Page 1

HOME

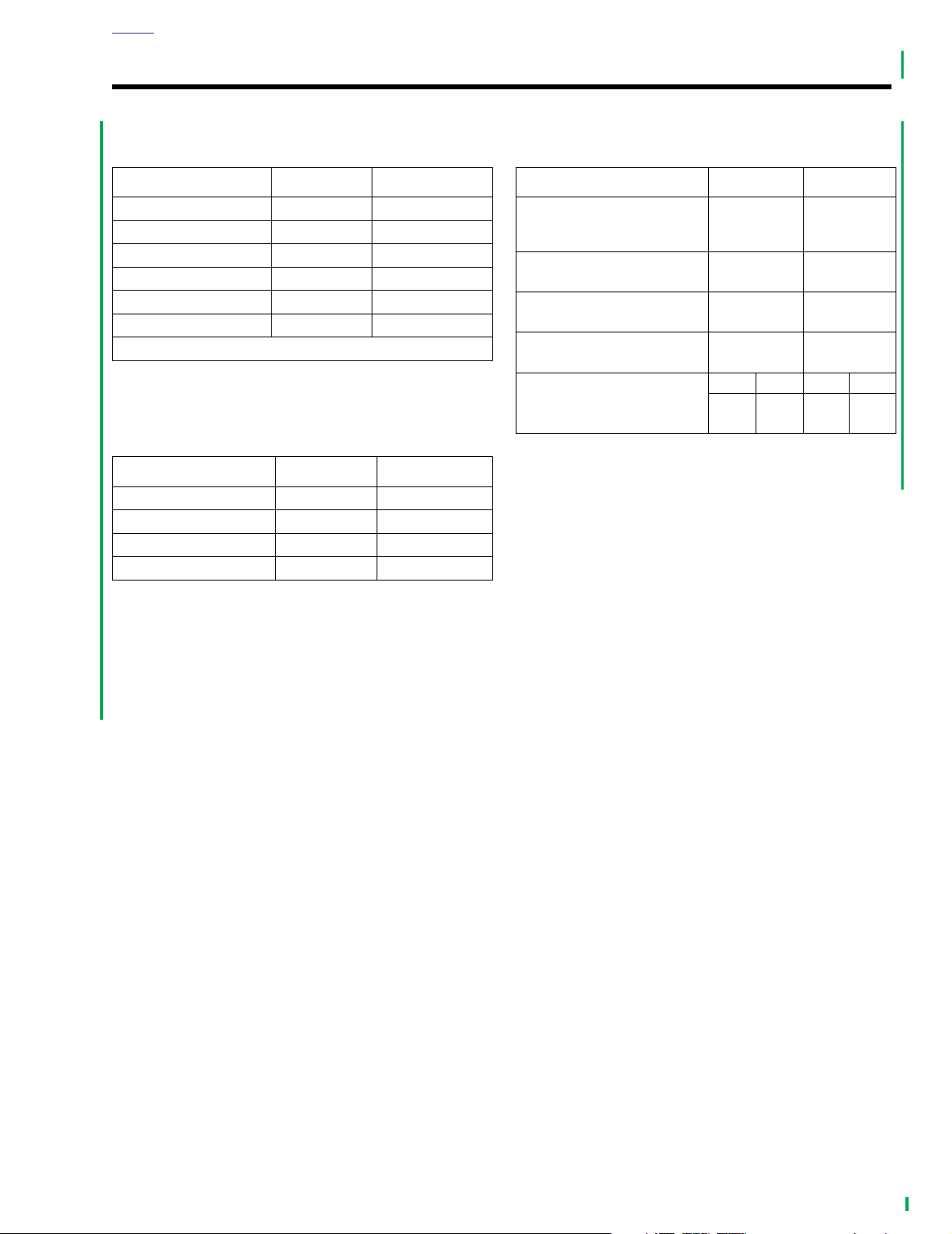

SPECIFICATIONS 2.1

Table 2-1. Dimensions

ITEM IN. MM

Wheel Base 63.5 1613

Overall Length

Overall Width 38.5 977.9

Road Clearance 4.21

Overall Height 51.75 1314.45

Saddle Height* 26.7

With 180 Lb. Rider

*

91.9

2334

106.9

678

Table 2-2. Weight

ITEM LBS. KG

DRY WEIGHT** 776/788 352.3/357.8

GVWR 1259 572

GAWR – Front 500 227

GAWR – Rear 827 375

As shipped from the factory

**

Table 2-3. Capacities

ITEM U.S. METRIC

Fuel Tank (gallons)

To t al

Reserve

Oil Tank (quarts)

with filter 4 Quarts 3.78 Liters

Tr ansmission

(Ounces, approximate)

Primary Chaincase

(Ounces, approximate) 32 Ounces 946 Mililiters

Front Fork (Ounces)

5

0.9 Gal.

20-24

Ounces

Left Right Left Right

10.6 10.6

18.9

3.4 Liters

591-710 Mil-

liliters

314ml314

ml

NOTE

Gross Vehicle Weight Rating (GVWR) (maximum allowable

loaded vehicle weight) and corresponding Gross Axle Weight

Ratings (GAWR) are given on a label located on the inside of

the right front frame downtube.

2004 FLHTCSE: Chassis 2-1

Page 2

HOME

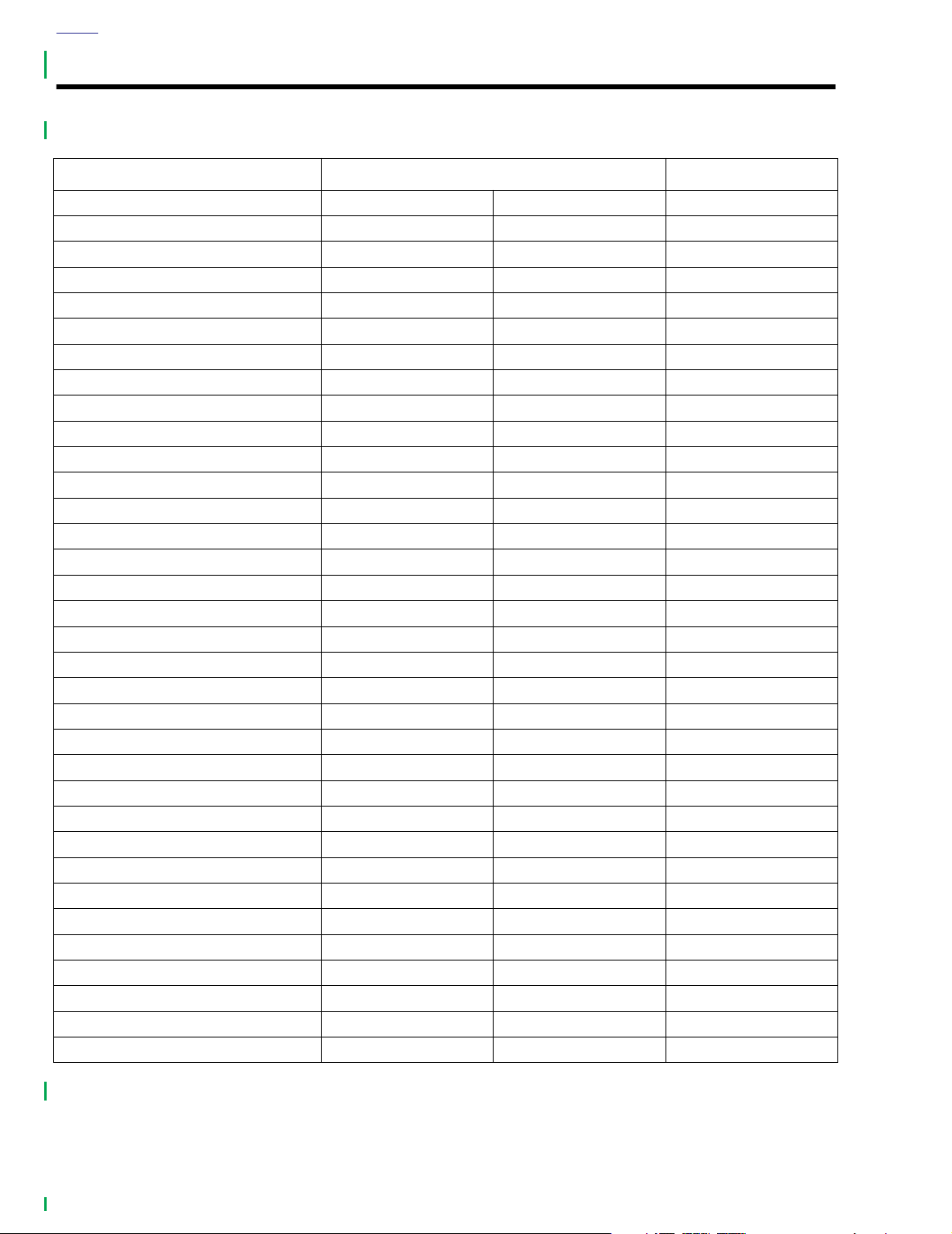

TORQUE VALUES 2.2

ITEM TORQUE NOTES

Actuator bleeder valve 80-100

Actuator bleeder valve 80-100

Banjo bolt 17-22 ft-lbs 23-31 Nm page 2-24

Banjo bolt 17-23 ft-lbs 23-31 Nm page 2-25

Brake caliper pad pins 180-200

Brake fluid reservoir cover 6-8

Brake pedal to brake arm 25-29 ft-lbs 34-39 Nm page 2-9

Clutch fluid line flare nut 80-115

Clutch fluid line flare nut 80-115

Clutch fluid reservoir cover 6-8

Clutch master cylinder banjo bolt 17-22 ft-lbs 23-31 Nm page 2-21

Clutch reservoir cover screws 6-8

Clutch reservoir cover screws 6-8

Fender mounting bolt 15-20 ft-lbs 20.4-27.1 Nm page 2-28

Filler strip 15-20 ft-lbs 20.4-27.1 Nm page 2-30

Footboard hinge bolts 84-108

Footboard hinge bolts 84-108

Front axle cover set screw 60-84

Handlebar clamp screws 71-80

Handlebar top clamp 12-16 ft-lbs 16.3-20.3 Nm page 2-16

Left footboard brackets 15-20 ft-lbs 20.4-27.1 Nm page 2-7

Pad pins 180-200

Passenger backrest docking points 15-20 ft-lbs 20.4-27.1 Nm page 2-28

Passenger backrest mounting bracket 15-20 ft-lbs 20.4-27.1 Nm page 2-30

Passenger mounting bracket fasteners 15-20 ft-lbs 20.4-27.1 Nm page 2-28

Rear axle cone nut 95-105 ft-lbs 128.9-142.4 Nm page 2-4

Right footboard brackets 30-35 ft-lbs 41.7-47.4 Nm page 2-7

Right footboard brackets 30-35 ft-lbs 41.7-47.4 Nm page 2-7

Saddlebag support to support bracket 15-20 ft-lbs 20.4-27.1 Nm page 2-30

Secondary actuator bleeder valve 80-100

Shift lever clamp bolts 90-110

Shift lever peg 144-168

Tr iple clamp cover backside fasteners 70-110

Tr iple clamp lower Allen head fastener 120-180

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

in-lbs

9-11 Nm page 2-24

9-11 Nm page 2-25

21-22 Nm page 2-6

0.7-0.9 Nm page 2-6

9-13 Nm page 2-24

9-13 Nm page 2-25

0.7-0.9 Nm page 2-21

0.7-0.9 Nm page 2-24

0.7-0.9 Nm page 2-25

9.5-12.2 Nm page 2-7

9.5-12.2 Nm page 2-7

6.8-9.5 Nm page 2-10

8-9 Nm page 2-21

21-22 Nm page 2-6

9-11 Nm page 2-21

10.2-12.4 Nm page 2-9

16.3-18.9 Nm page 2-9

7.9-12.4 Nm page 2-11

13.5-20.3 Nm page 2-11

2-2 2004 FLHTCSE: Chassis

Page 3

HOME

10528

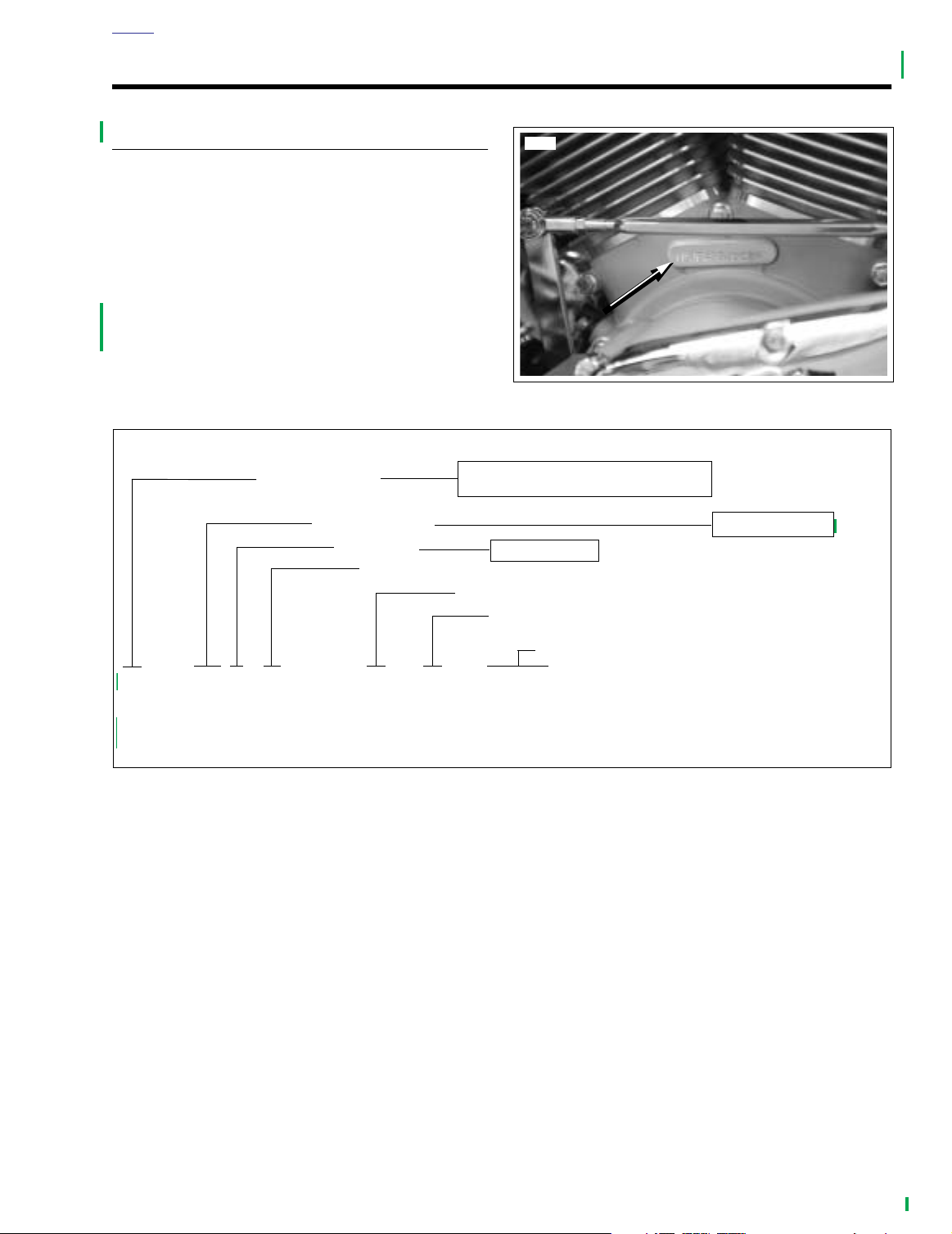

VEHICLE IDENTIFICATION NUMBER (V.I.N.) 2.3

GENERAL

See Figure 2-1. An abbreviated V.I.N. is stamped on the left

side crankcase at the base between the cylinders.

NOTE

Always give the full 17 digit Vehicle Identification Number

when ordering parts or making any inquiry about your motorcycle.

See Figure 2-2. The full 17 digit serial, or Vehicle Identification Number (V.I.N.) is stamped on the right side of the steering head and on a label located on the left side of the

steering head.

Figure 2-1. Abbreviated V.I.N. Location

Market Designation

Model Designation

Engine Type

Varies - 1 thru 8

1 - Manufactured for U.S.A.

5 - Manufactured for International Countries

E - 1690 (EFI)

Model Year - 2004

Y - Manufactured in York, PA

K - Manufactured in Kansas City, MO

Sequential Number

1 HD1 PJ E 1*4 Y 950000

*

Var ies - can be 0 thru 9 or X

Sample V.I.N. as it appears on the steering head - 1HD1PJE1*4Y950000

Sample abbreviated V.I.N. as it appears on the left crankcase - PJE4950000

Figure 2-2. Vehicle Identification Number

PJ - FLHTCSE

2004 FLHTCSE: Chassis 2-3

Page 4

HOME

REAR WHEEL 2.4

REMOVAL

1. Block motorcycle under frame so rear wheel is off the

ground.

2. Remove saddlebags. See SADDLEBAG in Touring Models Service Manual.

3. Remove mufflers. See REAR WHEEL in Touring Models

Service Manual.

4. Remove e-clip from groove on right end of rear axle.

5. Remove cone nut and adjuster cam from axle.

6. Using a soft mallet, gently tap end of axle towards left

side to loosen.

7. Pull the axle out to saddlebag support.

8. To clear the saddlebag support, rotate the axle to lowest

cam position and push the bottom of the tire to the right

to angle the assembly in the fender with the left end of

axle tilted down.

9. Pull the axle the rest of the way out.

10. Pull wheel to release brake disc from caliper. Pry inner

and outer brake pads back for additional clearance. If

necessary, use a putty knife with a wide thin blade to

avoid scratching the brake disc.

NOTE

Do not operate the rear brake pedal with the rear wheel

removed or the caliper pistons may be forced out. Reseating

pistons requires disassembly of the caliper.

11. Move wheel forward to slip belt off sprocket and remove

wheel from rear fork.

4. Tilt the bottom of the tire to the right.

5. Orient the axle to the lowest cam position and angle the

axle to match angle of rear wheel.

6. With the larger OD on the outboard side, hold external

spacer between the rear fork and belt sprocket. Slide the

axle through left side of rear swingarm, external spacer,

and sprocket into the wheel hub.

7. When the axle emerges from the hub, straighten the

wheel and push axle through short external spacer, caliper bracket and rear fork.

8. Rotate flat on threaded end of axle to the top. With the

thumb down and the cam forward, install adjuster cam

on end of axle.

9. Apply a thin film of LOCTITE ANTI-SEIZE to inboard

side of cone nut. Install cone nut on axle, but finger

tighten only.

10. Verify that adjuster cam just contacts weld nub on both

sides of rear fork. If necessary push wheel forward

slightly to achieve the desired result. Snug the cone nut

to 15-20 ft-lbs (20-27 Nm).

11. Lower motorcycle to ground.

12. Rotate weld nut on left side of axle in a clockwise direction.

13. Check belt deflection. See DRIVE BELT under SCHEDULED MAINTENANCE PROCEDURES.

14. When belt deflection is within specifications, hold weld

nut and final tighten cone nut to 95-105 ft-lbs (128.9-

142.4 Nm).

15. With the flat side out, install

16. Install mufflers. See REAR WHEEL in the Touring Models Service Manual.

new

e-clip in axle groove.

1WARNING1WARNING

NOTE

Removal of the rear wheel can be also facilitated by removing the lower shock bolts and dropping the rear fork below

the saddlebag support brackets. This provides access to the

rear axle.

INSTALLATION

1. Place rear wheel in rear swingarm. Slide wheel forward

and slip belt over sprocket.

CAUTION

Do not bend or fold belt backward or into loops smaller

than 5 inches in diameter. Sharp bending can weaken

the belt and cause premature failure.

2. Seat caliper on anchor weldment of rear swingarm. Position wheel in rear fork, so that brake disc is centered

between brake pads.

3. Coat the axle with LOCTITE ANTI-SEIZE.

2-4 2004 FLHTCSE: Chassis

After installation of caliper and BEFORE moving motorcycle, pump rear brake pedal until pistons push pads

against the brake disc. If fluid pressure is not pumped

up, the rear brake will not be available the first time it is

used, a situation that could result in death or serious

injury.

17. Press rear brake pedal several times to set brake pads.

18. Install saddelbags. See SADDLEBAG in the Touring

Models Service Manual.

Page 5

HOME

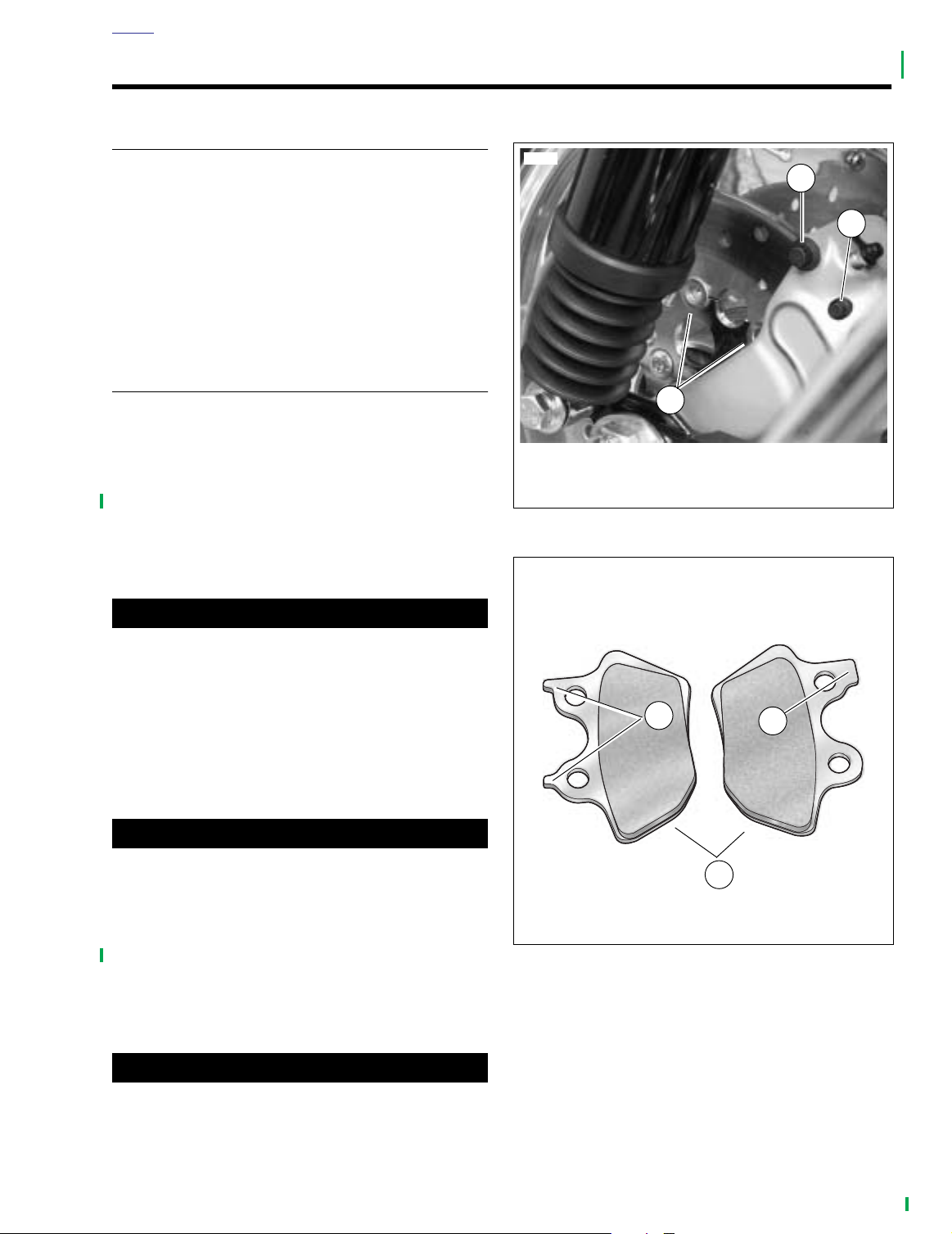

1. Bridge bolt

2. Pad pin

3. Spring washer and rivet

1

3

2

8696

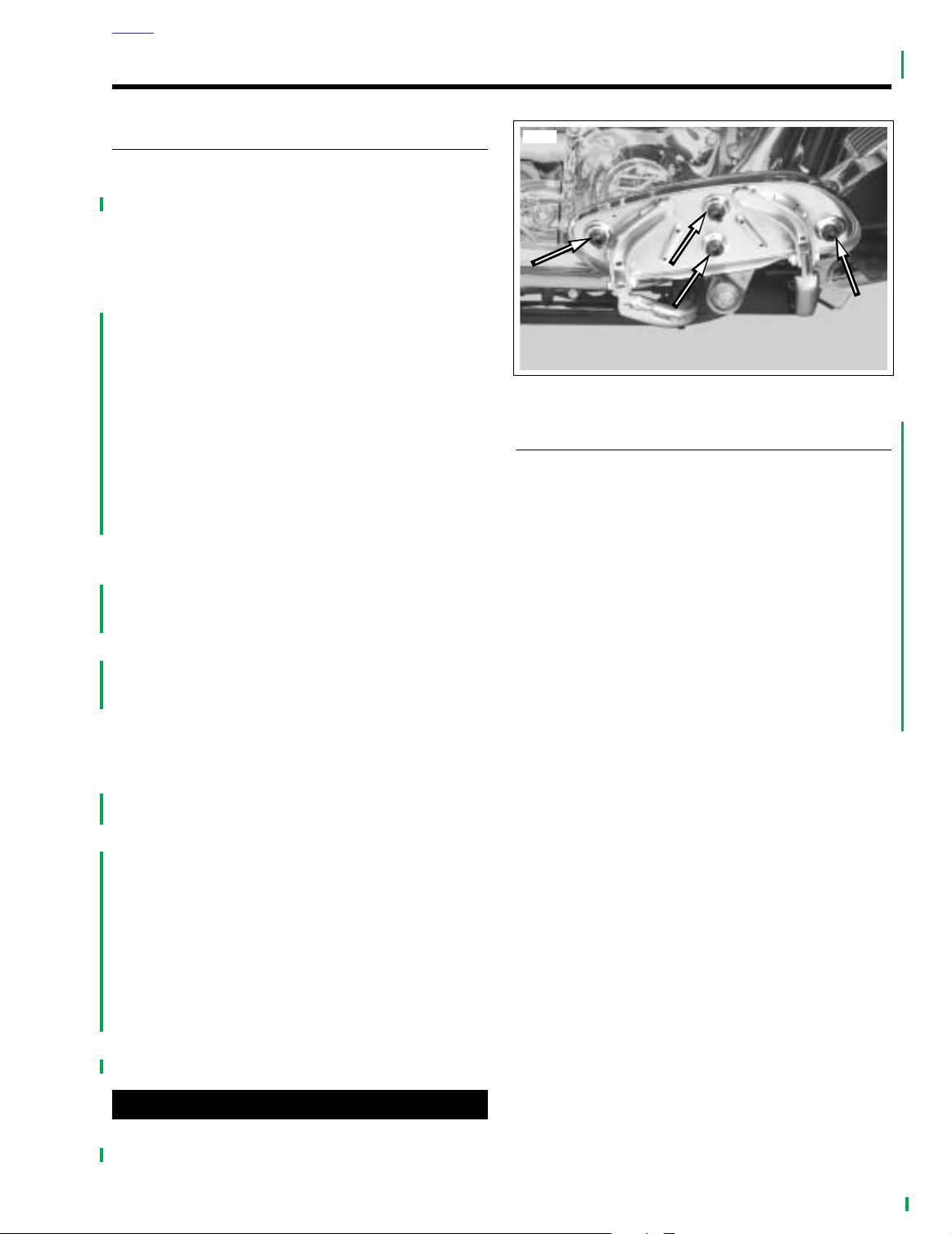

Inner brake pad

Outer brake pad

o0035x0x

1. Two tabs

2. Single tab

3. Curved portion faces rear

1

2

3

REAR BRAKE PADS 2.5

GENERAL

Follow service instructions for INSPECTION, BRAKE DISC

THICKNESS/WARPAGE, BRAKE PADS, and BRAKE LINE/

HOSE INSPECTION. See REAR BRAKE CALIPER in Touring Models Service Manual.

Procedures for rear brake pad replacement are similar. However, the brake pads must be rotated along the arc of the

brake disc to clear the disc rivets and spring washers during

brake pad removal and installation.

REPLACEMENT

1. Raise the rear wheel off the ground.

2. Remove right side saddlebag. See SADDLEBAGS,

REMOVAL in Touring Models Service Manual.

3. See Figure 2-3. Loosen both pad pins, but do not

remove.

4. Remove two Phillips screws to release cover from rear

master cylinder reservoir.

Figure 2-3. Rear Brake Disc and Caliper

CAUTION

As the pistons are pushed back into the caliper, fluid

level may rise more than 1/8 inch (3.2 mm) and overflow

the reservoir. Watch the fluid level as the pistons are

retracted and remove fluid from the reservoir if necessary.

5. Pry the inner pad back pushing the pistons into their

bores. Use a putty knife with a wide thin blade to avoid

scoring or scratching the brake disc.

CAUTION

Do not completely pull pad pins from caliper during the

next step. Completely removing pad pins at this time will

make assembly difficult.

6. Once the pistons have been retracted, pull the pad pins

part way out to free the inside pad.

7. Slide the inside pad along the arc of the brake disc to

remove pads from calipers. Note the orientation of the

pad.

1WARNING1WARNING

Figure 2-4. Rear Brake Pad Orientation

Always replace brake pads in pairs. Never replace just

one brake pad. Mismatched brake pads can lead to brake

system damage and loss of braking performance, which

could result in death or serious injury.

2004 FLHTCSE: Chassis 2-5

Page 6

HOME

8. See Figure 2-4. Orient

brake disc. Curved portion must face rear of motorcycle.

9. Hold brake pad against brake disc and rotate the rear

wheel to rotate the pad forward into caliper.

10. Install pad pins, but do not fully tighten.

11. Pump rear brake pedal to move inside pistons out until

they contact inner brake pad.

12. Pry the outside pad back pushing the pistons into their

bores. Use a putty knife with a wide thin blade to avoid

scoring or scratching the brake disc.

13. Verify that inner pad is captured between brake disc and

pistons.

14. Completely remove pad pins to free outer brake pad.

Note the orientation of the outer brake pad.

15. Orient

16. Hold brake pad against brake disc and rotate the rear

new

outer brake pad against the brake disc.

Curved portion of pad must face rear of motorcycle.

wheel to rotate the pad forward into caliper. If the inside

pad moved during the previous step, reinstall.

new

inner brake pad against the

20. Verify that brake fluid level is 1/8 inch (3.2 mm) below top

of reservoir with master cylinder in a level position. Add

D.O.T. 5 SILICONE BRAKE FLUID, if necessary. Install

master cylinder reservoir cover. Install two Phillips

screws to fasten cover to reservoir and tighten to 6-8

lbs

(0.7-0.9 Nm).

21. Install right side saddlebag. See SADDLEBAGS,

INSTALLATION in Touring Models Service Manual.

22. Test operation of brake lamp with the rear brake applied

and the ignition/light key switch turned to IGNITION.

in-

1WARNING1WARNING

After completing repairs or bleeding the system, always

test motorcycle brakes at low speed. If brakes are not

operating properly or braking efficiency is poor, testing

at high speeds may result in death or serious injury.

23. Test ride motorcycle. If the brakes fell spongy, bleed the

brake lines. See BLEEDING HYDRAULIC BRAKE

LINES in Touring Models Service Manual.

17. Inspect pad pins and clean or replace as required.

18. Install two pad pins and tighten to 180-200

22.6 Nm).

in-lbs

(20.3-

1WARNING1WARNING

After installation of new pads and BEFORE moving

motorcycle, pump rear brake pedal until pistons push

pads against the brake disc. If fluid pressure is not

pumped up, the rear brake will not be available the first

time it is used, a situation that could result in death or

serious injury.

19. Pump rear brake pedal to move pistons out until they

contact both brake pads. Verify piston location against

pads.

2-6 2004 FLHTCSE: Chassis

Page 7

HOME

10518

FOOTBOARDS AND CONTROLS 2.6

RIDER FOOTBOARDS

NOTE

Unless the inserts or bottom assemblies are being replaced,

they do not have to be removed from footboard brackets.

Removal

1. See Figure 2-5. With footboards in up position, use a

screwdriver to work cover rubber collars out through

footboards. Remove insert assemblies.

2. See Figure 2-6. Remove right footboard pivot bolts, nuts

and remove footboard bottom assembly.

3. Remove screws, washer, lock washer and right rear footboard bracket.

4. Remove screws, lock washers, nuts and right front footboard bracket.

5. Remove left footboard pivot bolts, nuts and remove footboard bottom assembly.

6. Remove screws, washers, lock washers and both front

and rear left footboard brackets.

Figure 2-5. Footboard Cover Rubber Collars

PASSENGER FOOTBOARDS

Removal

1. See Figure 2-6. Remove socket screw and lockwasher

to remove footboard bracket from swingarm bracket

Installation

1. See Figure 2-6. Install right front footboard bracket. Posi-

tion for rider posture. Install lock washers, washers, nuts

and screws. Tighten screws to 30-35 ft-lbs (41.7-47.4

Nm).

2. Install right rear footboard bracket. Position for rider posture. Install lock washer, washer and screw. Tighten

screws to 30-35 ft-lbs (41.7-47.4 Nm).

NOTE

The right and left footboard frame mounts allow a small variance in height and angle.

3. Install right footboard bottom assembly. Install and

tighten pivot bolts and nut to 84-108

Nm).

4. Install left footboard brackets. Position for rider posture.

Install washers, lock washers, and screws. Tighten

screws to 30-35 ft-lbs (41.7-47.4 Nm).

5. Install left footboard bottom assembly. Install and tighten

pivot bolts and nut to 84-108

6. Moisten footboard cover rubber collars with soapy water.

7. With left footboard bottom assembly in up position, hold

new

footboard cover in position.

8. From underside of footboard use a pliers to pull each

rubber collar through footboard hole.

9. Repeat for other side.

in-lbs

in-lbs

(9.5-13.5

(9.5-13.5 Nm).

Installation

1. Insert pin on footboard bracket into hole in swingarm

bracket.

NOTE

Passenger footboards can be adjusted to one of three positions. To move footboards to a new position, remove plastic

plugs from holes in rear swingarm bracket as necessary.

2. Install socket screw with lockwasher. Tighten socket

screw to 15-18 ft-lbs (20-24 Nm).

CAUTION

Avoid contacting chrome surfaces with abrasive materials (stones, sand, etc.) as damage will result.

2004 FLHTCSE: Chassis 2-7

Page 8

HOME

Disassembly

NOTE

If only replacing the rubber pad, refer to step 1 below and

then see steps 4-5 under ASSEMBLY.

1. Tilt footboard bottom assembly upward. From bottom

side, use a small blade screwdriver to push rubber

beads on pad up through holes in footboard bottom

assembly. Remove insert assembly.

2. Using a brass drift and rubber mallet, tap two retaining

pins toward center of footboard and remove.

3. Remove footboard bottom assembly from footboard

bracket.

4. Remove ball and spring from hole in footboard bracket.

5. Remove footboard bracket from rear swingarm bracket.

See PASSENGER FOOTBOARD, REMOVAL in this section.

z0020d

6

5

1

2

4

3

7

Assembly

1. Install footboard bracket. See PASSENGER FOOTBOARD INSTALLATION, in this section.

2. Place spring into hole in footboard bracket. Place ball on

top of spring.

3. Place footboard bottom assembly into position on

bracket and install retaining pins from the outboard side.

Using a brass drift and rubber mallet, tap pins until centered in lugs of bracket.

4. Moisten rubber beads on new insert assembly with

soapy water. Place insert assembly into position on footboard bottom assembly. Press firmly on footboard insert

in areas of rubber beads.

9

22

11

21

24

23

13

14

15

10

12

2

8

18

17

1. Insert Assembly, passenger footboard, right-side

(Left-side not shown)

2. Pivot pin

3. Spring

4. Ball

5. Socket screw

6. Lockwasher

7. Bracket, footboard, passenger

8. Bottom assembly, footboard, passenger

9. Insert assembly, rider, left-side

10. Bottom assembly, with hinge, left-side

11. Nut

12. Pivot bolt

Figure 2-6. Footboard and Passenger Footrest Components

15

19

20

14

15

14

16

13. Bracket, support, footboard, left-side

14. Washer

15. Lockwasher

16. Bracket, support, footboard, right-side

17. Bottom assembly, right-side

18. Insert assembly, right-side

19. Bracket, support footboard, right rear

20. Screw

21. Screw

22. Bracket, support footboard, left rear

23. Lockwasher

24. Locknut

2-8 2004 FLHTCSE: Chassis

Page 9

HOME

SHIFT LEVER

Replacement

1. Remove and replace shift lever pegs. Tighten fasteners

to 144-168

2. If necessary, loosen clamp bolts and pull shift levers off

splined shaft.

3. Position shift levers on splined shaft for rider posture and

tighten clamp bolts to 90-110 in-lbs (10.2-12.4 Nm).

in-lbs (16.3-18.9 Nm).

REAR BRAKE PEDAL PAD

Replacement

1. Remove screws (4) and remove brake pedal from brake

arm. Disassemble.

f2287x0x

1

3

4

1. Metal brake pedal cover

2. Rubber tread

3. Metal backing plate

4. Screws

Figure 2-7. Rear Brake Pedal

2. See Figure 2-7. Assemble metal brake pedal cover to

rubber tread.

3. Slide metal backing plate into metal brake pedal cover/

rubber tread assembly.

4. Install pedal to brake arm with screws. Tighten screws to

22-29 in-lbs (2.5-3.3 Nm).

2

2004 FLHTCSE: Chassis 2-9

Page 10

HOME

FRONT AXLE COVERS 2.7

REPLACEMENT

1. See Figure 2-8. Loosen but do not remove set screw

under cover. Remove cover.

2. Remove set screws from cover.

3. Liberally apply LOCTITE THREADLOCKER 262 (red)

(HD-94759-77) to threads of set screw.

4. Orient cover over axle end so that set screw is on the

bottom and will tighten down against a flat on the axle

nut.

5. Install and tighten set screw to 60-84 in-lbs (6.8-9.5

Nm).

6. Repeat for opposite side.

10522

Figure 2-8. Front Axle Cover Set Screw

2-10 2004 FLHTCSE: Chassis

Page 11

HOME

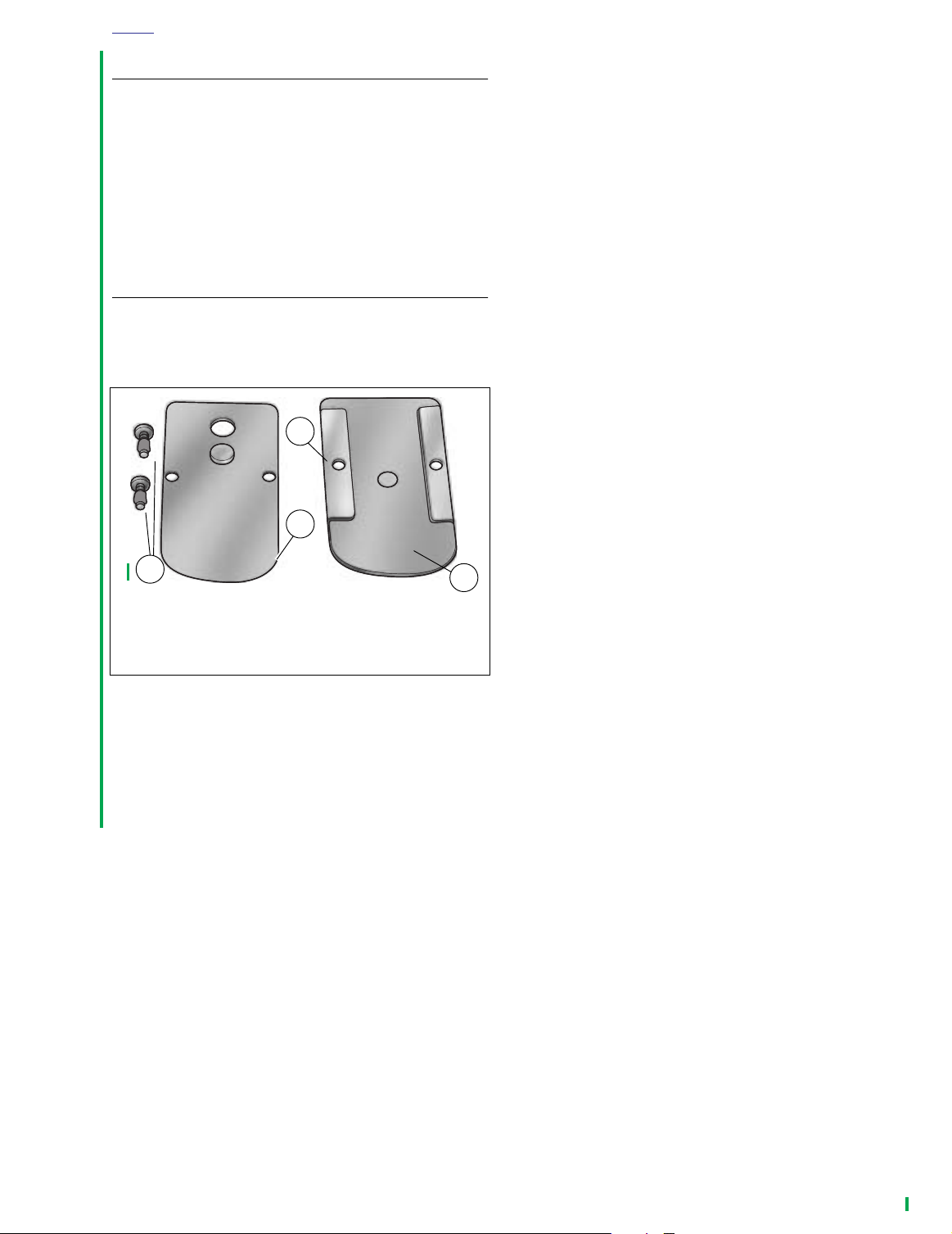

1. Backside fasteners

2. Washer

3. Lower triple clamp cover

4. Lower Allen head fastener

o0041x0x

4

2

1

3

LOWER TRIPLE CLAMP COVER 2.8

REPLACEMENT

1. See Figure 2-9. Loosen but do not remove the two fasteners on the backside of cover.

2. Remove the lower Allen fastener through the brake line

manifold on bottom.

3. Remove two backside fasteners and washers and

remove cover.

4. To replace cover, fit cover inside bottom of nacelle and

around triple clamp. Hold in place.

5. Install but do not tighten all three fasteners and washers.

Verify that the cover is snug against the rear surface of

triple clamp.

NOTE

Plastic plugs in locator holes in rear surface of triple clamp

can cause interference with the cover. Verify that the center

plug has been removed.

6. Tighten backside fasteners to 70-110 in-lbs (7.9-12.4

Nm).

7. Tighten lower Allen head fastener to 120-180 in-lbs

(Nm).

8. Verify that the brake line does not rub on cover. Adjust

line or cover as necessary.

Figure 2-9. Lower Triple Clamp Cover

2004 FLHTCSE: Chassis 2-11

Page 12

HOME

HANDLEBARS 2.9

REMOVAL/REPLACEMENT

1WARNING1WARNING

To prevent accidental vehicle start-up, which could

cause death or serious injury, remove maxi-fuse before

proceeding. (00251a)

1. Remove left side cover.

2. Remove Maxi-Fuse.

3. Remove outer fairing and fairing cap. See FAIRING CAP

in Touring Models Service Manual.

4. Remove radio chassis. See RADIO REMOVAL in Touring Models Service Manual.

5. See Figure 2-10. Separate handlebar switch connectors

[22] and [24] and turn signal multilock connector [31].

6. See Figure 2-11. Remove wires from socket side hous-

ings from socket terminal wires:

a. Use a screw driver to pry out the secondary locking

wedges. See DEUTSCH ELECTRICAL CONNECTORS in Touring Models Service Manual.

b. See Figure 2-13. Depress internal terminal latches

and pull socket terminals out of the wire seal.

7. Using mechanic’s wire, neatly wrap the socket terminals

and wires with 1 or 2 twists to form leaders for turn signal and handlebar switch connector wires.

8. String wire along the turn signal wire. String sufficient

wire to pull conduits through handlebars.

9. Wrap with electrical tape from the open end of the conduit past the turn signal lamp sockets to form a leader.

f2238x8a

3

f1915x8x

1

2

3

4

7

5

6

1. Locking wedge

2. Internal seal

3. Socket housing

4. Wire seal

5. Seal pin

6. Socket terminal

7. External latch

Figure 2-11. 12-place Deutsch Socket Side Connector

10. Shorten throttle and idle cable adjustors and pull idle

and throttle cable inserts and elbows from switch housing.

11. Remove upper and lower fasteners holding right turn

signal and cruise control housings to handlebars.

12. See Figure 2-14. Use a screwdriver to rotate cable ferrules in throttle grip notches. Remove cables from

notches on inboard side of throttle grip and remove

throttle grip from handlebar.

13. Remove the cables from the housing.

14. Protect chrome and painted surfaces and tie idle and

throttle cables away from chrome and paint finishes.

Maintain the routing of the cables.

15. See Figure 2-12. Insert a 5/32 in. (4 mm) cardboard

between front brake lever and lever bracket.

16. Remove fasteners securing handlebar clamp to master

cylinder and front brake lever.

1

1. Right handlebar switch connector [22]

2. Left handlebar switch connector [24]

3. Turn signal multilock connector [31]

2-12 2004 FLHTCSE: Chassis

CAUTION

See Figure 2-12. Do not remove the 5/32 in. (4 mm) cardboard insert wedged between the brake lever and lever

bracket. Removal will result in damage to the rubber

boot and plunger of the front stoplight switch during

installation of the master cylinder assembly.

2

17. Protect chrome and painted surfaces and tie the master

cylinder, reservoir and brake line out of the way.

18. Remove upper and lower fasteners holding left turn signal and cruise control housings to handlebars.

19. Remove fasteners and washers securing the handlebar

clamp to the clutch lever bracket.

20. Protect chrome and painted surfaces and tie the master

cylinder, reservoir and clutch fluid line out of the way.Figure 2-10. Turn Signal and Cruise Switch Connectors

Page 13

HOME

10521

8688

8689

f1225x2x

1

2

1. Notch for switch housing

2. 5/32 in. (4 mm) cardboard

Figure 2-12. Cardboard Insert

21. Remove upper handlebar clamps and lift handlebars,

turn signal housings, and wire harness from motorcycle.

NOTE

If handlebar rubber mounts require service. See HANDLEBARS in the Touring Models Service Manual.

o0031x0x

Figure 2-14. Throttle and Idle Cable Ferrules

26. If necessary to repair wires, unwrap the electrical tape

and wire from the socket terminals.

27. Repair and replace switches and socket wires as necessary.

NOTE

For handlebar switch repair procedures, see HANDLEBAR

SWITCHES in Touring Models Service Manual.

Figure 2-13. Internal Deutsch Terminal Latches

22. Place handlebars and wiring on work bench.

23. Cut wire tie at handlebar.

24. See Figure 2-15. Lightly lubricate conduits and tape with

glass cleaner then pull the left and right side wiring and

conduits from the handgrip ends through the handlebar

and handlebar grommets.

25. If installing original handlebars, leave the wire leader in

each handlebar half. If installing new bars, string wire

leader through grommets on outside ends of bars and

through the center hole.

Figure 2-15. Wire Leader in Handlebars

2004 FLHTCSE: Chassis 2-13

Page 14

HOME

HANDGRIPS

NOTE

It is not necessary to remove the handlebars from the motorcycle to replace the handgrips. Remove the control levers

and control housings according to the instructions in this section and replace the hand grips.

1. Replace right hand throttle grip. Slide throttle grip on in

operating position.

2. Pry off end cap from left hand grip and using a sharp

blade carefully cut rubber between metal sleeve until the

metal sleeve can be pulled off the bars.

3. Clean left handlebar end.

NOTE

Before installing left hand grip, remove end cap to prevent

trapping air.

1WARNING1WARNING

FLAMMABLE, INJURIOUS TO EYES, HARMFUL IF SWALLOWED, VAPOR HARMFUL. FLAMMABLE: CONTAINS

METHYL ETHYL KETONE. Use only in well ventilated

areas. Avoid contact with eyes, mucous membranes, and

prolonged skin contact. KEEP OUT OF REACH OF CHILDREN. If swallowed, do not induce vomiting. Call a physician immediately. This product contains a chemical(s)

known to the State of California to cause cancer or other

reproductive harm.

4. Apply a coat of HARLEY-DAVIDSON ADHESIVE (Part

No. 99839-95) to inside surface of new left hand grip at

a point 1 in. (25.4 mm) from open end. Apply a coat of

adhesive to handlebar end.

5. Immediately push grip completely onto the handlebar

end. Install grip with a twisting motion while aligning the

horizontal pattern on the left hand grip to the pattern on

the right hand grip in the closed position.

NOTE

Do not hesitate when installing left grip or adhesive will dry

before installation is complete. Allow 6-8 hours at 70

C) to achieve full cure of the adhesive.

6. Install end caps.

° F (21˚

ASSEMBLY/INSTALLATION

1. Using mechanic’s wire, neatly wrap the socket terminals

and wires with a few twists to form leaders for turn signal

and cruise control wires and conduit.

NOTES

If installing the original handle bars, use the wire end left in

the handlebar half to wrap the socket terminals.

2. String wire along the turn signal lamp wire. String suffi-

cient wire to pull conduits through handlebars.

3. Wrap socket wires with electrical tape.

1WARNING1WARNING

Without protective grommets around wire entry openings in handlebars, wires can rub against sharp metal

edges of opening. A short or broken connection can

cause loss of electrical control which can lead to death

or serious injury.

4. Lubricate wire conduits with glass cleaner. With the wire

leader, pull wire bundles through grommets and handlebar to the handlebars center hole.

5. See Figure 2-16. and Figure 2-17. Orient wires in switch-

housings. The right hand RUN and STOP wires are

wrapped over the front of the bars and back and into the

handlebar through the grommet. The wires should be to

the outside of the clamping post inside the housing.

6. Loosely install left and right switch housings.

7. Pull wire leaders and unwrap the tape and mechanic’s

wire.

8. Cable wrap wire conduits at exit from handlebars.

9. See Figure 2-11. Fit wire seal into back of Deutsch

socket housings.

10. Insert wire color coded socket terminals into numbered

chambers in socket housings:

a. Hold socket terminal 1 in. (25.4 mm) behind contact

barrel.

b. Gently push socket terminal through hole in wire

seal into chamber until it “clicks” in place.

c. Verify that socket will not back out of chamber. Tug

on the wire to confirm that is locked.

2-14 2004 FLHTCSE: Chassis

Page 15

HOME

CAUTION

NOTE

An ELECTRICAL TERMINAL CRIMP TOOL (Part No. HD-

39965) can be used to install Deutsch pin and socket terminals on wires.

f1270x2x

1

1. Run/stop switch wiring

Figure 2-16. Wiring in Upper Right Hand Control Housing

f1328x2x

2

1

4

3

5

Table 2-4. Handlebar Deutsch Connectors

Wire Color Chamber No.

RH Connector (12 socket) (BLACK)

Orange/White (O/W) 1

Red/Blue (R/BE) 2

Gray (GY) 3

White/Black (W/BK) 4

White/Brown (W/BN) 5

Black/Red (BK/R) 6

Brown/White (BN/W) 7

Gray/White (GY/W) 8

Pink/White (PK/W) 9

Violet/Black (V/BK) 10

White/Blue (W/BE) 11

Blue/Black (BE/BK) 12

LH Connector (12 socket) (GRAY)

Orange/White (O/W) 1

Ye llow (Y) 2

Blue/White (BE) 3

White (W) 4

White/Violet (W/V) 5

Ye llow/Black (Y/BK) 6

BLANK 7

Brown/Black (BN/BK) 8

Pink/White (PK/W) 9

Green/Blue (GN/BE) 10

Gray/Green (GY/GN) 11

BLANK 12

1. Right turn signal control and wiring

2. Cruise control switch

3. Mode select switch

4. Lower bracket

5. Clamping post

Figure 2-17. Wiring in Lower Right Hand Control Housing

11. Install internal seals on lip of socket housings.

12. Snap tapered end of locking wedges into socket housings.

NOTE

If the locking wedge does not snap into position, verify that all

terminals are fully seated in the socket housing.

13. Gently tug on wire ends to verify that all terminals are

locked.

Improperly aligned handlebars can hit tank when turned

lock to lock. Verify turning clearance before maneuvering

or riding motorcycle.

14. Carry handlebars with internal wire harness and control

housings to the motorcycle.

15. Set handlebars on lower clamps and loosely install

upper handle bar clamps and fasteners. Position wires

so they exit under radio to front of vehicle from between

risers.

2004 FLHTCSE: Chassis 2-15

Page 16

HOME

CAUTION

Never adjust handlebars using excessive force. Doing so

may result in damage to handlebar.

NOTE

If handlebars are positioned for a rider of normal size, postpone adjustment until rider has checked their position. If customer requests changing handlebar position, perform the

adjustment before delivering the motorcycle.

16. Center handlebars laterally (sideways) in clamps.

17. Snug front fasteners until upper clamp contacts lower

clamps.

18. Position handlebars in normal rider posture.

19. Tighten fasteners in the following order:

a. Rear fasteners - 12-16 ft-lbs (16.3-20.3 Nm).

b. Front fasteners - 12-16 ft-lbs (16.3-20.3 Nm).

20. Push left and right harness Deutsch connectors into the

pin side housings.

21. Remove loosely installed control housing fasteners.

22. Push throttle and idle control cable inserts into lower

switch housing.

NOTE

The smaller idle cable insert is gold while the larger throttle

cable insert is silver. The inserts only fit their corresponding

hold in switch housing.

23. Slide throttle control grip onto handlebar until it bottoms.

Pull grip back about 1/8 in. (3.2 mm).

24. Use a screwdriver to rotate barrels and fit cables through

notches in throttle control grip. Be sure cables ride in

grooves of throttle control grip.

CAUTION

See Figure 2-12. Do not remove 5/32 in. (4 mm) cardboard insert wedged between brake lever and lever

bracket. Removal will result in damage to rubber boot

and plunger of front stoplight switch during installation

of master cylinder assembly.

25. Assemble upper and lower control housing to handle-

bars and brake lever bracket.

a. Position upper switch housing so wire conduit wraps

around outside of handlebar and sets in clearance

at bottom of handlebar.

b. Verify that wires will not be pinched when fasteners

are tightened.

c. Verify that throttle and idle control cables work

freely.

d. Install switch housing fasteners.

26. Loosely assemble handlebar clamp to front brake control

lever bracket master cylinder and reservoir.

a. Engage tab on switch with notch at top of brake

lever bracket.

b. Alternately tighten housing and bracket fasteners

until all components fit and wires route without interference. fasteners should only be snug.

c. Verify housing and bracket clamp are tight against

handgrip shoulder/edge of bar.

27. Remove cardboard insert between brake lever and

bracket.

a. Control lever clamps beginning with top fastener to

60-80 in-lbs (6.8-9.0 Nm). The gap, if any must be

at clearance flat on handlebar.

b. Tu rn signal and cruise control housings beginning

with bottom fastener to 35-45 in-lbs (4-5 Nm). Rear

gap, if any, should be tighter.

28. Loosely assemble clutch master cylinder/reservoir and

clamp to handlebar. Alternately tighten fasteners until

clamp is snug to bracket.

29. Install left turn signal and cruise control housings.

a. Position upper switch housing so wire conduit wraps

around front of handlebar.

b. Verify wires will not be pinched when fasteners are

tightened.

c. Position upper switch housing to wire conduit sets in

clearance at bottom of handlebar and upper harness will not be pinched when fasteners are tightened.

d. Engage lower switch housing tab with notch in

clutch master cylinder reservoir.

30. Install but do not tighten switch housing fasteners.

31. Position controls for rider posture and tighten fasteners:

a. Clutch master cylinder/reservoir clamp beginning

with top fastener to 60-80 in-lbs (6.8 Nm). Top gap,

if any, must be at handlebar clearance.

b. Tu rn signal and cruise control housings beginning

with bottom fastener to 35-45 in-lbs (4-5 Nm). Rear

gap, if any, should be tighter.

32. Verify routing of wire conduits, brake line and clutch fluid

line. See FRONT BRAKE LINE in Touring Models Service Manual and 2.12 CLUTCH FLUID LINE in this book.

33. Install right rear view mirror stem through mirror spacer,

and the brake control lever bracket. Install lock washer

and acorn nut on mirror stem.

34. Install left rear view mirror stem through tapered spacer

and clutch master cylinder. Install lock washer and acorn

nut.

35. With motorcycle upright and with front fork pointed

straight ahead, adjust mirrors to clearly reflect area

behind motorcycle.

NOTE

Adjust mirrors so a small portion of riders shoulder is visible

in each mirror. This visually establishes the distance of vehicles to rear of motorcycle.

36. Tighten acorn nuts to 144 in-lbs (16.3 Nm).

37. Install radio according to procedure in Touring Models

Service Manual.

38. Install outer fairing, wind deflector and fairing cap

according to procedure in touring Models Service Manual.

39. Install Maxi-Fuse and side cover.

40. Test clutch lever and front brake lever for pressure and

operation.

41. Turn throttle and idle adjusters out.

2-16 2004 FLHTCSE: Chassis

Page 17

HOME

42. Verify throttle and idle cable routing. Test for correct

operation Adjust as required. See CRUISE CONTROL in

the Touring Models Service Manual.

43. Verify brake and clutch fluid line routing.

44. Turn ignition/light key switch to IGNITION and test

switches for proper operation.

45. Apply brake lever to test stop light lamp.

2004 FLHTCSE: Chassis 2-17

Page 18

HOME

CLUTCH MASTER CYLINDER/RESERVOIR 2.10

GENERAL

The clutch is hydraulically actuated. Squeezing the clutch

hand lever causes the clutch master cylinder to apply pressure via the clutch fluid in the clutch line to the secondary

clutch actuator mounted in the clutch release cover. The secondary clutch actuator piston extends and contacts the clutch

release bearing which disengages the clutch.

A bleeder valve at the secondary clutch actuator is used to

bleed air from the clutch line. D.O.T. 5 SILICONE BRAKE

FLUID is used in the clutch system.

Check the clutch fluid level in the clutch fluid reservoir on left

handlebar. If the sight glass is dark, the fluid level in the reservoir is above the sight glass prism and the reservoir is full.

If the sight glass appears clear, the fluid level is below the

sight glass prism and the fluid level should be checked.

Clutch fluid should be level with the internal shelf marked

FILL LEVEL with the motorcycle upright and the gasket surface level.

CAUTION

D.O.T. 5 SILICONE BRAKE FLUID is used for the hydraulic clutch and is referred to as clutch fluid in this manual.

Do not use other types of fluid as they are not compatible.

REMOVAL

1. Remove acorn nut, washer and rear view mirror with

tapered spacer. Support turn sign bullet housing and

bracket.

2. Remove electrical controls.

CAUTION

To prevent dirt and other contaminants from entering the

master cylinder reservoir, thoroughly clean the cover

before removal.

3. See Figure 2-18. Loosen, but do not remove, screws

with flat washers that detach handlebar clamp from

clutch master cylinder/reservoir.

4. Loosen both screws on cover to relieve pressure in master cylinder reservoir.

1WARNING1WARNING

Be sure NO clutch fluid gets on tires, wheels, or brakes

when draining clutch fluid. Traction will be adversely

affected which could result in loss of control of the

motorcycle and death or serious injury.

NOTE

Place a large cup under the banjo fitting. Hydraulic fluid will

begin draining from the reservoir as the banjo bolt is

removed.

CAUTION

Clutch fluid volume increases with clutch wear. Do not

overfill clutch reservoir.

CAUTION

Damaged banjo bolt surfaces will leak when reassembled.

Prevent damage to seating surfaces by carefully removing clutch line components.

5. Slowly loosen banjo bolt and allow clutch fluid from reservoir to drain into cup.

IMPORTANT NOTE

Dispose of clutch fluid in accordance with local regulations.

6. Remove banjo bolt and two steel/rubber washers to disconnect fitting of hydraulic clutch fluid line from clutch

reservoir and master cylinder. Discard steel/rubber

washers.

NOTE

To prevent the rest of the clutch fluid from draining from the

clutch line and secondary clutch actuator, support the banjo

fitting and clutch fluid line upright. Plug the banjo bolt hole

with a finger to transfer the assembly to a workbench without

spilling clutch fluid.

7. Remove handlebar clamp screws and take clamp and

clutch master cylinder/reservoir assembly to a workbench.

2-18 2004 FLHTCSE: Chassis

Page 19

HOME

CAUTION

1WARNING1WARNING

1WARNING1WARNING

v0035x2x

10

1

9

2

8

7

4

6

1. Cover

2. Clutch hand lever

3. Cover hold down screws

4. Banjo fitting

5. Clutch fluid line

6. Banjo bolt

7. Steel/rubber washers

8. Handlebar clamp

9. Washer

10. Clamp screw

Figure 2-18. Clutch Master Cylinder/Reservoir

5

DISASSEMBLY

To prevent dirt and other contaminants from entering the

master cylinder reservoir, thoroughly clean the cover

before removal.

3

1. Drain additional clutch fluid from master cylinder/reservoir.

2. Remove screws securing master cylinder cover.

Remove cover and gasket. Turn housing upside down to

remove remaining clutch fluid from reservoir.

Always wear proper eye protection when removing

retaining rings. Use the correct retaining ring pliers. Verify that the tips of the pliers are not damaged or excessively worn. Slippage could propel the ring with force

which could cause death or serious injury.

3. Remove retaining ring from pivot pin groove.

NOTE

To take the piston spring load off the pin and remove the pivot

pin, gently force the clutch lever toward the piston (as if operating the clutch).

4. Remove pivot pin through top of housing. Remove and

save pivot pin and clutch lever.

5. See Figure 2-19. Using a toothpick or small screwdriver,

gently pry outer edge of piston boot out of piston bore.

6. Remove piston and spring.

Always use denatured alcohol or D.O.T. 5 SILICONE

BRAKE FLUID to clean clutch system components. Do

not use mineral base solvents (such as gasoline or paint

thinner) or deterioration of rubber parts may occur after

assembly. Deterioration of components may result in premature brake failure and death or serious injury. Wipe the

housing with a lint free cloth. With a clean air supply,

blow out drilled passages and bore in the master cylinder

housing.

NOTE

Do not use a wire or sharp instrument to clean drilled oil passages.

7. Inspect cylinder housing bore for scoring, pitting or corrosion. Also check outlet port for damage. Replace

housing if necessary.

8. Inspect the cover, sight glass, and gasket for cuts, tears

or general deterioration.

2004 FLHTCSE: Chassis 2-19

Page 20

HOME

9370

ASSEMBLY

1

2

7

5

8

3

6

3

4

To rebuild clutch master cylinder, use the components found

in the SERVICE PARTS KIT No. 46244-01.

1. See Figure 2-19. Lightly lubricate inside of primary cup

and fit over lip on spring end of piston so the closed end

(small ID) contacts evenly with the shoulder in primary

cup grove.

2. Lightly lubricate inside of secondary cup (steep taper

from center to outside diameter) and fit over the lip on

outboard end of piston so that flared end is open toward

the shoulder of the secondary cup groove.

3. Install boot, large sealing ID first, on piston until seal on

smaller ID fits snugly into thin groove in piston.

NOTE

See Figure 2-20. The flared ends of the primary cup and the

secondary cup face the spring end of the piston.

4. Using lubricant in SERVICE PARTS KIT (Part No.

46244-01) thoroughly coat outside diameters of primary

and secondary cups. Coat master cylinder piston bore.

5. With tapered end out, install spring into opening on

inboard side of piston assembly.

6. Align and install piston assembly into bore. Firmly press

on flat end of piston, compressing spring, until the entire

assembly slides into cylinder bore.

1. Boot

2. Piston

3. Shoulder

4. Spring

5. Primary cup

6. Groove - primary cup

7. Secondary cup

8. Groove - secondary cup

NOTE

When fitting the piston sealing boot, be careful not to tear,

perforate or damage the piston sealing boot.

7. Compress piston until it is even with the end of bore.

Using a small dull bladed screwdriver or similar tool,

gently work around sealing edges of boot until entire circumference of boot is seated in cylinder bore groove.

8. If cover gasket and/or sight glass replacement is necessary. Proceed as follows:

a. From inboard side, push sight glass toward top of

cover until free.

b. Pull rubber gasket from cover.

c. Fit nipple of new gasket into hole of cover aligning

gasket and cover thru holes.

d. From bottom of gasket, push flat end of sight glass

through nipple until top of glass is flush with top of

gasket. Verify that glass is square in bore. If lubrication is necessary, use clean D.O.T. 5 SILICONE

BRAKE FLUID.

Figure 2-19. Clutch Master Cylinder Components

2-20 2004 FLHTCSE: Chassis

Page 21

HOME

CAUTION

1WARNING1WARNING

9. Install cover with gasket on master cylinder reservoir.

Install two screws to fasten the cover to reservoir, but do

not tighten.

1WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify that

the tips of the pliers are not damaged or excessively

worn. Slippage could propel the ring with force which

could cause death or serious injury.

10. To install existing clutch hand lever, install clutch hand

lever, pivot pin, and a new retaining ring.

11. To install a replacement clutch hand lever, use SERVICE

PARTS KIT (Part No. 46243-01). See 2.11 CLUTCH

HAND LEVER.

9686

1

2

3

INSTALLATION

1. See Figure 2-18. Attach master cylinder/reservoir to

handlebars with handlebar clamp. Orient lever to rider

position and tighten two clamp screws.

2. Attach banjo fitting of clutch fluid line to master cylinder

with new steel/rubber washers. Install electrical controls.

3. Loosen bleeder valve on clutch release cover. See 7.4

CLUTCH RELEASE COVER.

4. Fill reservoir with D.O.T. 5 SILICONE BRAKE FLUID.

Allow fluid to fill clutch line until a steady flow of clutch

fluid flows from bleeder valve. Finger tighten bleeder

valve.

5. Bleed clutch line. See BLEEDING CLUTCH FLUID

LINE.

6. Verify that fluid level in clutch fluid reservoir is at FILL

LEVEL with motorcycle upright and gasket surface level.

Clutch fluid volume increases with clutch wear. Do not

overfill clutch reservoir.

1. Boot in piston groove

2. Secondary cup flare

3. Primary cup

Figure 2-20. Assembled Cups and Piston

7. Verify pressure by squeezing clutch hand lever.

8. Tighten fasteners as follows:

a. Banjo bolt to 17-22 ft-lbs (23-31 Nm).

b. Bleeder screw to 80-100 in-lbs (9-11 Nm).

c. Reservoir cover screws to 6-8 in-lbs (0.7-0.9 Nm).

9. Install rear view mirror and turn signals with bracket. See

8.1 TURN SIGNALS.

Check for proper turn signal lamp operation before

riding motorcycle. Visibility is a major concern for motorcyclists. Failure to have proper lamp operation could

result in death or serious injury.

10. Test ride motorcycle.

2004 FLHTCSE: Chassis 2-21

Page 22

HOME

CLUTCH HAND LEVER 2.11

INSTALLATION

9477

1. See Figure 2-21. Slide bushing cups onto pins of roller

with cup flanges against roller.

NOTE

Be careful when handling the bushing cups. The bushing

cups are hard plastic and can be easily broken.

1

2. With connector bow portion of the bushing cups parallel

with groove in clutch handle, snap roller pin with the

bushing cups installed into clutch lever roller groove. If

bushing is positioned correctly, roller/bushing assembly

will install with a snap and will be held securely.

2

3

4

3. Lightly grease pivot bushing and install into clutch hand

lever pivot hole. Position bushing until it is flush with both

sides of lever.

NOTE

If the clutch master cylinder/reservoir is full of clutch fluid

under pressure, it may be necessary to apply force to the

hydraulic piston (in the clutch hand lever mount) in order to

align the clutch hand lever and to allow the pivot pin to be

inserted.

4. Orient clutch lever in lever mounting bracket. Insert pivot

pin from top and tap into place.

5. Install new retaining ring on pivot pin.

1. Clutch hand lever

2. Pivot bushing

3. Bushing cups connector bow

4. Roller pin

Figure 2-21. Clutch Hand Lever

2-22 2004 FLHTCSE: Chassis

Page 23

HOME

1WARNING1WARNING

1WARNING1WARNING

CAUTION

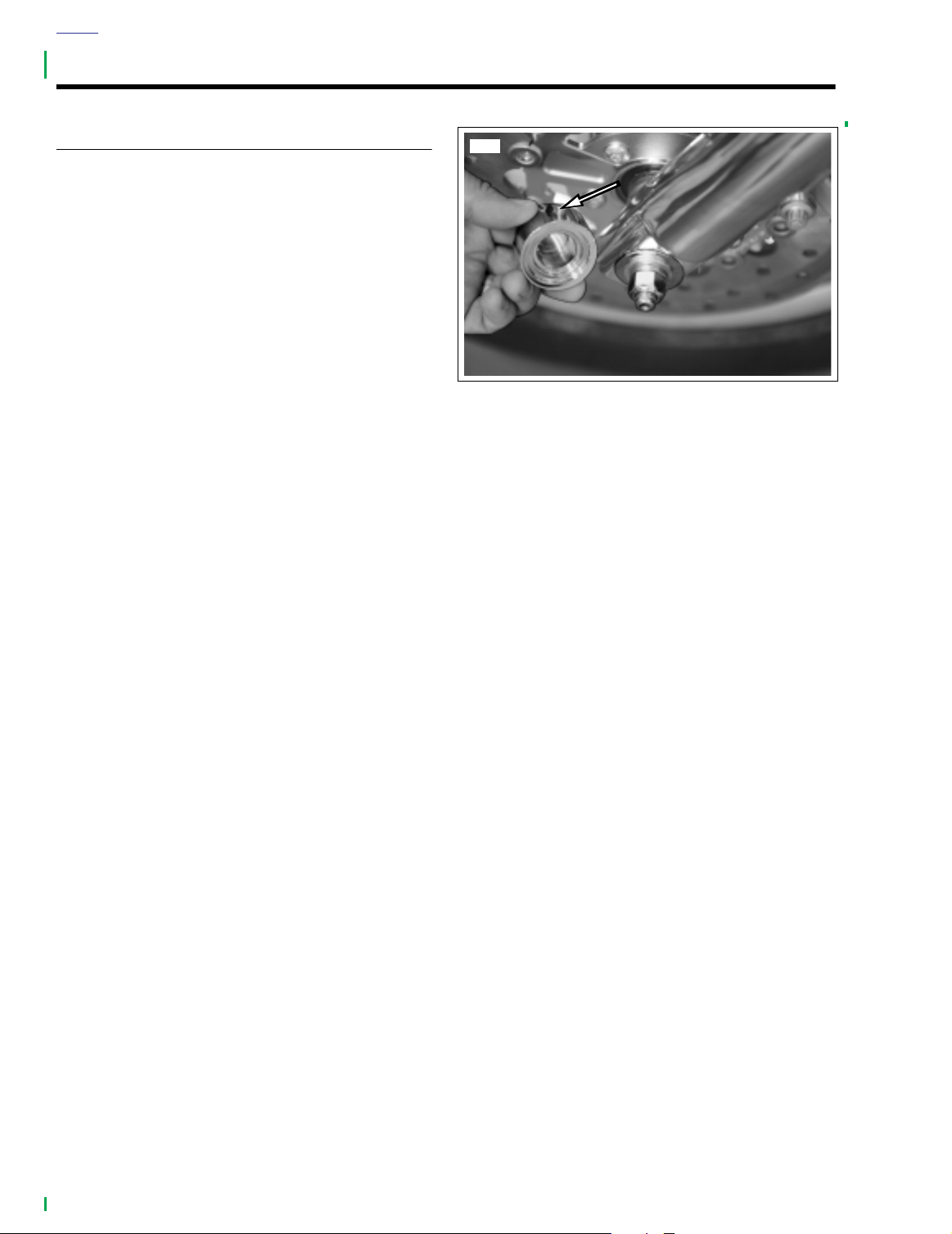

9930

3

1

2

1. Bleeder valve (cap removed)

2. Flare nut

3. Clutch fluid line

CLUTCH FLUID LINE 2.12

REPLACEMENT

1. Remove outer fairing.

1WARNING1WARNING

Be sure NO clutch fluid gets on rear tire, wheel or brakes

when draining clutch fluid. Traction will be adversely

affected which could result in loss of control of the

motorcycle and death or serious injury.

2. See Figure 2-22. Place a suitable container under clutch

release cover.

3. Loosen the clutch master cylinder/reservoir cover.

4. Loosen flare nut and allow clutch fluid to drain.

5. Remove flare nut on outside of the clutch release cover.

6. Drain clutch fluid line.

NOTE

Dispose of clutch fluid in accordance with local regulations.

Figure 2-22. Clutch Release Cover

(exhaust system removed)

7. See Figure 2-23. Remove and discard o-ring.

NOTE

Clutch fluid line o-ring may stick to inside of clutch release

cover. Use a pick to remove old o-ring and other debris.

8. Remove banjo bolt and two steel/rubber washers to disconnect fitting of hydraulic clutch fluid line from clutch

reservoir and master cylinder. Discard washers.

9. Carefully pull banjo bolt end of clutch fluid line out

through inner fairing.

10. See Figure 2-26. Route new clutch fluid line back

through fairing retracing path of old.

11. Loosely install banjo bolt and tie free end away from

chrome and painted surfaces.

12. See Figure 2-26. Loosen clamps and cut cable ties

around old clutch fluid line along right side frame down

tube and behind cam cover around the rear brake line in

front of the clamp.

13. Remove old clutch fluid line.

14. Route new clutch fluid line down right side frame tube,

under cam cover and up to clutch release cover. See

CLUTCH FLUID LINE ROUTING.

15. See Figure 2-23. Install new o-ring on end of clutch fluid

line.

16. Thread in and finger tighten flare nut fastening clutch

fluid line to clutch release cover.

17. Attach banjo fitting of the clutch fluid line to master cylinder with new steel/rubber washers.

18. Cable wrap clutch fluid line in original places on inner

fairing bracket and behind cam cover around the rear

brake line in front of the clamp.

19. Install outer fairing assembly. See FAIRING in this Service Manual.

Be sure NO clutch fluid gets on tires, wheels or brakes

when adding clutch fluid. Traction will be adversely

affected which could result in loss of control of the

motorcycle and death or serious injury.

Do not allow dirt or debris to enter the clutch master cylinder reservoir. Dirt or debris in the reservoir can cause

improper operation of the clutch and equipment damage. (00205a)

Direct contact of D.O.T. 5 brake fluid with eyes can cause

eye irritation, swelling, and redness. Avoid eye contact.

Incase of eye contact flush with large amounts of water

and get medical attention. Swallowing large amount of

D.O.T 5 brake fluid can cause digestive discomfort. If

swallowed, obtain medical attention. Use in well ventilated area. (00144a)

20. Loosen bleeder valve.

21. Remove clutch master cylinder/reservoir cover and fill

reservoir with D.O.T. 5 SILICONE BRAKE FLUID. Allow

fluid to fill clutch line until a steady flow of clutch fluid

flows from bleeder screw. Finger tighten bleed screw.

NOTE

A Snap-on BASIC VACUUM BRAKE BLEEDER with a fitting

that mates to the bleeder valve can be used to draw the fluid

down the clutch line.

22. Bleed clutch fluid line. See BLEEDING CLUTCH FLUID

LINE.

2004 FLHTCSE: Chassis 2-23

Page 24

HOME

CAUTION

Clutch fluid volume increases with clutch wear. Do not

overfill clutch reservoir.

23. Verify that fluid level in clutch fluid reservoir is at FILL

LEVEL with motorcycle upright and gasket surface level.

24. Test pressure by squeezing clutch hand lever.

25. Tighten fasteners as follows:

a. Clutch fluid reservoir banjo bolt to 17-22 ft-lbs (23-

31 Nm).

b. Clutch line flare nut to 80-115 in-lbs (9-13 Nm).

c. Actuator bleeder valve to 80-100 in-lbs (9-11 Nm).

d. Reservoir cover screws to 6-8 in-lbs (0.7-0.9 Nm).

26. Test ride motorcycle. Incorrect pressure or fluid lever can

cause:

a. Dragging clutch.

b. Hard shifting.

9994

2. Route clutch fluid line:

a. Route line through inner fairing grommet.

b. See Figure 2-26. Route line around top of steering

head and back out to P-clamp used for throttle

cables.

c. Run clutch fluid line behind engine guard and in

front of right frame downtube.

d. Run line behind foot controls bracket.

e. Following inboard side of frame downtube, route

cable between bottom of cam cover and top of lower

frame tube.

f. See Figure 2-26. Line is cable wrapped along rear

brake line just in front of main wire harness conduit.

g. Route line up to clutch release cover.

3. See Figure 2-26. Install clamps to retain clutch fluid line

at two locations on right frame downtube.

4. Install outer fairing. See FAIRING.

10555

Figure 2-23. Clutch Fluid Line O-ring

CLUTCH FLUID LINE ROUTING

1. Remove outer fairing.

Figure 2-25. Clamp Locations on Frame Down Tube

9991

Figure 2-26. Cable Wrap Location around Brake Line

Figure 2-24. Clutch Fluid Line Inner Fairing Grommet

2-24 2004 FLHTCSE: Chassis

Page 25

HOME

CAUTION

BLEEDING CLUTCH FLUID LINE

1WARNING1WARNING

Be sure NO clutch fluid gets on tires, wheels or brakes

when adding clutch fluid. Traction will be adversely

affected which could result in loss of control of the

motorcycle and death or serious injury.

CAUTION

Do not allow dirt or debris to enter the clutch master cylinder reservoir. Dirt or debris in the reservoir can cause

improper operation of the clutch and equipment damage. (00205a)

CAUTION

Direct contact of D.O.T. 5 brake fluid with eyes can cause

eye irritation, swelling, and redness. Avoid eye contact.

Incase of eye contact flush with large amounts of water

and get medical attention. Swallowing large amount of

D.O.T 5 brake fluid can cause digestive discomfort. If

swallowed, obtain medical attention. Use in well ventilated area. (00144a)

NOTE

When filling an empty clutch fluid line, a Snap-on BASIC

VACUUM BRAKE BLEEDER with a fitting that mates to the

secondary clutch actuator bleeder valve can be used to initially draw the fluid down the clutch line.

1. Stand motorcycle upright and turn handlebars right lock

as required to level clutch reservoir. Remove reservoir

cover.

CAUTION

Clutch fluid volume actually increases with clutch wear.

Do not overfill reservoir.

2. If necessary, add D.O.T. 5 SILICONE BRAKE FLUID,

(HD-99902-77) to master cylinder reservoir. Initial fluid

level should not exceed FILL LEVEL with reservoir level.

4. Fill reservoir to FILL LEVEL and repeat the previous

step three times or more until only a steady flow of clutch

fluid escapes banjo fitting and fluid level in reservoir is at

FILL LEVEL with motorcycle in an upright position.

5. Cover exhaust with towel and place a suitable pan under

clutch release cover to catch excess clutch fluid.

IMPORTANT NOTE

Dispose of clutch fluid in accordance with local regulations.

6. While holding reservoir cover in place:

a. Pump clutch hand lever 5 times.

b. Hold clutch hand lever against handlebar.

c. Loosen secondary clutch actuator bleed valve.

d. Run hose from bleeder valve to suitable container.

e. Watch bleeder valve for air bubbles.

f. Tighten bleeder valve.

g. Release hand lever.

7. With reservoir level, fill reservoir to FILL LEVEL and

repeat the previous step three times or more until only a

steady flow of clutch fluid escapes bleeder valve and

fluid level in reservoir is at FILL LEVEL with motorcycle

in an upright position.

Clutch fluid volume actually increases with clutch wear.

Do not overfill reservoir.

8. Test pressure by squeezing clutch hand lever.

9. Tighten fasteners as follows:

a. Clutch fluid reservoir banjo bolt to 17-22 ft-lbs (23-

31 Nm).

b. Clutch line flare nut to 80-115 in-lbs (9-13 Nm).

c. Actuator bleeder valve to 80-100 in-lbs (9-11 Nm).

d. Reservoir cover screws to 6-8 in-lbs (0.7-0.9 Nm).

1CAUTION

Loosen banjo bolt only enough to allow air bubbles to

escape. Clutch fluid under pressure can squirt a steady

stream several feet.

3. While holding reservoir cover in place:

a. Pump clutch hand lever 5 times.

b. Hold clutch hand lever against handlebar.

c. Hold shop towel under fitting and loosen banjo bolt.

d. Watch banjo fitting for air bubbles.

e. Retighten banjo fitting.

f. Release hand lever.

10. Replace cap on actuator bleeder valve.

11. Test ride motorcycle. Incorrect pressure or fluid level can

cause:

a. Dragging clutch.

b. Hard shifting.

2004 FLHTCSE: Chassis 2-25

Page 26

HOME

SEAT 2.13

REMOVAL

1. Remove rider and passenger backrests.

2. Remove saddlebag.

3. See Figure 2-27. Remove fastener with flat washer holding one side of passenger grabstrap.

4. Remove fastener holding seat to fender.

5. Slide seat backward to free tongue on bottom front of

seat from slot in frame backbone. and remove seat.

CLEANING AND INSPECTION

CAUTION

Do NOT use bleach or detergents containing bleach on

saddlebags, seats, or tank panels. Doing so may result

in equipment damage.

● Do not use ordinary soap to clean leather. It could

dry or remove the oils from the leather.

● Use ONLY a good quality saddle soap to clean

leather. Be sure to rinse saddle soap off thoroughly

before treating leather.

● Never try to dry leather quickly, using artificial

means. Always let leather dry naturally at room temperature.

f2149x0a

3

1

2

5

6

1. Passenger grabstrap

2. Seat

3. Fastener

4. Tongue

5. Bracket

6. Retention nut

Figure 2-27. Seat Components

4

INSTALLATION

1. See Figure 2-27. Set seat on frame and slide seat for-

ward until tongue engages slot in frame backbone.

2. Push seat forward until retention nut in fender is centered in hole of bracket. Install fastener.

NOTE

HARLEY-DAVIDSON LEATHER DRESSING (Part No.

98261-91V) has been tested and approved for materials

used in FLHTCSE seats.

1. Inspect seat for wear or damage.

2. Clean underside of pillion and seat. Clean fender and

frame mounting surfaces.

2-26 2004 FLHTCSE: Chassis

1WARNING1WARNING

After installing the seat, pull upward on the front of the

seat to be sure it is locked into position. If seat is loose,

it could shift during operation, resulting in loss of control of the motorcycle and death or serious injury.

3. Pull up on seat to verify that it is properly secured.

4. Install passenger grabstrap to saddlebag mounting

bracket.

5. Install rider and passenger backrests.

Page 27

HOME

10566

1

2

o0163xox

1. Seat

2. Keyed support bracket

2

1

RIDER BACKREST 2.14

REMOVAL

1. See Figure 2-28. Spread the seat covering at the base of

the backrest exposing the two spring loaded support

arms.

2. See Figure 2-29. Using two hands, squeeze together the

spring loaded support arms.

10564

Figure 2-28. Removable Rider Backrest

3. Pull upward to remove the backrest from the bracket.

INSTALLATION

1. See Figure 2-30. Spread the seat opening to expose the

keyed backrest support bracket.

Figure 2-30. Backrest Installation

10565

Figure 2-29. Backrest Removal - Spring Loaded Support

Arms

2. Squeeze together the two spring loaded support arms

on the backrest.

3. See Figure 2-31. Insert the support arms into the keyed

support bracket.

4. Test to assure the seat is secured into the bracket.

NOTE

The backrest is spring loaded to assist the passenger in getting on and off the vehicle.

Figure 2-31. Backrest Mounting Bracket

2004 FLHTCSE: Chassis 2-27

Page 28

HOME

PASSENGER BACKREST 2.15

REMOVAL

1. Remove the saddlebags. See SADDLEBAG, REMOVAL

in Touring Models Service Manual.

2. See Figure 2-32. Push in the spring-loaded locking latch

and pull the swivel latch rearward on the passenger

backrest.

3. Lift the backrest off by lifting upward and then toward the

rear of the motorcycle.

4. See Figure 2-33. Remove front docking point bolt,

washer and front docking bushing.

5. Remove rear docking point bolt, washer, docking point

(4), nut and docking point bracket.

6. Remove fender mounting bolt.

7. Remove rear mounting bolt, lock washer, washer and

nut.

8. Cover filler strip to protect finish and remove lower

mounting bolt, washer and nut.

9. Remove mounting bracket and saddlebag mounting

bracket.

10. Repeat for opposite side.

11. Inspect all parts and replace as required.Passenger

backrest

Your motorcycle comes with a detachable passenger backrest.

INSTALLATION

9993

1

2

3

7

1. Front docking bushing

2. Docking points bracket

3. Air suspension valve

4. Rear docking point

5. Fender mounting bolt

6. Rear mounting bolt

7. Mounting bracket

8. Lower mounting bolt

9. Saddlebag mounting bracket

Figure 2-33. Passenger Backrest Mounting Location

5

4

8

9

6

o0181xox

1 2

1. Rear latch

2. “C” bracket guides

Figure 2-32. Detachable Passenger Backrest

1. See Figure 2-34. Install mounting bracket with fender

mounting bolt.

2. Install upper mounting bolt, lock washer and washer.

3. Cover filler strip to protect finish.

4. Install lower mounting bolt and washer with saddlebag

mounting bracket.

5. Install rear docking point, fastener, washer and nut with

the dock point bracket.

6. Install the front docking bushing with fastener and

washer through the dock point bracket into the frame.

7. Align saddlebag mounting hole with saddlebag.

8. Tighten fasteners:

a. Fender mounting bolt to 15-20 ft-lbs (12-27 Nm).

b. Upper and lower mounting bolts to 15-20 ft-lbs

(20.3-27 Nm).

c. Front and rear docking point bolts to 15-20 ft-lbs

(20.3-27 Nm).

9. Repeat for opposite side.

10. Install passenger backrest by sliding bracket c-guides

onto front docking bushing and pushing down on the

rear of the bracket with latches aligned to rear docking

points until the rotate and lock into position.

11. Check that passenger backrest is locked in place before

operating motorcycle.

2-28 2004 FLHTCSE: Chassis

Page 29

HOME

z0021f

16

19

17

1

2

3

4

7

18

9

6

5

15

14

13

1. Fastener

2. Backrest mounting bracket

3. Passenger backrest

4. Pad

5. Docking points bracket

6. Nut

7. Washer

8. Front docking bushing

9. Washer

10. Docking point bolt

11. Rear docking point

12. Washer

13. Docking point bolt

14. Lower mounting bolt

15. Washer

16. Upper mounting bolt

17. Lock washer

18. Mounting bracket

19. Spacer

8

11

12

Figure 2-34. Passenger Backrest Components

10

9

2004 FLHTCSE: Chassis 2-29

Page 30

HOME

SADDLEBAG SUPPORTS 2.16

REMOVAL

1WARNING1WARNING

To prevent accidental vehicle start-up, which could

cause death or serious injury, remove maxi-fuse before

proceeding. (00251a).

1. Remove the saddlebags. See SADDLEBAG, REMOVAL

in Touring Models Service Manual.

2. Remove side cover.

3. Remove Maxi-Fuse.

4. See Figure 2-35. Remove filler strip fasteners and

remove filler strip.

8879

INSTALLATION

1. Install the trim to the support bracket. Loosely fasten

support bracket to fender support bracket.

2. Install passenger backrest mounting bracket to support

bracket. Pull docking points bracket and docking points

into place.

3. Loosely install fasteners into passenger backrest bracket

and rear saddlebag bracket. Be sure the washers are in

place behind and in front of passenger backrest bracket.

4. Tighten fasteners:

a. Passenger backrest mounting bracket to support

bracket - 15-20 ft-lbs (20.4-27 Nm).

b. Fender support bracket to support bracket 15-20 ft-

lbs (20.4-27 Nm).

c. Support to support bracket 15-20 ft-lbs

(20.4-27 Nm).

5. Install filler strip with washers between filler strip and

support bracket. Tighten fasteners to 15-20 ft-lbs

(20.3-27 Nm).

6. Install Maxi-Fuse.

7. Install side cover.

8. Install saddlebags.

Figure 2-35. Removing Filler Strip

5. Remove fastener holding support to support bracket.

6. Remove fastener holding saddlebag support to fender

support bracket. See Touring Models Service Manual.

7. Remove the three fasteners holding the passenger

backrest mounting bracket. Remove the rear saddlebag

bracket. See 2.15 PASSENGER BACKREST.

8. Loosen but do not remove the rear docking point fastener and the front docking point fastener. Fold the docking points bracket out of the way.

9. Remove the support bracket and trim.

10. Remove fasteners holding support to muffler.

11. Remove fasteners holding support and remove support.

12. Repeat for opposite side.

2-30 2004 FLHTCSE: Chassis

Page 31

1. Rear saddlebag bracket

2. Clip nut

3. Filler strip

4. Washer

5. Support bracket

6. Locknut

7. Fastener and washer

8. Front saddlebag bracket

9. Receptacle

10. Nut

11. Fastener

12. Support

13. Fastener

14. Fastener and washer

15. Fastener and washer

f2249a2x

4

1

2

3

5

6

7

8

9

10

11

12

13

14

14

9

15

HOME

Figure 2-36. Saddlebag Support Components

2004 FLHTCSE: Chassis 2-31

Page 32

HOME

MUFFLER END CAP 2.17

REPLACEMENT

1. See Figure 2-37. Loosen and remove three fasteners

holding muffler end cap in place. Remove end cap.

2. Install muffler end cap, align holes. Install and tighten

fasteners.

10553

Figure 2-37. Muffler End Cap Fastener Locations

2-32 2004 FLHTCSE: Chassis

Loading...

Loading...