Page 1

f1939x9x

MAP Sensor

7

HOME

DTC P0107, P0108 5.19

GENERAL

MAP Sensor

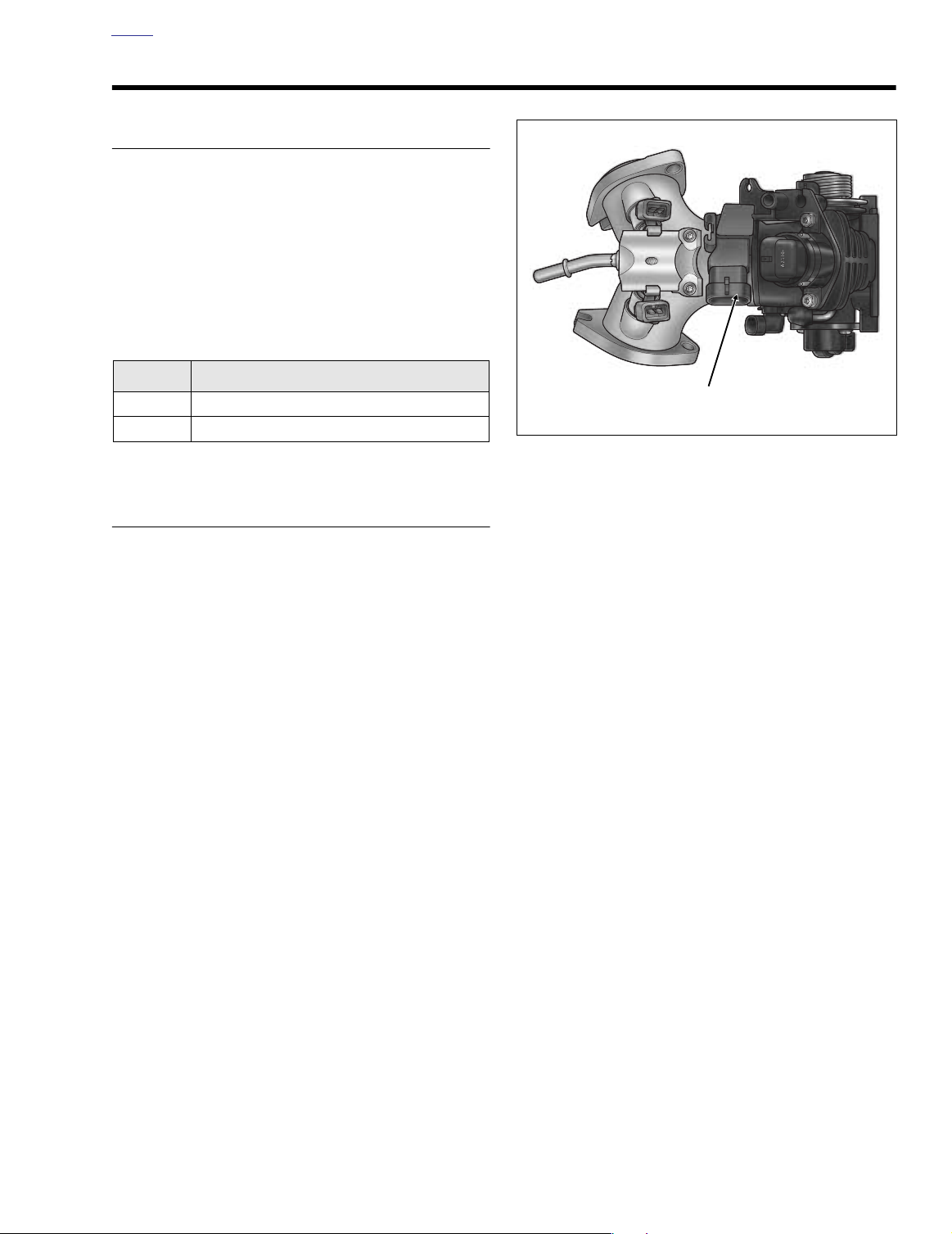

See Figure 5-45. The manifold absolute pressure sensor

(MAP sensor) is supplied 5 volts from the ECM (Pin 14) and

sends a signal back to the ECM (Pin 25). This signal varies in

accordance with engine vacuum and atmospheric barometric

pressure. Changes in barometric pressure are influenced by

weather and altitude.

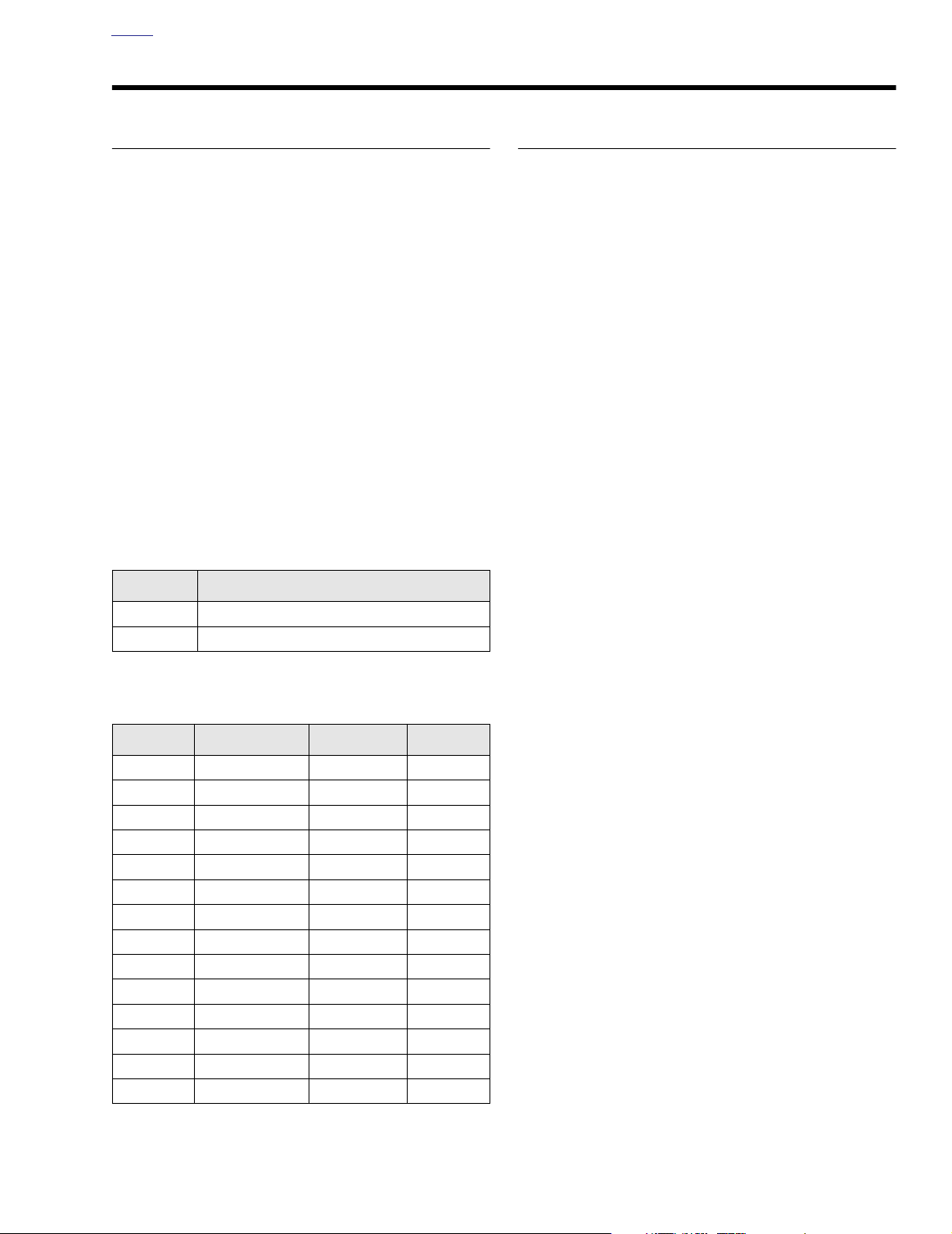

Table 5-26. Code Description

DTC

P0107 MAP sensor open/low

P0108 MAP sensor high

DESCRIPTION

DIAGNOSTICS

Diagnostic Tips

●

These codes will set if the MAP sensor signal is out of

range. Code P0108 can only be detected with the engine

running.

MAP sensor output check. Using the VACUUM PUMP

●

(Part No. HD-23738), apply a vacuum to the pressure

port of the MAP sensor. The signal voltage should lower

as the vacuum is applied.

●

The MAP, TP and VSS sensors are connected to the

same reference line (+5V Vref). If the reference line goes

to ground or open, multiple codes will be set (DTC

P0107, P0108, P0122, P0123, P0501, P0502).

Figure 5-45. Induction Module (Top View)

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.19 flow charts.

1. Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ECM. See Section 5.7 BREA-

KOUT BOX: EFI.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probes and patch cords.

2004 Touring: Engine Management (EFI) 5-69

Page 2

HOME

f1743q9s

MAP

Sensor

[80A]

[80B]

AB

A

BC

V/W

BK/W

To TP and

VSS sensors

C

R/W

R/W

To TP, ET &

IAT Sensors

V/W

BK/W

[78B]

[78A]

14 25 26

ECM

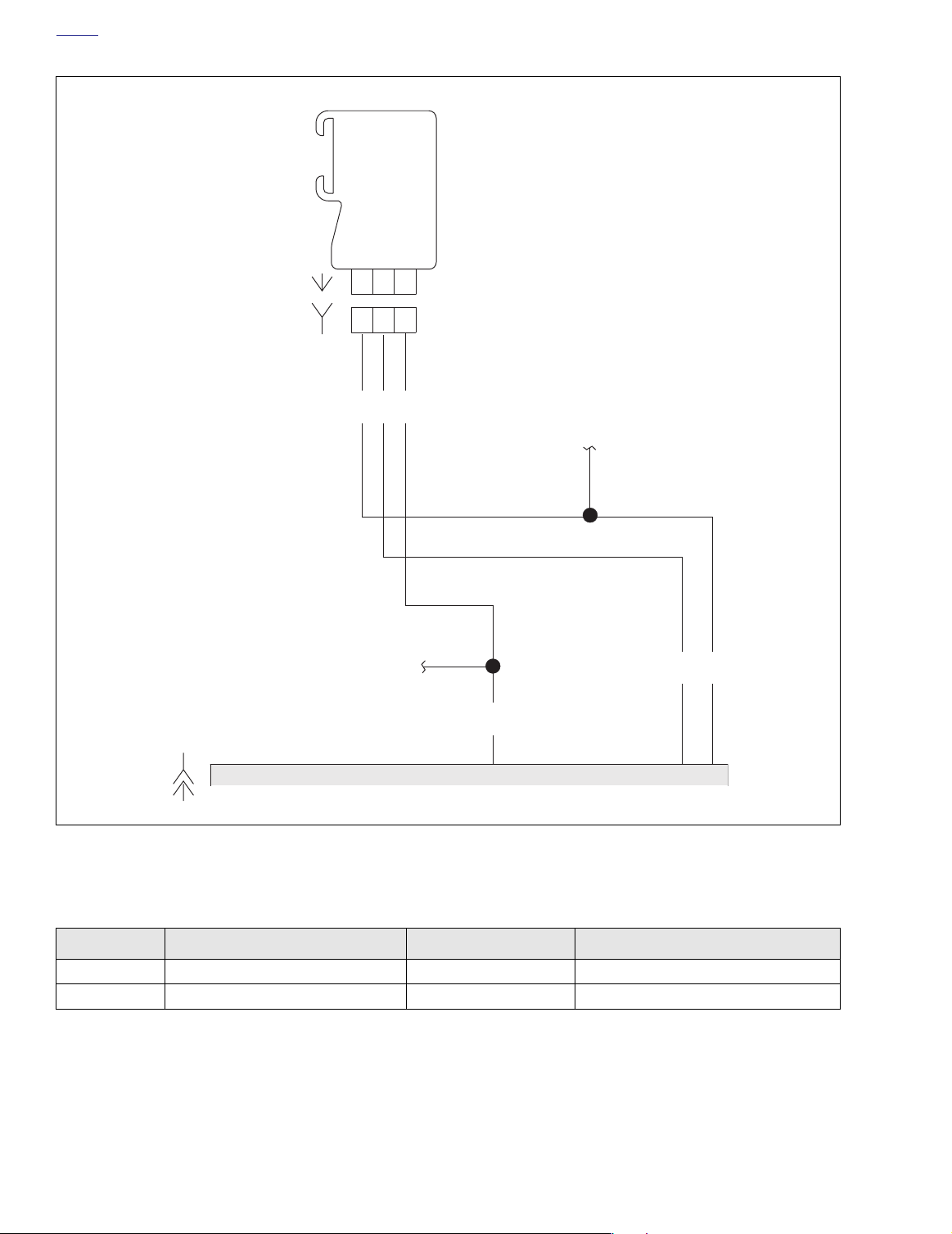

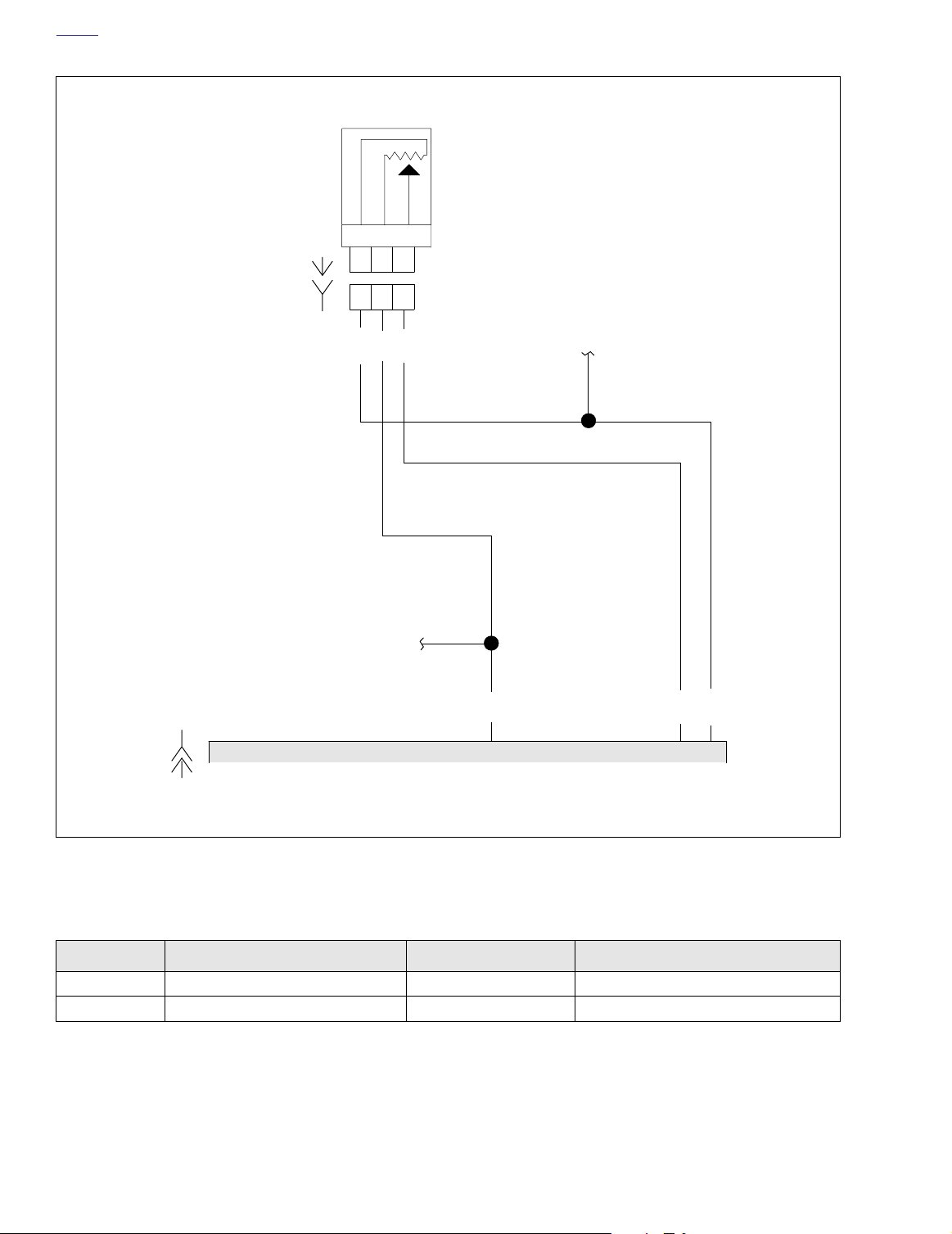

Figure 5-46. MAP Sensor Circuit

Table 5-27. Wire Harness Connectors in Figure 5-46.

NO.

[78] ECM 36-Place Packard Under Right Side Cover

[80] MAP Sensor 3-Place Packard Top of Induction Module

5-70 2004 Touring: Engine Management (EFI)

DESCRIPTION TYPE LOCATION

Page 3

HOME

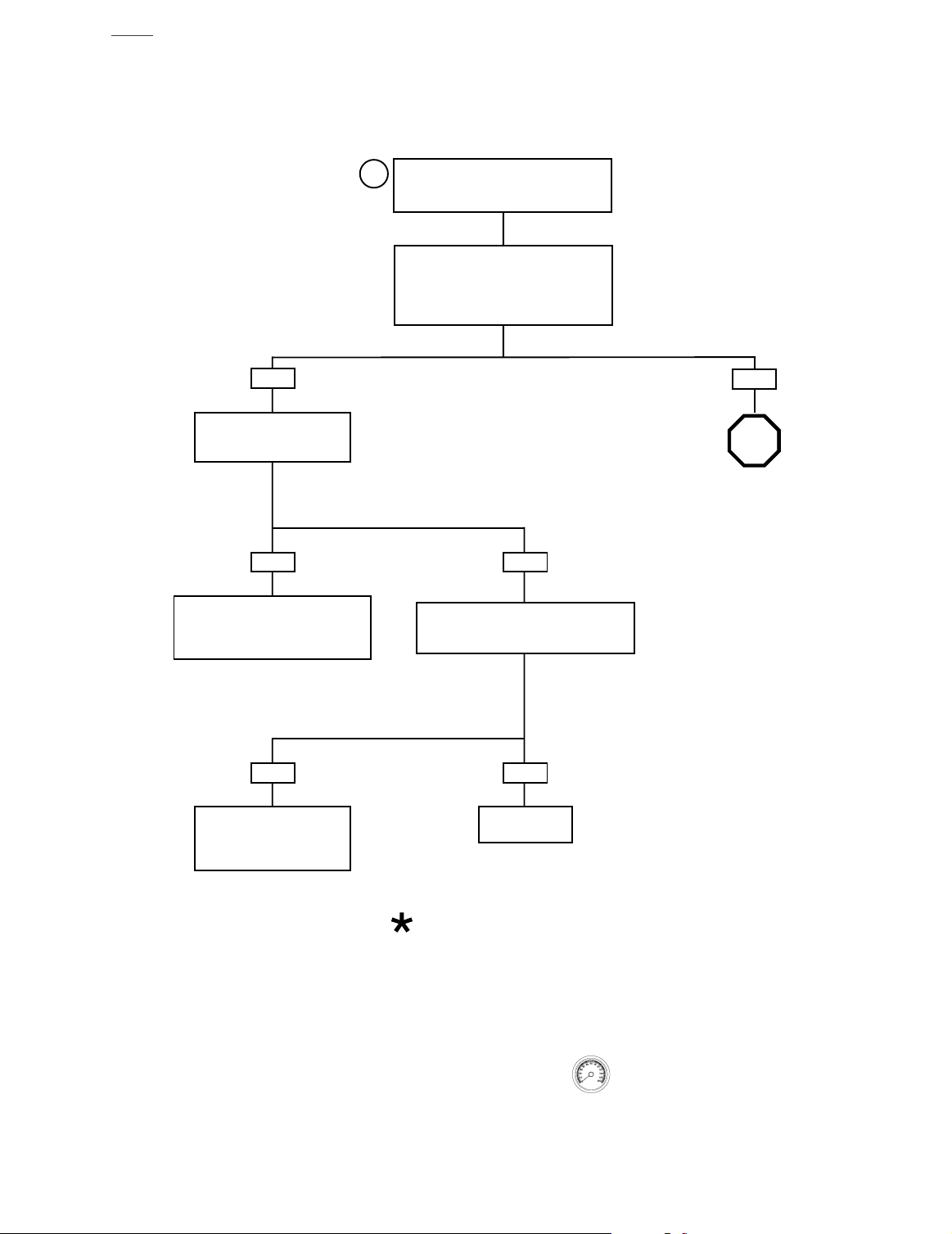

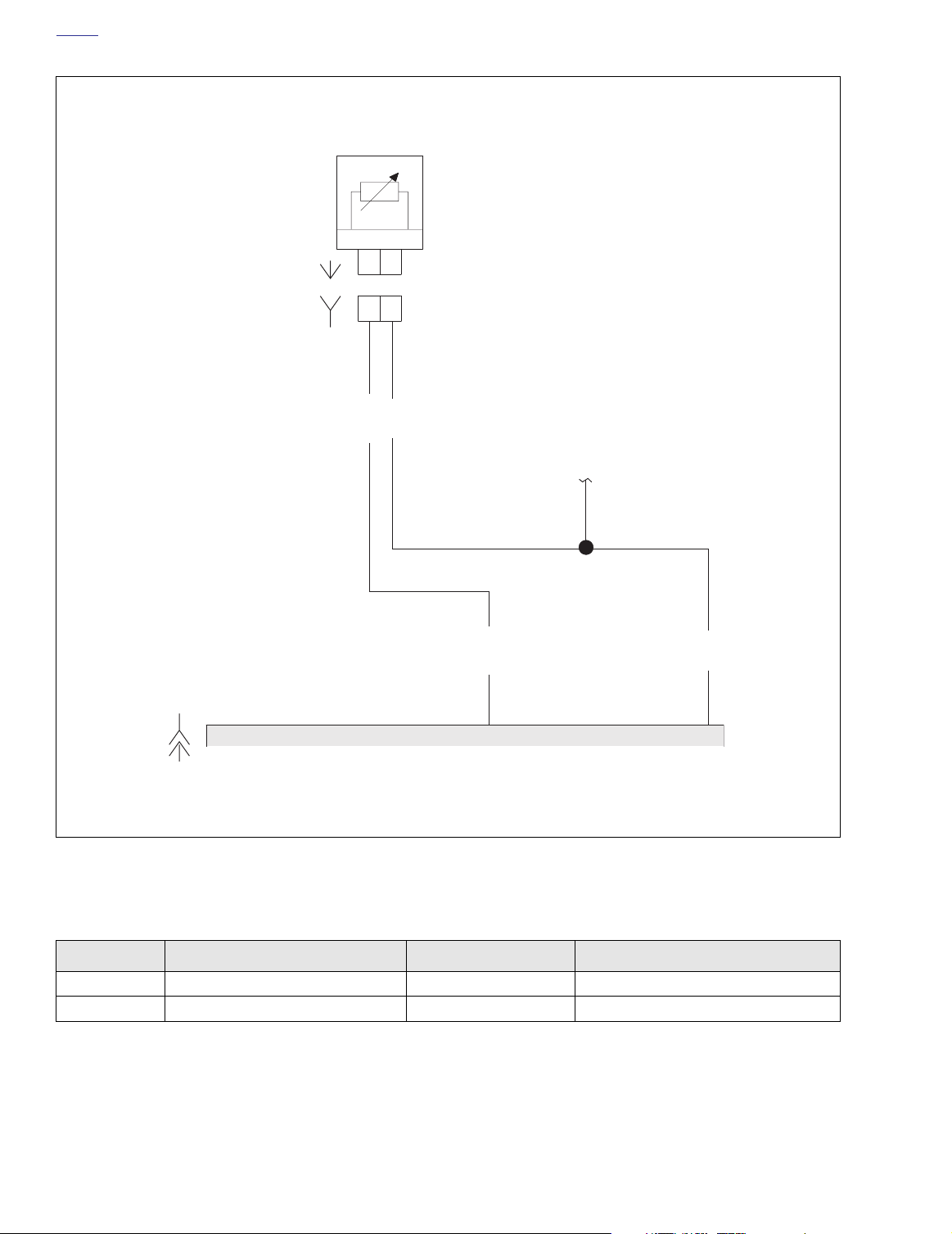

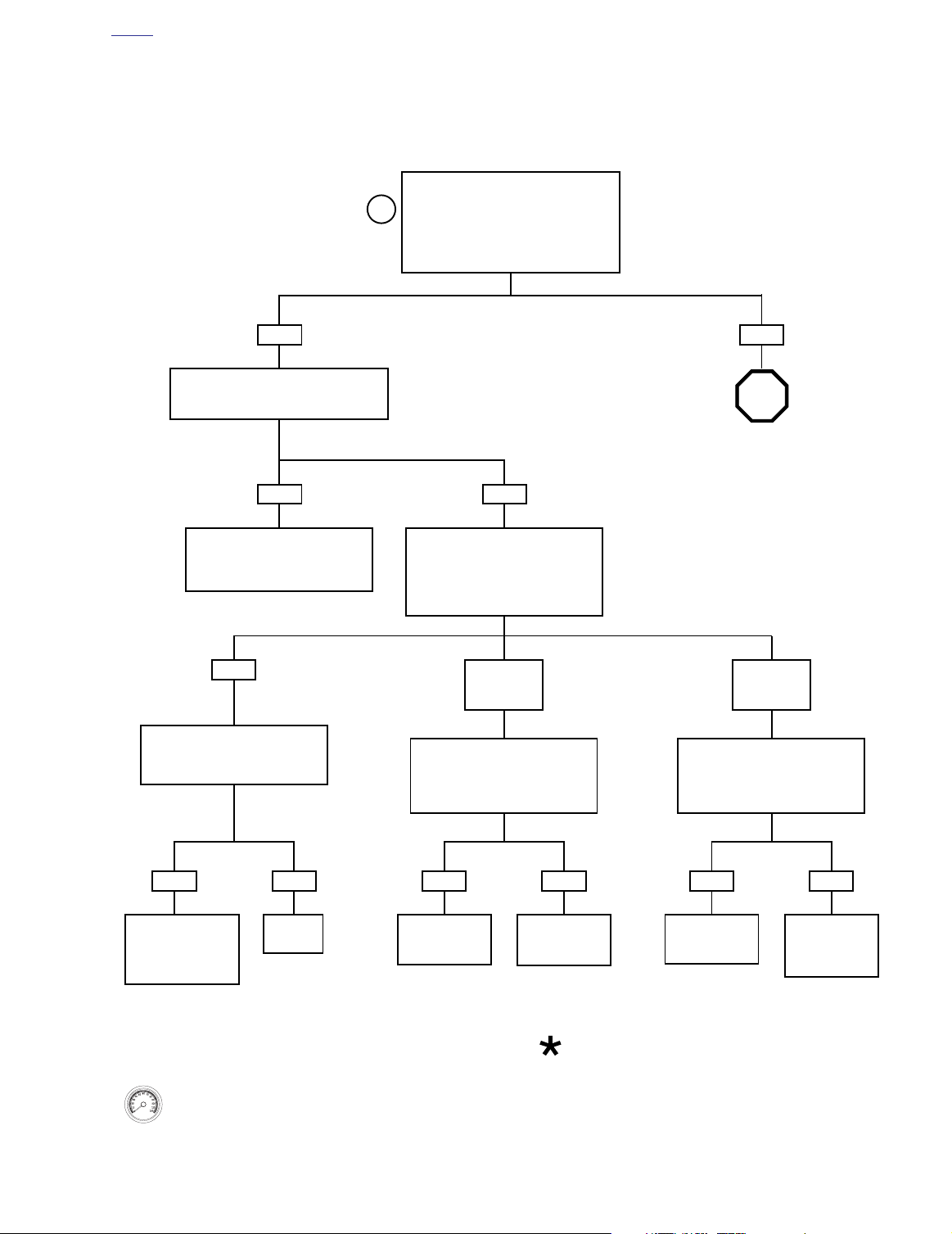

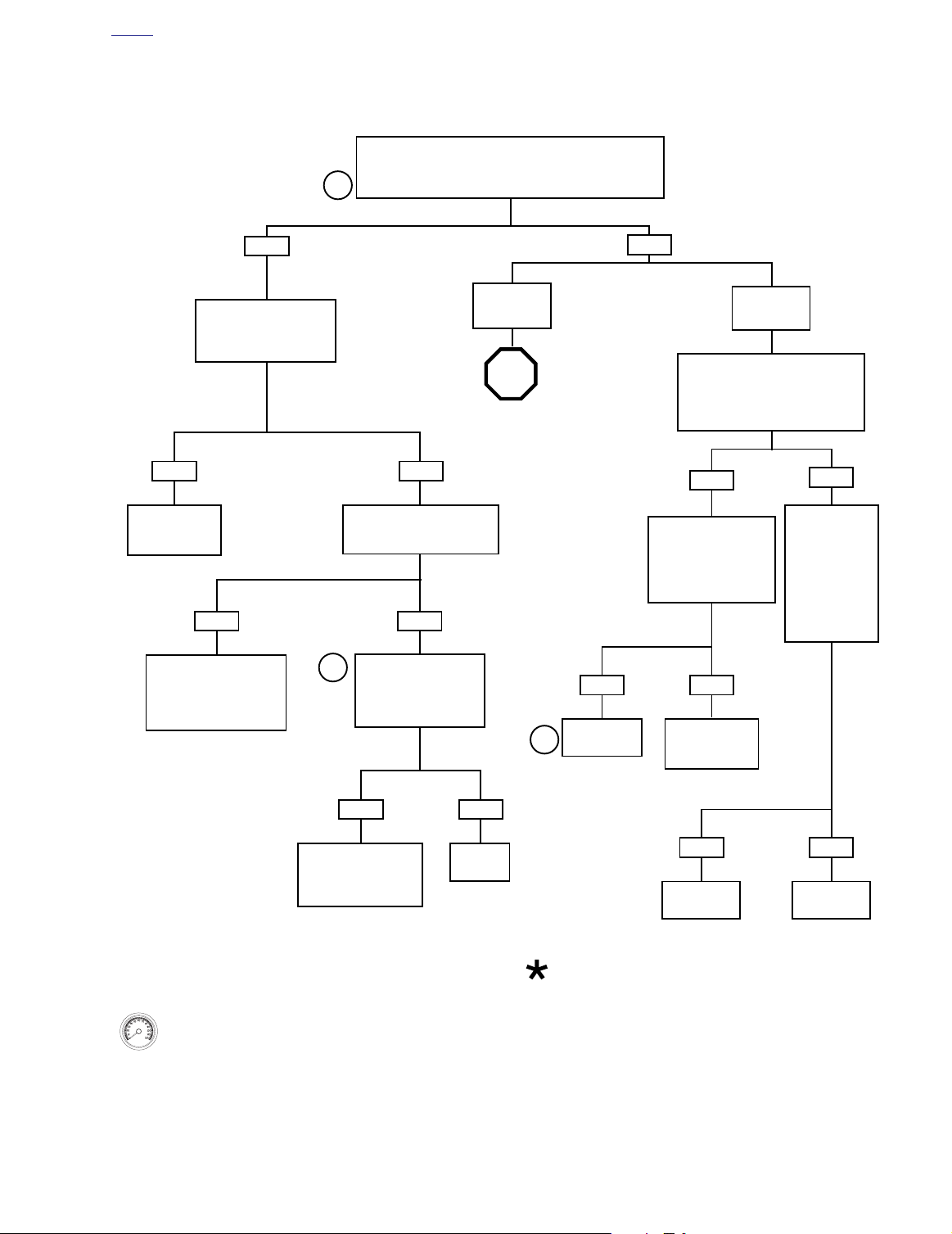

Test 5.19 (Part 1 of 2)

MAP SENSOR: DTC P0107, P0108

Connect Breakout Box. With ignition ON,

1

measure voltage between terminal 25

and terminal 26 on Breakout Box.

With key ON, engine OFF, voltage must be

between 3.5 and 5.0 volts.

With key ON, engine running, voltage must

be between 1.5-3.0 volts at hot idle.

Does voltage fit specifications?

YES

Perform 5.8 WIGGLE TEST

to check for intermittents.

Intermittents present?

YES

To identify the source of intermittents,

start with box marked by Bold Asterisk

under Test 5.19 (Part 2 of 2). Wiggle

harness while watching DVOM.

YES

Install original MAP sensor.

Replace ECM (reprogram,

relearn) and road test again

to verify.

NO

Replace MAP sensor. Clear codes and road

test. Did check engine lamp illuminate and

set DTC P0107 or P0108?

NO

System

now OK.

NO

STOP

Go to Test 5.19 (Part 2 of 2).

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

2004 Touring: Engine Management (EFI) 5-71

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Page 4

HOME

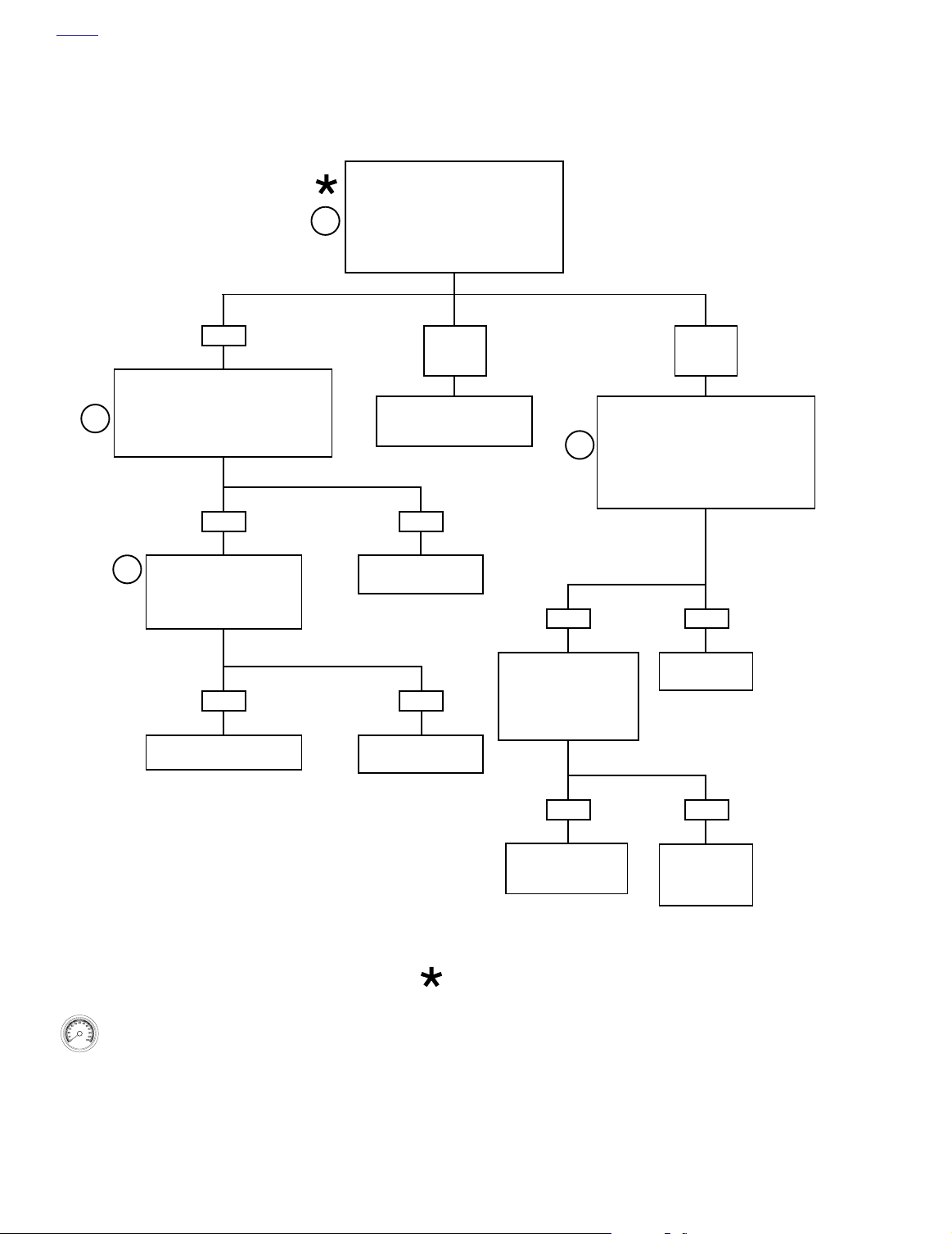

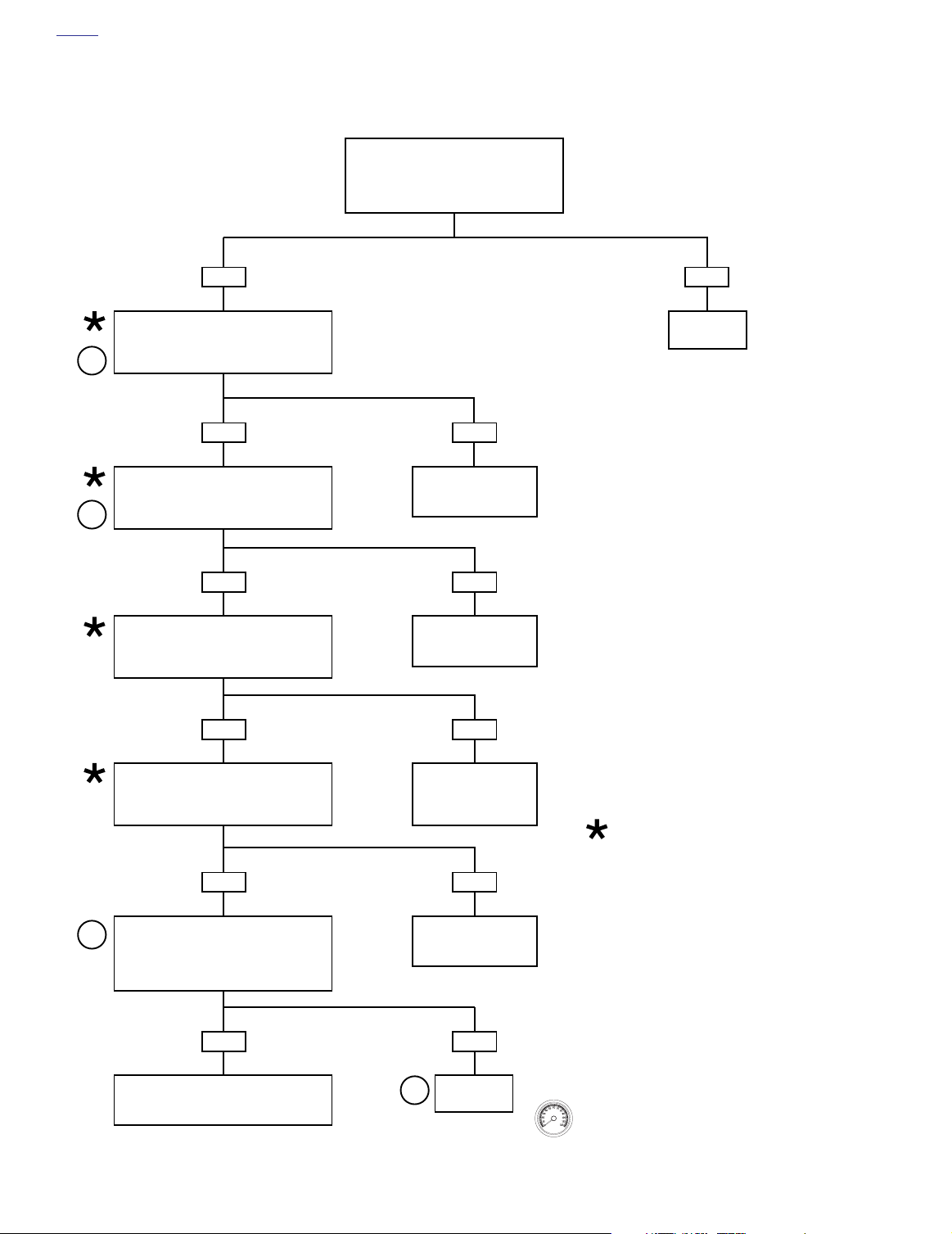

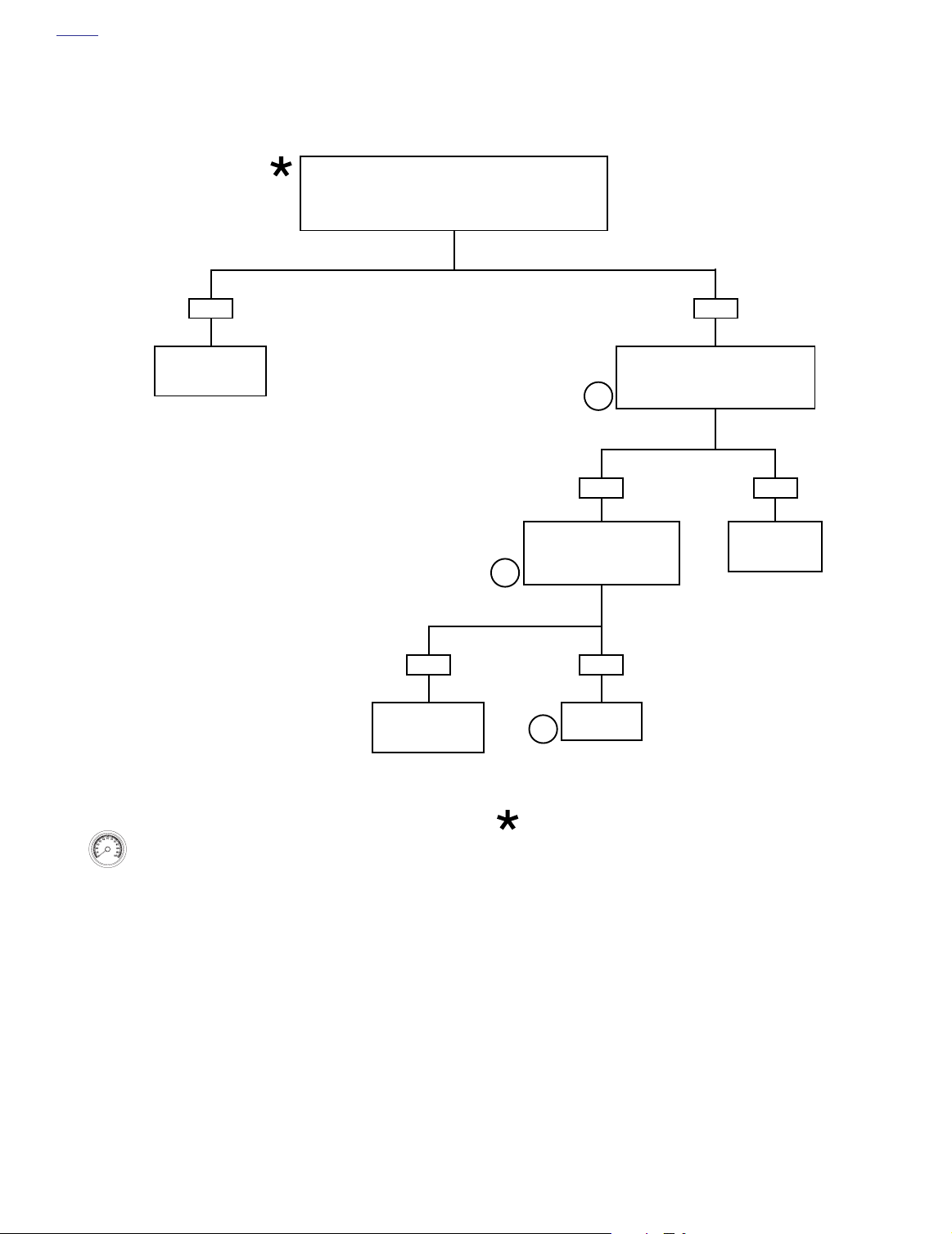

Test 5.19 (Part 2 of 2)

MAP SENSOR: DTC P0107, P0108

Continued from

Test 5.19 (Part 1 of 2).

Check the 5 volt reference supply at

the MAP sensor connector [80B]. With

2

ignition ON, measure voltage between

terminal C (R/W) and terminal A (BK/W).

Voltage approximately 5.0 volts?

YES

Connect Breakout Box to connector [78B]

leaving ECM disconnected.

OPEN CHECK: Measure resistance

2

between MAP connector [80B]

Terminal B and Breakout Box terminal 25.

Resistance less than 1 ohm?

YES

SHORT CHECK: Measure

2

resistance between MAP connector Terminal B and chassis

ground. Resistance greater

than 1 megohm?

YES

Replace MAP sensor. See

Touring Service Manual.

NO.

Greater

than 6V.

Locate short to 12 volts on R/W

wire in wire harness. Repair as

necessary.

NO

Locate and repair

open on V/W wire.

NO

Locate and repair

grounded V/W wire.

Connect Breakout Box to connector [78B]

Check continuity between MAP connector

[80B] Terminal C and Breakout Box

2

terminal 14. Then measure continuity

between MAP connector [80B] Terminal A

YES

Check resistance between

MAP connector [80B]

Terminal C and

Breakout Box terminal 26.

Resistance greater than

1 megohm?

YES

NO.

Less

than 4.5V.

leaving ECM disconnected.

and Breakout Box terminal 26.

Resistance less than 1 ohm?

NO

Repair

open wire.

NO

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

5-72 2004 Touring: Engine Management (EFI)

Replace ECM.

Reprogram and learn

password.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

Locate and repair

short between

R/W and BK/W

wires.

Page 5

HOME

DTC P0112, P0113 5.20

GENERAL

IAT Sensor

The ECM supplies and monitors a voltage signal (terminal 7)

to one side of the intake air temperature sensor (IAT sensor).

The other side of the IAT sensor is connected to a common

sensor ground, which is also connected to the ECM (terminal

26).

The IAT sensor is a thermistor device, meaning that at a spe-

cific temperature, it will have a specific resistance across its

terminals. As this resistance varies, so does the voltage on

(terminal 7).

At high temperatures, the resistance of the sensor is very

●

low, which effectively lowers the signal voltage on terminal 7.

●

At low temperatures, the resistance is very high, allowing

the voltage to rise close to 5 volts.

The ECM monitors this voltage to compensate for various

operating conditions.

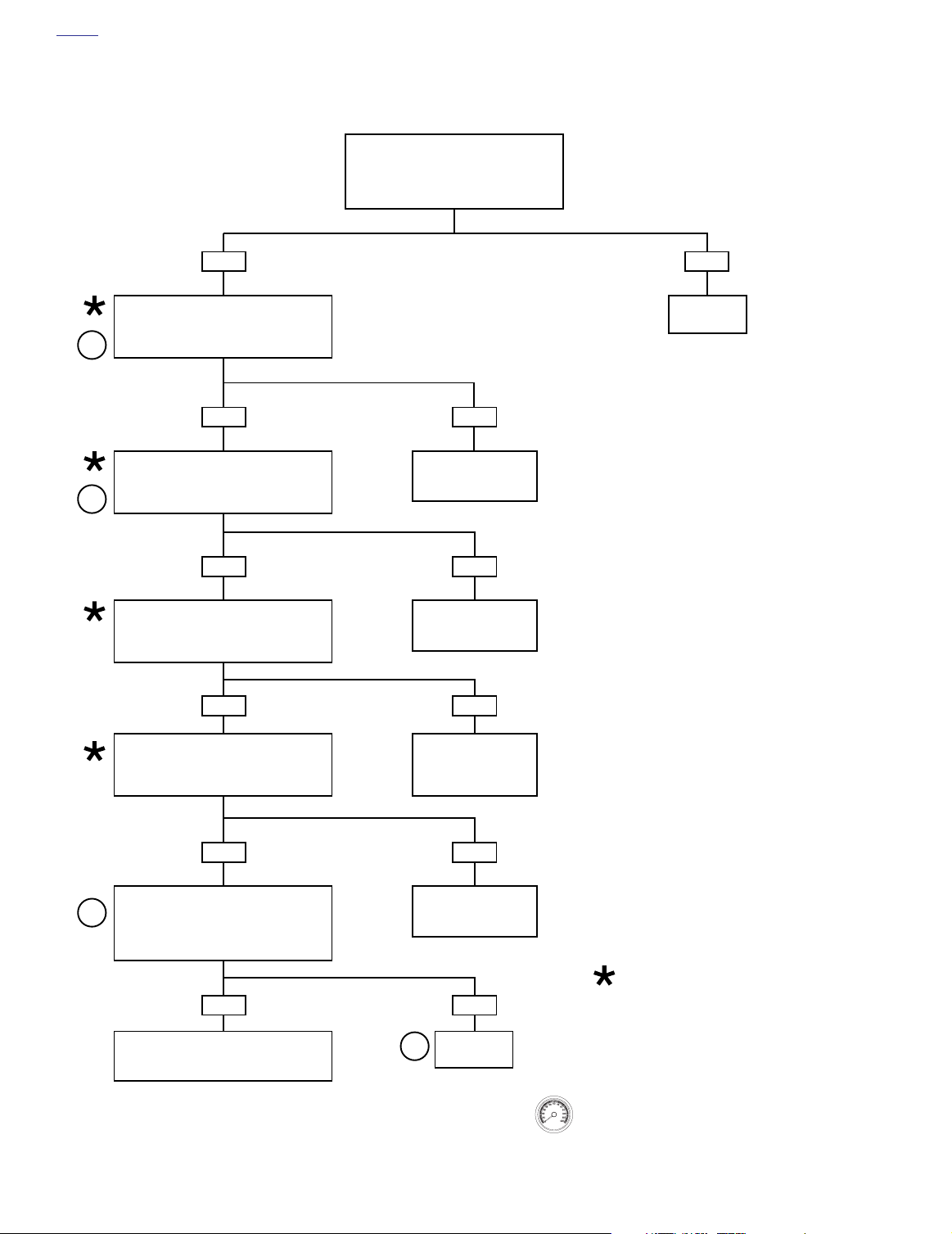

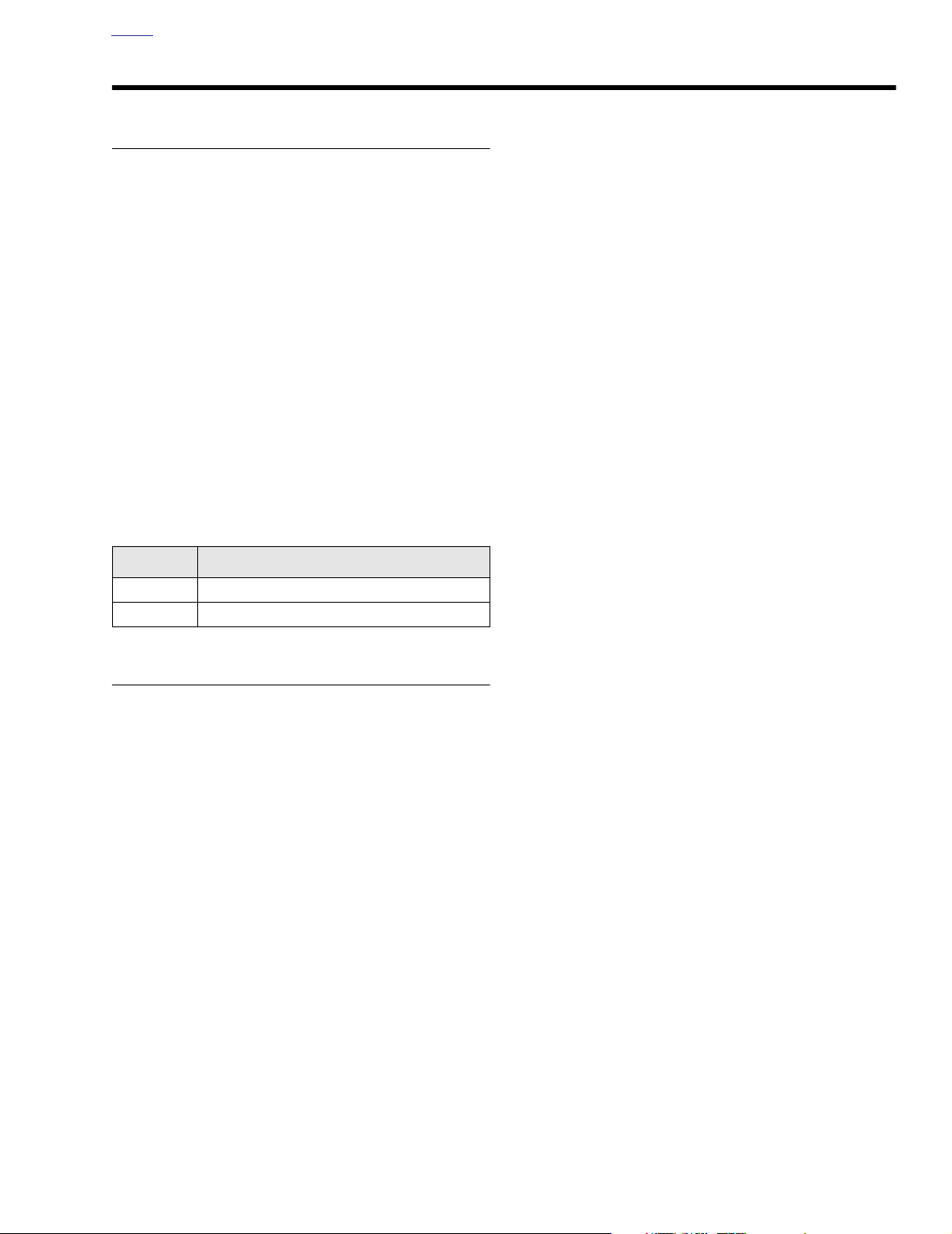

Table 5-28. Code Description

DTC

P0112 IAT sensor voltage low

P0113 IAT sensor open/high

DESCRIPTION

DIAGNOSTICS

Diagnostic Tips

An intermittent may be caused by a poor connection, rubbed

through wire insulation or a wire broken inside the insulation.

Check the following conditions:

●

Poor connection:

[78] for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, poor terminal-to-wire connection and damaged harness.

●

Perform

connections and harness check out OK, use a DVOM to

check the intake air temperature sensor voltage reading

while moving related connectors and wiring harness. If

the failure is induced, the intake air temperature sensor

voltage reading will change.

Shifted sensor:

●

used to test the intake air temperature sensor at various

temperature levels in order to evaluate the possibility of a

shifted (out-of-calibration) sensor which may result in

driveability problems.

All voltage and resistance values are approximate (±20%).

Measure IAT sensor resistance between ECM Terminal 7 and

system ground (ECM Terminal 26).

5.8 WIGGLE TEST

Inspect ECM and harness connector

to locate intermittents:

Refer to Tab le 5-29. This table may be

NOTE

If

Table 5-29. IAT Sensor Table

TEMP °C

-20 29121 4.9 -4

-10 16599 4.8 14

09750 4.6 32

10 5970 4.3 50

20 3747 4.0 68

25 3000 3.8 77

30 2417 3.6 86

40 1598 3.1 104

50 1080 2.6 122

60 746 2.2 140

70 526 1.7 158

80 377 1.4 176

90 275 1.1 194

100 204 0.9 212

RESISTANCE VOLTAGE TEMP °F

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.20 flow charts.

1. Connect BREAKOUT BOX (Part No. HD-43876) to EFI

wire harness

BREAKOUT BOX: EFI.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probes and patch cords.

3. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray socket probes and patch cords.

4. Replace IAT sensor. See Touring Service Manual.

only

(leave ECM disconnected). See 5.7

2004 Touring: Engine Management (EFI) 5-73

Page 6

HOME

f1743r9s

[89A]

IAT

Sensor

A

B

[78B]

[78A]

[89B]

A

Lt GN/Y

B

BK/W

To TP, ET &

MAP Sensors

Lt GN/Y

7 26

ECM

BK/W

Figure 5-47. IAT Sensor Circuit

Table 5-30. Wire Harness Connectors in Figure 5-47.

NO. DESCRIPTION TYPE LOCATION

[78] ECM 36-Place Packard Under Right Side Cover

[89] IAT Sensor 2-Place Packard Below Fuel Tank (Right Side)

5-74 2004 Touring: Engine Management (EFI)

Page 7

HOME

Test 5.20 (Part 1 of 2)

IAT SENSOR: DTC P0112, P0113

Connect Breakout Box to connector [78B] leaving

ECM disconnected. With engine at room temperature

(60-90° F or 16-32° C), use a DVOM to measure

1

resistance across terminals 7 and 26 on Breakout

Box. If engine is warm, refer to Tab le 5-29.

Resistance between 2.0k ohms and 5.0k ohms at

room temperature?

YES

Connect ECM to Breakout Box.

Perform 5.8 WIGGLE TEST to check for

intermittents. Intermittents present?

YES

While wiggling harness, perform

steps marked by BOLD ASTER-

ISKS under Test 5.20 (Part 2 of 2).

Repair as necessary.

YES

Replace IAT sensor, clear codes and

road test. Did check engine lamp illu-

minate and set DTC P0112 or

P0113?

NO

Disconnect IAT sensor connector [89].

Tu rn ignition ON. Using a DVOM, mea-

between ECM terminal 7 (positive) and

terminal 26 (negative) on Breakout Box.

1

disconnect ECM from breakout box.

Breakout Box terminal 7 and terminals

sure the voltage

Voltage approximately 5 volts?

NO.

Less than

4.7 volts.

With IAT sensor disconnected,

Measure resistance between

Resistance less than 1 megohm?

10 or 28.

NO

STOP

Go to Test 5.20 (Part 2 of 2).

NO.

Greater than

5.3 volts.

Unplug ECM leaving Breakout Box con-

1

nected at vehicle harness.

Measure voltage between

Breakout Box terminal 7 and terminals 10

or 28.

Voltage 0 volts?

YES

Install original IAT

sensor, replace ECM,

perform password

learning and road test.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

NO

System

OK.

YES

Repair short to

ground on

Lt GN/Y wire.

NO

Replace ECM.

Reprogram and

learn password.

2004 Touring: Engine Management (EFI) 5-75

YES

Replace ECM.

Reprogram and

learn password.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

Examine IAT sig-

nal wire (Lt GN/Y)

for short to volt-

age and repair.

NO

Page 8

HOME

Test 5.20 (Part 2 of 2)

IAT SENSOR: DTC P0112, P0113

Continued from

Test 5.20 (Part 1 of 2).

Disconnect IAT sensor connector [89B] and

examine for damage. Connector OK?

YES

Using a DVOM, measure the resistance

between IAT sensor connector [89B]

Terminal A and ECM terminal 7 on Breakout

2

2

Box. Resistance less than 1.0 ohm?

YES

Using a DVOM, measure the resistance

between IAT sensor connector [89B]

Terminal B and ECM terminal 26 on Break-

out Box. Resistance less than 1.0 ohm?

YES

Using a DVOM, measure the resistance

between ECM terminal 7 and terminal 26 on

Breakout Box. Resistance greater

than 1.0 megohm?

YES

NO

Examine Lt GN/Y wire in

harness for open circuit

and repair.

NO

Examine BK/W wire in

harness for open circuit

and repair.

NO

NO

Repair

connector.

Using a DVOM, measure the resistance

between ECM terminal 7 on Breakout Box

and ground. Resistance greater

than 1.0 megohm?

YES

Remove IAT sensor and measure resistance

across the terminals of the IAT sensor

3

directly. Again, with sensor at room tempera-

ture 60-90° F or 16-32° C), is resistance

between 2.0k ohms and 5.0k ohms?

YES

Perform 5.8 WIGGLE TEST on steps

marked with a BOLD ASTERISK above to

locate intermittents. Repair as necessary.

5-76 2004 Touring: Engine Management (EFI)

Examine Lt GN/Y and

BK/W wires in harness

for short between these

two circuits and repair.

NO

Examine harness for

short to ground and

repair.

NO

Replace

4

IAT sensor.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Page 9

HOME

DTC P0117, P0118 5.21

GENERAL

ET Sensor

The ECM supplies and monitors a voltage signal (terminal 6)

to one side of the engine temperature sensor (ET sensor).

The other side of the ET sensor is connected to a common

sensor ground (terminal 26) of the ECM.

The ET sensor is a thermistor device, which means that at a

specific temperature it will have a specific resistance across

its terminals. As this resistance varies, so does the voltage

(terminal 6).

At high temperatures, the resistance of the sensor is very

●

low, which effectively lowers the signal voltage on terminal 6.

●

At low temperatures, the resistance is very high, allowing

the voltage to rise close to 5 volts.

The ECM monitors this voltage to compensate for various

operating conditions. The ECM also uses the sensor input as

a reference for determining IAC pintle position.

Table 5-31. Code Description

DTC

P0117 ET sensor voltage low

P0118 ET sensor open/high

DESCRIPTION

DIAGNOSTICS

Diagnostic Tips

Once the engine is started, the ET voltage should rise

●

steadily.

●

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation.

Check the following conditions:

Poor connection:

●

[78] for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, poor terminal-to-wire connection and damaged harness.

Perform

●

connections and harness check out OK, use a DVOM to

check the engine temperature sensor voltage reading

while moving related connectors and wiring harness. If

the failure is induced, the engine temperature sensor

voltage reading will change.

Shifted sensor:

●

used to test the engine temperature sensor at various

temperature levels in order to evaluate the possibility of a

shifted (out-of-calibration) sensor which may result in

driveability problems.

5.8 WIGGLE TEST

Inspect ECM and harness connector

to locate intermittents:

Refer to Tab le 5-32. This table may be

If

Table 5-32. ET Sensor Table

TEMP °C

-20 28144 4.4 -4

-10 15873 4.0 14

09255 3.5 32

10 5571 3.0 50

20 3457 2.4 68

25 2750 2.1 77

30 2205 1.8 86

40 1442 1.3 or 4.1

50 965 1.0 or 3.7

60 661 3.3 140

70 462 2.9 158

80 329 2.5 176

90 238 2.1 194

100 175 1.7 212

*

Between 40-50°C the ECM changes scaling. Voltages for ECT

sensor will shift scales in that range. This provides proper sensor resolution for all temperatures.

RESISTANCE VOLTAGE TEMP °F

*

*

104

122

NOTE

All voltage and resistance values are approximate (±20%).

Measure ET sensor resistance between ECM Terminal 6 and

system ground (ECM Terminal 26).

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.21 flow charts.

1. Connect BREAKOUT BOX (Part No. HD-43876) to EFI

wire harness

BREAKOUT BOX: EFI.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probes and patch cords.

3. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray socket probes and patch cords.

4. Replace ET sensor. See Touring Service Manual.

only

(leave ECM disconnected). See 5.7

2004 Touring: Engine Management (EFI) 5-77

Page 10

HOME

f1743s9s

ET

Sensor

[90A]

[90B]

AB

A

B

PK/Y

BK/W

PK/Y

To TP, IAT &

MAP Sensors

BK/W

[78B]

[78A]

ECM

6 26

Figure 5-48. ET Sensor Circuit

Table 5-33. Wire Harness Connectors in Figure 5-48.

NO.

[78] ECM 36-Place Packard Under Right Side Cover

[90] ET Sensor 2-Place Packard Back of Front Cylinder (Left Side)

5-78 2004 Touring: Engine Management (EFI)

DESCRIPTION TYPE LOCATION

Page 11

HOME

Test 5.21 (Part 1 of 2)

ET SENSOR: DTC P0117, P0118

Connect Breakout Box to connector [78B]

leaving ECM disconnected. With engine at

room temperature (60-90° F or 16-32° C),

1

use a DVOM to measure resistance across

terminals 6 and 26 on Breakout Box. If

engine is warm, refer to Table 5-32. Resistance between 2.0k ohms and 5.0k ohms?

YES

Connect ECM to Breakout Box.

Perform 5.8 WIGGLE TEST to check for

intermittents. Intermittents present?

YES

While wiggling harness, perform

steps marked by BOLD ASTER-

ISKS under Test 5.21 (Part 2 of 2).

Repair as necessary.

YES

Replace ET sensor, clear codes and

road test. Did check engine lamp illu-

minate and set DTC P0117 or

P0118?

NO

Disconnect ET sensor connector [90].

Turn ignition ON. Using a DVOM, mea-

sure the voltage between

terminal 6 (positive) and

terminal 26 (negative) on Breakout Box.

Voltage approximately 5 volts?

NO.

Less than

4.7 volts.

With ET sensor disconnected,

disconnect ECM connector [78B].

Measure resistance between

terminal 6 and terminals 10 or 28.

Resistance less than 1 megohm?

NO

STOP

Go to Test 5.21 (Part 2 of 2).

NO.

Greater than

5.3 volts.

Unplug ECM leaving Breakout Box

connected at vehicle harness.

Measure voltage between

terminal 6 and terminals 10 or 28.

Voltage 0 volts?

YES

Install original

ET sensor,

replace ECM, perform

password learning

and road test.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

NO

System

OK.

YES

Repair short to

ground on

PK/Y wire.

NO

Replace ECM.

Reprogram and

learn password.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

2004 Touring: Engine Management (EFI) 5-79

YES

Replace ECM.

Reprogram and

learn password.

NO

Examine ET sig-

nal wire (PK/Y) for

short to voltage

and repair.

Page 12

HOME

Test 5.21 (Part 2 of 2)

ET SENSOR: DTC P0117, P0118

Continued from

Test 5.21 (Part 1 of 2).

Disconnect ET sensor connector [90B] and

examine for damage. Connector OK?

YES

Using a DVOM, measure the resistance

between ET sensor connector [90B]

Terminal A and ECM terminal 6 on Breakout

2

2

Box. Resistance less than 1.0 ohm?

YES

Using a DVOM, measure the resistance

between ET sensor connector [90B]

Terminal B and ECM terminal 26 on Break-

out Box. Resistance less than 1.0 ohm?

YES

Using a DVOM, measure the resistance

between ECM terminal 6 and terminal 26 on

Breakout Box. Resistance greater

than 1.0 megohm?

YES

NO

Examine PK/Y wire in

harness for open circuit

and repair.

NO

Examine BK/W wire in

harness for open circuit

and repair.

NO

NO

Repair

connector.

Using a DVOM, measure the resistance

between ECM terminal 6 on Breakout Box

and ground. Resistance greater

than 1.0 megohm?

YES

Remove ET sensor and measure resistance

3

across the terminals of the ET sensor

directly. Again, with sensor at room tempera-

ture (60-90° F or 16-32° C), is resistance

between 2.0k ohms and 5.0k ohms?

YES

Perform 5.8 WIGGLE TEST on steps

marked with a BOLD ASTERISK above to

locate intermittents. Repair as necessary.

5-80 2004 Touring: Engine Management (EFI)

Examine PK/Y and

BK/W wires in harness

for short between these

two circuits and repair.

NO

Examine harness for

short to ground and

repair.

NO

Replace

4

ET sensor.

At some point in the flow chart

you may be instructed to jump

directly to a the box with the bold

asterisk. Disregard the asterisk

(but not the instruction box) if your

normal progression through the

chart brings you to this location.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Page 13

HOME

DTC P0122, P0123 5.22

GENERAL

TP Sensor

The ECM supplies a 5 volt signal (terminal 14) to the throttle

position sensor (TP sensor). The TP sensor sends a signal

back to the ECM (terminal 24). The returned signal varies in

voltage according to throttle position.

At idle (closed throttle), the signal is typically in the range

●

of 0.20-0.80 volts.

●

At wide open throttle, the signal is normally 4.0-4.9 volts.

A code P0122 or P0123 will set if the TP sensor voltage signal does not fall within the acceptable range.

Check TP sensor voltage reading with DVOM. If TP sen-

●

sor is equal to or greater than 3.8 volts then the system is

in “clear flood” mode and engine will not start. While

spark is present, fuel is shut off. Problem can be

mechanical, such as stuck throttle cables.

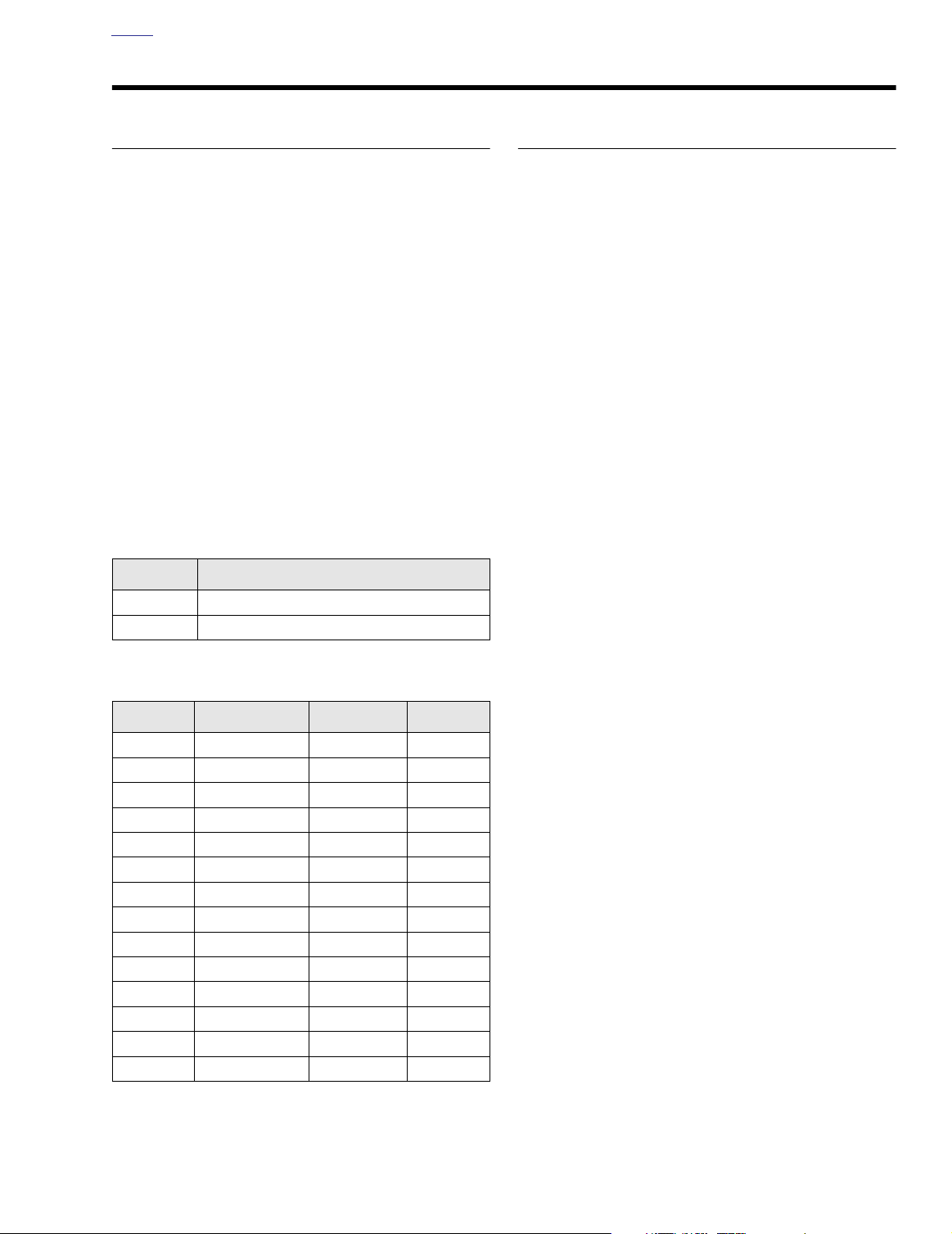

Table 5-34. Code Description

DTC

P0122 TP sensor open/low

P0123 TP sensor high

DESCRIPTION

DIAGNOSTICS

Check for the following conditions:

Poor Connection:

●

[78B] for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, poor terminal-to-wire connection and damaged harness.

●

Perform

connections and harness check out OK, monitor TP sensor voltage using a DVOM while moving related connectors and wiring harness. If the failure is induced, the TP

sensor voltage reading will change.

●

TP sensor scaling:

play while opening the throttle with engine stopped and

ignition key ON. Display should vary from closed throttle

TP sensor voltage (when throttle is closed) to greater

than 4.0 volts (when throttle is held wide open). As the

throttle is

gradually without spikes or low voltages being observed.

5.8 WIGGLE TEST

Inspect ECM and harness connector

to locate intermittents:

Observe the TP sensor voltage dis-

slowly

moved, the voltage should change

If

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.22 flow charts.

1. Connect a BREAKOUT BOX (Part No. HD-43876)

between EFI wire harness and ECM before measuring

voltage. See 5.7 BREAKOUT BOX: EFI. If using a DVOM

to measure voltage, take reading across terminal 24

(positive lead) and terminal 26 (negative lead) on Breakout Box.

2. Replace TP sensor. See Touring Service Manual.

Diagnostic Tips

The DVOM reads throttle position in volts. Voltage should

increase at a steady rate as the throttle is moved from idle to

wide open. A short to ground or open on the GY/V or R/W

wires also will result in a DTC P0122. A short to ground or

open on the R/W wire (+5v REF) sets multiple codes as

described below.

NOTE

The MAP, TP and VSS sensors are connected to the same

reference line (+5V Vref). If the reference line goes to ground

or open, multiple codes will be set (DTC P0107, P0108,

P0122, P0123, P0501, P0502). Start with the trouble code

having the lowest ranking value.

3. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probes and patch cords.

2004 Touring: Engine Management (EFI) 5-81

Page 14

HOME

s0452x9x

TP

sensor

[88A]

[88B]

ABC

A

BC

R/W

BK/W

To MAP

sensor

GY/V

R/W

To MAP, ET &

IAT sensors

GY/V

BK/W

[78B]

[78A]

14 24 26

ECM

Figure 5-49. TP Sensor Circuit

Table 5-35. Wire Harness Connectors in Figure 5-49.

NO. DESCRIPTION TYPE LOCATION

[78] ECM 36-Place Packard Under Right Side Cover

[88] TP Sensor 3-Place Packard Below Fuel Tank (Right Side)

5-82 2004 Touring: Engine Management (EFI)

Page 15

HOME

Test 5.22 (Part 1 of 2)

TP SENSOR: DTC P0122, P0123

With ignition key ON, measure TP sensor voltage while gradu-

ally opening throttle. Does voltage increase steadily

with no spikes or low voltages from 0.2-0.8 volts at idle

1

(closed throttle) to 4.0-4.9 volts at wide open throttle?

Check engine lamp ON

continuously and

DTC P0122 or P0123

the only one set?

YES

YES

Replace ECM.

Reprogram and

learn password.

YES NO

While wiggling harness,

start with the first step of

Test 5.22 (Part 2 of 2)

(marked by BOLD ASTER-

ISK). Repair as necessary.

YES

NO

Perform 5.8 WIGGLE TEST

to check for intermittents.

Intermittents present?

Replace TP sensor, clear

2

codes and road test.

Did check engine lamp

illuminate and set DTC

P0122 or P0123?

Voltage is

greater than

4.95 volts.

STOP

Go to Test 5.22 (Part 2 of 2).

2

YES

Replace

TP sensor.

NO

Low voltage

observed.

Unplug TP sensor connector [88B]

and measure voltage between

Terminal B (+) and Terminal A (-)

with ignition ON.

Is reading 4.8-5.0 volts?

YES

Disconnect ECM from

Breakout Box. Check

resistance between ECM

terminal 24 on Breakout

Box to chassis ground.

Greater than 1 megohm?

NO

Find short to

ground on GY/V

signal wire.

or spikes

NO

Measure

resistance

between

TP sensor

connector [88B]

Terminal B to

ECM terminal 14

on Breakout Box.

Less than

1.0 ohm?

YES

Install original

TP sensor, replace ECM

(reprogram and learn

password) and road test.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

NO

System

OK.

YES

Repair open

in BK/W wire.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

NO

Repair open

in R/W wire.

2004 Touring: Engine Management (EFI) 5-83

Page 16

HOME

Test 5.22 (Part 2 of 2)

TP SENSOR: DTC P0122, P0123

YES NO

Continued from Test 5.22 (Part 1 of 2).

With ignition key OFF, disconnect ECM connector [78B]. Turn

ignition key ON. Voltage greater than 0 volts across terminal 24

and terminal 26 on Breakout Box?

Repair short

between GY/V signal

wire and 12 volts.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

YES

Repair short

between R/W and

GY/V signal wire.

ECM terminal 24 on Breakout Box and

TP sensor connector [88B] Terminal C.

3

YES

Measure resistance from TP

sensor connector [88B]

Terminal C to Terminal B.

Less than 1.0 megohm?

3

NO

Replace

TP sensor.

2

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

Measure resistance between

Less than 0.5 ohm?

NO

Repair open

GY/V

signal wire.

5-84 2004 Touring: Engine Management (EFI)

Page 17

HOME

s0472x9x

HD34730-2C

DTC P0261, P0262, P0263, P0264 5.23

GENERAL

Fuel Injectors

The fuel injectors are solenoids that allow pressurized fuel

into the intake tract. The injectors are timed to the engine

cycle and triggered sequentially. The power for the injectors

comes from the system relay. The system relay also provides

power for the fuel pump and the ignition coil. The ECM provides the path to ground to trigger the injectors.

NOTE

ECM fuse and system relay failures or wiring harness problems will cause 12 volt power to be lost to both injectors, ignition coils and fuel pump.

Table 5-36. Code Description

Figure 5-50. Fuel Injector Connector

DTC

P0261 Front injector open/low

P0262 Front injector high

P0263 Rear injector open/low

P0264 Rear injector high

DESCRIPTION

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.23 flow charts.

1. See Touring Service Manual for all service information.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), purple pin probe and patch cord.

3. Connect a BREAKOUT BOX (Part No. HD-43876)

between EFI wire harness and ECM. See 5.7 BREAK-

OUT BOX: EFI.

Figure 5-51. Fuel Injector Test Lamp

(Part No. HD-34730-2C)

2004 Touring: Engine Management (EFI) 5-85

Page 18

HOME

f2208h8x

System relay

Power gnd.

Switch power

ECM

Power gnd.

Constant power

Coil R

Inj. R

Inj. F

Ion sense

Coil F

[78A] [78B]

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10 11 12

10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

GN/O

GN/GY

Y/BE

W/Y

BE/GY

BE/O

W/BK

W/Y

AB

[84B] [84A]

AB

[85B] [85A]

ECM fuse

GY/BE

BK

W/BK

[8B] [8A]

AB

AB

15 amp

R

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

Y/GN

Y/GN

GY/BE

Y/BE

BE/O

W/BK

BK

BE/GY

IGN fuse

W/BK

R

15 amp

GY

10

12

11

10

12

11

Y/GN

[83B] [83A]

R/BK

DCBA

9

9

15 amp

fuel pump

fuse

AB CD

AB CD

R

[33B]

[33A]

Ignition

switch

12345

678

12345

678

[62B]

Y/GN

BE/GY

GN/O

W/BK

[13A] [13B]

123

123

BK

Ignition

coil

40 Amp

Maxi Fuse

[1B]

[1A]

System relay

87

IQCPR

87A

30 85 86

Fuel pump

123

O/GY

[141B][141A]

Battery

123

–+

BK

BK

BK

BK

10

12

11

9

10

12

11

9

12345

678

678

[22A]

[22B]

12345

Engine stop

switch

Figure 5-52. Battery Voltage Circuit (FLTR, FLHT/C/U)

Table 5-37. Wire Harness Connectors in Figure 5-52.

NO.

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing (Right Fairing Bracket)

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inner Fairing (Right Fairing Support Brace)

[33] Ignition/Light Key Switch 4-Place Packard Inner Fairing (Top Fork Bracket)

[78] ECM 36-Place Packard Under Right Side Cover

[83] Ignition Coil 4-Place Packard Below Fuel Tank (Left Side)

[84] Front Injector 2-Place Packard Below Fuel Tank (Left Side)

[85] Rear Injector 2-Place Packard Below Fuel Tank (Left Side)

5-86 2004 Touring: Engine Management (EFI)

DESCRIPTION TYPE LOCATION

Page 19

HOME

f2208m8x

System relay

Power gnd.

Switch power

ECM

Ion sense

Power gnd.

Constant power

Coil R

Inj. R

Inj. F

Coil F

[78A] [78B]

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10 11 12

10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

GN/O

GN/GY

Y/BE

W/Y

BE/GY

BE/O

W/BK

W/Y

BK

BK

AB

[84B] [84A]

AB

[85B] [85A]

15 amp

ECM fuse

GY/BE

BK

W/BK

[8B] [8A]

AB

AB

12

11

10

9

8

7

6

5

4

3

2

1

[62B]

Y/GN

BE/GY

System relay

[62B]

87

IQCPR

87A

30 85 86

GN/O

W/BK

Fuel pump

123

Y/GN

15 amp

fuel pump

fuse

Y/GN

Y/GN

BK

123

[141B][141A]

Y/GN

AB CD

AB CD

GY/BE

Y/BE

Ignition

coil

BE/O

W/BK

[83B] [83A]

BE/GY

–+

Battery

R

12

BK

11

10

9

8

7

6

5

4

3

2

1

W/BK

BK

R

R/BK

15 amp

IGN fuse

10

12

11

10

12

11

12-Place on

FLHP Only

GY

9

9

I B A

R

678

678

40 Amp

Maxi Fuse

[33B]

[33A]

Ignition

switch

12345

[22A]

[22B]

12345

Engine stop

switch

BK

Figure 5-53. Battery Voltage Circuit (FLHR/C/S)

Table 5-38. Wire Harness Connectors in Figure 5-53.

NO.

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inside Headlamp Nacelle

[33] Ignition/Light Key Switch 3-Place Packard Under Console

[78] ECM 36-Place Packard Under Right Side Cover

[83] Ignition Coil 4-Place Packard Below Fuel Tank (Left Side)

[84] Front Injector 2-Place Packard Below Fuel Tank (Left Side)

[85] Rear Injector 2-Place Packard Below Fuel Tank (Left Side)

DESCRIPTION TYPE LOCATION

2004 Touring: Engine Management (EFI) 5-87

Page 20

HOME

Test 5.23 (Part 1 of 3)

FUEL INJECTORS: DTC P0261, P0262, P0263, P0264

Is wire bail on connector securely

1

YES NO

attached to the fuel injector?

See Figure 5-51. Using Fuel

Injector Test Lamp, crank

engine. Does lamp flash?

YES NO

Recheck connections.

Perform 5.8 WIGGLE TEST

to check for intermittents.

Intermittents present?

YES NO

Repair

intermittent.

YES NO

Measure resistance of

suspect injector across

2

injector terminals.

Resistance

10.0-25.0 ohms?

2

YES NO

STOP

Go to Test 5.23 (Part 2 of 3).

YES NO

Reconnect.

Check Terminal A (Y/GN wire)

on injector connector to ground.

Voltage equivalent to

battery voltage for 2 seconds

after key ON?

Check for 12 volts at terminal 87 of sys-

tem relay during first 2 seconds after

key ON. Correct voltage present?

Check for loose

or corroded terminals

in harness.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

1

5-88 2004 Touring: Engine Management (EFI)

Replace

injector.

YES NO

Perform 5.8 WIGGLE TEST

to check for intermittents.

Repair as necessary.

System relay OK. Measure

resistance between terminal 87 of

system relay and Terminal A

(Y/GN wire) at injector connector.

Resistance less than 0.5 ohm?

Find and repair

bad connection

or open wire.

STOP

Go to Test 5.23

(Part 3 of 3).

Page 21

HOME

Test 5.23 (Part 2 of 3)

FUEL INJECTORS: DTC P0261, P0262, P0263, P0264

2

3

FRONT INJECTOR: DTC P0261 or P0262.

Measure resistance between Breakout Box terminal 21

(W/Y wire) and Terminal B of front injector connector

Check for continuity between terminal

Front injector codes: Check continuity

between terminal 21 and terminal 10.

Rear injector codes: Check continu-

ity between terminal 19 and terminal

10 and ground.

Continuity present?

[84B].

YES

or

10.

YES

Resistance

less than 0.5 ohm?

Repair open

REAR INJECTOR: DTC P0263 or P0264.

Measure resistance between Breakout Box terminal 19

(GN/GY wire) and Terminal B of rear injector connector

NO

NO

[85B].

NO

Repair open or

poor connection.

2

3

Repair short

to ground.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Check for voltage with key on.

Front injector codes: Check

Breakout Box terminal 21.

Rear injector codes: Check

Breakout Box terminal 19.

Voltage present after 2 seconds?

YES

Repair short

to voltage.

NO

Replace ECM. Reprogram

and learn password.

2004 Touring: Engine Management (EFI) 5-89

Page 22

HOME

Test 5.23 (Part 3 of 3)

FUEL INJECTORS: DTC P0261, P0262, P0263, P0264

Continued from Test 5.23 (Part 1 of 3).

Check for 12 volts at terminal 30 of the system relay.

Correct voltage present?

Check for 12 volts at terminal 86

3

of the system relay.

Correct voltage present?

Measure resistance between

terminal 86 of the system

relay and ECM terminal 13 on

Breakout Box.

Resistance less than 0.5 ohm?

Measure resistance between

terminal 85 of the system relay

and ECM terminal 4 on Break-

Resistance less than 0.5 ohm?

out Box.

YES

YES

YES

NO

Find and repair open on

BE/GY wire between

fuse and relay.

NO

See 5.11 NO ECM

POWER.

NO

Find and repair

open on W/BK

wire.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

5-90 2004 Touring: Engine Management (EFI)

YES

Install known good relay.

Does fuel pump run for first

2 seconds after key ON?

YES

Replace

relay

NO

Find and repair

open on GN/O

wire.

NO

Reinstall original relay.

Replace ECM. Reprogram

and learn password.

Page 23

HOME

f2217x8x

Socket Screw

f2256x8x

Crankshaft

Position Sensor

Connector [79]

Under Voltage Regulator

DTC P0373, P0374 5.24

GENERAL

CKP Sensor

If the crank position sensor (CKP sensor) signal is weak or

absent, diagnostic trouble codes P0373 or P0374 will be set.

NOTE

If signal is not detected or cannot synchronize (DTC P0374),

engine will not start.

Table 5-39. Code Description

DTC

P0373 CKP sensor intermittent

P0374 CKP sensor synch error

DESCRIPTION

DIAGNOSTICS

Diagnostic Tips

Engine must be cranked for more than five seconds with-

●

out CKP signal to set code.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.24 flow chart.

1. Connect BREAKOUT BOX (Part No. HD-43876) to ECM

wire harness

BREAKOUT BOX: EFI.

2. One megohm is very high resistance. Some meters will

read ∞, OL, etc.

3. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), brown socket probes and patch cords.

4. For testing purposes, install sensor without running wiring along normal path. Disconnect and route wiring properly if system is now OK.

only

(leave ECM disconnected). See 5.7

Figure 5-54. Crankshaft Position Sensor

Figure 5-55. Voltage Regulator (Left Side View)

2004 Touring: Engine Management (EFI) 5-91

Page 24

HOME

s0453x9x

CKP

sensor

[78B]

[78A]

[79A]

[79B]

ECM

12

1

2

R

BK

BK

Gnd.

BK

BK

1210 28 30

CKP.

Gnd.

R

CKP.

Figure 5-56. CKP Circuit

Table 5-40. Wire Harness Connectors in Figure 5-56.

NO.

[78] ECM 36-Place Packard Under Right Side Cover

[79] CKP Sensor 2-Place Mini-Deutsch Under Right Side Cover

5-92 2004 Touring: Engine Management (EFI)

DESCRIPTION TYPE LOCATION

Page 25

HOME

Test 5.24

CKP SENSOR: DTC P0373, P0374

Connect Breakout Box to harness only,

1

Measure resistance between terminals 30 and 28

and between terminals 12 and 28 on Breakout Box.

2

leaving ECM disconnected.

Resistance more than 1 megohm?

YES

Check for intermittent connection, pinched

or damaged wires, and loose CKP sensor

fasteners. Conditions found?

YES

Repair as

necessary.

YES

With DVOM still connected, check for inter-

mittents using 5.8 WIGGLE TEST. Intermit-

tents present?

YES

Repair as

necessary.

Install known

good CKP sensor. Clear codes

and retest. DTC

P0373 or P0374

4

NO

NO

Connect DVOM to terminals 12 and 30

Set DVOM to AC volts and crank engine.

3

on Breakout Box.

Does DVOM read 1 VAC minimum

during cranking?

NO

Connect DVOM at Ter minals 1

and 2 of connector [79A].

Does DVOM read 1 VAC

minimum while cranking?

YES

Check for continuity between

Terminal 1 of connector [79B]

and terminal 30 on Breakout

Box.

Continuity present?

NO

Disconnect connector [79]. Leaving

ECM disconnected, measure resistance

between terminals 12 and 28 and

terminals 30 and 28 on Breakout Box.

Continuity to ground

(less than 1 megohm resistance)?

YES

Repair short to

ground on R or

BK wire between

connectors [78B]

and [79B].

NO

Replace CKP sen-

sor. See Touring

Service Manual.

CKP sensor.

See Touring Ser-

vice Manual.

NO

Replace

YES

Reinstall original

CKP sensor.

Replace ECM.

Reprogram and

learn password.

NO

Replace CKP

sensor

YES

Repair open on BK wire

between Terminal 2 of

connector [79B] and

terminal 12 of Breakout Box.

NO

Repair open on R wire

between Terminal 1 of

connector [79B] and

terminal 30 of Breakout Box.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (EFI) 5-93

Page 26

HOME

DTC P0501, P0502 5.25

GENERAL

Vehicle Speed Sensor

See Figure 5-57. The vehicle speed sensor is powered and

monitored by the ECM. The ECM processes the vehicle

speed signal and transmits this signal to the TSM/TSSM and

speedometer through serial data.

NOTE

When the vehicle speed is greater than 0, the closed loop idle

speed control is inhibited.

Table 5-41. Code Description

DTC

P0501 VSS sensor low

P0502 VSS sensor high/open

DESCRIPTION

DIAGNOSTICS

7951

Figure 5-57. Vehicle Speed Sensor

f2183x8x

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.25 flow charts.

1. The speedometer has a built-in diagnostic mode. See

2.3 SPEEDOMETER SELF DIAGNOSTICS.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black pin probe and patch cord.

3. Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ECM. See 5.7 BREAKOUT

BOX: EFI.

1

2

1. Vehicle Speed Sensor [65]

2. P&A Security Siren [142]

Figure 5-58. Electrical Bracket (Inboard Side)

5-94 2004 Touring: Engine Management (EFI)

Page 27

HOME

f2208v8x

[39A]

[39B]

Vehicle speed

sensor

R

W

BK

A

B

C

[65A]

Speedometer

2

LGN/V

A

B

C

[65B]

To Cruise and Sound System

R/W

W/GN

BK

BK

To TP, MAP Sensors

[78B]

[78A]

5

10

14

33

ECM

VSS

serial data

ground

5v power

Figure 5-59. Vehicle Speed Sensor Circuit

Table 5-42. Wire Harness Connectors in Figure 5-59.

NO.

[39] Speedometer

[65] Speedometer Speed Sensor All 3-Place Deutsch

[78] ECM All 36-Place Packard Under Right Side Cover

DESCRIPTION MODEL TYPE LOCATION

FLTR 12-Place Packard

Under Instrument Bezel

(Back of Speedometer)

FLHT/C/U 12-Place Packard Inner Fairing (Back of Speedometer)

FLHR/C/S 12-Place Packard Back of Speedometer (Under Console)

Under Right Side Cover

(Behind Electrical Bracket)

2004 Touring: Engine Management (EFI) 5-95

Page 28

HOME

Test 5.25 (Part 1 of 2)

VEHICLE SPEED SENSOR: DTC P0501, P0502

Inspect connector [65]. Is connector mated properly?

1

YES

System OK.

YES

Remove and inspect speedometer sensor. Inspect for

debris and clean if necessary. Place speedometer

into diagnostic mode and clear fault codes. Connect

all circuits and ride motorcycle for approximately 1.0

mile (1.6 km). Check for speedometer function.

Speedometer functioning properly?

Check for continuity between terminal

2

A of connector [65B] (R/W wire) and

ground. Continuity present?

YES

Repair short to ground.

NO

Mate connector [65].

NO

Check for continuity between terminal A

2

of connector [65B] (R/W wire) and ter-

minal 14 of breakout box. Continuity

3

present?

NO

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

YES

STOP

Go to. Test 5.25

(Part 2 of 2)

5-96 2004 Touring: Engine Management (EFI)

YES

Check for continuity between terminal C

of connector [65B] (BK wire) and

ground. Continuity present?

Repair open on Black wire

between [65B] and ground.

Locate and repair open on

R/W wire between [78B]

NO

NO

and [65B].

Page 29

HOME

Test 5.25 (Part 2 of 2)

VEHICLE SPEED SENSOR: DTC P0501, P0502

YES

Check for voltage on W/GN wire of connector

[65B] while connected. Meter should read 4-6

volts when gear tooth absent and 0-1 volts

when gear tooth is present. Does it?

YES NO

Replace ECM. Reprogram

and learn password.

2

3

4-6 volts not present.

Continued from Test 5.25 (Part 1 of 2).

Check for continuity between terminal B of connector

[65B] and terminal 33 of breakout box. Continuity

present?

fluctuation from 0-1 volts.

Locate and repair open on

W/GN wire between [78B]

4-6 volts present but no

NO

and [65B].

Replace ECM. Reprogram

and learn password.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Replace speed sensor.

2004 Touring: Engine Management (EFI) 5-97

Page 30

HOME

DTC P0562, P0563 5.26

GENERAL

Battery Voltage

Battery voltage is monitored by the ECM (terminal 13). If the

battery voltage fails to meet normal operating parameters, a

code is set.

● Code P0562 is displayed when battery positive voltage is

less than 11.0 volts at 2000 RPM for longer than 5 seconds.

● Code P0563 is displayed when battery positive voltage is

greater than 16.0 volts for more than 4 seconds.

NOTES

● Warm idle speed will be automatically increased if bat-

tery voltage is low at idle.

● TSSM problems may also set a code P0562 or P0563.

Table 5-43. Code Description

DTC DESCRIPTION

P0562 Battery voltage low

P0563 Battery voltage high

System Fuse Block (Under Left Side Cover)

FLHR/C/S

10

9

8

5

11

12

f2210x8x

1

FLTR, FLHT/C/U

10

9

2

8

3

7

6

5

11

4

4

DIAGNOSTICS

Diagnostic Tips

● Low voltage generally indicates a loose wire, corroded

connections, battery and/or a charging system problem.

● A high voltage condition may be caused by a faulty volt-

age regulator.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.26 flow charts.

1. Was battery allowed to discharge? Was battery drawn

down by a starting problem?

a. Yes. Charge battery.

b. No. See charging system troubleshooting.

2. Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ECM. See 5.7 BREAKOUT

BOX: EFI.

3. Use DVOM with RPM Pick-up to check RPM on vehicles

without tachometers.

f2204x8x

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory

4. This checks for voltage drops in the ECM circuit.

a. Place (+) probe to battery positive terminal.

b. Place (-) probe to W/BK terminal on Breakout Box.

5. Problem is most likely the ground connection at the

frame.

6. Connect BREAKOUT BOX (Part No. HD-42682) to Connector [22]. FLHR/C/S models will also need HD-42962

adapters.

1

Figure 5-60. Fuse Locations

2

7. Radio Power

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

12. Starter Relay

3

5-98 2004 Touring: Engine Management (EFI)

Page 31

HOME

f2208k8x

System relay

Power gnd.

Switch power

ECM

[78A] [78B]

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10 11 12

10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

GN/O

BK

W/BK

Y/GN

BE/GY

GN/O

W/BK

[62B]

87

IQCPR

87A

30 85 86

System relay

Power gnd.

Constant power

15 amp

ECM fuse

R/BK

15 amp

IGN fuse

GY

10

12

11

10

12

11

10

12

11

10

12

11

DCBA

9

9

9

9

BE/GY

BK

BK

BK

W/BK

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

[8B] [8A]

W/BK

Engine stop

switch

Figure 5-61. Battery Voltage Circuit (FLTR, FLHT/C/U)

678

678

678

678

R

[33B]

[33A]

Ignition

switch

12345

12345

12345

12345

40 Amp

Maxi Fuse

[1B]

[1A]

[22A]

[22B]

–+

Battery

BK

Table 5-44. Wire Harness Connectors in Figure 5-61.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing (Right Fairing Bracket)

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inner Fairing (Right Fairing Support Brace)

[33] Ignition/Light Key Switch 4-Place Packard Inner Fairing (Top Fork Bracket)

[78] ECM 36-Place Packard Under Right Side Cover

2004 Touring: Engine Management (EFI) 5-99

Page 32

HOME

f2208j8x

System relay

Power gnd.

Switch power

ECM

Power gnd.

Constant power

[78A] [78B]

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10 11 12

10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

GN/O

BK

W/BK

15 amp

ECM fuse

BE/GY

BK

BK

BK

W/BK

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

[8B] [8A]

R/BK

15 amp

IGN fuse

W/BK

12

11

12

11

12-Place on

FLHP Only

[62B]

87

Y/GN

BE/GY

GN/O

W/BK

IQCPR

87A

30 85 86

System relay

40 Amp

Maxi Fuse

–+

Battery

BK

R

I B A

[33B]

[33A]

678

678

Ignition

switch

12345

12345

[22A]

[22B]

GY

10

9

10

9

Engine stop

switch

Figure 5-62. Battery Voltage Circuit (FLHR/C/S)

Table 5-45. Wire Harness Connectors in Figure 5-62.

NO. DESCRIPTION TYPE LOCATION

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inside Headlamp Nacelle

[33] Ignition/Light Key Switch 3-Place Packard Under Console

[78] ECM 36-Place Packard Under Right Side Cover

5-100 2004 Touring: Engine Management (EFI)

Page 33

HOME

Test 5.26 (Part 1 of 2)

BATTERY VOLTAGE: DTC P0562, P0563

Perform charging system tests.

1

Charging system OK?

YES

Connect Breakout Box. Measure voltage on

2

Breakout Box between terminal 13 (+) and

terminal 10 (-) and again between terminal

13 and terminal 28 (-) with engine running at

3

2000 RPM or higher for 10 seconds or

longer. Is voltage above 11.0 volts?

YES

1

System

OK.

NO

With ignition ON, measure voltage drop

4

between battery positive (+) terminal

and Breakout Box terminal 13 (-).

Is voltage drop greater

than 0.5 volt?

YES

With ignition ON, measure voltage drop

between battery positive (+) terminal

and connector [22A] terminal 4 (-) (black). Is

voltage drop greater than 0.5 volt?

NO

Repair charging system.

See Section 1.

NO

Check for voltage drop between battery

negative (-) terminal and terminal 10 (+)

on Breakout Box connector and between

battery negative (-) terminal and terminal 28

Breakout Box. Is voltage drop greater than

on

0.5 volt?

YES

With ignition ON, measure voltage drop

between battery positive (+) terminal

and connector [22A] terminal 3 (-). Is voltage

drop greater than 0.5 volt?

YES

STOP

Go to Test 5.26 (Part 2 of 2).

NO

Replace W/BK

wire between

[22A] and [78B] or

terminals.

NO

Inspect [22] for corrosion or

loose wires. If above conditions

are not present, replace engine

stop switch.

YES

Locate and repair

bad connection.

NO

Problem is intermittent.

Perform 5.8 WIGGLE

TEST. Locate and

repair bad connection.

5

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (EFI) 5-101

Page 34

HOME

Test 5.26 (Part 2 of 2)

BATTERY VOLTAGE: DTC P0562, P0563

With ignition ON, measure voltage drop between battery positive (+) terminal and GY terminal on 15 amp

ignition fuse (-). Is voltage drop greater than 0.5 volt?

Continued from Test 5.26 (Part 1 of 2).

YES

With ignition ON, measure voltage drop

between battery positive (+) terminal and

R/BK terminal at 15 amp ignition fuse. Is

voltage drop greater than 0.5 volt?

YES

With ignition ON, measure voltage drop

between battery positive (+) and both fuse

Is voltage drop greater than 0.5 volt?

With ignition ON, measure voltage drop

between battery positive (+) terminal and

Is voltage drop greater than 0.5 volt?

terminals (-).

YES

one fuse terminal (-).

NO

Replace GY wire

or terminals.

NO

Replace fuse or

fuse terminals.

NO

Replace ignition

switch or terminals.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

5-102 2004 Touring: Engine Management (EFI)

YES

High resistance between

maxi fuse and battery. Replace

wire or terminals.

NO

Replace maxi fuse.

Page 35

HOME

DTC P0603, P0605 5.27

GENERAL

ECM Failure

Refer to Ta bl e 5-46. The codes listed indicate a failure which

requires replacement of the ECM. See the Touring Service

Manual for replacement information.

NOTE

After replacing ECM, perform password learning procedure

and clear codes.

Table 5-46. Code Description

DTC DESCRIPTION

P0603 ECM EEPROM error

P0605 ECM flash error

DIAGNOSTICS

NOTE

These codes are set under two conditions.

● If DTC P0603 or P0605 occur during normal operation,

replace ECM. Reprogram and learn password.

● If DTC P0603 or P0605 occur during or after reprogram-

ming, perform the following:

DTC P0603

1. Clear codes.

2. Power down the vehicle. Wait 10 seconds.

3. Turn ignition ON,

4. Replace ECM if codes reappear.

DTC P0605

1. Clear codes.

2. Power down the vehicle.

3. Attempt to reprogram ECM using correct calibration.

4. Restart vehicle. If code reappears, replace ECM.

2004 Touring: Engine Management (EFI) 5-103

Page 36

HOME

DTC P1009, P1010 5.28

GENERAL

f1917x9x

Password Problem

The ECM, TSM/TSSM and speedometer exchange passwords during operation. An incorrect password or missing

password will set a diagnostic code.

NOTE

If the TSM/TSSM is not connected to the wiring harness, the

vehicle will not start.

Table 5-47. Code Description

DTC DESCRIPTION

P1009 Incorrect password

P1010 Missing password

Data Link

DIAGNOSTICS

Connector [91]

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.28 flow charts.

1. DTC P1009 may be set if a recent ECM or TSM/TSSM

replacement did not follow the correct password assignment procedure. See 3.24 PASSWORD LEARN for

details.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black socket probes and patch cord.

3. Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ECM. See 5.7 BREAKOUT

BOX: EFI.

4. Historic codes DTC U1300 or DTC U1301 would also

have been set. Clear codes.

5. See the Touring Service Manual for TSM/TSSM replacement. See PASSWORD LEARNING under 3.24 PASS-

WORD LEARN for the password learning procedure.

Figure 5-63. Electrical Bracket (Under Right Side Cover)

7844

Figure 5-64. TSM/TSSM

5-104 2004 Touring: Engine Management (EFI)

Page 37

HOME

f2208u8x

321654987121110

321654987121110

Speedometer

BK

LtGN/V

O

BN/GY

[39B]

[39A]

[108B]

[108A]

BN/GY

321654987121110

321654987121110

Tachometer

[156B] [156A]

6

6

5

5

4

4

3

3

2

2

1

1

Main to Interconnect

Harness

LtGN/V

GY

65

4

32

1

1

65

4

32

GY

987

987

321654987121110

321654987121110

TSM/TSSM

BK

[8B]

121110

121110

[8A]

Harness

BK

[30B]

[30A]

EFI

[1B] [1A]

123

123

Main to Interconnect

Harness

6

6

15A

Ignition

Fuse

1

2

3

4

[91A]

Data Link

[2B]

[2A]

15A

Accessory

Fuse

321654987121110

321654987121110

Main to Interconnect

Harness

101112 78945

101112 78945

LtGN/V

15A

Battery

Fuse

LtGN/R

51

Flash pin

ECM

Serial data

[78B]

[78A]

Figure 5-65. Serial Data Circuit (FLTR, FLHT/C/U)

Table 5-48. Wire Harness Connectors in Figure 5-65.

NO. DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect

[1]

Harness

Main to Interconnect

[2]

Harness

[8] Main to EFI Harness All 12-Place Deutsch Under Right Side Cover

[30]

Tu rn Signal/Security

Module

[39] Speedometer

[78] Electronic Control Module All 36-Place Packard Under Right Side Cover

[91] Data Link All 4-Place Deutsch Under Right Side Cover

[108] Tachometer

[156]

Main to Interconnect

Harness

FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

FLTR 12-Place Deutsch (Black) Inner Fairing - Below Radio (Left Side)

FLHT/C 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

FLTR 12-Place Deutsch (Gray) Inner Fairing - Below Radio (Left Side)

All 12-Place Deutsch

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

FLHT/C 12-Place Packard Inner Fairing (Back of Tachometer)

FLTR 12-Place Packard Under Bezel (Back of Tachometer)

FLHT/C 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

FLTR 6-Place Deutsch Inner Fairing - Front of Right Fairing Bracket

2004 Touring: Engine Management (EFI) 5-105

Page 38

HOME

f2208t8x

BN/GY

321654987121110

321654987121110

Speedometer

15A

Battery

Fuse

BK

15A

Accessory

Fuse

LtGN/V

BN/GY

O

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

3

21

321

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

98

7

65

4

98

7

65

4

121110

[8B]

121110

[8A]

EFI

Harness

1

2

3

4

Data Link

[91A]

LtGN/V

LtGN/R

[78B]

[78A]

1

Flash pin

5

Serial data

ECM

Figure 5-66. Serial Data Circuit (FLHR/C/S)

Table 5-49. Wire Harness Connectors in Figure 5-66.

NO. DESCRIPTION TYPE LOCATION

[8] Main to EFI Harness 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[78] Electronic Control Module 36-Place Packard Under Right Side Cover

[91] Data Link 4-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

5-106 2004 Touring: Engine Management (EFI)

Page 39

HOME

Test 5.28

PASSWORD PROBLEM: DTC P1009, P1010

Which diagnostic trouble

code was set?

1

5

5

DTC P1009.

Bad password.

Reprogram password.

See 3.24 PASSWORD

Replace TSSM and

relearn password.

System OK?

LEARN.

YES

YES

System

OK.

NO

System

OK.

NO

Reinstall original TSSM.

Replace ECM.

5

Reprogram and relearn

password.

Troubleshoot

lowest U-code.

4

Repair short

to ground.

4

Repair short

to voltage.

DTC P1010.

No password.

Are there any

U-codes set?

NOYES

Remove ECM connector [78]. Check

for continuity to ground at data

connector [91A] Terminal 3.

Continuity present?

NOYES

Check for battery voltage on termi-

Test data connector [91A]

Terminal 3 against Breakout Box terminal 5 for continuity. Continuity present?

nal 3.

Battery voltage present?

NOYES

2

2

3

Replace TSM/TSSM and relearn

5

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

password. System OK?

YES

YES

System

OK.

NO

Inspect terminals

for damage or repair

opens as necessary.

2

NO

Reinstall original TSSM.

5

Replace ECM.

Reprogram and relearn

password.

2004 Touring: Engine Management (EFI) 5-107

Page 40

HOME

DTC P1351, P1352, P1354, P1355 5.29

GENERAL

Ignition Coil

Ignition coil codes will set if the ignition coil primary voltage is

out of range. This could occur if there is an open coil or loss of

power to the coil. If front and rear codes are set simultaneously, it is likely a coil power failure or a coil failure.

The coil receives power from the system relay at the same

time that the fuel pump and injectors are activated. The system relay is active for the first 2 seconds after the ignition is

turned ON and then shuts off until RPM is detected from the

CKP sensor, at which time it is reactivated. The ECM is

responsible for turning on the system relay by providing the

ground to activate the relay, which in turn powers the coil.

Table 5-50. Code Description

DTC DESCRIPTION

P1351 Front ignition coil open/low

P1352 Front ignition coil high/shorted

P1354 Rear ignition coil open/low

P1355 Rear ignition coil high/shorted

7863

Figure 5-67. Ignition Coil Circuit Test

s0475x9x

D

C

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.29 flow charts.

1. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probes and patch cord.

CAUTION

Gently connect test lamp to connector [83B]. Forcefully

inserting test lamp will result in ignition connector terminal damage.

2. See Figure 5-67. Plug IGNITION COIL CIRCUIT TEST

ADAPTER (Part No. HD-44687) and FUEL INJECTOR

TEST LAMP (Part No. HD-34730-2C) into Breakout Box.

Note that cranking the engine with test lamp in place of

the ignition coil can sometimes cause a DTC P1351,

P1352, P1354 or P1355. This condition is normal and

does not by itself indicate a malfunction. Codes must be

cleared if this condition occurs.

3. Connect BREAKOUT BOX (Part No. HD-43876)

between EFI wire harness and ECM. See 5.7 BREAK-

OUT BOX: EFI.

B

A

Figure 5-68. Ignition Coil Connector Terminals

Table 5-51. Coil Terminal Description

TERMINAL DESCRIPTION

APower

BFeedback signal pin

C Rear coil

DFront coil

4. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray socket probes and patch cord.

5-108 2004 Touring: Engine Management (EFI)

Page 41

HOME

f2208h8x

System relay

Power gnd.

Switch power

ECM

Ion sense

Power gnd.

Constant power

Coil R

Inj. R

Inj. F

Coil F

[78A] [78B]

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10 11 12

10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

GN/O

GN/GY

Y/BE

W/Y

BE/GY

W/BK

BE/O

W/Y

GY/BE

AB

AB

[84B] [84A]

AB

AB

[85B] [85A]

15 amp

ECM fuse

12

11

10

9

8

BK

7

6

5

W/BK

4

3

2

1

[8B] [8A]

Y/GN

Y/GN

GY/BE

Y/BE

BE/O

W/BK

BE/GY

15 amp

fuel pump

fuse

Y/GN

AB CD

[83B] [83A]

[62B]

Y/GN

BE/GY

GN/O

W/BK

[13A] [13B]

BK

AB CD

Ignition

coil

123

123

System relay

87

IQCPR

87A

30 85 86

Fuel pump

123

O/GY

[141B][141A]

123

–+

Battery

R

BK

12

11

10

9

8

7

6

5

4

3

2

1

W/BK

R

R/BK

15 amp

IGN fuse

GY

10

12

11

10

12

11

DCBA

9

9

678

678

R

[33B]

[33A]

Ignition

switch

12345

12345

40 Amp

Maxi Fuse

[1B]

[1A]

BK

BK

BK

BK

10

12

11

9

10

12

11

9

12345

678

678

[22A]

[22B]

12345

Engine stop

switch

Figure 5-69. Battery Voltage Circuit (FLTR, FLHT/C/U)

Table 5-52. Wire Harness Connectors in Figure 5-69.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing (Right Fairing Bracket)

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inner Fairing (Right Fairing Support Brace)

[33] Ignition/Light Key Switch 4-Place Packard Inner Fairing (Top Fork Bracket)

[78] ECM 36-Place Packard Under Right Side Cover

[83] Ignition Coil 4-Place Packard Below Fuel Tank (Left Side)

[84] Front Injector 2-Place Packard Below Fuel Tank (Left Side)

[85] Rear Injector 2-Place Packard Below Fuel Tank (Left Side)

2004 Touring: Engine Management (EFI) 5-109

Page 42

HOME

f2208m8x

System relay

Power gnd.

Switch power

ECM

Ion sense

Power gnd.

Constant power

Coil R

Inj. R

Inj. F

Coil F

[78A] [78B]

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10 11 12

10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

GN/O

GN/GY

Y/BE

W/Y

BE/GY

BE/O

W/BK

W/Y

BK

BK

AB

[84B] [84A]

AB

[85B] [85A]

15 amp

ECM fuse

GY/BE

BK

W/BK

[8B] [8A]

AB

AB

12

11

10

[62B]

Y/GN

BE/GY

System relay

[62B]

87

IQCPR

87A

30 85 86

GN/O

W/BK

Fuel pump

123

Y/GN

15 amp

fuel pump

fuse

Y/GN

Y/GN

BK

123

[141B][141A]

Y/GN

AB CD

AB CD

GY/BE

Y/BE

Ignition

coil

BE/O

W/BK

[83B] [83A]

BE/GY

–+

Battery

R

12

BK

11

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

W/BK

BK

R

R/BK

15 amp

IGN fuse

10

12

11

10

12

11

12-Place on

FLHP Only

GY

9

9

I B A

678

678

40 Amp

R

Maxi Fuse

[33B]

[33A]

Ignition

switch

12345

12345

Engine stop

switch

[22A]

[22B]

BK

Figure 5-70. Battery Voltage Circuit (FLHR/C/S)

Table 5-53. Wire Harness Connectors in Figure 5-70.