect harness as follows:

●

Speedometer connector [39], 12-place Packard.

Tachometer connector [108], 12-place Packard.

●

Indicator lamps connector [21], 10-place Multilock.

●

5. Remove bezel from motorcycle.

6. Partially disassemble domestic ignition switch as follows:

NOTE

For partial disassembly of HDI ignition switch, see Section

8.18 IGNITION/LIGHT KEY SWITCH AND FORK LOCK,

FLHT/C/U, FLTR (INTERNATIONAL), REMOVAL, steps 1-4.

a. To remove the ignition switch knob, insert the Igni-

tion Switch key and turn to the UNLOCK position.

Leaving the key installed, rotate the knob to

ACCESS. Depressing the release button at bottom

(left side) with a small screwdriver, push key down

and turn an additional 60 degrees in a counterclockwise direction. Lift and remove knob. See

upper frame of Figure 8-79.

b. Using a 7/8 inch wrench on flats, loosen switch nut

and remove from threaded post of ignition switch

housing. Remove collar and spacer. See lower

frame of Figure 8-79.

c. Remove the switch position plate from threaded

post of ignition switch housing.

7. Follow instructions based on location of defective switch.

LEFT SIDE SWITCH

a. See Figure 8-78. Disconnect left side switch from

instrument nacelle switch harness as follows:

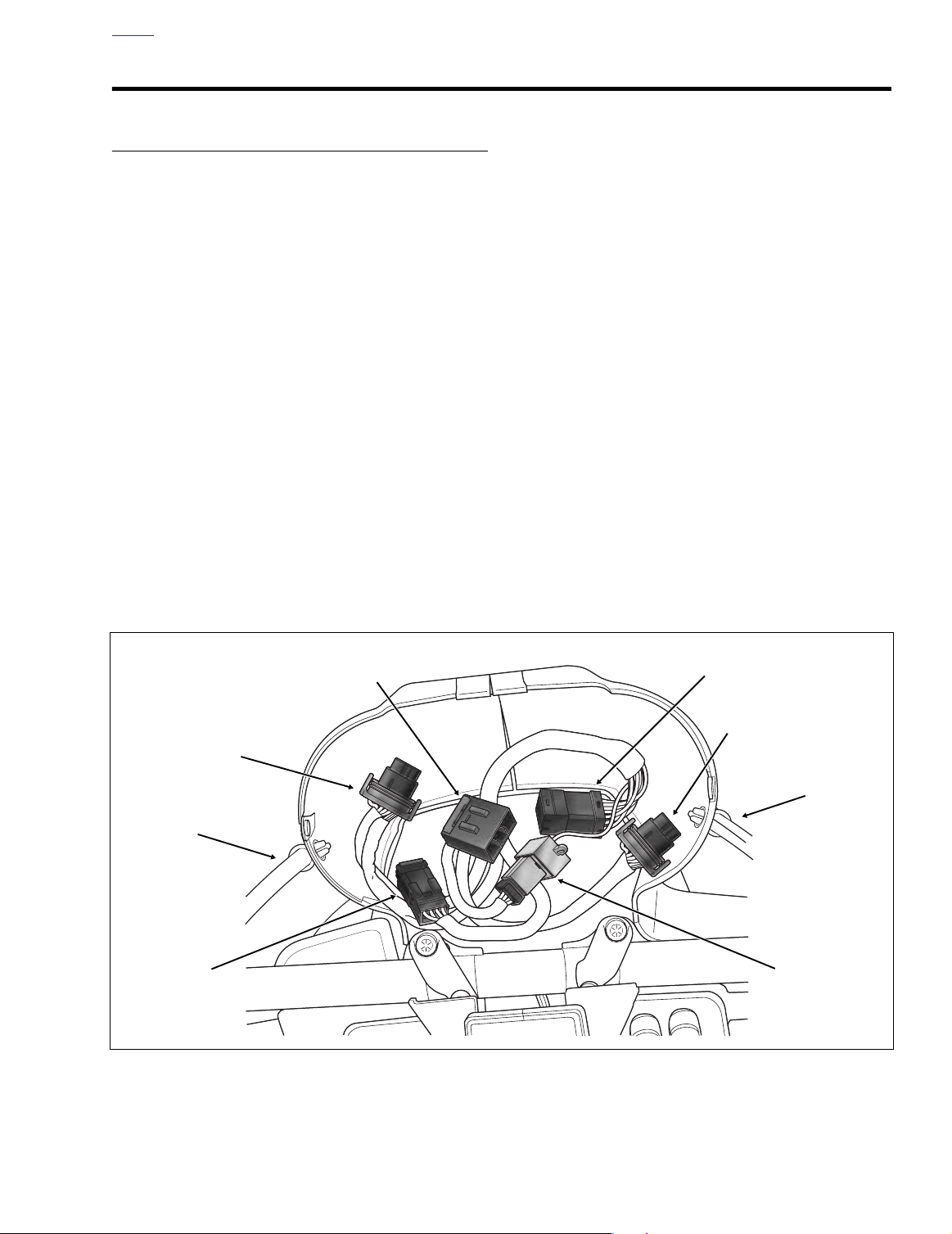

f2219x8x

Speedometer

Gauge [39]

Clutch

Cable

Speaker

Switch [105]

Indicator

Lamps [21]

Figure 8-78. Instrument Nacelle (Bezel Removed)

Instrument Nacelle

Switches [105]

Tachometer

Gauge [108]

Throttle

Cables

Ambient

Temperature

Sensor [107]

2004 Touring: Electrical 8-59

Page 12

H

OME

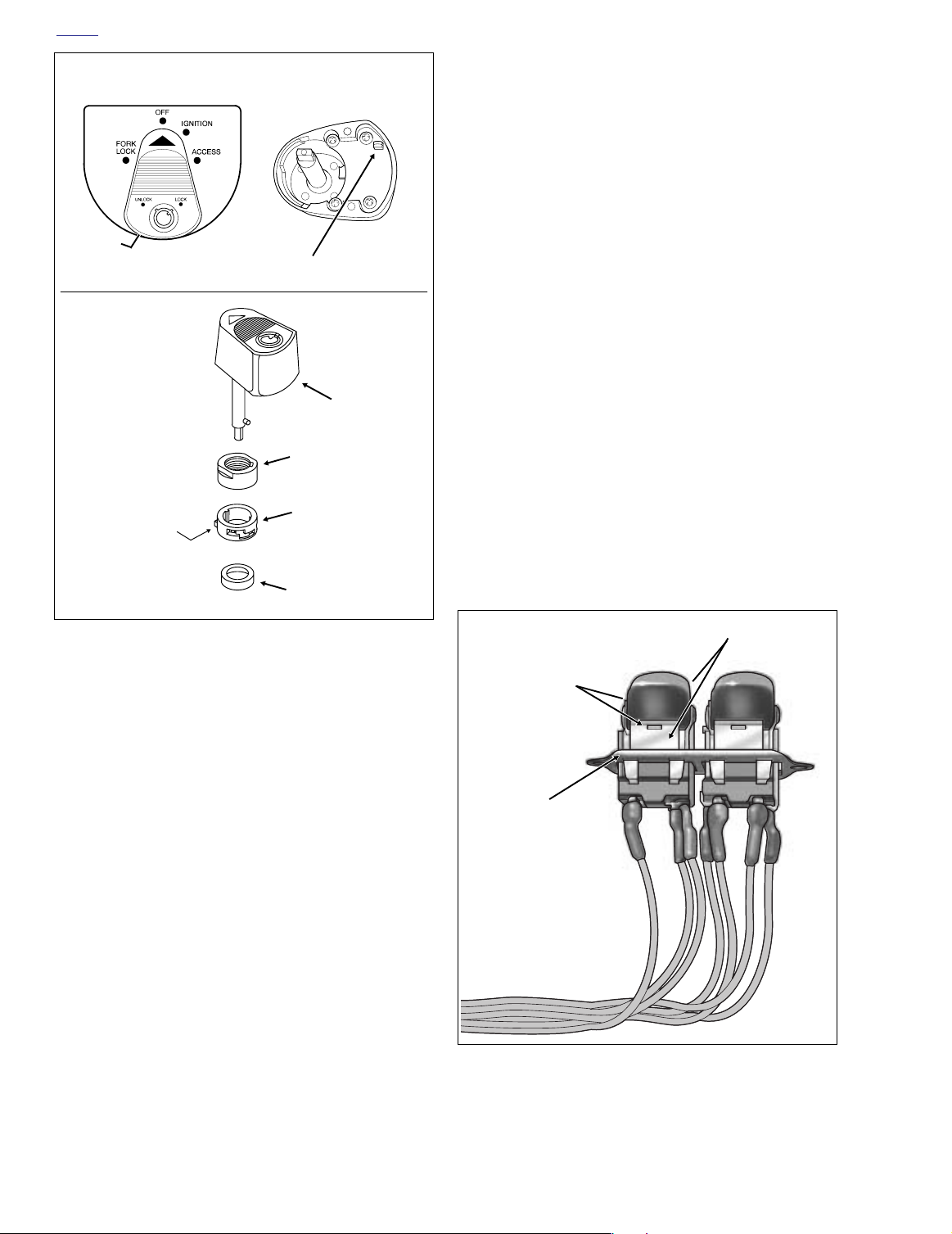

TOP VIEW BOTTOM VIEW

Button

Button

f1240x2x f1476x8x

f1297b2x

Knob

Nut

Tab

Down and Forward

Collar

RIGHT SIDE SWITCHES

a. See Figure 8-78. Disconnect left side switch from

instrument nacelle switch harness as follows:

●

Speaker Switch connector [105], 4-place Multilock.

b. See Figure 8-78. Disconnect instrument nacelle

switches from interconnect harness as follows:

Instrument nacelle switch connector [105], 12-place

●

Multilock.

c. Pull throttle cable clip from hole on right side of

instrument nacelle.

d. Using a T40 TORX drive head, remove two bolts

(with flat washers) to release right side of instrument nacelle from fork side. Move right side of

nacelle to bench area leaving left side on motorcycle. See Figure 8-82.

e. Gently bend back molded retainer to release switch

bracket assembly from instrument nacelle.

f. Carefully pry two latches on bracket outward to

release tabs on switch. Remove switch from

bracket. See Figure 8-80.

g. Remove the appropriate terminals from the socket

and pin housings. Follow the wires of the faulty

switch or reference Table 8-11 for the applicable

chamber numbers. For wire location purposes,

numbers are stamped into the secondary locks. See

Figure 8-81.

Spacer

Figure 8-79. Ignition Switch Knob (Domestic)

●

Speaker Switch connector [105], 4-place Multilock.

b. Pull clutch cable clip from hole on left side of instru-

ment nacelle.

c. Using a T40 TORX drive head, remove two bolts

(with flat washers) to release left side of instrument

nacelle from fork side.

d. Unthread rubber boot from odometer reset switch,

and while carefully removing left side instrument

nacelle from motorcycle, pull odometer reset switch

from hole. Move left side of nacelle to bench area

leaving right side on motorcycle. See Figure 8-82.

e. Gently bend back molded retainer to release switch

bracket assembly from instrument nacelle.

f. Carefully pry two latches on bracket outward to

release tabs on switch. Remove switch from

bracket. See Figure 8-80.

Latch

Tab

Switch

Bracket

f2215x8x

Figure 8-80. Bend Latches Outward to Release Tabs

8-60 2004 Touring: Electrical

Page 13

H

OME

Instrument Nacelle Switches

Switch

Accessory

Cruise

Table 8-11. Right Side

Chamber Number

Wire Color

Orange/Red 1

Orange 2

Black 3

Orange/Violet 4

Red/Green 5

Black/Green

(Double Lugged)

3

1

2

– AMP

7910

8

6

12-Place

Multilock

Socket

12 4

4

5

5

12

11

4-Place

Multilock

Pin

b. Snap switch bracket into molded retainer in instru-

ment nacelle.

c. While carefully placing left side of instrument

nacelle on motorcycle, slide odometer reset switch

through hole and install rubber boot.

d. See Figure 8-78. Connect left side switch to instru-

ment nacelle switch harness as follows:

Speaker Switch connector [105], 4-place Multilock.

●

e. Using a T40 TORX drive head, install two bolts (with

flat washers) to fasten left side instrument nacelle to

fork side. Alternately tighten bolts to 15-20 ft-lbs

(20-27 Nm).

f. Capture clutch cable in cable clip. Insert cable clip

into hole in left side of instrument nacelle.

g. Move to RIGHT SIDE SWITCHES, step 2.

RIGHT SIDE SWITCHES

a. Place

b. Push terminals through two lengths of conduit to

c. Install terminals into socket or pin housing. See

new

switch into position in bracket. Engaging

tabs on switch in slots of latches, gently bend tabs

upward to lock position of switch in bracket. See

Figure 8-80.

wire end of socket or pin housing. For best results,

push one wire through conduit at a time.

Ta bl e 8-12 and Figure 8-81.

Secondary Locks Open

f1287b2x

Figure 8-81. Numbers Stamped on Secondary Locks

(Socket Housing Shown)

NOTE

For instructions on properly removing wire terminals, see

APPENDIX B.2 AMP MULTILOCK ELECTRICAL CONNEC-

TORS, REMOVING SOCKET/PIN TERMINALS.

h. Carefully pull wires to draw terminals through con-

duit to backside of switch. For best results, pull one

wire at a time.

INSTALLATION

1. Follow instructions based on location of defective switch.

LEFT SIDE SWITCH

a. Place

new

switch into position in bracket. Engaging

tabs on switch in slots of latches, gently bend tabs

upward to lock position of switch in bracket.

NOTE

For instructions on properly installing wire terminals, see

APPENDIX B.2 AMP MULTILOCK ELECTRICAL CONNEC-

TORS, INSTALLING SOCKET/PIN TERMINALS.

d. Snap switch bracket into molded retainer in instru-

ment nacelle.

e. Install right side of instrument nacelle on motorcy-

cle.

f. See Figure 8-78. Connect left side switch to instru-

ment nacelle switch harness as follows:

Speaker Switch connector [105], 4-place Multilock.

●

g. See Figure 8-78. Connect instrument nacelle

switches to interconnect harness as follows:

●

Instrument nacelle switch connector [105], 12-place

Multilock.

h. Using a T40 TORX drive head, install two bolts (with

flat washers) to fasten right side instrument nacelle

to fork side. Tighten bolts to 15-20 ft-lbs (20-27 Nm).

i. Capture throttle cables in cable clip. Insert cable clip

into hole in right side of instrument nacelle.

2. Assemble domestic ignition switch as follows:

2004 Touring: Electrical 8-61

Page 14

H

OME

f2214x8x

Throttle

Cable Clip

Speaker

Switch [105D]

4-Place Multilock

LEFT SIDE

CONNECTOR

NUMBER

[105A, 105B] Interconnect to Nacelle Switch Harness

[105]

[105C, 105D] Nacelle Switch Harness to Speaker Switch

DESCRIPTION

[A, C] = Pin [B, D] = Socket

RIGHT SIDE

Clutch

Cable Clip

Instrument Nacelle

Switches [105B]

12-Place Multilock

f2213x8x

Figure 8-82. Instrument Nacelle Halves

NOTE

For assembly of HDI ignition switch, see Section 8.18 IGNI-

TION/LIGHT KEY SWITCH AND FORK LOCK, FLHT/C/U,

FLTR (INTERNATIONAL), INSTALLATION, steps 5-10.

a. Install the switch position plate over threaded post

of ignition switch housing. Tabs on plate fit in holes

at top of instrument nacelle.

b. Slide spacer over threaded post of ignition switch

housing until it contacts switch position plate. Slide

collar over post with the tab side down (and forward). Install nut, and using a 7/8 inch wrench on

flats, tighten to 50-70

in-lbs

(5.7-7.9 Nm). See

lower frame of Figure 8-79.

Speaker

Switch [105C]

4-Place Multilock

c. With the red arrow pointing toward the ACCESS

position, install the ignition switch knob. Turn key

clockwise to UNLOCK position and then turn knob

to OFF.

3. See Figure 8-78. Looking into the instrument nacelle,

connect instruments and indicator lamps to interconnect

harness as follows:

●

Speedometer connector [39], 12-place Packard.

Ta chometer connector [108], 12-place Packard.

●

●

Indicator lamps connector [21], 10-place Multilock.

4. Install anchor on ambient temperature sensor into hole

in bottom inboard ear of speedometer bracket.

8-62 2004 Touring: Electrical

Page 15

H

OME

5. Verify that left and right sides of instrument nacelle are

properly mated. Pins on left side of nacelle must fully

engage holes on right.

6. Insert tab at rear of bezel into slot of instrument nacelle

(just in front of ignition switch). Holding left and right

sides of nacelle together, place bezel over instrument

nacelle flange. When properly mated, tabs at front of

instrument nacelle engage lip in slot at front of bezel

(behind decorative adhesive strip).

NOTE

If tabs do not properly engage slot at front of bezel, then a

loose fit will result. Remove decorative adhesive strip by gently prying up outer edges, and using a flat bladed screwdriver,

carefully raise tabs so that they engage lip in slot. If damaged, install

new

decorative adhesive strip.

7. Using a T25 TORX drive head, install screw on each

side of bezel. Tighten screws to 25-35

in-lbs

(2.8-4.0

Nm).

2004 Touring: Electrical 8-63

Page 16

H

OME

HANDLEBAR SWITCHES 8.21

GENERAL

The basic switch configuration is the “Road King.” The Road

King switches have no specialized functions. Other switches,

referred to as the Road King Classic, Classic and Ultra, have

additional functions, such as cruise control, sound system

controls, etc., which cause them to differ from the Road King

switches. To accommodate these added functions, special

lower switch housings are provided.

NOTE

Regardless of model or option, all vehicles use the same

upper switch housings. The vehicles and their switch configurations are as follows:

Table 8-12. Handlebar Switches

Road King

FLHR FLHRI FLHRS FLHRSI

Road King Classic

FLHRCI

Classic

FLHT FLHTI FLHTC FLHTCI

Ultra

FLTRI FLHTCUI

NOTE: See Figures 8-91 thru 8-94 for illustrations.

NOTE

To replace or repair individual switches in either the right or

left handlebar switch assemblies, see SWITCH REPAIR/

REPLACEMENT in this section.

NOTE

Use the eyelet of an ordinary cable strap if the cardboard

insert is not available.

1. Place the cardboard insert between the brake lever and

lever bracket. See Figure 8-83.

2. Using a T27 TORX drive head, remove the two screws

with flat washers securing the handlebar clamp to the

master cylinder housing. Remove the brake lever/master

cylinder assembly and clamp from the handlebar.

3. Using a T25 TORX drive head, remove the upper and

lower switch housing screws.

4. Remove the friction shoe from the end of the tension

adjuster screw (non cruise equipped models only).

NOTE

The friction shoe is a loose fit and may fall out or become dislodged if the lower switch housing is turned upside down or

shaken.

5. Remove the brass ferrules from the notches on the

inboard side of the throttle control grip. Remove the ferrules from the cable end fittings.

6. Remove the throttle control grip from the end of the han-

dlebar.

7. Pull the crimped inserts at the end of the throttle and idle

control cable housings from the lower switch housing.

For best results, use a rocking motion while pulling.

Place a drop of light oil on the retaining rings, if necessary. Remove the cables from the switch housing.

8. Cut two cable straps to release wire harness conduit

from handlebar.

7959

REMOVAL

NOTE

While there are four different switch configurations for Touring

models (Road King, Road King Classic, Classic and Ultra),

the removal procedures are the same. To simplify these

instructions, only the Road King switch configuration is represented in the photographs and illustrations which follow.

RIGHT HANDLEBAR CONTROLS

CAUTION

Do not remove the switch housing assembly without first

placing the 5/32 inch (4.0 mm) cardboard insert between

the brake lever and lever bracket. Removal without the

insert may result in damage to the rubber boot and

plunger of the Front Stoplight Switch.

8-64 2004 Touring: Electrical

5/32 Inch

(4.0 mm)

Cardboard

Insert

Figure 8-83. Install Cardboard Insert

Page 17

H

7958

End

Fittings

Upper

Switch Housing

Cable

OME

LEFT HANDLEBAR CONTROLS

1. Using a T27 TORX drive head, remove the two screws

with flat washers securing the handlebar clamp to the

clutch lever bracket. Remove the clutch hand lever

assembly and clamp from the handlebar.

2. Using a T25 TORX drive head, remove the upper and

lower switch housing screws.

3. Cut two cable straps to release wire harness conduit

from handlebar.

4. Remove hand grip from handlebar, if damaged. See

Section 2.23 HANDLEBARS, LEFT HAND GRIP,

REMOVAL.

INSTALLATION

Figure 8-85. Route Cable to Upper Switch Housing

NOTE

While there are four different switch configurations for Touring

models (Road King, Road King Classic, Classic and Ultra),

the installation procedures are the same. To simplify these

instructions, only the Road King switch configuration is represented in the photographs and illustrations which follow.

RIGHT HANDLEBAR CONTROLS

1. With the concave side facing upward, install the friction

shoe so that the pin hole is over the point of the adjuster

screw (non cruise equipped models only).

NOTE

The friction shoe is a loose fit and may fall out or become dislodged if the switch housing is turned upside down or

shaken.

2. Push the throttle and idle control cables into the lower

switch housing until they snap in place. Proceed as follows:

7961

Lower

Switch

Housing

Throttle

Cable Insert

(Silver)

Idle

Cable Insert

(Gold)

Figure 8-84. Install Throttle/Idle Control Cables

in Lower Switch Housing

Note the different diameter inserts crimped into the end

of the throttle and idle control cable housings. See Fig-

ure 8-84.

Push the larger diameter insert (silver) on the throttle

cable housing into the larger hole in front of the tension

adjuster screw.

Push the smaller diameter insert (gold) on the idle cable

housing into the smaller hole at the rear of the tension

adjuster screw.

NOTE

To aid assembly, place a drop of light oil on the retaining

rings of the crimped inserts. Always replace the retaining

rings if damaged or distorted.

3. Route the cable to the upper switch housing as shown in

Figure 8-85.

4. Slide the throttle control grip over the end of the right

handlebar until it bottoms against the closed end. Rotate

the grip so that the ferrule notches are at the top. To prevent binding, pull the grip back about 1/8 inch (3.2 mm).

5. Position the lower switch housing beneath the throttle

control grip. Install the brass ferrules onto the cables so

that the end fittings seat in the ferrule recess. Seat the

ferrules in their respective notches on the throttle control

grip. Verify that the cables are captured in the grooves

molded into the grip. See Figure 8-86.

6. Position the upper switch housing over the handlebar

and lower switch housing.

7. Verify that the wire harness conduit runs in the depression at the bottom of the handlebar. Be sure that the

upper switch housing harness will not be pinched under

the handlebar when the switch housing screws are tightened.

8. Start the upper and lower switch housing screws, but do

not tighten.

2004 Touring: Electrical 8-65

Page 18

H

OME

f1474x2x

Throttle

Cable

Idle

Cable

Throttle

Grip

Groove

Notch

Ferrule

Figure 8-86. Install Throttle/Idle Control Cables on

Throttle Control Grip

f1225x2x

Groove

CAUTION

See Figure 8-87. Do not remove the 5/32 inch (4.0 mm)

cardboard insert (or cable strap eyelet) wedged between

the brake lever and lever bracket. Removal will result in

damage to the rubber boot and plunger of the Front

Stoplight Switch during installation of the master cylinder assembly.

9. Position the brake lever/master cylinder assembly

inboard of the switch housing assembly engaging the

tab on the lower switch housing in the groove at the top

of the brake lever bracket. See Figure 8-88.

10. Align the holes in the handlebar clamp with those in the

master cylinder housing and start the two screws (with

flat washers). Position for rider comfort. Beginning with

the top screw, tighten the screws to 60-80

in-lbs

(6.8-9.0

Nm) using a T27 TORX drive head.

11. Using a T25 TORX drive head, tighten the lower and

upper switch housing screws to 35-45

in-lbs

(4-5 Nm).

NOTE

Always tighten the lower switch housing screw first so that

any gap between the upper and lower housings is at the front

of the switch.

12. Remove the cardboard insert between the brake lever

and lever bracket.

The completed assembly appears as shown in Figure 8-

91.

13. Secure wire harness conduit to handlebar using two

new

cable straps. Position first cable strap approximately 4-5 inches (102-127 mm) from handlebar clamp.

Cut any excess cable strap material.

14. Test the switches for proper operation.

Figure 8-87. Leave Cardboard Insert in Place

8-66 2004 Touring: Electrical

5/32 Inch

(4.0 mm)

Cardboard

Insert

f1785x8x

Tab

Groove

Switch

Housing

Assembly

Figure 8-88. Fit Brake Lever/Master Cylinder to

Right Handlebar Switch Housings

Brake

Lever

Bracket

Page 19

H

7964

Clutch

Lever

Bracket

Groove

Tab

Switch

Housing

Assembly

OME

Sleeve

Grip

Grooves

Ribs

7966

Figure 8-90. Fit Clutch Lever Bracket to

Left Handlebar Switch Housings

7. Using a T25 TORX drive head, tighten the lower and

upper switch housing screws to 35-45

in-lbs

(4-5 Nm).

Figure 8-89. Install Left Handlebar Switch Housings

LEFT HANDLEBAR CONTROLS

1. Install

2. Install upper and lower switch housings on handlebar.

3. Verify that the wire harness conduit runs in the groove at

4. Start the upper and lower switch housing screws, but do

5. Position the clutch hand lever assembly inboard of the

6. Align the holes in the handlebar clamp with those in the

new

hand grip, if removed,. See Section 2.23

HANDLEBARS, LEFT HAND GRIP, INSTALLATION.

Be sure that ribs on outboard side of switch housings fit

in grooves molded into grip. See Figure 8-89.

the bottom of the handlebar. Be sure that the upper

switch housing harness will not be pinched under the

handlebar when the switch housing screws are tightened.

not tighten.

switch housing assembly engaging the tab on the lower

switch housing in the groove at the bottom of the clutch

lever bracket. See Figure 8-90.

clutch lever bracket and start the two screws (with flat

washers). Position for rider comfort. Beginning with the

top screw, tighten the screws to 60-80

in-lbs

(6.8-9.0

Nm) using a T27 TORX drive head.

NOTE

Always tighten the lower switch housing screw first so that

any gap between the upper and lower housings is at the front

of the switch.

The completed assembly appears as shown in Figure 8-

91.

8. Secure wire harness conduit to handlebar using two

new

cable straps. Position first cable strap approximately 4-5 inches (102-127 mm) from handlebar clamp.

Cut any excess cable strap material.

9. Test the switches for proper operation.

2004 Touring: Electrical 8-67

Page 20

H

OME

Right Handlebar Switch Housings

Upper Switch Housing:

● Engine Start Switch

● Engine Stop Switch: Off/Run

Lower Switch Housing:

● Tu rn-Right Signal Switch

● Front Stoplight Switch

f1227a2x

f1228a2x

Left Handlebar Switch Housings

Upper Switch Housing:

● Horn Switch

● Light Switch: Hi(gh) and Lo(w) Beam

Lower Switch Housing:

● Tu rn-Left Signal Switch

Figure 8-91. Road King Handlebar Switch Assemblies

Right Handlebar Switch Housings

Upper Switch Housing:

● Engine Start Switch

● Engine Stop Switch: Off/Run

Lower Switch Housing:

● Tu rn-Right Signal Switch

● Front Stoplight Switch

● Cruise Control Switch: Set/Res(ume)

f2157x8x

f2158x8x

Left Handlebar Switch Housings

Upper Switch Housing:

● Horn Switch

● Light Switch: Hi(gh) and Lo(w) Beam

Lower Switch Housing:

● Tu rn-Left Signal Switch

● Cruise Control Switch: On/Off

Figure 8-92. Road King Classic Handlebar Switch Assemblies

8-68 2004 Touring: Electrical

Page 21

H

OME

Right Handlebar Switch Housings

Upper Switch Housing:

● Engine Start Switch

● Engine Stop Switch: Off/Run

Lower Switch Housing:

● Tu rn-Right Signal Switch

● Front Stoplight Switch

● Mode Select Switch: UP/DN

f1369a8x

f1370a8x

Left Handlebar Switch Housings

Upper Switch Housing:

● Horn Switch

● Light Switch: Hi(gh) and Lo(w) Beam

Lower Switch Housing:

● Tu r n-Left Signal Switch

● Audio Control Switch: +/-

Figure 8-93. Classic Handlebar Switch Assemblies

Right Handlebar Switch Housings

Upper Switch Housing:

● Engine Start Switch

● Engine Stop Switch: Off/Run

Lower Switch Housing:

● Tu rn-Right Signal Switch

● Front Stoplight Switch

● Mode Select Switch: UP/DN

● Cruise Control Switch: Set/Res(ume)

f1367a8x

f1368a8x

Left Handlebar Switch Housings

Upper Switch Housing:

● Horn Switch

● Light Switch: Hi(gh) and Lo(w) Beam

Lower Switch Housing:

● Tu rn-Left Signal Switch

● Audio Control Switch: +/-

● Squelch Control and Driver P(ush)

T(o) T(ransmit) Switch: SQ-/PTT/SQ+

Figure 8-94. Ultra Handlebar Switch Assemblies

2004 Touring: Electrical 8-69

Page 22

H

OME

SWITCH REPAIR/REPLACEMENT

RIGHT SIDE HANDLEBAR SWITCHES

DISASSEMBLY

CAUTION

Do not remove the switch housing assembly without first

placing the 5/32 inch (4.0 mm) cardboard insert between

the brake lever and lever bracket. Removal without the

insert may result in damage to the rubber boot and

plunger of the Front Stoplight Switch.

NOTE

Use the eyelet of an ordinary cable strap if the cardboard

insert is not available.

1. Place the cardboard insert between the brake lever and

lever bracket.

2. Using a T25 TORX drive head, remove the upper and

lower switch housing screws.

3. If replacing lower housing switches, proceed to step 4. If

replacing upper housing switches, proceed to step 8.

4. Using a T27 TORX drive head, loosen the upper screw

securing the handlebar clamp to the master cylinder

housing. Remove the lower clamp screw with flat

washer.

5. Remove the brass ferrules from the notches on the

inboard side of the throttle control grip. Remove the ferrules from the cable end fittings.

6. Remove the friction shoe from the end of the tension

adjuster screw (non cruise equipped models only).

NOTE

The friction shoe is a loose fit and may fall out or become dislodged if the lower switch housing is turned upside down or

shaken.

7. Remove the throttle control grip from the end of the handlebar.

8. See SPECIFIC REPAIR PROCEDURES, UPPER

SWITCH HOUSINGS for upper switch housing switches,

LOWER SWITCH HOUSINGS for lower switch housing

switches.

3. Using a T27 TORX drive head, loosen the upper screw

securing the handlebar clamp to the clutch lever bracket.

Remove the lower clamp screw with flat washer.

4. See SPECIFIC REPAIR PROCEDURES, UPPER

SWITCH HOUSINGS for upper switch housing switches,

LOWER SWITCH HOUSINGS for lower switch housing

switches.

SPECIFIC REPAIR PROCEDURES

NOTE

Regardless of model or option, all vehicles use the same

upper switch housings.

UPPER SWITCH HOUSINGS

NOTE

Replace the Engine Stop and Engine Start Switches as a

single assembly even if only one switch is determined to be

faulty.

RIGHT SIDE HANDLEBAR (ALL MODELS)

● Engine Stop Switch: OFF/RUN

● Engine Start Switch

[Continued from RIGHT SIDE HANDLEBAR

SWITCHES, DISASSEMBLY, on this page.]

1. From inside the switch housing, remove the Phillips

screw to release the bracket. Remove the bracket and

switch assembly from the housing. See Figure 8-95.

2. Move cable conduit from beneath wing of bracket. Cut

wires 1/4 inch (6.4 mm) from old switches. Discard old

switch and bracket assembly.

3. Slide conduit forward over severed ends of switch wires

and cut off 1/2 inch (12.7 mm) of conduit material. Push

conduit back to access switch wires.

4. Separate new Engine Stop Switch and Start Switch

wires into two bundles.

NOTE

Replacement Stop Switch and Start Switch wires are cut to

length (2-1/2 inches and 2 inches, respectively) and partially

stripped.

LEFT SIDE HANDLEBAR SWITCHES

DISASSEMBLY

1. Using a T25 TORX drive head, remove the upper and

lower switch housing screws.

2. If replacing lower housing switches, proceed to step 3. If

replacing upper housing switches, proceed to step 4.

8-70 2004 Touring: Electrical

5. See GENERAL REPAIR PROCEDURES in this section.

6. Loop switch wires so that spliced lengths are positioned

as shown in Figure 8-96. Route wires downstream of

splices beneath wing on Engine Stop Switch side of

bracket as seen in Figure 8-95.

7. Install a new 7 inch cable strap beneath wing on Engine

Start Switch side of bracket and capture wire splices.

Page 23

H

f1271x2x

Start

Switch

Stop

Switch

Conduit

Splices

Cable

Strap

OME

Screw

Start

Switch

Stop

Switch

Bracket

Wing

f1272x2x

Channel

Conduit

Figure 8-95. Upper Right Handlebar Switch Housing

(Without Splices)

8. Place switch assembly into upper housing aligning hole

in bracket with threaded hole in boss. Be sure that

bracket is fully seated. The step at the edge of the boss

captures the bottom edge of the bracket, while tabs on

each side of the bracket fit in slots cast into the housing.

9. Install Phillips screw to secure bracket inside housing.

Verify that wing on Engine Stop Switch side of bracket

captures edge of conduit as shown in Figure 8-95.

10. Securely tighten cable strap to draw splices to bracket.

Remove any excess cable strap material.

11. See RIGHT SIDE HANDLEBAR SWITCHES, ASSEM-

BLY, in this section.

NOTE

Replace the Horn and High/Low Beam Switches as a single

assembly even if only one switch is determined to be faulty.

LEFT SIDE HANDLEBAR (ALL MODELS)

● Hi(gh) and Lo(w) Beam Switch

● Horn Switch

[Continued from LEFT SIDE HANDLEBAR SWITCHES,

DISASSEMBLY, in this section.]

1. See Figure 8-97. From inside the switch housing,

remove Phillips screw to release the bracket. Remove

the bracket and switch assembly from the housing.

Figure 8-96. Upper Right Handlebar Switch Housing

(With Splices)

2. Move cable conduit from beneath wing of bracket. Cut

wires 1/4 inch (6.4 mm) from old switches. Discard old

switch and bracket assembly.

3. Slide conduit forward over severed ends of switch wires

and cut off 1/2 inch (12.7 mm) of conduit material. Push

conduit back to access switch wires.

4. Separate new Horn and High/Low Beam Switch wires

into two bundles.

NOTE

Replacement High/Low Beam Switch and Horn Switch wires

are cut to length (2-1/2 inches and 2 inches, respectively)

and partially stripped.

5. See GENERAL REPAIR PROCEDURES in this section.

6. Loop switch wires so that spliced lengths are positioned

as shown in Figure 8-98. Route wires downstream of

splices beneath wing on High/Low Beam Switch side of

bracket as seen in Figure 8-97.

7. Install a new 7 inch cable strap beneath wing on Horn

Switch side of bracket and capture wire splices.

8. Place switch assembly into upper housing aligning hole

in bracket with threaded hole in boss. Be sure that

bracket is fully seated. The step at the edge of the boss

captures the bottom edge of the bracket, while tabs on

each side of the bracket fit in slots cast into the housing.

2004 Touring: Electrical 8-71

Page 24

H

OME

f1269x2x

Screw

Horn

Switch

Beam

Switch

Bracket

Wing

f1270x2x

Conduit

Figure 8-97. Upper Left Handlebar Switch Housing

(Without Splices)

9. Install Phillips screw to secure bracket inside housing.

Verify that wing on High/Low Beam Switch side of

bracket captures edge of conduit as shown in Figure 8-

97.

10. Securely tighten cable strap to draw splices to bracket.

Remove any excess cable strap material. See Figure 8-

98.

11. See LEFT SIDE HANDLEBAR SWITCHES, ASSEM-

BLY, in this section.

LOWER SWITCH HOUSINGS

RIGHT SIDE HANDLEBAR

PRELIMINARY INSTRUCTIONS

[Continued from RIGHT SIDE HANDLEBAR

SWITCHES, DISASSEMBLY, in this section.]

1. From inside the switch housing, carefully cut cable strap

to free conduit from the turn signal switch bracket, if

present.

2. Remove the Phillips screw to release the turn signal

switch bracket. Remove the bracket and switch assembly from the housing.

NOTE

On Classic and Ultra models, pull the conduit back to introduce some slack in the wires or the tight fit of the bundle will

prevent removal of the turn signal switch bracket.

Horn

Switch

Cable

Strap

Beam

Switch

Splices

Figure 8-98. Upper Left Handlebar Switch Housing

(With Splices)

● Turn-Right Signal Switch

(All Models)

1. Cut wires 1-1/2 inches (38.1 mm) from old switch. Discard old switch assembly.

NOTE

Replacement Turn-Right Signal Switch wires are cut to length

(1-1/2 inches) and partially stripped.

2. See GENERAL REPAIR PROCEDURES in this section.

3. See RIGHT SIDE HANDLEBAR, FINAL INSTRUC-

TIONS in this section.

● Front Stoplight Switch

(All Models)

1. Carefully remove the wedge between the switch and

switch housing, if present. To remove the switch from the

housing, depress the plunger and slowly rotate switch

upward while rocking slightly.

2. Cut wires 1 inch (25.4 mm) from old switch. Discard old

switch.

NOTE

Replacement Stoplight Switch wires are cut to length (2-1/2

inches) and partially stripped.

3. See GENERAL REPAIR PROCEDURES in this section.

8-72 2004 Touring: Electrical

Page 25

H

f1309x2x

Lower Bracket

Screw

Lower Bracket

Screw

Turn Signal Switch

Bracket Screw

Cable

Strap

OME

4. Carefully depress plunger against inside wall of switch

housing. With thumb over plunger bore, move switch into

the installed position in the switch housing cavity. When

plunger is positioned against thumb, slowly rotate switch

downward while rocking slightly. Release the plunger

only after switch is properly positioned in the cavity.

5. Verify that the plunger is square in the bore and that the

boot is not compressed, collapsed or torn. If necessary,

gently work the plunger in and out until boot is fully

extended.

6. Push down on switch so that it bottoms against housing

and wires run in groove at base of cavity. With the concave side facing outward, insert wedge between switch

and outboard side of switch housing. See Figure 8-99.

7. Push wedge down until it also bottoms against housing.

Verify that the plunger is still square in the bore and then

place a drop of RTV Silicone Sealant on upper corner of

wedge.

8. See RIGHT SIDE HANDLEBAR, FINAL INSTRUC-

TIONS on the next page.

● Mode Select Switch

(Classic and Ultra Models)

1. Pull keycap from switch shaft.

2. Remove two lower bracket screws. Pull bracket and

switch from switch housing. See Figure 8-100.

f1280x2x

Cavity

Lower

Switch

Housing

Stoplight

Switch

Switch

Wires

Figure 8-99. Install Stoplight Switch

Wedge

Groove

Figure 8-100. Lower Right Handlebar Switch Housing

(Without Splices) - Classic/Ultra Models

3. Cut wires 1-1/4 inches (31.8 mm) from old switch. Discard switch assembly.

NOTE

Replacement Mode Select Switch wires are cut to length (21/4 inches) and partially stripped.

4. See GENERAL REPAIR PROCEDURES in this section.

5. Fit new switch into cavity so that it sits on edge in a verti-

cal position (gray/white wire topside). Properly installed,

the switch is captured by blocks cast into the lower housing. Verify that the switch shaft is aligned for proper keycap operation.

6. Place the lower bracket into the housing (with the weld

nut side down), but keep the splices above the bracket.

Verify that the slots in the upper step of the bracket

engage two tabs on switch body.

7. Install shorter screw to secure front side of lower bracket

to threaded boss. Install longer rear screw. To engage

threaded hole in casting, use thru hole in lower step of

bracket on Classic models, thru hole in upper step on

Ultra.

8. Install keycap on switch shaft.

9. See RIGHT SIDE HANDLEBAR, FINAL INSTRUC-

TIONS on the next page.

2004 Touring: Electrical 8-73

Page 26

H

OME

f1294x2x

Bracket

7 Inch

Cable Strap

7. Install shorter screw to secure front side of lower bracket

to threaded boss. Install longer rear screw. Use thru hole

in upper step of bracket to engage threaded hole in casting.

8. Note lettering for proper orientation and gently push keycap onto switch shaft.

9. See RIGHT SIDE HANDLEBAR, FINAL INSTRUC-

TIONS on this page.

RIGHT SIDE HANDLEBAR

FINAL INSTRUCTIONS

1. Insert tapered end of new 7 inch cable strap into round

hole in turn signal switch bracket and then feed back

through using the adjacent hole. Reserve the oblong

hole for the bracket screw. See Figure 8-101.

Right Turn

Signal Switch

Figure 8-101. Insert Cable Strap in Switch Bracket

● Cruise Set/Resume Switch

(Road King Classic and Ultra Models)

1. Pull keycap from switch shaft.

2. Remove two lower bracket screws. Pull bracket and

switch from switch housing.

3. Cut wires 1-1/2 inches (38.1 mm) from old switch. Discard switch assembly.

NOTE

Replacement Cruise Set/Resume Switch wires are cut to

length (2 inches) and partially stripped.

4. See GENERAL REPAIR PROCEDURES in this section.

5. Fit new switch into cavity so that it sits in a horizontal

position (blue/black wire towards master cylinder). Properly installed, the switch is captured by blocks cast into

the lower housing.

6. Keeping splices above the bracket, install the lower

bracket (weld nut side down), so that the lower step is

positioned over the switch. Slots in the upper step

engage two tabs on the Cruise On Lamp upper housing

(Road King Classic), or the body of the Mode Select

Switch (Ultra models).

NOTE

The Mode Select Switch is vertically oriented with the gray/

white wire topside.

NOTE

Be sure that all splices are positioned above the turn signal

switch bracket.

2. Place the turn signal switch assembly into the housing

aligning the oblong hole in the bracket with the lower

bracket weld nut (threaded boss on Road King Standard

models). Be sure that bracket is fully seated. Tabs on

each side of bracket are captured in slots cast into

switch housing.

3. Start Phillips screw to secure bracket inside housing.

CAUTION

If routed incorrectly, wires may be pinched by casting or

handlebar resulting in switch failure.

4. Loop switch wires so that spliced lengths are positioned

as shown in Figure 8-102.

5. Capturing conduit about 1/4 inch (6.4 mm) from end,

securely tighten cable strap to draw conduit to bracket.

Remove any excess cable strap material.

6. Install second 7 inch cable strap capturing conduit and

wire splices. Securely tighten cable strap to draw splices

to conduit. Remove any excess cable strap material.

7. Tighten Phillips screw to secure bracket inside housing.

8. Route wire bundle to upper switch housing by gently

pressing conduit into channel next to angular arm of

bracket. Secure bundle to arm using third cable strap.

Cut any excess cable strap material. If necessary, bend

angular arm of bracket downward to firmly secure Front

Stoplight Switch in installed position.

9. See RIGHT SIDE HANDLEBAR SWITCHES, ASSEM-

BLY, in this section.

8-74 2004 Touring: Electrical

Page 27

H

OME

f1311x2x

Splices

Cable Strap

(Splices to Conduit)

Angular

Arm

Cable Strap

(Wire Bundle to Arm)

Cable Strap

(Conduit to Bracket)

f1311x2x

Splices

Cable Strap

(Splices to Conduit)

Angular

Arm

Cable Strap

(Wire Bundle to Arm)

Cable Strap

(Conduit to Bracket)

MODE SELECT SWITCH

Figure 8-102. Lower Right Handlebar Switch Housing (With Splices) - Classic/Ultra Models

LEFT SIDE HANDLEBAR

PRELIMINARY INSTRUCTIONS

[Continued from LEFT SIDE HANDLEBAR SWITCHES,

DISASSEMBLY, in this section.]

1. From inside the switch housing, carefully cut cable strap

to free conduit from the turn signal switch bracket, if

present.

2. Remove the Phillips screw to release the turn signal

switch bracket. Remove the bracket and switch assembly from the housing.

NOTE

On Classic and Ultra models, pull the conduit back to introduce some slack in the wires or the tight fit of the bundle will

prevent removal of the switch bracket.

● Turn-L(eft) Signal Switch

(All Models)

1. Cut wires 1-1/2 inches (38.1 mm) from old switch. Discard old switch assembly.

CRUISE CONTROL SWITCH

NOTE

Replacement Turn-Left Signal Switch wires are cut to length

(1-1/2 inches) and partially stripped.

2. See GENERAL REPAIR PROCEDURES in this section.

3. See LEFT SIDE HANDLEBAR, FINAL INSTRUCTIONS

on the next page.

● Audio Control Switch

(Classic and Ultra Models)

1. Pull keycap from switch shaft.

2. Remove two lower bracket screws. See Figure 8-105.

Pull bracket and switch from switch housing.

3. Cut wires 1-1/4 inches (31.8 mm) from old switch. Discard switch assembly.

NOTE

Replacement Audio Control Switch wires are cut to length (21/4 inches) and partially stripped.

4. See GENERAL REPAIR PROCEDURES in this section.

2004 Touring: Electrical 8-75

Page 28

H

OME

Audio Control

Switch

Turn Signal Switch

and Bracket

Lower

Bracket

Stoplight

Switch

Turn Signal Switch

and Bracket

Lower

Bracket

Mode Select

Switch

Classic Models

Audio

Control

Switch

Audio Switch

Keycap

Turn Signal Switch

and Bracket

PTT

Switch

Lower

Bracket

PTT Switch

Keycap

f1327x2x

Mode Select

Keycap

Classic Models

Stoplight

Switch

Lower

Bracket

Cruise

Switch Keycap

f1326x2x

Turn Signal Switch

and Bracket

Cruise

Control Switch

Mode

Select Switch

Audio Switch

Ultra Models

Figure 8-103. Lower Left Handlebar Switch Assemblies

(Exploded View)

8-76 2004 Touring: Electrical

Keycap

f1329x2x

Mode Select

Keycap

Ultra Models

Figure 8-104. Lower Right Handlebar Switch Assemblies

(Exploded View)

f1328x2x

Page 29

H

OME

Lower Bracket

Lower Bracket

Screw

Screw

Turn Signal Switch

Bracket Screw

Cable

Strap

f1306x2x

2. Remove two lower bracket screws. See Figure 8-105.

Pull bracket and switch from switch housing.

3. Cut wires 1-1/2 inches (38.1 mm) from old switch. Discard switch assembly.

NOTE

Replacement Push-to-Transmit Switch wires are cut to length

(2 inches) and partially stripped.

4. See GENERAL REPAIR PROCEDURES in this section.

5. Fit new switch into cavity so that it sits in a horizontal

position (brown/black wire towards clutch lever bracket).

Properly installed, the switch is captured by blocks cast

into the lower housing.

6. Keeping splices above the bracket, install the lower

bracket (weld nut side down) so that the lower step is

positioned over the Push-to-Transmit Switch (horizontally oriented). Slots in the upper step engage two tabs

on body of Audio Control Switch (vertically oriented with

gray wire topside).

7. Install shorter screw to secure front side of lower bracket

to threaded boss. Install longer rear screw. To engage

threaded hole in casting, use thru hole in upper step of

bracket.

8. Note lettering for proper orientation and gently push keycap onto switch shaft.

9. See LEFT SIDE HANDLEBAR, FINAL INSTRUCTIONS

on this page.

Figure 8-105. Lower Left Handlebar Switch Housing

(Without Splices) - Classic/Ultra Models

5. Fit new switch into cavity so that it sits on edge in a vertical position (gray/green wire topside). Properly installed,

the switch is captured by blocks cast into the lower housing. Verify that the switch shaft is aligned for proper keycap operation.

6. Place the lower bracket into the housing (with the weld

nut side down), but keep the splices above the bracket.

Verify that the slots in the upper step of the bracket

engage two tabs on switch body.

7. Install shorter screw to secure front side of lower bracket

to threaded boss. Install longer rear screw. To engage

threaded hole in casting, use thru hole in lower step of

bracket on Classic models, thru hole in upper step on

Ultra.

8. Note lettering for proper orientation and gently push keycap onto switch shaft.

9. See LEFT SIDE HANDLEBAR, FINAL INSTRUCTIONS

on the next page.

● CB Push-To-Transmit Switch (Ultra Models)

1. Pull keycap from switch shaft.

● Cruise On/Off Switch

(Road King Classic Models)

1. Pull keycap from switch shaft.

2. Remove two lower bracket screws. Pull bracket and

switch from switch housing.

3. Cut wires 1-1/2 inches (38.1 mm) from old switch. Discard switch assembly.

NOTE

Cut replacement Cruise On/Off Switch wires to 2 inches and

strip 1/2 inch of insulation.

4. See GENERAL REPAIR PROCEDURES in this section.

5. Fit new switch into cavity so that it sits in a horizontal

position (orange/white wire towards clutch lever bracket).

Properly installed, the switch is captured by blocks cast

into the lower housing.

6. Keeping splices above the bracket, install the lower

bracket (weld nut side down), so that the lower step is

positioned over the switch. Slots in the upper step

engage two tabs on the Cruise On Lamp upper housing.

7. Install shorter screw to secure front side of lower bracket

to threaded boss. Install longer rear screw. Use thru hole

in upper step of bracket to engage threaded hole in casting.

2004 Touring: Electrical 8-77

Page 30

H

OME

f1295x2x

Bracket

7 Inch

Cable Strap

4. Loop switch wires so that spliced lengths are positioned

as shown in Figure 8-107.

5. Capturing conduit about 1/4 inch (6.4 mm) from end,

securely tighten cable strap to draw conduit to bracket.

Remove any excess cable strap material.

6. Tighten Phillips screw to secure bracket inside housing.

7. Route wire bundle to upper switch housing below and

then forward of the main wire harness positioning conduit in channel next to angular arm of bracket. See Fig-

ure 8-107. Secure bundle to arm using new cable strap.

Cut any excess cable strap material.

8. See LEFT SIDE HANDLEBAR SWITCHES, ASSEM-

BLY, which follows.

GENERAL REPAIR PROCEDURES

Left Turn

Signal Switch

Figure 8-106. Insert Cable Strap in Switch Bracket

8. Note lettering for proper orientation and gently push keycap onto switch shaft.

9. See LEFT SIDE HANDLEBAR, FINAL INSTRUCTIONS

below.

LEFT SIDE HANDLEBAR

FINAL INSTRUCTIONS

1. Insert tapered end of new 7 inch cable strap into round

hole in turn signal switch bracket and then feed back

through using the adjacent hole. Reserve the oblong

hole for the bracket screw. See Figure 8-106.

NOTE

Be sure that all splices are positioned above the turn signal

switch bracket.

2. Place the turn signal switch assembly into the housing

aligning the oblong hole in the bracket with the lower

bracket weld nut (threaded boss on Road King Standard

models). Be sure that bracket is fully seated. Tabs on

each side of bracket are captured in slots cast into

switch housing.

3. Start Phillips screw to secure bracket inside housing.

CAUTION

If routed incorrectly, wires may be pinched by casting or

handlebar resulting in switch failure.

1. To better access wires and avoid damaging conduit with

radiant heating device, push conduit back and secure

with extra 7 inch cable strap in kit.

Angular

Splices

Arm

f1310x2x

Figure 8-107. Lower Left Handlebar Switch Housing

(With Splices) - Classic/Ultra Models

Cable

Strap

Cable

Strap

8-78 2004 Touring: Electrical

Page 31

H

1WARNING1WARNING

CAUTION

Ultra Torch UT-100

(HD-39969)

Robinair Heat Gun

Shrink Tool Attachment

(HD-41183))

Robinair Heat Gun

(HD-25070)

OME

A

B

C

Figure 8-108. Splice Switch Wires

f1313x2x

Use extreme caution when operating the UltraTorch UT100 or any other radiant heating device. Read the manufacturers instructions carefully before use. Always keep

hands away from tool tip area and heat shrink attachment. Avoid directing the heat toward any fuel system

component. Extreme heat can cause fuel ignition/explosion. Avoid directing heat toward any electrical system

component other than the connectors on which heat

shrink work is being performed. Be sure to turn the “ON/

OFF” switch to the “OFF” position after use. Inadequate

safety precautions could result in death or serious

injury.

6. See Figure 8-109. Using the UltraTorch UT-100, Robinair

Heat Gun with heatshrink attachment or other suitable

radiant heating device, uniformly heat the heat-shrink

tubing to insulate and seal the soldered connections.

Apply heat just until the meltable sealant exudes out

both ends of the tubing and it assumes a smooth cylindrical appearance.

2. Strip 1/2 inch of insulation off switch wires. Twist stripped

ends of switch wires until all strands are tightly coiled.

3. Cut dual wall heat-shrink tubing supplied in kit into one

inch (25.4 mm) segments. Slide tubing over each wire of

new switch assembly.

NOTE

If absent from kit, obtain heat shrink tubing (Part No. 72266-

94) and two 7 inch cable straps (Part No. 10181).

4. Matching wire colors, mate old and new switch wires and

splice as follows:

a. Hold the wires so that the stripped ends cross as

shown in A of Figure 8-108. Note that the wire on

the left is on top and two-thirds of its stripped length

lies beyond the point where they intersect. Looking

at the other wire, only 1/3 of its stripped length lies

beyond the intersection point.

b. Holding the wires together at their juncture, start the

splice by tightly twisting the top one-third length of

the right hand wire over the left as shown in B of

Figure 8-108.

c. Tightly coil the remaining two-thirds of the left hand

wire around the right with the results shown in C of

Figure 8-108.

d. Solder the spliced connections.

For best results, do one wire at a time.

NOTE

Electrically connected solder outside the tubing may